Page 1

Attention Contractors...

LUTRON

4000 Series

Installer’s Guide

A Step-by-Step Guide for Installing,

Operating and Maintaining a Complete

Lutron GRX-4000 Series System with

XP Series Switching Panels

1

Page 2

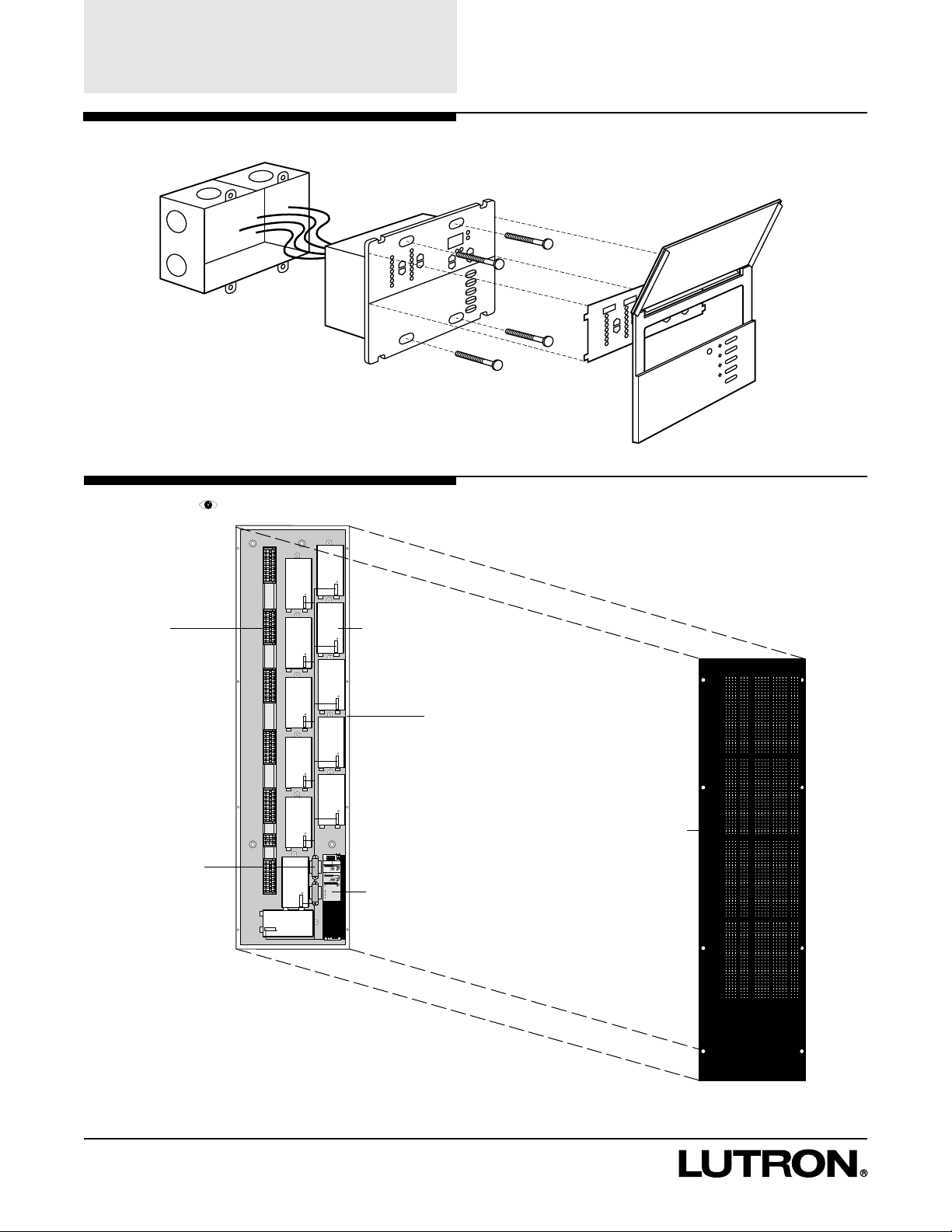

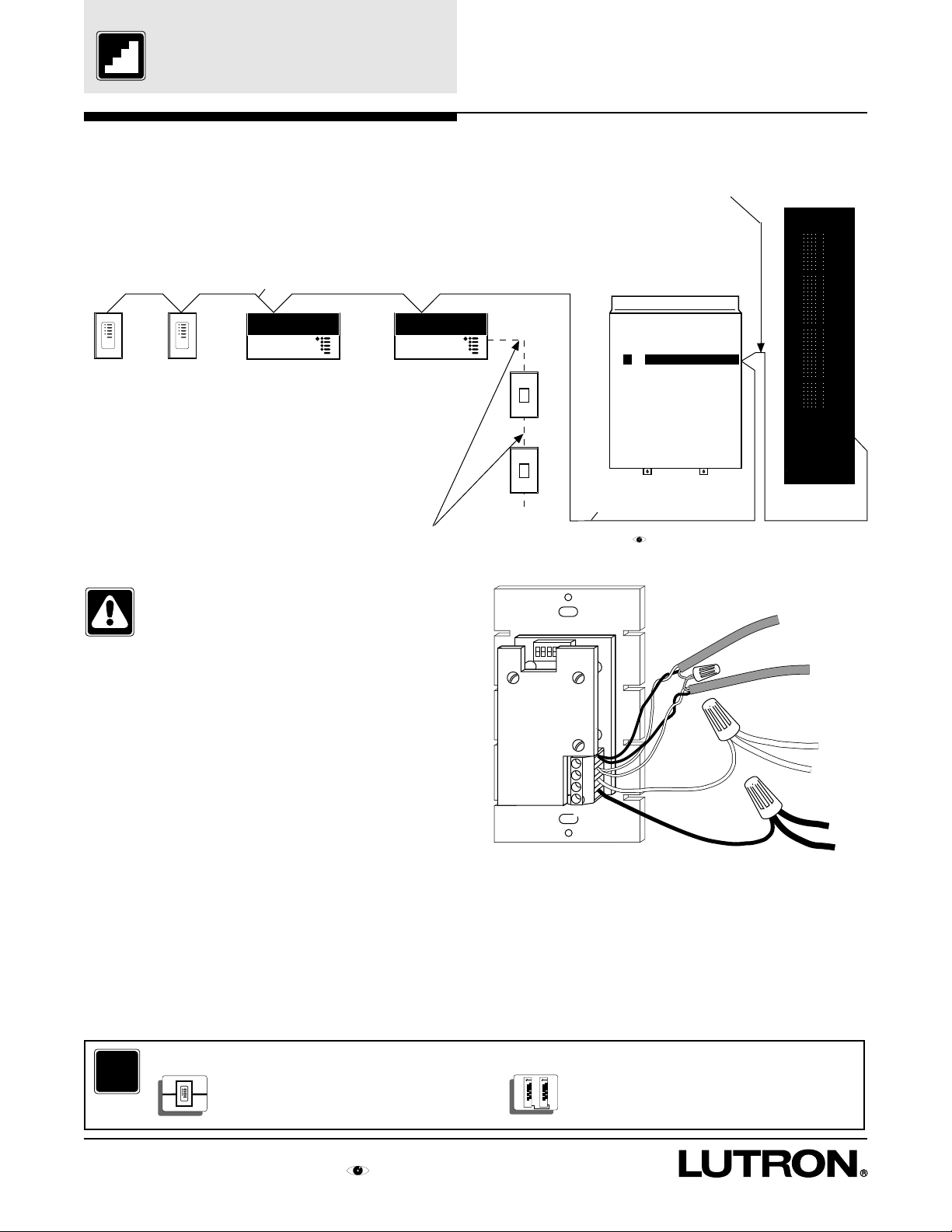

Overview

GRX-4000 Series Control Unit

GRAFIK Eye XP Series Panel

TERMINAL BLOCKS

CLASS 2 TRANSFORMERS

SWITCHING MODULE

PANEL

N

N

H

H

12345

Power (Pins

Link

Data (Pins

S

elecCircui

1

2

Circ

VIEV

AL

S

elecValu

3

4

Val

S

elecValuDisplay

5

Load

1

4 Non-

2

5 Elec.

_

3

Unassig

Control and Zone

Using circuit

Using Zone

T

Low End (optio

High End (optio

Circuit

R

LUTR

R

LUTR

CIRCUIT SELECTOR

COVER

2

Page 3

Table of Contents

B

e

l

i

e

v

eit

o

r

n

o

t

,

t

h

i

s

i

s

s

u

p

p

o

s

e

d

t

o

l

o

o

k

l

i

k

e

a

d

i

c

t

i

o

n

a

r

y

!

T

h

i

s

i

c

on

w

a

s

c

r

e

a

t

e

d

b

y

B

r

e

n

t

M

.

N

y

e

,

J

u

l

y

6

,

1

9

9

5

.

B

e

l

i

e

v

eit

o

r

n

o

t

,

t

h

i

s

i

s

s

u

p

p

o

s

e

d

t

o

l

o

o

k

l

i

k

e

a

d

i

c

t

i

o

n

a

r

y

!

T

h

i

s

i

c

on

w

a

s

c

r

e

a

t

e

d

b

y

B

r

e

n

t

M

.

N

y

e

,

J

u

l

y

6

,

1

9

9

5

,

u

n

d

e

r

the

d

i

r

e

c

t

i

o

n

o

f

D

e

r

e

k

R

.

T

h

o

m

a

s

.

T

h

i

s

i

c

on

w

a

s

c

r

e

a

t

e

d

b

y

B

r

e

n

t

M

.

N

y

e

,

J

u

l

y

6

,

1

9

9

5

.

B

e

l

i

e

v

eit

o

r

n

o

t

,

t

h

i

s

i

s

s

u

p

p

o

s

e

d

t

o

l

o

o

k

l

i

k

e

a

d

i

c

t

i

o

n

a

r

y

!

T

h

i

s

i

c

on

w

a

s

c

r

e

a

t

e

d

b

y

B

r

e

n

t

M

.

N

y

e

,

J

u

l

y

6

,

1

9

9

5

.

B

e

l

i

e

v

eit

o

r

n

o

t

,

t

h

i

s

i

s

s

u

p

p

o

s

e

d

t

o

l

o

o

k

l

i

k

e

a

d

i

c

t

i

o

n

a

r

y

!

T

h

i

s

i

c

on

w

a

s

c

r

e

a

t

e

d

b

y

B

r

e

n

t

M

.

N

y

e

,

J

u

l

y

6

,

1

9

9

5

.

B

e

l

i

e

v

eit

o

r

n

o

t

,

t

h

i

s

i

s

s

u

p

p

o

s

e

d

t

o

l

o

o

k

l

i

k

e

a

d

i

c

t

i

o

n

a

r

y

!

T

h

i

s

i

c

on

w

a

s

c

r

e

a

t

e

d

b

y

B

r

e

n

t

M

.

N

y

e

,

J

u

l

y

6

,

1

9

9

5

.

u

n

d

e

r

the

d

i

r

e

c

t

i

o

n

o

f

D

e

r

e

k

R

.

T

h

o

m

a

s

.

T

h

i

s

i

c

on

w

a

s

c

r

e

a

t

e

d

b

y

B

r

e

n

t

M

.

N

y

e

,

J

u

l

y

6

,

1

9

9

5

.

B

e

l

i

e

v

eit

o

r

n

o

t

,

t

h

i

s

i

s

s

u

p

p

o

s

e

d

t

o

l

o

o

k

l

i

k

e

a

d

i

c

t

i

o

n

a

r

y

!

