Page 1

Bench type, RS232/USB computer interface

R

g

g

g

pH, ORP, CD, TDS, DO, SALT

METER

Model : WA-2015

Your purchase of this

pH, ORP, CD, TDS, DO,

SALT METER with SD

CARD DATALOGGE

marks a step forward for

you into the field of

precision measurement.

Althou

a complex and delicate

instrument, its durable

structure will allow

many years of use if

proper operatin

techniques are

developed. Please read

the followin

instructions carefully

and always keep this

manual within easy

reach.

h this METER is

OPERATION MANUAL

Page 2

TABLE OF CONTENTS

.

.

.

.

.

.

.

.

.

1. FEATURES................................................................1

2. SPECIFICATIONS......................................................3

2-1 General Specifications..........................................3

2-2 Electrical Specifications........................................5

3. FRONT PANEL DESCRIPTION....................................

4. MODE SELECTION ( pH/CD/DO selection ).................

5. pH/mV MEASURING and CALIBRATION

PROCEDURE............................................................

6. CONDUCTIVITY/TDS MEASURING and

CALIBRATION PROCEDURE.......................................19

7. DO (Dissolved Oxygen) MEASURING

and CALIBRATION PROCEDURE................................

8. DATA HOLD, DATA RECORD, DATA LOGGER

LCD BACKLIGHT ON/OFF..........................................31

9. ADVANCED ADJUSTMENT PROCEDURE......................34

9-1 Check memory space..........................................

9-2 Clear Memory.....................................................

9-3 Set Date/Time ....................................................36

9-4 Set sampling time ..............................................

9-5 Auto power OFF management..............................37

9-6 Select the Temp. unit to or ..........................℃℉ 37

9-7 Set pH manual Temp. compensation value............38

9-8 Set DO salt% compensation value........................38

9-9 Set DO height ( meter ) compensation value.........39

9-10 Set DO height ( feet ) compensation value..........39

9-11 Set CD temperature compensation factor............40

9-12 ESC.................................................................. 40

10. SEND THE DATA OUT FROM THE METER.................

11. RS232 PC SERIAL INTERFACE.................................

12. BATTERY REPLACEMENT.........................................45

13. SYSTEM RESET.......................................................45

14. OPTIONAL ACCESSORIES........................................46

9

11

12

24

35

35

36

41

43

Page 3

1. FEATURES

* Professional bench type meter with large size

LCD display with green color back light.

* One meter for multi purpose operation :

pH/ORP, CD/TDS ( Total dissolved solids ),

Dissolved Oxygen.

* pH : 0 to 14.00 pH, ORP : ± 1999 mV.

* Conductivity : 200 uS/2 mS/20 mS/200 mS.

* Dissolved oxygen : 0 to 20.0 mg/L.

* Real time data logger ( record year, month, date,

hour, minute, second ), 16,000 data logger.

* Auto data record, 16,000 Data logger no.

* Wide sampling time adjustment range from one

second to 8 hours 59 minutes 59 seconds.

* Auto data logger, manual data logger.

* RS232 computer interface.

* Max., Min., Data hold.

* Can default auto power off or manual power off.

* Optional pH, ORP, CD/TDS, Dissolved Oxygen and

ATC probe.

* DC 1.5V ( UM-3, AA ) x 8 PCs or DC 9V adapter in.

* pH meter function can select pH or ORP.

* pH measurement can select ATC or manual temperature

adjustment.

* pH measurement can make the auto calibration for

pH 7, pH 4 and pH 10 or other value.

* Conductivity measurement can select uS/mS or TDS

* Conductivity measurement can select Temp. Coefficient

of measurement solution.

* ATC for the conductivity measurement.

1

Page 4

* Dissolved oxygen meter use the polar graphic type

oxygen probe with temperature sensor, high precision

measurement for Dissolved Oxygen ( DO ) and

temperature measurement.

* Heavy duty dissolved oxygen probe, probe head can

connect with BOD bottle.

* DO use the automatic Temp. compensation.

* DO meter build in " % SALT " & " Mountain Height "

compensation value adjustment.

* Super large LCD display with LCD backlight ON/OFF.

* Separate probe, easy for operation of different

measurement environment.

* Wide applications: water conditioning, aquariums,

beverage, fish hatcheries, food processing,

photography, laboratory, paper industry, plating

industry, quality control, school & college, water

conditioning.

2

Page 5

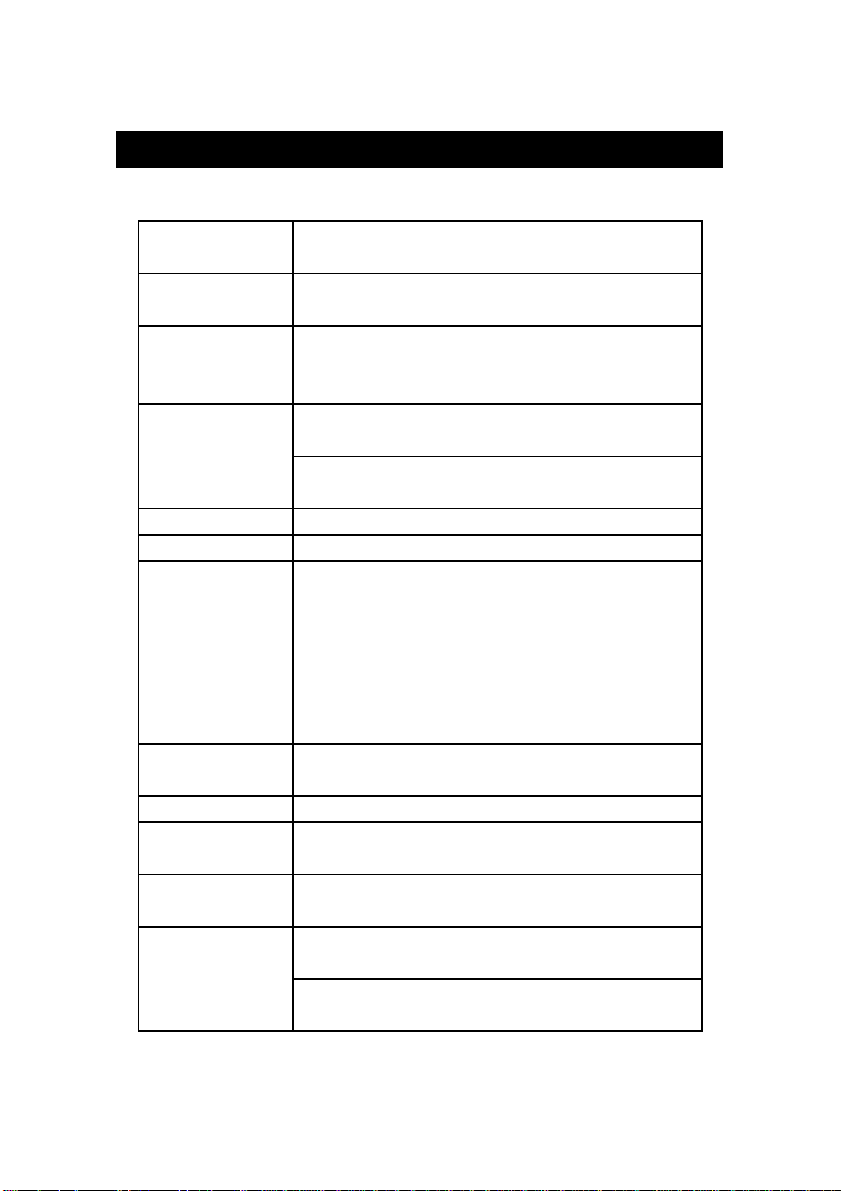

2. SPECIFICATIONS

@

@

2-1 General Specifications

Circuit Custom one-chip of microprocessor LSI

circuit.

Display LCD size : 82 mm x 61 mm.

* with green color backlight.

Measurement pH/ORP

Conductivity/TDS(Total Dissolved Solids)

Dissolved Oxygen

Sampling Time

of Data Logger 1 sec to 8 hour 59 min. 59 sec.

Data Hold Freeze the display reading.

Memory Recall Maximum & Minimum value.

Power off Auto shut off saves battery life or

Sampling Time Approx. 1 second.

of display

Data Output RS 232 PC serial interface.

Operating 0 to 50 . - Main instrument.℃

Temperature

Operating Less than 80% R.H.

Humidity

Power Supply DC 1.5 V battery ( UM3 ) x 8 PCs,

Auto data logger :

Manual data logger :

Set sampling time to 0 second.

manual off by push Button.

Can default auto power or manual

power off.

When default auto power function,

power will off automatically after

10 MIN, if no Button be pressed.

( Heavy duty type ).

DC 9V adapter input.

@ AC/DC power adapter is optional.

3

Page 6

Power Operation ( LCD backlight ON ) :

t

.

.

.

Consumption Approx. DC 32 mA

Operation ( LCD backlight OFF ) :

Approx. DC 8 mA

Power OFF ( only internal clock running ) :

Approx. DC 1.8 uA.

