Page 1

HomeWorks QS Palladiom

Thermostat Configuration Guide

P/N 032498h

P/N 032498h

Page 2

P/N 032498h

Table of Contents

Description.............................................................................................................................................................................4

Step 1: Identify the HVAC Equipment and Confirm Device Installation .......................................................5

Identify the HVAC Equipment .............................................................................................................................................5

Confirm Device Installation .................................................................................................................................................5

Programming Menu Overview .......................................................................................................................................7

Step 2: Equipment Configuration Mode .................................................................................................................... 7

Step 3: Select the HVAC Controller .............................................................................................................................8

Step 4: Set the SMC55-HWQS Basic Parameters for System Compatibility ............................................9

(01b): System Type .............................................................................................................................................................11

(02b): Heat Stages .............................................................................................................................................................11

(03b): Run Auxiliary Heat (Aux/W2) With Other Heat Stages .......................................................................................... 12

(04b): Auxiliary Heat (Aux/W2) Upstage Delay .................................................................................................................12

(05b): Cool Stages .............................................................................................................................................................13

(06b): Heat Fan Control .....................................................................................................................................................13

(07b): Changeover / Revers ing Valve (O / B) Type..............................................................................................................13

(08b): Valve / Element Type ................................................................................................................................................ 14

(09b): Fan Type ...................................................................................................................................................................14

(10b): 2-Pipe Mode .............................................................................................................................................................15

(11b): Underfloor Heating Control ..................................................................................................................................... 16

Saving and Exiting Basic Configuration ........................................................................................................................... 17

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the Functionality of the HVAC System ...18

Parameters Applicable to All types of HVAC Equipment ................................................................................................22

(01A) Function Type ...................................................................................................................................................... 22

(02A) Temperature Sensor Type ....................................................................................................................................22

(06A) Minimum Fan On Time .........................................................................................................................................22

(07A) Extended Cool Fan Time (OCFT) ...........................................................................................................................22

(08A) Extended Heat Fan Time (OHFT) ..........................................................................................................................22

(11A) Cool Fan On Delay (CFOD)....................................................................................................................................22

(12A) Heat Fan On Delay (HFOD) ...................................................................................................................................22

(18A) Standalone Temperature Operation Mode .............................................................................................................22

(19A) Standalone Temperature Fan Mode.......................................................................................................................22

(30A) Cannot Reach Setpoint Timeout ...........................................................................................................................23

(31A) Cannot Reach Setpoint Action ..............................................................................................................................23

Parameters Applicable to Conventional and Heat Pump Systems ................................................................................23

(70A) Minimum Compressor Run Time (MCRT) ..............................................................................................................23

(71A) Minimum Compressor Off Time (MCOT) ................................................................................................................ 23

(74A) Heat Stage 1-On Delta .........................................................................................................................................24

(75A) Heat Stage 1-Off Delta .........................................................................................................................................24

(76A) Heat Stage 2 (Y2/W2/Aux)-On Delta .......................................................................................................................24

(77A) Heat Stage 2-Off Delta ......................................................................................................................................... 24

(78A) Heat Stage 3 (Aux)-On Delta ................................................................................................................................24

(79A) Heat Stage 3 (Aux)-Off Delta ................................................................................................................................24

(80A) Cool Stage 1-On Delta ......................................................................................................................................... 24

(81A) Cool Stage 1-Off Delta .........................................................................................................................................24

(82A) Cool Stage 2-On Delta .........................................................................................................................................24

(83A) Cool Stage 2-Off Delta.........................................................................................................................................25

(84A) Compressor Cool Stage 2 Upstage Delay (CC2SUD) ..............................................................................................25

(85A) Compressor Heat Stage 2 Upstage Delay (CH2SUD) ..............................................................................................25

(88A) Reversing Valve Delay (RVD) .................................................................................................................................25

Continued on next page...

2

Page 3

P/N 032498h

Table of Contents (continued)

Parameters Applicable for Radiant Underfloor Heating System ....................................................................................26

Radiant Underfloor Heating Control Summary ............................................................................................................26

Pulse Width Modulation (PWM) Temperature Control (for relay signals only) ...................................................................26

0–10 V- Control (for 0–10 V- signal only) .....................................................................................................................26

Duty Cycle Sample Adaptation (for both relay and 0–10 V- signals) ..............................................................................26

Parameter details ...........................................................................................................................................................27

(54A) Minimum Pulse Width ..........................................................................................................................................27

(90A) Slab Maximum .................................................................................................................................................... 27

(91A) Slab Minimum .....................................................................................................................................................27

(92A) Slab Setpoint ......................................................................................................................................................27

(93A) Floor 100% Differential ........................................................................................................................................27

(94A) Floor 0% Differential ............................................................................................................................................ 27

(95A) Cycles Per Hour (CPH) .........................................................................................................................................27

Parameters Applicable for 0–10 V- Fan Coil Units ........................................................................................................27

(50A) Proportional Fan Minimum ...................................................................................................................................27

(51A) Proportional Fan Low Speed ................................................................................................................................27

(52A) Proportional Fan Medium Speed ..........................................................................................................................27

(53A) Proportional Fan High Speed ...............................................................................................................................27

(54A) Minimum Valve Percent Open ...............................................................................................................................27

(55A) Valve Fully Open Differential ................................................................................................................................. 27

(56A) Non-proportional Analog Output ..........................................................................................................................27

Parameters Applicable for 2-pipe Fan Coil Units ............................................................................................................28

(40A) Change Over to Heat for Pipe Temperature ............................................................................................................28

(41A) Change Over to Cool for Pipe Temperature ............................................................................................................28

(42A) Enable Purge Function .........................................................................................................................................28

(43A) Purge Valve On-Time ...........................................................................................................................................28

(44A) Purge Valve Off-Time ...........................................................................................................................................28

Parameters Applicable to a FCU with Multi Speed Fan ..................................................................................................28

05A) Fan High Differential .............................................................................................................................................28

(09A) Kick-Start Fan .....................................................................................................................................................28

Step 6: Verification ...........................................................................................................................................................29

Troubleshooting .................................................................................................................................................................30

Appendix A ...........................................................................................................................................................................31

1. Heat Stage Relays .........................................................................................................................................................31

2. Cool Stage Relays .........................................................................................................................................................31

3. Control Diagrams for Turning On / Off Different Heat and Cool Stages .....................................................................32

Appendix B: Installation Worksheet ..........................................................................................................................35

Appendix C: User Interface for the Thermostat...................................................................................................39

Appendix D: Reenter Configuration Menus ...........................................................................................................40

Appendix E: Determine Firmware Version (optional) .........................................................................................40

3

Page 4

P/N 032498h

Description

This programming guide provides information on how to configure the HomeWorks QS Palladiom Thermostat and

HomeWorks QS Palladiom HVAC controller (SMC55-HWQS, SMC55-RESI). All the references made to SMC55-HWQS

throughout the document will apply to SMC55-RESI as well.

The HomeWorks QS Palladiom thermostat and SMC55-HWQS are a two-piece solution offered by Lutron to control HVAC

equipment. The thermostat provides the user interface and the SMC55-HWQS sends signals to control the HVAC equipment.

The SMC55-HWQS must be configured correctly to control the HVAC equipment. The thermostat can also connect to third-party

HVAC controllers, or be used as a Companion Thermostat, which is described in later sections.

WARNING

This guide illustrates multiple steps for configuring the Palladiom thermostat and HVAC controller.

Step 1 illustrates how to identify the HVAC equipment and confirm system compatibility.

Step 2 covers the equipment configuration mode.

Step 3 explains the controller selection menu.

Step 4 details the basic parameters required to configure the SMC55-HWQS for compatibility.

Step 5 covers the details of the advanced parameters for the SMC55-HWQS which are used to modify the functionality of the

HVAC equipment. Advanced parameters are set to a default value and should only be changed if the system needs further

configuration.

After configuring both the basic and the advanced parameters, refer to Step 6 to verify the basic system functionality based

on the configuration of the SMC55-HWQS.

Appendix A includes control diagrams to explain the On/Off deltas for heating and cooling stages.

Appendix B provides a worksheet which should be kept and used by the installer during installation. Before configuring the

SMC55-HWQS, write the necessary values for the basic and advanced parameters in the allotted space.

Appendix C gives more details about the functionality of different buttons and user interface on the thermostat.

Shock Hazard - Improper configuration can cause property damage, personal injury, or death. Installation and

service must be performed by a licensed professional HVAC installer (or equivalent) or service agency.

4

Page 5

P/N 032498h

Step 1: Identify the HVAC Equipment and Confirm Device Installation

Identify the HVAC Equipment

First, identify the type of HVAC equipment that is installed. Check the installation manual or label on the HVAC equipment.

The Palladiom Thermostat solution is compatible with most residential HVAC systems, including:

1. Conventional forced air systems using gas, electric, or oil heat as well as compressor-based, cooling-only as split systems or

packaged units.

2. Fan Coil Units (FCUs)

3. Heat-pump systems

4. Hydronic or electric underfloor/radiant heating systems 1

5. Specific VRF/VRV systems. See the HomeWorks QS Palladiom Thermostat specification (Lutron P/N 3691033) at

www.lutron.com for further information.

Confirm Device Installation

Confirm the Palladiom Thermostat is installed. For hardware installation and wiring details, refer to the HomeWorks QS

Thermostat Installation Guide at www.lutron.com/TechnicalDocumentLibrary/043495.pdf. If connecting a third-party HVAC

controller to the thermostat, refer to the controller’s installation guides to confirm installation of the controller. Connecting the

Palladiom thermostat to third-party controllers is explained in the following Lutron app notes:

Daikin® VRV Systems and Other VRF Systems

Requires one of these hardware options:

• HomeWorks QS Palladiom thermostat and CoolAutomationTM CoolPlug interface. 2 See Application Note #660 (048660) at

www.lutron.com

• HomeWorks QS Palladiom thermostat with HomeWorks QS processor and CoolAutomationTM interface.

See Application Note #650 (048650) at www.lutron.com

Mitsubishi® VRF Systems

Requires one of these hardware options:

• HomeWorks QS Palladiom thermostat and Mitsubishi® Procon A1M interface. 2 See Application Note #661 (048661) at

www.lutron.com

• HomeWorks QS Palladiom thermostat with HomeWorks QS processor and CoolAutomationTM interface. 2

See Application Note #650 (048650) at www.lutron.com

• HomeWorks QS Palladiom thermostat with HomeWorks QS Palladiom HVAC controller and Mitsubishi® thermostat controller

inter face. 2 See Application Note #585 (048585) at www.lutron.com

LG® VRF Systems

Requires one of these hardware options:

• HomeWorks QS Palladiom thermostat and LG® PDRYCB500 interface. 2 See Application Note #662 (048662) at www.lutron.com

• HomeWorks QS Palladiom thermostat with HomeWorks QS processor and CoolAutomationTM interface. 2

See Application Note #650 (048650) at www.lutron.com

• HomeWorks QS Palladiom thermostat with HomeWorks QS Palladiom HVAC controller and LG® thermostat controller interface. 2

See Application Note #627 (048627) at www.lutron.com

Underfloor Heating Systems with Heatmiser Interface

Requires:

• HomeWorks QS Palladiom thermostat with HomeWorks QS processor and Heatmiser interface.

