Lutz Size 1 - 1/4, Size 2- 3/8"", Size 3 - 1/2"", Size 5 - 1 1/2"", Size 4 - 1"" Operating Instructions Manual

...

1

GB

Read this operating instructions before start up!

To be retained for future reference.

Operating Instructions

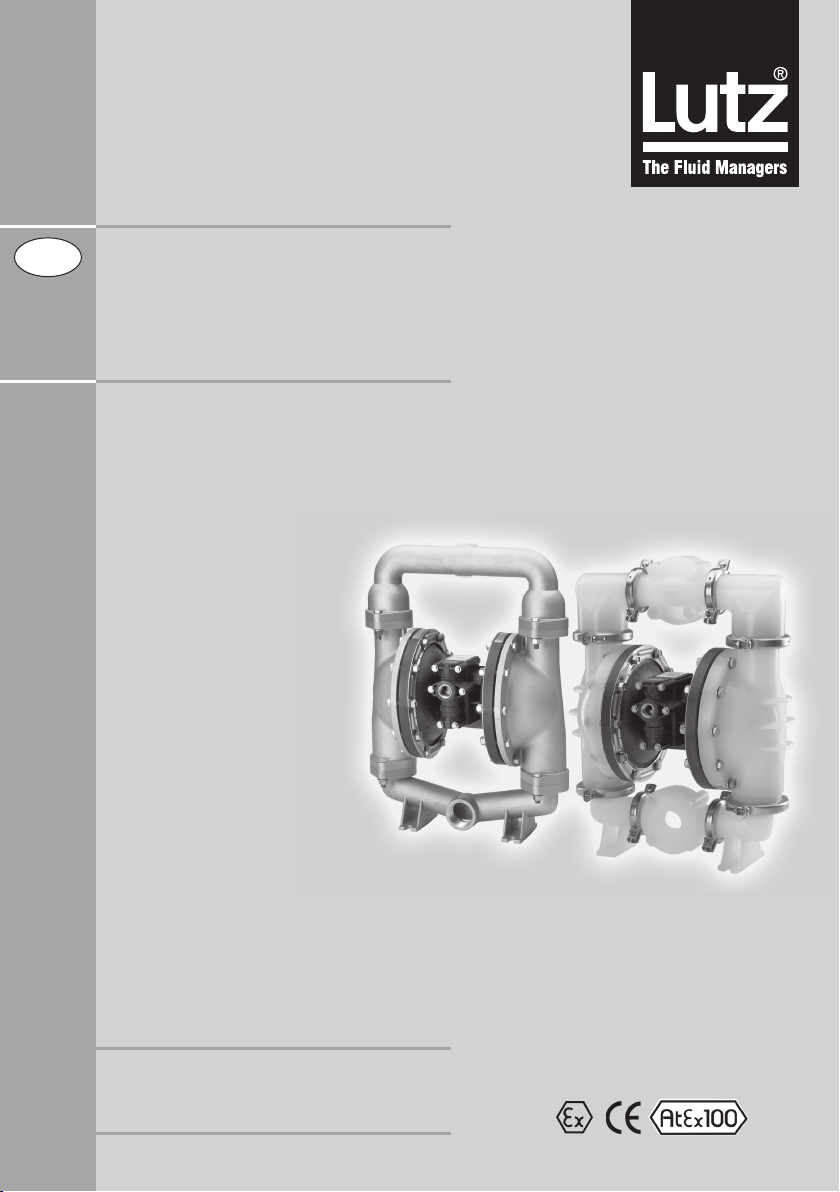

OIL-FREE, AIR OPERATED

DOUBLE DIAPHRAGM PUMPS

in non-metallic and metallic version

Model

1/4“

3/8“

1/2“

1“

1 1/2“

2“

3“

GB

2

GB

Table of Contents

1. Safety .........................................................................................................................................................4

1.1 Danger associated with this machine ..........................................................................................................4

1.2 Safety information and tips..........................................................................................................................4

1.3 Proper use ...................................................................................................................................................4

1.3.1 Specifications ............................................................................................................................... 7/8

1.3.2 Operation in hazardous location or pumping flammable liquids .......................................................9

1.3.2.1 Traceability ...........................................................................................................................9

2. Installation .......................................................................................................................................................10

2.1 Submerged Applications............................................................................................................................11

2.2 High Viscosity Applications .......................................................................................................................11

2.3 Low Temperature and UV Exposure ...........................................................................................................11

3. Maintenance .....................................................................................................................................................12

3.1 General Maintenance .................................................................................................................................12

3.2 Maintenance Model 1/4" ..........................................................................................................................12

3.2.1 Maintenance of Check Valve, Gasket and O-Ring ...........................................................................12

3.2.2 Maintenance of Diaphragms...........................................................................................................13

3.2.3 Maintenance of Air Valve and Diaphram Rod .................................................................................13

3.3 Maintenance Model 3/8", Band Clamp Version .......................................................................................15

3.3.1 Maintenance of Max-Pass- or check valve .....................................................................................15

3.3.2 Maintenance of Diaphragms...........................................................................................................15

3.3.3 Air Valve Assembly Inspection .......................................................................................................16

3.3.4 Fastener Torque Requirements .......................................................................................................17

3.4 Maintenance Model 1/2", Band Clamp Version .......................................................................................18

3.4.1 Maintenance of Check Valve and O-Ring ........................................................................................18

3.4.2 Maintenance of Diaphragm and Pilot Sleeve Assembly .................................................................18

3.4.3 External fastener torque requirements ...........................................................................................19

3.4.4 Maintenance of Air Valve ................................................................................................................20

3.5 Maintenance Model 1/2", Bolted Version ................................................................................................21

3.5.1 Maintenance of Check Valve and O-Ring ........................................................................................21

3.5.2 Maintenance of Diaphragm and Pilot Sleeve Assembly ..................................................................21

3.5.3 External fastener torque requirements ...........................................................................................22

3.5.4 Maintenance of Air Valve ................................................................................................................23

3.6 Maintenance Model 1", Band Clamp Version ..........................................................................................24

3.6.1 Maintenance of Check Valve and O-Ring ........................................................................................24

3.6.2 Maintenance of Diaphragm and Pilot Sleeve Assembly ..................................................................24

3.6.3 External fastener torque requirements ...........................................................................................25

3.6.4 Maintenance of Air Valve ................................................................................................................26

3.6.5 Dual manifold capability (non-metallic pumps only) ......................................................................26

3.7 Maintenance Model 1", Bolted Version ....................................................................................................27

3.7.1 Maintenance of Check Valve and O-Ring ........................................................................................27

3.7.2 Maintenance of Diaphragm and Pilot Sleeve Assembly ..................................................................27

3.7.3 External fastener torque requirements ...........................................................................................28

3.7.4 Maintenance of Air Valve ................................................................................................................28

3.8 Maintenance Model 1 1/2" and 2", Band Clamp Version .........................................................................29

3.8.1 Maintenance of Check Valve and O-Ring ........................................................................................29

3.8.2 Maintenance of Diaphragm and Pilot Sleeve Assembly ..................................................................29

3.8.3 External fastener torque requirements ...........................................................................................30

3.8.4 Maintenance of Air Valve ................................................................................................................31

3

GB

3.9 Maintenance Model 1 1/2“ and 2“, Bolted Version .................................................................................32

3.9.1 Maintenance of Check Valve and O-Ring ........................................................................................32

3.9.2 Maintenance of Diaphragm and Pilot Sleeve Assembly ..................................................................32

3.9.3 External fastener torque requirements ...........................................................................................

