LVS integra 9505, integra 9500 Operation Manual

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

INTEGRA 9500/9505

Barcode Quality Station

Operations Manual

Version 3.0.6

August 20, 2007

Version 3.0.3

Integra 9500

Integra 9505

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 1 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

No part of this publication may be reproduced or transcribed, stored in a retrieval

system, computer or otherwise, in any form or by any means, magnetic,

mechanical, electronic, optical, manual, or otherwise, and may not be translated

into any language without the express written permission of Label Vision

Systems, Inc. (“LVS”). Information in this document may be changed or updated

without notice.

All LVS publications contain proprietary confidential information of LVS, and

possession and use of such proprietary confidential information is subject to

restrictions set forth by LVS as described in the applicable non-disclosure

agreements and/or license agreements with LVS. Any use of this publication and

related materials beyond the terms of said agreements is prohibited, and LVS

reserves all rights in this publication and related materials.

The name LVS is a registered trademark of Label Vision Systems, Inc.

Copyright

Copyright 2010 Label Vision Systems, Inc.

All rights reserved

Printed in the United States of America

How to Contact Us

Label Vision Systems, Inc.

101 Auburn Court

Peachtree City, GA 30269 USA

Voice: +1-770-487-6414

Fax: +1-770-487-0860

Toll Free: +1-800-432-9430

Information: info@lvs-inc.com

Internet: www.lvs-inc.com

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 2 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

Table of Contents

Overview .......................................................................................................................... 6

Important Safety Instructions ........................................................................................ 6

Software Specifications for the 9500 and 9505 ............................................................ 8

Hardware Specifications for the INTEGRA 9500 ........................................................ 10

Hardware Specifications for the INTEGRA 9505 ........................................................ 11

Basic Operations ........................................................................................................... 12

Welcome Tab ................................................................................................................. 16

Setup Tab ....................................................................................................................... 19

Camera ....................................................................................................................... 19

Grading Mode ............................................................................................................. 20

Application Standards ................................................................................................. 20

Selecting an Application Standard .......................................................................... 21

Override Aperture .................................................................................................... 22

Creating Custom Reports ............................................................................................ 23

Current Information ..................................................................................................... 23

System Settings .......................................................................................................... 24

Minutes before auto logoff ....................................................................................... 24

Recalibration Cycle ................................................................................................. 24

Allow Non-ISO blemish to affect grade ................................................................... 25

Metric ....................................................................................................................... 25

Reference Box ......................................................................................................... 25

Company Name on Reports .................................................................................... 25

Setup Operators ...................................................................................................... 25

Product Lookup ....................................................................................................... 27

Distributor Information ............................................................................................. 27

Optional Features - Multi-Barcode Verification ........................................................... 28

Change Password ....................................................................................................... 31

Calibration Tab .............................................................................................................. 32

Calibrate the System ................................................................................................... 33

Replacement of the Calibrated Conformance Standard Test Card ............................. 35

Data Matrix Calibrated Conformance Test Card ......................................................... 35

Grading Tab ................................................................................................................... 37

Section 1: 1D Codes ................................................................................................... 37

1. Overall Grade .......................................................................................................... 38

2. ISO Grading ............................................................................................................ 38

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 3 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

3. View Box ................................................................................................................. 39

4. Grade Bar Graph..................................................................................................... 42

Bar Height Measurement ........................................................................................ 42

5. ISO/IEC Parameters Section .................................................................................. 43

6. Blemish (Non-ISO Parameter) ................................................................................ 44

Other Grading Screen Tools ....................................................................................... 45

Check for Opacity .................................................................................................... 45

Color Codes ............................................................................................................ 45

Height and Width Measurement .............................................................................. 46

BarCode Too Wide for Field of View (Stitching Function) ....................................... 47

Section 2: Matrix Codes .............................................................................................. 51

Verify a Matrix Code .................................................................................................... 51

View Section ............................................................................................................... 51

1. Overall Grade ...................................................................................................... 52

2. Defects ................................................................................................................ 52

3. Zoom ................................................................................................................... 52

4. OCR .................................................................................................................... 53

5. Modulation ........................................................................................................... 53

Multi-Rotation Codes ................................................................................................... 54

DataMatrix ............................................................................................................... 54

QR Code ................................................................................................................. 55

Section 3: Two-Dimensional Multi-Row Codes ........................................................... 56

Verify a PDF 417 or Micro PDF 417 Code .................................................................. 57

PDF417 Parameters ................................................................................................ 57

GS1 Databar Composite Verification .......................................................................... 58

Verify a Composite Code ............................................................................................ 59

Zoom Tab ....................................................................................................................... 60

SRP View Tab ................................................................................................................ 61

View Section ............................................................................................................... 61

Full Screen Waveform ............................................................................................. 62

Traditional Bar Growth and Shrinkage .................................................................... 63

Traditional Parameters Button ................................................................................. 64

Dimensional Analysis Button ................................................................................... 65

10-Line Grading Button ........................................................................................... 65

Print Button .............................................................................................................. 65

Structure Tab ................................................................................................................. 66

Printing ........................................................................................................................ 66

Use the Data Structure Analysis ................................................................................. 67

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 4 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

Data Structure Analysis Example ................................................................................ 68

Archive Tab .................................................................................................................... 69

Import Image from File ................................................................................................ 70

Export Image to File .................................................................................................... 70

Recent Reports (Last 30 Days) ................................................................................... 70

Delete Prior to Specific Date ....................................................................................... 71

Software Version History ............................................................................................. 72

Audit Trail Report ........................................................................................................ 72

Calibration Report ....................................................................................................... 72

Reference Report ........................................................................................................ 72

Export Reference Data ................................................................................................ 72

Change SQL Connection ............................................................................................ 73

Create Backup Database ............................................................................................ 73

Browse Backup Database ........................................................................................... 74

Print an Archived Report ............................................................................................. 74

Optional Accessories & Spare Parts ........................................................................... 75

Preventive Maintenance Schedule .............................................................................. 78

Documentation .............................................................................................................. 79

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 5 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

Overview

This manual covers the operating instructions for the INTEGRA 9500 and 9505

Barcode Verification Systems.

For installation assistance, see the notes below:

For installation assistance with the INTEGRA 9500, refer to the INTEGRA

9500 Quick Start Guide.

For installation assistance with the INTEGRA 9505 Flat Bed Verifier, refer

to the INTEGRA 9505 (Flat Bed Verifier) Installation Guide.

IMPORTANT: The INTEGRA 9500/9505 arrives to your site

packaged in a specially designed cardboard shipping carton.

DO NOT discard this shipping carton in case you must ship or

store the system for any reason. Failure to use this carton

when returning your product to LVS will void warranty.

Important Safety Instructions

This unit has been carefully designed to provide years of safe, reliable

performance. However, as with all electrical equipment, there are some basic

precautions that you should follow to avoid personal injury or damage to the

system:

Before using the system, carefully read all the installation and operating

instructions.

The exclamation point within an equilateral triangle is intended to

alert the user to the presence of important operating and

maintenance instructions in the literature accompanying this unit.

Observe all warning instruction labels on the system.

To protect your system from overheating, make sure no openings on the

system are blocked.

Never insert anything into the openings of the system.

Do not use the system near water or spill liquid into it.

All components used to create your system are UL and CE approved. All

circuits were designed to incorporate maximum safety. However, any

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 6 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

equipment using electrical voltages may cause personal injury if

improperly handled.

Do not attempt to work on the system with the main power lines

connected.

Ensure that the AC power source matches the ratings listed for the

system. If unsure, check with your dealer or local utility provider.

Do not place the AC power cord where it can be stepped on. If the AC

power cord becomes damaged or frayed, replace it immediately.

Avoid looking directly into any system lights. If you need to examine the

lights, or look at any component near the lights, be sure to first turn off the

lights. If the lights cannot be turned off, then wear polarized sunglasses

while examining the lights.

To avoid damaging the system, turn off and unplug the system before

cleaning.

If the system ever needs repair, consult Label Vision Systems or your

LVS® Distributor.

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 7 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

Software Specifications for the 9500

and 9505

Supported Symbologies include the following:

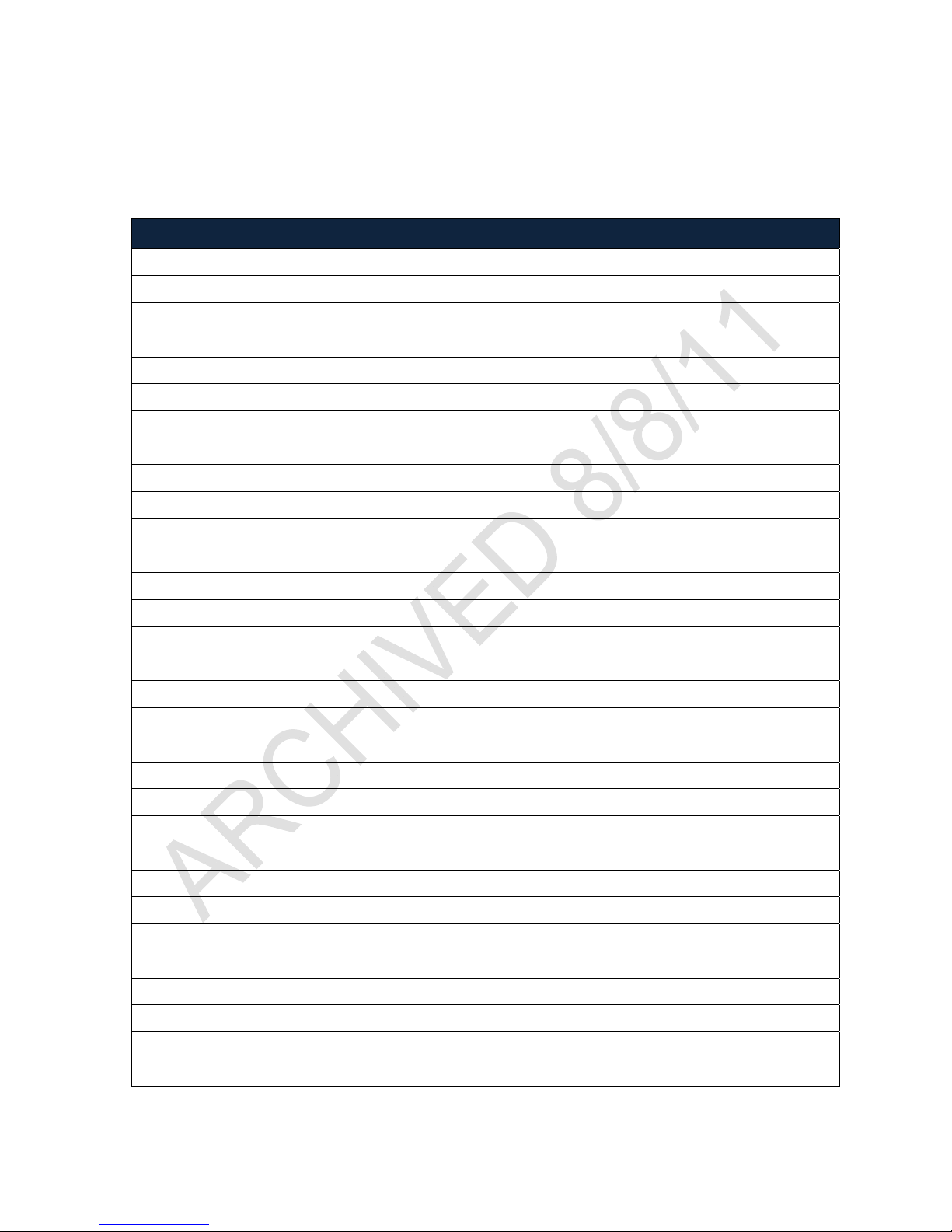

SYMBOLOGY SUPPORTED STANDARD(S)

Code 39 ISO 16388

Interleaved 2 of 5 ISO 16390

ITF-14

Code-128 ISO 15417

GS1-128 ISO 15417 & GS1 General Specifications

GS1-128 with CC-A ISO 15417, ISO 24723 & GS1 General Specifications

GS1-128 with CC-B ISO 15417, ISO 24723 & GS1 General Specifications

GS1-128 with CC-C ISO 15417, ISO 24723 & GS1 General Specifications

Code 93

Codabar AIM BC3

ISO 16390 & GS1 General Specifications

AIM BC5

UPC-A ISO 15420 & GS1 General Specifications

UPC-A with 2 Digit supplemental ISO 15420 & GS1 General Specifications

UPC-A with 5 Digit supplemental ISO 15420 & GS1 General Specifications

UPC-A with CC-A ISO 15420, ISO 24723 & GS1 General Specifications

UPC-A with CC-B ISO 15420, ISO 24723 & GS1 General Specifications

UPC-E ISO 15420 & GS1 General Specifications

UPC-E with 2 Digit supplemental ISO 15420 & GS1 General Specifications

UPC-E with 5 Digit supplemental ISO 15420 & GS1 General Specifications

UPC-A with CC-A ISO 15420, ISO 24723 & GS1 General Specifications

UPC-A with CC-B ISO 15420, ISO 24723 & GS1 General Specifications

EAN-13 ISO 15420 & GS1 General Specifications

EAN-13 with 2 Digit supplemental ISO 15420 & GS1 General Specifications

EAN-13 with 5 Digit supplemental ISO 15420 & GS1 General Specifications

EAN-13 with CC-A ISO 15420, ISO 24723 & GS1 General Specifications

EAN-13 with CC-B ISO 15420, ISO 24723 & GS1 General Specifications

EAN-8 ISO 15420 & GS1 General Specifications

EAN-8 with CC-A ISO 15420, ISO 24723 & GS1 General Specifications

EAN-8 with CC-B ISO 15420, ISO 24723 & GS1 General Specifications

GS1 Databar – 14 ISO 24724 & GS1 General Specifications

GS1 Databar – 14 with CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar – 14 with CC-B ISO 24724, ISO 24723 & GS1 General Specifications

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 8 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

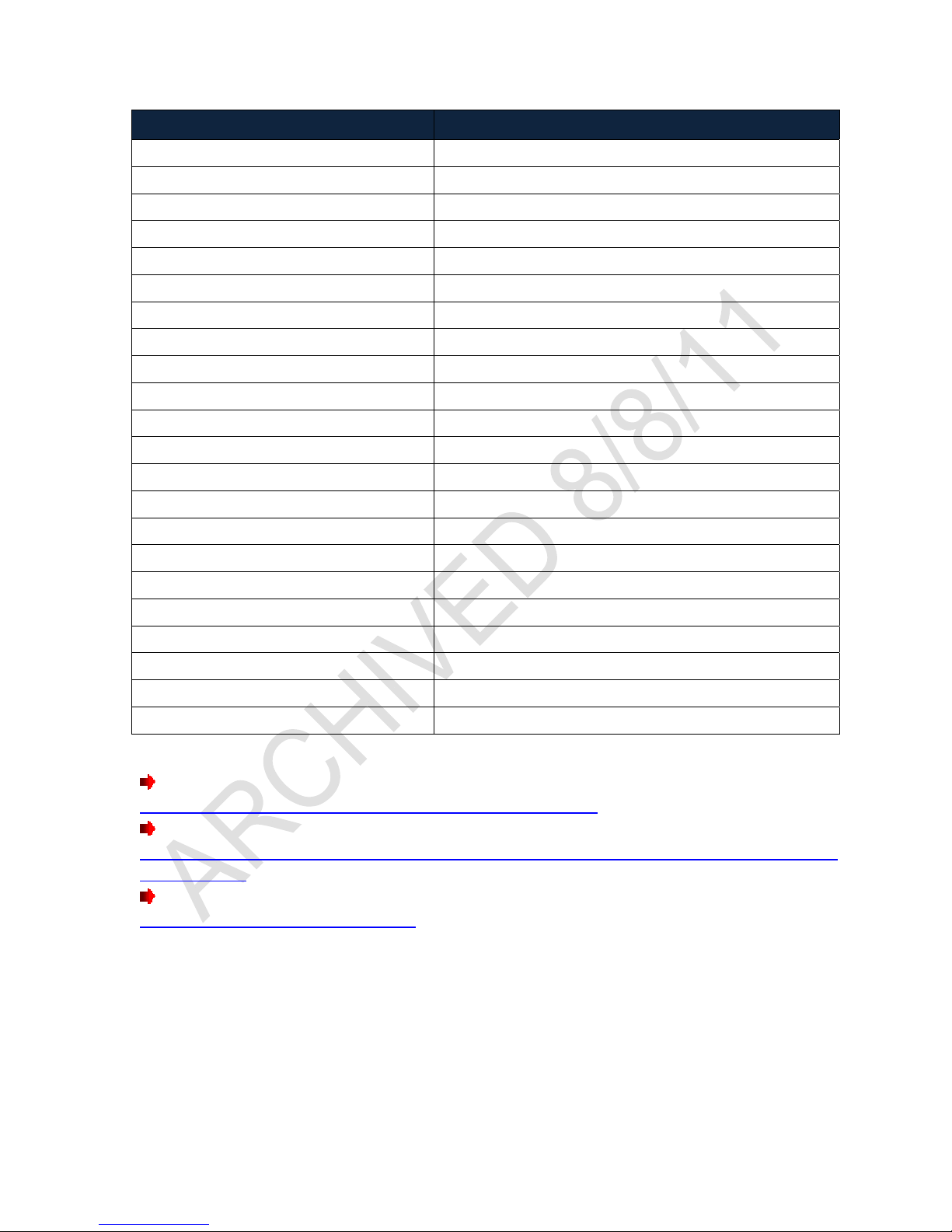

SYMBOLOGY SUPPORTED STANDARD(S)

GS1 Databar – 14 Stacked ISO 24724 & GS1 General Specifications

GS1 Databar – 14 Stacked with CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar – 14 Stacked with CC-B ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Limited ISO 24724 & GS1 General Specifications

GS1 Databar Limited with CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Limited with CC-B ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Expanded ISO 24724 & GS1 General Specifications

GS1 Databar Expanded CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Expanded CC-B ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Expanded Stacked ISO 24724 & GS1 General Specifications

GS1 Databar Expanded Stacked CC-A ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Databar Expanded Stacked CC-B ISO 24724, ISO 24723 & GS1 General Specifications

GS1 Data Matrix ISO 16022 & GS1 General Specifications

Data Matrix ISO 16022

PDF-417 ISO 15438

Micro PDF-417 ISO 15438

QR Code 2005

Micro QR Code 2005

Aztec

Laetus Pharmacode

MaxiCode

Han Xin

Additional Notes

ISO 18004

ISO 18004

ISO 24778

Laetus

ISO 16023

Draft AIM Specification

GS1 General Specifications are downloadable from this link:

http://www.gs1uk.org/EANUCC/WORD_Files/word.html

ISO Symbology Standards can be purchased from this link:

http://www.iso.org/iso/en/CatalogueListPage.CatalogueList?ICS1=35&ICS2=40&ICS

3=&scopelist=

AIM Symbology Standards can be purchased from this link:

https://www.aimglobal.org/estore/

In addition to adherence to the symbology specifications, the INTEGRA 9500/9505

complies with the following standards:

ISO 15415 - Bar code print quality test specification - Two-dimensional symbols

ISO 15416 - Bar code print quality test specification - Linear symbols

ISO 15426-1 - Bar code verifier conformance specifications - Part 1: Linear symbols

ISO 15426-2 - Bar code verifier conformance specification - Part 2: Two-dimensional

symbols

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 9 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

