Luvata LVD, LVDV 40, LVDV 50 User Manual

GB

Air heater unit LVD

User’s Guide

About Luvata

Luvata is a world-leader in metal fabrication, component manufacturing and related

engineering and design services. We are committed to partnering with our customers

to help them increase their competitiveness. Our products and services enable our

customers to improve operational efficiency, improve products and reduce tied-up

capital. This focus on our customers’ results, backed by our unfailing reliability, makes

us a partner on which our customers base their future development.

General description

The air heater unit consists of a fan, motor and heat

exchanger and it is used to heat air with water. The water

circulates in the air heater unit’s heat exchanger and

heats the air with the help of the fan. The air heater unit

can be tted with various accessories to control the supply

of heat. Its low external height ensures that it can be

installed in premises with varying roof heights.

www.luvata.com/coiltech1034564 We reserve the right to alter speci cations

SE FI

Translated from the original Swedish version

1034564 We reserve the right to alter speci cations

Air heater unit LVD

GB

2

General

• Always read through the entire User’s Guide before

using the product.

• Always position the air heater unit so that it is not

accessible to unauthorised personnel.

• All work on the air heater unit must be carried out by

quali ed personnel with knowledge of the product and

the applicable safety instructions.

During operation, both the air heater unit and the

air it is blowing out can be hot, which can cause

personal injury.

The air heater unit must not be installed in

environ ments where there is an explosion risk.

Data plate

The data plate is located on one of the sides of the air

heater unit and contains information about:

• Order number

• Product code

• Maximum working temperature

• Maximum working pressure

• Test pressure

• Motor data

• Manufacturer

• Year of manufacture

• Net dry weight

• Fluid volume

Operating pressure

The air heater unit may only be used in a system designed

for its maximum working pressure (MPa) and its maximum

temperature (°C). The values are stated on the air heater

unit’s data plate.

Installation and pipe connections

The air heater unit must be permanently installed. Fasteners and brackets must be capable of withstanding the

load of the air heater unit’s total weight (net weight of air

heater unit and uid in air heater unit). The air heater

unit’s pipe connections must not be subjected to the

weight of the connecting pipe system nor to expansion

forces.

NOTE: Loads and impacts on the pipe system can cause

damage to the air heater unit.