33

3.9.4 Maintenance of Air Valve ................................................................................................................

34

3.10 Maintenance Model 3", Bolted Version ....................................................................................................35

3.10.1 Maintenance of Check Valve and O-Ring ........................................................................................

35

3.10.2 Maintenance of Diaphragm and Pilot Sleeve Assembly ..................................................................

35

3.10.3 External fastener torque requirements ...........................................................................................

36

3.10.4 Maintenance of Air Valve ................................................................................................................

37

4. Repairs .......................................................................................................................................................37

5.

Dimensions

5.1 Model 1/4“ .................................................................................................................................................38

5.2 Model 3/8", Band Clamp Version ...............................................................................................................39

5.3 Model 1/2", Band Clamp Version ...............................................................................................................

40

5.4 Model 1/2", Bolted Version ........................................................................................................................41

5.5 Model 1", Band Clamp Version ..................................................................................................................42

5.6 Model 1", Bolted Version ...........................................................................................................................

43

5.7 Model 1 1/2", Band Clamp Version ............................................................................................................44

5.8 Model 1 1/2", Bolted Version .....................................................................................................................

45

5.9 Model 2", Band Clamp Version .................................................................................................................46

5.10 Model 2", Bolted Version ..........................................................................................................................

47

5.11 Model 3", Bolted Version ..........................................................................................................................48

6. Performance curves

6.1 Model 1/4“ .................................................................................................................................................

49

6.2 Model 3/8", Band Clamp Version ...............................................................................................................49

6.3 Model 1/2", Band Clamp Version ...............................................................................................................

50

6.4 Model 1/2", Bolted Version ........................................................................................................................50

6.5 Model 1", Band Clamp Version ..................................................................................................................51

6.6 Model 1", Bolted Version ...........................................................................................................................51

6.7 Model 1 1/2", Band Clamp Version ............................................................................................................52

6.8 Model 1 1/2", Bolted Version .....................................................................................................................52

6.9 Model 2", Band Clamp Version ..................................................................................................................53

6.10 Model 2", Bolted Version ...........................................................................................................................53

6.11 Model 3", Bolted Version ...........................................................................................................................

54

7. Trouble shooting ...............................................................................................................................................55

Declaration of Conformity ..................................................................................................................................

57

Notice: In the operating instructions figures are mentioned in brackets. These refer to the item specifications in

the spare parts list of the respective model. The single steps in the operating instructions refer to the

non-metallic and metallic version. If the item number of the operating instructions is not included in the

spare parts list, the instruction must not be considered for this pump version.

4

GB

1. Safety

1.1 Danger associated with this machine

The air operated double diaphragm pumps are tested prior to delivery.

In case of maloperation or improper use there is danger for

• life and health of the user

• the pump and other material assets of the user

• the efficiency of the machine.

All persons who are dealing with the installation/assembly, starting, operation, servicing and maintenance of the

machine have

• to be accordingly qualified

• to exactly follow these operating instructions

It is your safety!

1.2 Safety information and tips

In these operating instructions the following explanations are used:

Danger!

Refers to a direct danger.

Non-observance of the precaution will cause death or extremely serious injury.

Warning!

Defines a possibly dangerous situation.

Non-observance of the precaution can cause death or extremely serious injury.

Caution!

Defines a possibly harmful situation.

The product or something in its environment may be damaged if this instruction is not observed.

1.3 Proper use

The air operated double diaphragm pumps are suitable for pumping pure, turbid, flammable and non-flammable,

aggressive and non-aggressive liquids. Following regulations however must be observed.

Please note the following chapters. No liability whatsoever can be assumed for failure of the pump or parts of the

pump, for personal injury or other claims if the pump is used for other purposes.

For safety reasons, the pump must not be converted or modified in any way without authorization!

Model 1/4": Pump has wear parts in the air flow system. A continuous operation therefore is limited.

5

GB

Danger!

Dangerous liquids can damage your health and the environment.

• When handling dangerous or toxic liquids you have to waer goggles and protective clothing.

• Before starting the pump check that the medium being pumped is compatible. Changes of temperature,

concentrations or combinations of chemicals may vary resistance of material. Always consult Material

Safety Data Sheets and Engineering Resistance Tables for chemical compatibility.

• If a diaphragm ruptures, the pumped liquid can enter the air side of the pump and exit through the air

exhaust (muffler). If a diaphragm rupture occurs immediately stop the pump, close suction- and discharge

lines and have pump repaired.

• When the fluid source is at a higher level than the pump (flooded suction), the exhaust should be piped to a

higher level than the fluid source. After operation of pump it should be possible to close the suction line by

means of e.g. a ball valve. Running out of the container can be effectively avoided in case a damage occurs

at the piping system or at the pump.

Danger!

Do not clean or service pump, hoses or dispensing valves when the system is pressurized – serious injury

may result.

Disconnect air supply line and relieve pressure from the system prior to disassembly.

Warning!

Maximum temperatures are based on mechanical stress only.

Certain chemicals will significantly reduce maximum safe operating temperature. Consult engineering guides

for chemical compatibility and temperature limits.

Always use minimum air pressure when pumping at elevated temperatures.

Warning!

Excessive air pressure can cause pump damage, personal injury or property damage.

Warning!

Excessive positive suction pressure can cause pump damage. The maximum positive suction pressure must

not exceed 0.6 bar.

Warning!

Pump must be reassembled properly after maintenance.

Caution!

Do not use the pump for the structural support of the piping system. Be certain the system components are

supported to prevent stress on the pump parts. The pump must be installed free of tension.

Flexible connections will avoid damage to piping due to vibration.

Caution!

The characteristic feature of double diaphragm pumps is a pulsating volume flow.

For reduction use a pulsation dampener if necessary.

6

GB

In addition please note for model 1/4":

Caution!

Following operating conditions can cause early damage of the pump by spring breakage:

• dirty, wet or contaminated air supply

• too small suction pipe diameter or too large particles in the pumped liquid

• blocked valve seats or viscosity of the liquid exceeding 10.000 mPas

• high flow rate at a back pressure of more than

∆p = 1.4 bar

• safe operating pressure exceeded

Caution!

Following conditions cut down the continuous operation of the pump:

• high stroke frequency

• Flow rate at maximum value

• resistance at suction side (large suction head, filter or valve)

• viscous liquid

• high operating pressure

• During continuous operation (t > 2h/day) operating pressure and flow rate must not exceed more than the

half of the maximum admissible operating pressure respectively the maximum possible flow rate.

