Page 1

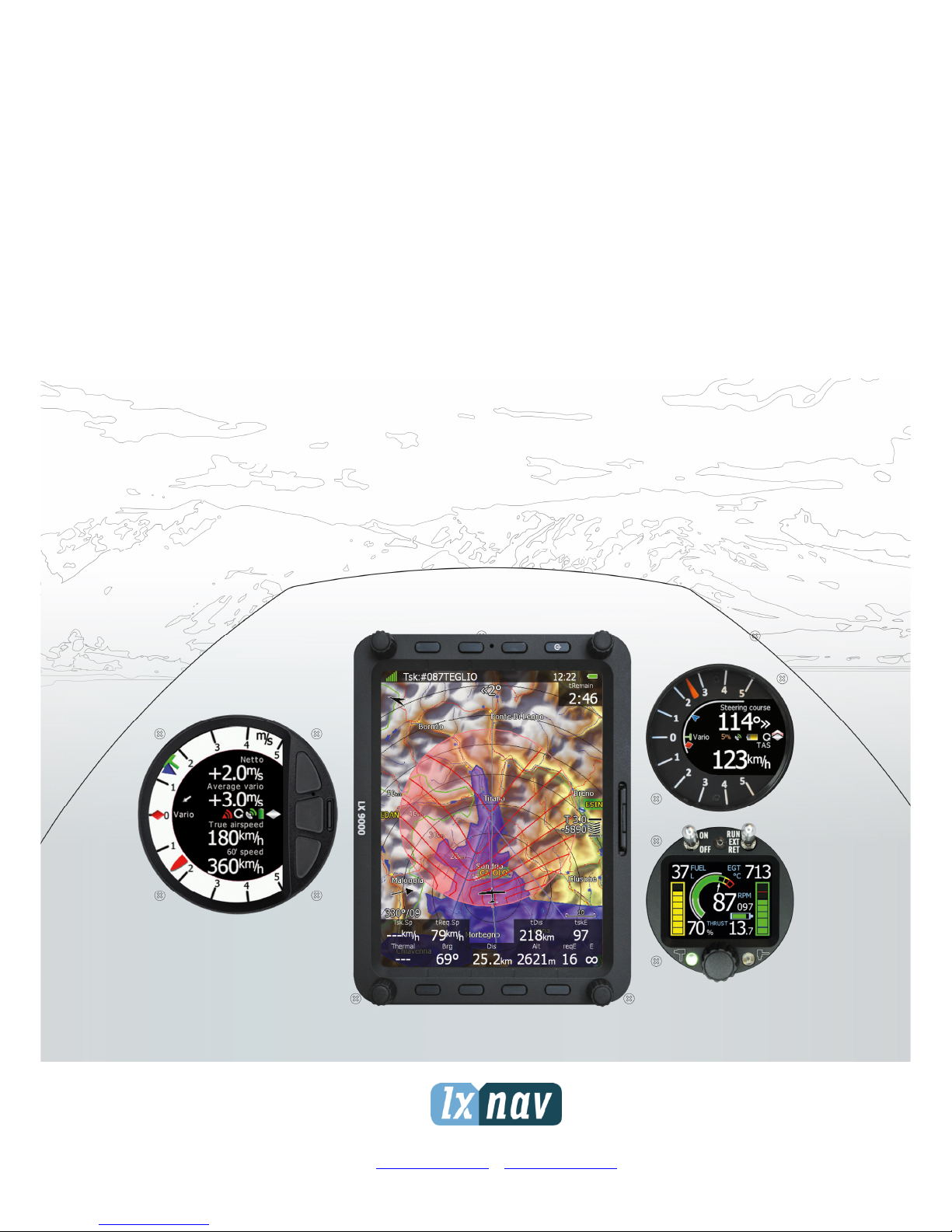

LX90xx and

LX80xx

System installation manual

LXNAV d.o.o. • Kidričeva 24a, 3000 Celje, Slovenia • tel +386 592 33 400 fax +386 599 33 522

