Page 1

Acceleration/Velocity/Displacement

V

Y

f

A

f

RMS/Peak/Max. Hold, Metric & Imperial unit

IBRATION METER

Model : VB-8213

our purchase of this

VIBRATION METER

marks a step forward for

you into the field o

precision measurement.

lthough this METER is

a complex and delicate

instrument, its durable

structure will allow

many years of use i

proper operating

techniques are

developed. Please read

the following

instructions carefully

and always keep this

manual within easy

reach.

OPERATION MANUAL

Page 2

TABLE OF CONTENTS

.

.

.

.

.

.

.

.

1 FEATURES.................................................................1

2 SPECIFICATIONS......................................................

2-1 General Specifications..........................................2

2-2 Electrical Specifications........................................ 4

3 FRONT PANEL DESCRIPTION..................................... 7

3-1 Display...............................................................

3-2 Power Button...................................................... 8

3-3 Hold/ESC Button ................................................

3-4 REC/ENTER Button .............................................8

3-5 FUNCTION/SEND Button......................................8

3-6 UNIT/LOGGER Button..........................................8

3-7 Battery Cover/Compartment.................................8

3-8 RS232 Output terminal........................................

3-9 BNC socket of meter............................................8

3-10 BNC plug of cable.............................................. 8

3-11 Mini plug of cable..............................................

3-12 Input socket of vibration sensor..........................8

3-13 Vibration sensor................................................

3-14 Magnetic base................................................... 8

2

8

8

8

8

8

4.MEASURING PROCEDURE.......................................... 9

5.ZERO ADJUSTMENT PROCEDURE............................... 11

6.POWER MANAGEMENT..............................................

7.DATA LOGGER..........................................................

8.HOW TO SEND THE DATA OUT FROM THE METER......14

9.RS232 PC SERIAL INTERFACE....................................15

10. BATTERY REPLACEMENT.........................................19

11. OPTIONAL ACCESSORIES........................................19

12. CLASSIFICATION RANGES.......................................20

13. SENSITIVITY RELATIVE TABLE ACCORDING

ISO 2954...............................................................21

12

12

Page 3

1. FEATURES

*Applications for industrial vibration monitoring :

All industrial machinery vibrates. The level of vibration is

a useful guide to machine condition. Poor balance,

misalignment & looseness of the structure will cause the

vibration level increase, it is a sure sign that the

maintenance is needed.

*Frequency range 10 Hz - 1 kHz, sensitivity relative meet

ISO 2954.

*Professional vibration meter supply with vibration sensor

& magnetic base, full set.

*Metric & Imperial display unit

*Acceleration, Velocity, Displacement measurement.

*RMS, Peak value, Max. hold measurement.

*Wide frequency range.

*Data hold button to freeze the desired reading.

*Memory function to record maximum and minimum

reading with recall.

*Separate vibration probe with magnetic base,

easy operation.

*RS 232 computer interface.

*Data Logger.

*Optional data acquisition software.

*Optional data logger ( data collection ) software.

*Super large LCD display with bar graph indicator.

*Microcomputer circuit, high performance.

*Auto shut off saves battery life.

*Built-in low battery indicator.

*Heavy duty & compact housing case.

*Complete set with the hard carrying case.

1

Page 4

2. SPECIFICATIONS

2-1 General Specifications

Display 52 mm x 38 mm, LCD display.

16 mm ( 0.63" ) digit size.

With bar graph indicator.

Measurement Velocity, Acceleration, Displacement

Function

Frequency 10 Hz to 1 KHz

range

Main

Others

RMS, Peak, Max. Hold.

Data hold, Max. & Min. value,

Data logger.

* Sensitivity relative during the

the frequency range meet ISO 2954

Refer to table 1, page 21.

Circuit Exclusive microcomputer circuit.

Data hold Freeze the desired reading.

Peak To measure the peak value.

measurement

Max. hold To measure and update the max. peak

measurement value.

Memory Maximum & Minimum value.

Power off Auto shut off, saves battery life,

or manual off by push button.

Sampling time Approx. 1 second.

Sampling Time 0, 1, 2, 10, 30, 60, 600, 1800, 3600 sec.

of Data Logger

* 0 second : Manual data logger.

* Other sampling time beyond 0

second : Auto data logger.

Data Logger 500 no. max.

No.

2

Page 5

Data output RS 232 serial output, isolate.

.

Operating 0 to 50 ( 32 to 122 ).℃℉

temperature

Operating Less than 80% RH.

humidity

Power supply Alkaline or heavy duty type,

DC 9V battery, 006P,

MN1604 (PP3) or equivalent.

Power Approx. DC 13 mA.

consumption

Weight Meter 230 g/0.50 LB

Probe with 38 g/0.09 LB

cable and

magnetic base

Dimension Meter :

180 x 72 x 32 mm

( 7.1 x 2.8 x1.3 inch ).

Vibration sensor probe:

Round 19 mm Dia. x 21 mm.

Accessories Instruction manual.................. 1 PC.

included Vibration sensor with cable...... 1 PC.

Magnetic base......................... 1 PC.

Carrying Case.........................