Weigh

* meter

1049 g/2.3 LB.

Dimension 225 X 125 X 64 mm

@ Meter

( 8.86 X 4.92 X 2.52 inch )

Accessories Instruction manual......................1 PC

Included

Optional * pH electrode.......................

Accessories PE-03, PE-11, PE-01, PE06HD

PE-04HD, PE-05T, PE-03K7

PE-02, PE-08, PE-21

* ATC ( Automatic Temperature

Probe )...............................

TP-07

* pH 7 buffer solution.............pH-07

* pH 4 buffer solution.............pH-04

* pH electrode hoder..............EH-20

* ORP electrode......................ORP-14

* Conductivity probe...............CDPB-03

* 1.413 mS Conductivity Standard

Solution..............................

CD-14

* Oxygen probe......................OXPB-11

* Spare Probe head with diaphragm set

..........................................OXHD-04

* Probe-filling Electrolyte........

OXEL-03

* Carrying case.......................CA-3K

* AC to DC 9V adapter.

* RS232 cable, UPCB-02.

*USB cable, USB-01

* Data Acquisition software,

SW-U801-WIN.

* Data Logger software, SW-DL2005.

4

Page 7

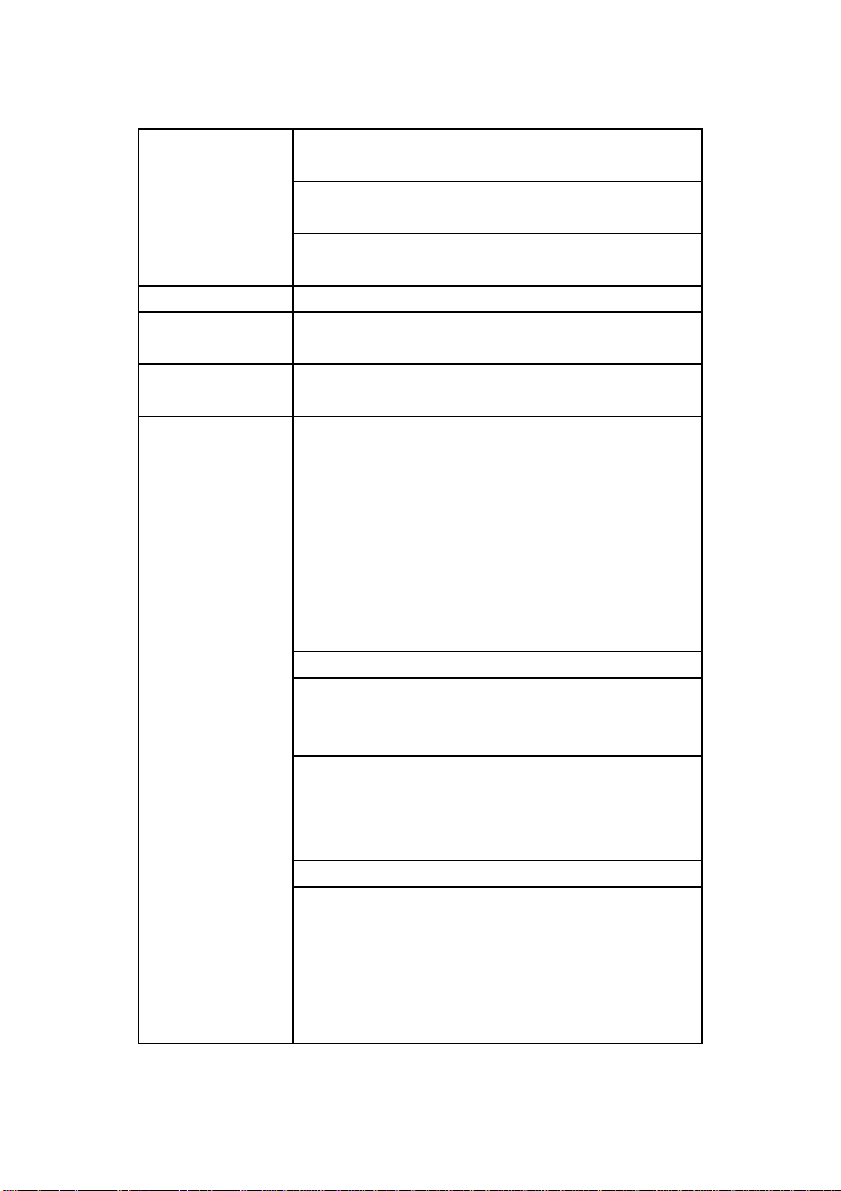

2-2 Electrical Specifications (23±5 )℃

A. pH/mV

pH Optional,

Electrode Any pH electrode with BNC connector.

Measurement pH 0 to 14 pH

mV -1999 mV to 1999 mV

Input 10^12 ohm

Impedance

Temperature Manual 0 to 100 , be adjusted by℃

Compensation push button on front panel.

for pH Automatic With the optional temperature

measurement ( ATC ) probe ( TP-07 )

0 to 65 .℃

pH pH7, pH4, and pH10, 3 points calibration

Calibration ensure the best linearity and accuracy.

Optional * pH electrode...........PE-03, PE-11, PE-01, PE06HD

probe and PE-04HD, PE-05T, PE-03K7

accessories * ATC ( automatic temperature

probe ).......................................TP-07

* pH 7 buffer solution....................pH-07

* pH 4 buffer solution....................pH-04

* ORP electrode.............................ORP-14

2-2 Electrical Specifications (23 ±5 )℃

Measurement Range Resolution Accuracy

pH 0 to 14 pH 0.01 pH ± (0.02 pH + 2 d)

mV 0 to 1999 mV 1 mV ± (0.5% + 2 d)

* pH accuracy is based on calibrated meter only.

5

Page 8

B. Conductivity

Conductivity Optional,

probe Carbon rod electrode for long life.

Function * Conductivity ( uS, mS )

* TDS ( Total Dissolved Solids, PPM )

* Temperature ( , )℃℉

Temperature Automatic from 0 to 60 (32 - 140 ),℃℉

Compensation with temperature compensation factor

variable between 0 to 5.0% per C.

Probe 0 to 60 .℃

Operating

Temperature

Probe Round, 22 mm Dia. x 120 mm length.

Dimension

Optional * Conductivity probe......................CDPB-03

probe and * 1.413 mS Conductivity Standard

accessories Solution......................................CD-14

1. Conductivity ( uS, mS )

Range Measurement Resolution Accuracy

200 uS 0 to 200.0 uS 0.1 uS

2 mS 0.2 to 2.000 mS 0.001 mS ± (2% F.S.+1d)

20 mS 2 to 20.00 mS 0.01 mS * F.S. - Full scale

200 mS 20 to 200.0 mS 0.1 mS

* Temperature Compensation :

Automatic from 0 to 60 ( 32 - 140 ), with temperature℃℉

compensation factor variable between 0 to 5.0% per C.

