Page 1

R

Setup and Maintenance Guide

Dimming and

Switching

SS yy ss tt ee mm

LCP128

TM

LCP128

TM

Page 2

Page 3

R

LCP128

TM Setup and Maintenance Guide 3

Table of Contents

Page

Overview .........................................................................................................................................................14

STEP 1: Panel Configuration ..........................................................................................................................15

STEP 2: Time Clock Configuration ..................................................................................................................22

STEP 3: Scene Modification ............................................................................................................................27

STEP 4: Control Stations.................................................................................................................................29

STEP 5: Time Clock Events.............................................................................................................................36

STEP 6: Panel Contact Closure Inputs ............................................................................................................42

STEP 7: Emergency Power Mode ...................................................................................................................46

Page

Referenced Functions

Overrides...........................................................................................................................................49

Locking and Unlocking the Controller ................................................................................................53

Troubleshooting Guide

Troubleshooting Guide.......................................................................................................................55

Maintenance

Maintenance......................................................................................................................................60

Glossary of Terms

Glossary of Terms..............................................................................................................................61

Tables

Panel Tables ......................................................................................................................................62

Module Type Table.............................................................................................................................66

Load Type Table ................................................................................................................................67

Control Location Table.......................................................................................................................68

Control Station Table .........................................................................................................................69

Time Clock Event Table .....................................................................................................................71

Reference Information

Step-by-Step Programming Instructions

Page

How to Use this Guide .........................................................................................................................................4

System Specifications ...........................................................................................................................................5

System Start-Up Checklist.....................................................................................................................................7

Controller Overview ...............................................................................................................................................9

Introduction and System Startup

e

e

s

s

d

d

o

o

p

p

p

p

t

t

o

o

u

u

s

s

l

l

o

o

s

s

o

o

i

i

k

k

s

s

i

i

l

l

h

h

i

i

t

t

k

k

,

,

e

e

t

t

a

a

o

o

n

n

d

d

r

r

i

i

c

c

o

o

t

t

t

t

i

i

o

o

n

n

ei

ei

a

a

v

v

r

r

y

y

e

e

i

i

!

!

l

l

e

e

t

t

M

M

n

n

e

e

r

r

.

.

B

B

N

N

y

y

y

y

b

b

e

e

,

,

B

B

d

d

J

J

e

e

t

t

u

u

a

a

l

l

y

y

e

e

r

r

6

6

c

c

,

,

s

s

1

1

a

a

9

9

9

9

w

w

5

5

n

n

.

.

o

o

c

c

i

i

s

s

i

i

e

e

s

s

d

d

o

o

p

p

t

o

u

s

l

h

h

o

s

o

i

k

s

i

l

h

i

T

T

t

k

,

e

t

a

o

n

n

d

r

r

i

c

o

o

t

t

t

i

o

i

n

e

ei

a

v

v

r

y

e

e

i

i

!

l

l

e

e

t

M

n

e

r

.

B

N

y

y

b

e

,

B

B

d

J

e

t

u

a

l

y

e

r

6

c

,

s

s

1

a

a

9

9

w

w

5

,

on

on

c

c

i

i

s

s

i

i

h

h

.

T

R

k

h

e

o

r

m

e

T

T

D

a

s

f

.

o

n

o

i

t

c

c

e

e

r

r

i

i

d

d

e

e

h

h

t

t

r

r

e

e

d

d

n

n

t

M

n

e

r

.

B

N

y

y

b

e

,

u

u

d

J

e

t

u

a

l

y

e

r

6

c

,

s

s

1

a

a

9

9

w

w

5

n

n

.

o

o

c

c

i

i

s

s

i

i

e

s

d

o

p

p

t

o

u

s

l

h

h

o

s

o

i

k

s

i

l

h

i

T

T

k

t

,

e

t

a

o

n

n

d

r

r

i

c

o

o

t

t

t

i

o

i

n

e

ei

a

v

v

r

y

e

e

i

i

!

l

l

e

e

t

M

n

e

r

.

B

N

y

y

b

e

,

B

B

d

J

e

t

u

a

l

y

e

r

6

c

,

s

s

1

a

a

9

9

w

w

5

.

on

on

c

c

i

i

s

s

i

i

h

h

T

T

p

p

t

o

u

s

l

o

s

o

i

k

s

i

l

h

i

t

k

,

e

t

a

o

d

i

c

t

i

o

n

a

r

y

!

t

M

n

e

r

.

B

N

y

y

b

e

,

d

J

e

t

u

a

l

y

e

r

6

c

,

1

9

9

5

.

.

T

R

k

h

e

o

r

m

e

D

a

s

f

.

o

n

o

i

t

t

M

n

e

r

.

B

N

y

y

b

e

,

d

J

e

t

u

a

l

y

e

r

6

c

,

1

9

9

5

.

e

s

d

o

p

p

t

o

u

s

l

o

s

o

i

k

s

i

l

h

i

k

t

,

e

t

a

o

d

i

c

t

i

o

n

a

r

y

!

t

M

n

e

r

.

B

N

y

y

b

e

,

d

J

e

t

u

a

l

y

e

r

6

c

,

1

9

9

5

.

Page 4

R

4 LCP128TM Setup and Maintenance Guide

Introduction

How to Use this Guide

This programming guide contains three main sections:

• Introduction - Includes system specifications, electrical contractor Start-Up Checklist, and an overview of the

controller and how to use it.

• Step by Step Programming Instructions - Walks you through each step needed to program your system.

• Reference Information - Includes additional procedures that you may need to perform after the system is

programmed, including how to override system settings and lock/unlock the controller. This section also includes

troubleshooting tips, system maintenance, a glossary of terms, and system planning tables.

When programming the LCP128 system, you will need to know the following key information:

• How many panels are in this system and how many circuits are in each panel.

• How many modules are in the system and the module types.

• What the load schedule is.

• Where each wallstation and key switch is located and what each button or key turn should do.

• What each contact closure input and output should do.

• What the time clock should do.

Please read the guide completely before attempting to program the system.

Tables are provided at the back of this guide to record the above information. Photocopy the tables as

needed, and leave them for the occupant after they are completed.

Note: For mounting and wiring information, refer to the LCP128 Installation Guide, Lutron P/N 032-150.

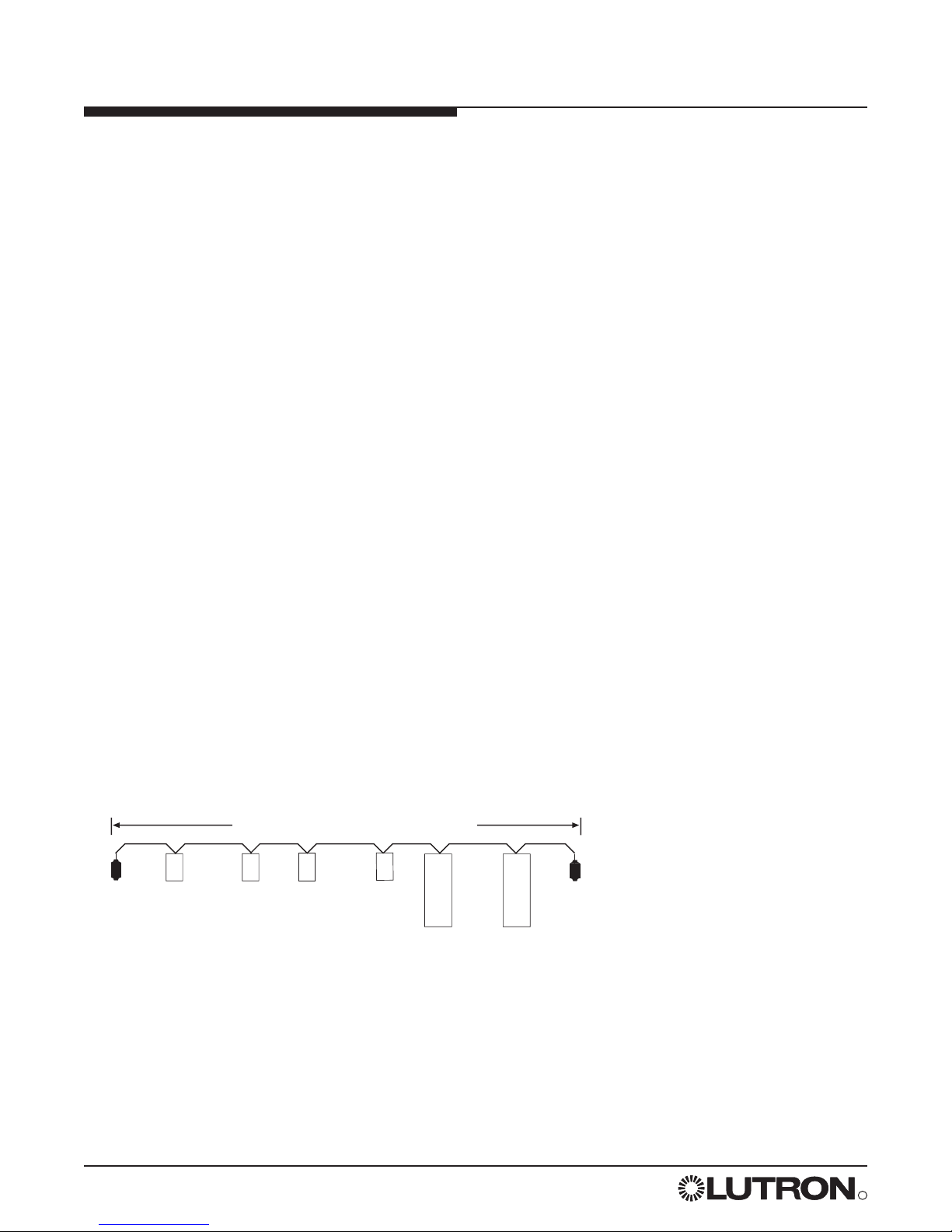

Control Link 2000 ft. (600 m) maximum

LCP128 Panels

Control Stations:

Wallstations, key switches, contact

closure devices, and RS232 devices

System Overview Diagram

LT-1

LT-1

Page 5

R

LCP128

TM Setup and Maintenance Guide 5

Introduction

System Specifications

LCP128 is a lighting control system designed for commercial buildings. It consists of up to 8 dimming panels

and up to 32 control stations. Control stations can be wallstations, key switches, contact closure input and

output devices (OMX-AV), contact closure output devices (OMX-CCO-8), or building management system

interfaces (OMX-RS232). All panels and control stations are connected by a digital communications link. Refer

to the LCP128 Installation Guide for wiring details. Other system specifications are described below.

Time Clock

• 7 weekly schedules.

• Up to 40 holiday schedules.

• Each holiday schedule can be 1-90 days.

• Up to 500 time clock events.

• Maximum of 25 time clock events per day.

• Up to 32 scenes and 1 Off scene.

• With each time clock event or control station input, you can select which circuits turn on or off and, for dimming

circuits, set specific dimming levels.

• Time clock events can occur at a fixed time of day or at a time relative to sunrise or sunset (astronomical).

• Events can be placed on either a weekly schedule (for example, occurring every Monday) or a holiday schedule

(for example, occurring only on January 1).

• Holiday schedules override weekly schedules.

• Time clock events can start and end afterhours mode. Afterhours is an energy saving mode where lights that

are set to be off will automatically, after a period of time, turn themselves off. Afterhours mode can be

temporarily overridden by any control station action. See STEP 5 for more information.

• Time clock events can enable and disable control stations.

Control Station - Wallstation

Wallstation buttons can be individually programmed to:

• Select a scene or custom scene. A scene is a combination of preset lighting levels used to automatically turn

on, off, or dim a circuit or group of circuits. Each time the wallstation button is pressed, the circuits go to the

programmed scene settings.

• Raise or lower circuits. Dimming circuits progressively raise or lower as long as the button is pressed. Circuits

stay at this setting until another event or control station input occurs.

• Toggle circuits on and off. Each press of the button alternates between turning the circuits on and off. If the

circuits are in a mixed state (some on and some off), the lights turn on.

• Turn off with a time delay. When the button is pressed, the circuits turn off after a preset amount of time.

• Enable or disable time clock.

Control Station - Key Switch

• The key switch (NTOMX-KS) can be programmed for clockwise and counterclockwise turns and with the same

functions as a wallstation button.

Control Station - Contact Closure Inputs

Two contact closure inputs are available on each LCP128 controller – more are available by purchasing a Lutron

OMX-AV control station (five inputs per OMX-AV that can be added anywhere on the digital control station link).

• The contact closure inputs can be programmed on the open and/or closure of the contact to perform the same

functions as a wallstation button.

Page 6

R

6 LCP128

TM Setup and Maintenance Guide

Introduction

Control Station - Contact Closure Outputs

Contact closure outputs can be added with either a Lutron OMX-AV control station (five outputs per OMX-AV) or

with a Lutron OMX-CCO-8 (eight outputs per OMX-CCO-8). Either control station can be added anywhere on

the digital control station link.