• high suction prepressure

These operating conditions and long running times can wear movable parts after 3-6 months.

7

GB

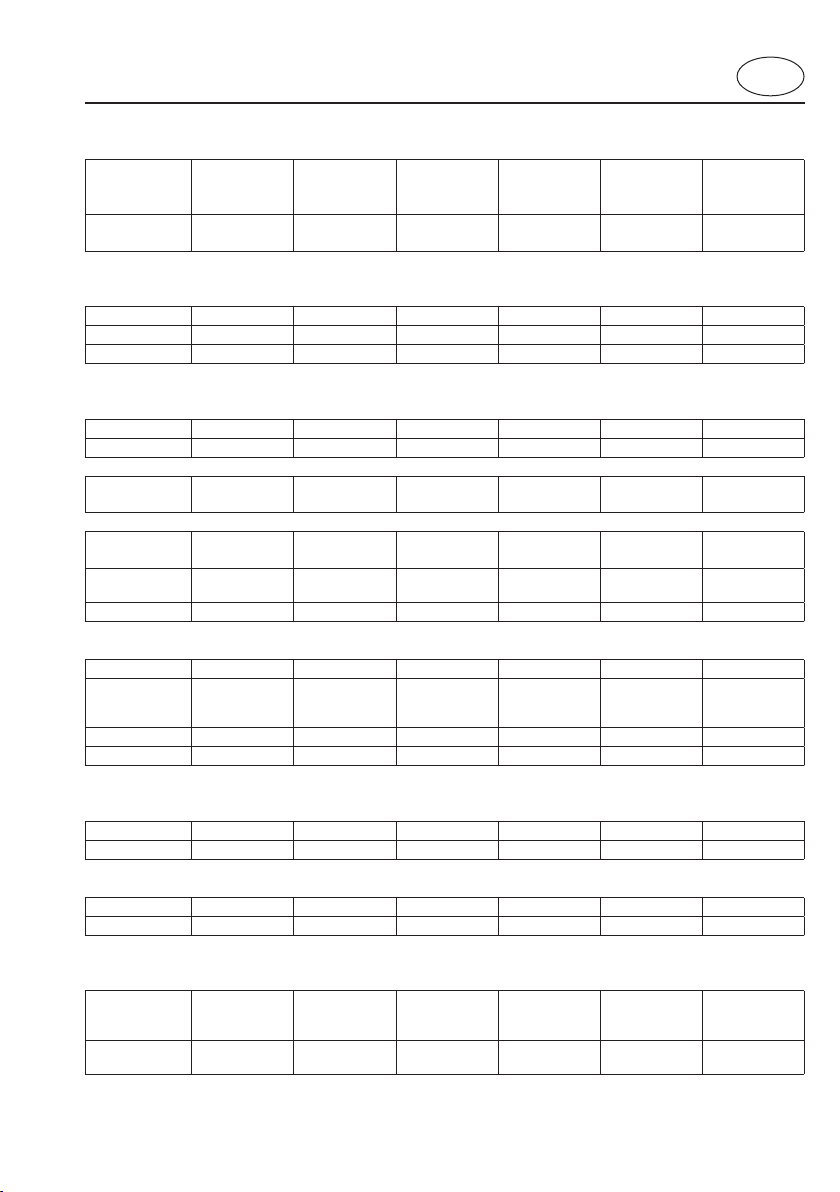

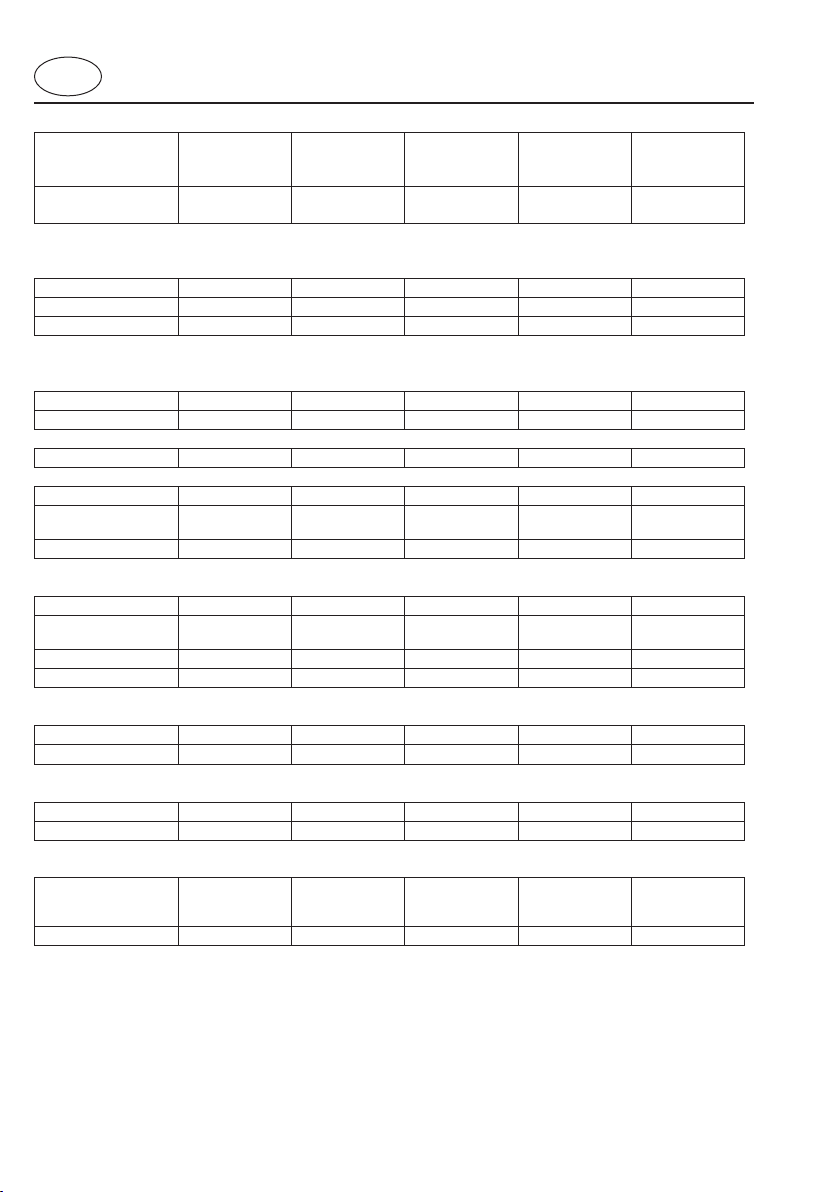

1.3.1 Specifications

Model 1/4“ 1/2“

Bolted

Version

1“

Bolted

Version

1 1/2“

Bolted

Version

2“

Bolted

Version

3“

Bolted

Version

Capacity

Adjustable

0-16 l/min

Adjustable

0-65 l/min

Adjustable

0-156 l/min

Adjustable

0-492 l/min

Adjustable

0-681 l/min

Adjustable

0-965 l/min

Maximum

temperature

PVDF models +93°C +93°C +93°C +93°C +93°C –

PP models +66°C +66°C +66°C +66°C +66°C –

Metallic models – +93°C +93°C +93°C +93°C +93°C

Maximum

air pressure

PVDF models 8.0 bar 8.0 bar 8.2 bar 8.2 bar –

Other models 6.8 bar 8.0 bar 8.0 bar 8.2 bar 8.2 bar 8.5 bar

Minimum

air pressure 1.2 bar 1.2 bar 1.3 bar 1.3 bar 1.3 bar

Dry lift

capacity at:

6.8 bar 8.0 bar 8.0 bar 8.2 bar 8.2 bar 6.8 bar

Models with

Teflon balls 5.0 m 3.0 m 3.0 m 3.0 m 3.0 m 3.0 m

Other models 5.0 m 4.5 m 4.5 m 4.5 m 4.5 m 4.5 m

Weight

PVDF models 3.2 kg 5.4 kg 13.7 kg 29.5 kg 31 kg –

Other

non-metallic

models

2.3 kg 4.1 kg 9.1 kg 21 kg 22 kg –

Stainless steel – 8.6 kg 20.4 kg 60 kg 60 kg –

Aluminium – 4.5 kg 10.5 kg 27 kg 28 kg 59 kg

Maximum

solids

Max-Pass valves – – – – – –

Others 1.6 mm 3.1 mm 6.4 mm 6.4 mm 6.4 mm 11.1 mm

Air supply

Inlet 1/4" NPT female 1/4" NPT female 1/4" NPT female 3/4" NPT female 3/4" NPT female 3/4" NPT female

Outlet 1/4" NPT female 3/8" NPT female 3/8" NPT female 3/4" NPT female 3/4" NPT female 3/4" NPT female

Fluid inlet/

discharge

Non-metallic

models

1/4" BSP female 1/2" BSP female 1“

DIN/ANSI-

Flange

1 1/2“

DIN/ANSI-

Flange

2“ DIN/ANSI-

Flange

3" BSP female

Metallic

models

dto. dto. 1" BSP female dto. 2" BSP female dto.

8

GB

Model 3/8“

Band clamp

Version

1/2“

Band clamp

Version

1“

Band clamp

Version

1 1/2“

Band clamp

Version

2“

Band clamp

Version

Capacity

Adjustable

0-34 l/min

Adjustable

0-53 l/min

Adjustable

0-152 l/min

Adjustable

0-360 l/min

Adjustable

0-569 l/min

Maximum

temperature

PVDF models +93°C +93°C +93°C +93°C +93°C

PP models +66°C +66°C +66°C +66°C +66°C

Metallic models – +93°C +93°C +93°C +93°C

Maximum

air pressure

PVDF models 8.2 bar 4.8 bar 4.8 bar 4.8 bar

Other models 8.2 bar 6.8 bar 6.8 bar 6.8 bar 6.8 bar

Minimum air pressure 1.3 bar 1.3 bar 1.3 bar 1.3 bar 1.3 bar

Dry lift capacity at:

8.2 bar 6.8 bar 6.8 bar 6.8 bar 6.8 bar

Models with

Teflon balls 3.0 m 3.0 m 3.0 m 3.0 m 3.0 m

Other models 5.2 m 4.5 m 4.5 m 4.5 m 4.5 m

Weight

PVDF models 2.3 kg 4.9 kg 9.9 kg 30 kg 30 kg

Other

Non-metallic models

1.7 kg 3.6 kg 8.6 kg 24 kg 24 kg

Stainless steel – 7.2 kg 19.1 kg 51 kg 59 kg

Aluminium – 3.8 kg 8.6 kg 28 kg 28 kg

Maximum solids

Max-Pass valves 6.4 mm – – – –

Others 3.2 mm 3.1 mm 6.4 mm 6.4 mm 6.4 mm

Air supply

Inlet 1/4" NPT female 1/4" NPT female 1/4" NPT female 3/4" NPT female 3/4" NPT female

Outlet 3/8" NPT female 3/8" NPT female 3/8" NPT female 3/4" NPT female 3/4" NPT female

Fluid inlet/discharge

Non-metallic models 3/8" BSP female 1/2" BSP female

3/4" BSP male

1" BSP female 1 1/2“

DIN/ANSI-

Flange

2“

DIN/ANSI-

Flange

Metallic models – dto. dto. dto. dto.

9

GB

1.3.2 Operation in hazardous location or pumping flammable liquids

Pump may only be used at atmospheric conditions of 0.8 bar up to 1.1 bar, normal air moisture conditions and

within a temperature range of –20°C up to +40°C. Pump must not be used within atmospheres containing inflammable dust.

Danger!

Pumping of flammable liquids may cause a build-up of a static charge within the electrically non conductive

pumps. Static spark can cause explosion resulting in severe injury or death. Ground pump and pumping

systems when pumping flammable liquids or when used in a location where surrounding atmosphere is

conductive to spontaneous combustion.

The rating plate of the pump must show a respective Ex-identification according to the application.

Use grounding plugs and always connect to a good ground source. Actual valid regulations concerning the

grounding have to be observed.

• Secure pump, connections and all contact points to avoid vibrations and generation of contact or static

spark. Periodically verify continuity of electrical path to ground with an ohmmeter from each component.

Resistance of grounding must not exceed 106 ohm.

• Note local building codes and regulations for explosion protection.

• Use conductive hoses.

• Use proper ventilation.

• Keep flammables away from heat, open flames and sparks.

• Keep containers closed when not in use.

• Use only new genuine spare parts for repairs.

• Pumps which are modified by the customer may vary from the EC-Declaration of Conformity.

Observe rating plate!

1.3.2.1 Traceability

Products manufactured by Lutz-Pumpen for potentially explosives atmospheres are identified by an individual

batch number which allows them to be traced. This number provides the year of construction and the design of the

equipment.

This product is an appliance for potentially explosive atmospheres. In this regard and in compliance with the EC

ATEX 94/9 Directive, provisions must be made to ensure ascending and descending traceability.

Our ATEX notified quality system ensures this traceability up to the initial point of delivery.

Except as otherwise agreed in writing, anyone that guarantees to redeliver said equipment undertakes to put in place

a system that allows for equipment that is not conform to be recalled if necessary.