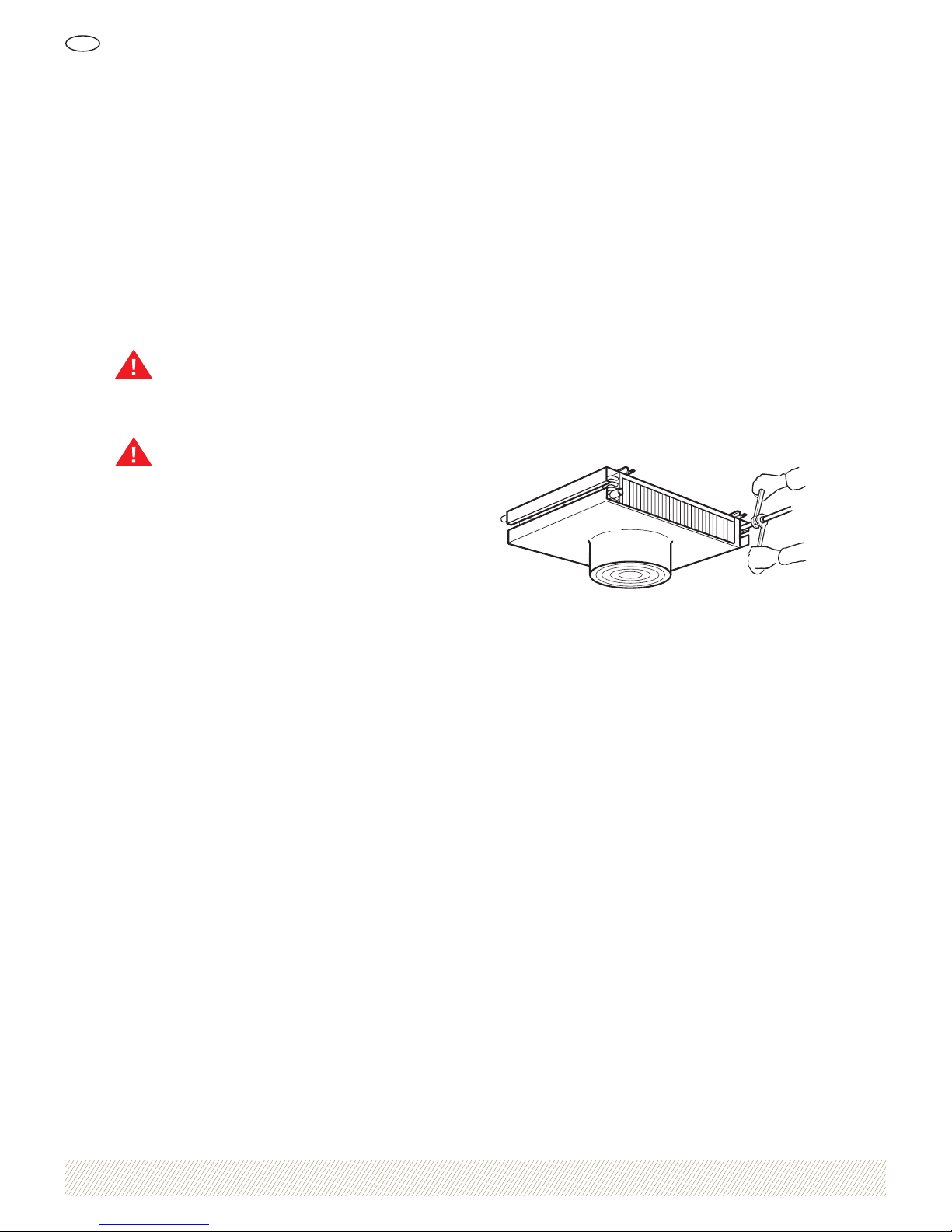

Use a counterhold when tightening the connecting

coupling to prevent the connecting pipes from rotating,

see Figure 1.

Figure 1. Tightening the connecting coupling

Cleaning

Always use environmentally friendly cleaning agents that

will not damage the air heater unit.

Certi cation

Luvata is accredited in accordance with the ISO 9001

quality management system and ISO 14001 environmental management system.

Product description and safety instructions

1034564 We reserve the right to alter speci cations

Air heater unit LVD

GB

3

On delivery

The air heater unit is designed to withstand normal loads

during transport. After transport and unloading it is

important to check that no damage has occurred. Check

in particular the ns of the heat exchanger and the outer

casing and connecting pipes of the air heater unit. Any

transport damage should be reported immediately to the

carrier and to Luvata. Also make notes on the consignment note.

Installation and pipe connections

The air heater unit must be permanently installed and

positioned so that the required air supply is obtained.

