Luxaire TM9T Technical Manual

A

444561-LTG-H-1016

DESCRIPTION

These compact units employ induced combustion, reliable hot

surface ignition and high heat transfer aluminized tubular heat

exchangers. The units are factory shipped for installation in

upflow or horizontal applications and may be converted for

downflow applications.

These furnaces are designed for residential installation in a

basement, closet, alcove, attic, recreation room or garage and

TECHNICAL GUIDE

96% AFUE TWO STAGE RESIDENTIAL

GAS FURNACES MULTI-POSITION

MODELS: TM9T

NATURAL GAS

60 - 120 MBH INPUT

are also ideal for commercial applications. All units are factory

assembled, wired and tested to assure safe dependable and

economical installation and operation.

These units are Category IV, National Fuel Gas Code and may

be vented either through side wall or roof applications using

approved plastic combustion air and vent piping. Approved

plastic combustion air and vent piping include Selkirk Polyflue,

Duravent Polypro, & Centrotherm Innoflue polypropylene venting systems.

FEATURES

• Two stage heating operation includes two stage gas valve,

two stage inducer operation and 4 speed, direct drive PSC

motor blower operation. Adjustable delay timer allows two

stage operation with a single stage thermostat.

• Easily applied in upflow, horizontal left or right, or downflow

installation with minimal conversion necessary.

• Compact, easy to install, ideal height 33" tall cabinet.

• Blower-off delay for cooling SEER improvement.

• Easy access to controls to connect power/control wiring.

• Built-in, high level self diagnostics with fault code display.

• Low unit amp requirement for easy replacement application.

• All models are convertible to use propane (LP) gas.

• Electronic Hot Surface Ignition saves fuel cost with

increased dependability and reliability.

• 100% shut off main gas valve for extra safety.

• 24V, 40 VA control transformer and blower relay supplied

for add-on cooling.

• Hi-tech tubular aluminized steel primary heat exchanger

with stainless steel tube/aluminum fin secondary heat

exchanger for outstanding efficiency.

• Solid removable bottom panel allows easy conversion.

• Airflow leakage less than 1% of nominal airflow at duct

formance testing

• No knockouts to deal with, making installation easier.

Due to continuous product improvement, specifications

are subject to change without notice.

Visit us on the web at

www.upgnet.com and www.luxaire.com

dditional rating information can be found at

www.ahridirectory.org

WARRANTY SUMMARY

A 20-year limited warranty on heat exchangers in residential

applications.

A 10-year warranty on the heat exchanger in commercial

applications.

Standard 5-year limited Parts warranty.

Extended lifetime heat exchanger and 10-year limited

parts warranty when product is registered online within

90 days of purchase for replacement or closing for new

home construction.

See Limited Warranty certificate in Users Information Manual for details.

• Movable duct connector flanges for application flexibility.

• Quiet inducer operation.

• Inducer rotates for easy conversion of venting options.

• Fully supported blower assembly for easy access and

removal of blower.

• External air filters used for maximum flexibility in meeting

customers IAQ needs.

• Insulated blower compartment for thermal and acoustic

performance.

• 1/4 turn knobs provided for easy independent door

removal.

• Internal condensate trap design (patent pending) provides

condensate management options and is self priming to

prevent nuisance problems.

• Protection included from air intake, exhaust vent or condensate blockage.

• Venting applications maybe installed as either 2 pipe

sealed combustion or single pipe vent using indoor combustion air.

conditions.