* The accuracy is specified under measurement value 100 mS.≦

* mS - milli Simens * @ 23± 5 ℃

6

Page 9

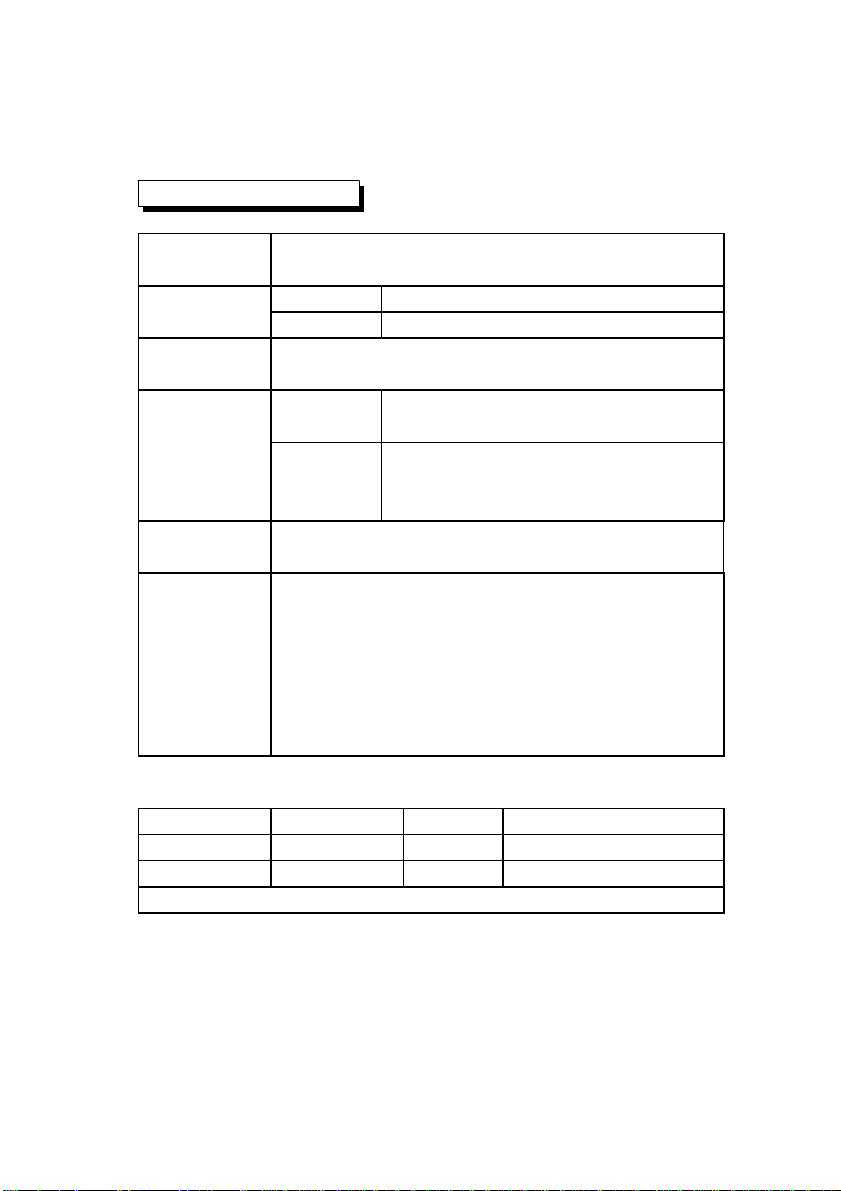

2. TDS ( Total Dissolved Solids )

Range Measurement Resolution Accuracy

200 PPM 0 to 132 PPM 0.1 PPM

2,000 PPM 132 to 1,320 PPM 1 PPM ± (2% F.S.+1d)

20,000 PPM 1,320 to 13,200 PPM 10 PPM * F.S. - Full scale

200,000 PPM 13,200 to 132,000 PPM 100 PPM

* Temperature Compensation :

Automatic from 0 to 60 ( 32 - 140 ), with temperature℃℉

compensation factor variable between 0 to 5.0% per .℃

* The accuracy is specified under measurement value 66,000 PPM.≦

* PPM - parts per million * @ 23± 5 ℃

3. Temperature

Function Measuring Range Resolution Accuracy

℃ 0 to 60 ℃℃ 0.1 ℃ ±0.8 ℃

℉ 32 to 140 ℉℉ 0.1 ℉ ±1.5 ℉

* @ 23± 5 ℃

C. Dissolved oxygen

Oxygen Optional,

Probe The polarograpHic type oxygen probe with

Measurement Dissolved Oxygen 0 to 20.0 mg/L ( liter ).

& Range Oxygen in Air 0 to 100.0 %.

Temperature 0 to 50 .℃

Resolution Dissolved Oxygen 0.1 mg/L.

Oxygen in Air 0.1 % O2 .

Temperature 0.1 .℃

7

Page 10

Accuracy Dissolved Oxygen ± 0.4 mg/L.

.

(23± 5 )℃ Oxygen in Air ± 0.7% O2.

Temperature ± 0.8 /1.5 .℃℉

Probe Temperature 0 to 50 ,℃

Compensation Automatic

& Adj. Salt 0 to 50 % Salt

Height ( M. T.) 0 to 8900 meter

Probe Weight 335 g/0.74 LB ( batteries & probe included )

Probe Size 190 mm x 28 mm Dia. ( 7.5" x 1.1" Dia. )

Optional * Oxygen probe.................................OXPB-11

Accessories * Spare Probe head with diaphragm set

.....................................................

* Probe-filling Electrolyte....................OXEL-03

OXHD-04

8

Page 11

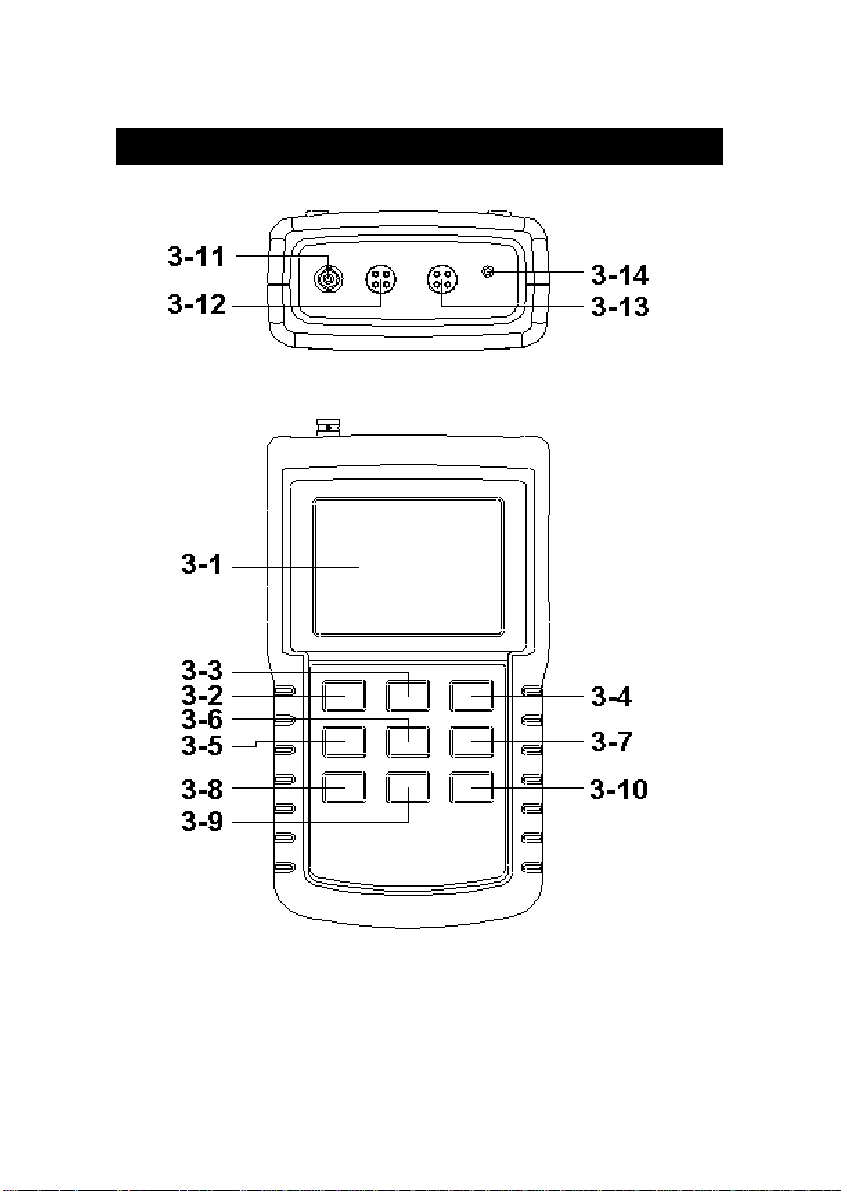

3. FRONT PANEL DESCRIPTION

Fig. 1-1

9

Page 12

3-1 Display

3-2 Power Button ( LCD Backlight Button )

3-3 HOLD Button ( ESC Button )

3-4 REC Button ( Enter Button )

3-5 Mode Button ( Zero Button )

3-6 Function Button ( Range Button )

3-7 Send Button ( Clock Button )

3-8 SET Button ( Logger Button )

3-9 Up Button▲

3-10 Down Button ▼

3-11 PH Socket ( BNC Socket )

3-12 CD Socket

3-13 DO Socket

3-14 Temp. Socket ( pH ATC Socket )