Optional *RS232 cable, UPCB-01

accessories *USB cable, USB-01

*Data Acquisition software,

SW-801-WIN

*Data Logger ( data collection )

software, DL-2005.

3

1 PC.

Page 6

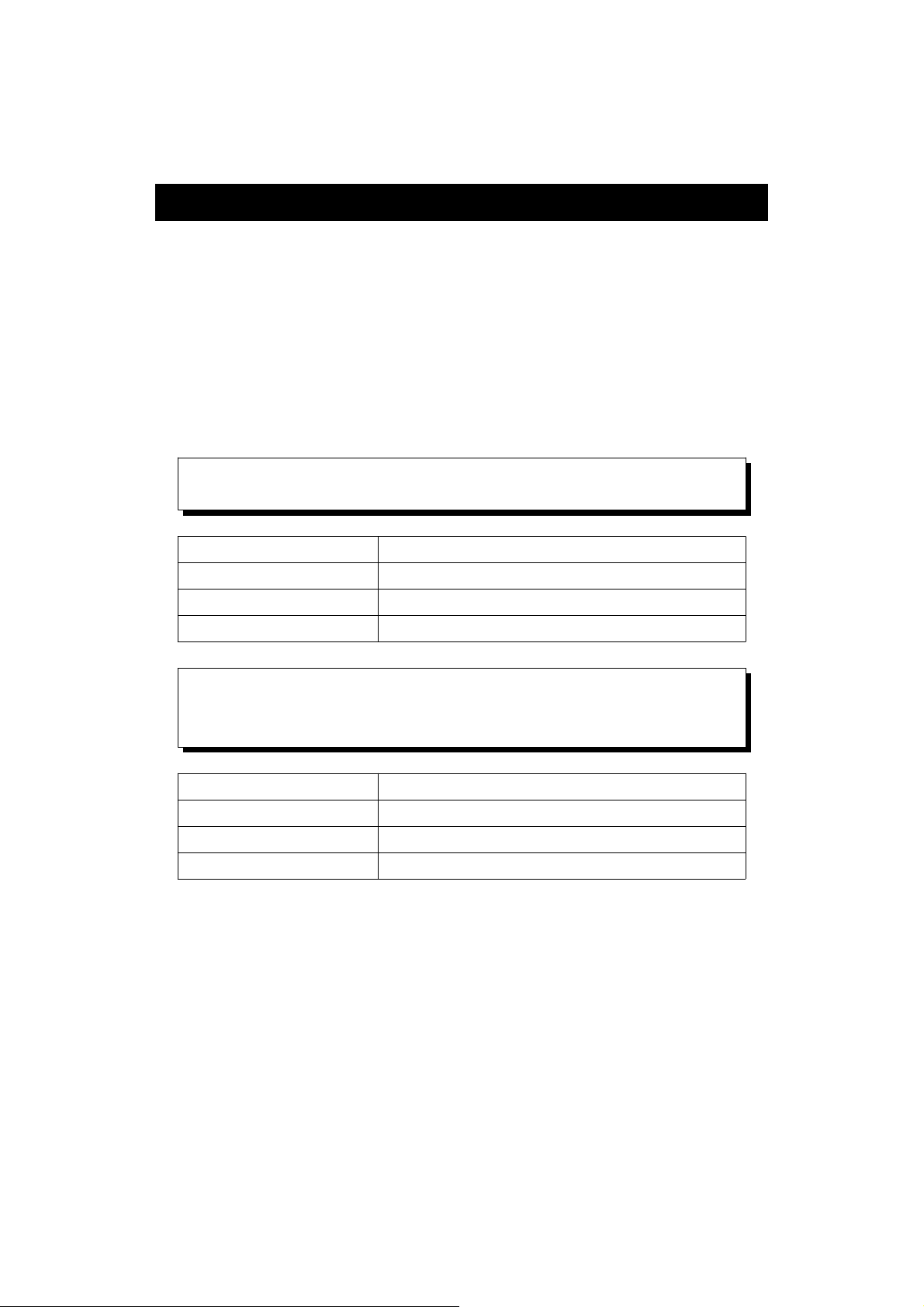

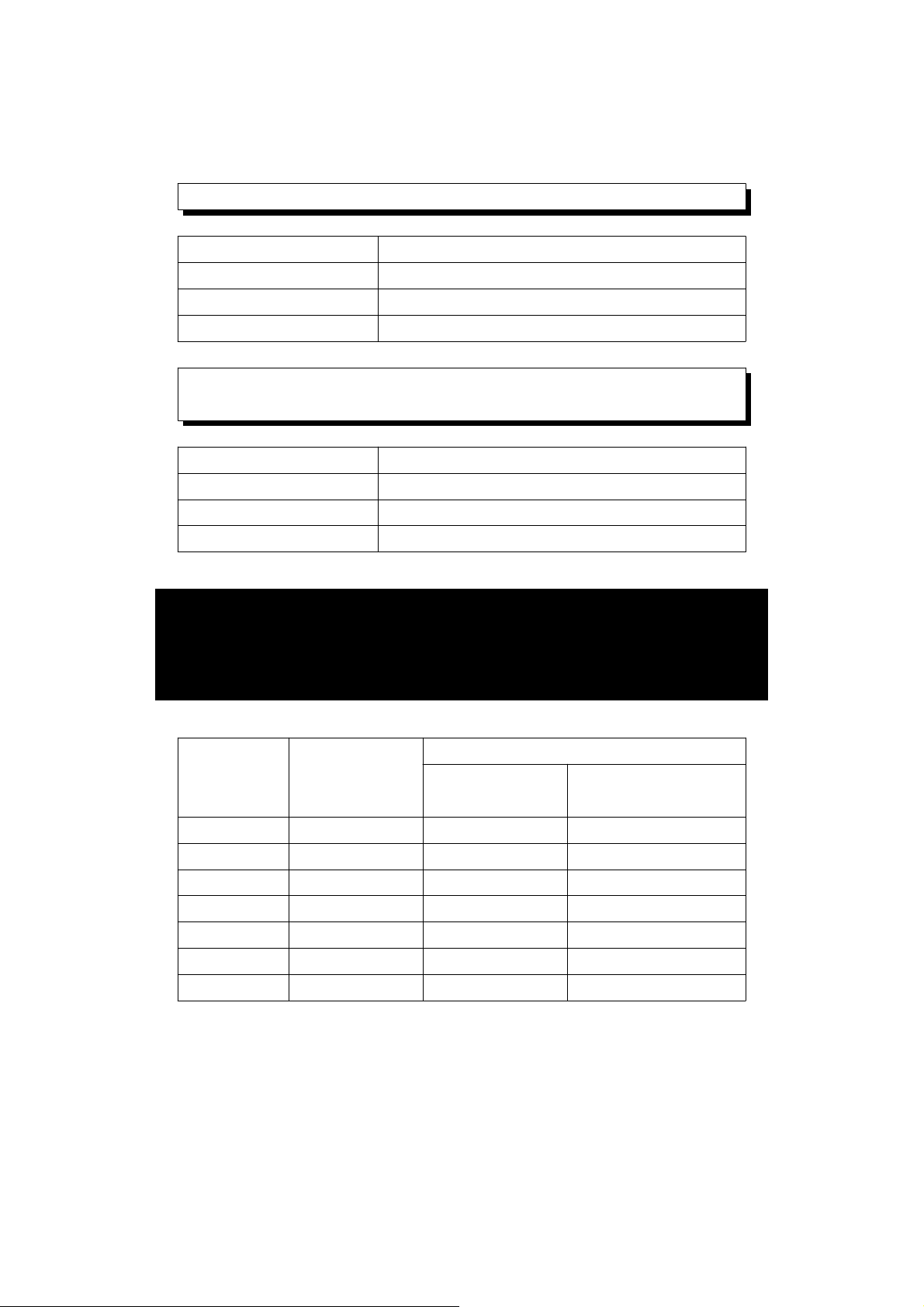

2-2 Electrical Specifications

50 ( 160 Hz )

50 ( 160 Hz )

50 ( 160 Hz )

Acceleration ( RMS, Peak, Max Hold )

Unit

Range 0.5 to 199.9

Resolution 0.1

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration

Point

Unit G

Range 0.05 to 20.39 G

Resolution 0.01 G

Accuracy ± ( 5 % + 2 d ) reading

@ 1 G = 9.8

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration

Point

Unit

Range 2 to 656

Resolution 1

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration

Point

4

Page 7

Velocity ( RMS, Peak, Max Hold )

Unit mm/s

Range 0.5 to 199.9 mm/s

Resolution 0. 1 mm/s

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 50 mm/s ( 160 Hz )

Point

Unit cm/s

Range 0.05 to 19.99 cm/s

Resolution 0. 01 cm/s

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 50 mm/s ( 160 Hz )

Point

Unit inch/s

Range 0.02 to 7.87 inch/s

Resolution 0.01 inch/s

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 50 mm/s ( 160 Hz )

Point

5

Page 8

Displacement p-p ( RMS, Max Hold )

Unit mm

Range 1.999 mm

Resolution 0.001 mm

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 0.141 mm ( 160 Hz )

Point

Unit inch

Range 0.078 inch

Resolution 0.001 inch

Accuracy ± ( 5 % + 2 d ) reading

@ 160 Hz, 80 Hz, 23 ± 5 ℃

Calibration 0.141 mm ( 160 Hz )

Point

* Remark :

