PULITO PERSONALIZZATO • CUSTOMIZED CLEANING • NETTOYAGE PERSONNALISÉ •

KUNDENORIENTIERTE REINIGUNG • LIMPIEZA PERSONALIZADA

ATTENZIONE!

NON USARE L’APPARECCHIO SENZA AVER LETTO LE ISTRUZIONI PER L’USO

ATTENTION! DO NOT USE THE MACHINE BEFORE READING THE INSTRUCTIONS FOR USE

ATTENTION! NE PAS UTILISER LA MACHINE SANS LIRE LES INSTRUCTIONS POUR L’EMPLOI

ACHTUNG! DIE MASCHINENICHT GEBRAUCHEN, OHNE VORHER DIE ANLEITUNGEN GELESEN ZU HABEN

ATENCIÓN! LA MÁQUINA NO DEBE SER UTILIZADA SIN HABER LEÍDO LAS INSTRUCCIONES PARA EL EMPLEO

USO E MANUTENZIONE

USE AND MAINTENANCE

EMPLOI ET ENTRETIEN

BEDIENUNG UND

WARTUNGSANLEITUNG

USO Y MANTENIMENTO

Magna 85-100-85S-100S

CODICE T5114002 GB 01/2005

LVC UK

Unit 1 Brookside, Colne Way Industrial Estate

Watford , Hertfordshire, WD24 7QJ

Tel: 01923 445 550

info@lvcuk.com

www.lvcuk.com

2

SUMMARY

SUMMARY .............................................................................................................................................................................2

ON DELIVERY OF THE MACHINE.............................................................................................................................................3

INTRODUCTION......................................................................................................................................................................3

SOUND POWER LEVEL LABEL................................................................................................................................................................... 3

TECHNICAL DESCRIPTION.......................................................................................................................................................4

TECHNICAL DESCRIPTION............................................................................................................................................4

SYMBOLOGY USED ON THE MACHINE....................................................................................................................................5

SYMBOLOGY USED ON THE MACHINE.................................................................................................................................... 6

MACHINE PREPARATION........................................................................................................................................................ 8

1. HANDLING THE PACKED MACHINE...................................................................................................................................................... 8

2.HOW TO UNPACK THE MACHINE.......................................................................................................................................................... 8

3. INSTALLATION OF THE BATTERIES INTO THE MACHINE.......................................................................................................................... 9

4. CONNECTION OF THE BATTERY CONNECTOR........................................................................................................................................ 9

5. CONNECTION OF THE BATTERY CHARGER............................................................................................................................................10

6. RECHARGING THE BATTERIES.............................................................................................................................................................10

7. BATTERY CHARGE LEVEL INDICATOR..................................................................................................................................................10

8. SQUEEGEE.........................................................................................................................................................................................11

9. ASSEMBLY; SIDE BARS 85S-100S......................................................................................................................................................11

10. ADJUSTMENT; SQEEGEE HEIGHT SUPPORT........................................................................................................................................12

11. BRUSHES ASSEMBLY; MAGNA 85-100..............................................................................................................................................13

12.SOLUTION WATER.............................................................................................................................................................................14

13. RECOVERY TANK ..............................................................................................................................................................................14

GENERAL RULES OF SECURITY.............................................................................................................................................. 15

PERFORMANCE ....................................................................................................................................................................16

CHECK MOTOR BRUSHES......................................................................................................................................................................18

BRUSH PRESSURE.................................................................................................................................................................................18

TRACTION.............................................................................................................................................................................................18

SQUEEGEE; AUTOMATIC – MANUAL .......................................................................................................................................................19

BRAKES................................................................................................................................................................................................19

BRAKES................................................................................................................................................................................................19

HORN...................................................................................................................................................................................................19

BLINKING AND WORKING LIGHTS..........................................................................................................................................................20

ON COMPLETION OF WORK.................................................................................................................................................. 21

ON COMPLETION OF WORK.................................................................................................................................................. 22

DAILY MAINTENANCE ......................................................................................................................................................... 23

CLEANING OF THE RECOVERY TANK........................................................................................................................................................23

CLEANING THE SQUEEGEE......................................................................................................................................................................23

REPLACEMENT OF THE SQUEEGEE RUBBER .............................................................................................................................................24

REMOVAL OF BRUSHES; MAGNA 85/100.......................................................................................................................................24

REMOVAL OF THE CYLINDRICAL BRUSHES; MAGNA 85S-100S................................................................................................25

SOLUTION TANK AND FILTER CLEANING..................................................................................................................................................26

DIRT HOPPER CLEANING........................................................................................................................................................................27

DAILY MAINTENANCE...........................................................................................................................................................28

ADJUSTMENT; SPLASH GUARD BRUSHES BASE MAGNA 85......................................................................................................................28

ADJUSTMENT; SPLASH GUARD BRUSHES BASE MAGNA 100....................................................................................................................28

ADJUSTMENT; SIDE BARS MAGNA 85/S 100/S.........................................................................................................................................29

CLEANING OF THE SUCTION HOSE.........................................................................................................................................................29

CLEANING SUCTION MOTOR FILTER.......................................................................................................................................................29

TROUBLE SHOOTING GUIDE.................................................................................................................................................. 30

INSUFFICIENT WATER ONTO THE BRUSHES..............................................................................................................................................30

THE MACHINE DOES NOT CLEAN SATISFACTORILY...................................................................................................................................30

THE SQUEEGEE DOES NOT DRY PERFECTLY..............................................................................................................................................30

THE SUCTION MOTOR DOES NOT FUNCTION............................................................................................................................................31

THE MACHINE DOES NOT START.............................................................................................................................................................31

EXCESSIVE FOAM PRODUCTION..............................................................................................................................................................31

CHOICE AND USE OF BRUSHES.............................................................................................................................................32

3

On delivery of the machine

When the machine is delivered to the customer, an

immediate check must be performed to ensure all the

material mentioned in the shipping documents have

been received and moreover to find out that the

machine has not suffered damage during transportation.

If damage has occurred, get the shipping agent to verify

immediately the amount and nature of the damage

suffered and at the same time inform our claim

department. It is only by prompt action of this type that

compensation for damage may be successfully claimed.

Introduction

This is a floor cleaning machine which, using the

mechanical abrasive action of two cylindrical brushes

and the chemical action of a water-detergent solution,

is able to clean any type of hard floor, picking up during

its forward movement, the removed dirt / detergent

solution from the floor. The machine must be used only

for such purpose. We would impress upon you that any

machine will function efficiently and operate

successfully, only if used correctly and maintained in

fully efficient working order. We therefore suggest that

you read this instruction booklet carefully and re-read it

whenever difficulties arise in the course of machine use.

Our service department is at your disposal for such

advice and servicing as may prove necessary.

SOUND POWER LEVEL LABEL

4

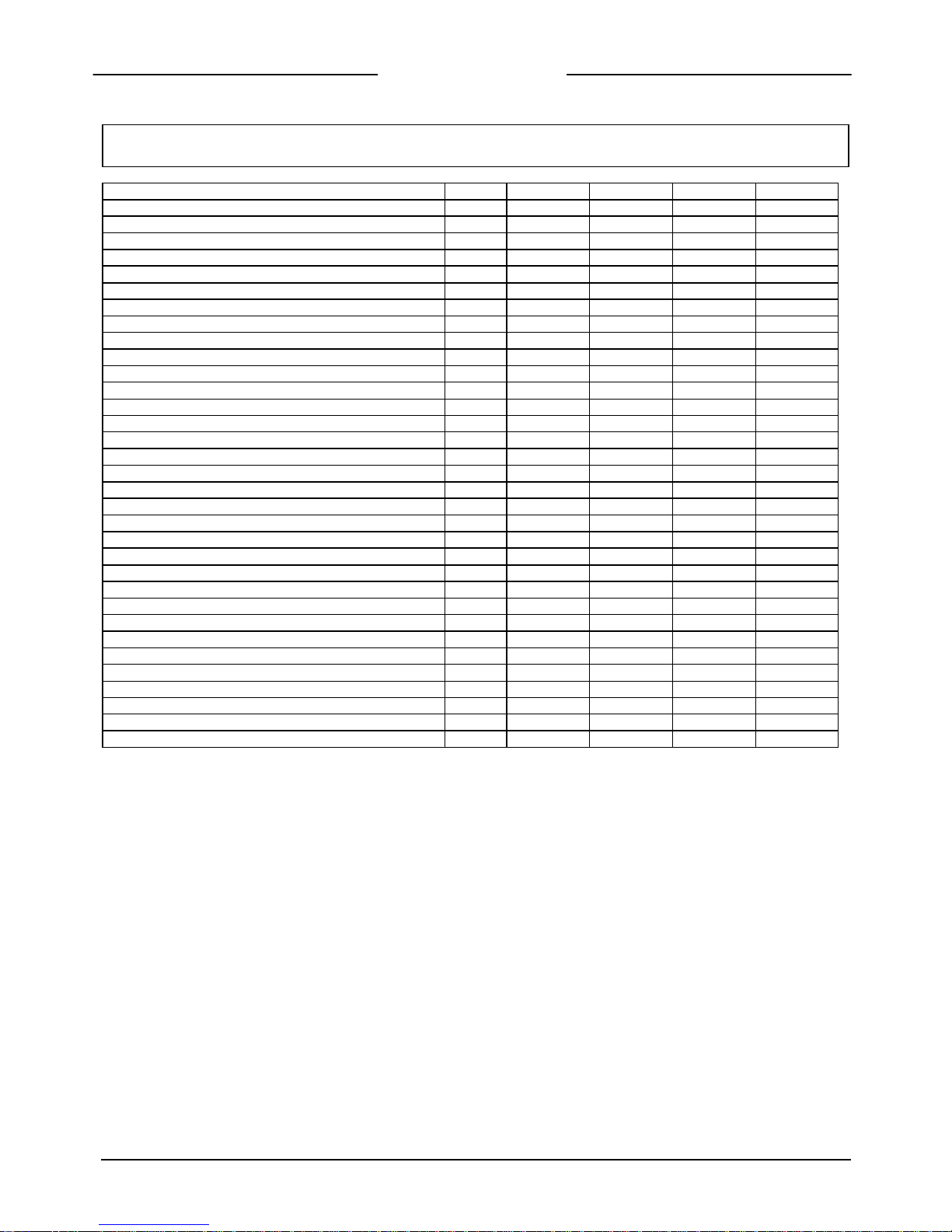

TECHNICAL DESCRIPTION

TECHNICAL DESCRIPTION Magna 85 Magna 100 Magna 85S Magna 100S

Cleaning width mm 850 1000 850 1000

Base side movement mm 150 150

Squeegee width mm 1120 1279 1120 1279

Working capacity (at max. speed) mq/h 5500 6500 5500 6500

Water consumption g/m2 90 90 70 70

Brushes (No,)

∅ mm 430 (x2) 510 (x2)

Cylindrical brushes (No,) ∅ xmm 210x850 (2) 210x1000 (2)

Brushes rpm giri/min 180 180 700 700

Brushes pressure kg 130max 150max 63 60

Max. specific pressure g/cm2 54 52 70 68

Brushes motor V 36 36 36 36

Brushes motor W 1500 2000 2x1000 2x1000

Traction motor V 36 36 36 36

Traction motor W 1100 1100 1100 1100

Traction wheel ∅ mm 300 300 300 300

Movement speed km/h 0÷6.5 0÷6.5 0÷6.5 0÷6.5

Max. gradient under full load 10% 10% 10% 10%

Suction motor V 36 36 36 36

Suction motor (No,) W 670(x2) 670(x2) 670 (x2) 670 (x2)