per-

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

444561-LTG-H-1016

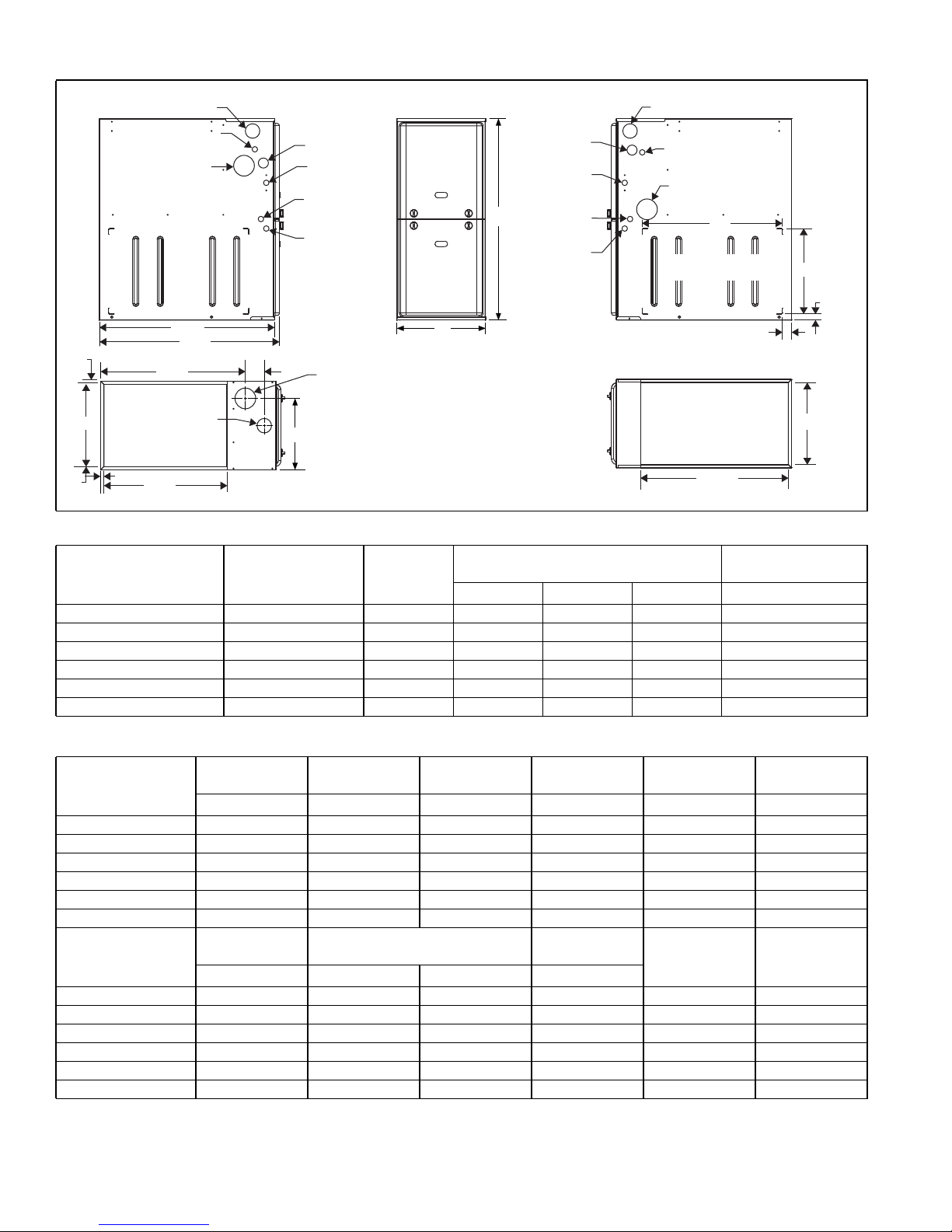

LEFT SIDE

Combustion Air Inlet

Condensate Drain

(Downflow)

Vent Outlet

28.5”

29.5”

.56”

.56”

B

.56”

23.8”

Combustion

Air Inlet

20”

SUPPLY END

Cabinet & Duct Dimensions

FRONT

Gas Pipe

Entry

Electrical

Entry

Condensate

Drain

Thermostat

Wiring

A

3”

Vent

Outlet

C

33

Gas Pipe

Entry

Electrical

Entry

Condensate

Drain

Thermostat

Wiring

RIGHT SIDE

Combustion Air Inlet

Condensate Drain

(Downflow)

Vent Outlet

23”

Optional Return Air

Cutout (Either side)

24.25”

14”

1”

1.5”

B

RETURN END

BTUH (kW)

Input

Nominal

CFM (m

3

/min)

Cabinet

Size

Cabinet Dimensions (Inches)

A B C Lbs

Approximate

Operating Weights

TM9T060B12MP11 1200 B 17 1/2 16 3/8 13 1/4 122

TM9T080B12MP11 1200 B 17 1/2 16 3/8 14 3/4 126

TM9T080C16MP11 1600 C 21 19 7/8 16 1/2 136

TM9T100C16MP11 1600 C 21 19 7/8 18 1/4 142

TM9T100C20MP11 2000 C 21 19 7/8 18 1/4 145

TM9T120D20MP11 2000 D 24 1/2 23 3/8 21 3/4 156

Ratings & Physical / Electrical Data

Input

Model

High/Low

MBH MBH Amps % °F °F

TM9T060B12MP11 60/39 58/37 10 96 35 - 65 35 - 65

TM9T080B12MP11 80/52 77/50 10 96 45 - 75 20 - 50

TM9T080C16MP11 80/52 77/50 11.5 96 45 - 75 25 - 55

TM9T100C16MP11 100/65 96/62 11.5 96 35 - 65 35 - 65

TM9T100C20MP11 100/65 96/62 17 96 45 - 75 20 - 50

TM9T120D20MP11 120/78 115/75 17 96 45 - 75 35 - 65

Max. Outlet

Model

Air Temp.

°F HP Amps In.

TM9T060B12MP11 190 0.50 7 11 x 8 15 14

TM9T080B12MP11 190 0.50 7 11 x 8 15 14

TM9T080C16MP11 190 0.75 8.8 11 x 10 15 14

TM9T100C16MP11 190 0.75 8.8 11 x 10 15 14

TM9T100C20MP11 190 1.00 14.5 11 x 11 20 12

TM9T120D20MP11 190 1.00 14.5 11 x 11 20 12

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

Output

High/Low

Blower

Total

Unit

AFUE

Blower

Size

High Fire

Air Temp. Rise

Max.

Over-current

Protect

Low Fire

Air Temp. Rise

Min. Wire Size

(awg) @ 75 ft.

One Way

2 Johnson Controls Unitary Products

Loading...

Loading...