T

h

i

s

i

c

on

w

a

s

c

r

e

a

t

e

d

b

y

B

r

e

n

t

M

.

N

y

e

,

J

u

l

y

6

,

1

9

9

5

.

Step-by-Step Instructions

Install System Page

STEP 1: Mount Wallboxes ................................... 2

STEP 2: Mount Panels....................................... 2,3

STEP 3: Wire System......................................... 4,5

STEP 4: Set Address Switches..............................6

STEP 5: Set Function Switches.............................7

STEP 6: Install Controls.........................................8

Start Up System

STEP 7: Activate Loads in Bypass........................8

STEP 8: Activate Controls..................................... 9

STEP 9: Assign Load T ypes................................10

STEP 10: Address GRX-4000 Control Units......... 11

STEP 11: Remove Bypass Jumpers..................... 12

STEP 12: Check System....................................... 13

Reference Sheets

Look Inside a Panel Page

XP

XP Series Panels..................................20

Set Up System Page

STEP 13: Assign Zones.........................................14

STEP 14: Set Up Scenes on the GRX-4000......... 15

STEP 15: Set Up Accessory Controls...............16,17

STEP 16: Set Normal/Emergency Switch............. 18

Troubleshooting Guide Page

Troubleshooting Guide.......................24,25

Control Wiring

Accessory to Control Unit to Panel .......21

Panel to Panel ......................................22

Circuit Selector

Circuit Selector Functions.....................23

Directories

Circuit Directory ......................................26

Control Directory.....................................27

Maintenance

Maintenance ...........................................28

Glossary of Terms

Glossary of Terms...................................29

Table of Contents for GRAFIK Eye Switching Panel

3

Page 4

Mount Wallboxes and

Panels

STEP 1: Mount Wallboxes

Use wallboxes with a minimum depth of 2-3/4"

(70mm) for Accessory Controls and 3-1/2" (89mm)

for GRX-4000 Series Control Units.

Multigang installations may require spacers between

wallboxes.

Mount wallboxes flush to 1/8" (3mm) below finished

wall surface.

Finished wall should not have gaps around the

wallbox of greater than 1/8" (3mm).

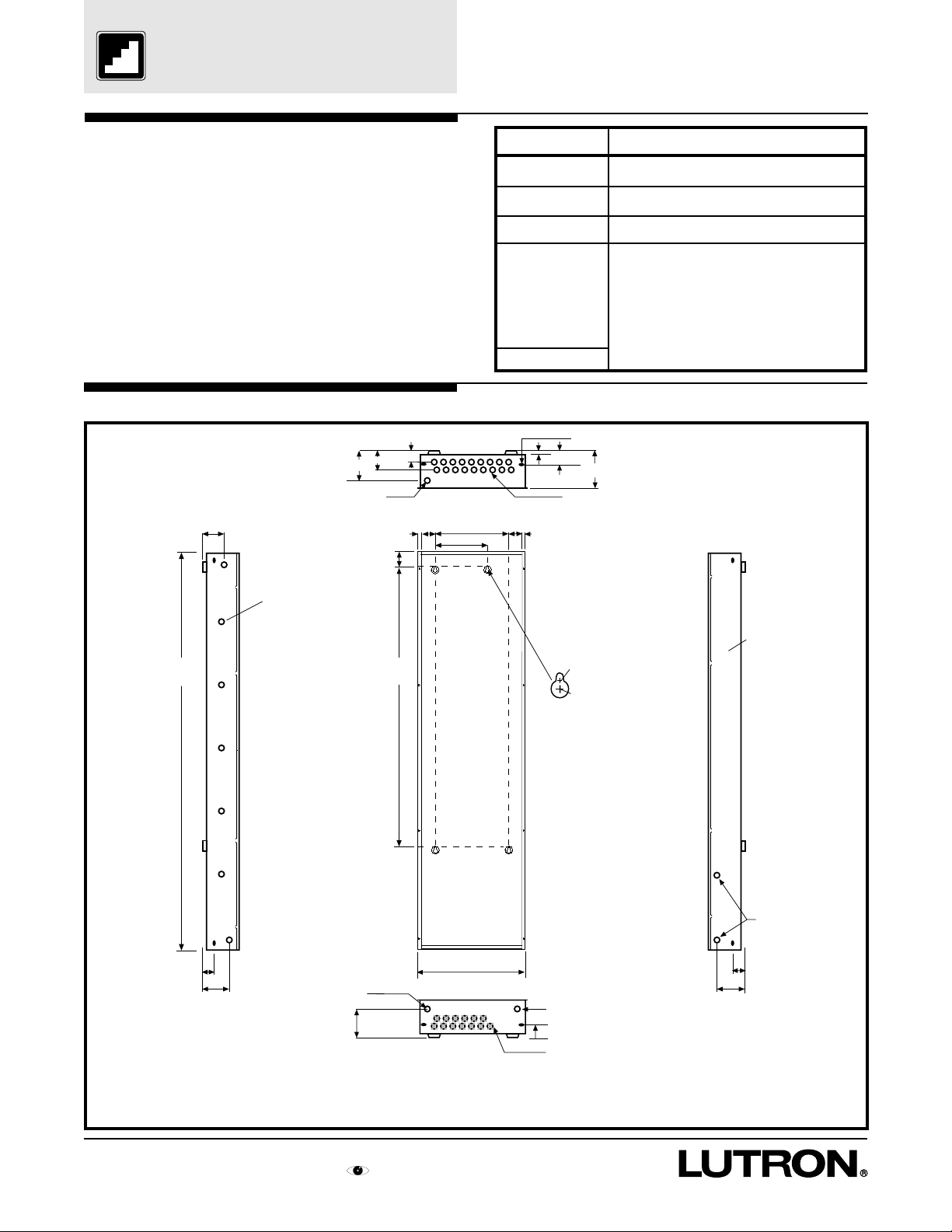

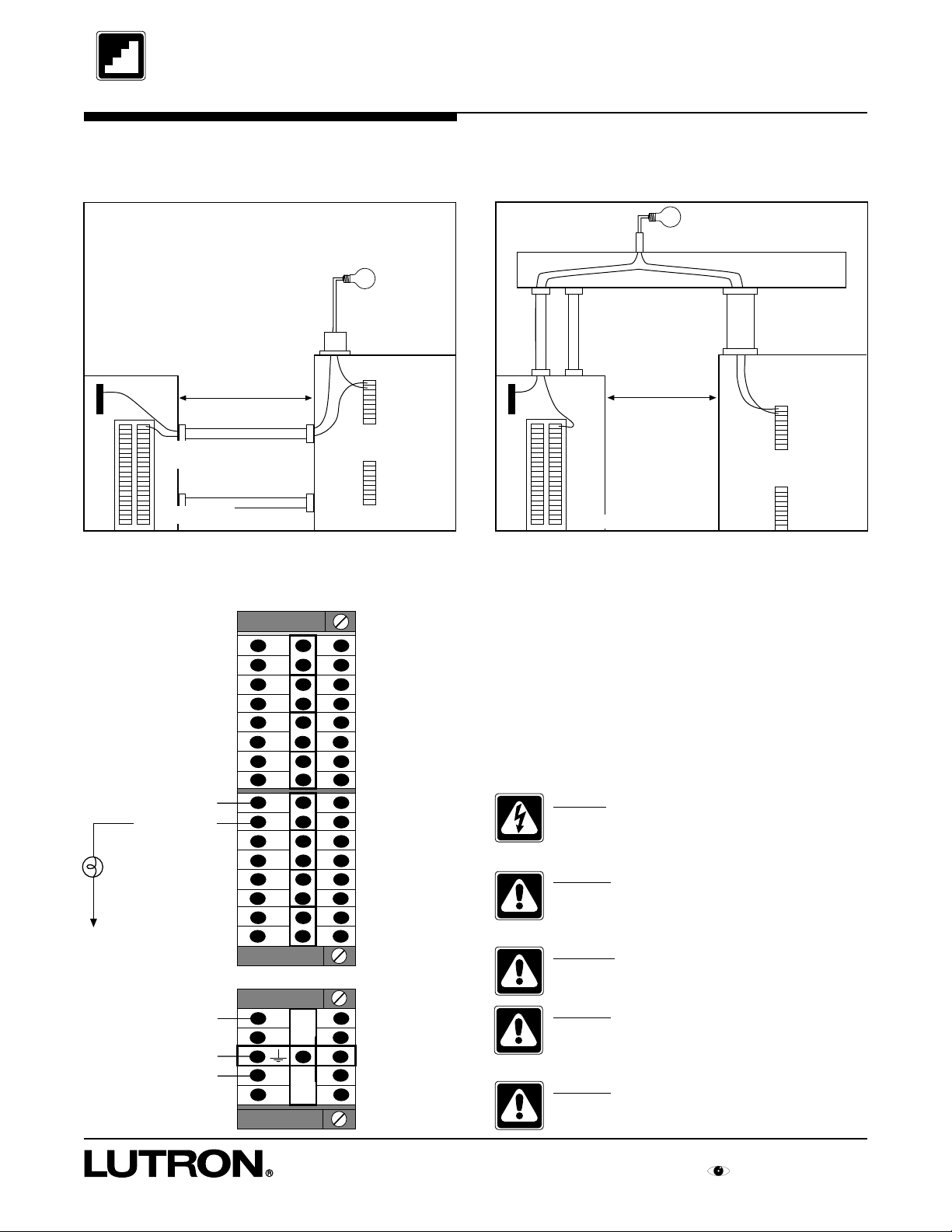

STEP 2: Mount Panels

XP Series

(Dimensions and Conduit Entry)

2"

2-5/16" (6.7cm)

Preferred feed and load

wire entry—may be

expanded to 2" max.

2-1/8"

2-7/16"

(6.2cm)

3/8"

3/4"

1-5/8"

Top View

11" (28 cm)

8" (20 cm)

Control

GRX-CIR

GRX-4S-DW

GRX-AV‘s

GRX-4000 Series

Control Units

2 zone (2 gang)

3 zone (3 gang)

4 zone (4 gang)

6 zone (4 gang)

8 zone (4 gang)

All Others (1 gang)

Slot for recessed mounting

1/8"

3/8"

screws (8 places)

1"

4-1/16" (10.3cm)

7/8" diameter knock out (44 places)

Wallbox

Mounts in Ceiling with special mounting ring (provided)

Lutron # 241-399 (provided)

1900 Box (4"x4" junction box) or Lutron #241-496

Lutron # 241-519 3-1/2" (89mm) deep

(1 gang each, gangable)

or

2-3/4" (70mm), 3-1/2" (89mm) deep US Wallbox

Left side may

be punched

59"

(150cm)

Left Side Right Side

1

2-1/4"

WHEN SURFACE MOUNTING, THE KEYHOLE

ACCEPTS A MAXIMUM OF 1/4" MOUNTING

BOLT (1/4" IS RECOMMENDED)

WHEN FLUSH MOUNTING, MOUNT PANEL

FLUSH TO 1/8" (3MM) BELOW FINISHED WALL

SURFACE

Front View

Second preferred feed and

load wire entry—may be

extended to 2" max.

2-5/16" (5.9cm)

41-3/4"

(106cm)

15-1/8" (38.4cm)

Bottom View

.312 dia.

.624 dia.