• Each contact closure may be momentary or maintained.

• Each contact closure output can be assigned to an action that is programmed to a wallstation button, key turn,

contact closure input, time clock event, or emergency state.

Integration through RS232

The LCP128 system can be integrated with a building management system through the Lutron RS232 interface

(OMX-RS232).

Emergency Power Mode

When a LCP128 panel is placed into emergency power mode (loss of normal power), circuits are changed to

emergency settings and remain at those settings until the controller exits emergency power mode (return of

normal power). All control station inputs and time clock events are ignored while in emergency power mode.

Emergency power mode can be activated using:

• Panel to panel emergency sense line. This method requires that the system have at least two panels. The

system must have at least one normal (non-essential) feed panel and at least one emergency (essential) feed

panel. When power to the normal panel is interrupted, the emergency panel(s) will go into emergency mode.

Note that the normal / emergency switches at the bottom of the controllers need to be set correctly.

• The Lutron emergency lighting interface (LUT-ELI-3PH), a UL 924 listed device, senses the normal (nonessential) line voltage on all three phases (3PH) of normal power. When one or more phases of power are lost,

the LUT-ELI-3PH sends a signal to the LCP128 controller. If the LCP128 controller’s normal / emergency switch

is set to emergency, the emergency lighting scene or programmed circuit levels are activated.

For more information on emergency lighting applications, refer to Application Note #106. Available at

www.lutron.com.

Page 7

LCP128 System Start-Up Checklist for Electrical Contractor

Important Note:

To ensure that the LCP128 System is ready for Start-Up, please complete the following checklist.

The LCP128 panel(s) and control station(s) have been mounted in accordance with the installation instructions.

Control stations have been wired to the panel in accordance with installation instructions.

Feed and load wiring to panel have been installed in accordance with the installation instructions.

All load circuits have been activated in bypass mode (bypass jumpers installed) and are correctly and

permanently lamped.

Bypass jumpers have been removed and all circuits activated as default Non-Dim load type.

Load schedule for each panel has been completed.

Correct load type for each circuit has been determined and recorded.

When the above checklist is completed, please fax this sheet along with the completed load schedule

for each panel to Lutron Field Service Scheduling at (610) 282-0298.

Signature: ___________________________ Job Name: _________________________________________

Today’s Date: _________________________ Lutron Job Number: _________________________________

Printed Name: _______________________ Scheduled Startup Date: _____________________________

Phone Number: _______________________ Scheduled Startup Time: _____________________________

Fax Number: _________________________ Job Site Number: ___________________________________

Bill of Material (panels, control stations, etc.):

____________________________________ Qty. ___________

____________________________________ Qty. ___________

____________________________________ Qty. ___________

Lutron Electronics Co., Inc.

7200 Suter Road

Coopersburg, PA 18036-1299

Telephone: 800-523-9466 (Listen to menu for scheduling)

System Start-Up Checklist

R

LCP128

TM Setup and Maintenance Guide 7

Page 8

Page 9

R

LCP128

TM Setup and Maintenance Guide 9

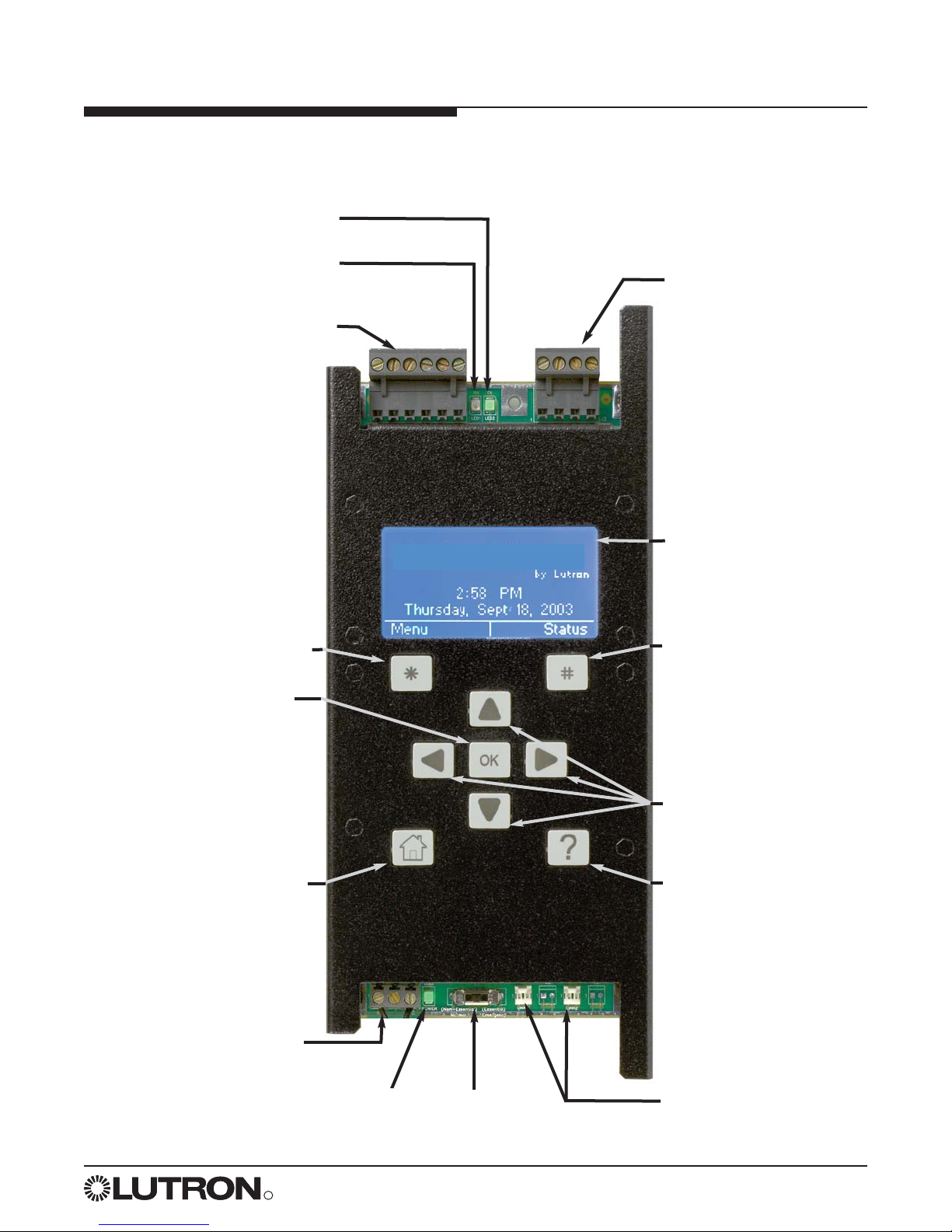

LCP128 Controller Layout

Digital Control Station Link

and Emergency Sense Line

Connector

Panel Contact Closure

Inputs Connector

Digital Link Receive (RX) LED

Digital Link Transmit (TX) LED

24 VAC Power

Input Connector

Normal /

Emergency Switch

Module Control

Harness Connectors

Help Button

Home Button

Navigation Arrows

Right Soft Labeled

Button

LCD Screen

OK Button

Power OK LED

Controller Overview

Left Soft Labeled Button

LCP128TM

Page 10

R

10 LCP128

TM Setup and Maintenance Guide

Main Menu

Overrides

Time Clock Setup

Control Station Setup

Panel CCI Setup

Back

OK

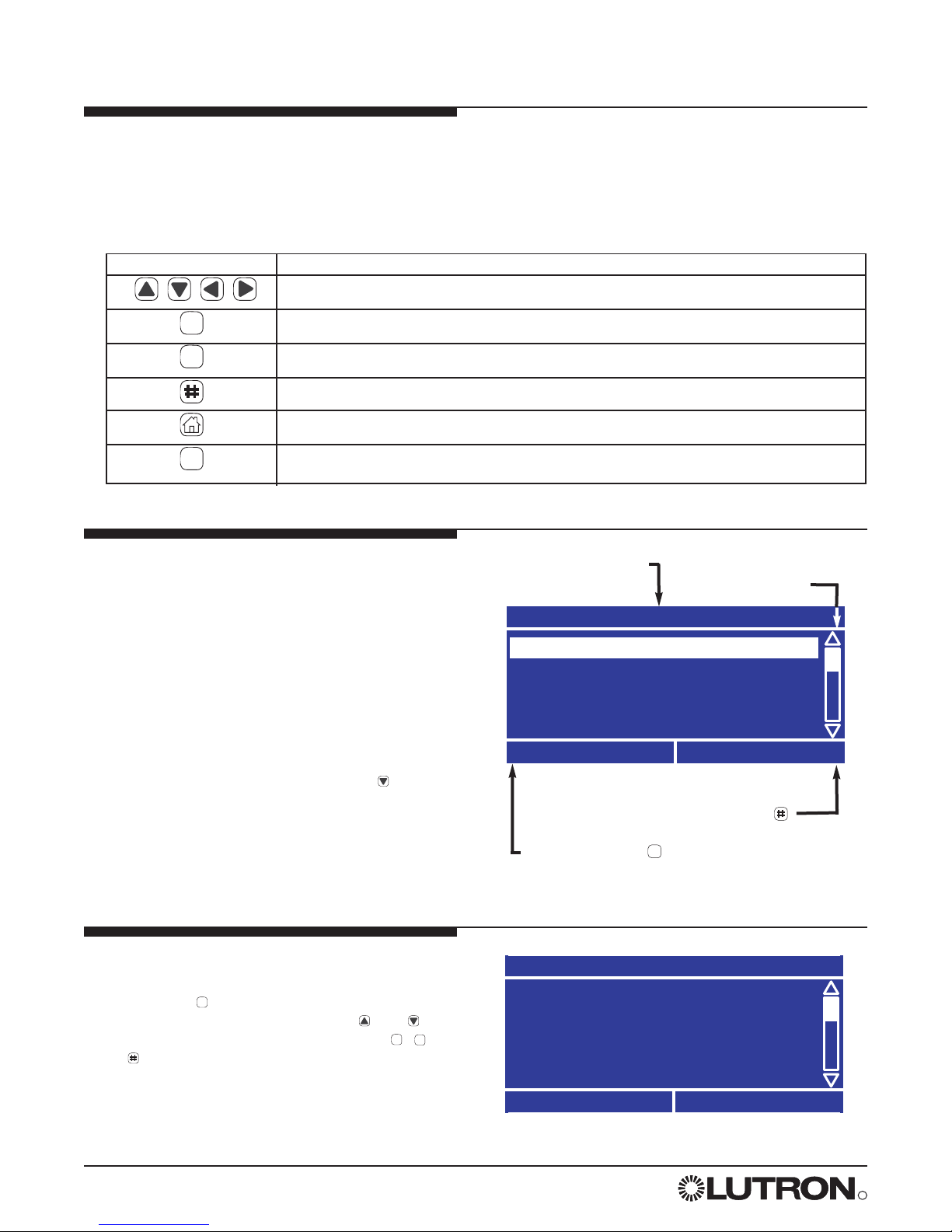

Screen Title

Scroll Bar

Left Soft Label ( )

Right Soft Label ( )