Integration with HomeWorks QS document.

1

Included with SMC55-HWQS version 7420 or newer, SMC55-RESI version 7302 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

2

Provided by others.

3

For information about additional CoolAutomation interfaces, see www.coolautomation.com

Continued on next page...

1

2,3

2

See Heatmiser HVAC

5

Page 6

P/N 032498h

Step 1: Identify the HVAC Equipment and Confirm Device Installation

(continued)

Confirm Device Installation

(continued)

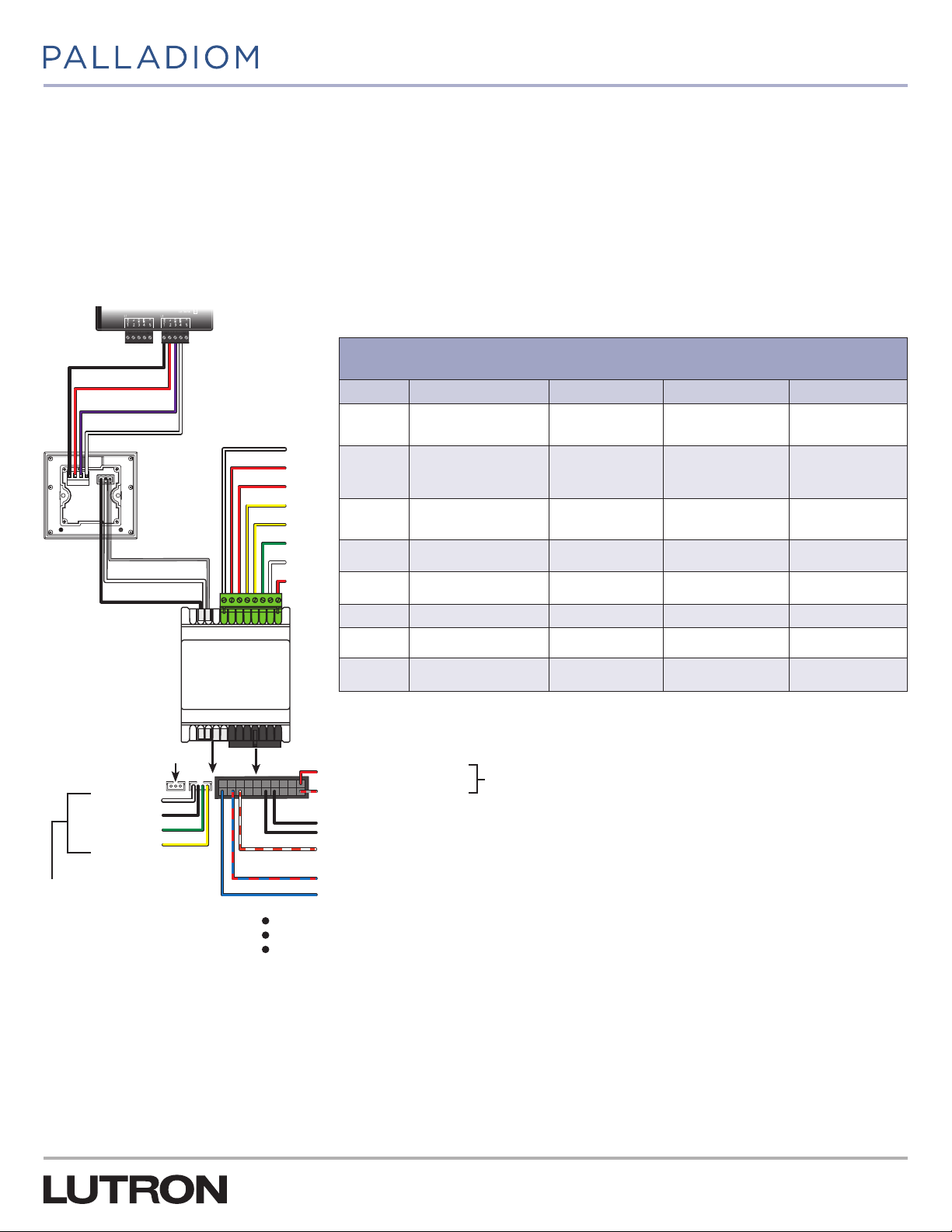

If connecting the Palladiom Thermostat to the SMC55-HWQS, they must be connected over the HVAC controller communication

link. Refer to Figure 1 for the wiring required to install the SMC55-HWQS with the thermostat. For hardware installation and

wiring details refer to the HomeWorks QS Thermostat Installation Guide (P/N 043495) at www.lutron.com.

Figure 1: SMC55-HWQS Setup for Configuration Using a Thermostat

HomeWorks QS

processor

Relay Terminals

SPST(NO) 1 A 24 V~ maximum relays

Terminal Conventional Heat Pump

#5 Heat stage 1 (W1)

Heating stage1

#6

transformer (RH)

Cooling / compressor

#7

transformer (R

)

C

#8 Compressor stage1 (Y

Compressor stage2

#9

1

(Y

)

2

Changeover heat

pump valve (O/B)

Heating

transformer(RH)

Cooling

transformer(RC)

Compressor

)

1

stage 1(Y1)

Compressor

stage 1(Y2)

1

Fan Coil Unit Radiant Floor

Hot valve (H

Heat valve

transformer(RH) or

Valve transformer(R)

Fan transformer (R

) Heat stage 1 (W1)

VALVE

Heat stage 1

transformer (R1)

) –

FAN

Fan high (G3) –

Fan medium (G2) –

#10 Fan (G) Fan (G) Fan low (G1) –

#11 Heat stage 2 (W

#12

Heating stage2

transformer (R

1

)

2

1

)

H2

Auxiliary heat (AUX) Cold valve (C

Auxiliary heat

transformer(R

AUX

)

Cold valve

transformer (RC)

) –

VALVE

2

–

43

21

Common

V+

MUX

_

HomeWorks

QS Palladiom

thermostat

Gray (G) Com

White (+) MUX

Black (−) _

QS Link

Power and

communication

#5

#6

#7

#8

#9

#10

#11

#12

HomeWorks QS

Palladiom HVAC

Controller

Not used

HVAC Controller Power (from HVAC system transformers)

24 V~ IEC / SELV / PELV / NECR Class 2

White (heat)

Black (common)

Green (fan)

Yellow (cool)

43G5

Red (R

AO

) Heat transformer

H

Gray /Red (C) Common

Black

Black

Orange / White (connect to black common wire for additional HVAC controllers only. This connection will set

the Modbus address to 02)

Wire harness for 0–10Vvalves and fan controls

Blue / Red (FCU changeover sensor or radiant floor slab sensor)

Blue (remote temperature sensor)

Optional signal wires

1

Included with SMC55-RESI version 7302 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

2

Included with SMC55-HWQS version 7420 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

6

Page 7

P/N 032498h

Programming Menu Overview

1. Equipment configuration mode: Indicates if 1 or 2 HVAC equipment types are used and what equipment is connected.

2. HVAC controller selection mode: Indicates what type of HVAC controller is being used and sets the address for it (if needed).

3. Basic configuration mode: Configures the HVAC controller according to the type of HVAC system.

Note: Depending on the options selected, certain programming modes may be skipped. It may be necessary to enter certain

programming modes twice if there are two equipment types. The thermostat will only display menus that are relevant to the

configurations selected.

4. Advanced configuration mode (Optional)

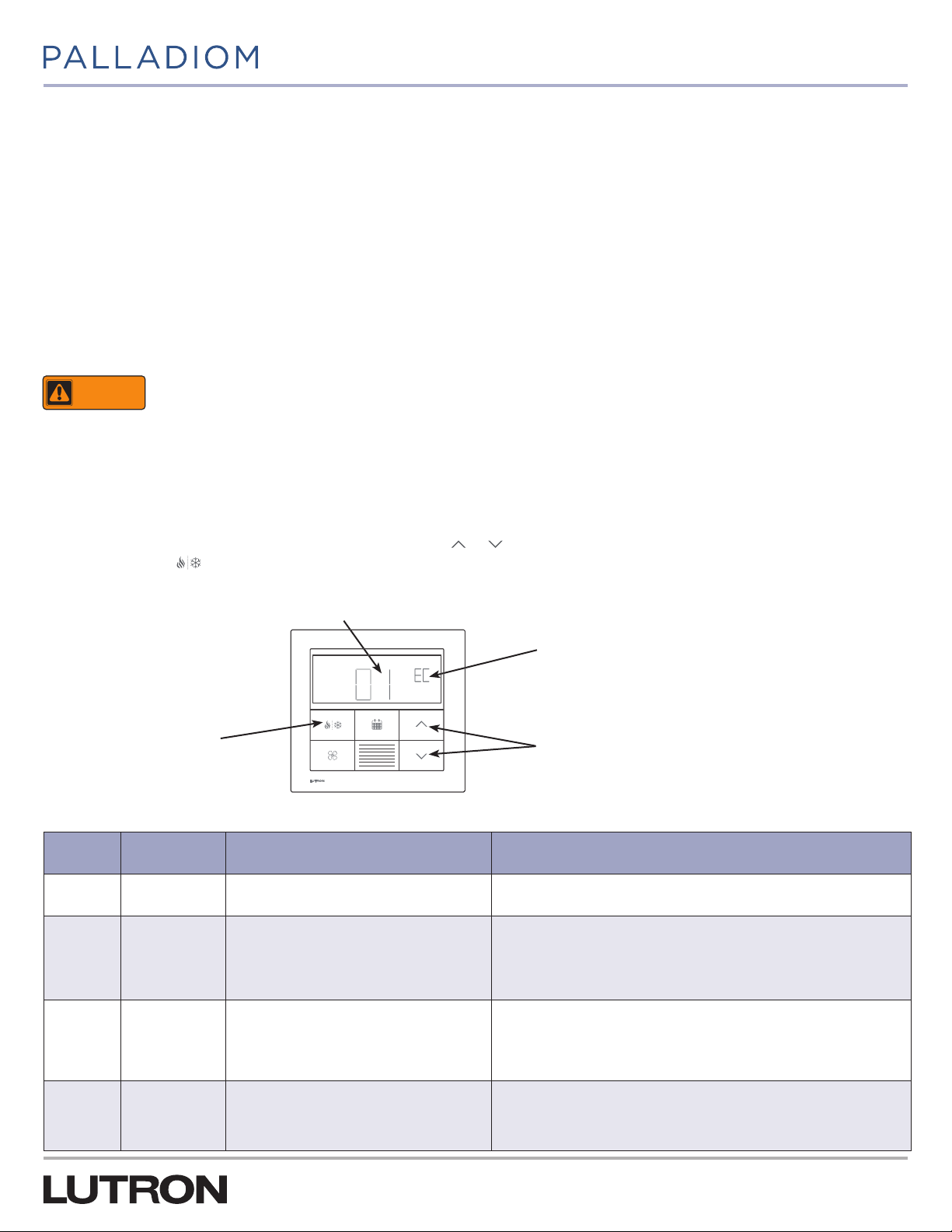

Step 2: Equipment Configuration Mode

Included with thermostat version 3.0 or later

WARNING

1. Enter equipment configuration mode. When a thermostat receives power, it will automatically enter equipment configuration

mode if equipment configuration has not been previously completed.

