Page 1

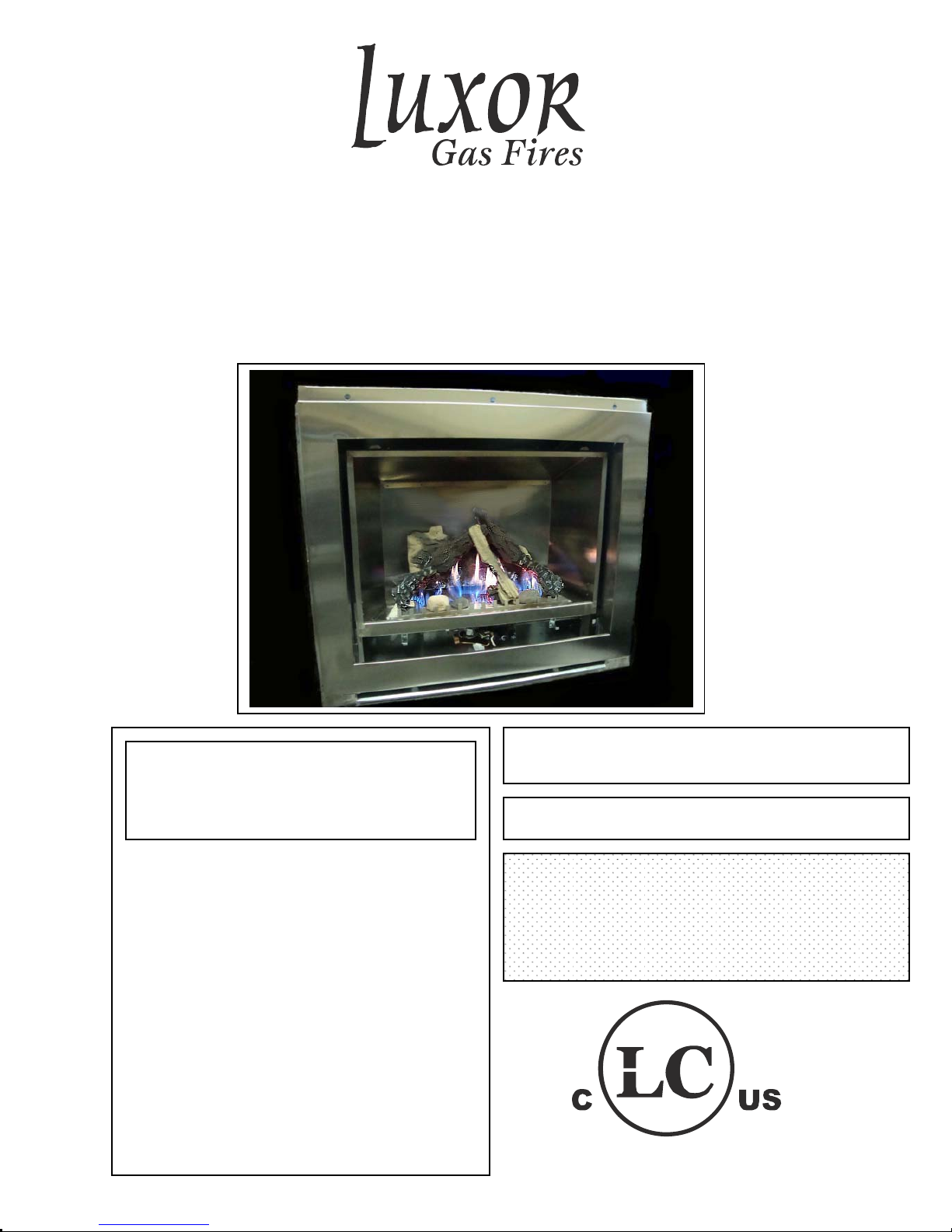

Stainless Steel Gas Fireplace

Installation and Owner’s Manual

Outdoor Ventless

Model MBO-36

Canadian Fire Hearth Mfg

7075-Beatty Drive, Mission B.C. V2V-6C4

.

WARNING: If the information in these

.

instructions is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or death.

--Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

--WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electrical switch; do

not use any phone in your building;

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fire department.

-- Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

INSTALLER: Leave this manual with the customer

CUSTOMER

FOR OUTDOOR INSTALLATION ONLY

PLEASE NOTE: This product has been manufactured

using steel and screws. As a result, there are many

sharp edges that can easily cut exposed skin. It is

highly recommended that you wear proper protective

gloves while installing the unit, and during routine

cleaning or maintenance.

: Retain this manual for future reference

1

Page 2

Table of Contents

Page 1……………………………………………………….Cover Page with Safety Information

Page 2……………………………………………………….Table of Contents

Page 3 & 4…………………………………………………..Customer Greeting & Safety Information

Page 5 ………………………………………………………Features and Specifications

Page 6……………………………………………………….Framing Specifications

Page 7……………………………………………………… Finishing/Mantel Allowances

Page. 8…………………………………………… …………Installation

Page 9……………………………………………………….Installation cont.