info@lxnav.com

•

www.lxnav.com

Page 2

Page 3

1 Important Notices 5

1.1 Limited Warranty 5

2 Introduction 6

3 System planning 7

3.1 Power consumption 7

3.2 Power supply 9

3.3 Sizes and weights 10

3.4 Temperature specifications 11

3.5 Location requirements 11

3.5.1 LX9000 and Lx9070 11

3.5.2 Lx9050 12

3.5.3 LX8080 12

3.5.4 LX8000 12

3.5.5 V5, V9 vario 12

3.5.6 V8 vario 12

3.5.7 V80 vario 12

3.5.8 I9 and I8 vario indicators 12

3.5.9 I80 vario indicator 12

3.5.10 Flap sensor 13

3.5.11 Magnetic compass 13

3.5.12 FlarmLED and FlarmView 13

3.5.13 FlarmView57 13

3.5.14 Wi-Fi module 13

3.5.15 Bluetooth module 13

3.5.16 MOP sensor (for jet engine) 13

3.5.17 MOP sensor (for electric propulsion gliders) 13

3.5.18 Bridges 13

3.6 Cooling requirements 13

3.7 Mounting requirements 13

4 Overview of the system 14

4.1 Overview 14

4.2 Communication BUS 14

4.3 Harness and Cables 14

4.4 Splitters 15

4.5 Ethernet port 15

4.6 Available Cables and Harnesses 15

4.7 Examples of systems 17

5 Installation and Configuration 20

5.1 Main unit and repeater unit 20

5.1.1 Installation of Options 20

5.1.2 Cut-outs 21

5.1.2.1 Lx9000 cut-out 21

5.1.2.2 Lx9070 cut-out 22

5.1.2.3 Lx9050 cut-out 23

5.1.2.4 Lx8080 cut-out 23

5.1.2.5 Lx8000 cut-out 24

5.1.3 Dimensions 25

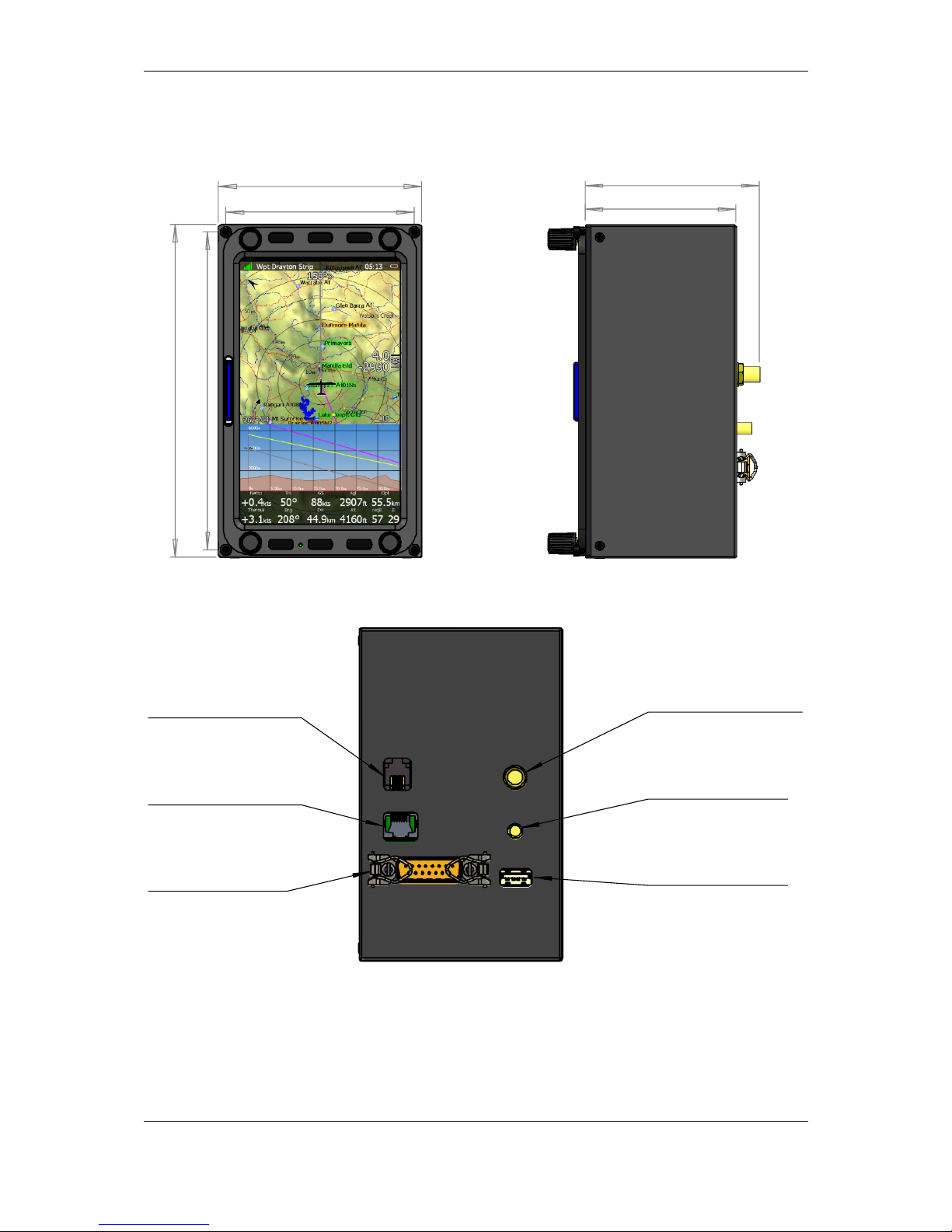

5.1.3.1 LX9000 dimensions 25

5.1.3.2 LX9070 dimensions 26

5.1.3.3 LX9050 dimensions 27

5.1.3.4 LX8080 dimensions 28

5.1.3.5 LX8000 dimensions 29

Page 4

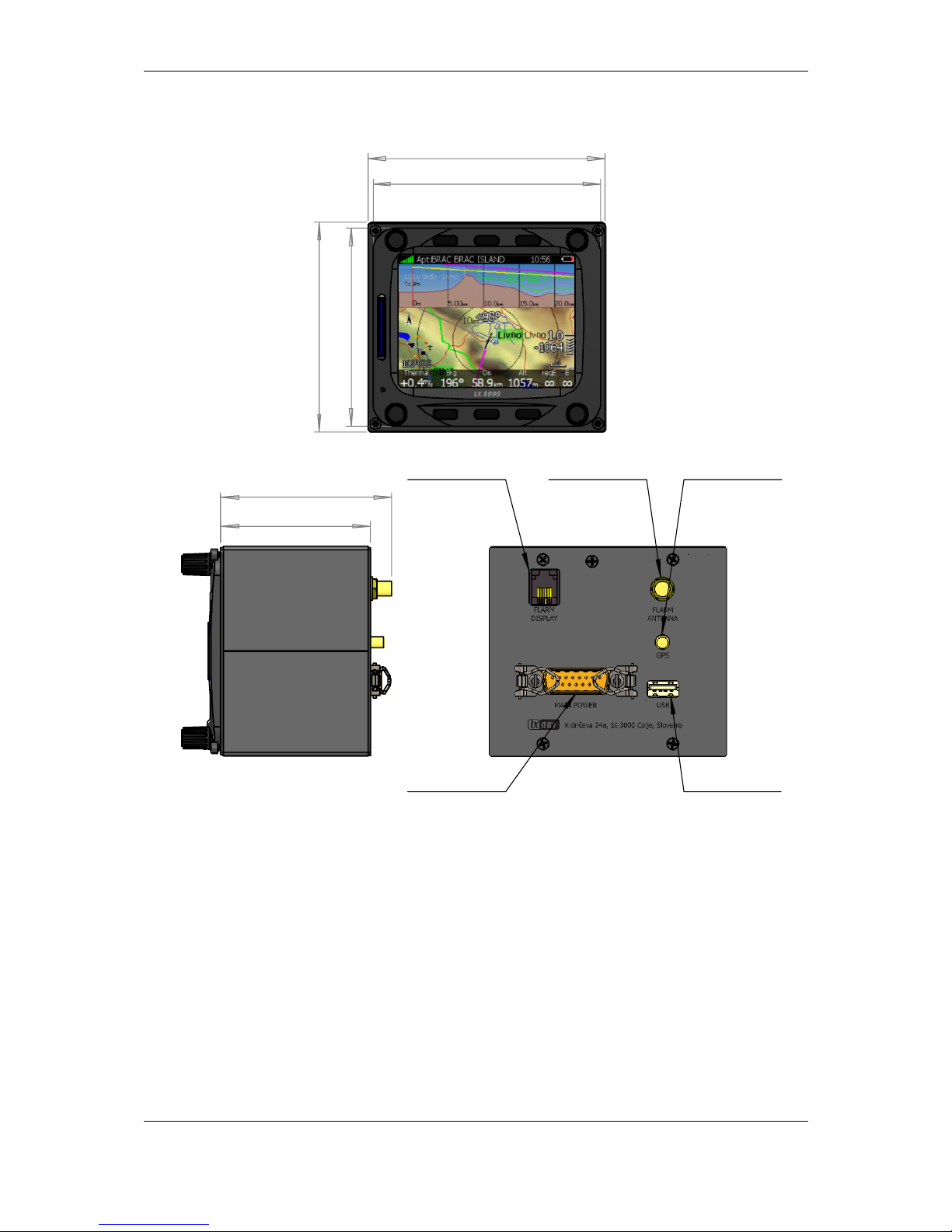

5.1.3.6 V5, V9 dimensions 30

5.1.3.7 V8 dimensions 31

5.1.3.8 V80 dimensions 32

5.1.3.9 I5, I8 dimensions 32

5.1.3.10 I80 dimensions 32

5.1.1 Ports 33

5.1.1.1 LX9000 33

5.1.1.2 LX9050 33

5.1.1.3 LX9050 simple 34

5.1.2 LX8000 Digital unit 34

5.1.3 LX8000 Digital unit Version 2 35

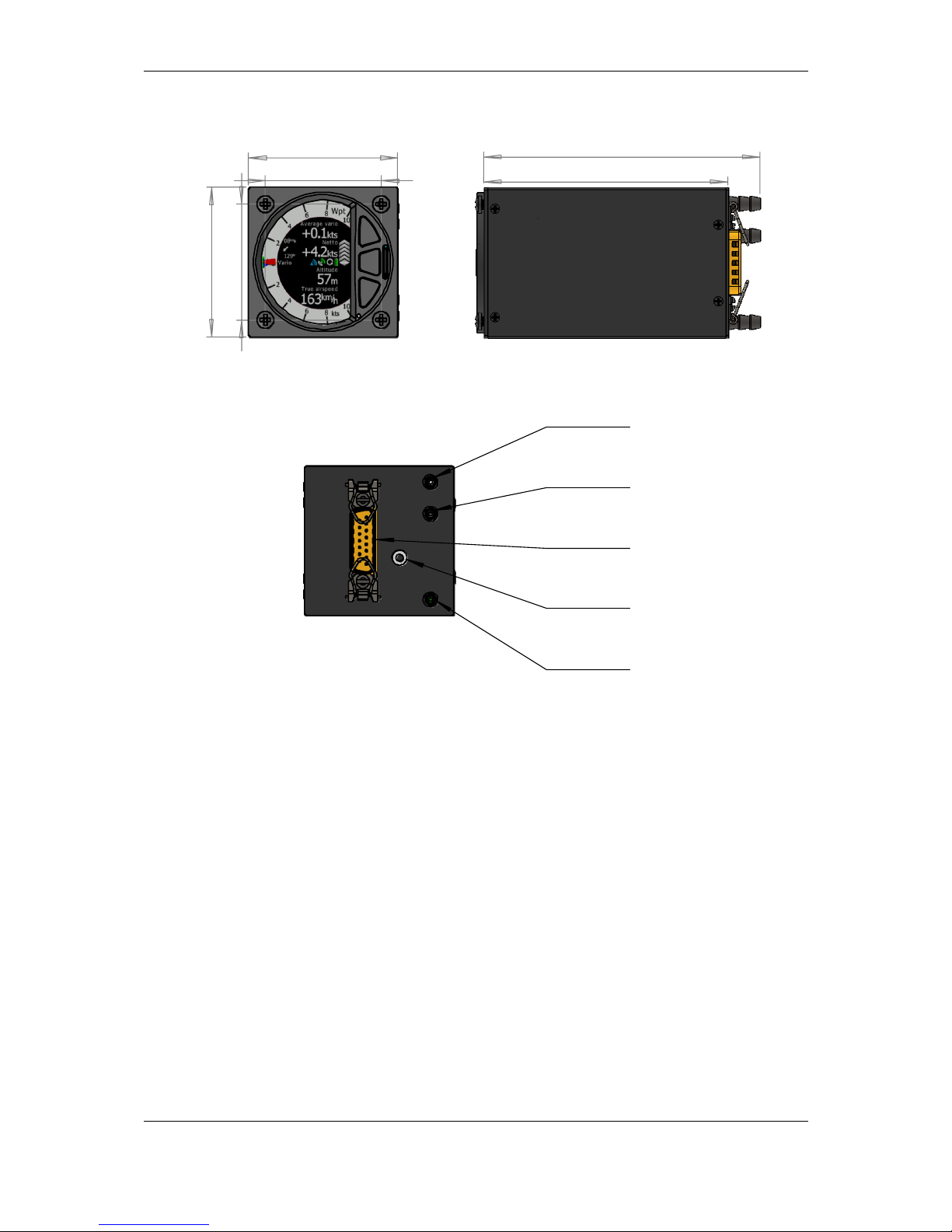

5.1.4 LX8080 Digital unit 35

5.1.5 LX8080 Digital unit Version 2 36

5.1.6 LX8080 Digital unit Simple Version 36

5.1.7 Flarm Port (for LX8000 Versions 1 – no 12V output) 37

5.1.7.1 Flarm port on LX9xxx 37

5.1.7.2 PDA port (RJ45 38

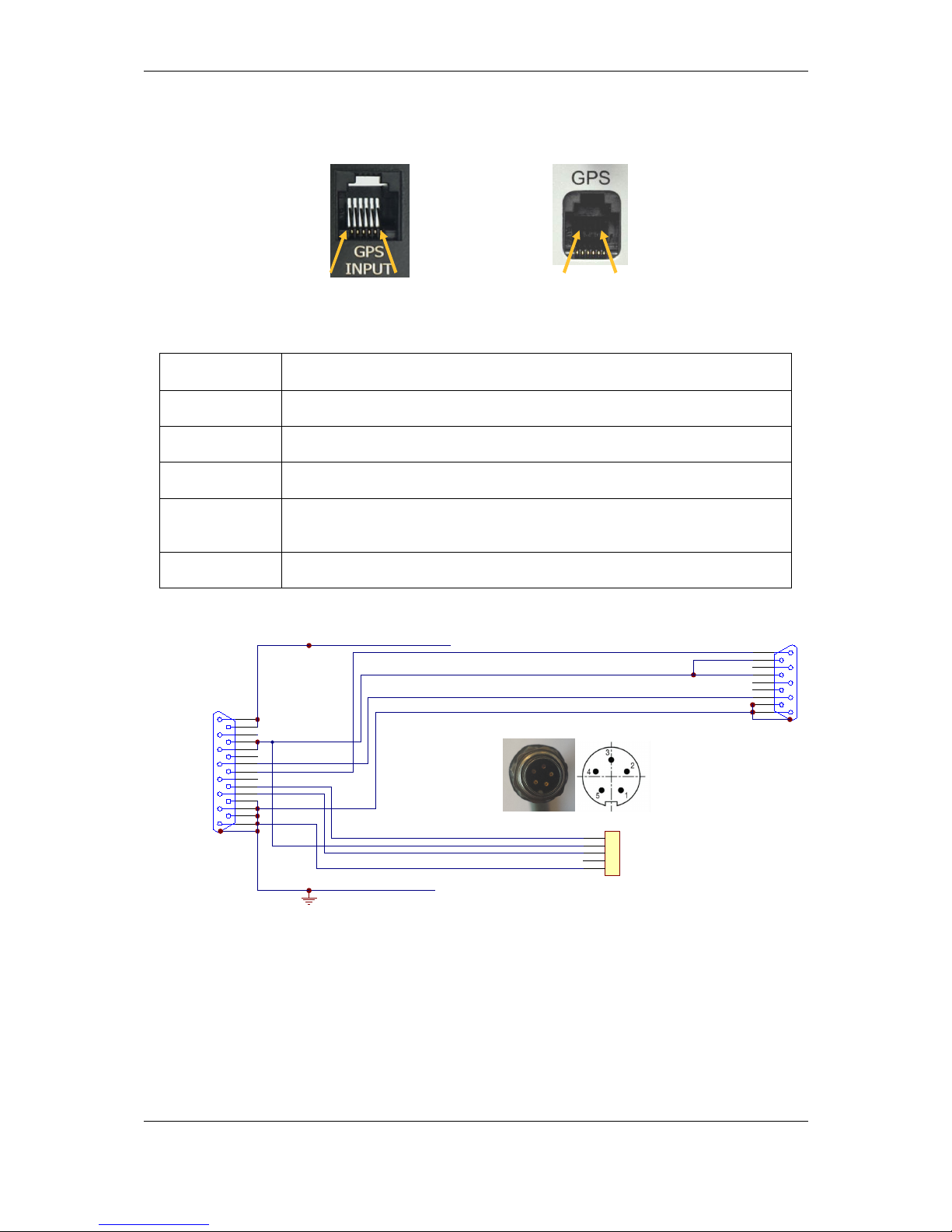

5.1.7.3 GPS ports (RJ11) only on Simple version 39

5.1.1 Wirings 39

5.2 Connection and Functionality Check of All Peripheral Units 39

5.2.1 Vario Unit 40

5.2.1.1 Connecting vario unit 40

5.2.1.2 Cut-outs 40

5.2.1.1 Wirings 41

5.2.1.2 Connection to the bus 42

5.2.1.3 Pneumatics 42

5.2.1.4 Audio 44

5.2.1.5 Inputs 44

5.2.2 Installation of Options 45

5.2.2.1 Remote Sticks 45

5.2.2.2 Flarm 46

5.2.2.3 External Flarm or Power Flarm 46

5.2.2.4 ADSB receiver 47

5.2.2.5 Additional indicators 50

5.2.2.6 Flap Sensor 50

5.2.2.7 485 to 232 bridge 50

5.2.2.8 Wi-Fi___33 53

5.2.2.9 Compass 53

5.2.2.10 AHRS 54

5.2.2.11 FES Bridge 54

5.2.2.12 JDU Bridge 54

5.2.2.13 FlarmLED display 55

5.2.2.14 FlarmView display 56

5.2.2.15 FlarmView57 display 57

5.2.2.16 Flarm ACL 59

5.2.2.17 Bluetooth module 60

6 Firmware updates 61

7 Troubleshooting 62

7.1 Export Diagnostic Files 62

8 Revision History 63

Page 5

Important Notices Version 1.0, June 2015

Page 5 of 65

1 Important Notices

The LXNAV system is designed for VFR use only as an aid to prudent navigation. All

information is presented for reference only. Terrain, airports and airspace data are provided

only as an aid to situation awareness.

Information in this document is subject to change without notice. LXNAV reserves the right

to change or improve their products and to make changes in the content of this material

without obligation to notify any person or organisation of such changes or improvements.

A Yellow triangle is shown for parts of the manual which should be read very

carefully and are important for operating the system.

Notes with a red triangle describe procedures which are critical and may result in

loss of data or any other critical situation.

A bulb icon is shown when a useful hint is provided to the reader.

1.1 Limited Warranty

This LXNAV product is warranted to be free from defects in materials or workmanship for

two years from the date of purchase. Within this period, LXNAV will, at its sole option,

repair or replace any components that fail in normal use. Such repairs or replacement will

be made at no charge to the customer for parts and labour, provided that the customer shall

be responsible for any transportation cost. This warranty does not cover failures due to

abuse, misuse, accident, or unauthorised alterations or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES EXPRESSED OR IMPLIED OR STATUTORY, INCLUDING ANY

LIABILITY ARISING UNDER ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES YOU

SPECIFIC LEGAL RIGHTS, WHICH MAY VARY FROM STATE TO STATE.

IN NO EVENT SHALL LXNAV BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR

CONSEQUENTIAL DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE, OR

INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN THE PRODUCT. Some states do

not allow the exclusion of incidental or consequential damages, so the above limitations may

not apply to you. LXNAV retains the exclusive right to repair or replace the unit or software,

or to offer a full refund of the purchase price, at its sole discretion. SUCH REMEDY SHALL

BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

To obtain warranty service, contact your local LXNAV dealer or contact LXNAV directly.

June 2015 © 2015 LXNAV. All rights reserved.

Page 6

Introduction Version 1.0, June 2015

Page 6 of 65

2 Introduction

The printed version of this installation manual is in grayscale. Some figures and diagrams

are in colour information. Please refer to electronic version to see colours. The latest

electronic version of this manual can be downloaded on http://www.lxnav.com section

downloads-manuals.

This manual will guide you through installation process of all systems, components, basic

setup and check of the system.

Before use of any part of the system, please read and understand installation and

user manual!

Inside unit is not any serviceable part, so the unit must be taken to service at the

factory.

Opening unit by user will void warranty and airworthy

Page 7

System planning Version 1.0, June 2015

Page 7 of 65

3 System planning

In this chapter, installer will be informed, how and where can be installed particular parts of

equipment. Some parts have environmental and location requirements, some not.

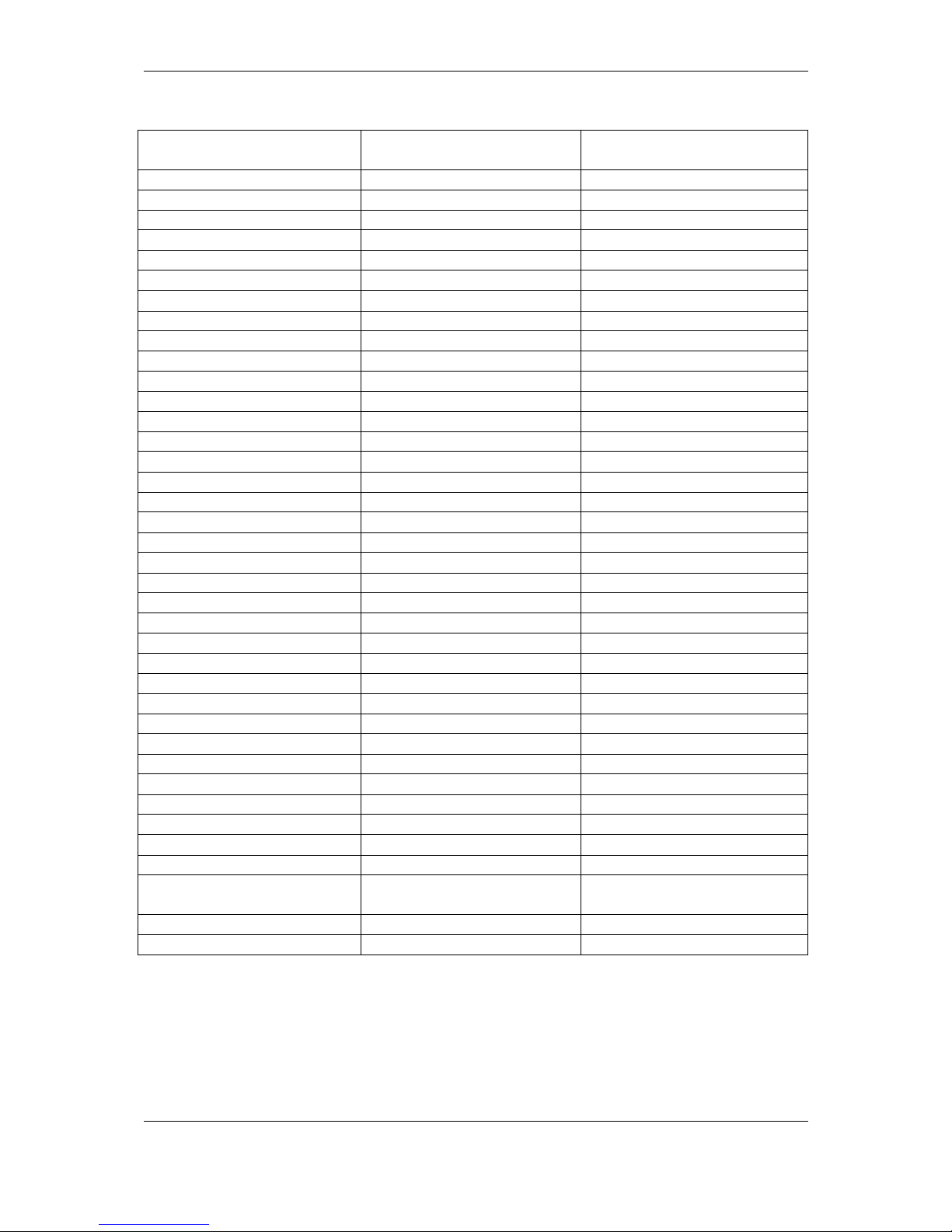

3.1 Power consumption

Some modules get power supply from the main unit. These modules do not need a circuit

breaker. It is calculated for main unit. Other parts of equipment that are having its own

power supply, should have installed specified circuit breakers.

Page 8

System planning Version 1.0, June 2015

Page 8 of 65

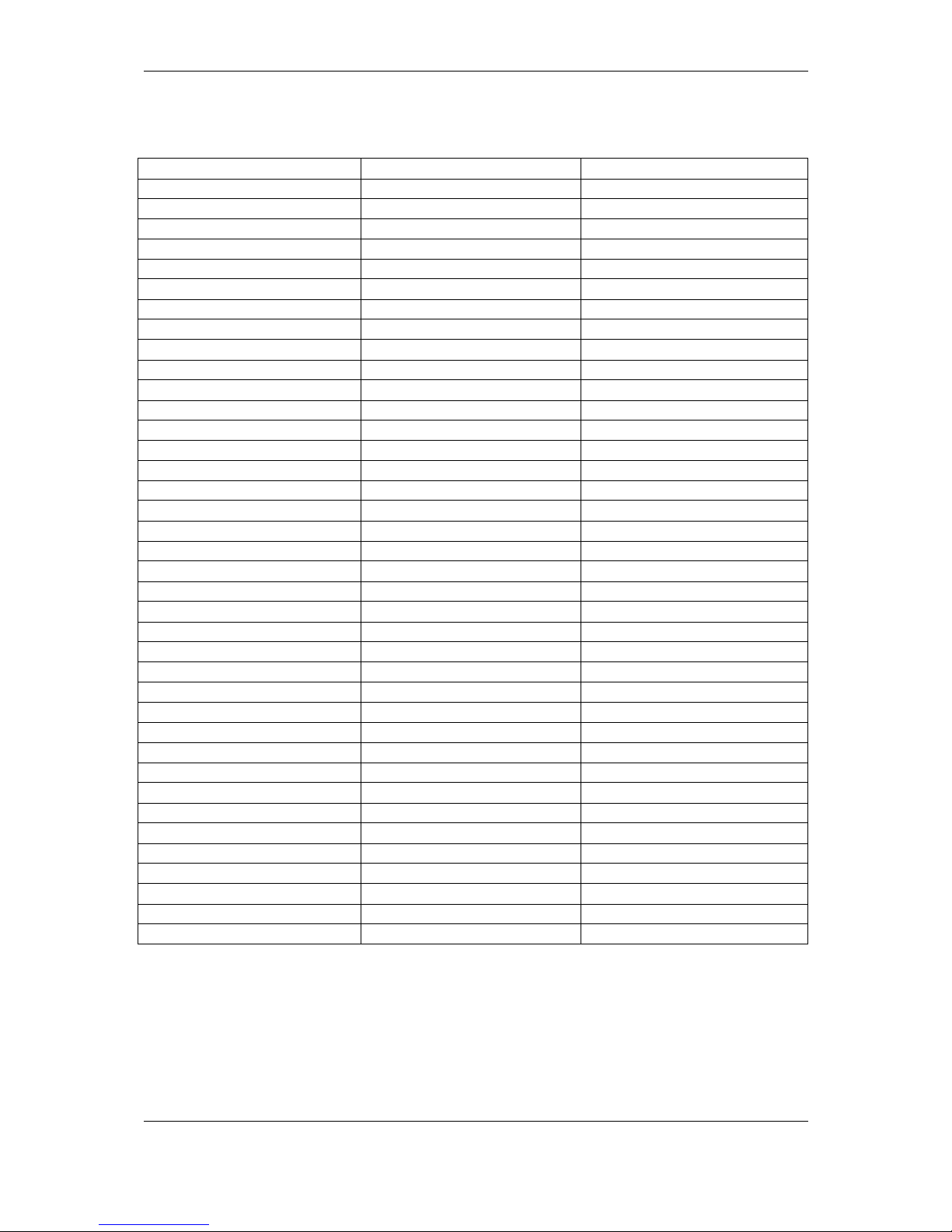

Appro

ximate Current

consumption at 12V DC

Recommended circuit

breaker

LX9000 main unit

500mA (at max. brightness)

