Page 1

Luminex 100E

™

User Manual

Page 2

© LUMINEX® CORPORATION, 2004. All rights reserved. No part of this publication may be r eproduced,

transmitted, transcribed, or translated into any language or computer language, in any form or by any means

without prior express, written consent of:

LUMINEX CORPORATION

12212 Technology Boulevard

Austin, Texas 78727-6115

U.S.A.

V oice: (512) 219-8020

Fax: (512) 219-5195

Luminex 100ETM User Manual

CN-M028-01

PN 89-00002-00-013 Rev. D

July 2004

Luminex Corporation (Luminex) reserves the right to modify its product s and services at any time. This guide

is subject to change without notice. Although prepared to ensure accuracy, Luminex assumes no liability for

errors or omissions, or for any damages resulting from the application or use of this information.

The following are trademarks of Luminex: Luminex, Luminex HTS, Luminex 100, Luminex 100 IS, LabMAP,

xMAP, LumAvidin, Luminex SD, Luminex XYP, Luminex FlexMAP. All other trademarks, including Windows,

Cheminert, Pentium, and Dell

The contents of this manual and the associated Luminex software are the proper ty of L uminex and are

copyrighted. Except as specified in the End User License Agreement, any reproduction in whole or in part is

strictly prohibited.

are trademarks of their respective companies.

Page 3

Contents

Introduction 1-1

Safety 2-1

Instrument Components 3-1

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Laser, Luminex 100E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Biological . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Decontamination of the Luminex 100E for Return Shipment . . . .2-6

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

xMAP Reagents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Laboratory Reagents Required . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 -2

Other Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Luminex Real-time (LXR) Library. . . . . . . . . . . . . . . . . . . . . . . . .3-3

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

General, Luminex 100E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Fluidics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

User-Accessible Components. . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Power Input Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

P1 Communications Port (DB9-PIN). . . . . . . . . . . . . . . . .3-7

P2 Synchronization Port (DB15-PIN) . . . . . . . . . . . . . . . .3-8

Air Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Fluidics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Regulated Flow Sheath Supply . . . . . . . . . . . . . . . . . . . .3-10

Sample Input Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Optical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Installing the Luminex 100E into the Host System. . . . . . . . . . . .3-12

PN 89-00002-00-013 Rev. D i

Page 4

Luminex® 100E™ User Manual Version 1.0 xMAP Technology

Maintenance and Cleaning 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Daily. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Before Running Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

After Running Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Instrument Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Calibrate the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Semi-Annually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Remove or Replace the Syringe Seal. . . . . . . . . . . . . . . . . . . . 4-3

As Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Instrument Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Remove the Instrument Front Panel . . . . . . . . . . . . . . . . . 4-4

Reinstall the Instrument Front Panel. . . . . . . . . . . . . . . . . 4-4

Air Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Remove the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Clean the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Reinstall the Air Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Syringe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Remove the Syringe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Replace the Syringe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Verify Syringe Operation . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Product Numbers 5-1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

xMAP Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Index Index-1

ii PN 89-00002-00-013 Rev. D

Page 5

Introduction

1

About This Manual This manual introduces you to the Luminex

explains the features of the Luminex 100E analyzer and provides

instructions on installation and use of the analyzer.

®

100E™ analyzer. It

Intended Use The Luminex 100E analyzer is designed as a component in a host

system. This component is designed for a wide range of laboratory

testing applications measuring biomolecular reactions on the surfaces

of xMAP

indoor use only.

Systems analysts, software designers, and programmers who need an

overall perspective of the capabilities and functions of the Luminex

Runtime (LXR) should refer to the LXR Programmer’s Reference

provided by the LXR Software Development Kit (LXR SDK)

version 2.0 or greater for more information. The Luminex 100E

analyzer responds to applications developed using the LXR SDK

version 2.0. LXR SDK version 2.0 supplies the runtime software and

several utility applications needed to develop new applications and

maintain the Luminex 100E analyzer.

®

and customer-specific microspheres. It is intended for

LXR is packaged as a collection of Windows

The interfaces of the various components are written as Component

Object Model (COM) objects that conform to the Microsoft

automation standards. This COM Automation support allows access

to the Luminex 100E analyzer via programming and scripting

software.

PN 89-00002-00-013 Rev. D 1 - 1

®

binary and data files.

®

Page 6

Luminex 100E User Manual xMAP Technology

Technical Support You can contact Luminex Technical Support for questions or

concerns regarding the Luminex 100E analyzer.

Users in the U.S. and Canada may call 1-877-785-BEAD (-2323)

between the hours of 7:00 a.m. and 7:00 p.m. Central Time, Monday

through Friday for assistance. Users outside of the U.S. and Canada

can contact us at + 1 512-381-4397 between the hours of 7:00 a.m. to

7:00 p.m. Central Time, Monday through Friday.

Inquiries may also be sent by email to support@luminexcorp.com.