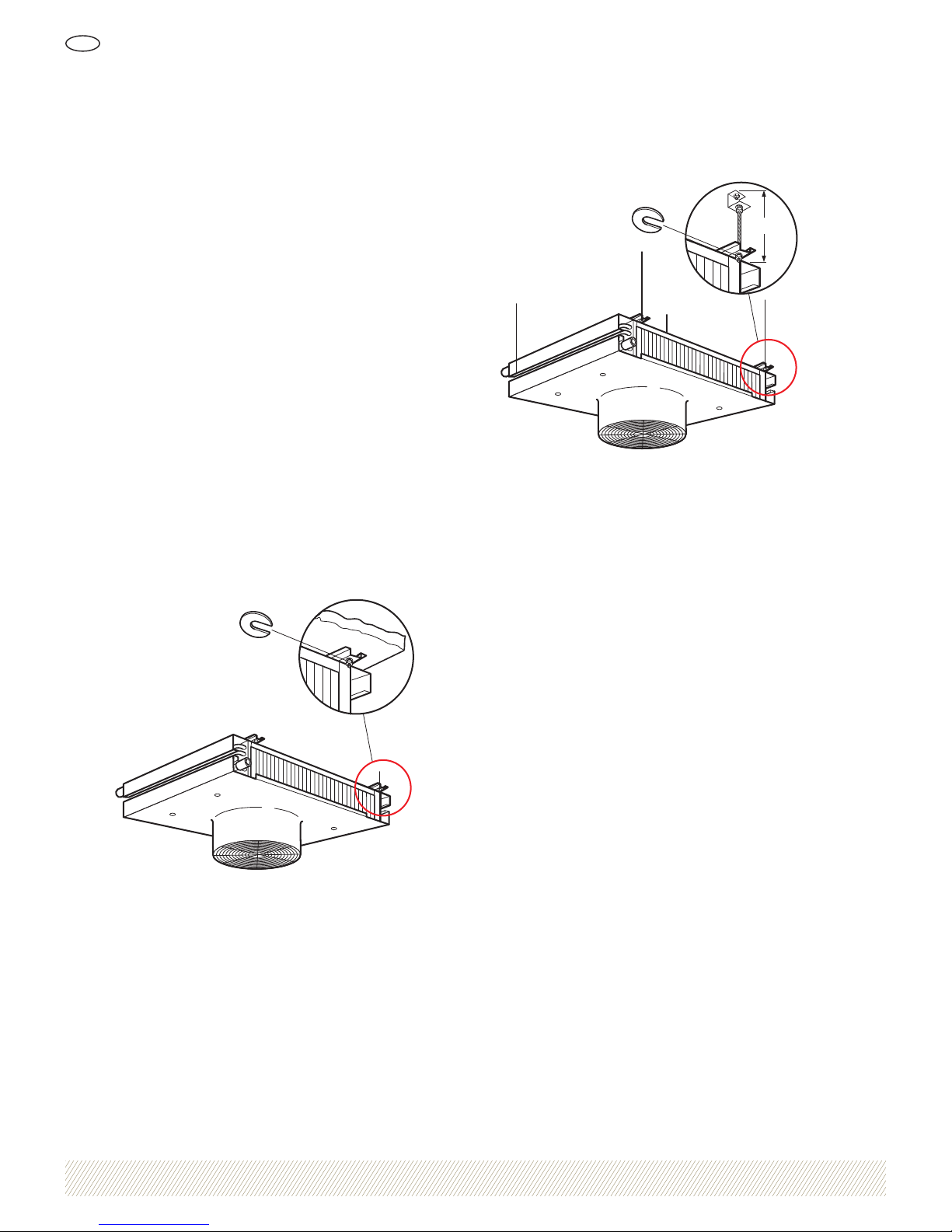

The air heater unit is intended to be installed directly on

the ceiling or by using drop rods (accessory LVDZ-03),

see Figure 2 and Figure 3. Both the air heater unit and

accessories are provided with holes which are designed for

installation.

If air discharge sleeve LVDZ-04 is used, the contact guard

should be tted to it. The air discharge sleeve is tted to

the air heater unit’s fan outlet.

Any pipe connections can be used for the uid connections.

Figure 2. Installation on the ceiling

350 mm

Figure 3. Installation using drop rods

Electrical connection

The fan motor must be connected to a lockable safety

switch. The safety switch must not be used to start and

stop the unit, but it must be started/stopped using other

external equipment.

Ahead of the motor a motor cut-out should be tted which

must not be set higher than the motor’s maximum permitted current. A motor cut-out is not necessary on motors

with an integrated temperature monitor when the temperature monitor is connected.

On delivery the fan motor is connected to a junction box

located on one of the sides of the air heater unit.

The connecting electrical cable is connected as illustrated

in the wiring diagram in the section headed Connection

diagram. Then check that the fan rotates in the direction

of the rotation arrow. The arrow is located on the outside

of the fan ring.

Dismantling

When dismantling the air heater unit from a system, it

must rst be drained of all liquid.

NOTE: Environmentally hazardous liquids must be

collected in a container and left for disposal/recycling.

Installation

1034564 We reserve the right to alter speci cations

Air heater unit LVD

GB

4

Preventive maintenance

The following should be checked regularly to prevent

operational failures:

• Abnormal sounds or vibrations – check motor bearing

and fan impeller.

• Fastening devices – check that all bolted joints are

undamaged.

• Electrical installation – check for any damage and that

the safety switch functions correctly.

• Fin structure – check that it is clean and undamaged.

• Fan impeller – check that it is clean and undamaged.

Fan unit

The fan motors do not require regular maintenance

because they have permanently lubricated bearings.

