LUX WS-125 Original Instructions Manual

WS-125

302 249

GB Angle grinder GR Γωνιακός τροχός

Winkelschleifer_302249.book Seite 1 Mittwoch, 16. September 2015 12:59 12

2

GB Original instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

GR Πρωτότυπο οδηγιών χρήσης . . . . . . . . . . . . . . . . . . . . . . . . . 13

Winkelschleifer_302249.book Seite 2 Mittwoch, 16. September 2015 12:59 12

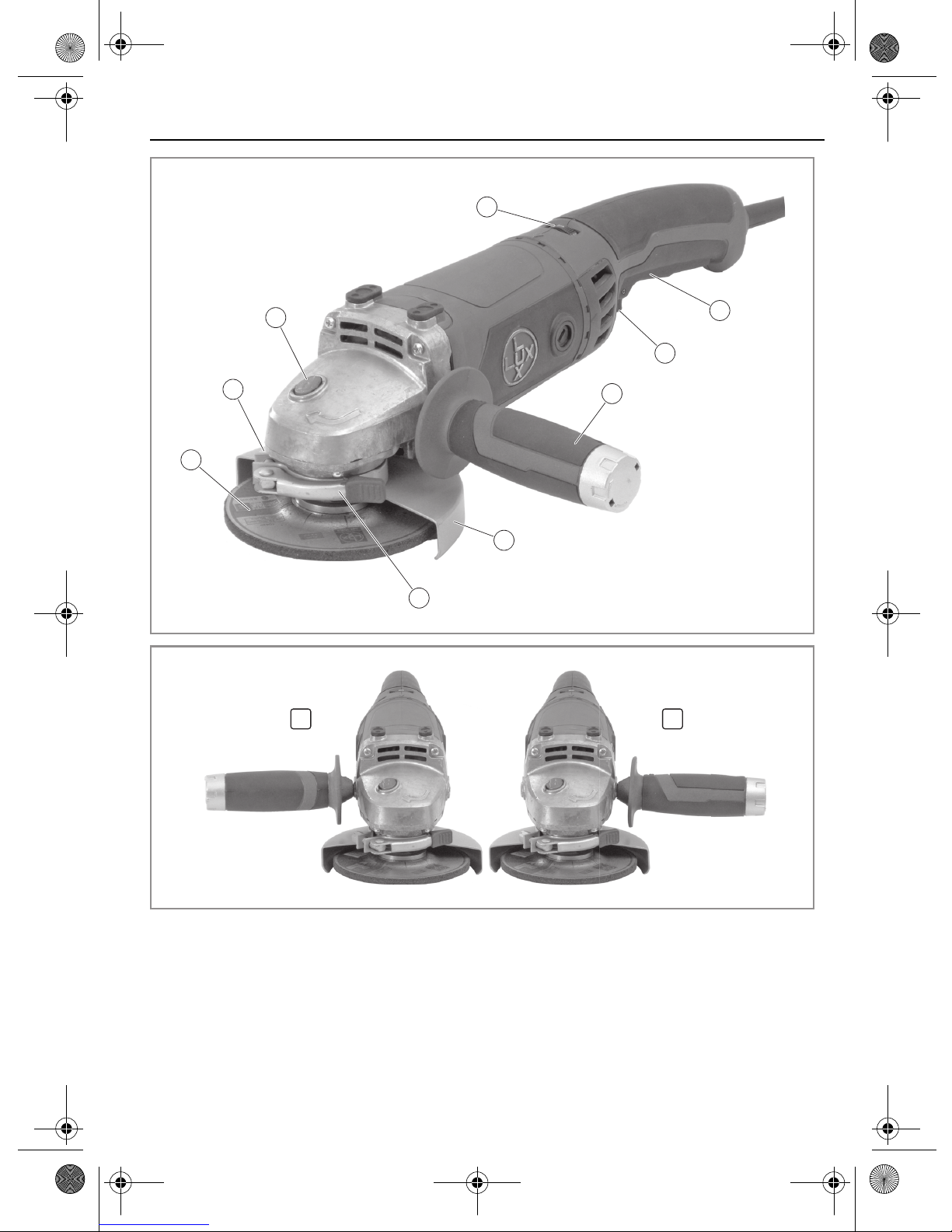

3

1

9

8

7

3

2

4

5

6

1

21

2

Winkelschleifer_302249.book Seite 3 Mittwoch, 16. September 2015 12:59 12

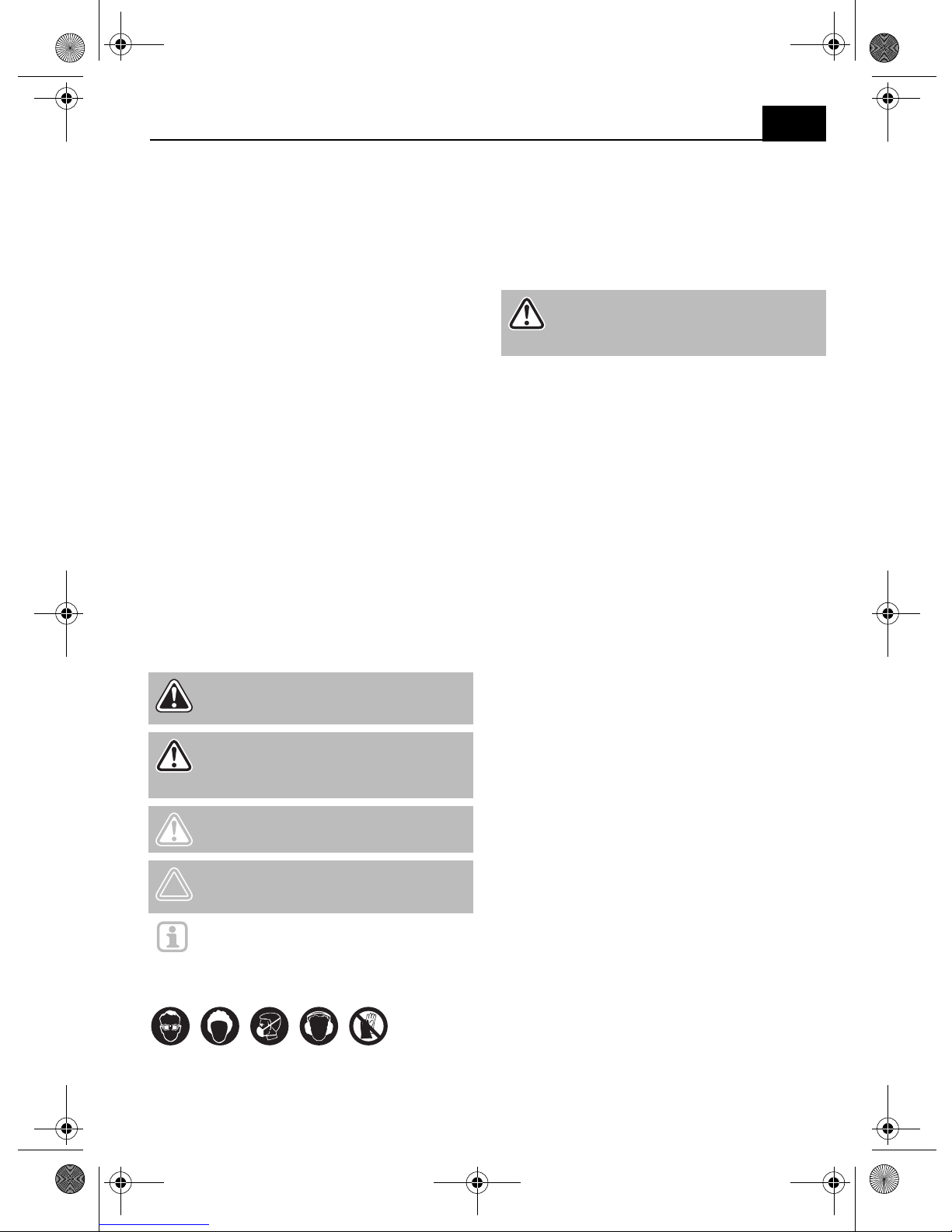

4

10

2

1

3

3 2

1

4

5 11

8

6

5

Winkelschleifer_302249.book Seite 4 Mittwoch, 16. September 2015 12:59 12

5

Original instructionsAngle grinder

Table of contents

Before you begin… . . . . . . . . . . . . . . . . . . . . . . . 5

For your safety. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Your machine at a glance . . . . . . . . . . . . . . . . . . 9

Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Storage, transportation . . . . . . . . . . . . . . . . . . 11

Malfunctions and troubleshooting . . . . . . . . . 11

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Before you begin…

Intended use

The appliance is intended exclusively for non-professional use for dry sanding and cutting of metal and

stone materials.