1 - 2 PN 89-00002-00-013 Rev. D

Page 7

Safety

2

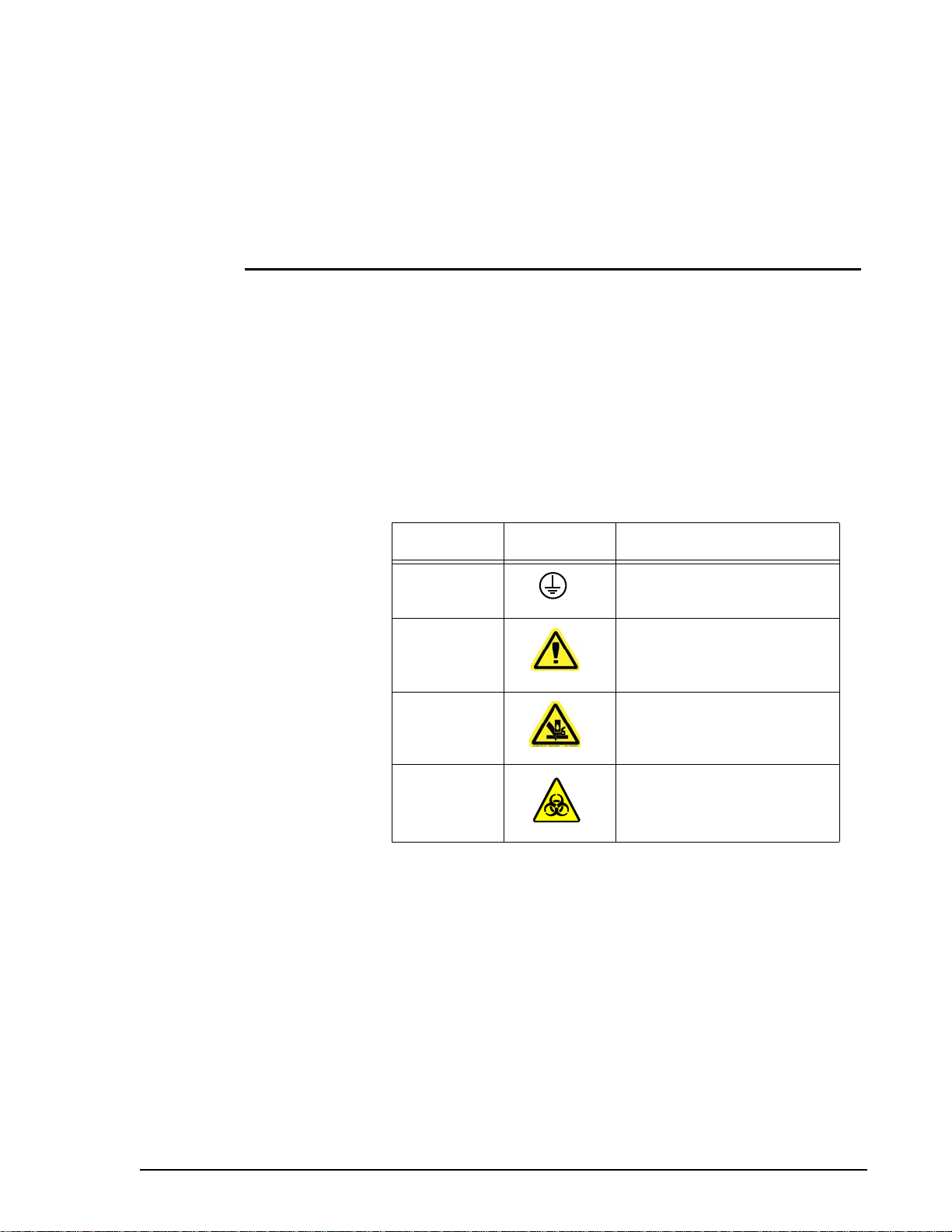

Symbols These symbols describe warnings, cautions, and general information

used in the operation of this Luminex 100E analyzer. These symbols

are further defined under “Safety Precautions.”

Number Symbol Description

1 Protective ground

2 Warning (refer to manual)

3 Warning (refer to manual)

4 Warning (refer to manual)

Safety Precautions Read the following safety information before setting up or using the

Luminex 100E analyzer. The user should be present during

operation. The Luminex 100E analyzer contains electrical,

mechanical, and laser components which, if handled improperly, are

potentially harmful. In addition, biological hazards may be present

during system operation. Therefore, we recommend that all Luminex

100E analyzer users become familiar with the specific safety

advisories below, in addition to adhering to standard laboratory

safety practices. The protection provided by the equipment may be

impaired or the warranty voided if the system is used in a manner not

specified by the instructions or Luminex Corporation.

PN 89-00002-00-013 Rev. D 2 - 1

Page 8

Luminex 100E User Manual xMAP Technology

The following labels appear on the back panel of the Luminex 100E

analyzer.

Figure 1. Voltage Label

Figure 2. FCC Label

Note: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the

receiver.

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

2 - 2 PN 89-00002-00-013 Rev. D

Page 9

xMAP Technology Safety

Do not perform any maintenance or cleaning of the electrical

.

components of this system.

The Luminex 100E analyzer complies with European Union (EU)

safety requirements.

This analyzer contains fluidic components. In the event of a fluidic

leak, disconnect the power. Contact Luminex Corporation for further

information.