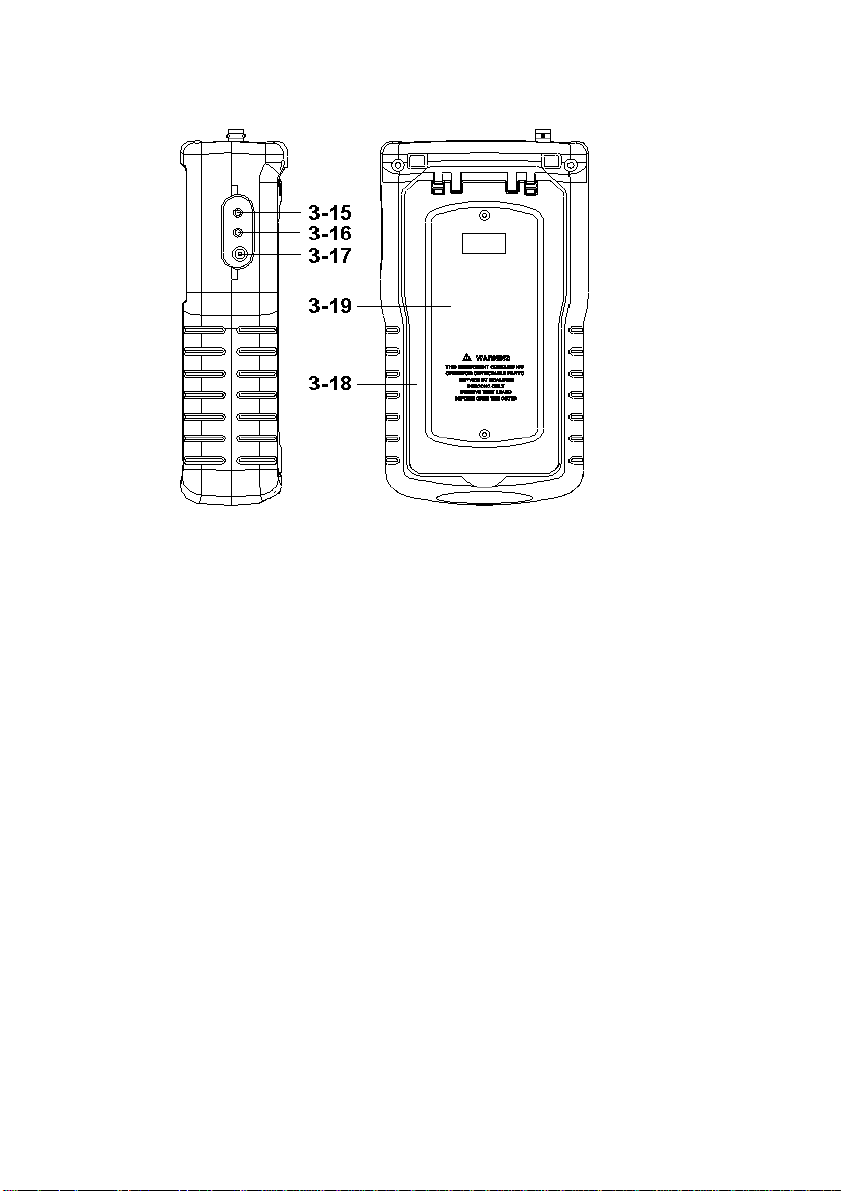

3-15 RS232 socket

3-16 Reset button

3-17 DC 9V power adapter socket

3-18 Stand

3-19 Battery Cover/Battery compartment

Fig. 1-2

10

Page 13

4. MODE SELECTION

( pH/CD/DO selection )

1)Turn on the meter by pressing the " Power Button "

( 3-2, Fig. 1 ) momentarily.

*

Pressing the " Power Button " ( 3-2, Fig. 1 )

continuously and > 2 seconds again will turn off the

meter.

2)The meter can select 3 kind Mode as :

a. pH, mV ( ORP ) measurement

b. Dissolved Oxygen measurement

c. Conductivity, TDS measurement

Pressing the " Mode Button " ( 3-5, Fig. 1 ) once, the

Display will show the following text in sequence :

PH pH, mV ( ORP ) measurement

do Dissolved Oxygen measurement

Cd Conductivity, TDS measurement

Until the Display show the desired mode the meter will

execute this Mode with default.

11

Page 14

5. pH/mV MEASURING and

CALIBRATION PROCEDURE

The meter default function are following :

*The display unit is set to pH.

*The temperature unit is set to .℃

*Manual ATC ( without connect the ATC probe )

*Auto power off.

*The sampling time of data logger function is

2 seconds.

Fig. 2

If the meter is first time to connect

the pH electrode, it should make the

calibration before operation, the

calibration procedures refer chapter

5-4, page 14.

12

Page 15

5-1 pH measurement ( manual Temp compensation )

1)Prepare the pH Electrode ( optional ), install the

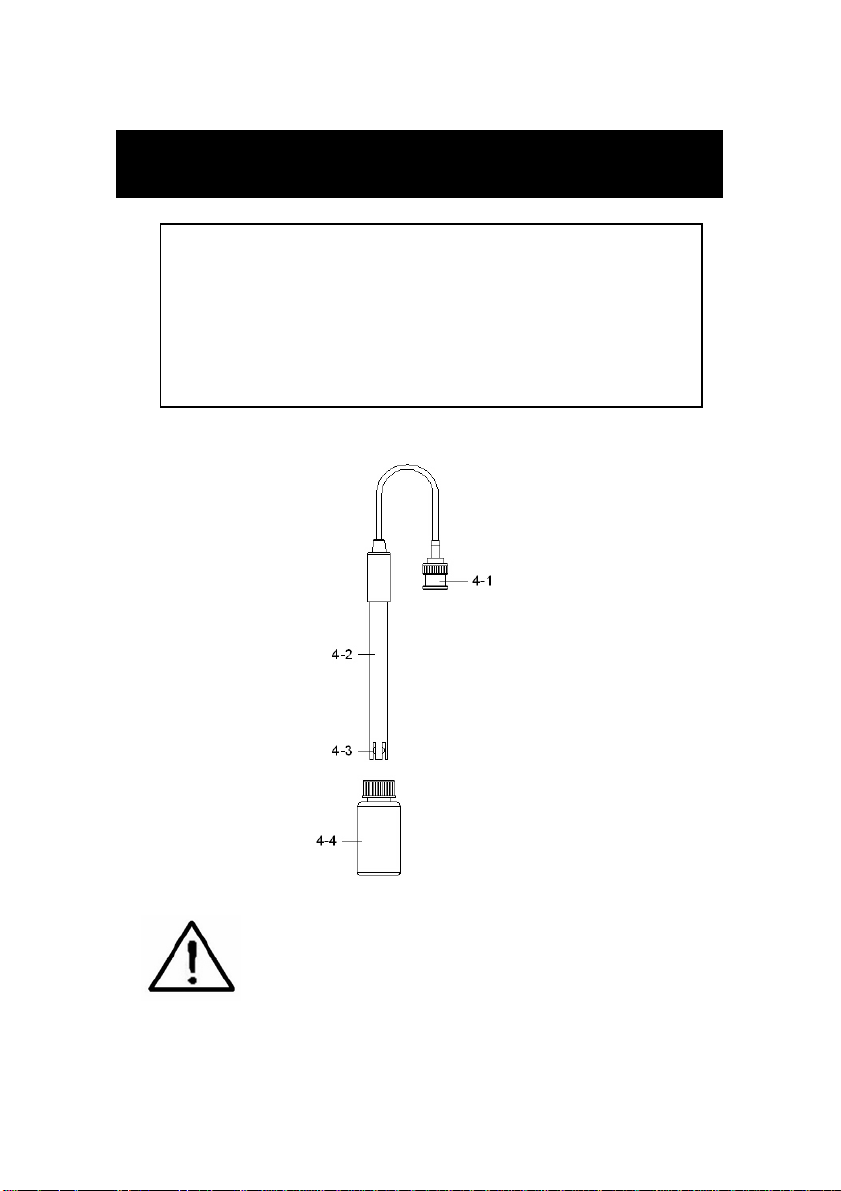

" Probe Plug " ( 4-1, Fig. 2 ) into the " pH Socket/BNC

Socket " ( 3-11, Fig. 1 ).

2)Power on the meter by pressing " Power Button "

( 3-2, Fig. 1 ) once.

Select the measurement mode to " pH, mV ( ORP )

measurement ". refer chapter 4, page 11.

The Display will show " pH " and " Temp. " indicator.

3)Adjust the manual Temp. value same as the

solution's temperature exactly, the procedures

refer chapter 9-7, page 38.

4)Hold the " Electrode Handle " ( 4-2, Fig. 2 ) by hand

and let the " Sensing head " ( 4-3, Fig. 2 ) immersed

wholly into the measured solution and little shake the

probe.

5)The up main display will show the pH value, the left

bottom display will show the setting manual Temp.

value.

5-2 pH measurement ( ATC , automatic Temperature )

1)All the procedures are same as

5-1 pH measurement ( manual ATC )

but should prepare one temperature probe ( optional,

TP-07 ), insert the TP-07's plug into the " Temp. Socket "

( 3-14, Fig. 1 ), immerse the sensing head of temperature

probe ( TP-07 ) into the measurement solution.

2)The up main display will show the pH value, the left

bottom display will show the sensing Temp. value of

the measured solution.

When not use the Electrode, it should immerse

the " Electrode sensing head " ( 4-3, Fig. 2 ) into

the " Protection bottle " ( 4-4, Fig. 2 )

13

Page 16

5-3 mV Measurement

The instrument build in mV ( millivolt ) measurement

function, which enable you to make ion-selective, ORP

(oxidation-reduction potential), and other precise mV

measurements.

1)Prepare the ORP Electrode ( optional, ORP-14 ), install

the " Probe Plug " of ORP electrode into the " pH

Socket/BNC Socket " ( 3-11, Fig. 1 ).

2)Power on the meter by pressing " Power Button "

( 3-2, Fig. 1 ) once.

Select the measurement mode to " pH, mV ( ORP )

measurement ". refer chapter 4, page 11 .

Pressing the " Function Button " ( 3-6, Fig. 1 )

once until the Display show " mV " indicator.

3)The up main display will show the mV value.