p-p = Peak to Peak

6

Page 9

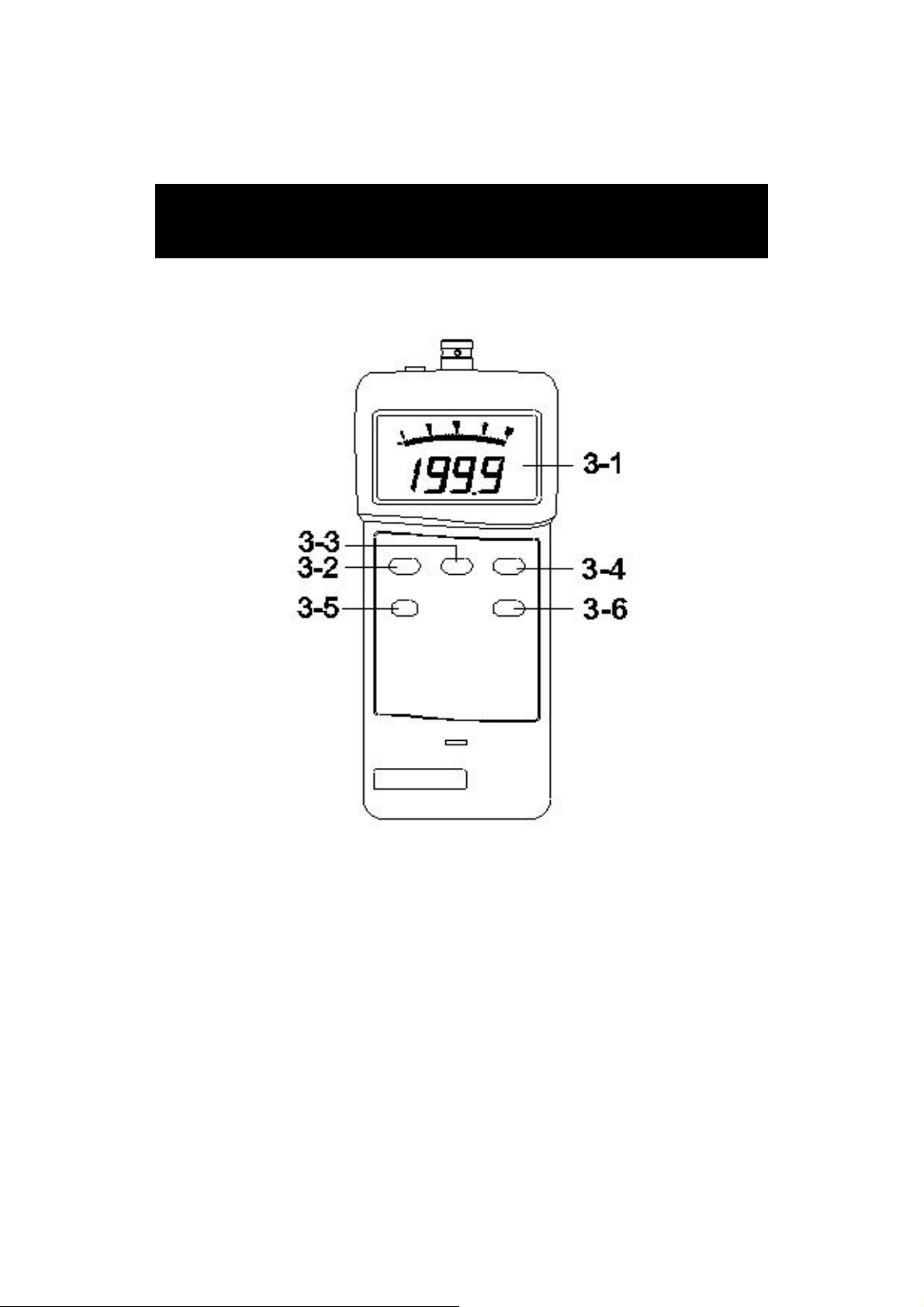

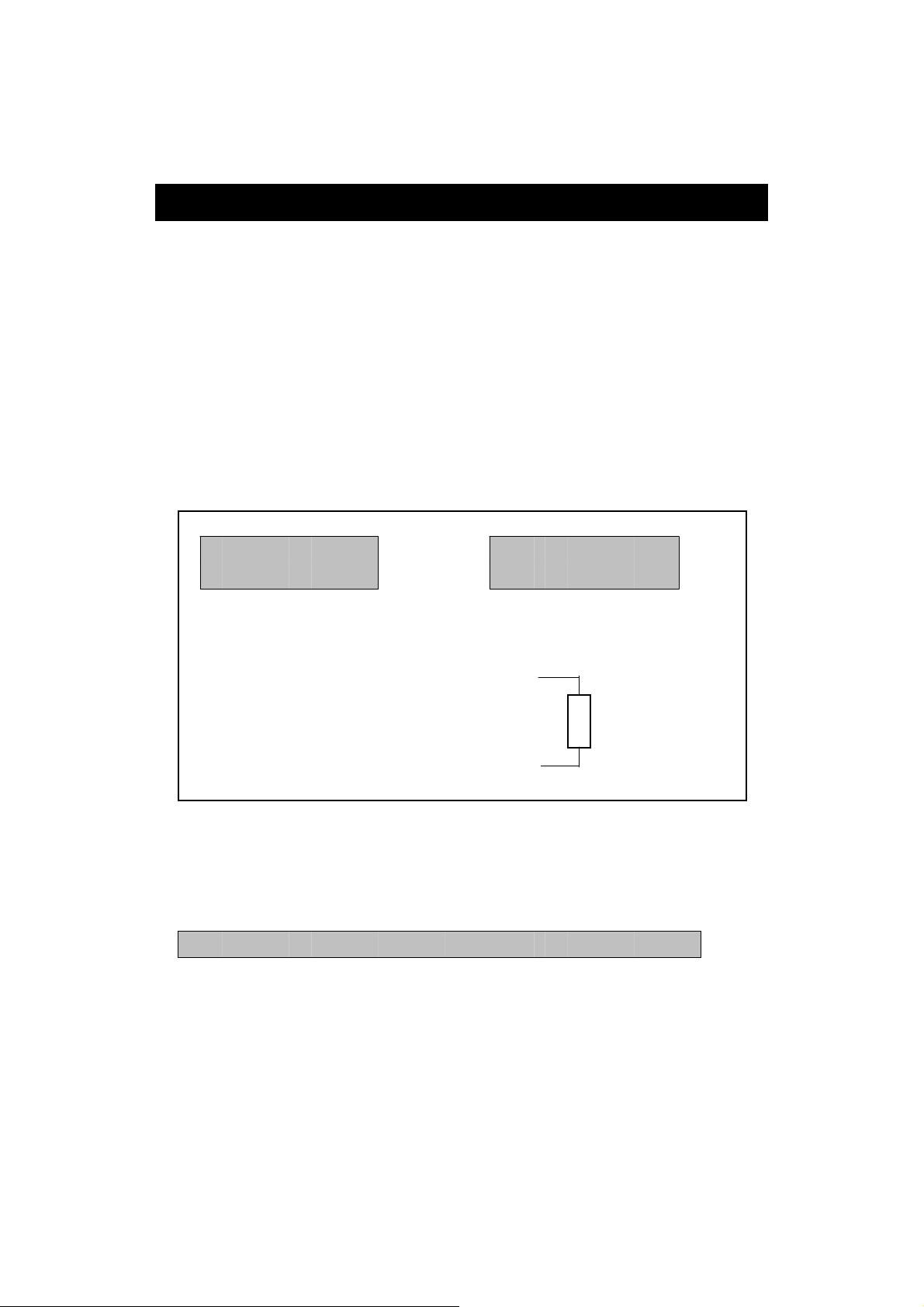

3. FRONT PANEL & LAYOUT

DESCRIPTION

Fig. 1

7

Page 10

3-1 Display

3-2 Power Button

3-3 Hold/ESC Button

3-4 REC/ENTER Button

3-5 FUNCTION/SEND Button

3-6 UNIT/LOGGER Button

3-7 Battery Cover/Compartment

3-8 RS232 Output terminal

3-9 BNC socket of meter

3-10 BNC plug of cable

3-11 Mini plug of cable

3-12 Input socket of vibration sensor

3-13 Vibration sensor

3-14 Magnetic base

Fig. 2

8

Page 11

4. MEASURING PROCEDURE

.

1)Plug in the " BNC plug of cable " ( 3-10, Fig. 2 ) to the

" BNC socket of meter " ( 3-9, Fig. 1 ).

2)Plug in the " Mini plug of cable " ( 3-11, Fig. 2 )

to the " Input socket of vibration sensor " ( 3-12, Fig. 2 ).

3)Power on the meter by press the " Power Button "

( 3-2, Fig. 1 ) once a while.

4) *If the surface material of measuring article is not

the ferrous material, hold the vibration sensor by

hand & touch the sensor to the surface of the

measuring article,

*If the surface material of measuring article is the ferrous

material, connect " Vibration sensor " ( 3-13, Fig. 2 )

with the " Magnetic base " ( 3-14, Fig. 2 ).

Put the whole unit ( Vibration sensor & Magnetic

base ) to the surface of measuring article.

5)FUNCTION SELECTION :

Select the desired function ( RMS, PEAK, MAX-HOLD )

by pressing the " FUNCTION Button " ( 3-5, Fig. 1 ).

Remarks :

a

For general applications of industrial vibration

monitoring, select " RMS " typically.

b. PEAK measurement is intend to measure the

peak vibration value.

c. MAX HOLD measurement is intend to measure and