Button Function

Navigate the screen and change highlighted values

Select an item

Left Soft-Labeled – Function defined on screen

Right Soft-Labeled – Function defined on screen

Go to the Home screen

On-Screen Help

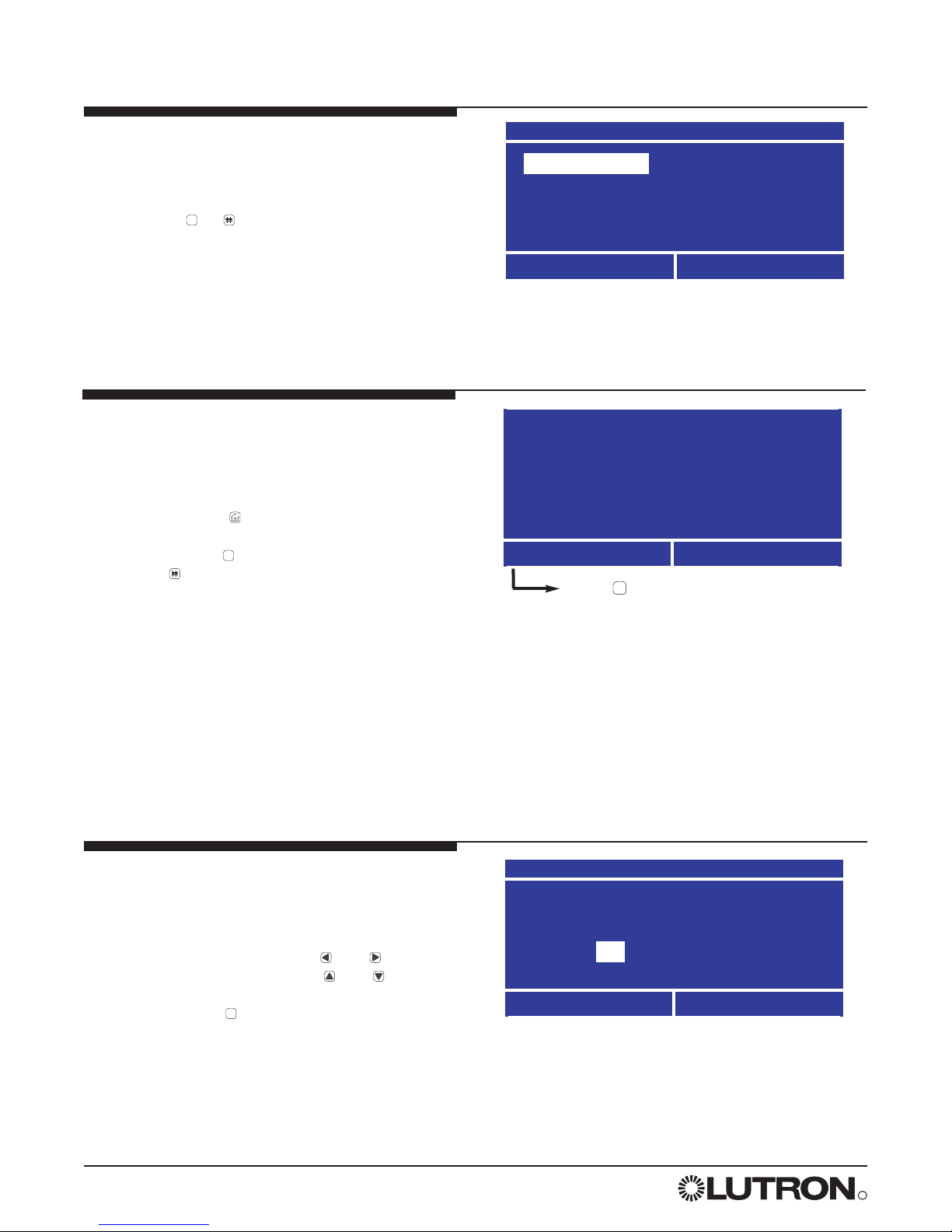

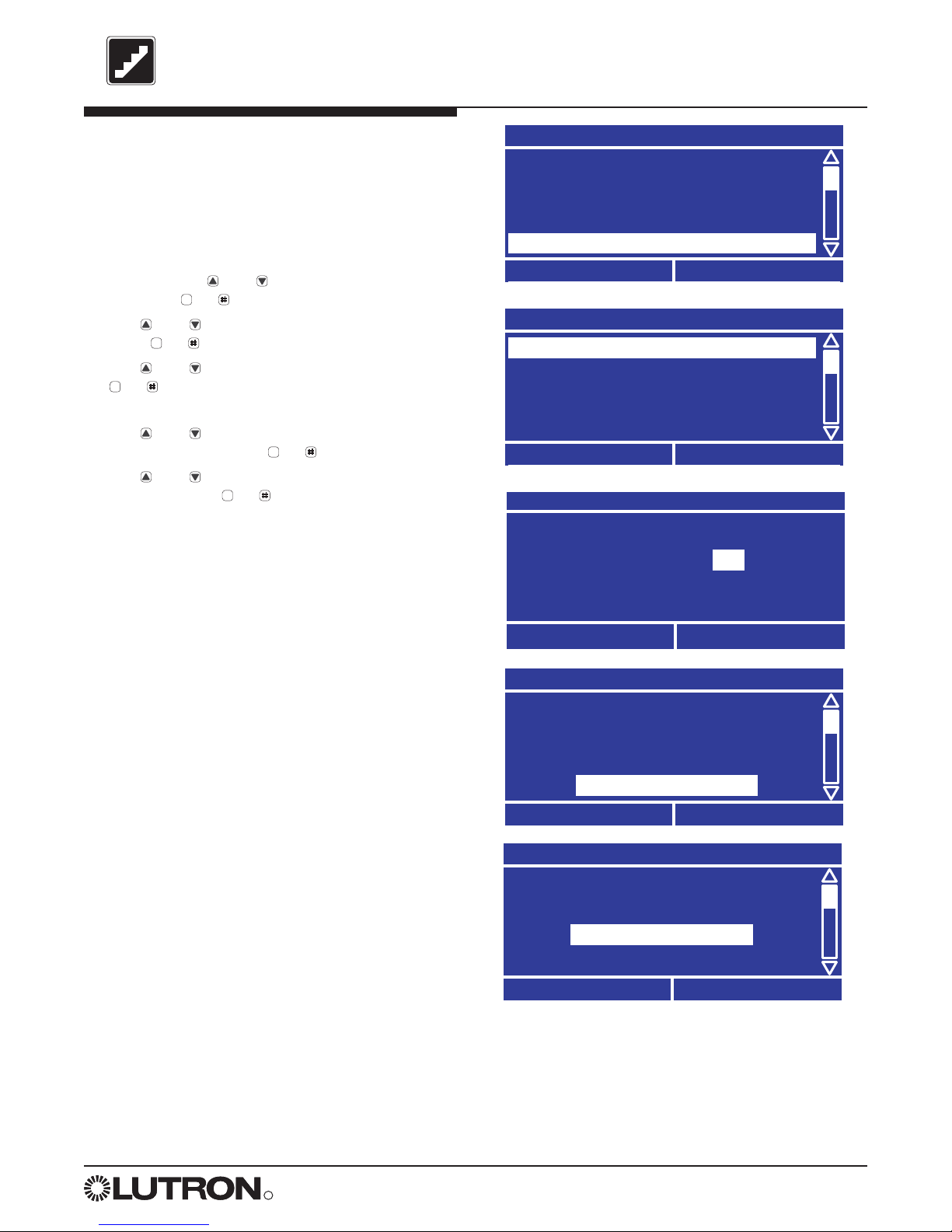

Navigation

The LCP128 controller uses certain methods for navigating, selecting, setting values, etc. Please read this

section carefully before using the controller to program your system.

The LCP128 controller has nine buttons below the display. The table below explains their functions.

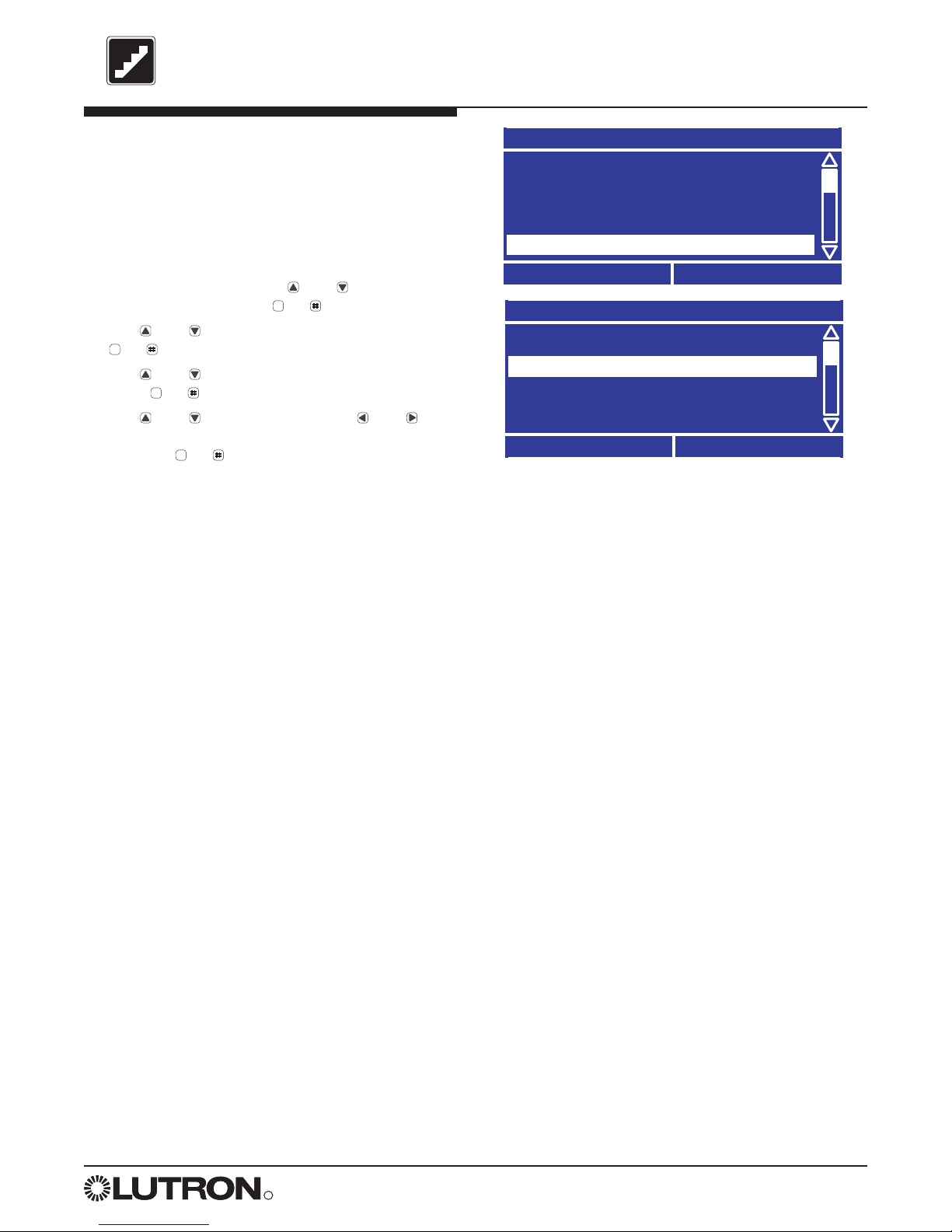

The Screen

All screens on the LCP128 controller have a

similar look with some common elements.

These are:

• A screen title

• Left and right soft button labels

• A scroll bar (only present if more information is

available than will fit on the screen.)

The example shows the Main Menu. The scroll

bar indicates that there is more information in the

menu than fits on the screen. Pressing

repeatedly scrolls through the menu and shows

other choices. The shaded slider on the scroll

bar indicates what portion of the menu is being

displayed.

Help

Help on the current screen is always available by

pressing the button. If more information is

available than fits on the screen, use and

to scroll through the text. Pressing either ,

or returns you to the screen you were on.

Help

The home screen shows the

current date and time. Press *

to go to the Menus, press # to go

to the Status screen.

Back

OK

Controller Overview

OK

*

?

*

?

