Lycoming IO-320-B1A, IO-320-A2A, IO-320-E2B, IO-320-E1A, IO-320-B1B Operator's Manual

...

NOTE

In order to accommodate clearer type, larger charts and graphs, and more

detailed illustrations, this edition of the IO-320 Series Operator’s Manual,

Lycoming Part Number 60297-31 is presented in an 8-1/2 x 11 inch

format. This edition is a complete manual, current as of the date of issue.

The manual incorporates all previously issued revisions.

This manual will be kept current by revisions available from Lycoming

distributors or from the factory. All revisions will be accompanied by an

Operator’s Manual Revision page which will identify the revision level, the

date of the revision, and the pages revised, added or deleted. All revisions

will be supplied in the 8-1/2 x 11 inch format.

Operator’s Manual

Lycoming

IO-320 Series

Approved by FAA

3rd Edition Part No. 60297-31

652 Oliver Street

January 2007

Williamsport, PA. 17701 U.S.A.

570/323-6181

IO-320 Series Operator’s Manual

Lycoming Part Number: 60297-31

©2006 by Lycoming. All rights reserved.

Lycoming and “Powered by Lycoming” are trademarks or registered trademarks of

Lycoming.

All brand and product names referenced in this publication are trademarks or registered

trademarks of their respective companies.

For additional information:

Mailing address:

Lycoming Engines

652 Oliver Street

Williamsport, PA 17701 U.S.A.

Phone:

Factory: 570-323-6181

Sales Department: 570-327-7268

Fax: 570-327-7101

Lycoming’s regular business hours are Monday through Friday from 8:00 AM

through 5:00 PM Eastern Time (-5 GMT)

Visit us on the World Wide Web at:

http://www.lycoming.textron.com

LYCOMING OPERATOR’S MANUAL

ATTENTION

OWNERS, OPERATORS, AND MAINTENANCE PERSONNEL

gine, its specifications, and detailed information on

how to operate and maintain it. Such maintenance procedures that may be required in conjunction with

periodic inspections are also included. This manual is intended for use by owners, pilots and maintenance

personnel responsible for care of Lycoming powered aircraft. Modifications and repair procedures are

contained in Lycoming overhaul manuals; maintenance personnel should refer to these for such procedures.

SAFETY WARNING

Neglecting to follow the operating instructions and to carry out periodic maintenance procedures can result

in poor engine performance and power loss. Also, if power and speed limitations specified in this manual

are exceeded, for any reason, damage to the engine and personal injury can happen. Consult your local

FAA approved maintenance facility.

SERVICE BULLETINS, INSTRUCTIONS, AND LETTERS

Although the information contained in this manual is up-to-date at time of publication, users are urged to

keep abreast of later information through Lycoming Service Bulletins, Instructions and Service Letters

which are available from all Lycoming distributors or from the factory by subscription. Consult the latest

revision of Service Letter No. L114 for subscription information.