Cleaning

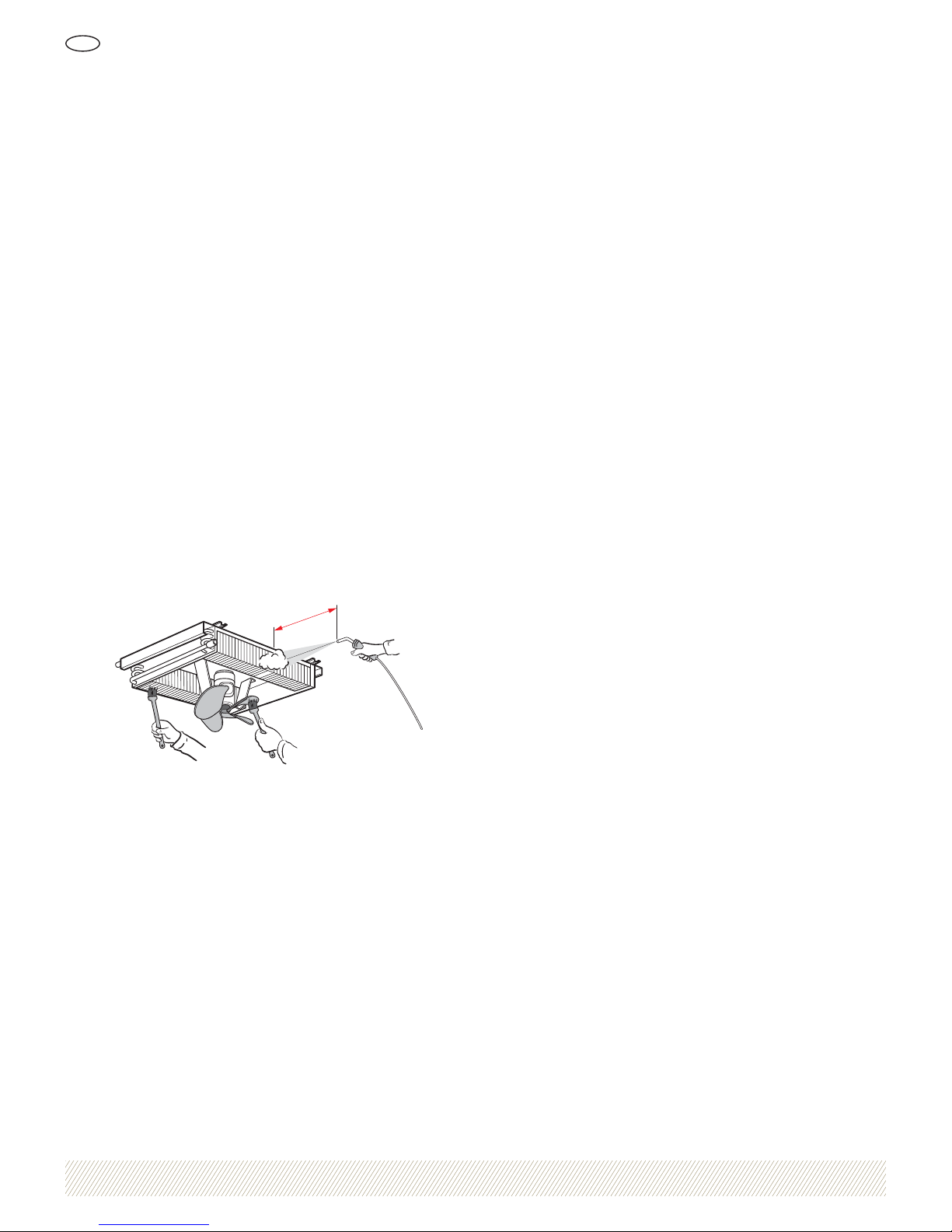

The best method of cleaning the air heater unit’s n heat

exchanger is to use compressed air or a high pressure

washer. The nozzle should always be held at right angles

to the surface of the ns and not closer than 150 mm so

as not to damage the ns, see Figure 4. Fins damaged

during cleaning can be straightened using a n comb

(accessory QLAZ-20).

Min 150 mm

Figure 4. Cleaning the n heat exchanger

When cleaning with compressed air:

1. Switch off the mains supply to the air heater unit.

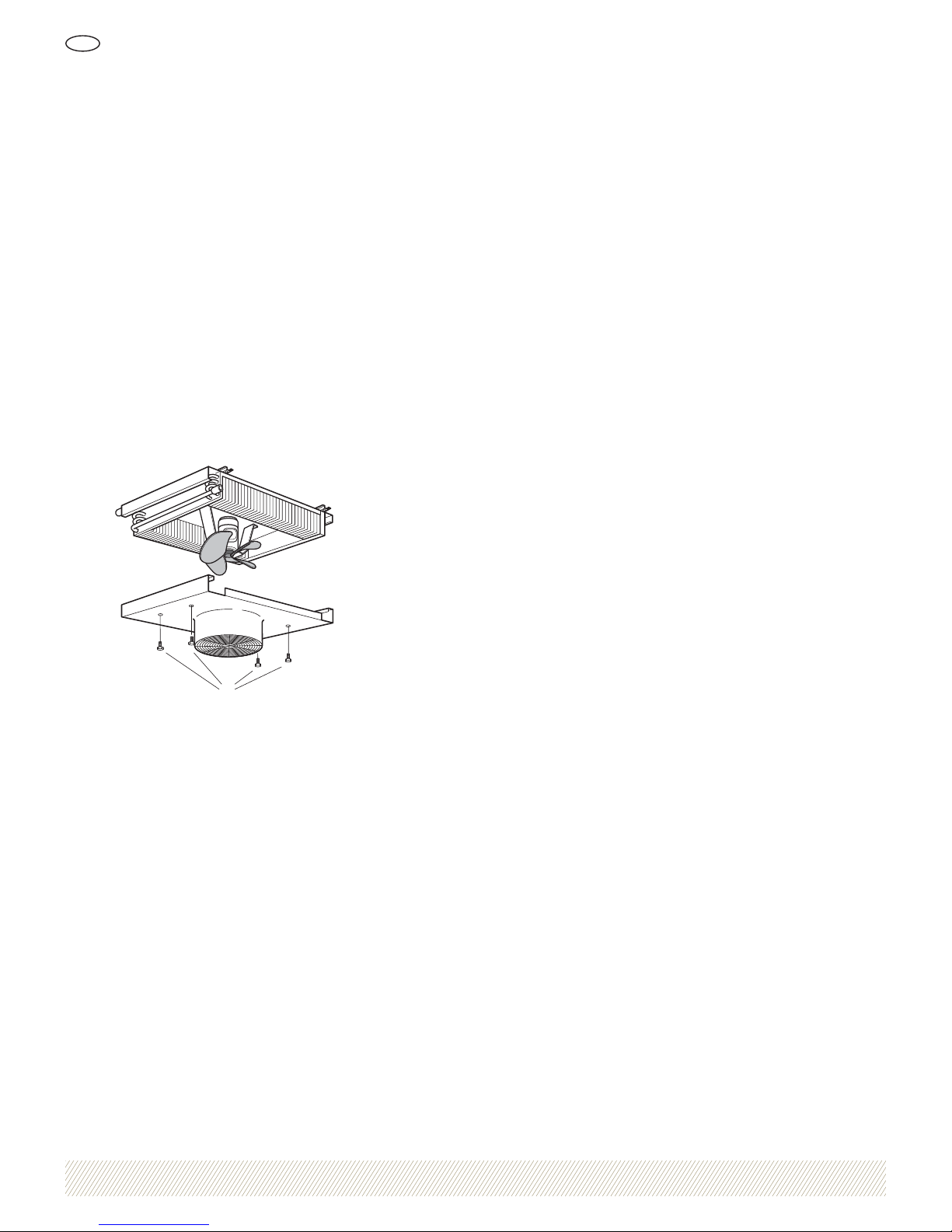

2. Loosen the four screws (A) and remove the front, see

Figure 5.

3. Set the nozzle at right angles to the surface of the ns

so as not to damage the ns.

When cleaning with a high pressure washer:

1. Switch off the mains supply to the air heater unit.

2. Loosen the four screws (A) and remove the front, see

Figure 5.

3. Cover the motor with plastic to protect the motor from

moisture.

4. Spray environmentally friendly cleaning agent at low

pressure onto the n heat exchanger.

5. High pressure wash with water after 10-12 minutes.

Remember to hold the nozzle at right angles to the

surface of the ns.

6. Check that no remnants of the cleaning agent are left

after cleaning, since they can bind fresh dust.

Spare parts

In installations with very high demands on availability, we

recommend that one motor is kept as a spare part.

NOTE: Motors kept as spare parts should be stored

indoors in dry and dust-free conditions.

NOTE: Only parts and materials recommended by Luvata

are to be used in order for the warranty speci ed in the

order con rmation to be valid.

Maintenance and service

1034564 We reserve the right to alter speci cations

Air heater unit LVD

GB

5

Replacing the motor and fan impeller

1. Switch off the mains supply to the air heater unit and

lock the safety switch in the OFF position.

2. Loosen the four screws (A) and remove the front,

see Figure 5.

3. Loosen the locking screw on the fan and dismantle the

fan from the motor.

4. Disconnect the electrical cable from the junction box.

5. Loosen the four screws holding the motor on the motor

mounting and lift off the motor.

