Luxaire PAC060, PAC036, PAC024, PAC042, PHP024 Technical Manual

...

246836-LTG-E-0107

TECHNICAL GUIDE

CLIMASURE™ SERIES

R-22, 13 SEER

60 Hertz

Description

These Luxaire® Climasure™ packaged cooling/heating air

conditioners are designed for outdoor installation. Only utility

and duct connections are required at the point of installation.

Field-installed electric heater accessories are available to

provide electric heat, if required. (Single phase only)

Tested in accordance with:

ISO 9001

Certified Quality

Management System

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

246836-LTG-E-0107

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Capacity Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Airflow Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Sound Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

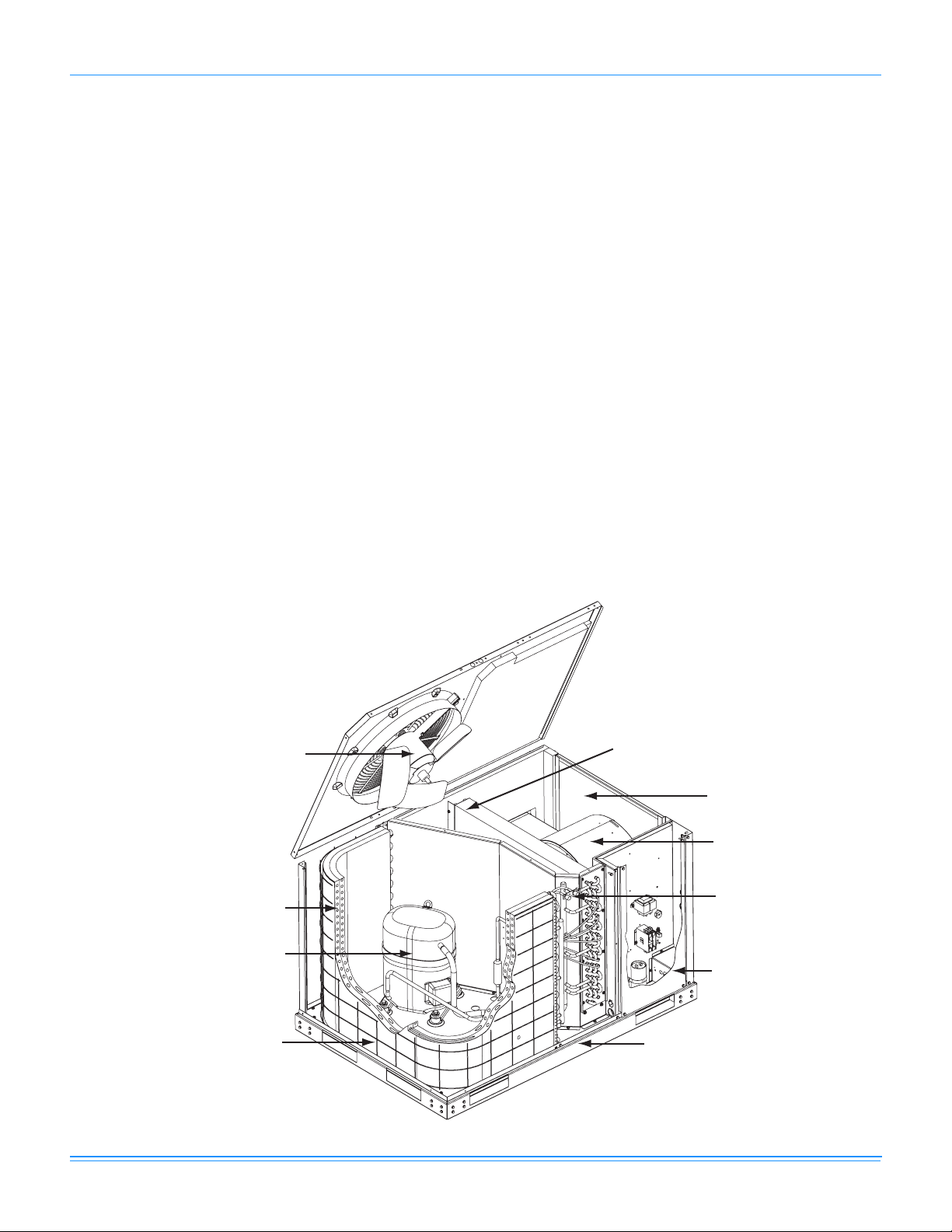

Component Location

Cooling Unit and Heat Pump

'LUHFW'ULYH

&RQGHQVHU)DQ0RWRU

+LJK(IILFLHQF\(QKDQFHG

&RSSHU7XEH$OXPLQXP)LQ

2XWGRRU&RLO

+LJK(IILFLHQF\

&RPSUHVVRU5LJLGO\

0RXQWHG

+LJK(IILFLHQF\(QKDQFHG

&RSSHU7XEH$OXPLQXP)LQ

InGRRU&RLO

%ORZHU6HUYLFH

$FFHVV3DQHO

;'LUHFW'ULYH

%ORZHU0RWRU

5HIULJHUDQW

&RQQHFWLRQV

&RQWURO%R[6HUYLFH

$FFHVV3DQHO

'HFRUDWLYH3URWHFWLYH

&RLO*XDUG

+HDY\*DXJH

%DVH5DLOV

2 Unitary Products Group

246836-LTG-E-0107

Nomenclature

Cooling Unit

PAC = Air Conditioner, Single Package, R-22

Heat Pump

3+3 +HDW3XPS6LQJOH3DFNDJH5

Product Category

Nominal Cooling Capacity (MBH)

024 = 2.0 Ton

030 = 2.5 Ton

036 = 3.0 Ton

3URGXFW&DWHJRU\

1RPLQDO&RROLQJ&DSDFLW\0%+

7RQ

7RQ

7RQ

PAC 036

042 = 3.5 Ton

048 = 4.0 Ton

060 = 5.0 Ton

Cabinet Layout

H = Horizontal

3+3

7RQ

7RQ

7RQ

&DELQHW/D\RXW

+ +RUL]RQWDO

Unit Efficiency

13 = 13 SEER

13

2 1 AH

1 = First Generation

2 = Second Generation

Voltage Code

2 = 208/230-1-60

3 = 208/230-3-60

4 = 460-3-60

8 = 380/415-3-50

$+

)LUVW*HQHUDWLRQ

6HFRQG*HQHUDWLRQ

9ROWDJH&RGH

Product Style

A = Style A

Product Generation

3URGXFW6W\OH

$ 6W\OH$

3URGXFW*HQHUDWLRQ

8QLW(IILFLHQF\

6((5

Features and Benefits

state of the art computerized process system are used to

insure product quality. Refrigerant charge and component

Standard Features

• Operating Efficiency - All cooling units provide a SEER

of 13.0.

All heat pump units provide operating efficiency of 13.0

SEER and 7.7 HSPF. All efficiencies meet legislated

minimum levels.

• Lower Installation Cost - Installation time and costs are

reduced by easy power and control wiring connections.

The small base dimension means less space is required

on the ground or roof, plus, the installer can fit this unit

between the wheel wells of full size pick-up truck. All

models are well under 400 pounds.

All units are completely wired, charged with R-22 and

tested prior to shipment. Unique test stations using a new

part numbers are verified via computers at assembly. Vital

run test statistics such as system pressure, motor

currents, air velocity and temperature, unit vibration, and

gas system safeties are monitored and recorded by the

system to insure unit performance.

Equal size, side supply and return duct connections

allows easy hook-up of ducts to match low crawl spaces

without transition pieces.

• Utility Connections Made Easy - Electric utility

knockouts are provided through the side of the unit. Utility

connections can be made quickly and with a minimum

amount of field labor. A field supplied and field installed

electrical disconnect switch must be installed.

• Condensate Pan - A non-corrosive, long-lasting, watertight pan is positioned below the evaporator coil to collect

Unitary Products Group 3

246836-LTG-E-0107

and drain all condensate. Less collection of stagnate

condensate will build-up. The condensate pan conforms

to ASHRAE 62-89 standards (Ventilation for Acceptable

Indoor Air Quality).

• Condensate Drain - The heavy duty, 3/4 inch NPTI

copper connection is more durable over time. The

connection is rigidly mounted to assure proper fit and leak

tight seal.

• Durable Finish - With a heavy duty cabinet made of prepainted, galvanized steel the neutral color blends into

surrounding areas. The pre-paint provides a better paint

to steel bond, which resists corrosion and rust creep,

insures less fading when exposed to sunlight and offers a

more attractive on site appearance.

• Full Perimeter Base Rails - The base rails provide a

solid foundation for the entire unit and protects the unit

during shipment. The rails provide fork lift access from all

sides. On applications where the unit is placed on a pad,

the base will keep the unit off the pad to deter corrosion.

• More Attractive Appearance - A single piece Water

Shed top cover containing a top discharge condenser fan

arrangement requires less square footage on installation

and provides a wider variety of installations. The one

piece design adds greater water integrity.

• Top Discharge - The top discharge condenser fan does

not disrupt neighboring areas or dry-out vegetation

surrounding the unit. The warm air from the top mounted

fan is blown up away from the structure and any

landscaping. This allows compact location on multi-unit

applications.

• Condenser Coil Guard - A multi-piece totally enclosed,

rigidly mounted condenser coil guard provides protection

from objects after installation and provides protection

during transit.

• Low Operating Sound Level - The upward air flow

carries the normal operating noise up and away from the

living area. The rigid top panel effectively isolates any

motor sound. Isolator mounted compressor and the

rippled fins of the condenser coil muffle the normal fan

motor and compressor operating sounds.

• Fan System - All models operate over a wide range of

design conditions with a constant torque fan motor. These

units have 5 speed taps to provide greater on site flexibility

to match comfort requirements.

• Protected Compressor - The compressor is internally

protected against high pressure and temperature. This is

accomplished by the simultaneous operation of high

pressure relief valve and a temperature sensor which protect

the compressor if undesirable operating conditions occur.

• Pressure Switches - High pressure switches standard in

all heat pump units. When abnormal conditions are

sensed through the pressure switches, the unit will lock

out after 3 tries preventing any further operation until reset

or problem is corrected.

• Exclusive Coil Design - Grooved copper tubes and

enhanced aluminum fin construction improves heat

transfer for maximum efficiency and durability.

• Low Maintenance - Long life, permanently lubricated

condenser and evaporator fan motor bearings need no

annual maintenance adding greater reliability to the unit.

• Secured Service Access Ports - Protected, externally

mounted, re-usable service access ports are provided on

both the high and low lines for ease of evacuating and

charging the system. No final field mounting required.

• Easy Service Access - A large, single panel covers the

electrical controls makes servicing easy. The blower

compartment has a large panel which when removed will

allow the blower fan assembly to slide-out for ease of

maintenance and trouble shooting.

• Replacement Parts - The installer requires no special

training to replace any of the components of these units

and does not need to maintain an inventory of unique

parts.

Field Installed Accessories

• Wall Thermostat - The units are designed to operate with

24-volt electronic and electro-mechanical thermostats.

• Electric Heat Kit - Available in 3 different kW capacities

(5, 10 and 15 kW). (Single phase only)

• Start Assist Kits - Available for all models.

• Outdoor Thermostat - Available for all heat pump models.

Guide Specifications

GENERAL

Units shall be factory-assembled, single packaged, Electric

Cooling units, designed for outdoor mounted installation. Units

shall have minimum SEER ratings of 13.0. Heat pump 7.7 HSPF.

The units shall be factory wired, piped, charged with R-22

refrigerant and factory tested prior to shipment. All unit wiring

shall be color coded.

All units shall be manufactured in a facility certified to ISO 9001

standards, and the cooling performance shall be rated in

accordance with DOE and ARI test procedures. Units shall be

certified to UL 1995/CAN/CSA C22.2 No. 236 standards.

