A Step-by-Step Guide for Installing, Operating and Maintaining a Lutron

AC Motor Group Controller

Please Read Before Installing

Models:

WC-2M-GC 2 Motor Controller

WC-4M-GC 4 Motor Controller

AC Motor Group Controller

Installer’s Guide

2

Table of Contents

Description and Ratings . . . . . . . . . . . . . . . . . . . . . . .2

Important Information . . . . . . . . . . . . . . . . . . . . . . . . .2

System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Determine a Mounting Location . . . . . . . . . . . . . . . . .4

Pre-installation Motor Wiring Check . . . . . . . . . . . . . .5

Line Voltage Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Configuring the Motor Direction for

Open and Close Functions . . . . . . . . . . . . . . . . . . . . .7

Contact Closure Input Control Wiring . . . . . . . . . . . .7

Example of Individual Control

(no dedicated stop input) . . . . . . . . . . . . . . . . . . .8

Example of individual Control

(with dedicated stop input) . . . . . . . . . . . . . . . . . .9

Example of Master Control

(with dedicated stop input) . . . . . . . . . . . . . . . . .10

Connecting Multiple Group Controllers . . . . . . .11

Setting the Contact Closure Input Type . . . . . . . . . .12

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Important Information

• Before starting the installation, please completely read

these installation instructions.

• This control must be installed by a certified electrician.

• Install in accordance with all local and national electrical

codes.

• Turn power OFF at circuit breaker or remove fuse

before installing and wiring the controller. Do not wire

with power ON.

• Operating environment should be between 32° F to

104° F (0° C to 40° C).

• Proper short circuit protection and overload protection

must be provided at the distribution panel. You can use

up to a 20 A breaker for your application, where

applicable.

Description

The WC-2M-GC and WC-4M-GC Group Controllers are

designed to control AC motorized window treatments and

projection screens. Both control single phase, bi-directional

AC motors (three wire motors: open, close, neutral). Two

models are available to control up to two motors (WC-2MGC) or up to four motors (WC-4M-GC). Both accept inputs

from controls that provide low-voltage, Class 2, dry contact

closures. Each Group Controller has individual motor

control inputs as well as a master control input. This allows

individual control of each motor or control of all motors at

the same time.

