luxvision LM 300 User Manual

USER’S MANUAL

LENSMETER

LM 300

Notication

Dear Users,

Thank you for your purchase of LM 300 Lensmeter. Please take time to read our

user’s manual carefully before use.

This guarantees you to make full use of this unit and prolongs the operation life of

this unit.

Precautions

If you have detected abnormal heat, smoke, noise or smell, immediately stop using

the product.

In the event of an abnormality, turn off the power and disconnect the power plug from

the power socket. Continuing to use the product may result in electric shock or re.

Observe the instructions given below regarding the power cable:

• Be sure to use the supplied or specied power cable.

• Do not modify, forcibly bend, kink or pull the power cable.

• When disconnecting the power cable from the AC outlet, be sure to hold the cable

by the plug.

Pulling the cable may cause wire breakage or shot circuit, resulting in re or

electric shock.

• Do not connect or disconnect the plug of the power cable to/from the AC outlet

using wet hands.

Doing so may result in electric shock.

• Do not touch the product with wet hands while the power cable is connected

to the AC outlet.

Doing so may result in electric shock.

• If the product will not be used for a long period, disconnect the power cable from

the power source. Leaving the cable connected to the power socket for a prolonged

period will consume electricity and may result in heating.

Content

1. Function Introduction .....................................................................................4

2. Working Principle Device ................................................................................4

3. Functions ......................................................................................................5

4. Operation ......................................................................................................8

5. Maintenance ................................................................................................18

6. Common Trouble Shooting ...........................................................................19

7. Specications ..............................................................................................20

1. Function Introduction

This device is divided into two models, A and B, in which A is standard model

and B is strengthened model with prism compensator.

In the following description, all sections or content marked with “*” before them are

specialized content of model B device.

Optic, machine and microelectronic integrated technologies are adopted in this device,

where, yellow liquid crystal display is available to achieve stable and precise measuring

result, proven to be an ideal device for having one’s eyesight tested for spectacles.

This device is applicable to all level measurement testing departments, spectacles

manufacturers, spectacles retail stores, hospital’s department of ophthalmology

and optical elements factories for conducting measurement of spherical lens diopter

of spectacles or lens, diopter of cylindrical lens, astigmatism axis angle of cylindrical

lens, diopter of bifocal lens, prism degree and prism basal angle.