UNIT CABINET

1. Unit cabinet shall be constructed of G90, pre-paint textured

steel, certified at 500 hours salt spray test per ASTMB117

standards.

2. The unit top shall be a single piece "Water Shed" design.

3. Unit shall have a rigidly mounted condenser coil guard to

provide protection from objects and personnel after

installation.

4. Indoor blower section shall be insulated with up to 3/4"

thick insulation.

5. Cabinet panels shall be "large" size, easily removable for

servicing and maintenance.

4 Unitary Products Group

246836-LTG-E-0107

6. Unit shall be built on a formed, "Super-Structure" design

base pan, with embossments at critical points to add

strength, rigidity and aid in minimizing sound.

7. Full perimeter base rails shall be provided to assure

reliable transit of equipment.

8. Condensate pan shall be internally sloped and conform to

ASHARE 62-89 self-draining standards, with 3/4" NPTI

copper, ridged mount connection.

INDOOR (EVAPORATOR) FAN ASSEMBLY

1. Fan shall be direct drive, constant torque design with 5

available speed selections.

2. Fan wheel shall be double-inlet type with forward-curved

blades, dynamically balanced to operate smoothly

throughout the entire range of operation. Airflow design

shall be constant air volume.

3. Bearings shall be sealed and permanently lubricated for

longer life and no maintenance.

4. Fan assembly shall be accessible via removable inlet ring.

OUTDOOR (CONDENSER) FAN ASSEMBLY

1. The outdoor fan shall be of the direct-driven propeller type,

discharge air vertically, have aluminum blades riveted to

corrosion resistant steel spider bracket and shall be

statically balanced for smooth operation.

2. The outdoor fan motor shall be totally enclosed with

permanently lubricated bearings and internally protected

against overload conditions.

REFRIGERANT COMPONENTS

Compressors:

a. Shall be fully hermetic reciprocating, rotary or scroll type,

direct drive, internally protected with internal highpressure relief and over temperature protection. The

hermetic motor shall be suction gas cooled and have a

voltage range of + or - 10% of the unit nameplate

voltage.

b. Shall have internal isolation and sound muffling to

minimize vibration and noise, and be externally isolated

on a dedicated, independent mounting.

Coils:

a. Evaporator and condenser coils shall have aluminum

plate fins mechanically bonded to seamless internallyenhanced copper tubes with all joints brazed.

b. Evaporator and Condenser coils shall be of the direct

expansion, draw-thru design.

Refrigerant Circuit and Refrigerant Safety Components shall

include:

a. Independent fixed-orifice or TXV expansion devices.

b. Filter/strainer to eliminate any foreign matter.

c. Accessible service gage connections on both suction

and discharge lines to charge, evacuate, and measure

refrigerant pressure during any necessary servicing or

troubleshooting, without losing charge and without

disrupting condenser or evaporator air flow.

Unit Controls:

a. Controls shall be mounted in a large control box, allowing

easy access for trouble shooting and maintenance

without affecting the normal system operation pressures.

b. Unit shall have large, easily removable panels, covering

electrical controls and compressor, allowing easy access

for any necessary maintenance or servicing.

ELECTRIC HEATING SECTION

1. An electric heating section, with nickel chromium elements,

shall be provided in a range of 5 thru 15 KW, single phase

only.

2. The heating section shall have a primary limit control(s)

and automatic reset, to prevent the heating element

system from operating at an excessive temperature.

3. The heating section assembly shall slide out of the unit for

easy maintenance and service.

UNIT OPERATING CHARACTERISITCS

1. Unit shall be capable of starting and running at 125° F

outdoor temperature, exceeding maximum load criteria of

ARI Standard 210/240.

2. The compressor, with standard controls, shall be capable

of cooling operation down to 45° F outdoor temperature.

Accessory low ambient kit shall be available for operation

to 0° F.

ELECTRICAL REQUIREMENTS

All unit power wiring shall enter unit cabinet at a single factory

provided location.

Separate openings shall be provided for the control wiring.

Unitary Products Group 5

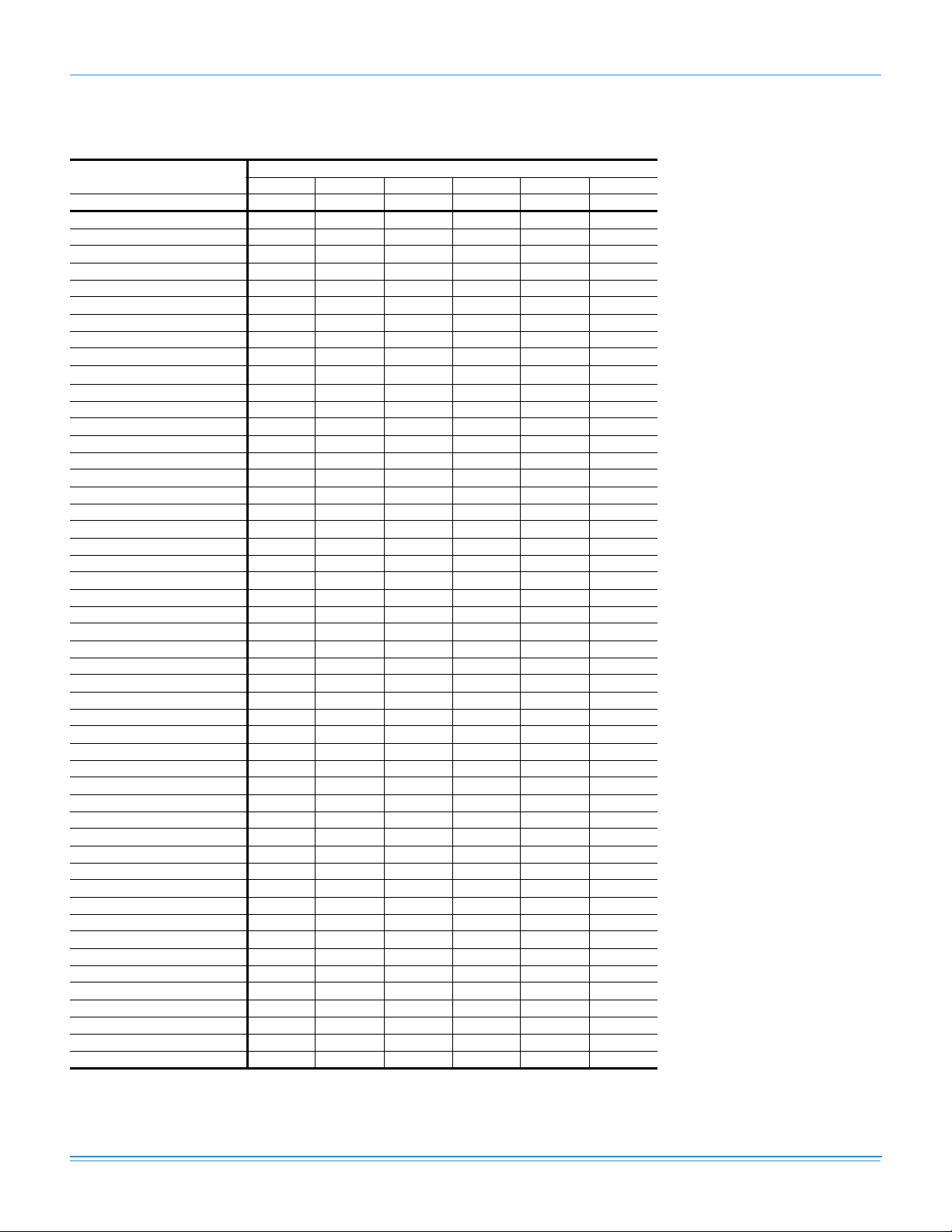

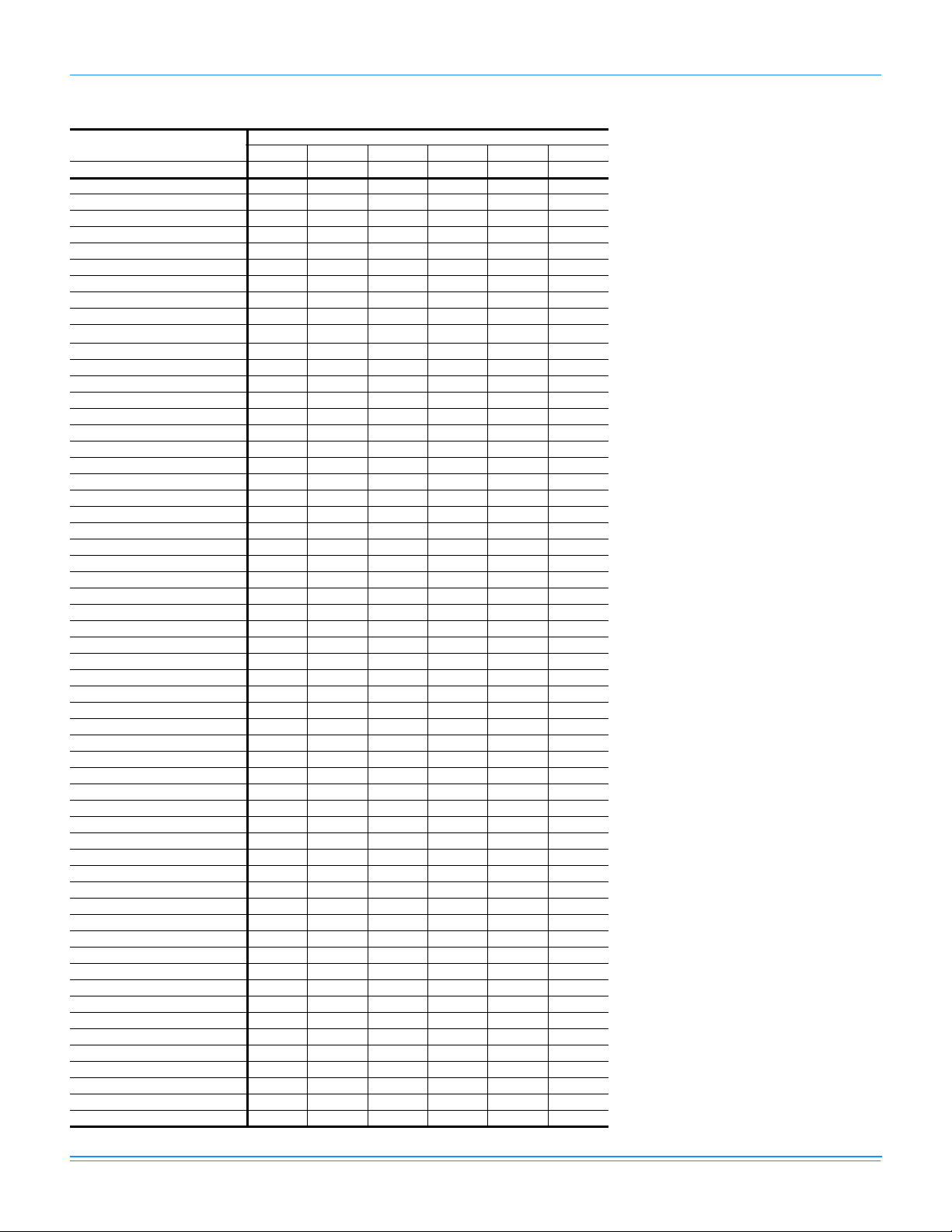

Physical Data

PAC024-060 Physical Data

Component

Nominal Tonnage 2.0 2.5 3.0 3.5 4.0 5.0

ARI COOLING PERFORMANCE

Gross Capacity @ ARI A point (Btu) 22900 28800 36100 42100 47100 58000

ARI net capacity (Btu) 22500 28000 35100 41000 46200 56400

EER 11.5 11.4 11.3 11.4 11.65 11.4

SEER 13 13 13 13 13 13

Nominal CFM 800 1000 1100 1200 1400 1650

System power (KW) 1.96 2.6 3.10 3.60 3.97 4.94

Refrigerant type R-22 R-22 R-22 R-22 R-22 R-22

Refrigerant charge (lb-oz)