5-4 pH calibration

Calibration Consideration

The most ideal pH ELECTRODE generates 0 mV at pH

7.00 ( 177.4 mV at pH 4 ) and meter has been always

calibrated with signals which simulate the most ideal pH

ELECTRODE ( based on 25 ambient environment ).℃

However not every pH ELECTRODE is as accurate as the

most ideal one, so calibration procedures are necessary

to be done before the first time measurement.

In addition to the first time measurement, users are also

recommended to execute the calibration procedures to

ensure the high accuracy measurement.

14

Page 17

Required Equipment for Calibration

1)pH ELECTRODE ( optional ).

2)pH buffer solutions ( optional ).

Calibration Procedure

1)Prepare the pH Electrode ( optional ), install the

" Probe Plug " ( 4-1, Fig. 2 ) into the " pH Socket/BNC

Socket " ( 3-11, Fig. 1 ).

2)Power on the meter, set the mode to the pH

measurement, the right bottom display will show " pH ".

3)Adjust the " Temperature Compensation Value " to

make it same as the temperature value of the pH

buffer solution.

* Manual temperature compensation value

adjustment procedure, refer to 9-7, page 38.

* Automatic temperature compensation, refer

to 5-2, page 13.

.

4)Hold the " Electrode Handle " ( 4-2, Fig. 2 ) by hand

and let the " Sensing head " ( 4-3, Fig. 2 ) immersed

wholly into the measured solution and little shake the

probe.

Display will show the pH value.

* If use the ATC probe, should immerse the

ATC probe into the solution together.

15

Page 18

5)Use the two fingers to press the " REC Button " ( 3-4,

Fig 1 ) and " HOLD Button " ( 3-3, Fig. 1 ) at the

same time. Until Display will show the following screen

then release the both fingers.

PH

CAL

6)Press the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) once in sequence to select the following

screen.

a For pH 7.00 calibration

7.00

CAL

b For pH 4.00 calibration

4.00

CAL

c For pH 10.00 calibration

10.00

CAL

d Clear the existing calibration data

CLr

CAL

7)After the above a, b, c, d is selected, press the

" Enter Button " ( 3-4, Fig. 1 ) to execute the

calibration procedures.

16

Page 19

When select the

CLr

CAL

and press the " Enter Button " will clear the existing

calibration data.

7)Fine adjustment of calibration value

During the calibration when the main Display ( 7.00,

4.00 or 10.00 ) is flashed, it can use the " Button "▲

( 3-9, Fig. 1 ) or " Button " ( 3-10, Fig. 1 ) to make▼

the fine adjust of the calibration value, for example

the exact calibration value is 4.01, 4.02, 3.98....

7.01, 7.02. 6.98....10.01, 10.02, 9.98

After the fine calibration value is adjusted, release the

Button ( Button ), the main Display will be flashed▲▼

few second then execute the calibration according

the new calibration value.

7)The complete procedures should execute

the two calibration points :

pH7 calibration, pH4 calibration

pH7 calibration, pH10 calibration

* The calibration procedures should execute start from

pH7 calibration then follow pH4 ( or pH10 ) calibration.

* Rinse the electrode with distilled water again when

make each point calibration ( pH7, pH4 or pH10 ).

* Repeat above two points procedures two times at least.

17

Page 20

5-5 ORP calibration

1)Prepare the ORP electrode ( optional, ORP-14 ), connect

the ORP electrode to the meter.

2)Power on the meter, set the mode and the function

to " mV ", refer chapter 5-3, page 14.

3)Immerse the sensing head of ORP electrode into the

ORP standard buffer solution, the up display will

show the ORP value in mV.

4)Use the two fingers to press the " REC Button " ( 3-4,

Fig 1 ) and " HOLD Button " ( 3-3, Fig. 1 ) at the

same time. The display will show the following screen

as example, then release the both fingers.

OrP

CAL

5)Use " Button " ( 3-9, Fig. 1 ), " Button " ( 3-10,▲▼

Fig. 1 ) to adjust the up display value exact same as

the standard ORP buffer solution value. Press the

" Enter Button " will save the calibration the data

and finish the calibration procedures.

* The ORP calibration procedures are available

only the ORP buffer solution value is > 100 mV.

* If the ORP calibration procedures is less than

100 mV the calibration is not allow.

18

Page 21

6. CONDUCTIVITY/TDS MEASURING

and CALIBRATION PROCEDURE

The meter default function are following :

*The display unit is set to conductivity ( uS, mS ).

*The temperature unit is set to .℃

*Temp. compensation factor is set to 2.0% per C.

*Auto range.

*Auto power off.

*The sampling time of data logger function is

2 seconds.

Fig. 3

If the meter is first time to connect

the conductivity probe, it should

execute the calibration procedures

before operation, the calibration

procedures refer chapter 6-3, page 22.

19

Page 22

6-1 uS, mS measurement

1)Prepare the Conductivity Probe ( optional, CDPB-03 ),

install the " Probe Plug " ( 5-1, Fig. 3 ) into the

" CD Socket " ( 3-12, Fig. 1 ).

2)Power on the meter by pressing " Power Button "

( 3-2, Fig. 1 ) once.

Select the measurement mode to " Conductivity, TDS

measurement ". refer chapter 4, page 11.

The Display will show " uS " and " Temp. " indicator.

3)Hold the " Probe Handle " ( 5-2, Fig. 3 ) by hand

and let the " Sensing head " ( 5-3, Fig. 3 )

immersed wholly into the measured solution. Shake

the probe to let the probe's internal air bubble drift

out from the sensing head.

4)Display will show the conductivity mS ( uS ) values.

at the same time the left bottom display will show the

Temp. value of the measured solution.

Manual range operation

The meter is default to be used for the auto range

mode.

If intend to let the meter be used under the

manual range mode, the procedures are following :

*

Press the " Range Button " once a while, it can

change the range, the range name ( Auto, 200 uS, 2

mS, 20 mS, 200 mS ) will show under the

measurement value.

20

Page 23

* If the display shows " ", it indicates an

overload condition, select the next higher range.

* If the display shows " ", it indicates an

out-of-range, select the next lower range.

* If intend to change the operation mode from Manual

range back to Auto Range, press the " Range Button

" ( 3-6, Fig. 1 ) once in sequence until the Display

show the text " Auto ", release the " Range Button ",

the meter is ready for the Auto range mode again.

`

Change the Temp. unit to ℉

If intend to change the Temp. unit from to , please℃℉

refer page 37, chapter 9-6 ( Temp. Unit Default Setting )

Change the Temp. Coefficient Factor

The default Temp. compensation factor value of the

measurement solution is to 2.0% per . If intend to℃

change it, please refer page 39, chapter 9-11 ( Temp.

Compensation Factor Setting ).

Zero adjustment

If the probe not immerse the measurement solution

and display not show zero value, pressing the " Zero

Button " ( 3-5, Fig. 1 ) > 10 seconds continuously will

let display show zero. The zero function only valid when

the no zero value less than 1.0 uS.

21

Page 24

6-2 TDS ( PPM ) measurement

The measuring procedures are same as above

5-1 Conductivity ( uS, mS ) measurement,

except to change the display unit from uS, mS to PPM.

The procedures are :

* Press the " Function Button " ( 3-6, Fig. 1 ) > 2

seconds continuously until the Display show the text "

tdS ", then release the " Function Button " will enter the

the TDS measurement function.

* Under the TDS measurement, press the " Function

Button " ( 3-6, Fig. 1 ) > 2 seconds continuously until

the Display show the text " Cd ", then release the

" Function Button " will enter the Conductivity

measurement function again.

6-3 Calibration

1)Prepare the standard conductivity solution ( optional )

For example :

2 mS range calibration solution :

1.413 mS Conductivity Standard Solution, CD-14

200 uS range calibration solution :

80 uS Conductivity Standard Solution

20 mS range calibration solution :

12.88 mS Conductivity Standard Solution

or other Conductivity Standard Solution

2)Install the " Probe Plug " ( 5-1, Fig. 3 ) into the

" CD Socket " ( 3-12, Fig. 1 ).

3)Power on the meter, set the mode to the conductivity

measurement ( uS, mS ).

4)Hold the " Probe Handle " ( 5-2, Fig. 3 ) by hand

and let the " Sensing head " ( 5-3, Fig. 3 )

immersed wholly into the measured solution. Shake

the probe to let the probe's internal air bubble drift

out from the sensing head.

Display will show the conductivity mS ( uS ) values.

22

Page 25

5)Use the two fingers to press the " REC Button " ( 3-4,

*

*

Fig 1 ) and " HOLD Button " ( 3-3, Fig. 1 ) at the same

time. the display will show the following screen as

example, release the both fingers.

Cd

CAL

6)Use " Button " ( 3-9, Fig. 1 ), " Button " ( 3-10,▲▼

Fig. 1 ) to adjust the up display value exact same as

the standard conductivity value. Press the " Enter

Button " will save the calibration data and finish

the calibration procedures.

If only intend to make the one point calibration,

just execute the 2 mS range ( 1.413 mS Cal. )

is enough.

Multi-points calibration procedures should

execute the 2 mS range ( 1.413 mS Cal. )

calibration at first, then make other ranges

(20 uS range, 20 mS range or 200 mS range )

calibration procedures following if necessary.

23

Page 26

7. DO (Dissolved Oxygen)

MEASURING and CALIBRATION

PROCEDURE

1)Prepare the Oxygen Probe ( optional, OXPB-11 )

ATTENTION :

Fill the Probe's Electrolyte at first.

Intend to keep the DO probe under the

best condition, it should fill the

Probe's Electrolyte at first.

Probe-filling Electrolyte

Probe head with diaphragm set

The procedures that to fill the Probe's

Electrolyte, refer the chapter 7-3

" Probe maintenance ", page 29 .

24

Page 27

The meter default function are following :

*The display unit is set to mg/L.

*The temperature unit is set to .℃

*Auto power off.

*The sampling time of data logger function is

2 seconds.

7-1 Dissolved Oxygen measurement

Fig. 4

25

Page 28

1)Prepare the Oxygen Probe ( optional, DOPB-11 ),

install the " Probe Plug " ( 6-1, Fig. 4 ) into the

" DO Socket " ( 3-13, Fig. 1 ).

2)Power on the meter by pressing " Power Button "

( 3-2, Fig. 1 ) once.

Select the measurement mode to " Dissolved Oxygen

measurement ". refer chapter 4, page 11.

The Display will show " mg/L " and " Temp. " indicator.

Calibration at first !

Press the " Function Button " ( 3-6, Fig. 1 ) once,

the Display will show the " % O2 " indicator.

Wait approx. 2 minute until the reading value

reach stable, if the reading value not within

20.7 to 21.1 ( 20.9 ±0.2 ), then should be

processed the calibration procedures first.

The calibration procedures, please refer

chapter 7-2, page 28.

After execute the calibration procedures, the

display should show the value near 20.9

( 20.8 to 21.0 ).

3)Press the " Function Button " ( 3-6, Fig. 7 ) once,

the right low display will show the " mg/L " unit,

the meter is ready for the Dissolved Oxygen

measurement.

4)a. Immersed the probe to a depth at least 10 cm of

the measured liquid in order for the probe to be

influenced by the temperature & automatic

temperature compensation to take place.

26

Page 29

b.As for the thermal equilibrium to occur between the

probe & the measurement sample must be allowed

to pass, which usually amounts to a few minutes if

the Temp. difference between the two is only

several Celsius degrees.

5)a. In order to measure the dissolved oxygen content in

any given liquid, it is sufficient to immerse the tip of

the probe in the solution, making sure that velocity

of the liquid coming into contact with the probe is at

least 0.2 - 0.3 m/s or to shake the probe.

b.During laboratory measurements, the use of a

magnetic agitator to ensure a certain velocity in the

fluid is recommended. In this way, errors due to the

diffusion of the oxygen present in the air in the

solution are reduced to a minimum.

6)Display will show the Dissolved Oxygen values ( mg/L )

at the same time the left bottom display will show the

Temp. value of the measured solution.

7)Rinsed the probe accurately with normal tap water after

each series of measurement.

Oxygen in the air

When the display unit show " %O2 ", it show the

air Oxygen value approximately.

Change the Temp. unit to ℉

If intend to change the Temp. unit from to ,℃℉

please refer page 37, chapter 9-6 ( Temp. Unit

Default Setting )

27

Page 30

"% Salt" compensation value adjustment

If intend to change the % Salt compensation value,

refer page 38, chapter 9-8 ( % Salt Compensation

value Setting ).

"Height" compensation value adjustment

If intend to change the Height compensation value,

refer page 39, chapter 9-9, 9-10 ( Height Compensation

value Setting ).

7-2 Calibration

1)Install the " Probe Plug " ( 6-1, Fig. 4 ) into the

" DO Socket " ( 3-13, Fig. 1 ).

2)Power on the meter by pressing " Power Button "

( 3-2, Fig. 1 ) once.

Select the measurement mode to " Dissolved Oxygen

measurement ", the Display will show " mg/L " indicator.

Pressing the " Function Button " ( 3-6, Fig. 1 ) once

until the right bottom display show " %O2 ".

3)Wait for approx. 5 minutes at least until the

display reading values become stable & no

fluctuation.

4)Use the two fingers to press the " REC Button " ( 3-4,

Fig 1 ) and HOLD Button " ( 3-3, Fig. 1 ) at the same

time, the display will show the following screen as

example, release the both fingers.

20.9

CAL %O2

28

Page 31

5)Press the " Enter Button " ( 3-4, Fig. 1 ), the Display

.

value will count down from 30 to 0, then return to

normal measuring screen and finish the calibration

procedures. The complete calibration procedures will

take 30 seconds approximately.

After finish the calibration, press the " Function

Button " ( 3-6, Fig. 1 ) once, to let Display unit to

return " mg/L ".

Calibration Consideration :

a.As the oxygen in air is 20.9 % typically, so use

the environment air oxygen value for quick &

precise calibration.

Please process calibration procedures under

b

wide and ventilating environment for best effect.

7-3. Probe maintenance

User first time to use the meter :

Intend to let the DO probe keep the best

condition, when user receive the Oxygen Probe,

it should fill the Probe's Electrolyte at first.

User already use the probe for a certain

period :

Whenever user can not calibrate the meter

properly or the meter's reading value is not stable,

please check the oxygen probe to see if the

electrolyte in the probe head container is run out

or the diaphragm ( probe head with diaphragm

set) exist problem ( dirty ). If yes, please fill the

electrolyte or change the " Probe head with

diaphragm set " and make the new calibration.

29

Page 32

The consideration of diaphragm ( probe head

with diaphragm set ) :

The oxygen probe component is the thin Teflon

diaphragm housed in the tip of the probe. The

diaphragm is permeable by the oxygen molecules but

not by the considerably larger molecules contained in

the electrolyte. Due to this characteristic, the oxygen

may diffuse throughout the electrolyte solution

contained in the probe, and its concentration may be

quantified by the measurement circuit.

This sensitive diaphragm is rather delicate & is easily

damaged if it comes into contact with solid objects or is

subjected to blows. If the diaphragm is damaged or the

electrolyte is run out, it must be replaced in the following

way :

Probe-filling Electrolyte,

OXEL-03

Probe head with diaphragm set

1)Unscrew the " Probe head " ( 7-3, Fig 5 ).

2)Pour out the old Electrolyte from the

container of the " Probe head ".

3)Fill the new Electrolyte ( OXEL-03 )

into the container of the " Probe

head " .

30

Page 33

4)Screw the " Probe head " ( 7-3, Fig 5 )

)

into the probe body.

When not use the

5

probe, should insert

the " Probe head "

into the " Probe 7-1 Probe handle

protection cover " 7-2 Temp. sensing metal

( 6-5, Fig. 4 ) 7-3 Probe head

Fig. 5

8. DATA HOLD, DATA RECORD,

DATA LOGGER,

LCD BACKLIGHT

8-1 Data Hold

During the measurement, press the " Hold Button " ( 3-3,

Fig. 1 ) once will hold the measured value & the LCD will

display a " HOLD " symbol.

Press the " Hold Button " once again will release the data

hold function.

8-2 Data Record ( MAX, MIN reading )

* The data record function records the maximum and

minimum readings. Press the " REC Button " ( 3-4, Fig.

1 ) once to start the Data Record function and there

will be a " REC " symbol on the display.

* With the " REC " symbol on the display :

a)Press the " REC Button " ( 3-4, Fig. 1 ) once, the

" REC MAX " symbol along with the maximum value

will appear on the display.

If intend to delete the maximum value, just press

the " Hold Button " ( 3-3, Fig. 1 ) once, then the

display will show the " REC " symbol only & execute

the memory function continuously.

31

Page 34

b)Press the " REC Button " ( 3-4, Fig. 1 ) again, the

" REC MIN " symbol along with the minimum value

will appear on the display.

If intend to delete the minimum value, just press

the " Hold Button " ( 3-3, Fig. 1 ) once, then

the display will show the " REC " symbol only &

execute the memory function continuously.

c)To exit the memory record function, just press the

" REC " Button > 2 seconds at least. The display will

revert to the current reading.

8-3 Data Logger

The data logger function can save 16,000 measuring

data with the clock time ( Real time data logger, build

in clock ( hour-min.-sec., year-month-date ).

The data logger procedures are as following :

a)If push the " Logger Button " ( 3-8, Fig. 1 ) once will

show the sampling time value on the bottom left

display then disappeared.

b)Press the " REC Button " ( 3-4, Fig. 1 ) once to

start the Data Record function and there will be a

" REC " symbol on the display.

Auto Data Logger ( Sampling time set from

1 second to 8 hours 59 minutes 59 seconds )

Press the " Logger Button " ( 3-8, Fig. 1 ) once to start

the Auto Data Logger function, The upper display will

show " DATALOGGER " indicator along with " REC "

marker.

