Page 1

A Step-by-Step Guide for Installing, Operating and Maintaining a Lutron

AC Motor Group Controller

Please Read Before Installing

Models:

WC-2M-GC 2 Motor Controller

WC-4M-GC 4 Motor Controller

AC Motor Group Controller

Installer’s Guide

Page 2

2

Table of Contents

Description and Ratings . . . . . . . . . . . . . . . . . . . . . . .2

Important Information . . . . . . . . . . . . . . . . . . . . . . . . .2

System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Determine a Mounting Location . . . . . . . . . . . . . . . . .4

Pre-installation Motor Wiring Check . . . . . . . . . . . . . .5

Line Voltage Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Configuring the Motor Direction for

Open and Close Functions . . . . . . . . . . . . . . . . . . . . .7

Contact Closure Input Control Wiring . . . . . . . . . . . .7

Example of Individual Control

(no dedicated stop input) . . . . . . . . . . . . . . . . . . .8

Example of individual Control

(with dedicated stop input) . . . . . . . . . . . . . . . . . .9

Example of Master Control

(with dedicated stop input) . . . . . . . . . . . . . . . . .10

Connecting Multiple Group Controllers . . . . . . .11

Setting the Contact Closure Input Type . . . . . . . . . .12

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Important Information

• Before starting the installation, please completely read

these installation instructions.

• This control must be installed by a certified electrician.

• Install in accordance with all local and national electrical

codes.

• Turn power OFF at circuit breaker or remove fuse

before installing and wiring the controller. Do not wire

with power ON.

• Operating environment should be between 32° F to

104° F (0° C to 40° C).

• Proper short circuit protection and overload protection

must be provided at the distribution panel. You can use

up to a 20 A breaker for your application, where

applicable.

Description

The WC-2M-GC and WC-4M-GC Group Controllers are

designed to control AC motorized window treatments and

projection screens. Both control single phase, bi-directional

AC motors (three wire motors: open, close, neutral). Two

models are available to control up to two motors (WC-2MGC) or up to four motors (WC-4M-GC). Both accept inputs

from controls that provide low-voltage, Class 2, dry contact

closures. Each Group Controller has individual motor

control inputs as well as a master control input. This allows

individual control of each motor or control of all motors at

the same time.