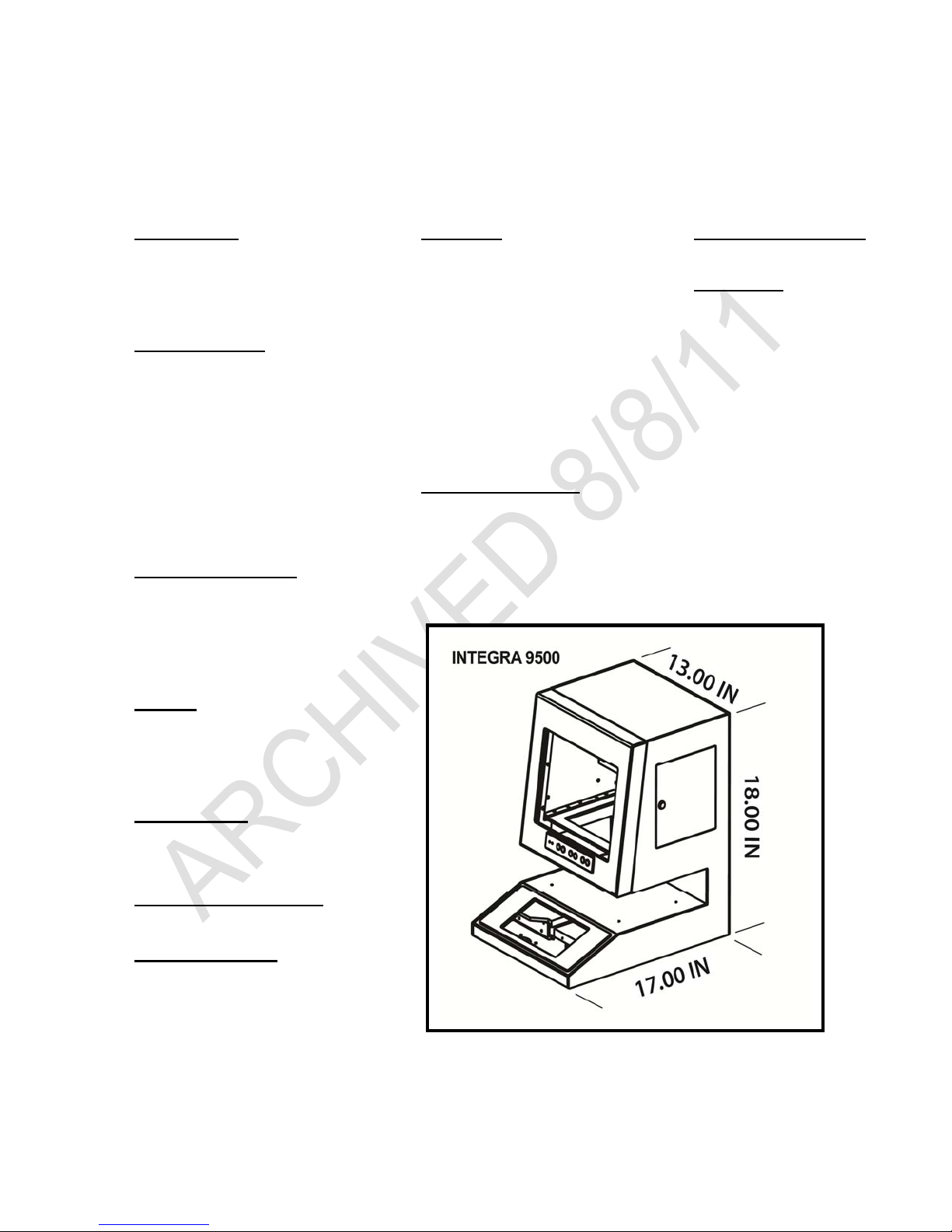

Hardware Specifications for the

INTEGRA 9500

Light Source Computer Storage Temperature

White Light Intel-based processor 0ºC (32ºF) to 40ºC (104ºF)

Red Filter 512 MB memory

660 nm 40 GB hard drive (minimum)

Inputs / Outputs

3 USB ports Windows XP Professional

1 Serial port 12V @ 4.87 A

1 External VGA port 5V @ 12.2 A

CD / DVD Re-writer

Calibration

EAN/UPC Test Card

Part Number: LAB0026

OR

GS1 128 Test Card

Part Number: LAB0033

External USB mouse Elastomer keyboard

10/100 LAN (Ethernet)

12 vdc @ 1 amp (nominal) D = 432 mm (17”)

5 vdc @ 2.4 amps (nominal) W = 330 mm (13”)

Main Power Supply:

Internal fuse (5A) Weight = 12.5 kg (27.5 lbs)

350 watt ATX power supply

50/60 hz 100 to

240 VAC

Monitor

Built in

12.1 inch

800 x 600 LCD Display

Video Camera

Monochrome

2.1 or 1.3 Mega-pixel

Operating Temperature

Physical Properties

H = 18 mm (18”)

10º C (50ºF) to 30º C (86ºF)

Relative Humidity

20% to 70% (non-condensing)

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 10 of 82

Specifications are subject to change without notice.

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

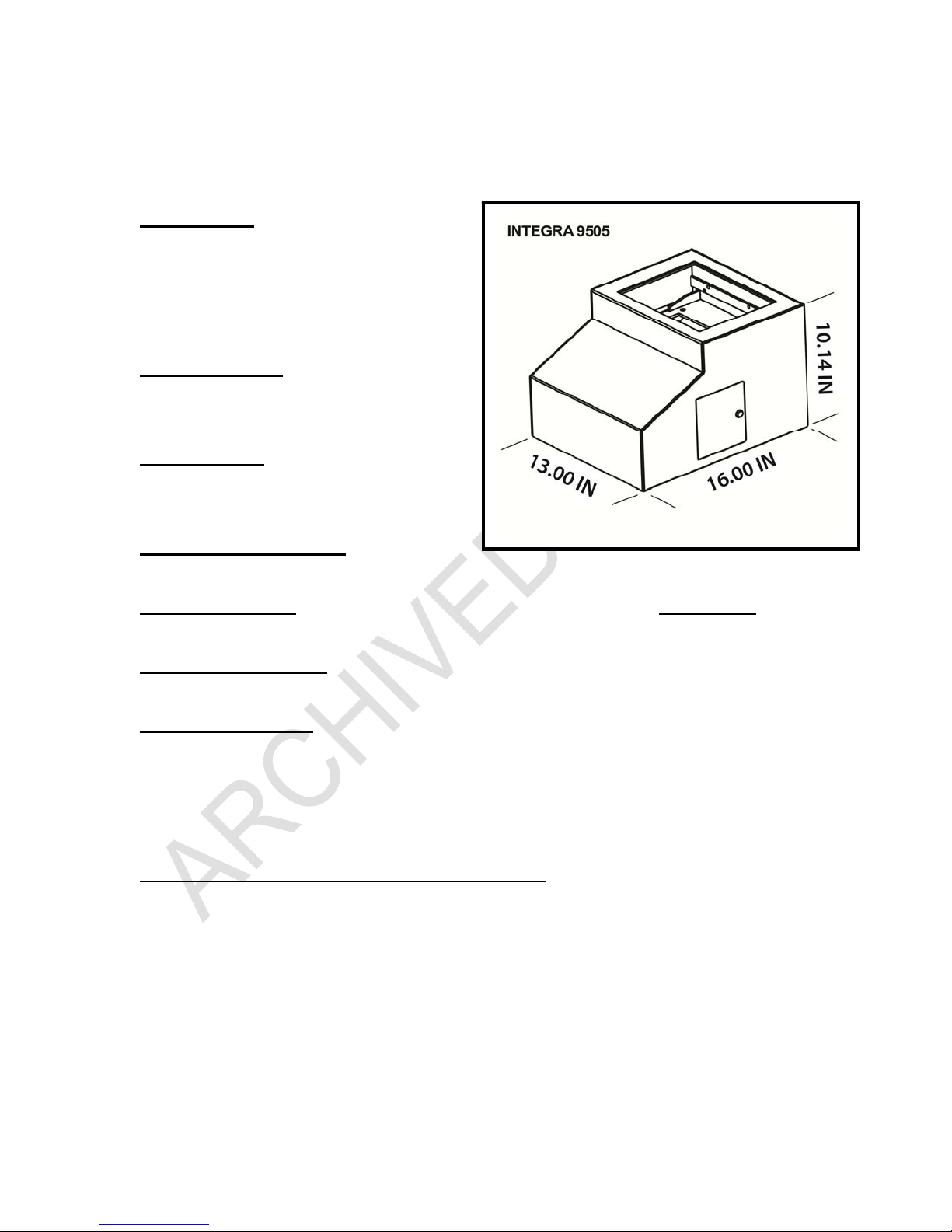

Hardware Specifications for the

INTEGRA 9505

Light Source

White Light

Red Filter

660 nm

12 vdc @ 1.6 amps

Inputs / Outputs

USB 2.0 port

12 vdc @ 1.10 amps

Video Camera

Monochrome

2.1 or 1.3 Mega-pixel

Operating Temperature

10º C (50ºF) to 30º C (86ºF)

Relative Humidity Calibration

20% to 70% (non-condensing)

Storage Temperature

EAN/UPC Test Card

Part Number: LAB0026

0ºC (32ºF) to 40ºC (104ºF)

Physical Properties

D = 406 mm (16”)

GS1 128 Test Card

Part Number: LAB0033

OR

W = 330 mm (13”)

H = 258 mm (10.14”)

Weight = 5 kg (11 lbs)

Minimum PC Requirements (PC Not Supplied)

Windows XP Professional

Intel Celeron 2.4 Ghz

512 MB RAM (1 GIG Recommended)

40 GB HDD

800 x 600 Resolution

(2) USB 2.0 ports

Specifications are subject to change without notice.