* Pause the data logger function :

Press the " Logger Button " ( 3-8, Fig. 1 ) once.

* Exit the data logger function :

Press the " REC Button " ( 3-4, Fig. 1 ) > 2 seconds.

32

Page 35

Manual Data Logger ( Sampling time set to 0

)

second )

Press the " Logger Button " ( 3-8, Fig. 1 ) once will

save the data one time into the memory.

Beeper will sound and the upper display will show

" DATALOGGER " indicator along with " REC " marker.

* Exit the data logger function :

Press the " REC Button " ( 3-4, Fig. 1 ) > 2 seconds.

d

Memory full

Under execute the data logger, if the bottom right

display show the " Full ", it indicate the memory data

already over 16,000 no. and the memory is full.

e)During execute the Auto Data Logger function, press the

Logger Button " ( 3-8, Fig. 1 ) once will stop to execute

" the data logger function, the " DATALOGGER " indicator

will be disappeared.

If press the " Logger Button " ( 3-8, Fig. 1 ) once again

will continuous the Auto Data Logger function.

Remark :

1)

If intend to change the data logger sampling time,

please refer chapter 9-4, page 36.

2)

If intend to know the space of balance data numbers

into the memory IC, please refer chapter 9-1, page 35.

3)

If intend to clear the saving data from the memory

please refer chapter 9-2, page 35.

8-4 LCD Bcklight ON/OFF

After power ON, the " LCD Backlight " will light

automatically. During the measurement, press the

" Backlight Button " ( 3-2, Fig. 1 ) once will turn OFF the

" LCD Backlight ".

Press the " Backlight Button " once again will turn ON the

" LCD Backlight " again.

33

Page 36

9. ADVANCED ADJUSTMENT

.

.

.

.

.

.

.

PROCEDURES

Under do not execute the Datalogger function,

press the " SET Button " ( 3-8, Fig. 1 ) continuously at

least two seconds will enter the " Advanced Setting " mode,

press the " SET Button " ( 3-8, Fig. 1 ) once a while

in sequence to select the 13 main function, the

display will show :

SPACE..

Clr........

dAtE.....

SP-t......Set sampling time ( Hour/Minute/Second )

PoFF.....Auto power OFF management

t-CF......Select the Temp. unit to or ℃℉

Check memory space

Clear Memory

Set clock time ( Year/Month/Date, Hour/Minute/

Second )

t-SEt.....Set pH manual Temp. compensation value, pH only

SALt.....

High-...

Set DO salt% compensation, DO only

Set DO height (meter) compensation, DO only

Highf....Set DO height (feet) compensation, DO only

PEr C....

tdS.......

ESC...... Escape from the advanced setting

Set CD temperature compensation factor, CD only

Set CD to TDS or TDS to CD, CD only

Remark :

a.DO - Dissolved oxygen Mode

CD - Conductivity/TDS Mode

pH - pH/mV Mode

34

Page 37

b.During execute the " Advanced Setting " function,

if press " ESC Button " ( 3-3, Fig. 1 ) will exit the

" Advanced Setting " function, the LCD will return

to normal screen.

9-1 Check memory space

When the display show " SPACE "

To check the balance data numbers that exist into the

memory ( allow the balance memorize data no. ).

@The bottom value XXXXX is the balance data numbers,

for example XXXXX=15417.

9-2 Clear Memory

When the display show " CLr "

1)To delete the existing save data numbers from the

memory.

2)Push ENTER Button to enter " Memory clear " function.

Use the " Button " ( 3-9, Fig. 1 ) or " Button " (▲▼

3-10, Fig. 1 ) to select the upper value to " yES " or

" no ".

yES - Intend to clear the Memory.

no - Not to clear the Memory.

3)If select the upper to " yES ", press the " Enter Button

" ( 3-4, Fig. 1 ) once will clear the Memory, the bottom

value will show " 0 ".

Press the ESC Button once to quite and return to

the main measurement screen.

35

Page 38

9-3 Set Date/Time ( Year/Month/Date,

Hour/Minute/ Second )

When the upper display show " dAtE "

1)Use the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) to adjust the value ( Setting start from

Year value ). After the desired value is set, press the

" Enter Button " ( 3-4, Fig. 1 ) once will going to

next value adjustment ( for example, first setting

value is Year then next to adjust Month, Date, Hour,

Minute, Second value ).

Remark :

The adjusted value will be flashed.

2)After set all the time value ( Year, Month, Date, Hour,

Minute, Second ), press the " SET Button " ( 3-8, Fig.

1 ) once will save the time value, then the screen will

jump to Sampling time " setting screen ( Chapter 9-4 ).

Remark :

After the time value is setting, the internal clock will

run precisely even Power off if the battery is under

normal condition ( No low battery power ).

9-4 Set sampling time ( Hour/Minute/Second )

When the upper display show " SP-t "

1)Use the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) to adjust the value ( Setting start from

Hour value ). After the desired value is set, press the

" Enter Button " ( 3-4, Fig. 1 ) once will going to next

value adjustment ( for example, first setting value is

Hour then next to adjust Minute, Second value ).

36

Page 39

Remark :

The adjusted value will be flashed.

2)After set all the sampling time value ( Hour, Minute,

Second ), press the " SET Button " ( 3-8, Fig. 1 ) once

will save the sampling value with default then the

screen will jump to " Auto power OFF " setting

screen ( Chapter 9-5 ).

9-5 Auto power OFF management

When the lower display show " PoFF "

1)Use the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) to select the upper value to " yES " or

" no ".

yES - Auto Power Off management will enable.

no - Auto Power Off management will disable.

2)After select the upper text to " yES " or " no ", press the

" Enter Button " ( 3-4, Fig. 1 ) will save the setting

function with default.

9-6 Select the Temp. unit to or ℃℉

When the lower display show " t-CF "

1)Use the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) to select the upper Display text to " C " or

" F ".

C - Temperature unit is ℃

F - Temperature unit is ℉

37

Page 40

2)After Display unit is selected to " C " or " F ", press the

" Enter Button " ( 3-4, Fig. 1 ) will save the setting

function with default.

9-7 Set pH manual Temp. compensation value

When the lower display show " t-SEt "

1)This function only for the pH measurement of

adjusting the pH electrode's manual Temp.compensation

value. The default value is 25 ( 77 ).℃℉

2)Use the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) to select the upper value to the desired

Temp. compensation value ( or ), then press the ℃℉

" Enter Button " ( 3-4, Fig. 1 ) will save the setting

value with default.

9-8 Set DO salt% compensation value

When the lower display show " SALt "

1)This function only for the DO ( Dissolved oxygen ) mode

of adjusting the probe's salt% compensation value.

The default value is 0% salt.

2)Use the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) to select the upper value to the desired

salt% compensation value, then press the " Enter

" Enter Button " ( 3-4, Fig. 1 ) will save the setting

value temporally.

38

Page 41

9-9 Set DO height ( meter ) compensation value

When the lower display show " High- "

1)This function only for the DO ( Disolved oxygen ) mode

of adjusting the probe's height compensation value in

meter unit. The default value is 0 meter.

2)Use the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) to select the upper value to the desired

height compensation value ( meter ), then press the

" Enter Button " ( 3-4, Fig. 1 ) will save the setting

value temporally.

9-10 Set DO height ( feet ) compensation value

When the lower display show " Highf "

1)This function only for the DO ( Dissolved oxygen ) mode of

adjusting the probe's height compensation value in

feet unit. The default value is 0 FEET.

2)Use the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) to select the upper value to the desired

height compensation value ( feet ), then press the

" Enter Button " ( 3-4, Fig. 1 ) will save the setting

value temporally.

39

Page 42

9-11 Set CD temperature compensation factor

When the lower display show " PEr C "

1)This function only for the Conductivity ( TDS ) mode of

adjusting the probe's Temp. compensation value in

%/per unit. The default value is 2 %/ per .℃℃

2)Use the " Button " ( 3-9, Fig. 1 ) or " Button " ▲▼

( 3-10, Fig. 1 ) to select the upper value to the desired

Temp. compensation value ( %/per ), then press the ℃

" Enter Button " ( 3-4, Fig. 1 ) will save the setting

value temporally.

9-12 ESC

When the display show " ESC "

When the Display show the text " ESC ", then press the

" Enter Button " ( 3-4, Fig. 1 ) will finish the Advanced

Setting procedures and return to the normal measuring

screen.

40

Page 43

10. SEND THE DATA OUT FROM

THE METER

1)If intend to send the data out from the meter, it

should exit the " Hold function " and the " Record

function " first. The display should be not show the

" HOLD " and the " REC " marker.

2)Press the " SEND Button " ( 3-7, Fig. 1 ) at least 2

seconds until the Display show " SEnd ", then release

the Button.

LCD display will show the following screen :

188 Data no. that saved into the block.

3Block no.

Use " Up Button", " Down Button " to select▲▼

the different data memory block no. ( 1 to 250 ).

The meter can save 16,000 data Max. , those

data will saved into 250 memory blocks max..