Page 10………………………………………………………Clearance Specifications

Page 11………………………………………………………Lighting Instructions

Page 12………………………………………………………Thermostat

Page 13………………………………………………………Log Set Installation

Page 14………………………………………………………Log Set Installation cont.

Page 15………………………………………………………Log Set Installation cont.

Page 16 ……………………………………………………..Flame Quality

Page 17………………………………………………………Replacement Parts

Page 18………………………………………………………Final Checks

Page 19………………………………………………………Warranty

WARNING!

•FOR OUTDOOR USE ONLY. This appliance can only be installed in a well-vented space

and shall NOT be used inside a building, garage, or any other enclosed area.

•DO NOT LEAVE FIREPLACE UNATTENDED WHEN IN USE.

•THIS APPLIANCE MUST NOT BE USED FOR COOKING.

•THIS APPLIANCE IS NOT FOR USE WITH SOLID FUEL.

•DO NOT ALLOW WIND TO BLOW DIRECTLY INTO THE APPLIANCE. Avoid any strong

drafts that alter the flame pattern.

•DO NOT ALLOW HEAVY RAIN FALL DIRECTLY INTO APPLIANCE. Although this unit

meets certification standards for outdoor appliances it maybe installed unsheltered and

exposed directly to many weather conditions. Avoid any prolonged heavy rain exposure

directly into the firebox. Use the optional cover when extended shutdown periods are

anticipated

2

Page 3

CONGRATULATIONS

–

We hope you’ve had an easy and enjoyable time choosing from our line of products, and we certainly

appreciate your business. Please take some time to read through the following information, and make

sure to heed all of the warnings. Even though our fireplaces are easy to install and simple to operate,

they are still gas burning units with some inherent dangers if not careful

Date Purchased:_____________________________

Dealer:__________________________________________________________________

Installer:________________________________________________________________

Phone:_________________________________ Serial Number:____________________

FOR YOUR SAFETY

DO NOT: Use tools to operate controls. Use only your hand to push in and turn controls.

DO NOT: Clean the appliance when hot.

DO NOT: Use this appliance if you smell gas.

DO NOT: Use this appliance if any part has been under water. Immediately call a qualified service technician to

inspect the appliance and replace any part of the control system and any gas control whi ch h as been under water.

General Safety (Home Owner)

•Fire Extinguisher: Every home should have at least on fire extinguisher. An approved Class A-B-C extinguisher should be

mounted on the wall near an exit and close to the application, but not so close that accessibility to the extinguisher cou ld be

blocked by a fire. Your local Fire Department can advise you concerning the most appro priate location.

•Smoke Detectors & Carbon Monoxide Detectors on each floor of your home to ensure your safety. It should be located away

from the gas appliance and close to the sleeping areas. Follow the detector’s manufacturer’s plac ement installation and

maintenance instructions.

Safety for the installer

Wear gloves and safety glasses for protection.

Be aware of electrical wiring locations in walls and

ceilings.

Use a back support for heavy lifting.

Installation and repair should be done by a qualified service person. The appliance

should be inspected before use and at least annually by a professional service person.

More frequent cleaning may be required due to excessive lint from carpet, bedding

material, etcetera. It is imperative that control compartments, burners and circulating

air passageways of the appliance be keep clean.

Welcome to Our Luxor Gas Fireplace Family

Read before lighting

Carbon Monoxide Poisoning: Early signs of carbon monoxide

poisoning are similar to the flu with headaches, dizziness and/or

nausea. If you have these signs, obtain fresh air immediately.

3

Page 4

This appliance is only for use with Natural Gas as indicated on the rating plate.

Q

Note: The copy in the manual is for reference only. In the event of a discrepancy, the label on the

unit is to be taken as the latest version.

ONLY PERSONS LICENSED TO WORK WITH GAS PIPING MAY MAKE THE NECESSARY GAS CONNECTION

TO THIS APPLIANCE. YOU ARE NOW READY TO HOOK UP THE GAS SUPPLY. BE SURE GAS PLUMBING

INSTRUCTIONS AND ALL PROVINCIAL AND LOCAL CODES ARE CAREFULLY FOLLOWED. USE APPROVED

FLEXIBLE GAS CONNECTIONS OR RIDGID PIPING, DEPENDING ON PROVINCIAL AND LOCAL CODES, TO

ATTACH BURNER TO GAS SUPPLY. BE SURE TO USE PROPER SIZE GAS SUPPLY LINE. CAREFULLY

CHECK ALL CONNECTIONS FOR GAS LEAKS WITH SOAP AND WATER SOLUTION.

EACH INSTALLATION MUST CONFORM TO ALL LOCAL, PROVINCIAL, AND NATIONAL CODES. REFER TO

THE NATIONAL FUEL GAS CODE, LOCAL ZONING AND CODE AUTHORITIES FOR DETAILS ON

INSTALLATION RE

UIREMENTS.