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 11 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

Basic Operations

The basic operational procedures for the INTEGRA 9500/9505 are listed below:

1. Turn on the system and wait 2 minutes for the lights to stabilize.

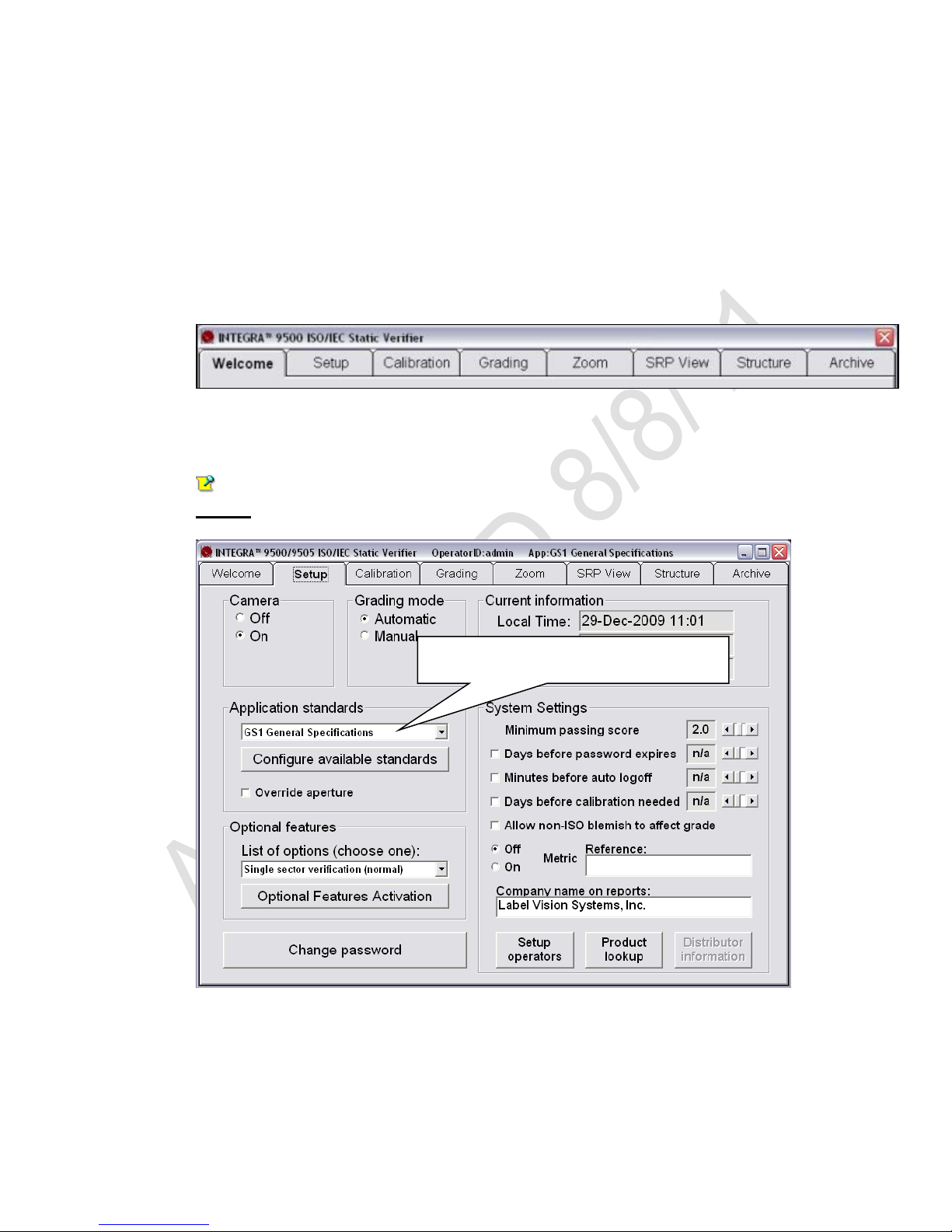

2. The system is setup with tabs located across the top of the screen. Each

tab is discussed in this guide.

Click the Setup tab and choose the desired Application standard (see

Figure below).

Note: When prompted for an Operator ID and Password, enter

admin for both the Operator ID and Password.

Choose an Application standard

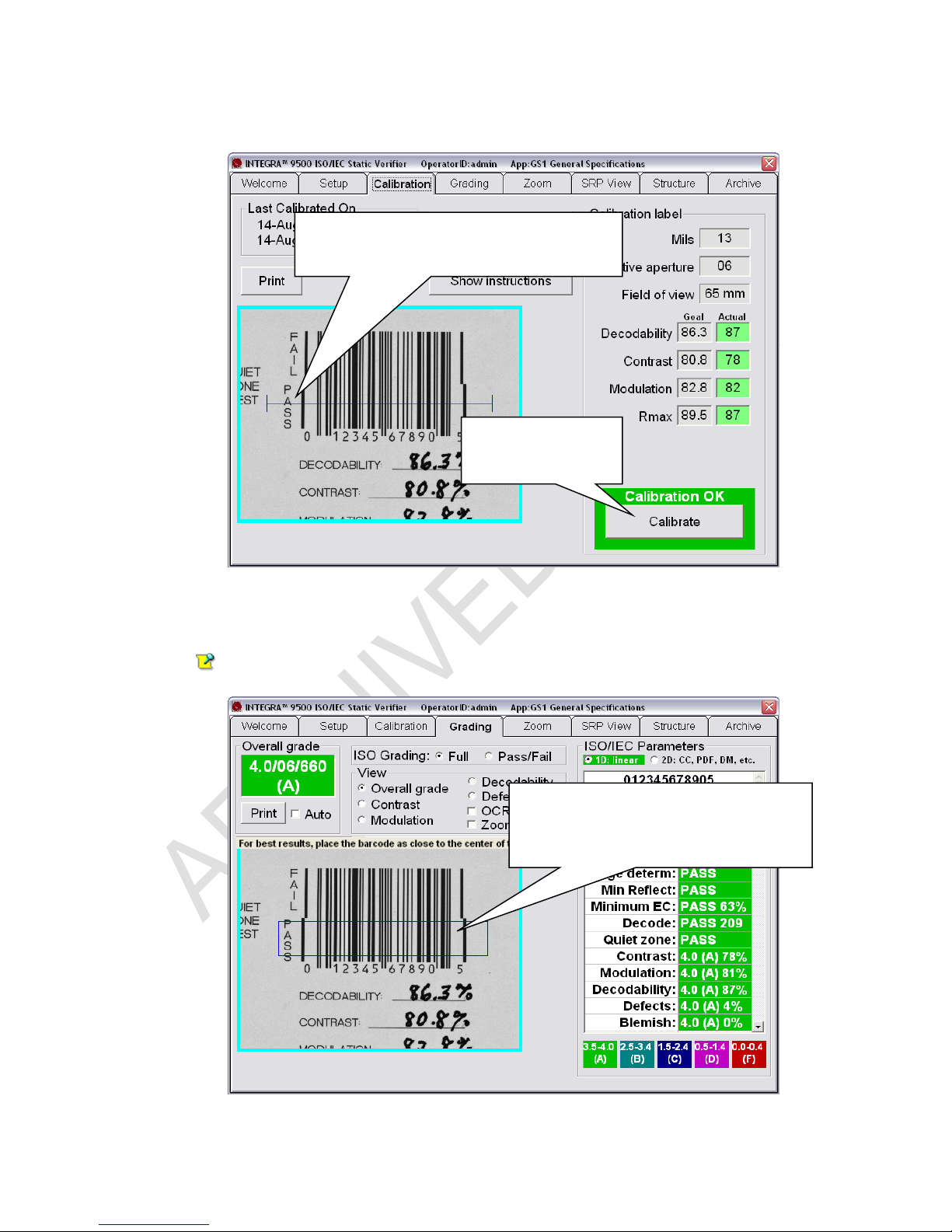

3. Click the Calibration tab and calibrate the system by placing either of the

Master Grade barcodes (located on the supplied Calibration Test Card)

into the center of the field of view, ensuring that the blue line passes

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 12 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

through the “PASS” portion of the calibration label. Then, click the

Calibrate button (see Figure below).

The blue line must pass through the

PASS portion of the calibration label.

Click the

Calibrate button

4. Click the Grading tab and place a barcode into the field of view and draw

a box as shown in the Figure below. The verification results are displayed

immediately.

Important: Position the barcode as close to the center of the field of

view as possible.

Draw a box around the PASS

portion of the barcode, ensuring

enough space for the quiet zone.

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 13 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

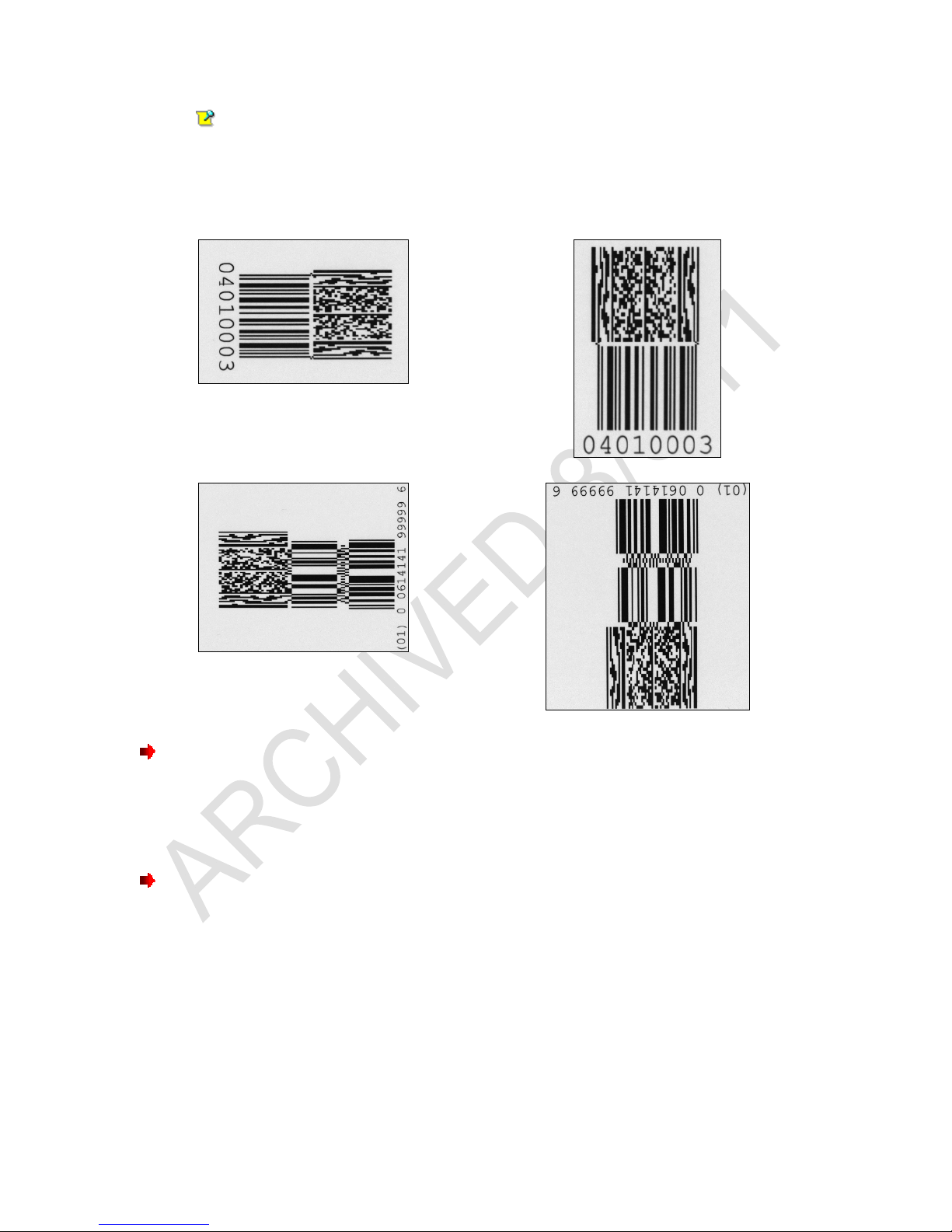

IMPORTANT: Barcodes can be verified in any orientation, which is an

integer multiple of 90 degrees. See examples below:

Barcodes Verified Horizontally:

Barcodes Verified Vertically:

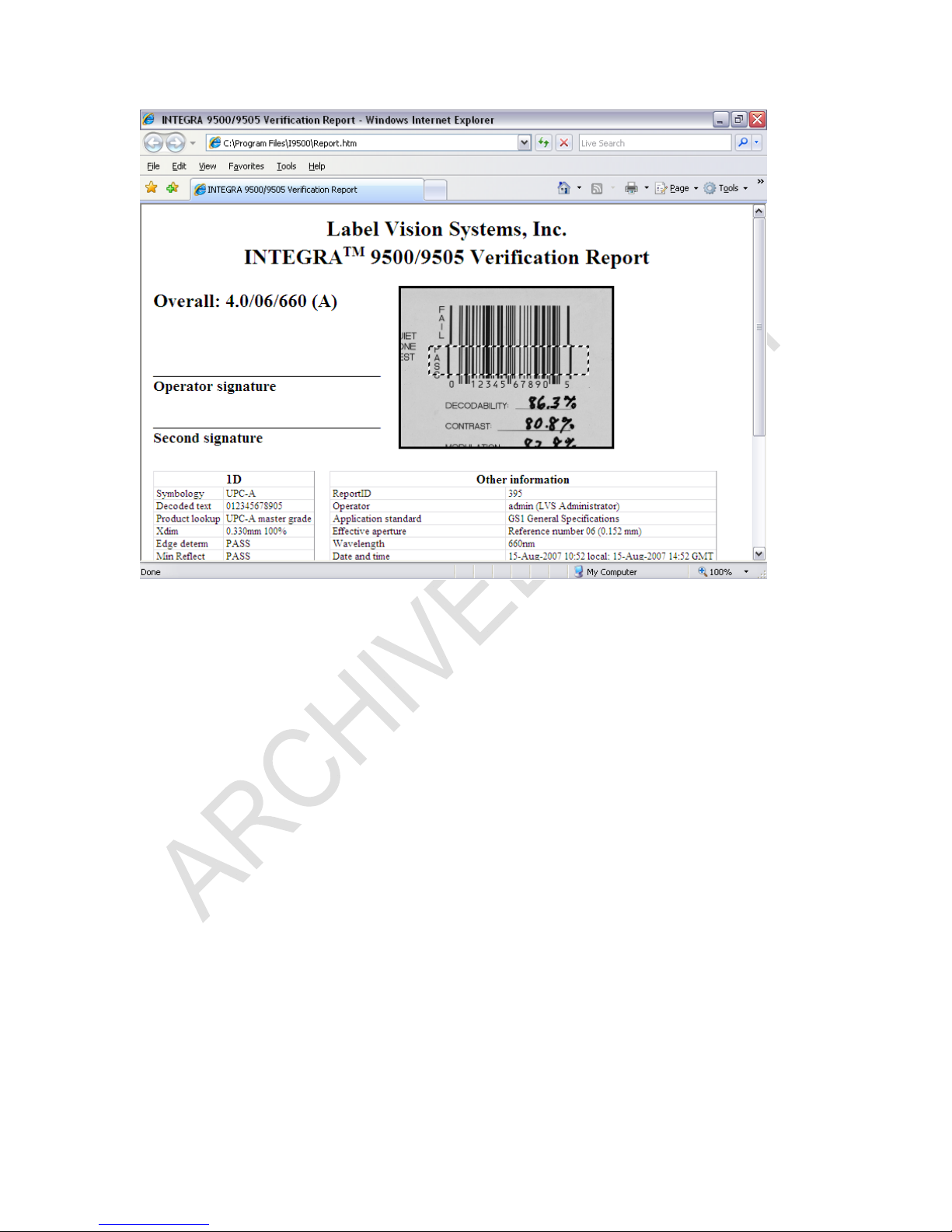

To Print the Results:

To print the verification results, click the Print button on the top, left corner of the

Grading Tab screen.

To View the Report:

To view the report, right-click on the Print button and an HTML document is

generated and displayed on the screen (see Figure below).

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 14 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

This concludes the Basic Operations of the INTEGRA 9500/9505. Each tab at

the top of the screen is explained in detail in the following sections.

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 15 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

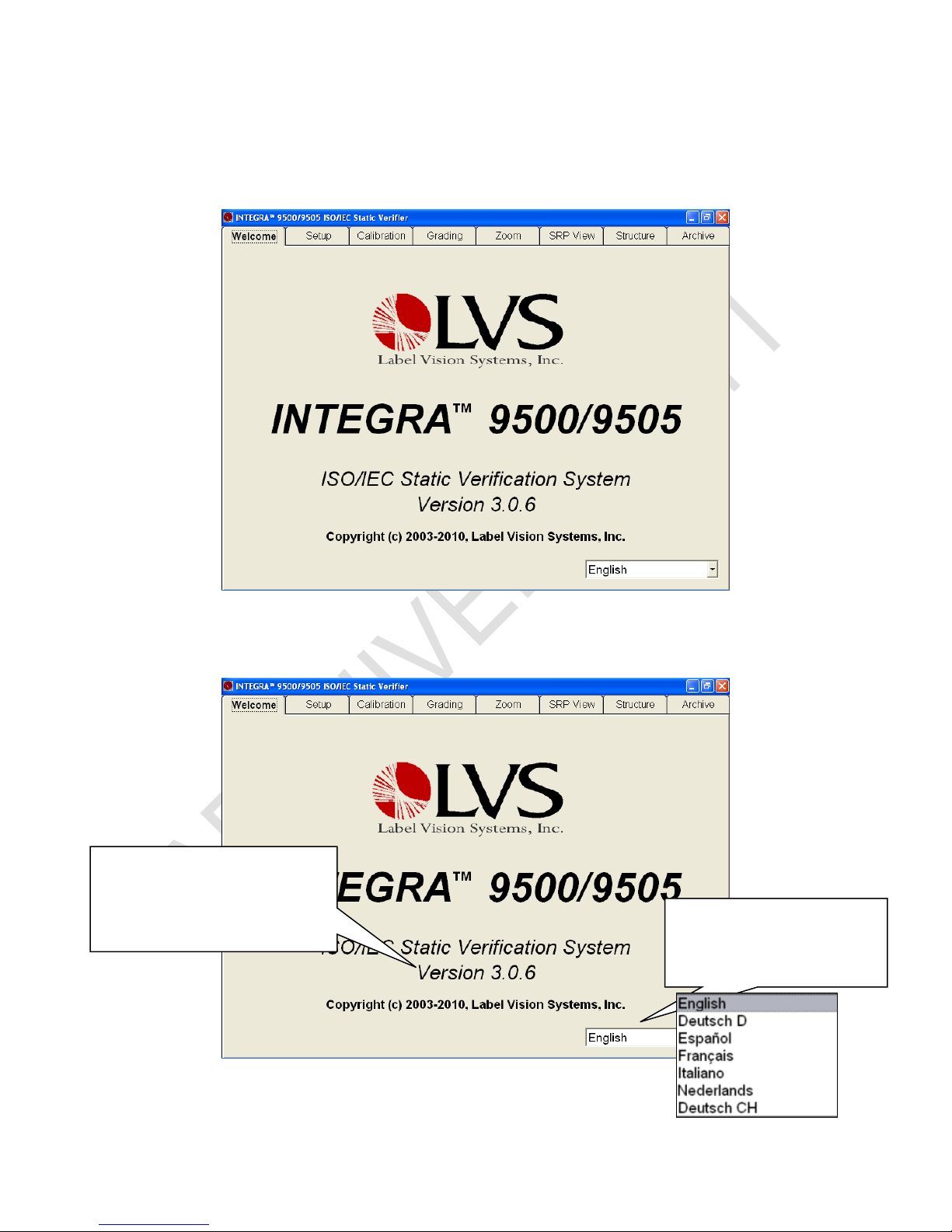

Welcome Tab

The Welcome tab is the first tab to appear when starting the INTEGRA

9500/9505.

Choice of Language

Click the drop-down box in the lower right section of the screen to change the

software language (see Figure below).

Double-click on the term

Version to view a

complete list of the latest

software versions.

Click this drop-down

box to select your

preferred language.