Suction vacuum mbar 190 190 190 190

Rear wheels ∅ mm 300x90 300x90 300x90 300x90

Solution tank l 200 200 200 200

Recovery tank l 215 215 215 215

Steering diameter mm 2500 2500 2500 2500

Machine length mm 1960 1960 1960 1960

Machine height mm 1500 1500 1500 1500

Machine width mm 870 1120 860 1115

Batteries (No,) V/Ah 36/360max (1) 36/360max (1) 36/360max (1) 36/360max (1)

Batteries weight kg 370 max 370 max 370 max 370 max

Machine weight (empty and without batteries) kg 490 515 475 500

Noise level (in conformity with IEC 704/1) dB (A) 69 69 69 69

Hand vibration level m/s² 2,1 2,1 1,6 1,6

Body vibration level m/s² 1,1 1,1 0,3 0,3

5

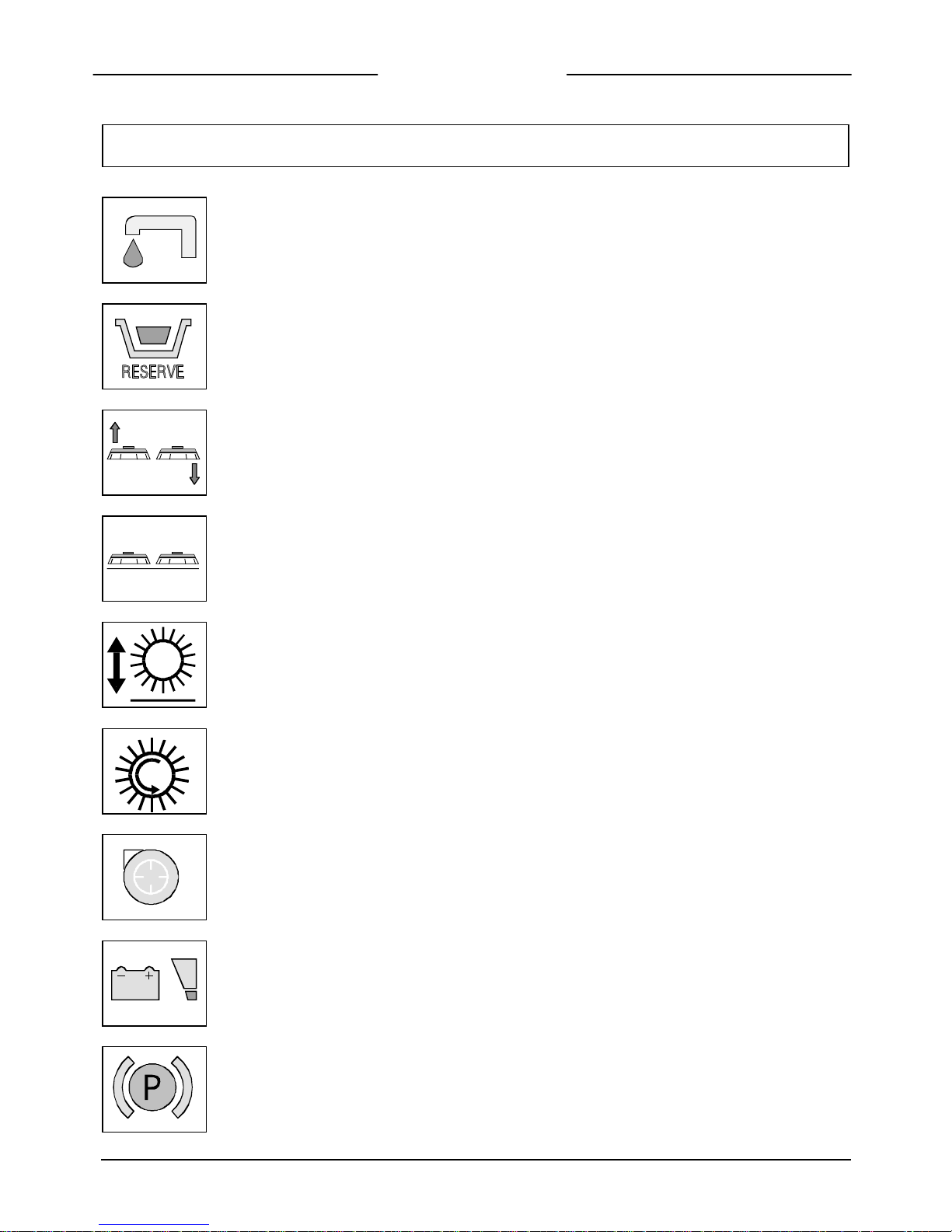

SYMBOLOGY USED ON THE MACHINE

Symbol denoting solenoid valve open

It is used to indicate the switch of the solenoid valve

Symbol denoting solution tank empty

Symbol denoting up - down of the brushes base Magna 85/100.

It is used to indicate the signal lamp of the brushes actuator when operating.

Symbol denoting brush Magna 85/100.

It is used to indicate the brushes motor switch

Symbol denoting ‘up-down’ of the cylindrical main brushes on Magna 85S/100S

It is used to indicate the light showing movement of the brush actuator

Symbol denoting cylindrical brushes of Magna 85S/100S

It is used to indicate the brush motor switch

Symbol denoting suction motor

It is used to indicate the suction motor switch

Symbol denoting charge level of batteries

Symbol denoting brake

It is used to indicate the signal lamp of the activated hand brake

It is used to indicate oil low-level warning in the working brake system

It is used on the top of the emergency brake lever

6

SYMBOLOGY USED ON THE MACHINE

Symbol denoting up – down of the squeegee

It is used to indicate the commutator for squeegee lifting

Symbol denoting manipulator brushes Magna 85/100.

It is used on the instrument board to indicate the manipulator of the brushes base. Making side

movements with the manipulator, they correspond to side movements of the brushes base.

Longitudinal movements correspond to vertical movements of the brushes base.

Symbol denoting stop base side movement Magna 85/100.

The green signal lamp comes on when the brushes base is moved all to the left side.

Symbol denoting squeegee fully down (green signal lamp).

Symbol denoting high running amps of the brushes motor (red signal lamp)

The signal lamp comes on when the brushes motor is over-loaded

Symbol denoting pressure carried on the brushes Magna 85/100

Symbol denoting water supply regulation cock

3

2

Symbol denoting speed selector, forwards and reverse

7

SYMBOLOGY USED ON THE MACHINE

Symbol denoting the switches ‘blinking’

Symbol denoting the selector working mode; automatic or manual

Symbol of the ‘Travel drive’ joy-stick.

Depending on its position the machine moves in a Forward or Reverse direction

Symbol denoting the ‘on/off’ switch

Symbol of the ‘Brush’ joy

-

stick of Magna 85S/100S

It is used on the instrument panel to indicate the ‘joy-stick’ for brush movement.

Pushing the lever forwards lowers the brushes, pulling it backwards raises them

Symbol open book

In order to point out that the operator should read the handbook before using the machine