If no HVAC controller is going to be connected directly to the thermostat, skip this section. This is known as a companion thermostat

and configuration will be completed by a certified Lutron dealer via the HomeWorks QS designer software.

2. Select value for equipment configuration: Select the configuration option which describes the HVAC equipment

connected to the thermostat. Using the table below, press or to select the correct equipment configuration being used

and press and hold to save the configuration. The thermostat will then enter HVAC controller selection mode for the first zone.

Shock Hazard. Improper configuration can cause property damage, personal injury, or death. Installation and

service must be performed by a licensed professional HVAC installer (or the equivalent) or service agency.

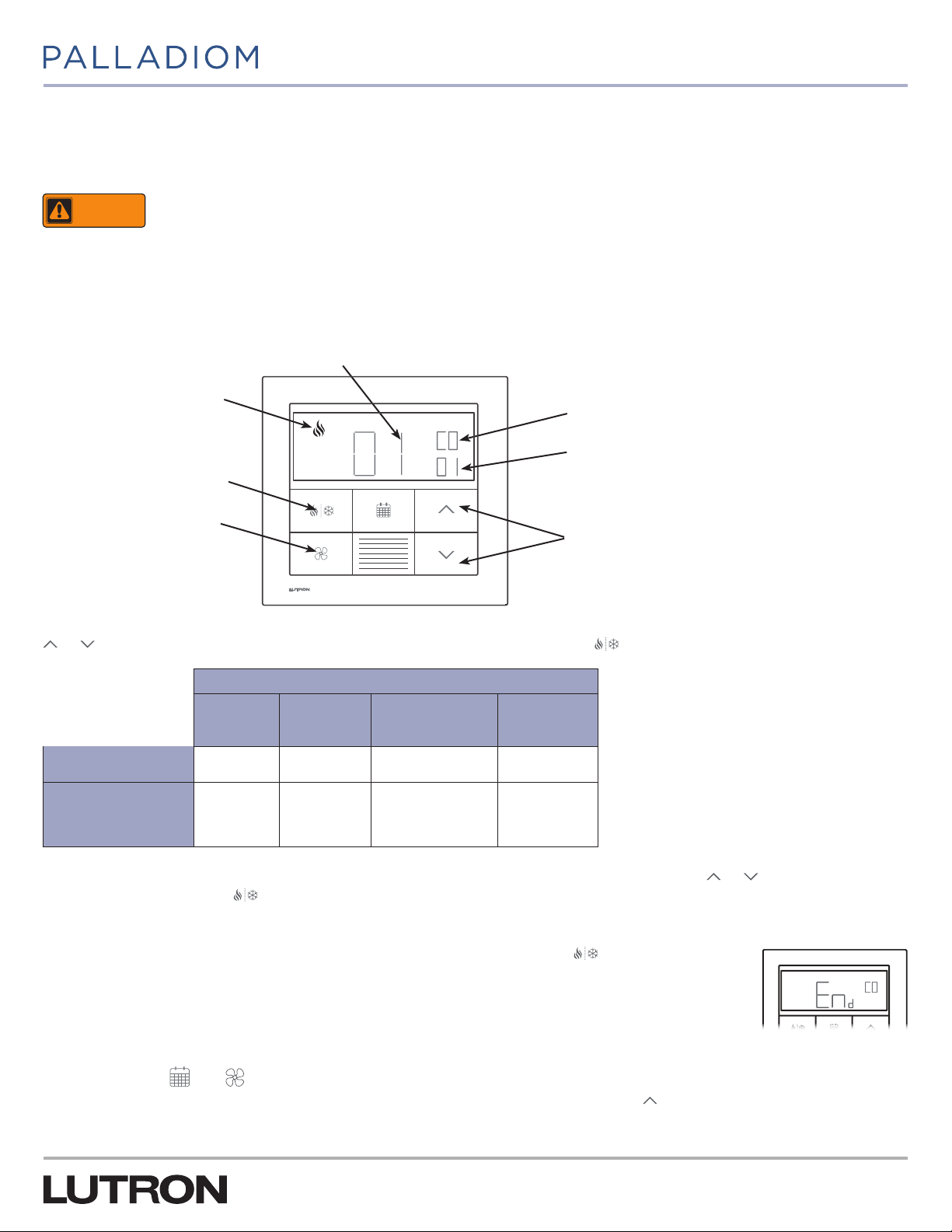

Figure 2: Display on Thermostat in Equipment Configuration Mode

Parameter value

Set

Hold 3 seconds to save and

exit configuration mode.

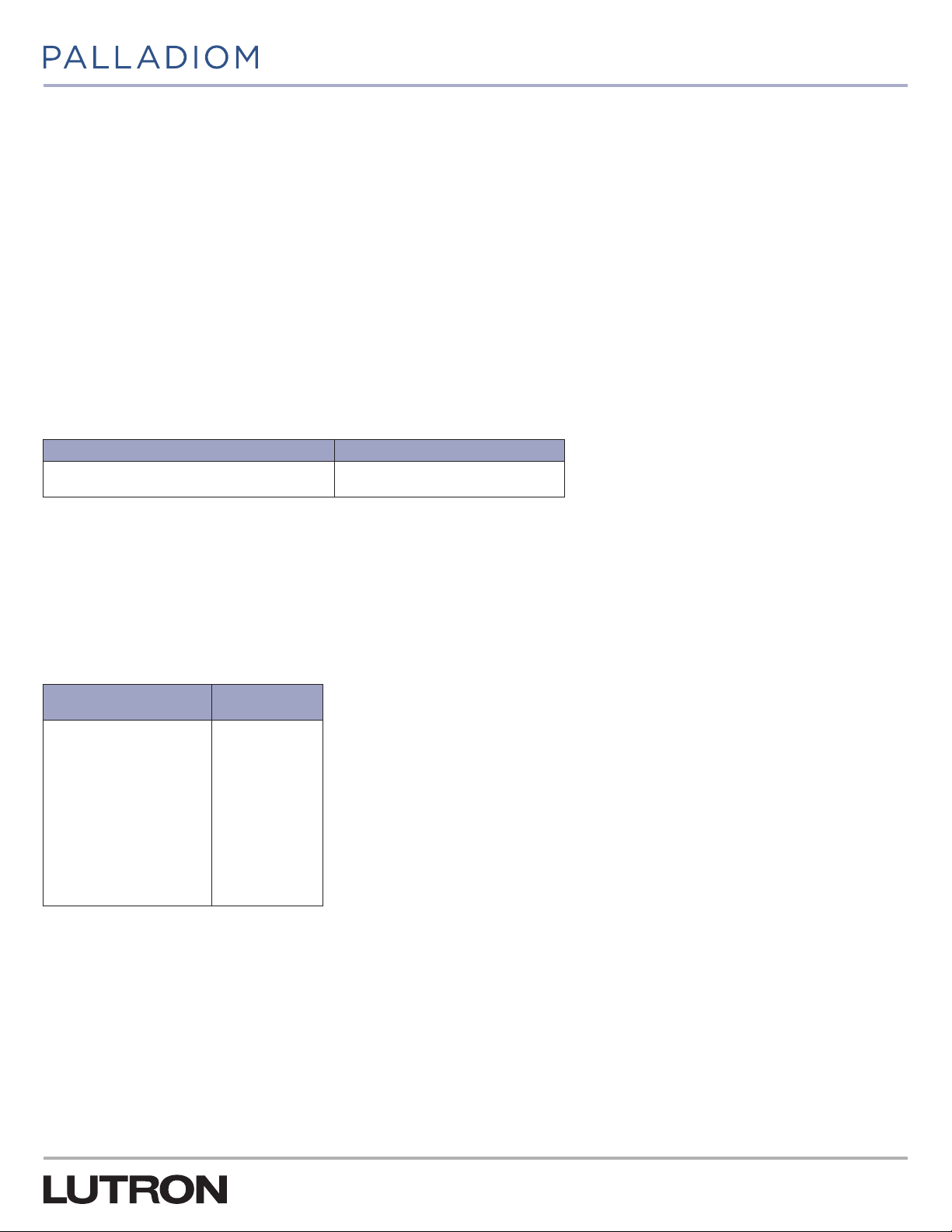

Table 1: Options for Equipment Configuration

Parameter

Value

01 1

02

03

Equipment

Typ e

2 – both heating

and cooling

equipment

connected to the

thermostat

2 – only heating

equipment

connected to the

thermostat

Description System Example

There is a single piece of equipment attached

to the HVAC controller communication link.

The thermostat controls two dif ferent HVAC

equipment types. Both pieces of HVAC

equipment are connected to the HVAC

controller communication link.

The thermostat controls two dif ferent HVAC

equipment types. Only heating equipment is

physically connected to the HVAC controller

communication link.

EC = Equipment configuration mode

Press to change parameter value

The thermostat is connected to an SMC55-HWQS which handles both

heating and cooling of the HVAC zone.

The thermostat is connected to an SMC55-HWQS used for underfloor

heating of the HVAC zone. There is also a Cool Automation CoolPlug

interface connected to the same thermostat used to cool the space. Both

pieces of equipment are in the same HVAC zone and the thermostat can

be used to heat or cool the zone.

The thermostat is connected to an SMC55-HWQS used for underfloor

heating of the HVAC zone. There is also 3rd party HVAC equipment

connected to the HomeWorks QS processor via integration, which is used

to cool the same zone. The thermostat can be used to heat or cool the

zone.

04

2 – only cooling

equipment

connected to the

thermostat

The thermostat controls two dif ferent HVAC

equipment types. Only cooling equipment is

physically connected to the HVAC controller

communication link.

The thermostat is connected to a Cool Automation CoolPlug interface to

handle cooling the HVAC zone. There is also 3rd party HVAC equipment

connected to the HomeWorks QS processor via integration, which is used to

heat the same zone. The thermostat can be used to heat or cool the zone.

7

Page 8

P/N 032498h

Step 3: Select the HVAC Controller

1

This section explains configuring the thermostat for the type of controller connected to it. Configuration is required when a new

thermostat is added.

WARNING

Shock Hazard. Improper configuration can cause property damage, personal injury, or death. Installation and

service must be performed by a licensed professional HVAC installer (or the equivalent) or service agency.

1. Enter HVAC controller selection mode. The thermostat will automatically enter HVAC controller selection mode if an HVAC

controller has not previously been selected.

If no HVAC controller is going to be connected directly to the thermostat, skip this section. This is known as a companion thermostat

and configuration will be completed by a certified Lutron dealer via the HomeWorks QS Designer software.