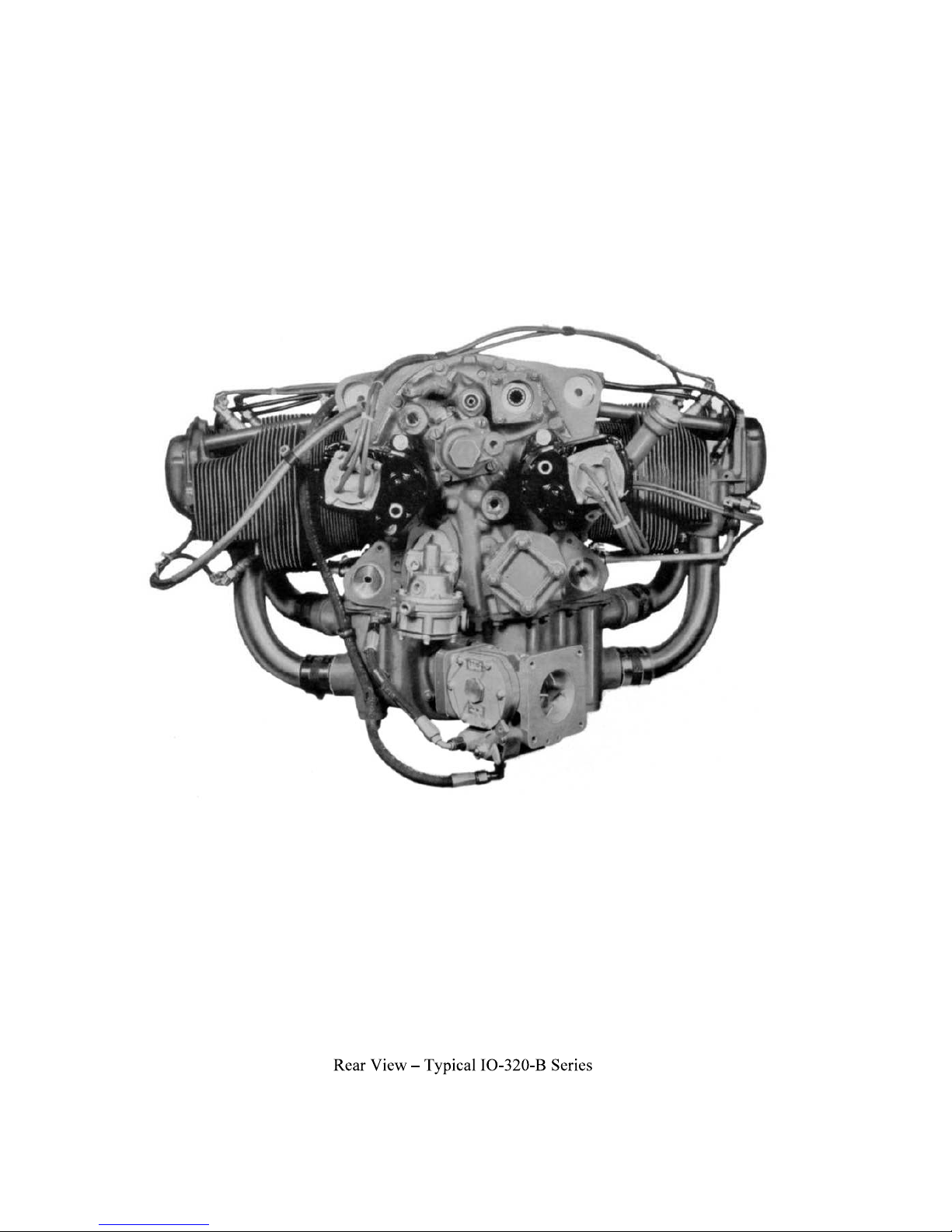

NOTE

The illustrations, pictures and drawings shown in this publication are typical of the subject matter they

portray; in no instance are they to be interpreted as examples of any specific engine, equipment or part

thereof.

iii

LYCOMING OPERATOR’S MANUAL

IMPORTANT SAFETY NOTICE

Proper service and repair is essential to increase the safe, reliable operation of all aircraft engines. The

service procedures recommended by Lycoming are effective methods for performing service operations.

Some of these operations require the use of tools specially designed for the task. These special tools must be

used when and as recommended.

It is important to note that most Lycoming publications contain various Warnings and Cautions which

must be carefully read in order to minimize the risk of personal injury or the use of improper service

methods that may damage the engine or render it unsafe.

It is also important to understand that these Warnings and Cautions are not all inclusive. Lycoming could

not possibly know, evaluate or advise the service trade of all conceivable ways in which service might be

done or of the possible hazardous consequences that may be involved. Accordingly, anyone who uses a

service procedure must first satisfy themselves thoroughly that neither their safety nor aircraft safety will be

jeopardized by the service procedure they select.

iv

WARRANTY

NEW AND REBUILT ENGINES

(1) WARRANTY AND REMEDY: Lycoming Engines, a division of Avco Corporation (hereinafter “Lycoming”)

warrants each new Lycoming reciprocating engine to be free from defect in material or workmanship under normal

use and service. Lycoming’s sole obligation under this warranty is limited to replacement or repair of parts which

are determined by Lycoming to have been defective within a period of twenty-four (24) months after new aircraft

delivery to the original retail purchaser or first user, or twenty-four (24) months from the date of first operation. The

warranty period of twenty-four (24) months commences on the earlier of the date of first operation after new aircraft

delivery to the original retail purchaser or first user, or twenty-four (24) months from the date of shipment from

Lycoming. Lycoming will, in connection with the foregoing warranty, cover reimbursement of reasonable freight

charges with respect to any such warranty replacement or repair.

(2) Within the warranty period, Lycoming will reimburse the Purchaser for labor charges associated with warranty

related issues. Lycoming will only reimburse the cost of such labor charges in connection with repair or

replacement of parts as provided in Lycoming’s then current Removal and Installation Labor and Allowance

Guidebook. Spare parts installed as warranty replacement on engines which are covered by this New Engine

Warranty will be warranted for the balance of the original warranty period or for the spare part warranty, whichever

is the greater. Replacement of parts may be with either new or reconditioned parts, at Lycoming’s election. A claim

for warranty on any part claimed to be defective must be reported in writing to Lycoming’s Warranty

Administration within 60 days of being found to require repair or replacement by the purchaser or service facility.

Warranty adjustment is contingent upon the Purchaser complying with the Lycoming’s Warranty Administration

disposition instructions for defective parts. Failure to comply with all of the terms of this paragraph may, at

Lycoming’s sole option, void this warranty.

(3) THIS WARRANTY IS GIVEN AND ACCEPTED IN PLACE OF (i) ALL OTHER WARRANTIES OR

CONDITIONS, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES

OR CONDITION OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND (ii) ANY

OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN CONTRACT OR IN TORT (DELICT),

INCLUDING PRODUCT LIABILITIES BASED UPON STRICT LIABILITY, NEGLIGENCE, OR IMPLIED

WARRANTY IN LAW AND PURCHASER HEREBY WAIVES SUCH RIGHTS AND CLAIMS.