Keyholes for

surface mounting

(4 places)

Class 2 (SELV) only

alternate control

wiring entry

1" (2.5cm)

No entrance on all

x'd out knockouts

READ THE MAINTENANCE REFERENCE SHEET

BEFORE PAINTING THE PANEL OR COVER

2-1/4"

(5.7cm)

1"

No entrance on right

side except Class 2

knockouts

Class 2 (SELV) only

control wiring entry

2

Step by Step instructions for GRAFIK Eye Switching Panel

Page 5

Mount Wallboxes and

Panels

STEP 2: Mount Panels (cont.)

FEED AND LOAD

CIRCUIT WIRING

DISTRIBUTION

PANEL

ALTERNATE

FEED AND

LOAD CIRCUIT

WIRING

Suggested Surface Mount

CEILING

CLASS 2 (SELV)

WIRING TO

CONTROLS

N

N

H

H

12345

Power (Pins

Link

Data (Pins

S

elecCircui

1

2

Circ

VIEV

AL

S

elecValu

3

4

Val

S

elecValuDisplay

5

Load

4 Non-

1

5 Elec.

2

_

Unassig

3

Control and Zone

Using circuit

Using Zone

T

Low End (optio

High End (optio

Circuit

LUTR

R

R

LUTR

WALL

FEED AND LOAD

CIRCUIT WIRING

DISTRIBUTION

PANEL

ALTERNATE

FEED AND

LOAD CIRCUIT

WIRING

Suggested Recess Mount

CEILING

CLASS 2 (SELV)

WIRING TO

CONTROLS

N

N

H

H

12345

Power (Pins

Link

Data (Pins

S

elecCircui

1

2

Circ

VIEV

AL

S

elecValu

3

4

Val

S

elecValuDisplay

5

Load

1

4 Non-

2

5 Elec.

_

3

Unassig

Control and Zone

Using circuit

Using Zone

T

Low End (optio

High End (optio

Circuit

LUTR

R

R

LUTR

WALL

Front View Side View Front View Side View

Notes:

• Keep length of raceway below 24" to avoid possible

derating (per NEC code for 10 or more conductors).

• Panel generates heat (see table at right). Mount

only where ambient temperature will be 0-40°C

(32°F-104°F).

• Reinforce wall structure as required for weight and

local codes.

• Panel clearances are 1-1/2" (38mm) to each side.

• Distribution Panel not included with XP Series Panel.

• Indoor Use Only. Type 1 enclosure.

• Relative Humidity < 90% non-condensing.

• XP Panels should be mounted within 7° of true

vertical.

For More Information...

?

Look inside an XP........................... 20

XP

Weight w/o PackagingPanel

55 lbs (25 kg)

60 lbs (27 kg)

70 lbs (32 kg)

XP-24

XP-32

XP-48

Max BTU/Hrs.

310

350

430

Caution - Internal relays will click while in

operation. Mount where audible noise is

acceptable.

Caution - Where and how the XP panel is

mounted may depend upon the wiring

method you choose (see step 3).

Step by Step instructions for GRAFIK Eye Switching Panel

3

Page 6

Wire System

STEP 3: Wire System

GRX Wiring

2 #12 AWG (2.5mm2) FROM TERMINALS 1 TO 1, AND 2 TO 2

2 #18 AWG (1.0mm

BELDEN #9461 OR ALPHA #2211 ARE #22 AWG AND ARE RECOMMENDED.

ALL 4 WIRES ARE AVAILABLE IN ONE CABLE FROM LIBERTY CABLE AT 1-800-530-8998.

LIBERTY P/N IS LUCOM-12/22-RBL

NOTE: TOTAL LENGTH OF WIRE MAY BE NO MORE THAN 2000 FEET FOR #12 AWG

2

) TWISTED SHIELDED PAIR FROM TERMINALS 3 TO 3, AND 4 TO 4 -

(450m for 2.5mm

2

).

CLASS 2 WIRING

FOR PANEL TO PANEL WIRING, INCLUDE AN ADDITIONAL 1 #18 AWG (1.0mm

BETWEEN PANELS FROM TERMINALS 5 TO 5.

NOTE: WIRING LIMITATIONS INCLUDE

PANEL TO PANEL WIRING.

2

)

SEQUENCE

ZONE LOCK

SCENE LOCK

FADE OVERRIDE

ACCESSORY

CONTROLS

(16 MAX.)

NTGRX-4S

NTGRX-4S-IR

GRX-CIR

GRX-4S-DW

NTGRX-RL

NTGRX-4Q

NTGRX-4PS

NTGRX-4M

GRX-AV

GRX-AV-SER

GRX-AV-RS232

GRX-AV-RS232/ATC

NTGRX-2B

SEQUENCE

ZONE LOCK

SCENE LOCK

FADE OVERRIDE

LUTRON

GRX-4000 SERIES CONTROL UNITS

# = 1 for GRX-4100’s, 5 for GRX-4500’s

2 #18 AWG (1mm

SSA AND SSARET OF THE

INDIVIDUAL CONTROL UNIT TO HAVE

ITS SCENE 1 TOGGLED ON AND OFF.

(8 MAX.)

GRX-4#02 (2 zone)

GRX-4#03 (3 zone)

GRX-4#04 (4 zone)

GRX-4#06 (6 zone)

GRX-4#08 (8 zone)

LUTRON

2

) TO TERMINALS

Caution - Wire in a daisy-chain

arrangement as shown - no variations.

Do not substitute cables!

Notes:

• All control wiring is Class 2 (Extra Low Voltage).

Do not place any of these wires in with line voltage

(mains voltage) wiring.

• Panel may be placed in the middle of the wiring as

opposed to on the end as shown, but panel to

panel wiring may be more difficult.

• 2 #12 AWG (2.5mm2) wires will not fit in the

Accessory Control terminal blocks. Use the

diagram shown at right to make the connections

in the wallbox. #12 AWG (2.5mm2) is necessary

due to voltage drop on the wire.

• Shielding must be connected as shown, but do not

connect to Ground (Earth) or Accessory Control. It

is easiest to connect the bare drain wires and cut

off the outside shield.

• Make wire connections inside the wallbox, GP and

XP panel or in a junction box (provided by others)

within 8ft. (2.4m) from the terminals.

LUTRON

LUTRON

CLASS 2 WIRING

SSA CONTROLS

(10 MAX.)

NTGRX-1S

GRAFIK Eye GP, LP, or XP SERIES LIGHTING CONTROL PANELS

(Number of panels max = 33 - Number of Control Units -

4

3

2

1

Number of Accessory Controls)

-SHIELD/DRAIN

2 #12 AWG (2.5mm2)

1 #18 AWG

(1mm2)

2 #12 AWG (2.5mm

2

)

• Maximum number of lighting control panels may

be increased using a repeater—contact Lutron.

• The following cables: Liberty #LUCOM-12/22-RBL,

Belden #9461, and Alpha #2211 are made with #22

AWG wire, and have been tested and approved.

Not all #22 AWG cable will work. Any #18 AWG

twisted, shielded pair will work.

For More Information...

?

Accessory Control to Control Unit Panel to Panel Wiring.................................22

to Panel Wiring.................................21

4

Step by Step instructions for GRAFIK Eye Switching Panel

Page 7

Wire System

STEP 3: Wire System (cont.)

Suggested wiring when panels are close together

Suggested wiring when panels are far apart

Neutral Wire (N)

Hot/Live

Wire (H)

Distribution Panel

Module wiring

Hot/Live In

Switched Hot

Load 16 A max

Neutral

Large

Distance

H

SH

H

SH

H

SH

H

SH

H

SH

H

SH

H

SH

H

SH

SH

Small

Load 16A Max.

SH

H

Splice Neutrals

in Trough

SH

H

Switched Hot/Live

Wire (SH)

XP Panel

N

N

SH

XP Panel

Load 16A Max.

H

Switched Hot/Live

Wire (SH)

Neutral

Wire (N)

Hot/Live

Wire (H)

Distribution Panel

N

N

H

H

Distance

Notes:

• Terminal blocks accept one #14 AWG (2.5mm2)

through #10 AWG (4.0mm2) or two AWG #18 AWG

through #16 AWG wire.

• Two modules and the control feed are shown to the

left. The module terminal blocks are typical of the

rest of the possible 12 modules

• Lutron recommends that the Control Feed be a

dedicated circuit even though the control wiring

will draw 0.5 Amps max.

Danger - An XP Series panel is fed by

multiple circuits. Locate and lock each

feed in the OFF position.

Caution - XP Series panels require entry

of wires as specified. Improper entry will

block serviceable parts or violate NEC codes.

Warning - Do not remove bypass jumpers

at this step.

Neutral

Ground

Dedicated Hot/Live

N

N

H

H

Reference Sheets for GRAFIK Eye Switching Panel

Caution - Lutron recommends the use of

a trough for ease of wiring (where space

permits).

Caution - Follow all local wiring codes.

5

Page 8

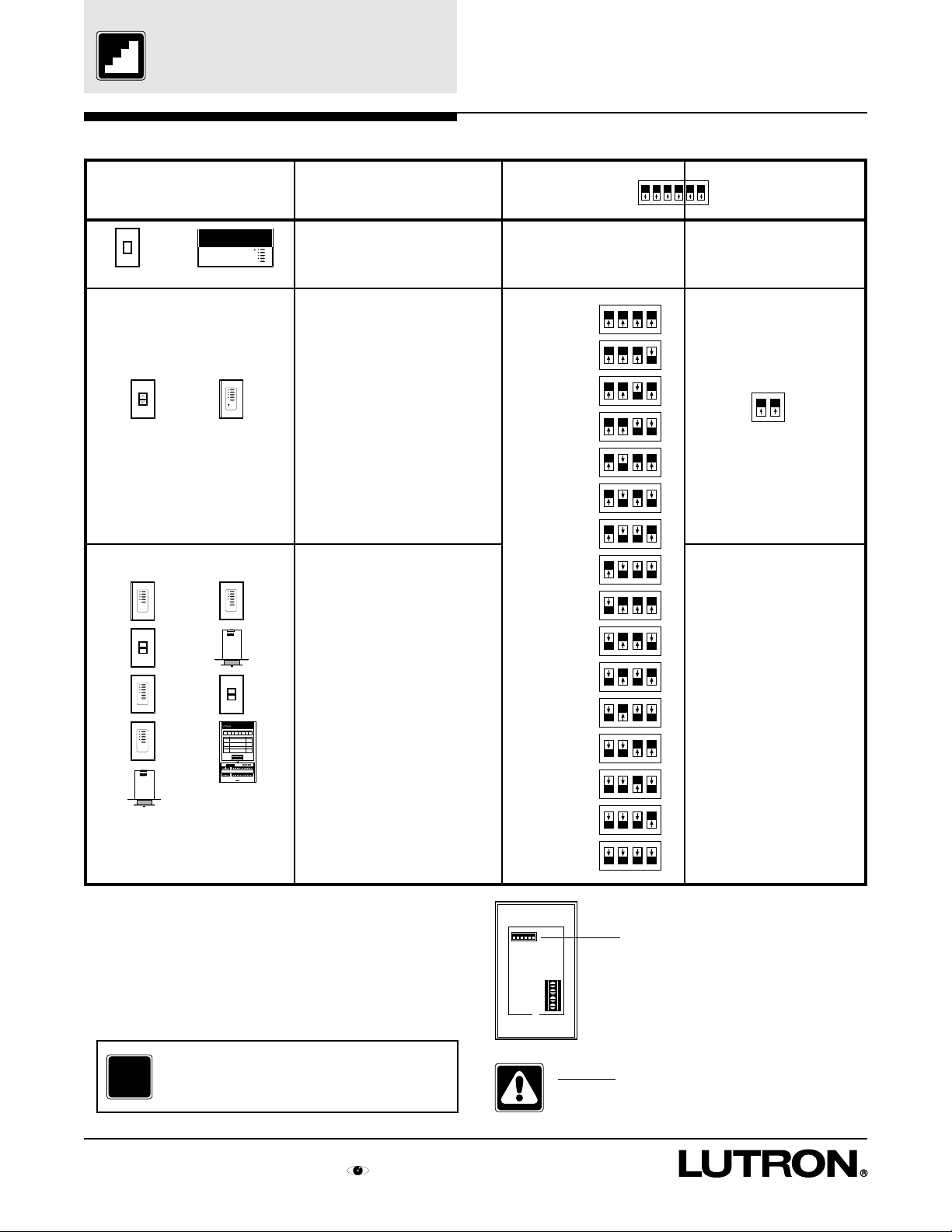

Set Address Switches

STEP 4: Set Address Switches

Control

LUTRON

LUTRON

NTGRX-1S GRX-4000 Series

No switches for addressing.