10

GB

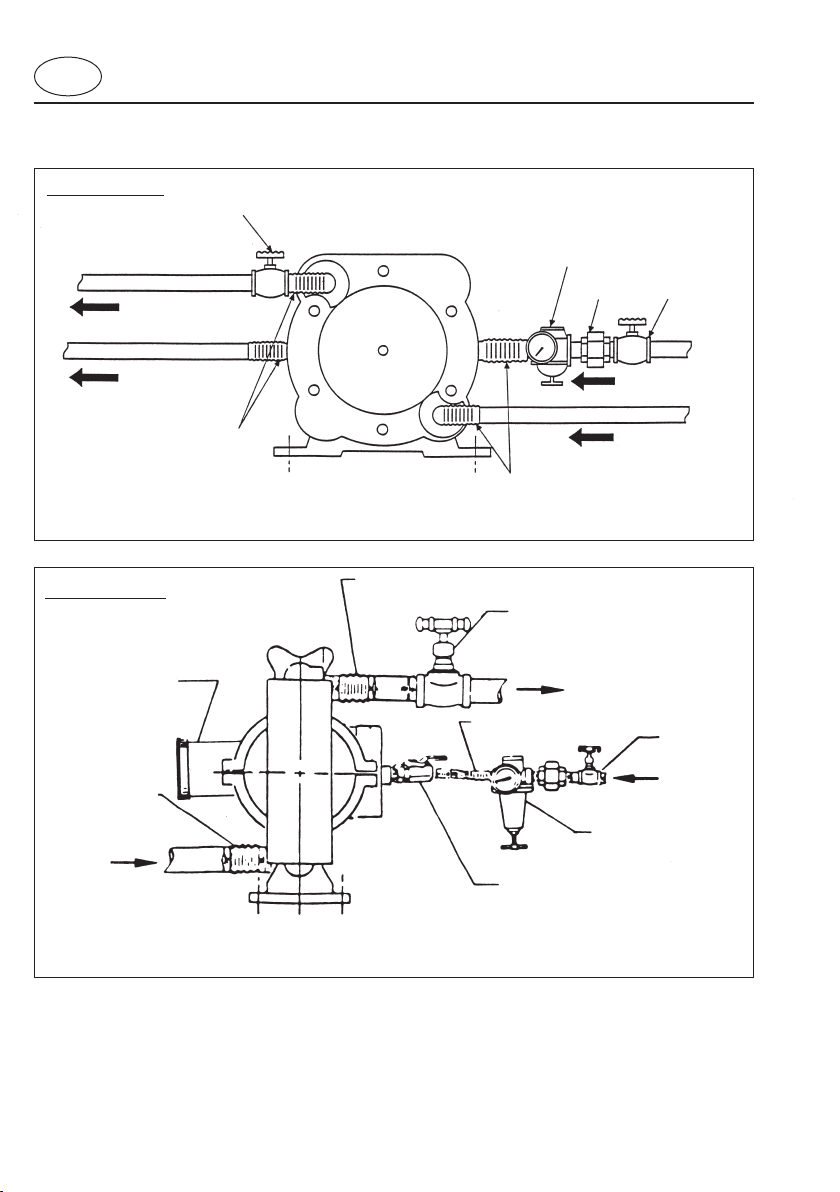

2. Installation

Valve (optional)

Valve

(optional)

Fluid inlet

Regulator/Filter

Union (optional)

Flexible

Connection

Air Outlet

Flexible

Connection

Fluid out discharge

Caution: Do not use air line lubrication

Air supply should be clean and dry.

Air Inlet

Notice: Suction and discharge ports may be repositioned to suit the application.

Flexible Connection

Valve or Flow meter

Discharge

Flexible Connection

Maintenance unit

(must be supported)

Air flow control valve

Valve

Air Inlet

Flexible

Connection

Muffler

(Air Outlet)

Suction

All other models

Only Model 1/4"

11

GB

Notice: Re-torque fasteners prior to use. See respective chapter in this maintenance manual.

Danger!

Danger of fire and explosion due to inflammable compressed gases within the air supply system!

Combustion hazard. Blast wave: Flying parts can kill you.

Do not operate the pump with compressed flammable gases.

1. A lube-free, clean, dry, compressed air source is recommended. Use a filter that is capable of filtering out particles larger than 50 microns.

2. All pumps should be mounted in an upright position.

3. When particles exceed the maximum particle specification of the pump or are sharp enough to cut elastomers

install a particle fluid filter on the fluid suction line.

4. Fluid suction lines and air exhaust lines should never be smaller than the specified pipe size of pump.

5. Apply Teflon tape to threads upon assembly to prevent leakage.

6. Never use pipe dope on air line connections.

7. Never use collapsible tube on fluid inlet.

8. Do not exceed 14 Nm of torque on plastic pipe threads.

9. For installation with connection flanges tighten fasteners to 25 Nm of torque.

10. If changing to a different application reconfirm compatibility of fluid.

2.1 Submerged Applications

1. Fluid must be compatible with fasteners and with intermediate material.

2. Pipe exhaust above the level of the fluid.

2.2 High Viscosity Applications

1. Position the pump close to or below the level of the fluid source.

2. Suction lines should be increased in size – up to three times the size of the inlet manifold. The use of dual

manifolds may increase flow rate (only possible with 1/2"- models).

3. Start the pump slowly using a valve on the air line.

2.3 Low Temperature and UV Exposure

1. Polypropylene tends to embrittle at freezing temperature. Pump must be insulated or heated, otherwise use

pumps with different materials of construction.

2. If excessive icing occurs at the pump exhaust, air source must be dried using mechanical means or through

the introduction of ethyl alcohol in the air line (note explosion protection!).

3. UV rays will damage polypropylene pumps. Either shroud the pumps from UV rays or use pumps with UV sta-

bilized materials.

12

GB

3. Maintenance

3.1 General Maintenance

1. Check periodically for product or air leakage. Tighten any joint where leakage is occuring.

2. When pumping hazardous or toxic liquids, diaphragms should be replaced at regularly scheduled intervals based

upon pump usage.

3. When pumping highly abrasive fluids reduce discharge flow rate to prolong life of diaphragm, valve balls, valve

seats etc. or optionally use a larger pump which can be operated at a lower stroke frequency.