update the max. peak value.

d. For the " Displacement " measurement only can

select the ' RMS " and " MAX HOLD " function only.

9

Page 12

5)UNIT SELECTION :

change the Metric unit ( , G, mm/s, cm/s, mm ) to

Imperial unit ( , inch/s, inch ) each other.

the LCD will indicate " " symbol.

Push the " Data hold button " again to release the

Select the desired display unit by pressing the " UNIT

Button " ( 3-6, Fig. 1 ).

The unit can be selected as :

Measurement Metric unit Imperial unit

Acceleration , G

Velocity mm/s, cm/s inch/s

Displacement mm inch

Remarks :

For general applications of industrial vibration

monitoring, select " Velocity " or " Acceleration "

typically.

How to change the Metric unit to Imperial

unit each other

If press the " UNIT Button" ( 3-6, Fig. 1 )

continuously at least 5 seconds, then will

6)Data Hold :

During the measurement, push the " Hold button "

( 3-3, Fig. 1 ) will hold the measured value &

data hold function.

10

Page 13

7)Data Record ( Max., Min. reading )

The DATA RECORD function displays the maximum,

and minimum readings.

a.Get into RECORD mode by momentarily pressing

" REC Button " ( 3-4, Fig. 1 ) once. REC icon will be ON.

b.Get out RECORD mode by pressing and hold " REC

Button " ( 3-4, Fig. 1 ) for 2 seconds. REC icon will

be OFF.

c. During RECORD mode ( REC icon ON ), momentarily

pressing " REC Button " to get into Max/Min mode, MAX

( both MAX and REC icons ON ) and MIN ( both MIN

and REC icons ON) cycling. Momentarily pressing

" HOLD Button " ( 3-3, Fig, 1 ) to leave Max/Min mode

and execute the RECORD function continuously.