6. Install the new fan unit by following the above

instructions in reverse order.

7. Check that the fan impeller is centred in the fan ring

and that the fan rotates in the direction indicated by

the arrow.

8. Start the air heater unit.

A

Figure 5. Removing the front

Risk of freezing

In installations with an ambient temperature of less than

0°C, there is a risk of damage due to freezing if the heat

exchanger becomes too cold. The air heater unit should

be drained of water if the system is not used during the

winter. Use compressed air to blow out any remaining

water when the heat exchanger cannot be fully drained.

The air heater unit does not need to be drained if it is

lled with water containing anti-freeze.

Long-term storage

When the unit is stored for longer than one month, the

following applies:

• Store the air heater unit indoors in the position in

which it is to be installed.

• Cover the air heater unit with reinforced plastic or

some other mechanical protection to prevent contamination and water from penetrating and soiling or

damaging the n structure and fan unit.

• The air heater unit’s pipe connections should be

sealed.

• If the air heater unit is stored in a damp environment,

the surface nish must be checked regularly to ensure

that damage does not occur. Touch up any damage to

paintwork.

Maintenance and service

1034564 We reserve the right to alter speci cations

Air heater unit LVD

GB

6

Operating data

Max air temperature around the motor: +70°C

Min air temperature around the motor: -15°C.

Max permitted operating pressure: 1.6 MPa at 100˚C

All heat exchangers are leak-tested under water using dry air.

Motor data

For information, refer to the air heater unit’s data plate.