GAS SUPPLY

DO NOT burn ANY materials in this fireplace.

All occupants of the home, especially children, should be alerted about the hazards of the high surface

temperature and the chance of severe burning or the possible ignition of clothing.

Young children should be carefully supervised when they are in the same room as the appliance.

Due to the high temperatures, the fireplace should be installed away from traffic areas.

Nothing should ever be placed on or near the surface of the fireplace, including the top of the unit.

Clothing or other flammable material should not be placed on or near the appliance.

Make certain the control panel, burner are kept clean. Inspection of these systems should be inspected

annually by a qualified service technician.

Any safety screen or guard removed for servicing the appliance must be replaced prior to operating the

appliance.

The fireplace, under NO circumstances, should ever be modified.

Do not alter gas orifice

Do not operate the fireplace if damaged. Any repairs must be done by a certified technician.

WARNING

The Model MBO-36 is listed and certified for installation in the U.S.A. and Canada under the

The installation must conform with local codes or, in the absence of local codes, with the

National Fuel Gas and Propane Installation Code, ANSI Z223.1 / NFPA 54 in the US or the

Please contact Canadian Fire Hearth Manufacturing if you have any questions regarding the certification of this appliance.

Natural Gas and Propane Installation Code, CSA B149.1 in Canada.

ANSI Z21.97 2010/CR97-003.

Certification

following standards:

4

Page 5

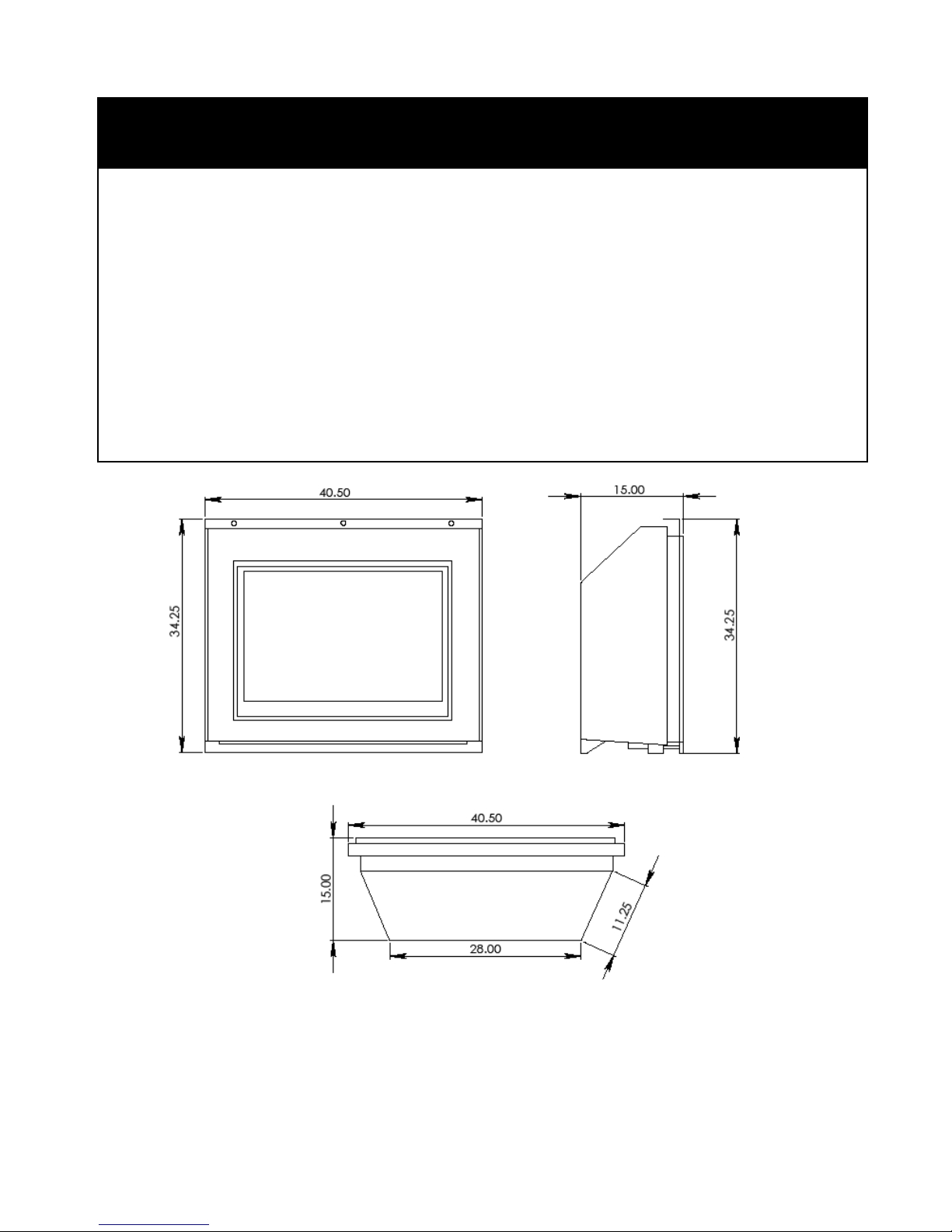

FEATURES AND SPECIFICATIONS

Note: Always check appliance label for correct information

MODEL: MBO36 Natural Gas

Manifold Pressure 3.5in. w.c.