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 16 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

Current Software Version List

Double-clicking on the term Version (see Figure above) allows you to view a

complete list of the latest software versions. After double-clicking on this term,

the following page appears (see Figure below). This information is important if it

is necessary to contact the LVS technical helpline

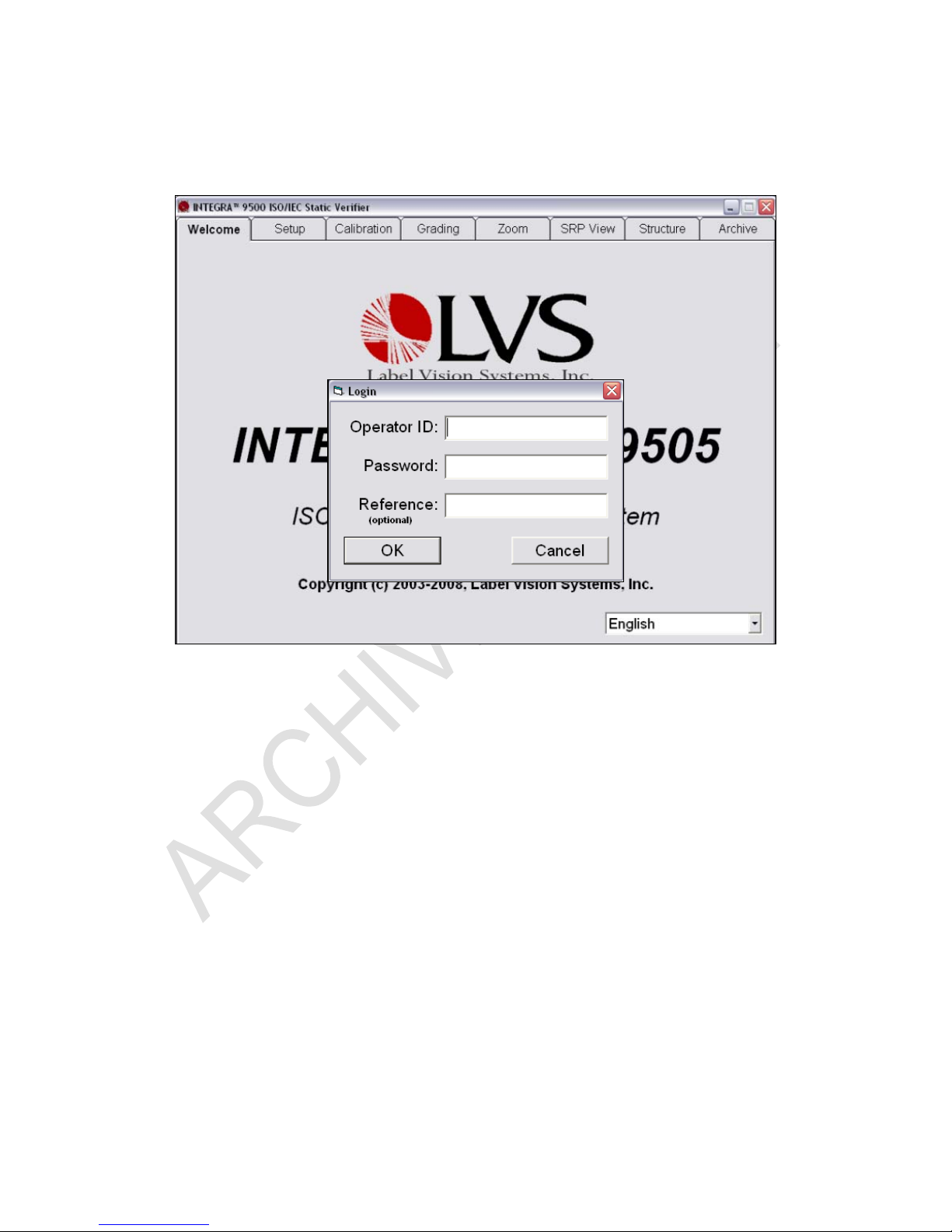

Password Login

The password Login box (see Figure below) appears when you click on any of

the tabs located at the top of the screen.

Enter the Operator ID and Password. When the system is used for the first time,

the Operator ID is admin and the password is admin. This enables the

administrator to gain access to where the software sets up and maintains all

passwords and levels of Permissions for each operator.

The Reference field, which is optional, allows operators to enter a reference

number for the work they are performing. This number can be used to reference

a Job Number, Control Number, Purchase Order, etc.

The reference number can also be entered in the Reference field located on the

Setup tab screen.

IMPORTANT: The last updated Reference field overrides the secondary

Reference field. For example, a user updating the Reference field on the Setup

tab screen overrides the reference number entered in the Login box.

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 17 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

Passwords and permission levels are explained in the next chapter under the

Setup Operators section.