Go to Step 6 if no other types of

Accessory Controls.

Action

Address

Control 1

N/A

1 2 3 4 5 6

Function

Factory Set

N/A

1 2 3 4

1

2

3

4

LUTRON

PARTITION STATUS

OPEN

CLOSED

NTGRX-RL NTGRX-4PS

SEQUENCE

ZONE LOCK

SCENE LOCK

FADE OVERRIDE

LUTRON

LUTRON

LUTRON

1 2 3 4 5 6

LUTRON

1 2 3 4 5 6

LUTRON

GRX-AV

Must set switches BEFORE

installing these controls.

Set Switches 1-4 on each

Accessory Control to a unique

address.

Must set switches BEFORE

installing these controls.

Set Switches 1-4 on each

Accessory Control to a unique

address.

Set Switches 5-6 to define the

function of control.

Control 2

Control 3

Control 4

Control 5

Control 6

Control 7

Control 8

Control 9

Control 10

Control 11

Control 12

Control 13

Control 14

5 6

Leave switches as factory

set.

Go to Step 6 if no other

types of Accessory controls.

Setting Switches 5 and 6

requires system knowledge.

See Step 5 for function

options.

ALL OTHERS

Notes:

• GRX-AV has 8 switch positions. Positions 7 and 8

also set the function.

• GRX-AV-RS232’s do not have an address—

follow instructions packaged with each control

and skip to step 6.

For More Information...

?

6

Step by Step instructions for GRAFIK Eye Switching Panel

See also One-Line Diagram from submittals.

Control 15

Control 16

Back of Accessory Control

Switch

location

4

3

2

1

Caution - Do not install controls in

wallbox without setting the Address and

Function Switches.

Page 9

LUTRON

R

LUTRON

R

Set Function Switches

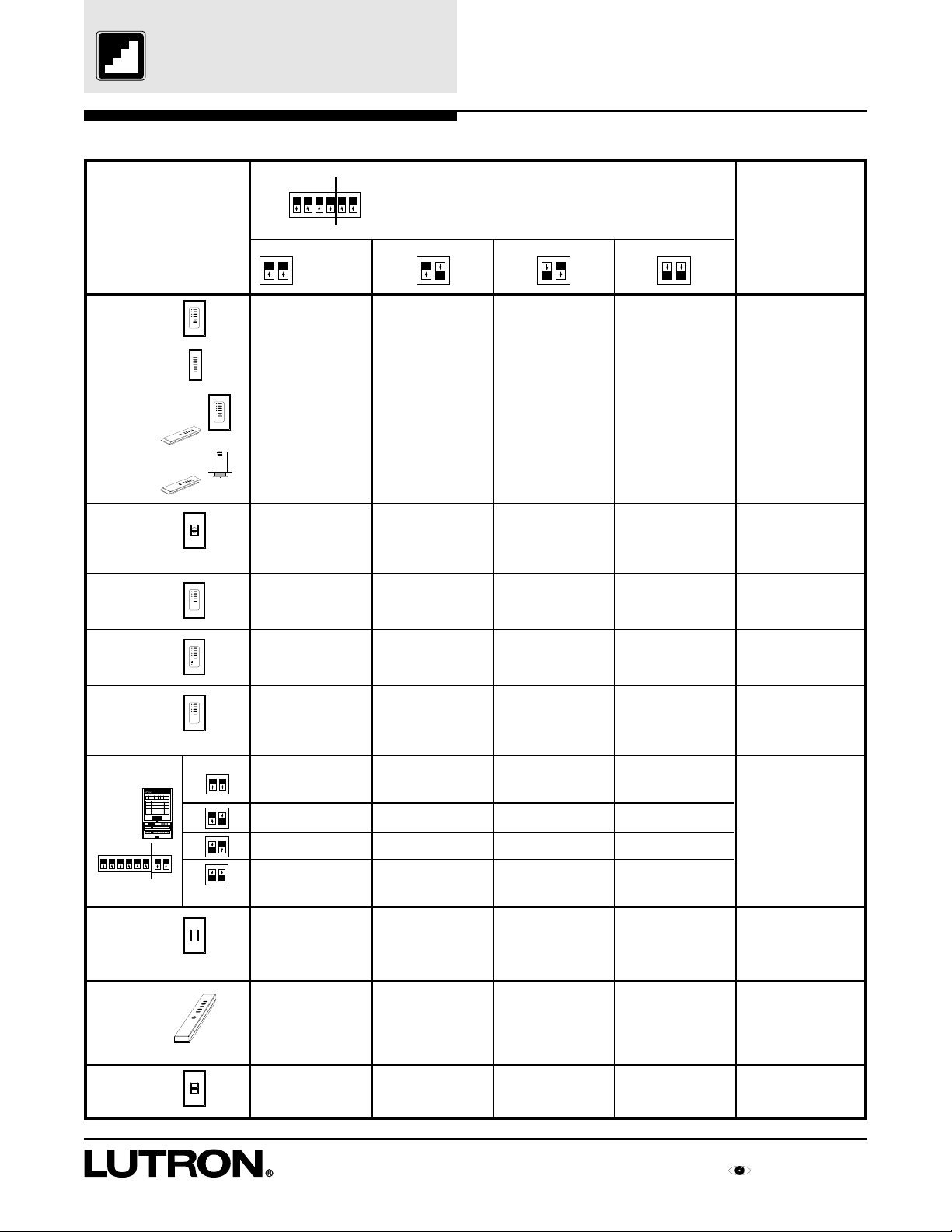

STEP 5: Set Function Switches

Accessory Control

NTGRX-4S,

GRX-4S-DW

NTGRX-4S-IR

w/GRX-IT,

GRX-CIR

w/GRX-IT

NTGRX-RL

NTGRX-4Q

LUTRON

LUTRON

1 2 3 4 5 6

LUTRON

SEQUENCE

ZONE LOCK

SCENE LOCK

FADE OVERRIDE

1 2 3 4 5 6

Function Set by Switches

on Back of Control

Factory Set

5 6 5 6 5 6 5 6

Factory Set

Activate Scenes 1-4

Not Applicable

Sequence Scenes 1-4

Activate Scenes 5-8

Not Applicable

Not Applicable

Activate Scenes 9-12

Not Applicable

Not Applicable

Activate Scenes 13-16

Not Applicable

Sequence Scenes 5-16

Function Set

with Front

Buttons

(See Step 17)

Activate Scenes on

specified GRX-4000

Series Control Units

Raise/Lower specified

Zones on specified

GRX-4000 Series

Control Units

Affect specified GRX4000 Series Control

Units

NTGRX-4PS

NTGRX-4M

GRX-AV

GRX-AV

7 8

Factory Settings

NTGRX-1S

GRX-IT

GRX-8IT

NTGRX-2B

1

2

3

4

PARTITION STATUS

OPEN

CLOSED

Not Applicable

Fifth button turns

LUTRON

Control Units On only.

Not Applicable

Not Applicable

Not Applicable

Not Applicable

Not Applicable

Fifth button turns

Control Units Off only.

Parallel specified GRX4000 Series Control

Units

Toggle 4 specified

groups of GRX-4000

Series Control Units On

and Off.