5. ZERO ADJUSTMENT PROCEDURE

Due to drift of environment temperature value, battery

power change or, meter used for a long time or other

reasons. The display value may exist not zero value ( few

digits ) in case of no signal into the " Vibration Sensor ".

General speaking those not zero value will not effect the

measurement typically. However if intend to make the

precision measurement, the following zero adjustment

procedures should be executed as :

1)Plug in the " BNC plug of cable " ( 3-10, Fig. 2 ) to the

" BNC socket of meter " ( 3-9, Fig. 2 ).

2)Plug in the " Mini plug of cable " ( 3-11, Fig. 1 )

to the " Input socket of vibration sensor " ( 3-12, Fig. 2 ).

3)Power on the meter by press the " Power Button "

( 3-2, Fig. 1 ) once a while.

11

Page 14

4)Set the function and the unit to " ACC, RMS " .

T

5)Keep the vibration sensor motionless, no signal into

the vibration sensor.

6)Press the " HOLD Button " ( 3-3, Fig. 1 ) continuously

at least 2 seconds will let the display reach

zero value.

7)The zero adjustment can be execute only

the display value show the no. less than 10 digits.

6. POWER MANAGEMEN

The meter is built the " Auto power shut off " to saves

battery life. If not any function button be pushed within

approx. 10 minutes, the power will be off automatically.

If the user intend to disable the " Auto Power off "

function, it should take the following procedures :

During the measurement, push the " Record

Button " ( 3-4, Fig. 1 ) to execute the memory

record function.

7. Data Logger

The data logger function can save max. 500 measuring

data.

The data logger procedures are as following :

12

Page 15

Auto data logger

If the data sampling time already set to

1, 2, 10, 30, 60, 600, 1800 or 3600 second,

then the meter can be executed the auto data logger

function. The procedures that to set the data logger

sampling time, please refer page 14.

1.Press the " REC Button " ( 3-4, Fig. 1 ) once to

start the Data Record function and there will be a

" REC " symbol on the display.

2.Press the " LOGGER Button " ( 3-6, Fig. 1 ) once to start

the Auto Data Logger function. The upper display will

show the sampling time in seconds ( For example, 1, 2,

10, 30, 60, 600, 1800, 3600 ) once a while then revert

to the normal display screen. In the same the " REC "

indicator will be flash per the sampling time, in the

same time, the beeper will sound a while.

Now the data Logger function is executed and the

measuring data will save into the memory per

the sampling time.

3.During the Data Logger function is executed, press the

" LOGGER Button " ( 3-6, Fig. 1 ) once will stop to

execute the data logger function, then the " REC "

indicator will stop to flash.

Pressing the " REC Button " ( 3-4, Fig. 1 ) at least

two seconds, then the " REC " indicator will be

disaapeared.

13

Page 16

Manual data logger

If the data sampling time already set to 0 second,

then the meter can be executed the manual data logger

function. The procedures that to set the data logger

sampling time, please refer page 14.

1.Press the " REC Button " ( 3-4, Fig. 1 ) once to

start the Data Record function and there will be a

" REC " symbol on the display.

2.Press the " LOGGER Button " ( 3-6, Fig. 1 ) once to start the

Manual Data Logger function. The upper display will

show " 0 " ( 0 second sampling time ) once a while then

revert to the normal display screen.

Press the " LOGGER Button " ( 3-6, Fig. 1 ) once again

will save one measuring data into the memory,

indicator will be flash per the sampling time, in the

same time, the beeper will sound a while.

3.If intend exit the Manual Data Logger function, just

pressing the " REC Button " ( 3-4, Fig. 1 ) at least

two seconds, then the " REC " indicator will be

disaapeared.

Change the data logger sampling time

1.Power off the meter.

2.Use the two fingers to press the " HOLD Button " ( 3-3,

Fig, 1 ) and the " REC Button " ( 3-4, Fig. 1 ) at the same

time and not release those fingers, use another finger

to push the " POWER Button " ( 3-2, Fig, 1 ) once, then

until the display show the existing sampling time ( for

example 1, 2...), then release the two fingers at the

same time.

14

Page 17

3.Press the " UNIT Button " ( 3-6, Fig. 1 ) once a while

will change the sampling time ( 1, 2, 5, 10, 30, 60,

600, 1800, 3600 seconds ). After the desired sampling

be selected, then press the " REC Button " ( 3-4, Fig. 1 )

to save.

4 Press the " ESC Button " ( 3-3, Fig. 1 ) once will return

the normal measuring screen.

Clear the memory ( clear the existing save data )

1.Power off the meter.

2.Use the two fingers to press the " HOLD Button " ( 3-3,

Fig, 1 ) and the " REC Button " ( 3-4, Fig. 1 ) at the same

time and not release those fingers, use another finger

to push the " POWER Button " ( 3-2, Fig, 1 ) once, then

until the display show the existing sampling time ( for

example 1, 2...), then release the two fingers at the

same time.