OK

*

Page 11

Main Menu

Overrides

Time Clock Setup

Control Station Setup

Panel CCI Setup

Back

OK

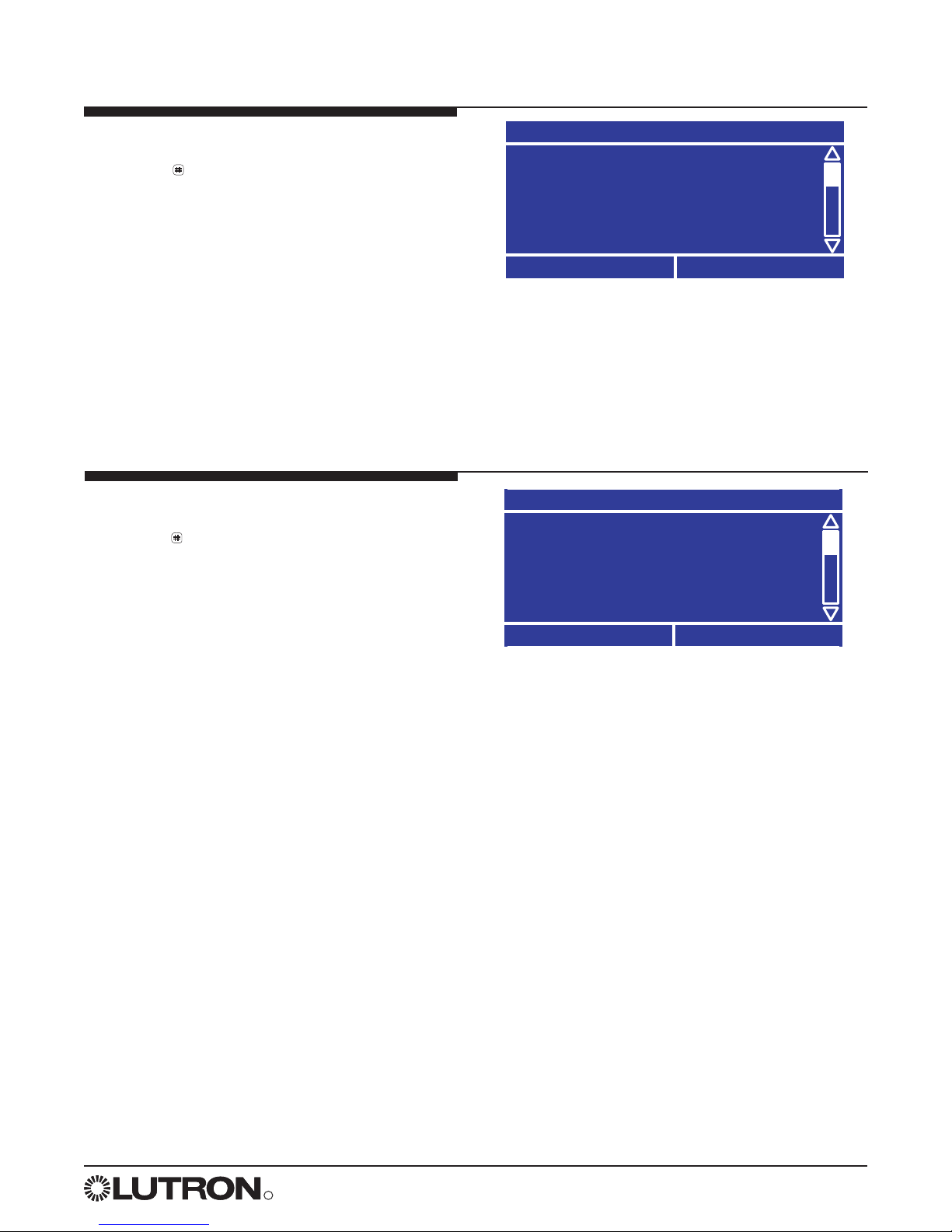

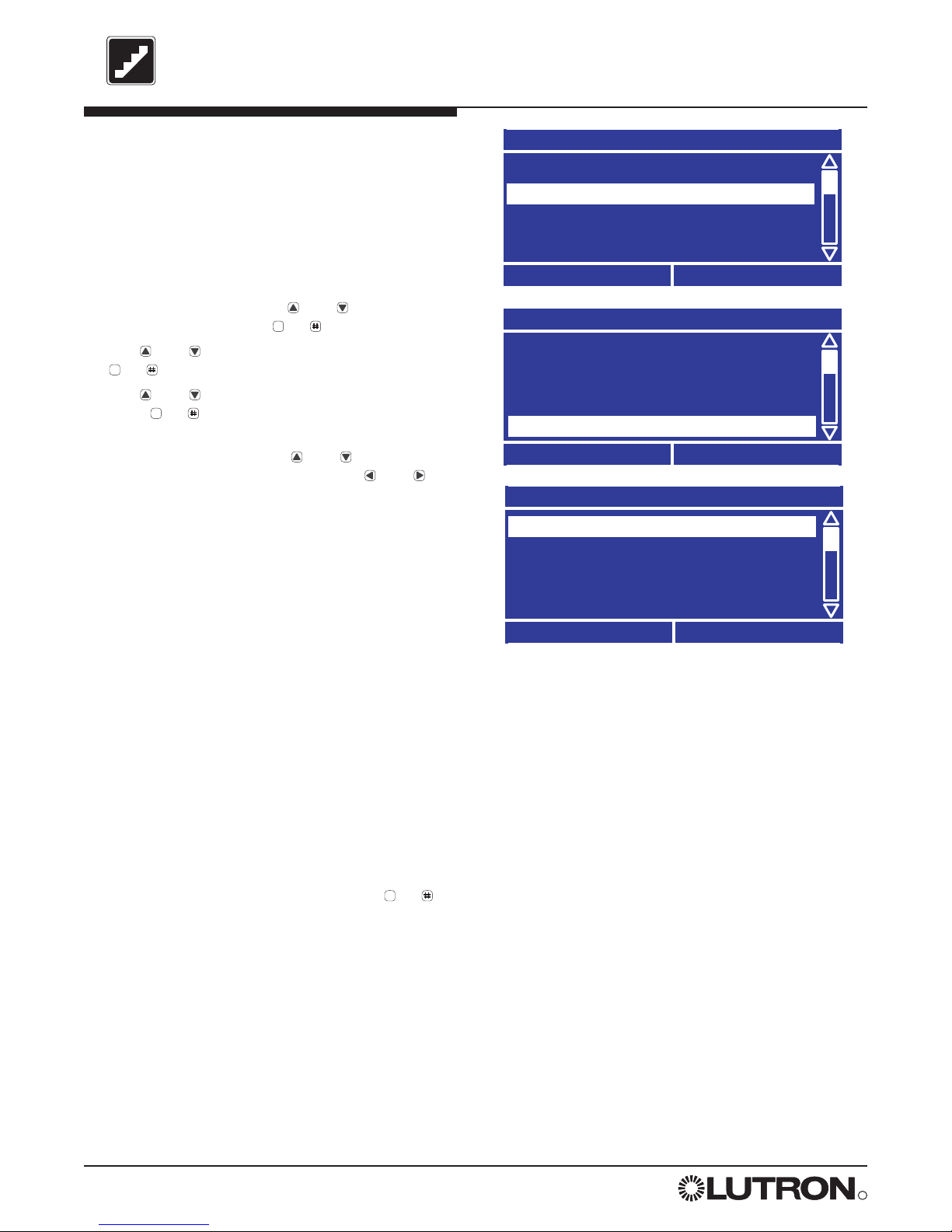

Getting to the Home Screen

Press from any screen to go back to the Home

screen.

Accessing the Main Menu

From the Home screen, press to go to the Main

Menu. If a password has been set, you need to

enter it before continuing (see “Locking and

Unlocking the Controller” in the reference section

later in this guide).

LCP128

TM

by Lutron

8:00 AM

Wednesday, Nov 3, 2004

Menu

Status

Press to Activate the Menu

Navigating the Menus

When in a menu, use and to change the

highlighted item and press or (OK) to select

that item. Pressing provides help on that item.

To go back to the previous screen, press (Back).

Entering Data

One or more screens are used to program the

information required for each system feature.

If only one screen is required, the screen has the

soft labeled buttons “Cancel” and “Done”.

If multiple screens are required, the first screen has

the soft labeled buttons “Cancel” and “Next”.

Intermediate screens have the soft labeled buttons

“Previous” and “Next”, and the last screen has the

soft Labeled buttons “Previous” and “Done”.

Note: Data is not stored in the LCP128 system

database until “Done” is selected.

Afterhours Setup

Warn Time: min

Cancel

Next

Afterhours Setup

Flash Count: 0

Previous

Next

Afterhours Setup

Off Delay: min

Previous

Done

01

05

15

R

LCP128

TM Setup and Maintenance Guide 11

Controller Overview

(continued)

*

OK

?

*

*

Page 12

R

12 LCP128

TM Setup and Maintenance Guide

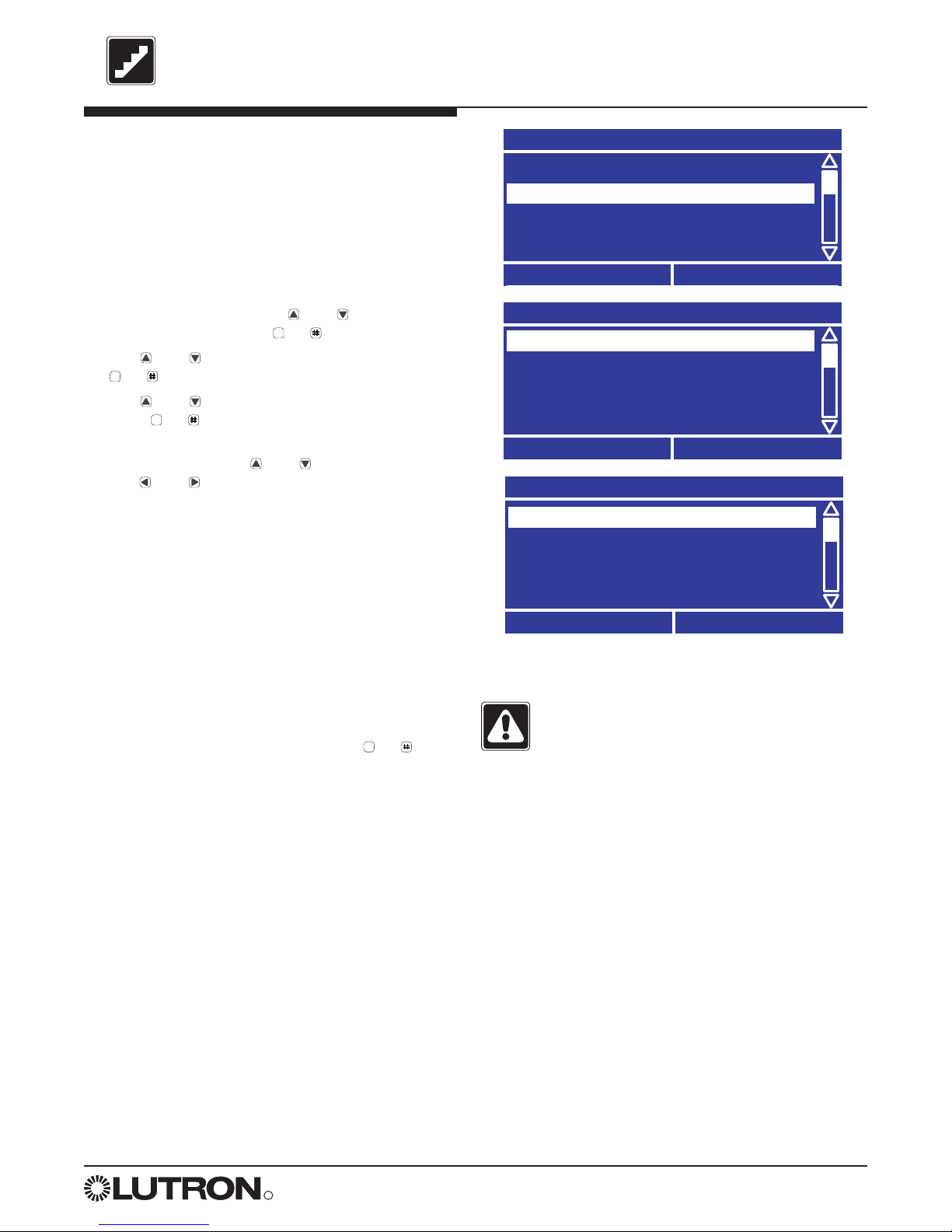

Getting Started - The Home

Screen

• When the controller is first powered or is not used

for 20 minutes, the display shows the Home

screen. Pressing (the Home button) always

takes you back to this screen. From the Home

screen, pressing displays the Main Menu and

pressing displays the Panel Status screen.

• The Home screen shows the current day, date and

time set on the controller. If either of these are

incorrect, refer to STEP 2 to set the date, time, and

location.

• The backlight on the LCD turns off after 25 minutes

of no activity. Pressing any button on the control

turns the backlight on and displays the Home

screen.

Unlocking the Controller

If the controller has been locked (see “Locking the

Controller” in the referenced function section) you

are prompted to enter the password before the

Main Menu is activated. Press and to select

the digit to change. Then press and to

change each digit. When you have entered the

password, press .

If you forget the password, contact Lutron technical

support at 1 (800) 523-9466 to unlock the

controller.

LCP128

TM

by Lutron

8:00 AM

Wednesday, Nov 3, 2004

Menu

Status

Press to Activate the Menu

Unlock Panel

Enter Password

0 0 0 0

Cancel

OK

0

Controller Overview

(continued)

Language Select Screen

When the controller is first powered, you are

prompted to choose a language for the screens.

Use the navigation arrows to select a language,

then press or (Done).

