luxvision SL 1400 User Manual

USER’S MANUAL

SLIT LAMP

SL 1400

Notication

Dear Users,

Thank you for your purchase of SL 1400 Slit Lamp. Please take time to read our

user’s manual carefully before use.

This guarantees you to make full use of this unit and prolongs the operation life of

this unit.

Precautions

If you have detected abnormal heat, smoke, noise or smell, immediately stop using

the product.

In the event of an abnormality, turn off the power and disconnect the power plug from

the power socket. Continuing to use the product may result in electric shock or re.

Observe the instructions given below regarding the power cable:

• Be sure to use the supplied or specied power cable.

• Do not modify, forcibly bend, kink or pull the power cable.

• When disconnecting the power cable from the AC outlet, be sure to hold the cable

by the plug.

Pulling the cable may cause wire breakage or shot circuit, resulting in re or electric

shock.

• Do not connect or disconnect the plug of the power cable to/from the AC outlet

using wet hands.

Doing so may result in electric shock.

• Do not touch the product with wet hands while the power cable is connected

to the AC outlet.

Doing so may result in electric shock.

• If the product will not be used for a long period, disconnect the power cable

from the power source. Leaving the cable connected to the power socket for

a prolonged period will consume electricity and may result in heating.

Content

1. Name of Parts............................................................................................... 4

2. Assembly....................................................................................................... 8

3. Operation.................................................................................................... 19

4. Maintenance............................................................................................... 28

5. Common Trouble Shooting......................................................................... 35

6. Optional Photographic Attachment............................................................. 37

7. Optional Observation Tube.......................................................................... 65

8. Optional TV Accessories............................................................................. 67

9. Optional Barrier Filter.................................................................................. 68

10. Applanation Tonometer................................................................................ 69

11. 12.5x measuring eyepieces......................................................................... 70

12. Resopnsibility............................................................................................... 71

13. Transportation............................................................................................. 71

14. Specications.............................................................................................. 72

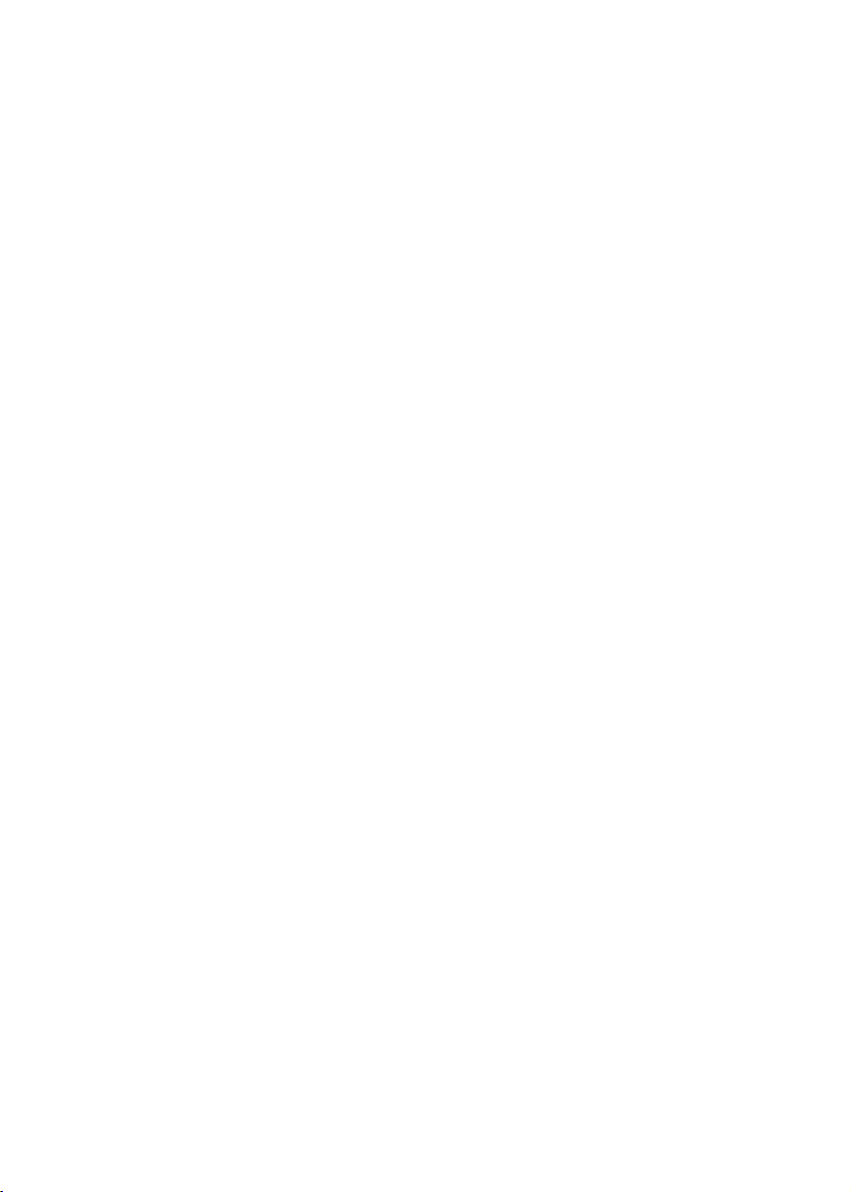

1. Name of Parts

24

23

22

21

19

20

18

17

16

15

14

12

13

25

26

27

28

29

30

31

32

33

34

35

36

1

11

10

9

8

7

2

3

4

5

6

4

1. Joystick

Incline joystick slightly to move the instrument in the horizontal plane and

rotate it to adjust the elevation of the microscope.

2. Base Locking Screw

The base will be locked when this screw is tightened.

3. Rail Cover

Protects the rail surface

4. Base

Supports the microscope and the illumination arms with the joystick controlling

its movement.

5. Work Table

6. Accessory Drawer

Stores the focusing test rod and other accessories.

7. Brightness Control Switch

Two levels are available – H (HIGH), N ( NORMAL). Avoid working continuously

at the high setting, as the service life of the bulb will be shortened.

8. Main Power Switch

9. Pilot Lamp

10. Microscope Arm Locking Knob

Prevents rotational movement of the microscope arm.

11. Angle Mark Ring

Marks on the angle mark ring of the illumination arm align to the long mark

on the microscope arm. When 0 on the ring aligns to the short mark at one

side of the user, the right eyepiece may be obstructed, and the side of the

patient the left eyepiece.

12. Chin-rest Elevation Adjustment Knob

Rotate the knob to adjust the elevation of the chinrest.

13. Location Roller

When the roller is in the middle, the included angle between the microscope

arm and the illumination arm is 0º, when it is to the right or left the included

angle is 10º.

5

14. Microscope and Illumination arm Coupling Bolt

Tightening this bolt permits the illumination arm and the microscope arm

to be rotated simultaneously. Loosening the bolt allows the illumination arm

and microscope arm to rotate separately.

15. Hruby Lens Guide Plate

The plate is also used for the applanation tonometer.

16. Microscope Fixation Screw

17. Chin-Rest

18. Magnication Select Dial

Five magnications are provided.

19. Prism Boxes

The prism boxes are used to adjust the interpupillary distance.