3A

LX9000F main unit

520mA (at max. brightness)

3A

LX9000D repeater unit

480mA (at max. brightness)

3A

LX9070 main unit

660mA (at max. brightne

ss) 3A LX9070F main unit

680mA (at max. brightness)

3A

LX9070D repeater unit

640mA (at max. brightness)

3A

LX9050 main unit

590mA (at max. brightness)

3A

LX9050F main unit

610mA (at max. brightness)

3A

LX9050D repeater unit

570mA (at max. brightness)

3A

LX8080 main unit

250mA (at max. brightness)

3A

LX8080F main unit

270mA (at max. brightness)

3A

LX8080D repeater unit

230mA (at max. brightness)

3A

LX8000 main unit

300mA (at max. brightness)

3A

LX8000F main unit

350mA (at max. brightness)

3A

LX800

0D repeater unit

250mA (at max. brightness)

3A

V5 Vario

150mA (no audio)

-

V9 Vario

130mA (no audio)

-

V80 Vario

180mA (no audio)

-

V8 Vario

150mA (no audio)

-

Vario indicator (57mm I5)

80mA

-

Vario indicator (57mm I8)

110mA

-

Vario indicator (80mm

I80) 100mA

-

Remote stick

20mA

-

Flap sensor

30mA

-

Magnetic compass

70mA

-

Radio bridge

20mA

-

Transponder bridge

20mA

-

NMEA bridge

20mA

-

PDA port *

800mA

- Wi-Fi

module

20mA

-

FES bridge

40mA

-

JDU bridge

40mA

-

Flarm LED display

30mA (with

out beeper)

-

FlarmView display

70mA

-

FlarmView

57 display

70mA

-

Flarm ACL

30mA (without current for

driving LEDs)

3A Bluetooth

module

10mA

-

MOP sensor

100mA

-

* Not on all types of devices

Page 9

System planning Version 1.0, June 2015

Page 9 of 65

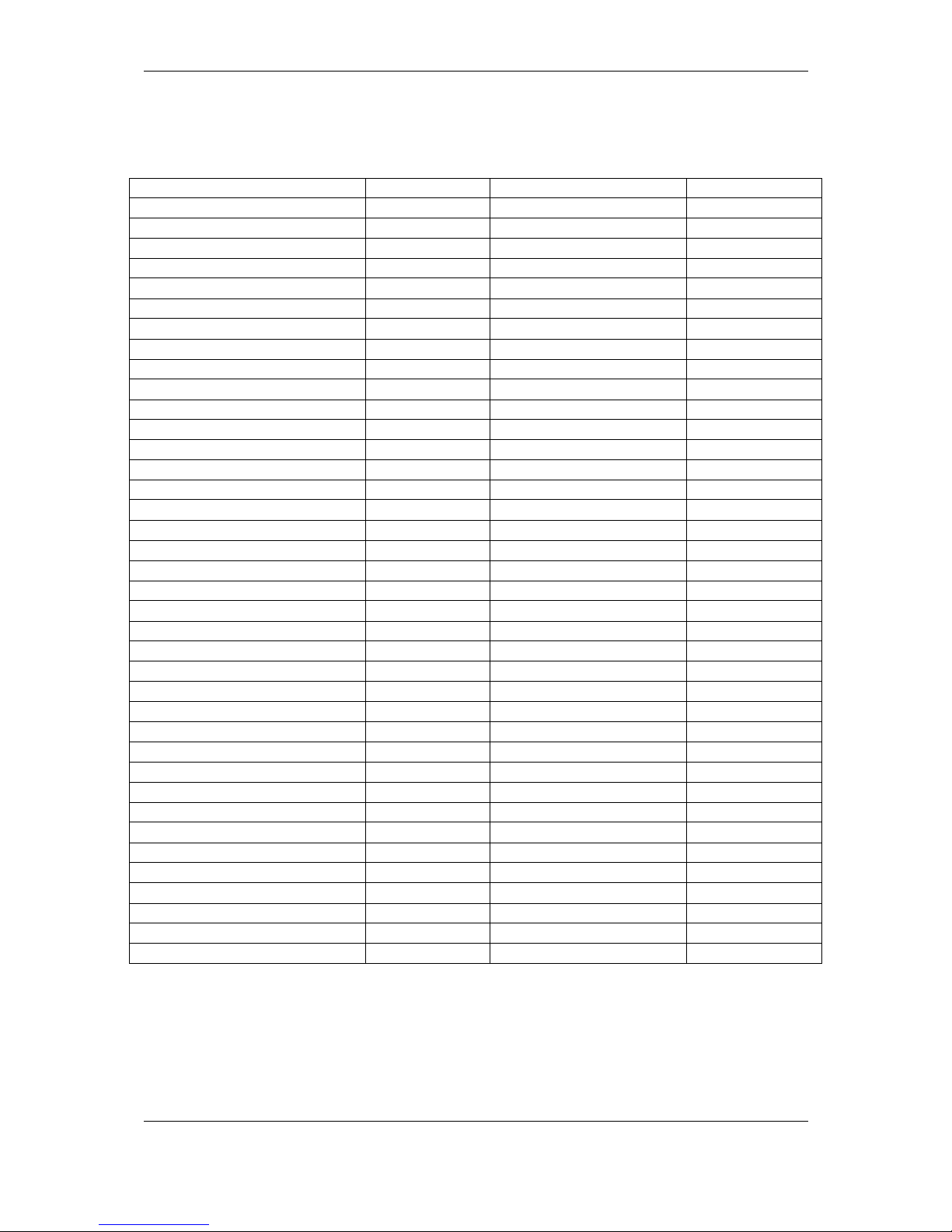

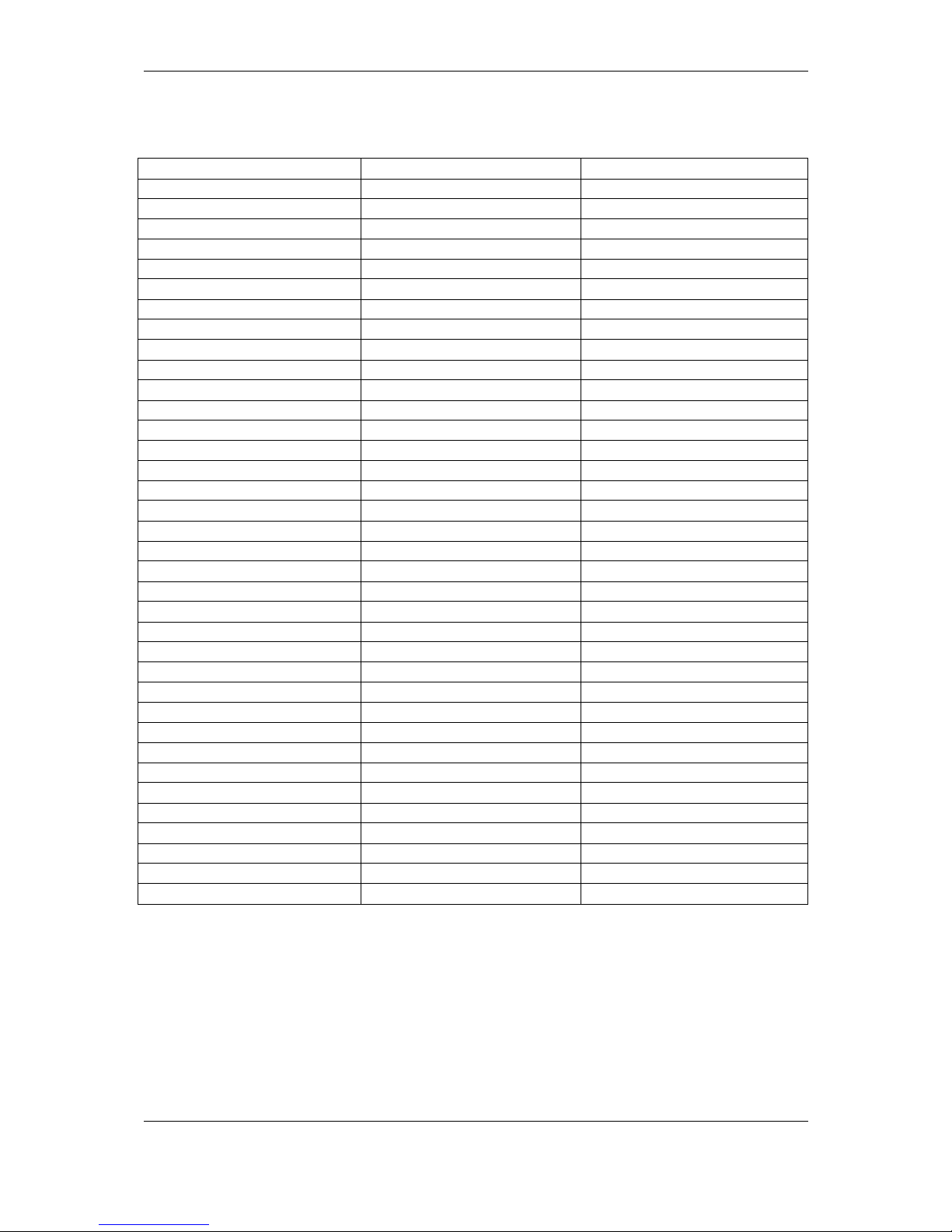

3.2 Power supply

Min.

voltage

Nominal

voltage

Max

. Voltag

e LX9000 main unit

10V 12V 16V LX9000F main unit

10V 12V 16V LX9000D repeater unit

10V 12V 16V LX9070 main unit

10V 12V 16V LX9070F main unit

10V 12V 16V LX9070D repeater unit

10V 12V 16V LX9050 main unit

10V 12V 16V LX9050F main unit

10V 12V 16V LX9050D repeater unit

10V 12V 16V LX8080 main unit

10V 12V 16V LX8080F main unit

10V 12V 16V LX8080D repeater unit

10V 12V 16V LX8000 main unit

10V 12V 16V LX8000F main unit

10V 12V 16V LX8000D repeater unit

10V 12V 16V V5 Vario

12V (from RS485)

V9 Vario

12V (from RS485)

V80 Vario

12V (from RS485)

V8 Vario

12V (from RS485)

Vario indicator (57mm

I5) 12V (from RS485)

Vario indicator (57mm

I8) 12V (from RS485)

Vario indicator (80mm

I

80)

12V (from RS485)

Remote stick

12V (from RS485

)

Flap sensor

12V (from RS485)

Magnetic compass

12V (from RS485)

Radio bridge

12V (from RS485)

Transponder bridge

12V (from RS485)

NMEA bridge

12V (from RS485)

Wi-Fi___33

module

5V (from USB)

FES bridge

12V (from RS485)

JDU bridge

12V

(from RS485)

Flarm LED display

3.2V

3.3V (from Flarm port)

3.4V

FlarmView display

9V

12V (from Flarm port)

16V FlarmView

2 display

9V

12V (from Flarm port)

16V FlarmView

57 display

9V

12V (from Flarm port)

16V Flarm ACL

9V

12V 18V Bluetooth

module

5V (from PDA)

MOP sensor

12V

Page 10

System planning Version 1.0, June 2015

Page 10 of 65

3.3 Sizes and weights

Dimensions

Weight

LX9000 main unit

113 x 145 x 38 mm 615 g

LX9000F main unit

113 x 145 x 38 mm 635 g

LX9000D repeater unit

113 x 145 x 38 mm 615 g

LX9070 main unit

113 x 181 x 38 mm 630 g

LX9070F main unit

113 x 181 x 38 mm 650 g

LX9070D repeater unit

113 x 181 x 38 mm 630 g

LX9050 main unit

136 x 83 x 61 mm

515 g

LX9050F main unit

136 x 83 x 61 mm

535 g

LX9050D repeater unit

136 x 83 x 61 mm

515 g

LX8080 main unit

82 x 82 x

60 mm

435 g

LX8080F main unit

82 x 82 x

60 mm

454 g

LX8080D repeater unit

82 x 82 x

60 mm

435 g

LX8000 main unit

98 x 88 x

65 mm

500 g

LX8000F main unit

98 x 88 x

65 mm

520 g

LX8000D repeater unit

98 x 88 x

65 mm

500 g

V5 Va

rio 61 x 61 x 92 mm

300 g

V9 Vario

61 x 61 x 92 mm

310 g

V80 Vario

81 x 81 x 130 mm

400 g

V8 Vario

61 x 61 x 92 mm

305 g

Vario indicator (57mm V5)

61 x 61 x

42 mm 200 g

Vario indicator (57mm V8)

61 x 61 x

48 mm 200 g

Vario indicator (80mm V80)

81 x 81 x 44 mm

270 g

Remote stick

Approx. 150

mm App

rox. 290 g

Flap sensor

52 x 23 x 16 mm

Approx. 190 g

Magnetic compass

56 x 40 x 15 mm

Approx. 100 g

Radio bridge

52 x 32 x 16 mm

45 g

Transponder bridge

52 x 32 x 16 mm

45 g

NMEA bridge

52 x 32 x 16 mm 45 g Wi-Fi module

40 x 20 x 9 mm

16 g

FES bridge

61 x

32 x 16 mm

20 g

JDU bridge

61 x

32 x 16 mm

20 g

Flarm LED display

42mm x 25mm x 5mm

10 g

FlarmView display

65 x 42 x 11 mm 27 g FlarmView

57 display

60 x 60 x 26 mm 98 g FlarmView

2 display

65 x 42 x 18 mm 36 g

Flarm ACL

76

x 63 x 26 mm 75 g

Bluetooth

module

64 x 18 x 10 mm 8 g MOP sensor

66 x 50 x 25 mm 71 g

Page 11

System planning Version 1.0, June 2015

Page 11 of 65

3.4 Temperature specifications

Storage temperature

Operating temperature

LX9000 main unit

-40°C to +80°C

-30°C to +

60°C

LX9000F main unit

-40°C to +80°C

-30°C to +60°C

LX9000D repeater unit

-40°C to +80°C

-30°C to +60°C

LX9070 main unit

-40°C to +80°C

-30°C to +60°C

LX9070F main unit

-40°C to +80°C

-30°C to +60°C

LX9070D repeater unit

-40°C to +80°C

-30°C to +60°C

LX9050 main unit

-40°C

to +80°C

-30°C to +60°C

LX9050F main unit

-40°C to +80°C

-30°C to +60°C

LX9050D repeater unit

-40°C to +80°C

-30°C to +60°C

LX8080 main unit

-40°C to +80°C

-30°C to +60°C

LX8080F main unit

-40°C to +80°C

-30°C to +60°C

LX8080D repeater unit

-40°C to

+80°C

-30°C to +60°C

LX8000 main unit

-40°C to +80°C

-30°C to +60°C

LX8000F main unit

-40°C to +80°C

-30°C to +60°C

LX8000D repeater unit

-40°C to +80°C

-30°C to +60°C

V5 Vario

-40°C to +80°C

-2

0°C to +60°C

V9 Vario

-40°C to +80°C

-2

0°C to +60°C

V80

Vario

-40°C to +80°C

-2

0°C to +60°C

V8 Vario

-40°C to +80°C

-2

0°C to +60°C

Vario indicator (57mm I5)

-40°C to +80°C

-30°C to +60°C

Vario indicator (57mm I8)

-40°C to +80°C

-30°C to +60°C

Vario indicator (80mm I80)

-40°C to +80°C

-30°C to +60°C

Remote

stick

-40°C to +80°C

-30°C to +60°C

Flap sensor

-40°C to +80°C

-30°C to +60°C

Magnetic compass

-40°C to +80°C

-2

0°C to +60°C

Radio bridge

-40°C to +80°C

-30°C to +60°C

Transponder bridge

-40°C to +80°C

-30°C to +60°C

NMEA bridge

-40°C to +80°C

-30°C t

o +60°C

PDA port *

-40°C to +80°C

-30°C to +60°C

Wi-

Fi___33

module

-40°C to +80°C

-30°C to +60°C

FES bridge

-40°C to +80°C

-30°C to +60°C

JDU bridge

-40°C to +80°C

-30°C to +60°C

Flarm LED display

-40°C to +80°C

-2

0°C to +60°C

FlarmView display

-40°C

to +80°C

-30°C to +60°C

Flarm ACL

-40°C to +80°C

-30°C to +60°C

Bluetooth

module

-40°C to +80°C

-30°C to +60°C

3.5 Location requirements

3.5.1 LX9000 and Lx9070

- Requires 35 mm of space behind the panel

- main unit harness needs additionally 45 mm of the space

- Choose position, that display will be viewable

Page 12

System planning Version 1.0, June 2015

Page 12 of 65

3.5.2 Lx9050

- Requires 65 mm of space behind the panel

- main unit harness needs additionally 45 mm of the space

- Choose position, that display will be viewable

3.5.3 LX8080

- Requires 60 mm of space behind the panel

- main unit harness needs additionally 45 mm of the space

- Choose position, that display will be viewable

3.5.4 LX8000

- Requires 65 mm of space behind the panel

- main unit harness needs additionally 45 mm of the space

- Choose position, that display will be viewable

3.5.5 V5, V9 vario

- Requires 92 mm of space behind the panel

- V5 and V9 vario unit harness needs additionally 45 mm of the space

- Some space should be taken in account also for pitostatic tubes connection

- Choose position, that display will be viewable

- If the instrument panel is not at right angle, additional AHRS alignment is required

