Luxaire G8D-UH, G8D-DN Installation Instructions Manual

INSTALLATION

TWO-STAGE

MID-EFFICIENCY GAS-FIRED

INSTRUCTION

CONTENTS

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . 3

UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

VENTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

UPFLOW/HORIZONTAL MODELS - . . . . . . . . . . . . . . . . 10

FILTERS INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 10

UPFLOW/HORIZONTAL MODELS - . . . . . . . . . . . . . . . . 11

TUBULAR HEAT EXCHANGER SERIES

MODELS: P*DU & G8D-UH (Upflow / Horizontal)

P*DD & G8D-DN (Downflow)

57 - 120 MBH INPUT

DOWNFLOW MODEL APPLICATION . . . . . . . . . . . . . . . 12

OPERATION AND MAINTENANCE. . . . . . . . . . . . . . . . . 23

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

FURNACE ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . 28

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . 29

WIRING DIAGRAM - UPFLOW / HORIZONTAL . . . . . . . 30

WIRING DIAGRAM - DOWNFLOW . . . . . . . . . . . . . . . . . 31

CAUTION: READ ALL SAFETY GUIDES BEFORE YOU

START TO INSTALL YOUR FURNACE.

SAVE THIS MANUAL

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Open windows.

• Do not touch any electrical switch;do not use any phone in

your building.

• Extinguish any open flame.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

035-14527-000 REV A (599) Form 650.77-N3U

035-14527-000 REV A (599) Form 650.77-N3U

CONTENTS

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . 3

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IMPROPER INSTALLATION MAY CREATE A

CONDITION WHERE THE OPERATION OF THE

PRODUCT COULD CAUSE PERSONAL INJURY

OR PROPERTY DAMAGE.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE INJURY OR PROPERTY DAMAGE.

REFER TO THIS MANUAL FOR ASSISTANCE

NOTES, CAUTIONS & WARNINGS. . . . . . . . . . . . . . . . . . . . . . 3

LIMITATIONS AND LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . 3

UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

COMBUSTION AIR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

VENTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CATEGORY I VERTICAL VENTING . . . . . . . . . . . . . . . . . . . . . 6

VENT SAFETY CHECK PROCEDURE . . . . . . . . . . . . . . . . . . . 9

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OR ADDITIONAL INFORMATION, CONSULT A

QUALIFIED INSTALLER, SERVICE AGENCY OR

THE GAS SUPPLIER.

UPFLOW/HORIZONTAL MODELS -. . . . . . . . . . . . . . . . . 10

UPFLOW APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

FILTERS INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 10

(UPFLOW/HORIZONTAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

UPFLOW/HORIZONTAL MODELS -. . . . . . . . . . . . . . . . . 11

HORIZONTAL APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . 11

THIS PRODUCT MUST BE INSTALLED IN

ATTIC INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CRAWL SPACE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 12

STRICT COMPLIANCE WITH THE ENCLOSED

INSTALLATION INSTRUCTIONS AND ANY

APPLICABLE LOCAL, STATE, AND NATIONAL

CODES INCLUDING BUT NOT LIMITED TO,

BUILDING, ELECTRICAL AND MECHANICAL

CODES.

The furnace area must not be used as a broom

closet or for any other storage purposes, as a fire

hazard bay be created. Never store items such as

the following on, near or in contact with the furnace.

1. Spray or aerosol cans, rags, brooms, dust mops,

vacuum cleaners or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning

compounds; plastic items or containers; gasoline,

kerosene, cigarette lighter fluid, dry cleaning fluids

or other volatile fluid.

3. Paint thinners and other painting compounds.

DOWNFLOW MODEL APPLICATION . . . . . . . . . . . . . . . 12

DOWNFLOW FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SUPPLY AIR DUCTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

GAS PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ELECTRICAL POWER CONNECTION . . . . . . . . . . . . . . . . . . 14

ELECTRICAL CONTROL CONNECTIONS . . . . . . . . . . . . . . . 14

SAFETY CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

START-UP AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . 16

IGNITION SYSTEM CHECKOUT/ADJUSTMENT . . . . . . . . . . 17

CHECKING GAS INPUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ADJUSTMENT OF MANIFOLD GAS PRESSURE . . . . . . . . . . 18

ADJUSTMENT OF TEMPERATURE RISE . . . . . . . . . . . . . . . 19

ADJUSTMENT OF FAN-OFF CONTROL SETTINGS . . . . . . . 19

ACCESSORY CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . 20

OPERATION AND MAINTENANCE . . . . . . . . . . . . . . . . . 23

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . 23

INTERMITTENT BLOWER - COOLING. . . . . . . . . . . . . . . . . . 23

HEATING OPERATIONAL SEQUENCE . . . . . . . . . . . . . . . . . 23

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

BLOWER CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CLEANING THE HEAT EXCHANGER. . . . . . . . . . . . . . . . . . . 25

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

FURNACE CONTROL DIAGNOSTICS . . . . . . . . . . . . . . . . . . 26

FURNACE ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . 28

4. Paper bags, boxes or other paper products

Never operate the furnace with the blower door

removed. To do so could result in serious personal

injury and/or equipment damage.

2 Unitary Products Group

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . 29

WIRING DIAGRAM - UPFLOW / HORIZONTAL. . . . . . . . 30

WIRING DIAGRAM - DOWNFLOW . . . . . . . . . . . . . . . . . 31

035-14527-000 REV A (599) Form 650.77-N3U

GENERAL INFORMATION

DESCRIPTION

This Category I furnace is designed for installation in a residential or commercial application. A Category I furnace has a

fan assisted combustion system equipped with an integral

mechanical means to draw products of combustion through

the combustion chamber and heat exchanger. It may be

installed in a basement, garage, equipment room, alcove,

attic or any other indoor location where all required clearances to combustibles and other restrictions are met. It is

designed for natural gas-fired operation, but may be converted to propane (LP).