(4) THIS WARRANTY IS THE ONLY WARRANTY MADE BY LYCOMING. THE PURCHASER’S SOLE

REMEDY FOR A BREACH OF THIS WARRANTY OR ANY DEFECT IN A PART IS THE REPAIR OR

REPLACEMENT OF ENGINE PARTS AND REIMBURSEMENT OF REASONABLE FREIGHT CHARGES AS

PROVIDED HEREIN. LYCOMING EXCLUDES LIABILITY, WHETHER AS A RESULT OF A BREACH OF

CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO, DAMAGE TO THE ENGINE OR

OTHER PROPERTY (INCLUDING THE AIRCRAFT IN WHICH THE ENGINE IS INSTALLED), COSTS AND

EXPENSES RESULTING FROM REQUIRED CHANGES OR MODIFICATIONS TO ENGINE COMPONENTS

AND ASSEMBLIES, CHANGES IN RETIREMENT LIVES AND OVERHAUL PERIODS, LOCAL CUSTOMS

FEES AND TAXES, AND COSTS OR EXPENSES FOR COMMERCIAL LOSSES OR LOST PROFITS DUE TO

LOSS OF USE OR GROUNDING OF THE AIRCRAFT IN WHICH THE ENGINE IS INSTALLED OR

OTHERWISE. LYCOMING’S TOTAL LIABILITY FOR ANY AND ALL CLAIMS RELATED TO ANY

ENGINE SHALL IN NO CASE EXCEED THE ORIGINAL SALES PRICE OF THE ENGINE. SELLER MAKES

NO WARRANTY AND DISCLAIMS ALL LIABILITY WITH RESPECT TO COMPONENTS OR PARTS

DAMAGED BY, OR WORN DUE TO, CORROSION.

(5) This warranty shall not apply to any engine or part thereof which has been repaired or altered outside

Lycoming’s factory in any way so as, in Lycoming’s sole judgment, to affect its durability, safety or reliability, or

which has been subject to misuse, negligence or accident. Repairs and alterations which use or incorporate parts and

components other than genuine Lycoming parts or parts approved by Lycoming for direct acquisition from sources

other than Lycoming itself are not warranted by Lycoming, and this warranty shall be void to the extent that such

repairs and alterations, in Lycoming’s sole judgment, affect the durability, safety or reliability of the engine or any

part thereof, or damage genuine Lycoming or Lycoming-approved parts. No person, corporation or organization,

including Distributors of Lycoming engines, is authorized by Lycoming to assume for it any other liability in

connection with the sale of its engines or parts, nor to make any warranties beyond the foregoing warranty nor to

change any of the terms hereof. NO STATEMENT, WHETHER WRITTEN OR ORAL, MADE BY ANY

PERSON, CORPORATION OR ORGANIZATION, INCLUDING DISTRIBUTORS OF LYCOMING ENGINES

MAY BE TAKEN AS A WARRANTY NOR WILL IT BIND LYCOMING. NO AGREEMENT VARYING THE

TERMS OF THIS WARRANTY OR LYCOMING’S OBLIGATIONS UNDER IT IS BINDING UPON

LYCOMING UNLESS IN WRITING AND SIGNED BY A DULY AUTHORIZED REPRESENTATIVE OF

LYCOMING.

(6) All legal actions based upon claims or disputes pertaining to or involving this warranty including, but not limited

to, Lycoming’s denial of any claim or portion thereof under this warranty, must be filed in the courts of general

jurisdiction of Lycoming County, Commonwealth of Pennsylvania or in the United States District Court for the

Middle District of Pennsylvania located in Williamsport, Pennsylvania. In the event that Purchaser files such an

action in either of the court systems identified above, and a final judgment in Lycoming’s favor is rendered by such

court, then Purchaser shall indemnify Lycoming for all costs, expenses and attorneys’ fee incurred by Lycoming in

defense of such claims. In the event Purchaser files such a legal action in a court other than those specified, and

Lycoming successfully obtains dismissal of that action or transfer thereof to the above described court systems, then

Purchaser shall indemnify Lycoming for all costs, expenses and attorneys’ fees incurred by Lycoming in obtaining

such dismissal or transfer.

(7) Any invalidity of a provision of this Warranty shall not affect any other provision, and in the event of a judicial

finding of such invalidity, this Agreement shall remain in force in all other respects.

Effective September 2006 Revision “M”

Ô§½±³·²¹ Û²¹·²»-

652 Oliver Street

Williamsport, Pennsylvania

17701

(570) 323-6181

www.lycoming.textron.com

LYCOMING OPERATOR’S MANUAL

TABLE OF CONTENTS

Page

SECTION 1 DESCRIPTION 1-1

SECTION 2 SPECIFICATIONS 2-1

SECTION 3 OPERATING INSTRUCTIONS 3-1

SECTION 4 PERIODIC INSPECTIONS 4-1

SECTION 5 MAINTENANCE PROCEDURES 5-1

SECTION 6 TROUBLE-SHOOTING 6-1

SECTION 7 INSTALLATION AND STORAGE 7-1

SECTION 8 TABLES 8-1

v

LYCOMING OPERATOR’S MANUAL

vi

LYCOMING OPERATOR’S MANUAL

SECTION 1

DESCRIPTION

Page

General.......................................................................................................................................................... 1-1