Min. Supply pressure 5.5in. w.c.

for purpose of input adjustment

Max Supply pressure 11in. w.c.

Orifice size #35

Nominal input rating 35000 BTU/hr

High altitude (US) 0-2000ft / 0-610m

High altitude (Canada) 0-4500ft / 0-1370m

Primary Air Opening

Vent System Ventless

Clean Face Kit (factory installed on all units) 304 Stainless Steel

Please Note: Only products supplied by the manufacturer may be used in the installation of this appliance.

5

Page 6

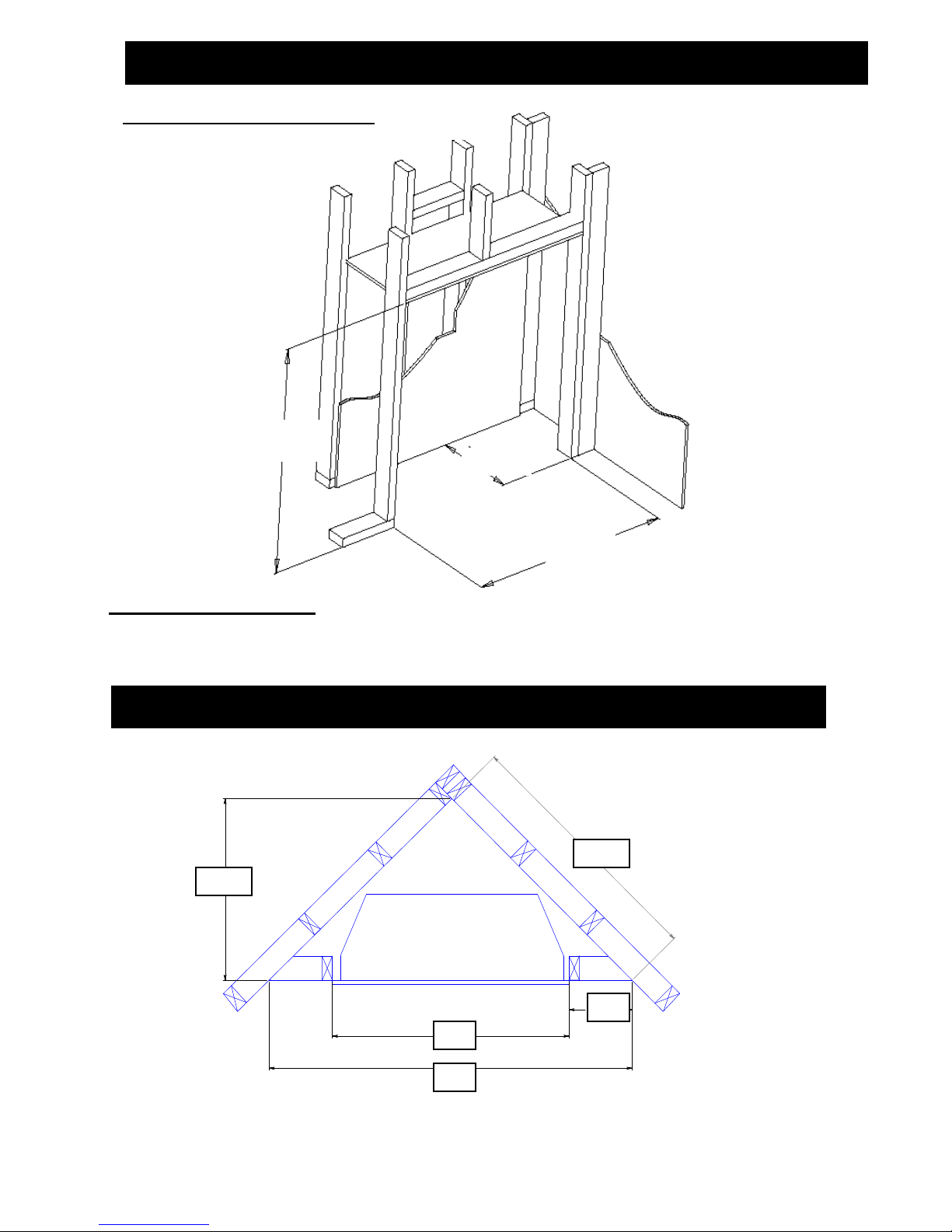

Installation

Minimum Framing Dimensions

Framing and Clearance

Unit maybe installed in any location that maintains proper clearances to air conditioning ducts, electrical

wiring and plumbing. Safety, as well as efficiency of operation must be considered in selecting a fireplace

location. Select a location that does not interfere with foot traffic has adequate air movement.