8

MACHINE PREPARATION

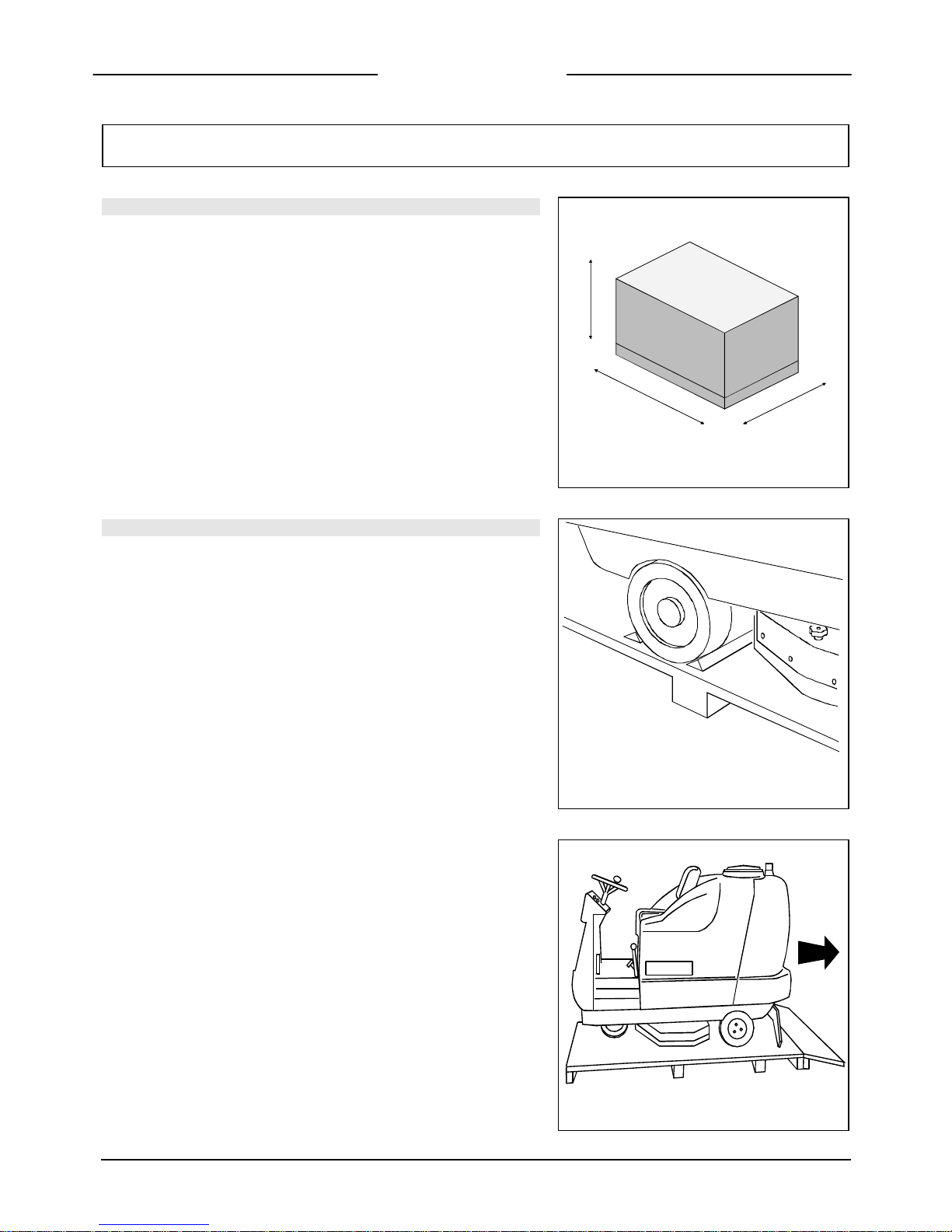

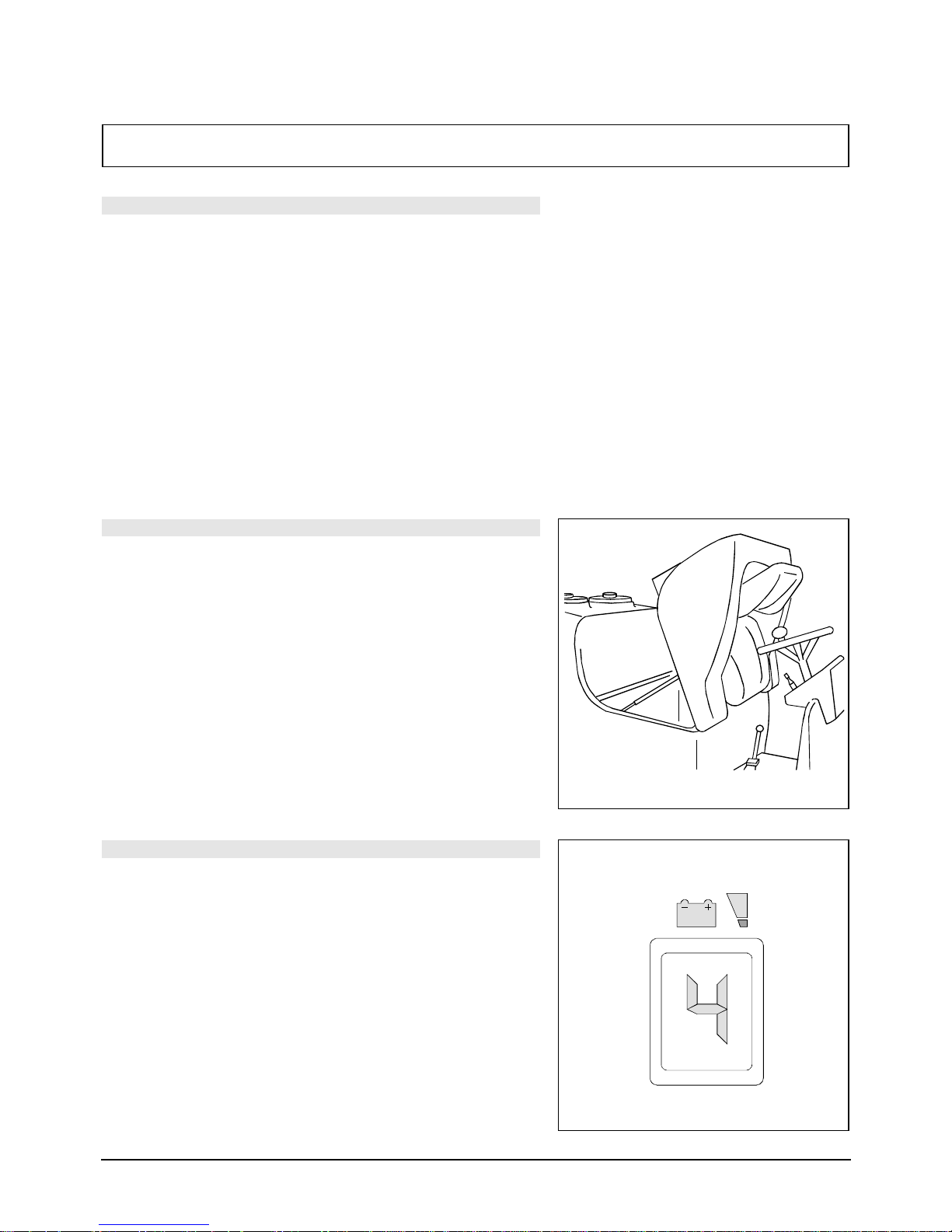

1. HANDLING THE PACKED MACHINE

Figure 1

The machine is packed in a special package provided on a pallet for

handling with fork trucks. The packages cannot be placed on top of each

other.

The total weight is 555 kg for the Magna 85, 580 kg for the Magna 100,

590 kg for the Magna 85/S and 619 kg for the Magna 100/S

The overall dimensions are:

A : 1620 mm

B : 1300 mm

C : 2010 mm

A

C

B

2. HOW TO UNPACK THE MACHINE

Figure 2

1. Remove the outer packaging

2. The machine is fixed on the pallet with wooden wedges which block

the wheels

3. Remove these wedges

Figure 3

4. Use a ramp to get the machine down from the pallet, pushing it in

reverse motion. Avoid violent blows to the base.