Cylinders.......................................................................................................................................................1-1

Valve Operating Mechanism ...................................................................................................................... 1-1

Crankcase .....................................................................................................................................................1-1

Crankshaft.................................................................................................................................................... 1-1

Connecting Rods .......................................................................................................................................... 1-1

Pistons ...........................................................................................................................................................1-2

Accessory Housing.......................................................................................................................................1-2

Oil Sump.......................................................................................................................................................1-2

Cooling System.............................................................................................................................................1-2

Induction System..........................................................................................................................................1-2

Lubrication System...................................................................................................................................... 1-2

Priming System............................................................................................................................................ 1-3

Ignition System.............................................................................................................................................1-3

Model Application Table............................................................................................................................. 1-3

This Page Intentionally Left Blank.

LYCOMING OPERATOR’S MANUAL SECTION 1

IO-320 SERIES DESCRIPTION

SECTION 1

DESCRIPTION

The IO, AIO and LIO-320 series are four cylinder, direct drive, and horizontally opposed air-cooled

engines.

In referring to the location of the various engine components, the parts are described in their relationship

to the engine as installed in the airframe. Thus, the power take-off end is considered the front and the

accessory drive end the rear. The sump section is considered the bottom and the opposite side of the engine

where the shroud tubes are located the top. Reference to the left and right side is made with the observer

facing the rear of the engine. The cylinders are numbered from front to rear, odd numbers on the right, even

numbers on the left. The direction of rotation for accessory drives is determined with the observer facing the

drive pad. The direction of rotation of the crankshaft, viewed from the rear, is clockwise.

NOTE

The letter “L” in the model prefix denotes the reverse rotation of the basic model. Example:

model IO-320-C has clockwise rotation of the crankshaft. Therefore, LIO-320-C has

counterclockwise rotation of the crankshaft. Likewise, the rotation of the accessory drives of

the LIO-320-C are opposite those of the basic model as listed in Section 2 of this manual

Operational aspects of both engines are the same and performance curves and specifications

for the basic model will apply to the model with reverse rotation.

Cylinders – The cylinders are of the conventional air-cooled construction with the two major parts, head and

barrel, screwed and shrunk together. The heads are made from an aluminum alloy casting with a fully

machined combustion chamber. Rocker shaft bearing supports are cast integral with the head along with

housings to form the rocker boxes for both valve rockers. The cylinder barrels, which are machined from

chrome nickel molybdenum steel forgings, have deep integral cooling fins and the inside of the barrels are

ground and honed to a specified finish.

Valve Operating Mechanism – A conventional type camshaft is located above and parallel to the crankshaft.

The camshaft actuates hydraulic tappets, which operate the valves through push rods and valve rockers. The

valves rockers are supported on full floating steel shafts. The valve springs bear against hardened steel seats

and is retained on the valve stems by means of split keys.

Crankcase – The crankcase assembly consists of two reinforced aluminum alloy castings, fastened together

by means of studs, bolts and nuts. The mating surfaces of the two castings are joined without the use of a

gasket, and the main bearing bores are machined for use of prevision type main bearing inserts.

Crankshaft – The crankshaft is made from a chrome nickel molybdenum steel forging. All bearing journal

surfaces are nitrided.

Connecting Rods – The connecting rods are made in the form

They have replaceable bearing inserts in the crankshaft ends and bronze bushings in the piston ends. Two

bolts and nuts through each cap retain the bearing caps on the crankshaft ends.

1-1

SECTION 1 LYCOMING OPERATOR’S MANUAL

DESCRIPTION IO-320 SERIES

Pistons – The pistons are machined from an aluminum alloy. The piston pin is of a full floating type with a

plug located in each end of the pin. Depending on the cylinder assembly, pistons may employ either half

wedge or full wedge rings. Consult the latest revision of Service Instruction No. 1037 for proper piston and

ring combinations.

Accessory Housing – The accessory housing is made from an aluminum casting and is fastened to the rear of

the crankcase and the top rear of the sump. It forms a housing for the oil pump and the various accessory

drives.

Oil Sump (Except AIO Series) – The sump incorporates an oil drain plug, oil suction screen, mounting pad

for fuel injector, the intake riser and intake pipe connections.

Crankcase Covers (AIO Series) – Crankcase covers are employed on the top and bottom of the engine.

These covers incorporate oil suction screens and oil scavenge line connections. The top cover incorporates a

connection for a breather line and the lower cover a connection for an oil suction line.

Cooling System – These engines are designed to be cooled by air pressure. Baffles are provided to build up a

pressure and force the air through the cylinder fins. The air is then exhausted to the atmosphere through gills

or augmenter tubes usually located at the rear of the cowling.

Induction System – Lycoming IO-320 series engines are equipped with a Bendix type RSA fuel injector.

The fuel injection system schedules fuel flow in proportion to air flow and fuel vaporization takes place at

the intake ports.