Ratings

Input

110–127 V

~, 60 Hz Single Phase

20 A maximum input current

Load Capacity

5 A, 1/4 HP motor load per channel @ 120 V~

Page 3

3

12345

ON

COM1

CLOSE1

STOP1

OPEN1

OPEN1 CLOSE1 OPEN2 CLOSE2 OPEN3 CLOSE3 OPEN4 CLOSE4 OPEN ALL CLOSE ALL

MASTER CONTROLS

PROGRAM

STATUS

POWER

OPTIONS

MS 240V 120V N N C1 O1 N C2 O2 N C3 O3 N C4 O4

COM2

CLOSE2

STOP2

OPEN2

COM3

CLOSE3

STOP3

OPEN3

COM4

CLOSE4

STOP4

OPEN4

COM

CLOSE

STOP

OPEN

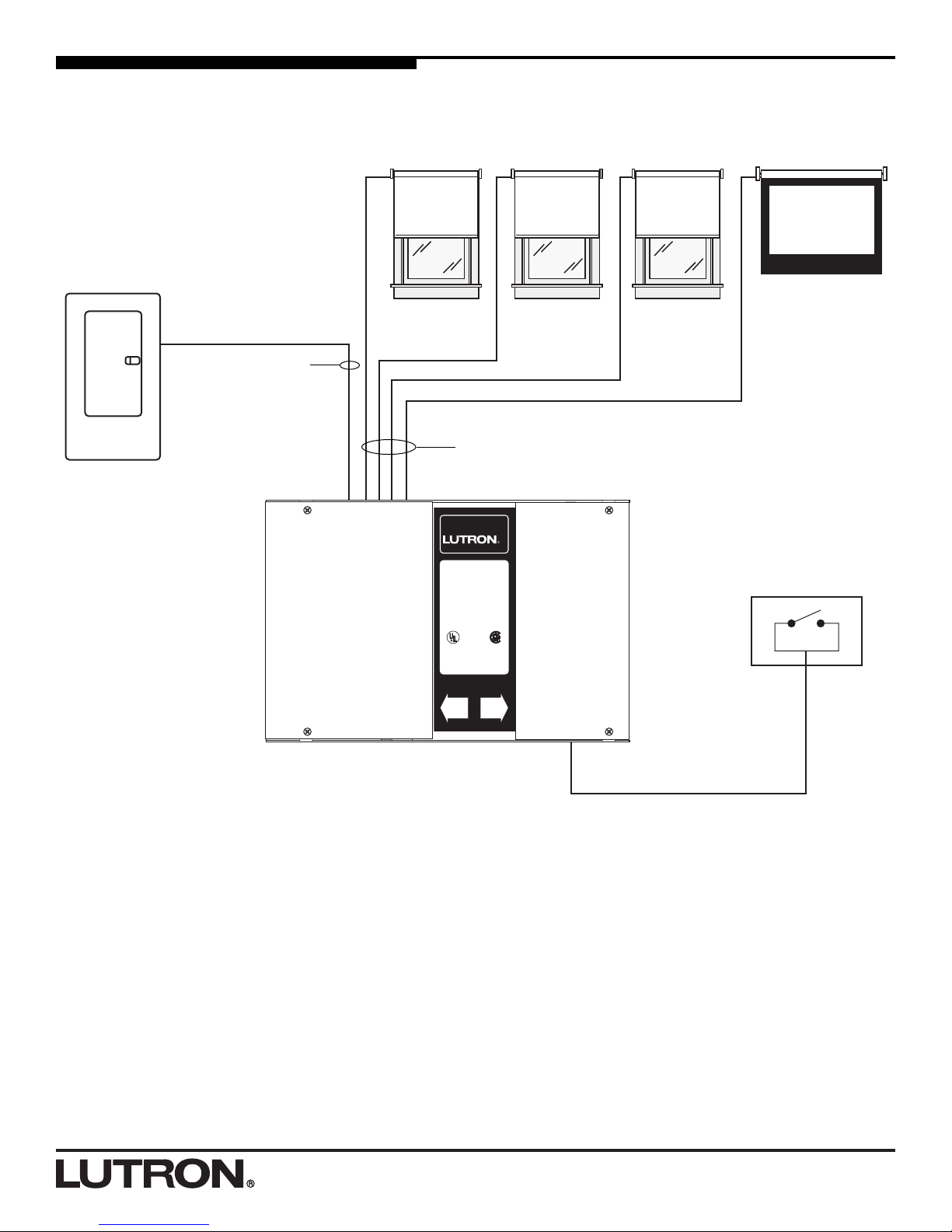

System Diagram

AC Motorized

Window

Treatment

WC-4M-GC Group Controller

Distribution Panel

Class 2/PELV Wiring

Line-Voltage 3 Wire AC Motor Wiring

3 conductors plus ground

Line-Voltage Wiring

AC Motor

Group Controller

Coopersburg, PA 18036 USA

www.lutron.com

®

WC-4M-GC

4 MOTOR GROUP CONTROLLER

110-127 V~ 60 Hz

20 A Max. Input Current

LOAD TYPES

Single Phase, Bi-directional Motor

5 A, 1/4 HP per Channel at 120 V~

TYPES DE CHARGES

Phase Simple, Moteur Bidirectionel

5 A, 1/4 HP par Canal a 120 V~

Listed 243C

Ind. Cont. Eq.

Questions? Call Lutron Technical Support

1-800-523-9466 (24 hrs/7 days)

110-127 V~ USA: Class 2

AC Motorized

Window

Treatment

AC Motorized

Window

Treatment

AC Motorized

Projection Screen

Contact Closure Device

(provided by others)

2 conductors

plus ground

Page 4

44

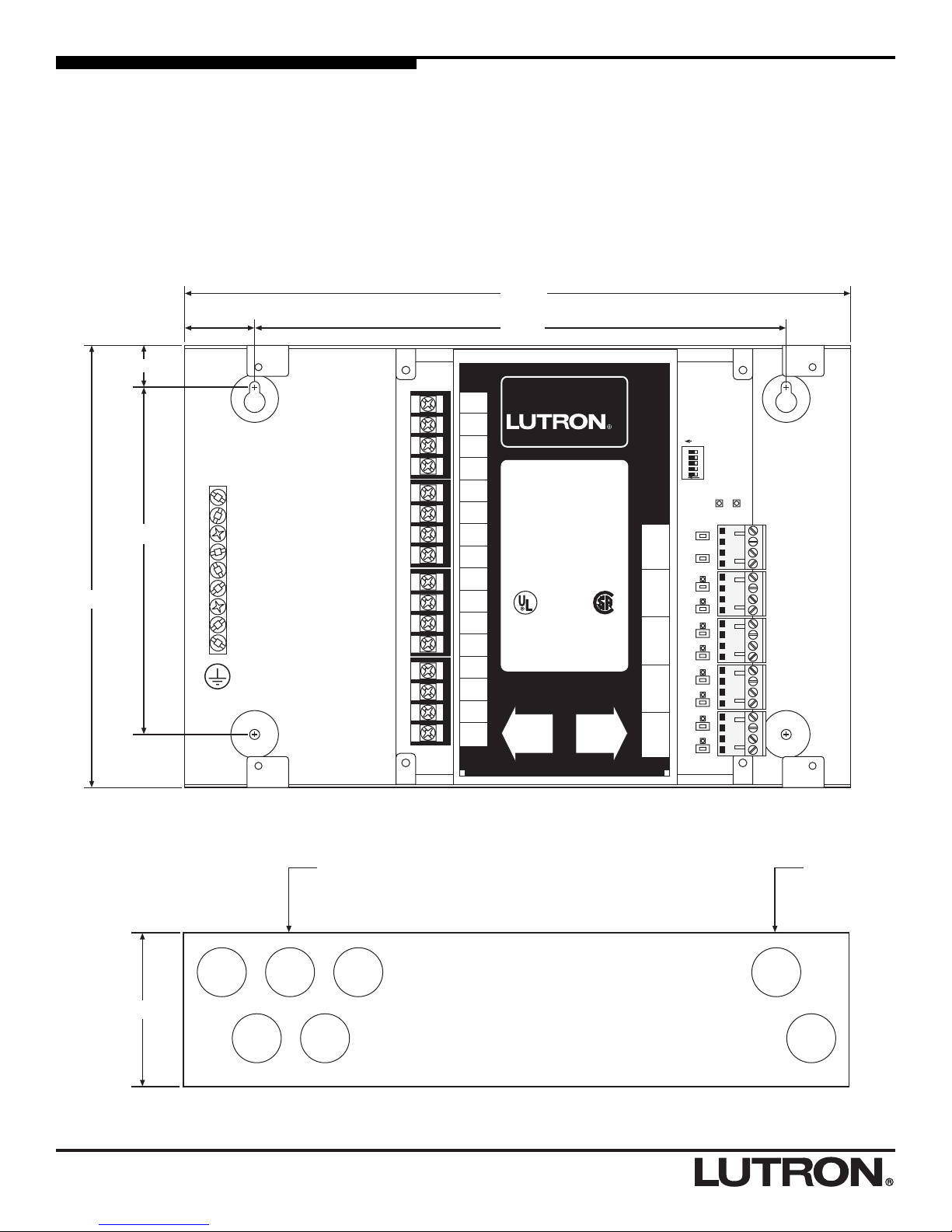

Determine a Mounting Location

• Mount the WC-2M-GC, WC-4M-GC on a dry, flat indoor

surface such as an electrical closet wall.

• Mount unit in a location that is accessible to allow for

system programming and setup.

• Unit may be mounted in any orientation.

• The unit’s relays will click audibly in normal use. Mount

in a location where this is acceptable.

• The keyholes accept a maximum of 3/16" (5 mm)

mounting bolt. No. 8 (M4) bolt recommended.

• Knockouts are 7/8" (22 mm) in diameter.

12345

ON

STATUS POWER

OPTIONS

Neutral

120V

240V

Motor

Supply

ON

OPEN 1

CLOSE 1

OPEN ALL

CLOSE ALL

OPEN 4

CLOSE 4

OPEN 3

CLOSE 3

OPEN 2

CLOSE 2

SW Live

1B

SW Live

1A

Neutral

SW Live

2B

SW Live

2A

Neutral

SW Live

3B

SW Live

3A

Neutral

SW Live

4B

SW Live

4A

Neutral

9.5 in.

12 in.

6.2 in.

1.25 in.

7.9 in.

.735 in.

AC Motor

Group Controller

Coopersburg, PA 18036 USA

www.lutron.com

500-9575 Rev. B

®

WC-4M-GC

4 MOTOR GROUP CONTROLLER

110-127 V~ 60 Hz

20 A Max. Input Current

LOAD TYPES

Single Phase, Bi-directional Motor

5 A, 1/4 HP per Channel at 120 V~

TYPES DE CHARGES

Phase Simple, Moteur Bidirectionel

5 A, 1/4 HP par Canal a 120 V~

Listed 243C

Ind. Cont. Eq.

Questions? Call Lutron Technical Support

1-800-523-9466 (24 hrs/7 days)

110-127 V~ USA: Class 2

COM

Open

Stop

Close

COM

Open4

Stop4

Close4

COM

Open3

Stop3

Close3

COM

Open2

Stop2

Close2

COM

Open1

Stop1

Close1

Neutral

120 V

Motor

Supply

Jumper

SW Live

4B

SW Live

4A

Neutral

SW Live

3B

SW Live

3A

Neutral

SW Live

2B

SW Live

2A

Neutral

SW Live

1B

SW Live

1A

Neutral

Line-voltage input power and

motor power wiring entry

Class 2/PELV

wiring entry

2.75 in.

Front View

Side View

Page 5

55

Distribution

Panel

Neutrals Earth/Grounds

Hot/Live

Danger - Locate and lock the supply breaker in

the OFF position or remove the supply fuse

before working on any circuit.

Momentary

SPDT Switch

(wallbox not

shown)

AC Motorized

Window

Treatment Shown

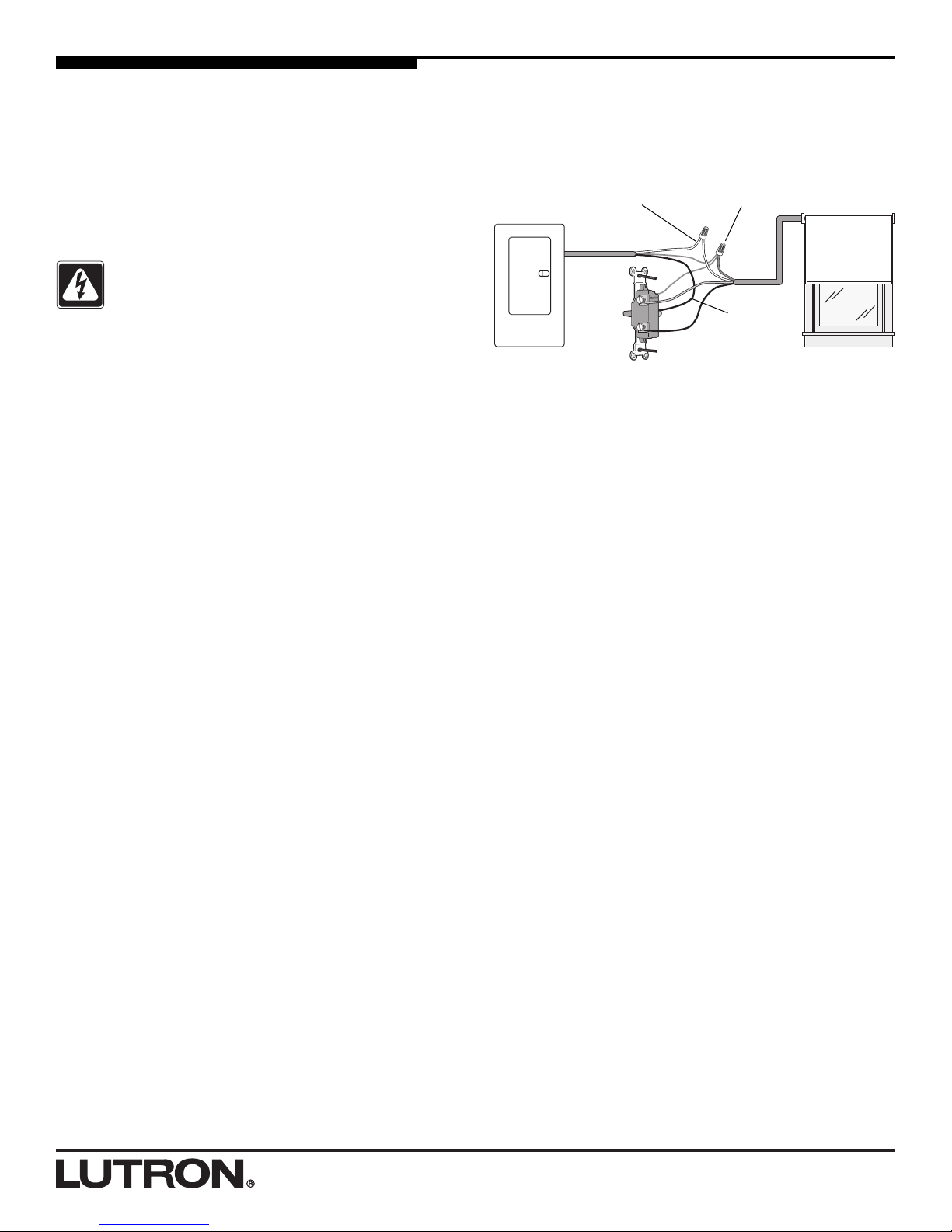

Pre-installation Motor Wiring Check

Test your wiring before connecting to the Group Controller.

Use either a momentary, Single Pole Double Throw

(SPDT) switch (as described below) or a motor wiring test

kit (available from Lutron). To order the motor wiring test

kit, contact Lutron at 1-888-SIVOIA1 (1-888-748-6481) and

ask for model 6020086.

Note: If using the motor wiring test kit, please refer to the

instructions provided with the kit.

Testing motor wiring using a SPDT switch:

1. Turn power OFF at circuit breaker (MCB) or remove

fuse.

2. Connect the motor ground wire to earth ground.

Connect earth ground to the ground terminal on the

switch.

3. Connect the motor neutral wire to supply neutral.

4. Using one momentary, Single Pole Double Throw

(SPDT) switch for each motor, connect hot/live to the

common terminal on the switch.

5. Connect one each of the motor power wires to the

output terminals on the switch. Never wire more than

one motor to a switch.

6. Mount switch in a wallbox. Be sure no bare wires or

terminals on the switch are exposed.

7. After verifying it is safe to restore power, turn power

ON.

8. Verify motor will raise/open and lower/close properly. If

necessary, remove power and correct wiring.

Page 6

66

Line-Voltage Wiring

Connect line voltage and the AC Motors to the Group

Controller.

12345

ON

STATUS POWER

OPTIONS

Neutral

120V

240V

Motor

Supply

ON

OPEN ALL

CLOSE ALL

OPEN 4

CLOSE 4

OPEN 3

CLOSE 3

OPEN 2

CLOSE 2

OPEN 1

CLOSE 1

SW Live

1B

SW Live

1A

Neutral

SW Live

2B

SW Live

2A

Neutral

SW Live

3B

SW Live

3A

Neutral

SW Live

4B

SW Live

4A

Neutral

WC-4M-GC Group Controller

AC Motor 1

Motor 4 Power Wires

Motor 3 Power Wires

Motor 2 Power Wires

Motor 1 Power Wires

Power Feed Wiring

Danger - Locate and lock the supply breaker in

the OFF position or remove the supply fuse

before working on any circuit.

• Only connect one motor to each output. Never wire

motors in parallel.

• The WC-2M-GC and WC-4M-GC accepts 110-127 V~,

60 Hz.

• Strip 1/2" of insulation from all power feed and motor

power wires.

• Run power to the Motor Supply Jumper terminal.

Connect the Motor Supply Jumper terminal to the

120 V Input Voltage terminal using a piece of wire of

the same gauge as the power feed wiring.

• Connect the motor power wires to the appropriate

terminals indicated in the diagram below.

• There is a dedicated earth/grounding block to land the

ground connections for the power feed and each motor.

The recommended tightening torque is 9.0 in-lbs for

line-voltage connections and 10 in-lbs for earth ground

connections.

• Run all power feed and motor power wiring through the

knockout holes on the sides of the unit.

Wiring Detail

Neutral

120V

240V

Motor

Supply

SW Live

1B

SW Live

1A

Neutral

SW Live

2A

Neutral

Power Feed Wiring

Motor 1 Power Wires

SW Live 1B

SW Live 1A

Neutral

Neutral

120 V Input

Motor Supply Jumper

Wiring Overview

Note: Motor power wire colors may

vary depending on the motor

manufacturer. Refer to the motor

manufacturer’s instructions for more

detailed wiring information.

Earth/Grounding

Block

AC Motor 2 AC Motor 3 AC Motor 4

Ground *

* Motor earth/ground wire is not shown in

this diagram. See Wiring Detail below.

Wiring entry knockouts

AC Motor

Group Controller

Coopersburg, PA 18036 USA

www.lutron.com

500-9575 Rev. B

®

WC-4M-GC

4 MOTOR GROUP CONTROLLER

110-127 V~ 60 Hz

20 A Max. Input Current

LOAD TYPES

Single Phase, Bi-directional Motor

5 A, 1/4 HP per Channel at 120 V~

TYPES DE CHARGES

Phase Simple, Moteur Bidirectionel

5 A, 1/4 HP par Canal a 120 V~

Listed 243C

Ind. Cont. Eq.

Questions? Call Lutron Technical Support

1-800-523-9466 (24 hrs/7 days)

110-127 V~ USA: Class 2

COM

Open

Stop

Close

COM

Open4

Stop4

Close4

COM

Open3

Stop3

Close3

COM

Open2

Stop2

Close2

COM

Open1

Stop1

Close1

Neutral

120 V

Motor

Supply

Jumper

SW Live

4B

SW Live

4A

Neutral

SW Live

3B

SW Live

3A

Neutral

SW Live

2B

SW Live

2A

Neutral

SW Live

1B

SW Live

1A

Neutral

Page 7

77

Contact Closure Input Control Wiring

The WC-2M-GC and WC-4M-GC accept Class 2, dry

contact closure inputs. The contact closure inputs for this

unit may be either momentary or maintained. The contact

closure type selected using the Options switch #5 (OFF =

Momentary, ON = Maintained). Momentary dry contact

closure inputs require a minimum closure time of 0.2

seconds.

The contact closure device must be able to switch 2 mA

at 30 Vdc. If multiple channels or Group Controllers are

wired in parallel to one contact closure, the contact

closure device must be rated for the total current of all the

channels or Group Controllers wired together (total

current = 2 mA times the number of Group Controllers or

channels in parallel). Example, if you connect 4 Group

Controllers in parallel, the contact closure device would

need to be rated for at least 8 mA, at 30 Vdc.

12345

ON

PROGRAM

STATUS POWER

OPTIONS

ON

OPEN ALL

CLOSE ALL

OPEN 4

CLOSE 4

OPEN 3

CLOSE 3

OPEN 2

CLOSE 2

OPEN 1

CLOSE 1

Operate the

channel using the

Open and Close

buttons

8036 USA

500-9575 Rev. B

®

CONTROLLER

Technical Support

USA: Class 2

COM

Open

Stop

Close

COM

Open4

Stop4

Close4

COM

Open3

Stop3

Close3

COM

Open2

Stop2

Close2

COM

Open1

Stop1

Close1

Change the

desired channel’s

output direction by

switching the

corresponding

Options switch

Configuring the Motor Direction for the

Open and Close Functions

For each Channel of the unit, the motor’s direction of

rotation needs to be configured for the Open and Close

functions so that the AC Motor will move in the proper

direction. This is accomplished using the Options

Switches, #1 through #4. This step needs to be performed

whether each channel is controlled individually or all

channels are controlled together.

1. Restore power to unit. Once the appropriate line

voltage and motor connections have been made to the

unit, replace the cover on the line voltage wiring

compartment. Remove the cover from the Class 2

wiring compartment. Turn power back ON.

2. Determine AC motor position. Determine whether

the AC Motor that is controlled by Channel 1 is open

or closed. If it is open, press the Close 1 manual

override button. If it is closed, press the Open 1

manual override button. If the AC Motor moves to the

desired position, the Channel is configured properly.

Proceed to Step 4. If the AC Motor does not move to

the desired position, proceed to Step 3.

3. Verify motor movement. If the AC Motor did not

move to the desired position in the prior step, slide the

Options Switch #1 to the opposite position. Press the

same button again that was pressed in Step 2 (Open

or Close). If the AC Motor moves to the desired

position Channel 1 is now configured properly.

Proceed to Step 4.

4. Repeat for remaining motors. Repeat Steps 2 and 3

for the rest of the Channels that are connected to AC

Motors. Options Switch #2 configures Channel 2,

Options Switch #3 configures Channel 3*, and Options

Switch #4 configures Channel 4*.

Each motor channel has a contact closure input terminal

block. In addition, the unit has a master control contact

closure input terminal block. The master control contact

closure input will operate all four motor channels

simultaneously. See the wiring diagrams on pages 10–11.

The stop function can be achieved either by providing a

contact closure input to the stop terminal of the input

terminal block, or by simultaneously providing a closure

on the open and close terminals of the input terminal

block. Both stop methods will be addressed in the wiring

diagrams on pages 8–11.

2

3

Note: Do not change the position of Options Switch #5.

This switch is used to change the contact closure input

type. See section Setting the Contact Closure Input Type

on page 12 for more details on the Options Switch #5.

* Channel 3 and 4 are only available on Group Controller model GRX-

4M-GC.

Page 8

88

WC-4M-GC Group Controller Shown

Class 2/PELV Wiring

Com 1

Open 1

Close 1

Com 2

Open 2

Close 2

Com 3

Open 3

Close 3

Com 4

Open 4

Close 4

Example of Individual Control (no dedicated stop

input)

In this wiring example, the stop function is achieved by

simultaneously providing a closure on the open and close

terminals of the input terminal block. No connection is

made to the stop terminal on the input terminal block.

Contact

closure inputs

3 and 4 are

only available

on the WC-

4M-GC

ler

SA

500-9575 Rev. B

®

120 V~

COM

Open

Stop

Close

COM

Open4

Stop4

Close4

COM

Open3

Stop3

Close3

COM

Open2

Stop2

Close2

COM

Open1

Stop1

Close1

ON

12345

ON

OPTIONS

OPEN ALL

CLOSE ALL

CLOSE 4

CLOSE 3

CLOSE 2

CLOSE 1

OPEN 4

OPEN 3

OPEN 2

OPEN 1

STATUS POWER

Page 9

99

Example of Individual Control (with dedicated stop

input)

In this wiring example, the stop function is achieved by

providing a closure to the stop terminal of the input

terminal block.

WC-4M-GC Group Controller Shown

Class 2/PELV Wiring

Com 1

Open 1

Stop 1

Close 1

Com 2

Open 2

Stop 2

Close 2

Com 3

Open 3

Stop 3

Close 3

Com 4

Open 4

Stop 4

Close 4

Contact

closure inputs

3 and 4 are

only available

on the WC-

4M-GC

ler

SA

500-9575 Rev. B

®

120 V~

COM

Open

Stop

Close

COM

Open4

Stop4

Close4

COM

Open3

Stop3

Close3

COM

Open2

Stop2

Close2

COM

Open1

Stop1

Close1

ON

12345

ON

OPTIONS

OPEN ALL

CLOSE ALL

CLOSE 4

CLOSE 3

CLOSE 2

CLOSE 1

OPEN 4

OPEN 3

OPEN 2

OPEN 1

STATUS POWER

Page 10

1010

Example of Master Control (with dedicated stop input)

In this wiring example, each master function is achieved

by providing a closure to the open, stop, or close terminal

of the input terminal block. Activating any closure will

affect all motors connected to this Group Controller.

12345

ON

STATUS POWER

OPTIONS

ON

OPEN ALL

CLOSE ALL

OPEN 4

CLOSE 4

OPEN 3

CLOSE 3

OPEN 2

CLOSE 2

OPEN 1

CLOSE 1

WC-4M-GC Group Controller Shown

Class 2/PELV Wiring

Com

Open All

Stop All

Close All

Input controls

channel 1

motor only

(optional)

Input controls

channel 2

motor only

(optional)

Input controls

channels 3

and 4 motors

only

(optional)*

Input simulta-

neously

controls all

four channels

* Contact closure inputs 3 and 4 are only available on the

WC-4M-GC

ler

SA

500-9575 Rev. B

®

120 V~

COM

Open

Stop

Close

COM

Open4

Stop4

Close4

COM

Open3

Stop3

Close3

COM

Open2

Stop2

Close2

COM

Open1

Stop1

Close1

Page 11

1111

Connecting Multiple Group Controllers

Multiple Group Controllers can be wired in parallel on the

Class 2/PELV side to obtain simultaneous control of

multiple shades. To do this, parallel wire the control wires

from the contact closure device to each Group Controller’s

contact closure input terminal block. See the diagram

below. This may be used for the individual inputs and/or

master control input.

12345

ON

STATUS POWER

OPTIONS

ON

OPEN ALL

CLOSE ALL

OPEN 4

CLOSE 4

OPEN 3

CLOSE 3

OPEN 2

CLOSE 2

OPEN 1

CLOSE 1

12345

ON

STATUS POWER

OPTIONS

ON

OPEN ALL

CLOSE ALL

OPEN 4

CLOSE 4

OPEN 3

CLOSE 3

OPEN 2

CLOSE 2

OPEN 1

CLOSE 1

WC-4M-GC Group Controller Shown

Class 2/PELV Wiring

To Additional Group

Controllers

WC-4M-GC Group Controller Shown

Input controls channels

1 and 2 motors on this

unit only

Input simultaneously

controls all four

channels on all units

parallel wired together

Note: When connecting multiple Group Controllers in

parallel, make sure the contact closure device is rated for

the total amount of current delivered by each Group

Controller (total current = 2 mA times the number of Group

Controllers). Example, if you connect 4 Group Controllers

in parallel, the contact closure switch would need to be

rated for at least 8 mA, at 30 Vdc.

ller

500-9575 Rev. B

®

ROLLER

t 120 V~

irectionel

cal Support

Class 2

COM

Open

Stop

Close

COM

Open4

Stop4

Close4

COM

Open3

Stop3

Close3

COM

Open2

Stop2

Close2

COM

Open1

Stop1

Close1

ller

500-9575 Rev. B

®

ROLLER

t 120 V~

irectionel

cal Support

Class 2

COM

Open

Stop

Close

COM

Open4

Stop4

Close4

COM

Open3

Stop3

Close3

COM

Open2

Stop2

Close2

COM

Open1

Stop1

Close1

Page 12

1212

Setting the Contact Closure Input Type

When operating from contact closure inputs, the WC-2MGC and WC-4M-GC can accept either momentary or

maintained contact closure inputs. See Appendix A on

page 13 for a more detailed description

Momentary Inputs: The unit will accept a momentary

closure input of greater than 0.2 seconds to activate the

desired function, i.e. raise, lower, or stop. The power

relays will open 2 minutes after either the open or close

contact closure is received, or when another contact

closure is received, whichever comes first. The relays will

open immediately upon receiving the stop contact

closure.

Maintained Inputs: The power relays remain closed as

long as the input closure remains closed. However, the

most recent command received will be executed even if

the previous contact closure is still maintained.

Momentary or maintained inputs are selected using

Options switch #5. In the ON position, maintained mode

is selected. In the OFF position, momentary operation is

selected.

ON =

Maintained Inputs

Options DIP Switch

Options DIP Switch

OFF =

Momentary Inputs

ON

12345

ON

12345

Page 13

13

Contact Closure Inputs:

Maintained Mode Operation

In maintained mode, the Switched Live output for a

channel, for instance SW Live 1A, is energized only while

the contact closure is provided to the input for that

channel. As soon as the contact closure is removed from

the input, the Switched Live output is de-energized. This

gives rise to possible conflicts if a contact closure is

provided during the time another contact closure is

provided. Below are descriptions of how the Group

Controller addresses these situations.

Inputs on a single channel

When a contact closure is provided to a single input on an

individual channel, the Group Controller will energize the

appropriate Switched Live output. If a contact closure is

then provided to another input on that same channel while

the first contact closure is provided, the Group Controller

will recognize this combination as a request to stop. This

will happen regardless of how much time elapses between

the application of the two contact closure inputs.

For example, if a contact closure is provided to Close 1,

the Group Controller will energize the Switched Live

output to close the AC motor on Channel 1. If a contact

closure is provided to Open 1 while a contact closure is

still provided to Close 1, the Group Controller will deenergize the Switched Live output on Channel 1, stopping

the AC motor.

If contact closures are provided to both the Open and

Close inputs on a particular channel, the Group Controller

will de-energize the Switched Live outputs for that

channel. If one of the contact closures is then released,

the Group Controller will NOT recognize that as a request

to move the AC motor to the position indicated by the

contact closure that is still provided. Instead, the Group

Controller will leave the Switched Live outputs deenergized. In order for the Group Controller to recognize a

new input signal, the contact closure must be removed

and then provided again.