20. 12.5x Eyepiece

Before use, adjust the diopter ring for each eyepiece to get a clear image.

21. Microscope Fixation Screw

22. Accessory Mount

The accessory mount will accept the Model R-900 Goldmann applanation

tonometer in addition to other accessories.

23. Horizontal Mark

The horizontal center of the patient’s eye is aligned to the mark by changing

the elevation of the microscope using the joystick.

24. Forehead Belt

25. Diffusion Lens

The diffusion lens is used for photographing at low magnications and for

enlarging the eld of magnication.

26. Lamp Cap

27. Aperture height and display window

28. Filter Selection Lever

There are four lter selections.

6

29. Aperture and Slit Height Control Knob

Rotate this knob to adjust the spot and the slit height. Turn the knob

horizontally to rotate the slit.

30. Fixation Target

An illuminated xed spot for patient to look at.

31. Reecting Mirror

Both long and short reecting mirrors are provided.

The long mirror is used for most examination procedures.

The short mirror is used when the long mirror interferes with the optical path

as may happen a during funduscopy.

32. Hruby Lens

Used for observation of fundus and the posterior segment of the vitreous

body.

33. Hruby Lens Holder

34. Centering Knob

Loosening the knob allows the illumination light to be moved from the center

of the eld of vision for indirect retro-illumination. Tightening the knob brings

the illumination light back to the center.

35. Slit Width Control Knob

The slit width is continuously adjustable from 0 to 9mm.

7

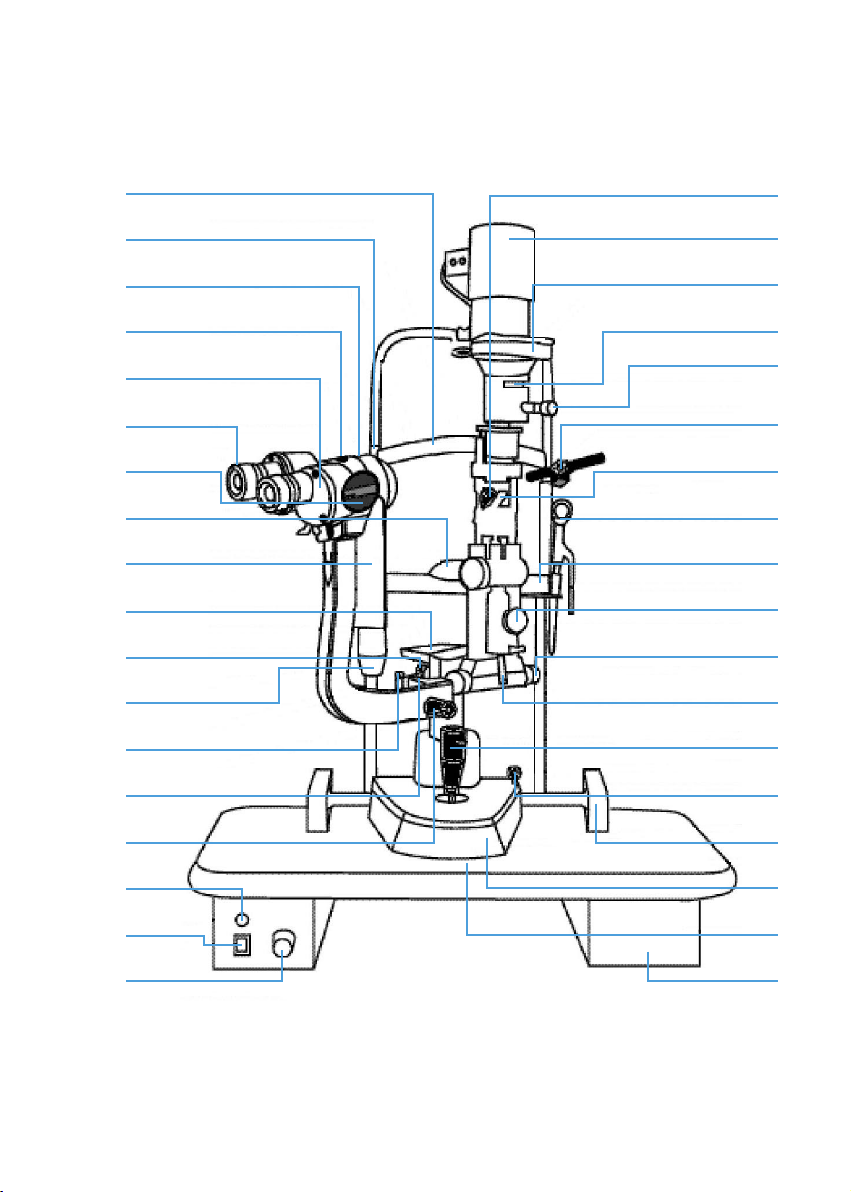

2. Assembly

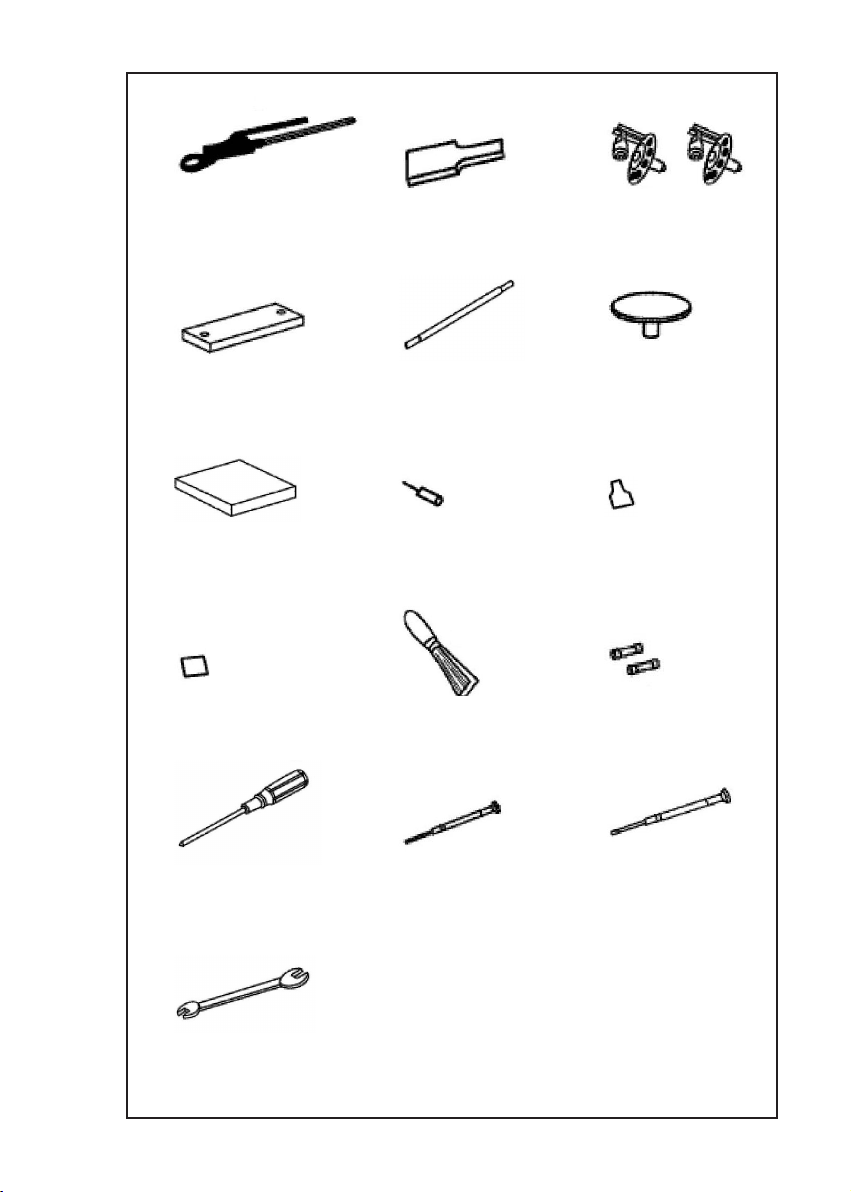

2.1 Components

A B

C D

E F

HG

8

I J K

L M N

PO Q

R TS

U V

X

W

9

Name Quantity

A Illumination Part

B Microscope (with 10x eyepieces)