A brief description of the fuel injector follows:

The Bendix RSA type fuel injection system is based on the principle of measuring airflow and using the

airflow signal in a stem type regulator to convert the air force into a fuel force. This fuel force (fuel pressure

differential) when applied across the fuel metering section (jetting system) makes fuel flow proportional to

airflow. A manual mixture control and idle-cut-off are provided.

Lubrication System – The lubrication system is of the pressure wet sump type. The main bearings,

connecting rod bearings, camshaft bearings, valve tappets, push rods and crankshaft idler gears are

lubricated by means of oil collectors and spray. The oil pump, which is located in the accessory housing,

draws oil through a drilled passage leading from the oil suction screen located in the sump. The oil from the

pump then enters a drilled passage in the accessory housing, where a flexible line leads the oil to the

external oil cooler. In the event that cold oil or an obstruction should restrict the flow of oil to the cooler, an

oil cooler bypass valve is provided. Pressure oil from the cooler returns to a second threaded connection on

the accessory housing from which point a drilled passage conducts the oil to the oil pressure screen, which

is contained in a cast chamber located on the accessory housing below the tachometer drive.

The oil pressure screen is provided to filter from the oil any solid particles that may have passed through

the suction screen in the sump. After being filtered in the pressure screen chamber, the oil is fed through a

drilled passage to the oil relief valve, located in the upper right side of the crankcase in front of the

accessory housing.

1-2

LYCOMING OPERATOR’S MANUAL SECTION 1

IO-320 SERIES DESCRIPTION

This relief valve regulates the engine oil pressure by allowing excessive oil to return to the sump, while

the balance of the pressure oil is fed to the main oil gallery in the right half of the crankcase. During its

travel through this main gallery, the oil is distributed by means of separate drilled passages to the main

bearings of the crankshaft. Separate passages from the rear main bearings supply pressure oil to both

crankshaft idler gears. Angular holes are drilled through the main bearings to the rod journals. Oil from the

main oil gallery also flows to the cam and valve gear passages, and is then conducted through branch

passages to the hydraulic tappets and camshaft bearings. Oil enters the tappets through indexing holes and

travels out through the hollow push rods to the valve mechanism, lubricating the valve rocker bearings and

valve stems. Residual oil from the bearings, accessory drives and the rocker boxes is returned by gravity to

the sump, where after passing through a screen it is again circulated through the engine. Pressure build up

within the crankcase is held to a minimum by means of a breather located on the accessory housing.

In addition, model IO-320-C1A incorporates oil jets in the crankcase. The oil jets furnish an oil spray to

provide internal cooling for the pistons.

Priming System – Provision for a primer system is provided on all engines employing a carburetor. Fuel

injected engines do not require a priming system.