Ratings

Input

110–127 V

~, 60 Hz Single Phase

20 A maximum input current

Load Capacity

5 A, 1/4 HP motor load per channel @ 120 V~

3

12345

ON

COM1

CLOSE1

STOP1

OPEN1

OPEN1 CLOSE1 OPEN2 CLOSE2 OPEN3 CLOSE3 OPEN4 CLOSE4 OPEN ALL CLOSE ALL

MASTER CONTROLS

PROGRAM

STATUS

POWER

OPTIONS

MS 240V 120V N N C1 O1 N C2 O2 N C3 O3 N C4 O4

COM2

CLOSE2

STOP2

OPEN2

COM3

CLOSE3

STOP3

OPEN3

COM4

CLOSE4

STOP4

OPEN4

COM

CLOSE

STOP

OPEN

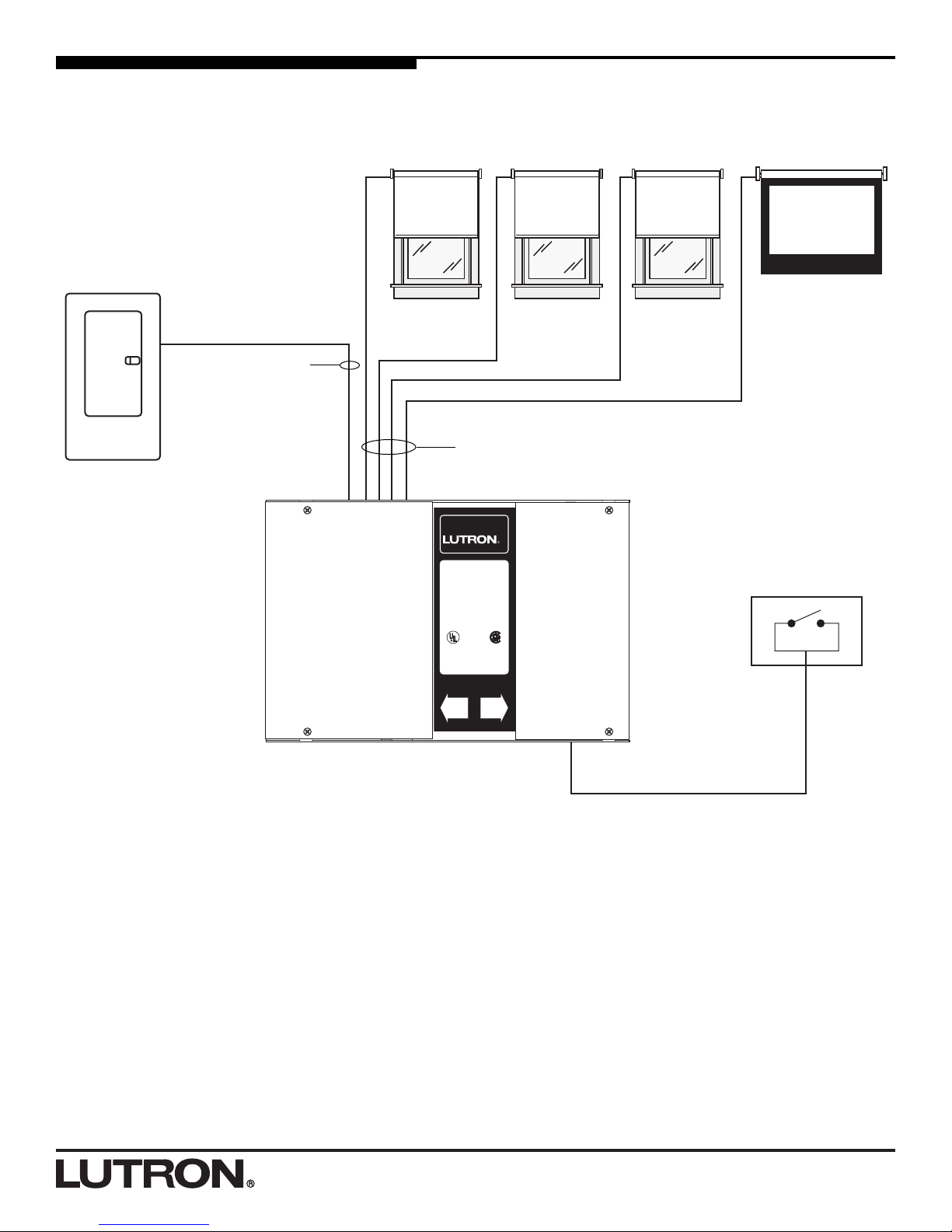

System Diagram

AC Motorized

Window

Treatment

WC-4M-GC Group Controller

Distribution Panel

Class 2/PELV Wiring

Line-Voltage 3 Wire AC Motor Wiring

3 conductors plus ground

Line-Voltage Wiring

AC Motor

Group Controller

Coopersburg, PA 18036 USA

www.lutron.com

®

WC-4M-GC

4 MOTOR GROUP CONTROLLER

110-127 V~ 60 Hz

20 A Max. Input Current

LOAD TYPES

Single Phase, Bi-directional Motor

5 A, 1/4 HP per Channel at 120 V~

TYPES DE CHARGES

Phase Simple, Moteur Bidirectionel

5 A, 1/4 HP par Canal a 120 V~

Listed 243C

Ind. Cont. Eq.