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 18 of 82

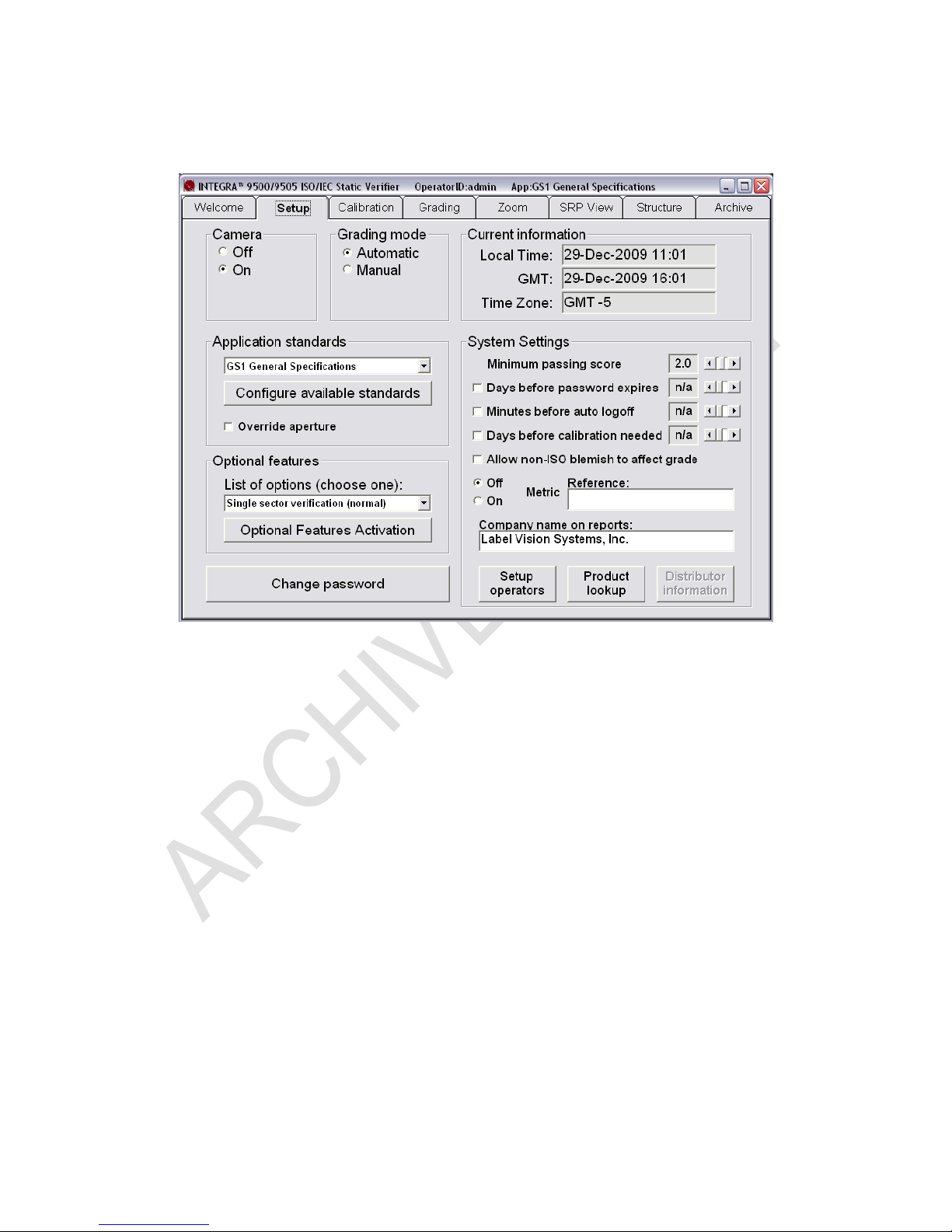

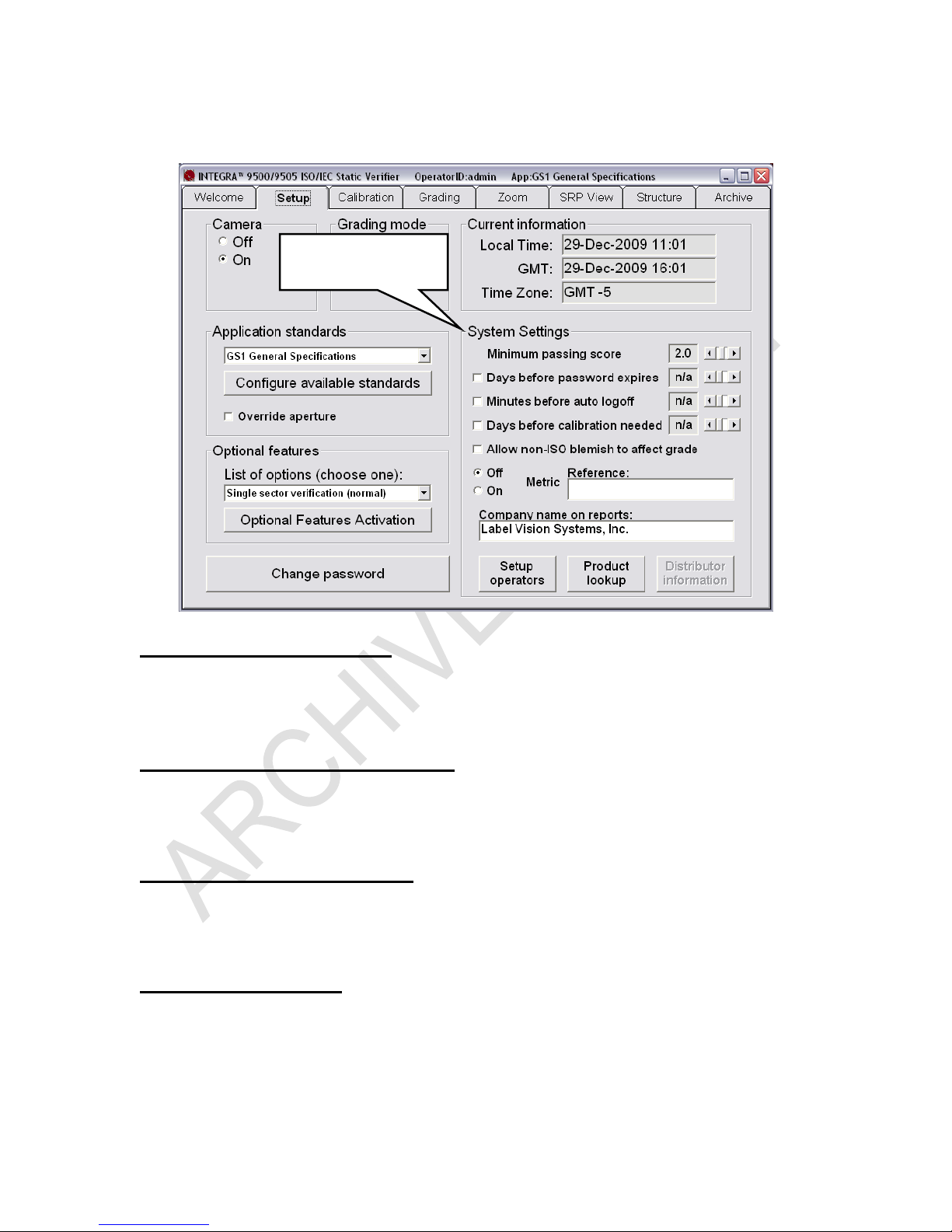

Setup Tab

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

The Setup tab contains the following sections:

Camera

Grading Mode

Application Standards

Current Information

System Settings

Optional Features

Change Password button

Each of the aforementioned sections is listed below:

Camera

On – This option is selected for nearly all activities.

Off – The camera automatically turns Off when the following occurs:

o When an imported image is reviewed (see the Archive Tab

section for more information).

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 19 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

o After performing a “stitching” operation (see the BarCode Too

Wide for Field of View (Stitching Function) section for more

information).

After you have finished inspecting either of the above images, the camera

must be turned back On to see live images again.

Grading Mode

The “Grading mode” section allows you to choose one of two ways to grade

barcodes after a sector has been drawn.

Automatic: After a sector has been established, you can remove the

barcode and place another barcode into the field of view and the new barcode

is graded automatically.

Manual: After a sector has been established, you can remove the barcode

and place another barcode into the field of view and the new barcode is

graded after the Click to grade button is pushed or if a new box is drawn.

When choosing to manually grade an image, the software also archives the

verification data.

Application Standards

An Application standard is a specific protocol established by a group or industry,

such as the military, hospitals, FDA, etc. Currently, the INTEGRA 9500/9505

supports the following Application standards:

1. AIAG / JAMA / JAPIA / ODETTE

2. ALDI

3. AS9132-A / AIM DPM Cat 0

4. Automatic GS1 or ISO (read important note below)

5. Chinese Sensible (Han Xin) Code

6. DHL

7. French CIP

8. GS1 General Specifications

9. GS1 Report.doc (requires the use of Microsoft Word)

Note: GS1 Report.doc is the default custom report. You can create

your own custom report(s) by following the steps outlined in Appendix

G: Custom Report.

10. IFAH

11. ISO/IEC 15415/15416

12. Italian Pharmacode

13. Japan Post

14. Japanese Codabar

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 20 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

15. Laetus Pharmacode

16. MIL-STD-130M

17. Miniature Pharmacode

18. Multi-rotation Data Matrix

19. Multi-rotation QR Code

20. PZN-big (German Pharmacode)

21. PZN-normal (German Pharmacode)

22. PZN-small (German Pharmacode)

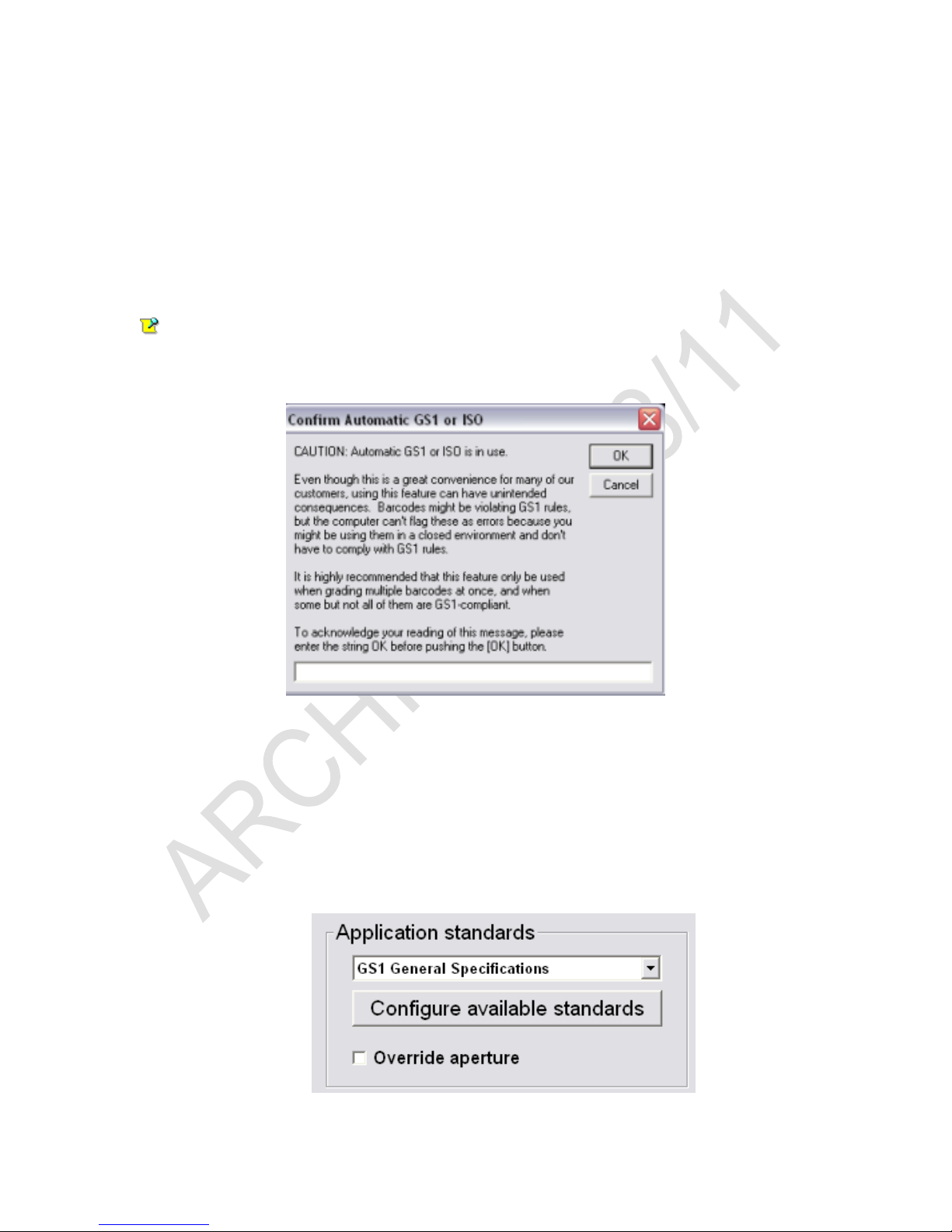

Important note about Automatic GS1 or ISO Application standard:

When selecting the Automatic GS 1 or ISO standard, the following message

appears. You must read the message, enter OK in the text field, and then click

OK.

The aforementioned Application standards vary according to specific industry

norms. Failure to use the correct standard causes the final grade to be incorrect.

When no Application standard is specified, the ISO/IEC 15415/15416 should be

used.