3.Press the " REC Button " ( 3-4, Fig. 1 ) continuously

at least 5 seconds, then display will show " 0 ".

Now the memory already be cleared.

Check the existing data that save into the memory

1.Power off the meter.

2.Use the two fingers to press the " HOLD Button " ( 3-3,

Fig, 1 ) and the " REC Button " ( 3-4, Fig. 1 ) at the same

time and not release those fingers, use another finger

to push the " POWER Button " ( 3-2, Fig, 1 ) once, then

until the display show the existing sampling time ( for

example 1, 2...), then release the two fingers at the

same time.

15

Page 18

3.Press the " HOLD Button " ( 3-3, Fig, 1 ) or the

FUNCTION Button " ( 3-5, Fig. 1 ) will search the

the data that already save into the memory.

* " HOLD Button " - Increase the data no.

* " FUNCTION Button " - Decrease the data no.

Memory full

During execute the data logger function, if the meter's

Beeper generate the " Long beeper sound along a short

stop " continuously. It means that the Memory is full.

8. HOW TO SEND THE DATA OUT

FROM the METER

If intend to send the data out from the meter, it should

cancel the " Hold function " and the " Record function "

first. The display will not show the " HOLD " and the "

REC " marker.

1)Press the " Send Button " ( 3-5, Fig. 1 ) at least 2

seconds until the display show " 232 " ( flashing ),

release the button.

2)Push the " Send Button " ( 3-5, Fig. 1 ) once again,

the display will show the saved data no, then decrease

to " 1 " and the display will present " 232 " again, now

all the memory data already send out from the meter

via the " RS-232 Output Terminal " ( 3-8, Fig. 2 ).

3)If intend up load the data to the computer, then should

connect the RS232 cable ( optional, model : UPCB-02)

or USB cabke ( optional, model : USB-01 ) and apply

the Data Logger software ( optional, Model : DL-2005 ).

16

Page 19

9. RS232 PC SERIAL INTERFACE

.

The instrument has RS232 PC serial interface via a 3.5

mm terminal ( 3-8, Fig. 2 ).

The data output is a 16 digit stream which can be

utilized for user's specific application.

A RS232 lead with the following connection will be

required to link the instrument with the PC serial port.

PC

Meter (9W 'D" Connector)

Center Pin............................................

Pin 4

(3.5 mm jack plug)

Ground/shield......................

Pin 2

2.2 K

resister

Pin 5

The 16 digits data stream will be displayed in the

following format :

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

17

Page 20

Each digit indicates the following status :

D0 End Word

D1 & D8 Display reading, D1 = LSD, D8 = MSD

For example :

If the display reading is 1234, then D8 to

D1 is : 00001234

D9 Decimal Point(DP), position from right to the

left

0 = No DP, 1= 1 DP, 2 = 2 DP, 3 = 3 DP

D10 Polarity

0 = Positive 1 = Negative

D11 & D12 Annunciator for Display

= 92 = 97

mm/s = 93 cm/s = 95 inch/s = 98

mm = 94 inch = 96 g = 57

D13 When send the upper display data = 1

When send the lower display data = 2

D14 4

D15 Start Word

RS232 setting

Baud rate 9600

Parity No parity

Data bit 8 Data bits

no.

Stop bit 1 Stop bit

18

Page 21

10. BATTERY REPLACEMENT

When the left up corner of LCD show " " indicator,

it is necessary to replace the battery. However,

1)

in-spec measurement may still be made for several

hours after low battery indicator appears before the

instrument become inaccurate.

2)Open the " Battery Cover " ( 3-7, Fig. 2 ) away from

the instrument and remove the battery.

3)Install a 9 V battery ( Alkaline or heavy duty ) and

replace the cover.

11. OPTIONAL ACCESSORIES

RS-232 cable, Interface cable used for connecting the

Model : UPCB-01 vibration meter & the computer ( COM port ).

USB cable, Interface cable used for connecting the

Model : USB-01 vibration meter & the computer ( USB port ).

Data Acquisition After setup whole hardware

software,

SW-801-WIN Vibration meter + RS-232 cable +

Computer + software ( SW-U801-WIN )

whole system can execute as a data logger,

data recorder.... record data can be retrieved

for EXCEL, LOTUS-123.....

Data Logger Vibration meter + RS-232 cable ( or USB cable

( data collection ) ) + Computer + software ( DL-2005 ) It can

software, down load the MEMORY data out from the

DL-2005 meter to the computer.

19

Page 22

12. CLASSIFICATION RANGES

For the valuation of machines and equipment in the ISO

2372 and VDI 2056, four different kinds of machine groups

with four classification ranges and their limits for vibration

severity ( mm/s ) are determined.

The classifications for each machine group are specified as

follows :

Small machines, especially production electrical

motors of up to 15 KW ( Group K )

Good 0 to 0.71 mm/s

Acceptable 0.72 to 1.80 mm/s

Still permissible 1.81 to 4.5 mm/s

Dangerous > 4.5 mm/s

Medium sized machines, especially electrical

motors with 15 up to 75 KW output, without

special foundations ( Group M )

Good 0 to 1.12 mm/s

Acceptable 1.13 to 2.80 mm/s

Still permissible 2.81 to 7.1 mm/s

Dangerous > 7.1 mm/s

20

Page 23

Large machines on heavy foundations ( Group G )

Good 0 to 1.80 mm/s

Acceptable 1.81 to 4.50 mm/s

Still permissible 4.51 to 11.2 mm/s

Dangerous > 11.2 mm/s

Largest machines and turbo machines with a

special foundations ( Group T ).

Good 0 to 2.80 mm/s

Acceptable 2.81 to 7.10 mm/s

Still permissible 7.11 to 18.0 mm/s

Dangerous > 18 mm/s

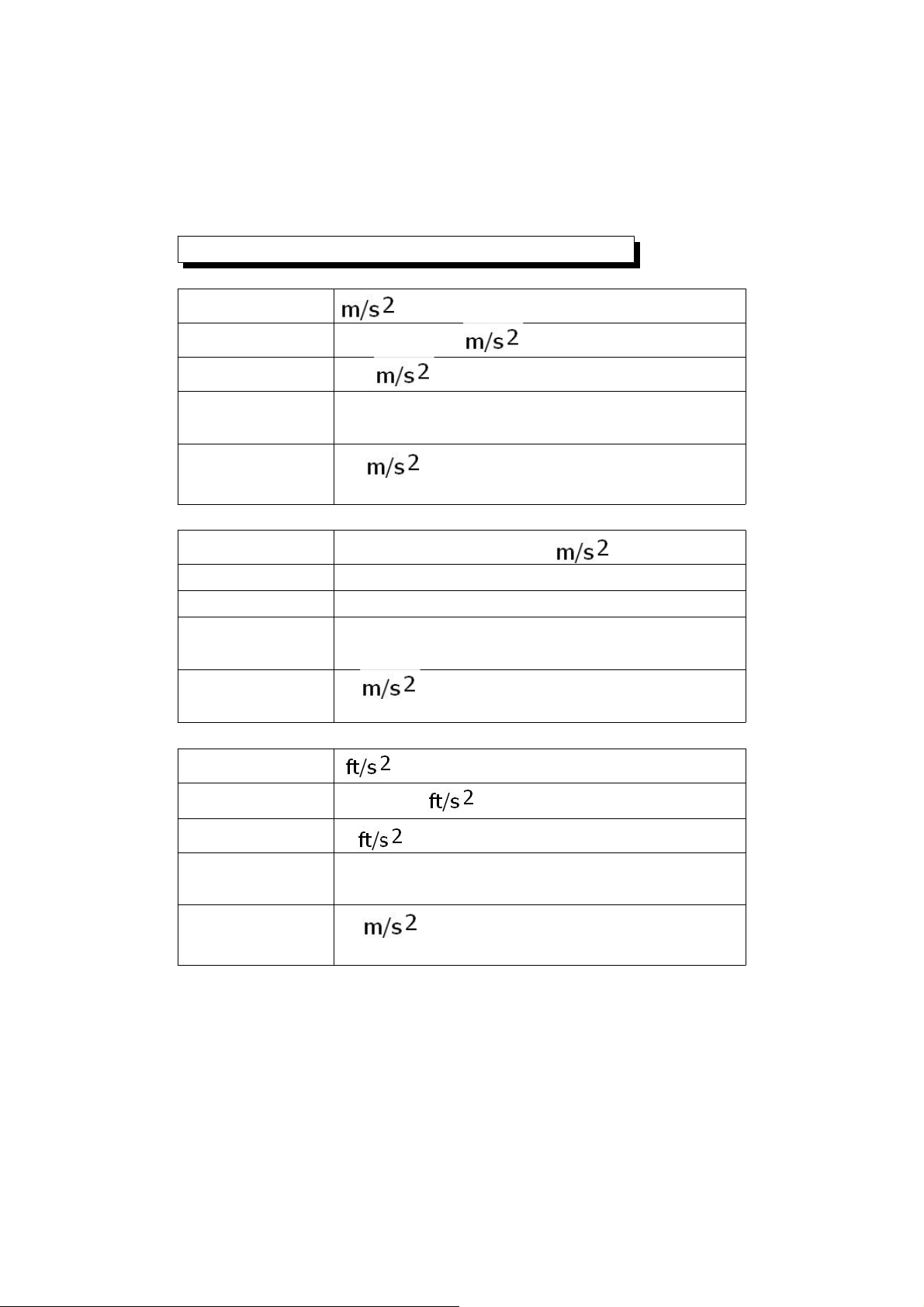

13. SENSITIVITY RELATIVE to the

reference sensitivity at 80 Hz ,

according ISO 2954

Frequency Normal Relative sensitivity

value Minimum Maximum

value value

10 Hz 1.0 0.8 1.1

20Hz Hz 1.0 0.9 1.1

40 Hz 1.0 0.9 1.1

80 Hz 1.0 1.0 1.0

160 Hz 1.0 0.9 1.1

500 Hz 1.0 0.9 1.1

1000 Hz 1.0 0.8 1.1

Table 1

21

0702-VB8213

Loading...

Loading...