.

30.5

3.42

35

16.75

38

Corner Installation

4.46

41

6.84

60

4

.

8

41.5

2

1.19

10

6

Page 7

Finishing and Facing Material Considerations

Sliding drain tray

No combustible materials

can extend past this line

In order to adequately drain the

appliance a sliding drain tray is built

into the lower section of the unit. In an

application where the existing stainless

face will be featured, the tray can

remain in the inner most position. If a

non-combustible material like stone or

brick is to be added over the facing the

drain tray must not be covered. Doing

so will prevent proper water drainage.

The tray can be pulled out to match the

thickness of any desired material.

Mantel Requirements

Framing

The attached chart represents the maximum allowable

mantel or shelf limits using combustible materials determined

by in the certification guidelines. Due to the wide range of

designs and materials of non-combustible mantels, shelves,

and overlays caution must be exercised when choosing to

finish this appliance. Any such installations must conform to

local codes. For any further information contact CFH Mfg.

framing

Fireplace Cleanface

Top edge of

fireplace opening

Side wall

1.5”

The MBO-36 is shipped with non-combustible panels which must be installed with the appliance

to conform with to certified safety standards. the panel is secured above the Cleanface

Mantel/Surround Side clearance

7

Page 8

Placements of Non-combustible Panels

In any installation in which the unit is installed into a chase constructed of combustible materials ie:

plywood, wood framing, convention wall board (including “waterproof” type) a certified non-combustible

½ in thickness or greater board must be installed in the designated areas. PLEASE NOTE: It is

mandatory that all supplied non-combustible panels be installed. Failure to do so could result in damage

to adjacent materials and/or fire.

Enclosure space around and above

the appliance must be left free of any

obstruction.

non-combustible

29.5” x 4” x 0.5”

34.5

Combustible

Non-combustible

36 x 4 x 0.5”

This wall can either be

inside or outside wall

3.82

Non-Combustible

sheet material

14” x 28” x 0.5”

1.70

17

NOTE: All non-combustible boards provided by the manufacturer.

8

Page 9

The recommended order of installation is as follows:

1 – Familiarize yourself with this manual.

2 – Check the minimum installation dimensions.

3 – Check your local installation codes.

4 – Check you have the parts and components necessary to complete the installation.

5 – Check the gas and electrical supplies are ready.

6 – Prepare opening (remove any loose materials)

7 – Install base unit.

8 – Connect gas.

9 – Install operational components and prepared for first test fire.

10 – Check to verify adequate accessibility clearance for service & proper operation.

11 – Check operation of unit.

12 – Take time to explain operation to customer (most call backs are caused by the customer not understanding the operatio n

of the unit.)

Installation Planning

Installing Gas and Electrical Supply Lines.

S

Gas and lines must be installed and accessible for the installation of the MBO-36.

Natural Gas requires a minimum inlet gas pressure of 5.5 in W.C.. IMPORTANT: Installer please allow a portion of

the gas line connecting to the appliance to be flexible enough for moving and aligning the appliance into the

chase.

Before interrupting the existing gas supply it is recommended that the following be checked.

Shut down all gas appliances and carry out a pressure test to ensure there are no leaks in the system.

Before connecting the appliance to the gas supply line, double check that the appli ance you have purchased is designed for the

gas type you are using. The gas type markings are located on the certification label and also on the appliance’s gas valve.

Check the gas pressure immediately upstream to ensure you will be able to supply the minimum inlet pressure for the

appliance.

Check your pipe sizing to ensure sufficient volume will be supplied to the appliance.

Existing Gas Supply

Provide adequate clearance for the proper installation and c hecking of the gas connection.

Have your gas supplier or a qualified gas fitter run a gas supply line into th e gas fireplace. The line must be properly sized and

fitted according to the installation codes. Upstream of the appliance supply connection, the fitter shall provide an easil y

accessible manual shut-off valve.

The gas supply pipe should enter the appliance case through the opening at the right sid e. T he supply pipe should be

connected to the appliance gas inlet pipe situated at the right side of the control unit. Supply line connection to the inlet pipe is

3/8 NPT.

Use only new black iron or steel pipes or copper tubing if acceptable – check local codes.

Note that in the USA copper tubing must be internally tinned for protection against sulfur compounds.

Unions in gas should be of ground joint type. Sealant used must be resistant to the action of all gas constituents including LP

gas. Sealant should be applied lightly to male threads to ensure excess sealant does not enter gas lines.