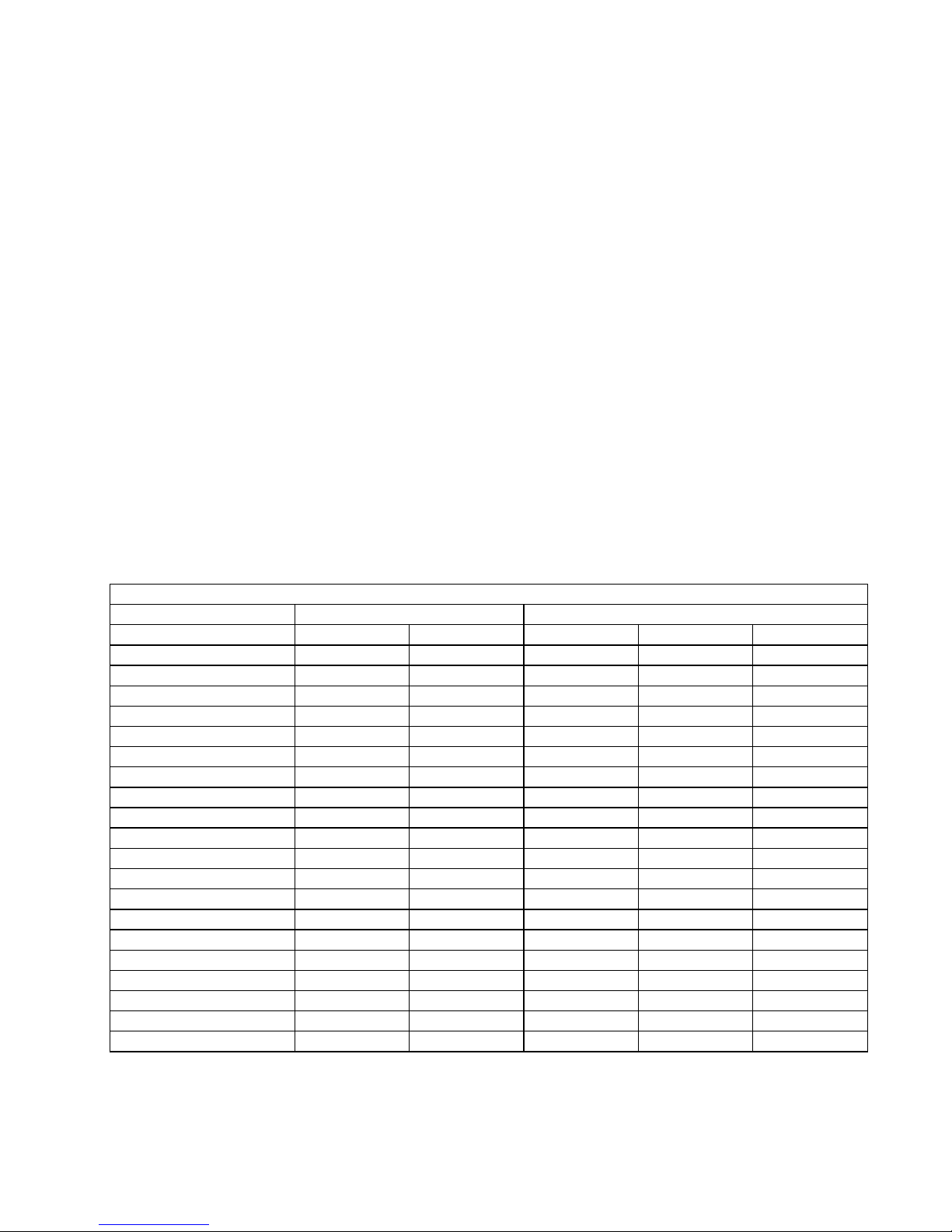

Ignition System – Two magnetos furnish dual ignition. Consult Table 1 for model application. Bendix

magnetos are designed to permit periodic internal maintenance; Slick Electro magnetos are designed to

operate approximately 900 hours without internal maintenance.

TABLE 1

MODEL APPLICATION

Model Magnetos Dimensions

IO-320 Left Right Height Width Length

-A1A, -A2A* S4LN-200 S4LN-204 19.22 32.24 33.59

-B1A, -B2A* S4LN-21 S4LN-20 19.22 32.24 33.59

-B1B S4LN-21 S4LN-20 19.22 32.24 33.59

-B1C S4LN-21 S4LN-20 19.22 32.24 32.09

-B1D S4LN-1208 S4LN-1209 19.22 32.24 32.09

-B1E 4251 4250 19.22 32.24 32.09

-C1A, -C1B S4LN-21 S4LN-21 19.22 32.24 33.59

-D1A, -D1B S4LN-1227 S4LN-1209 23.18 32.24 30.70

-D1C 4251 4250 23.19 32.24 29.05

-E1A, -E2A* S4LN-21 S4LN-20 23.18 32.24 29.56

-E1B 4051 4050 23.19 32.24 29.05

-E2B* 4051 4050 23.18 32.24 29.05

AIO-320

-A1A, -A2A* S4LN-1208 S4LN-1209 20.76 32.24 30.08

-A1B, -A2B* S4LN-1227 S4LN-1209 20.76 32.24 30.08

-B1B S4LN-1227 S4LN-1209 20.76 32.24 30.08

-C1B S4LN-1227 S4LN-1209 25.57 32.24 30.08

LIO-320

-B1A S4RN-21 S4RN-20 19.22 32.24 33.59

-C1A S4RN-21 S4RN-21 19.22 32.24 33.59

* - Fixed Pitch Propeller

1-3

This Page Intentionally Left Blank.

LYCOMING OPERATOR’S MANUAL

SECTION 2

SPECIFICATIONS

Page

Explanatory Note.........................................................................................................................................2-1

Specifications – IO-320-A1A, -A2A, -E1A, -E1B, -E2A, -E2B................................................................. 2-2

Specifications – IO-320-B1A, -B1B, -B1C, -B1D, -B2A, -E1A, -D1B;

AIO-320; LIO-320......................................................................................................................................2-2

Specifications – IO-320-C1A, -C1B............................................................................................................ 2-2

Specifications – IO-320-B1E, -D1C............................................................................................................ 2-3

Accessory Drive Ratio..................................................................................................................................2-3

Detail Weights .............................................................................................................................................. 2-3

This Page Intentionally Left Blank.

LYCOMING OPERATOR’S MANUAL SECTION 2

IO-320 SERIES SPECIFICATIONS

SECTION 2

SPECIFICATIONS

The model specifications shown on the following pages of this section are divided according to model

designation. When differences among models can be clearly stated, the specifications of more than one

model are combined in a single group; otherwise each model has its specifications listed separately. Also, as

additional models are added to this series, new specification pages containing data pertinent to the new

models will be added.