(V9)

3.5.6 V8 vario

- Requires 94 mm of space behind the panel

- V8 vario unit harness needs additionally 45 mm of the space

- Some space should be taken in account also for pitostatic tubes connection

- Choose position, that display will be viewable

- If the instrument panel is not at right angle, additional AHRS alignment is required

3.5.7 V80 vario

- Requires 130 mm of space behind the panel

- V80 vario unit harness needs additionally 45 mm of the space

- Some space should be taken in account also for pitostatic tubes connection

- Choose position, that display will be viewable

- If the instrument panel is not at right angle, additional AHRS alignment is required

3.5.8 I9 and I8 vario indicators

- Requires 43 mm of space behind the panel

- Cable connection needs additionally 45 mm of the space

- Some space should be taken in account also for pitostatic tubes connection

- Choose position, that display will be viewable

3.5.9 I80 vario indicator

- Requires 45 mm of space behind the panel

- Cable connection needs additionally 45 mm of the space

- Some space should be taken in account also for pitostatic tubes connection

- Choose position, that display will be viewable

Page 13

Version 1.0, June 2015

Page 13 of 65

3.5.10 Flap sensor

- Is connected to flap rod – please consult with glider manufacturer about installation

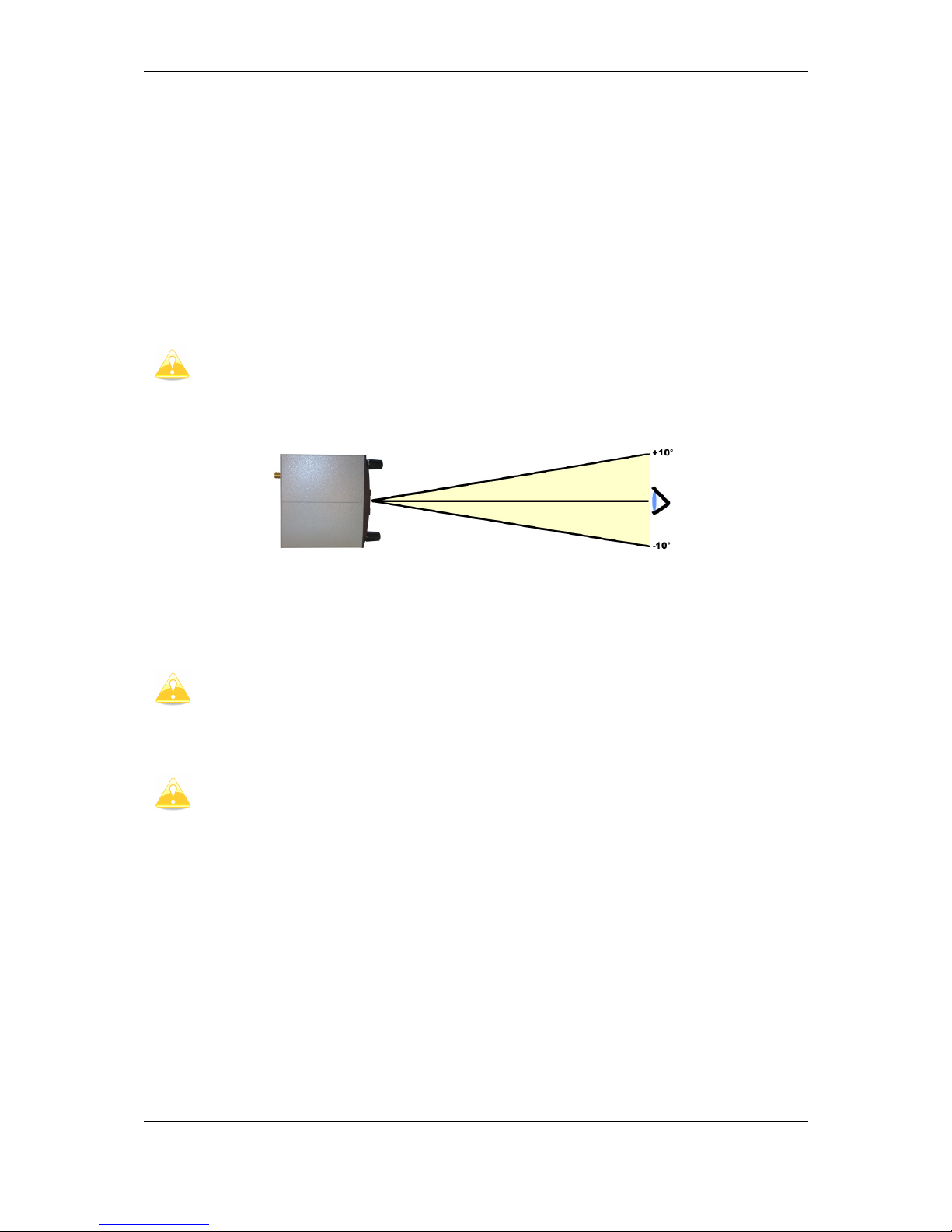

3.5.11 Magnetic compass

- The location should be magnetically benign.

- As far as possible of metal parts, power cables

- In case of small magnetic interferences is available user calibration

- Very important is orientation of the magnetic compass (compass has marked TOP

position and flight direction position)

3.5.12 FlarmLED and FlarmView

- Flarm display should be placed on visible place on panel

- They requires 15 mm of space behind the panel

- Cable will take additional 10 mm of space

3.5.13 FlarmView57

- FlarmView57 should be placed on visible place on panel

- It requires 28 mm of space behind the panel

- Cable will take additional 10 mm of space

3.5.14 Wi-Fi module

- It is plugged in USB port of main unit

- It will take additional 62 mm of space behind the panel

3.5.15 Bluetooth module

- It is plugged in PDA port of main unit (not available at all types)

- It will take additional 55 mm of space behind the panel

3.5.16 MOP sensor (for jet engine)

- It is installed in the engine compartment, so it can easily detect engine noise

3.5.17 MOP sensor (for electric propulsion gliders)

- It is installed near main power lines that are coming out of the battery and measures

the current from batteries.

3.5.18 Bridges

Bridges are designed to be installed into any convenient place of the glider.

3.6 Cooling requirements

In the moment there is no cooling requirements, if possible ventilation should pass through

instrument panel to exchange some warm air. That will drop the temperature behind the

panel for few degrees.

3.7 Mounting requirements

Most of LXNAV units are fastened with screws.

Page 14

Overview of the system Version 1.0, June 2015

Page 14 of 65

4 Overview of the system

4.1 Overview

LXNAV system consists of many different displays, units and sensors, which talk to each

other via LXNAV RS485 bus.

4.2 Communication BUS

Most devices in LXNAV system talk to each other via RS485 bus. We are using standard

SUBD-9 pin connectors. Bus signals can be split via RS485 splitters. More splitters can be

bridged together with RS485 bridge cables.

Another way of communication with peripheral devices is RS232 serial interface. This

interface is mostly used to connect 3rd party devices into LXNAV system (external Flarm,

ADSB, radio, transponder, PDA). For each device we have specially designed cable.

4.3 Harness and Cables

Main unit cable has two power supply wires (red for positive +12V DC and blue for ground

potential), RS485 bus cable with DB9 connector and serial RS232 cable with rounded 5 pin

connector. This rounded 5 pin connector is designed to be mounted in to the panel. It can

be used for connection with PDA device.

Vario harness has also one DB9 RS485 connector, which can be directly plugged in RS485

connector from main unit. In case, we need to connect additional RS485 device (Remote

stick, flap sensor, Magnetic compass, Radio Bridge,), we need to have RS485 splitter. If

splitter has not enough sockets, we must expand RS485 bus to another RS485 splitter

Page 15

Overview of the system Version 1.0, June 2015

Page 15 of 65

through RS485 bridge cable. Compass and Flap sensor have DB9 connectors that can be

plugged directly into the RS485 splitter.

Flarm displays are using standard cables that fit’s to IGC/Flarm standard RJ11 connectors.

4.4 Splitters

LXNAV system can use two types of splitters

- RS485 splitter

- Flarm splitter

RS485 splitter is detailed described in chapters above.

Flarm splitter is used, when we want to connect more than one Flarm display to Flarm port.

4.5 Ethernet port

Almost all devices having Ethernet port which is in the moment used only for development

purposes.

4.6 Available Cables and Harnesses

Cable Part Number

Description

Connection cable NANO power/V7PDA - OUDIE

Order Nr.:CC-NP-OUDIE1

Cable

for connection between

O

udie and

PDA port

Connection cable NANO power/V7PDA

-

standard RS232

Order Nr.:CC-NP-232

Cable for connection between PDA port and

standard RS232 (DB9) connector

Connection cable NANO power/V7PDA

- IPAQ

38xx

Order Nr.:CC-NP-38

Cable

for connection between

PDA and

IPAQ with 38xx family connector

Connection cable NANO power/V7PDA

- PNA

V2, IPAQ 31x

Order Nr.:CC-NP-IPAQ310

Cable

for connection between PDA and

IPAQ with 310 family connector

Connection cable NANO power/V7PDA

-

V7/LX16x/LX16xx

Order Nr.:CC-NP-LX

Cable

fo

r connection between PDA and

LX

device with standard RJ11 port

Connection cable NANO power/V7PDA

-

Lx7xxx

Order Nr.:CC-NP-IGC

Cable for connection between PDA and LX

device with standard IGC RJ11 port

Connection cable NANO power/V7PDA

-

Cable

for connection between PDA and LX

Page 16

Overview of the system Version 1.0, June 2015

Page 16 of 65

Butterfly Connect

Order Nr.:CC-NP-BFC

device with

butterfly connect

Cable Digital Unit (for LX90

xx

/LX80

xx

)

Order

Nr.:du-ca

Main unit harness

Cable Vario Unit (for V5/V9

/V80/V8

)

Order Nr.:vu-

ca

Harness for vario units

Cable Double Seat (for LX90xx/LX80xx)

Order

Nr.:ds-ca

Harness for repeater units, includes 4m

RS485 cable

Cable USB or USB

-

D

Order Nr.: usb-ca

Harness for old types of vario units

Cable RS485 extension cable (4m)

Order Nr.: 485-

4m-ca

Extension cable for connection to

the rear

repeater unit

Cable RS485 bridge (30cm)

Order Nr.: 485-bridge-ca

RS485 bridge cable to bri

d

ge two RS485

splitters

Cable Instrument panel (5P) – PC

Order Nr.: lx5pc-ca

PC communication cable with rounded 5pin

connector. Used for RS232 communication

between PC and main unit. It can be used

also for Flarm firmware update, if update

via DS card is not successful

Cable LX8000/8080/9000 (5P) – FLARM (RJ11)

Order Nr.: lx5flarm-ca

Serial cable for external

Flarm

connection

between rounded 5pin connector and

standard Flarm RJ11 plug, including power

supply.

Cable LX8000/8080/9000 (5P)

PowerFLARM(RJ45)

Order Nr.:lx5PF-ca

Serial cable for external

PowerFLARM

connection between rounded 5pin

connector and standard Flarm RJ45 plug,

including power supply.

Cable LX8000/8080/9000 (5P) – PowerFLARM

Core (DB9)

Order Nr.:lx5pfcore-ca

Serial cable for external

PowerFLARM

connection between rounded 5pin

connector and standard DB9 plug for Power

Flarm Core including power supply.

Cable Flarm (RJ11) FlarmView/

FlarmL

ED

(RJ11)

(cca. 3.5m) Order Nr.:FlarmView3.5m-ca

Standard cable for Flarm displays 3.5m long

Cable Flarm (RJ11) FlarmView/FlarmLED(RJ11)

(cca. 40cm) Order Nr.:FlarmView-ca

Standard cable for

Flarm

displays 40cm

long

Cable PowerFLARM (RJ45)

FlarmView/FlarmLED(RJ11)

(cca. 40cm) Order

Nr.:FlarmViewPF-ca

Standard cable for

Flarm

displays 40cm

long on one side with RJ45 (PowerFLARM)

and another side with RJ11 (FlarmView)

Cable LX9000 TRX1090

Order Nr.:lx9000-TRX-ca (lx5pf-

ca + FlarmView-ca)