Gas Supply Installation

9

Page 10

Clearance Specifications

D

FP

A

G

H

P

FP

G

FP

Q

J

or

X

K

FP

FP

B

B

C

FP

FP

F

FP

A

B

I

M

L

= fireplace opening X

FP

A = 2in. clearance above grade I = 3ft. (USA) clearance to service regulator

veranda, porch, deck or 6ft.(Canada) vent outlet and electrical service.

balcony

B = 12in. clearances to wind ow or door J = 9in. (USA) clearance to non-mechanical air

that may to opened, or to 12in.(Canada) supply inlet to building or the

permanently closed window. combustion air inlet to any other

36in. vinyl windows or siding. appliance.

C = 72in. clearance below an K = 3ft .(USA) clearance to a mechanical air

operable window. 6ft.(Canada) supply inlet.

D = 47in. vertical clearance to unventi- L*= 54in. clearance above paved sidewalk or

located above the fireplace. public property.(see note 1)

60in. vinyl clad soffits. M**= 47in. clearance under veranda,porch,deck

G = 4in. Clearance to inside corner balcon y or ove r hang

48in. Vinyl window or siding Not Allowed Vinyl

H = 36in.(Canada)Not to be installed above a gas P = 92in. see note 2) .

meter/regulator assembly within 3ft. Q = 72in.

horizontally from the center line of the

regulator.

lated or a ventilated soffit a paved drive way located on

= air supply inlet

= area where fireplace is not permitted

* A fireplace shall not open directly above a sidewalk or paved 3)All gravity air intakes within 3 ft of the fireplace must be

driveway which is located between two single family dwellings a minimum of 1 ft below the face top opening.

and service both dwellings. This fireplace is approved for installation in screened

**Only permitted if veranda, porch, deck or balcony is fully open porches with the following:

on a minimum of 2 sides beneath the floor, or if the screened Minimum porch area – 96 sq ft

porch guidelines are followed. Minimum ceiling height – 92 in.

Minimum of two walls must be screened or open

Note 1: Local codes or regulations may require different clearances Minimum top of screen height, side walls 6ft 8in.

Note 2: Fireplaces in an alcove space (spaces open on one side and Minimum screen area – 64 sq ft

with an overhang) are permitted with the dimensions Notes: There may be some odor and small amount of soot

specified for vinyl or non-vinyl siding and soffits. 1) There associated with burning the fireplace in a screened porch.

must be a 3 ft minimum between terminations or between Ensuring good cross draft ventilations and routine maintenance

the fireplace and termination. 2) All mechanical air intakes of the routine maintenance of the fireplace will maximize

within 10 ft of the top of the fireplace opening must be a comfort and cleanliness.

minimum of 3 ft below the top of the fireplace opening.

Lighting Instructions

10

Page 11

For your safety, read the following before lighting:

WARNING: If you do not follow these instructions exactly, a fire or explosion may

result causing property damage and personal injury or death.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B.

BEFORE LIGHTING smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS - Do not

try to light any appliance. - Do not touch any electric

switch; do not use any phone in your building. -

Immediately call your gas supplier from a neighbour’s

phone. Follow the gas supplier’s instructions. - If you

cannot reach your gas supplier, call the fire department.

Lighting Instructions

1. STOP! Read the safety information above on

this label.

2. Set the thermostat to lowest setting.

3. Tu rn off all electrical power to the appliance.

4. Remove louvers.

5. Pu sh in gas control knob slightly and turn

clockwise to “OFF”. Note: knob cannot be

turned from “PILOT” to “OFF” unless knob is

pushed in slightly. Do not force.

6. Wait five minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow “B” in the safety

information on this label. If you don’t smell gas

go on to the next step.

7. Turn knob on gas control counterclockwise to

“PILOT”

C. Use only your hand to push in or turn the gas or control

knob. Never use tools. If the knob will not push in or

turn by hand, don’t try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and replace any part of the control

system and any gas control which has been under water.

8. Pu sh in control knob all the way and hold in.

Immediately push in piezo ignition button.

Continue to hold the control knob in for about

one minute after the pilot is lit. Release knob

and it will pop back up. Pilot should remain lit.

If it goes out, repeat steps five through eight. –

If knob does not pop up when released, stop and

immediately call your service technician or gas

supplier. – If the pilot will not stay lit after

several tries, turn the gas control knob to “OFF”

and call your service technician or gas supplier.

9. Tu rn gas control knob counterclockwise to

“ON.”

10. Replace louvers panel.

11. Turn on all electrical power to the appliance.

12. Set the thermostat to desired setting.

To Turn Off Gas to the Appliance

1. Set the thermostat to lowest setting.

2. Tu rn off all electrical power to the appliance if

service is to be performed.

3. Remove louvers.

SIT NOVA 820

Gas Valve

4. Pu sh in gas control knob slightly and turn

clockwise to “OFF”. Do not force.

5. Replace louvers.

11

Page 12

Thermostat Installation (not allowed in US installations)

The burner control switch is located in the centre of the control department opening. For your convenience, the unit can

also be operated by a thermostat or a wall switch control. Electronic are available from any authorized CFHMfg dealer.

Please note, bedroom installations require the use of a wall thermostat. Mount the thermostat or switch in the desired

location and run “two conductor thermostat wires” to the heater’s lower right hand corner, close to the gas supply line.

For maintenance, proper re-assembly and resealing of the venting system is required.

The appliance should be inspected before use and at least annually by a professional service

person.

More frequent cleaning may be required due to excessive lint from carpet bedding material etc. It is imperative

that control compartment, covers of the appliance to be kept clean.

The appliance and its individual shut-off valve must be disconnected from the gas supply piping system during any pressure

testing of the system at test pressures in excess of ½ psig (3.4kPa). The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psig (3.5kPa). Failure to do so will damage the appliance’s gas valve. Such damage is not

covered by the manufacturer’s warranty.

When testing for leaks:

Make sure that the appliance is turned off.

Open the manual shut-off valve.

Test for leaks by applying a liquid detergent or soap solution to all ball joints. Bubbles forming indicate a gas leak.

Correct any leak detected immediately.

Never use an open flame to check for leaks.

The pressure test point locations are built in to the regulator that controls the burner manifold pressure. The correct pressure

range is shown in the table in the specification section of this manual. The pressure check should be made with the burner lit.

See lighting instruction section for full operating details.

Note: The wall switch MUST be rated for electronic

Minimize splicing

in all wiring and solder all unavoidable splices.

Thermostat Wire Information

AWG mm ft. m

22 0.6 10 3.0

20 0.8 25 7.6

18 1.0 40 12.2

16 1.3 64 19.5

1.6 100 30.5 14

wall switch installation

Pressure testing the supply line for leaks

12

Page 13

MB0-36 Outdoor Gas Log Set

5

6

1

3

2

4

Log set up

Place the largest log on the log support

shelf located on the rear panel above the

air inlet. A small tab folded up from the

shelf is provided to secure to log in

position. Push the logs down onto the shelf

so that the tab forces into the logs. Use

sufficient force only to push the tab into the

log material. The log’s material is fragile

and excessive force will seriously damage

the log and would need to

be replaced

13

Page 14

Logs #2 and #3 join together at the tops so that the pin inserts into the

corresponding hole as shown in the insert.. Support the lower end of

Place log #4 onto the logs set in the previous step. Use the Pin and

hole provided to secure it as with the other logs

14

Page 15

The Next and final steps are to place the small

log pieces #4 and #5 as shown then the three

rocks shown in the illustration below.

NOTE:

• It is important that while placing the logs and

stones they must not directly cover any of the

burner ports

• If the outdoor installation will be subjected to

much greater than normal wind conditions the

small logs and stones maybe secured to the

burner with a high heat rated adhesive to

prevent movement.

15

Page 16

Flame Quality Adjustment

e

WARNING: Incorrect adjustment of flame can lead to improper combustio n which can be a safety hazard.

Flame Types Adjustment

1. Blue at the base with

2. All blue with little or no

3. Lazy yellow with little or

Pilot Check: The MBO-36 utilizes a standing pilot which remains on at all times. Pilot assembly is

covered almost entirely by the wind shield and maybe difficult to see. The visible part of the flame tips

should always be blue in colour. If the flame characteristics are in doubt a qualified technician or gas

installer can remove the wind shield and make any adjustments if required.

active light orange.

Medium height (ideal)

orange. Short height (too

much air)

no blue. Long stringy

flame (no air) May result

in sooty deposits on glass

e

Non

Close damper

Open d

amper

Pilot Flame

Thermopile

Therm o c oupl

Ignit er Electrode

16

Page 17

BURNER COMPONENTS

Pilot Assy. (NG) DC006NG

MBO36 Valve Tray MBO36 Gas Tray

Valve tray Gasket GK01

CFH Electronic Pilot Assembly DC006E

Main Burner Orifice (Natural Gas) MBO36NG

Replacement Log Set LSMBO36

NON-COMBUSTABILE COMPONENTS

Top Panel (placed on top edge of Cleanface Surround) 40”x4” FB006

Back Panel (placed on the back of the appliance) 24”x16” FB007

Cleanface/Firebox panel 37”x4” FB008

Replacement Parts List

17

Page 18

Final Checks

Installer: Before leaving the appliance with the customer, you

must check the operation of the appliance.

*Check correct rating by clocking the appliance at 15 minutes.

(See label)

*Check flame description as seen on page 22. Adjust primary air if

required.

*Take time to go through the unit with the customer.

Note: When first fired, the unit will produce an odour. This is

normal and is part of the paint curing process. It is recommended

that you open a few windows to ventilate the room. This will be

noticeable for at least 4 hours. During the first hour, smoke

detectors in the house may be set off.

*Following the initial burn-in period, the glass panel may require

cleaning.

Caution: Do not clean the glass when the

appliance is hot!

*When the appliance is fired from cold, the glass may fog up.

This is due to condensation and is normal.

*Make yourself familiar with these instructions before operating the

appliance.

*Check any loose electrical wires that may cause a shock.