2-1

SECTION 2 LYCOMING OPERATOR’S MANUAL

SPECIFICATIONS IO-320 SERIES

SPECIFICATIONS

IO-320-A1A, -A2A, -E1A, -E1B, -E2A, -E2B

FAA Type Certificate ................................................................................................................................. 1E12

Rated horsepower...........................................................................................................................................150

Rated speed, RPM........................................................................................................................................2700

Bore, inches.................................................................................................................................................5.125

Stroke, inches..............................................................................................................................................3.875

Displacement, cubic inches.........................................................................................................................319.8

Compression ratio ....................................................................................................................................... 7.0:1

Firing order ............................................................................................................................................. 1-3-2-4

Spark occurs, degrees BTC..............................................................................................................................25

Valve rocker clearance (hydraulic tappets collapsed) ......................................................................... .028-.080

Propeller drive ratio ....................................................................................................................................... 1:1

Propeller drive rotation (viewed from rear) ........................................................................................Clockwise

IO-320-B1A, -B1B, -B1C, -B1D, -B2A, -D1A, -D1B; AIO-320; LIO-320

FAA Type Certificate ................................................................................................................................. 1E12

Rated horsepower...........................................................................................................................................160

Rated speed, RPM........................................................................................................................................2700

Bore, inches.................................................................................................................................................5.125

Stroke, inches..............................................................................................................................................3.875

Displacement, cubic inches.........................................................................................................................319.8

Compression ratio ....................................................................................................................................... 8.5:1

Firing order* ........................................................................................................................................... 1-3-2-4

Spark occurs, degrees BTC..............................................................................................................................25

Valve rocker clearance (hydraulic tappets collapsed) ......................................................................... .028-.080

Propeller drive ratio ....................................................................................................................................... 1:1

Propeller drive rotation

All but LIO-320 Series......................................................................................................................Clockwise

LIO-320 Series......................................................................................................................Counterclockwise

IO-320-C1A, -C1B

FAA Type Certificate ................................................................................................................................. 1E12

Rated horsepower...........................................................................................................................................160

Rated speed, RPM........................................................................................................................................2700

Bore, inches.................................................................................................................................................5.125

Stroke, inches..............................................................................................................................................4.375

Displacement, cubic inches.........................................................................................................................319.8

Compression ratio ....................................................................................................................................... 8.5:1

Firing order* ........................................................................................................................................... 1-3-2-4

Spark occurs, degrees BTC..............................................................................................................................25

Valve rocker clearance (hydraulic tappets collapsed) ......................................................................... .028-.080

Propeller drive ratio ....................................................................................................................................... 1:1

Propeller drive rotation

All but LIO-320 Series......................................................................................................................Clockwise

LIO-320 Series......................................................................................................................Counterclockwise

* - LIO-320 Series Only

2-2

LYCOMING OPERATOR’S MANUAL SECTION 2

IO-320 SERIES SPECIFICATIONS

SPECIFICATIONS (CONT.)

IO-320-B1E, -D1C

FAA Type Certificate ................................................................................................................................. 1E12

Rated horsepower...........................................................................................................................................160

Rated speed, RPM........................................................................................................................................2700

Bore, inches.................................................................................................................................................5.125

Stroke, inches..............................................................................................................................................4.875

Displacement, cubic inches.........................................................................................................................319.8

Compression ratio ....................................................................................................................................... 8.5:1

Firing order ............................................................................................................................................. 1-3-2-4

Spark occurs, degrees BTC..............................................................................................................................25

Valve rocker clearance (hydraulic tappets collapsed) ......................................................................... .028-.080

Propeller drive ratio ....................................................................................................................................... 1:1

Propeller drive rotation (viewed from rear) ........................................................................................Clockwise

*Accessory Drive Drive Ratio **Direction of Rotation

Starter 13.556:1 Counterclockwise

Starter 16.556:1 Counterclockwise

Generator 1.910:1 Clockwise

Generator 2.500:1 Clockwise

Alternator 3.250:1 Clockwise

Tachometer 0.500:1 Clockwise

Magneto 1.000:1 Clockwise

Vacuum Pump 1.300:1 Counterclockwise

Prop. Gov. AN20010

Mounted on Accy. Hsg. 0.866:1 Clockwise

Mounted on Crankcase 0.895:1 Clockwise

Fuel Pump AN20003 1.000:1 Counterclockwise

Dual Drives

* - When applicable.

** - Viewed facing drive pad.

NOTE that LIO-320 series engines will have opposite rotation to the above.

DETAIL WEIGHTS

1. Engine, Standard, Dry Weight.

Includes fuel injector, magnetos, spark plugs, ignition harness, intercylinder baffles, tachometer drive,

starter and generator (alternator) drive, starter and generator (alternator) with mounting bracket.

2-3

SECTION 2 LYCOMING OPERATOR’S MANUAL

SPECIFICATIONS IO-320 SERIES

DETAIL WEIGHTS (CONT.)

IO-320 SERIES

LBS.

-A1A, -A2A ...................................................................................................................................................280

-E1B ...............................................................................................................................................................283

-B1B, -E1A, -E2A, -E2B ...............................................................................................................................285

-B1A, -B2A, -B1C .........................................................................................................................................287

-B1D...............................................................................................................................................................288

-D1A ..............................................................................................................................................................291

-D1B...............................................................................................................................................................293

-C1A...............................................................................................................................................................301

-D1C...............................................................................................................................................................306

-B1E ...............................................................................................................................................................307

-C1B...............................................................................................................................................................313

AIO-320 SERIES

LBS.

