EOS Thru-Hull Integrated System

TIX 802 & TIX 1602 Thru-Hull Light

Lumishore EOS Full Colour Change light

Installation and Operating Guide

Congratulations! You have purchased a LUMISHORE advanced technology underwater light. Every care has been

taken to ensure your Thru-Hull light arrives in perfect condition, so please enjoy the ultimate experience in

underwater lighting.

LUMISHORE Thru-Hull high intensity lights are designed for those owners who prefer the integrity of a thru-hull

installation in a light that employs the most powerful, ecient and cost eective underwater LED lighting on

the market today. The LUMISHORE Thru-Hull is suitable for many sizes and types of watercraft, including Sports

Boats, Cruisers, Yachts and Super Yachts. LUMISHORE Thru-Hull LED lights come with a compact electronic driver

module to ensure trouble free operation for years to come.

Please read the following pages before attempting installation to ensure complete understanding of

the LUMISHORE LED lights.

BEFORE YOU START

• High Intensity LED light – Do not stare into the LED module at close proximity.

• Always ensure that the vessel’s power source and battery are disconnected or isolated prior to installation

• A qualied professional should carry out both the electrical and mechanical installation. If in doubt please contact LUMISHORE;

Refer to product support section

• Always use a suitable fuse or circuit breaker to protect the complete system. Each light to be individually fused.

• The Thru-Hull maybe installed into GRP (Glass Reinforced Plastic or Fibreglass) and wooden hulls.

• For metal hull or carbon bre installations an isolation kit will be required.

• The light should be installed 6” - 10” (150-250mm) below the minimum load waterline.

• For best results install the lights between 2.5ft (0.8m) and 6.5ft (2m) apart.

• Never try to install or remove light with the vessel in the water.

• Lights should not be exposed to any temperatures in excess of 150°F (65°C). For example, next to hot engine components or

where exhaust emissions could be expelled onto the light while underwater.

• Do not over tighten the retaining bolts. A force of 3Nm on each bolt should not be exceeded.

• All LUMISHORE products should have a bonding to the DC system via bonding strap for galvanic protection.

• Choose a location - The light must be installed onto a at (not curved) surface. Mount on transom or side hull only.

The following components should be used;

• Fuse (1 per light)

• Waterproof junction box

• Power Relay

• EOS Controller

• Power cable - See cable gauge

guide for more information

• Power Switch

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

45-0057-REV-3

The following tools will be required;

• Hand Drill

• Screwdriver (Cross head)

• Appropriate Sealant (e.g. 3M 4200)

• Cleaning rags

• Holesaw - Refer to holesaw size on

page 8

www.Lumishore.com

1

Planning the Installation & Wiring Diagram

3m Light Cable (can be extended

see cable extension table on

Fuse

Junction

Box

All connections need to be made waterproof. Use

a suitable junction box or waterproof connectors.

Music

Install DMX

Terminator

(24-0087)

page 4)

DMX Cable 2 x 1m length supplied.

Extension Cables available(see cable

extension table on page 4)

GREEN DMX +

To third party

DMX Controller

WHITE DMX GND

Distribution Panel

BLUE DMX -

RED + BLACK -

To Distribution

Panel (10.5 - 31 volts)

Note: 1602 Products are

24V DC ONLY

2 Core Power cable

keep as short as possible

If extended consult cable

gauge guide (Pages 3 & 4)

Junction

Box

Junction

Box

Fuse

Fuse

Male

DMX Cable 2 x 1m length supplied.

Extension Cables available(see cable

extension table on page 4)

DMX Connector Pinouts

GND

(Scrn)

(Scrn)

GND

Female

Data-

(White)

Data+

(Black)

Battery

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

Front View

Data+

(Black)

Data-

(White)

www.Lumishore.com

2

Cable Gauge Tables

It is important to use the correct cable gauge for the installation. This can be spilt into two sections.

First work out the gauge required from the power source to the junction box, second work out the minimum gauge

needed from the junction box to the lights – these tables are given on page 4.

First, calculate the cable gauge required from the power source to the junction box. The method for doing this is:

1. Calculate the TOTAL CURRENT IN AMPS of the circuit. i.e. number of lights x max current at chosen voltage

2. Find circuit LENGTH IN FEET (or metres) along the left side of the chart. Note that the total length of the circuit

is the ROUNDTRIP distance from power source (usually the battery) to the junction box and back.

3. Read o the cable gauge required for the TOTAL CURRENT for the circuit length.

0

0

|

2

AWG

1

AWG

2

AWG

0

|

|

4

3

0

|

0

2

AWG

0

1

AWG

AWG

AWG

0

0

|

|

3

AWG

AWG

4

AWG

AWG

0

0

0

|

2

AWG

|

|

4

3

AWG

AWG

4

4

6

6

6

8

CURRENT F L O W IN AMP S

10

12

AWG

14

AWG

2

AWG

AWG

4

AWG

AWG

AWG

AWG

AWG

10

12

AWG

1

2

AWG

AWG

8

AWG

AWG

2

AWG

4

2

AWG

AWG

4

AWG

4

AWG

6

AWG

6

8

8

10

AWG

AWG

6

AWG

8

AWG

AWG

2

AWG

AWG

0

|

0

2

AWG

AWG

0

1

AWG

0

1

AWG

1

2

AWG

2

AWG

4

AWG

4

AWG

AWG

6

AWG

0

|

0

1

|

|

4

3

AWG

AWG

AWG

0

0

|

|

4

3

AWG

AWG

0

|

2

AWG

0

AWG

1

2

AWG

4

AWG

AWG

AWG

0

|

3

AWG

AWG

AWG

2

4

0

|

4

AWG

0

|

2

0

1

AWG

AWG

AWG

0

|

3

AWG

AWG

AWG

0

|

4

AWG

2

AWG

0

|

3

AWG

0

|

2

AWG

0

AWG

1

AWG

AWG

0

|

4

AWG

0

|

3

AWG

0

|

2

AWG

0

1

AWG

2

AWG

0

|

4

AWG

0

|

3

AWG

0

|

2

AWG

AWG

0

AWG

1

AWG

0

0

14

AWG

16

AWG

Critical

10

12

AWG

12

14

AWG

AWG

16

AWG

15 ft

10 ft

8

AWG

14

AWG

10

AWG

12

AWG

AWG

20 ft

25 ft

30 ft

6

AWG

8

AWG

10

AWG

40 ft

50 ft

4

AWG

6

AWG

8

AWG

60 ft

70 ft

80 ft

90 ft

0 to 6 ft

VOLTAGE

DROP

3%

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

2

AWG

4

AWG

100 ft

110 ft

2

AWG

6

AWG

120 ft

130 ft

www.Lumishore.com

3

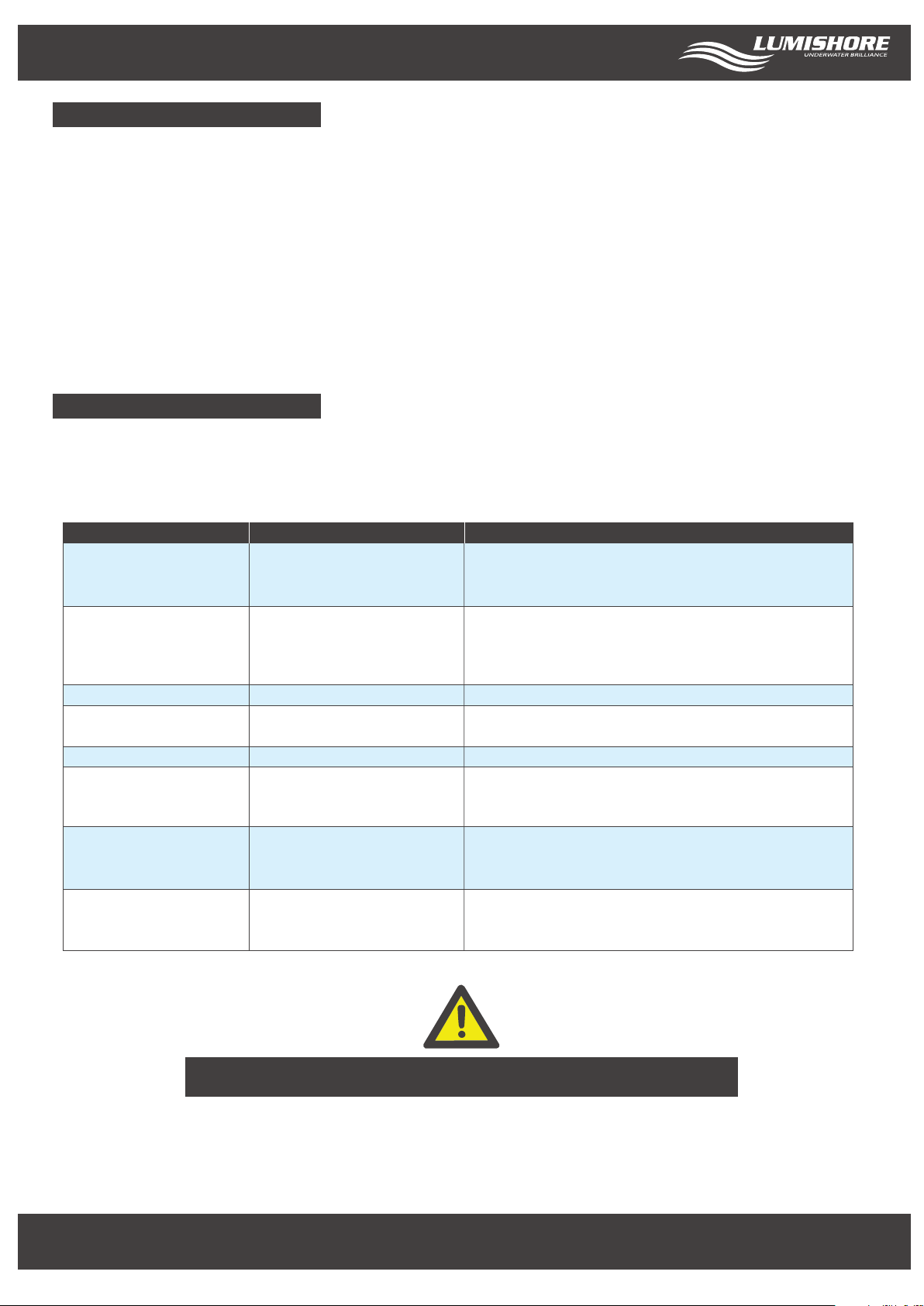

Cable Gauge Tables - Continued

The DMX cable can be extended, contact your dealer for details of light extension cables.

DMX Extension Part Number

1m

5m

15m 24-0099

The light power cable can be extended, however the correct cable gauge should be used. See the tables below.

The tables below give the minimum cable gauge required depending on the supply voltage, and distance from the power

source to the lights. Please ensure that the correct cable gauge is used in the installation

Note : The cable distance there and back has been taken into consideration in these calculations.

24-0077

24-0078

Model

TIX802

TIX1602

Fuse Table

Model

TIX802

TIX1602

AWG to Metric conversion table

AWG Size Cross sectional Area Cable diameter

18

16

14

12

10

8

6

4

2

Gauge Length of Cable

14AWG

14AWG N/A

12V

Do Not Extend

Fuse Rating

12V

15A

N/A 10A

1mm²

1.3mm²

2.0mm²

3.3mm²

5.2mm²

8.3mm²

13mm²

20mm²

33mm²

24V

7.5A

24V

32ft

30ft

0.8mm

1.3mm

1.6mm

2.0mm

2.5mm

3.2mm

4.1mm

5.1mm

6.5mm

Each light must be individually fused

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

www.Lumishore.com

4

Planning the Installation (802 & 1602)

Bonding Attention: Failure to bond the lights properly and maintain the appropriate protection will invalidate

the LUMISHORE warranty.

LUMISHORE lights should be connected to the vessel’s DC Bonding system to ensure protection from electrolytic /

galvanic corrosion. All bonding connections should be fully checked prior to returning the vessel to the water.

LUMISHORE lights have integrated circuitry to protect lights from external issues, but these are dependent upon

correct bonding.

Installation into a metal or carbon bre hull requires an isolation sleeve kit.

Metal or Carbon Fibre Hull Isolation Kit

Model

TIX802

TIX1602

Installation Considerations:

• Location - Positioning will be dependent on both external and internal obstacles; consideration should be given to

installation wiring and internal access within the vessel. Ideally the light modules should be installed 6” to 10”

(150-250mm) below the water line and spaced between 2.5ft to 6.5ft (0.8-2m) apart.

• Select a at surface; make sure that both the internal and external surfaces of the hull are even and parallel. It may

be necessary to sand or grind the surface.

• A hole will be drilled to allow the Thru-Hull light to be inserted; care must be taken to ensure there is unrestricted

access inside the hull

• The light is temperature sensitive and must not be located close to the exhaust or other heat sources.

• If multiple lights are installed, each light should be evenly spaced to ensure the best water illumination. The number

of lights and the spacing on your vessel will depend on a few factors: vessel size, location of lights and water clarity.

Part Number

60-0211

60-0212

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

www.Lumishore.com

5

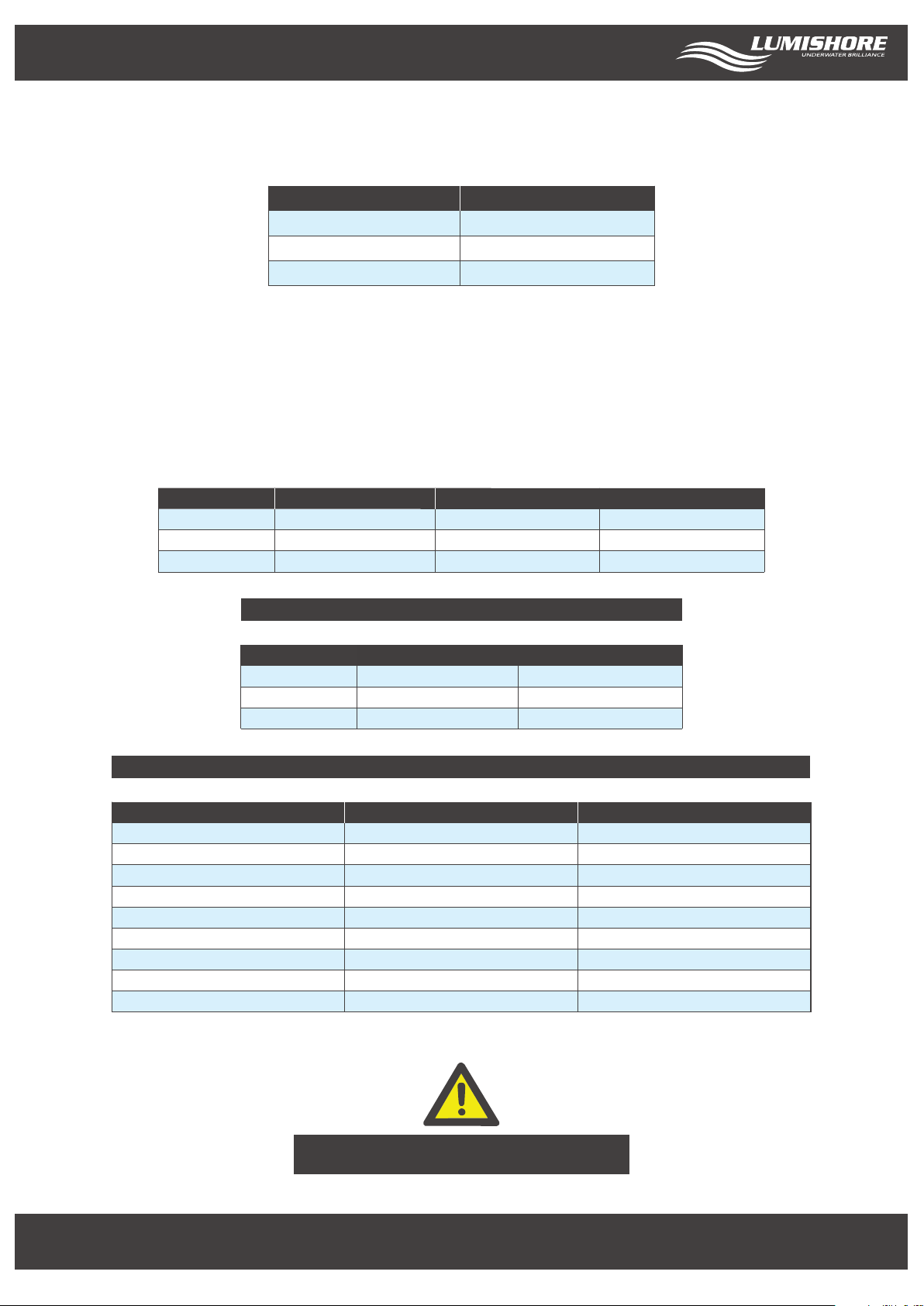

TIX 802 - Basic Dimensions

Light Unit

120mm

(4.72in)

LED ARRAY SHOWN

FOR ILLUSTRATION

PURPOSES ONLY

193mm

(7.60in)

184mm

(7.24in)

8.5mm

(0.34in)

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

(3.31in)

84mm

www.Lumishore.com

6

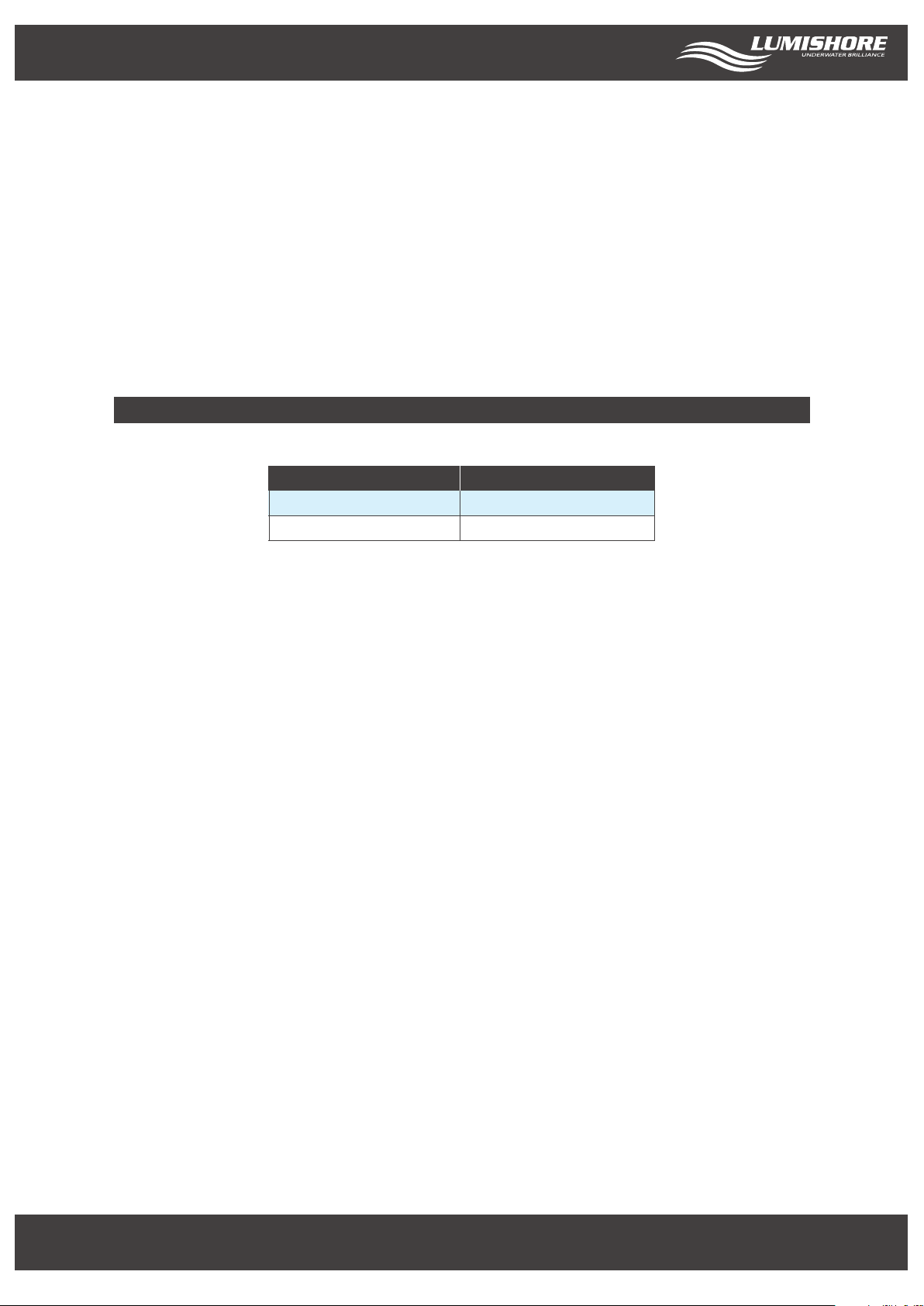

TIX 1602 - Basic Dimensions

Light Unit

140mm

(5.51in)

LED ARRAY SHOWN

FOR ILLUSTRATION

PURPOSES ONLY

195mm

(7.68in)

184mm

(7.24in)

11mm

(0.43in)

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

(3.54in)

90mm

www.Lumishore.com

7

Light Installation

Tools Required

5mm Allen Wrench

1. Measure the position of the lights on a at part of the hull. Mark carefully, and double-check for internal obstacles.

2. Check the required hole size against the table below. Drill a perpendicular hole through the hull using an appropriate

cutter for the hull material.

Model

TIX 802

TIX 1602

3. The exposed inner hull surface must be properly sealed to prevent water intrusion into the hull before the Thru-Hull

is secured in place.

4. Before inserting the Thru-Hull light ensure that the hull surface is free from dirt and grease and remove any existing

anti-foul from the hull surface.

Drill/Driver

Holesaw

Hole Size

86mm (3.375”)

92mm (3.625”)

Marine Sealant

(Use only 3M 4200)

Hole Size W/Delrin Sleeve

92mm (3.625”)

100mm (3.9375”)

Rags for clean-up

Rear Side

Note: Do not use an alcohol-based solvent as this may have an adverse eect on the sealant

5. Using an approved adhesive (3M 4200 Marine (recommended) or similar), apply liberally a continuous bead of sealant

around the entire circumference of the sealant groove, on the base of the stem and on the shaft of the Thru-Hull.

6. Feed the connector and cable through the hole in the hull avoiding any strain on the cable. Gently insert the stem of

the Thru-Hull light assembly through the hole in the hull.

7. Apply even pressure with a slight circular motion until the Thru-Hull is ush with the hull surface. Ensure the light

is orientated correctly. See page 9 for more information.

8. From inside the vessel, feed the supplied washer down the shaft of the Thru-Hull tting. Screw the locking nut in place

and tighten the retaining bolts so that they are hand tight (less than 1Nm) - Do not tighten fully at this stage, excess

pressure will push all of the sealant out.

9. Remove excess sealant that is squeezed from behind the light with a rag.

10. Allow the sealant to cure according to the sealant manufacturer’s instructions. Once fully cured, using a 5mm Allen

wrench, re-tighten each retaining bolt (force less than 3Nm). Care should be taken not to exceed this force as damage

to the light module or hull of the vessel may occur.

11. Attach the vessel’s bonding protection to the bonding bolt on the locking ring.

Apply sealant

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

www.Lumishore.com

8

Light Installation - Continued

Ensure that each light module has correct vertical and horizontal alignment with the hull, and that the correct

orientation of the light module is achieved (refer to the module below).

Top

A2283

Front View

Max Currents

Model Max Current (12V DC) Max Current (24V DC)

TIX 802 8.8A

TIX 1602 N/A

NOTE : Refer to the EOS controller manual for set up instructions.

4.4A

6.5A

Ensure correct electrical polarity. Incorrect installation will invalidate warranty!

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

www.Lumishore.com

9

Maintenance & Product Support

The underwater lighting system should always be tested before the boat goes back in the water. Check that each light comes

on and all lights change in sequence as per the system operation section above. See the problem solving guide for advice on

resolving any issues you may have. Once the boat is back in the water check for any water ingress around the installed lights.

Check again after several hours. Water ingress should be dealt with immediately. The lights should be checked several times

over the rst 24hrs and periodically after that to ensure installation is satisfactory.

Maintenance and Cleaning

The locking nut and retaining bolts should be inspected on a regular basis to ensure they are kept tight. LUMISHORE

recommends general inspection of the light module, driver and cable attachments every month.

LUMISHORE lights require simple cleaning. Lights should be checked often to ensure the light body and lens area

are free from sea growth. In the event that your light requires cleaning, we recommend the use of a soft cloth or

soft bristled brush. The glass should be kept clean with a plastic scraper or soft brush. Regular cleaning of the lens

will ensure that the light module delivers maximum optical output. DO NOT use an abrasive cloth or cleaning agent

as permanent damage to the lens may occur.

DO NOT use any abrasive cleaning materials as these may damage the body of the light.

DO NOT use any cleaning uids that contain solvents, acids or alkalis.

DO NOT clean using pressure washing or sandblasting equipment.

Slight discolouration of body may occur over life. This does not aect performance, and is not subject to warranty.

Due to nature and high build quality it may on rare occasions be possible to see small levels of condensation,

this is normal for high power LEDs and will disappear after cooling and does not harm operation in any way.

No chemicals, cleaners, chemical sprays or sandblasting should ever be applied / used on lights — this will

negate warranty

To prolong device lifetime and prevent marine growth build up, a good quality anti-fouling system must be used to

coat the external body of the device. This should be renewed regularly.

Product Support

If you have questions or comments, please e-mail info@lumishore.com or call USA (941) 405-3302,

United Kingdom +44(0)208 144 1694, or France +33(0)493 582 537.

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

www.Lumishore.com

10

Warranty & Troubleshooting

Warranty

LUMISHORE Ltd warrants the Thru-Hull lighting system to be free from defects in workmanship for a period of 3

years, starting from the date of original purchase. Should your lighting system have a problem during this period,

please contact your dealer as soon as you become aware of the defect.

Misuse, abuse, improper installation, neglect, improper shipping, damage caused by disasters (e.g. re, ood and

lightning), installation by unqualied personnel, unauthorized repair or modication will void this warranty.

For the avoidance of confusion and doubt, non compliance with all installation, maintenance and operating

instructions in this document constitute non conformance with warranty terms.

Full warranty details are available at www.lumishore.com.

Troubleshooting

In the event of one or more of the lights not lighting up then check the LED status on the back of the light. The LED

will either be continually ON (healthy), OFF (no power to driver) or ashing. Please refer to the table below for what

the number of ashes means and what action to take.

LED Status

No LED light

Solid LED

Flashing 2 times

Flashing 3 times

Flashing 4 times

Flashing 7 times

Flashing 8 times

Continuous rapid ashing

Meaning

No power to light

Power On

Low input voltage to driver

Light temp too high

Internal Driver temp too high

LED array voltage out of range

Light not detected

Internal Driver program corrupt

Action to take / Things to check

Check fuse / breaker

Check connections

Check voltage at input to light connections

Light is receiving voltage and operating properly

Check the controller is operating correctly

Check EOS/DMX connections

Check intensity is turned up

Check power connections or battery voltage

Could happen when light is out of water or next

to exhaust

Light is mounted too close to an engine or exhaust

Disconnect power for 30 seconds, re-connect and check.

If problem persists, disconnect light and contact

LUMISHORE for help

Disconnect power for 30 seconds, re-connect and check.

If problem persists, disconnect light and contact

LUMISHORE for help

Reset driver by switching o power for 1 minute, and

then switching on again

Contact LUMISHORE if problem persists

If a light does not switch on, or function normally, it should be disconnected from the power source

Thank you!

For purchasing LUMISHORE lights

Lumishore UK Unit 3, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34234 | (941) 405-3302 | Sales @LumishoreUSA.com

www.Lumishore.com

11

Loading...

Loading...