4. If you are pumping a fluid that will settle or compact the pump must be flushed before shut down.

5. In freezing temperatures, the pump must be completely drained when idle.

3.2 Maintenance Model 1/4"

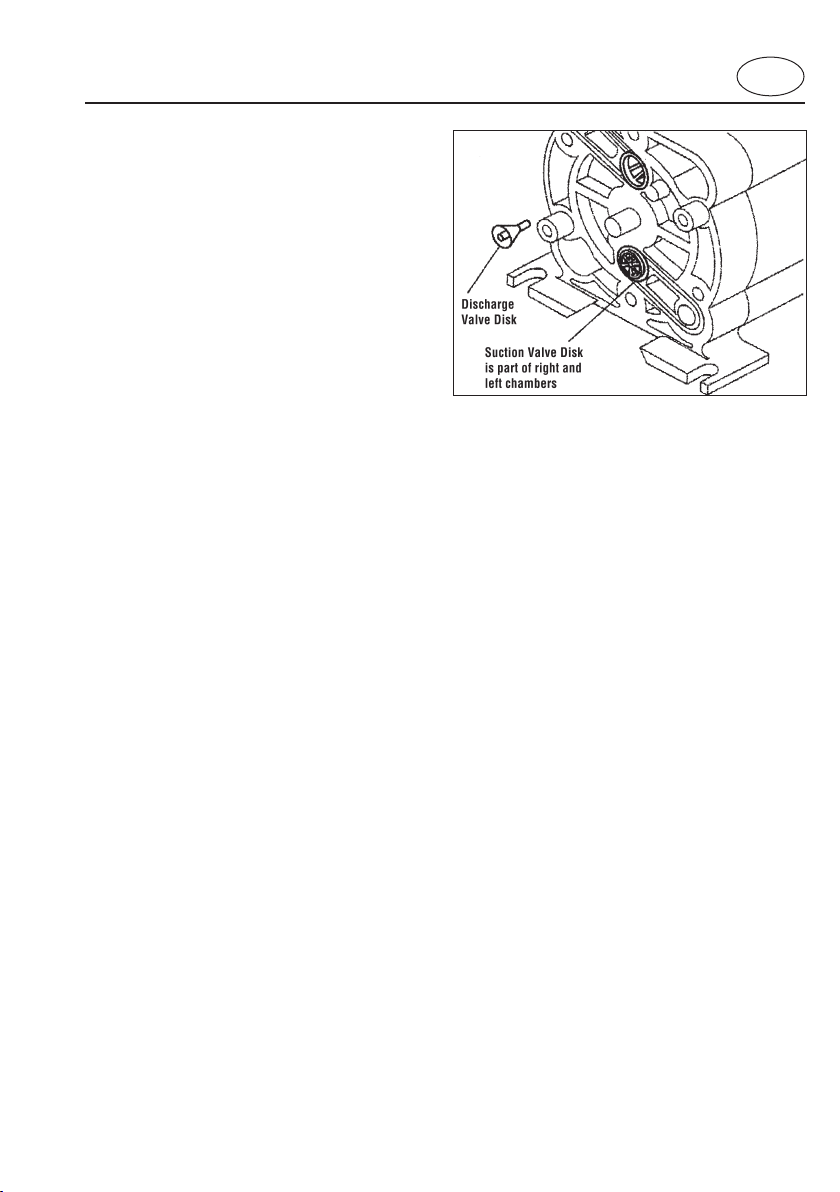

3.2.1 Maintenance of Check Valve, Gasket and O-Ring

1. Flush the pump to be certain all corrosive or hazardous materials are removed. Remove suction, discharge and

air supply lines.

2. Remove the nuts (28) and slide the six cap screws (27) that hold the pump together out of the pump.

Remove the

eight screws (5) and two screws (5A) from the left and right manifold plates (1,19) and inspect the gaskets (2).

The suction (or lower) check valves are an integral part of the left and right chambers and should not be dis-

mantled. If replacement of the valve seats is necessary, items (6) and (18) which contain the valves must be

replaced.

The upper discharge valve disks (3) are not sealed into the chambers and may be inspected for wear.

Caution!

Due to the distortion of gaskets under pressure, gaskets may need to be replaced after pump has been disassembled to assure a positive seal.

3. To inspect manifold tube o-rings (17) remove right chamber (18).

4. Both diaphragms (9) can be inspected after removing the right and left chamber (6.18). If diaphragms appear

worn or ruptured go to step 7. If diaphragms do not need replacing, proceed with steps 5 and 6.

5.

To reassemble: Insert the discharge valve disks (3) into place. Press gaskets (2) into groove in chambers (6, 18).

Maintenance Model 1/4"

13

GB

6. Align left and right manifolds (1,19) on the bosses

of the chambers (6,18). Secure to each chamber

with the eight screws (5) and two screws (5A). Slide

left chamber tubes (6) through intermediate (15).

Position o-ring retainers (4) and o-rings (17) on the

end of the tubes. Lubricate o-rings and right chamber holes (18). Slide a flat washer (26) onto each of

the six cap screws (27) and insert through the entire

assembly. Secure with a flat washer (26) and a tension washer (29) under each nut. Tighten to 7 Nm.

Apply torque evenly.

3.2.2 Maintenance of Diaphragms

7. Remove outer diaphragm plates (7) by holding one diaphragm plate and twisting off the other plate.

8. The diaphragm o-ring (8) is used only with Teflon diaphragms. Replace diaphragms if ruptured or worn. Inspect

inner diaphragm plates (10). If diaphragm rod needs replacing go to step 10.

9. If no further inspection is necessary reassemble inner diaphragm plates and diaphragms onto stud of outer

diaphragm plates and screw each assembly into diaphragm rod. (Make sure optional diaphragm o-ring is in position in the o-ring groove on either side of the intermediate if using Teflon diaphragms. When positioning Teflon

diaphragms make sure that the concave side is facing the wet ends of pump.) Tighten outer diaphragm plates to

4.5 Nm. Reassemble pump according to steps 5 and 6.

3.2.3 Maintenance of Air Valve and Diaphram Rod

10. To remove the diaphragm rod twist the two rod halves (11,16) apart by using a wrench on the flats at the end

of each half. Pull each half out of the pump. Inspect for corrosion.

11. To inspect diaphragm rod lip seals (14) remove the two self tapping screws (12) from the retaining plates (13).

Gently remove lip seals and inspect for damage. To reassemble lubricate diaphragm rod lip seals (14) and insert

into bore with the u-cup portion facing inward.

Maintenance Model 1/4"

14

GB

12. To remove spring clip assembly (23) firmly pull air valve plug (25) from pump.

13. Inspect spring clip assembly (23) and shuttle (22) for damage. Surface of intermediate around air ports and flat

surface of shuttle must be smooth, no scratches or debris. Replace or clean if necessary.

14. Attach seal retainer (13) with flat surface toward lip seals (14). Do not over tighten self-tapping screws (12).

15. To reinsert diaphragm rod halves, drop shuttle (22) into intermediate over ports. Groove in should be aligned

vertically in pump and should face outward. Insert spring

side of spring clip assembly into groove in shuttle. At

this point the assembly is not affixed to anything. Press

down as shown below to insert long half of diaphragm

rod (16) through spring clip assembly and position under spring ends.

Apply pressure with finger while inserting and assem-

bling the diaphragm rods.

16. While continuing to apply pressure to spring clip

assembly, screw short half of diaphragm rod (11) into long half.

17. Follow instructions for assembly of diaphragms in step 9. Final tightening of diaphragm rod will occur when

outer diaphragm plates (7) are tightened.

18. Make sure valve plug o-ring (21) is well lubed, position o-ring and press air valve plug into the intermediate

making sure that tab and indentation are aligned. If o-ring is not well lubricated, it will not permit reinsertion.

19. Follow procedure for final assembly of pump in step 6.

Maintenance Model 1/4"

15

GB

Maintenance Model 3/8", Band Clamp Version

3.3 Maintenance Model 3/8"

3.3.1 Maintenance of Max-Pass- or Check Valve

1. Flush and neutralize the pump to be certain all corrosives or hazardous materials are removed prior to any maintenance. This procedure should always be followed when returning pumps for factory service also.