C Base Part

D Head-Rest Part

E Breath Shield

F Worktable with Power Box

G Rail Cover

H Input Power Cable

I Hruby Lens

J Hruby Lens Guide Plate

K Spare Main Illumination Bulb

L Chin-Rest Paper

M Focusing Test Rod

N Protection Cap

O Dust-Proof cover

P Fixation Target

Q Spare Long Reecting Mirror

R Spare Short Reecting Mirror

S Brush

T Spare Fuse

U Phillips Screw Driver with wood handle

V Watch Screw Driver (big)

W Watch Screw Driver (small)

X Spanner

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1*

1

1

1

1

2

1

1

1

1

(*Optionally available in some region)

2.2 Assembly Procedure

Phillips Screwdriver with wood handle (U)

Watch screwdriver (V)

Wrench (X)

10

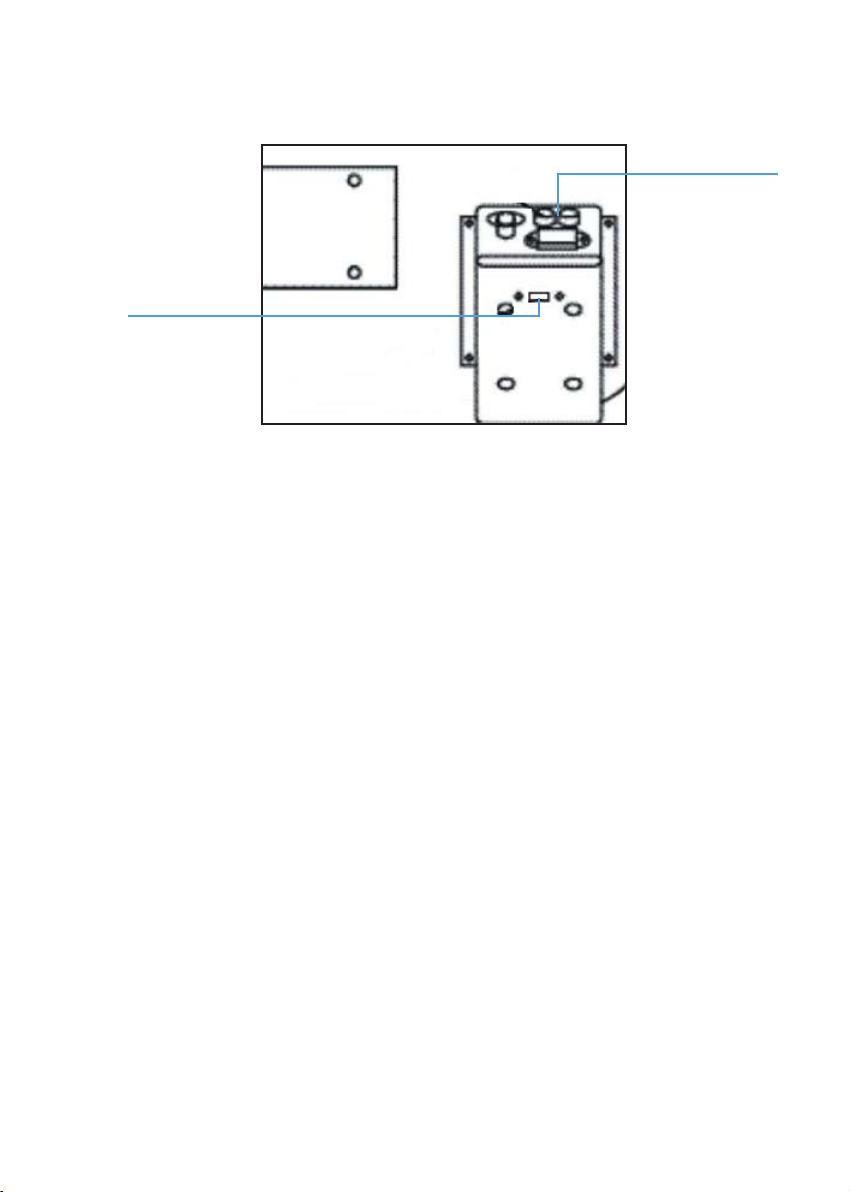

1. Selecting voltage and fuse

Fuse holder

Voltage

selector

Selector voltage and fuse

• Check the setting on the voltage selector located on the bottom of the power

box. If it doesn’t match with the input voltage, slide it to the proper position

with screwdriver (V).

• Open the fuse holder with screw driver (U) and take out the fuse, ensure that

its rated value corresponds to the mains voltage:

110 Volt.....................1A

220 Volt.....................0.5A

The 220 V- 0.5 A is installed by the factory.

Important Matters

Set the input voltage and frequency of the instrument according to that of the mains.

2. Assembling the worktable (F)

• To attach the worktable on the LSL1400 motorized instrument table, please

unscrew the four M8x20mm bolts with spring washers with the wrench (X).

• Align the worktable screw hole to the assembly hole of the instrument table.

11

• Place the worktable so that the power panel faces the user, then refasten

the bolt securely with the wrench.

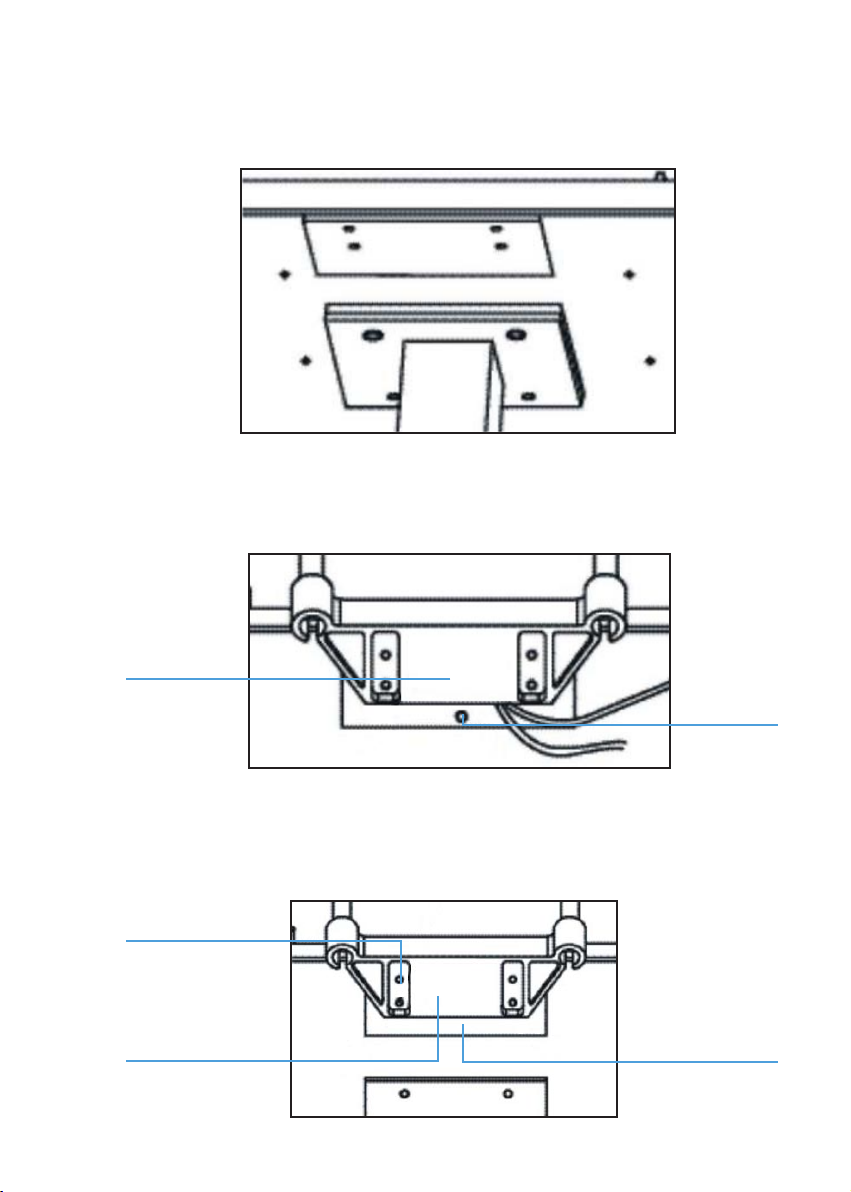

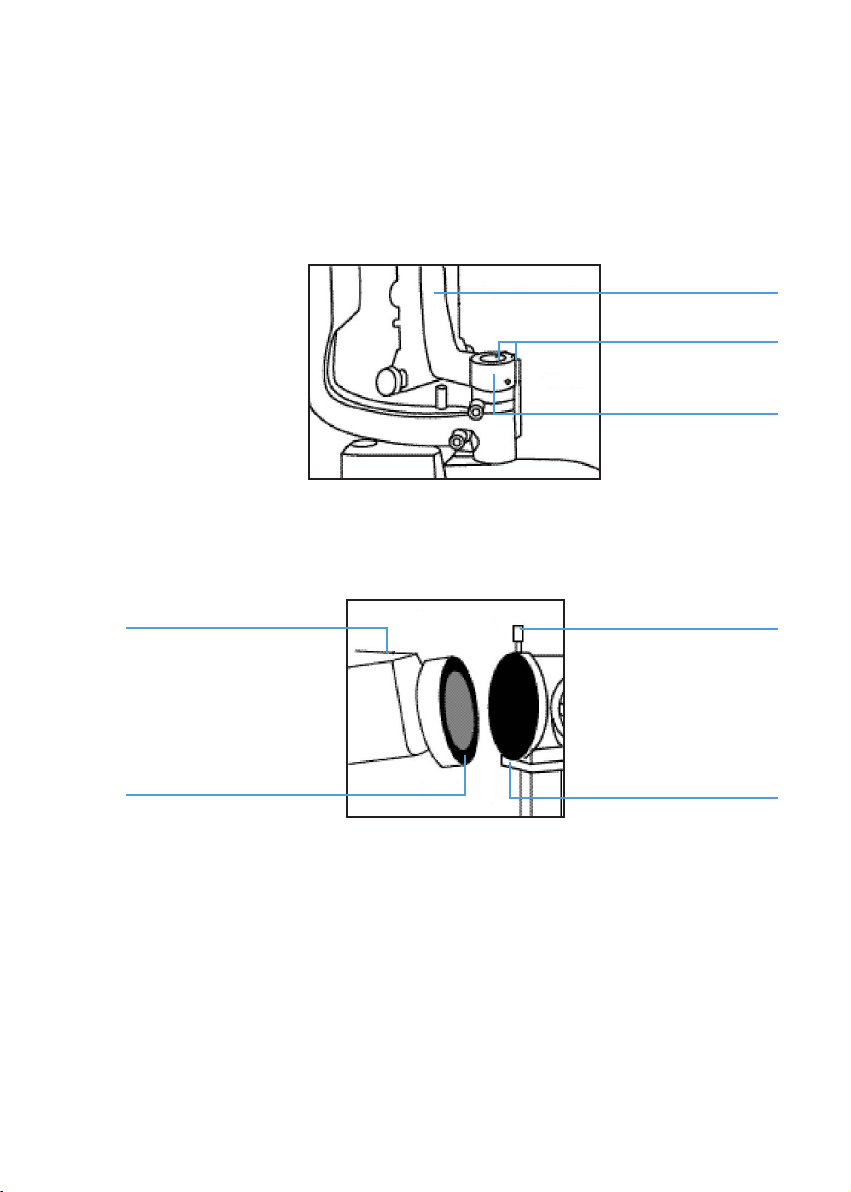

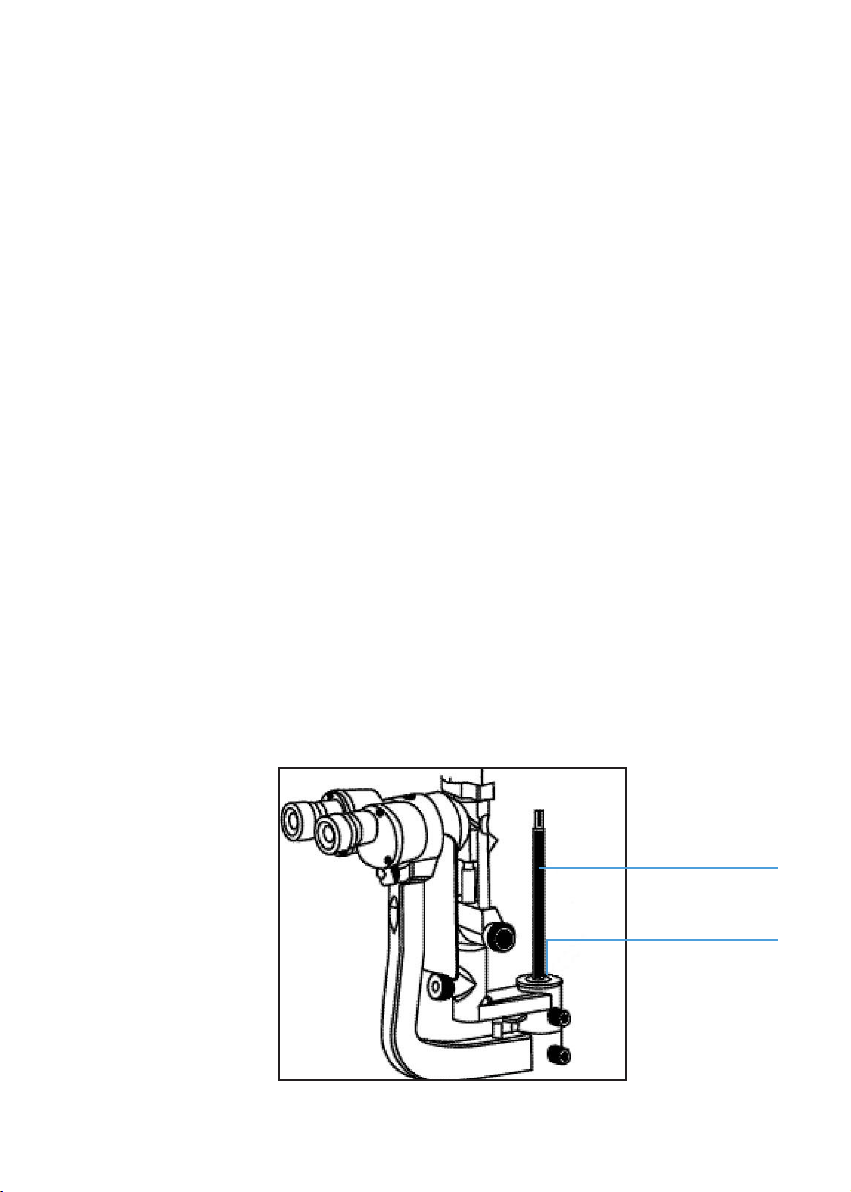

3. Assembling the Head-rest Part (D)

Head rest

xation plate

Chin rest

connection

board

• Remove the four screws attached to the chinrest connection board with the

screw driver (U).

Screw

Head rest

xation plate

connection board

Chin rest

12

• Put two cables in the gap between the headrest xation plate and the chin rest connection board.

• While ensuring the cables are not compressed, retighten the previously

removed screws.

4. Assembling the base part (C) and the rail covers (G)

Wheel

Rail

• Place the wheels of both sides of the base (C) on the rails on the worktable

• Check whether the wheels can be rolled smoothly on the rails.

• Remove the four screws attached to the rail with the screw driver (W).

• Place the rail cover (G) to the rail and retighten the previously removed screws.

Mark

Shaft sleave

Limiting board

13

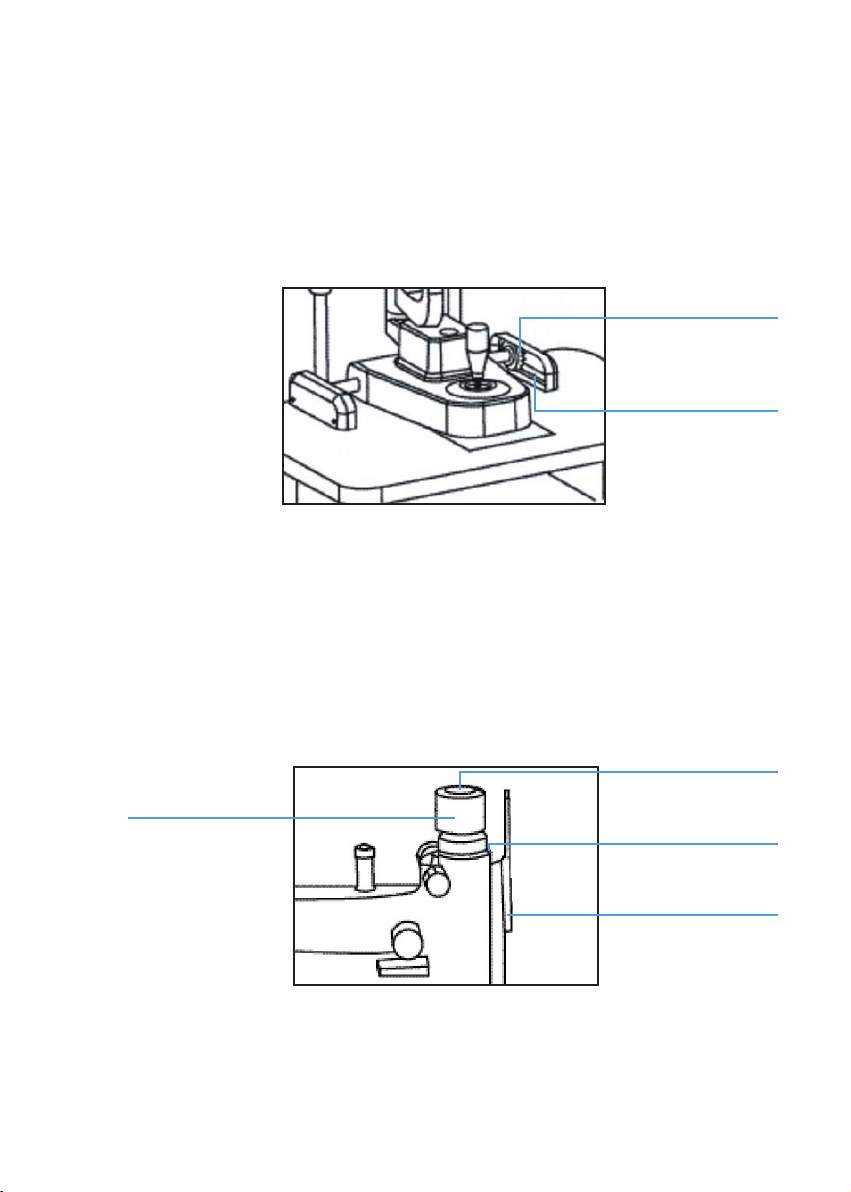

5. Assembling Illumination part (A)

• Loosen the illumination arm bolt (13).

13

• Rotate the brass shaft sleeve to make the angle of the red mark and the

illumination arm between 30º and 90º.

• Loosen the screw on the illumination arm with the screwdriver (V). Align the

assembly hole of the illumination arm to the brass shaft sleeve and lower

carefully, while simultaneously aligning the two red marks.

Illumination arm

Mark

Screw

• After the two red marks are accurately aligned, retighten the screw.

B

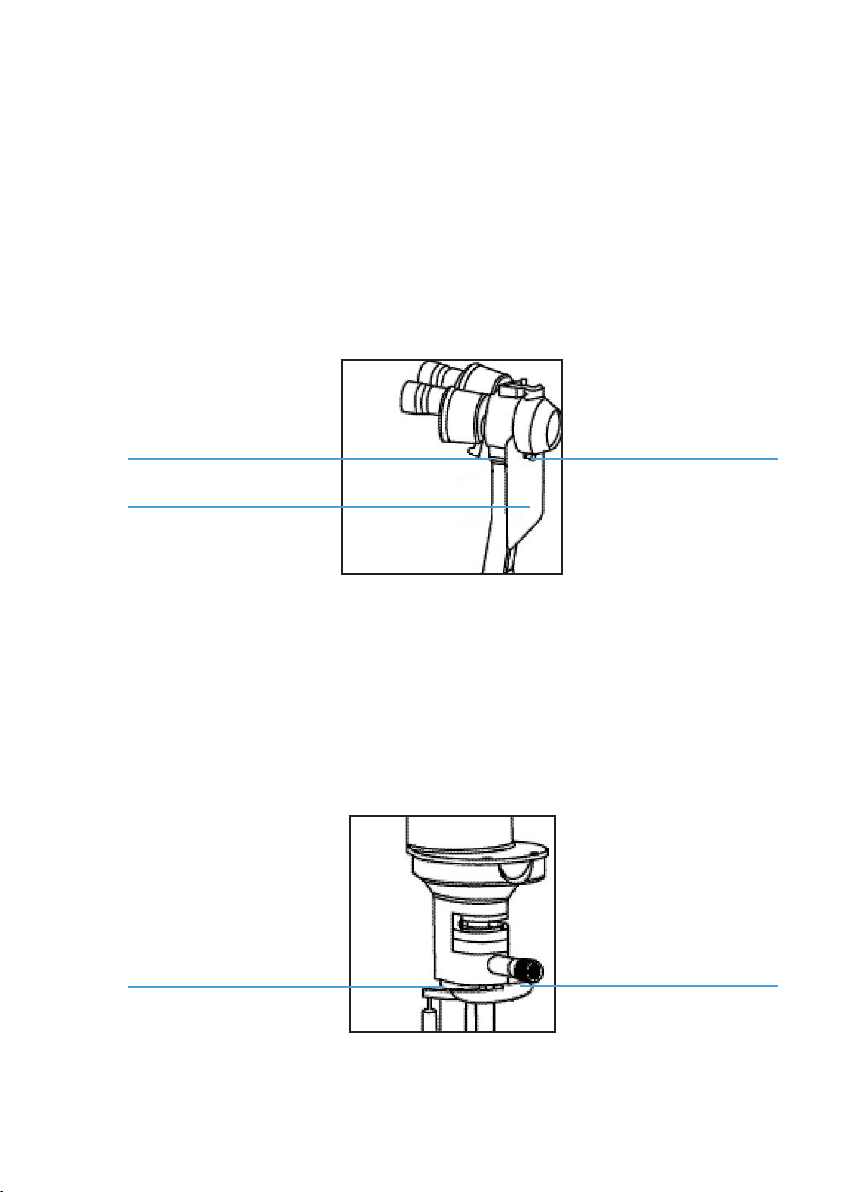

6. Assembling the binocular tubes (B)

• Align the groove on the binocular tubes with the pin on the microscope body.

• Tighten the xing screw.

Fixing screw

PinGroove

14

7. Assembling the breath shield (E)

Important Matters

Avoid touching any lens surface while assembling the breath shield (E).

• Remove the breath shield xation screw from the microscope arm.

• Pass the removed screw through the hole of the breath shield then re-screw

it into the arm.

Microscope arm

Breath shield

8. Removing the illumination part shipping pad

• This pad is used to protect the slit mechanism of the illumination part during

shipping.

• Remove the rubber band and gently pull the pad out.

Rubber band Pad

Fixing screw

15

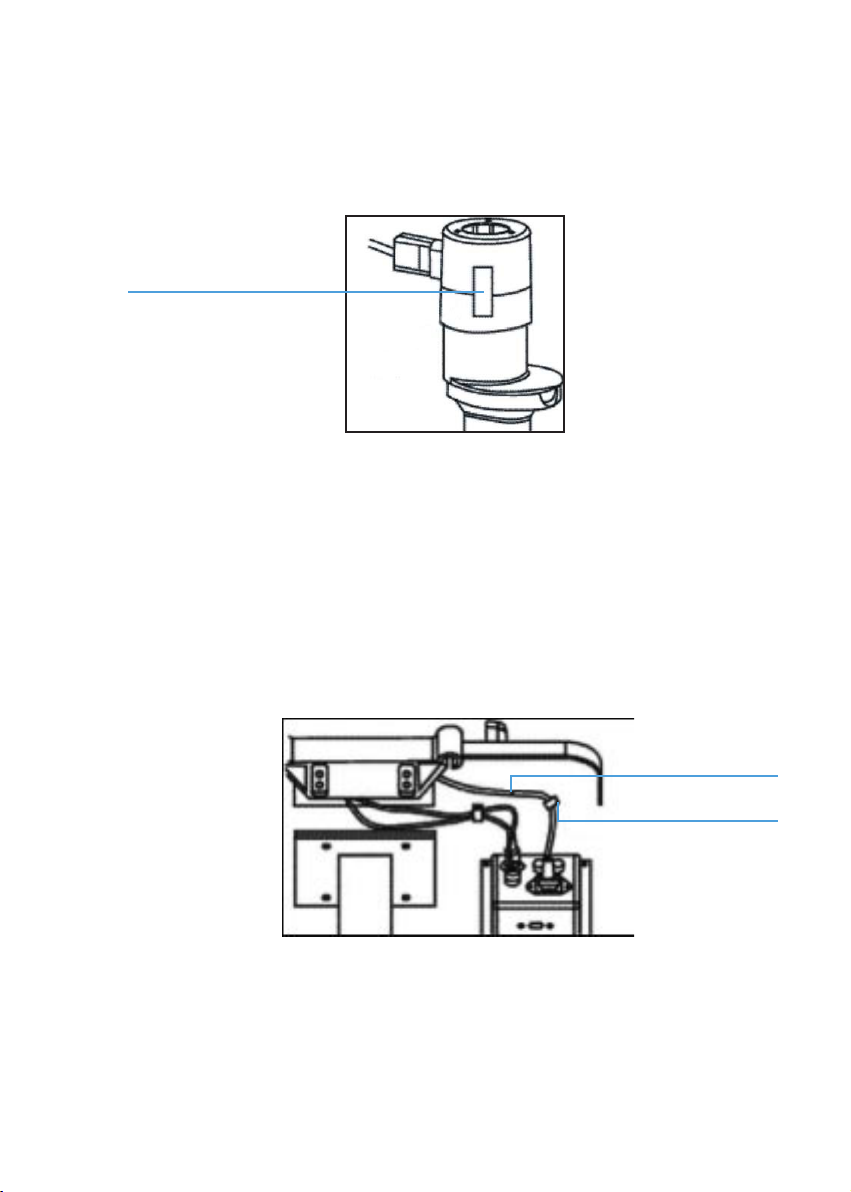

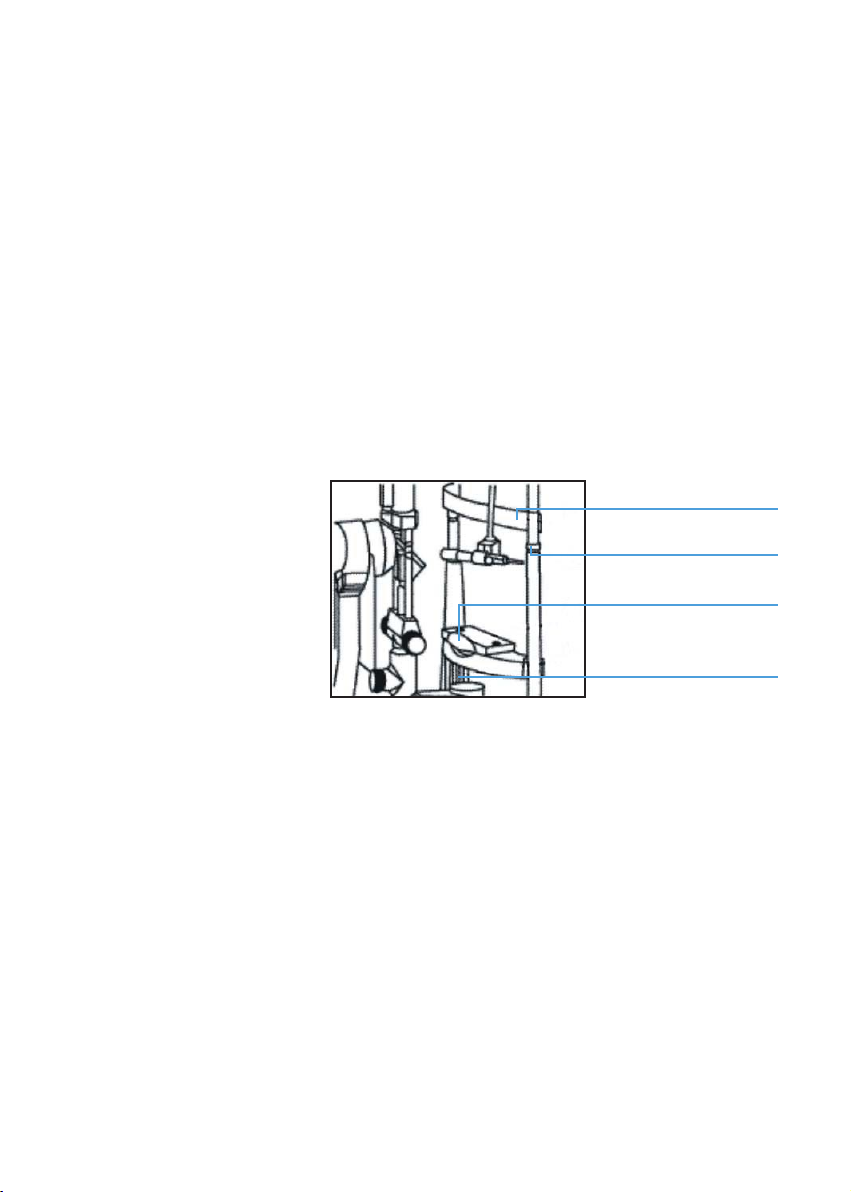

9. Connecting Plug

• Remove the sticky shipping tape from the cap. The tape ensures that the

cap is remains fastened to the lamp base during transportation.

Sticky tape

• Insert the plug on the top of the headrest part (D) into the socket of the lamp

cap (26) on the illumination part (A).

• Connect the two plugs below the headrest part with the corresponding output

sockets of the power box.

• Insert the plug of the input power cable (H) into the input socket of the power

box.

H

Cable clip

• Remove the cable clips from the bottom of the worktable with screwdriver

(U) and route the output and input cables through them, then re-attach them

to the bottom of the worktable.

16

10. Assemble the Hruby Lens (I)

• Insert the Hruby lens ( I ) into the Hruby lens holder (26) on the headrest part.

Be careful not to touch the lens surface.

• Place the Hruby lens guide plate (J) into the main shaft hole of the base part

with the small end pointed at the headrest part.

Hruby lens

holder

11. Assembling the chin-rest (E)

• Pull out the two xing pins from the chinrest.

I

J

• Remove and discard the packaging for the chin-rest paper and position the

paper.

• Insert the xing pins through the holes.

17

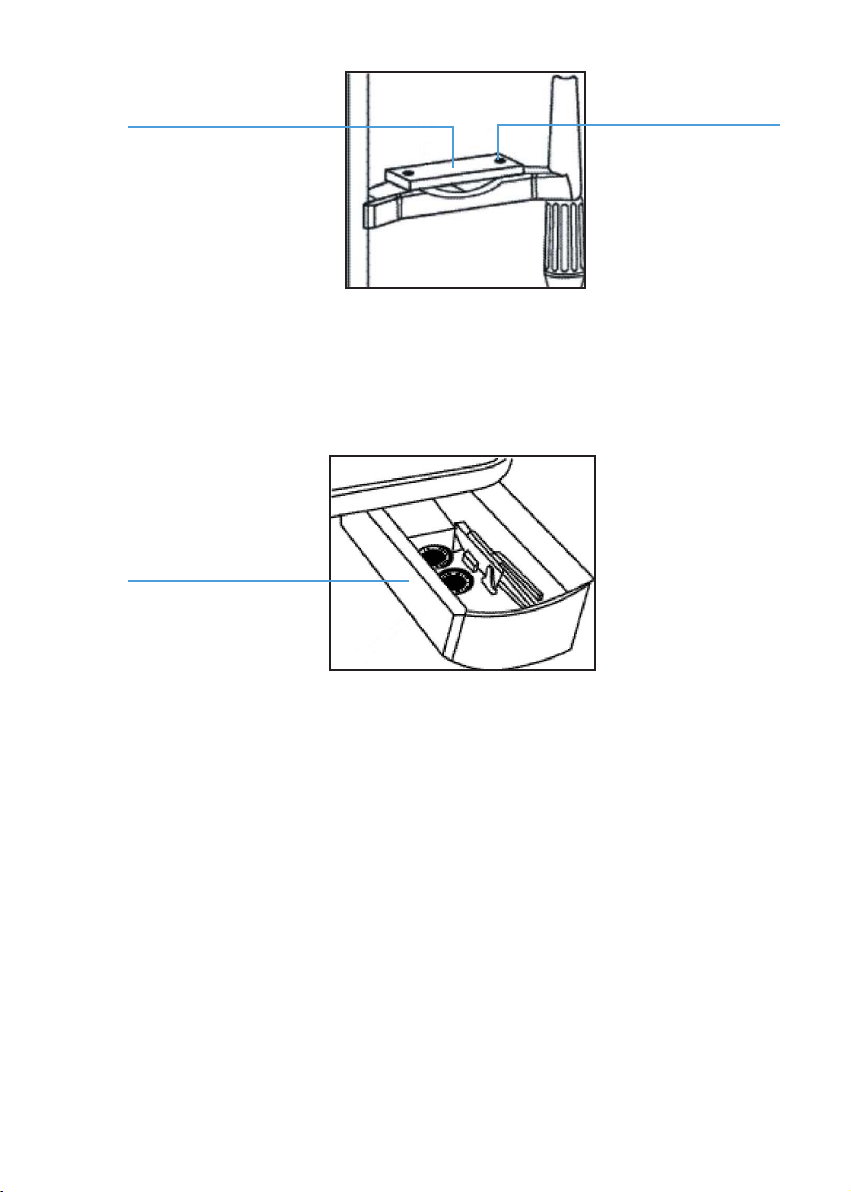

12. Storing spare parts

Spare parts may be stored in the accessory drawer.

6

PinH

2.3 Inspection procedure after assembly

1. Power plug

• This instrument supplied with a 3-wire grounded line cord. Do not remove

or disconnect the ground. Please select proper power sockets and plugs

• Always ensure that the instrument is well grounded.

Important Matters

Please use the special cable supplied with this instrument.

18

2. The power box and the illumination part

• When the main power switch (8) of the power box is placed at “1” it turns

on, and when located at “0” it turns off. The main power switch should be

set to the “0” position before connecting the input cable with the power

socket.

• Turn on the main power switch, and the pilot lamp (9) will illuminate.

Open the slit width control knob (35) to examine the illumination.

• Press the brightness control switch (7) in each of the two positions, the

brightness should be change accordingly.

• Check the xation target device to conrm it is lit.

• Check that all the movable parts such as aperture and slit height control knob

(29), lter selection lever (28), and magnication lever (18), etc. move freely.

• After inspection, turn off the main power and cover the instrument with the

dust cover (O).

3. Operation

3.1 Diopter compensation and pupillary distance adjustment.

1. Use of the focusing test rod (M)

Focusing

test rod

Shaft holder

19

The focusing test rod is used to conrm that the microscope is adjusted correctly.

Insert it into the main shaft hole with the at surface facing the objective lens in

the direction of the user.

Important Matters

After adjustment, remember to remove the rod and insert the protective cap.

2. Brightness adjustment

Turn on the main power switch and set the brightness control switch (7) at

the “N” position. Turn the slit width control knob (35) to make the slit width

between 2 and 3mm.

3. Diopter compensation

The focus of the microscope is calibrated according to the emmetropia.

If the user is ametropic, he should adjust the eyepiece diopter.

Adjustment should be performed as follows:

• Rotate the diopter adjustment ring (19) counter clockwise until it stops.

• Rotate the ring clockwise until a sharp slit image appears on the focusing

test rod.

• Adjust the other eyepiece using the same procedure.

• Record the diopter value on each eyepiece for future reference.

Prism boxDiopter scale

Adjustment ring

20

4. Pupillary distance adjustment

Separate the prism boxes of the microscope with both hands to adjust the

pupillary distance until both eyes can stereoscopically see the same image

on the focusing test rod.

3.2 Patient position and xation target

1. Positioning the patient’s head

Have the patient place his chin on the chin-rest (17) and the forehead against

the forehead belt (24). Adjust the chin-rest elevation adjustment knob (12)

below the chin-rest until the patient’s canthus aligns with the horizontal

mark (23).

24

23

17

12

2. Use of the xation target

• Direct the patient to look at the xation target (30) with the eye not to be

examined. To change the xation position, move the lamp bar and curved

lever around the headrest.

• The xation target with diopter compensation supplies a dot and concentric

circles target. Slide the knob to adjust the diopter compensation from – 15D

to + 10 D.

21

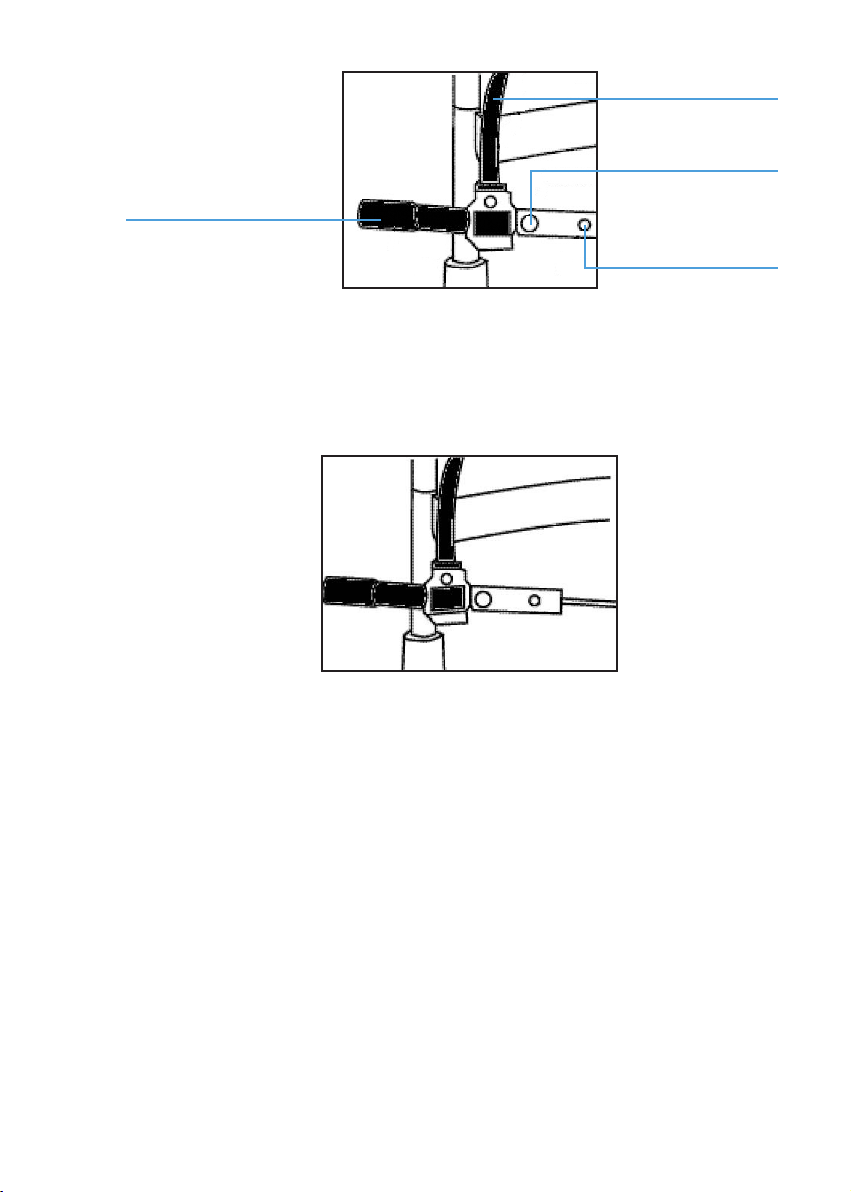

Curved level

Fixing screw

Fixaation target bar

Adjusting knob

The xation target with the spot light is intended for the patient whose diopter

exceeds – 15D. When changing, just loosen the xation screw, replace the xation

target with the spot light source and tighten the xation screw.

3.3 Base operation

1. Horizontal coarse adjustment

Keeping the joystick (1) straight up, move the base (4) to coarsely align the

microscope in the horizontal plane.

2. Vertical adjustment

Rotate the joystick to adjust the microscope’s height until it aligns with the

target. Turn the joystick clockwise to raise the microscope and counter

clockwise to lower it.

3. Horizontal ne adjustment

Tilt the joystick to make the microscope move slightly in the horizontal plan.

22

White watching through the eyepieces, tilt the joystick to align the microscope

at the object for a sharp image.

1

2

4

4. Locking the base

When nishing the adjustment, fasten the base locking screw (2) to lock the

base (4) and prevent it from sliding.

3.4 Illumination parts operation

1. Changing the slit width

Turn the slit width control knob (35) to adjust the slit width from 0 to 9mm.

The slit becomes a circle at the 9mm size.

Scale of slit width 35

2. Changing the aperture and slit height

Turn the aperture and slit height control knob (29) and 6 different circular

beams of light are available at full aperture: 9, 8, 5, 3, 1, 0.2mm diameters

23

Loading...

Loading...