-A1A, -A2A ...................................................................................................................................................306

-A1B, A2B, -B1B, -C1B................................................................................................................................307

2-4

LYCOMING OPERATOR’S MANUAL

SECTION 3

OPERATING INSTRUCTIONS

Page

General.......................................................................................................................................................... 3-1

Prestarting Items of Maintenance.............................................................................................................. 3-1

Starting Procedures..................................................................................................................................... 3-1

Cold Weather Starting ................................................................................................................................ 3-2

Ground Running and Warm-Up................................................................................................................3-2

Ground Check.............................................................................................................................................. 3-3

Operation in Flight ...................................................................................................................................... 3-4

Fuel Mixture Leaning Procedure........................................................................................................... 3-4

Leaning to Exhaust Gas Temperature Gage..................................................................................... 3-4

Leaning to Flowmeter..........................................................................................................................3-5

Leaning with Manual Mixture Control.............................................................................................3-5

Engine Flight Chart..................................................................................................................................... 3-5

Operating Conditions .................................................................................................................................. 3-6

Engine Shut Down .......................................................................................................................................3-7

Performance Curves.................................................................................................................................... 3-9

This Page Intentionally Left Blank.

LYCOMING OPERATOR’S MANUAL SECTION 3

IO-320 SERIES OPERATING INSTRUCTIONS

SECTION 3

OPERATING INSTRUCTIONS

1. GENERAL. Close adherence to these instructions will greatly contribute to long life, economy and

satisfactory operation of the engine.

NOTE

YOUR ATTENTION IS DIRECTED TO THE WARRANTIES THAT APPEAR IN THE

FRONT OF THIS MANUAL REGARDING ENGINE SPEED, THE USE OF SPECIFIED

FUELS AND LUBRICANTS, REPAIRS AND ALTERATIONS. PERHAPS NO OTHER ITEM

OF ENGINE OPERATION AND MAINTENANCE CONTRIBUTES QUITE SO MUCH TO

SATISFACTORY PERFORMANCE AND LONG LIFE AS THE CONSTANT USE OF

CORRECT GRADES OF FUEL AND OIL, CORRECT ENGINE TIMING, AND FLYING

THE AIRCRAFT AT ALL TIMES WITHIN THE SPEED AND POWER RANGE SPECIFIED

FOR THE ENGINE. DO NOT FORGET THAT VIOLATION OF THE OPERATION AND

MAINTENANCE SPECIFICATIONS FOR YOUR ENGINE WILL NOT ONLY VOID YOUR

WARRANTY BUT WILL SHORTEN THE LIFE OF YOUR ENGINE AFTER ITS WARRANTY

PERIOD HAS PASSED.

New engines have been carefully run-in by Lycoming; therefore, no further break-in is necessary insofar

as operation is concerned; however, new or newly overhauled engines should be operated on straight

mineral oil for a minimum of 50 hours or until oil consumption has stabilized. After this period, a change to

an approved additive oil may be made, if so desired.

NOTE

Cruising should be done at 65% to 75% power until a total of 50 hours has accumulated or

oil consumption has stabilized. This is to ensure proper seating of the rings and is applicable

to new engines, and engines in service following cylinder replacement or top overhaul of one

or more cylinders.

The minimum fuel octane rating is listed in the flight chart, Part 8 of this section. Under no circumstances

should fuel of a lower octane rating or automotive fuel (regardless of octane rating) be used.

2. PRESTARTING ITEMS OF MAINTENANCE. Before starting the aircraft engine for the first flight of the

day, there are several items of maintenance inspection that should be performed. These are described in

Section 4 under Daily Pre-Flight Instruction. They must be observed before the engine is started.

3. STARTING PROCEDURES.

The following starting procedures are recommended, however, the starting characteristics of various

installations will necessitate some variation from these procedures.

NOTE

Cranking periods must be limited to ten (10) to twelve (12) seconds with a five (5) minute

rest between cranking periods.

3-1

SECTION 3 LYCOMING OPERATOR’S MANUAL

OPERATING INSTRUCTIONS IO-320 SERIES

a. Fuel Injected Engines (Cold).

(1) Perform preflight inspection.

(6) Open throttle wide open, move until a slight but steady flow is

noted (approximately 3 to 5 second

(8) Open throttle ¼ of travel.

(9) Set magneto selector switch. (Consult airf

(10) Engage starter.

(12) Move mixture control slowly

(13) Check oil pressure gage. If minimum oil pressure is not indicated within thirty seconds, stop

engine and determine trouble.

b. Fuel Injected Engines (Hot). Because of the fact that the fuel percolates and the system must be

cleared of vapor, it is recommended that the same procedure be used as outlined for cold engine start.

4. COLD WEATHER STARTING. During extreme cold weather, it may be necessary to preheat the engine

and oil before starting.

5. GROUND RUNNING AND WARM-UP.

The engines covered in this manual are air-pressure cooled and depend on the forward speed of the aircraft

to maintain proper cooling. Particular care is necessary, therefore, when operating these engines on the

ground. To prevent overheating, it is recommended that the following precautions be observed.

NOTE

Any ground check that requires full throttle operation must be limited to three minutes, or

less if the indicated cylinder head temperature should exceed the maximum stated in this

manual.

3-2

Loading...

Loading...