2. Remove the nuts (3) and washers (4) from the bolts (23) in manifolds. Remove the manifolds (20), (11). Two

of the four max-pass valves and back-ups (13, 14) are located inside of the bottom of the outer chambers (16).

Gently remove and inspect for excessive wear, pitting or other signs of degradation. Inspect manifold o-ring (12)

as well and replace if necessary. The other two max-pass valves are located inside of the bottom of the discharge

manifold (20). Repeat the procedure for inspection of discharge valves, back-ups and o-rings.

(Some pumps such as those built with PTFE have ball valves in place of the max-pass valves. Repeat the proce-

dure – inspect valve seat (28), balls (29), ball cage (27) and o-ring (12)).

3. When re-assembling the max-pass pump, the sleeve (15) should be assembled into the valve cavity first, followed by the max-pass valve (13), the valve back-up (14) and finally the o-ring (12).

For pumps with ball valves, the cage (27) should be assembled into the valve cavity first, followed by the ball

(29), valve seat (28) and finally the o-ring (12).

Lightly tighten all external fasteners when assembling, torquing them to their requirements after pump is com-

pletely assembled.

Caution!

When using pumps built with PTFE o-rings always replace with new PTFE o-rings, since the original o-rings

may not reseal the pump.

3.3.2 Maintenance of Diaphragms

4. To inspect diaphragms, remove the nuts (7) from the carriage bolts (8) on the band clamps (6) surrounding the

outer pump chambers (16). If replacement is necessary due to abrasion or rupture unscrew the outer diaphragm

plates (17). Only models that have PTFE elastomers will have both a PTFE overlay (18) that faces the outer pump

chamber and an o-ring (25) on the air side of pump. Note: Pumps that do not contain PTFE will not have o-ring

(25), they are built with diaphragms (19) only.

5. To inspect the diaphragm rod`s lip seals (26) remove diaphragm rod (5). Before remove the air valve assembly

(2) by unscrewing the screws (9). Replace if necessary. Be sure to reinsert the lip seals with open cup facing the

inside of the pump. Make sure that the rod guide is facing the air valve assembly and slide the diaphragm rod

back into the intermediate.

6. Take one diaphragm and with the curved side of the inner diaphragm plate facing the diaphragm, assemble onto

the outer diaphragm plate stud (17). Screw the assembly into the end of the diaphragm rod. Repeat for the other

side. Tighten the outer diaphragm plates to 4.5 Nm of torque.

7. Position outer diaphragm chambers onto the intermediate, making sure that the witness line of the intermediate

matches with the parting line of the chamber.

8. When positioning band clamps use soapy water or a compatible lubricating spray on the inside of band clamps to

aid assembly. Tap with a mallet on the outside of clamp to help position the clamp while tightening the fasteners.

The band clamp fasteners are stainless steel. To prevent galling always apply anti-seize compound to the thread.

Tighten all external fasteners to final torque requirement after pump is completely assembled.

9. Position the reassembled manifolds making sure of the proper orientation in relation to the air valve for your

application. Also make sure that the valve seat o-rings do not shift from their grooves during reassembly. Flat

washers should be placed under the head of each cap screw and nut. Tighten all external fasteners to final torque

requirement after pump is completely assembled.

16

GB

Maintenance Model 3/8", Band Clamp Version

3.3.3 Air Valve Assembly Inspection

Caution!

Only one side of the mechanism has a hard-stop. Shifting the mechanism past its operating position can

cause the spring to pop free and many small components to come loose. Use caution when shifting the

mechanism manually.

10. If there has been a diaphragm rupture and fluid has entered the air side of the pump, the complete air system

should be inspected. Remove the air valve assembly (2) by unscrewing the screws (9).

11. Clean or replace the air valve assembly if there is excessive wear, dirt build-up or chemical attack. Inspect for

proper shifting of the spring mechanism by manually pushing the metal spring retainer from one side to the

other.