5. Keep the pallet in case of further transport needs

9

MACHINE PREPARATION

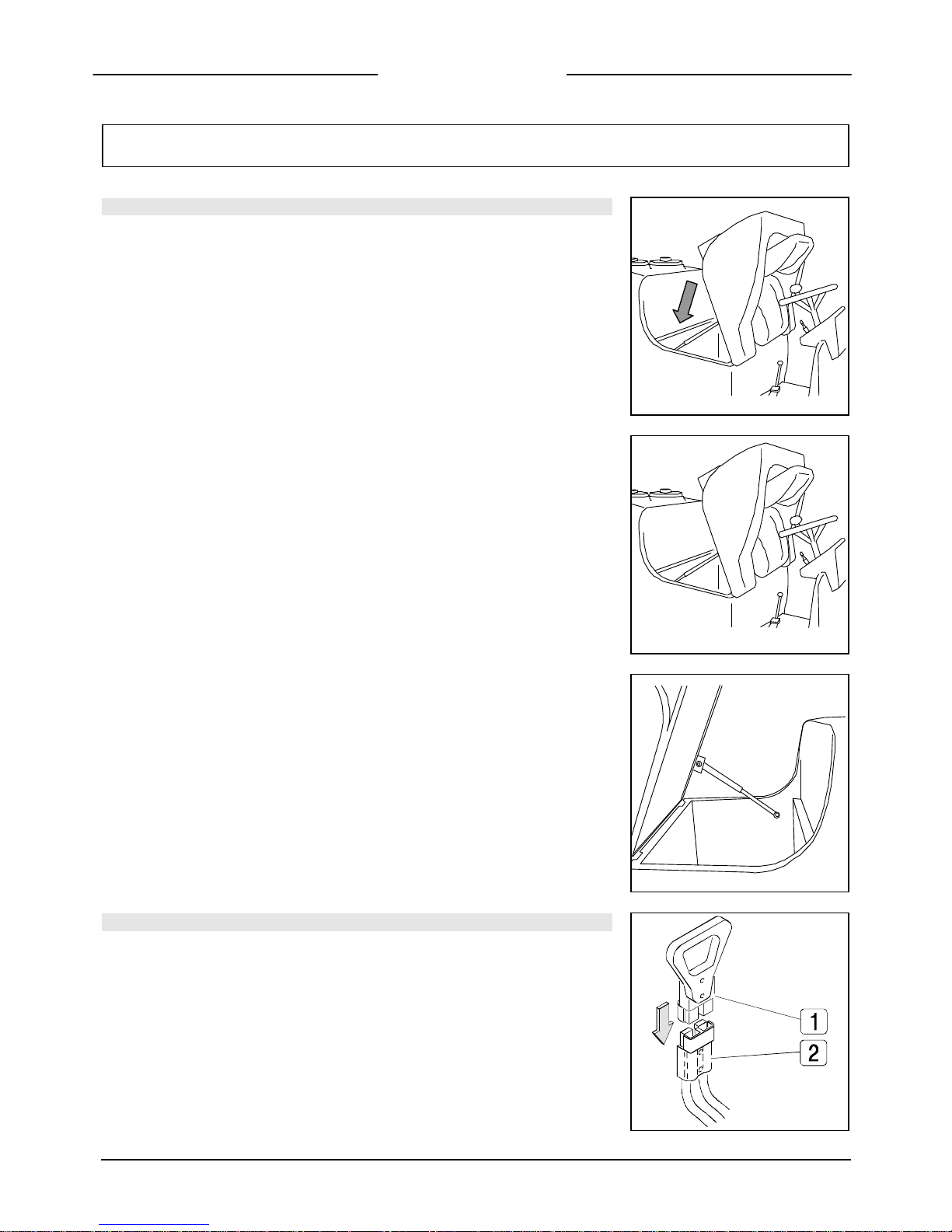

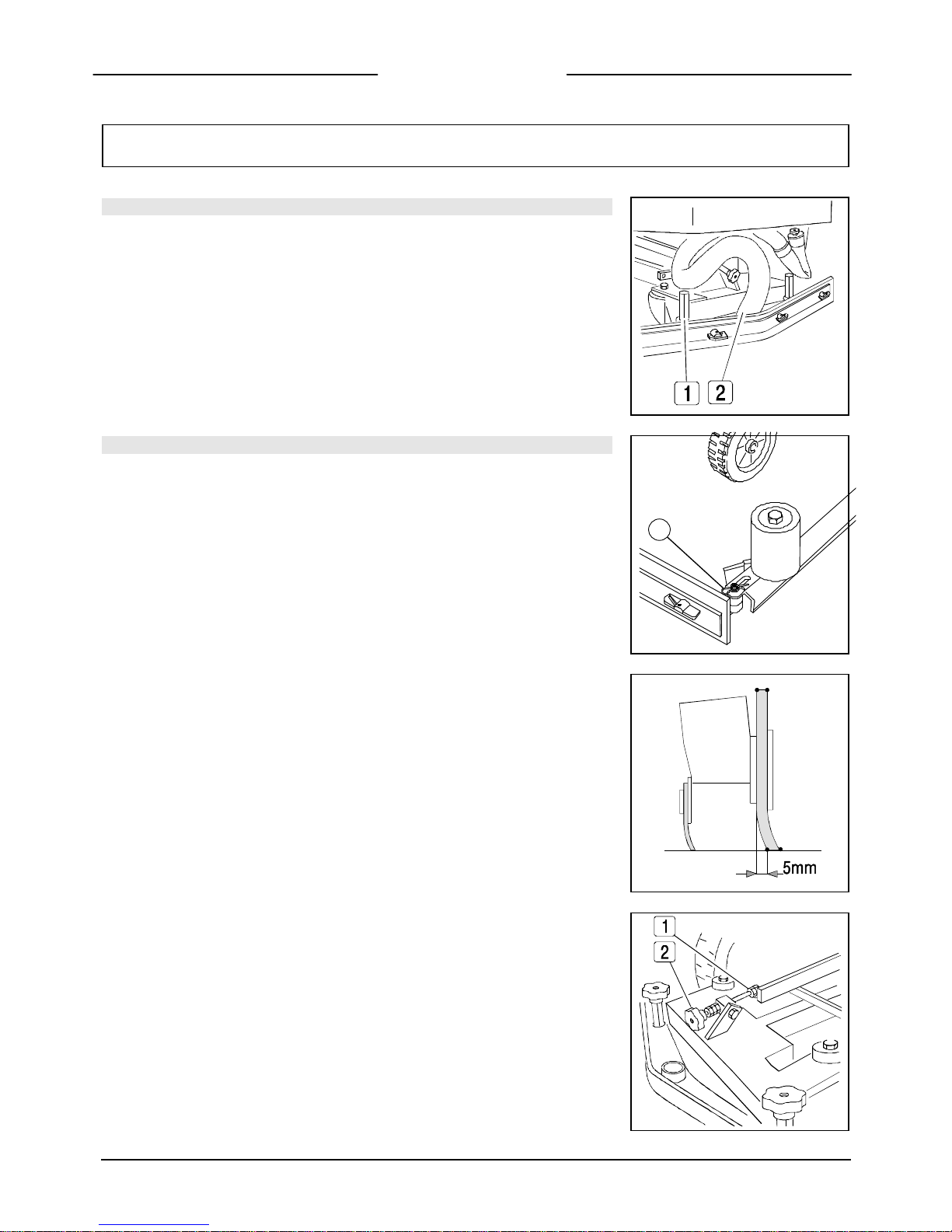

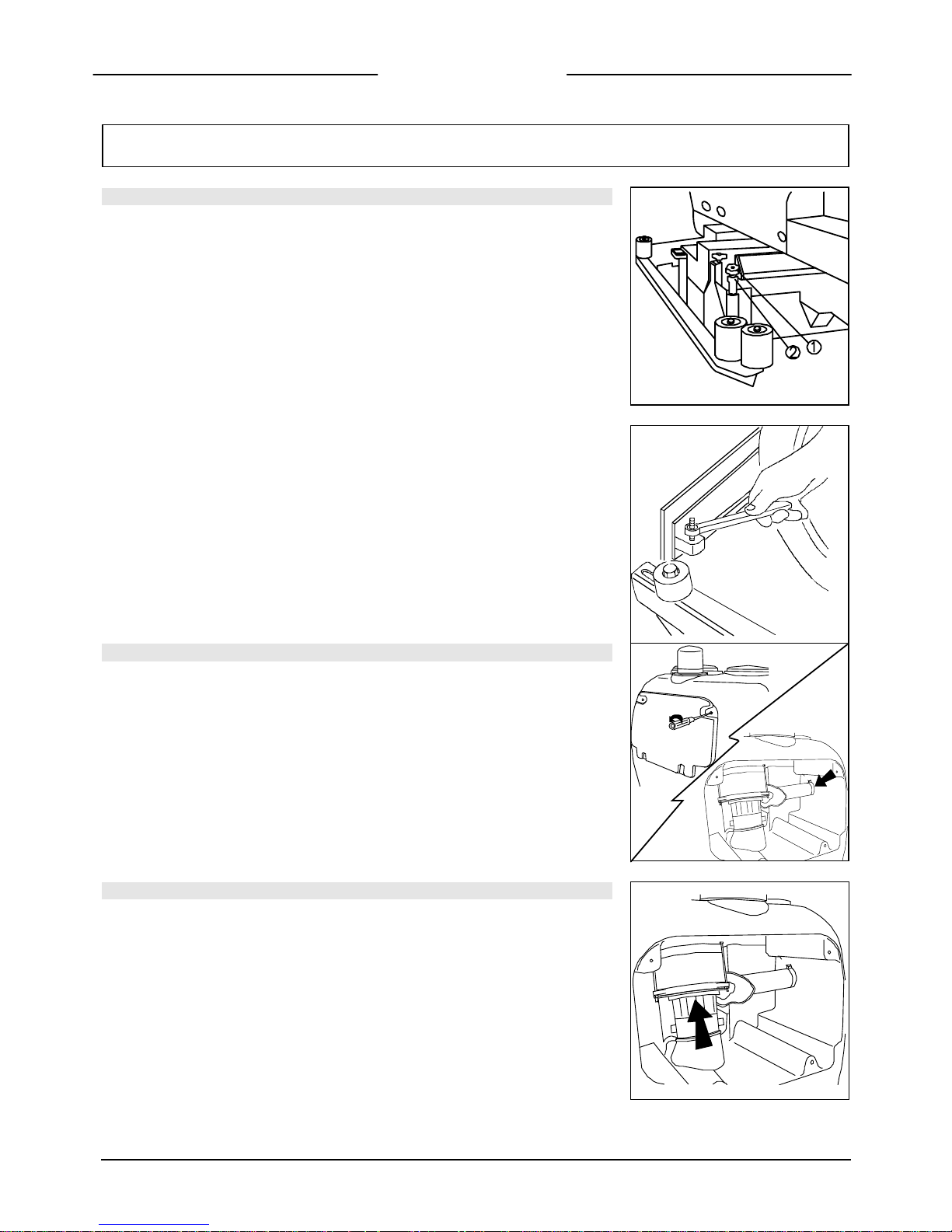

3. INSTALLATION OF THE BATTERIES INTO THE MACHINE

Figure 4

The batteries are fitted in the appropriate compartment under the seat and must be

handled by using lifting equipment suitable both for the weight and for the coupler

system. They must moreover satisfy the requirements quoted in the Specification CEI

21-5.

For maintenance and daily recharging of the batteries, it is necessary to follow strictly

all the indstructions given by the manufacturer or from his dealer. Specialized staff

must carry out all the installation and maintenance operations.

Figure 5

In order to insert the batteries it is necessary to:

1. Lift the seat support

2. Extract the prop from its slot

3. Lean the seat on the steering wheel

4. Insert the batteries

Figure 6

5. Lower the base support of the seat being careful to have at first refastened the tie.

4. CONNECTION OF THE BATTERY CONNECTOR

Figure 7

The battery connector (1) is placed in the left lower part of the operators seat and

must be connected to the connector (2) of the machine.

MACHINE PREPARATION

5. CONNECTION OF THE BATTERY CHARGER

The connector is placed in the left lower part of the operator seat. The

upper part (1), which is connected to the batteries, is the one which has to

be inserted to the connector (2) fixed to the cables of the battery charger.

The coupling connector of the battery charger is delivered in the bag

(together with this instruction booklet ) and must be assembled on the

battery charger cables following the provided instructions (see

instructions booklet for the battery charger).

6. RECHARGING THE BATTERIES

Figure 8

To ensure no permanent damage to the battery it is essential to avoid

complete discharge by arranging to recharge as soon as the blinking

signal indicating the discharged batteries switches on.

NOTE: Never leave the batteries completely discharged, even if the

machine is not being used.

When recharging the batteries, keep the base support of the seat

lifted. Every 20 recharging operations, check the level of the electrolyte

and, if necessary, top up with distilled water.

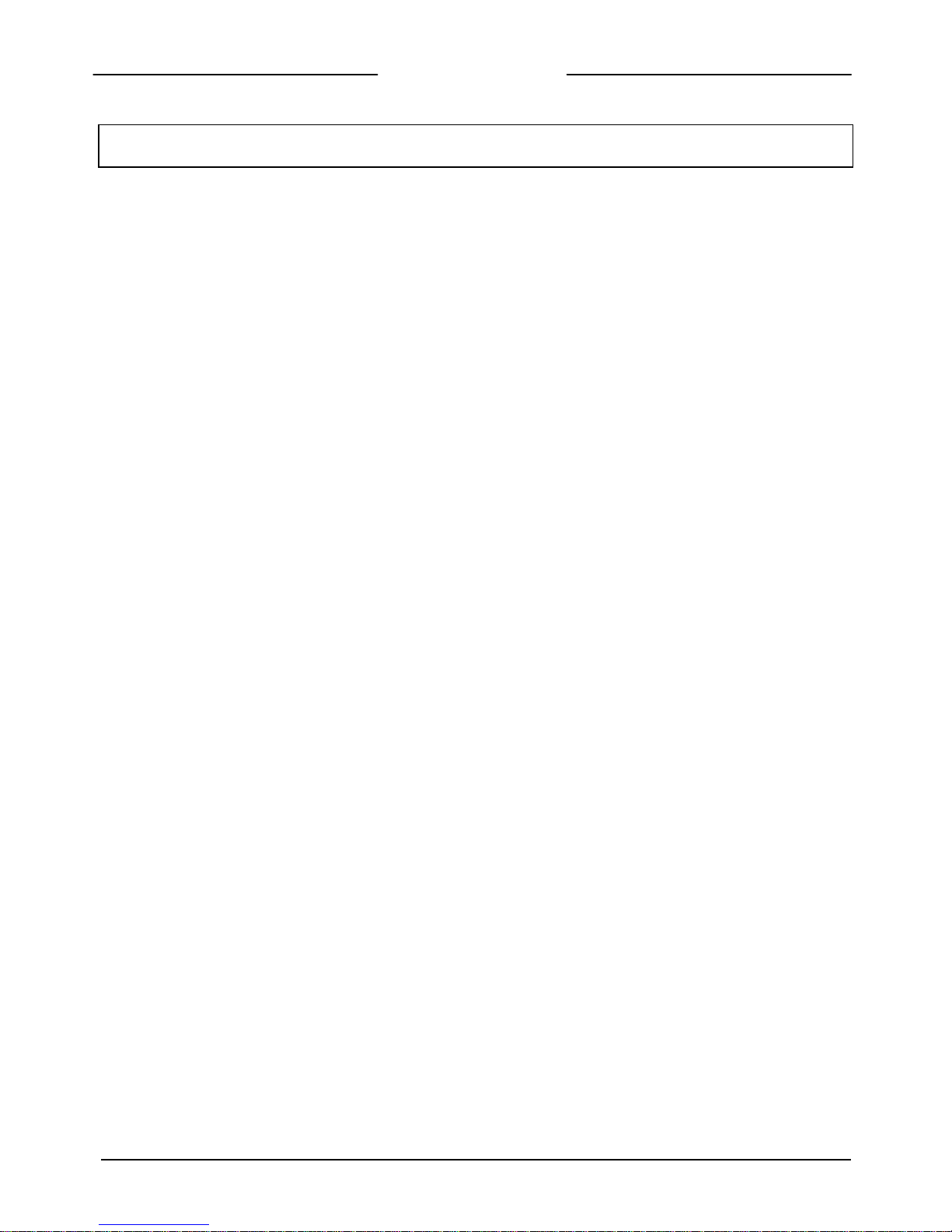

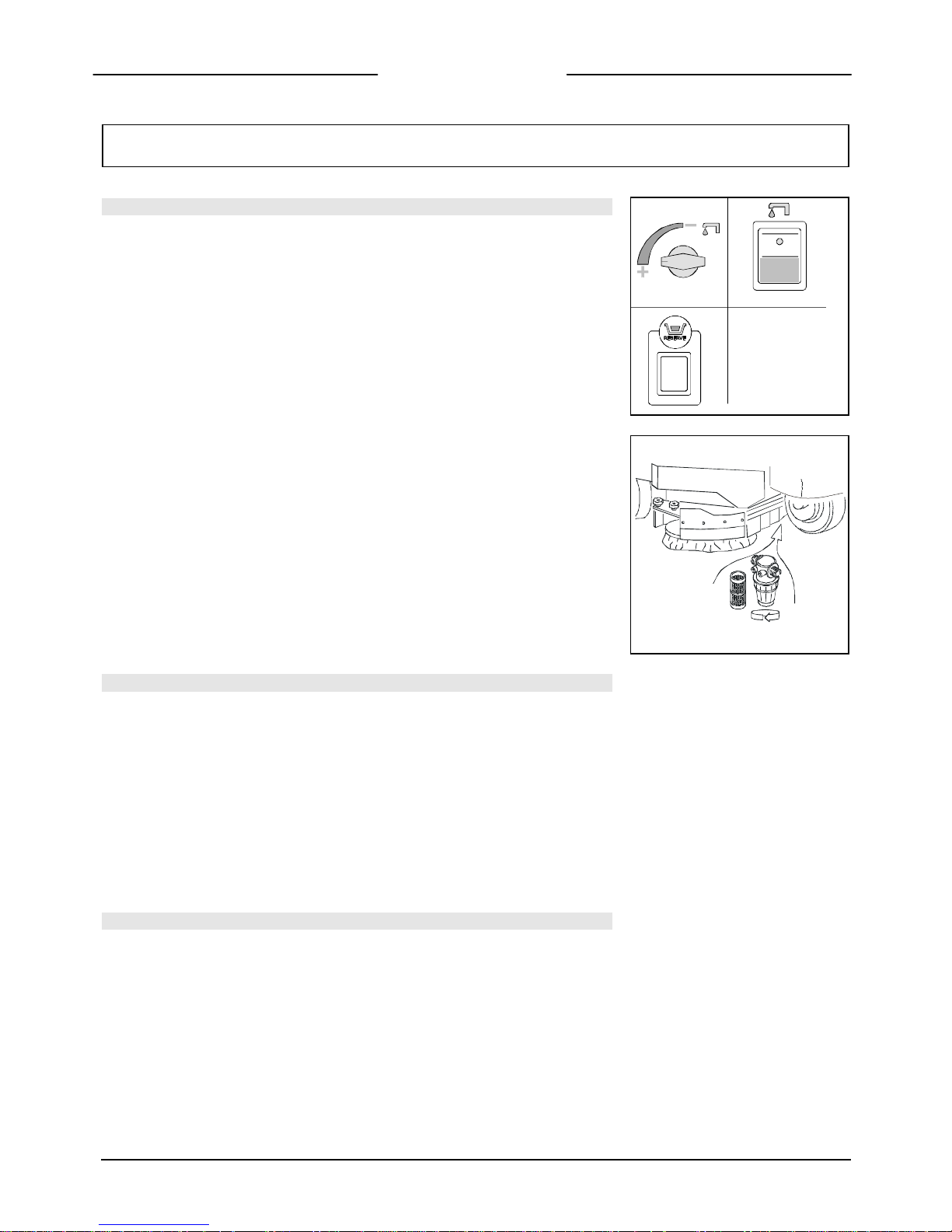

7. BATTERY CHARGE LEVEL INDICATOR

Figure 9

The digital battery signal has 4 fixed positions and a blinking one. The

numbers which appear in the display show the approximate charge level.