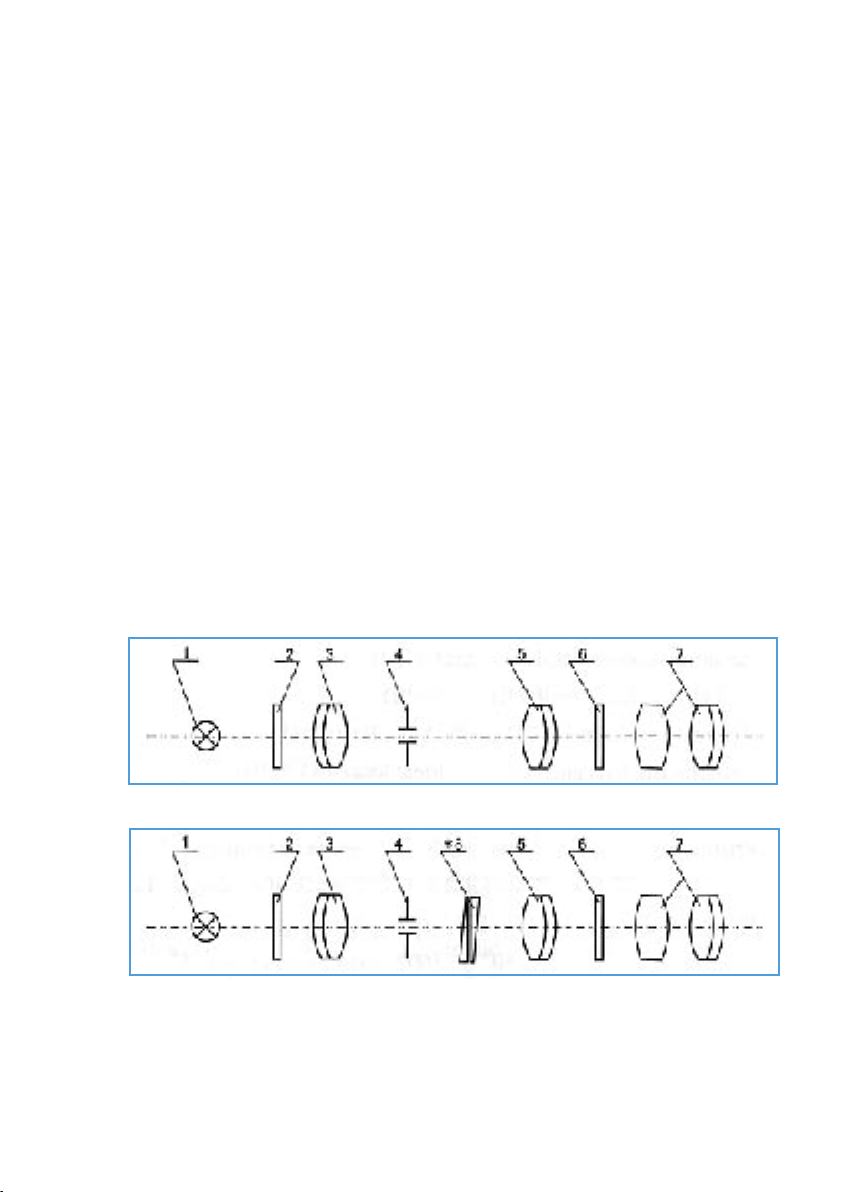

2. Working Principle of Device

Fig. 1 Drawing of Optical Principle for Model A

Fig. 2 Drawing of Optical Principle for Model B

1. Light source 2. Mark Dividing Plate 3. Measurement Objective

4. Diaphragm 5. Telescopic Objective 6. Eyepiece Dividing Plate

7. Eyepiece Set *8. Prism Compensator

4

This device consists of a coaxal optic system. Light sent forth from 1-Light Source

(LED) lights up 2-Mark Dividing Plate. After passing though 3-Measurement Objective

and 5-Telescopic Objective, 2-Mark Dividing Plate is imaged at position of 6-Eyepiece

Dividing Plate. At this time, through 7-Eyepiece Set, the distinct reticule images of

2-Mark Dividing Plate and 6-Eyepiece Dividing Plate can be seen.

During operation, put spectacle lens at the place of 4-Diaphragm (measurement

bearing scat), and turn diopter measuring hand-wheel and astigmatism turning handwheel so that distinct image of 2-Mark Dividing Plate is obtained. Now, the number

showing on the liquid crystal display screen is just the diopter value of this lens.