Note: It is not recommended to connect two or more

contact closure devices on the same channel if

Momentary mode is selected. If this is done, it is possible

for a channel to become unresponsive to inputs if contact

closures are provided by the two devices at the same

time.

For instance, if one device provides a contact closure to

the Open input, the Group Controller energizes the

Switched Live output that opens the AC motor. If the

second device then provides a contact closure to the

Close input, the Group Controller will then de-energize the

Switched Live output, stopping the AC motor. At this point,

both contact closures must be removed before the Group

Controller will recognize a new request.

If it is desired to connect two or more contact closure

devices on the same channel, use Maintained mode.

Inputs on a single channel and Master Control

When a contact closure is provided to a single input on an

individual channel, the Group Controller will energize the

appropriate Switched Live output. If a contact closure is

then provided to a Master Control input while the first

contact closure is still provided, the Group Controller will

energize the Switched Live outputs requested by the

Master function on all channels of the Group Controller.

For example, if a contact closure is provided to Close 1,

the Group Controller will energize the Switched Live

output to close the AC motor on Channel 1. If a contact

closure is then provided to the Master Open input while a

contact closure is still provided to the Close 1 input, the

Group Controller will energize the Switched Live outputs

to open the AC motor on all channels.

When a contact closure is provided to a Master Control

input, the Group Controller will energize the appropriate

Switched Live outputs on all channels of the Group

Controller. If a contact closure is then provided to a single

input on an individual channel while the Master Control

contact closure is still provided, the Group Controller will

activate the Switched Live output requested by the

individual input, while keeping the Switched Live output in

the same state for the other three channels.

For example if a contact closure is provided to the Master

Open input, the Group Controller will energize the

Switched Live outputs to open the AC motor on all

channels. If a contact closure is then provided to the

Close 1 input, the Group Controller will energize the

Switched Live output on Channel 1 to close the AC motor

on Channel 1, but continue energizing the Switched Live

outputs on Channels 2, 3 and 4

Appendix A

Page 14

14

AC motor does not move in either

direction when manual override

buttons pressed.

• Motor wired to Group Controller

improperly.

• Limit switches on motor not set

properly.

• Motor Supply Jumper terminal is not

jumpered to 120 V terminal.

Verify motor wiring.

Verify limit switch settings on motor.

Place a jumper wire of sufficient wire

gauge between Motor Supply Jumper

and 120 V Input Voltage terminals.

See page 6.

Troubleshooting

Motors cannot be controlled from lowvoltage contact closure inputs but

operate properly with the manual

Open/Close buttons.

• Contact closure miswire. Verify connections on contact closure

inputs.

Motors only move while low-voltage

contact closure is applied.

• Options Switch #5 in ON position. Change position of Options Switch #5

to OFF. See page 11.

Motor moves in the wrong direction. • Options Switch not set properly. Reverse the corresponding Options

Switch. See page 7.

Symptom Possible Cause Solution

Page 15

15

Notes

Page 16

Lutron Electronics Co., Inc.

7200 Suter Road

Coopersburg, PA 18036-1299 U.S.A.

Made and printed in U.S.A. 12/02 P/N 031-216 Rev. A

Worldwide Technical and Sales

Assistance

If you have questions concerning the installation or operation of

this product, call the Lutron Technical Support Center. Please

provide exact model number when calling.

(800) 523-9466 (U.S.A., Canada, and the Caribbean)

Other countries call (610) 282-3800

Fax (610) 282-3090

Visit our web site at www.lutron.com

LIMITED WARRANTY

Lutron will, at its option, repair or replace any unit that is defective in materials or manufacture

within one year after purchase. For warranty service, return unit to place of purchase or mail to

Lutron at 7200 Suter Rd., Coopersburg, PA 18036-1299, postage pre-paid.

THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES, AND THE IMPLIED

WARRANTY OF MERCHANTABILITY IS LIMITED TO ONE YEAR FROM PURCHASE. THIS

WARRANTY DOES NOT COVER THE COST OF INSTALLATION, REMOVAL OR

REINSTALLATION, OR DAMAGE RESULTING FROM MISUSE, ABUSE, OR IMPROPER OR

INCORRECT REPAIR, OR DAMAGE FROM IMPROPER WIRING OR INSTALLATION. THIS

WARRANTY DOES NOT COVER INCIDENTAL OR CONSEQUENTIAL DAMAGES. LUTRON’S

LIABILITY ON ANY CLAIM FOR DAMAGES ARISING OUT OF OR IN CONNECTION WITH

THE MANUFACTURE, SALE, INSTALLATION, DELIVERY, OR USE OF THE UNIT SHALL

NEVER EXCEED THE PURCHASE PRICE OF THE UNIT.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. Some states do not allow limitations on how long an implied warranty lasts, so the

above limitation may not apply to you. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

Lutron is a registered trademark and RadioTouch is a trademark of Lutron Electronics Co., Inc. ©

2002 Lutron Electronics Co., Inc.

Loading...

Loading...