This is a cable set to connect ADSB receiver

Page 17

Overview of the system Version 1.0, June 2015

Page 17 of 65

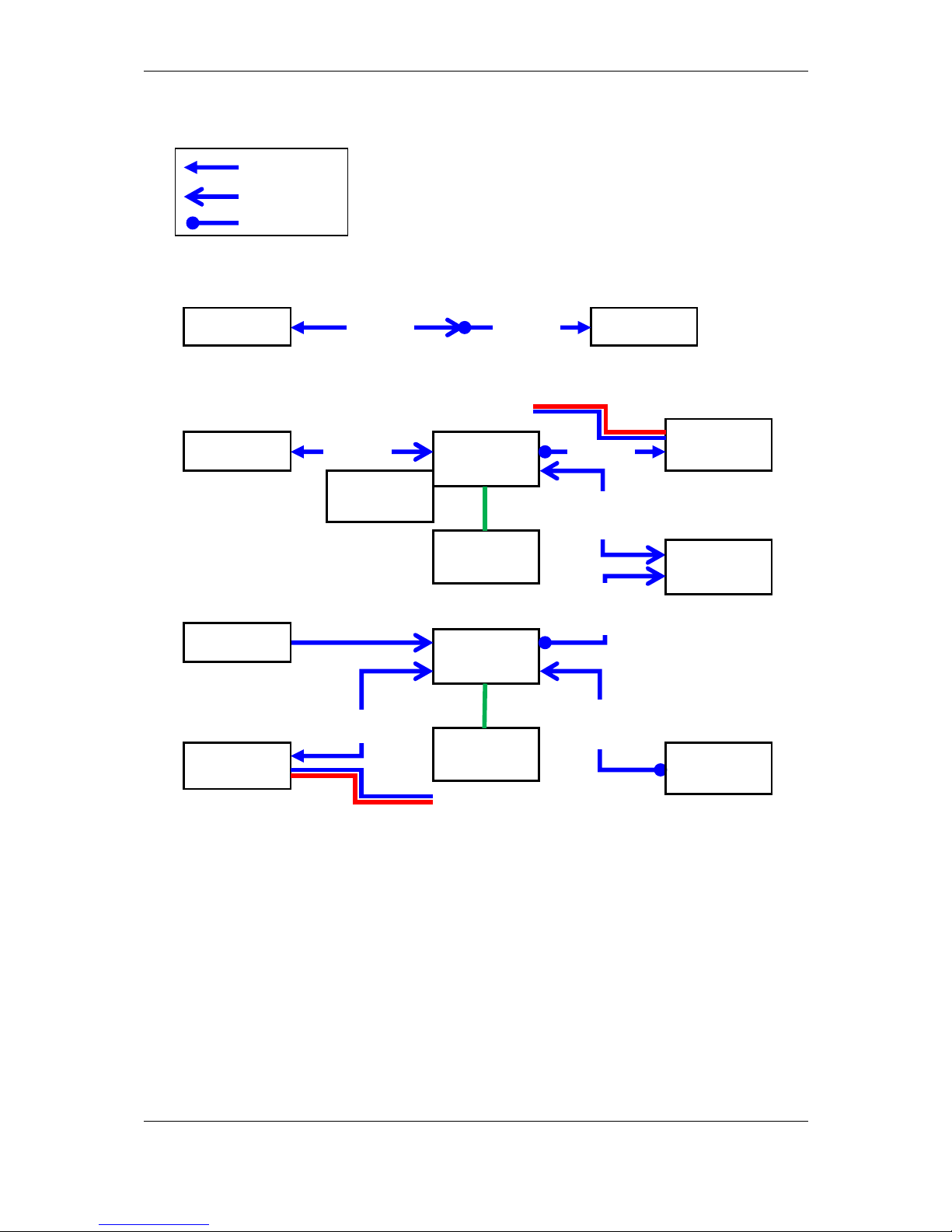

4.7 Examples of systems

Basic installation

More complex installation

DB15 Male

DB9 Female

DB9 Male

RS485

splitter

RS485

splitter

RS485

4m

MOP

sensor

Vario

indicator

RS48

5

MOP

Remote

stick 1

Flap sensor

LX90xxD

DS-CA RS485

Bridge

Radio

Bridge

Remote

stick 2

LX90xx Vario

VU-CA DU-CA

Vario

VU-CA

LX90xx

DU-CA

Power

Power

Page 18

Overview of the system Version 1.0, June 2015

Page 18 of 65

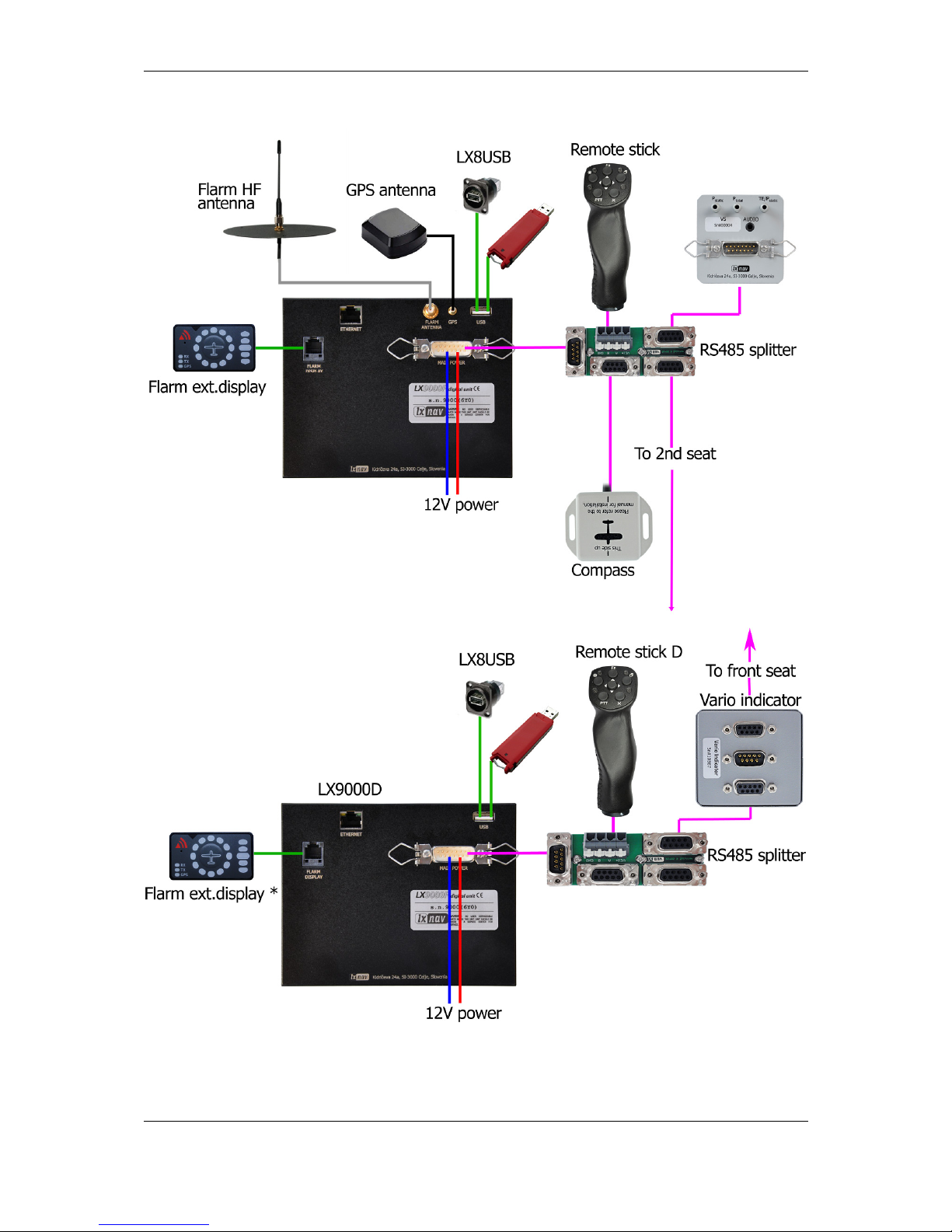

General connection options

* This function may not work on older types of LX9000D

Page 19

Overview of the system Version 1.0, June 2015

Page 19 of 65

Page 20

Installation and Configuration Version 1.0, June 2015

Page 20 of 65

5 Installation and Configuration

5.1 Main unit and repeater unit

Before cutting out the panel, the whole cutting plan of the panel, including all indicators,

must be prepared. Next figure shows the cut-outs for the all types of the units that can be

installed into the panel.

Prepare the cut-out in the instrument panel according to the drilling template. Position the

Main display unit in the cut-out in the instrument panel. Tighten the main display unit with

attached 2.5 mm screws.

When installing the main display unit (LX90xx, LX8000) it is not necessary to

remove the rotary knobs. To install LX8080, is necessary to remove rotary knobs.

Position the main unit in the cut-out in the instrument panel. Tighten the main digital unit

with attached 2.5 mm screws.

When installing the LX8000, LX90xx it is not necessary to remove the rotary

knobs. Only by LX8080 is necessary to remove rotary knobs.

For LX8080 please remove the press

-

in covers from the four main rotary switches

on the LX8080. While holding the knobs, slacken t

he screws with a screwdriver.

Now the knobs can be removed (never use power to remove the knobs, you can

damage rotary switches). Remove the four M6 screws. Position the LX8080 in the

cut-out in the instrument panel. Tighten the LX8080. Tighten the knobs and fix

the covers

5.1.1 Installation of Options

All options except AHRS (LX8000D, LX8080D, Remote Control, Compass Module &

secondary vario indicators) are prepared to be connected to the RS485 system bus by use of

RS485 splitting units. Installation of any option is plug-and-play and therefore requires only

mechanical installation work. The LX8000 digital unit also powers all devices connected to

the bus. An automatic fuse built into the LX8000 digital unit prevents damage to the digital

unit should a short circuit in the wiring or in some attached device occurs.

Page 21

Installation and Configuration Version 1.0, June 2015

Page 21 of 65

5.1.2 Cut-outs

5.1.2.1 Lx9000 cut-out

Drawing is not to scale

Page 22

Installation and Configuration Version 1.0, June 2015

Page 22 of 65

5.1.2.2 Lx9070 cut-out

Drawing is not to scale

Page 23

Installation and Configuration Version 1.0, June 2015

Page 23 of 65

5.1.2.3 Lx9050 cut-out

Drawing is not to scale

5.1.2.4 Lx8080 cut-out

Drawing is not to scale

Page 24

Installation and Configuration Version 1.0, June 2015

Page 24 of 65

5.1.2.5 Lx8000 cut-out

Drawing is not to scale

Page 25

Installation and Configuration Version 1.0, June 2015

Page 25 of 65

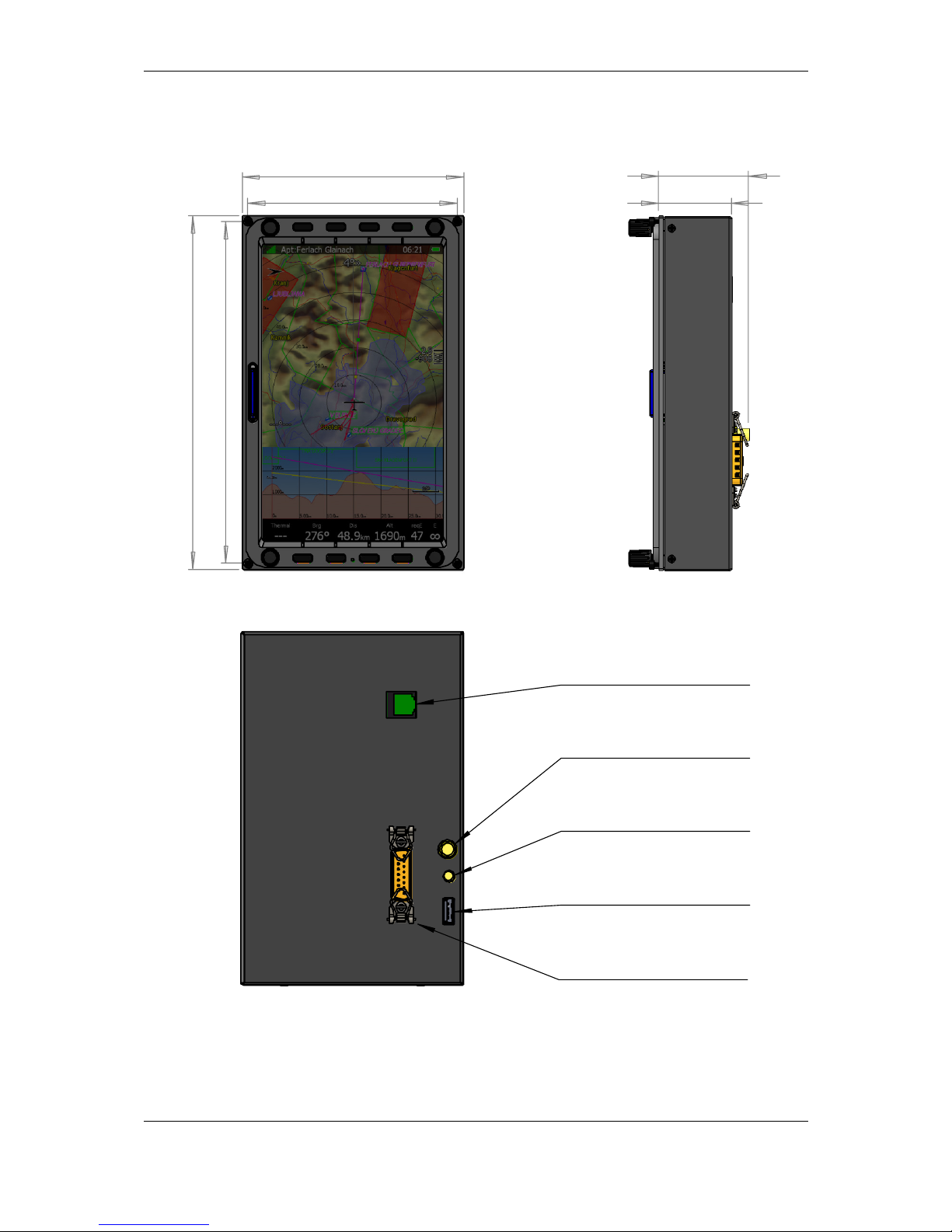

5.1.3 Dimensions

5.1.3.1 LX9000 dimensions

113

145,18

107

139

37,11

46,08

Flarm port

GPS antenna

Flarm antenna

USB port

Main port

Page 26

Installation and Configuration Version 1.0, June 2015

Page 26 of 65

5.1.3.2 LX9070 dimensions

113,50

180,70

174,70

107

46,08

37,11

Flarm port

GPS antenna

Flarm antenna

USB port

Main port

Page 27

Installation and Configuration Version 1.0, June 2015

Page 27 of 65

5.1.3.3 LX9050 dimensions

83

136

130

77

71,05

61,57

Flarm port

GPS antenna

Flarm antenna

USB port

Main port

PDA port

Page 28

Installation and Configuration Version 1.0, June 2015

Page 28 of 65

5.1.3.4 LX8080 dimensions

82

82

63

63

R

3

9

,

8

5

68,35

59,61

Page 29

Installation and Configuration Version 1.0, June 2015

Page 29 of 65

5.1.3.5 LX8000 dimensions

69,85

61,11

97

93

85,60

81

Page 30

Installation and Configuration Version 1.0, June 2015

Page 30 of 65

5.1.3.6 V5, V9 dimensions

93,51

107,01

61

61

23,58

13,50

15

13,50

52

47,38

47,38

R56,30

Page 31

Installation and Configuration Version 1.0, June 2015

Page 31 of 65

5.1.3.7 V8 dimensions

61

47,38

61

47,38

112,90

99,70

Page 32

Installation and Configuration Version 1.0, June 2015

Page 32 of 65

5.1.3.8 V80 dimensions

80,20

80,90

63

63

131,65

148,52

5.1.3.9 I5, I8 dimensions

TBD

5.1.3.10 I80 dimensions

TBD

Page 33

Installation and Configuration Version 1.0, June 2015

Page 33 of 65

5.1.1 Ports

5.1.1.1 LX9000

5.1.1.2 LX9050

GPS antenna

Flarm HF

antenna

Network connector

DO NOT USE IT!

Flarm external

indicators, splitters

USB memory stick

Main power supply

(LX9000DU wiring)

Flarm external

indicators, splitters

PDA port

Flarm HF antenna

GPS antenna

USB memory s

tick Main power supply

(LX9000DU wiring)

Page 34

Installation and Configuration Version 1.0, June 2015

Page 34 of 65

5.1.1.3 LX9050 simple

5.1.2 LX8000 Digital unit

PDA port

GPS input port

USB memory stick

Main power supply

(LX9000DU wiring)

GPS antenna

Network connector

DO NOT USE IT!

Flarm HF

antenna

Flarm external

indicators, splitters

USB memory sticks

Connector to USB1 port

Colibri or any other IGC

Flight recorder

Main power supply

(LX8000DU wiring)

Page 35

Installation and Configuration Version 1.0, June 2015

Page 35 of 65

5.1.3 LX8000 Digital unit Version 2

5.1.4 LX8080 Digital unit

GPS antenna

Flarm HF

antenna

PDA port

Read manual

Flarm external

indicators, splitters

USB memory stick

Main power supply

(DU wiring)

GPS antenna

Flarm HF

antenna

Flarm external

indicators, splitters

USB memory sticks

Connector to USB1 port

Main power supply

(LX8080DU wiring)

Page 36

Installation and Configuration Version 1.0, June 2015

Page 36 of 65

5.1.5 LX8080 Digital unit Version 2

5.1.6 LX8080 Digital unit Simple Version

GPS antenna

Flarm HF

antenna

Flarm external

indicators, splitters

PDA port

Read manual

USB memory stic

ks

Connector to USB1 port

Main power supply

(LX8080DU wiring)

GPS port

Read manual

PDA port

Read manual

USB memory sticks

Connector to USB1 port

Main power supply

(LX8080DU wiring)

Page 37

Installation and Configuration Version 1.0, June 2015

Page 37 of 65

5.1.7 Flarm Port (for LX8000 Versions 1 – no 12V output)

LX8080 LX8000

1 2 3 4 5 6 6 5 4 3 2 1

Pin numbers

Pin number Description

1 open

2 3.3V DC (max 100mA)

3 GND

4 Flarm Data Out

5 Flarm Data In

6 Ground

5.1.7.1 Flarm port on LX9xxx

1 2 3 4 5 6

Pin numbers

Pin number Description

1 (output) 12V DC, to supply GPS

2 (output) 3.3V DC (max 100mA)

3 GND

4 Flarm Data Out

5 Flarm Data In

6 Ground

Page 38

Installation and Configuration Version 1.0, June 2015

Page 38 of 65

Flarm port can be also configured on newer types of LX9000D. It can be enabled

in Setup-NMEA Output with selecting FLARM

5.1.7.2 PDA port (RJ45

Newer types of units have also expansion port called PDA (RJ45). On this port can be

connected different types of PDA devices.

1 2 3 4 5 6 7 8 8 7 6 5 4 3 2 1

Pin numbers Pin numbers

Pin number Description

1,2 Ground

3 (output) Transmit from LXNAV RS232 (e.g. Computer, IPAQ38/39xx)

4 (input) Receive to LXNAV RS232 (e.g. Computer, IPAQ38/39xx)

5 (output) Transmit from LXNAV V7 LV-TTL (3.3V) (e.g. Oudie, HP302,

HP31x)

6 (input) Receive to LXNAV LV-TTL (3.3V) (e.g. Oudie, HP302, HP31x)

7,8 5V OUTPUT (maximum 1A)

RJ45 plug is NOT designed in accordance with IGC standard. It can be used only

with dedicated cable. Do not plug unknown cable to it as it may damage unit or

PDA port.