7 8

LUTRON

Momentary Input

Activate Scenes 1-4

Momentary Input

Sequence Scenes 1-4

Momentary Input

4PS functions

Momentary Input

1 Channel fine tuning

Not Applicable

Momentary Input

Activate Scenes 9-12

Momentary Input

Sequence Scenes 5-16

N/A

Momentary Input

NTGRX-4M Function

Not Applicable

Momentary Input

Activate Scenes 5-8

Maintained Input

Sequence Scenes 1-4

Maintained Input

4PS functions

Maintained Input

Occupant Sensor

Scene 1 and Off

Not Applicable

Momentary Input

Activate Scenes 13-16

Maintained Input

Sequence Scenes 5-16

N/A

Maintained Input

Occupant Sensor

Off Only

Not Applicable

Affect specified GRX4000 Series Control

Units

Toggle between Scene 1

and Off of connected

GRX-4000 Series

Control Unit

Not Applicable

Not Applicable

Not Applicable

Not Applicable

Activate Scenes 1-4 or

1-8 and Off, and Raise/

LUTRON

R

Lower all zones of target

GRX-4000 Series

Control Unit

LUTRON

Activate Scene 1 and

Off

Activate Scenes 13

and 14

Single Partition

Function

Activate Scene 16 w/

lockout or previous

Scene w/o lockout

Affect specified GRX4000 Series Control

Units

Step by Step instructions for GRAFIK Eye Switching Panel

7

Page 10

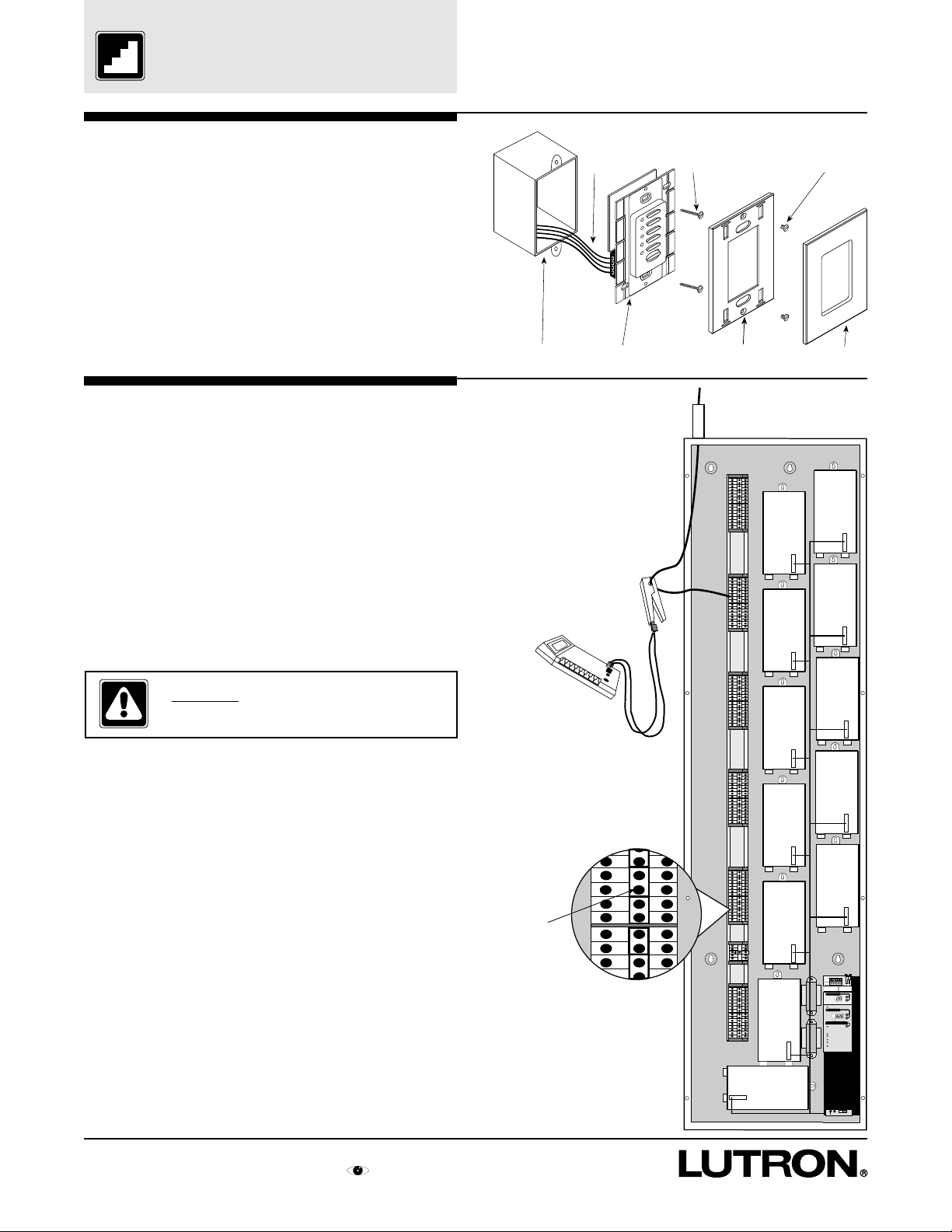

Faceplate

Adapter

Control Facepla

Adapter M

Screws

Control Mounting

Screws

Wallbox

Control

Link

Install Controls and

Activate Loads

STEP 6: Install Controls

After completing steps 4 and 5, mount controls.

Refer to detailed mounting instructions packaged with

each control.

STEP 7: Activate Loads in Bypass

A. Check that the bypass jumpers are in place.

These jumpers protect the switch mechanism from

wiring faults and must be used to check load wiring

when it is installed or modified.

B. Complete load wiring.

C. Turn a load’s input circuit breaker ON.

The loads should energize, the feed breaker should

not trip, and total load current must be no more

than 16 Amps.

D. Repeat ‘C.’ for each circuit with completed load

wiring.

WALLBOX

CONTROL

LINK

CONTROL

CONTROL

MOUNTING SCREWS

FACEPLATE

ADAPTER

ADAPTER

MOUNTING SCREWS

FACEPLATE

Warning - DO NOT remove bypass

jumpers at this time.

2 position

Bypass

Jumper

N

N

H

H

12345

Power (Pins

Link

Data (Pins

S

electCircuit

1

2

Circui

VIEV

ALU

S

electValue

3

4

Valu

S

electValueDisplayed

5

Load

1 Inc/Mag

4 Non-

2

5 Elec.

_

3

Unassigne

Control and Zone

Using circuit

T

Using Zone

Low End (optional

High End (optional

Circuit

R

LUTRO

R

LUTRO

8

Step by Step instructions for GRAFIK Eye Switching Panel

Page 11

Activate Controls

STEP 8: Activate Controls

Once all controls are installed and wiring verified, turn

the control wiring feed circuit breaker ON.

Check that the Power OK LED at the top of the

Circuit Selector is ON. If the Power OK LED is

off, turn off the control breaker, check for shorts

between wires 1 and 2, or 2 and ground.

Note:

For multiple panels once one Power OK LED is

ON, all the Power OK LED’s in all system Circuit

Selector’s should turn ON.

Circuit

Value

4 Non-dim

5 Elec. LV

– Unassigned

Power OK (Pins 1,2)

Data OK (Pins 3,4)

TM

Link Status

S

ELECT CIRCUIT

V

IEW VALUE

S

ELECT VALUE

S

ELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Low End Trim (optional)

High End Trim (optional)

Circuit Level

1

2

3

4

5

®

‘Power OK’ LED

Push scene buttons on Accessory Controls. All GRX4000 Series Control Units and Accessory Controls

should act in parallel (e.g. pressing scene 1 on a

control will select scene 1 on all controls, pressing a

raise button will raise all zones).

Notes:

• NTGRX-4Q, NTGRX-4PS, NTGRX-4M

and GRX-AV-RS232’s will be inactive until

Control Set Up is completed.

• GRX-AV will be active only if set to affect Scenes

1-4 and OFF (switches 5,6,7, and 8 all UP).

• NTGRX-2B will be active only if set to affect Scene

1 and OFF (switches 5 and 6 both UP).

• Check for miswires if the controls do not act as

described.

ZONE 6ZONE 5ZONE 4ZONE 3ZONE 2ZONE 1

LUTRON

FADE OVERRIDE

SM

GRX-4000 Series Control Unit

(6 zone unit shown)

Push

LUTRON

ZONE

MASTER

Push

?

For More Information...

Troubleshooting Guide.................24, 25

Accessory Control

(NTGRX-4S shown)

Step by Step instructions for GRAFIK Eye Switching Panel

9

Page 12

Assign Load Types

STEP 9: Assign Load Types

Assigning Load Types is done using the Circuit

Selector located in each XP Series panel.

Press button 5 repeatedly until Load Type lights.

Use buttons 1 and 2 to view present load type of each

circuit. Note that ‘ - ’ in the Value display means a

Load Type is not assigned to the circuit.

If load types are already assigned, compare them to

the Circuit Directory (if provided).

If there are no changes to be made, skip to Step 10.

To change Load Types:

A. Press and hold buttons 1 and 5 until

SELECT VALUE

LED lights.

B. Press button 5 repeatedly until Load Type lights.

C.Tap button 2 so that ‘AC’ (All Circuits) appears in

the Circuit display.

D.Press button 3 repeatedly (press button once per

second since updating is slower in all circuits) until

‘4’ appears in the Value display.

E. Press and hold buttons 1 and 5 until

VIEW VALUE LED lights.

Notes:

• Most applications will use Load Type 4. Use Load

Type 6 for circuits controlling screens.

• The Circuit Selector Display will go out automatically

after 20 minutes of the last button press.

• Mark all changes to the Circuit Selector’s Values on

the Circuit Directory for future reference.

Circuit Selector

Circuit

Value

4 Non-dim

5 Elec. LV

– Unassigned

Circuit

Value

4 Non-dim

5 Elec. LV

– Unassigned

Power OK (Pins 1,2)

Data OK (Pins 3,4)

TM

Power OK (Pins 1,2)

Data OK (Pins 3,4)

44

4

44

TM

Link Status

S

ELECT CIRCUIT

V

IEW VALUE

S

ELECT VALUE

S

ELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Link Status

Low End Trim (optional)

High End Trim (optional)

S

ELECT CIRCUIT

Circuit Level

V

IEW VALUE

S

ELECT VALUE

S

ELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Low End Trim (optional)

High End Trim (optional)

Circuit Level

1

2

3

4

5

1

®

2

3

4

5

®

A,F

For More Information...

?

Circuit Selector Functions.................23

Circuit Directory.................................26

10

Step by Step instructions for GRAFIK Eye Switching Panel

Page 13

Address GRX-4000

Control Units

STEP 10: Address GRX-4000 Control

Units

Push the scene 1 button on a GRX-4000 Series

Control Unit. The scene 1 LED should go on.

Address Control Unit as follows:

A. Push and hold top and bottom scene buttons until

scene LEDs begin to cycle.

B. Push FADE button until ‘A-’ is displayed in the

FADE window. If A1 through A8 appears, then go

to D since the Control Unit is already addressed.

C.Push MASTER button once. The control will

automatically choose the next available address.

Note the address of each on the Control Directory

(A1-A8).

If a Control or Load Directory already exists, push

MASTER and buttons to have the address

match these directories.

D.Push and hold the top and bottom buttons until the

scene LEDs stop cycling.

Repeat Steps A-D on all GRX-4000 Series Control

Units.

ZONE 6ZONE 5ZONE 4ZONE 3ZONE 2ZONE 1

LUTRON

FADE OVERRIDE

SM

GRX-4000 Series Control Unit

ZONE

MASTER

B

C

A,D

As soon as a GRX-4000 Series Control Unit is

addressed, check that the Data OK LED (located

below the Power OK LED on the Circuit Selector)

begins to blink. Blinking indicates that the wiring from

a GRX-4000 Series Control Unit to the panel is

correct.

Note:

As soon as a GRX-4000 Series Control Unit is

addressed, Accessory Controls will no longer have

any affect on the GRX-4000 Series Control Units.

The Accessory Controls will be reactivated in

Step 16.

For More Information...

?

Troubleshooting Guide.................24, 25

Circuit

Value

4 Non-dim

5 Elec. LV

– Unassigned

Power OK (Pins 1,2)

Data OK (Pins 3,4)

TM

Link Status

S

ELECT CIRCUIT

V

IEW VALUE

S

ELECT VALUE

S

ELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Low End Trim (optional)

High End Trim (optional)

Circuit Level

Not lit before addressing

Blinking after

1

2

3

4

5

addressing

(approximately once per

second)

®

Control Directory...............................27

Step by Step instructions for GRAFIK Eye Switching Panel

11

Page 14

Remove Bypass

Jumpers

STEP 11: Remove Bypass Jumpers

Repeat Step 7 if load wiring has been modified.

Turn circuit breakers OFF.

Danger - Do not remove or replace

bypass jumpers while power is ON.

Loosen both screws of each bypass jumper.

Remove and store the bypass jumpers for possible

later use.

Store the bypass jumpers at the bottom of the panel.

DO NOT place them on top of the module.

Warning - When working on any load

(such as replacing a bulb), turn Off

power to the module that powers the

load. Turn the module power off by

switching its input circuit breaker

(MCB) Off.

Turning ON to a load fault WILL

irreparably damage the switch module.

Damage caused by short circuits and

miswiring is not covered in the product

warranty.

BYPASS JUMPERS—

Replace whenever a load

is serviced.

H

SH

H

SH

H

SH

H

SH

H

SH

H

SH

H

SH

H

SH

Terminal blocks

for 2 modules

Turn Circuit Breakers ON.

12

Step by Step instructions for GRAFIK Eye Switching Panel

Page 15

Check System

STEP 12: Check System

Until zones are assigned in Step 13, all circuits will be

controlled by the first zone of the GRX-4000 Series

Control Unit addressed to ‘A1’. Locate zone 1 of this

‘A1’ control (referred to as A1 1 in the Circuit Selector)

and use it to check that all circuits turn ON and OFF

as expected.

(This address was set in Step 10.)

Note:

If the system has already been Set Up, scenes will

work and A1 1 will not control all circuits.

ZONE 6ZONE 5ZONE 4ZONE 3ZONE 2ZONE 1

LUTRON

First zone of GRX-4000 Series

Control Unit addressed ‘A1’

FADE OVERRIDE

SM

ZONE

MASTER

STOP!

?

To assure proper Set Up, you must have

one or more of the following:

• Factory Customized Set Up.

• Knowledge of how the system is

to operate.

