Page 1

Lum/nex

®

Luminex 100

Version 1.7

™

User Manual

Page 2

© LUMINEX CORPORATION, 1998 - 2004. All rights reserved. No part of this publication may be

reproduced, transmitted, transcribed, or translated into any language or computer language, in any form or

by any means without prior express, written consent of:

LUMINEX CORPORATION

12212 Technology Boulevard

Austin, Texas 78727-6115

U.S.A.

Voice: (512) 219-8020

Fax: (512) 219-5195

Technical Support U.S. and Canada: toll-free 1-877-785-2323

Technical Support international: +1 512-381-4397

Technical Support fax: 512-219-5195

Technical Support website:

http://luminexcorp.custhelp.com.

Luminex® 100™ User Manual Version 1.7

CN-M027-01

PN 89-00002-00-063 Rev. A

March, 2004

Luminex reserves the right to modify its products and services at any time. This guide is subject to change

without notice. Although prepared to ensure accuracy, Luminex assumes no liability for errors or omissions,

or for any damages resulting from the application or use of this information.

The following are trademarks of Luminex Corporation: Luminex, Luminex 100, Luminex HTS,

Luminex 100 IS, LabMAP, LumAvidin, Luminex XYP, Luminex SD, xMAP, and FlexMAP. All other

trademarks, including Windows, Cheminert, Tween, Pentium, Dell, Alexa and Titertube

trademarks of their respective companies.

The contents of this manual and the associated Luminex software are the property of LUMINEX

CORPORATION and are copyrighted. Any reproduction in whole or in part is strictly prohibited.

are registered

Page 3

End-User License Agreement (EULA) for Luminex® Software

This Luminex End-User License Agreement (“EULA”) is a legal agreement between you (either an individual

or a single entity, also referred herein as “you”) the end-user and Luminex Corporation (“Luminex”) regarding

the use of the Luminex software product identified above, which includes computer software and online or

electronic documentation and may include associated media and printed materials (if any) (“SOFTWARE

PRODUCT” or “SOFTWARE”).

The SOFTWARE PRODUCT is protected by copyright laws and international copyright treaties, as well as

other intellectual property laws and treaties. The SOFTWARE PRODUCT is licensed, not sold.

1. GRANT OF LICENSE. Subject to the terms and conditions of this EULA, Luminex hereby grants to you a

nonexclusive, nontransferable, nonassignable license (without right to sublicense) under Luminex’s

copyrights and trade secrets to use the SOFTWARE PRODUCT on a hardware platform purchased from

Luminex pursuant to Luminex’s terms and conditions of sale. You may make one (1) copy of the

SOFTWARE PRODUCT for backup or archival purposes only. Although no rights or licenses under any

of Luminex's patents are granted by or shall be implied from the license of the SOFTWARE or the sale of

Luminex instrumentation to you, the purchaser, you may obtain a license under Luminex’s patents, if any,

to use this unit of Luminex instrumentation with fluorescently labeled microsphere beads authorized by

Luminex by purchasing such microspheres from Luminex or an authorized Luminex reseller.

2. RESTRICTIONS.

• You must maintain all proprietary notices on all copies of the SOFTWARE PRODUCT.

• You may not distribute copies of the SOFTWARE PRODUCT to third parties.

• You may not reverse-engineer, decompile, disassemble, or otherwise attempt to derive source

code from the SOFTWARE PRODUCT.

• You may not copy (other than one backup or archival copy), distribute, sublicense, rent, lease,

transfer or grant any rights in or to all or any portion of the SOFTWARE PRODUCT.

• You must comply with all applicable laws regarding the use of the SOFTWARE PRODUCT.

• You may not modify or prepare derivative works of the SOFTWARE PRODUCT.

• You may not use the SOFTWARE PRODUCT in a computer-based service business or publicly

display visual output of the SOFTWARE PRODUCT.

• You may not transmit the SOFTWARE PRODUCT over a network, by telephone, or

electronically by any means.

3. TERM AND TERMINATION. Your rights under this EULA are effective until termination. You may

terminate this EULA at any time by destroying the SOFTWARE PRODUCT, including all computer

programs and documentation, and erasing any copies residing on your computer equipment. Luminex

may terminate this EULA upon thirty (30) days written notice to you. Your rights under this EULA

automatically terminate without further action on the part of Luminex if you do not comply with any of the

terms or conditions of this EULA. Upon any termination of this EULA, you agree to destroy the

SOFTWARE PRODUCT and erase any copies residing on your computer equipment.

4. RIGHTS IN SOFTWARE. All rights and title in and to the SOFTWARE PRODUCT and any copies

thereof are owned by Luminex or its suppliers. This EULA is not a sale and does not transfer to you any

title or ownership interest in or to the SOFTWARE or any patent, copyright, trade secret, trade name,

trademark or other intellectual property right therein. You shall not remove, alter, or obscure any

proprietary notices contained on or within the SOFTWARE and shall reproduce such notices on any

back-up copy of the SOFTWARE. All title and intellectual property rights in and to the content which may

Page 4

be accessed through use of the SOFTWARE PRODUCT is the property of the respective content owner

and may be protected by applicable copyright or other intellectual property laws and treaties. This EULA

grants you no rights to use such content.

5. EXPORT RESTRICTIONS. You agree that you will not export or re-export the SOFTWARE PRODUCT

to any country, person, entity, or end-user subject to U.S.A. export restrictions. You hereby warrant no

state or federal agency has suspended, revoked, or denied your export privileges.

6. NO WARRANTY. THE SOFTWARE PRODUCT IS LICENSED “AS IS.” ANY USE OF THE SOFTWARE

PRODUCT IS AT YOUR OWN RISK. THE SOFTWARE PRODUCT IS PROVIDED FOR USE ONLY

WITH LUMINEX PRODUCTS. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW,

LUMINEX AND ITS SUPPLIERS DISCLAIM ALL WARRANTIES, EITHER EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR

A PARTICULAR PURPOSE, AND NONINFRINGEMENT.

7. LIMITATION OF LIABILITY. IN NO EVENT SHALL LUMINEX OR ITS SUPPLIERS BE LIABLE FOR

ANY SPECIAL, INCIDENTAL, INDIRECT, OR CONSEQUENTIAL DAMAGES WHATSOEVER

(INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS

INTERRUPTION, LOSS OF BUSINESS INFORMATION, OR ANY OTHER PECUNIARY LOSS)

ARISING OUT OF THE USE OF OR INABILITY TO USE THE SOFTWARE PRODUCT, EVEN IF

LUMINEX HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

MISCELLANEOUS. This EULA is governed by the laws of the State of Texas, U.S.A., without reference to

conflicts of laws principles. You shall not assign or sublicense or otherwise transfer the rights or license

granted hereunder, by agreement or by operation of law, without the prior written consent of Luminex, and all

assignments in violation of this prohibition shall be null and void. This EULA is the complete and exclusive

agreement of Luminex and you and supersedes all other communications, oral or written, relating to the subject matter hereof. No change to this EULA shall be valid unless in writing and signed by the party against

whom enforcement is sought. The waiver or failure of Luminex or you to exercise in any respect any right or

rights provided for herein shall not be deemed a waiver of any further right hereunder. If any provision of this

EULA is held unenforceable, the remainder of this EULA will continue in full force and effect.

EULA PN: 89-30000-00-070

Page 5

Contents

Introduction 1-1

Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Basic Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Fluidics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Excitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

xMAP Microspheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Reporter Fluorochromes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Fluorescence Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Repetitive Microsphere Measurements . . . . . . . . . . . . . . . . . .1-4

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Safety 2-1

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Warnings and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Fluidics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Biological . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Blue Indicator Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

System Overview 3-1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

xMAP Reagents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Luminex 100 Analyzer Specifications . . . . . . . . . . . . . . . . . . . . . .3-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Laser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Fluidics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Luminex XYP Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

PN 89-00002-00-063 Rev. A i

Page 6

Luminex 100 User Manual Version 1.7 xMAP Technology

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Uninterruptible power supply (UPS) . . . . . . . . . . . . . . . . . . . . 3-4

Surge Protector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Luminex 100 Analyzer Overview . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Electronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Fluidic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Optical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Luminex XYP Instrument Overview . . . . . . . . . . . . . . . . . . . . . . 3-10

Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Heater Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Installation 4-1

Luminex 100 System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Luminex 100 Software Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Adjusting the Sample Probe Height . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Installing Software and Firmware . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

What to Do Next. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

System Startup 5-1

Luminex Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Add New Classification Channel Calibration Lots . . . . . . . . . 5-2

Add New Reporter Channel Calibration Lots . . . . . . . . . . . . . 5-4

Calibrate the Luminex 100 Analyzer. . . . . . . . . . . . . . . . . . . . 5-5

Preview or Print Calibration Report . . . . . . . . . . . . . . . . . . . . 5-7

Analyzer menu commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Data Acquisition 6-1

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

User tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Acquisition tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Advanced tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Info tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Setup XY Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Sessions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Create a Session Using Default Settings. . . . . . . . . . . . . . . . . 6-6

Create a Session Using a Template . . . . . . . . . . . . . . . . . . . . . 6-6

Open and Add to an Existing Session . . . . . . . . . . . . . . . . . . . 6-8

Open an Existing Session and Save it as a New Session. . . . . 6-9

Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Create a Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Modify a Template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Delete a Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Multiplex Acquisition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

ii PN 89-00002-00-063 Rev. A

Page 7

xMAP Technology Contents

File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Main Control and Session Detail . . . . . . . . . . . . . . . . . . . . . . 6-12

Right-Click Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Session Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

General tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Bead Set tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Gates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

Bar Graph/Dot Plot Display . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

System Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Run an Entire Plate of Samples . . . . . . . . . . . . . . . . . . . . . . .6-25

Run a Range of Samples. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Run a Single Sample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Interrupt a Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

Maintenance and Cleaning 7-1

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Check Fluid Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Check for Leaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Sanitize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Clean Accessible Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Clean Sample Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Replace Air Intake Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Replace Syringe Seal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Clean Luminex 100 Analyzer Ventilation Filter. . . . . . . . . . . . . . . 7-7

Change Sheath Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

Change the Sheath Filter and Quick-disconnect O-rings . . . . . . . .7-8

Change Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Adjust Sample Probe Vertical Height . . . . . . . . . . . . . . . . . . . . . . .7-9

Adjusting the Sample Probe Horizontal Position . . . . . . . . . . 7-11

Decontaminating the Luminex 100 Analyzer for

Return Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

PN 89-00002-00-063 Rev. A iii

Page 8

Luminex 100 User Manual Version 1.7 xMAP Technology

Troubleshooting 8-1

Power Supply Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Pressurization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Fluid Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Sample Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Calibration Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Acquisition Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Bead Detail Irregularities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Printing Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Protocols 9-1

xMAP Microsphere Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Microsphere Dispersion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Probe Sonicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Bath Sonicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Enumeration of xMAP Microsphere Suspensions. . . . . . . . . . 9-3

xMAP Microsphere Separation Methods. . . . . . . . . . . . . . . . . 9-3

xMAP Microsphere Agitation During Assay . . . . . . . . . . . . . 9-3

xMAP Microsphere Stability and Storage . . . . . . . . . . . . . . . . 9-4

Two-Step Carbodiimide Coupling of Protein to xMAP

Carboxylated Microspheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Technical Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

One-Step Carbodiimide Coupling of Oligonucleotides to xMAP

Carboxylated Microspheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Technical notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Binding Biotin-conjugated Molecules to LumAvidin-Modified

xMAP Microspheres. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Technical notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

iv PN 89-00002-00-063 Rev. A

Page 9

xMAP Technology Contents

Glossary A-1

Product Numbers B-1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Luminex Sheath Delivery System C-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Using the Sheath Delivery System . . . . . . . . . . . . . . . . . . . . . . . . C-5

Audible Alarm and

Fault LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Index Index-1

PN 89-00002-00-063 Rev. A v

Page 10

Luminex 100 User Manual Version 1.7 xMAP Technology

vi PN 89-00002-00-063 Rev. A

Page 11

1

Introduction

The Luminex® 100 system is a compact analysis unit consisting of a

Luminex 100 analyzer, the Luminex XY Platform (Luminex

XYP™), a PC, Luminex software, and reagents. The Luminex 100

analyzer integrates optics, fluidics, and advanced signal processing in

a 17 inch by 20 inch footprint. The Luminex XYP provides efficient

handling of 96-well microtiter plates. The PC uses Luminex software

to control the analyzer. The optional Luminex Sheath Delivery

system (Luminex SD™) is used to provide sheath fluid directly from

a 20 liter container.

Photodiodes and a photomultiplier tube receive fluorescent signals

from xMAP

and delivers the signals to a digital signal processor (DSP).

Proprietary algorithms function with the DSP to greatly increase the

sensitivity.

®

microspheres. The analyzer digitizes the waveforms

Hardware and preloaded software simplify installation and setup, and

with the help of this manual, you will be able to begin using xMAP

technology.

Principle of

Operation

PN 89-00002-00-063 Rev. A 1 - 1

The Luminex 100 system analyzes immunoassays, complex genetic

analyses, and enzymatic assays in one simple format. The reactants

(antibodies, oligonucleotides, substrates, etc.) of these assays are

anchored to the surfaces of uniquely fluorescent microscopic beads,

called microspheres. The unique fluorescent emission spectra of a

given microsphere identifies each of the assays performed

simultaneously on a single sample.

The Luminex 100 analyzer individually analyzes xMAP

microspheres in a flow stream. Every xMAP microsphere is

accurately classified to its own subset, based on its fluorescent

Page 12

Luminex 100 User Manual Version 1.7 xMAP Technology

signature. In addition, the Luminex 100 analyzer scans each

microsphere for the presence of a reporter fluorescence that

quantifies the assay at the microsphere’s surface.

The Luminex XYP works with 96-well plates that are no thicker than

0.75 inches. If you are not using the heater block, any brand of

microtiter plate that meets this size requirement will work. If you are

using the heater block, we recommend one of these two plates:

• Polyfiltronics

black.

•Costar

The system reads the wells in column-first order. An entire column

of wells is read; that is, well A1, B1, C1, D1, and so on to the end of

the column. Then the XY Platform moves over to the next column

and reads well A2, B2, C2, D2, and so on. When placing a plate on

the plate holder, place it so well A1 is in the upper-left corner of the

holder. You can run an entire plate, a consecutive range of samples

from the plate, or a single sample from the plate.

®

model P.

®

96-well plate, 200 µL, catalog #7703-1902,

Thermowell® 96-well plate, thin-wall polycarbonate,

Basic Concepts Luminex has pioneered a versatile and robust technology for the

measurement of soluble analytes. The Luminex 100 system performs

simultaneous, discrete measurements of multiple microsphere-based

reactions from a single specimen aliquot. A clear understanding of

the concepts and functionality associated with the instrument and

xMAP microspheres contributes to greater success with this

technology. We present a brief overview of some of the basic

concepts. For more information, refer to Practical Flow Cytometry,

4th edition, by Howard M. Shapiro, M.D. (New York: Wiley-Liss

Inc., 2003).

Fluidics There are two fluidic paths in the Luminex 100 analyzer. The first

path is a syringe-driven mechanism that controls the sample uptake.

This mechanism permits small sample uptake volumes from small

reaction volumes. The syringe-driven system transports a userspecified volume of sample from a microtiter plate to the cuvette.

The sample is injected into the cuvette at a steady rate for analysis.

After analysis, the sample path is purged with sheath fluid by the

second fluidics path. This process expels sheath fluid into the sample

container and effectively removes residual sample within the tubing,

valves, and probe. The second fluidics path is driven under positive

air pressure and supplies sheath fluid to the cuvette.

1 - 2 PN 89-00002-00-063 Rev. A

Page 13

xMAP Technology Introduction

Excitation The excitation system in the Luminex 100 analyzer uses two solid-

state lasers. A reporter laser excites fluorescent molecules bound to

biological reactants at the microsphere surface, and a classification

laser excites fluorochromes embedded in the microsphere. The lasers

illuminate the xMAP microspheres as they flow single-file through

the cuvette. These fluorescent signals are discriminated with

selective emission filters and are converted into intensity units by a

digital signal processor.

xMAP Microspheres The xMAP microspheres are highly uniform, polystyrene particles

that have been crosslinked during polymerization for great physical

and thermal stability. Varying amounts of fluorochromes embedded

within each microsphere give each microsphere set an unique

fluorescent signal. To ensure the stability of this address, it is

essential to protect the xMAP microspheres from light. Do not

subject xMAP microspheres to prolonged high temperatures, and

protect them from freeze/thaw manipulations.

Reporter Fluorochromes Each xMAP microsphere is dyed to emit light in a certain

classification channel. All xMAP microspheres of a given emission

represent a distinct assay within a multiplex of assays. A reporter

channel is used to detect fluorescence bound to the surface of each

microsphere, and each reporter emission quantitates each of the

distinct assays. Only one reporter emission is used for multi-analyte

assays in the Luminex 100 analyzer. The Luminex 100 analyzer uses

an excitation wavelength of 532 nm, and has an emission wavelength

of 575 nm ± 12 nm.

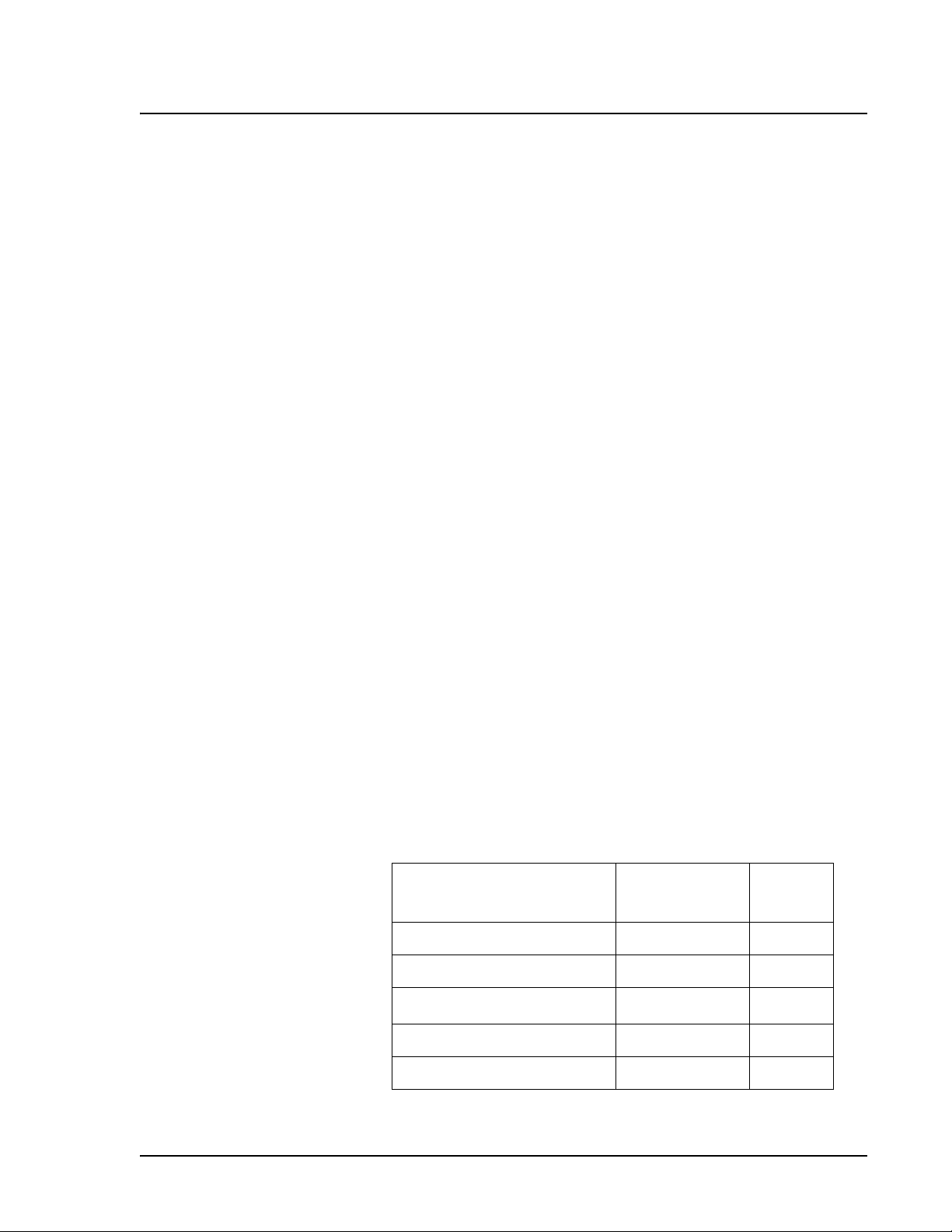

Fluorochromes R-Phycoerythrin, and Alexa

Luminex 100 analyzer, but you are not limited to these two. You may

have success using other fluorochromes such as Cyanine 3.

Phycoerythrin

Formula weight (Daltons) 240,000 470

Absorbance max (nm) 480, 546, 565 531

Extinction max (M

-1cm-1

)

1,960,000 83,800

532 work well with the

®

R-

Alexa

532

Emission max (nm) 578 554

Quantum yield 0.82 0.8

PN 89-00002-00-063 Rev. A 1 - 3

Page 14

Luminex 100 User Manual Version 1.7 xMAP Technology

Fluorescence

Compensation

Repetitive Microsphere

Measurements

Fluorescent spillover occurs when an emission spectrum overlaps

other emission criteria; therefore, selective filtering cannot occur. In

most analyzers, emission spillover is corrected using a technique

called compensation. Compensation involves subtraction of emission

percentage from another emission signal. In the Luminex 100

system, compensation is not necessary—the reporter signal does not

spill over into classification emissions.

Bound to reagents at the surfaces of the xMAP microspheres, the

reporter provides raw analytical data. Because a microsphere

suspension provides near liquid phase reaction kinetics, each

microsphere theoretically binds an equal number of reporter

molecules. Equal binding results in a statistically even distribution of

reporter on each microsphere in a set. When the Luminex 100

analyzer registers numerous events for each set, the system reports

individual population values based on an even coating of reporter.

This means that numerous replicates for each microsphere population

are measured from a single reaction vessel. The confidence in a

given measurement strengthens with increased replicate

measurements. For adequate confidence, 100 collected events per

microsphere set in each reaction vessel is usually sufficient.

Measurements are reported as the median for the xMAP

microspheres having a specific color signal.

About this Manual This manual introduces you to the Luminex 100 system. With step-

by-step instructions, the manual guides you through initial setup and

powering-on procedures. Next, it offers a concepts section which

describes some of the key topics encountered during system

operation. Once you have a working knowledge of the analyzer, the

manual’s text and figures lead you through the data collection

process, giving detailed explanations of available options and

offering examples when necessary. Glossary and troubleshooting

sections assist as references. In short, this manual instructs you

through each operational stage—from unpacking the Luminex 100

analyzer and XYP to collecting your data.

The conventions in this document assume a basic familiarity with

computers and a knowledge of Windows

document only one method of accessing a command, although many

commands are available through more than one method, such as

1 - 4 PN 89-00002-00-063 Rev. A

®

software. We typically

Page 15

xMAP Technology Introduction

from the main menu bar, from the toolbar, and from menus that

appear when you right-click an area of the screen.

Technical

Assistance

You can find answers to frequently asked questions (FAQs) on our

website: http://luminexcorp.custhelp.com.

Technical assistance is available to users in the U.S. and Canada by

calling toll free 1-877-785-BEAD (1-877-785-2323) between the

hours of 7:00 a.m. and 7:00 p.m. Central Time, Monday through

Friday. Users outside of the U.S. and Canada can call us at +1 512381-4397 between the hours of 7:00 a.m. and 7:00 p.m. Central

Time, Monday through Friday.

Inquiries may also be sent by email to support@luminexcorp.com.

PN 89-00002-00-063 Rev. A 1 - 5

Page 16

Luminex 100 User Manual Version 1.7 xMAP Technology

1 - 6 PN 89-00002-00-063 Rev. A

Page 17

Safety

Your safety is important. Please do not perform procedures on your

Luminex 100 system that are not specifically contained in this

manual, unless you are directed to do so by Luminex Technical

Support. This chapter discusses the following safety topics

• Intended Use

• Symbols

• Safety Precautions

Intended Use The Luminex 100 analyzer is designed for a wide range of indoor

laboratory testing applications measuring biomolecular reactions on

the surfaces of xMAP microspheres. This system is intended for

indoor research use only and not for use in diagnostic procedures.

The Luminex XYP instrument is intended for use with the Luminex

100 analyzer. With the Luminex XYP, you can process 96-well

microtiter plates without handling individual samples. The Luminex

XYP works with microtiter plates that are no thicker than 0.75 in.

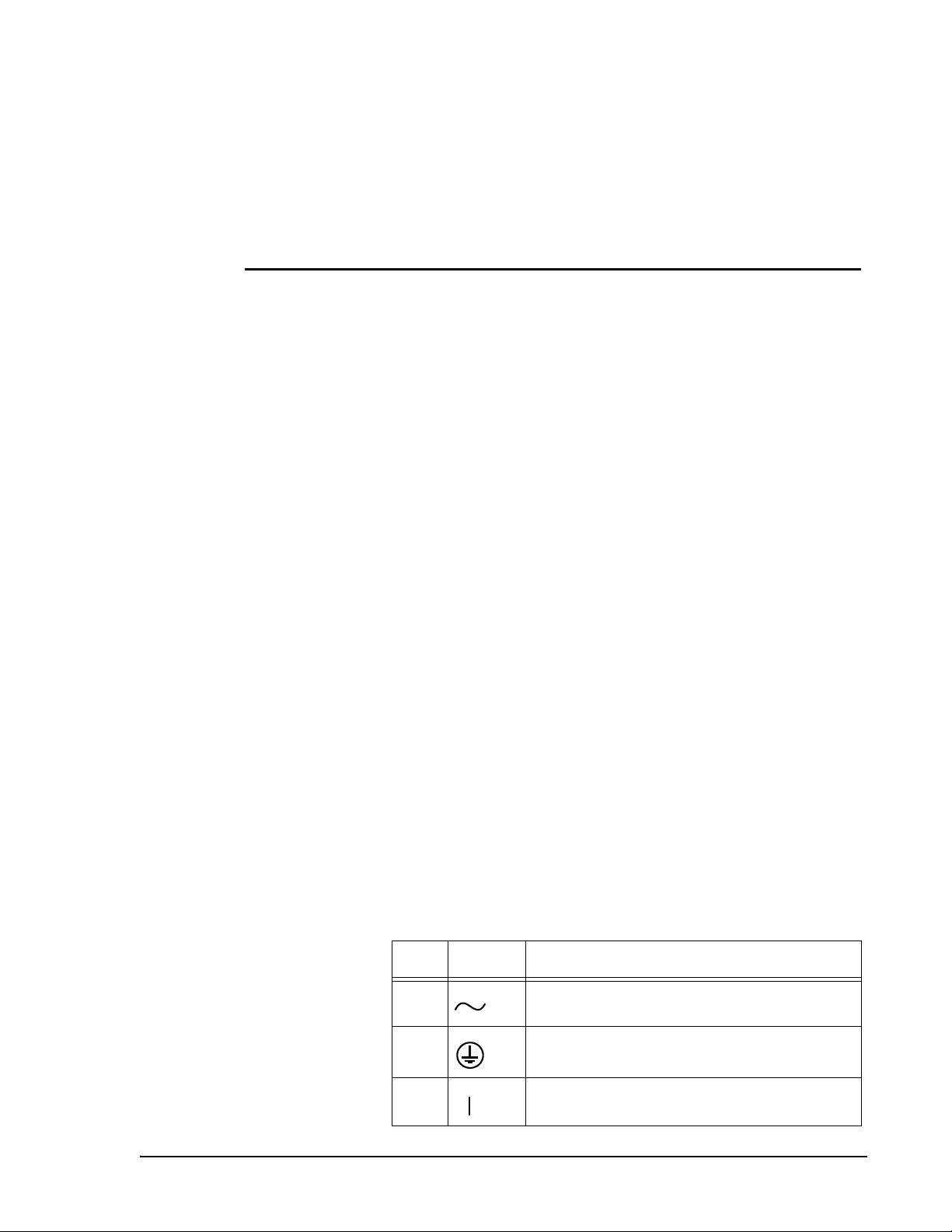

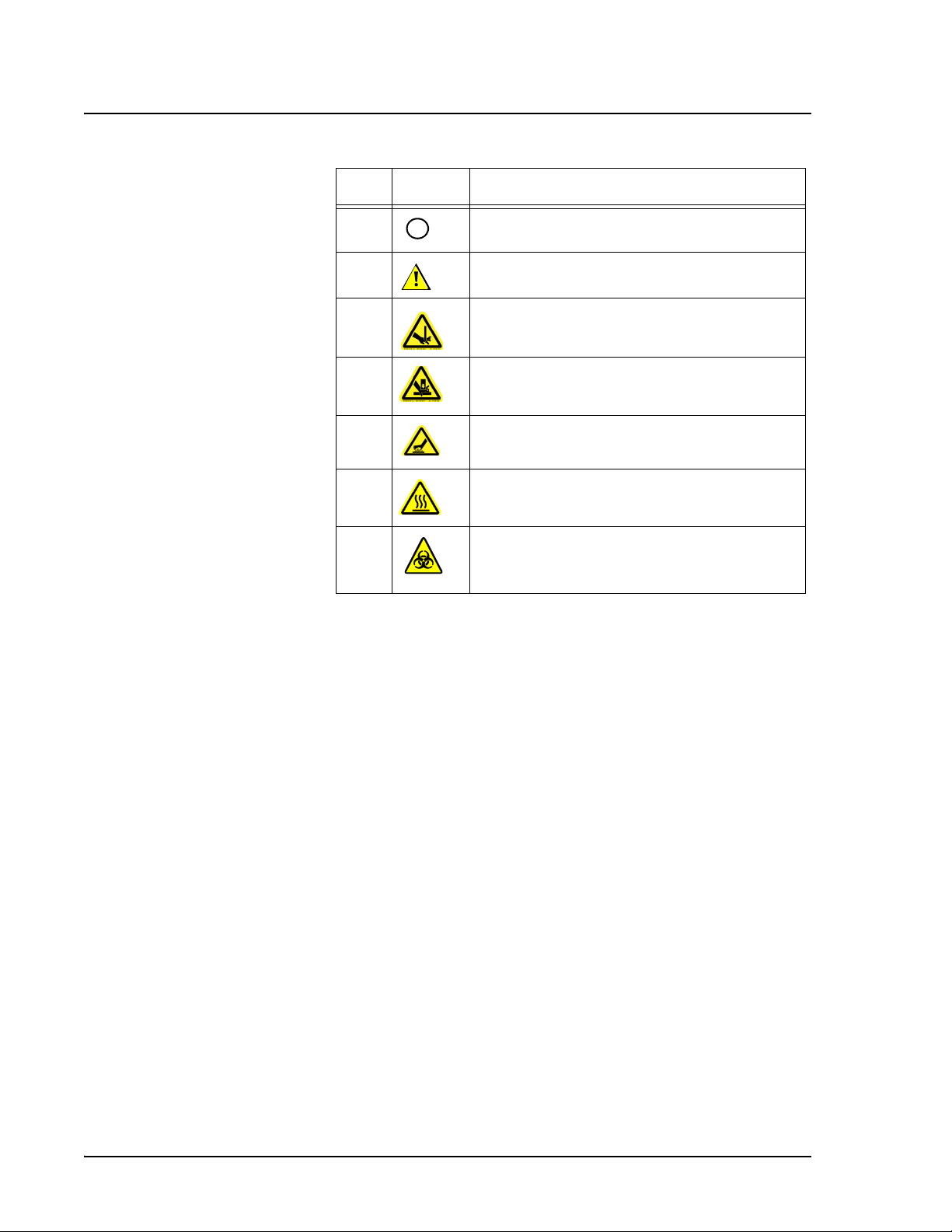

Symbols These symbols describe warnings, cautions, and general information

used in the operation of this analyzer.

Symbol Description

1 Alternating current

2 Protective ground

3On

PN 89-00002-00-063 Rev. A 2 - 1

Page 18

Luminex 100 User Manual Version 1.7 xMAP Technology

Symbol Description

4Off

5 Warning (see manual).

6 Warning (see manual).

7 Warning (see manual).

8 Warning (see manual).

9 Warning (see manual).

10

Warning (refer to manual)

Warnings and Notes Informational notes and warnings may appear in this manual.

Note: A note provides general helpful information. No safety or

performance issues are involved.

Caution: This message is used in cases where the hazard is minor or

only potential hazard is present. Failure to comply with the caution

may result in potentially hazardous conditions.

Warning: This message is used in cases where danger to the

operator or to the performance of the instrument is present. Failure to

comply with the warning may result in incorrect performance,

instrument failure, invalid results, or hazard to the operator.

Danger: This message is used in cases where significant risk of

serious injury or death is present.

Safety Precautions Please read the following safety information before setting up or

using the Luminex 100 system. A user should always be present

during system operation. This system contains electrical, mechanical,

and laser components which, if handled improperly, are potentially

harmful. In addition, biological hazards may be present during

Luminex 100 analyzer operation. Therefore, Luminex Corporation

recommends that all Luminex 100 analyzer users become familiar

2 - 2 PN 89-00002-00-063 Rev. A

Page 19

xMAP Technology Safety

with the specific safety advisories below, in addition to adhering to

standard laboratory safety practices. The protection provided by the

equipment may be impaired or the warranty voided if the equipment

is used in a manner not specified by Luminex Corporation.

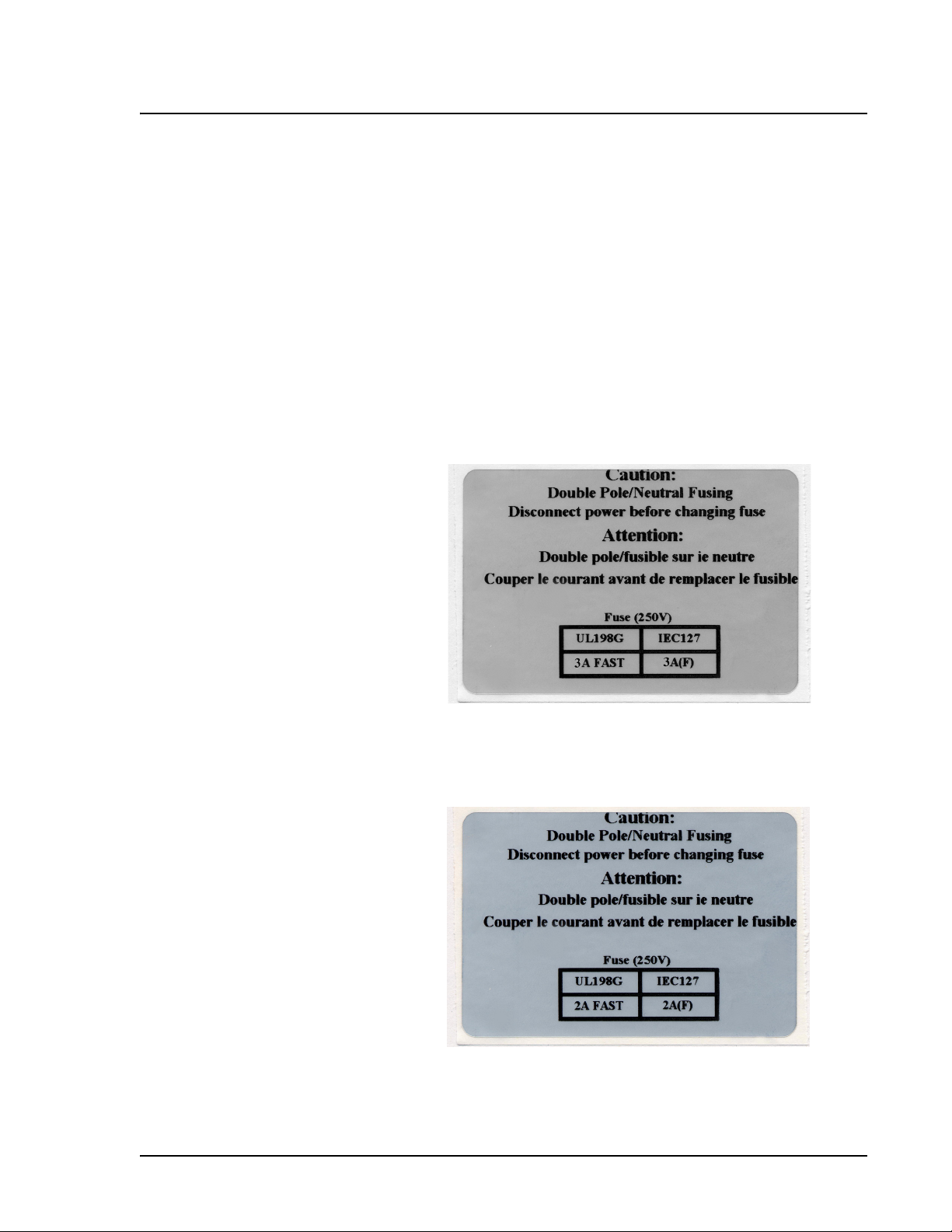

Electrical The Luminex 100 analyzer and Luminex XYP must be connected to

approved power sources.

Do not perform any maintenance or cleaning of the system’s

electrical components (except for the fuses).

This caution label appears on the back of Luminex 100 analyzers

using the Coherent laser, and on the Luminex XYP:

Figure 2-1. Fuse Replacement Warning Label

This label appears on the back of Luminex 100 analyzers using the

Uniphase laser:

Figure 2-2. Fuse Replacement Warning Label - Uniphase Laser

PN 89-00002-00-063 Rev. A 2 - 3

Page 20

Luminex 100 User Manual Version 1.7 xMAP Technology

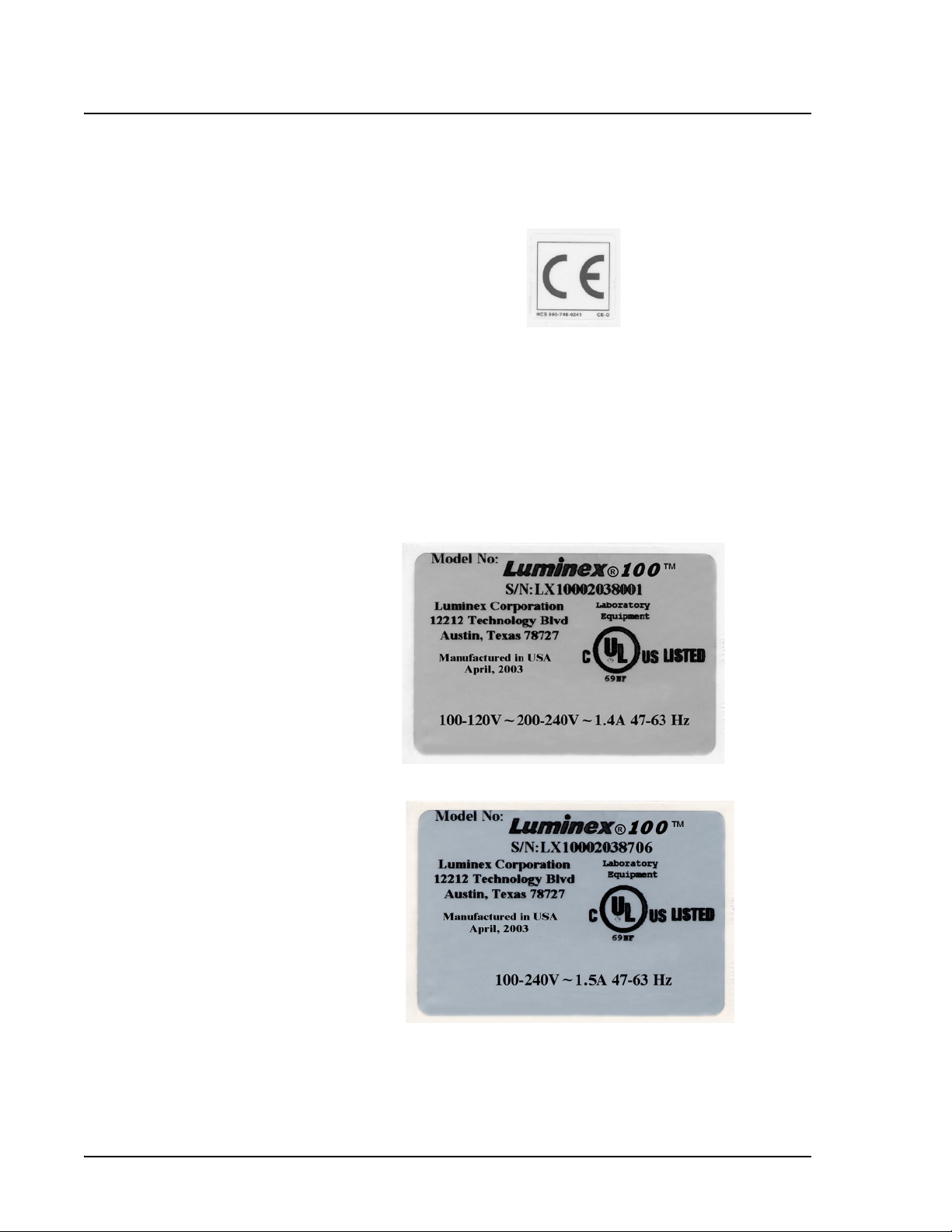

This label appears on the back of the Luminex 100 analyzer and the

Luminex XYP.

Figure 2-3. European Safety Requirements Label

The Luminex 100 analyzer complies with European Union (EU)

safety requirements and, therefore, may be marketed in the Europe

Single Market.

One of the following voltage labels displays on the back of the

Luminex 100 analyzer, depending if the instrument uses a Coherent

or Uniphase laser:

Figure 2-4. Luminex 100 Voltage Label (Coherent)

Figure 2-5. Luminex 100 Voltage Label (Uniphase)

2 - 4 PN 89-00002-00-063 Rev. A

Page 21

xMAP Technology Safety

This voltage label displays on the back of the Luminex XYP:

Figure 2-6. Luminex XYP Voltage Label

Fluidics The Luminex 100 analyzer contains fluidics. In the event of a fluid

leak, turn off all power to the system and disconnect all power cords.

Warning: If the system is used

to test biological samples, use

your standard laboratory safety

practices when handling system

waste.

Remember that the on/off switch is not a disconnect means - the

power cord must be removed from the outlet. Contact Luminex

Corporation for further information.

You must manually monitor waste levels. Do not allow the waste

container to overflow. Empty the waste container each time you fill

the sheath fluid container. Do not place the waste container on top of

the analyzer.

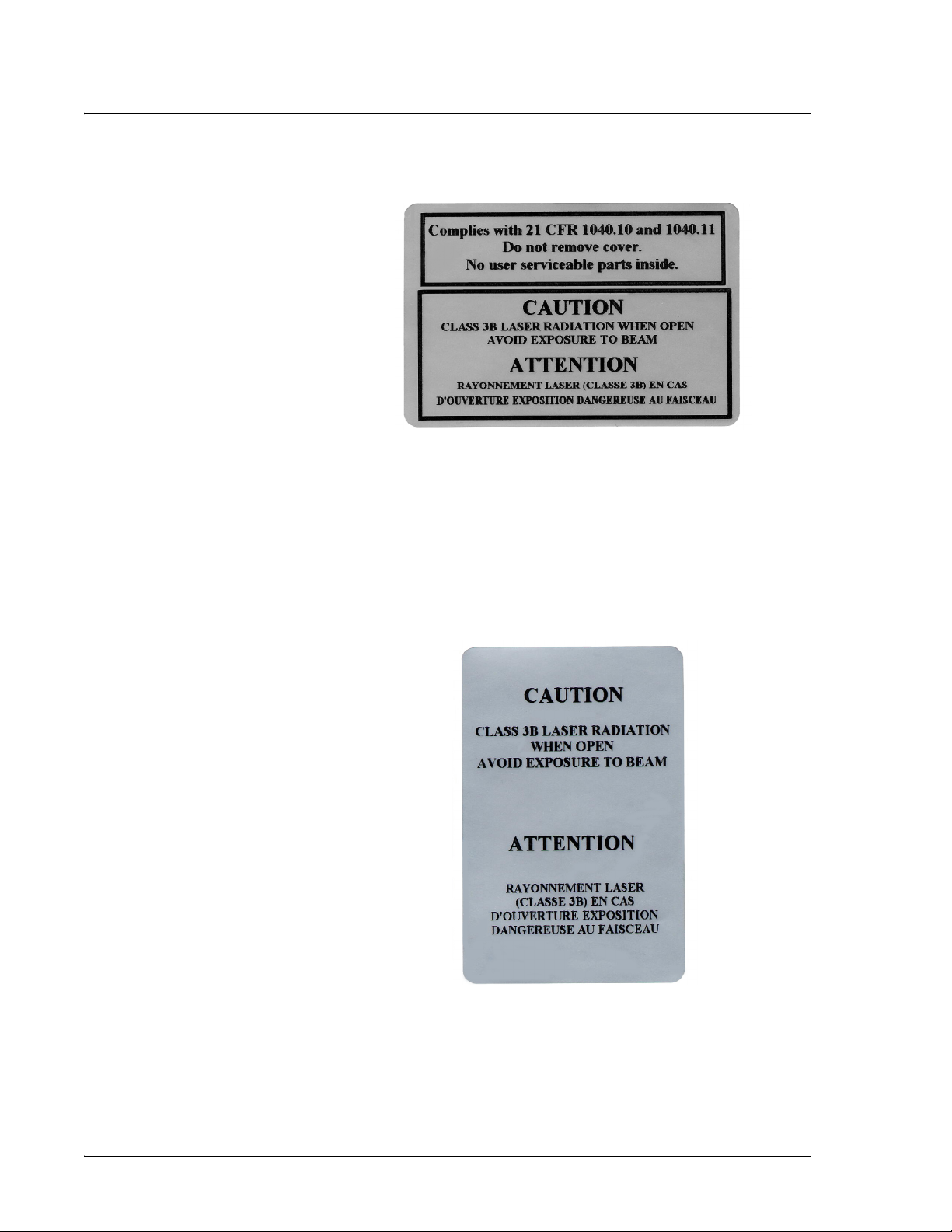

United States and international regulations require the following

warnings to appear on the analyzer during operation and

maintenance.

This label appears on the back panel of the analyzer:

Figure 2-7. Laser Class Label

PN 89-00002-00-063 Rev. A 2 - 5

Page 22

Luminex 100 User Manual Version 1.7 xMAP Technology

This label appears on the back panel of the Luminex 100 analyzer:

Figure 2-8. Laser Caution Label

Do not remove the analyzer cover. When performing routine

maintenance, ensure that power to the analyzer is OFF and the power

cord is disconnected.

All laser apertures in the analyzer are contained within a protective

housing. This label appears on the optics cover within the Luminex

100 analyzer.

Figure 2-9. Laser Caution Label on Optics Cover

This label appears above the laser apertures located inside the optics

enclosure inside the Luminex 100 analyzer.

2 - 6 PN 89-00002-00-063 Rev. A

Page 23

xMAP Technology Safety

Figure 2-10. Avoid Exposure Label

Caution: Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

Caution: To avoid exposure to hazardous radiation, only perform

procedures and adjustments as specified in this manual.

Mechanical

Warning: During operation, this system contains exposed,

moving parts. Risk of personal injury is present. Observe all

warnings and cautions.

Note: Access doors must be

closed while operating the

instrument. An operator must

be present during operation of

the instrument.

Biological

Warning: During operation, this system contains exposed,

moving parts which could result in puncture hazard. Risk of

personal injury is present. Keep hands and fingers away from the

sample probe. Keep hands and fingers out of the Luminex XYP

slot during operation.

Warning: During operation, this system contains exposed,

moving parts which could result in pinch point hazard. Risk of

personal injury is present. Keep hands and fingers away from the

syringe arm.

Warning: Human/animal samples may contain biohazardous

infectious agents. Where exposure (including aerosol) to potentially

biohazardous materials exists, follow appropriate biosafety

procedures and use personal protective equipment, such as gloves,

gowns, laboratory coats, face shields or masks, eye protection, and

ventilation devices. Observe all local, state, and federal biohazard

handling regulations when disposing of biohazardous waste

material.

PN 89-00002-00-063 Rev. A 2 - 7

Page 24

Luminex 100 User Manual Version 1.7 xMAP Technology

Heat

Warning: The heater plate of the Luminex XYP may be hot and

could cause personal injury if touched. Do not touch the heater

plate.

Blue Indicator Light

The blue light above the sample arm simply indicates the on/off

status of the instrument, and is harmless. The blue light emitting

diode (LED) does not emit light in the UV spectrum.

2 - 8 PN 89-00002-00-063 Rev. A

Page 25

System Overview

3

Hardware The Luminex 100 Version 1.7 system includes a Luminex 100

Version 1.7 analyzer, the Luminex XYP, and a PC.

The Luminex 100 analyzer includes the following hardware:

• Luminex 100 analyzer

• Sample tube holders (1.5 mL and 1.2 mL)

• Sheath fluid container

• Waste container

• Communications cable to connect analyzer with computer

The Luminex XYP includes the following hardware:

• Luminex XYP instrument

• Power cord

• Communication cable to connect to the Luminex XYP

• Alignment guide

• Luminex XYP sample probe (long probe)

• Reservoir

•Shield

• Luminex XYP heater block

• Probe alignment toolkit

• Allen wrench, 3/32 inch hexagonal

The PC includes the following hardware:

• Computer: a Pentium

• Monitor

• Power cords

• Keyboard

•Mouse

PN 89-00002-00-063 Rev. A 3 - 1

®

microprocessor class PC

Page 26

Luminex 100 User Manual Version 1.7 xMAP Technology

In addition, you can purchase the optional Luminex Sheath Delivery

system (Luminex SD).

xMAP Reagents • xMAP classification calibration microspheres (CAL1)

• xMAP reporter calibration microspheres (CAL2)

• Sheath fluid

Software Luminex Data Collector software provides complete control of the

Luminex 100 analyzer and performs real-time digital analysis of

assays. The Luminex 100 system is preloaded with the Luminex

software. However, we supply a software CD in case you need to

reinstall the software.

Luminex 100

Analyzer

Specifications

General • Operating temperature: 15°C to 30°C (59°F to 86°F)

• Storage temperature: 0°C to 50°C (32°F to 122°F)

• Humidity: 20% to 80%, noncondensing

• Altitude: designed to operate up to 2400 m (7874 ft.) above

mean sea level

• Physical dimensions: 43 cm (17 in) W x 51 cm (20 in) D x 23 cm

(9 in) H

• Weight: 23 kg (60 lbs)

• UL installation category: UL Installation Category II, as defined

in Annex J of UL 61010A-1

• Pollution degree: UL Pollution Degree 2, as defined in section

3.7.3.2 of UL 61010A-1

Power • Input voltage range:

• 100-240 V~, 1.5 Amps, 47-63 Hz

OR

• 100-120 V~ and 200-240 V~, 1.4 Amps, 47-63 Hz. See label

on rear of instrument.

• AC inlet fuse: 3A, 250V~, Fast Acting

OR

2A, 250 V~, Fast Acting. See label on rear of instrument.

• Shipping and storage: allowable shipping and storage

temperature and humidity ranges, 0°C to +50°C and 20%-80%

noncondensing, respectively.

3 - 2 PN 89-00002-00-063 Rev. A

Page 27

xMAP Technology System Overview

Laser • Reporter laser: 532 nm, nominal output 10-16.5 mW, maximum

500 mW, frequency-doubled diode; mode of operation mW,

continuous wave (CW)

• Classification laser: 635 nm, nominal output 9.1 mW ± 6%,

maximum output 25 mW, diode; mode of operation, continuous

wave (CW)

Fluidics • Sheath flow rate: 90 µL/second ± 5 µL/second

• Cuvette: 200 micron square flow channel

• Sample injection rates: 60 µL/minute, 45 µL/minute, or 30 µL/

minute

• Sample uptake volume: 10-200 µL

Electronics • Reporter channel detection: photomultiplier tube,

A/D resolution, 14 bits

• Classification and doublet discriminator channel detection:

avalanche photo diodes (APD) with temperature

compensation, A/D resolution 12 bits

• Communications interface: RS 232

Signal Processing • Signal modes: linear, with logarithmic or linear display option

PC • Computer: a Pentium III microprocessor or equivalent class PC,

minimum speed 933 MHz

• Main memory: minimum of 128 MB

• Hard disk drive: 10 GB minimum storage capacity

• Communications, serial ports: minimum of 2 RS-232 compatible

serial ports

• Operating system support: MS

• CE marked and UL listed

• Two-button mouse or equivalent

• Monitor: minimum of 17-inch diagonal monitor

• Keyboard: a 104-key keyboard or equivalent

• Power cords for the US and Canada are included in the system.

Power cords for other countries must be ordered separately.

• Power: 115-230 V~, Maximum 6.0 Amps, 50-60 Hz

Windows

®

PN 89-00002-00-063 Rev. A 3 - 3

Page 28

Luminex 100 User Manual Version 1.7 xMAP Technology

Luminex XYP

Specifications

General • Operating temperature: 15°C to 30°C (59°F to 86°F)

• Humidity: 20% to 80%, noncondensing

• Altitude: designed to operate at 2400 m (7874 ft.) above mean

sea level or below.

• Physical dimensions: 44 cm (17.25 in) W x 61 cm (24 in) D x 8

cm (3 in) H

• Weight: 14.5 kg (32 lbs)

• UL installation category: UL Installation Category II, as defined

in Annex J of UL 3101-1.

• Pollution degree: UL Pollution Degree 2, as defined in section

3.7.3.2 of UL 3101-1.

• Heater operating range: 35°C to 60°C (95°F to 140°F) with

tolerance 0°C to +2°C.

• Shipping and storage: allowable shipping and storage

temperature and humidity ranges, 0°C to +50°C and 20%-80%

noncondensing, respectively.

Power • Input voltage range: 100-240 V~, 1.8 Amps, 47-63 Hz

• AC Inlet Fuse: 3 Amp, 250 V~, Fast Acting

Electronics Communications interface: RS-232

Recommended

Equipment

You may find the following items helpful to protect the electronic

components of your Luminex 100 System.

Printer We recommend that you have a printer installed to your system so

that you can print reports and diagnostics. We recommend an HP

LaserJet 2200 printer.

Uninterruptible power

supply (UPS)

Luminex highly recommends using an uninterruptible power supply

(UPS) to protect your system from a power outage. Choose a supply

that can provide 1050 Watts for at least 45 minutes. The UPS should

be UL listed and CSA certified. The UPS also needs to be CE

marked if used internationally.

Surge Protector If you do not use a UPS, use a surge protector. Choose a protector

that meets your needs. Factors to consider include electrical

environment, endurance, suppressed voltage rating, and method of

protection. It should have six outlets, be rated at least 1500 Watts,

and be UL listed, CSA certified, CE marked for nondomestic use

when used internationally.

3 - 4 PN 89-00002-00-063 Rev. A

Page 29

xMAP Technology System Overview

Luminex 100

Analyzer Overview

The Luminex 100 analyzer consists of three subsystems: electronic,

fluidic and optical. The following section describes the useraccessible components of each subsystem. Chapter 7, "Maintenance

and Cleaning", describes routine maintenance for each of these

components.

Electronic Power input module: Houses the analyzer on/off switch and

fuses.

P1 communications port (DB9): Connects the Luminex 100

analyzer to the computer.

Analyzer ventilation filter: Provides filtration for the analyzer

ventilation system. To ensure proper ventilation, do not obstruct the

area below the analyzer. Allow at least two inches of clearance

around the analyzer.

Air Intake Access Door

h

c

i

t

w

S

er

w

o

P

Power Input Module

XYP Instrument

Ventilation Filter

PN 89-00002-00-063 Rev. A 3 - 5

Communications

Ports (DB9)

Figure 3-1. Rear View of Luminex 100 Analyzer

XYP to PC

Serial cable

Analyzer

Ventilation Filter

Page 30

Luminex 100 User Manual Version 1.7 xMAP Technology

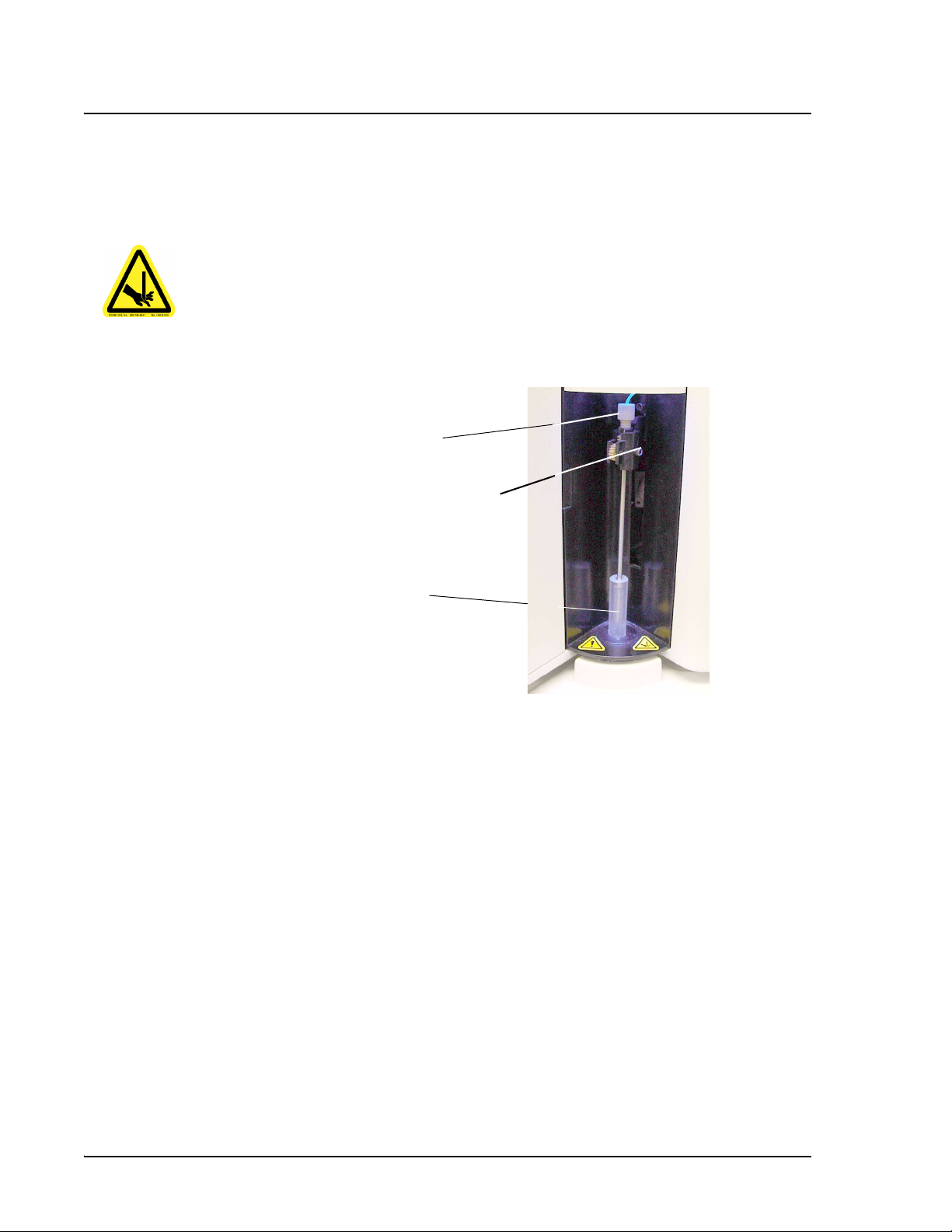

Fluidic Sample Arm: Transports the sample from the sample plate to the

cuvette. Upon operation, the carriage drops automatically to the

sample plate for sample retrieval.

Sample Probe: Acquires sample from the sample plate.

Warning: During operation,

this system contains exposed,

moving parts which can cause

puncture wounds. Risk of personal injury is present. Keep

hands and fingers away from the

sample probe.

Note: The probe shield is not in

place for this photo. You should

always replace the probe shield

before operating the system.

Cheminert

® fitting: Holds the sample probe in place. Use the

wheel to adjust the sample probe height.

Alignment Guide: Directs the sample probe into the Luminex

XYP instrument.

Cheminert

Fitting

Vertical Adjustment

Screw

Alignment

Guide

Figure 3-2. Sample Uptake Components

Access doors: There are two access doors on the face of the

analyzer. The center door provides access to the syringe. The left

door provides service panel access. Inside the left door, a bracket

holds the heater block for the Luminex XYP. There is also a clip for

the allen wrench included with the Luminex 100 analyzer.

3 - 6 PN 89-00002-00-063 Rev. A

Page 31

xMAP Technology System Overview

Left Door, Access

to Service Panel

Figure 3-3. Front View of Luminex 100 Analyzer Showing Access Doors

Center Door,

Access to Syringe

Air filter and access door: Cleans the air used to pressurize

sheath fluid. This filter is enclosed behind an access door located on

the back of the Luminex 100 analyzer.

Figure 3-4. Air Filter on Rear of Instrument

PN 89-00002-00-063 Rev. A 3 - 7

Page 32

Luminex 100 User Manual Version 1.7 xMAP Technology

Syringe: Delivers sample from the sample plate to the cuvette. It is

located in the compartment behind the center door.

Syringe

Seal

Syringe

Figure 3-5. Syringe

Sheath filter: Removes particles greater than 10 microns in

diameter from the sheath fluid. It is located behind the left access

door.

Sheath Filter

Assembly

Figure 3-6. Sheath Filter Assembly

Air, waste fluid, and sheath fluid connectors: Connect to the

sheath and waste fluid containers. The air connector is green, the

sheath fluid connector is blue, and the waste fluid connector is

orange.

3 - 8 PN 89-00002-00-063 Rev. A

Page 33

xMAP Technology System Overview

Sheath Fluid

Connector (Blue)

Figure 3-7. Left Side of Analyzer - Air and Fluid Connectors

Air Connector

(Green)

Waste

Connector

(Orange)

Sheath fluid container (not shown): Holds sheath fluid. For

proper operation, place the container at the same level as the

analyzer. Do not place the container on top of the Luminex 100

analyzer.

The sheath fluid level should be below the air inlet connection and

above the sheath outlet connection. Sheath fluid levels must be

monitored manually. Check the sheath fluid level before starting a

run or procedure.

Waste fluid container (not shown): Receives waste from the

system. Monitor the waste fluid levels—do not allow the waste

container to overflow! Empty the waste container each time you fill

the sheath fluid container. Do not put the waste container on top of

the Luminex 100 analyzer.

Optical The optical system contains the optics assembly and the excitation

lasers. The optical assemblies do not require user adjustment.

PN 89-00002-00-063 Rev. A 3 - 9

Page 34

Luminex 100 User Manual Version 1.7 xMAP Technology

Luminex XYP

Instrument

The Luminex XYP is a self-contained system. There is one access

door that contains a plate holder and a reservoir. A heater plate can

be placed in the plate holder.

Overview

Reservoir You can use 70% isopropanol or 70% ethanol, deionized water, and

10%-20% bleach solution in the reservoir for Luminex 100 analyzer

cleaning and maintenance procedures.

Heater Block Use the heater block as required by your assay procedures. When

you are not using the heater block you can store it in the bracket

inside the left access door of the Luminex 100 analyzer.

3 - 10 PN 89-00002-00-063 Rev. A

Page 35

4

Installation

Luminex 100

System Installation

Note: The Luminex 100 System is

too heavy for one person to lift

alone. Two people should unpack

and lift the system to the

workbench.

Ensure that the facility complies with all system and safety

requirements.

If you are using the optional Luminex SD, install it after completely

installing the Luminex 100 analyzer and the Luminex XYP. See the

Luminex Sheath Delivery System appendix for instructions.

To set up and start up the Luminex 100 system:

1. Unpack the Luminex 100 analyzer, Luminex XYP instrument,

and the PC. Review the hardware list on page 3-1 and identify

each system component.

2. Place the Luminex XYP on a clean, flat surface.

3. Remove the red shipping pin. Leave the silver knob in place.

Shipping Pin

Figure 4-1. XYP With Shipping Pin in Place

4. Attach the power cord and the communication cable to the

Luminex XYP. Do not plug the power cord into the outlet.

5. Place the Luminex 100 on top of the Luminex XYP. Do not plug

it into the power outlet.

PN 89-00002-00-063 Rev. A 4 - 1

Page 36

Luminex 100 User Manual Version 1.7 xMAP Technology

6. Replace the short sample probe with the long sample probe as

follows: Unsnap the light housing above the probe. Loosen the

Cheminert fitting that holds the sample probe in place. Gently

grasp the probe and push up. Remove the sample probe out of

the top of the sample arm. Push the long sample probe into the

top of the sample arm, and tighten the Cheminert fitting.

7. Install the alignment guide by screwing it into the Luminex XYP

as shown below. Adjust the position of the Luminex 100

analyzer with the Luminex XYP as necessary.

Alignment Guide

Figure 4-2. Front of Luminex 100 System, Alignment Guide in Place

8. Attach the waste container.

9. Fill and attach the sheath fluid container. Fill the container with

sheath fluid to just below the air intake.

To set up the PC:

1. Place the PC to the right of the Luminex 100 analyzer and

Luminex XYP. Do not place the PC on top of the analyzer.

2. Place the monitor on top of the PC and connect the cable

between the monitor and the PC.

3. Attach a power cable to the power input modules of the PC and

monitor. Do not plug the power cable into the power outlet.

4. Connect the mouse and keyboard to the PC.

5. Connect one of the communications cables between the Luminex

100 analyzer communications port and COM Port 1 on the PC.

6. Connect the other communications cable to between the XYP

instrument communications port to and COM port 2 on the PC.

7. Plug all instrument power cords into an approved power source.

4 - 2 PN 89-00002-00-063 Rev. A

Page 37

xMAP Technology Installation

Luminex 100

Software Setup

After performing the Luminex 100 system assembly, ensure that the

proper interface between the analyzer and PC is in place.

To set up the software:

1. Turn on the Luminex 100 analyzer, then turn on the PC. The

Luminex software launches automatically.

2. Click Ye s to accept the End-User License Agreement. If the

system does not prompt you to accept this agreement, read the

agreement shown after the title page of this manual. If you reject

the agreement, you cannot use the Luminex 100 system. Contact

Luminex Technical Support if you reject the agreement.

3. Verify that the analyzer status, shown in the System Monitor box

on the Luminex Main window, is at “Standby.” If the status is

“Bad Link,” exit the Luminex software and start it again.

4. On the Analyzer menu, click Setup. The Machine Setup dialog

box opens.

Figure 4-3. Machine Setup Dialog Box

5. Ensure that the analyzer type shown is Luminex 100.

6. Make sure that COM Port is set to 1. This setting refers to the

port on your computer, not on the Luminex 100 analyzer.

7. Make sure that the XY Port is set to 2. If communication

between the Luminex 100 analyzer and the Luminex XYP

instrument fails, switch ports so that the Luminex 100 analyzer is

on COM port 2 and the XY Port is set to 1. This task enables you

to check if the serial cable is the cause of the communication

errors.

PN 89-00002-00-063 Rev. A 4 - 3

Page 38

Luminex 100 User Manual Version 1.7 xMAP Technology

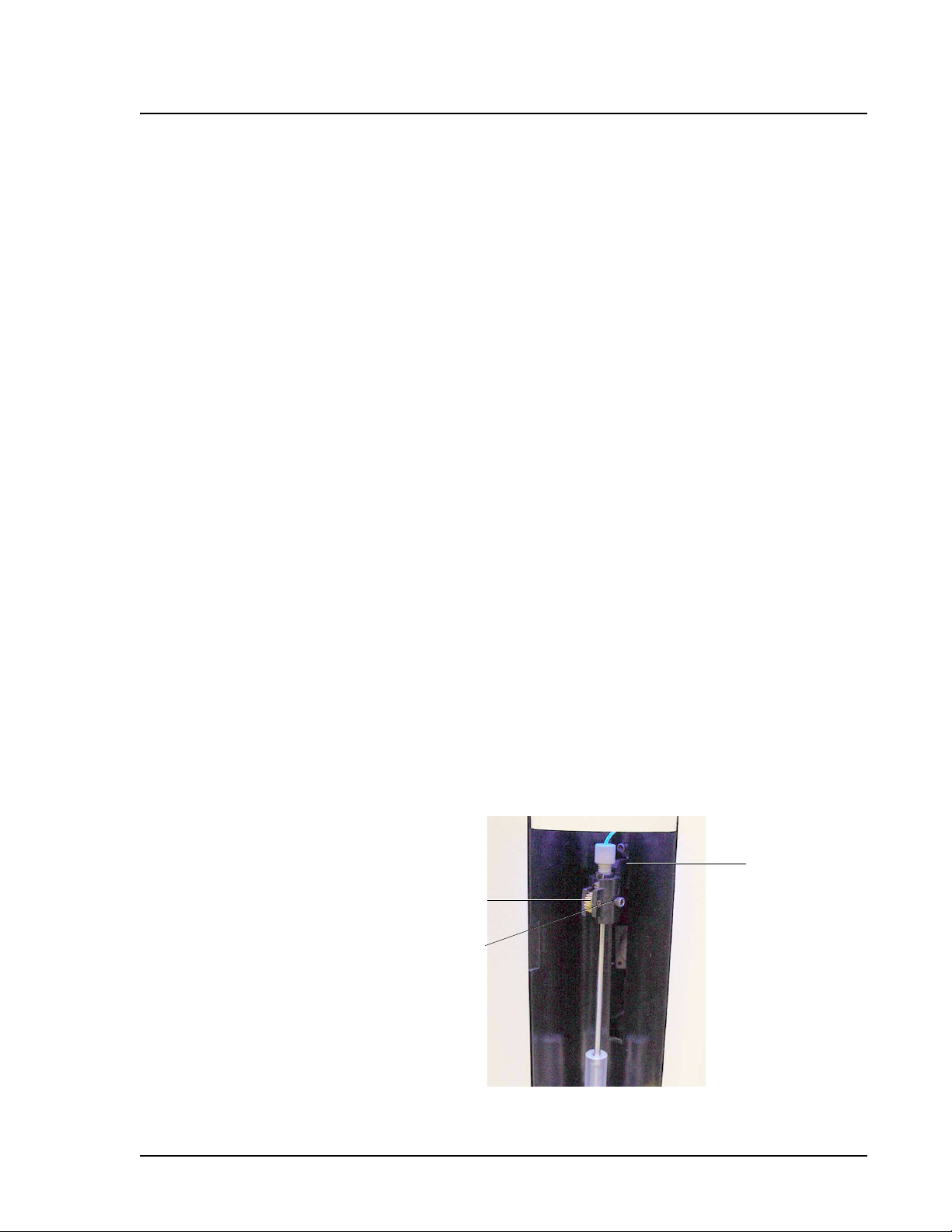

Adjusting the

Sample Probe

Height

Note: Adjusting the sample probe

vertical height is critical.

You must adjust the Sample Probe vertical height each time you

install a Sample Probe, change the type or style of microtiter plate,

or move the instrument.

Thumb Wheel

ent

m

t

s

u

dj

A

t

i

gh

e

H

ew

c

r

S

g

i

n

k

Loc

Figure 4-4. Sample Probe Height Adjustment Tools

To adjust the Sample Probe’s vertical height:

1. Turn on the Luminex XYP and the Luminex 100 analyzer, and

PC. Wait for the Luminex Data Collector software to start.

2. If already installed, remove the clear plastic shield covering the

sample probe area.

3. In a 96-well microtiter plate where overall height is no more than

0.75 inches, place the appropriate alignment tool in the plate.

• For a standard plate with flat-bottomed wells, stack two of

the larger (5.08 mm diameter) alignment disks in well A1.

• For filter-bottom plates, stack three of the larger alignment

disks into well A1.

• For half-volume plates with flat-bottomed wells, stack two

small (3.35 mm diameter) alignment disks in well A1.

• For a plate with conical wells, place one alignment sphere

into well A1.

• For round-bottom wells, stack 2 small disks in well A1.

4. Click Eject.

4 - 4 PN 89-00002-00-063 Rev. A

Page 39

xMAP Technology Installation

5. Place the 96-well microtiter plate on the Luminex XYP with

position A1 in the top left corner and click Retract to retract the

plate.

6. Use the 3/32 inch hexagonal allen wrench to loosen the height

adjustment locking screw. See the photo on page 4-4.

7. Click Options on the toolbar.

8. Click Setup XY, then click Setup. This dialog box appears:

9. Click Test to lower the sample probe into well A1.

10. Using the thumb wheel, raise and lower the Sample Probe until it

rests on, but does not apply pressure to, the top of the alignment

disk or sphere.

Note: To avoid adjusting the sample probe too low, open the

Luminex XYP door as you begin adjusting the probe height. The

plate should not bounce up or plunge down as you lower or raise

the sample arm. DO NOT PUT YOUR HAND INSIDE THE

LUMINEX XYP!

11. Use a 3/32 inch hexagonal allen wrench to tighten the height

adjustment locking screw.

12. Click Test to raise the Sample Probe, then click OK to close the

dialog box.

13. Replace the clear plastic shield that covers the Sample Probe

area.

PN 89-00002-00-063 Rev. A 4 - 5

Page 40

Luminex 100 User Manual Version 1.7 xMAP Technology

Installing Software

and Firmware

The Luminex 100 system arrives preloaded with the Data Collector

software. It is possible that you may need to reload the software at

some time.

To reinstall the software:

1. Backup log files. Copy your template directory and the file

named calibrationlog.mdb to a backup location. These files may

be found in the Luminex setup directory.

2. Uninstall the Luminex Data Collector software using the

Windows Add/Remove programs function. On the lower left

corner of your screen, click Start > Settings > Control Panel.

The Control Panel window opens. Click Add/Remove

Programs. The Add/Remove Programs window opens. Click

Luminex Data Collector, then click Change/Remove. Follow

the prompts throughout the rest of the removal process.

3. Insert the Luminex CD into the CD ROM drive. The program

manager beings installing the software, displaying instructions

when necessary.

4. Restart your computer after installing the Luminex software.

5. Copy your template file directory and the calibrationlog.mdb file

from the backup location toe the Luminex setup directory.

6. Verify that the firmware version, listed in the Help menu, is the

most recent version. Contact Technical Support to check this

information.

What to Do Next After you assemble and power the system, verify that your analyzer

is correctly installed and functions properly using the “Verification”

section beginning on page 8-14 in the “Troubleshooting” chapter.

You can find answers to frequently asked questions (FAQs) on our

website: http://luminexcorp.custhelp.com.

For assistance, contact Luminex Technical Support. Users in the U.S.

and Canada can call us at 1-877-785-BEAD (1-877-785-2323)

between the hours of 7:00 a.m. and 7:00 p.m. Central Time, Monday

through Friday. Users outside of the U.S. and Canada can call us at

+1 512-381-4397 between the hours of 7:00 a.m. and 7:00 p.m.

Central Time, Monday through Friday. Inquiries may also be sent by

email to support@luminexcorp.com.

4 - 6 PN 89-00002-00-063 Rev. A

Page 41

System Startup

Title B

This chapter describes how to start up your system. The topics

included are:

• Luminex Main Window - a tour of the Luminex Main window

• Setup - describes how to set up the system

• Calibration - describes how to calibrate the instrument, add new

lots of calibration microspheres, how to print calibration reports.

Luminex Main

Window

ar

Menu Bar

Tool Bar

Startup

Display

Status Bar

Use the Luminex software to start the system. To start the software

and open the main window, double-click the Luminex Data

Collector icon on the Windows desktop.

System

Monitor

Figure 5-1. Luminex Main Window

PN 89-00002-00-063 Rev. A 5 - 1

Page 42

Luminex 100 User Manual Version 1.7 xMAP Technology

The Luminex Main window has six components: Title bar, Menu bar,

Tool bar, Startup display, Status bar, and System monitor.

The Title bar shows the name of the software, and changes

depending on what section of the software you are using.

The Menu bar contains commands to set up the Luminex 100

analyzer and perform data acquisition. See Chapter 6 for more detail.

The Tool bar, also discussed in greater detail in Chapter 6, contains

icons for commands that are frequently used when running the

Luminex software.

The Startup display shows icons for many frequently-used

commands. You use most of these commands when starting the

system, acquiring data, and shutting the system down.

The Status bar shows the status of current software events.

The System monitor displays Device and Calibration status.

Calibration You should perform Luminex 100 analyzer calibration after system

installation, instrument service, whenever the system is moved, and

monthly with routine use. For optimal performance, calibrate the

instrument daily as part of your startup routine and whenever the d

Cal Temp temperature shown on the system monitor panel indicates

Add New Classification

Channel Calibration Lots

a change of more than 3 degrees Celsius (

xMAP microspheres with known light-scattering properties and

known fluorescent intensities in the reporter (RP1), classification 1

(CL1), and classification 2 (CL2) wavelength ranges. The calibration

process uses these xMAP microspheres to adjust voltage settings for

optimal and consistent microsphere classification and reporter

readings. Current calibrated settings automatically apply to any new

session.

Before you perform an initial calibration for the analyzer, and

whenever you receive a new supply of xMAP calibration

microspheres, enter the product and lot numbers and the calibration

target values.

°C). The calibrators are

5 - 2 PN 89-00002-00-063 Rev. A

Page 43

xMAP Technology System Startup

To add a new lot of xMAP classification calibration

microspheres:

1. Click Calibrate. The Start Calibration dialog box opens.

Figure 5-2. Start Calibration Dialog Box

2. Click New in the Classification Channel box. The Add New

Classification Calibrator dialog box opens.

Figure 5-3. Add New Classification Calibrator Dialog Box

3. Enter the information into the dialog box, using the values on the

Certificate of Quality that came with your xMAP calibration

microspheres. You do not need to enter a value for CL3;

however, you must click within the CL3 box and press Enter to

save the values.

4. Click OK. You can now use this classification channel xMAP

calibration microsphere lot to calibrate your instrument.

PN 89-00002-00-063 Rev. A 5 - 3

Page 44

Luminex 100 User Manual Version 1.7 xMAP Technology

Add New Reporter

Channel Calibration Lots

Before you perform initial calibration for the analyzer, and whenever

you receive a new supply of xMAP Calibration microspheres, enter

the product and lot numbers and the calibration target values.

To add a new lot of xMAP reporter calibration microspheres:

1. Click Calibrate. The Start Calibration dialog box opens.

Figure 5-4. Start Calibration Dialog Box

2. Click New in the reporter channel area. The Add New Reporter

Calibrator dialog box opens.

Figure 5-5. Add New Reporter Calibrator Dialog Box

3. Fill in the information on this dialog box using the values on the

Certificate of Quality Analysis included with your xMAP

calibration microspheres. Press Enter.

4. Click OK. You can now use this xMAP reporter channel

calibration microsphere lot to calibrate your instrument.

5 - 4 PN 89-00002-00-063 Rev. A

Page 45

xMAP Technology System Startup

Calibrate the Luminex 100

Analyzer

Note: Do not dilute the xMAP

calibration microspheres. Limit

exposure to light!

In addition to calibrating the analyzer after installation, you can

enhance optimal performance by calibrating the instrument daily as

part of your startup routine and whenever the d Cal Temp

temperature shown on the system monitor panel indicates a change

of more than 3 degrees Celsius (

°C).

To calibrate the Luminex 100 analyzer:

1. Turn on the Luminex 100 analyzer. Click Warmup on the main

screen, then click OK on the dialog box that appears. After the

30-minute warmup, go on to the next step.

2. Click Prime on the main screen. Click OK when you want to

begin the prime cycle.

3. Click Options on the toolbar and ensure that the default settings

for alcohol flush is set to Reservoir, and that the wells selected

for CAL1 and CAL2 correspond to the wells in the plate that you

want to use for calibration.

4. Vortex the xMAP calibration microspheres (CAL1 and CAL2).

5. Dispense 5 drops (~ 200 µL) of xMAP classification calibration

microspheres (CAL1) and 5 drops of xMAP reporter calibration

microspheres into the wells you designated in the Setup XY tab

of the options menu.

Place classification

calibrator in a well

(i.e., A1).

(You may assign

different well

locations, if

Place reporter

calibrator in a

well (i.e., B1).

1 2 3 4 5 6 7 8 9 10 11 12

A

B

C

D

E

F

G

H

Figure 5-6. 96-well Plate. Well A1 and B1 Filled

6. Click Eject on the toolbar and place the plate on the plate holder

with well A1 in the top, left-hand corner.

PN 89-00002-00-063 Rev. A 5 - 5

Page 46

Luminex 100 User Manual Version 1.7 xMAP Technology

7. Fill the reservoir with a solution of 70% isopropanol or 70%

ethanol. Click Retract on the toolbar to retract the plate holder.

8. Click Alcohol Flush, then click OK. The alcohol flush removes

air from the fluidics. This takes about 5 minutes.

9. Click Calibrate on the main screen. The Start Calibration dialog

box opens.

Figure 5-7. Start Calibration Dialog Box

10. Enter your name in the Operator text box.

11. Select the Product / Lot Number for the xMAP classification

calibration and reporter microspheres.

12. Click OK. The Calibration dialog box opens.

Figure 5-8. Calibration Dialog Box

13. Make sure Classification is selected, and click Start.

The progress bar shows the calibration progress, which should

take less than two minutes. If the status changes to “Sample

Empty” before calibration completes, a “Calibration Failed”

message appears. Click OK and restart the process. When

calibration finishes for the classification microspheres, a

5 - 6 PN 89-00002-00-063 Rev. A

Page 47

xMAP Technology System Startup

“Calibration Succeeded” message appears. The settings and any

comment you enter are logged into the calibration report.

14. Click OK in the confirmation dialog box. The Calibration dialog

box opens again.

15. Select Reporter and click Start. The progress bar shows you the

calibration progress. Calibration should take less than two

minutes. If the status in the system monitor changes to “Sample

Empty” before calibration completes, a “Calibration Failed”

message appears. Click OK and start the process again. When

calibration finishes for the reporter microspheres, a “Calibration

Succeeded” message appears. The settings and any comment you

enter are logged into the calibration report.

16. Click OK on the confirmation dialog box.

xMAP Calibration microspheres are very concentrated. Each

time you calibrate the instrument, follow it with 4 wash cycles

using deionized water or sheath fluid.

Preview or Print

Calibration Report

17. Click Eject from the toolbar and remove the plate.

18. Click Retract to retract the plate holder.

The calibration report is a quality control tool that shows the

frequency of past calibrations, operators of past calibrations, and

trends in instrument settings. The calibration report is available as a

log or as a detailed report.

To print or preview the calibration report:

1. Close all open sessions.

2. Click Print on the toolbar. The Print dialog box opens.

Figure 5-9. Print Dialog Box

PN 89-00002-00-063 Rev. A 5 - 7

Page 48

Luminex 100 User Manual Version 1.7 xMAP Technology

3. Check the box in front of the report type you want. You can

check both boxes to see both kinds of calibration report.

4. Click OK to print the calibration report, or Preview to see the

report on your screen. Figure 5-10 shows an example of a

calibration log. Figure 5-11 shows an example of calibration

detail report.

Figure 5-10. Calibration Log

The calibration log shows gain values associated with each

calibration. A gain value is a representation of the voltage. Use this

log to observe the gain values. If you see a spike in voltage (20 V or

more) in the gain value for a channel from one calibration to the

next, the difference may indicate a problem with the instrument. It is

normal to see a value of -1 for RP1 gain for classification

calibrations. You also see gain values of -1 listed for DD, CL1, and

CL2 for reporter calibrations.

5 - 8 PN 89-00002-00-063 Rev. A

Page 49

xMAP Technology System Startup

Analyzer menu

commands

Figure 5-11. Luminex Calibration Detail Report

The calibration detail report is often used by Luminex field service

personnel when performing system maintenance. The report shows

system temperature, Voltage, and pressure readings.

Use the Analyzer commands to prepare the Luminex 100 analyzer

for sample acquisition, analysis, and shut down. On the Analyzer

menu, choose the command you want to perform. Many of these

commands also have buttons on the main screen.

Calibrate: Opens the Start Calibration dialog box. See page 5-2 for

calibration procedures.

Setup: Opens the Machine Setup dialog box. System connections