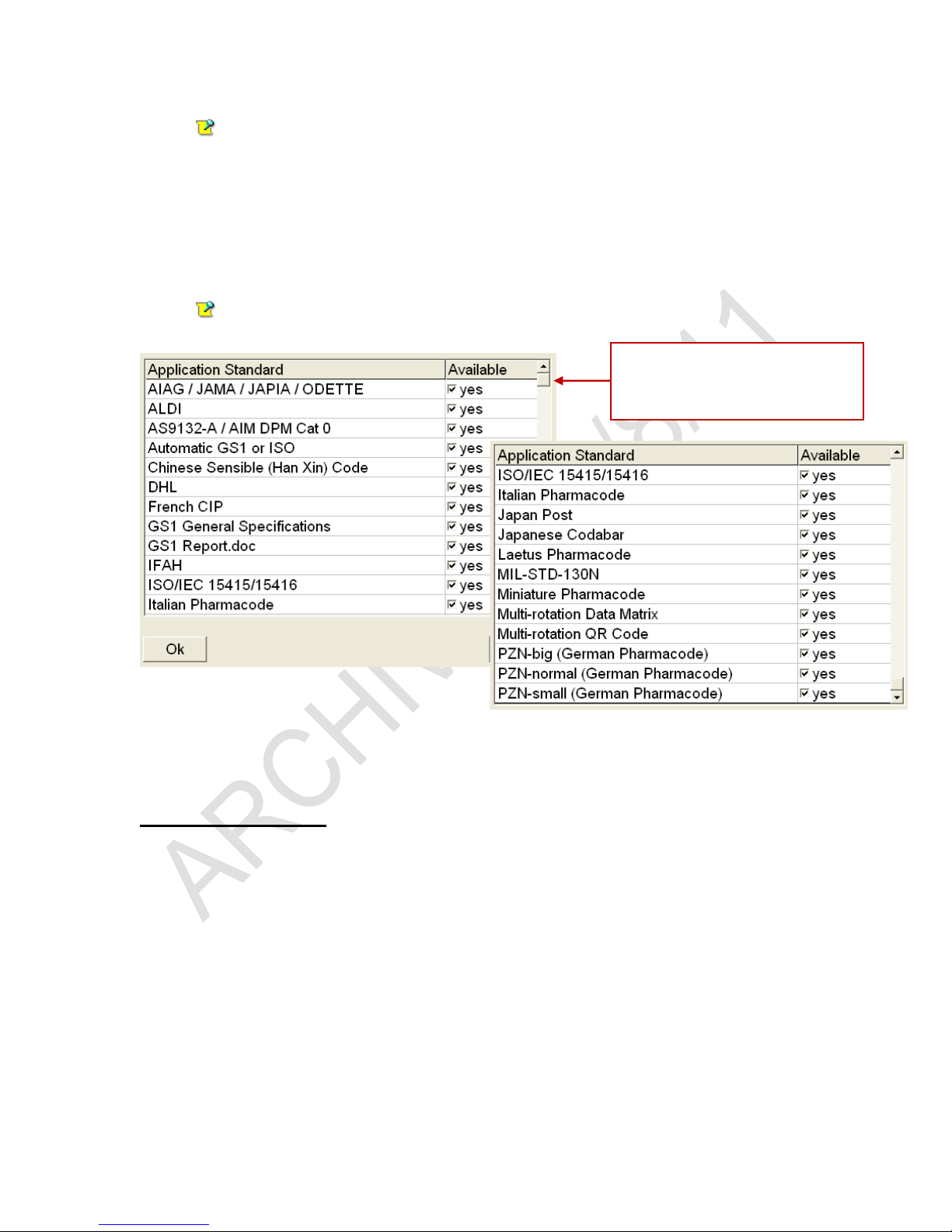

Selecting an Application Standard

1. Select an Application standard from the drop-down box, or click the

Configure available standards button to view the entire list of Application

standards (see Figure below).

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 21 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

Note: The Application standards appearing in the drop-down list are

the standards marked Yes in the main Application standards window; this

window appears after clicking the Configure available standards button

(see next step for more information about this feature).

2. If you select the Configure available standards button, select the Yes

checkbox for each desired Application standard (see Figure below). Each

selected Application standard appears in the Application standards dropdown list.

Note: Clicking the Available column header toggles all Application

standards between Yes or No options.

Use the scroll bar to view

additional Application

Standards.

Additional Application Standards

3. Click OK to save your changes or Cancel to discard your changes.

Override Aperture

ISO 15415 and ISO 15416 outline rules regarding what aperture should be used

based on symbology and cell size / x-dimension. ISO 15415 and ISO 15416 also

state that apertures can be overridden by an Application Standard and that the

Application Standard rules shall take precedence over the ISO standards. While

the INTEGRA 9500/9505 supports a number of common Application Standards,

it is conceivable that an aperture other than those stated either in the ISO

standards or the supported Application Standards may be desired.

If an Application standard other than those specified is desired, you may override

the aperture by clicking the Override aperture checkbox. Enter the diameter of

the aperture expressed in one thousandths of an inch (.0254 mm); use this value

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 22 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

even when using metric. If the aperture has been overridden, a clear warning is

displayed on the Grading screen as well as on the Grading Report.

Creating Custom Reports

GS1 General Specifications is the default custom report. You can create your

own custom report(s) by following the steps outlined in Appendix G: Custom

Report.

Note: Appendix G is not included in this manual; it is included on the

installation CD that arrives with your INTEGRA 9500 or 9505.

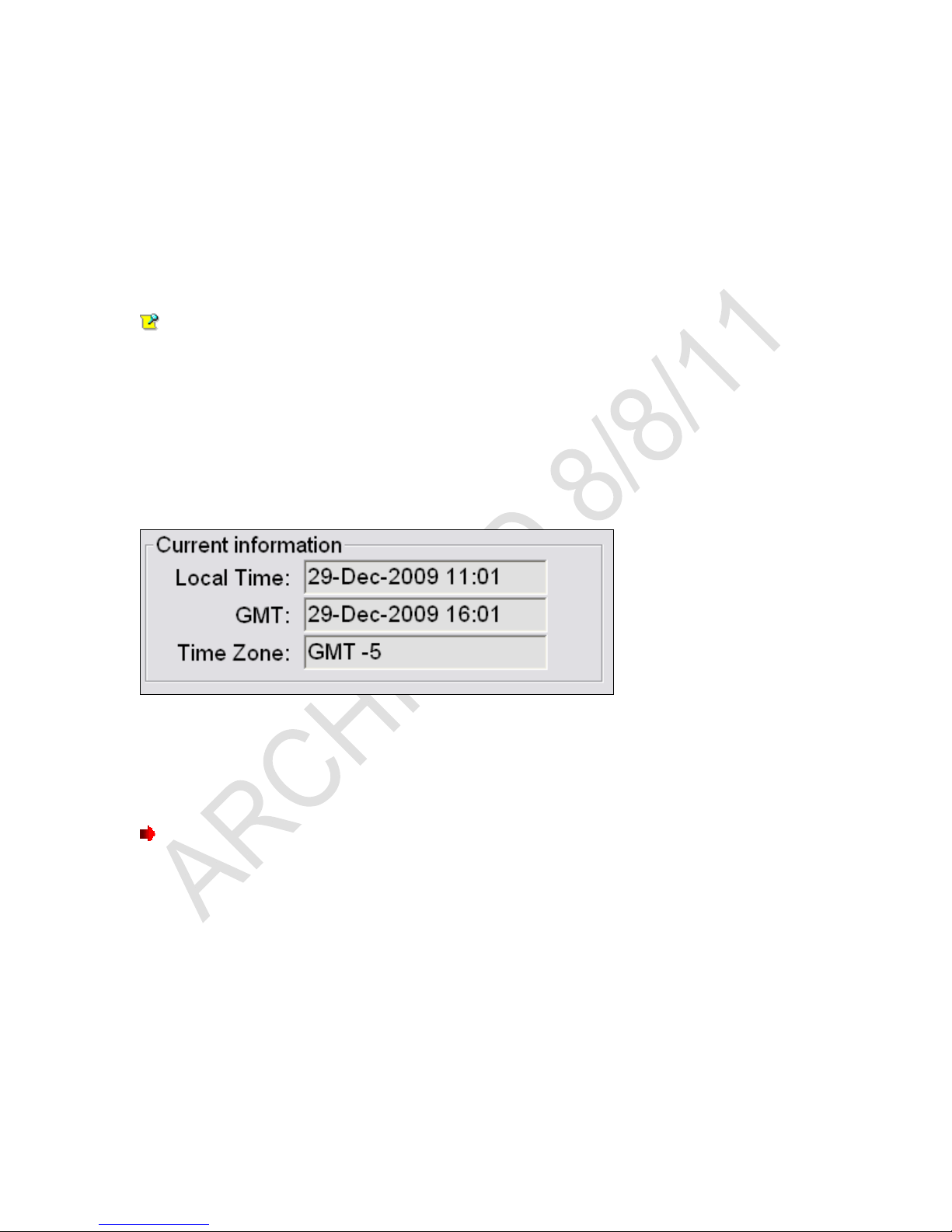

Current Information

The top-right of the Setup Tab screen contains a box of information indicating

the local time of day, date, Greenwich Mean Time (GMT), and time zone (see

below).

GMT is defined as the local time at the 0 meridian passing through Greenwich,

England and is the same as UT (Universal Time). GMT remains the same

throughout the year and does not change in the Spring or Autumn. This

information is attached to all Calibration Reports.

Change the Time Zone:

Minimize the INTEGRA 9500/9505 screen and right click on the time box

at the lower right corner of the computer screen.

Choose Adjust Date/Time.

Click the Time Zone tab and change the time zone to the correct time

zone.

Push the Apply button.

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 23 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

System Settings

System Settings

Minimum Passing Score

There is a PASS/FAIL mode of operation used to simplify barcode verification

(this is explained in more detail in the section entitled Pass / Fail ISO Grading in

the Grading Tab section). This is where the minimum passing score is selected.

Days before password expires

Use the arrow keys to select the number of days before the current password

expires. As soon as you use the arrow keys, the checkbox will automatically be

enabled.

Minutes before auto logoff

An automatic “Logoff” feature is set by clicking on the box and then choosing a

period of time desired to make the system automatically log off after that period

of time. Choosing n/a causes this feature to be turned off.

Recalibration Cycle

It is important to calibrate the system over a period of time. This feature sets up

the desired number of days between system calibration. When the period of time

has been reached, the software will not allow you to continue until calibration has

been completed.

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 24 of 82

M-9500-3.0.6-0 INTEGRA 9500-9505 Operations Manual – English

Allow Non-ISO blemish to affect grade

If this option is not checked, a barcode where many lines are not decodable will

not be penalized since the ISO standard does not mandate how long decoded

lines should be handled.

If this option is checked, non-decoded lines will degrade the overall ISO grade.

Metric

The Metric option allows you to choose between measurements being reported

in inches or metric units (mm/microns).

Reference Box

You can choose to add a reference number to a final verification report by

entering a number in this box, such as a Job Number, Control Number, Purchase

Order Number, etc; this allows you to sort results by reference.

A reference number can also be entered in the Login box when a user logs onto

the system. Note that the last updated Reference field overrides the secondary

Reference field. For example, a user updating the Reference field in the Login

box overrides the reference number entered on the Setup tab screen.

Company Name on Reports

This feature gives you the ability to place your company name on all final

verification reports. Delete the Label Vision Systems, Inc name from the field

and type in your company name.

Setup Operators

Many national and international standards stipulate that the operator of a

verification system must be identified in order for the verification process to be

valid. To set this up, push the Setup operators button.

The administrator of the system can now choose to add, delete, or change an

operator’s name and password (see Figure below).

IMPORTANT: A password must have a minimum number of 8 characters

and must contain at least (1) alpha character and (1) numeric character.

This is also where the administrator of the system chooses which operator’s have

permission to perform the listed tasks (see Figure on next page). Be sure to push

the OK button when you are finished entering new users or updating levels of

permissions. Following is a list of permissions and descriptions:

Approved: Spike Reed Effective: 15 Nov 2010 Supersedes: 28 Jan 2010

LVS®

CONFIDENTIAL All contents copyright © LVS® 2010 Page 25 of 82

Loading...

Loading...