The machine must be operated in accordance with

the specifications provided in these instructions.

This product is not intended for commercial use.

Generally acknowledged accident prevention regulations and enclosed safety instructions must be

observed.

Only perform work described in these instructions for

use. Any other use is improper. The manufacturer will

not assume responsibility for damage resulting from

such use.

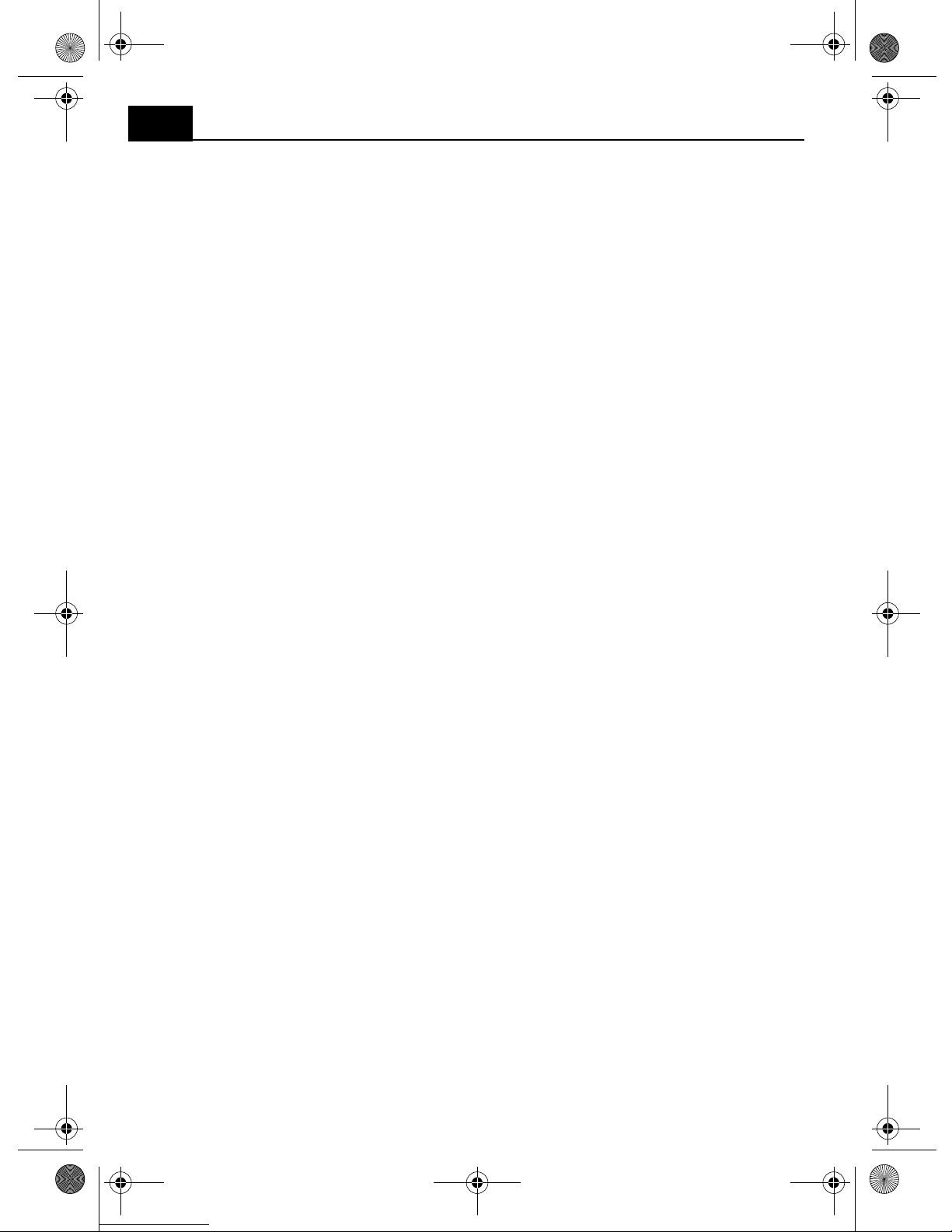

What are the meanings of the symbols used?

Danger notices and information are clearly marked

throughout these instructions for use. The following

symbols are used:

These symbols identify the required personal protection equipment:

For your safety

General safety instructions

• To operate this device safely, the user must have

read and understood these instructions for use

before using the device for the first time.