• Plans and specifications from owner’s

representative on how the system is to

be set-up.

• Owner or owner’s representative

For More Information...

Circuit Directory.................................26

Possible questions:

•

What should each scene be used for?

Examples include - Day lighting, Night lighting,

Meeting, Accenting, etc...

•

Which circuits should be on in each scene?

Control Directory...............................27

Step by Step instructions for GRAFIK Eye Switching Panel

13

Page 16

Assign Zones

STEP 13: Assign Zones

A. Press and hold buttons 1 and 5 until

SELECT VALUE

lights.

B. Press button 5 repeatedly until

Using Circuit Schedule lights.

C.Use buttons 3 and 4 to assign control (factory set

to A1) and zone (factory set to 1) for each circuit.

Whichever item is blinking can be changed. See

the Control Schedule for control locations. If zones

are already assigned, skip to Step 15.

Example - If the control desired is addressed to

‘A2’ and the zone desired is the 3rd from the left,

use buttons 3 and 4 to get ‘A23’ as a value for the

appropriate circuit.

D.Use buttons 1 and 2 to change to the next circuit

and then repeat Step C. Do this for all affected

circuits. Record each circuit’s control and zone on

the Circuit Directory.

E. Press and hold buttons 1 and 5 until

VIEW VALUE lights. The Circuit Selector’s

display will go out automatically after 20 minutes

of the last button push.

Notes:

• More than one circuit can be assigned to the

same zone.

•

Zone Capture TM

assigning zones. It is described in the Circuit

Selector Functions Reference Sheet.

is an alternate method for

Circuit

Value

4 Non-dim

5 Elec. LV

– Unassigned

Circuit

Value

4 Non-dim

5 Elec. LV

– Unassigned

Power OK (Pins 1,2)

Data OK (Pins 3,4)

TM

Power OK (Pins 1,2)

Data OK (Pins 3,4)

TM

Link Status

S

ELECT CIRCUIT

V

IEW VALUE

S

ELECT VALUE

S

ELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Low End Trim (optional)

High End Trim (optional)

Circuit Level

Link Status

S

ELECT CIRCUIT

V

IEW VALUE

S

ELECT VALUE

S

ELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Low End Trim (optional)

High End Trim (optional)

Circuit Level

1

2

A,E

3

4

5

®

1

2

3

4

5

®

For More Information...

?

Circuit Selector Functions.................23

Circuit Directory.................................26

Control Directory...............................27

14

Step by Step instructions for GRAFIK Eye Switching Panel

Page 17

Set Up Scenes on the

GRX-4000

STEP 14: Set Up Scenes on the GRX-4000

A. Lift the cover flap on a GRX-4000 Series Control

Unit (flap hinges up).

B. Press the Scene 1 button.

C.Press and buttons of each zone to create a

scene. As soon as a zone is changed, the GRX4000 Series Control Unit will remember it.

D.Adjust the fade time using and FADE

buttons.

Note:

The fade time can be adjusted from 0 to 59

seconds or 1 to 60 minutes.

E. Press Scene 2 and repeat C-D. Do this for all

scenes.

Note:

Off scene may have Fade time adjusted.

F. Repeat Steps A-E for all of the GRX-4000 Series

Control Units on the job.

ZONE 6ZONE 5ZONE 4ZONE 3ZONE 2ZONE 1

LUTRON

GRX-4000 Series Control Unit

FADE OVERRIDE

ZONE

SM

MASTER

DC

A

B

E

Step by Step instructions for GRAFIK Eye Switching Panel

15

Page 18

Set Up Accessory

LUTRON

R

Controls

STEP 15: Set Up Accessory Controls

All Accessory Controls (except NTGRX-1S) must be

set up to make a Control Unit(s) “listen” to button

presses on the Accessory Control.

• Only one Accessory Control can be set up at one

time.

• A Control Unit can also be made to “listen” to

another Control Unit and is therefore listed with the

Accessory Controls at right.

Follow Steps A-C for each Accessory Control.

Notes:

• Accessory Controls can not be made to “listen” to

each other , but a GRX-4000 Series Control Unit

can be made to “listen” to more than one

Accessory Control.

• When it is desired for two GRX-4000 Series

Control Units to always respond to each other’s

button presses, the first Control Unit must be set up

to respond to the second Control Unit’s buttons,

and then the second Control Unit must be set up to

respond to the first Control Unit’s buttons.

• An NTGRX-1S is wired directly to the GRX-4000

Series Control Unit that is to “listen” to it. No set-up

is required.

• GRX-AV-RS232’s do not follow this chart. See

instructions packaged with each control.

STEP A: Place Control to ‘Talk’ in Set-Up Mode

Control

(only 1 at a time)

GRX-4000

Series Control

Unit

NTGRX-4S

NTGRX-4Q

NTGRX-4S-IR

GRX-CIR

w/GRX-IT

GRX-4S-DW

NTGRX-RL

NTGRX-4PS

LUTRON

Press and hold first and fifth buttons of a Control

Unit.

LUTRON

SEQUENCE

ZONE LOCK

SCENE LOCK

FADE OVERRIDE

Press and hold first and fifth buttons on Accessory

Control until its LEDs cycle sequentially.

LUTRON

Note: GRX-CIR only has 1 LED. Use the GRX-IT

1 2 3 4 5 6

to activate the first and fifth buttons.

Press and hold Raise and Lower buttons of

LUTRON

NTGRX-RL until its LED blinks (LED is located

behind faceplate)

Press and hold first and fifth buttons of the

1

2

3

4

PARTITION STATUS

OPEN

CLOSED

NTGRX-4PS until LED 1 blinks.

Action

NTGRX-4M

GRX-AV

Press and hold first and fifth buttons of the

LUTRON

NTGRX-4M until LED 1 blinks.

GRX-AV

Press and hold the Program Switch until its LEDs

react like the simulated Accessory.

NTGRX-2B

as a Scene

Selector

LUTRON

Press and hold both buttons of the NTGRX-2B until

NTGRX-2B

as a

Partition

its LED blinks (LED is located behind faceplate).

LUTRON

Switch

16

Page 19

Set Up Accessory

LUTRON

R

LUTRON

R

Controls

STEP 15: Set Up Accessory Controls (cont.)

STEP B: Make Control Unit “Listen” STEP C: Take Control Out of Set-Up Mode

Control

(only 1 at a time)

GRX-4000

Series Control

Unit

NTGRX-4S

NTGRX-4Q

NTGRX-4S-IR

GRX-CIR

w/GRX-IT

GRX-4S-DW

NTGRX-RL

NTGRX-4PS

LUTRON

Action

Press and hold another Control Unit’s Scene 1

button until its LEDs blink in unison. (To make it

stop “listening”, hold OFF button until LEDs go dark.

LUTRON

SEQUENCE

ZONE LOCK

SCENE LOCK

FADE OVERRIDE

Press and hold Scene 1 on a Control Unit until its

LEDs blink in unison. (T o make it stop “listening”,

LUTRON

hold OFF button until LEDs go dark.)

1 2 3 4 5 6

Press button of GRX-4000 Control Unit on

LUTRON

all zones that are to be affected by the NTGRX-RL

(to remove, press button).

Choose two Control Units on either side of a

Partition. Press and hold Scene 1 on a Control

Unit until its LEDs blink in unison. Repeat Scene 1

hold on the other Control Unit. Press the next

1

2

3

4

PARTITION STATUS

OPEN

CLOSED

button on the NTGRX-4PS. Choose another pair

of Control Units. Repeat Scene 1 hold procedure

for each of the NTGRX-4PS buttons. (To remove,

hold OFF button on each Control Unit until LEDs

go dark.)

Control

(only 1 at a time)

GRX-4000

Series Control

Unit

NTGRX-4S

NTGRX-4Q

NTGRX-4S-IR

GRX-CIR

w/GRX-IT

GRX-4S-DW

NTGRX-RL

NTGRX-4PS

LUTRON

Action

Press and hold first and fifth buttons of the original

GRX-4000 Series Control Unit until LEDs stop

sequencing.

LUTRON

SEQUENCE

ZONE LOCK

SCENE LOCK

FADE OVERRIDE

Press and hold first and fifth buttons on Accessory

Control until all LEDs stop cycling.

LUTRON

1 2 3 4 5 6

Press and hold Raise and Lower buttons on

LUTRON

NTGRX-RL until its LED stops blinking.

Press and hold first and fifth buttons of the

1

2

3

4

PARTITION STATUS

OPEN

CLOSED

NTGRX-4PS until all LEDs stop blinking.

NTGRX-4M

GRX-AV

NTGRX-2B

as a Scene

Selector

NTGRX-2B

as a

Partition

Switch

Choose a Control Unit to be toggled by the

NTGRX-4M. Press and hold Scene 1 on the

Control Unit until its LEDs blink in unison. Repeat

Scene 1 hold on other Control Units to be toggled.

Press the next button on the NTGRX-4M. Choose

LUTRON

a Control Unit to be toggled. Repeat Scene 1 hold

procedure for all 5 of the NTGRX-4M buttons.

Button 5 only turns ON or OFF (it does not toggle).

(To remove, hold OFF button on the Control Unit

until its LEDs go dark).

GRX-AV

See above instructions for the simulated

Accessory Control.

Press and hold Scene 1 on a Control Unit until its

LEDs blink in unison. (To remove, hold OFF button

LUTRON

until LEDs go dark).

Press and hold Scene 1 on a Control Unit until its

LEDs blink in unison. Repeat Scene 1 hold

LUTRON

procedure for the other Control Units to be affected.

(To remove, hold OFF button until LEDs go dark)

NTGRX-4M

GRX-AV

Press and hold first and fifth buttons of the

LUTRON

NTGRX-4M until all LEDs stop blinking.

If the GRX-AV’s LEDs are sequencing, press and

GRX-AV

hold the Program Switch until the LEDs stop

sequencing. If the GRX-AV has 1 LED blinking,

press the program switch repeatedly until there are

no blinking LEDs.

NTGRX-2B

as a Scene

Selector

LUTRON

Press and hold both buttons of the NTGRX-2B

NTGRX-2B

as a

Partition

until the LED stops blinking.

LUTRON

Switch

STEP D: Repeat Steps A-C for All Accessory Controls

Step by Step instructions for GRAFIK Eye Switching Panel

17

Page 20

Set Normal/Emergency

Switch

STEP 16: Set Normal/Emergency Switch

(Non-Essential/Essential)

Note:

This step is only performed if there are any panels

with Emergency (Essential) Lighting Circuits on

the job.

Panels are shipped with Switch 6 (located at the base

of each Circuit Selector) in the center position for

operation without any Emergency (Essential) Lighting

Circuits.

Identify a panel supplied with Normal (Non-Essential)

power. Move its Switch 6 to the left position.

For all the Emergency (Essential) Lighting Panels,

move switch 6 to the right position.

In this arrangement, the Emergency (Essential)

Lighting Panel will “sense” the Normal (Non-Essential)

Panel’s power. When Normal (Non-Essential) power

is removed, the Emergency (Essential) Lighting will

go to ‘ord’ override levels (factory set to ON).

Loss of Normal (Non-Essential) power can be

simulated by turning off all connected Normal (NonEssential) Panels’ Control Breakers.

When Switch 6 is left in its center position (as

shipped), terminal 5 has no affect on the Circuit

Selector operation.