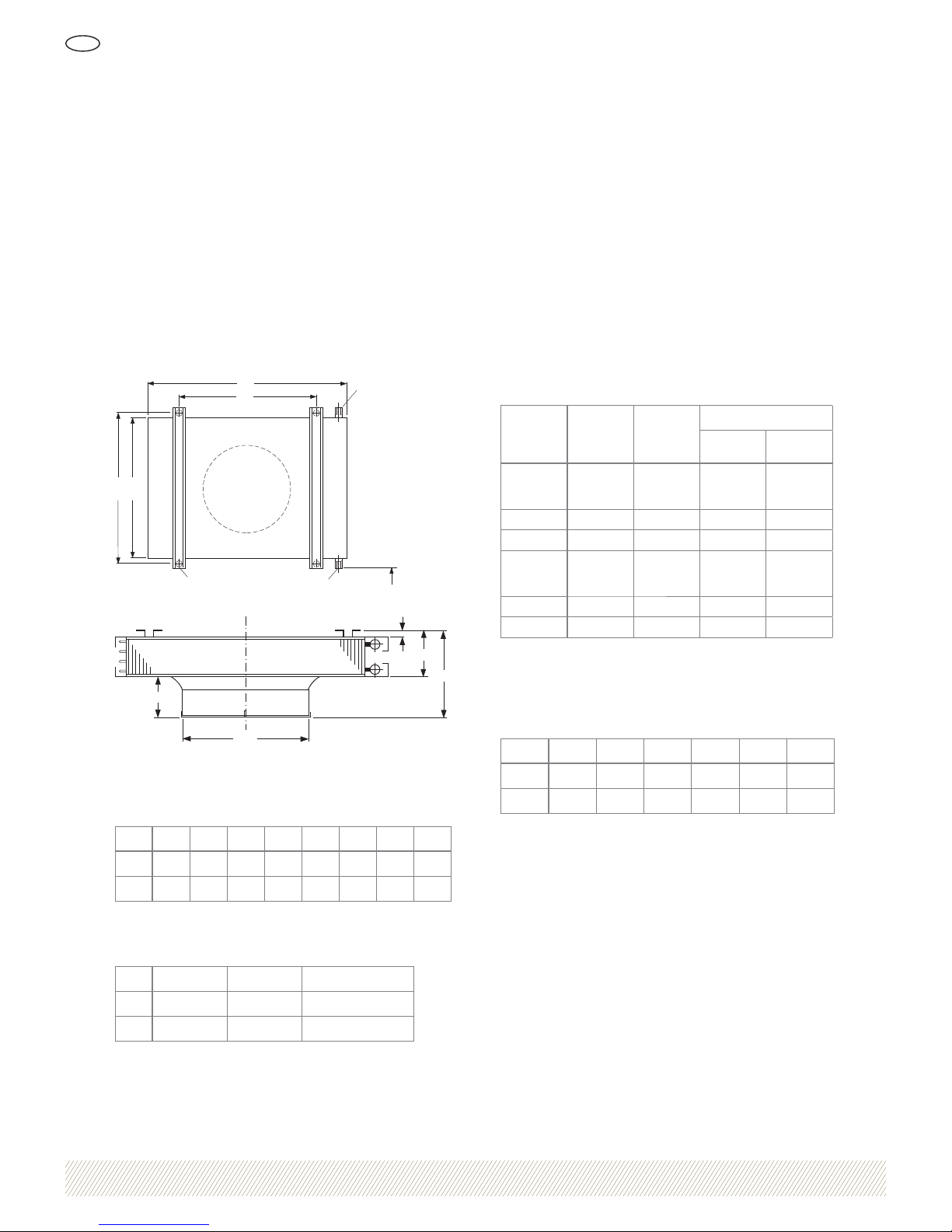

Dimensions, weight and volume

30

Ø 15

CB

A

D

K

K

20

E

F

H

Ø G

Figure 6. Dimensions

Table 1. Dimensions (mm)

LVDV ABCDEFGH

40 930 600 635 760 155 345 406 190

50 1130 700 735 960 220 380 514 160

Table 2. Weight, volume and pipe connections

LVDV Weight (kg) Volume (litres) K (pipe connection)

40 31 1.6 DN 20

50 45 3.8 DN 25

Heat exchanger

The heat exchanger consists of tubes that are mechanically expanded onto the ns. The ns are manufactured

as whole plates without slots to avoid dust and bres

collecting on the n structure.

Fan unit

The fan unit’s motor is a ange motor, journalled on ball

bearings, with a self-resetting thermal cut-out (not on

three phase). The fan impeller has a painted steel hub

and aluminium blades.

Table 3. Technical data, fan unit

LVDV

Rotational

speed (rpm)

Rated output

(kW)

Rated current (A), 50 Hz

Single phase

230 V

Three phase

400 V Y

40-1

1300

1)

900

670

0.15

1.50

1.0

0.7

–

–

–

40-6 920

1)

0.18 – 0.7

40-4 1380

1)

0.18 – 0.7

50-1

900

1)

670

570

0.17

1.7

1.2

0.7

–

–

–

50-6 920

1)

0.18 – 0.7

50-4 1410

1)

0.55 – 1.5

1)

Speed as delivered. Other speeds can be obtained by altering the motor

connections as indicated in the connection diagram, see Figures 8–10.

Table 4. Speed with accessories for voltage control

LVDV 230 V 150 V 130 V 115 V 100 V 80 V

40-1 1300

1)

980

1)

820 690

1)

560 380

50-1 900

1)

770 690

1)

610

1)

510 370

1)