4 = maximum charge, 3 = ¾ charge, 2 = ½ charge, 1 = ¼ charge,

0 = discharged batteries (blinking)

ATTENTION: A few seconds after the appearance of the blinking “0” the

brush motor automatically switches off. With the rest of the charge it is

possible to finish any drying operation before starting the recharge.

11

MACHINE PREPARATION

8. SQUEEGEE

Figure 10

The squeegee, which for packing reasons is delivered separated from the machine,

must be assembled as indicated in the drawing by hooking the stud bolts (1-MAGNA

85) of the squeegee into their seat on the squeegee support fixing them with a key

CH17.

Insert the suction hose (2) with its coupling and fix it with the appropriate clamp.

9. ASSEMBLY; SIDE BARS 85S-100S

Figure 11

The side-bars are already fixed to the front part, but it is necessary to place the back

part. Therefore proceed as follows:

1. Insert the back part of the side bar into the pin of the squeegee

2. Insert the fixing clip

3. Repeat the same operations for the second side bar

1

Figure 12

During working operation, the rear rubber should tilt backwards slightly and equally

along its whole length by about 5 mm.

This allows for all four leading edges of the squeegee to be used before it neds to be

replaced.

Figure 13

If it is necessary to increase the rubber deflection in the central part, tilt the squeegee

body backwards, loosen the adjuster nut (1) and rotate the knob (2) counter-clockwise.

If the rubber deflection is to be noticeable at the sides of the squeegee, loosen the

adjuster nut (1) and rotate the knob (2) clockwise. After regulations are completed

tighten the adjuster nut.

12

MACHINE PREPARATION

10. ADJUSTMENT; SQEEGEE HEIGHT SUPPORT

Figure 14

The squeegee has to be regulated in height depending on the wear on the rubbers. To

adjust this:

Loosen the ring nut (1)

With a key CH17 rotate the castor wheel through the nut (2) clockwise to lift the

squeegee and counter-clockwise to lower it

Fix the ring nut (1)

NOTE: The right and left castor wheels should be regulated equally.

13

MACHINE PREPARATION

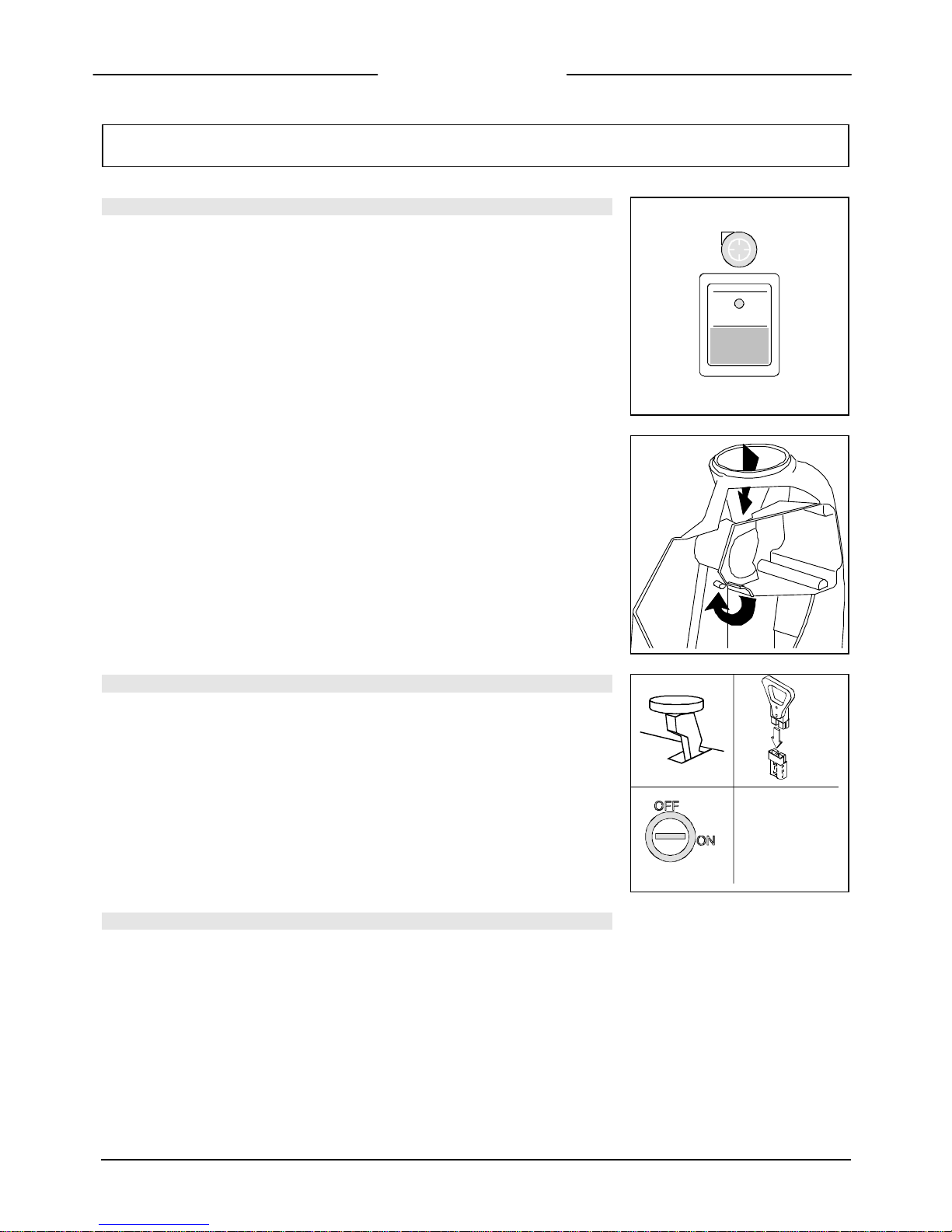

11. BRUSHES ASSEMBLY; MAGNA 85-100

Magna 85/100

Figure 15

1. Connect the battery connector

2. Turn the key to the ‘ON’ position

3. With the manipulator lift the brushes base

4. Turn the key to the ‘OFF’ position and remove it from the instrument

board (to carry out the operations of brushes assembly with connected

current can cause injury).

2

1 3

4

Figure 16

5. With the brushes base in lifted position, insert the brushes into the

seat of the plate under the base until the three buttons fit into the

holes of the plate. Turn the brush so that the buttons are pushed

towards their retaining springs until the brush is clamped in place. The

figure shows the direction of rotation for the coupling of the right

brush. The left brush has to be rotated inversely.

Figure 17

6. It is recommended to change daily the position of the right brush with

the left one and vice versa. If the brushes are not new and they show

deformed bristles, it is better to reassemble them in the same position

(the right to the right side and the left to the left side), to avoid that

the different inclination of the bristles causes an overload to the

brushes motor and /or excessive vibrations.

14

MACHINE PREPARATION

12. SOLUTION WATER

Figure 18

Fill the solution tank with clean water at a temperature not more than 50°C and add

liquid detergent in the proper concentration following the instructions of the

manufacturer. Excess foam in the recovery tank could damage the suction motor, so

use only the minimum amount of detergent necessary.

NOTE: Always use low foam detergent. To avoid the production of foam, before

starting to clean, put a minimum quantity of antifoam liquid into the recovery tank.

Never use pure acid.

13. RECOVERY TANK

Figure 19

Check that the hopper (2) is closed properly,

Figure 20

and that the exhaust plug of the tank is closed

Figure 21

and the plug of the exhaust hose is closed.

15

GENERAL RULES OF SECURITY

The rules below have to be followed carefully in order to avoid damages to the operator and to the machine.

r Read the labels on the machine carefully. Do not cover them for any reason and replace them immediately if damaged

r The machine must be used exclusively by authorized staff that have been instructed in its use

r During the working of the machine, pay attention to other people and especially to children

r Do not mix different detergents, avoiding harmful odours

r Do not place any liquid containers onto the machine

r The storage temperature has to be between -25°C and +55°C

r The perfect operating temperature should be between 0°C and 40°C

r The humidity should be between 30 and 95%

r Do not use the machine in explosive atmosphere

r Do not use the machine as a means of transport

r Do not use acid solutions which could damage the machine and/or persons

r Avoid working with the brushes when the machine stands still, in order to avoid floor damage

r Do not vacuum inflammable liquids

r In case of fire, use a powder extinguisher. Do not use water

r Do not strike shelvings or scaffoldings, where there is danger of falling objects

r Adapt the speed to the adhesion conditions

r Do not exceed the gradient limit in order to avoid conditions of instability

r When the machine is in parking conditions, remove the ignition key and insert the parking brake

r The machine has to carry out the operations of washing and drying simultaneously. Different operations have to be carried

out in areas which are not permitted for the passage of staff or the public. Cordon off the areas of moist floors with

suitable signs

r If the machine does not work properly, check by conducting simple maintenance procedures. Otherwise, it is better to ask

for FIMAP technical service

r If parts have to be replaced, ask for ORIGINAL spare parts from an agent and/or from an authorized dealer

r In case of danger act immediately upon the emergency lever (connector placed on the left side of the operator)

r For any maintenance operation emove the power supply from the machine.