High altitude and propane (LP) changes or conversions

required in order for the appliance to satisfactorily meet the

application must be made by an authorized distributor, dealer,

licensed technician or other qualified agency, using factory

specified and/or approved parts.

Upflow/horizontal furnaces and downflow furnaces may be

used only as Category I units.

The furnace must be installed so that all electrical components are protected from water.

INSPECTION

As soon as a unit is received, it should be inspected for possible damage during transit. If the damage is evident, the

extent of the damage should be noted on the carrier's freight

bill.

damage may occur if installation procedures are not handled

properly.

Each furnace in this series is a Category I furnace,

suitable for common venting with other gas-fired

appliances as allowed by the National Fuel Gas

Code, NFPA 54/ANSI Z223.1-latest edition

This appliance is not to be used for temporary

heating of buildings or structures under construction.

Do not install this furnace in a corrosive or contaminated atmosphere.

Do not install this furnace in a mobile home or recreational vehicle.

Furnaces shall not be installed directly on carpeting, tile or other combustible material other than

wood flooring.

LIMITATIONS AND LOCATION

This furnace should be installed in accordance with all

national/local building/safety codes and requirements, or in

the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1 - (latest edition) or, in Canada, CAN/CGA

B149.1 or.2 - (latest edition), and other applicable codes.

A separate request for inspection by the carrier's agent

should be made in writing. Also, before installation, the unit

should be checked for screws or bolts which may have loosened in transit.

NOTES, CAUTIONS & WARNINGS

The installer should pay particular attention to the words:

NOTE, CAUTION and WARNING. NOTES are intended to

clarify or make the installation easier. CAUTIONS are given

to prevent equipment damage. WARNINGS are given to alert

the installer that personal injury and/or equipment or property

Use only the type of gas approved for this furnace; refer to

the furnace rating plate.

Only use natural gas in furnaces designed for natural gas. Only use propane (LP) gas for furnaces

that have been properly converted to use propane

(LP) gas. Do not use this furnace with butane.

Using wrong gas could create a hazard, resulting

in damage, injury or death.

For installations above 2,000 feet, reduce input 4% for each

1,000 feet above sea level. Canadian installations must be

derated 10% for elevations from 2,000 ft. to 4,500 ft. See

Form 650.74-N1.1V for information to properly derate furnace.

In the U.S. only, furnace shall not be connected to a chimney

flue serving a separate appliance designed to burn solid fuel.

Unitary Products Group 3

035-14527-000 REV A (599) Form 650.77-N3U

Check the rating plate and power supply to be sure that electrical characteristics match. All models use nominal 115 vac,

1phase, 60 Hz. power supply.

A furnace installed in a residential garage must be located so

that all burners and burner ignition devices are located no

less than 18" above the garage floor, and located or protected to prevent damage by vehicles.

The size of the unit should be based on an acceptable heat

loss calculation for the structure. ACCA, Manual J or other

approved methods may be used.

The furnace should be located using these guidelines:

1. Where a minimum amount of vent piping and elbows will

be required.

2. As centralized with the air distribution as possible.

3. Where adequate combustion air will be available.

4. In an area where ventilation facilities provide for safe limits of ambient temperature under normal operating conditions.

5. Where it will not interfere with proper air circulation in the

confined space.

6. Where the vent will not be blocked or restricted.

7. Where sufficient space is provided to allow proper service access. Minimum recommended service clearances

are as follows:

• Twenty-four (24) inches between the front of the fur-

nace and an adjacent wall or another appliance,

when access is required for servicing and cleaning.

• Eighteen (18) inches at the side where access is

required for passage to the front when servicing or

for inspection or replacement of flue/vent connections.

8. Where it will not interfere with the cleaning, servicing or

removal of other appliances.

9. Where the following minimum clearances (in inches) to

combustibles can be maintained: (Refer to Table1 on

page4).