On PDA port can be connected following connection cables:

Device

Cable code

OUDIE

CC-NP-

OUDIE1

Generic RS232 with female DB9

CC-NP-

232 IPAQ 310/314

CC-NP-

IPAQ310

IPAQ 38/39xx/47xx

CC-NP-38

Page 39

Installation and Configuration Version 1.0, June 2015

Page 39 of 65

5.1.7.3 GPS ports (RJ11) only on Simple version

1 2 3 4 5 6 1 2 3 4 5 6

Pin numbers Pin numbers

Pin number Description

1 (output) 12V DC, to supply GPS

2,3 N.C.

4 (input) Receive to main display unit RS232 (e.g.: NANO power 232)

5 (output) Transmit from LXNAV main display unit RS232 (e.g.: NANO power

232)

6 Ground

5.1.1 Wirings

1

6

2

7

3

8

4

9

5

SUBD15 Connector / female

LX9000 DIGITAL UNIT

+12V DC OUT

white

red

shield

black

yellow

GND

+12V

B

A

RS485 - OUT

SUBD9 / female

GND

LABEL: +12V DC IN

1

9

2

10

3

11

4

12

5

13

6

14

7

15

8

Data Out

Data In

B

A

1

2

3

4

5

BINDER 5Pin Male

PC-RS232C

09 0097 00 05

White - Data In

Black - Data Out

Shield GND

1

3

5

30 cm

50cm

Red +12V 2

GND

GND

GND

shield

shield

LABEL:RS232

LABEL:RS485

5.2 Connection and Functionality Check of All Peripheral Units

The main display unit is connected to 12 Volt power via the 15-pin SUB-D connector. The

main display unit, vario unit and other vario indicators are connected via the RS485 bus and

the connectors are labelled with “RS485” at each end.

Please ensure that both units are connected correctly before the first power on. The power

wires (red and blue) should be connected to the main display unit.

Page 40

Installation and Configuration Version 1.0, June 2015

Page 40 of 65

Even though there is an automatic fuse in the instrument it is VERY IMPORTANT

to use an external fuse (max. 3A). Power supply cables should use a minimum of

0.5 mm² AWG20 wires.

When main unit is connected to vario and other peripheral units, we can make functionality

test. After power up, vario unit should turn on. Other peripheral units have on visual

indication, so they will be tested on main unit.

5.2.1 Vario Unit

5.2.1.1 Connecting vario unit

Vario unit is connected to main unit through RS485 bus. SC cable is used for external switch,

for switching between climb and cruise mode. In case that SC is connected to flaps switch,

VP (vario priority) is connected to switch on stick. Inputs IN1...4 are used to connect to gear

switch, airbrakes, etc...

5.2.1.2 Cut-outs

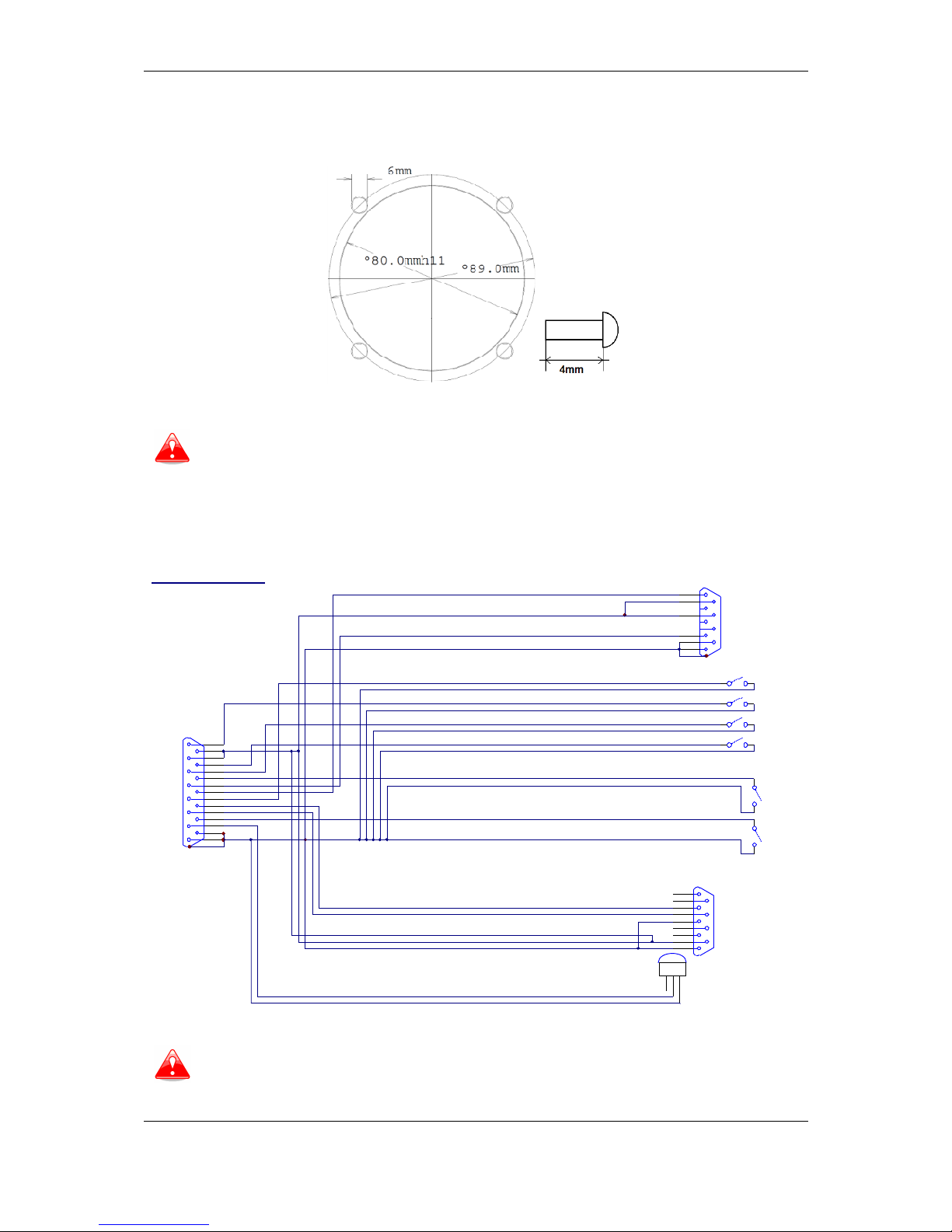

5.2.1.2.1 Cut-out for V5 and V9

Drawing is not to scale

5.2.1.2.2 Cut-out for V8

Drawing is not to scale

Length of screw is limited to max 4mm!

Page 41

Installation and Configuration Version 1.0, June 2015

Page 41 of 65

5.2.1.2.3 Cut-out for V80

Drawing is not to scale

Length of screw is limited to max 4mm!

5.2.1.1 Wirings

5.2.1.1.1 V5 Ver1 wiring with CAN bus (discontinued)

1

6

7

4

9

5

SUBD15 Connector / female

SBOX

white

red

shield

black

yellow

GND

+12V

B

A

GND SHIELD

SC

1

9

2

10

3

11

4

12

5

13

6

14

7

15

8

B

A

SC switch

30 cm

30 cm

50 cm

V5 V1.0 Wiring

VP switch

VP

50 cm

(green)

(Brown)

OAT

1.5m

OAT

LABEL:OAT

LABEL: VARIO PRIORITY

LABEL:SC

LABEL:RS485

shield

Reserved for CAN BUS

SUBD9 / female

CAN H

CANH

CANL

INPUT2

INPUT1

INPUT3

INPUT4

12V IN

IN1

IN3

IN2

IN0

LABEL:IN-1

LABEL:IN-2

LABEL:IN-3

LABEL:IN-4

1

6

2

7

3

8

4

9

5

J3

CAN L

CAN GND

CAN GND

12V

LABEL: CAN BUS

50 cm

50 cm

50 cm

50 cm

1 2 3

GND

LM335Z

GND SHIELD

GND SHIELD

GND SHIELD

GND SHIELD

GND SHIELD

GND SHIELD

4 zilni tasker

RS485 - IN

SUBD9 / male

There is also CAN bus connector, which is prepared for future.

DO NOT CONNECT IT ANYWHERE

Page 42

Installation and Configuration Version 1.0, June 2015

Page 42 of 65

5.2.1.1.2 V5/V8/V9/V80 vario unit wiring

1

6

7

4

9

5

SUBD15 Connector / female

V5

white

red

shield

black

yellow

GND

+12V

B

A

GND SHIELD

SC

1

9

2

10

3

11

4

12

5

13

6

14

7

15

8

B

A

SC switch

30 cm

50 cm

VP switch

VP

50 cm

(green)

(Brown)

OAT

1.5m

OAT

LABEL:OAT

LABEL: VARIO PRIORITY

LABEL:SC

LABEL:RS485

(pusti olupljen pospajkan kabel)

shield

CANH

CANL

INPUT2 - AIRBRAKES

INPUT1 - GEAR

INPUT3 - WATER BALLAST - VALVE

INPUT4 - FREE

12V IN

IN1

IN3

IN2

IN0

LABEL:IN-1

LABEL:IN-2

LABEL:IN-3

LABEL:IN-4

Free

Closed, when valve is closed

Closed, when Airbrakes are closed

Closed, when gear is down

50 cm

50 cm

50 cm

50 cm

1 2 3

GND

LM335Z

GND SHIELD

GND SHIELD

GND SHIELD

GND SHIELD

GND SHIELD

GND SHIELD

RS485 - IN

SUBD9 / male

5.2.1.1.3 USB-D or Analog unit wiring (discontinued)

1

6

7

4

9

5

SUBD15 Connector / female

LX9000 VARIO UNIT

white

red

shield

black

yellow

GND

+12V

B

A

RS485 - IN

SPEAKER

SUBD9 / male

GND

+12V DC IN

SC

1

9

2

10

3

11

4

12

5

13

6

14

7

15

8

Data Out

Data In

B

A

RCA Jack Receptacle (CHINCH/Female)

SC switch

Speaker

30 cm

30 cm

50 cm

LABEL:AUDIO OUT

LX 9000 VARIO UNIT Wiring

VP switch

VP

50 cm

(green)

(Brown)

DS1820 OAT

1.5m

OAT

LABEL:OAT

LABEL: VARIO PRIORITY

LABEL:SC

LABEL:RS485

shield

shield

5.2.1.2 Connection to the bus

Vario is connected to main instrument via RS485 bus directly or via RS485 splitter, if there

will be more units connected to the system.

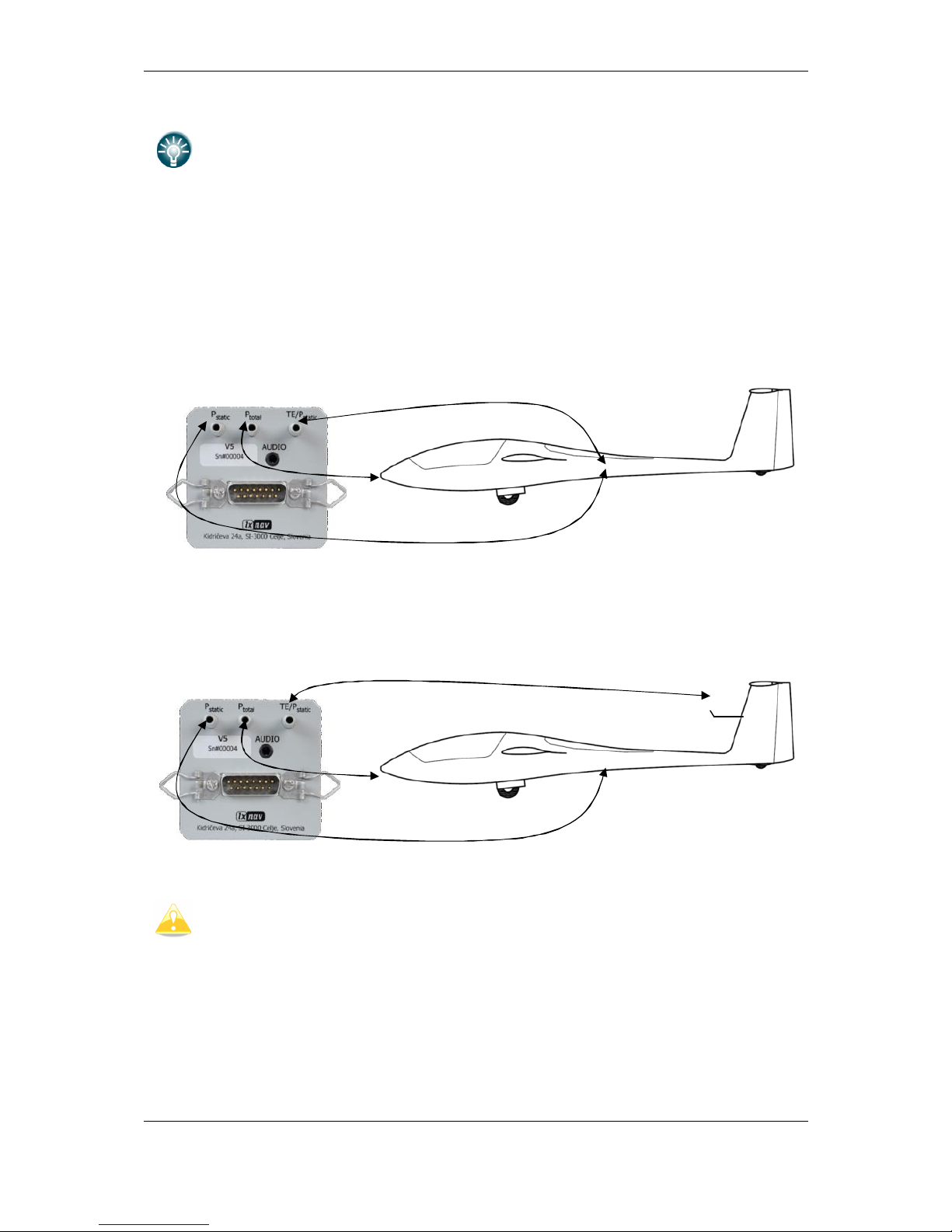

5.2.1.3 Pneumatics

Please carefully connect tubes to the right port of vario unit.

Three pressure connectors are fitted to the back of the vario unit. A label shows their

functions.

Page 43

Installation and Configuration Version 1.0, June 2015

Page 43 of 65

V9 vario has same functionality than V5, the only difference is, that has built in

inertial platform (AHRS)

• P

static

means static pressure connector.

• P

total

means pitot or total pressure connector.

• TE means total energy TE connector.

If the unit is to be configured for electronic TE compensation the connections are as follows:

• P

static

Static

• P

total

Pitot or Total pressure

• TE/P

static

Static

If the unit is to be configured for pneumatic TE compensation using a TE tube, then the

connections are:

• TE/P

static

TE tube

• P

static

Static

• P

total

Pitot or Total pressure

If the P

total

and Static are connected the wrong way around there will be no

integrator reading (average climb) during the flight.

The main display unit is connected to 12 Volt power via the 15-pin SUB-D connector. The

main display unit, vario unit and other vario indicators are connected via the RS485 bus and

the connectors are labelled with “

RS485

” at each end.

Please ensure that both units are connected correctly before the first power on. The power

wires (red and blue) should be connected to the main display unit.

Page 44

Installation and Configuration Version 1.0, June 2015

Page 44 of 65

It is VERY IMPORTANT to use an external fuse (max. 3A). Power supply cables

should use a minimum of 0.5 mm² wires.

5.2.1.4 Audio

Audio speaker is plugged on vario unit Audio port. Audio port has standard 3.5mm phonojack (mono).

5.2.1.5 Inputs

V9, V8, V80 and V5 variometers are having 6 programmable digital inputs. They are labelled

with SC, VP, IN1, IN2, IN3 and IN4 on V5/V9 cable-set. In the moment digital input can

represent the state of following actions:

• SC

• Vario priority

• Gear down and lock

• Airbrakes open

• Water ballast open

• Mute vario sound

Digital input shall be wired via switch to ground and it shall open or close, when selected

action is performed. A green light will light.

If necessary, check

Invert

check box, to reverse the operation of digital input.

Once digital inputs are connected the system will warn pilot, if airbrakes are open on takeoff and when gear is not locked prior to landing.

Page 45

Installation and Configuration Version 1.0, June 2015

Page 45 of 65

5.2.2 Installation of Options

All options (Rear Seat Device, Remote Control, Compass Module & secondary vario

indicators) are prepared to be connected to the RS485 system bus by use of RS485 splitting

units. Installation of any option is plug-and-play and therefore requires only mechanical

installation work. The main display unit also powers all devices connected to the bus. An

automatic fuse built into the main display unit prevents damage to the digital unit should a

short circuit in the wiring or in some attached device occurs.