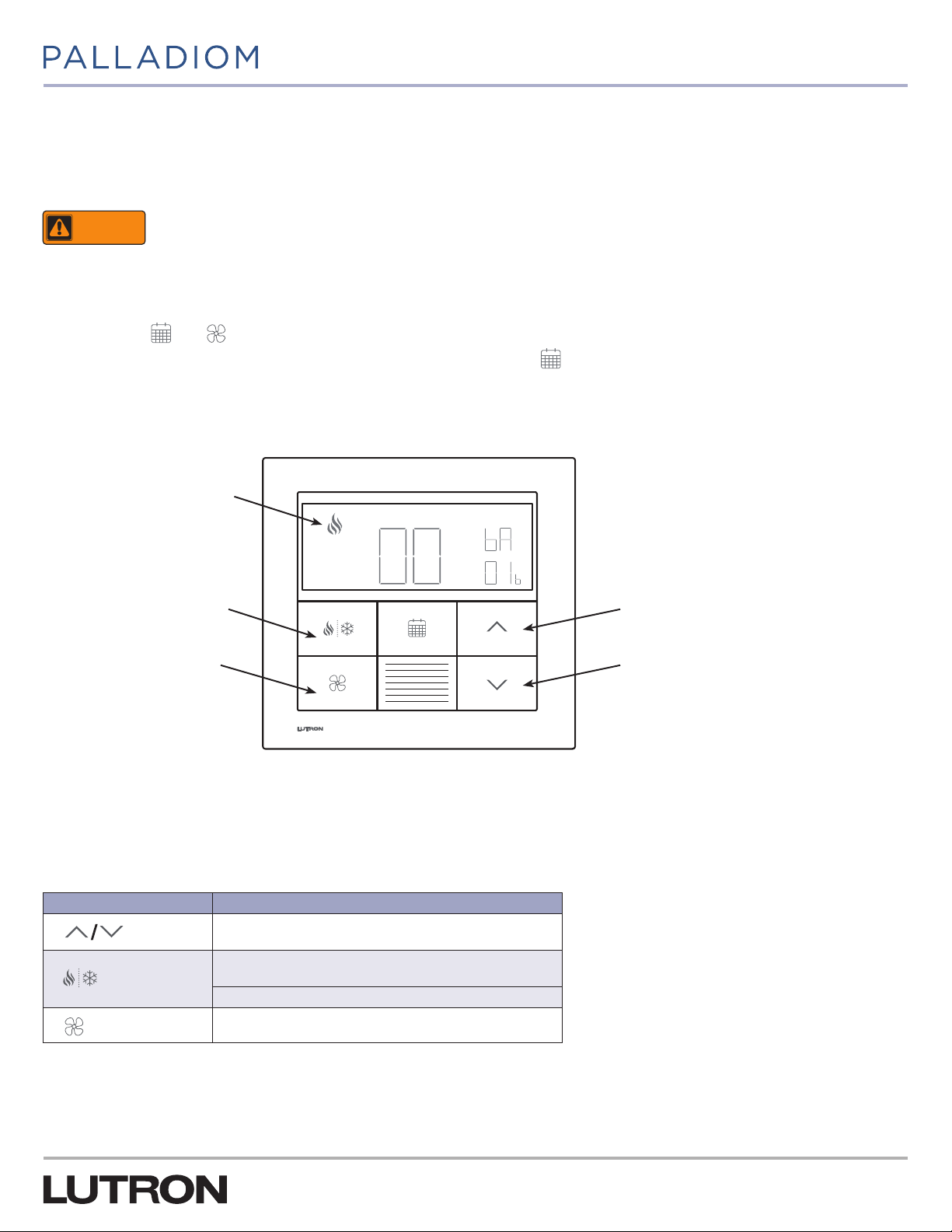

Figure 3: Display on Thermostat in HVAC Controller selection mode

Parameter value

Equipment type configuration

(if two equipment types).

Set

Press to select current value

and proceed to next parameter.

Press to go back to previous

step.

CO = HVAC controller

selection mode

Parameter ID

Press to change parameter value

2. Select value for parameter ID “01”: Select the HVAC controller connected to the thermostat. Using the table below, press

or to select the correct option for the HVAC controller being used and press .

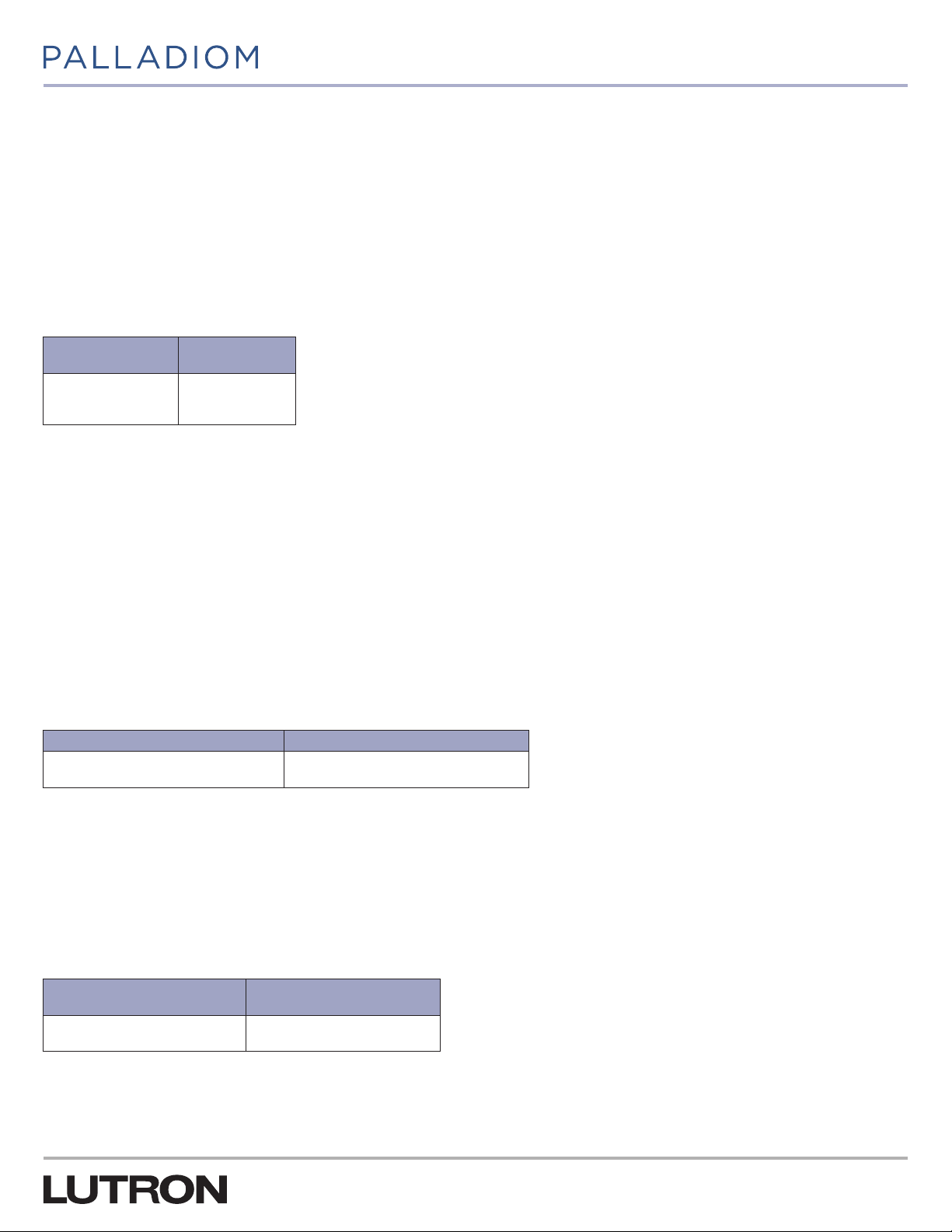

Values based on HVAC controller

Parameter ID 01:

HVAC controller option

Parameter ID 02:

Modbus address

SMC55-RESI

01 02 03 04

01-02*

Mitsubishi

A1M

01-31

(set by DIP

switches

1-5 )*

Cool Automation

CoolPlug

99*

LG

PDRYCB500

01-08

(set by DIP

switches 1-4)*

3. Select value for parameter ID “02”: Select the Modbus address.* Using the table above, press or to select the desired

Modbus address and press .

* For information see instructions included with the controller.

4. Exit HVAC controller selection mode. When “End” is shown, press and hold until the backlight

flashes (3seconds).

Note: “E1” will show on the display if the thermostat is not able to communicate with the HVAC controller.

See the Troubleshooting section on page 30.

Note: If a new HVAC controller is connected to the thermostat, the HVAC controller selection mode will

need to be re-entered. To re-enter the controller selection menu follow the steps below.

a. Press and hold

b. For controller selection mode - Release the buttons and immediately press and hold

and until the backlight flashes (3 seconds).

until the backlight stops flashing and

“CO” is shown (3 seconds).

1

Included with HomeWorks Palladiom Thermostat version 1.10 or newer.

8

Page 9

P/N 032498h

Step 4: Set the SMC55-HWQS Basic Parameters for System Compatibility

This section explains the basic configuration parameters for the SMC55-HWQS. Basic parameters are the critical parameters

which must be configured to control the HVAC equipment. The thermostat will not begin normal operation until these parameters

are configured.

WARNING

If a thermostat is connected to an SMC55-HWQS that has not yet been configured, the thermostat will automatically enter Basic

Configuration Mode. If it is desired to enter Basic Configuration Mode manually, follow the steps below.

1. Cycle power to the thermostat. The remaining 2 steps need to be completed within 15 minutes. If not, repeat Step 1.

2. Press and hold and for 3 seconds until the button backlight is lit and the display flashes.

3. Release the buttons and immediately (with in 15 seconds) press and hold for 3 seconds until the button backlight stops

flashing.

The display on the thermostat will be as shown in Figure 4:

Figure 4: Display on Thermostat in Basic Configuration Mode

Equipment type configuration

(if two equipment types).

Shock Hazard. Improper configuration can cause property damage, personal injury, or death. Installation and

service must be performed by a licensed professional HVAC installer (or the equivalent) or service agency.

Set

Save current parameter value

and go to next parameter

Return to previous parmeter

Increase current parameter value

Decrease current parameter value

In Figure 4, ‘01b’ represents the basic configuration parameter for SMC55-HWQS. ‘00’ represents the value of this parameter

and ‘bA’ indicates that this is a basic parameter.

The following table describes the buttons that are used to select a value of the basic configuration parameter for configuring the

SMC55-HWQS.

Table 2: Buttons Used for Configuring Basic Configuration Parameters

Thermostat Buttons Action

Press to increase/decrease the value of the basic

configuration parameter being displayed on the thermostat.

Press to save the value and go to the next applicable basic

configuration parameter.

Press and hold to exit the ‘End’ screen

Continued on next page...

Press to go back to the previous parameter.

9

Page 10

P/N 032498h

Step 4: Set the SMC55-HWQS Basic Parameters for System

Compatibility (continued)

Verify the wiring connections between the thermostat, the SMC55-HWQS, and HVAC equipment as shown in Figure 1 before

starting to configure the SMC55-HWQS. Table 3 below lists the details of all the basic configuration parameters - applicable

systems, basic configuration parameter index, description, default value, and the range of values for each parameter. For the

HVAC system to function properly these parameters must be configured correctly.