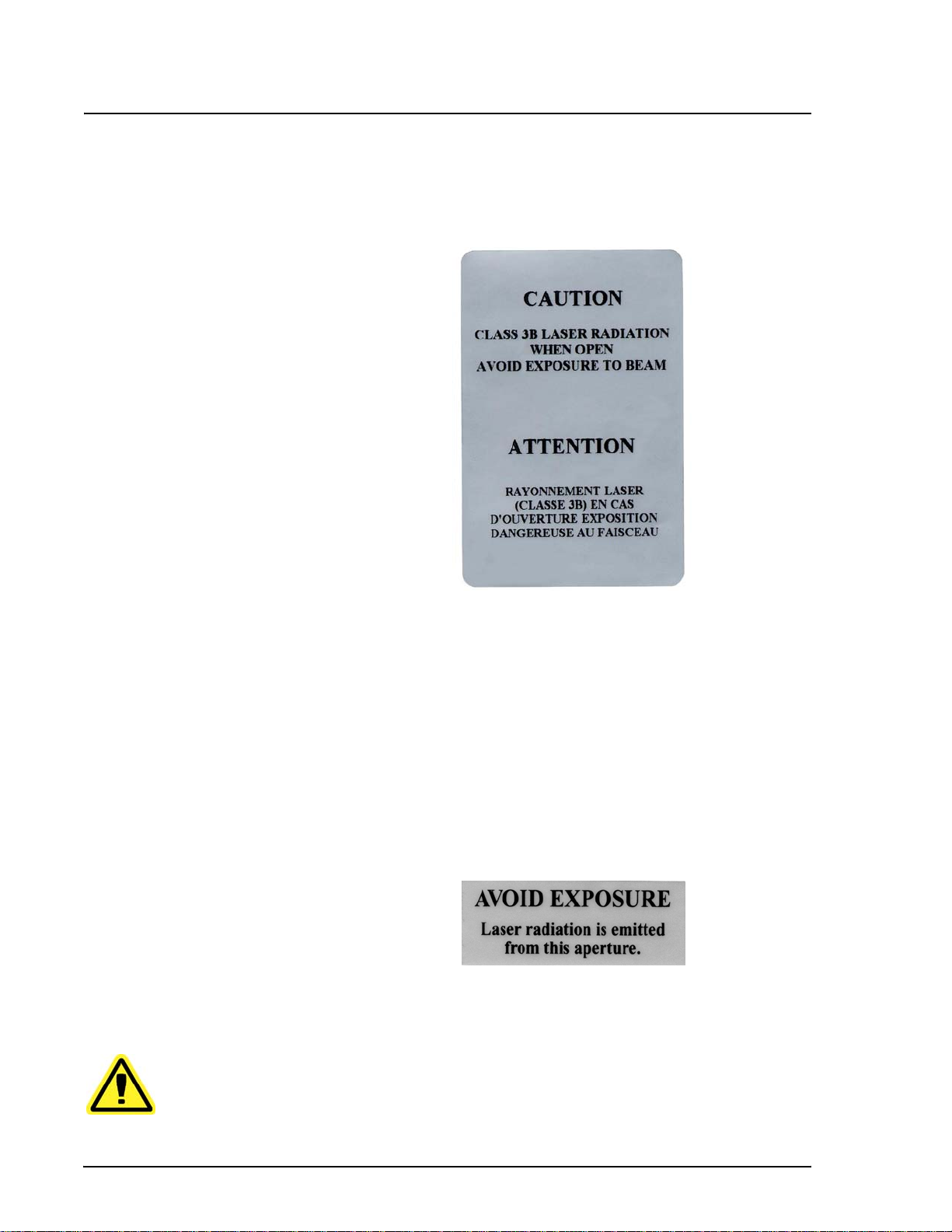

Laser, Luminex 100E United States and international regulations require the following

warnings to appear on the analyzer during operation and

maintenance. The labels in this section are representative.

Figure 3. Laser Class Label

The following label appears on the back panel of the Luminex 100E

analyzer.

Figure 4. Laser Caution Label

Under NO circumstances should you remove the Luminex 100E

analyzer cover or this label! When performing routine

maintenance, disconnect power to the analyzer.

PN 89-00002-00-013 Rev. D 2 - 3

Page 10

Luminex 100E User Manual xMAP Technology

All Luminex 100E analyzer laser apertures are contained inside a

protective housing within the analyzer. This label appears on the

optics cover within the Luminex 100E analyzer.

Mechanical

Figure 5. Laser Caution Label on Optics Cover

CAUTION — Use of controls or adjustments or performance of

procedures other than those specified herein may result in hazardous

radiation exposure.

Attention — L’utilisation des commandes ou réglages ou l’exéction

des procédures autres que celles spécifiées dans les présentes

prescriptions peuvent être cause d’une exposition à un rayonnement

dangereux.

This label appears above the laser apertures located inside the optics

enclosure inside the Luminex 100E analyzer.

Figure 6. Avoid Exposure Label

Warning: During operation, this analyzer contains moving parts.

Risk of personal injury is present. Observe all warnings and cautions.

2 - 4 PN 89-00002-00-013 Rev. D

Page 11

xMAP Technology Safety

Warning: During operation, this analyzer contains moving parts that

result in a pinch point hazard. Risk of personal injury is present.

Keep hands and fingers away from the syringe arm.

Biological Warning: All human/animal samples may contain hazardous

infection agents.Where exposure (including aerosol) to potentially

biohazardous materials exists, operators should follow appropriate

biosafety procedures and use personal protective equipment, such as

gloves, gowns, laboratory coats, face shields (or mask and eye

protections), and ventilation devices.

Observe all local, state, and federal biohazard handling regulations

when disposing of biohazardous waste material.

PN 89-00002-00-013 Rev. D 2 - 5

Page 12

Luminex 100E User Manual xMAP Technology

Decontaminating

the Luminex 100E

Analyzer for Return

Shipment

Note: You are responsible for

decontaminating the unit prior

to shipment.

Luminex Technical Support will provide a Return Material

Authorization (RMA) number if they direct you to return the

analyzer to Luminex; they will also instruct you in returning the

analyzer according to Luminex procedures.

Before returning the Luminex 100E analyzer, sanitize and

decontaminate the accessible surfaces and internal fluidics system.

This is particularly important if you have analyzed biohazardous

samples. Make a copy of this page to complete and return with the

analyzer. Submit the completed checklist, both signed and dated,

with the Luminex 100E analyzer.

1. Replace the fluid in the sheath system with a freshly prepared

solution of 10% - 20% household bleach and water.

2. Using a solution of 10% - 20% household bleach and water,

sanitize the analyzer using maintenance tools in the LXR library.

Follow this by washing twice with distilled water.

3. Disconnect the power plug from the analyzer

4. Disconnect the fluidic lines.

5. Disconnect the sample probe from the host’s sample mount

sample probe line.

6. Wash all exterior surfaces with a mild detergent, followed by a

10%-20% bleach solution.

7. Remove the air filter from the analyzer and clean all accessible

surfaces with detergent followed by a 10%-20% bleach solution.

8. Pack the analyzer using a biohazard bag, place it in an approved

shipment box, and then insert it into a shipping crate. Attach this

checklist to the top of the corrugated box prior to packaging in

the crate.

Was there an internal leak in the system? Yes No

Print Name:___________________________ ____ _____ ____

Signature:__________________________________________

Date:______________________________________________

2 - 6 PN 89-00002-00-013 Rev. D

Page 13

Luminex 100E Analyzer Overview

3

Theory of Operation The Luminex 100E analyzer was specifically designed to be a

component of a host system.

Luminex 100E analyzer technology is based on flow cell fluorometry

with Luminex-developed innovations. The fluidics and optics work

together to enable simultaneous analysis of up to 25 analytes in a

single test sample using the Luminex 25 beadmap.