Speed as delivered

Protection classes

Motor: IP55

Junction box: IP44

Technical data

1034564 We reserve the right to alter speci cations

Air heater unit LVD

GB

7

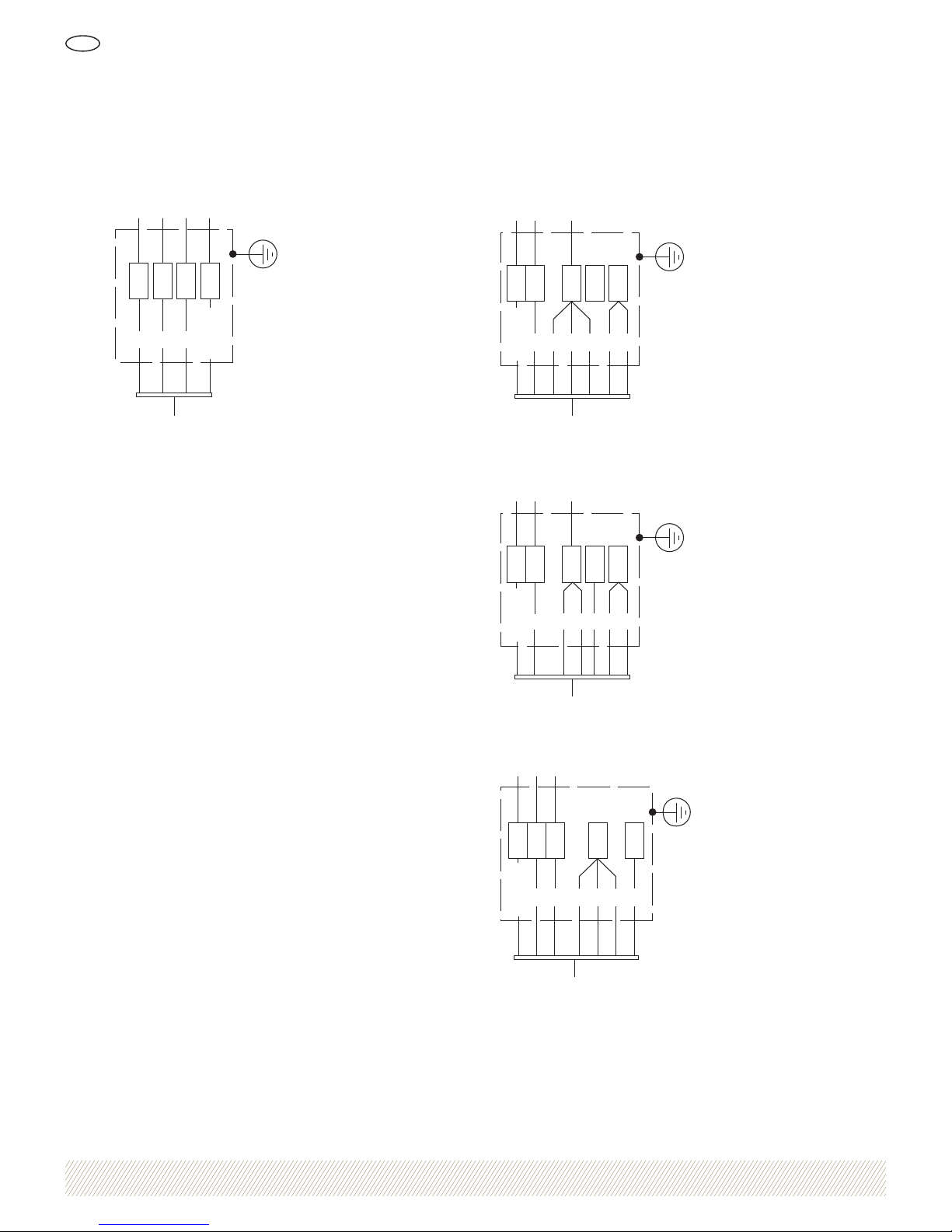

Three phase

R S T PE

12

3

Yellow/

Green

Fan motor

Figure 7. Y-coupling, design as supplied

Single phase with thermal cut-out

PE L N

12345 6

Yellow/

Green

Motor

Figure 8. High speed, design as supplied

12

3456

PE L N

Yellow/

Green

Motor

Figure 9. Intermediate speed

12 34 56

PE L N

Yellow/

Green

Motor

Figure 10. Low speed

Connection diagram

Luvata Söderköping AB

SE-614 81 Söderköping, Sweden

Phone +46 121 191 00

Fax +46 121 101 01

www.luvata.com/coiltech

5000-0096 • September 2009

Air heater unit LVD

GB

A COILTECH PRODUCT MANUFACTURED BY LUVATA SÖDERKÖPING AB

Standard design

Air heater unit LVDV-aa-b-c-d

Size (aa)

40, 50

Motor (b)

1 = 1x230 V

4 = 3x400 V, 4-pin (without controls, c = 0)

6 = 3x400 V, 6-pin (without controls, c = 0)

Control equipment (c)

0 = without controls

A = A box

B = B box

C = C box

Design digit (d)

1 = 2004 –

Control equipment

Air heater unit installation pack LVDZ-a-1

Type (a)

A = A box

B = B box

C = C box

Accessories

Drop rods, set LVDZ-03-1

Air discharge sleeve LVDZ-04-bb

Size (bb)

40, 50

Spare parts for LVDV 40

Fan impeller LVDV-99-01-5

Motor (1x230 V, 3 speeds) LVDV-99-02-12

Motor (3x400 V, 4-pin) LVDV-99-02-14

Motor (3x400 V, 6-pin) LVDV-99-02-16

Contact guard LVDV-99-03-3

Heat exchanger LVDV-99-04-1

Spare parts for LVDV 50

Fan impeller LVDV-99-01-6

Motor (1x230 V, 3 speeds) LVDV-99-02-13

Motor (3x400 V, 4-pin) LVDV-99-02-17

Motor (3x400 V, 6-pin) LVDV-99-02-15

Contact guard LVDV-99-03-4

Heat exchanger LVDV-99-04-2

Product code

Loading...

Loading...