System 1

DIMENSIONS (inches)

Length 45-1/4 45-1/4 47-1/4 47-1/4 57-9/16 57-9/16

Width 30-13/16 30-13/16 32-13/16 32-13/16 32-13/16 32-13/16

Height 26-11/16 26-11/16 30-11/16 30-11/16 34-11/16 34-11/16

OPERATING WT. (lbs.) 259 270 345 349 375 385

COMPRESSORS

Type Recip Rotary Recip Recip Recip Scroll

Quantity 111111

CONDENSER COIL DATA

Face area (Sq. Ft.) 9.2 9.2 11.3 11.3 16.0 16.0

Rows 222222

Fins per inch 15 15 15 15 15 15

Tube diameter (in.) 3/8 3/8 3/8 3/8 3/8 3/8

Circuitry Type Intertwined Intertwined Intertwined Intertwined Intertwined Intertwined

EVAPORATOR COIL DATA

Face area (Sq. Ft.) 3.61 3.61 4.67 4.67 5.44 5.44

Rows 334434

Fins per inch 13 13 13 13 13 13

Tube diameter 3/8 3/8 3/8 3/8 3/8 3/8

Circuitry Type Intertwined Intertwined Intertwined Intertwined Intertwined Intertwined

Refrigerant control Orifice Orifice Orifice Orifice Orifice Orifice

CONDENSER FAN DATA

Quantity 111111

Fan diameter (Inch) 18 18 20 20 22 22

Type Prop Prop Prop Prop Prop Prop

Drive type Direct Direct Direct Direct Direct Direct

No. speeds 1 1 1 1 1 1

Number of motors 1 1 1 1 1 1

Motor HP each 1/4 1/4 1/4 1/4 1/3 1/3

RPM 850 850 1100 1100 1100 1100

Nominal total CFM 2200 2200 2800 2800 3200 3200

DIRECT DRIVE EVAP FAN DATA

Quantity 111111

Fan Size (Inch) 10 x 7 10 x 7 10 x 7 10 x 7 11 x 10 11 x 10

Type Centrifugal Centrifugal Centrifugal Centrifugal Centrifugal Centrifugal

Motor HP each 1/2 1/2 1/2 1/2 1 1

RPM 1100 1100 1100 1100 1100 1100

Frame size 48 48 48 48 48 48

FILTERS

Quantity - Size ------

PAC024 PAC030 PAC036 PAC042 PAC048 PAC060

5-5 6-6 7-0 7-12 8-0 10-8

Models

246836-LTG-E-0107

6 Unitary Products Group

246836-LTG-E-0107

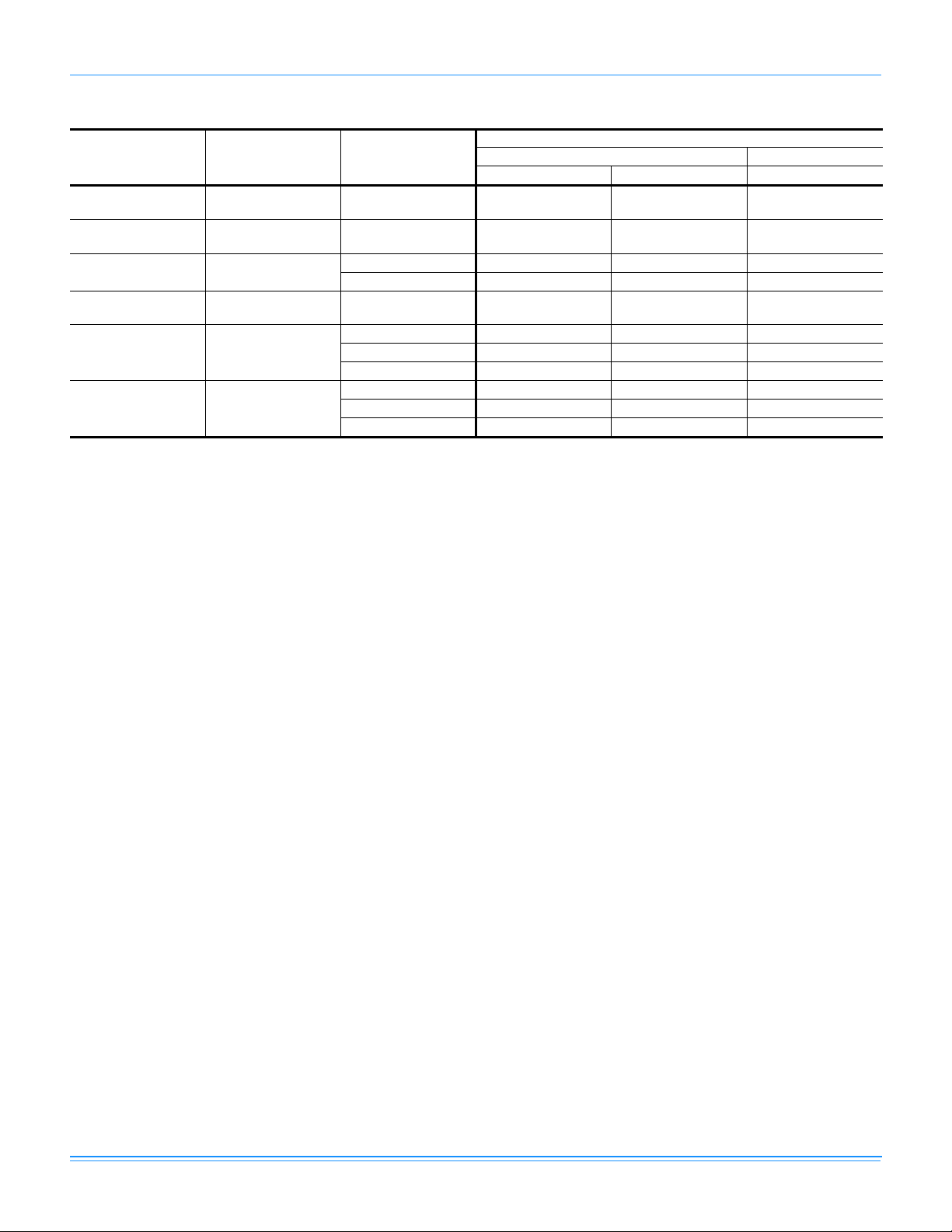

PHP024-060 Physical Data

Component

Nominal Tonnage 2.0 2.5 3.0 3.5 4.0 5.0

ARI COOLING PERFORMANCE

Gross Capacity @ ARI A point (Btu) 25160 29700 37000 45800 50600 55700

ARI net capacity (Btu) 24660 29000 36000 44700 49300 53600

EER 11.95 11.5 11.3 11.9 12.2 11.15

SEER 13 13 13 13 13 13

Nominal CFM 900 1000 1150 1400 1500 1750

System power (KW) 2060 2500 3200 3740 4030 4820

Refrigerant type R-22 R-22 R-22 R-22 R-22 R-22

Refrigerant charge (lb-oz)

System 1

ARI HEATING PERFORMANCE

47°F Capacity Rating (MBH) 22400 25900 32100 39600 43900 50000

System Power KW/COP 1760/3.70 2100/3.60 2780/3.40 3420/3. 40 3750/3.45 4580/3.25

17°F Capacity Rating (MBH) 10500 12900 17300 19900 23600 29000

System Power KW/COP 1490/2.10 1770/2.15 2410/2.10 2835/2.05 3400/2.05 3980/2.10

HSPF BTU/Watts-hr 7.7 7.7 7.7 7.7 7.7 7.7

DIMENSIONS (inches)

Length 47-1/4 47-1/4 47-1/4 57-9/16 57-9/16 57-9/16

Width 32-13/16 32-13/16 32-13/16 32-13/16 32-13/16 32-13/16

Height 30-11/16 30-11/16 30-11/16 34-11/16 34-11/16 34-11/16

OPERATING WT. (lbs.) 342 347 350 372 382 390

COMPRESSORS

Type Recip Recip Recip Recip Scroll Scroll

Quantity 111111

CONDENSER COIL DATA

Face area (Sq. Ft.) 11.28 11.28 11.28 16 16 16

Rows 222222

Fins per inch 15 15 15 15 15 15

Tube diameter (in.) 3/8 3/8 3/8 3/8 3/8 3/8

Circuitry Type Intertwined Intertwined Intertwined Intertwined Intertwined Intertwined

Refrigerant Control TXV TXV TXV TXV TXV TXV

EVAPORATOR COIL DATA

Face area (Sq. Ft.) 4.67 4.67 4.67 5.44 5.44 5.44

Rows 444444

Fins per inch 13 13 13 13 13 13

Tube diameter 3/8 3/8 3/8 3/8 3/8 3/8

Circuitry Type Intertwined Intertwined Intertwined Intertwined Intertwined Intertwined