Choose Language

English

Francais

Espanol

Italiano

Done

Deutsch

Nederlands

Portugues

OK

*

*

OK

Page 13

R

LCP128

TM Setup and Maintenance Guide 13

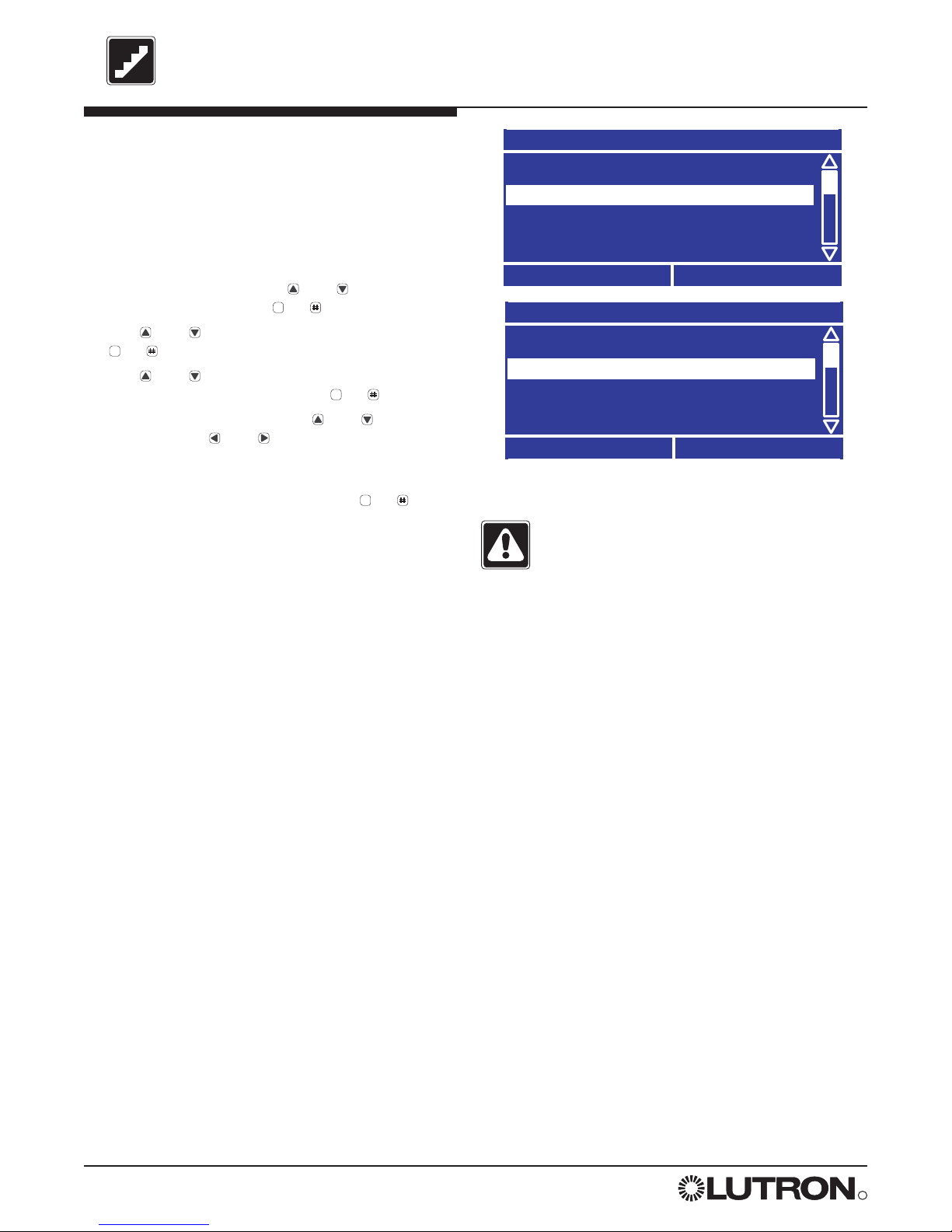

The Panel Status Screen

Pressing from the Home screen displays the

Panel Status screen. The Panel Status screen

shows:

• Your location.

• Sunrise and sunset times for the current system

date (note that the time, date, and location must be

configured correctly).

• Whether time clock events are enabled or disabled.

• Whether control stations are enabled or disabled.

Panel Status

Philadelphia, Pennsylvania

Today’s Sunrise: 05:59AM

Today’s Sunset: 6:07PM

Time Clock : Enabled

Back

Link Detail

The Wallstation Status Screen

Pressing from the Panel Status screen displays

the Wallstation Status screen. The Wallstation

Status screen shows:

• If the station is present and is recognized, the

control is labeled by its type (for example,

“seeTouch”).

• If a station is not present, it is labeled as “No

Station”. This could also indicate a control station

address conflict.

• If the unit is present and is not a control that is

known to the system, the control is labeled as

“???”. This could also indicate a control station

address conflict.

Wall Station Status

A01 - No Station

A02 - seeTouch

A03 - NT/KS/FOMX

A03 - ???

Back

OK

Controller Overview

(continued)

Page 14

R

14 LCP128TM Setup and Maintenance Guide

Step by Step Programming Instructions

Overview

Programming your LCP128 system is done in seven steps.

1. Panel Configuration

This step selects a language for the controller LCD and configures the load setup. For multiple panel systems,

this step also assigns panel addresses and configures the number of circuits in each panel.

2. Time, Date, and Location

Required if the time clock will be used. This step shows how to set the clock.

3. Scene Modification

Required if changes to the default scene settings are needed.

4. Control Stations

Required if there is a remote wallstation, key switch, contact closure device, and/or RS232 device. This step is

performed to configure their function.

5. Time Clock Events

Required if the time clock will be used. This step is used to automatically dim or turn circuits on/off at either a

specific time of day or at a time relative to sunrise or sunset.

6. Panel Contact Closure Inputs

Required if the panel contact closure inputs are used. This step defines what each input will do.

7. Emergency Power Mode

Required if emergency lighting is needed when normal power is lost. Control station inputs and time clock

events are ignored while in emergency power mode. This step defines if the panel has emergency circuits and

how to configure the emergency lighting.

The following pages explain how to perform each of the programming steps.

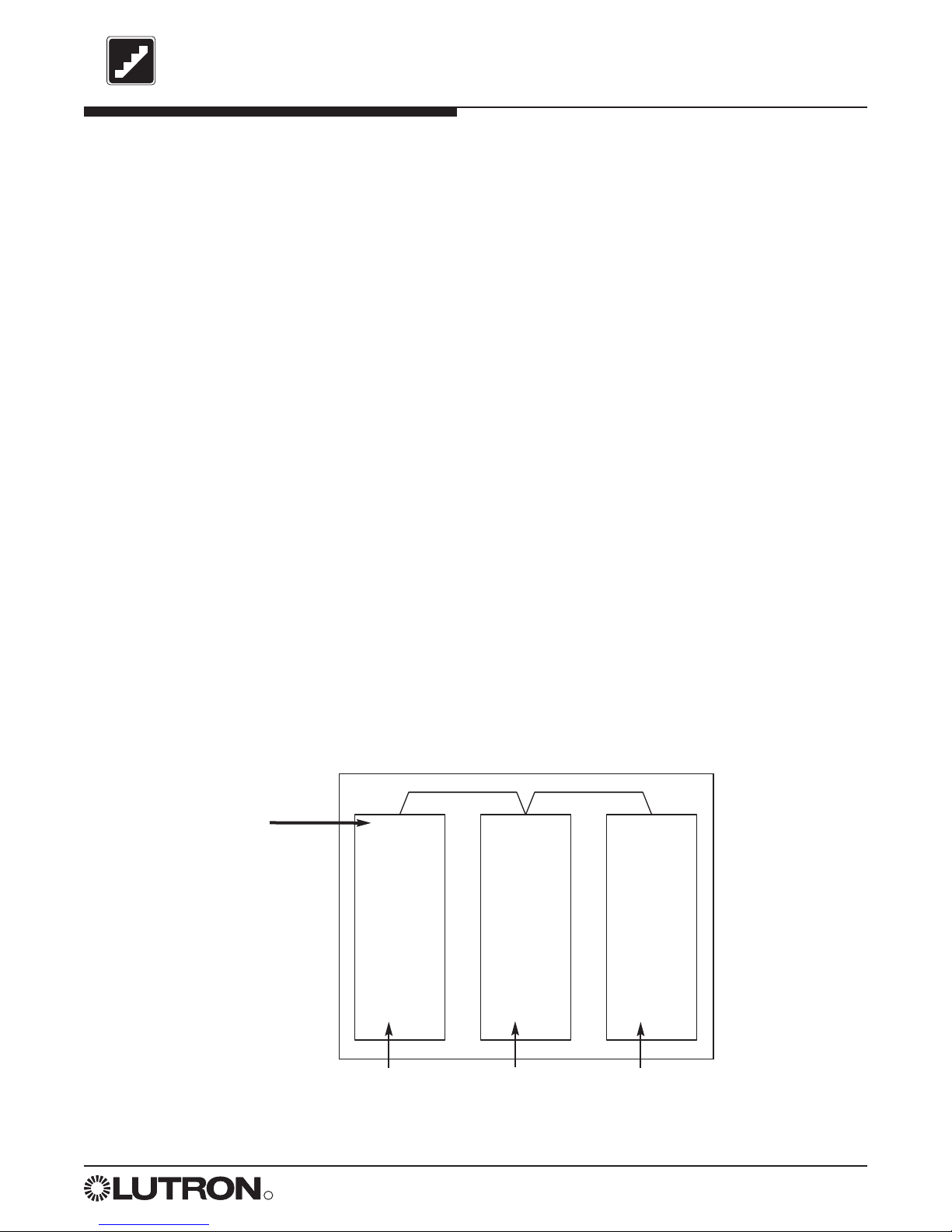

Page 15

R

LCP128

TM Setup and Maintenance Guide 15

Panel

Address 1

12

Circuits

System

Circuits

1-12

Panel

Address 2

24

Circuits

System

Circuits

13-36

Panel

Address 3

16

Circuits

System

Circuits

37-52

STEP 1

Panel Configuration

To program a LCP128 panel, you need to:

• Choose a language for the controller LCD.

• Set the panel configuration, including:

• Panel address

• First circuit number in the panel

• Number of circuits in the panel

Each circuit in the system is identified by a system circuit number. This number will be used to identify the

circuit for programming purposes. For example, if Panel 1 has 12 circuits, the first circuit in Panel 2 will be

circuit 13 on the LCP128 controller. The figure below shows a sample system.

Note: If your system has only one panel, you do not need to set the panel configuration. The panel address,

first system circuit number, and number of circuits are preprogrammed. However, for multi-panel systems,

you must set the panel configuration from the master panel (address 1) and then from each remote panel.

• Configure the load setup, including:

• Module type setup

• System size

• Load type

• High end trim

• Low end trim

All system programming (covered in programming STEPS 2-7) is performed at panel address 1. In a multi-

panel system, panel address 1 becomes the master programming panel and all other panels are remote panels.

Remote panels have limited menu options and functionality.

Before proceeding with STEP 1, complete the Panel, Module Type, Load Type, and Control Station

Tables located at the back of this guide.

Master Panel:

All system

programming

must take place

at this panel

First circuit in

this panel

First circuit in

this panel

First circuit in

this panel

Page 16

R

16 LCP128TM Setup and Maintenance Guide

STEP 1 (continued)

Choose a Language

A. From the Main Menu use and to highlight

Panel Setup and press or (OK).

B. Use and to highlight Choose Language and

press or (OK).

C. Use and to set the Language and press or

(Done). The default is English.

Panel Setup

Choose Language

Load Setup

Emergency Setup

Afterhours Setup

Back

OK

B.

Main Menu

Control Station Setup

Panel CCI Setup

Panel Setup

Scene Setup

Back

OK

A.

Choose Language

Cancel

Done

C.

Set System Size

You can set the system size so that controller

screens display only the circuits used by your

system. The default system size is 128 circuits.

A. From the Main Menu use and to highlight

Panel Setup and press or (OK).

B. Use and to highlight Load Setup and press

or (OK).

C. Use and to highlight System Size and press

or (OK).

D. Use and to set the total number of system

circuits and press or (Done).

System Size

How many circuits

are in this system?

Cancel

Done

52

D.

Load Setup

System Size

Chicago Setup

Low End Trim Setup

High End Trim Setup

Back

OK

C.

English

Francais

Espanol

Italiano

Deutsch

Nederlands

Portugues

OK

OK

OK

OK

OK

OK

OK

Page 17

R

LCP128

TM Setup and Maintenance Guide 17

STEP 1 (continued)

Set Panel Configuration Multi-Panel Systems Only

For multi-panel systems, you must set the address

and number of circuits for each panel, beginning

with the master panel.

A. From the Main Menu at the master panel

controller, use and to highlight Panel Setup

and press or (OK).

B. Use and to highlight Panel Addressing and

press or (OK).

C. Use and to set the Panel Address and press

or (Next).

Master panel address = 01

D. Use and to set the first system circuit number

in the panel, and press or (Next).

E. Use and to set the number of circuits in the

panel and press or (Done) to update the

database.

F. Repeat this procedure at each remote panel to set

the panel address and number of circuits.

Panel 2 address = 02

Panel 3 address = 03

Etc.

Panel Setup

Panel Addressing

Load Setup

Emergency Setup

Afterhours Setup

Back

OK

Panel Addressing

Panel Address:

Master Programming Panel

Cancel

Next

01

B.

C.

Circuit Offset Setup

What is the first

system circuit number

in this panel?

Previous

Next

D.

001

Circuit Offset Setup

How many circuits

are in this panel?

Previous

Done

E.

36

Main Menu

Control Station Setup

Panel CCI Setup

Panel Setupetup

Scene Setup

Back

OK

A.

OK

OK

OK

OK

OK

Page 18

R

18 LCP128TM Setup and Maintenance Guide

STEP 1 (continued)

Module Type Setup

Your LCP128 system contains modules configured

with one or more outputs (circuits). The module

types are set by the model numbers of the panels

in the system. Complete the Module Type Table at

the back of this guide and then program the

module types for your system. The factory default

module type is X (4 Switches).

A. From the Main Menu use and to highlight

Panel Setup and press or (OK).

B. Use and to highlight Load Setup and press

or (OK).

C. Use and to highlight Module Type Setup and

press or (OK).

D. The Module Type Setup screen lists all the circuits.

To program a module, use and to select the

first circuit number in the module and and to

set the module type.

