Page 1

02001346 Rev 1

HPP-1000/6000 User Manual

Page 1 of 19

26 Ward Hill Ave., Bradford, MA 01835

Phone: 978-241-8260 Fax: 978-241-8262

USER MANUAL

HPP-1000 thru 6000-XX-YY-ZZ

XX= Ioutmax

YY = Maximum Compliance Voltage

ZZ = Max Pulse Width in µsec

Page 2

02001346 Rev 1

HPP-1000/6000 User Manual

Page 2 of 19

Table of Contents

1. Warnings ...................................................................................................................... 3

2. Description of HPP System ......................................................................................... 4

3. Pulsing Characteristics ................................................................................................ 5

4. DC power supply for HPP ........................................................................................... 7

5. Supply Interface Connections ...................................................................................... 8

6. LDD/HPP integration and theory of operation ............................................................ 9

7. LDD with HP option.................................................................................................. 11

8. LDN with VP option.................................................................................................. 12

9. HPP-6000 Specifications ........................................................................................... 13

10. HPP Interface ............................................................................................................. 14

11. Operation of the HPP ................................................................................................. 15

12. Product Limited Warranty ......................................................................................... 18

13. Service ....................................................................................................................... 19

Tables and Figures

Table 1, HPP Interface ...................................................................................................... 14

Figure 1, HPP Block Diagram ............................................................................................ 4

Figure 2, Typical Rise Time ............................................................................................... 5

Figure 3, Typical Fall Time ................................................................................................ 5

Figure 4, Pulse Output ........................................................................................................ 6

Figure 5, Repetition Rate .................................................................................................... 6

Figure 6, Connection Diagram ............................................................................................ 8

Figure 7, HPP Mechanical Outline Drawing .................................................................... 16

Figure 7, HPP Connections ............................................................................................... 17

Page 3

02001346 Rev 1

HPP-1000/6000 User Manual

Page 3 of 19

1. Warnings

Warning – Voltage Compliance Requirement

Warning – Output Floating

Each HPP is custom configured to deliver current pulses into a diode array requiring a

predefined compliance voltage.

See the Serial Number label of the unit for the compliance voltage rating. The HPP

takes DC input voltage and will not operate properly when the input is great than 10V

higher than the load compliance voltage and will not start when the input is 20V lower

that the rating on the S/N label or lower than 20V.

Consult factory more wider operating window.

The output of the HPP is floating and therefore, neither side of the laser diode is

allowed to be connected to the same ground as signal ground (Program, Monitor).

WARNING: Only Lumina Power, Inc. qualified service personnel are allowed to

remove the covers and service this equipment.

WARNING: NEVER OPERATE THE POWER SUPPLY:

1. Without providing adequate protection of personnel from high voltage.

2. Without proper ground connections.

3. Without covers and panels properly installed.

4. Without a suitable load for the application and properly rated for the

required power dissipation.

Page 4

02001346 Rev 1

HPP-1000/6000 User Manual

Page 4 of 19

2. Description of HPP System

High Power

Linear Regulator

DC

Input Voltage

Control System

Hall Effect

Sensor

Laser

Diode

Iout Control

Iout Monitor

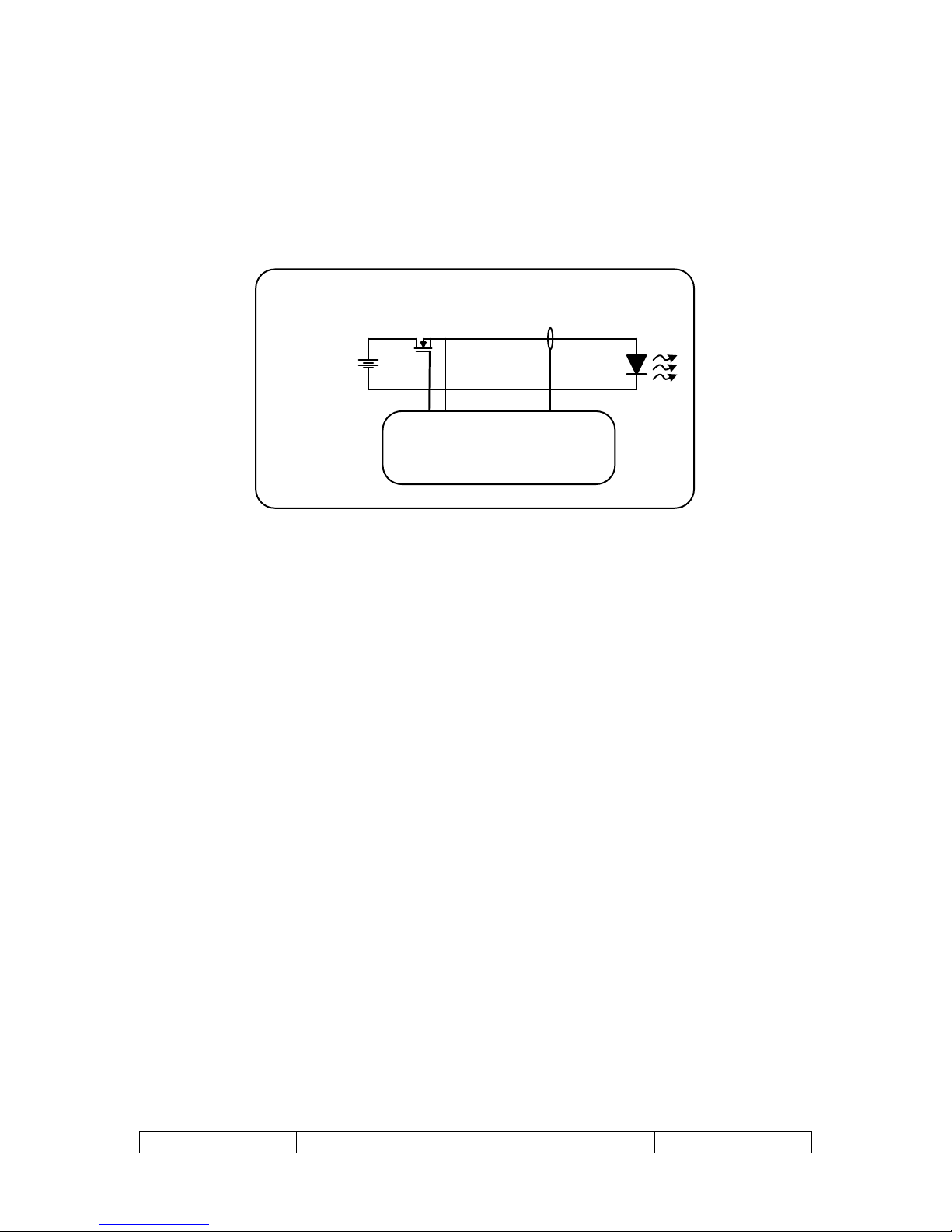

Lumina Power’s HPP power supplies are designed for pulsing diode lasers in Quasi-CW

applications. Before operating this unit, it is important to understand the operation. A

block diagram of the power supply is shown below.

Figure 1, HPP Block Diagram

Referring to Figure 1, it’s easiest to think of the basic elements of the system as a high

power linear regulator. The four main components are:

• A storage capacitor which holds the energy for a high power pulse.

• A high power linear regulator which is controlled by an error signal.

• A high current sensing circuit.

• Control system.

The DC input voltage source must be voltage programmable and have current limit but

not fold-back. It must be able to deliver constant current into a big capacitor which is a

short at start up and the voltage will be discharged to a low level at the end of every

pulse. Set the output voltage at 2 to 5V higher that the load compliance voltage for

optimal efficiency.

Even though the HPP output current has better than 15us rise/fall time, the compliance

voltage is only a few volts higher than the load voltage and the LDD-xx-yy-HP will

perform this requirement automatically.

The high power linear regulator is typically a bank of high power MOSFETS mounted

on an appropriate heat sink with over-temp protection.

The control system provides the interface to the supply and provides various protection

circuits for the laser diode.

Page 5

02001346 Rev 1

HPP-1000/6000 User Manual

Page 5 of 19

3. Pulsing Characteristics

The rise and fall times of HPP pulses are a compromise between speed and minimization

of overshoot. The following figures show typical pulse performance for a HPP with

300Apeak output.

Figure 2, Typical Rise Time

Channel 1: Output Current. 100Amp/V

Channel 2: Pulse Command Signal

Channel 3: Current Monitor

Figure 3, Typical Fall Time

Channel 1: Output Current. 100Amp/V

Channel 2: Pulse Command Signal

Channel 3: Current Monitor

Page 6

02001346 Rev 1

HPP-1000/6000 User Manual

Page 6 of 19

Figure 4, Puls e Output

Channel 1: Output Current. 100Amp/V

Channel 2: Pulse Command Signal

Channel 3: Current Monitor

Channel 1: Output Current. 100Amp/V

Channel 2: Pulse Command Signal

Channel 3: Current Monitor

Figure 5, Repetition Rate

Page 7

02001346 Rev 1

HPP-1000/6000 User Manual

Page 7 of 19

4. DC power supply for HPP

The HPP can be driven by any DC power source without current foldback.

When the HPP in on, it will draw high current from the DC source which should send

continuous limited current to the HPP and should not fold back because the HPP needs

certain input voltage to operate.

It is recommended to use a LDD-3000 or LDD-6000 with a HP option to drive the HPP.

The LDD-3000/6000-xx-yy-HP is configured to run with the HPP. Output voltage can be

set to match the laser load and output current can be set to meet the max average load

current.

Besides, the LDD-3000/6000-xx-yy-HP interfaces with the HPP to regulate the output

voltage to perfectly match the load voltage for the highest efficiency and least heat

dissipation inside the HPP.

For lower average power a LDN-2000 series power supply can be used with the VP

option. This power supply does not have the HP feedback to automatically adjust the

output voltage to the HPP demand. However, this version has a voltage adjust control

input on pin 2 of the control interface to allow the user to match the LDN output voltage

to the HPP load requirements.

Page 8

02001346 Rev 1

HPP-1000/6000 User Manual

Page 8 of 19

5. Supply Interface Connections

*

The programming, monitoring and control functions of the HPP Interface are shown

below. Refer to Figure 6 below for a simple laser setup.

Due to high switching current at high frequency and the capacitive coupling from the

laser diodes to heatsinks , a ground loop is usually hard to avoid and interferes with the

pulse current. An isolator board has been designed to use in series with the interface

cable of the HPP to break the ground loop.

Please refer to document 33001346, HPP-LDD Interconnection Instructions.

* Note, the voltage control feedback is only available when using a LDD-3000/6000 with

the HP option.

Figure 6, Connection Diagram

Page 9

02001346 Rev 1

HPP-1000/6000 User Manual

Page 9 of 19

6. LDD/HPP integrat ion and theory of ope r a t ion

The HPP was designed to work with Lumina Power’s LDD power supplies with the HP

option, which is the output voltage programmable feature.

The complete system includes:

1 LDD-pp-xx-yy-HP where pp is max power, xx is max current, yy is max output

voltage and HP designates output voltage program feature.

2 HPP-pp-xx-yy-zz. pp is maximum average power, xx is maximum output current,

yy is maximum load voltage, zz is maximum pulse width up to CW.

3 HPP Isolator PCB. Due to possible ground loops at high pulsing current and

frequency, the isolator PCB will be inserted between the HPP and the customers’

control system to break the ground loop.

Isolator PCB theory of operation:

The Isolator has 2 elect ri call y isolat ed secti ons: one is connected to the H PP and another

is connected to the customer’s control system.

The HPP supplies 15V to operate the isolator pc board. Th e customer’s control system

must supply 15V to run the section that is connected to the customer’s controller per HP P

pin out assignment.

The Isolator carries all control signals through linear optocouplers for analog signals and

logic optocouplers for logic signals. The pin outs of the isolator PCB is 1-to-1 as an

extension of the control cable with a male connector for the customer’s c ontroller and a

female connector for the HPP.

HPP theory of operation.

The HPP is a High Power Pulser. It is a linear current regulator with fast rise and fall

time. The input voltage of the HPP must be higher than its output voltage. The ratio of

Vout/Vin is roughly its efficiency.

The HPP is the most efficient pulser on the market given the rise time and fall time better

than 15µs. In pulse mode, it communicates with the LDD power supply to adjust the

LDD output voltage which is the HPP input voltage to match the load voltage. The

average input voltage for a given load varies due to pulse current, pulse width but is

regulated such that at the end of the pulse, there will be about 1V across the “linear

regulator”. The average input voltage is higher than the load voltage because the voltage

on the internal capacitors will have some droop during the pulse.

The HPP utilizes a proprietary scheme to have fast rise time even though the input

voltage is a few volts higher than the output voltage and this gives the HPP the highest

efficiency for a linear regulator and the inductance of the output cable seems to have

disappeared.

This feature also allows the voltage tracking when the laser diodes get hot and reduce

their forward voltage drop, Vf.

Page 10

02001346 Rev 1

HPP-1000/6000 User Manual

Page 10 of 19

The HPP communicates with the LDD to decrease the output voltage up to 25% of the

programmed voltage in order to have good efficiency. The requirement is that the LDD

output voltage must be programmed to be higher than the expected load voltage but not

too high that the HPP cannot pull it down to have 1V at the end of the pulse. The HPP

has a “load-Match” det ector circuit and will sh ut down i f the differ ence betw een Vin and

Vout is too high (more than 10V at more than 51% rated output current). To allow the

best Vout program, the HPP will defeat this protection feature when the output current is

programmed less than 50%.

For proper voltage programming, we can set and record the input voltage as follows:

Program the output voltage to about 20% higher than the expected load voltage.

Run pulses with lower than 50% max pulse current. The input voltage will be reduced

automatically. Monitor the output current to make sure the pulse shape is correct. Reduce

the input voltage further by reducing the V-program signal on the LDD until the output

current fails to regulate at the end of the pulse. This is the minimum input voltage

required for this particular load. Now we can stop the pulser and program the LDD

output voltage about 20% higher than this minimum voltage. Make sure the HPP is OFF

(disabled) at this time.

If the voltage is so high that the HPP cannot pull it down to have 1V at the end of the

pulse, the system will be inefficient and will result in over heat and thermally shut down.

If the voltage is too high, the HPP will shut off by the “load-match” detector when the

output current is higher than 50%.

The HPP has an optional programmable simmer up to 10Amp. The simmer current is

ON when the pulse current is OFF and OFF when the pulse current is ON.

CW/Pulse mode selection: (Optional)

In some applications where the system can switch from pulse to CW, the signal

CW/Pulse can be used.

When in Pulse mode, the HPP is working as a linear regulator and puts out the pulsed

current requested at the I-program signal. This operation will require some voltage

across the linear regulator and that translate into power loss.

When in CW mode, the transistors in the linear regulator are saturated and the onl y loss

will be the Rds-on of the FET bank against the output current. The HPP is now acting as

a wire with the impedance of the Rds-on and the current should be controlled by the

LDD.

It is advisable that the HPP must be disabled, LDD output voltage should be programed

to lower than the load voltage and current should be programmed to minimum when

switching from pulse to CW mode.

If the output voltage is higher than the load voltage, there will be current spikes to the

load and may damage the load.

Another option is to run the HPP at 100% duty cycle. In this case, we can turn the HPP

current program to 105% and control the output current by the LDD.

Page 11

02001346 Rev 1

HPP-1000/6000 User Manual

Page 11 of 19

7. LDD with HP opti on

In a standard LDD, the output voltage is set to be 105% of the required load voltage and

it is just the compliant voltage, determined by the load.

The LDD is the Laser Diode Drive and the HP option designates the additional feature of

programming the output voltage. The LDD-HP is set to normally have 5V higher than

the companion HPP.

Additionally, the LDD-HP has a pair of twisted wires to communicate with the HPP.

This pair of wires is working in conjunction with the V-Program signal to determine the

output voltage.

This pair can only lower the output voltage by 20 – 25%.

At the end of the pulse, the HPP compares the cap bank voltage against the load voltage

and tells the LDD to adjust the voltage so that it has about 1V difference.

The communication is active only when the HPP is running (pulsing).

If the HPP is in standby, the output voltage will rise to the level set by the V-Program

signal.

When running with the HPP, set the LDD output current about 5% more than the max

average HPP current. For example: HPP-2000-200-50-500. That is 2000 Watts, 200

Amp, 50V, 500us max pulse width.

Calculation:

Pulse power: 200A * 50V = 10,000 Watts.

Pulse energy: 500uS of 10000 Watts is 5 Joules.

Max frequency: 2000 Watts/5 Joules = 400 Hz.

Duty Cycle: 500us/400Hz = 20%.

Setting on LDD: Vout ~55V

I-out = 105% * P/Vload = 1.05 * (2000/50) = 42 Amp.

The LDD interface is listed below for reference.

Page 12

02001346 Rev 1

HPP-1000/6000 User Manual

Page 12 of 19

LDD-6000-XX-YY -HP

Pin #

Pin Name

Functional Voltage

Level

Description

High = RUN = +5V to

The Enable function turns the output

the Enable signal.

V-Program

0 – 10V = 0-Full Scale

Program Output Voltage. Open =

Default = Full Scale.

Interlock

Open = OFF

The Interlock function can be

switches.

4

GND

V-Monitor:

impedance)

0 – 10V = 0 – Full Scale

Monitors output Voltage.

I-Mon

impedance)

0 – 10V = 0 – Full Scale

Monitor Output Cu rrent

I-Program

0-10V = 0 - Ioutmax

The power supply output current is

Iprogram(+).

9

GND

5V @0.2A

(output)

Auxiliary 5V power supply for user.

Up to 0.2A output current available.

-15V @0.2A

(output)

Auxiliary -15V power supply for user.

Up to 0.2A output current available.

15V @0.2A

(output)

Auxiliary 15V power supply for user.

Up to 0.2A output current available.

15

GND

Connector Type 15 pin D-sub Female

1

2

3

5

6

7

Enable

(input. 10k

impedance)

(Output 100Ω

(Output 100Ω

(Input 200k

impedance)

+15V

Low = OFF = 0V

Connect to GND = RUN

section of the power supply ON and

OFF. Enable signal must be inserted

AFTER AC power has been applied

as the power supply starts up

Disabled disregarding the state of

connected to external interlock

switches such as door or over-temp

set by applying

a 0-10V analog signal to

10, 11

12

13, 14

8. LDN with VP option

Another compatible power supply is the LDN series with the VP option. This option sets

pin 2 on the control interface to be a voltage output control supply. Although the output

voltage control feedback feature from the HPP is not used, the customer can set the Vprogram on pin 2 of the LDN to match the voltage requirements for op erating the HPP.

Please consult the factory for further information.

Page 13

02001346 Rev 1

HPP-1000/6000 User Manual

Page 13 of 19

9. HPP-6000 Specifications

Average

Pout

Input

Voltage

Up to 600A Pulse

150A CW

XX * YY* Duty Cycle cannot exceed 6000W

Model

HPP-6000-XX-YY-ZZ 6000W

Where XX = Iout

YY = Vcompliance

Auxiliary Outputs: +15V @0.2A,

max

max

Output Current

Size (L x W x H)

15 – 150VDC 12” x 8.1” x 3.5

Input

Voltage 15-160 VDC current source, voltage limited

Output

Power 6000 Watts average

Pulsed Current up to 600 A peak

Continuous Current up to 150 A

Interface

Connector 15 Pin “D” Sub Female

Pulse Current Program 0-10V for 0-Max Current

Current Monitor 0-10V for 0-Max Current

Simmer Current Program 0-10V for 0-Max Current

Aux. Output +15VDC @ 0.2A on interface

Performance

Max Rep Rate: 5 kHz

Rise/Fall Time: ~15 µs typical (10% to 90% Full Current)

Current Regulation: 0.5% of maximum output current

Current Ripple: <0.5% of maximum output current

Current Overshoot: <1% of maximum output current

Efficiency: >90% at full load

Environment

Operating Temp 0 to 40 oC

Storage -40 to 85 oC

Humidity 0 to 90% non-condensing

Cooling Forced air

Altitude and Pressure 2000 meters maximum, 80 to 103 kPa

Dimensions Please see Figure 7, HPP Mechanical Outline Drawing

Outline 13.8 inch length, 8.15 inch wide, 3.93 inch high

(does not include mounting flanges or electrical terminals)

Page 14

02001346 Rev 1

HPP-1000/6000 User Manual

Page 14 of 19

10. HPP Interface

Pin #

Pin Name

Functional Level

Description

Pulse Input

impedance)

High = RUN = +5V

Low = OFF = 0V

The Pulse function turns the pulse current On/OFF at

is delivered to load as programmed via Iprogram(+)

2, 3

GND

Temp-Fault

impedance)

0V = Good

Fault

0 – 10V = 0 – Full

Iprogram(+):

impedance)

The power supply output current is se t by applying a 0higher than simmer program on pin 8.

Poor Load Match

impedance)

Too low load voltage causes excessive voltage across

end of each pulse. Toggle Enable signal to clear fault.

Return Signal for

supply

Simmer Program

(Optional)

CW mode = +5 to

default

15V @0.2A

(output)

Auxiliary 15V power supply for user. Up to 0.2A output

current available.

Ready

Impedance)

Automatically adjusts the output voltage of the LDD

varies. DO NOT CONNECT

OFF = 0V, default

The Enable function turns the output section of the

delivered to the load as programmed via Iprogram(+).

The Interlock function can be connected to external

to operate.

Connector Type 15 pin D-sub Female

Table 1, HPP Interface

1

4

5

6

7

8

9

(input, 10k

(Output, 10k

Iout Monitor:

(output)

(input, 20k

(Output, 10k

Voltage Adjust

Return

(input, 100k

impedance)

to +15V

15V = Over Temp

Scale

0 – 10V = 0 – Full

Scale

0V=Good.

15V = Fault

Voltage Adjust loop

to LDD power

0 – 10V = 0 to

12Amp simmer

current

high speed when the power supply is enabled. Current

Stops power supply when internal heatsink(s) reaches

75 ºC

Monitors output cur rent in real ti me.

10V analog signal to Iprogram(+). Iprogram must be

the series regulator. This voltage is measured at the

DO NOT CONNECT

Programmed DC simmer current will be present when in

Pulse mode and when the power supply is Enabled.

CW/Pulse

10

11

12

13

14 Enable

15 Interlock

(Input, 10k

impedance)

(output, 10k

Auto Voltage

Adjust

+15V

0V = Pulse mode,

0V = Not Ready.

15V = Ready.

Output to LDD-HP

RUN = +5V to 15V

Open = OFF

GND = Operate

Pulser becomes a virtual short in CW mode.

Power supply starts up = OFF. Insert Enable signal

after power-up to initiate Ready signal.

power supply for optimal efficiency if load voltage

power supply ON and OFF. When the power supply is

enabled, Pin 1 pulse control is operational and current is

interlock switches such as a door. Ground to pin 2 or 3

Page 15

02001346 Rev 1

HPP-1000/6000 User Manual

Page 15 of 19

11. Operation of the HPP

Warning – Voltage Compliance Requirement

Warning – Output Floating

allowed to be connected to the same ground as signal ground (Program, Monitor).

Each HPP is custom configured to deliver current pulses into a diode array requiring a

predefined compliance voltage.

See the Serial Number label of the unit for the compliance voltage rating. The HPP

takes DC input voltage and will not operate properly when the input is great than 10V

higher than the load compliance voltage and will not start when the input is 20V lower

that the rating on the S/N label or lower than 20V.

Consult factory more wider operating window.

The output of the HPP is floating and therefore, neither side of the laser diode is

1. Connect diode laser load to the HPP. A custom strip line cable has been supplied to

minimize inductance. Please note the cable is marked with (+) and (-) labels. Do not

extend output cable or performance will be compromised.

2. Connect appropriate interface to HPP Interface Connector. Make sure Iprogram(+),

pin 6, is set to 0.0V.

3. Connect HPP to the feeding DC power supply which is OFF.

4. Turn ON the feeding DC power supply. Increase DC output voltage and the HPP will

start when it sees appropriate DC voltage. After a few seconds the cooling fan should

begin to operate.

5. Set Iprogram(+), Pin 6 of the interface connector, This signal is the 0-10V program

which will program the output current level. Calibration is set so that 0-10V = 0 –

Iout

6. Enable the output by applying a TTL level high signal to pin 14 of the interface

connector. The Enable control checks for faults and prepares the system for pulsing.

7. Pulse the unit via the Pulsing Input control, pin 1. Maximum pulse widths should

not be greater than specified on the system label. The amplitude of the pulses will be

determined via the analog Iprogram(+) signal. Maximum average power delivered

to the load should not exceed the rated power capability of the unit.

max

.

Unit Faults

The unit is designed to monitor various faults such as:

• Temp Fault: (Output, TTL, Pin 4) When the temperature of the internal heat sink

has exceeded a safe operating level, the system is shut off and this fault is transmitted.

Fault output is TTL high. Fault can be cleared by setting the Enable, pin 14, to TTL

low and then high.

• Poor load match: (Output, TTL, Pin 7) When the voltage compliance of the diode

laser load is 8V lower than the DC input voltage. This fault may be cleared via the

Enable signal.

Page 16

02001346 Rev 1

HPP-1000/6000 User Manual

Page 16 of 19

Figure 7, HPP Mechanical Outline Drawing

Page 17

02001346 Rev 1

HPP-1000/6000 User Manual

Page 17 of 19

Figure 8, HPP Connections

Page 18

02001346 Rev 1

HPP-1000/6000 User Manual

Page 18 of 19

12. Product Limited Warranty

Lumina Power, Inc., as Seller, warrants that each Product sold by it is free of defects in materials and

workmanship. Duration of warranty is as follows:

a. All Chassis enclosed products are covered for twenty four (24) months from date of shipment. Products

included but are not limited t o the following product families: CCPF, CCHP, LDY, LDYHC, LDQCW,

XLB (exclud ing XLB-300), and MLB. Custom fully enclosed products may be covered for the same 24

months. Please consult factory for specific terms.

b. All Open Frame products are covered for 12 months from date of shipment. Open frame power supplies

are defined as any product that is not enclosed in a metal or plastic enclosure. Products included but are not

limited to the following produc t families: LDPC, LDQPC, XLB-300 and any open frame custom products.

c. All products returned for repair are covered for a period of 6 month or the balance of the original

warranty, whichever is longer.

Warranty is not transferable t o parties outside of original Buyer's corporate or educational organization.

Seller will have sole discretion in making de termination of validit y of warranty if the Pr oduct is transferred

to a different user group than the original Buyer .

Normal wear and tear and items expendable in normal use are not covered by this warranty. All warranty

repair or replacement o f parts shall b e li mited to P r oduct malfunct ions, which, in the so le o pinion o f Sel ler,

are due or traceable to defects in original materials or workmanship. Such determination will be made when

the Product is returned to the Seller's factory, transportation prepaid by the Buyer, within the warranty

period.

All obligations under this warranty shall cease immediately in the event of abuse, accident, alteration,

misuse, or neglect of the Product. Us e and ser vice of the Product i n a manner not in ac cordance with the

Owner's Manual (if furnished) will likewise cause all obligations under this warranty to cease. Repaired or

replacement parts are warranted only for the remaining unexpired portion of t he origina l warranty pe riod

for the Product. After expiration of the applicable warranty period, Buyer shall be charged at the then

current prices for parts, labor and transportation.

Seller has no responsibility under this warranty for the cost of any work (material, labor, and/or other

expenses) performed by or incurred by Buyer or any third party for modification or repair of the Product

unless specifically authorized in advance in writing by Seller.

Reasonable care must be used to avoid hazards. Seller expressly disclaims responsibility for loss or damage

caused by use of its Products other than in accordance with proper operation procedures. Other than those

expressly stated herein, there are no other warranties of any kind, expressed or implied, and specifically

included but not by way of limitation are the implied warranties of fitness or merchantability for a

particular purpose.

It is understood and agreed the seller’s liability whether in contract, in tort, under any warranty, in

negligence or otherwise shall not exceed the return of the amount of the purchase price paid by the

purchaser and under no circumstance shall seller be liable for special, indirect, incidental or consequential

damages. The price stated for the product is a consideration in limiting seller's liability. No action,

regardless of form, arising out of the transactions of this agreement may be brought by purchaser more than

one year after the cause of action has accrued.

Seller’s maximum liability sh all not exceed and b uyer 's remedy is limited to either (i) repair or replacement

of the defective part of product, or at seller's option (ii) return of the product and refund of the purchase

price, and such remedy shall be the buyer's entire and exclusive remedy.

Page 19

02001346 Rev 1

HPP-1000/6000 User Manual

Page 19 of 19

13. Service

Rev

ECO

Description

Doc Ctrl

Date

App

1

7682

Initial Release

MJ

6/20/2017

EK

This unit contains no use r serviceable parts.

performed only by qualified personnel from Lumina Power, Inc. For more

information contact

Email: sales@luminapower.com Web site: www.luminapower.com

Service and repair should be

Lumina Power, Inc.

26 Ward Hill Ave.,

Bradford, MA 01835

Ph: 978-241-8260

Fx: 978-241-8262

Your distributor:

Loading...

Loading...