Refrigerant control Orifice Orifice Orifice Orifice Orifice Orifice

CONDENSER FAN DATA

Quantity 111111

Fan diameter (Inch) 20 20 20 22 22 22

Type Prop Prop Prop Prop Prop Prop

Drive type Direct Direct Direct Direct Direct Direct

No. speeds 111111

Number of motors 111111

Motor HP each 1/4 1/4 1/4 1/3 1/3 1/3

RPM 850 850 1100 1100 1100 1100

Nominal total CFM 2500 2500 2850 3200 3200 3200

DIRECT DRIVE EVAP FAN DATA

Quantity 111111

Fan diameter (Inch) 10 x 7 10 x 7 10 x 7 11 x 10 11 x 10 11 x 10

Type Centrifugal Centrifugal Centrifugal Centrifugal Centrifugal C entrifugal

Drive type Direct Direct Direct Direct Direct Direct

No. speeds 555555

Number of motors 111111

Motor HP each 1/2 1/2 1/2 1 1 1

RPM 1100 1100 1100 1100 1100 1100

Frame size 48 48 48 48 48 48

PHP024 PHP030 PHP036 PHP042 PHP048 PHP060

10-4 10-8 10-8 11-8 11-8 11-8

Models

Unitary Products Group 7

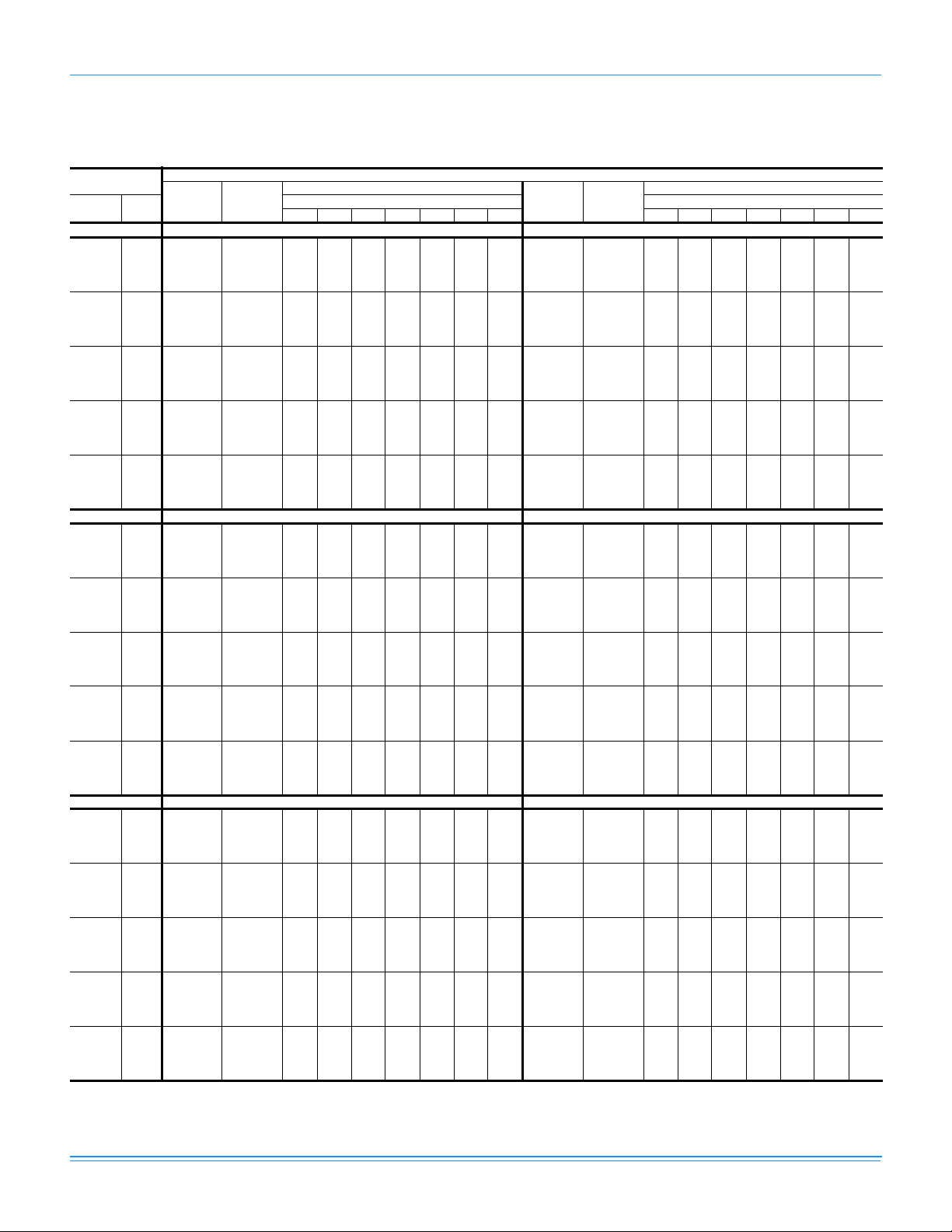

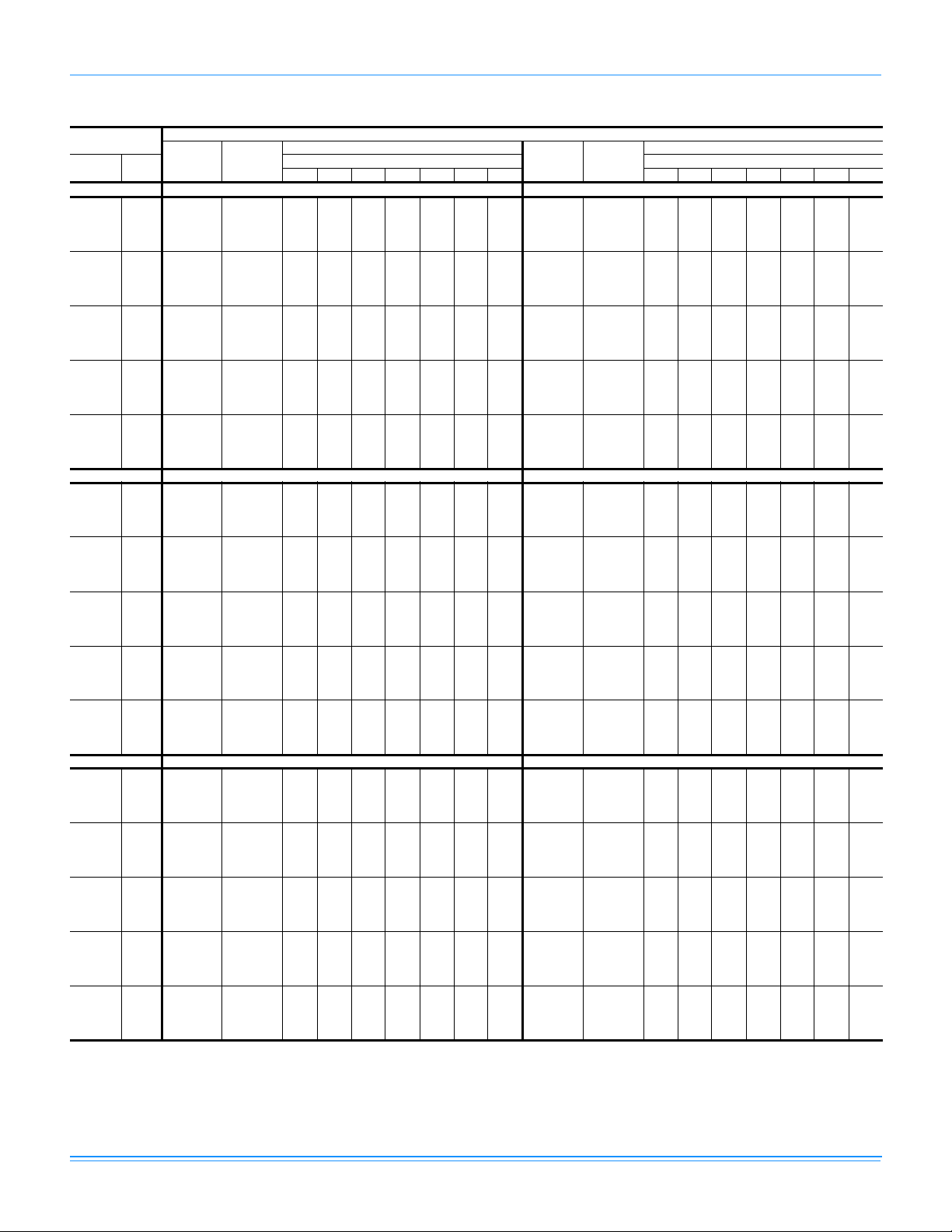

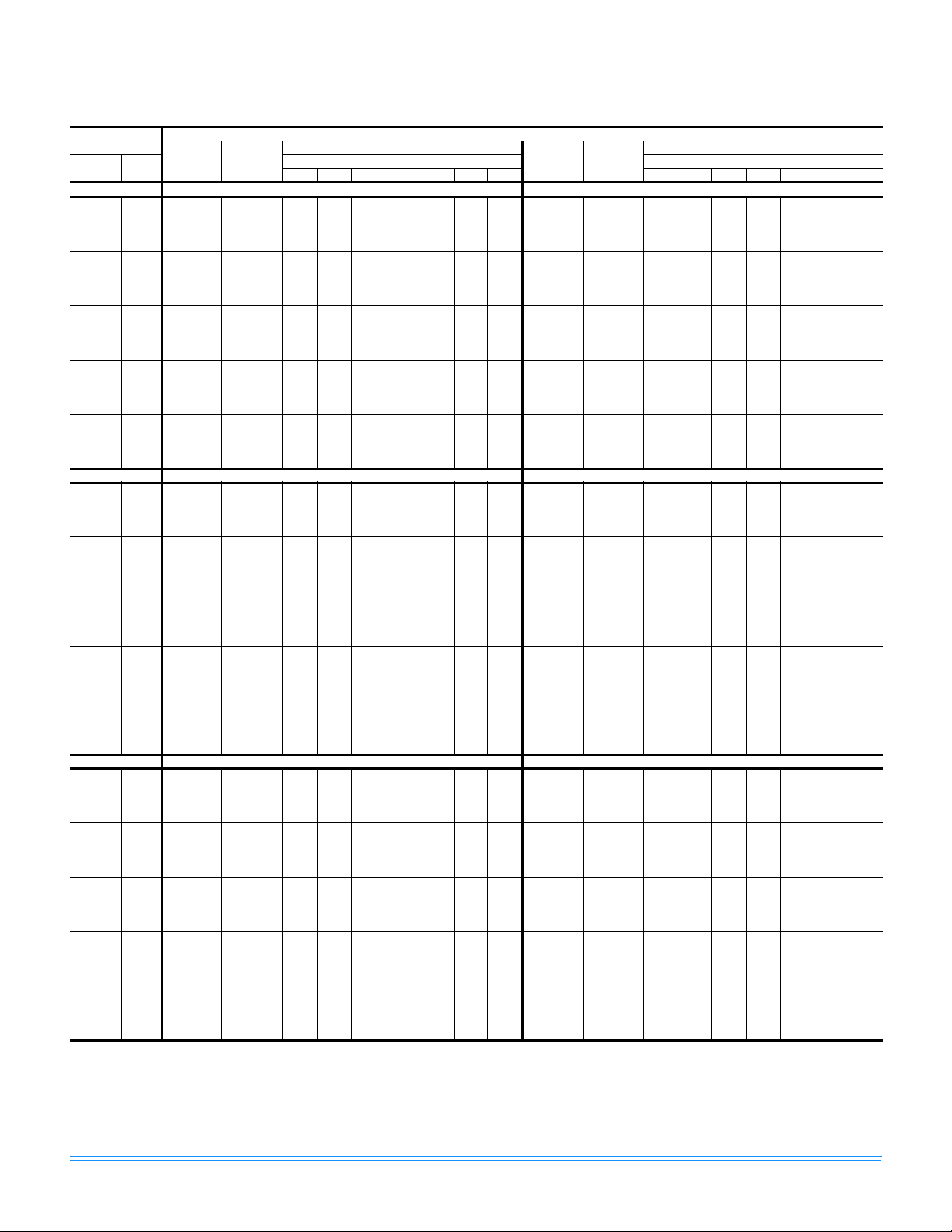

PAC and PHP Unit Limitations

246836-LTG-E-0107

Size

(Tons)

024

(2.0)

030

(2.5)

036

(3.0)

042

(3.5)

048

(4.0)

060

(5.0)

Model Unit Voltage

PAC

PHP

PAC

PHP

PAC

PHP

PAC

PHP

PAC

PHP

PAC

PHP

208/230-1-60 187 252 125

208/230-1-60 187 252 125

208/230-1-60 187 252 125

208/230-3-60 187 252 125

208/230-1-60 187 252 125

208/230-1-60 187 252 125

208/230-3-60 187 252 125

460-3-60 432 504 125

208/230-1-60 187 252 125

208/230-3-60 187 252 125

460-3-60 432 504 125

Unit Limitations

Applied Voltage Outdoor DB Temp

Min Max Max (°F)

8 Unitary Products Group

246836-LTG-E-0107

Capacity Performance

PAC024-060 Cooling Capacities

PAC024 (2.0 Ton)

Air on

Evaporator Coil

CFM

1000

1000

1000

WB

(°F)

600

700

800

900

600

700

800

900

600

700

800

900

1. These capacities are gross ratings. For net capacity, deduct air blower motor, MBh = 3.415 x kW. Refer to the appropriate Blower Performance Table for the

kW of the supply air blower motor.

2. These ratings include the condensate fan motors (total .25 kW) and th e compressor motors but not the supply air blower motor.