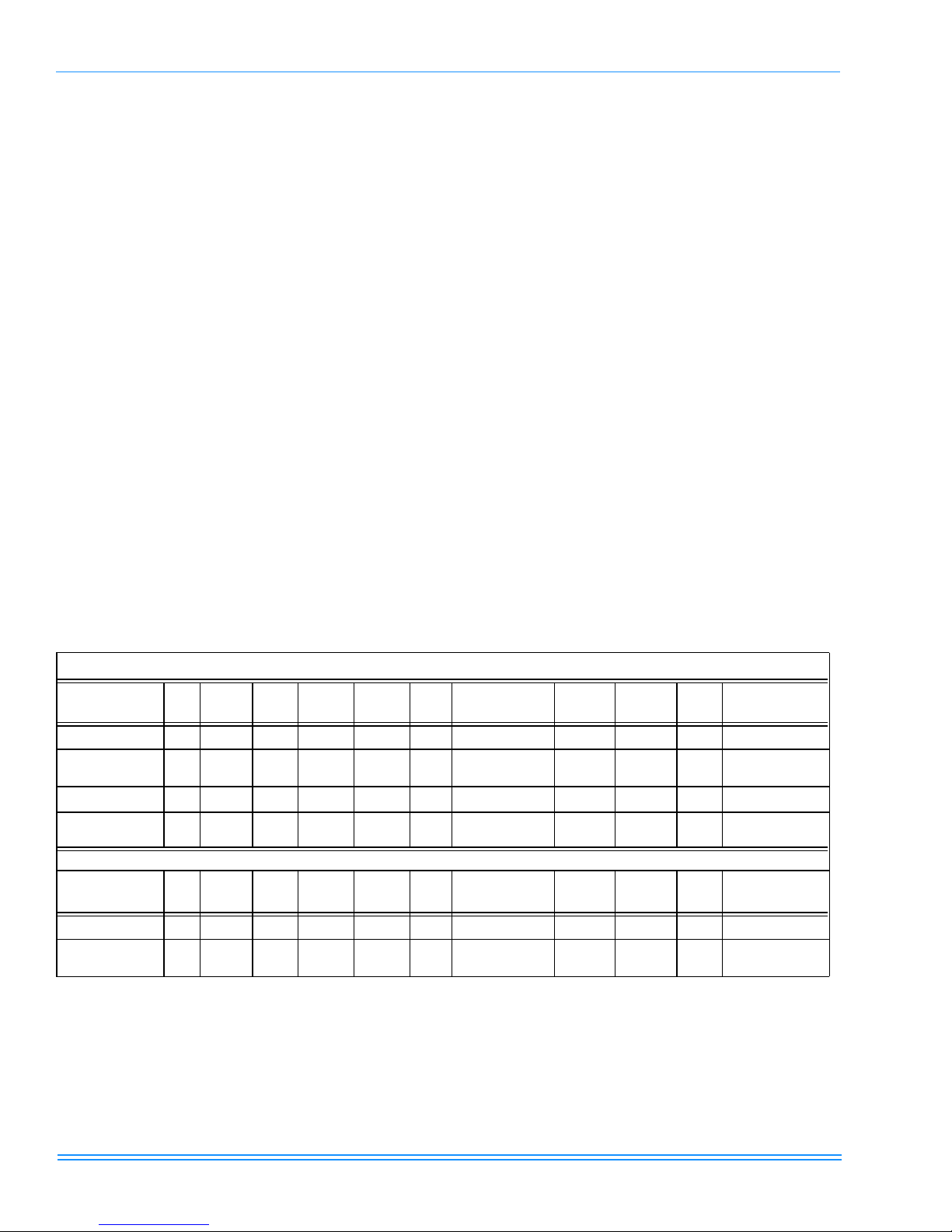

TABLE 1: UNIT CLEARANCES TO COMBUSTIBLES

UPFLOW / HORIZONTAL MODELS - (P*DU & G8D—UH)

APPLICATION TOP FRONT REAR

UPFLOW 1 6 0 0

UPFLOW

B-VENT

HORIZONTAL

HORIZONTAL

B-VENT

DOWNFLOW MODELS (P&DD & G8D—DN)

APPLICATION TOP FRONT REAR

DOWNFLOW 1 6 0 0

DOWNFLOW

B-VENT

1.

14-1/2” cabinet models only - all other units “0” clearance

2.

14-1/2” cabinet left airflow applications only - all other units and all right hand air flow applications “0” clearance.

3.

Special floor base or air conditioning coil required for use on combustible floor.

4.

Line contact only permitted between lines formed by the intersection of the rear panel and side panel (top in horizontal position)

of the furnace jacket and building joists, studs or framing.

1 3 0 0 0 1 COMBUSTIBLE YES YES YES NO

2

6 0 1 0 6 COMBUSTIBLE NO YES YES

3

0 3 0 1 0 1 COMBUSTIBLE NO YES YES

1 3 0 0 0 1

LEFT

SIDE

LEFT

SIDE

RIGHT

SIDE

1

3

RIGHT

SIDE

1

3

FLUE

FLUE

FLOOR/

BOTTOM

6 COMBUSTIBLE YES YES YES NO

FLOOR/

BOTTOM

6

1"

1"

4

4

CLOSET ALCOVE ATTIC

CLOSET ALCOVE ATTIC

YES YES YES NO

YES YES YES NO

LINE

CONTACT

YES

YES

LINE

CONTACT

3

3

4 Unitary Products Group

035-14527-000 REV A (599) Form 650.77-N3U

UNIT INSTALLATION

COMBUSTION AIR

All installations must comply with Section 5.3, Air for Combustion and Ventilation of the National Fuel Gas Code, ANSI

Z223.1 or Sections 7.2, 7.3 or 7.4 of CAN/CGA B149.1 or.2

Installation Code - latest editions.

An unconfined space: is not less than 50 cubic feet per

1000 Btu/hr input rating for all appliances installed in that

area.

Rooms communicating directly with the space containing the

appliances are considered part of the unconfined space, if

openings are not furnished with doors.

A confined space: is an area with less than 50 cubic feet

per 1000 Btu/hr input rating for all appliances installed in that

area.

The following must be considered to obtain proper air for

combustion and ventilation in confined spaces.

Air Source from Inside the Building -

Two permanent openings, one within 12 inches of the top of

the confined space and one within 12 inches of the bottom,

shall each have a free area of not less than one square inch

per 1,000 Btuh of total input rating of all appliances located in

the space. The openings shall communicate freely with interior areas having adequate infiltration from the outside.

NOTE : At least 100 square inches free area shall be used

for each opening.

Air Source from Outdoors -

1. Two permanent openings, one within 12 inches of the

top of the confined space and one within 12 inches of the

bottom, shall communicate directly, or by means of

ducts, with the outdoors or to such crawl or attic spaces

that freely communicate with the outdoors.

a. Vertical Ducts - Each opening must have a free

area of not less than one square inch per 4,000 Btuh

of total input of all appliances located in the space.