There are two fluidics paths in the Luminex 100E analyzer. The first

path involves a syringe-driven mechanism that draws the sample into

the Luminex 100E analyzer for analysis. The host system drives the

second fluidics path at a controlled rate to supply sheath fluid to the

cuvette. The Luminex analyzer’s syringe-driven system transports a

specified volume of sample from a sample container to the cuvette.

The sample is injected into the cuvette at a steady rate for analysis.

Following analysis, the sample path is automatically purged with

sheath buffer by the second fluidics path. This process removes

residual sample within the tubing, valves, and probe.

Sheath fluid is the delivery medium of the sample to the optics

component. The analysis sample is acquired using the host system’s

sample aspiration interface and is injected into the base of the

cuvette. The sample passes through with sheath fluid at a controlled

rate in a narrow sample core to ensure that each microsphere is

illuminated individually. The sample injection rate is such that the

microspheres are introduced to the optics path as a series of single

events.

The optics assembly consists of two lasers. One laser excites the dye

mixture inside the microspheres, and the second laser excites the dye

bound to the surface of the microspheres. Avalanche photo

PN 89-00002-00-013 Rev. D 3 - 1

Page 14

Luminex 100E User Manual xMAP Technology

diode (APD) detectors measure the excitation emission intensities of

the color coding classification dye mixtures inside the microspheres

and a photomultiplier tube detects the excitation emission intensity

of the reporter dye bound to the surface of the microspheres. High

speed digital signal processors (DSP) and advanced computer

algorithms provide analysis of the microspheres as they are

processed through the Luminex 100E analyzer.

Hardware The Luminex 100E analyzer consists of these major components:

• Analog PCBA

• Digital PCBA

• Sensor distribution PCBA

• Laser driver PCBA

• Optics assembly

• Syringe pump

• Pressure sensor

• Backflush valve

• Sample valve

• Air filter

xMAP Reagents • Classification calibration microspheres (CAL1)

• Reporter calibration microspheres (CAL2)

• Sheath fluid

Laboratory

Reagents Required

• Household bleach

• 70% isopropanol or 70% ethanol

• Mild detergent

• Distilled water

Other Reagents • Customer-specified reagents

3 - 2 PN 89-00002-00-013 Rev. D

Page 15

xMAP Technology Luminex 100E Analyzer Overview

Luminex Runtime

(LXR)

Luminex Runtime (LXR) version 2.0 is a set of software components

that provides simple, standardized mechanisms for programmable

control of the Luminex 100E analyzer .

Use the LXR Software Development Kit (SDK) version 2.0 or

greater to write your own programs that analyze the results from the

Luminex 100E analyzer. It includes sample test programs. Online

documentation and other test programs are in the LXR Programmer’s

Reference.

LXR SDK version 2.0 allows the application developer to connect to

a Luminex 100E analyzer, collect data, access its state, and control

its operations. LXR version 2.0 performs these functions:

• controls the operations of Luminex 100E analyzers through

• processes real-time Luminex 100E analyzer data

• retrieves classified, statistical data in real time

• monitors and sets Luminex 100E analyzer status

• interacts with Luminex 100E analyzers using high-level, user-

• adds on higher-level extensions, such as monitoring, data tracing,

• performs automatic and custom activity logging

• provides maintenance diagnostic information

commands

oriented software and development tools, achieving easy, rapid

application development

standardized calibration, and user error reporting

General, Luminex

100E Analyzer

See the LXR version 2.0 Programmer’s Reference for more details.

• Installation into host < 2 hours

• System calibration < 10 minutes

• Analyze up to 100 samples per hour (dependent upon

microsphere concentration within the sample)

• Analyze up to 25 xMAP microsphere sets per sample using the

Luminex 25 beadmap.

• Luminex 100E analyzer warmup: 30 minutes. Software functions

that remain inactive for at least 4 hours (programmable default)

require a warmup to restart. Warmup is required 4 hours

(programmable default) from the time the last sample was

analyzed.

• Operating temperature: 15°C to 30°C (59°F to 86°F)

• Storage temperature: 0°C to 50°C (32°F to 122°F)

• Humidity: 20% to 80%, noncondensing

• Altitude: Operation up to 2400 m (7874 ft) above mean sea level

PN 89-00002-00-013 Rev. D 3 - 3

Page 16

Luminex 100E User Manual xMAP Technology

• Physical dimensions, excluding mounting brackets, connectors,

and tubing, are: 31.1 cm (12.25 inches) W x 50 cm (19.7 inches)

D x 29.2 cm (11.5 inches) H

• Weight: 21.8 kg (48.0 lbs.)

• Shipping and storage: The allowable shipping and storage

temperature and humidity ranges are 0°C to +50°C and up to

80% noncondensing

• Underwriters Laboratories, Inc. (UL

Installation Category II, as defined in Annex J of UL 61010A-1

• Pollution degree: UL Pollution Degree II, as defined in Section

3.7.3.2 of UL 61010A-1

• Classification of microspheres > 80%

• Misclassification of microspheres < 0.5%

• Internal sample carry over < 3%

• Soluble background fluorescence emission at 575 nm

automatically subtracted from median fluorescence intensity

(MFI) value

®

) installation category: UL

Sensitivity • Detect 1000 fluorochromes phycoerythrin (PE) per microsphere

• Reporter channel dynamic range: 3.5 decades of detection

Capacity • Sample core: 15 - 20 µm core at 1 µL/sec sample injection rate

Optics • Reporter laser: 532 nm, nominal output 15-16.5 mW , maximum

of 500 mW, frequency -doubled diode; mode of operation,

continuous wave (CW)

• Classification laser: 635 nm, 9.1 mW ± 6%, maximum output

25 mW, diode; mode of operation, continuous wave (CW)

• Reporter detector: Photomultiplier tube, detection bandwidth of

565 - 585 nm

• Classification detector: Avalanche photo diode (APD) with

temperature compensation

• Doublet discrimination detector: Avalanche photo diode (APD)

with temperature compensation

3 - 4 PN 89-00002-00-013 Rev. D

Page 17

xMAP Technology Luminex 100E Analyzer Overview

Fluidics • Sheath flow specification rate: 90 µL/second ± 5 µL/second

• Cuvette: 200 micron square flow channel

• Sample injection rate: 1 µL/second ± .05 µL variable default

• Sample uptake volume: 20 - 200 µL

• Pressure connections to the unit should not exceed 10 PSI during

normal operating conditions.