5.2.2.1 Remote Sticks

LXNAV remote stick is connected to RS485 bus through RS485 splitter.

Be careful, that connect correct colour wire to pin, which is marked with same colour.

PTT wires are connected to radio, SC is connected to Speed to fly input of vario unit.

If you are installing remote stick into double seater gliders or aircraft, be careful.

Stick for rear seat is marked as DS. DS remote stick is programming to control

Page 46

Installation and Configuration Version 1.0, June 2015

Page 46 of 65

repeater unit, which is installed on 2

nd

seat.

5.2.2.2 Flarm

Mostly Flarm is built inside main display unit. In this case we need to connect Flarm

antenna to the connector marked with Flarm.

Flarm antenna connector is SMA type. Normally we supply dipole antenna on approx. 1m

long cable.

For good Flarm reception, Flarm antenna must be positioned vertically, as far as possible

from metal parts, cables and instruments.

We had very good experience installing Flarm antenna in the tail of the glider.

5.2.2.3 External Flarm or Power Flarm

If main display unit has no internal Flarm, user has a possibility to connect to it external

Flarm or Power Flarm. All Flarm/Power Flarm items will be displayed on the navigation map,

with same functionality as is with built-in Flarm.

External Flarm/Power Flarm can be connected to the main display unit with

LX5FLARM

cable.

On main display unit side LX5FLARM is connected to 5 pin rounded connector. On the other

side of LX5FLARM cable is 6 pin standard IGC RJ12 plug connector, which is plugged into

Flarm/Power Flarm port.

Using improper type of cable may harm your display unit or Flarm/Power Flarm

units.

For connection to the power Flarm is prepared special cable LX5PF, with RJ45 on

Flarm side.

Page 47

Installation and Configuration Version 1.0, June 2015

Page 47 of 65

5.2.2.4 ADSB receiver

It is possible to connect to the system with build in Flarm an ADSB-receiver TRX-1090 from

Garrecht Avionics (www.garrecht.com).

TRX-1090 can only be connected to the system with integrated Flarm option.

The TRX-1090 has been developed to upgrade the FLARM collision avoidance system, which

is installed in more than 13.000 aircraft worldwide. The unit will be connected between

FLARM and a FLARM compatible external display unit and will simultaneously show FLARM

targets and Mode-S transponder equipped aircraft with ADS-B output capability. The

presence of transponder equipped aircraft not broadcasting ADS-B output will be detected

and indicated on the connected display as a non-directional target. The TRX-1090 comes

with a high sensitivity low distortion receiver unit and a highly complex and powerful signal

processing unit with multi-level error correction algorithms to provide data with a very high

accuracy.

5.2.2.4.1 TRX tool

Using the TRX-Tool program you should configure also TRX-1090 to be used together with

the system. TRX-Tool can be downloaded on the web (http://www.garrecht.com) under

Support/Downloads/Software section. Run the TRX-Tool program and connect the TRX1090 to PC using a USB cable. Select Port4 tab and change connected equipment to LX8000

(or FLARM without RX line connected).

Page 48

Installation and Configuration Version 1.0, June 2015

Page 48 of 65

Select Port2 tab and change

Baud rate

to 19200bps.

The LX90xx system and TRX-1090 are now ready for operation. On the info page you

should see the TX sign and number of received objects.

Page 49

Installation and Configuration Version 1.0, June 2015

Page 49 of 65

5.2.2.4.2 Connecting TRX-1090 to the system

Disconnect cable from the Flarm external display and connect the free cable to Port4 on the

TRX-1090. Use the LX9000-TRX cable (not-included, must be ordered separately) and

connect it between PORT2 and PC port on the main display unit.

On the main display unit go to the setup menu and choose Hardware->Flarm menu item.

Change mode to

Ext. (PC)

.

Port on LX9000 Cable Port on TRX 1090

LX9000 FLARM -> via cable (Flarm-TRX1090) -> TRX Port4 (Flarm original or

compatible)

LX9000PC (5pin

rounded

connector)

<- via cable (TRX LX9000) <- TRX Port2 (Flarm Compatible

display, set to 19200)

Page 50

Installation and Configuration Version 1.0, June 2015

Page 50 of 65

5.2.2.5 Additional indicators

Indicators are coupled on RS485 bus via supplied RS3485 cables and additional RS485

splitters.

5.2.2.6 Flap Sensor

Flap sensor is also communicating with main system through RS485 bus. Installation of flap

sensor may be complicated for particular gliders. Please contact glider manufacturer for

more details.

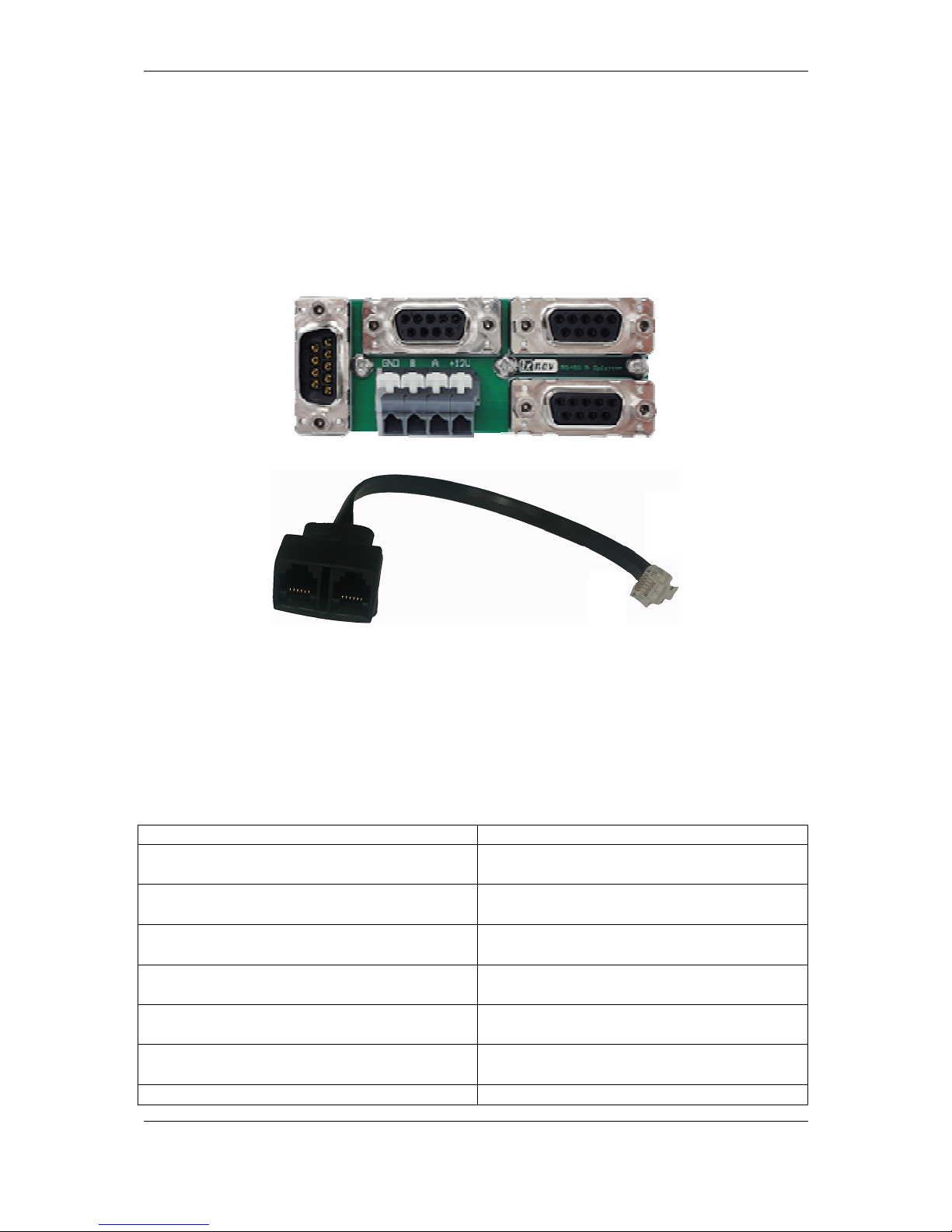

5.2.2.7 485 to 232 bridge

LXNAV RS485toRs232 Bridge (Bridge) is connected to RS485 bus through RS485 splitter DB9

connector. RS485 splitter is not part of package. If you don’t have spare port on RS485

splitter, you must order it.

5.2.2.7.1 Installation

RS485 splitter needs small modification, the Bridge can be fitted. It's necessary to remove

two HEX screws, where Bridge will be connected and screw bask two spring locks that are in

package.

After that fixing Bridge to RS485 splitter will be very easy.

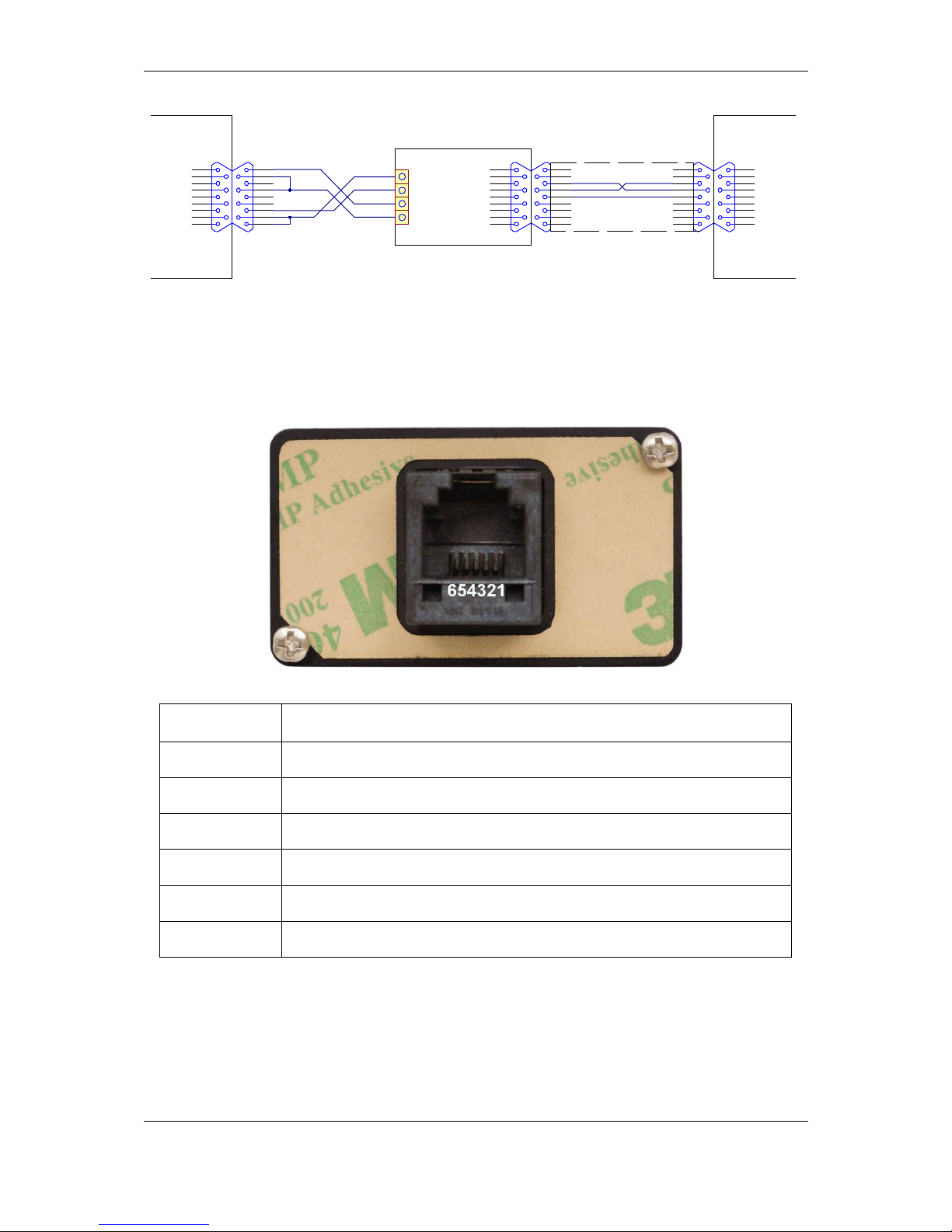

On the other side of Bridge is RJ12 connector with standard IGC/FLARM pinout

1 2 3 4 5 6

Pin numbers

Pin number Description

1 (output) 12V DC, to supply GPS

2 3.3V DC (max 100mA)

3 GND

4 Flarm Data Out

Page 51

Installation and Configuration Version 1.0, June 2015

Page 51 of 65

5 Flarm Data In

6 Ground

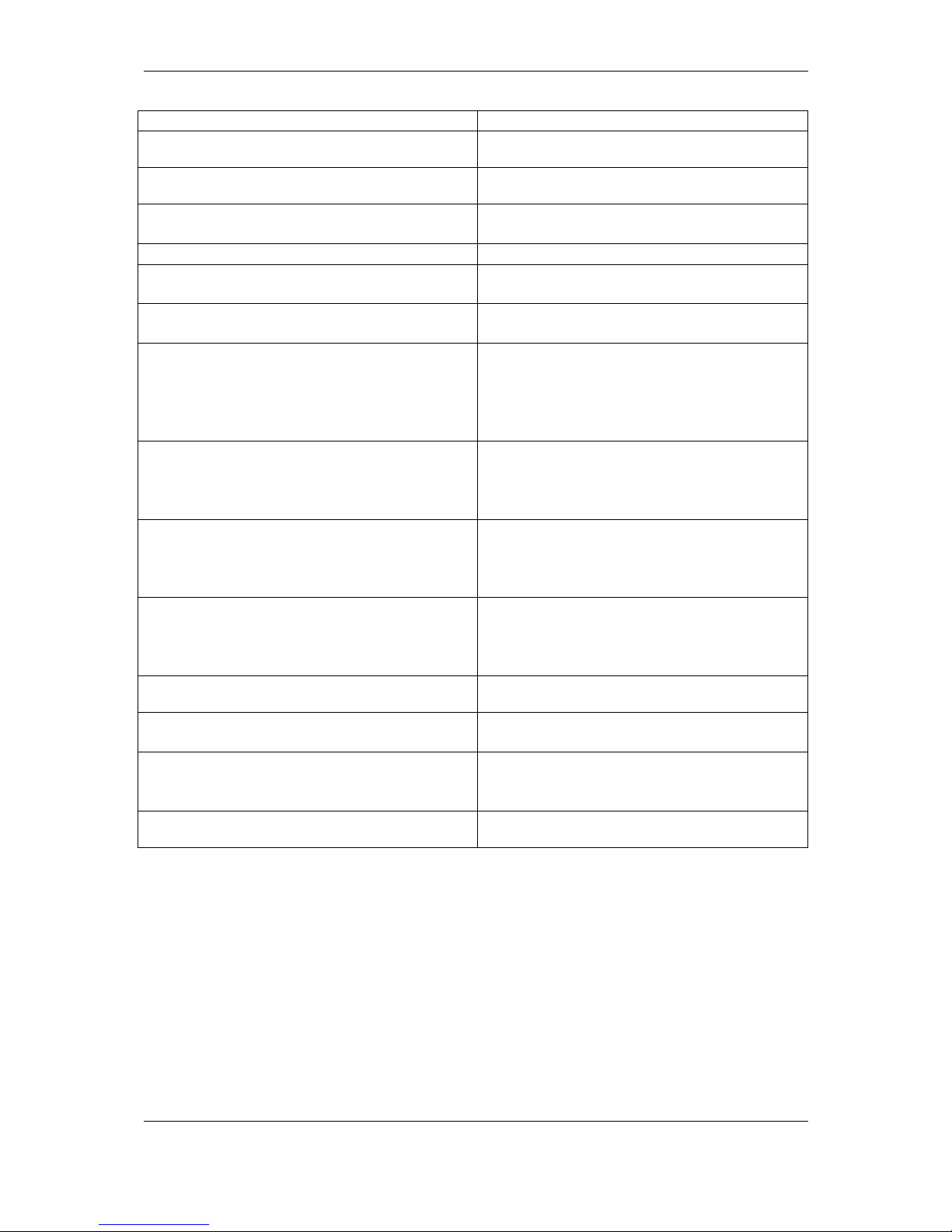

By default Bridge is programmed to stream NMEA data on 4800bps. It streams standard

GPS and Flarm data. 485 to 232 bridges can be configured as NMEA Bridge, Radio Bridge or

Transponder Bridge.