Module type options include:

X: Four-Circuit Switching (Relay) Module (XP)

S: One-output (circuit) Dimming Module (1U)

D: Two-output (circuit) Dimming Module (2U)

Q: Four-output (circuit) Dimming Module (4U)

E: Four-output (circuit) Electronic Low Voltage

Dimming Module (4E)

M: Four-output (circuit) Motor Module (4M)

F: Four-output (circuit) Quiet Fan Speed Module

(4FSQ)

Notes:

As you set each module type, the appropriate

circuit numbers are automatically assigned to the

module.

If you set the system size earlier in STEP 1, the

Module Type Setup screen lists only the circuits

used in your system.

E. When all the module types are set press or

(Done).

Load Setup

Module Type Setup

Chicago Setup

Low End Trim Setup

System Size

Back

OK

C.

Module Type Setup

001-004 - E:4 ELV

005-006 - D:2 dimmers

007-010 - X:4 switches

Cancel

Done

D.

011-014 - Q:4 dimmers

Panel Setup

Load Setup

Panel Addressing

Emergency Setup

Afterhours Setup

Back

OK

B.

OK

OK

OK

OK

Page 19

R

LCP128

TM Setup and Maintenance Guide 19

STEP 1 (continued)

Load Type Setup

Complete the Load Type Table at the back of this

guide and then program the load types for your

system circuits. The factory default load type for

each circuit is Non-Dim.

Note: If you are unsure of the load type for a

particular circuit, set the load type to Non-Dim

until the correct setting is determined.

A. From the Main Menu use and to highlight

Panel Setup and press or (OK).

B. Use and to highlight Load Setup and press

or (OK).

C. Use and to highlight Load Type Setup and

press or (OK).

D. The Load Type Setup screen lists all the circuits.

For each circuit, use and to select the circuit

and and to select the load type.

Load type options depend on the module type

assigned to the circuit:

Switching: Non-dim, DSI, 0-10V, DALI, PWM

Dimming: Incandescent, MLV (Magnetic Low

Voltage), Tu-Wire (ballasts), Neon, ELV (Electronic

Low Voltage), Non-dim, DSI, 0-10V, DALI, PWM

Motors: Motor

Fans: Fan

NNoottee::

Switching or dimming modules controlling

DSI, 0-10V, DALI, or PWM load types require

TVM(s).

E. When all the load types are set press or

(Done).

Load Type setup is now complete and all

settings are saved in the event of a power

failure.

Panel Setup

Load Setup

Panel Addressing

Emergency Setup

Afterhours Setup

Back

OK

B.

Load Setup

Load Type Setup

High End Trim Setup

Low End Trim Setup

Chicago Setup

Back

OK

C.

Load Type Setup

001 Dim - Incandescent

002 Dim - ELV

003 Relay - Non-Dim

Cancel

Done

D.

004 Dim - Tu-Wire

Caution! Failure to correctly assign load types

may damage loads, especially certain

electronic transformers, electronic ballasts,

and motors. Verify with the transformer or

ballast manufacturer that the product can be

dimmed with phase control dimming before

setting to any load type other than Non-Dim.

OK

OK

OK

OK

Page 20

R

20 LCP128TM Setup and Maintenance Guide

STEP 1 (continued)

High/Low End Trim Setup

High and low end trim settings limit the maximum

and minimum output of a dimming circuit. Levels

are set automatically when the load type is

assigned. You should change the high or low end

trim for a circuit only if the default setting needs to

be adjusted.

A. From the Main Menu use and to highlight

Panel Setup and press or (OK).

B. Use and to highlight Load Setup and press

or (OK).

C. Use and to highlight High End Trim Setup or

Low End Trim Setup and press or (OK).

D. For each dimming circuit, use and to select

the circuit and and to set the trim level. Nondimming, motor, and fan circuits are set to NA (not

any).

E. When all the trim levels are set press or

(Done).

Load Setup

High End Trim Setup

Load Type Setup

Low End Trim Setup

Chicago Setup

Back

OK

C.

High End Trim Setup

001 Dim - 90%

002 Dim - 95%

003 Relay - NA

Cancel

Done

D.

All Circuits -

Caution! Do not reduce the low end trim on a

fluorescent load type. This will decrease lamp

life and may damage ballasts.

OK

OK

OK

OK

Page 21

R

LCP128

TM Setup and Maintenance Guide 21

STEP 1 (continued)

Chicago Setup

This function is used to meet electrical installation

codes in the city of Chicago, IL (USA). This setting

limits how low a light level can be, including the

levels in the “off” scene. This setting can be

changed to a value from 10% to 60%, in 1%

increments.

A. From the Main Menu use and to highlight

Panel Setup and press or (OK).

B. Use and to highlight Load Setup and press

or (OK).

C. Use and to highlight Chicago Setup and

press or (OK).

D. Use and to select a circuit and and to

set the Chicago limit. When all the circuit limits are

set press or (Done).

Load Setup

Chicago Setup

Load Type Setup

Low End Trim Setup

High End Trim Setup

Back

OK

C.

Chicago Setup

Cancel

Done

D.

001 Dim - OFF

002 Dim - 10%

003 Relay - ON

All Circuits -

OK

OK

OK

OK

Page 22

R

22 LCP128TM Setup and Maintenance Guide

STEP 2

Time Clock Configuration

The LCP128 system can be programmed to initiate scenes and other actions automatically at either a specific

time of day or at a time relative to sunrise or sunset. It is important to configure the time clock as needed for

your location.

Time clock configuration includes:

• Selecting a time format (12 or 24 hour).

• Setting the time.

• Setting the date.

• Setting the location, either by country/city or longitude/latitude.

• Adjusting sunrise and sunset times to accommodate special circumstances.

• Selecting whether to use daylight savings time and, if so, what rules to use.

Page 23

R

LCP128

TM Setup and Maintenance Guide 23

STEP 2 (continued)

Time Format

A. From the Main Menu use and to highlight

Time Clock Setup and press or (OK).

B. Use and to highlight Setup Clock and press

or (OK).

C. Use and to highlight Time Format and press

or (OK).

D. Use and to specify 24 Hr. or AM / PM

(12 Hr). Press or (Done) to save changes.

Time

A. From the Setup Clock menu use and to

highlight Time and press or (OK).

B. Use and to change the current time. Use

and to alternate between hours and minutes.

C. Press or (Done) to save changes.

Date

A. From the Setup Clock menu use and to

highlight Date and press or (OK).

B. Use and to change the current date. Use

and to change between month, day, and year.

The first 2 digits are the month, the middle 2 are

the day, and the last 4 are the year.

C. Press or (Done) to save changes.

Time

: 35 AM

HH : MM

Cancel

Done

Date

/ 16 / 2004

MM / DD / YYYY

Cancel

Done

06

11

Setup Clock

Date

Location

Daylight Savings Time

Time Format

Back

OK

C.

B.

B.

Time Format

Specify by:

Cancel

Done

24 Hr.

D.

OK

OK

OK

OK

OK

OK

OK

OK

Page 24

R

24 LCP128TM Setup and Maintenance Guide

STEP 2 (continued)

Location

Note: Location must be set if using time clock

events relative to sunrise or sunset.

A. From the Setup Clock menu use and to

highlight Location and press or (OK).

B. Use and to select whether you want to set

the location by country and city (recommended) or

by latitude and longitude (if there are no nearby

cities listed). Press or (OK) when done.

Set Location Method

Country, City

Latitude, Longitude

Back

OK

B.

Set Time Zone

GMT -5:00 Eastern Time

GMT -4:00 Atlantic Time

GMT -3:30 Newfoundland

GMT -3:00 Brasilia

Previous

Next

Set Country

USA

Austria

Belgium

China

Cancel

Next

Specify Latitude, Longitude

Latitude Longitude

9 . 6 N 075 . 1 W

(DEGREES) (DEGREES)

Cancel

Next

3

C.

C.

D.

If Setting by Country and City

C. Use and to select the Country then press

or (Next).

In the USA, use and to select the State then

press or (Next).

D. Use and to select the City then press or

(Next).

If Setting by Latitude and Longitude

C. Use and to select the digit and use and

to set the latitude and longitude of your location in

degrees and press or (Next).

D. Use and to select the time zone for this

location and press or (Next). Values are listed

as an offset from Greenwich Mean Time.

Example: If your location is 39 degrees 36 minutes

north, enter 39.6N degrees. The minutes are

converted to a decimal of a degree by dividing by

60.

OK

OK

OK

OK

OK

OK

OK

Page 25

R

LCP128

TM Setup and Maintenance Guide 25

STEP 2 (continued)

Location (continued)

Adjusting Sunrise and Sunset

E. If needed, use this feature to shift your location’s

sunrise and sunset times by a fixed amount. This

can be useful if there is a geographic feature (such

as a mountain) that offsets the sunrise or sunset

time for your location by a fixed amount. This can

also be used to shift all time clock events that are

relative to sunrise and sunset after they have been

programmed.

If no offset is required, leave the offsets at 0:00

(default). Press or (Done) to save changes.

Note: Do not use this function to compensate for

daylight savings time. For procedures on how to

program daylight savings time settings, refer to

the next page.

Adjust Sunrise / Sunset

Sunrise Sunset

+ 00 : 00 + 00 : 00

Previous

Done

+

E.

OK

Page 26

R

26 LCP128TM Setup and Maintenance Guide

STEP 2 (continued)

Daylight Savings Time

Use this feature to set whether or not your location

uses daylight savings time. If it does, you can

configure when it starts and ends. When daylight

savings time is used, the time will change

automatically.

A. From the Setup Clock menu use and to

highlight Daylight Saving Time and press or

(OK).

B. Use and to set whether or not your location

uses daylight savings time, then press or

(Next).

C. If your location follows the United States rules for

daylight savings time (Starts on the 1st Sunday in

April, ends on the last Sunday in October at 2 AM,

offset by 1 hour) then select United States.

Otherwise select Other. Press or (Done) to

save changes.

D. If you select Other, you are prompted to enter the

rules. The default rules are set based on your

location. You will need to know:

• The start month, week, and day.

• The end month, week, and day.

• The number of minutes to adjust for daylight

savings time, up to 120 minutes.

Daylight Savings

Does this location

use daylight savings?

Yes

Cancel

Next

Daylight Savings

Current Setting

United States

Previous

Done

B.

C.

Setup Clock

Date

Location

Time

Daylight Saving Time

Back

OK

A.

OK

OK

OK

Page 27

R

LCP128

TM Setup and Maintenance Guide 27

STEP 3

Scene Modification

Scenes are stored lighting levels for each circuit in your system. Scenes can be used to create different lighting

effects using a programmed mix of dimming and switching settings.

The LCP128 system comes with 32 pre-configured scenes and 1 Off scene (see the table below for default

scene settings). As you program your system, you can assign these scenes to time clock events. For example,

at 6 PM each evening certain dimming circuit levels rise and additional circuits turn on. You can also assign

scenes to control station inputs (wallstation buttons, key switches, and contact closures). This way, any time a

button is pressed, key is turned, or contact closure is made, the system activates the desired scene.

In STEP 3, you can modify the preconfigured scenes as needed to create your own specific lighting

environments.

Note: In STEPS 4 and 5, you can also create additional custom scenes associated with a specific timeclock

event or control station input.

Scene

Default Settings

for Dimming Circuits

Default Settings

for Switching Circuits

Off OFF OFF

1 100% ON

2 75% ON

3 50% ON

4 25% ON

5 to 32 100% ON

Page 28

R

28 LCP128TM Setup and Maintenance Guide

STEP 3 (continued)

Modify Scenes

A. From the Main Menu use and to highlight

Scene Setup and press or (OK).

B. The Scene Modification screen lists the

preconfigured scenes stored in your system. Use

and to choose the scene you want to modify

and press or (Next).

C. The system lists each circuit and its current setting

for this scene. Use and to select a circuit and

and to change the setting for that circuit. To

simultaneously change all circuits, select All

Circuits and use and to change the setting.

Note: The All Circuits function enables you to

simultaneously adjust the percentage for all

dimming circuits or to turn all circuits off or on.

Scene circuit settings depend on the circuit type:

Switching: ON, OFF, --- (unaffected)

Dimming: OFF, 1 - 100%, --- (unaffected)

Motors: Open, Close, Stop, Jog Up, Jog Down,

--- (unaffected)

Fans: Low, Medium, Medium-High, High,

--- (unaffected)

Note: The --- (unaffected) setting means that the

circuit is not affected by this scene.

When you are finished modifying the scene press

or (Next).

D. The Select CCO Address screen is displayed only if

control station devices with contact closure outputs

(OMX-AV or OMX-CCO-8) have been entered into

the system (see STEP 4).

Use and to select the output to be associated

with the scene being programmed. The letter “A”

followed by a two digit number at the beginning of

each line refers to the the address of the device.

Use and to change the setting for that output:

maintained open, maintained close, momentary

pulse, or --- (unaffected).

When the outputs are programmed press or

(Done).

Example: A01 CCO2 is address1 contact closure

output 2.