EXAMPLE:

NOTE: Ducts must have the same cross-sectional area as

the free area in the opening to which they are connected. The

minimum dimension of rectangular ducts shall be three

inches.

2. One permanent opening, commencing within 12 inches

of the top of the enclosure shall be permitted where the

equipment has clearances of at least 1 inch from the

sides and back and 6 inches from the front of the appliance. The opening shall communicate through a vertical

or horizontal duct to the outdoors, or spaces (crawl or

attic) that freely communicate with the outdoors and shall

have a minimum free area of:

a. 1 sq. in. per 3000 Btu per hr of the total input rating

of all equipment located in the enclosure.

b. Not less than the sum of the areas of all vent con-

nectors in the confined space.

3. Louvers, Grilles and Screens

a. In calculating free area, consideration must be given

to the blocking effects of louvers, grilles and

screens.

To estimate free area of a specific louver or grille (Refer to

Table2 on page5)..

TABLE 2: ESTIMATED FREE AREA

Wood or Metal

Louvers or Grilles

2

Screens

1.

Do not use less than 1/4 in. mesh

2.

Free area or louvers an grilles varies widely; installer

should follow louver or grille manufacturer’s instructions.

Wood 20-25%

Metal 60-70%

1/4 in. mesh or larger 100%

NOTE: If mechanically operated louvers are used, a means

to prevent main burner ignition and operation must be provided should louvers close during startup or operation.

Special Combustion and Ventilation Considerations

Operation of a mechanical exhaust, such as an exhaust fan,

kitchen ventilation system, clothes dryer or fireplace may create conditions requiring special attention to avoid unsatisfactory operation of gas appliances.

1

1

Total Input of All Appliances

= Square Inches Free Area

4000

b. Horizontal Ducts - Each opening must have a free

area of not less than one square inch per 2,000 Btuh

of total input of all appliances located in the space.

Unitary Products Group 5

Specially Engineered Installations

The above requirements shall be permitted to be waived

where special engineering, approved by the authority having

jurisdiction, provides an adequate supply of air for combustion, ventilation and dilution of flue gases.

035-14527-000 REV A (599) Form 650.77-N3U

Combustion Air Quality

The recommended source of combustion air is to use the outdoor air supply. Excessive exposure to contaminated combustion air will result in safety and performance related

problems. However, the use of indoor air in most applications

is acceptable, except as follows:

1. If the furnace is installed in a confined space it is recommended that the necessary combustion air come from

the outdoors by way of attic, crawl space, air duct or

direct opening.

2. If outdoor combustion air is used, there must be no exposure to the installations or substances listed in 3" below.

3. The following types of installations may require OUTDOOR AIR for combustion, due to chemical exposure.

a. Commercial buildings

b. Buildings with indoor pools

c. Furnaces installed in laundry rooms

d. Furnaces installed in hobby or craft rooms

e. Furnaces installed near chemical storage areas

Exposure to the following substances in the combustion air

supply may also require OUTDOOR AIR for combustion.

VENTING

It is the responsibility of the installer to verify

proper vent system operation.

CATEGORY I VERTICAL VENTING

Category I venting consists of vertically venting one or more

appliances in B-vent or masonry chimney (as allowed), using

single wall metal pipe or B-vent connectors. Type B-vent system extends in a general vertical direction and does not contain offsets exceeding 45 degrees, except that a vent system

having not more than one 60-degree offset is permitted.

NOTE: This appliance may be common vented with another

gas appliance as allowed by the following codes and standards.

The furnace rating plate lists the maximum vent gas temperature. This temperature must be used to select appropriate

venting materials and clearances. A typical example is shown

below.

f. Permanent wave solutions

g. Chlorinated waxes and cleaners

h. Chlorine based swimming pool chemicals

i. Water softening chemicals

j. De-icing salts or chemicals

k. Carbon tetrachloride

l. Halogen type refrigerants

m. Cleaning solvents (such as perchloroethylene)

n. Printing inks, paint removers, varnishes, etc.

o. Hydrochloric acids

p. Cements and glues

q. Antistatic fabric softeners for clothes dryers

r. Masonry acid washing chemicals

CATEGORY 1 - 450 F. MAX. VENT TEMP.

All installations must be vented in accordance with the

National Fuel Gas Code, NFPA 54/ANSI Z223.1 - latest edition. For reference, the National Fuel Gas Code Handbook,

available from NFPA (item JP-54HB96) is recommended.

The appliance must also be vented in compliance with all

local utility and code requirements. In Canada, the furnace

must be vented in accordance with the National Standard of

Canada, CAN/CGA-B149.1 and.2 - latest editions.

A furnace shall not be connected to a chimney flue

serving a separate appliance designed to burn

solid fuel.

6 Unitary Products Group

035-14527-000 REV A (599) Form 650.77-N3U

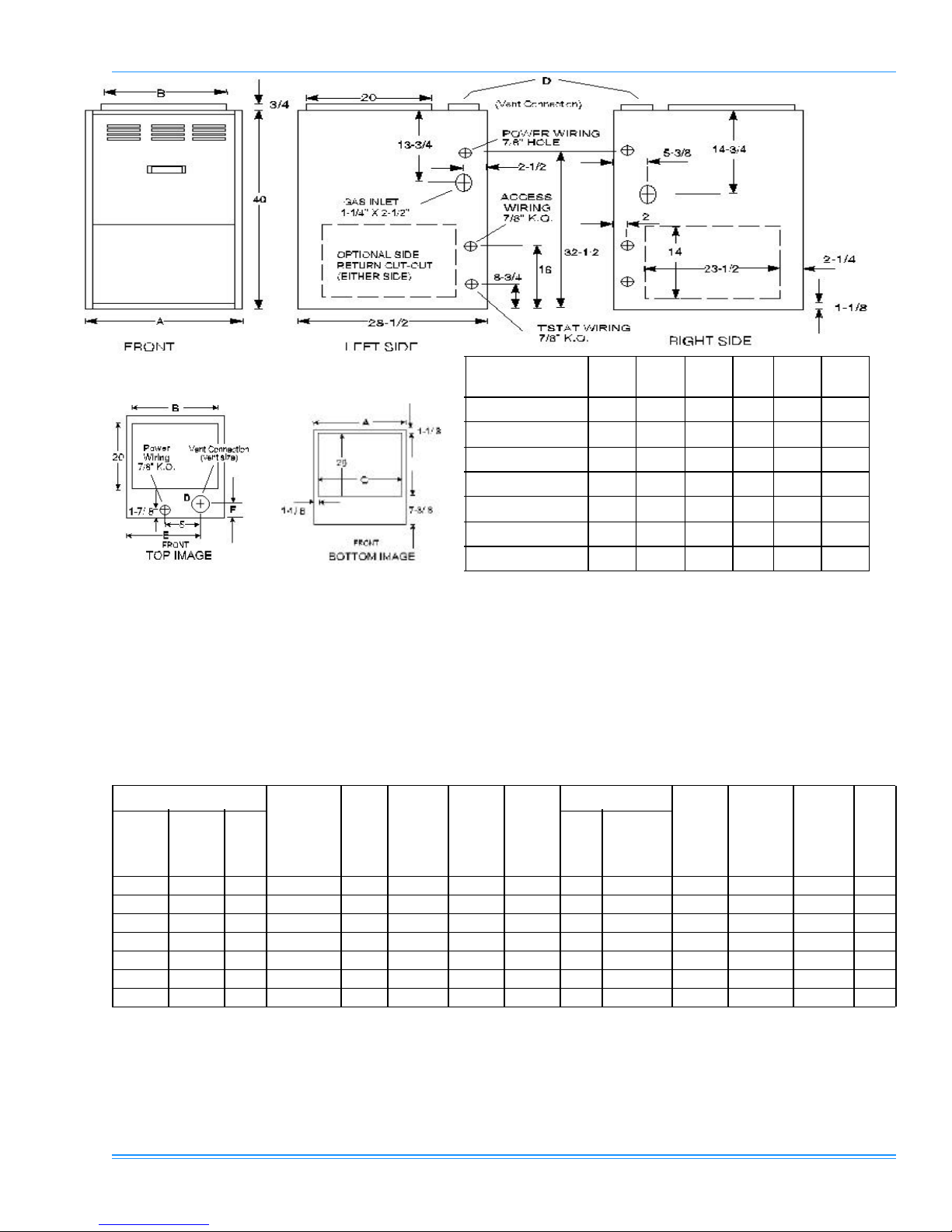

Models P*DU &

G8D—UH

A B C D E F

57 / 46 / 800 / “A” 14-1/2 13-1/4 10-1/8 3 10-1/8 4-3/16

80 / 64 / 1200 / “A” 14-1/2 13-1/4 10-1/8 4 10-1/8 3-3/4

80 / 64 / 1600 / “B” 17-1/2 16-1/4 13-1/8 4 11-5/8 3-3/4

100 / 80 / 1200 / “B” 17-1/2 16-1/4 13-1/8 4 11-5/8 3-3/4

100 / 80 2000 / “C” 21 19-3/4 16-5/8 4 13-3/8 3-3/4

120 / 92 / 1600 / “C” 21 19-3/4 16-5/8 4 13-3/8 3-3/4

120 / 80 / 2000 / “C” 21 19-3/4 16-5/8 4 13-3/8 3-3/4

* Input / Output / CFM / Cabinet

All dimensions are in inches and are approximate

FIGURE 1: 2-STAGE UPFLOW/HORIZONTAL FURNACE DIMENSIONS

TABLE 3: 2-STAGE UPFLOW/HORIZONTAL RATINGS & PHYSICAL/ELECTRICAL DATA

MODELS P* DU & G8D--UH CAB INE T

INPU T

MBH H/L

OUTPUT

MBH H/L

NOM.

CFM

WIDTH (IN.)

57/42 46/34 800 “A” 14-1/2 80 25 - 55 35 - 65 165 1/4 9 x 6 9.0 20 14 105

80/59 64/48 1200 “A” 14-1/2 80 30 - 60 40 - 70 175 1/3 10 x 7 9.0 20 14 117

80/59 64/48 1600 “B” 17-1/2 80 25 - 55 25 - 55 160 3/4 11 x 8 12.0 20 14 126

100/65 80/53 1200 “B” 17-1/2 80 25 - 55 40 - 70 170 1/2 10 x 8 12.0 20 14 128

100/65 80/53 2000 “C” 21 80 25 - 55 30 - 60 160 1 11 x 10 12.0 20 14 145

120/78 96/64 1600 “C” 21 80 25 - 55 45 - 75 180 1/2 10 x 10 12.0 20 14 145

120/78 96/64 2000 “C” 21 80 25 - 55 35 - 65 170 1 11 x 10 12.0 20 14 147

1.

AFUE numbers are determined in accordance with DOE test procedures.

2.

Wire size and overcurrent protection must comply with the National Electrical Code (NFPA-70-latest edition).

• For altitudes above 2,000 ft., reduce capacity 4% for each 1,000 ft. above sea level. Refer to Form 650.74-N1.1V.

• Wire size based on copper conductors, 60° C, 3% voltage drop.

• Continuous return air temperature must not be below 55° F.

AFU E

1

LOW FIRE

TEMP RISE

HIGH

°F

FIRE

TEMP

RISE °F

MAX.

OUTLET

AIR TEMP

°F

BLOWER TOTAL

HP SIZE (IN)

UNIT

AMPS

MAX.

OVER-

CUR REN T

PROTECT

MIN WIRE

(AWG) @

2

ONE WA Y

SIZE

75 FT.

2

OPER

WGT.

(L BS )

Unitary Products Group 7

035-14527-000 REV A (599) Form 650.77-N3U

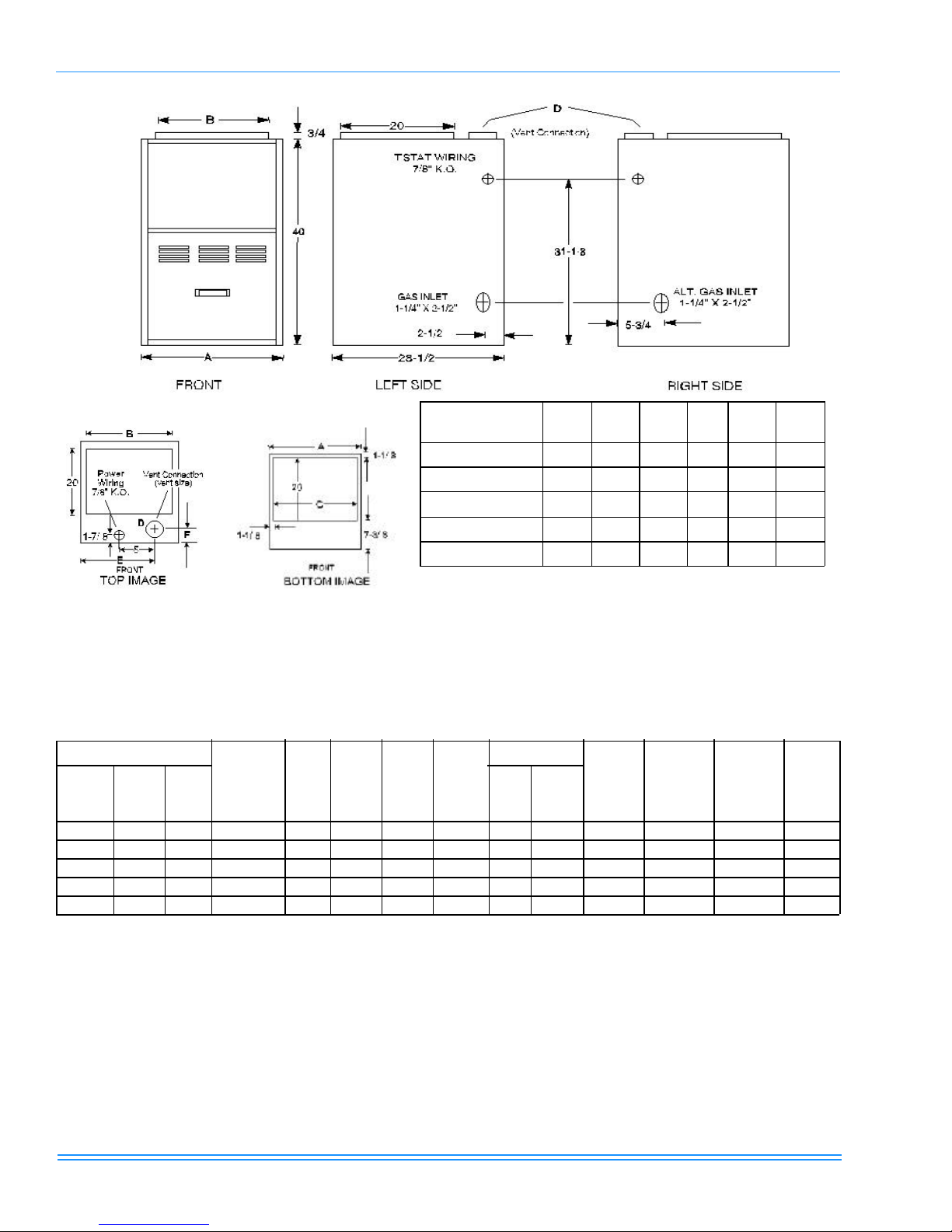

Models P*DD &

G8D—DN

A B C D E F

57 / 46 / 800 / “A” 14-1/2 13-1/4 12-1/4 3 10-1/8 4-3/16

80 / 64 / 1200 / “A” 14-1/2 13-1/4 12-1/4 4 10-1/8 3-3/4

80 / 64 / 1600 / “B” 17-1/2 16-1/4 15-1/4 4 11-5/8 3-3/4

100 / 80 / 1200 / “B” 17-1/2 16-1/4 15-1/4 4 11-5/8 3-3/4

120 / 80 / 2000 / “C” 21 19-3/4 18-3/4 4 13-3/8 3-3/4

* Input / Output / CFM / Cabinet

All dimensions are in inches and are approximate.

FIGURE 2 : 2-STAGE DOWNFLOW FURNACE DIMENSIONS

TABLE 4: 2-STAGE RATINGS & PHYSICAL/ELECTRICAL DATA

M ODE LS P *DD & G8D--DN CABI NET

INPUT

MBH

H/L

OU TPU T

MBH H /L

NOM.