*Check all around the appliance for gas leaks. If you smell gas,

follow the instructions on the front cover of this manual.

*Check the pilot light should be visible.

*Check to make sure that venting is secure.

*Check all external parts, such as grills, doors and control covers

to make sure they are attached and fastened properly

Caution: Do not turn the unit off and on again

without a minimum of a 60 second wait.

*The appliance area must be kept clear & free from combustible

materials, gasoline, and other flammable vapors or liquids.

Log set & burner require no maintenance.

.

Cold Weather Operation

When using any gas appliance (LP or NG Fuels) water is a

byproduct of the combustion process. Under normal conditions,

this is expelled into the atmosphere and does not cause any harm.

In extremes of cold weather however, the vapors may condense

and freeze on any exposed surface it comes into contact with.

This can cause a problem by restricting or blocking the vent,

particularly with direct vent wall terminations as the exhaust is only

a few inches away from the outside wall surface. What happens to

the moisture after it leaves the vent cannot be controlled by the

manufacturer. To extend the vent further out from the wall can

sometimes be an advantage. Extending the vent out from the wall

can present other design problems such as ice falling from the

eaves above. It is the home owner’s responsibility to ensure that

there is not an excessive build-up of ice on the termination.

Caution: When operating your appliance

during cold weather, you must frequently

check the exhaust cap for excessive ice buildup.

Operating Your Fire

The operating instructions are also on a chained plate inside the

control access door. For your safety, this appliance is fitted with a

flame supervision device which will shut off the gas supply if for

any reason, the pilot flame goes out. This device incorporates a

fixed probe, which senses the heat from the pilot flame. If the

probe is cool, the device will prevent any gas flow unless the

burner control knob is kept pushed in at the “PILOT” position.

When first turned on, the decorative flames will appear

predominantly blue. After approximately 15 minutes, the flames

will turn yellow.

18

Page 19

CFHMfg warrants its products against manufacturing defects to the original purchaser only – i.e., the individual or legal entity

(registered customer) whose name appears on the warranty registrati on card filed with CFHMfg – provided that the purchase was

made through an authorized CFHMfg dealer and is subject to the following terms and limitations:

This factory warranty is nontransferable and may not be extended whatsoever by any of our representatives.

The gas fireplace or fireplace insert must be installed by a licensed, authorized service technician, or contractor. Installation must

be done in accordance with the installation instructions included with the product and all local and national building and fire codes.

This limited warranty does not cover damage caused by misuse, lack of maintenance, accident, alterations, abuse, or neglect, and

parts installed from other manufacturers will nullify this warranty.

This limited warranty further does not cover any scratches, dents, corrosion, or discolouring caused by excessive heat, abrasive

and chemical cleaners, nor breakage of logs and embers, nor any venting components used in the installation of the fireplace.

CFHMfg warrants its steel burners against defects in workmanship and material for life, subject to the following conditions: During

the first 10 years, CFHMfg will replace or repair the defective parts at our option free of charge. From 10 years to life, CFHMfg will

provide replacement burners at 50% of the current retail price.

In the first year only, this warranty extends to the repair or replacement of warranted parts which are defective in material or

workmanship provided that the product has been operated in accordance with the operation instructions and und er normal

conditions.

After the first year, with respect to the Luxor Limited Lifetime Warranty, CFHMfg may, at its discretion, fully discharge all obligations

with respect to this warranty by refunding to the original warranted purchaser the wholesale price of any warranted but defective

part(s).

After the first year, CFHMfg

of a warranted part, and such expenses are not covered by this warranty.

Notwithstanding any provisions contained in this Luxor Limited Lifetim e W arranty, CFHMfg’s responsibility under this warranty is

defined as above and it shall not in any event extended to any incidental, consequential, or indirect damages.

This warranty defines the obligation and liability of CFHMfg with respect to the Luxor gas appliance and any other warranties

expressed or implied with respect to this product, its components, or accessories are excluded.

CFHMfg neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale of this

product. CFHMfg will not be responsible for: over-firing, downdrafts, spillage caused by environmental conditions such as rooftops,

buildings, nearby trees, hills, mountains, inadequate vents, or ventilation, excessive venting configurations, insufficient makeup air,

or negative air pressure which may or may not be caused by mechanical systems such as exhaust fans, furnaces, clothes dryers,

etc.

Any damages to fireplace, combustion chamber, or other components due to water, weather, longs periods of dampness,

condensation, chemicals, or cleaners, will not be the responsibility of CFHMfg.

The bill of sale or copy will be required together with a serial number and a model number when makin g a ny warranty claims from

your authorized dealer. The warranty registration card MUST be returned within fourteen days of purch ase to register the warranty.

CFHMfg reserves the right to have its representative inspect any product or part thereof prior to honouring any warranty claim.

Conditions and Limitations of Warranty

will not be responsible for installation, labour, or any other costs or expenses related to the

reinstallation

19

Loading...

Loading...