r Do not leave off any covers which require the use of tools to be removed

r Do not wash the machine with direct water jets or with high water pressure nor with corrosive liquids

r Every 200 working hours have the machine checked by a FIMAP service department

r The machine should not be abandoned, because of the presence of toxic-harmful materials (batteries, oil etc.). This disposal

must be subject to the rules which provide for its scrapping in appropriate centres

r The machine does not cause dangerous vibrations

16

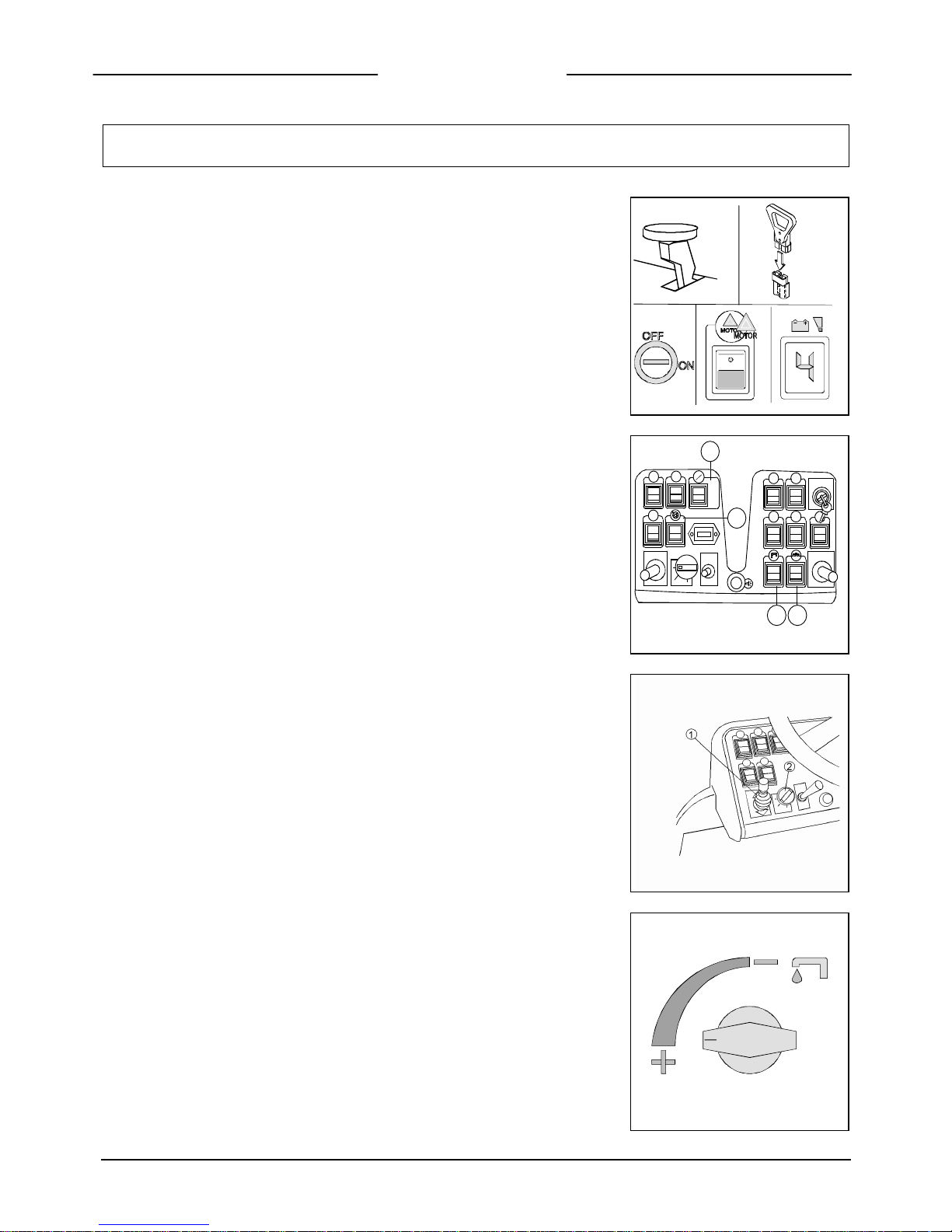

PERFORMANCE

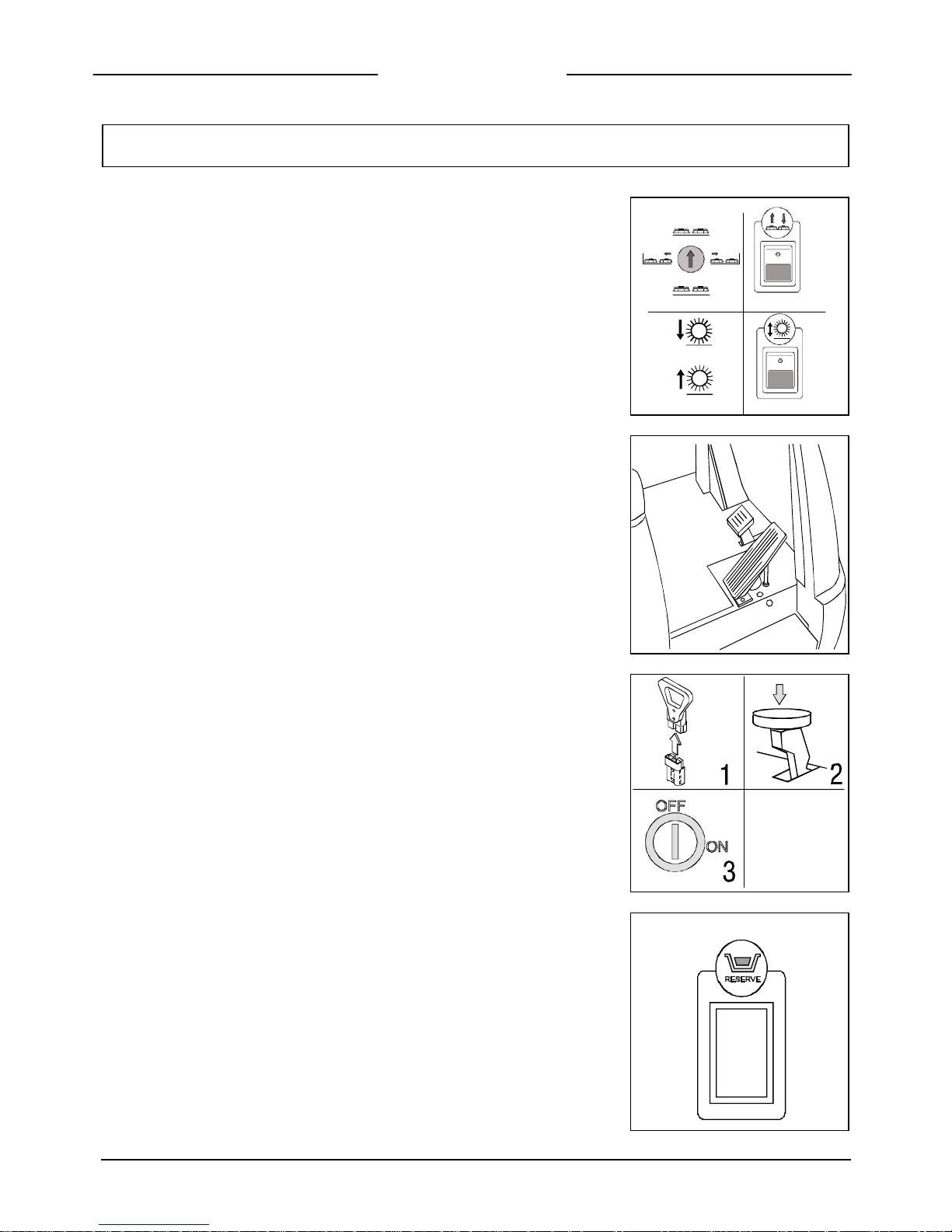

Figure 22

1. Carry out the operations for the preparation of the machine

2. Sit on the driver’s seat

3. Check that the parking brake is released (1)

4. Connect the connector to the batteries (2)

5. Turn the key of the general switch (3) clockwise a quarter turn. Immediately, the

red signal lamp (4) on the instrument board begins to blink and the batteries’

display (5) comes on. The blinking indicates that the checking of the brushes motor

is taking place.

3

1

2

4 5

Figure 23

6. Place the switch into its automatic position (1)

7. Press the suction motor switch (2)

8. Press the switch of the brushes motor (3)

9. Press the solenoid valve switch (4)

Figure 24

10. Place the drive selector (1) in forward position

11. Select the speed movement by rotating the knob (2)

Figure 25

12. Open the cock rotating the knob (1) counter clockwise. The signal lamp of the

water comes on only during the moving period.

MAN

AUTO

AUTO

MAN

1

4 3

2

17

PERFORMANCE

Figure 26

Magna 85/100

13. Push forward the brushes manipulator (1) in order to lower the base. During the

descent, the signal lamps of the actuator and the brushes motor come on. The

brushes base will be in its working position when the yellow signal lamp (2)

switches off.

Magna 85S/100S

14. Push forward the brushes manipulator (3) in order to lower the base. During the

descent, the signal lamps of the actuator and the brushes motor come on. The

brushes base will be in its working position when the yellow signal lamp (4)

switches off.

4

3

1

2

Figure 27

Press the accelerator pedal. The machine begins to move, the squeegee begins to

lower itself and the suction motor comes on.

During the first few metres of operating, check that the brush pressure is suitable

(see further on under “BRUSH PRESSURE”), that the quantity of detergent solution

is sufficient and that the squeegee dries perfectly.

The machine will now start to work efficiently until the detergent solution runs

out.

Figure 28

Immediately disconnect the emergency lever (1) situated on the left side from the

operator and apply the emergency brake (2), whenever problems occur during

work. These commands disconnect all the functions on the machine. To start the

machine again, once the problem has been solved, turn off the key (3), reconnect the

connector (1), switch on the key (3) and lower the parking brake lever (2).

Figure 29

The machine will not start if the operator is not properly seated.

When the solution tank is empty, the signal lamp on the instrument board comes on.

When the recovery tank is full, the suction motor stops. To start it up again, even if

the tank has been emptied, it is necessary to first turn off the main switch key and

then on again.

18

PERFORMANCE

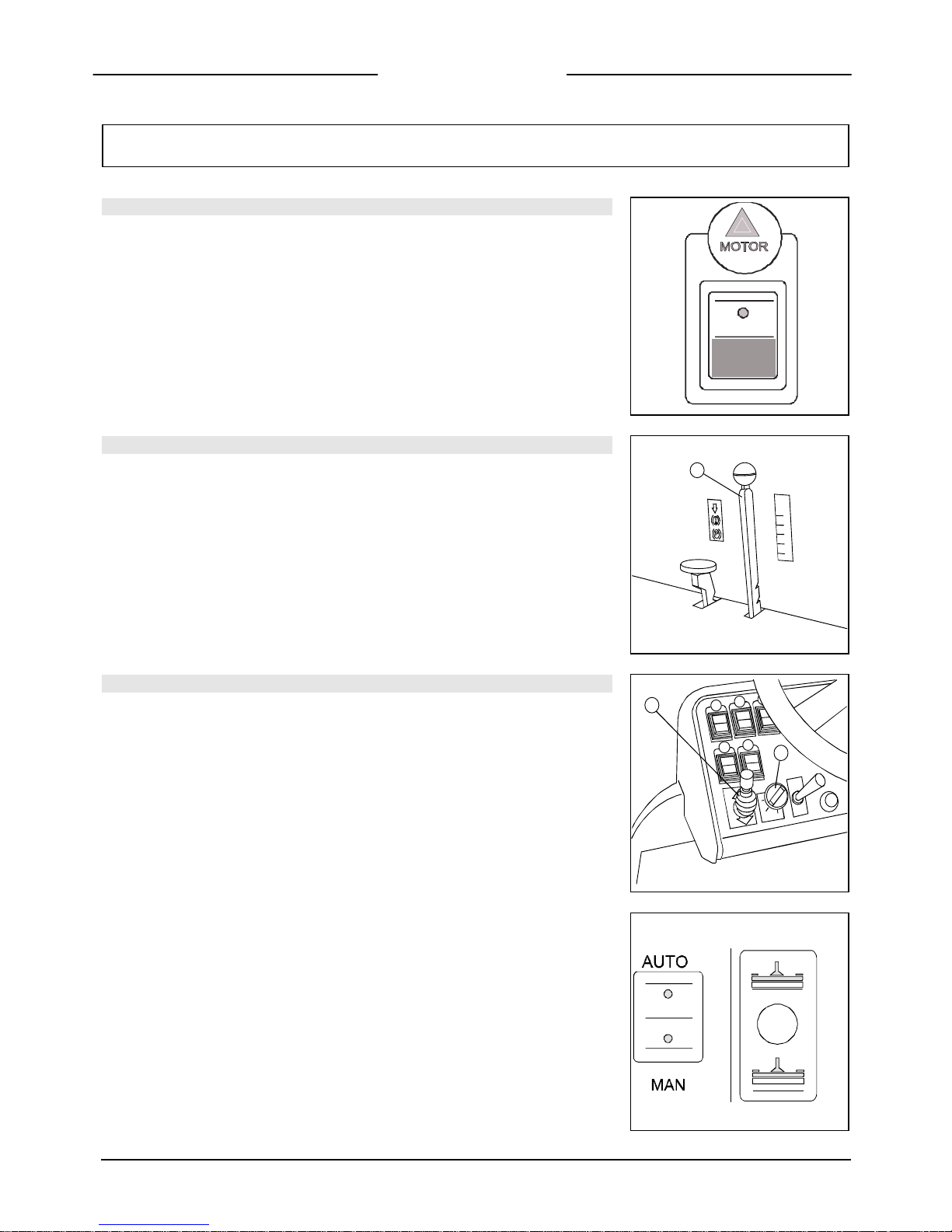

CHECK MOTOR BRUSHES

Figure 30

The brushes motor is electronically controlled. If it reaches established overload limits,

the red signal lamp (1) on the instrument board starts to blink. After a few seconds the

motor stops and the signal lamp of the brushes switch goes off. To start up the motor

again, turn the main switch key (2) off and on again. If the motor stops again, check

the reason of the overload to prevent motor damage. Generally, it is enough to reduce

the brushes pressure.

BRUSH PRESSURE

Figure 31

It is possible to adjust the brush pressure using the proper lever (1) placed on the left

side of the operator. To increase the pressure, push the lever downwards.

The pressure must be chosen based on the type of floor and the type of dirt. Excessive

pressure causes higher brushes wear and a major energy consumption (for further

information read on “CHOICE AND USE OF BRUSHES”)

TRACTION

Figure 32

These machines are equipped with electronically commanded traction, with three

speeds forwards and one backwards. To move the machine, it is necessary to turn the

key and then move forwards (forward movement) or backwards (rear movement) the

manipulator (1). Press the drive pedal and the machine will start to move. The

movement speed can be adjusted rotating the selector (2) also when the machine is in

motion.

Figure 33

NOTE: During reverse motion, if the switch automatic-manual of the squeegee is in

‘manual’ position (1), remember to lift the squeegee through the commutator (2).

During transfer, put the switch onto manual.

1

2

1

1

2

19

PERFORMANCE

SQUEEGEE; AUTOMATIC – MANUAL

Figure 34

Automatic: If the switch is placed on automatic, lowering of the squeegee is obtained

with the machine advancement. Also, lifting of the squeegee is achieved with the

reverse motion of the machine.

Manual: If the switch is placed on manual, the squeegee has to be lifted and lowered

manually through the commutator (2).

The operation of the suction motor is independent from the squeegee position and it

is controlled only by the suction switch.

1

2

BRAKES

Figure 35

To brake, press with the left foot the pedal of the service brake (2).

2

BRAKES

Figure 36

In case of poor operation of this brake, or in case of necessity (interruption, danger),

act upon the parking brake (1).

1

HORN

Figure 37

The machine is equipped with a horn switch. To operate it, press the push button as

shown in the figure.

MAN

AUTO

AUTO

MAN

20

PERFORMANCE

BLINKING AND WORKING LIGHTS

Figure 38

The machine is equipped with blinking lights. For their operation press the switch as

shown in the figure.

21

ON COMPLETION OF WORK

Figure 39

Magna 85/100

Having finished the job and before any type of maintenance is done:

1. Close the cock

2. Raise the brushes base

3. Switch off the brushes motor switch

4. Switch off the solenoid valve switch

3

1

2

4

Figure 40

Magna 85S/100S

Having finished the job and before any type of maintenance is done:

1. Close the cock

2. Raise the brushes base

3. Switch off the brushes motor switch

4. Switch off the solenoid valve switch

3 43

1111 2

Figure 41

5. Place the squeegee switch onto manual

6. Lift the squeegee

7. Switch off the suction motor switch

8. Bring the machine up to the place provided for the water outlet

9. Turn the key 1/4 round counter clockwise

AUTO

MAN

7

5

6

9

Figure 42

10.Remove the exhaust hose from its hook, unscrew the exhaust plug and empty the

recovery tank. To simplify draining operation, it is recommended to hold the hose

bent with one hand and with the other unscrew the knob and take off the plug.

Slowly straighten the hose and the liquid will start draining at the desired speed.

This operation should be carried out using gloves to protect from contact with

dangerous solutions

22

ON COMPLETION OF WORK

11. The squeegee has to be lifted when the machine is not operating. In this way

damage to the squeegee rubbers is avoided.

12. Take off the brushes and clean them with a water jet (for the brushes removal

please read further on under “REMOVAL OF THE BRUSHES”)

13. Clean the dirt hopper (only for Magna 85S 100S) (see the paragraph “DIRT

HOPPER CLEANING)

23

DAILY MAINTENANCE

CLEANING OF THE RECOVERY TANK

Figure 43

1. Empty the tank through the flexible hose, unscrewing with some turns the knob

and then taking off the plug

Figure 44

2. Open the side plug by unscrewing the knob and rotating the closing blade

3. Rinse the tank and clean the exhaust plug

4. Check the perfect position of the side plug gasket

5. Retighten the side plug and the plug onto the exhaust hose

CLEANING THE SQUEEGEE

Clean the squeegee with a water jet. Check the rubber wear and if necessary, turn

them upside-down or change them. The careful cleaning of the complete suction

group assures higher life of the suction motor.

24

DAILY MAINTENANCE

REPLACEMENT OF THE SQUEEGEE RUBBER

Figure 45

If the squeegee rubber is worn and does not dry well, it is possible to

change the drying edge proceeding as follows:

1. Push and rotate the fixing plates

2. Slip off the rubber blade and the rubber itself

3. Turn the rubber upside-down and if necessary, replace it

4. Adjust the squeegee height as indicated in “ADJUSTMENT HEIGHT

SQUEEGEE SUPPORT” under “MACHINE PREPARATION”

5. Reassemble everything in reverse to the above mentioned operations

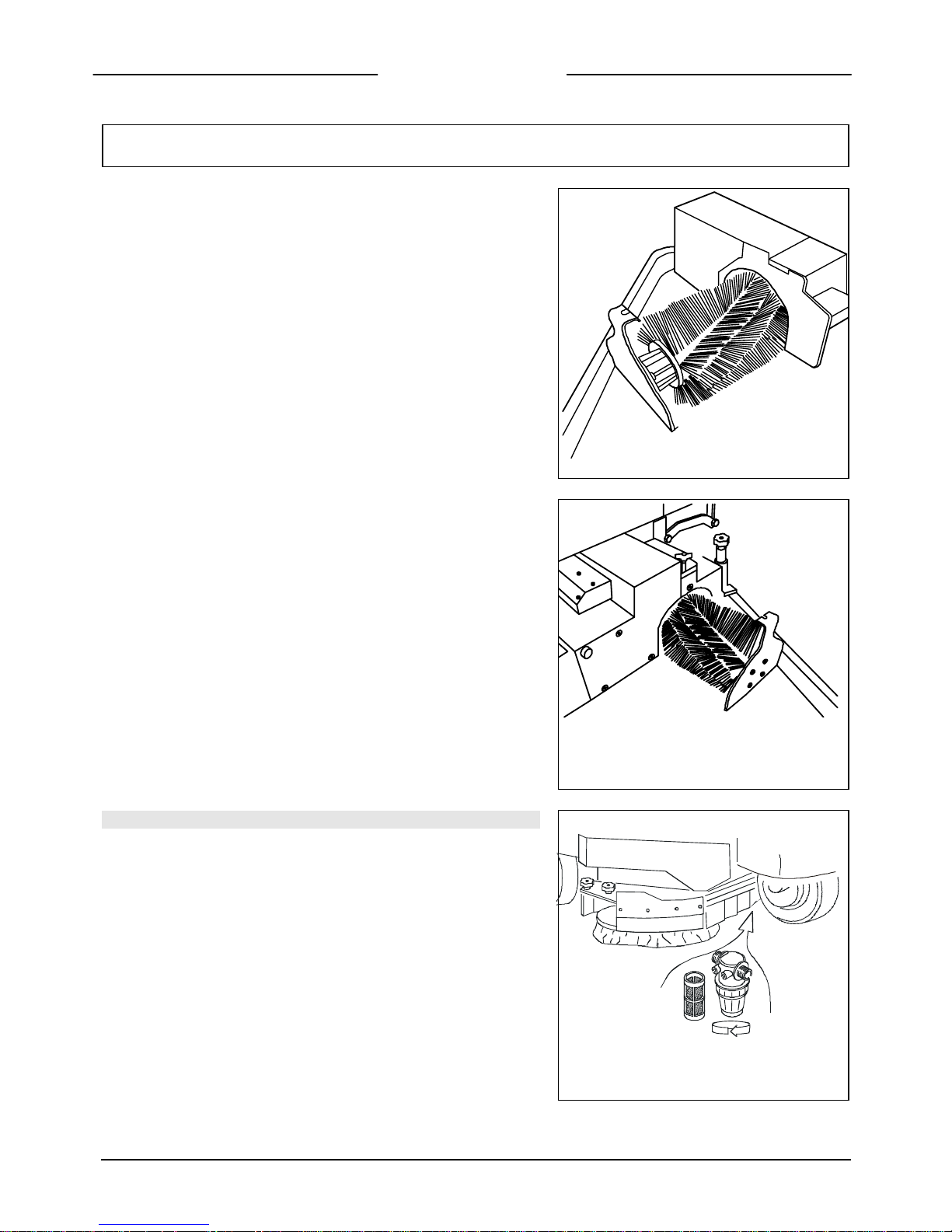

REMOVAL OF BRUSHES; MAGNA 85/100

Figure 46

1. Connect the battery connector if it is not connected

2. Turn the key into position ON

3. With the manipulator lift the brushes base

4. Turn the key into position OFF and remove it from the instrument

board (to carry out the operations of brush disassembly with

connected current can cause injury)

2

1 3

4

Figure 47

5. With the brushes base in lifted position, rotate the brush until it comes

off from the brush plate seat as shown in the figure. The figure shows

the rotating direction for the disassembly of the right brush, the left

one has to be rotated inversely.

25

DAILY MAINTENANCE

REMOVAL OF THE CYLINDRICAL BRUSHES; MAGNA 85S-

100S

Figure 48

1. Connect the battery connector if it is not connected

2. Turn the key into position ON

3. With the manipulator lift the brushes base

4. Turn the key into position OFF remove it from the instrument board

(to carry out the operations of brush removal with connected current

can cause injury)

1

2 4

3

Figure 49

5. Unfasten the side bars taking out the pin that fixes them to the

squeegee (1)

Figure 50

6. Unscrew the knob (1) and remove the movable plate of the brush

support (2)

26

DAILY MAINTENANCE

Figure 51 (Left broom)

7. Remove the brush checking the bristles inclination in order to be able

to reassemble it in the same way

Figure 52 (right broom)

Remove the brush checking the bristles inclination in order to be able to

reassemble it in the same way

SOLUTION TANK AND FILTER CLEANING

Figure 53

When the solution tank is empty:

1. Unscrew the filter and rinse the inside thoroughly

2. Take off the cartridge and clean it

3. Open the cock

4. Reassemble everything in reverse order the above operations

27

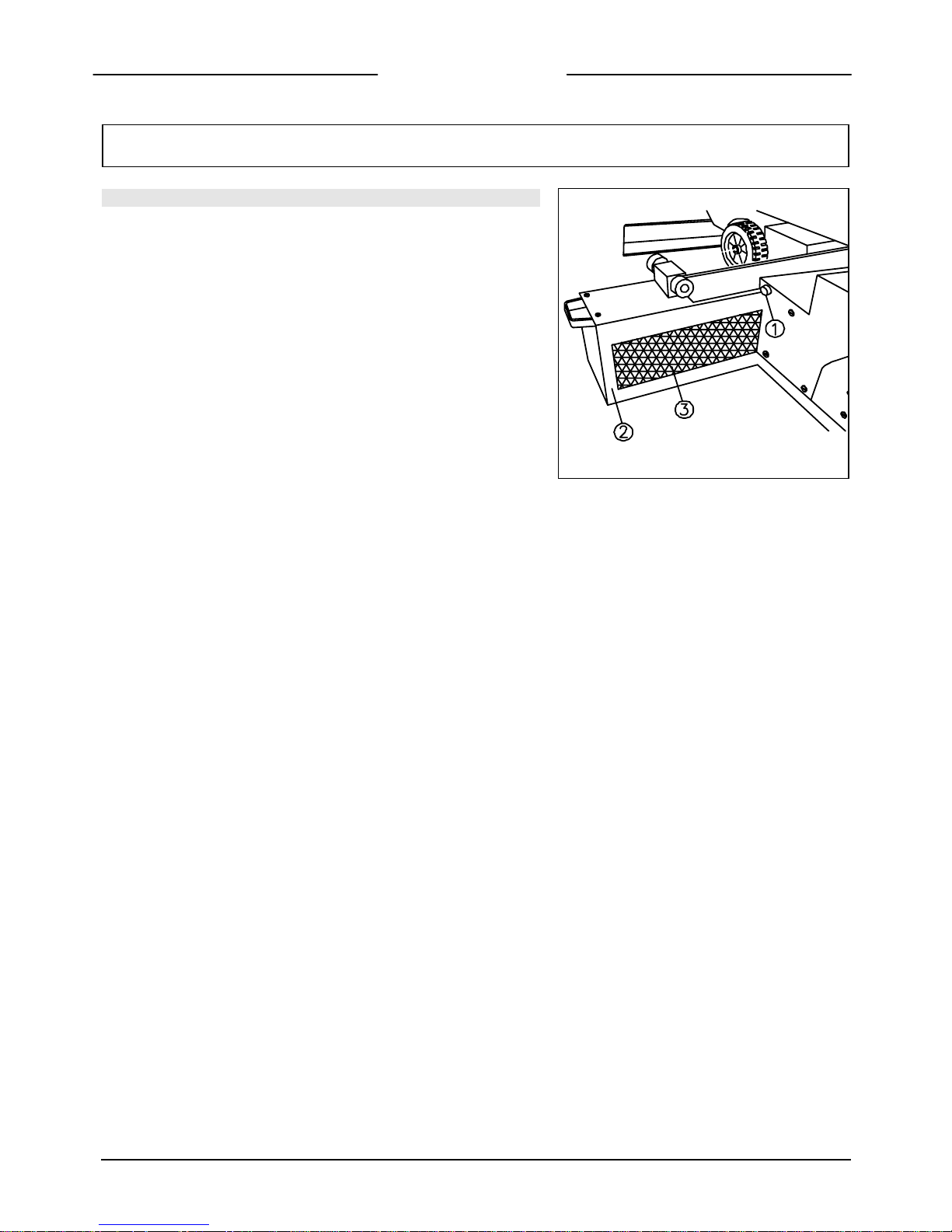

DAILY MAINTENANCE

DIRT HOPPER CLEANING

Figure 54

Magna 85S/100S

1. Take the pin out of the right side bar and rotate it outwards

2. Unfasten the bolt of the hopper (1)

3. Remove the hopper (2) and clean it

4. Take off the filter (3) and clean it

5. Reassemble in reverse order the above operations

28

DAILY MAINTENANCE

ADJUSTMENT; SPLASH GUARD BRUSHES BASE MAGNA 85

Figure 55

Periodically proceed with the height adjustment of the side covers of the brushes base.

This operation has to be carried out with the brushes base down.

1. Loosen the fixing knobs of the covers

2. Slip off the covers from their seats

Figure 56

3. Tighten the upper nut with a key CH17 as much as necessary

4. Put the covers back into their position

5. Retighten the knobs

Keep in mind that the rubber must skim the floor and be parallel to it. This is verified

when the nuts have been tightened equally on both stud bolts.

ADJUSTM

ENT; SPLASH GUARD BRUSHES BASE MAGNA 100

Figure 57

Periodically proceed with the height adjustment of the side covers of the brushes base.

This operation has to be carried out with the brushes base down.

1. Loosen the fixing screws of the covers (1)

2. Slip off the covers from their seats

3. Tighten the upper nut (2) with a key CH17 as much as necessary

4. Put the covers back into their position

5. Retighten the screws.

Keep in mind that the rubber must skim the floor and be parallel to it. This is verified

when the nuts have been tightened equally of both stud bolts.

29

WEEKLY MAINTENANCE

ADJUSTMENT; SIDE BARS MAGNA 85/S 100/S

Figure 58

Periodically proceed with the height adjustment of the side-bars. This operation has to

be carried out with the base lowered.

1. Loose the knob (1)

2. Tighten the adjuster (2) to lift the side bar or unscrew the adjuster (2) to lower the

side bar

3. When the adjustment has been completed, fix the knob (1)

Figure 59

4. Take off the retaining clip

5. Take off the side bar

6. Adjust the height of the support nut

7. Put the side bar and the retaining clip back into their position

Keep in mind that the side bars must be parallel to the floor

These adjustments have to be carried out on both side bars

CLEANING OF THE SUCTION HOSE

Figure 60

Whenever suction seems to be unsatisfactory, check that the suction hose is not

obstructed. Eventually, clean it with a water jet introduced from the side where it is

connected to the tank. Proceed as follows:

1. Unscrew the four screws and take off the suction motor cover

2. Loosen the clamp which tightens the hose

3. Clean with a water jet introduced from the side where it is connected to the tank

4. Reassemble everything in reverse order to the above mentioned operations

CLEANING SUCTION MOTOR FILTER

Figure 61

Unscrew the four screws and take off the suction motor cover

2. Unscrew the three knobs which fix the suction motor to the support

3. Take off the suction motor

4. Extract the filter and clean it thoroughly

Reassemble everything in reverse order to the above operations.

30

TROUBLE SHOOTING GUIDE

INSUFFICIENT WATER ONTO THE BRUSHES

Figure 62

1. Make sure that the cock is open

2. Check that the solenoid valve switch is on

3. Make sure that there is water in the solution tank (signal lamp “RESERVE” off)

3

1 2

Figure 63

4. Clean the solution filter

THE MACHINE DOES NOT CLEAN SATISFACTORILY

1. Check the conditions of the brushes and replace them, if necessary. The cylindrical

brushes have to be replaced when the bristles reach around 15 mm for Magna

85/100 and 10 mm for Magna85S/100S).

2. Check that the pressure on the cylindrical brushes is sufficient, eventually increase

it (see “PRESSURE CYLINDRICAL BRUSHES” under “PERFORMANCE”).

3. Use different kind of brushes to the ones fitted as standard. For cleaning

operations on floors where the dirt proves to be particularly resistant, we

recommend using special brushes which may be supplied optionally according to

needs (see under “CHOICE AND USE OF BRUSHES”).

THE SQUEEGEE DOES NOT DRY PERFECTLY

1. Check that the squeegee is clean

2. Check the squeegee adjustments (see under “MACHINE PREPARATION”)

3. Clean the whole suction group (see under “WEEKLY MAINTENANCE”)

4. Replace the rubbers, if worn

31

TROUBLE SHOOTING GUIDE

THE SUCTION MOTOR DOES NOT FUNCTION

Figure 64

1. Check that the suction motor switch is on

2. Check whether the recovery tank is full and eventually empty it

Figure 65

3. Check the perfect condition of the float switch (see also “CLEANING OF THE

RECOVERY TANK FILTER” under “DAILY MAINTENANCE”)

4. To reactivate the suction motor, after operation of the float switch, switch off and

then on again the main switch key.

THE MACHINE DOES NOT START

Figure 66

1. The operator must be properly seated in the driving position

2. Check that the hand brake lever is completely released

3. Check that the general switch key is In the ‘ON’ position

4. Check that the connector is connected to the batteries

3

2

4

EXCESSIVE FOAM PRODUCTION

Check that a low foam detergent has been used. If required, add a small quantity of

antifoam liquid into the recovery tank.

Remember that, when the floor is not very dirty, more foam is generated. In this case

dilute the detergent further.

32

CHOICE AND USE OF BRUSHES

POLYPROPYLENE BRUSH (PPL)

It is used on all types of floors which are hot water resistant (not more than 60°C). The Polypropylene brush is non-hygroscopic

and therefore conserves its characteristics even if working in wet conditions.

NYLON BRUSH

It is used on all types of floors with excellent wear and hot water resistance (more than 60°C). The nylon is hygroscopic and so,

over time, looses its characteristics working on the wet.

TYNEX BRUSH

The brush bristles are charged with very aggressive abrasives. It is used to clean very dirty floors. To avoid floor damages, work

strictly only with the necessary pressure.

STEEL BRUSHES

Bristles are made of steel wire or flat blades or are mixed steel and synthetic fibres. The steel wire brush is used to remove scale

from badly uneven floors or floors with wide joints between tiles. Brushes with flat steel bristles (stiffer) are used to clean the

toughest scale.

THICKNESS OF THE BRISTLES

The thicker the bristles are, the more rigid they will be. These ones are therefore used on smooth floors or with small joints.

On uneven floors with deep joints it is recommended that, softer bristles, which enter more easily in depth, be used.

Please bear in mind that, when the bristles are worn out and get too short, they will get rigid and cannot penetrate anymore.

As well as for thick bristles, the brush will begin to jump.

PAD HOLDER

The pad holder is recommended to clean glossy areas.

There are two types of pad holders:

1. The traditional pad holder is equipped with anchor points which allow the abrasive pad to be held and dragged during the

work process.

2. The pad holder is of the CENTER LOCK type, apart from the anchor points, is equipped with a central locking release system

made of plastic. This allows a perfect match with the abrasive pad and to hold it without the risk of falling down. This type of

pad holder is recommended especially for machines with more brushes, where the centreing of the pads is difficult.

BRUSH CHOICE LIST

Machine Q.ty Code Bristles type Ø bristles Ø Brush Notes

Magna 85 2

E6803040

E6814020

E6814030

E6703010

PPL

NYLON

TYNEX

Pad holder

0.9

1.2

1.5

430

430

430

410

Magna 100 2

E6821020

E6821040

E6727010

PPL

TYNEX

Pad holder

1

1.5

510

510

505

CYLINDRICAL BRUSH CHOICE LIST

Machine Q.ty Code Bristles type Ø bristles Ø Brush

Length

Colour

Magna 85/S 2

E6814040

E6814050

PPL

TYNEX

0.1

1/0.6

210

210

862

862

BLACK

GREY

Magna 100/S

2

2

E6827010

E6827020

PPL

TYNEX

0,1

1/0,6

210

210

1012

1012

BLACK

GREY

Loading...

Loading...