3. Functions

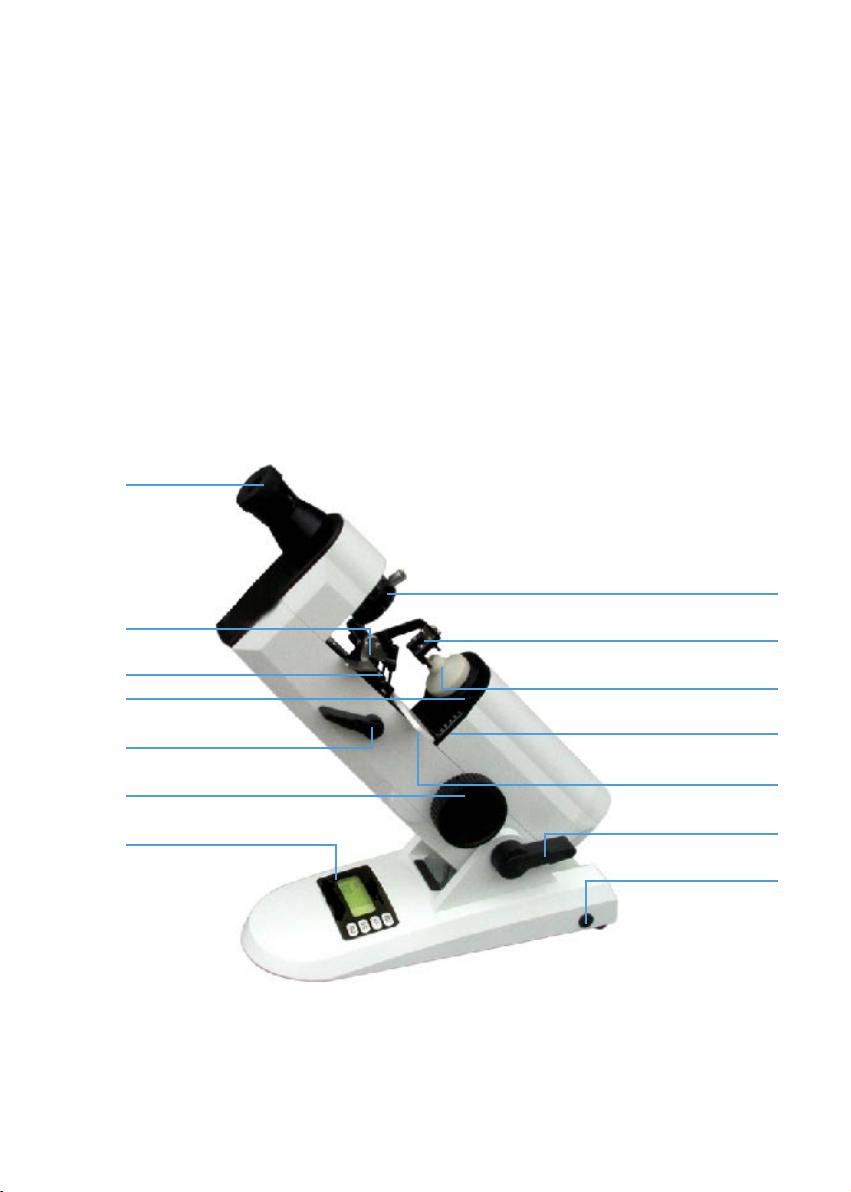

3.1 Main View (Fig3)

1

2

10

11

5

12

13

14

3

4

7

6

8

9

Fig. 3

5

1. Eyepiece

Eyepiece part is a screw type focusing unit with focusing range of ±5D,

adaptable to different eye-sights of human eyes.

*2. Prism Compensator

It is used to measure prism lens with prism degree bigger than 5∆.

3. Lens Pressing Mechanism

3 plastic pressing feet equipped with spring are used to press lens, able to

stably press lens with any shape of surface, with no damage to lens surface.

4. Measurement Bearing Seal

It can hold lens with any shape of surface with no damage to lens surface.

5. Astigmatism Turning Hand-Wheel

It is used to measure and locate astigmatism axis angle of cylindrical lens

and basal angle of prism lens.

6. Lens Pushing Board

When lens on the lens frame is conducted, lower part of lens frame (i.e. two

lens rings) shall contact the lens pushing board.

7. Diameter Indication Measuring Scale

When lens pushing board contacts edge of lens, it is possible to read lens

diameter.

8. Inclining Angle Adjusting Handle of Device

It is able to enable measurement user to adjust inclining angle of the device

easily, who can work with a comfortable posture. By rotating backwards

the adjusting handle, measurement user may tilt me device to a proper angle

according to specic status of work table, then simply lock up the handle.

9. Power Supply Socket

10. Dot-Making Mechanism

This mechanism consists of 3 identical dot-making pens connected into

a line, where, one in the middle is used to mark lens center, and connected

line of marking dots of 3 pens is used to mark astigmatism axis angle of lens

and basal angle of prism lens.

11. InkpadBox

It is used to store inkpad or ink for print.

6

12. Lens Pushing Hand Lever

It is used to move lens pushing board back and forth.

13. Diopter Measuring Hand-wheel

3.2 Drone and Eyepiece Dividing Plate (Fig.4)

Round-dot drone

Cross-line drone

Fig. 4

14. Liquid Crystal Display Screen

It displays diopter value of the measured lens.

15

16

15. Eyepiece Dividing Plate

Prism degree measuring scale and calibrated dial are marked on it. Prism

degree is marked with space of 1∆, where, integral prism degree is read

directly on the measuring scale, and decimal prism degree is read by

estimation from measuring scale. Calibrated dial 0 ~ 180° is marked with

space of 1°, and 180º ~ 360° with space of 5°.

16. Drone

Distinct image of mark dividing plate involves round-dot drone and cross-line

drone.

7

Loading...

Loading...