E. For dimming circuits affected by the scene, use

and to set a fade time and press or (Next).

F. For a combination of dimming and switching

circuits, use and to set whether switches

react at Start of Fade or End of Fade. Then press

or (Done).

Scene Modification

Off Scene

Scene 01

Scene 02

Scene 03

Cancel

Next

B.

Scene 02

All Circuits -

001 Dim - 50%

002 Dim - 75%

003 Relay - ON

Previous

Next

C.

Select CCO Address

A01 CCO1 -Maintained Open

A01 CCO2 - ---

A01 CCO3 - --A01 CCO4 - ---

Previous

Next

D.

Scene 02 Fade Time

Fade Time:

20 sec

Previous

Next

E.

Scene 02 Switches

When do

switches react?

Start of Fade

Previous

Done

F.

OK

OK

OK

OK

OK

OK

Page 29

R

LCP128

TM Setup and Maintenance Guide 29

STEP 4

Control Stations

Control stations are connected to the LCP128 panel via the digital control link. Control stations can be

wallstations (with various numbers of buttons), key switches (NTOMX-KS), contact closure input and output

devices (OMX-AV), contact closure output devices (OMX-CCO-8), or OMX-RS232 interfaces. Each control

station must be assigned a unique address. Addressing may be found in either the LCP128 Installation Guide

or installation guides for the individual devices. To set the address, refer to the instructions for each device.

Every wallstation button, key switch, or contact closure input can be assigned one of the following functions:

• Scene - A scene consists of a specified light level and fade time. Each time the button, key switch, or contact

closure input is activated, the assigned circuits go to the programmed scene. A scene can also be used to

control contact closure outputs.

• Custom Scene - A custom scene is a scene assigned to and programmed for a specific button press, key

switch turn, or contact closure input. A custom scene may be recalled only by that single action to which it is

assigned.

• Lower Circuits - Assigned dimming circuits are progressively lowered as long as input is received from the

control station (for example, the button is held down, key is turned, contact closure is maintained). Circuits stay

at this setting until another event or control station input occurs.

• Raise Circuits - Assigned dimming circuits are progressively raised as long as input is received from the control

station (for example, the button is held down, key is turned, contact closure is maintained). Circuits stay at this

setting until another event or control station input occurs.

• Toggle - Each time the button, key switch, or contact closure input is activated, the assigned circuits toggle

between on and off. If the assigned circuits are in a mixed state (some on and some off), the circuits turn on.

• Delay To Off - Each time the button, key switch, or contact closure input is activated, the assigned circuit(s) turn

off after the preset amount of time (1 - 90 minutes).

• Enable Time Clock - Enable the function of the time clock.

• Disable Time Clock - Disable the function of the time clock.

Before proceeding with STEP 4, complete the Control Station Table at the back of this guide. Record

what each input (button, key switch, or contact closure) on each control station should do.

Note: In STEP 4, you will configure contact closure inputs wired to a Lutron OMX-AV control station.

Contact closure inputs wired directly to a panel are configured later in STEP 6.

Page 30

R

30 LCP128TM Setup and Maintenance Guide

STEP 4 (continued)

Configure the Wallstations

A. From the Main Menu use and to highlight

Control Station Setup and press or (OK).

B. Use and to choose the Address of the

wallstation you would like to configure and press

or (Next).

Note: The wallstation Address selected must

match the Address switch setting on the

wallstation.

C. Use and to set the Type to Wall Station and

press or (Next).

D. Use and to select whether the station has

Permanent Raise and Lower Buttons and press

or (Next).

E. Use and to set the Number of buttons and

press or (Next).

Note: Do not count raise/lower buttons.

F. Use and to select the Button you want to

program and press or (Next).

G. Use and to select the type of Action for this

button: Lower Circuits, Raise Circuits, Scene,

Custom Scene, Enable Time Clock, Disable

Time Clock, Delay to Off, Toggle, or No Action

and press or (Next).

Refer to the following pages to program each type

of action.

Control Station Setup

Address 01

Address 02

Address 03

Address 04

Cancel

Next

Address 03 Setup

Number of Buttons:

Previous

Next

03

Address 01 Setup

Button 01

Button 02

Button 03

Previous

Next

B.

E.

F.

Address 03 Button 01

Action:

Previous

Next

Lower Circuits

G.

Address 03 Setup

Type:

Previous

Next

Wall Station

C.

OK

OK

OK

OK

OK

OK

OK

Page 31

R

LCP128

TM Setup and Maintenance Guide 31

STEP 4 (continued)

Select Circuits

All Circuits - ---

001 Dim - 10%

002 Dim - 20%

003 Relay - ON

Previous

Next

Configure the Wallstations

(continued)

If Selecting a Scene Action

H. In step G, if you selected Scene, use and to

select the scene and press or (Done).

H.

Select CCO Address

A01 CCO1 - Maintained Open

A01 CCO2 - ---

A01 CCO3 - --A01 CCO4 - ---

Previous

Done

I.

Select Scene

Scene:

02

Previous

Done

H.

Custom Scene Fade Time

Fade Time:

20 sec

Previous

Next

J.

If Selecting a Custom Scene Action

H. In step G, if you selected Custom Scene, the

Select Circuits screen lists all the circuits. Use

and to select a circuit and and to change

the setting for that circuit. Or to simultaneously

change all circuits, select All Circuits and use

and to change the setting.

Note: The All Circuits function enables you to

simultaneously adjust the percentage for all

dimming circuits or to turn all circuits off or on.

Circuit settings depend on the circuit type:

Switching: ON, OFF, --- (unaffected)

Dimming: OFF, 1 - 100%, --- (unaffected)

Motors: Open, Close, Stop, Jog Up, Jog Down

Fans: Low, Medium, Medium-High, High

Note: The --- (unaffected) setting means the

circuit is not affected by this scene.

When the circuits are programmed for this custom

scene press or (Next).

I. The Select CCO Address screen is displayed only if

control station devices with contact closure outputs

(OMX-AV or OMX-CCO-8) have been entered into

the system.

Use and to select the output to be associated

with the button being programmed. Use and

to change the setting for that output: maintained

open, maintained close, momentary pulse, or

--- (unaffected). When the outputs are

programmed for this custom scene, press or

(Done).

J. For dimming circuits affected by the custom scene,

use and to set the Fade Time and press

or .

K. For a combination of dimming and switching

circuits, use and to set when the switches

react (Start of Fade or End of Fade). Then press

or .

Custom Scene Fade Time

When do

switches react?

Start of Fade

Previous

Done

K.

Address

number

Contact closure

output number

OK

OK

OK

OK

OK

Page 32

R

32 LCP128TM Setup and Maintenance Guide

STEP 4 (continued)

Configure the Wallstations

(continued)

If Selecting a Delay to Off Action

H. In step G, if you selected Delay to Off, use and

to set the Time to Off and press or .

I. The Assign Circuits screen lists all the circuits.

Unassigned circuit numbers have hash lines going

through them. Move the cursor to a circuit number

and press to toggle between Assigned and

Unassigned (dashed). All circuits can be toggled

by selecting ALL Circuits and pressing . When

the circuits are programmed press .

J. For dimming circuits affected by the action, use

and to set the Fade Time and press or .

K. For a combination of dimming and switching

circuits, use and to set when the switches

react (Start of Fade or End of Fade). Then press

or .

Set Delay Time

Time to Off:

10 min

Previous

Next

H.

Assign Circuits

PRESS OK TO SELECT CIRCUIT

ALL Circuits

001 002 003 004

005 006 007 008

Previous

Done

I.

If Selecting a Lower Circuits, Raise

Circuits, or Toggle Action

H. In step G, if you selected Lower Circuits, Raise

Circuits, or Toggle, the Assign Circuits screen lists

all the circuits. Unassigned circuits are presented as

numbers with hash lines going through them.

Move the cursor to a circuit number and press to

toggle between Assigned and Unassigned

(dashed). All circuits can be toggled by selecting

ALL Circuits and pressing . When the circuits

are programmed press .

I. For dimming circuits affected by the action, use

and to set the Fade Time.

J. For a combination of dimming and switching

circuits, use and to set when the switches

react (Start of Fade or End of Fade). Then press

or .

Assign Circuits

PRESS OK TO SELECT CIRCUIT

ALL Circuits

001 002 003 004

005 006 007 008

Previous

Done

001

H.

001

OK

OK

OK

OK

OK

OK

OK

OK

Page 33

R

LCP128

TM Setup and Maintenance Guide 33

STEP 4 (continued)

Configure Key Switch

(NTOMX-KS)

Lutron’s NTOMX-KS key switch control station can

be programmed to initiate an action for a clockwise

and counter-clockwise turn.

A. From the Main Menu use and to highlight

Control Station Setup and press or (OK).

B. Use and to highlight the address of the

NTOMX-KS you would like to configure and press

or (Next).

C. Use and to change control type to

Key Switch and press or (Next).

D. Use and to highlight which direction turn to

program and press or (Next). Each key

switch can be programmed for a clockwise or

counter-clockwise turn. Both may be programmed.

E. Use and to select the type of Action for this

key turn: Lower Circuits, Raise Circuits, Scene,

Custom Scene, Enable Time Clock, Disable

Time Clock, Delay to Off, Toggle, and No Action

and press or (Next). Refer to the beginning of

STEP 4 for an explanation of the various action

types.

F. Program the Lower Circuits, Raise Circuits,

Scene, Custom Scene, Delay to Off, or Toggle

action using the same screen methods used to

configure a wallstation button. Refer to “Configure

the Wallstations” earlier in STEP 4.

Address 03 Setup

Type:

Key Switch

Previous

Next

Main Menu

Overrides

Time Clock Setup

Control Station Setup

Panel CCI Setup

Back

OK

Control Station Setup

Address 01

Address 02

Address 03

Address 04

Cancel

Next

A.

B.

C.

Address 03 Setup

Clockwise Turn

Counter - Clockwise Turn

Previous

Next

D.

Address 03 Key Switch

Action:

Previous

Next

Scene

F.

OK

OK

OK

OK

OK

Page 34

R

34 LCP128TM Setup and Maintenance Guide

STEP 4 (continued)

Configure Contact Closure

Inputs on OMX-AV

Lutron’s OMX-AV control station can be

programmed to initiate actions for up to five contact

closure inputs.

Note: For contact closure inputs wired directly to

the LCP128 panel, refer to STEP 6.

A. From the Main Menu use and to highlight

Control Station Setup and press or (OK).

B. Use and to highlight the address of the

OMX-AV you would like to configure and press

or (Next).

C. Use and to set the control Type to OMX-AV

and press or (Next).

D. Each OMX-AV provides 5 inputs. Use and to

highlight the Contact Closure Input (CCI) to

program and press or (Next). Or select

No CCI’s if only the contact closure outputs (CCOs)

are being used.

E. Use and to select whether you want define an

action for when the contact opens or when it

closes and press or (Next).

Note: If there should be an action on both, first

set up the Open Action, then follow this

procedure again but choose Closure Action.

F. Use and to select the type of Action for this

CCI: Lower Circuits, Raise Circuits, Scene,

Custom Scene, Enable Time Clock, Disable

Time Clock, Delay to Off, Toggle, and No Action

and press or (Next). Refer to the beginning of

STEP 4 for an explanation of the various action

types.

G. Program the Lower Circuits, Raise Circuits,

Scene, Custom Scene, Delay to Off, or Toggle

action using the same screen methods used to

configure a wallstation button. Refer to “Configure

the Wallstations” earlier in STEP 4.

Address 03 Setup

Type:

OMX-AV

Previous

Next

Address 03 CCI 2 Setup

Open Action

Closure Action

Previous

Next

Main Menu

Overrides

Time Clock Setup

Control Station Setupetup

Panel CCI Setup

Back

OK

Control Station Setup

Address 01

Address 02

Address 03

Address 04

Previous

Next

A.

B.

C.

E.

Address 03 OMX-AV

No CCI’s

CCI 01

CCI 02

CCI 03

Previous

Next

D.

OK

OK

OK

OK

OK

OK

Page 35

R

LCP128

TM Setup and Maintenance Guide 35

STEP 4 (continued)

Integration through RS232

Lutron’s OMX-RS232 control station enables you to

integrate your LCP128 system with a building

management system.

A. From the Main Menu use and to highlight

Control Station Setup and press or (OK).

B. Use and to highlight the address of the

OMX-RS232 you would like to configure and press

or (Next).

C. Use and to change control Type to OMX-

RS232 and press or (Done).

Using the GRAFIK 6000

RS232 protocol.