• If you sell or pass the device on, you must also

hand over these operating instructions.

General power tool safety warnings

• Save all warnings and instructions for future

reference. The term power tool in the warnings

refers to your mains operated (corded) power

tool or battery operated (cordless) power tool.

Work area safety

• Keep work area clean and well lit. Cluttered

and dark areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or

fumes.

• Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical safety

• Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

• When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

• If operating a power tools in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

Personal safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

DANGER! Direct danger to life and risk

of injury! Directly dangerous situation that

may lead to death or severe injuries.

WARNING! Probable danger to life and

risk of injury! Generally dangerous situa-

tion that may lead to death or severe injuries.

CAUTION! Possible risk of injury! Dangerous situation that may lead to injuries.

NOTICE! Risk of damage to the device!

Situation that may lead to property damage.

Note: Information to help you reach a better understanding of the processes

involved.

WARNING! Read all safety warnings and

all instructions. Failure to follow the warn-

ings and instructions may result in electric

shock, fire and/or serious injury.

GB

Winkelschleifer_302249.book Seite 5 Mittwoch, 16. September 2015 12:59 12

6

• Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to power source and/or battery pack,

picking up or carrying the tool. Carrying

power tools with your finger on the switch or

energizing power tools that have the switch on

invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better con-

trol of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities,

ensure these are connected and properly

used. Use of these devices can reduce dust-

related hazards.

Power tool use and care

• Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the switch does

not turn it on and off. Any power tool that can-

not be controlled with the switch is dangerous

and must be repaired.

• Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate the power tool. Power tools are dangerous

in the hands of untrained users.

• Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect

the power tool’s operation. If damaged, have

the power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

• Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

• Have your power tool serviced by a qualified

repair person using only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

Shared safety notes regarding grinding,

sandpaper sanding, working with wire brushes,

polishing and abrasive cutting.

• This power tool is to be used as an sandpaper

grinder, sandpaper sander, wire brush and

abrasive cutting tool. Observe all the safety

notes, instructions, representations and data

received with the power tool. If you do not

observe the following instructions, electrical

shock, film and/or serious injuries may be the

result.

• This electrical tool is not suitable for polishing. Applications for which the power tool are

not intended may cause risks and injuries.

• Do not use accessories that have not been

designed and recommended by the manufacturer for this specific power tool. Just

because you are able to attach an accessory to

your power tool this does not guarantee that it is

safe to use.

• The permitted revolutions of the tool must be

at least as high as the highest revolutions

specified on the power tool. Accessories that

rotate faster than they are permitted to may

break and fly.

• The external diameter and thickness of the

tool must match the dimensional specification of your power tool. Incorrectly dimen-

sioned tools cannot be sufficiently shielded or

controlled.

• Sanding discs, flanges, sanding plates or

other accessories must fit precisely to the

sanding spindle of your power tool. Tools

that do not fit precisely to the sanding spindle of

the power tool will rotate unevenly, vibrate heavily and may cause loss of control over the device.

• Do not use damaged tools. Before each use,

check tools like sanding discs for chips and

tears, sanding plates for tears, wear or heavy

use, wire brushes for loose or broken bristles.

If the power tool or the tool itself are dropped,

check to see whether it is damaged or use an

undamaged tool. When you have checked

and inserted the tool, ensure that you and any

other people in the vicinity are out of the

sphere of influence of the rotating tool and

operate the power tool for a minute at the

highest revolutions. Damaged tools will usually

break within this test period.

• Wear personal safety gear. Depending on the

work you are doing, wear a full-face visor,

visor or protective goggles. If appropriate,

wear a dust mask, ear defenders, protective

gloves or a special apron designed to keep

sanding and material particles away from

you. Your eyes should be protected from the fly-

ing objects that may be generated during various

applications. Dust or breathing masks must be

capable of filtering the dust generated during

GB

Winkelschleifer_302249.book Seite 6 Mittwoch, 16. September 2015 12:59 12

7

operation. If you are exposed to loud noise for

extended periods, you may suffer a loss of hearing.

• Ensure that other people are kept a safe distance from your workplace. Anyone entering

the workplace must wear personal protective

gear. Pieces of the work piece or broken tools

may fly away and cause injuries even outside the

direct working area.

• Hold the device by the insulated surfaces only

when carrying out work during which it is

possible that the tool may come across hidden power cables or its own cable. Contact

with a cable that carries power will subject the

metal parts of the device to current and will lead

to electrical shock.

• Keep the power cable away from rotating

tools. If you loose control over the power tool,

the power cable may be cut or caught and your

hand or arm may be pulled into the rotating tool.

• Never set the power tool down before the tool

has come to a completed standstill. The

rotating tool may come into contact with the surface and cause you to loose control over the

power tool.

• Never operate the power tool when you are

carrying it. Your clothing may be caught as a

result of accidental contact with the rotating tool

causing the tool to injure you.

• Clean the ventilation slots of your power tool

regularly. The motor fans draw dust into the

housing and a large deposit of metal dust can

cause electrical hazards.

• Never use power tool near flammable materials. Sparks may set fire to these materials.

• Do not use tools that require a liquid cooling

agent. The use of water or other liquid cooling

agents may lead to electrical shock.

Kickback and the appropriate safety notes

Kickback is a sudden reaction caused as a result of

a jammed or blocked rotating tool, for example, a

sanding disc, sanding plate, wire brush etc. Jamming or blocking causes the rotating tool to come to

an abrupt stop. This causes an uncontrolled power

tool to accelerate against the direction of rotation of

the tool at the blocked point.

For example, if a grinding disc becomes stuck or

blocked in a work piece, the edge of the grinding

disc that dips into the work piece may get caught

and the grinding disc will break away or cause kickback. The grinding disc will then move towards the

operator or away from them in accordance with the

direction of rotation of the disc at the blocked point.

This may also cause grinding discs to break.

A kickback is a consequence of incorrect or faulty

use of the power tool. It can be prevented by the use

of suitable measures, as described below:

• Hold the power tool securely with both hands

and position your body and arms in such a

way that you are able to absorb any kickback.

Always use the additional handle, if there is

one available, in order to ensure you have the

greatest possible control over kickback

forces or reaction torque when the tool is at

top speed. The operator is able to master kick-

back or reaction forces if they take the appropriate care.

• Never put your hand close to the rotating

tool. The tool may move over your hand in the

event of kickback.

• Keep your body out of the area that the power

tool would jump to in the event of kickback.

Kickback pushes the power tool in the opposite

direction to the movement of the sanding disc at

the blocked point.

• Be especially careful around corners, sharp

edges etc. Avoid tools bouncing off work

pieces and becoming jammed. The rotating

tool will tend to jam at corners, sharp edges or

when it bumps against something. This will lead

to a loss of control or kickback.

• Do not use chained or toothed saw blades.

Such tools will often cause kickback of the loss

of control over the power tool.

Special safety notes regarding grinding and

abrasive cutting:

• Only use grinding tools permitted for use with

your power tool and the protective hood

designed for use with these tools. Grinding

tools that have not be designed for use with the

power tool cannot be sufficiently shielded and

are thus unsafe.

• The protective hood must be affixed securely

to the electrical tool and set in such a way

that it ensures the maximum level of safety

possible, i.e. the smallest possible area of the

grinding tool is exposed to the operator. The

protective hood should protect the operator

from broken pieces and accidental contact with

the grinding tool.

• Grinding tools may only be used for the purposes recommended. For example: Never

use the side surface of a cutting disc to

grind. Cutting discs are designed to be used to

remove material with the edge of the disc. Lateral forces on these tools may break them.

• Always used undamaged tensioning flanges

in the correct size and shape for the cutting

disc you have selected. Suitable flanges sup-

port the cutting disc and thus reduce the risk of

the disc breaking. Flanges for cutting discs may

differ from flanges for other grinding discs.

• Do not use worn grinding disc from larger

power tools. Grinding discs for larger power

tools are not designed to cope with the higher

revolutions of smaller power tools and may

break.

Further additional safety notes regarding

abrasive cutting:

• Avoid jamming the cutting disc or applying

too high a pressure. Do not carry out any

excessively deep cuts. Overloading the cutting

disc increases the pressure and the tendency to

tilt or block and thus increases the risk of kickback or of the disc breaking.

GB

Winkelschleifer_302249.book Seite 7 Mittwoch, 16. September 2015 12:59 12

8

• Avoid the area in front of and behind the rotat-

ing disc. If you operate the device in such a way

that the cutting disc in the work piece is moved

away from you, in the event of kickback, the

power tool and the rotating disc may be thrown

towards you.

• If the cutting disc is jammed or you need to

interrupt your work, switch the power tool off,

and hold it motionless until the disc has come

to a standstill. Never attempt to pull a still

operating cutting disc out of the cut as this

may cause kickback. Investigate and take cor-

rective actions to eliminate the cause of the jam.

• Do not switch the power tool back on as long

as it remains stuck in the work piece. Allow

the cutting disc to achieve the full revolutions

before you continue to cut carefully. Other-

wise, the disc may get caught, jump out of the

work piece or cause kickback.

• Support panels or large work pieces to minimise the risk of kickback caused by a trapped

disc. Large work pieces may bend under their

own weight. The work piece must be supported

on both sides, near the line of cut and near the

edge.

• Be very carefully when making plunge cuts in

existing walls or in other areas that are difficult to see. The plunging disc may cut into gas

or water pipes, electrical cables or other objects

and cause kickback.

Special safety notes regarding sandpaper

sanding

• Do not use over dimensioned sanding sheets,

instead following the manufacturer’s instructions regarding size. Sanding sheets that pro-

trude beyond the sanding plate may cause injuries, jamming and tearing of the sheets or cause

kickback.

Special safety notes regarding working with

wire brushes

• Please note that wire brushes will loose wire

bristles during normal operation. Do not overload the wires by applying too high a pressure. Flying wire bristles may easily pass

through very thing clothing and/or skin.

• If a protective good is recommended, make

sure that the hood and the wire brush do not

make contact. Wheel and cup brushes may

increase in diameter as a result of pressure and

centrifugal forces.

Additional safety notes

• Prior to starting work, use appropriate tool to

determine whether there are any hidden supply lines are located on the area you are working in. If in doubt, ask the relevant supply services. Contact with power lines may cause fire

and electrical shock. Damaging a gas pipe may

cause an explosion. Damaging a water pipe

leads to considerable property damage and may

cause electrical shock.

• Secure the work piece. Use tensioning equipment or a vice to secure the work piece to help

prevent kickback or uncontrolled flying of the

work piece (e.g. when getting jammed in the

work piece).

• Keep your workplace clean. Mixed contamination by various materials is particularly dangerous. Light metal dust (e.g. aluminium) can

ignite or explode easily.

• Inform yourself about the surface to be

sanded and any dusts and vapours that may

be generated. If in doubt, do not breath in

even small amounts of the generated dusts

and vapours. When sanding certain surfaces

(various metals, minerals or woods as well as

weather protecting paints) damaging/poisonous

dusts may be generated which can cause allergic reactions or serious illness. Do not breathe

these dusts and vapours in and avoid all contact.

Materials containing asbestos may only be processed by specialists.

• Never use the power too with a damaged

cable. Do not touch a damaged cable and pull

out the power plug. Damaged cables increase

the risk of electric shock.

• Prevent overheating of the device and the

work piece. Excess heat may damage the tool

and the device.

• Shortly after being used, the tool may be very

hot. Allow a hot tool to cool down. Touching

a hot tool may cause burns.

• Never clean a hot tool with flammable liquids. There is a risk of fire and explosion.

• Keep the handles dry and free of grease.

Slippery handles can lead to accidents.

• Always comply with the all applicable domestic and international safety, health, and working regulations. Inform yourself before you start

work about the regulations that apply at the site

of the device.

• Remember that moving parts may also be

located behind ventilation and venting slots.

• Remember that moving parts may also be

located behind ventilation and venting slots.

Risks caused by vibrations

The vibration values specified in the technical data

represent the main uses of the device. The actual

existing vibrations during use may deviate from

these as a result of the following factors:

• Incorrect use of the product;

• Unsuitable tools inserted;

• Unsuitable material;

• Insufficient maintenance.

You can reduce the risks considerably by following

the tips below:

– Maintain the device in accordance with the

instructions in the operating instructions.

– Avoid working at low temperatures.

CAUTION! Risk of injury due to vibrations! Vibrations may, in particular for per-

sons with circulation problems, cause damage to blood vessels and/or nerves.

If you notice any of the following symptoms, stop working immediately and consult a doctor. Numbness of body parts, loss

of sense of feeling, itching, pins and needles, pain, changes in skin colour.

GB

Winkelschleifer_302249.book Seite 8 Mittwoch, 16. September 2015 12:59 12

Loading...

Loading...