Total

Capacity

(MBh)

72 28.6 1.4 16.5 14.8 13.1 11.4 9.7 - - 26.6 1.6 15.9 14.2 12.5 10.8 9.1 - 67 26.4 1.5 20.0 18.3 16.5 14.8 13.1 11.4 9.7 24.5 1.7 19.3 17.6 15.9 14.2 12.5 10.7 9.0

62 24.5 1.6 24.3 22.2 20.5 18.8 17.1 15.4 13.7 22.8 1.7 22.7 21.0 19.3 17.6 15.9 14.2 12.5

57 24.5 1.6 24.3 22.2 20.5 18.8 17.1 15.4 13.7 22.8 1.7 22.7 21.0 19.3 17.6 15.9 14.2 12.5

72 29.4 1.4 18.2 16.2 14.1 12.1 10.1 - - 27.3 1.6 17.6 15.5 13.5 11.5 9.5 - 67 27.2 1.5 21.9 19.9 17.9 15.9 13.8 11.8 9.8 25.2 1.6 21.2 19.2 17.2 15.1 13.1 11.1 9.1

62 25.2 1.6 25.1 24.0 22.2 20.1 18.1 16.1 14.1 23.4 1.7 23.4 22.5 20.9 18.9 16.8 14.8 12.8

57 25.2 1.6 25.1 24.0 22.2 20.1 18.1 16.1 14.1 23.4 1.7 23.4 22.5 20.9 18.9 16.8 14.8 12.8

72 30.2 1.4 19.9 17.5 15.2 12.9 10.5 - - 28.0 1.5 19.2 16.9 14.5 12.2 9.9 - 67 27.9 1.5 23.9 21.5 19.2 16.9 14.5 12.2 9.9 25.8 1.6 23.1 20.8 18.5 16.1 13.8 11.5 9.1

62 25.8 1.6 25.8 25.8 23.8 21.5 19.1 16.8 14.5 24.0 1.7 24.0 24.0 22.5 20.1 17.8 15.5 13.1

57 25.8 1.6 25.8 25.8 23.8 21.5 19.1 16.8 14.5 24.0 1.7 24.0 24.0 22.5 20.1 17.8 15.5 13.1

72 30.8 1.3 21.5 18.9 16.2 13.6 10.9 - - 28.5 1.5 20.8 18.2 15.5 12.9 10.2 - 67 28.4 1.5 26.4 23.1 20.5 17.8 15.2 12.5 9.9 26.3 1.6 24.9 22.4 19.7 17.1 14.4 11.7 9.1

62 26.3 1.5 26.3 26.3 25.3 22.6 20.0 17.3 14.7 24.5 1.7 24.5 24.5 23.7 21.0 18.4 15.7 13.0

57 26.3 1.5 26.3 26.3 25.3 22.6 20.0 17.3 14.7 24.5 1.7 24.5 24.5 23.7 21.0 18.4 15.7 13.0

72 31.3 1.3 23.2 20.2 17.2 14.2 11.3 - - 29.0 1.5 22.5 19.5 16.5 13.5 10.5 - 67 28.9 1.4 28.9 24.7 21.8 18.8 15.8 12.8 9.8 26.7 1.6 26.7 23.9 21.0 18.0 15.0 12.0 9.0

62 26.8 1.5 26.8 26.8 26.8 23.8 20.8 17.8 14.8 24.9 1.6 24.9 24.9 24.9 21.9 18.9 15.9 13.0

57 26.8 1.5 26.8 26.8 26.8 23.8 20.8 17.8 14.8 24.9 1.6 24.9 24.9 24.9 21.9 18.9 15.9 13.0

72 24.6 1.7 15.3 13.6 11.9 10.2 8.5 - - 21.1 1.9 14.5 12.7 11.0 9.3 7.6 - 67 22.5 1.8 18.6 16.9 15.2 13.5 11.8 10.1 8.4 19.3 1.9 17.4 15.9 14.2 12.5 10.8 9.1 7.3

62 21.1 1.8 21.1 19.8 18.1 16.4 14.7 13.0 11.3 18.2 1.9 18.2 17.6 16.5 14.8 13.1 11.4 9.7

57 21.1 1.8 21.1 19.8 18.1 16.4 14.7 13.0 11.3 18.2 1.9 18.2 17.6 16.5 14.8 13.1 11.4 9.7

72 25.2 1.7 16.9 14.9 12.9 10.9 8.8 - - 21.7 1.9 16.0 14.0 12.0 10.0 7.9 - 67 23.1 1.8 20.5 18.5 16.5 14.4 12.4 10.4 8.4 19.8 1.9 18.5 17.2 15.4 13.4 11.4 9.3 7.3

62 21.7 1.8 21.7 21.0 19.6 17.6 15.6 13.5 11.5 18.7 1.9 18.7 18.4 18.0 15.9 13.9 11.9 9.9

57 21.7 1.8 21.7 21.0 19.6 17.6 15.6 13.5 11.5 18.7 1.9 18.7 18.4 18.0 15.9 13.9 11.9 9.9

72 25.8 1.7 18.5 16.2 13.9 11.5 9.2 - - 22.3 1.9 17.6 15.3 12.9 10.6 8.3 - 67 23.7 1.8 22.4 20.0 17.7 15.4 13.0 10.7 8.4 20.4 1.9 19.7 18.5 16.6 14.3 12.0 9.6 7.3

62 22.2 1.8 22.2 22.2 21.1 18.8 16.4 14.1 11.8 19.2 1.9 19.2 19.2 19.4 17.0 14.7 12.4 10.1

57 22.2 1.8 22.2 22.2 21.1 18.8 16.4 14.1 11.8 19.2 1.9 19.2 19.2 19.4 17.0 14.7 12.4 10.0

72 26.3 1.7 20.1 17.5 14.8 12.2 9.5 - - 22.7 1.9 19.1 16.5 13.8 11.2 8.5 - 67 24.1 1.8 23.5 21.6 18.9 16.3 13.6 11.0 8.3 20.7 1.9 20.4 19.4 17.8 15.1 12.5 9.8 7.2

62 22.6 1.8 22.6 22.6 22.1 19.4 16.7 14.1 11.4 19.5 1.9 19.5 19.5 19.6 17.0 14.3 11.7 9.0

57 22.6 1.8 22.6 22.6 22.1 19.4 16.7 14.1 11.4 19.5 1.9 19.5 19.5 19.6 17.0 14.3 11.7 9.0

72 26.8 1.7 21.8 18.8 15.8 12.8 9.8 - - 23.0 1.9 20.5 17.7 14.8 11.8 8.8 - 67 24.6 1.7 24.6 23.2 20.2 17.2 14.2 11.2 8.3 21.1 1.9 21.1 20.4 19.0 16.0 13.0 10.0 7.0

62 23.0 1.8 23.0 23.0 23.0 20.0 17.0 14.1 11.1 19.9 1.9 19.9 19.9 19.9 16.9 13.9 10.9 7.9

57 23.0 1.8 23.0 23.0 23.0 20.0 17.0 14.1 11.1 19.9 1.9 19.9 19.9 19.9 16.9 13.9 10.9 7.9

72 17.7 2.1 13.6 11.9 10.2 8.5 6.7 - - 14.2 2.2 12.7 11.0 9.3 7.6 5.9 - 67 16.1 2.1 16.1 14.9 13.2 11.5 9.7 8.0 6.3 12.9 2.2 12.9 12.9 12.1 10.4 8.7 7.0 5.3

62 15.3 2.0 15.3 15.3 15.0 13.2 11.5 9.8 8.1 12.4 2.2 12.4 12.4 12.4 11.7 9.9 8.2 6.5

57 15.3 2.0 15.3 15.3 15.0 13.2 11.5 9.8 8.1 12.4 2.2 12.4 12.4 12.4 11.7 9.9 8.2 6.5

72 18.2 2.1 15.1 13.1 11.1 9.1 7.0 - - 14.7 2.2 14.2 12.2 10.2 8.2 6.1 - 67 16.5 2.1 16.5 15.9 14.4 12.3 10.3 8.3 6.3 13.3 2.2 13.3 13.3 13.3 11.3 9.3 7.2 5.2

62 15.7 2.1 15.7 15.7 16.3 14.3 12.3 10.2 8.2 12.8 2.2 12.8 12.8 12.8 12.6 10.6 8.6 6.6

57 15.7 2.1 15.7 15.7 16.3 14.3 12.3 10.2 8.2 12.8 2.2 12.8 12.8 12.8 12.6 10.6 8.6 6.6

72 18.7 2.1 16.7 14.3 12.0 9.7 7.3 - - 15.1 2.2 15.1 13.4 11.1 8.7 6.4 - 67 17.0 2.1 17.0 17.0 15.5 13.2 10.9 8.5 6.2 13.6 2.2 13.6 13.6 13.6 12.1 9.8 7.5 5.1

62 16.2 2.1 16.2 16.2 17.7 15.3 13.0 10.7 8.3 13.2 2.2 13.2 13.2 13.2 13.2 11.3 8.9 6.6

57 16.2 2.1 16.2 16.2 17.7 15.3 13.0 10.7 8.3 13.2 2.2 13.2 13.2 13.2 13.2 11.3 8.9 6.6

72 19.0 2.1 18.0 15.5 12.9 10.2 7.5 - - 15.4 2.3 15.4 14.5 11.9 9.2 6.6 - 67 17.3 2.1 17.3 17.3 16.6 14.0 11.3 8.7 6.0 13.9 2.2 13.9 13.9 13.9 12.8 10.2 7.5 4.9

62 16.5 2.1 16.5 16.5 17.2 14.5 11.9 9.2 6.6 13.4 2.2 13.4 13.4 13.4 12.1 9.5 6.8 4.1

57 16.5 2.1 16.5 16.5 17.2 14.5 11.9 9.2 6.6 13.4 2.2 13.4 13.4 13.4 12.1 9.5 6.8 4.1

72 19.3 2.1 19.3 16.7 13.7 10.7 7.8 - - 15.6 2.3 15.6 15.6 12.7 9.7 6.7 - 67 17.6 2.1 17.6 17.6 17.8 14.8 11.8 8.8 5.8 14.1 2.2 14.1 14.1 14.1 13.6 10.6 7.6 4.6

62 16.7 2.1 16.7 16.7 16.7 13.8 10.8 7.8 4.8 13.6 2.2 13.6 13.6 13.6 10.6 7.6 4.7 1.7

57 16.7 2.1 16.7 16.7 16.7 13.8 10.8 7.8 4.8 13.6 2.2 13.6 13.6 13.6 10.6 7.6 4.7 1.7

Total

1

Input

2

(kW)

86 83 80 77 74 71 68 86 83 80 77 74 71 68

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

75°F 85°F

95°F 105°F

115°F 125°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

Unitary Products Group 9

246836-LTG-E-0107

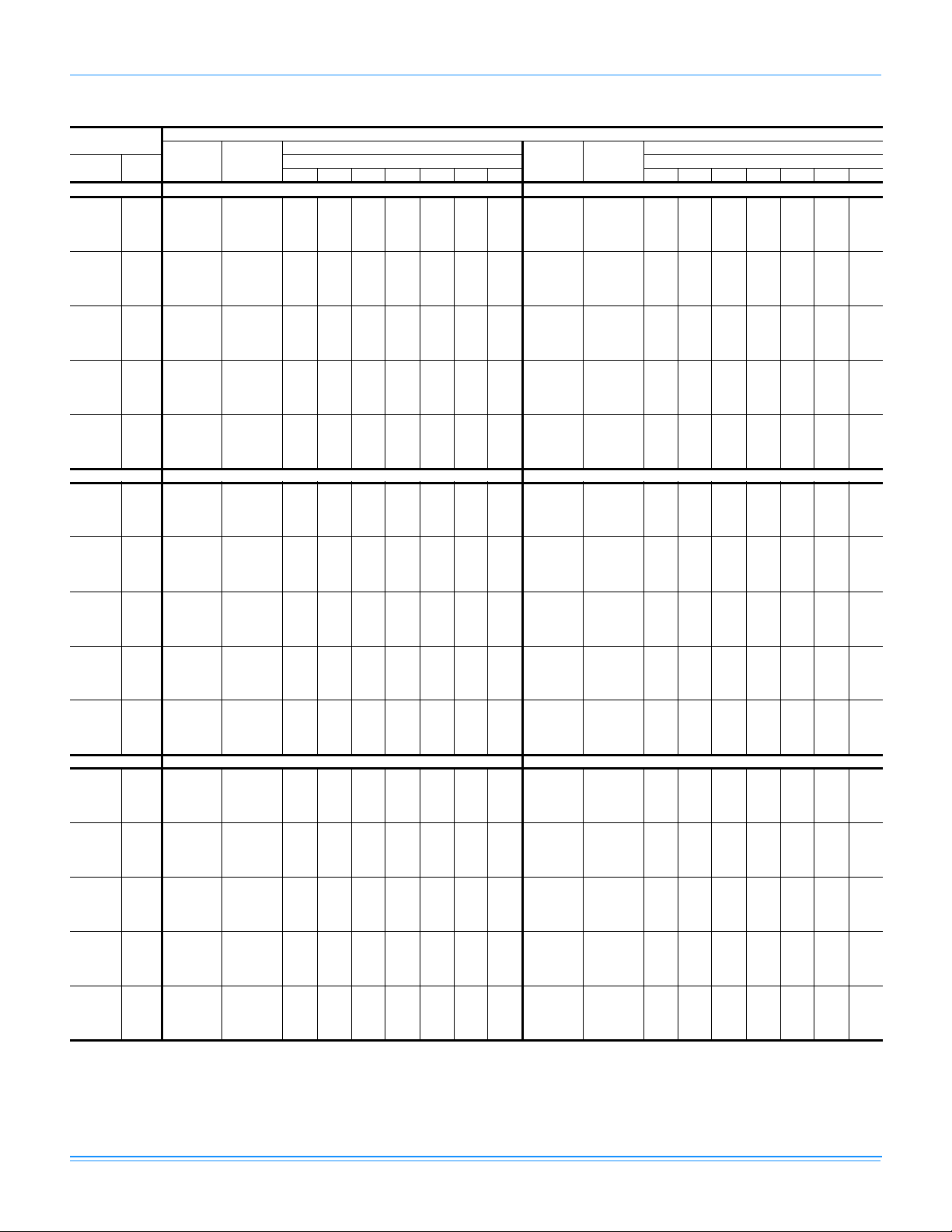

PAC030 (2.5 Ton)