*" One " Memory Block " means :

Execute the Data logger function ( Push " REC "

Button, following push the " Logger " Button to save

the data..... . ) will generate the first Memory block

* Exit the Data logger function and execute

the Data logger function again will generate the

second Memory " Block " again.

41

Page 44

Block 1 Data 1

@

@

to

Data X

↓

Block 2 Data X+1

to

Data Y

↓

..................

..................

↓

Block 250 Data Z

to

Data 16,000

3)Until the desired Memory Block no. be selected.

Push the " Send Button " ( 3-7, Fig. 1 ) once, the

data in the Memory Block will send out.

During the data send out, the bottom display will show

the " SEend " indicator, the upper value ( Data no. that

saved into the Block ) will count down until zero.

4)Push the " ESC Button " ( 3-3, Fig. 1 ) will exist

the data sending function and return to the normal

display.

Remarks :

If intend to load the data to the computer,

should connect the RS232 cable

( optional, model : UPCB-02) or the USB cable

( optional, model : USB-01 ) and apply the

Data Logger software ( optional, Model :

SW-DL2005 ).

When sending the data, each time just can

send one Memory Block data out. for example

block 1 data, block 2 data... or block 250 data.

42

Page 45

11. RS232 PC SERIAL INTERFACE

The instrument has RS232 PC serial interface via the

RS-232 Out Terminal " ( 3-15, Fig. 1 ).

The data output is a 16 digit stream which can be

utilized for user's specific application.

A RS232 lead with the following connection will be

required to link the instrument with the PC serial port.

Meter PC

(3.5 mm jack plug) (9W 'D" Connector)

Center Pin........................Pin 4

Ground/shield.....................Pin 2

2.2 K

resister

Pin 5

The 16 digits data stream will be displayed in the

following format :

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

43

Page 46

Each digit indicates the following status :

D15 Start Word = 02

D14 4

D13 When send the upper display data = 1

When send the lower display data = 2

D12, D11 Annunciator for Display

uS = 13 mS = 14 PPM = 19

pH = 05 mV = 18

mg/L = 07 % O2 = 06

D10 Polarity

0 = Positive 1 = Negative

D9 Decimal Point(DP), position from right to the

left

0 = No DP, 1= 1 DP, 2 = 2 DP, 3 = 3 DP

D8 to D1 Display reading, D1 = LSD, D8 = MSD

For example :

If the display reading is 1234, then D8 to

D1 is : 00001234

D0 End Word = 0D

RS232 setting

Baud rate 9600

Parity No parity

Data bit no. 8 Data bits

Stop bit 1 Stop bit

44

Page 47

12. BATTERY REPLACEMENT

1)When the left corner of LCD display show " ", it

is necessary to replace the batteries ( UM3/1.5 V x 8 PCs ).

2)Slide the " Battery Cover " ( 3-19, Fig. 1 ) away from the

instrument and remove the batteries.

3)Replace with batteries ( UM3/1.5 V x 8 PCs )

and reinstate the cover.

4)Make sure the battery cover is secured after changing

the battery.

13. SYSTEM RESET

If the meter happen the troubles such as :

CPU system is garbled ( for example, the key Button can

not be operated..... ).

Then make the system RESET will fix the problem.

The system RESET procedures are as following.

Used a pin tool to push the " System Reset

Switch " ( 3-16, Fig. 1 ) once a while then

power on again will fix the problem.

45

Page 48

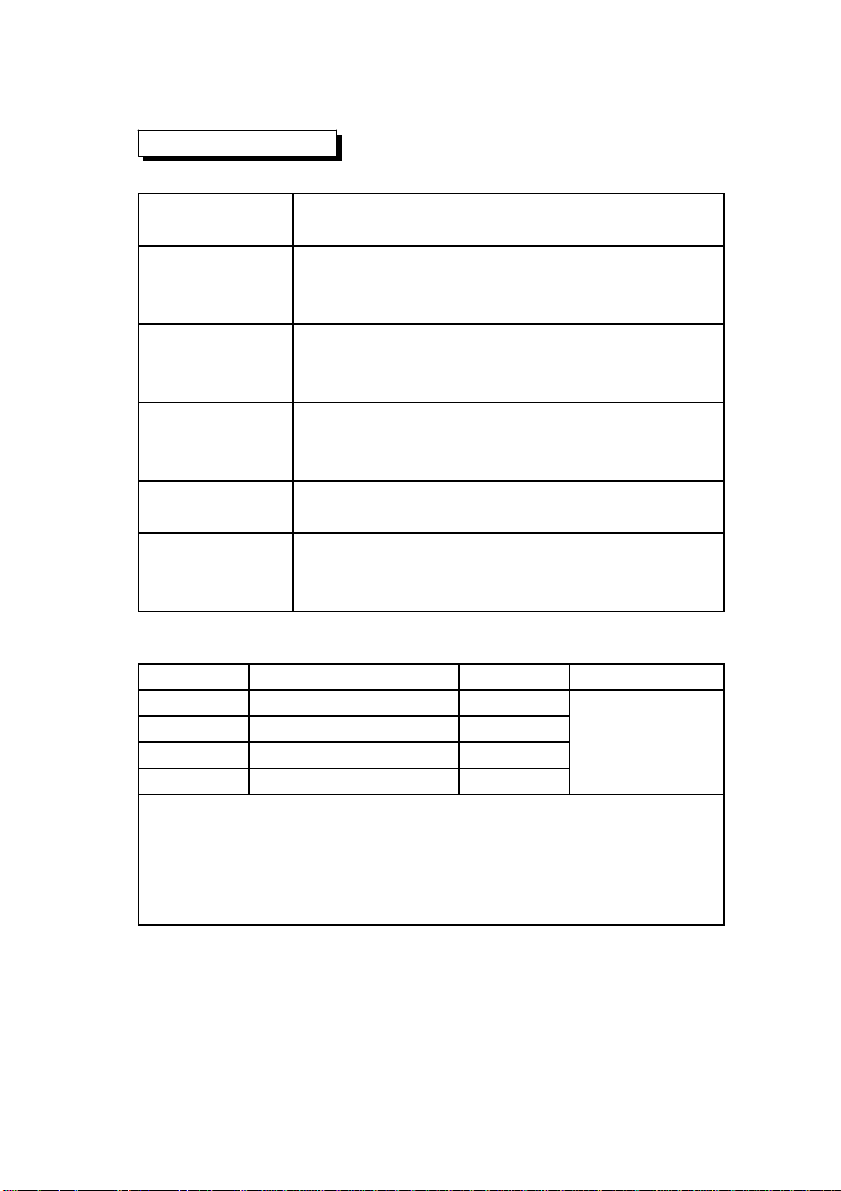

14. OPTIONAL ACCESSORIES

RS232 cable * Computer interface cable.

UPCB-02 * Used to connect the meter to

the computer ( COM port ).

USB cable * Computer interface cable.

USB-01 * Used to connect the meter to

the computer ( USB port ).

Data Logger * Software the used to download

software the data logger ( data recorder )

SW-DL2005 from the meter to computer.

Data Acquisition * The SW-U801-WIN is a multi

software displays ( 1/2/4/6/8 displays )

SW-U801-WIN powerful application software,

provides the functions of data

logging system, text display,

angular display, chart display,

data recorder high/low limit, data

query, text report, chart report..

.xxx.mdb data file can be

retrieved for EXCEL, ACESS..,

wide intelligent applications.

Power adapter AC 110V to DC 9V

USA plug

Power adapter AC 220V/230V to DC 9V

Germany plug

Carrying case Soft carrying case

Model : CA-3K

Electrode holder Electrode holder for all pH

electrodes and the ATC Temp. probe.

Model : EH-20

46

Page 49

pH *pH Electrode, 1 to 13 pH.

optional Model : PE-11

accessories *pH Electrode, 1 to 13 pH.

Model : PE-03

*pH Electrode, 0 to 14 pH.

Model : PE-01

*Glass body heavy duty pH Electrode,

0 to 14 pH.

Model : PE-02

*Glass body plane pH Electrode,

0 to 14 pH.

Model : PE-08

*Industrial in line pH Electrode,

0 to 14 pH.

Model : PE-21

*SPEAR pH Electrode

Model : pH-06HD, pH-04HD

*pH Electrode + Temp. probe, 2 in 1

Model : PE-03K7

*pH Electrode + Temp. probe, 2 in 1

Model : PE-05HT

*pH 7 BUFFER SOLUTION

Model : pH-07

*pH 4 BUFFER SOLUTION

Model : pH-04

*Temperature probe ( ATC probe )

Model : TP-07

Conductivity *Conductivity probe

optional Model : CDPB-03

accessories *1.413 mS standard solution.

Model : CD-14

Dissolved *Oxygen probe

Oxygen Model : OXPB-11

optional *Spare Probe head with DiapHragm set

accessories Model : OXHD-04

*Probe-filling Electrolyte

Model : OXEL-03

47

0907-WA2015

Loading...

Loading...