Questions? Call Lutron Technical Support

1-800-523-9466 (24 hrs/7 days)

110-127 V~ USA: Class 2

AC Motorized

Window

Treatment

AC Motorized

Window

Treatment

AC Motorized

Projection Screen

Contact Closure Device

(provided by others)

2 conductors

plus ground

44

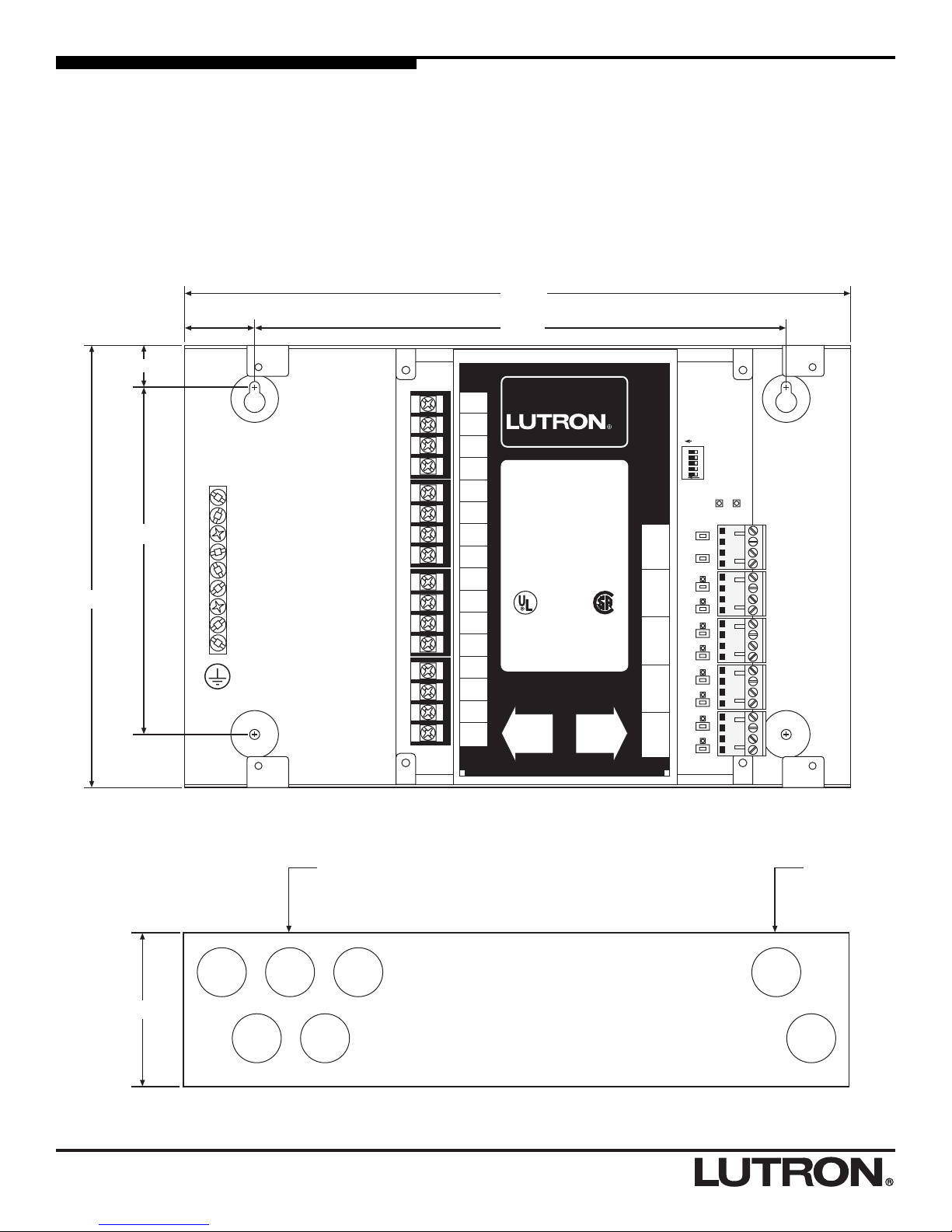

Determine a Mounting Location

• Mount the WC-2M-GC, WC-4M-GC on a dry, flat indoor

surface such as an electrical closet wall.

• Mount unit in a location that is accessible to allow for

system programming and setup.

• Unit may be mounted in any orientation.

• The unit’s relays will click audibly in normal use. Mount

in a location where this is acceptable.

• The keyholes accept a maximum of 3/16" (5 mm)

mounting bolt. No. 8 (M4) bolt recommended.

• Knockouts are 7/8" (22 mm) in diameter.

12345

ON

STATUS POWER

OPTIONS

Neutral

120V

240V

Motor

Supply

ON

OPEN 1

CLOSE 1

OPEN ALL

CLOSE ALL

OPEN 4

CLOSE 4

OPEN 3

CLOSE 3

OPEN 2

CLOSE 2

SW Live

1B

SW Live

1A

Neutral

SW Live

2B

SW Live

2A

Neutral

SW Live

3B

SW Live

3A

Neutral

SW Live

4B

SW Live

4A

Neutral

9.5 in.

12 in.

6.2 in.

1.25 in.

7.9 in.

.735 in.

AC Motor

Group Controller

Coopersburg, PA 18036 USA

www.lutron.com

500-9575 Rev. B

®

WC-4M-GC

4 MOTOR GROUP CONTROLLER

110-127 V~ 60 Hz

20 A Max. Input Current

LOAD TYPES

Single Phase, Bi-directional Motor

5 A, 1/4 HP per Channel at 120 V~

TYPES DE CHARGES

Phase Simple, Moteur Bidirectionel

5 A, 1/4 HP par Canal a 120 V~

Listed 243C

Ind. Cont. Eq.

Questions? Call Lutron Technical Support

1-800-523-9466 (24 hrs/7 days)

110-127 V~ USA: Class 2

COM

Open

Stop

Close

COM

Open4

Stop4

Close4

COM

Open3

Stop3

Close3

COM

Open2

Stop2

Close2

COM

Open1

Stop1

Close1

Neutral

120 V

Motor

Supply

Jumper

SW Live

4B

SW Live

4A

Neutral

SW Live

3B

SW Live

3A

Neutral

SW Live

2B

SW Live

2A

Neutral

SW Live

1B

SW Live

1A

Neutral

Line-voltage input power and

motor power wiring entry

Class 2/PELV

wiring entry

2.75 in.

Front View

Side View

55

Distribution

Panel

Neutrals Earth/Grounds

Hot/Live

Danger - Locate and lock the supply breaker in

the OFF position or remove the supply fuse

before working on any circuit.

Momentary

SPDT Switch

(wallbox not

shown)

AC Motorized

Window

Treatment Shown

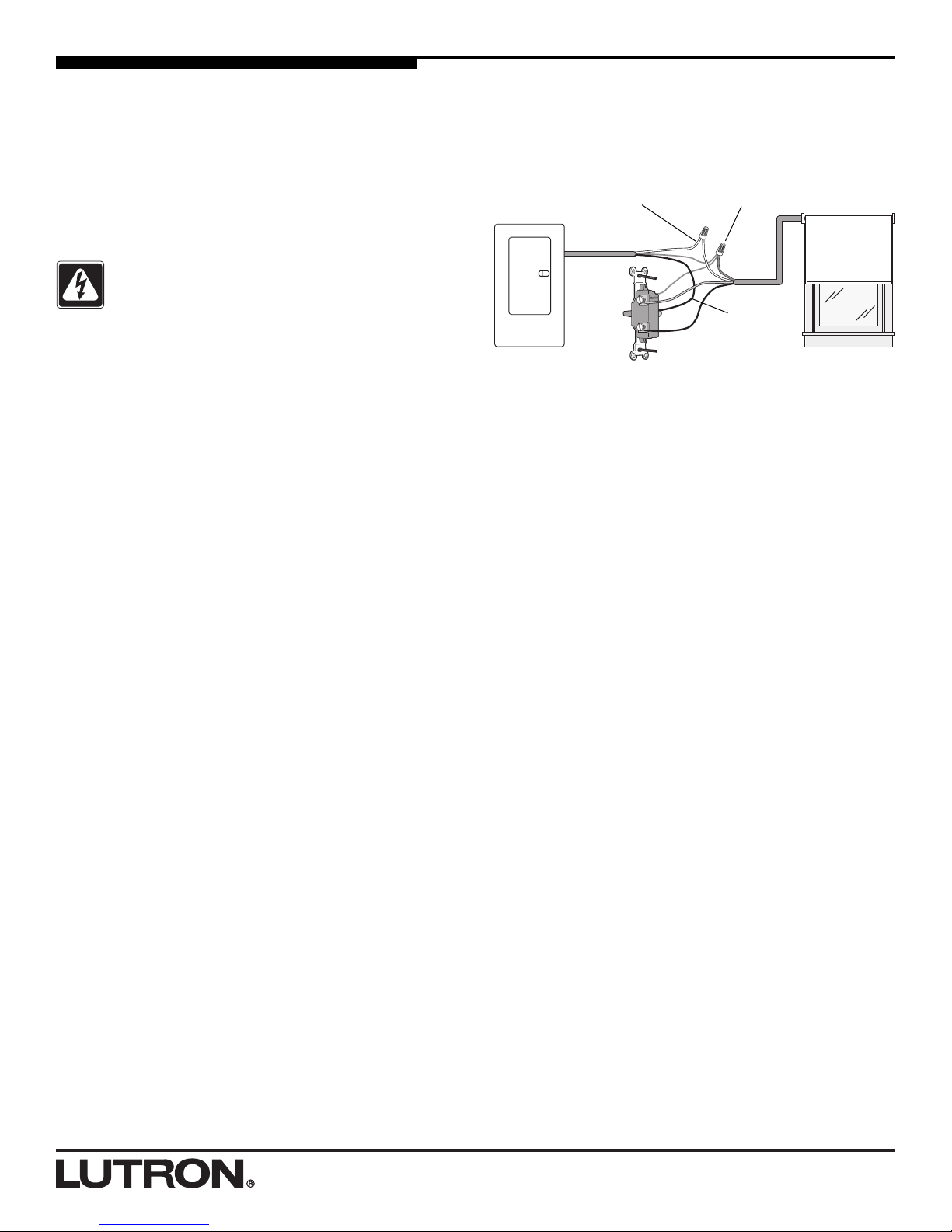

Pre-installation Motor Wiring Check

Test your wiring before connecting to the Group Controller.

Use either a momentary, Single Pole Double Throw

(SPDT) switch (as described below) or a motor wiring test

kit (available from Lutron). To order the motor wiring test

kit, contact Lutron at 1-888-SIVOIA1 (1-888-748-6481) and

ask for model 6020086.

Note: If using the motor wiring test kit, please refer to the

instructions provided with the kit.

Testing motor wiring using a SPDT switch:

1. Turn power OFF at circuit breaker (MCB) or remove

fuse.

2. Connect the motor ground wire to earth ground.

Connect earth ground to the ground terminal on the

switch.

3. Connect the motor neutral wire to supply neutral.

4. Using one momentary, Single Pole Double Throw

(SPDT) switch for each motor, connect hot/live to the

common terminal on the switch.

5. Connect one each of the motor power wires to the

output terminals on the switch. Never wire more than

one motor to a switch.

6. Mount switch in a wallbox. Be sure no bare wires or

terminals on the switch are exposed.

7. After verifying it is safe to restore power, turn power

ON.

8. Verify motor will raise/open and lower/close properly. If

necessary, remove power and correct wiring.

Loading...

Loading...