Electronics • Reporter channel detection, A/D resolution: 14 bits

• Communications interface: USB

• Classification and doublet discriminator channel detection:

Avalanche photo diode (APD) with temperature compensation,

A/D resolution: 12 bits

System Overview The Luminex 100E analyzer consists of three subsystems: electronic,

fluidic, and optical. An air filter fits under the front cover of the

analyzer. There is no user access to the optics.

User-Accessible

Components

Power Input

Connector

The following section describes the user-accessible components of

each subsystem, where applicable.

The power input connector receives power when connected to an

external source. The power input connector is shipped with a plastic

cap. Remove the cap to access the 21-pin connector. The 21-pin

cylindrical connector supplies the power for several different

components of the Luminex 100E analyzer, including the fan,

syringe pump, backflush valve, sample valve, analog board, digital

board, red laser, and green laser.

Figure 7. Power Input Connector

PN 89-00002-00-013 Rev. D 3 - 5

Page 18

Luminex 100E User Manual xMAP Technology

The power input connector type is a Amphenol JTP02RE-2221P(014), and it connects with Amphenol JT06RE-22-21S(014).

Equivalent parts can be used. The Luminex 100E analyzer operates

off of five separate dc voltage levels, including 24 volts, 15 volts, -15

volts, and 6 volts. The pinout follows below:

• +15 pins E, F

• -15 pin G

• +24 pin J

•+6 pin C

• +15 Return pins P, S

• +24 Return pin H

• +6 Return pin D

• Chassis ground pin A

• 5.4 volts pins L, M, W

• 5.4 Return pins F, K, N

• 5.4 V (+) sense pin B

• 5.4 V (-) sense pin R

• -15 volts return pin U

The user must provide power interruption and fusing means.

The power required from the host system to run the Luminex 100E

analyzer is listed below. The voltages listed are required at the dc

power connector. This power requirement allows for the use of

additional components at a later date.

Note: The 6 volt line must be at least 5.5 volts.

Note: The +15 volt supply must be at a minimum of 90% of rated

output at least 15 (±5) milliseconds before the 6 volt supply reaches

10% of rated output to ensure proper operation.

Note: The laser supply voltage (+5.4 volts) must be at a minimum of

90% of rated output no later than 15 (±5) milliseconds after the 15

volt supply is at 90% of rated output. The 5.4 volt supply must be

capable of providing a voltage of 5.3 to 5.5 volts dc at the sense

points located within the Luminex 100E analyzer. The load initially

varies between 0 and 50 W. After 15 seconds, the load decreases to

less than 40W.

3 - 6 PN 89-00002-00-013 Rev. D

Page 19

xMAP Technology Luminex 100E Analyzer Overview

P1 Communications

Port (DB9-PIN)

Supply voltage

(V)

Noise (mVpp) Maximum Current

(Amps)

+6.0 ±2% 60 1

+ 5.4 220 10

+24.0 ±2% 240 2

+15.0 ±3% 150 1

-15.0 ±3% 150 0.5

The 24 volt power supply should not be capable of delivering, under

any load condition including short circuit, 8 amps after one minute of

operation.

The 15 volt, negative 15 volt, and 6 volt, and 5.4 volt power supplies

should not be capable of delivering, under any load condition

including short circuit, 150 VA per supply after one minute of

operation.

The P1 Communications Port is a custom USB port that is the main

communications interface for two-way communication between the

Luminex 100E analyzer and the host computing and control system.

A custom DB9-to-USB cable is provided.

1

2

1. P1 9-pin Communications Port

2. P2 15-pin Synchronization Port

Figure 8. Communication Ports

PN 89-00002-00-013 Rev. D 3 - 7

Page 20

Luminex 100E User Manual xMAP Technology

The P1 Communications Port is a nine-pin DB female-style

connector for communication between the P1 port and the host

computing and control system.

Table 1 lists the P1 communications port pinouts.

Table 1: P1 Communications Port Pinout

Pin Number voltages Description

Pin 1 None USB DPin 2 Maximum of 5.25 Reserved

P2 Synchronization

Port (DB15-PIN)

Pin 3 No voltage originates from the

Luminex 100E analyzer at this

pin

Pin 4 None No connect

Pin 5 None Chassis

Pin 6 Maximum of 5.25 USB D+

Pin 7 None No connect

Pin 8 None USB ground

Pin 9 No voltage originates from the

Luminex 100E analyzer at this

pin

Reserved

ground

USB Vbus

The P2 Synchronization Port is a digital I/O port that provides one

input line and two output lines. The P2 synchronization port is used

to connect the Luminex 100E analyzer and the host computing and

control system. Refer to “P2 Synchronization Port Pinout” on

page 3-9 to see the P2 synchronization port.

The P2 Synchronization Port is a 15-pin DB female style connector

to allow communication between the Luminex 100E analyzer and the

host computing and control system.

The Luminex 100E analyzer uses open collector outputs; the inputs

are designed to interface with open collector outputs from the host

system.

3 - 8 PN 89-00002-00-013 Rev. D

Page 21

xMAP Technology Luminex 100E Analyzer Overview

Table 2 lists the P2 synchronization port pinouts.

Table 2: P2 Synchronization Port Pinout

Pin Number voltages Description

Pin 1 None Unused

Pin 2 None Input 1 return

Pin 3 Unloaded, maximum voltage of

5.25 volts

Pin 4 None Unused

Pin 5 None Output 1 return

Pin 6 No voltage originates from the

Luminex 100E analyzer at this

pin

Pin 7 None Unused

Pin 8 None Spare output

Pin 9 Unloaded, maximum voltage of

5.25 volts

Pin 10 None Unused

Pin 11 None Sp are input

Pin 12 No voltage originates from the

Luminex 100E analyzer at this

pin

Spare input

Output 2

return

Input 1

return

Output 1

Pin 13 None Unused

Pin 14 None Output 2 return

Pin 15 No voltage originates from the

Luminex 100E analyzer at this

pin

PN 89-00002-00-013 Rev. D 3 - 9

Sp are output

Page 22

Luminex 100E User Manual xMAP Technology

Air Filter The air filter is located on the front of the Luminex 100E analyzer

behind the front panel. See “Air Filter” on page 4-4 for more

information.

For proper ventilation, do not obstruct the area in front and allow at

least one inch (2.54 cm) of clearance around the Luminex 100E

analyzer.

Fluidics

Regulated Flow

Sheath Supply

Figure 9. Air Filter Inside the Front Cover of the

Luminex 100E Analyzer

Located on the side of the Luminex 100E analyzer are three

connectors that couple directly to the host system’s sheath and waste

fluid subsystems. The nonpressurized sheath fluid connector is blue,

the waste fluid connector is orange, and the pressurized sheath fluid

connector is green.

Note: The host instrument provides the means for waste disposal.

3 - 10 PN 89-00002-00-013 Rev. D

Page 23

xMAP Technology Luminex 100E Analyzer Overview

1

1. Nonpressurized Sheath Fluid Connector (Blue)

2. Waste Fluid Connector (Orange)

3. Pressurized Sheath Fluid Connector (Green)

Figure 10. Regulated Flow Sheath Supply

2

3

Sample Input Tube The sample input tube provides the sample fluid interface between

the sample probe from the host system to the Luminex 100E

analyzer. This sample input tube aspirates sample.

Figure 11. Sample Input Tube (Without Cap)

Optical The optical system consists of the optical assembly and the excitation

lasers. The optical assemblies do not require manual adjustment by

the user.

PN 89-00002-00-013 Rev. D 3 - 11

Page 24

Luminex 100E User Manual xMAP Technology

Installing the

Luminex 100E

Analyzer into the

Host System

Note: Due to the weight, use

two people to lift the Luminex

100E analyzer.

The Luminex 100E analyzer has three electrical and four fluid

connectors that interface to the host system:

• P1 Communications Port

•P2

• Power input connector

• Sample Input Tube

• Nonpressurized Sheath Fluid Connector

• Waste Fluid Connector

• Pressurized Sheath Fluid Connector

Synchronization Port

To install the Luminex 100E analyzer into the host system:

1. Connect the USB communications cable from the host system to

the P1 communications port (DB9) on the Luminex 100E

analyzer.

2. Connect the synchronization cable from the host system to the

P2 Synchronization Port (DB15) on the Luminex 100E analyzer.

3. Connect the nonpressurized sheath, waste, and pressurized

sheath fluid lines from the host system into the color-coordinated

connectors at the lower left of the sample input tube on the

Luminex 100E analyzer. The connectors snap into the injection

port using firm pressure.

4. Remove the white cap covering the sample input tube and

connect it to the sample aspiration interface from the host

system.

5. Remove the yellow cap covering the power input connector and

connect the power source from within the host system to the

power input connector (21-pin cylindrical connector) on the

Luminex 100E analyzer.

6. Place the Luminex 100E analyzer into the host system.

3 - 12 PN 89-00002-00-013 Rev. D

Page 25

xMAP Technology Luminex 100E Analyzer Overview

5

2

NOTES:

1. THE LUMINEX 100E IS A COMPONENT OF A LARGER HOST SYSTEM.

CLEARANCE FOR COOLING AND INTAKE/EXHAUST.

3. TOTAL UNIT WEIGHT: 48.0 lb. (21.7 kg.).

4. FOLLOW SHIPPING AND HANDLING INSTRUCTIONS ON PACKAGING AND INSTALLATION INSTRUCTIONS OF

SUPPLIED USER MANUAL (LX100E REQUIRES 2 PEOPLE LIFT).

CABLE CLEARANCE.

MOUNTING HOLES

9X 832UNC

3X 11.12

3X 1.12

3X 6.12

3X 3.06

3X 11.13

3X 18.02

SUPPORTING SURFACE

ISOMETRIC VIEW

01

LUMINEX 100E

48.0 lb. (21.7 kg.)

SUPPORTING SURFACE

GROUNDING

STUD

01

Figure 12. Installation Drawing

PN 89-00002-00-013 Rev. D 3 - 13

Page 26

Luminex 100E User Manual xMAP Technology

Figure 13. Installation Drawing

3 - 14 PN 89-00002-00-013 Rev. D

Page 27

Maintenance and Cleaning

y

4

Overview The Luminex 100E analyzer requires proper maintenance and

cleaning to ensure optimal performance. Read and follow all

instructions in this section.

The following list is a basic timeline for performing maintenance and

Warning: When analyzing

potentially infectious

biological samples on the

analyzer, follow standard

laboratory safety practices.

These safety precautions

should also be taken when

cleaning or maintaining the

analyzer.

Warning: Do not remove

the analyzer cover under an

circumstances!

cleaning procedures:

• Daily

– Before running samples

– After running samples

• Monthly

– Luminex 100E analyzer calibration

calibrate the analyzer

• Semi-annually

– Remove or replace the syringe seal

• As required

– Luminex 100E analyzer front panel

Remove the front panel

Reinstall the front panel

– Air filter

Remove the air filter

Clean the air filter

Reinstall the air filter

– Syringe

Remove the syringe

Replace the syringe

Verify syringe operation

PN 89-00002-00-013 Rev. D 4 - 1

Page 28

Luminex 100E User Manual xMAP Technology

Daily Note: If the Luminex 100E analyzer is powered on, but idle for more

than four hours, you must rewarm the optics. The Luminex 100E

analyzer and optics system take approximately 30 minutes to warm

up.

Before Running Samples Before running samples:

1. Perform a Sanitize command with 70% isopropanol or 70%

ethanol.

2. Perform two Wash commands with sheath fluid.

After Running Samples Perform a Sanitize command with 10%-20% household bleach

solution. If powering off the Luminex 100E analyzer, perform two

Wash commands with distilled water.

Monthly

Luminex 100E Analyzer

Calibration

Calibrate upon installing the Luminex 100E analyzer, at least once a

month, during routine use, and when:

• the system is moved

• a part is replaced

• the delta calibration temperature is more than three degrees

Calibrate the Luminex 100E analyzer to normalize settings for the

reporter channel, both classification channels, and the doublet

discriminator channel. See the calibration section from the host

system’s software manual for further information.

4 - 2 PN 89-00002-00-013 Rev. D

Page 29

xMAP Technology Maintenance and Cleaning

Semi-Annually

Remove or Replace the

Syringe Seal

Warning:

OFF and unplug the power

cord before replacing the

syringe plunger seal! The

syringe arm does not

deactivate when changing the

plunger; injury could result if

the analyzer is not

unplugged.

Turn the unit

Remove or replace the syringe plunger seal for optimal performance

in the Luminex 100E analyzer.

To access the syringe, you must first remove the Luminex 100E

analyzer front panel and air filter. See “Reinstall the Luminex 100E

Analyzer Front Panel” on page 4-4 for more information.

To remove or replace the syringe seal:

1. Turn the Luminex 100E analyzer off and unplug the power cord

before replacing the syringe plunger.

2. Replace the syringe plunger seal every six months. See the

warning to the left of this paragraph.

3. Remove the front panel from the front of the Luminex 100E

analyzer.

4. Locate the syringe (a glass cylinder with a metal rod).

5. Unscrew the knob on the syringe arm (at the bottom of the

syringe), and forcefully push the syringe arm down.

6. Unscrew the syringe from the top of its housing, and then pull

the plunger out of the syringe.

7. Remove and replace the plunger seal, and return the plunger to

the syringe.

8. Screw the syringe back into the top of its housing.

9. Return the syringe arm to its original position.

10. Hand-tighten the screw on the syringe arm.

11. Plug in the power cord and turn the Luminex 100E analyzer on.

12. Prime the Luminex 100E analyzer five times. Be sure to watch

for any leaks in the syringe area.

13. Replace the Luminex 100E analyzer front panel.

PN 89-00002-00-013 Rev. D 4 - 3

Page 30

Luminex 100E User Manual xMAP Technology

As Required

Luminex 100E Analyzer

Front Panel

Remove the Luminex

To access many of the analyzer’s components for periodic

maintenance, you must first remove the front panel. Additionally,

you may need to remove the air filter located behind the analyzer’s

front panel.

To remove the Luminex 100E analyzer front panel:

100E Analyzer Front

Panel

Reinstall the Luminex

1. Remove the six button-head screws and washers.

2. Lift out the Luminex 100E analyzer front panel.

To reinstall the Luminex 100E analyzer front panel:

100E Analyzer Front

Panel

1. Install the front panel with louvers facing down and out, and

align it with the six screw holes.

2. Install the six washers and button-head screws.

Air Filter Remove and replace the air filter as necessary.

Periodically , you may need to clea n the air filter for optimal Luminex

100E analyzer performance. To clean the air filter, you must first

remove it from the Luminex 100E analyzer. Do not run samples

when the air filter is not in place. Clean the air filter as necessary.

Remove the Air Filter To remove the air filter:

1. Remove the front panel from the Luminex 100E analyzer.

2. Remove the two spring clamp flaps from each side of the filter

and lift out the air filter.

Clean the Air Filter To clean the air filter:

1. Remove the air filter.

2. Clean the filter with a vacuum or by placing it under running

distilled water.

3. Stand the air filter up to air dry.

4. Reinstall the air filter.

4 - 4 PN 89-00002-00-013 Rev. D

Page 31

xMAP Technology Maintenance and Cleaning

Reinstall the Air Filter To reinstall the air filter:

1. Install the air filter and lift into position and place the two spring

clamp flaps.

2. Reinstall the Luminex 100E analyzer front panel.

Syringe Remove and replace the syringe every six months.

Remove the Syringe When removing the syringe and the air filter, you must remove the

front panel of the Luminex 100E analyzer. See “Luminex 100E

Analyzer Front Panel” on page 4-4 for more details.

To remove and replace the syring e:

1. Perform the decontamination procedure. See “Decontaminating

the Luminex 100E Analyzer for Return Shipment” on page 2-6

for details.

2. Turn off the Luminex 100E analyzer, but make sure the Luminex

100E analyzer is connected to protective ground. Wear a ground

strap.

3. Remove the front panel from the Luminex 100E analyzer. See

“Luminex 100E Analyzer Front Panel” on page 4-4 for more

information.

4. Remove the air filter.

5. Loosen the thumb screw on the bottom of the syringe arm.

6. Lower the syringe arm completely.

7. Unscrew the syringe from the pump head.

8. Remove the syringe.

Replace the Syringe To replace the syringe:

Note: Ensure that the Luminex 100E analyzer is powered off prior to

replacing the syringe.

1. Screw the new syringe into the syringe head.

2. Lift the syringe arm up to the bottom of the syringe.

3. Tighten the thumb screw.

PN 89-00002-00-013 Rev. D 4 - 5

Page 32

Luminex 100E User Manual xMAP Technology

4. Install the air filter.

5. Verify that the syringe works properly. See “Verify Syringe

Operation” for details below.

6. Reinstall the Luminex 100E analyzer front panel.

Verify Syringe

Operation

When you replace the syringe, you must verify that it runs properly.

If the syringe works improperly, it may not move freely or it may

leak. Leaks may occur where the metal threaded housing screws into

the syringe valve or at the bottom of the syringe.

To verify syringe operation:

1. Turn the analyzer on.

2. Run a Prime command using LXR and observe the syringe

(found behind the front panel). See if the syringe moves freely or

if there are leaks around the syringe. If the syringe does not

move freely, contact Technical Support. If the syringe leaks,

determine from where it leaks.

If it leaks at the top of the syringe where the metal threaded

housing screws into the syringe valve, order a new syringe.

If it leaks at the bottom of the syringe cylinder, you must replace

the syringe seal. A good indicator of a leak in the syringe

cylinder is if you see saline crystals forming at the bottom of the

syringe over time.

3. When the prime completes, see if the syringe leaks sheath fluid

beneath the analyzer.

4. Repeat steps 2-4 until you complete five primes. If the syringe

moves freely and no leaks or puddles appear around the syringe,

the syringe works correctly.

5. Calibrate the analyzer to normalize settings for the analyzer

reporter channel, both classification channels, and the doublet

discriminator channel.

Use xMAP control microspheres with the analyzer to verify that

calibration and optical integrity for the system exist.

4 - 6 PN 89-00002-00-013 Rev. D

Page 33

5

Hardware

Product Numbers

Note: These part numbers are subject to change without notification.

Assy, Weldment, Short Sample Sleeve

with Filter [Short Sample Probe]

CN-0006-01

xMAP Reagents

Filter, Air, Front Mount 7.5 x 10.63 [Air

filter behind Luminex 100E front cover]

Cable, USB CN-0018-01

Manual, Luminex 100E User Manual CN-M028-01

Syringe Cylinder with Seal CN-0013-01

Syringe Seal [Set of 4] CN-0014-01

Microspheres, LX100, CL1 CL2 Calibration [xMAP Classification Calibration Microspheres]

Microspheres, LX100, RP1 Calibration

[xMAP Reporter Calibration Microspheres]

Sheath Fluid, LX100 [xMAP Sheath

Fluid]

CN-0053-01

L100-CAL1

L100-CAL2

40-50000

Training

Luminex 100E Field Service Training Call for details

PN 89-00002-00-013 Rev. D 5 - 1

Page 34

Luminex 100E User Manual xMAP Technology

5 - 2 PN 89-00002-00-013 Rev. D

Page 35

Index

A

about this manual

Luminex 100E User Manual

access doors 2-4

after running samples 4-2

sanitize 4-2

wash twice 4-2

air filter

product number

analyzer operation 2-4

avoid 2-4

beam exposure 2-4

exposure 2-4

staring into laser beam 2-4

5-1

1-1

B

before running samples 4-2

before using 2-1

biohazard 2-1

biological 2-1

warning 2-5

C

calibrate, verify 4-2

calibration microspheres

product number

capacity

specifications

cautions 2-1, 2-3, 2-4

CE mark 2-3

classification laser

specifications

components

electrical

customer support 1-2

5-1

3-4

3-4

2-1

D

decontaminate Luminex 100E for return 2-6

decontamination 2-1, 2-6

during operation 2-1

E

electronics

Luminex 100Especifications

email for customer assistance 1-2

European Union (EU) safety requirements 2-3

3-5

F

flow cell fluorometry 3-1

flow rate 3-5

fluidic leaks 2-3

fluidics 2-3, 3-5

theory 3-1

G

general, Luminex 100E 3-3

general, optics

specifications

3-4

H

hardware specifications 3-2

hardware, product numbers 5-1

I

idle more than 4 hours 4-2

inquiries, via email 1-2

intended use 1-1

L

label 2-3

labels 2-4

laboratory reagents also required 3-2

laser 2-4

analyzer 2-3, 2-4

apertures 2-3, 2-4

location 2-4

radiation 2-3

PN 89-00002-00-013 Rev. D Index-1

Page 36

Luminex 100E User Manual xMAP Technology

laser apertures 2-4

laser radiation 2-4

laser warnings 2-3

laser, analyzer 2-1

location 2-4

Luminex 100E 1-1, 2-3

analytes 3-1

optics 3-4

returning 2-6

Luminex 100E User Manual

about

1-1

LXR Library (LXR) 3-3

M

manual

about

1-1

manual adjustment 3-11

marketing 2-3

mechanical 2-1, 2-4

mechanical warnings 2-4

microspheres

product number

theory 3-1

5-1

O

once a day, warmup 4-2

once a month, clean

exterior surfaces

needle 4-2

sample probe 4-2

optical 3-11

optical assembly 3-11

optics 3-4, 3-5

classification laser 3-4

laser 3-4

reporter laser 3-4

theory 3-1

optics specifications 3-4

other reagents 3-2

4-2

P

pictures 2-4

prime 4-2

product numbers 5-1

proper ventilation

analyzer ventilation filter

protection provided 2-1

3-10

protective housing 2-4

R

radiation exposure 2-4

reagents 3-2, 5-1

reagents, product numbers 5-1

regularly, as required

sheath, waste fluids

illustration 4-2

removing the air filter 4-4

replacing the air filter 4-5

reporter channel 3-5

reporter laser

specifications

returning Luminex 100E 2-6

routine maintenance 2-3

running samples

after running

before running 4-2

releasing pressure 4-2

3-4

4-2

S

safety advisories 2-1

safety precautions 2-1

sensitivity

specifications

sheath

manually monitor

sheath flow rate 3-5

sheath fluid

product number

shut-down procedure 4-2

software 3-1, 5-1

specifications 3-4

capacity 3-4

classification laser 3-4

electronics 3-5

general, optics specifications 3-4

hardware 3-2

Luminex 100E 3-4

Luminex 100E electronics, specifications 3-

optics 3-4

reporter laser 3-4

sensitivity 3-4

subsystems

electronics

3-4

4-2

5-1

5

3-5

Index-2 PN 89-00002-00-013 Rev. D

Page 37

xMAP Technology Index

syringe cylinder, product number 5-1

syringe seal, product number 5-1

system overview 3-5

T

test samples

theory

3-1

theory of operation

Luminex 100E technology

3-1

U

user-accessible components

system overview illustration

3-5

W

warning labels 2-3

warnings 2-1, 2-4

biological 2-5

laser 2-3

mechanical 2-4

warranty 2-1

PN 89-00002-00-013 Rev. D Index-3

Page 38

Luminex 100E User Manual xMAP Technology

Index-4 PN 89-00002-00-013 Rev. D

Loading...

Loading...