Circuit Selector in

Normal (Non-Essential)

Panel

Circuit

Value

4 Non-dim

5 Elec. LV

– Unassigned

Power OK (Pins 1,2)

Data OK (Pins 3,4)

1

2

3

4

5

TM

®

Link Status

SELECT CIRCUIT

VIEW VALUE

SELECT VALUE

SELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Low End Trim (optional)

High End Trim (optional)

Circuit Level

Circuit Selector in

Emergency (Essential)

Lighting Panel

Circuit

Value

4 Non-dim

5 Elec. LV

– Unassigned

Power OK (Pins 1,2)

Data OK (Pins 3,4)

1

2

3

4

5

TM

®

Link Status

SELECT CIRCUIT

VIEW VALUE

SELECT VALUE

SELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Low End Trim (optional)

High End Trim (optional)

Circuit Level

Notes:

• If there is no Normal Panel, contact Lutron

for GRAFIK Eye 4000 Application Note #5:

How to

create a ‘sense’ line.

• Override (‘ord’) Level is factory set to turn all circuits

ON. If the override level is to be OFF, contact Lutron

for GP Panel Advanced Function #1.

SW6 SW6

Move left Move right

18

Page 21

Congratulations!

Your state of the art

system is now ready

to operate!

Now:

• Place a copy of the Circuit and

Control Directories in each XP Panel.

• Replace the cover(s) securely.

• Give the customer a copy of this guide.

(The rest of this guide is reference material.)

Lutron is very interested in your comments on this Installer’s Guide and

on its products. Please call (800) 523-9466 with any comments or

suggestions. Thank you for your help.

Step by Step instructions for GRAFIK Eye Switching Panel

19

Page 22

Look Inside an XP

XP Series Switching Panels

The XP Series Switching Panel has 1 to 12 Switching

Modules and a Circuit Selector to set up Zone

Assignments and Load Types.

Each Switching Module has four switching

mechanisms. Each switching mechanism connects

or disconnects 16 Amps max. from Hot to Switched

Hot based on the intensity of its assigned zone of a

GRX-4000 Control Unit.

XP Series Panels are designed to mount between two

studs that are on 16" centers. Each panel may be

mounted in or on a wall.

All XP Series Panels have a Type 1 enclosure, are UL

listed under UL file 42071, and are CSA certified.

TERMINAL BLOCKS FOR

HOT AND SWITCHED HOT

WIRES. THERE ARE 8

TERMINAL BLOCKS PER

SWITCHING MODULE

LOAD WIRING 16A MAX PER

SWITCHING MODULE OUTPUT

NSH

2

4

NH

6

Reference Sheet

SP

XP

1

LED DIAGNOSTIC

1 BLINK/SEC = OK

1 BLINK/7 SEC = NO

3

COMMUNICATION

CONTROL WIRING

PLUG-IN CONNECTOR

(ADDRESSES MODULE)

5

SWITCHING MODULE

(UP TO 12)

DIN RAIL

TERMINAL BLOCKS FOR

A DEDICA TED CONTROL

WIRING FEED

CLASS 2 TRANSFORMER

TO POWER THE

CIRCUIT SELECTOR

AND GRX WIRING

CLASS 2 TRANSFORMER

TO POWER THE MODULES

N

N

H

H

NEUTRAL HOT/LIVE

WIRE WIRE

10

11

12

8

Link Status

S

electCircuit

V

S

S

electValueDisplayed

Load Type

Control and Zone Assigned

Low End Trim(optional)

High End Trim (optional)

Circuit Level

7

9

12345

IEWVALUE

electValue

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Using circuit schedule

Using Zone Capture

CONTROL WIRING

HARNESS (CLASS 2)

KEEP POWER WIRES

Power OK (Pins 1,2)

1/4 " AWAY FROM THIS

Data OK (Pins 3,4)

1

HARNESS

2

Circuit

3

4

Value

5

4 Non-dim

5 Elec. LV

_

Unassigned

TM

CIRCUIT SELECTOR

R

LUTRON

R

LUTRON

NORMAL/EMERGENCY

SWITCH TO DEFINE

WHICH PANEL IS

“NORMAL” AND WHICH

IS “EMERGENCY”

20

Reference Sheets for GRAFIK Eye Switching Panel

Page 23

Accessory to Control Unit

to Panel Wiring

Correct Wiring Technique

ACCESSORY

GP

CONTROL

SERIES

PANEL

GRX-4000

Reference Sheet

SERIES

PANEL

1 to 1 Wiring

TO ADDITIONAL

CONTROL UNITS

AND ACCESSORY

CONTROLS

XP

ACCESSORY

CONTROL

ACCESSORY

CONTROL

ACCESSORY

CONTROL

GRX-4000

GRX-4000

TO OTHER PANEL OR GRX-4000 SERIES

CONTROL UNITS OR ACCESSORY

CONTROLS

WIRING MUST BE DAISY-CHAINED, NOT BRANCHED OR HOME RUN.

XP SERIES PANEL

1 2 3 4 5

SHIELD SHIELD

4

3

2

1

ACCESSORY

CONTROL

(16 MAX.)

3

434

OUT

GRX-4000 SERIES CONTROL UNIT

SSARET

IN

(8 MAX.)

Notes:

• Connections are made inside the Accessory

Control’s backbox or in a junction box (provided by

others) located no more than 8 ft. (2.4m) from the

Accessory Control.

• Wiring shown must not be run in the same raceway

as line (mains) voltage wiring.

• Total Control wiring length is not to exceed 2000 ft.

(450m for 220V, 230V or 240V panels).

SSA

2

1

NTGRX-1S

• Panels may be in the middle of a control link.

They do not need to be at an end.

• Shielding must be connected at each junction,

but not earth grounded.

TO ANY NUMBER OF

SINGLE SCENE

ACTIVATORS

Reference Sheets for GRAFIK Eye Switching Panel

21

Page 24

Panel to Panel Wiring

1 to 1 Wiring

TO GRX-4000 SERIES

CONTROL UNITS AND

ACCESSORY CONTROLS

1

Reference Sheet

TO NEXT

XP SERIES PANEL

1

2

SHIELD SHIELD

3

4

1 2 3 4 5

Circuit

Value

4 Non-dim

5 Elec. LV

Power OK (Pins 1,2)

Data OK (Pins 3,4)

1

2

3

4

5

Wire

1

2

3

4

5

Link Status

S

ELECT CIRCUIT

V

IEW VALUE

S

ELECT VALUE

S

ELECT VALUE DISPLAYED

First XP Series Panel

Load Type

1 Inc/Mag LV

2 Fluorescent

Notes:

• The additional #18 AWG (1.0mm2) wire is a ‘sense’

line from terminal 5 of another panel. This sense

line allows an Emergency (Essential) Lighting

Panel to ‘sense’ when Normal (Non-Essential)

power is lost.

If more than one Emergency Lighting Panel needs

to sense off a specific Normal panel, a dedicated

wire may need to be run between each pair of

Normal (Non-Essential) and Emergency (Essential)

panels.

• Shielding must be connected as shown, but do not

connect to Ground (Earth) or Circuit Selector. It is

easiest to connect the bare drain wires and cut off

the outside shield.

Function

Common

24VFW

Mux

Mux

Sense Line

1 2 3 4 5

Circuit

Value

4 Non-dim

5 Elec. LV

Power OK (Pins 1,2)

Data OK (Pins 3,4)

1

2

3

4

5

Link Status

S

ELECT CIRCUIT

V

IEW VALUE

S

ELECT VALUE

S

ELECT VALUE DISPLAYED

Second XP Series Panel

Load Type

1 Inc/Mag LV

2 Fluorescent

2

3

4

5

Reference Sheets for GRAFIK Eye Switching Panel

22

Page 25

Circuit Selector Functions

Circuit Selector Functions

Circuit Selector listens to the GRX-4000 Series

Control Unit(s) and then tells the circuits whether to

be ON or OFF.

It can also be used to select Values for each Circuit:

• Load Type - allows the switch to operate at

specified times:

1,2,3,5 = Do not use for XP series

4 = Non-dim with load turned ON as the GRX

4000 Series Main Unit’s intensity changes

from below 100% to 100% (last ON), and

turned OFF as the intensity goes from

100% to below 100% (first OFF).

6 = Non-dim with load turned ON as the GRX

4000 Series Main Unit’s intensity changes

from 0% to 1% (first ON), and turned OFF

as the intensity goes from 100% to below

100% (first OFF).

– = Unassigned

• Control and Zone Assigned - allows two ways of

assigning a control and zone to a specific circuit.

1) ‘using Circuit Schedule’ see Step 13.

2) ‘

Using Zone Capture TM

Zone to be ‘captured’ by the Circuit Selector by

doing the following:

A. Press and hold buttons 1 and 5 until

lights.

B. Use buttons 1 and 2 to choose the correct

S

ELECT VALUE

circuit to be assigned.

C.Press button 5 repeatedly until

Using Zone CaptureTM

will now flash.

D.Go to the GRX-4000 Series Control Unit to be

assigned to this circuit.

E. Select Scene 1.

F. Identify the zone to be assigned to this circuit.

G.Press the zone button until all zone LEDs

are off.

H.Press the zone button until all zone LEDs

are on.

I. Press the zone button until all zone LED

are off.

(Steps H. and I. must take less than 15 seconds or

the Circuit Selector will not lock on the captured zone.)

J. Go back to the Circuit Selector and the proper

Control and Zone should be displayed.

Repeat this process for any other Circuits.

K. Press and hold buttons 1 and 5 until

VIEW VALUE lights.

• Low and High End Trims - not used.

• Circuit Test Level - See Troubleshooting

Reference section.

’ allows a Control and

lights. The Load

Reference Sheet

‘Power OK’ indicates

whether 24VFW is

present to terminal 2 or

not.

1 2 3 4 5

Link Status

S

ELECT CIRCUIT

V

IEW VALUE

S

ELECT VALUE

S

ELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Low End Trim (optional)

High End Trim (optional)

Circuit Level

The Circuit Selector can also provide or receive a ‘sense’

line depending on the location of Switch 6. See Step 16.

‘Data OK’ blinks when

the Circuit Selector is

receiving data from the

GRX-4000 Series Control

Unit(s).

Power OK (Pins 1,2)

Data OK (Pins 3,4)

1

2

Circuit

3

4

Value

5

4 Non-dim

5 Elec. LV

– Unassigned

TM

®

SW6

Reference Sheets for GRAFIK Eye Switching Panel

23

Page 26

Troubleshooting Guide

Troubleshooting Guide

Reference Sheet

Symptom

Normal

Operation as

Reference

All switches

controlled by

1st zone

No control-

Level Frozen

Any accessory

control or

main unit not

responding to

button pushes

LED

Switching

Module

“Heartbeat”

(~1 per sec)

“Heartbeat”

(~1 per sec)

“Light House”

(~1 per 7 sec)

“Light House”

(~1 per 7 sec)

Circuit Selector

‘Power OK’

LED

On

On

On

On

Off

On

On

Off

Link Status

‘Data OK’

LED

Blinking

Blinking

Blinking

Off

Off

Off

Off

Off

Power OK

Data OK

Circuit #

Display

OK

Out

OK

OK

OK

Out

OK

OK

OK

GRX LEDs

OK

OK

OK

OK

OK

Off

Off

OK

Off

Possible Cause/Solutions

• All LEDs show OK, see below for

other suggestions

• Push any button on Circuit Selector

(display turns off in 20 minutes)

• Circuit Selector not Set Up - see

instructions for zone assigning in

Step 13.

• 2 wire link on Control Harness

disconnected at the bottom of the

Circuit Selector

• Invalid Load Type chosen - see step 9

• GRX 4000 control units not addressed

- see instructions in step 10

• Wiring of Terminals 3 and 4 flipped

• GRX connector unplugged at control

unit

• Circuit Selector's Class 2 Transformer

open

• Miswire to control link wires 1,2,3,

and 4

• Miswire to control link wires 3 and 4

• Miswire shorting 24VFW (Terminal 2)

to Common (Terminal 1) or ground

Switching occurs

at the wrong

intensity

Switch stays ON

at all intensities

Out

“Heartbeat”

(~1 per sec)

“Heartbeat”

(~1 per sec)

Off

On

On

On

Off

Blinking

Blinking

Blinking

Out

OK

OK

OK

Off

OK

OK

OK

• Control Feed Breaker Off

• Module Class 2 Transformer open

• Circuit Selector not Set Up for proper

Load Type - see Step 9 and/or Step 1 5

• Relay tack weld - check that load

current is less than 16 Amps. Cycle

relay 10 times from the Circuit

Selector-see next page. If relay

continues to not respond, contact

Lutron for possible replacement.

24

Reference Sheets for GRAFIK Eye Switching Panel

Page 27

Troubleshooting Guide

Troubleshooting Guide (cont.)

After checking LED diagnostics, use this chart:

Reference Sheet

Symptom

Accessory Control will not go into Set Up Mode

Two Control Units have the same Address (usually A1)

Note:

The following voltages should be present on the

GRX wiring:

Terminals 2 to 1 ≈ 22VDC

Terminals 3 to 4 ≈ 3VDC

Terminals 5 to 1 if Switch 6 set for Normal ≈ 22VDC

Other Troubleshooting tools:

The Circuit Selector can be used to view the intensity

information being sent to the switch. Use buttons 1

and 2 on the Circuit Selector to access the circuit

number desired. Press button 5 repeatedly until

Circuit Level lights. Value displayed is now the

present intensity sent from the GRX-4000 Control Unit

controlling that circuit. Value = 0 is OFF, Value = 100

is ON full.

The Circuit Selector can also be used to manually

turn the switch mechanism ON or OFF. Press and

hold buttons 1 and 5 until lights. Use

SELECT VALUE

buttons 1 and 2 to access the circuit desired. Press

button 5 repeatedly until Circuit Level lights.

Buttons 3 and 4 will now control the desired circuit.

Value = 0 is OFF, Value = 100 is ON full, Value = CF

is Circuit Finder - load will cycle ON and OFF.

Note that while in the , Circuit Level

SELECT VALUE

mode, the display will not time out in 20 minutes.

Possible Cause/Solutions

• GRX-4000 Series Control Units are not addressed.

• Terminals 3 and 4 miswired.

• One of the units has wires 3 and 4 crossed or open. Wire terminal 3 to

terminal 3, 4 to 4.

1 2 3 4 5

Circuit

Value

4 Non-dim

5 Elec. LV

– Unassigned

Power OK (Pins 1,2)

Data OK (Pins 3,4)

1

2

3

4

5

TM

®

Link Status

SELECT CIRCUIT

VIEW VALUE

SELECT VALUE

SELECT VALUE DISPLAYED

Load Type

1 Inc/Mag LV

2 Fluorescent

3 Neon/CC

Control and Zone Assigned

Using circuit schedule

Using Zone Capture

Low End Trim (optional)

High End Trim (optional)

Circuit Level

Reference Sheets for GRAFIK Eye Switching Panel

25

Page 28

Circuit Directory

Reference Sheet

Circuit

Location

(Room or

Area)

Customer

Ckt. #

Panel

Ckt. #

C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Circuit

Description

(Fixture Name)

Control Feed-________ Volts

Non-Dim

Load T ype

ON OFF

4 Last First

6 First First

Zone

Assignments

Address Zone

A1-A8 1-8

or G600 Zone #

Actual Load

3 Phase, 4 Wire Shown

Circuit Rating is 16 Amps cont.

1

/3 HP @ 120V, 1/2 HP @ 277V

Phase A

Phase B

Phase C

Reference Sheets for GRAFIK Eye Switching Panel

26

Page 29

Control Directory

Control Directory - GRX-4000 Series Control Units

(8 max/link)

Reference Sheet

Area: Area: Area: Area:

A1

1

A1

2

A1

3

A1

4

A1

5

A1

6

A1

7

A1

8

A5

1

A1

LUTRON

Zone

A2

1

A2

2

A2

3

A2

4

A2

5

A2

6

A2

7

A2

8

Area:Area: Area: Area:

A5

LUTRON

Zone

1

A6

Zone DescriptionZone Description Zone DescriptionZone

LUTRON

Zone DescriptionZone Description Zone DescriptionZone

A2

A6

Zone

A3

A3

A3

A3

A3

A3

A3

A3

Zone

A7

1

2

3

4

5

6

7

8

1

A3 A4

Zone

A4

A4

A4

A4

A4

A4

A4

A4

A7 A8

LUTRON LUTRON

Zone

A8

LUTRONLUTRONLUTRON

Zone Description

1

2

3

4

5

6

7

8

Zone Description

1

A5

A5

A5

A5

A5

A5

A5

2

3

4

5

6

7

8

A6

A6

A6

A6

A6

A6

A6

2

3

4

5

6

7

8

Use this Directory as GRX-4000 Series Control Units

are addressed and zones are assigned. Keep this

Directory for job records and maintenance

information.

A7

A7

A7

A7

A7

A7

A7

2

3

4

5

6

7

8

A8

A8

A8

A8

A8

A8

A8

2

3

4

5

6

7

8

Reference Sheets for GRAFIK Eye Switching Panel

27

Page 30

Maintenance

Maintenance

Reference Sheet

XP Series Panels

Danger - Any liquid entering the panel

may reach internal components, cause

personal injury, damage the equipment,

and void the warranty.

1. If any extra wiring is brought into the panel,

temporarily cover the modules and thoroughly

remove all metal chips, wire strands, insulation,

or other debris before reapplying power.

2. In the unlikely event of damage to switching

equipment, replace bypass jumpers (see step 11).

This will take the switching equipment out of the

circuit and apply full power to fixtures.

3. To take manual control of the On or Off state of any

circuit, use the Circuit Selector (see Troubleshooting

Guide).

4. The exterior of the XP Panel may be painted as

follows:

a. Remove the front cover.

b. Cut a piece of paper slightly smaller than the

cover label (label is 7" x 2.675" with rounded

corners)

c. Tape the cut paper onto the label so that the tape

holds the paper and completely covers the

label. Avoid taping any of the label except the

outside edge.

d. For the cover or painted enclosure, sand the

existing paint to roughen it. For galvanized

enclosure - wipe the outside (do not paint the

inside) surface with a damp, soapy cloth.

e. Paint the cover or enclosure exterior. For

galvanized enclosure, use an acrylic (OVM

recommended) or urethane paint - not an oil

based paint.

Warning - When painting the panel cover,

keep all vent holes open and clear of any

paint pooling.

Danger - Turn power off before working on

any load. Each circuit may have an

individual, external disconnect switch.

Locate and lock the appropriate

disconnect switch (usually a breaker)

before servicing.

Warning - When working on any load

(such as rewiring a load), replace the

bypass jumpers to protect the switching

module until the load is proven.

GRX-4000 Series Control Units and Accessory

Controls

Clean front surface of control with a soft towel

moistened with a mild soap solution (nonammonia- based). Clean approximately every six

months.

Caution - Do not spray cleaning solution

onto control as it may reach internal

components.

Fixtures

It is important that lamps are maintained properly to

prevent what may appear as switching equipment

malfunctions. When lamps begin to fail on a circuit,

Lutron recommends group relamping of the entire

circuit.

28

Reference Sheets for GRAFIK Eye Switching Panel

Page 31

Glossary of Terms

Glossary of Terms

Reference Sheet

e

e

s

s

d

d

o

o

p

p

p

p

t

t

o

o

u

u

s

s

l

l

o

o

s

s

i

i

o

o

k

k

s

s

i

i

l

l

h

h

i

i

t

t

k

k

,

,

e

e

t

t

a

a

o

o

n

n

d

r

o

eit

v

e

i

l

e

B

a

w

on

c

i

s

i

h

T

r

o

eit

v

e

i

l

e

B

a

w

on

c

i

s

i

h

T

r

i

d

the

r

e

d

n

u

a

w

on

c

i

s

i

h

T

r

o

eit

v

e

i

l

e

B

a

w

on

c

i

s

i

h

T

d

r

i

i

c

c

o

t

ti

i

o

o

n

n

eit

a

a

v

r

r

y

y

e

i

!

!

l

e

t

t

M

M

n

n

e

e

r

r

.

.

B

B

N

N

y

y

y

y

b

b

e

e

,

,

B

d

d

J

J

e

e

t

t

u

u

a

a

l

l

y

y

e

e

r

r

6

6

c

c

,

,

s

s

1

1

a

9

9

9

9

w

5

5

.

.

on

c

i

s

i

e

e

s

s

d

d

o

o

p

p

p

p

t

t

o

o

u

u

s

s

l

l

h

o

o

s

s

o

o

i

i

k

k

s

s

i

i

l

l

h

h

i

i

T

t

t

k

k

,

,

e

e

t

t

a

a

o

o

n

n

d

d

r

i

i

c

c

o

t

t

i

io

o

n

n

eit

a

a

v

r

r

y

y

e

i

!

!

l

e

t

t

M

M

n

n

e

e

r

r

.

.

B

B

N

N

y

y

y

y

b

b

e

e

,

,

B

d

d

J

J

e

e

t

t

u

u

a

a

l

l

y

y

e

e

r

r

6

6

c

c

,

,

s

s

1

1

a

9

9

9

9

w

5

5

,

.

on

c

i

s

i

h

.

.

T

T

R

R

k

k

h

h

e

e

o

o

r

r

m

m

e

e

T

D

D

a

a

s

s

f

f

.

.

o

o

n

n

o

o

i

i

t

t

c

c

e

e

r

i

d

the

r

e

d

n

t

t

M

M

n

n

e

e

r

r

.

.

N

N

B

B

y

y

y

y

b

b

e

e

,

,

u

d

d

J

J

e

e

t

t

u

u

a

a

l

l

y

y

e

e

r

r

6

6

c

c

,

,

s

s

1

1

a

9

9

9

9

w

5

5

.

.

on

c

i

s

i

e

e

s

s

d

d

o

o

p

p

p

p

t

t

o

o

u

u

s

s

l

lo

h

o

s

s

i

i

o

o

k

k

s

s

i

i

l

l

h

h

i

i

T

k

k

t

t

,

,

e

e

t

t

a

a

o

o

n

n

d

d

r

i

i

c

c

o

t

ti

i

o

o

n

n

eit

a

a

v

r

r

y

y

e

i

!

!

l

e

t

t

M

M

n

n

e

e

r

r

.

.

N

N

B

B

y

y

y

y

b

b

e

e

,

,

B

d

d

J

J

e

e

t

t

u

u

a

a

l

l

y

y

e

e

r

r

6

6

c

c

,

,

s

s

1

1

a

9

9

9

9

w

5

5

.

.

on

c

i

s

i

h

T

Accessory Control - GRAFIK Eye control wired to a

GRX-4000 (or GRX-3000) Series Control Unit to

select scenes, raise and lower specific zones or

other functions on an attached Control Unit.

Addressing - a way for the controls on a link to