Air on

Evaporator Coil

CFM

1000

1125

1250

1000

1125

1250

1000

1125

1250

WB

(°F)

750

875

750

875

750

875

1. These capacities are gross ratings. For net capacity, deduct air blower motor, MBh = 3.415 x kW. Refer to the appropriate Blower Performance Table for the

kW of the supply air blower motor.

2. These ratings include the condensate fan motors (total .25 kW) and th e compressor motors but not the supply air blower motor.

Total

Capacity

(MBh)

72 30.6 2.1 20.5 18.4 16.2 14.1 12.0 - - 29.8 2.1 19.6 17.4 15.3 13.2 11.0 - 67 28.0 2.1 24.7 22.5 20.4 18.3 16.1 14.0 11.9 27.3 2.1 23.7 21.5 19.4 17.2 15.1 13.0 10.8

62 25.7 2.0 25.7 26.6 24.9 22.8 20.6 18.5 16.4 25.4 2.1 25.4 25.4 23.5 21.3 19.2 17.0 14.9

57 25.7 2.0 25.7 26.6 24.9 22.8 20.6 18.5 16.4 25.4 2.1 25.4 25.4 23.5 21.3 19.2 17.0 14.9

72 31.5 2.0 22.6 20.1 17.5 15.0 12.5 - - 30.7 2.1 21.6 19.1 16.5 14.0 11.5 - 67 28.8 2.0 27.1 24.6 22.0 19.5 17.0 14.4 11.9 28.1 2.1 26.0 23.5 21.0 18.4 15.9 13.4 10.9

62 26.4 2.0 26.4 26.9 26.9 24.4 21.8 19.3 16.8 26.1 2.1 26.1 26.1 25.4 22.9 20.3 17.8 15.3

57 26.4 2.0 26.4 26.9 26.9 24.4 21.8 19.3 16.8 26.1 2.1 26.1 26.1 25.4 22.9 20.3 17.8 15.3

72 32.3 1.9 24.6 21.7 18.8 15.9 13.0 - - 31.5 2.1 23.6 20.7 17.8 14.9 12.0 - 67 29.5 1.9 29.5 26.6 23.6 20.7 17.8 14.9 12.0 28.9 2.1 28.4 25.5 22.6 19.7 16.7 13.8 10.9

62 27.1 1.9 27.1 27.1 28.9 25.9 23.0 20.1 17.2 26.8 2.1 26.8 26.8 27.3 24.4 21.5 18.6 15.6

57 27.1 1.9 27.1 27.1 28.9 25.9 23.0 20.1 17.2 26.8 2.1 26.8 26.8 27.3 24.4 21.5 18.6 15.6

72 33.0 2.0 26.6 23.3 20.0 16.7 13.4 - - 32.1 2.1 25.6 22.3 19.0 15.7 12.3 - 67 30.2 2.0 30.2 28.5 25.1 21.8 18.5 15.2 11.9 29.4 2.1 29.2 27.4 24.1 20.7 17.4 14.1 10.8

62 27.7 2.0 27.7 27.7 28.6 25.3 22.0 18.6 15.3 27.3 2.1 27.3 27.3 27.6 24.2 20.9 17.6 14.3

57 27.7 2.0 27.7 27.7 28.6 25.3 22.0 18.6 15.3 27.3 2.1 27.3 27.3 27.5 24.2 20.9 17.6 14.3

72 33.7 2.1 28.7 24.9 21.2 17.5 13.8 - - 32.7 2.1 27.6 23.9 20.1 16.4 12.7 - 67 30.8 2.1 30.8 30.4 26.6 22.9 19.2 15.5 11.7 29.9 2.1 29.9 29.3 25.5 21.8 18.1 14.4 10.6

62 28.3 2.1 28.3 28.3 28.3 24.6 20.9 17.2 13.4 27.8 2.1 27.8 27.8 27.8 24.1 20.3 16.6 12.9

57 28.3 2.1 28.3 28.3 28.3 24.6 20.9 17.2 13.4 27.8 2.1 27.8 27.8 27.8 24.1 20.3 16.6 12.9

72 29.0 2.2 18.6 16.5 14.3 12.2 10.1 - - 25.7 2.5 17.6 15.4 13.3 11.2 9.0 - 67 26.6 2.1 22.6 20.5 18.4 16.2 14.1 11.9 9.8 23.6 2.4 21.4 19.3 17.2 15.0 12.9 10.7 8.6

62 25.0 2.1 25.0 24.1 22.0 19.9 17.7 15.6 13.4 22.4 2.4 22.4 22.0 20.1 18.0 15.8 13.7 11.5

57 25.0 2.1 25.0 24.1 22.0 19.9 17.7 15.6 13.4 22.4 2.4 22.4 22.0 20.1 18.0 15.8 13.7 11.5

72 29.8 2.3 20.6 18.1 15.6 13.0 10.5 - - 26.4 2.5 19.5 17.0 14.4 11.9 9.4 - 67 27.4 2.2 25.0 22.5 19.9 17.4 14.9 12.3 9.8 24.3 2.5 23.0 21.1 18.6 16.1 13.6 11.0 8.5

62 25.7 2.2 25.7 25.3 23.9 21.4 18.8 16.3 13.8 23.0 2.5 23.0 22.8 21.8 19.3 16.8 14.2 11.7

57 25.7 2.2 25.7 25.3 23.9 21.4 18.8 16.3 13.8 23.0 2.5 23.0 22.8 21.8 19.3 16.8 14.2 11.7

72 30.7 2.3 22.6 19.7 16.8 13.9 11.0 - - 27.1 2.6 21.4 18.5 15.6 12.7 9.7 - 67 28.2 2.3 27.3 24.4 21.5 18.6 15.7 12.7 9.8 24.9 2.5 24.5 23.0 20.1 17.2 14.2 11.3 8.4

62 26.5 2.3 26.5 26.5 25.8 22.8 19.9 17.0 14.1 23.6 2.5 23.6 23.6 23.5 20.6 17.7 14.8 11.9

57 26.5 2.3 26.5 26.5 25.8 22.8 19.9 17.0 14.1 23.6 2.5 23.6 23.6 23.5 20.6 17.7 14.8 11.9

72 31.2 2.3 24.6 21.3 17.9 14.6 11.3 - - 27.5 2.6 23.3 20.0 16.7 13.3 10.0 - 67 28.6 2.2 28.2 26.3 23.0 19.6 16.3 13.0 9.7 25.3 2.5 25.1 24.1 21.5 18.2 14.8 11.5 8.2

62 26.9 2.2 26.9 26.9 26.5 23.2 19.9 16.5 13.2 24.0 2.5 24.0 24.0 23.9 20.6 17.3 14.0 10.7

57 26.9 2.2 26.9 26.9 26.5 23.2 19.9 16.5 13.2 24.0 2.5 24.0 24.0 23.9 20.6 17.3 14.0 10.7

72 31.6 2.2 26.5 22.8 19.1 15.4 11.6 - - 27.9 2.5 25.2 21.5 17.8 14.0 10.3 - 67 29.0 2.2 29.0 28.2 24.4 20.7 17.0 13.3 9.5 25.7 2.5 25.7 25.2 22.9 19.2 15.4 11.7 8.0

62 27.3 2.1 27.3 27.3 27.3 23.5 19.8 16.1 12.3 24.4 2.5 24.4 24.4 24.4 20.6 16.9 13.2 9.5

57 27.3 2.1 27.3 27.3 27.3 23.5 19.8 16.1 12.3 24.4 2.5 24.4 24.4 24.4 20.6 16.9 13.2 9.5

72 22.4 2.8 16.6 14.4 12.3 10.1 8.0 - - 19.2 3.1 15.5 13.4 11.3 9.1 7.0 - 67 20.7 2.7 20.2 18.1 15.9 13.8 11.7 9.5 7.4 17.7 3.0 17.7 16.9 14.7 12.6 10.5 8.3 6.2

62 19.9 2.7 19.9 19.9 18.2 16.1 13.9 11.8 9.6 17.3 3.0 17.3 17.3 16.3 14.2 12.0 9.9 7.7

57 19.9 2.7 19.9 19.9 18.2 16.1 13.9 11.8 9.6 17.3 3.0 17.3 17.3 16.3 14.2 12.0 9.9 7.7

72 23.0 2.8 18.4 15.9 13.3 10.8 8.3 - - 19.5 3.1 17.3 14.7 12.2 9.7 7.2 - 67 21.1 2.8 20.9 19.8 17.3 14.8 12.3 9.7 7.2 18.0 3.0 18.0 18.0 16.0 13.5 10.9 8.4 5.9

62 20.3 2.7 20.3 20.3 19.7 17.2 14.7 12.2 9.6 17.7 3.0 17.7 17.7 17.7 15.2 12.6 10.1 7.6

57 20.3 2.7 20.3 20.3 19.7 17.2 14.7 12.2 9.6 17.7 3.0 17.7 17.7 17.7 15.2 12.6 10.1 7.6

72 23.5 2.8 20.2 17.3 14.4 11.5 8.5 - - 19.9 3.1 19.0 16.1 13.2 10.2 7.3 - 67 21.6 2.8 21.6 21.6 18.7 15.7 12.8 9.9 7.0 18.4 3.0 18.4 18.4 17.2 14.3 11.4 8.5 5.6

62 20.8 2.7 20.8 20.8 21.3 18.4 15.5 12.5 9.6 18.0 3.0 18.0 18.0 18.0 16.2 13.2 10.3 7.4

57 20.8 2.7 20.8 20.8 21.3 18.4 15.5 12.5 9.6 18.0 3.0 18.0 18.0 18.0 16.2 13.2 10.3 7.4

72 23.9 2.8 22.0 18.7 15.4 12.1 8.8 - - 20.2 3.1 20.2 17.5 14.1 10.8 7.5 - 67 22.0 2.8 22.0 21.9 20.0 16.7 13.4 10.0 6.7 18.7 3.0 18.7 18.7 18.5 15.2 11.9 8.6 5.2

62 21.2 2.8 21.2 21.2 21.4 18.1 14.7 11.4 8.1 18.3 3.0 18.3 18.3 18.3 15.5 12.2 8.9 5.5

57 21.2 2.8 21.2 21.2 21.4 18.1 14.7 11.4 8.1 18.3 3.0 18.3 18.3 18.3 15.5 12.2 8.9 5.5

72 24.2 2.8 23.9 20.2 16.4 12.7 9.0 - - 20.6 3.2 20.6 18.8 15.1 11.4 7.6 - 67 22.3 2.8 22.3 22.3 21.3 17.6 13.9 10.2 6.4 19.0 3.1 19.0 19.0 19.0 16.1 12.3 8.6 4.9

62 21.5 2.8 21.5 21.5 21.5 17.8 14.0 10.3 6.6 18.6 3.1 18.6 18.6 18.6 14.9 11.1 7.4 3.7

57 21.5 2.8 21.5 21.5 21.5 17.8 14.0 10.3 6.6 18.6 3.1 18.6 18.6 18.6 14.9 11.1 7.4 3.7

Total

1

Input

2

(kW)

86 83 80 77 74 71 68 86 83 80 77 74 71 68

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

75°F 85°F

95°F 105°F

115°F 125°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

10 Unitary Products Group

246836-LTG-E-0107

PAC036 (3.0 Ton)

Air on

Evaporator Coil

CFM

1050

1200

1350

1500

1050

1200

1350

1500

1050

1200

1350

1500

WB

(°F)

900

900

900

1. These capacities are gross ratings. For net capacity, deduct air blower motor, MBh = 3.415 x kW. Refer to the appropriate Blower Performance Table for the

kW of the supply air blower motor.

2. These ratings include the condensate fan motors (total .25 kW) and th e compressor motors but not the supply air blower motor.

Total

Capacity

(MBh)

72 43.4 2.6 25.6 23.1 20.5 17.9 15.4 - - 40.6 2.7 24.0 21.5 18.9 16.3 13.8 - 67 39.9 2.6 31.1 28.5 26.0 23.4 20.8 18.3 15.7 37.3 2.7 29.3 26.8 24.2 21.6 19.1 16.5 13.9

62 36.6 2.6 37.1 34.6 32.0 29.4 26.9 24.3 21.7 34.7 2.6 34.7 32.1 29.6 27.0 24.4 21.9 19.3

57 37.0 2.6 37.5 35.2 32.7 30.1 27.5 25.0 22.4 34.9 2.6 34.9 32.5 29.9 27.3 24.8 22.2 19.6

72 44.7 2.7 28.2 25.2 22.1 19.1 16.1 - - 41.7 2.7 26.5 23.5 20.4 17.4 14.4 - 67 41.1 2.6 34.1 31.1 28.0 25.0 22.0 18.9 15.9 38.4 2.7 32.3 29.2 26.2 23.2 20.1 17.1 14.1

62 37.7 2.6 37.9 36.7 34.6 31.5 28.5 25.5 22.4 35.7 2.6 35.7 34.4 32.0 29.0 25.9 22.9 19.9

57 38.1 2.6 38.4 37.2 35.3 32.3 29.2 26.2 23.2 35.9 2.6 35.9 34.7 32.3 29.3 26.3 23.3 20.2

72 46.0 2.7 30.8 27.3 23.8 20.3 16.8 - - 42.9 2.7 29.0 25.5 22.0 18.5 15.0 - 67 42.3 2.6 37.1 33.6 30.1 26.6 23.1 19.6 16.1 39.5 2.7 35.2 31.7 28.2 24.7 21.2 17.7 14.2

62 38.8 2.6 38.8 38.8 37.1 33.6 30.1 26.6 23.1 36.7 2.7 36.7 36.7 34.4 30.9 27.4 23.9 20.4

57 39.3 2.6 39.3 39.3 37.9 34.4 30.9 27.4 23.9 36.9 2.7 36.9 36.9 34.8 31.3 27.8 24.3 20.8

72 46.9 2.7 33.3 29.3 25.4 21.4 17.4 - - 43.7 2.7 31.4 27.4 23.4 19.5 15.5 - 67 43.1 2.7 40.4 36.1 32.1 28.1 24.2 20.2 16.2 40.2 2.7 38.0 34.0 30.0 26.0 22.1 18.1 14.1

62 39.5 2.6 39.5 39.5 38.7 34.7 30.7 26.7 22.7 37.3 2.7 37.3 37.3 36.2 32.2 28.2 24.2 20.3

57 40.0 2.6 40.0 40.0 39.3 35.3 31.4 27.4 23.4 37.6 2.7 37.6 37.6 36.5 32.5 28.6 24.6 20.6

72 47.8 2.7 35.9 31.4 27.0 22.5 18.0 - - 44.5 2.8 33.8 29.4 24.9 20.4 16.0 - 67 43.9 2.7 43.8 38.6 34.2 29.7 25.2 20.7 16.3 40.9 2.7 40.8 36.4 31.9 27.4 23.0 18.5 14.0

62 40.3 2.6 40.3 40.3 40.3 35.8 31.3 26.8 22.4 38.0 2.7 38.0 38.0 38.0 33.5 29.0 24.6 20.1

57 40.8 2.6 40.8 40.8 40.8 36.3 31.8 27.4 22.9 38.3 2.7 38.3 38.3 38.3 33.8 29.3 24.8 20.4

72 37.7 2.8 22.4 19.9 17.3 14.7 12.2 - - 33.9 3.1 21.5 19.0 16.4 13.8 11.3 - 67 34.7 2.7 27.6 25.0 22.5 19.9 17.3 14.8 12.2 31.1 3.0 26.4 23.9 21.3 18.7 16.2 13.6 11.0

62 32.8 2.7 32.3 29.7 27.1 24.6 22.0 19.4 16.9 29.7 3.0 29.4 27.9 25.3 22.7 20.2 17.6 15.0

57 32.8 2.7 32.3 29.7 27.1 24.6 22.0 19.4 16.9 29.7 3.0 29.4 27.9 25.3 22.7 20.2 17.6 15.0

72 38.8 2.8 24.8 21.8 18.8 15.7 12.7 - - 34.7 3.1 23.9 20.8 17.8 14.8 11.7 - 67 35.7 2.7 30.4 27.4 24.3 21.3 18.3 15.3 12.2 31.9 3.0 28.7 26.1 23.1 20.1 17.0 14.0 11.0

62 33.7 2.7 33.4 32.1 29.4 26.4 23.3 20.3 17.3 30.4 3.0 30.3 29.5 27.4 24.4 21.4 18.3 15.3

57 33.7 2.7 33.4 32.1 29.4 26.4 23.3 20.3 17.3 30.4 3.0 30.3 29.5 27.4 24.4 21.4 18.3 15.3

72 39.8 2.8 27.2 23.7 20.2 16.7 13.2 - - 35.6 3.1 26.2 22.7 19.2 15.7 12.2 - 67 36.6 2.8 33.2 29.7 26.2 22.7 19.2 15.7 12.2 32.7 3.0 31.0 28.4 24.9 21.4 17.9 14.4 10.9

62 34.6 2.7 34.6 34.6 31.7 28.2 24.7 21.2 17.7 31.1 3.0 31.1 31.1 29.6 26.1 22.6 19.1 15.6

57 34.6 2.7 34.6 34.6 31.7 28.2 24.7 21.2 17.7 31.1 3.0 31.1 31.1 29.6 26.1 22.6 19.1 15.6

72 40.5 2.8 29.5 25.5 21.5 17.6 13.6 - - 36.2 3.1 28.5 24.5 20.5 16.5 12.5 - 67 37.3 2.8 35.6 31.9 27.9 24.0 20.0 16.0 12.0 33.2 3.1 32.4 30.2 26.6 22.6 18.7 14.7 10.7

62 35.1 2.7 35.1 35.1 33.7 29.7 25.7 21.8 17.8 31.7 3.0 31.7 31.7 30.9 26.9 22.9 18.9 14.9

57 35.1 2.7 35.1 35.1 33.7 29.7 25.7 21.8 17.8 31.7 3.0 31.7 31.7 30.9 26.9 22.9 18.9 14.9

72 41.2 2.8 31.8 27.3 22.9 18.4 13.9 - - 36.8 3.1 30.8 26.3 21.8 17.4 12.9 - 67 37.9 2.8 37.9 34.1 29.6 25.2 20.7 16.2 11.8 33.8 3.1 33.8 31.9 28.3 23.9 19.4 14.9 10.5

62 35.7 2.7 35.7 35.7 35.7 31.3 26.8 22.3 17.8 32.2 3.0 32.2 32.2 32.2 27.7 23.3 18.8 14.3

57 35.7 2.7 35.7 35.7 35.7 31.3 26.8 22.3 17.8 32.2 3.0 32.2 32.2 32.2 27.7 23.3 18.8 14.3

72 30.0 3.4 20.6 18.1 15.5 12.9 10.4 - - 26.2 3.7 19.7 17.2 14.6 12.0 9.5 - 67 27.5 3.3 25.3 22.7 20.2 17.6 15.0 12.5 9.9 23.9 3.6 23.9 21.6 19.0 16.4 13.9 11.3 8.8

62 26.6 3.2 26.6 26.0 23.5 20.9 18.4 15.8 13.2 23.5 3.5 23.5 23.5 21.7 19.1 16.5 14.0 11.4

57 26.6 3.2 26.6 26.0 23.5 20.9 18.4 15.8 13.2 23.5 3.5 23.5 23.5 21.7 19.1 16.5 14.0 11.4

72 30.7 3.4 22.9 19.9 16.8 13.8 10.8 - - 26.6 3.7 21.9 18.9 15.9 12.8 9.8 - 67 28.1 3.3 27.0 24.9 21.9 18.8 15.8 12.8 9.7 24.3 3.6 24.3 23.7 20.6 17.6 14.6 11.5 8.5

62 27.1 3.3 27.1 26.9 25.5 22.4 19.4 16.4 13.3 23.9 3.6 23.9 23.9 23.5 20.5 17.4 14.4 11.4

57 27.1 3.3 27.1 26.9 25.5 22.4 19.4 16.4 13.3 23.9 3.6 23.9 23.9 23.5 20.5 17.4 14.4 11.4

72 31.3 3.4 25.1 21.6 18.1 14.6 11.1 - - 27.1 3.7 24.1 20.6 17.1 13.6 10.1 - 67 28.7 3.3 28.7 27.1 23.6 20.1 16.6 13.1 9.6 24.8 3.6 24.8 24.8 22.3 18.8 15.3 11.8 8.3

62 27.7 3.3 27.7 27.7 27.5 24.0 20.5 17.0 13.5 24.3 3.6 24.3 24.3 24.3 21.9 18.4 14.9 11.4

57 27.7 3.3 27.7 27.7 27.5 24.0 20.5 17.0 13.5 24.3 3.6 24.3 24.3 24.3 21.9 18.4 14.9 11.4

72 31.9 3.4 27.4 23.5 19.5 15.5 11.5 - - 27.5 3.8 26.4 22.4 18.4 14.5 10.5 - 67 29.2 3.4 29.2 28.4 25.3 21.3 17.3 13.4 9.4 25.2 3.7 25.2 25.2 24.0 20.0 16.0 12.0 8.1

62 28.2 3.3 28.2 28.2 28.1 24.1 20.1 16.1 12.1 24.7 3.6 24.7 24.7 24.7 21.3 17.3 13.3 9.3

57 28.2 3.3 28.2 28.2 28.1 24.1 20.1 16.1 12.1 24.7 3.6 24.7 24.7 24.7 21.3 17.3 13.3 9.3

72 32.4 3.5 29.7 25.3 20.8 16.3 11.9 - - 28.0 3.8 28.0 24.3 19.8 15.3 10.8 - 67 29.7 3.4 29.7 29.7 27.0 22.6 18.1 13.6 9.2 25.6 3.7 25.6 25.6 25.6 21.3 16.8 12.3 7.9

62 28.7 3.3 28.7 28.7 28.7 24.2 19.7 15.2 10.8 25.1 3.6 25.1 25.1 25.1 20.7 16.2 11.7 7.2

57 28.7 3.3 28.7 28.7 28.7 24.2 19.7 15.2 10.8 25.1 3.6 25.1 25.1 25.1 20.7 16.2 11.7 7.2

Total

1

Input

2

(kW)

86 83 80 77 74 71 68 86 83 80 77 74 71 68

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

75°F 85°F

95°F 105°F

115°F 125°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

Unitary Products Group 11

246836-LTG-E-0107

PAC042 (3.5 Ton)

Air on

Evaporator Coil

CFM

1050

1225

1400

1575

1750

1050

1225

1400

1575

1750

1050

1225

1400

1575

1750

WB

(°F)

1. These capacities are gross ratings. For net capacity, deduct air blower motor, MBh = 3.415 x kW. Refer to the appropriate Blower Performance Table for the

kW of the supply air blower motor.

2. These ratings include the condensate fan motors (total .25 kW) and th e compressor motors but not the supply air blower motor.

Total

Capacity

(MBh)

72 47.9 2.7 27.3 24.3 21.3 18.3 15.3 - - 45.5 2.9 26.7 23.8 20.8 17.8 14.8 - 67 44.2 2.6 33.2 30.2 27.2 24.2 21.2 18.2 15.2 42.0 2.9 32.7 29.7 26.7 23.7 20.7 17.7 14.8

62 40.8 2.5 39.8 36.8 33.8 30.8 27.8 24.8 21.8 39.2 2.8 38.7 35.7 32.7 29.7 26.7 23.7 20.7

57 40.8 2.5 39.8 36.8 33.8 30.8 27.8 24.8 21.8 39.2 2.8 38.7 35.7 32.7 29.7 26.7 23.7 20.7

72 49.2 2.7 30.0 26.5 22.9 19.4 15.9 - - 46.8 3.0 29.5 26.0 22.4 18.9 15.3 - 67 45.5 2.6 36.4 32.8 29.3 25.8 22.2 18.7 15.1 43.2 2.9 35.9 32.4 28.9 25.3 21.8 18.3 14.7

62 42.0 2.6 41.5 40.0 36.5 32.9 29.4 25.8 22.3 40.3 2.8 40.0 38.5 35.3 31.7 28.2 24.7 21.1

57 42.0 2.6 41.5 40.0 36.5 32.9 29.4 25.8 22.3 40.3 2.8 40.0 38.5 35.3 31.7 28.2 24.7 21.1

72 50.6 2.7 32.8 28.7 24.6 20.5 16.4 - - 48.0 3.0 32.2 28.2 24.1 20.0 15.9 - 67 46.7 2.7 39.6 35.5 31.4 27.3 23.3 19.2 15.1 44.4 2.9 39.2 35.1 31.0 26.9 22.8 18.8 14.7

62 43.2 2.6 43.2 43.2 39.1 35.0 30.9 26.9 22.8 41.4 2.8 41.4 41.4 37.9 33.8 29.7 25.6 21.6

57 43.2 2.6 43.2 43.2 39.1 35.0 30.9 26.9 22.8 41.4 2.8 41.4 41.4 37.9 33.8 29.7 25.6 21.6

72 51.4 2.7 35.4 30.8 26.1 21.5 16.8 - - 48.8 3.0 34.9 30.3 25.6 21.0 16.3 - 67 47.5 2.7 43.6 38.0 33.4 28.7 24.1 19.4 14.8 45.0 2.9 42.3 37.6 33.0 28.4 23.7 19.1 14.4

62 43.9 2.6 43.9 43.9 41.8 37.2 32.5 27.9 23.2 42.0 2.9 42.0 42.0 40.3 35.6 31.0 26.3 21.7

57 43.9 2.6 43.9 43.9 41.8 37.2 32.5 27.9 23.2 42.0 2.9 42.0 42.0 40.3 35.6 31.0 26.3 21.7

72 52.3 2.8 38.1 32.8 27.6 22.4 17.2 - - 49.5 3.0 37.6 32.4 27.2 22.0 16.7 - 67 48.2 2.7 47.6 40.5 35.3 30.1 24.9 19.6 14.4 45.7 2.9 45.4 40.2 35.0 29.8 24.6 19.3 14.1

62 44.6 2.6 44.6 44.6 44.6 39.4 34.2 28.9 23.7 42.7 2.9 42.7 42.7 42.7 37.5 32.2 27.0 21.8

57 44.6 2.6 44.6 44.6 44.6 39.4 34.2 28.9 23.7 42.7 2.9 42.7 42.7 42.7 37.5 32.2 27.0 21.8

72 43.2 3.2 26.2 23.2 20.2 17.3 14.3 - - 38.8 3.4 24.6 21.6 18.6 15.6 12.6 - 67 39.9 3.1 32.3 29.3 26.3 23.3 20.3 17.3 14.3 35.8 3.3 30.3 27.3 24.3 21.3 18.3 15.3 12.4

62 37.6 3.0 37.5 34.5 31.5 28.5 25.5 22.5 19.5 34.1 3.3 34.0 31.6 28.6 25.6 22.6 19.6 16.6

57 37.6 3.0 37.5 34.5 31.5 28.5 25.5 22.5 19.5 34.1 3.3 34.0 31.6 28.6 25.6 22.6 19.6 16.6

72 44.3 3.2 29.0 25.4 21.9 18.4 14.8 - - 39.7 3.5 27.3 23.7 20.2 16.7 13.1 - 67 40.9 3.1 35.5 32.0 28.4 24.9 21.4 17.8 14.3 36.7 3.4 33.1 29.9 26.4 22.8 19.3 15.8 12.2

62 38.6 3.1 38.5 37.0 34.1 30.6 27.0 23.5 20.0 34.9 3.3 34.9 33.7 31.0 27.5 24.0 20.4 16.9

57 38.6 3.1 38.5 37.0 34.1 30.6 27.0 23.5 20.0 34.9 3.3 34.9 33.7 31.0 27.5 24.0 20.4 16.9

72 45.4 3.2 31.7 27.6 23.6 19.5 15.4 - - 40.7 3.5 29.9 25.9 21.8 17.7 13.6 - 67 42.0 3.2 38.8 34.7 30.6 26.5 22.4 18.3 14.3 37.6 3.4 36.0 32.5 28.4 24.4 20.3 16.2 12.1

62 39.5 3.1 39.5 39.5 36.7 32.6 28.5 24.4 20.4 35.8 3.3 35.8 35.8 33.5 29.4 25.3 21.2 17.1

57 39.5 3.1 39.5 39.5 36.7 32.6 28.5 24.4 20.4 35.8 3.3 35.8 35.8 33.5 29.4 25.3 21.2 17.1

72 46.1 3.3 34.4 29.8 25.1 20.5 15.8 - - 41.3 3.5 32.6 28.0 23.3 18.7 14.0 - 67 42.6 3.2 41.0 37.3 32.6 28.0 23.4 18.7 14.1 38.2 3.4 37.4 34.8 30.4 25.8 21.1 16.5 11.8

62 40.1 3.1 40.1 40.1 38.7 34.1 29.4 24.8 20.1 36.3 3.4 36.3 36.3 35.2 30.5 25.9 21.2 16.6

57 40.1 3.1 40.1 40.1 38.7 34.1 29.4 24.8 20.1 36.3 3.4 36.3 36.3 35.2 30.5 25.9 21.2 16.6

72 46.8 3.3 37.2 31.9 26.7 21.5 16.3 - - 42.0 3.5 35.3 30.0 24.8 19.6 14.4 - 67 43.2 3.2 43.2 39.9 34.7 29.5 24.3 19.1 13.8 38.7 3.4 38.7 37.1 32.4 27.2 22.0 16.8 11.5

62 40.7 3.1 40.7 40.7 40.7 35.5 30.3 25.1 19.9 36.9 3.4 36.9 36.9 36.9 31.7 26.4 21.2 16.0

57 40.7 3.1 40.7 40.7 40.7 35.5 30.3 25.1 19.9 36.9 3.4 36.9 36.9 36.9 31.7 26.4 21.2 16.0

72 34.3 3.7 23.0 20.0 17.0 14.0 11.0 - - 29.9 3.9 21.4 18.4 15.4 12.4 9.4 - 67 31.7 3.6 28.3 25.4 22.4 19.4 16.4 13.4 10.4 27.5 3.8 26.4 23.4 20.4 17.4 14.4 11.4 8.4

62 30.5 3.5 30.5 28.7 25.7 22.7 19.7 16.7 13.7 27.0 3.8 27.0 25.8 22.8 19.8 16.8 13.8 10.8

57 30.5 3.5 30.5 28.7 25.7 22.7 19.7 16.7 13.7 27.0 3.8 27.0 25.8 22.8 19.8 16.8 13.8 10.8

72 35.1 3.7 25.6 22.1 18.5 15.0 11.4 - - 30.5 4.0 23.9 20.4 16.8 13.3 9.7 - 67 32.4 3.6 30.8 27.9 24.3 20.8 17.2 13.7 10.2 28.2 3.8 28.2 25.8 22.3 18.7 15.2 11.6 8.1

62 31.3 3.6 31.3 30.4 28.0 24.4 20.9 17.4 13.8 27.6 3.8 27.6 27.0 24.9 21.4 17.8 14.3 10.7

57 31.3 3.6 31.3 30.4 28.0 24.4 20.9 17.4 13.8 27.6 3.8 27.6 27.0 24.9 21.4 17.8 14.3 10.7

72 35.9 3.7 28.2 24.1 20.0 15.9 11.8 - - 31.2 4.0 26.4 22.3 18.2 14.1 10.1 - 67 33.2 3.6 33.2 30.4 26.3 22.2 18.1 14.0 9.9 28.8 3.9 28.8 28.2 24.1 20.0 16.0 11.9 7.8

62 32.0 3.6 32.0 32.0 30.2 26.1 22.1 18.0 13.9 28.2 3.8 28.2 28.2 27.0 22.9 18.8 14.7 10.7

57 32.0 3.6 32.0 32.0 30.2 26.1 22.1 18.0 13.9 28.2 3.8 28.2 28.2 27.0 22.9 18.8 14.7 10.7

72 36.5 3.8 30.8 26.1 21.5 16.8 12.2 - - 31.7 4.0 28.9 24.3 19.6 15.0 10.3 - 67 33.7 3.7 33.7 32.3 28.2 23.5 18.9 14.2 9.6 29.3 3.9 29.3 29.3 26.0 21.3 16.7 12.0 7.4

62 32.5 3.6 32.5 32.5 31.6 27.0 22.3 17.7 13.0 28.7 3.9 28.7 28.7 28.1 23.4 18.8 14.1 9.5

57 32.5 3.6 32.5 32.5 31.6 27.0 22.3 17.7 13.0 28.7 3.9 28.7 28.7 28.1 23.4 18.8 14.1 9.5

72 37.1 3.8 33.4 28.1 22.9 17.7 12.5 - - 32.2 4.0 31.5 26.2 21.0 15.8 10.6 - 67 34.2 3.7 34.2 34.2 30.1 24.9 19.7 14.5 9.3 29.7 3.9 29.7 29.7 27.8 22.6 17.4 12.2 7.0

62 33.0 3.6 33.0 33.0 33.0 27.8 22.6 17.4 12.1 29.2 3.9 29.2 29.2 29.2 23.9 18.7 13.5 8.3

57 33.0 3.6 33.0 33.0 33.0 27.8 22.6 17.4 12.1 29.2 3.9 29.2 29.2 29.2 23.9 18.7 13.5 8.3

Total

1

Input

2

(kW)

86 83 80 77 74 71 68 86 83 80 77 74 71 68

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

75°F 85°F

95°F 105°F

115°F 125°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

12 Unitary Products Group

Loading...

Loading...