CFM

WIDT H (IN.)

57/42 46/34 800 “A” 14-1/2” 80 20 - 50 30 - 60 160 1/4 10 x 6 9.0 20 14 110

80/59 64/48 1200 “A” 14-1/2” 80 25 - 55 30 - 60 160 1/2 10 x 8 12.0 20 14 120

80/59 64/48 1600 “B” 17-1/2” 80 20 - 50 25 - 55 160 3/4 11 x 10 12.0 20 14 130

100/65 80/52 1200 “B” 17-1/2” 80 25 - 55 40 - 70 170 1/2 10 x 8 12.0 20 14 125

120/78 96/64 2000 “C” 21” 80 25 - 55 30 - 60 160 1 11 x 10 12.0 20 14 150

1.

AFUE numbers are determined in accordance with DOE test procedures.

2.

Wire size and overcurrent protection must comply with the National Electrical Code (NFPA-70-latest edition).

• For altitudes above 2,000 ft., reduce capacity 4% for each 1,000 ft. above sea level. Refer to Form 650.74-N1.1V.

• Wire size based on copper conductors, 60° C, 3% voltage drop.

• Continuous return air temperature must not be below 55° F.

A FUE

1

LOW

FIRE

TEMP

R IS E °F

HIGH

FIRE

TEMP

R IS E °F

MAX.

OUT LE T

AIR T EMP

°F

B LOWE R TOTAL

HP SI ZE (IN)

AMPS

UNIT

MAX. OVER-

CUR REN T

PROTECT

MIN WIRE

SIZE (AWG)

2

@ 75 F T.

ONE WA Y

2

OPER

WGT.

(L BS )

8 Unitary Products Group

035-14527-000 REV A (599) Form 650.77-N3U

VENT SAFETY CHECK PROCEDURE

If this furnace is replacing a common-vented furnace, it may be necessary to resize the existing

vent line and chimney to prevent oversizing problems for the new combination of units. Refer to the

National Fuel Gas Code, ANSI Z223.1 or CAN/

CGA B149.1 or.2 Installation Code - latest editions.

The following steps shall be followed with each appliance

connected to the venting system placed in operation, while

any other appliances connected to the common venting system are not in operation.

1. Seal any unused openings in the common venting system.

2. Inspect venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code ANSI

Z223.1 or the CAN/CGA B149 Installation Codes and

these instructions. Determine that there is no blockage

or restriction, leakage, corrosion or other deficiencies

which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and windows and all doors between the space in which the appliance(s) connected to the venting system are located and

other spaces of the building. Turn on clothes dryers and

any other appliances not connected to the common venting system. Turn on any clothes dryers and any appliance not connected to the venting system.

7. If improper venting is observed during any of the above

tests, the venting system must be corrected.

8. Any corrections or resizing of the common venting system must be in accordance with the National Fuel Gas

Code, ANSI Z223.1 or Section 7, Venting Systems and

Air Supply for Appliances, CAN/CGA B149.1 or.2 Installation Code - latest editions. If the common vent system

must be resized, it should be resized to approach the

minimum size as determined using the appropriate

tables in Appendix G of the above codes or the venting

tables supplied with the furnace.

DUCTWORK

The duct system's design and installation must:

1. Handle an air volume appropriate for the served space

and within the operating parameters of the furnace specifications.

2. Be installed in accordance with standards of NFPA

(National Fire Protection Association) as outlined in

NFPA pamphlets 90A and 90B - (latest editions).

3. Create a closed duct system. The supply system must

be connected to the furnace outlet and the return duct

system must be connected to the furnace inlet. Both supply and return duct systems must terminate outside the

space containing the furnace.

4. Generally complete a path for heated or cooled air to circulate through the air conditioning and heating equipment and to and from the conditioned space.

Turn on any exhaust fans, such as range hoods and

bathroom exhausts so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close fireplace dampers.

4. Follow the lighting instructions. Place the appliance

being operated in operation. Adjust thermostat so appliance will operate continuously.

5. Test for draft hood equipped appliance spillage at the

draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

6. After it has been determined that each appliance connected to the venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas-burning appliance

to their previous conditions of use.

Unitary Products Group 9

The cooling coil must be installed in the supply air

duct downstream of the furnace.

When the furnace is used in conjunction with a cooling coil,

the furnace must be installed parallel with, or on the upstream

side of the cooling unit to avoid condensation in the primary

heat exchanger.

When a parallel flow arrangement is used, the dampers or

other means used to control air flow must be adequate to prevent chilled air from entering the furnace, and if manually

operated, must be equipped with means to prevent operating

of either unit unless the damper is in the full heat or cool position.

035-14527-000 REV A (599) Form 650.77-N3U

UPFLOW/HORIZONTAL MODELS -

UPFLOW APPLICATION

Supply Plenum Connection

Attach the supply plenum to the furnace outlet duct connection flanges.

This is typically through the use of S

cleat material when a metal plenum is

used. The use of an approved flexible

duct connector is recommended on all

installations. This connection should be

sealed to prevent air leakage.

If a matching cooling coil is used, it

may be placed directly on the furnace

outlet and sealed to prevent leakage.

Follow the coil instructions for installing

the supply plenum.

On all installations without a coil, a removable access panel

is recommended in the outlet duct such that smoke or

reflected light would be observable inside the casing to indicate the presence of leaks in the heat exchanger. This

access cover shall be attached in such a manner as to prevent leaks.