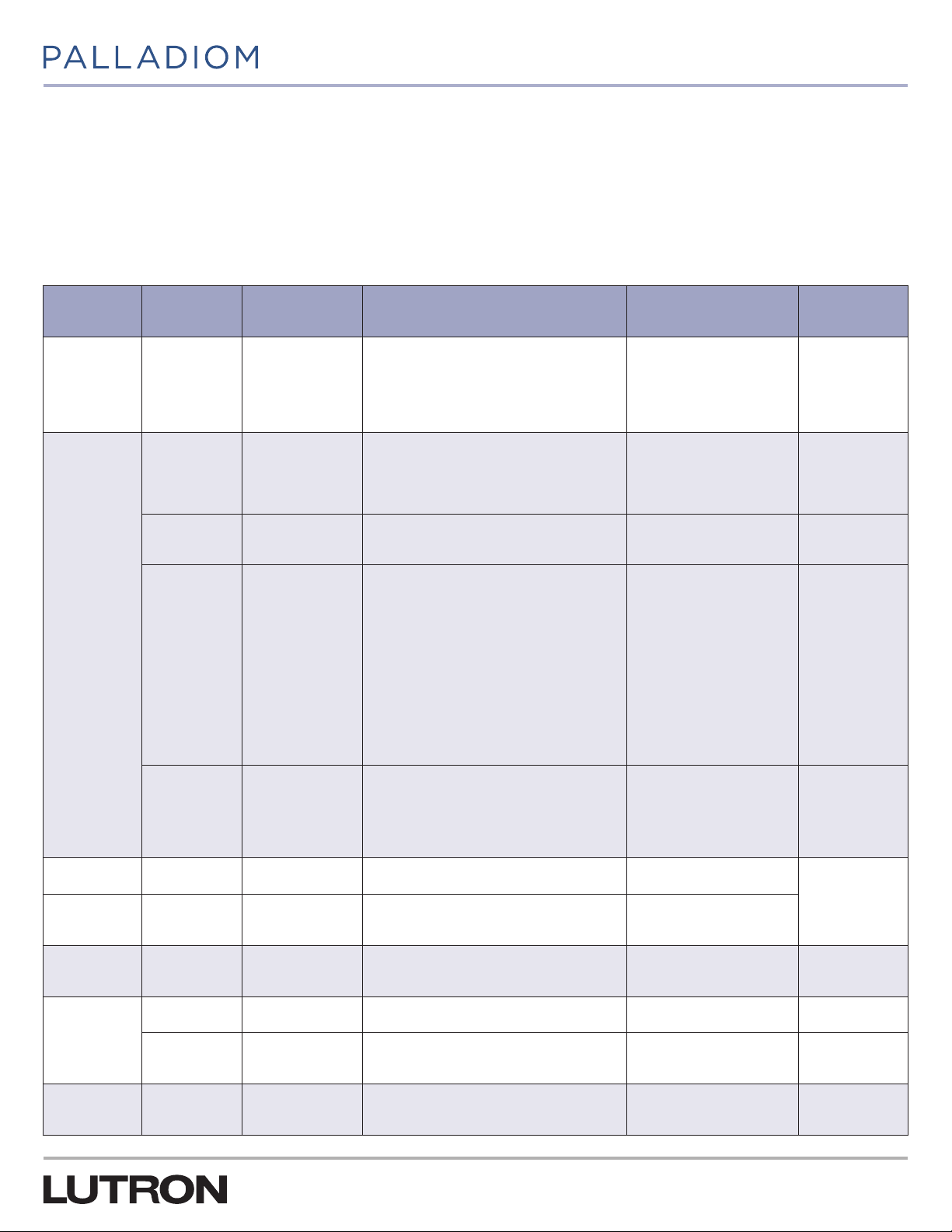

Table 3: Basic Configuration Parameters

Applicable

Systems

All 01b Sys tem Ty pe

Heat

Pump and

Conventional

Basic

Configuration

Parameter

02b Heat Stages

03b

04b

Name Description Default Value Range

Run Auxiliary Heat

) with

(Aux/W

2

other heat stages

Auxiliary Heat

) upstage

(Aux/W

2

delay

00: Conventional system

01: Heat pump

02: 2-Pipe FCU

03: 4-Pipe FCU

04: Underfloor radiant heat

05: Underfloor electric heat

00: None (No Heat Stage)

01: 1 Stage ( W

02: 2 Stage: 1 Compressor and 1 Auxiliar y

03: 2 Stage: 2 Compressor, No Auxiliary

04: 3 Stage: 2 Compressor and 1 Auxiliar y

00: No

01: Ye s

Skipped if no Aux/W

00: 0 minutes

01: 1 minute

02: 2 minutes

03: 5 minutes

04: 10 minutes

05: 20 minutes

06: 30 minutes

07: 1 hour

08: 2 hours

09: 4 hours

10: 8 hours

11- 24 : 11- 24 hour s

Skipped if no Aux/W

)

1

2

2

00: Conventional system 00–05

01: 1 Stage ( W1) 00–04

01: Yes 00–01

05: 20 minutes 00 –24

05b Cool Stages

Conventional 06b Heat Fan Control

Heat Pump 07b

Fan Coil Units

and Radiant

Floor

Fan Coil Units

Radiant Floor 11b Floor Control Type

08b

09b Fa n Type

10b 2-pipe Mode

Change over /

Reversing Valve

(O/B)

Valve / Eleme nt

Type

Continued on next page...

00: None (no cool stage)

01: 1 Cool stage ( Y1)

02: 2 Cool stages (Y1, Y2)

00: Equipment controls fan

01: Thermostat controls fan

00: On for cooling (O)

01: On for heating (B)

00: Relay

01: 0–10 V02: Floating point (Fan coil units only)

00: Relay (G1, G2, G3)

01: 0–10 V-

01: Heat only

02: Cool only

03: Changeover

01: Indoor air only

02: Indoor air and floor limiting

03: Floor temperature only

10

01: 1 Cool stage (Y1) 00–02

01: Thermostat controls fan

00–01

00: On for cooling (O)

00: Relay 00–01

00: Relay (G1, G2, G3) 00–01

03: Changeover 01–03

01: Indoor air only 01–03

Page 11

P/N 032498h

Step 4: Set the SMC55-HWQS Basic Parameters for System

Compatibility (continued)

The different basic configuration parameters and the values available for each of these parameters are listed below:

(01b): System Type

Use this parameter to select the HVAC system type. Refer to the HVAC equipment manual or label to identify the type of HVAC

equipment. The different options available for this parameter are listed in the table below:

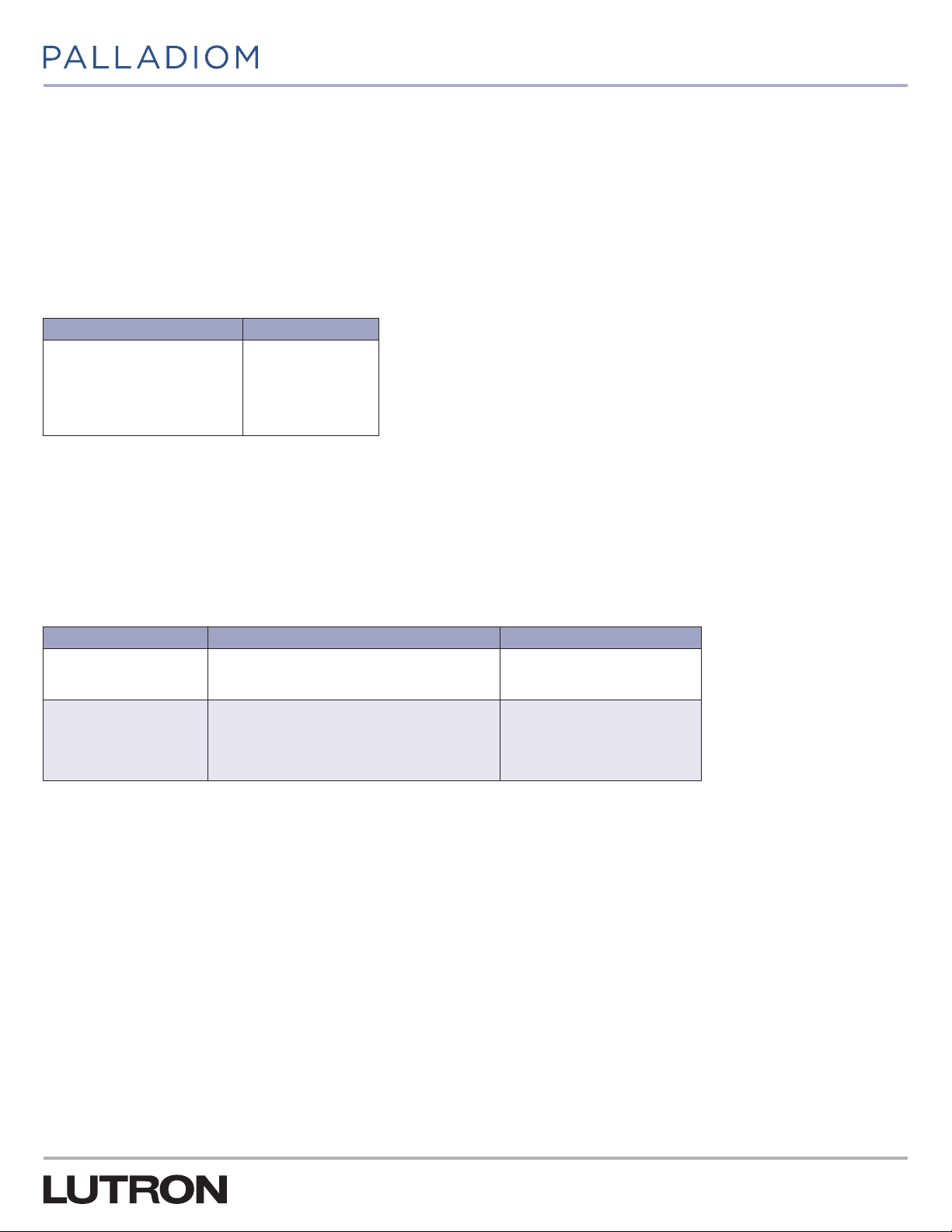

Table 4: Values for Different Types of HVAC Equipment

Available Options Default Value

00: Conventional

01: Heat pump

02: 2-pipe FCU

03: 4-pipe FCU

04: Hydronic underfloor heating

05: Electric underfloor heating

(02b): Heat Stages

Applicable systems: Conventional and Heat Pump.

Use this parameter to set the number of supported heat stages. This parameter will be skipped if you select an option anything

other than ‘00: Conventional’ or ‘01: Heat Pump’ for the previous parameter (01b). Refer to the HVAC equipment installation

manual or label for the number of supported heat stages. The different options available for this parameter are listed in the table

below:

00: Conventional

Table 5: Values for Different Heat Stages Based on System Type

System type (01b) Values for heat Stages (02b) Default Value

00: Conventional

01: Heat pump

00: No heat stage

01: 1 heat stage ( W

02: 1 primary source and 1 auxiliary source (W2)

00: No heat stage

01: 1 stage (W

02: 2 stage (1 compressor and 1 auxiliary)

03: 2 stage (2 compressors and no auxiliary)

04: 3 stage (2 compressors and 1 auxiliary

)

1

)

1

01: 1 heat stage ( W1)

02: 2 stage (1 compressor

and 1 auxiliary)

Continued on next page...

11

Page 12

P/N 032498h

Step 4: Set the SMC55-HWQS Basic Parameters for System

Compatibility (continued)

(03b): Run Auxiliary Heat (Aux / W2) With Other Heat Stages 1

Applicable Systems: Conventional and Heat Pump only if auxiliary heat stage is supported by the system.

Use this parameter to select whether or not the auxiliary heating stage can be allowed to run along with the other heat stages.

This parameter will be skipped if you select an option anything other than ‘02: 2 stages’ (1 Compressor and

1 Auxiliary/1 Primary source and 1 Auxiliary source [W2]) or ‘04: 3 stage’ (2 Compressor and 1 Auxiliary) for the previous

parameter (02b).

Note for Heat Pump: If auxiliary heat stage runs on gas/oil then it is recommended to choose a value 00: Do not run auxiliary

with other heat stages. Refer to the HVAC equipment manual to determine which value to select.

The different options available for this parameter are listed in the table below:

Table 6: Values for Running Auxiliary Heat With Other Heat Stages

Run Aux/W2 With Other Heat Stages (03b) Default Value of 03b

00: do not run auxiliary with other heat stages

01: Run auxiliary with other heat stages

(04b): Auxiliary Heat (Aux/W2) Upstage Delay 1

01: Run auxiliary with other heat

stages

Applicable systems: Conventional and Heat Pump only if an auxiliary heat stage is supported.

Use this parameter to select the delay between starting the first heat stage and starting the auxiliary heating stage. This

parameter will be skipped if you select a system without auxiliary heat

The different options available for this parameter are listed in the table below:

Table 7: Values for Upstage Auxiliary Delay

Auxiliary Heat (Aux/W2)

Upstage Delay (04b)

00: 0 minutes

01: 1 minute

02: 2 minutes

03: 5 minutes

04: 10 minutes

05: 20 minutes

06: 30 minutes

07: 1 hour

08: 2 hours

09: 4 hours

10: 8 hours

11- 24 : 11- 24 hour s

Default Value

of 04b

05: 20 minutes

1

Included with SMC55-HWQS version 7420 or newer, SMC55-RESI version 7302 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

Continued on next page...

12

Page 13

P/N 032498h

Step 4: Set the SMC55-HWQS Basic Parameters for System

Compatibility (continued)

(05b): Cool Stages

Applicable Systems: Conventional and Heat Pump.

Use this parameter to select the number of cool stages. This parameter will be skipped in the menu if you select any option other

than ‘00: Conventional’ or ‘01: Heat Pump’ for the previous parameter (01b). Refer to your HVAC equipment installation manual or

label for the number of supported cool stages. The different options available for this parameter are listed in the table below:

Table 8: Values for Cooling Stages

Values for Cooling

Stages in 05b

00: None

01: 1 stage

02: 2 stage

Refer to Table 21 in Appendix A for the details about the different relays that get energized in the different cool stages for Heat

Pump and Conventional systems.

(06b): Heat Fan Control

Applicable System: Conventional systems with at least one heat stage.

Default Value

01: 1 stage

Use this parameter to specify if the SMC55-HWQS should turn on the fan when turning on the heat. For some HVAC system

types, a control signal for the fan is not needed from the SMC55-HWQS because the equipment automatically turns the fan

on when there is a call for heat. In such cases ensure that AUTO is enabled in the available Fan Modes in the HomeWorks QS

designer software.

This parameter will be skipped and will default to have the fan turn on with the heating if you select a system type that is not

conventional or has no heating stages. Refer to your HVAC equipment manual and HVAC equipment label to identify the type of

conventional system. The different options available for this parameter are listed in the table below:

Table 9: Values for Heat Fan Type

Values for 07b Default Value

00: Equipment controls the fan relay

01: Thermostat controls the fan relay

01: Thermostat controls the fan relay

(07b): Changeover/Reversing Valve (O/B) Type 1

Applicable System: Heat Pump.

Use this parameter to select the type of reversing valve: energize for heating or energize for cooling. This parameter will be

skipped in the menu if you select any option other than ‘01: Heat Pump’ for the previous parameter (01b). Refer to your HVAC

equipment manual to identify the type of reversing valve (O/B). The different options available for this parameter are listed in the

table below:

Table 10: Values for Different Types of Reversing Valves

Changeover/Reversing Valve

(O/B) Type (07b)

00: Energize for cooling (O)

01: Energize for heating (B)

Default Value

00: Energize for cooling (O)

1

Included with SMC55-HWQS version 7420 or newer, SMC55-RESI version 7302 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

Continued on next page...

13

Page 14

P/N 032498h

Step 4: Set the SMC55-HWQS Basic Parameters for System

Compatibility (continued)

(08b): Valve / Element Type

Applicable Systems: Fan Coil Units and Radiant Underfloor heating.

Use this parameter to select the type of valve control for heating and cooling. The heating and cooling valves can either have a

relay control (two position On / Off) or a proportional control (0–10 V-). This parameter will be skipped in the menu if you select

any option other than ‘02: 2-pipe FCU’, ‘03: 4-pipe FCU’ or ‘04: Radiant Underfloor Heating’ for the previous parameter (01b).

Refer to your HVAC equipment manual to identify the type of valve control supported by your HVAC equipment. The different

options available for this parameter are listed in the table below:

Table 11: Values for Type of Valve Control

Valve / Eleme nt Type (08b) Default Value

00: Relay

01: 0–10 V02: Floating point (FCUs only)

(09b): Fan Type

Applicable System: Fan Coil Units.

Use this parameter to select the type of control for fan. The fan can have either a relay control (3-speed fan control) or a

proportional control (0–10 V-).

1

00: Relay

Note: Some of the Fan Coil Units can have a two-pole contact closure with a 2-speed fan (medium and high) or a single speed

fan (low). Refer to the wiring diagram in thermostat installation guide to install the SMC55-HWQS with Fan Coil Units with a

2-speed or single-speed fan.

This parameter will be skipped in the menu if you select any option other than ‘02: 2-pipe FCU’ or ‘03: 4-pipe FCU’ for the

previous parameter (01b). Refer to HVAC equipment manual to identify the type of fan control supported by your HVAC

equipment. The different options available for this parameter are listed in the table below:

Table 12: Values for Type of Fan Control

Fan Type (09b) Default Value

00: Relay 3-speed fan

01: 0–10 V- continuous speed

00: Relay 3-speed fan

1

For floating point control, see Application Note #630. Basic Configuration set for the valve type is overridden when selecting Floating Point.

Continued on next page...

14

Page 15

P/N 032498h

Step 4: Set the SMC55-HWQS Basic Parameters for System

Compatibility (continued)

(10b): 2-Pipe Mode

Applicable System: 2-pipe Fan Coil Units.

Use this parameter to select the type of 2-pipe mode. Heat only mode is used only for heating, Cool only mode is used only

for cooling. Changeover mode is used to either heat or cool depending on the temperature of the water in the pipes. In the

changeover mode, a changeover sensor must be connected to the SMC55-HWQS. Refer to the Thermostat installation guide to

install the changeover sensor.

When the water temperature is above the value selected for the advanced parameter ‘ChangeOverToHeatTemperature’,

the SMC55-HWQS switches to the heating mode. It stays in the heating mode until the water temperature falls below the

value selected for the advanced parameter ‘ChangeOverToCoolTemperature’. When the water temperature is below the

value selected for the advanced parameter ‘ChangeOverToCoolTemperature’, the SMC55-HWQS changes over to cooling

mode. It stays in the cooling mode until the water temperature rises above the value selected for the advanced parameter

‘ChangeOverToHeatTemperature’.

If the water temperature is between the two changeover points immediately after power up, the operating mode starts in the

previous mode as per the value in the advanced parameter ‘2PipePreviousOperatingMode’. The water temperature is measured

at 30 second intervals and the operating mode is updated accordingly.

This parameter will be skipped in the menu if you select any option other than 02: 2-Pipe for the previous parameter (01b). Refer

to HVAC equipment manual to identify the type of 2-pipe FCU. The different options available for this parameter are listed in the

table below:

Table 13: Values for 2-pipe Mode

2-Pipe Mode (10b) Default Value

01: Heat only

02: Cool only

03: Changeover

03: Changeover

Continued on next page...

15

Page 16

P/N 032498h

Step 4: Set the SMC55-HWQS Basic Parameters for System

Compatibility (continued)

(11b): Underfloor Heating Control 1

Applicable Systems: Radiant Underfloor heating.

Use this parameter to select the type of control for radiant underfloor heating systems. Radiant underfloor heating systems can

be controlled in three ways:

1. Based on indoor air temperature – This type of control is used to control the temperature depending on the room air

temperature.

2. Based on floor temperature sensor – This type of control is used to control the temperature depending on the temperature

measured by the floor temperature sensor.

3. Based on indoor air and floor limiting – This control type is similar to option ‘01: Indoor air temperature’. The air temperature is

controlled with the added feature to always maintain the temperature of the floor between the Slab Minimum and Slab Maximum

temperatures. This parameter will be skipped if you select any option other than ‘04: Radiant Underfloor Heating’ for the previous

parameter (01b). The different options available for this parameter are listed in the table below:

Table 14: Values for Underfloor Control

Underfloor Heating Control (11b) Default Value

01: Indoor air temperature

02: Indoor air and floor limiting

03: Floor temperature sensor only

01: Indoor air

temperature

Note: Refer to the installation manual of the underfloor heating equipment to install the floor sensor if the control type selected is

‘02: Indoor Air and Floor Limiting’ or ‘03: Floor Temperature Sensor’ only.

1

Included with SMC55-HWQS version 7420 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

Continued on next page...

16

Page 17

Step 4: Set the SMC55-HWQS Basic Parameters for System

Compatibility (continued)

Saving and Exiting Basic Configuration

Once the values for all the applicable basic configuration parameters are entered, the following will be displayed on the

thermostat.

Figure 5: End Screen for Basic Configuration Parmeters

Press and hold to save all

parameters to SMC55-HWQS

and exit to normal operation

Return to previous parameter

P/N 032498h

The display in Figure 5 indicates that all the parameters specific to the HVAC system type are selected. At this stage, it is

recommended to verify the values selected for each parameter. To verify the values selected for each parameter press the

button. Keep pressing the button until the values of all the parameters is verified. Once all the values are verified, press the

button till you enter the ‘End’ screen.

When in the ‘End’ screen, press and hold the button until the button backlights flash and the display shows the current

room temperature (3 seconds) or the HVAC controller selection mode for the second zone (depending on the equipment

configuration). This is the normal operating mode and the thermostat and the SMC55-HWQS will start controlling the HVAC

equipment. Refer to Figure 6 for an example of the display in normal operating mode.

Figure 6: Normal Operating Mode of the Thermostat

On

AUTO

Auto

Set

Set

17

Page 18

P/N 032498h

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the

Functionality of the HVAC System

Use the Advanced Configuration Mode if any advanced configuration parameters must change from their default value.

To change / modify the advanced parameters, follow the steps below.

1. Press and hold and for 3 seconds until the buttons backlight and the display flashes.

2. Release the buttons and immediately (with in 15 seconds) press and hold for 3 seconds until the button backlights stop

flashing. Advanced configuration parameter ‘01A’ will be shown.

The display on the thermostat will be as shown in Figure 7.

Figure 7: Advanced Configuration Mode

Flashes while editing the value

of the selected parameter

Flashes while selecting the

Set

Tap to save parameter value

Hold to save all settings and

exit mode

parameter ID to edit

Increase current parameter value

Returns to selecting the

parameters without saving

the current value

Decrease current parameter value

In Figure 7, 01A represents the advanced configuration parameter for SMC55-HWQS. ‘00’ represents the value of this parameter

and ‘Ad’ indicates that this is an advanced configuration parameter. The following table describes the buttons that are used to

select a value for the advanced configuration parameter to configure the SMC55-HWQS.

Table 15: Buttons Used to Select Advanced Configuration Parameters

Thermostat Buttons Action

Press to select the advanced parameter or the value of the advanced

configuration parameter. Either the advanced parameter or value of the

advanced parameter will flash on pressing the button.

Press and hold to exit the Advanced Configuration Mode.

Press to increase / decrease the advanced parameter or value of the

advanced parameter, whichever is flashing in the menu.

Press to go back to previous parameter.

Continued on next page...

18

Page 19

P/N 032498h

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the

Functionality of the HVAC System (continued)

Table 16 lists out the details of all the advanced configuration parameters. Some of the advanced parameters are applicable to

all types of HVAC equipment while some are applicable to a specific type of HVAC equipment. The table below also categorizes

these parameters based on the type of applicable systems.

Table 16: Advanced Configuration Parameters for the SMC55-HWQS

Applicable

Systems

All

All

(except

for radiant

underfloor

heat)

All

FCUs with

multi-speed

fan

Advanced

Configuration

Parameter

01A Function Type

02A

03A Deadband Inactive range above and below the Setpoint 1 °F 0.1 °F – 10 °F

06A

07A

08A

11A Cool Fan on Delay

12A Heat Fan on Delay

18A

19A

20A

26A

27A

05A

09A

Name Description Default Value Range

2: Not Configured

(sets itself to 0

automatically when

connected to a

thermostat and basic

configuration is entered)

1: Thermostat sensor 0 – 1

0 seconds 0 – 99

0 seconds 0 – 99

3: Auto 0 – 3

4: Au to 0 – 5

0° F -5.0 – +5.0

30 minutes 0.5 – 99.5

0: Alarm and keep trying 0 – 1

1.5 °F 0.1 – 10.0

0: Off 0 – 1

0 – 2

0 – 99.9

(minutes)

0 – 99.9

(minutes)

Temperature

Se n s or Ty p e

Minimum Fan

On Time

Overrun Cool

Fan Time

Overrun Heat Fan

Time

Standalone

Temperature

Operation Mode

Standalone Fan

Mode

(not applicable to

radiant floors)

Remote Sensor

Temperature

Offset

Cannot Reach

Setpoint Timeout

Cannot Reach

Setpoint Action

Fan High

Differential

Kick-Star t Fan

(multi-speed

fan only)

0: Operate with thermostat

1: Standalone

2: Not Configured

0: Flush mounted sensor connected to

HVAC controller

1: Thermostat sensor

Minimum time fan is on in auto mode (minutes) 2 minutes 0 – 99

Minutes the fan runs after cooling relay opens 0 minutes

Minutes the fan runs after heating relay opens 0.1 minutes

Time to delay start of fan after cooling star ts.

Only used with Fan Auto Speed when fan was

las t of f.

Time to delay start of fan after heating starts.

Only used with Fan Auto Speed when fan was

las t of f.

0: Off

1: Heat Only

2: Cool Only

3: Auto

0: Off

1: L ow

2: Medium

3: High

4: Au to

5: Single Speed On

Temperature offset for remote temperature

sensor. This allows for compensation based

on the installation location of the probe.

Cannot reach setpoint alarm time threshold

(minutes)

0: Alarm and keep trying

1: Alarm and enter failsafe

Auto fan mode temperature difference in

degrees to switch from medium to high fan

speed

0: Off

1: Set fan high for 1 second when turning on

Continued on next page...

19

Page 20

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the

Functionality of the HVAC System (continued)

Table 16: Advanced Configuration Parameters for the SMC55-HWQS (continued)

1

Advanced

Configuration

Parameter

40A

41A

42A

43A

44A

50A

51A

52A

53A

54A

55A

56A

60A

61A

70A

71A

72A

74A

75A

76A

77A

Name Description Default Value Range

Pipe Temperature

for Changeover to

Heat Mode

Pipe Temperature

for Changeover to

Cool Mode

Enable Purge

Function

Purge Valve

On-Time

Purge Valve

Off-T ime

Proportional Fan

Minimum

Proportional Fan

Low Speed

Proportional Fan

Medium Speed

Proportional Fan

High Speed

Minimum Valve

Percent Open

Valve Fully Open

Differential

Non-proportional

Analog output

Enable Floating

Point

Actuator Running

Time

Minimum

Compressor Run

Time (MCRT)

Minimum

Compressor Off

Time (MCOT)

Heat stage 1 delay

(WOD)

Heat Stage 1

) On

(Y

1/W1

Heat Stage 1

(Y1 / W1) Off

Heat Compressor

Stage 2 (Y2) On

Heat Compressor

Stage 2 (Y2) Off

Pipe temperature that designates heating

mode when using a 2-pipe system with a

changeover sensor on the pipe.

Pipe temperature that designates heating

mode when using a 2-pipe system with a

changeover sensor on the pipe.

Turns the valve on if left dormant to refresh

pipe temperature; 0: Disabled; 1: Enabled

Number of minutes to leave the valve on during

a purge. 0: Disabled

Hours to leave the valve off between purges

0: Disabled

The lowest percent output to apply for fan

speed. This determines the low end-point of

the fan being on. If at any time the fan output is

0% (Off), the valves will also close at 0%.

The % output to apply when the manual fanspeed is set to Medium.

The % output to apply when the manual fanspeed is set to Medium.

The % output to apply when the manual fanspeed is set to High.

The lowest % output to apply for valve

opening. This determines the low end-point of

the straight-line curve for valve opening.

The temperature offset from deadband at

which the valve is fully open (100% opening).

Enable 0–10 V- outputs for non-proportional

fan and valves.

0: Disabled, 1: Enabled (overrides basic valve

configuration)

Actuator Running Time for Floating Point

control.

Minimum run time for compressor. 0 minutes 0 – 99 minutes

Minimum off time for compressor. 5 minutes 0 – 99 minutes

Minimum off time for W1 (conventional heat

stage 1)

°F below setpoint to turn stage on. 1 °F

°F above setpoint to turn stage off. 1 °F

°F below setpoint to turn stage on. 2 °F

°F above setpoint to turn stage off. 0 °F

82 °F 75 – 99

60 °F 32 – 70

1: Enabled 0 – 1

2 minutes 0 – 60

2 hours

10% 0 – 100

20% 0 – 100

60% 0 – 100

100% 0 – 100

10% 0 – 100

1 °F .1 – 10.0

True (1)

0: Disabled 0 – 1

150 seconds 1 – 999

3 minutes 0 – 99 minutes

0.5 – 99.5

(hours)

0: disabled

1: enabled

1 °F – 10 °F

1 °F – 10 °F

1 °F – 10 °F

1 °F – 10 °F

Applicable

Systems

2-pi pe FCU

0–10 V- FCU

Floating Point

Valves

Heat

1

and

Pump

Conventional

Heat Pump

P/N 032498h

1

Included with SMC55-HWQS version 7420 or newer, SMC55-RESI version 7302 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

Continued on next page...

20

Page 21

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the

Functionality of the HVAC System (continued)

Table 16: Advanced Configuration Parameters for the SMC55-HWQS (continued)

Applicable

Systems

Heat

1

and

Pump

Conventional

Heat

1

Pump

Radiant

1

Floor

Advanced

Configuration

Parameter

78A Aux / W2 On

79A Aux / W2 Off

80A

81A

82A

83A

84A

85A

88A

90A Slab Maximum

91A Slab Minimum

92A

93A

94A

Name Description Default Value Range

Cool Stage 1 On

Cool Stage 1 Off

Cool Stage 2 On

Cool Stage 2 Off

Compressor

Cool Stage 2

Upstage Delay

Compressor

Heat Stage 2

Upstage Delay

Reversing

Valve Delay

(RVD)

Floor 100%

Differential

Temperature

Floor 0%

Differential

Temperature

Cycles Per Hour

°F below setpoint to turn stage on. If auxiliary is stage 2, this

differential is used to turn on.

°F above setpoint to turn stage off. If auxiliary is stage 2, this

differential is used to turn off.

°F above setpoint to turn stage on. 1 °F

°F below setpoint to turn stage off. 1 °F

°F above setpoint to turn stage on. 2 °F

°F below setpoint to turn stage off. 0 °F

Stage 2 cooling will not turn on until the first stage has run

for the chosen duration.

0: 0 minutes, 1: 1 minute, 2: 2 minutes, 3: 5 minutes,

4: 10 minutes, 5: 20 minutes, 6: 30 minutes, 7: 1 hour,

8: 2 hours, 9: 4 hours, 10: 8 hours, 11–99: 11–99 hours

Stage 2 compressor heating will not turn on until the first

stage has run for the chosen duration.

0: 0 minutes, 1: 1 minute, 2: 2 minutes, 3: 5 minutes,

4: 10 minutes, 5: 20 minutes, 6: 30 minutes, 7: 1 hour,

8: 2 hours, 9: 4 hours, 10: 8 hours, 11–99: 11–99 hours

Delay to wait for reversing valve to change over. When changing

between heat and cool, the thermostat will turn off the

compressor, then wait for MCOT. The thermostat will then change

the state of the O/B signal, and wait for the reversing valve delay

(RVD) before turning the compressor and fan back on.

If slab temperature rises above this maximum, must turn off

regardless of air temperature.

If slab temperature falls below this minimum, must turn on

regardless of air temperature.

°F below the setpoint to turn on system to 100%. 2.0 °F 0 – 20 °F

°F above the setpoint to turn on system to 0%. 2.0 °F 0 – 20 °F

Cycles per hour (CPH).

3 °F

0 °F

0 minutes

0 minutes, however

thermostat will default

based on stages

1 second

85 °F 0 – 120 °F

60 °F 0 – 120 °F

3 (20 minute signal period)

P/N 032498h

1 °F – 10 °F

1 °F – 10 °F

1 °F – 10 °F

1 °F – 10 °F

1 °F – 10 °F

1 °F – 10 °F

0 – 99

minutes

0 – 99

minutes

0 – 99

seconds

1-20 CPH

1

Included with SMC55-HWQS version 7420 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

Continued on next page...

21

Page 22

P/N 032498h

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the

Functionality of the HVAC System (continued)

Parameters Applicable to All Types of HVAC Equipment

Some of the advanced configuration parameters are applicable to all types of HVAC equipment. This sections lists out the details

about these parameters.

(01A) Function Type

Use this parameter to define if the SMC55-HWQS is configured to work with the thermostat or configured to work as a

standalone device without the thermostat. The SMC55-HWQS can work as a standalone HVAC controller if a remote air sensor

is connected to the SMC55-HWQS. The default value for this parameter is set as ‘02: Not Configured’. Saving and exiting the

basic configurations mode will automatically set this parameter to ‘00: Operate with Thermostat’ by default.

This parameter can be set to ‘01’ to still function without the thermostat connected. Once the thermostat is connected, you must

change the value of this parameter back to ‘00’ so that the SMC55-HWQS should work with the thermostat.

Note: Standalone mode (‘01’) requires connecting a wired remote air temperature sensor to the SMC55-HWQS. See the

SMC55-HWQS instruction sheet included in the box with the remote air temperature sensor. Set the parameter ‘02A’ to ‘00:

Remote Temperature Sensor’ so that SMC55-HWQS can work with the remote sensor.

(02A) Temperature Sensor Type

Use this parameter to identify the temperature sensor used to measure the room temperature. Set this parameter to ‘01’ if using

the sensor inside the thermostat to measure the room temperature. Set this parameter to ‘00’ if using the remote temperature

sensor to measure the room temperature.

(06A) Minimum Fan On Time

Use this parameter to identify the minimum time the fan will run once it has turned on irrespective of whether or not the system is

running. This minimum run time is used to avoid short cycling the fan motor.

(07A) Extended Cool Fan Time (OCFT)

Use this parameter to identify the extended amount of time which the fan runs after the system stops cooling. This is used to

purge the cool air out of the vents.

(08A) Extended Heat Fan Time (OHFT)

Use this parameter to identify the extended amount of time which the fan runs after the system stops heating. This is used to

purge the hot air out of the vents.

(11A) Cool Fan On Delay (CFOD)

Use this parameter to identify the time delay before the fan turns on after the system starts cooling. This is used so that

uncomfortably hot air is not blown out of the vents.

(12A) Heat Fan On Delay (HFOD)

Use this parameter to identify the time delay before the fan turns on after the system starts heating. This is used so that

uncomfortably cold air is not blown out of the vents.

(18A) Standalone Temperature Operation Mode

Use this parameter to identify the operating mode when the SMC55-RESI is set up to work in a standalone mode without the

thermostat.

(19A) Standalone Temperature Fan Mode

Use this parameter to identify the fan mode when the SMC55-RESI is set up to work in a standalone mode without the thermostat.

Continued on next page...

22

Page 23

P/N 032498h

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the

Functionality of the HVAC System (continued)

Parameters Applicable to All Types of HVAC Equipment (continued)

(26A) Cannot Reach Setpoint Timeout

Use this parameter to identify the maximum time it should take to reach the desired setpoint. If the desired setpoint is not

reached within this time then an alarm is triggered to notify the user.

(27A) Cannot Reach Setpoint Action

Use this parameter to identify whether or not the system should continue heating or cooling after the alarm for ‘Cannot Reach

Setpoint’ is triggered.

Set this parameter to ‘00’ if the system should continue heating/cooling. Set this parameter to ‘01’ if the system should stop

heating or cooling when ‘Cannot Reach Setpoint’ alarm is triggered.

Parameters Applicable to Conventional and Heat Pump Systems

This section lists out the details of the advanced configuration parameters applicable to Conventional and Heat Pump systems.

(70A) Minimum Compressor Run Time (MCRT)

Use this parameter to identify the minimum time the compressor must run to ensure proper lubrication. Refer to Figure 8 b elow.

Even though the desired temperature setpoint is met the compressor will run for an additional amount of time till the minimum

compressor run time expires.

Figure 8: Compressor Runs Until Minimum Compressor Time Expires

Min Compressor Run Time

Call Input for Compressor

Y

- Compressor

1

signal out

Call for no

compressor

MCRT = 1 minute MCRT = 1 minute

MCRT Starts MCRT Starts

Time

Call for no

compressor

(71A) Minimum Compressor Off Time (MCOT)

Use this parameter to identify the minimum time for which the compressor must remain Off before it can start. This delay is

intended to reduce compressor restart stress. Fan will stay off in Auto mode during this delay. Refer to the Figure 9 below, the

compressor will start only after MCOT has expired.

Figure 9: Minimum Time for Which The Compressor Must Remain Off Before It Can Start

Min Compressor Off Time

Call Input for Compressor

Y1 - Compressor

signal out

Call for no compressor,

MCOT Start

MCOT = 5 minute MCOT = 5 minute

Call for no compressor,

MCOT Start

G - Fan output signal

Continued on next page...

Time

23

Page 24

P/N 032498h

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the

Functionality of the HVAC System (continued)

Parameters Applicable to Conventional and Heat Pump Systems (continued)

(74A) Heat Stage 1 – On Del ta 1

Use this parameter to identify the temperature below the heat setpoint when Heat Stage 1 should turn on. Refer to the control

diagrams in Appendix A. These diagrams graphically represent the Heat Stage 1-On Delta for Conventional and Heat Pump

systems.

(75A) Heat Stage 1 – Off Delta 1

Use this parameter to identify the temperature above the heat setpoint when Heat Stage 1 should turn off. Refer to the control

diagrams in Appendix A. These diagrams graphically represent the Heat Stage 1-Off Delta for Conventional and Heat Pump

systems.

(76A) Heat Stage 2 (Y2/W2/Aux) – On Delta 1

Use this parameter to identify the temperature below the heat setpoint when Heat Stage 2 should turn on. Refer to the control

diagrams in Appendix A. These diagrams graphically represent the Heat Stage 2-On Delta for Conventional and Heat Pump

systems.

(77A) Heat Stage 2 – Off Delta 1

Use this parameter to identify the temperature above the heat setpoint when Heat Stage 2 should turn off. Refer to the control

diagrams in Appendix A. These diagrams graphically represent the Heat Stage 2-Off Delta for Conventional and Heat Pump

systems.

(78A) Heat Stage 3 (Aux) – On Del ta 1

Use this parameter to identify the temperature below the heat setpoint when Heat Stage 3 (Aux) should turn on. Refer to the

control diagrams in Appendix A. These diagrams graphically represent the Heat Stage 3-On Delta for Conventional and Heat

Pump systems.

(79A) Heat Stage 3 (Aux) – Off Delta 1

Use this parameter to identify the temperature above the heat setpoint when Heat Stage 3 (Aux) should turn off. Refer to the

control diagrams in Appendix A. These diagrams graphically represent the Heat Stage 3-Off Delta for Conventional and Heat

Pump systems.

(80A) Cool Stage 1 – On Delta 1

Use this parameter to identify the temperature above the cool setpoint when Cool Stage 1 should turn on. Refer to the control

diagrams in Appendix A. These diagrams graphically represent the Cool Stage 1-On Delta for Conventional and Heat Pump

systems.

(81A) Cool Stage 1 – Off Delta 1

Use this parameter to identify the temperature below the cool setpoint when Cool Stage 1 should turn off. Refer to the control

diagrams in Appendix A. These diagrams graphically represent the Cool Stage 1-Off Delta for Conventional and Heat Pump

systems.

(82A) Cool Stage 2 – On Del ta 1

Use this parameter to identify the temperature above the cool setpoint when Cool Stage 2 should turn on. Refer to the control

diagrams in Appendix A. These diagrams graphically represent the Cool Stage 2-On Delta for Conventional and Heat Pump

systems.

1

Included with SMC55-HWQS version 7420 or newer, SMC55-RESI version 7302 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

Continued on next page...

24

Page 25

P/N 032498h

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the

Functionality of the HVAC System (continued)

Parameters Applicable to Conventional and Heat Pump Systems (continued)

(83A) Cool Stage 2 – Off Delta 1

Use this parameter to identify the temperature below the cool setpoint when Cool Stage 2 should turn off. Refer to the control

diagrams in Appendix A. These diagrams graphically represent the Cool Stage 2-Off Delta for Conventional and Heat Pump

systems.

(84A) Compressor Cool Stage 2 Upstage Delay (CC2SUD) 1

Use this parameter to identify the time delay after the first stage of cooling has started before the Stage 2 for cooling starts. Refer to

Figure 10 below for the upstage delay before the Stage 2 of cooling is turned on.

Figure 10: Upstage Delay Before Starting Cooling Stage 2

Energizing O/B valve - Enable

cooling

Call Input for Compressor

- Compressor

Y

1

signal out

- Compressor

Y

2

signal out

G - Fan On

Cooling energized

Call for Stage 2 cooling

Upstage 2nd cool

stage delay = 2 min.

FODC

OCFT

FODC

OCFT

(85A) Compressor Heat Stage 2 Upstage Delay (CH2SUD) 1

Use this parameter to identify the time delay after the first stage of heating has started before the Stage 2 of heating starts.

(88A) Reversing Valve Delay (RVD) 1

Applicable System: Heat pump only.

Use this parameter to identify the time delay required for energizing the reversing valve. RVD is used to ensure that the reversing

valve is fully energized before turning on the compressor. This delay is used in the following scenarios:

a. Turning on the SMC55-HWQS.

b. Transitioning from heating to cooling and from cooling to heating (after MCOT expires).

c. Transitioning from operating mode ‘Off’ to operating mode ‘Heating’, ‘Cooling’, or ‘Auto’ (after MCOT expires).

Refer to Figure 11 below, the system will start after both MCOT and RVD have expired.

Figure 11: The Heat Pump Starts Heating/Cooling Only After Reversing Valve Delay Expires

Reversing Valve Delay

Call input for reversing valve

Call input for compressor

MCOT started

O/B - Reversing valve signal out

- Compressor signal out

Y

1

1

Included with SMC55-HWQS version 7420 or newer, SMC55-RESI version 7302 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.

MCOT (5 min.)

Call for compressor

RVD started

Reversing

Valve Delay

MCOT started

Call for compressor

MCOT (5 min.)

Continued on next page...

25

Page 26

Step 5: Set the SMC55-HWQS Advanced Parameters to Modify the

Functionality of the HVAC System (continued)

P/N 032498h

Parameters Applicable for Radiant Underfloor Heating System

1

Radiant Underfloor Heating Control Summary

Pulse Width Modulation (PWM) Temperature Control (for relay signals only)

Both indoor air temperature control and floor temperature control uses a PWM control algorithm when using relays. PWM works

by turning the heat on during a calculated percentage of the cycles per hour (parameter 94A).

For example, if the controller is configured to have 3 cycles per hour, there will be three 20-minute time periods in an hour. Every

time period will have the heat on for a calculated percentage of the period, known as a “duty cycle”. The duty cycle is calculated

mostly by the temperature difference from the setpoint.

• The duty cycle equals 100% of the time period when the temperature is at or below the setpoint minus the floor 100%

differential (parameter 92A).

Example: If the setpoint equals 70 °F, the duty cycle is 100% when the temperature is at or below 68°F (70 °F − 2 °F).

• The duty cycle equals 0% of the time period when the temperature is at or above the setpoint plus the floor 0% differential

(parameter 93A)

Example: If the setpoint equals 70 °F, the duty cycle is 0% (off) when the temperature is at or above 72 °F (70 °F + 2 °F).

Figure 12: Simplified Graph of the Duty Cycle Calculation

100

90

80

70

60

50

40

30

Duty Cycle On %

20

10

0

60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

Temperature (°F)

Short Cycle Prevention: To prevent the controller from cycling too quickly, duty cycle rounding is used if the cycle is almost fully

on or off. If the duty cycle value is 95% or higher, the duty cycle is rounded to 100%. If the duty cycle value is below the minimum

pulse width (Parameter 54A), the duty cycle is rounded to 0%.

0–10 V- Control (for 0–10 V- signal only)

If the valve control is set to 0–10 V-, the controller provides a continuous voltage output to the valve actuator. Similar to PWM

with relay control, the duty cycle calculated determines the output, but now in a voltage instead of an on / off interval. For

example, a duty cycle of 30% is similar to a 3.0 V output signal to the valve actuator.

Duty Cycle Sample Adaptation (for both relay and 0–10 V- signals)

The radiant floor control algorithm also uses a duty cycle sample adaptation. The purpose of the adaptation is to dynamically

change the duty cycle according to the newly sampled temperature.

1

Included with SMC55-HWQS version 7420 or newer and HomeWorks Palladiom Thermostat version 1.10 or newer.