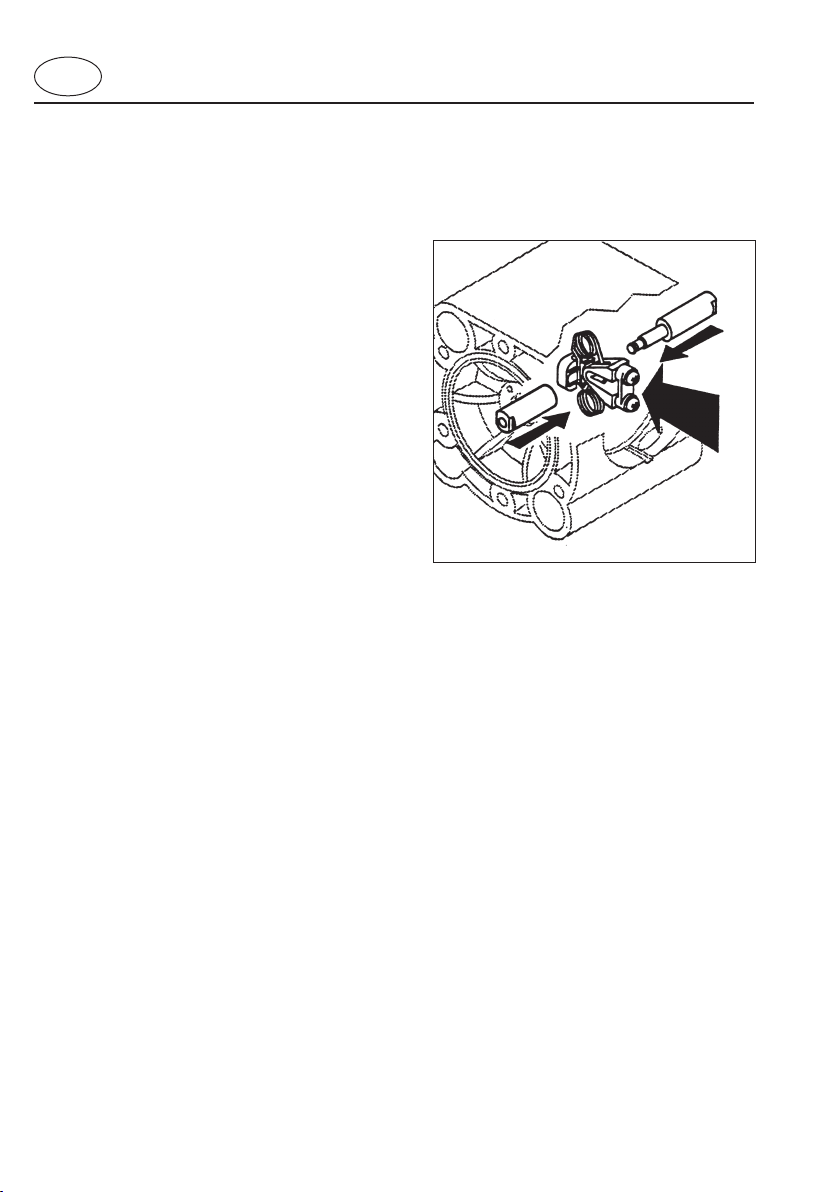

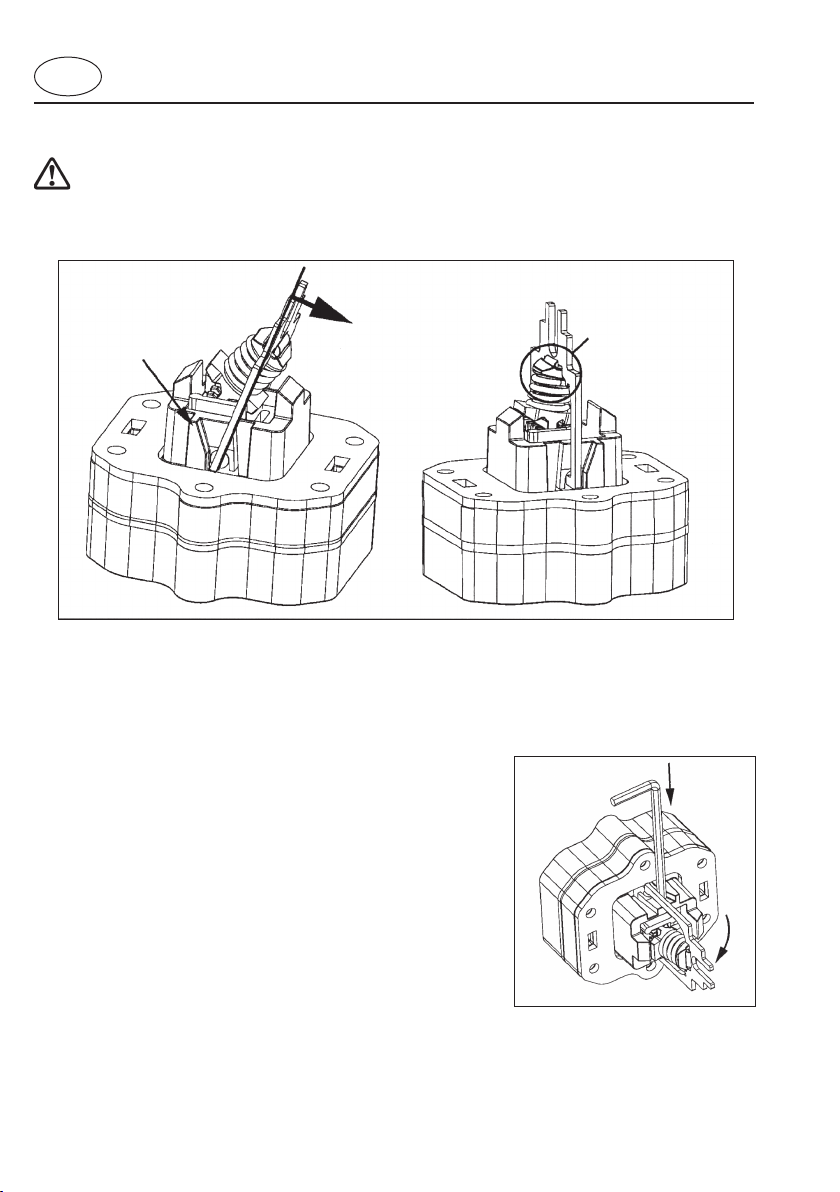

12. To reassemble the air valve, first shift the spring mechanism to the

side with the hard-stop. Next, prop the spring retainer into a more

neutral position by inserting a 3 mm hex key as shown between the

hard-stop and the spring retainer.

13. With the rod guide (1) positioned such that the opened end is facing

the air valve assembly opening, slide the air valve assembly in place

so that the forks slide into the rod guide. Once the fork of the spring

retainer is in the rod guide, pull the hex key free and push the air valve

assembly fully into place. Finally, reinsert and tighten the air valve

assembly screws to the torque listed below.

Caution

Past this point, the

spring and mechanism

parts will come free.

When manually shifting

the mechanism, firmly

hold the spring top

shown to avoid the

spring coming loose.

Hard-stop

17

GB

3.3.4 Fastener Torque Requirements

Caution!

When reassembling, loosely tighten all external fasteners adjusting and aligning and gradually, in an alternating fashion, tighten to torque requirements listed below.

Air valve assembly screws 1.35 Nm

Band clamps 18.8 Nm

Manifold bolts 1.13 Nm

Outer diaphragm plates 4.5 Nm

Maintenance Model 3/8", Band Clamp Version

18

GB

3.4 Maintenance Model 1/2", Band Clamp Version

3.4.1 Maintenance of Check Valve and O-Ring

1. Flush and neutralize the pump to be certain all corrosives or hazardous materials are removed prior to any main-

tenance. This procedure should always be followed when returning pumps for factory service also.

2. Remove the nuts (8) and washers (10) from the four long pumping cap screws (35). Suction check valve seats

and check balls (26, 27) are located inside of the bottom of the outer chamber (28). Gently remove and inspect

for excessive wear, pitting or other signs of degradation. Inspect valve seat and manifold o-rings (38). Replace if

necessary. Discharge check valves are located inside of the bottom of the discharge elbows (32).

3. To inspect the manifold o-rings (22) remove the eight sets of nuts, washers and bolts (10, 19, 20) from each

manifold assembly and replace if necessary. Then reassemble, lightly tighten fasteners. Align the single parts of

the complete pump and tighten the screws in turn with the admissible torque requirement. The check ball should

fit into the curved portion of the valve seat and be facing upward when reinserted into the valve seat location.

Caution!

When using pumps built with PTFE o-rings always replace with new PTFE o-rings, since the original o-rings

may not reseal the pump.

3.4.2 Maintenance of Diaphragm and Pilot Sleeve Assembly

4. To inspect diaphragms remove the band clamps (16) from the outer pumping chambers (28). If replacement is

necessary due to abrasion or rupture unscrew the outer diaphragm plates (29). Models that are built with PTFE

elastomers will have a PTFE overlay (30) that faces the outer pumping chamber (28) and a back-up diaphragm

(31) on the air side of pump. When changing diaphragms it is recommended to replace always both. Pumps

without PTFE will contain only the back-up diaphragms (31).

5. If a diaphragm has been ruptured and corrosive or viscous fluid has entered the air side of the pump, the com-

plete air system should be inspected. After removing diaphragms and inner diaphragm plate (33), the pilot sleeve

assembly (14, 40, 42, 45-47) and diaphragm rod assembly (13, 15) may be removed by removing the retaining

plates (41) and push the entire unit out through the bore in the intermediate (34). Diaphragm rod assembly must

be unscrewed to remove pilot sleeve.

Caution!

To aid in reassembly use a non-synthetic, petroleum based lubricating grease without EP additives.

Maintenance Model 1/2", Band Clamp Version

Loading...

Loading...