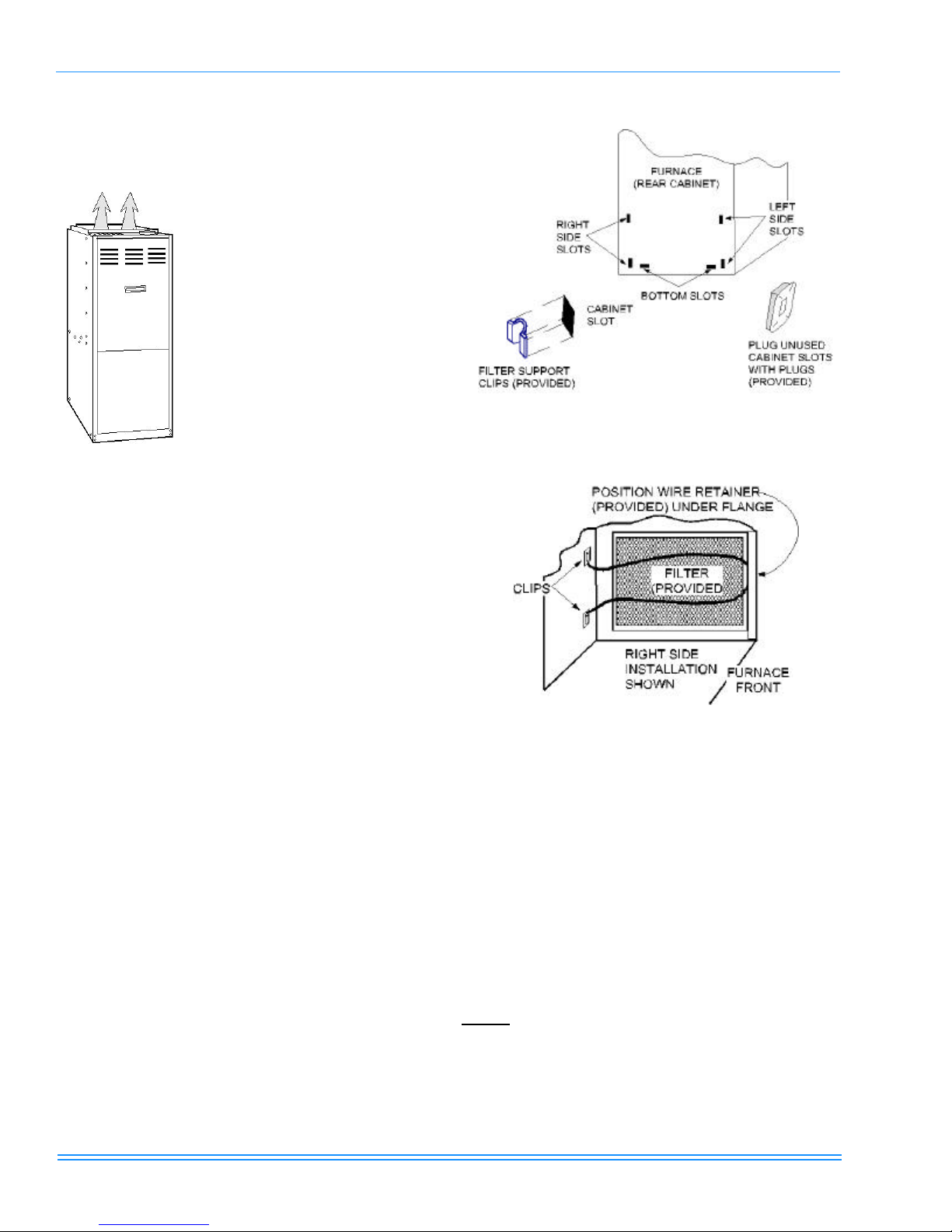

FIGURE 3 : FURNACE FILTER SLOT LOCATIONS

Return Duct Connection

Return air may enter the furnace through the side(s) or bottom depending on the type of application. Return air may not

be connected into the rear panel of the unit. See the specific

type application installation for details. Be sure to see the Filters section of this instruction.

FILTERS INSTALLATION

(UPFLOW/HORIZONTAL)

All applications require the use of a filter. A high velocity filter

and retainer are provided for field installation.

Internal Installation

1. Select desired filter position (left/right side, or bottom).

Remove the corresponding cabinet cut-outs per instructions provided.

2. Install snap-in retainer clips into the corresponding slots

from the outside rear of the cabinet. (Refer to Figure 3

on page10) To prevent cabinet air leaks, install snap-in

plugs (provided) into the unused slots at the outside rear

of the cabinet.

3. Install the wire retainer inside the cabinet. Insert the

open ends of the wire retainer into the clip loops at the

rear of the blower compartment. The retainer wire should

pivot freely like a hinge, on the clips at the rear of the

FIGURE 4 : SIDE FILTER RETAINER PLACEMENT

4. Install the filter(s) provided. Cut filter if necessary to

match air opening in cabinet. Filter should extend

beyond opening edge as much as possible to prevent air

from bypassing the filter. DO NOT remove stiffening rods

from inside the filter. Shorten the rods, if necessary, to

match final filter size.

5. Position the filter between the wire retainer and the cabinet wall (or floor) so it completely covers the cabinet air

opening and secure the filter in place at the front of the

cabinet by fastening the closed (looped) end of the

retainer wire under the flanged edge of the cabinet.

When properly installed the filter should fit flush with all

four sides of the cabinet wall.

NOTE: Air velocity through throw-away type filters may not

exceed 300 feet per minute. All velocities over this require the

use of high velocity filters.

10 Unitary Products Group

Loading...

Loading...