5.2.2.7.2 NMEA Bridge

NMEA Bridge has been designed to expand number of NMEA ports in the system. It can be

used as classic NMEA output for PDA device, to feed Mode-S transponder with NMEA.

5.2.2.7.3 Radio Bridge

Radio Bridge is same part of hardware as NMEA Bridge. On the main unit it can be

configured as Radio Bridge, which can communicate with following radios.

DEVICE TYPE DEVICE NAME

TESTED WITH PHYSICAL

DEVICE?

NOTES

RADIO

BECKER CM4201

NO Physical device needed to test.

RADIO

FUNKWERK ATR833

YES

RADIO

DITTEL KRT2

YES

RADIO

GARMIN SL40

NO Physical device needed to test.

RADIO

BECKER

- AR6201

- RT6201

- RCU6201

- AR6203

NO

Physical device needed to test.

(18.2.2015)

5.2.2.7.4 Transponder Bridge

Transponder Bridge is same part of hardware as NMEA Bridge. On the main unit it can be

configured as Transponder Bridge, which can communicate with following radios.

DEVICE TYPE DEVICE NAME

TESTED WITH

PHYSICAL DEVICE?

NOTES

TRANSPONDER

BECKER BXP6402

YES

TRANSPONDER

FUNKWERK

TRT800

NO

The status interface is a TX

-

only connection, not possible

to control it.

TRANSPONDER TRIG TT 21/22 YES

Page 52

Installation and Configuration Version 1.0, June 2015

Page 52 of 65

5.2.2.7.5 Wirings for radio and Transponder Bridge

5.2.2.7.5.1 Radios

5.2.2.7.5.1.1 Funkwerk ATR833

5.2.2.7.5.1.2 Dittel KRT2

5.2.2.7.5.2 Transponders

5.2.2.7.5.2.1 Becker BXP6402

Page 53

Installation and Configuration Version 1.0, June 2015

Page 53 of 65

5.2.2.7.5.2.2 Trig TT 21/22

5.2.2.8 Wi-Fi___33

Wi-Fi___33 dongle must be plugged in USB port. Wi-Fi___33 will be operative, when unit

will have enabled that option and wireless network is available.

5.2.2.9 Compass

Compass module must be connected to RS485 bus. It must be installed to the place where

is no strong magnetic fields (Irons or ferromagnetic materials), cables with AC current or not

constant DC currents.

When installing magnetic compass use screws made of non-ferromagnetic

materials (plastic or brass)

Page 54

Installation and Configuration Version 1.0, June 2015

Page 54 of 65

Orientation of compass module marked on housing as on picture above.

5.2.2.10 AHRS

AHRS hardware is built in each V9 unit, to see artificial horizon, is necessary to activate that

option.

It’s recommended, to install V9 vario as horizontally as possible. Small corrections

can be adjusted with pitch correction.

5.2.2.11 FES Bridge

FES Bridge is device which connects together FCU CAN bus and system RS485 bus.

Indication gauges can be created with LXStyler or LAYOUT function. On RS485 side is the

easiest way to connect on RS485 splitter on Remote Stick pins (parallel). Just connect

correct colour to the right pin. On the other side it should be connected to CAN bus (DB9)

of FCU. On this side 3 wires need to be soldered to the right pins.

1

6

2

7

3

8

4

9

5

DB9 Female

1

6

2

7

3

8

4

9

5

DB9 Female

1

6

2

7

3

8

4

9

5

DB9 Male

FCU

CAN Female-Female

CAN_HCAN_L

CAN_H CAN_L

GNDGND

No additional termination resistors needed

1

6

2

7

3

8

4

9

5

DB9 Male

FES bridge

1

6

2

7

3

8

4

9

5

DB9 Male

1

6

2

7

3

8

4

9

5

DB9 Female

LX9000

RS485-B

RS485-A

or

RS485 Splitter

12V

GND

RS485-A

RS485-B

12V

GND

(view from top)

5.2.2.12 JDU Bridge

JDU Bridge is device which connects together JDU CAN bus and system RS485 bus.

Indication gauges can be created with LXStyler or LAYOUT function. On RS485 side is the

easiest way to connect on RS485 splitter on Remote Stick pins (parallel). Just connect

correct colour to the right pin. On the other side it should be connected to CAN bus (DB9)

of FCU. On this side 3 wires need to be soldered to the right pins.

Page 55

Installation and Configuration Version 1.0, June 2015

Page 55 of 65

1

6

2

7

3

8

4

9

5

DB9 Female

1

6

2

7

3

8

4

9

5

DB9 Female

1

6

2

7

3

8

4

9

5

DB9 Male

JDU

CAN Female-Female

CAN_HCAN_L

CAN_H CAN_L

GNDGND

No additional termination resistors needed

1

6

2

7

3

8

4

9

5

DB9 Male

JDU bridge

(view from top)

1

6

2

7

3

8

4

9

5

DB9 Male

1

6

2

7

3

8

4

9

5

DB9 Female

LX9000

RS485-B

RS485-A

or

RS485 Splitter

12V

GND

RS485-A

RS485-B

12V

GND

5.2.2.13 FlarmLED display

FlarmLED display is used to display Flarm warnings. It must be installed on visible place,

that pilot can immediately see collision warning. Flarm led is connected via standard Flarm

cable with RJ12 (6 pin connectors). It is supplied over 3V pin

5.2.2.13.1 Pinout

Pin number Description

1 N.C.

2 (output) Transmit from LXNAV FLARM LED RS232 Level

3 (input) Receive to LXNAV FLARM LED RS232 Level

4 Ground

5 3.3V power supply (input)

6 N.C.

Page 56

Installation and Configuration Version 1.0, June 2015

Page 56 of 65

5.2.2.13.2 Cut-out

Front view

Drawing is not to scale

5.2.2.14 FlarmView display

FlarmView is similar display like FlarmLED, it has graphics display and provides to the pilot

more information, like Flarm radar screen and information about all visible targets. It must

be installed on visible place, where pilot can see collision warning immediately. FlarmView is

connected via standard Flarm cable with RJ12 (6 pin connectors). It is supplied over 12V

pin

5.2.2.14.1 Pinout

1 2 3 4 5 6

Pin numbers

Pin number Description

1 (Power input) 12VDC (On version 2)

2 (Power input) 3.3VDC (On version 1)

3 GND

4 (input) Data in RS232 – receive line

5 (output) Data out RS232 – transmit line

Page 57

Installation and Configuration Version 1.0, June 2015

Page 57 of 65

6 Ground

5.2.2.14.2 Cut-out

The LXNAV FlarmView cut-out is very simple. A square hole with dimensions 14mm x 15mm,

need to be cut.

Drawing is not to scale

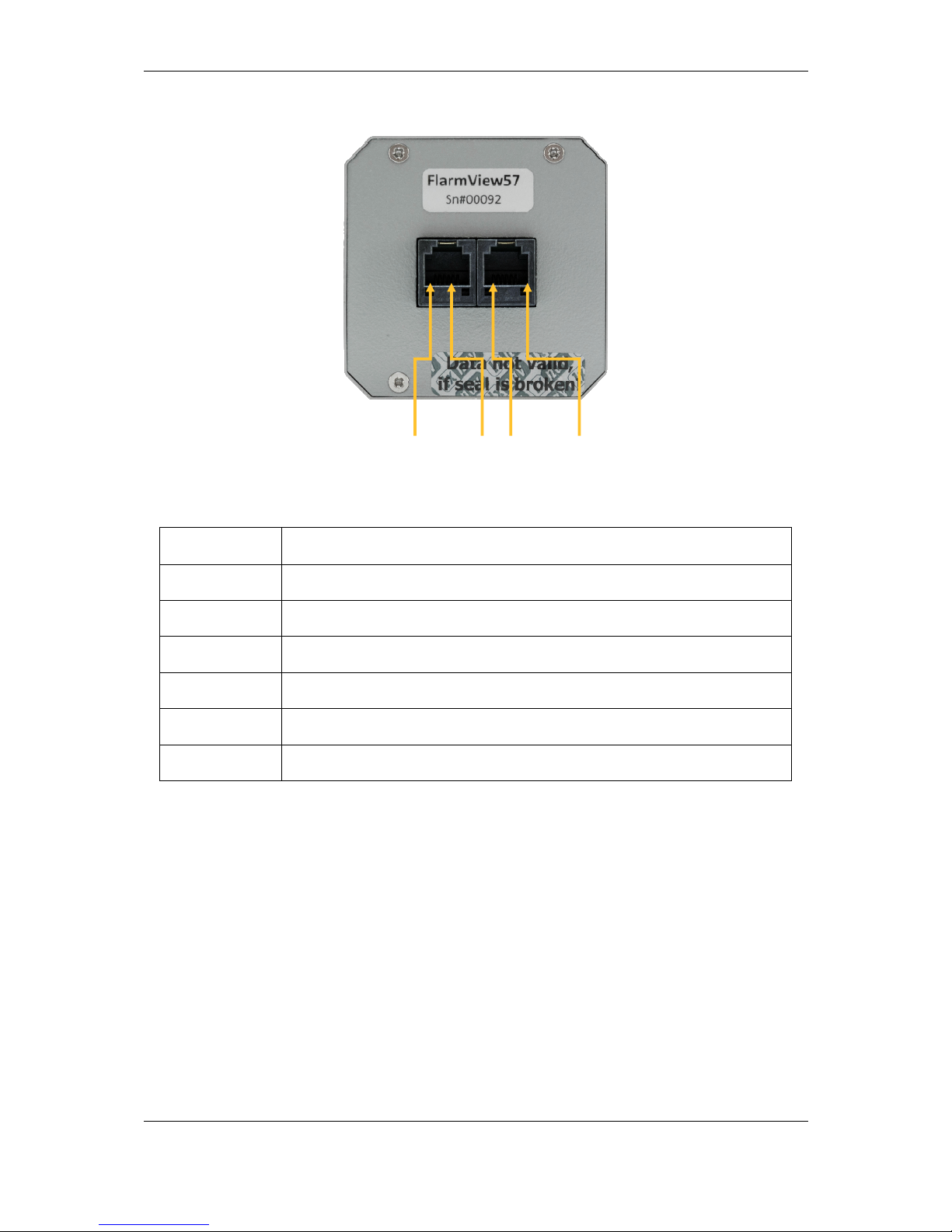

5.2.2.15 FlarmView57 display

FlarmView57 is same display like FlarmView, only different housing. FlarmView57 is

connected via standard Flarm cable with RJ12 (6 pin connectors). It is supplied over 12V

pin

5.2.2.15.1 Cut-out

The FlarmView57 is installed in one standard 57mm (2, 5’’) cut-out. If there is none, prepare

it according to the picture below.

Drawing is not to scale

Page 58

Installation and Configuration Version 1.0, June 2015

Page 58 of 65

5.2.2.15.2 Pinout

1 2 3 4 5 6 1 2 3 4 5 6

Pin numbers Pin numbers

Pin number Description

1 (Power input) 12VDC (On version 2)

2 (Power input) 3.3VDC (On version 1)

3 GND

4 (input) Data in RS232 – receive line

5 (output) Data out RS232 – transmit line

6 Ground

Page 59

Installation and Configuration Version 1.0, June 2015

Page 59 of 65

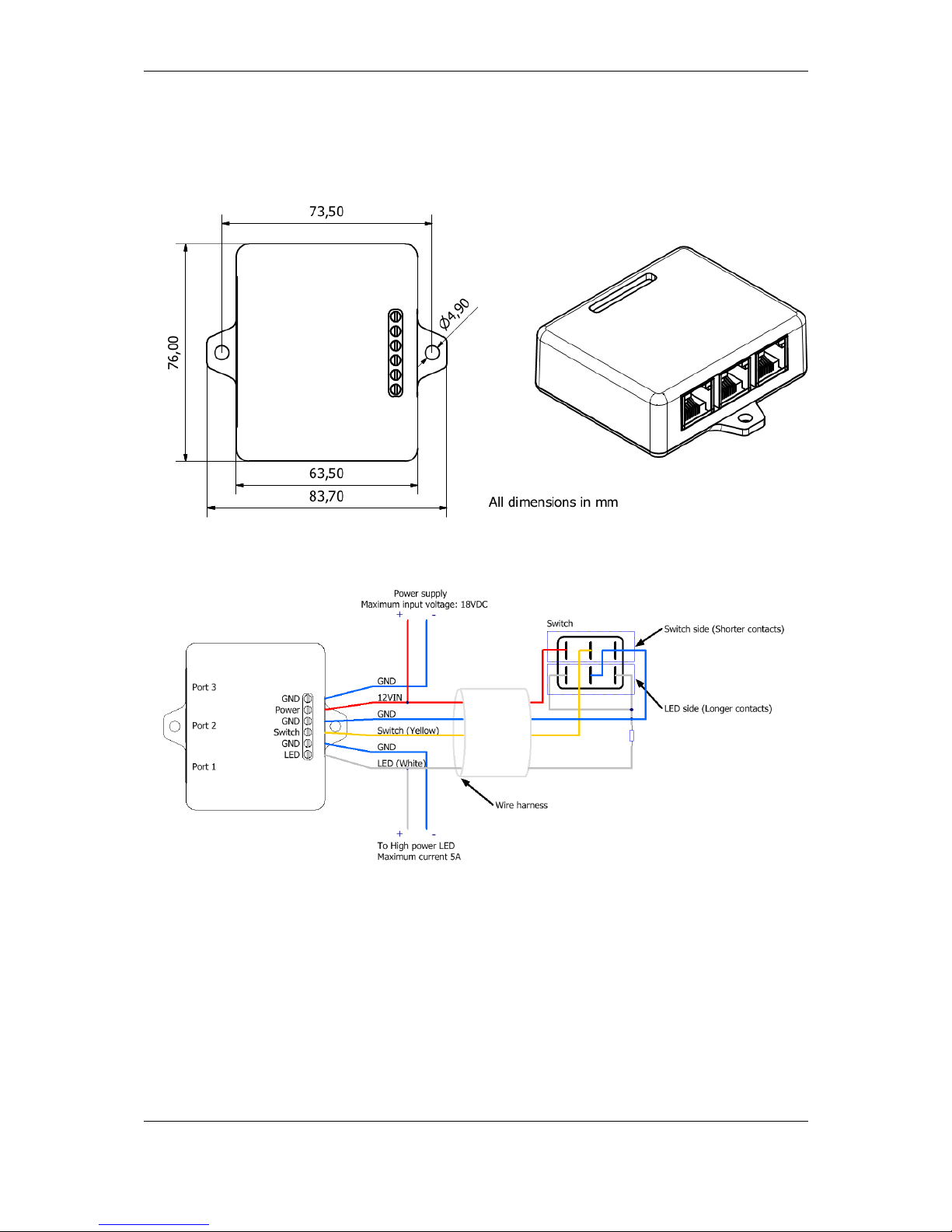

5.2.2.16 Flarm ACL

FlarmACL is a box which can switch on or off Anti Collision light. This switching can be

automatically or manually.

5.2.2.16.1 Wiring

Page 60

Version 1.0, June 2015

Page 60 of 65

5.2.2.16.2 Ports and Pinouts

FlarmACL connects together Pin 1 from Port 1-3, Pin 2 from Port 1-3, etc. Pin names are:

1- +12V

2- +12V

3- +3,3V (Flarm displays)

4- GND

5- Data Input (Output)

6- Data Output (Input)

7- GND

8- GND

5.2.2.17 Bluetooth module

LXNAV Bluetooth module is special device, which can be used only in combination with

LXNAV PDA port (RJ45). Connecting to other similar port will damage the unit.

Page 61

Firmware updates Version 1.0, June 2015

Page 61 of 65

6 Firmware updates

All firmware updates are performed entering password 89891 on the main unit. Next step is

to choose the firmware file. If main unit will detect right unit, firmware update will start.

In latest versions firmware for main unit includes also all firmwares for peripheral units.

Page 62

Troubleshooting Version 1.0, June 2015

Page 62 of 65

7 Troubleshooting

7.1 Export Diagnostic Files

Diagnostic file can be downloaded on main unit under Setup-About. If SD card is in the SD

socked, user can copy diagnostic file to SD card. If Wi-Fi module is plugged in and wireless

network is available, user can send this file over email directly to LXNAV.

Page 63

Revision History Version 1.0, June 2015

Page 63 of 65

8 Revision History

June

2015

Initial release of

installation

manual

Page 64

Page 65

The Pilot’s Choice

LXNAV d.o.o. • Kidričeva 24a, 3000 Celje, Slovenia • tel +386 592 33 400 fax +386 599 33 522

info@lxnav.com

•

www.lxnav.com

Loading...

Loading...