The OMX-RS232 is packaged and shipped with a

protocol document that details how to execute

each command. Only a subset of the commands

in that document work with the LCP128 system

and they are listed below:

Command LCP128 Function

Fade to Level: Sets a pattern or time

delay to off

Multilevel: Flash circuits

Get Level: Request level

Simulate

Press: Simulate button press

Simulate

Release: Simulate button release

Enable

Control

Stations: Enable control stations

Disable

Control

Stations: Disable control stations

Set Clock: Sets time and date

Time Now: Request time

Astro Times: Request sunrise / sunset times

Date: Request date

Enable

Time clock: Enable time clock

Disable

Time clock: Disable time clock

Address 03 Setup

Type:

OMX-RS232

Previous

Done

Main Menu

Overrides

Time Clock Setup

Control Station Setupetup

Panel CCI Setup

Back

OK

Control Station Setup

Address 01

Address 02

Address 03

Address 04

Previous

Next

A.

B.

C.

OK

OK

OK

Page 36

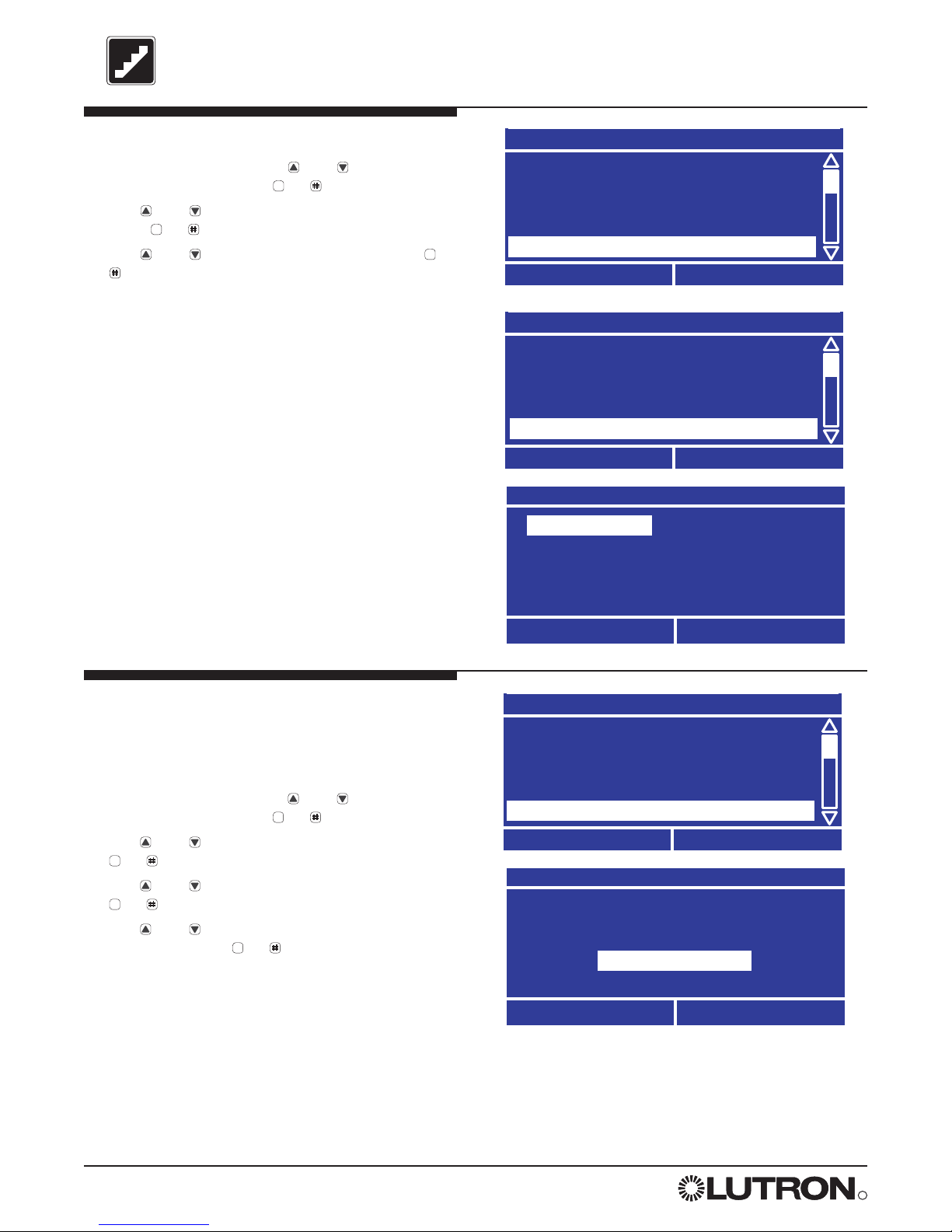

R

36 LCP128TM Setup and Maintenance Guide

STEP 5

Time Clock Events

Time clock events enable the system to initiate a scene or start/end afterhours mode at either a specific time of

day or at a time relative to sunrise or sunset. 47 schedules are available—one for every day of the week, and 40

holiday schedules. There can be a total of up to 500 events and no more than 25 on any day / holiday. Holiday

schedules always override the weekly schedule.

The options for time clock events are:

• Scene or Custom Scene - The assigned circuits go to the programmed scene/custom scene settings.

• Enable or Disable Controls - Enable or disable the function of control stations.

• Afterhours Start - Starts an energy saving mode that is used to turn lights off at the end of normal hours until

the beginning of the next day. First, a scene or pattern of circuit levels is recalled for the space (Afterhours

Start). Circuits programmed to turn off flash to warn any occupants that they are about to go out (number of

flashes specified by Flash Count). Lights remain on to allow the occupant a chance to press a button to keep

lights on (length of time is programmed as Off Delay). Finally, if a button has not been pressed, lights turn off

automatically at the end of the delay period.

If a button is pressed, occupancy sensor tripped, or another timeclock event occurs while the system is in

Afterhours mode or in Off Delay, lights turn on and remain on for the programmed number of minutes, (Warn

Time) then flash (number specified by Flash Count) and then turn off after the Off Delay.

• Afterhours End - When afterhours ends, the circuits are returned to their programmed state.

Example Scenario for Afterhours:

A. Afterhours start event—afterhours scene is recalled. The circuits that are going to turn off start to flash and off

delay starts counting down.

B. System enters afterhours.

C. Button is pressed to turn lights on.

D. Lights flash notifying they will be turning off soon.

E. Button is pressed to keep lights on.

F. Lights flash notifying they will be turning off soon.

G. Lights turn off.

H. Afterhours end event.

Before proceeding with STEP 5, complete the Time Clock Event Table located at the back of this guide.

Record when each event should occur and what it should do.

Off

Delay

Off

Delay

Off

Delay

Warn Time

Warn Time

Afterhours

A

B

C

D

E

F

G

H

Page 37

R

LCP128

TM Setup and Maintenance Guide 37

Adding Weekly Events

Weekly events occur each week on a specific day.

A. From the Main Menu use and to highlight

Time Clock Setup and press or (OK).

B. Use and to highlight Add Event and press

or (OK).

C. Use and to highlight Add Weekly Event and

press or (OK).

D. Use and to select the Day to which you

would like to add the event and press or

(Next).

E. Use and to select Fixed Time or at a time

relative to Sunset or Sunrise. Press to adjust

the time or offset. Adjust the time using and

and press or (Next).

F. Use and to select the desired Action for the

event: Scene, Custom Scene, Enable or Disable

Controls, Afterhours Start, or Afterhours End

and press or (Next). Refer to the beginning of

STEP 5 for an explanation of the various action

types.

Note: For Afterhours End, this step is complete.

Event Time

Type Time

Fixed Time

08:00 AM

Previous

Next

Event Time

Type Time

Sunrise +

00:15

HH : MM

Previous

Next

STEP 5 (continued)

Time Clock Setup

Setup Clock

Add Event

Copy Events

View / Modify Events

Back

OK

Fixed

Sunrise

B.

E.

Add Weekly Event

Cancel

Next

D.

Select Day:

Sunday

Add Event

Add Weekly Event

Add Holiday Event

Back

OK

C.

OK

OK

OK

OK

OK

OK

Page 38

R

38 LCP128TM Setup and Maintenance Guide

STEP 5 (continued)

Adding Weekly Events

(continued)

If Selecting a Scene Action

G. In step F, if you selected Scene, use and to

select the desired scene and press or (Done).

To add another event to this same schedule, select

Yes when prompted “Modify More Events?”

Select Scene

Previous

Done

G.

If Selecting an Afterhours Start Action

G. In step F, if you selected After Hours Start, choose

Select Scene or Set Circuit Level. Then press

or (Next).

H. Select the scene or set the circuit levels to be used

for afterhours mode. Then press or (Done).

Refer to the beginning of STEP 5 for a detailed

description of how afterhours mode works.

To add another event to this same schedule, select

Yes when prompted “Modify More Events?”

Note: You will set the afterhours warn time, flash

count, and off delay later in STEP 5.

If Adding a Custom Scene Action

G. In step F, if you selected Custom Scene, set the

circuit settings for the custom scene. Then press

or (Done).

To add another event to this same schedule, select

Yes when prompted “Modify More Events?”

Select Circuits

All Circuits - ---

001 Dim - 10%

002 Dim - 20%

003 Relay - ON

Previous

Done

G.

Scene:

03

Afterhours Setup

Select Scene

Set Circuit Levels

Previous

Next

G.

OK

OK

OK

OK

Page 39

R

LCP128

TM Setup and Maintenance Guide 39

STEP 5 (continued)

Adding Holiday Events

Holiday events occur on a specific date and can

last for 1 to 90 days.

A. From the Main Menu use and to highlight

Time Clock Setup and press or (OK).

B. Use and to highlight Add Event and press

or (OK).

C. Use and to highlight Add Holiday Event and

press or (OK).

D. Use and to select the holiday to which you

would like to add the event and press or

(Next).

To define a new holiday, select New Holiday.

• Enter the start date of the holiday.

• Enter the duration of the holiday. For example,

New Year’s might be defined as starting on

December 31st and lasting 2 days (Dec 31 and

Jan 1).

E. Use and to select Fixed Time or at a time

relative to Sunset or Sunrise. Press to adjust

the time or offset. Adjust the time using and

and press or (Next).

F. Use and to select the desired Action for the

event: Scene, Custom Scene, Enable or Disable

Controls, Afterhours Start, or Afterhours End

and press or (Next). Refer to the beginning of

STEP 5 for an explanation of the various action

types.

Program the action using the same method as for a

weekly event. Refer to “Adding Weekly Events”

earlier in STEP 5.

Note: For Afterhours End, this step is complete.

Add Holiday Event

Select Holiday:

Add New Holiday

Cancel

Next

Holiday Start Date

12 / 31

MM / DD

Previous

Next

Holiday Duration

Number of Days:

Previous

Next

02

Add Event

Add Weekly Event

Add Holiday Event

Back

OK

C.

D.

OK

OK

OK

OK

OK

OK

Page 40

R

40 LCP128TM Setup and Maintenance Guide

STEP 5 (continued)

Copying Events

A. From the Main Menu use and to highlight

Time Clock Setup and press or (OK).

B. Use and to highlight Copy Events and press

or (OK).

C. Use and to highlight Copy Weekly Event or

Copy Holiday Event and press or (OK).

D. Use and to select the day of the week or

holiday you would like to copy from and press or

(Next).

E. Use and to select the event you would like to

copy and press or (Next). If you would like to

copy all events programmed for this day or holiday,

select All Events.

F. Use and to select the day or holiday you

would like to paste to and press or (Done).

Holidays appear after the weekdays in the list. To

add a new holiday, select New Holiday at the end

of the list and then modify the existing holiday’s

information to save it as a new holiday

To paste the event to another day or holiday, select

Yes when prompted to “Paste Again?”.

Select Event to Copy

Sun - All Events

Sun - Fixed 08:00 AM

Sun - Sunrise +0:15

Sun - Sunset -0:30

Previous

Next

Paste Event To

Day:

Previous

Done

Deleting Events

A. From the Main Menu use and to highlight

Time Clock Setup and press .

B. Use and to highlight Delete Event.

C. Use and to highlight Delete Weekly Event or

Delete Holiday Event.

D. Use and to select the day of the week or

holiday you would like to delete from.

E. Use and to select the event you would like to

delete. If you would like to delete all events for that

schedule, select All Events.

F. You are asked to confirm deleting the event(s).

Press Yes to delete, otherwise press No.

To delete another event from that day or holiday,

select Ye s when prompted to “Delete Another?”.

Select Event to Delete

Sun - All Events

Sun - Fixed 08:00 AM

Sun - Sunrise +0:15

Sun - Sunset -0:30

Previous

Done

Time Clock Setup

Add Events

Copy Events

View / Modify Event

Delete Event

Back

OK

Friday

E.

F.

B.

E.

OK

OK

OK

OK

OK

OK

OK

Page 41

R

LCP128

TM Setup and Maintenance Guide 41

STEP 5 (continued)

Afterhours Setup

A. From the Main Menu use and to highlight

Panel Setup and press or (OK).

B. Use and to highlight Afterhours Setup and

press or (OK).

C. Use and to set a Warn Time, from 1 to 180

minutes and press or (Next).

D. Use and to set the Flash Count, from 1 to 15

flashes and press or (Next).

E. Use and to set an Off Delay, from 1 to 180

minutes and press or (Done).

Notes: