Page 1

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 1 of 17

26 Ward Hill Ave., Bradford, MA 01835

Phone: 978-241-8260 Fax: 978-241-8262

USER MANUAL

CCPF-500-XX

CCPF-750-XX

500 to 750 J/s Capacitor Charging

Power Supply Series

Page 2

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 2 of 17

Table of Conten t s

1. Description of CCPF-500/750 Power Supply ............................................................. 3

2. Explanation of Symbols............................................................................................... 4

3. CCPF-500/750-XX Specifications .............................................................................. 5

4. CCPF-500 Interface ..................................................................................................... 6

5. Typical Applications.................................................................................................. 11

5.1 Using a CCPF with a pulse forming network (PFN) ..................................................... 11

5.2 Using a CCPF with a partial discharge network (Reservoir Charging) ......................... 12

5.3 Using a CCPF with multiple PFNs or capacitors .......................................................... 13

6. Warnings .................................................................................................................... 14

7. Installation ................................................................................................................. 15

8. Product Limited Warranty ......................................................................................... 16

9. Service ....................................................................................................................... 17

Tables and Figures

Table 1, CCPF Interface ..................................................................................................... 6

Table 2, Optional 4 Pin Interface ........................................................................................ 8

Table 3, CCPF Connections .............................................................................................. 15

Figure 1, CCPF-500 Block Diagram .................................................................................. 3

Figure 2, CCPF-500 15-pin Interface Schematic ................................................................ 7

Figure 3, CCPF-500 Optional 4-pin Interface Schematic ................................................... 8

Figure 4, CCPF-500 Mechanical Outline Drawing ............................................................ 9

Figure 5, CCPF-500 Input Side Drawing ......................................................................... 10

Figure 6, CCPF-500 Output Side Drawing ....................................................................... 10

Page 3

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 3 of 17

1. Description of CCPF-500/750 Power Supply

The CCPF-500/750-XX capacitor charging power supplies are designed for OEM laser

manufacturers. The CCPF-500 power supply provides up to 500 J/s average charging

power for capacitor dischar ge PFN applications with universal AC mains input from 100

to 240 VAC. The CCPF-750 power supply provides up to 750 J/s charging power

operating from 200 to 240 VAC mains. The power output provides a constant current to

charge up a capacitor to the programmed value.

The CCPF-500/750-XX can be configured for maximum output voltages up to 4000V

where the XX indicates the maximum output voltage. As an example, a CCPF-500

configured for 1000V maximum output voltage is designated as a CCPF-500-1P, where P

indicates a positive output, which is the standard polarity.

The CCPF takes AC mains power input and rectifies it by the input rectifier bridge. The

rectified voltage is boosted to non-isolated 400 VDC by the Power Factor Correction

(PFC) circuit. The purpose of the PFC is to force the input current to be in phase with the

input voltage, close to unity power factor, such t hat from 20% to 100% load the power

factor is better th an 98%. The PFC also produces the auxiliary power for the fans and

control circuits. The 400 VDC power is the source for the inverter t o generate the hi gh

output voltage for the capacitor load.

Figure 1, CCPF-500 Block Diagram

Page 4

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 4 of 17

2. Explanation of Symbols

Hazard:

This equipment produces high voltages

High Voltage Present.

This power supply

equipment. Only qualified service personnel are

Chassis Ground:

which can be fatal. Only service personnel of Lumina

Power, Inc. are qualified to service this equipment.

produces lethal high voltages. Only service personnel

of Lumina Power, Inc., are qualified to service this

permitted to install this power supply.

This symbol where the protective

earth ground connection is located.

Page 5

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 5 of 17

3. CCPF-500/750-XX Specifications

XX indicates output voltage with P for positive and N for negative.

Input of CCPF-500

Voltage 100 - 240 VAC, single phase

Current 5.2 A max at 120 VAC and 2.6 A max at 240 VAC

Frequency 47 - 64Hz

Input of CCPF-750

Voltage 200 - 240 VAC, single phase for CCPF-750

Current 5A max at 240 VAC

Frequency 47 - 64Hz

Output

Power 500 J/s average charge rate for CCPF-500

750 J/s average charge rate for CCPF-750

Output Voltage Fixed voltage between the ranges of 200VDC – 4.0kVDC

(factory configured, contact factory for voltages >4kVDC)

Polarity Positive or Negative (factory configured)

Efficiency >80% at full output

Regulation: 0.5% @100Hz

Interface

Connector 15 Pin “D” Sub Female (4 Pin Molex interface optional)

Voltage Program 0-10V for 0-Max Voltage

Voltage Monitor 0-10V for 0-Max Voltage

Inhibit/Reset Input, low level (high level optional, contact factory)

End of Charge Output indication

+15V Aux Power

Environment

Operating Temp 0 to 40 oC

Storage -20 to 85 oC

Humidity 0 to 90% non-condensing

Cooling Forced air

Altitude and Pressure 2000 meters maximum, 80 to 103 kPa

Dimensions Please see Figure 4, Figure 5, and Figure 6 for outline details.

Outline 9.13 inch length, 6.00 inch wide, 3.70 inch high

232 mm length, 152 mm wide, 94 mm high

(does not include mounting flanges or electrical terminals)

Page 6

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 6 of 17

4. CCPF-500 Interface

Pin #

Pin Name

Functional Level

Description

This pin is the basic ON/OFF control pin for the power

operation if the power supply is not IN HIBITED.

2, 3, 6,

12

Voltage

(input)

(output)

(output)

0 – Vout

max

+15V @0.1A

(output)

Load charged

,

<0.5V

4, 14, 15

Ground

Ground return for control interfa c e s ig nals.

Connector Type 15 pin D-sub Female

Refer to Figure 2, CCPF-500 15-pin Interface Schematic

Table 1, CCPF Interface

Low = RUN, <0.3V

High = OFF, +5V to

+15V

1

Inhibit/Fault

Reset

(input)

supply. Grounding pin 1 ena bles pow er s upply

operation if all faults are clear. App lying +10 to 15V to

pin 1 prevents the inv e r te r from operating. Optional

High Enable av ailable, contact factory, see note 2.

NOTE: The power supply should be INHIBITED via Pin

1 before the capacitor is disc harged into the load.

Noise from the discharge c ou ld c a use improper

10, 11,

5

7

8

9

13

No connect

Program

Vout Peak

Hold

Vout Monitor

End of Charge

Status

Indicator

(output)

0 – 10V =

0 – Vout

0 – 10V =

0 – Vout

0 – 10V =

+15V ± 10%

High = Charging,

Low=

to Voltage Program

+15V

max

max

Optional, may be used f or cu s tomer s pec ified

functionality, contact factory. See note 2.

Output is programmed extern a lly with a 0 to +10V

signal for 0 to Voutmax. See note 1.

Peak detect circuit of the output volta ge monitor. The

time constant is approximately 5 seconds. See note 1.

Monitors output voltage. See note 1.

+15VDC for customer interface, maximum output

current is 100mA.

Open collector output rated 30V, 100mA connected to

10kohm pull-up resistor. When the load ca pacitor

reaches the programmed volta ge, pin 13 is pulled low

and latched low, cycling the Inhibit pin 1 resets th e

EOC signal.

Notes:

1. Analog voltage range of 0-5V available per customer request.

2. Other interface configurations are available to conform to customer requests, contact

Lumina Power for any interface changes.

Page 7

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 7 of 17

Figure 2, CCPF-500 15-pin Interface Schematic

Page 8

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 8 of 17

Pin #

Pin Name

Functional Level

Description

1

operation if the power supply is not IN HIBITED.

2

Ground

Ground return for control interfa c e s ig nals.

Voltage

4

No connect

Refer to Figure 3, CCPF-500 Optional 4-pin Interface Schematic

Table 2, Opti ona l 4 Pin Interface

This pin is the basic ON/OFF control pin for the power

supply. Grounding pin 1 ena bles pow er s upply

operation if all faults are clear. App lying +10 to 15V to

Inhibit/Fault

Reset

(input)

Low = RUN, <0.3V

High = OFF, +5V to

+15V

pin 1 prevents the inv e r te r from operating. Optional

High Enable av ailable, contact factory, see note 2.

NOTE: The power supply should be INHI BI TED via Pin

1 before the capacitor is disc harged into the load.

Noise from the discharge c ou ld c a use improper

3

Program

(input)

0 – 10V =

0 – Vout

max

Output is programmed extern a lly with a 0 to +10V

signal for 0 to Voutmax. See note 1.

Figure 3, CCPF-500 Optional 4-pin Interface Schematic

Molex connector 70553-003

Page 9

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 9 of 17

Figure 4, CCPF-500 Mechanical Outline Drawing

Dimensions in inches, [mm in parenthesis].

Page 10

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 10 of 17

Figure 5, CCPF-500 Input Side Drawing

Dimensions in inches, [mm in parenthesis].

Figure 6, CCPF-500 Output Side Drawing

Dimensions in inches, [mm in parenthesis].

Page 11

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 11 of 17

5. Typical App li cations

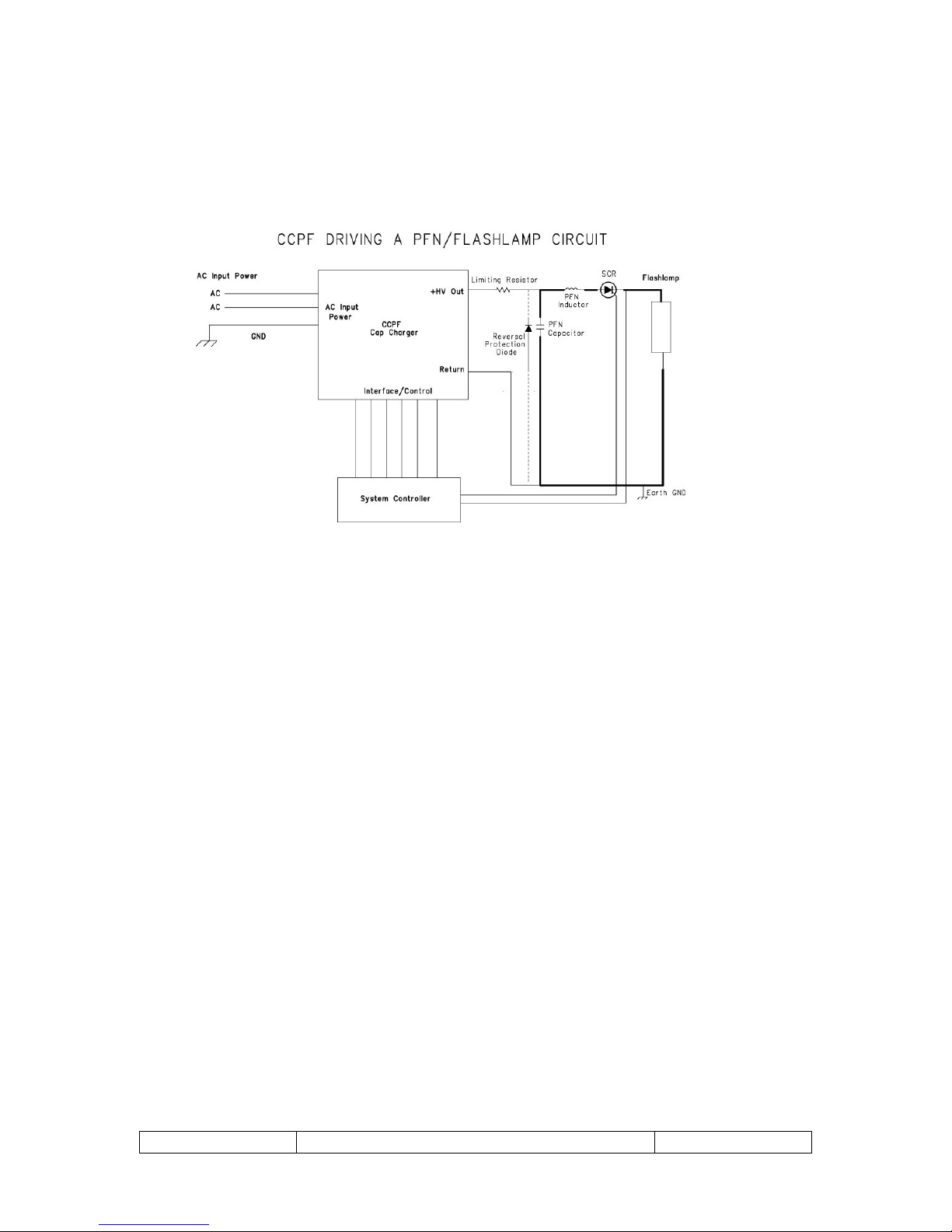

5.1 Using a CCPF with a pulse f or ming network (PFN)

The above block diagram shows a typical connection between a CCPF capacitor charging

power supply and an overdamped pulse-forming network. In a typical operation, when

the CCPF is ENABLED via Pin 1, the INHIBIT function, the CCPF will charge up the

PFN capacitor to the programmed value and then transmit an END OF CHARGE signal

to the user. Before discharging the load capacitor into the PFN, the CCPF should be

disabled via the INHIBIT function. Once the PFN is completely discharged and the SCR

has completely turned off, the charging function can be ENABLED via the INHIBIT

function and the CCPF will charge the capacitor again to the pro grammed value. PFN

designers may choose to include a limiting resistor and a reversal protection diode to

protect the power supply if there is any possibility of an arc in the PFN circuitry.

Page 12

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 12 of 17

5.2 Using a CCPF with a partial discharge network (Reservoir

Charging)

In this application, the power supply is ENABLED via the INHIBIT function and charges

up the capacitor bank to the programmed voltage. The IGBT will deliver short, high

current pulses to the flashlamp. The power supply does not need to be inhibited during

this process and continuously maintains the capacitor bank charged.

Page 13

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 13 of 17

5.3 Using a CCPF with multiple PFNs or capacitors

In applications where the power supply has to charge two or more separate capacitors,

which are dischar ged at different times, diodes must be used in series with the output to

prevent one cap from discharge into the other. In addition, a resistor must be in parallel

with each diode to help the power supply to “see” the cap voltage that is now blocked by

the diodes. Failure to add the parallel resistors will result in over charging the cap as the

power supply does not see the real voltage on the caps.

The diodes must have voltage rated at least 300V higher than the max voltage and 2 times

the current.

The resistor values are calculated as follows:

R (in Ohm) >= 100 * Vout.

P (in Watts) >= V^2 /R.

Page 14

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 14 of 17

6. Warnings

Warning:

connected to supply mains with protective earth

Warning:

anesthetic mixture with air or with oxygen or nitrous oxide.

Warning:

These power supplies are not provided with any isolation

on all poles simultaneously.

This equipment produces high voltages, which can be fatal.

High Voltage Present:

This power supply produces lethal high voltages. Only service

personnel of Lumina Power, Inc., are qualified to service this

equipment. Only qualified service personnel are permitted to

install this power supply.

Warning:

Only service personnel of Lumina Power, Inc. are qualified to

service this equipment.

Equipment is not suitable for use in presence of a flammable

devices and shall only be used inside other equipment that has

means to isolate its circuits electrically from the supply mains

To avoid risk of electric shock, this equipment must only be

WARNING: Only Lumina Power, Inc. qualified service personnel are allowed to

remove the covers and service this equipment.

WARNING: NEVER OPERATE THE POWER SUPPLY:

1. Without providing adequate protection of personnel from high voltage.

2. Without proper ground connections.

3. Without covers and panels properly installed.

4. With customer interlocks defeated.

5. Without a suitable load for the application and properly rated for the

required power dissipation.

Page 15

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 15 of 17

7. Installation

Connection

Description

Required Wire and Connectors

IMPORTANT APPLICATON NOTE REGARDING AC INPUT POWER

rated for at least 600V and 105 Degree C.

These power supplies are designed for and intended only for installation into OEM pulse

forming systems.

• Only qualified technicians or qualified assemblers may install these power

supplies.

• Only qualified Lumina Power personnel may service these power supplies.

• There are no user serviceable parts in this equipment.

• Required wire and connectors: Refer to Figure 5, CCPF-500 Input Side

Drawing and Figure 6, CCPF-500 Output Side Drawing for the locations of

connections. Table 3, CCPF Connections below shows required cables and

connectors:

Table 3, CCPF Connections

2 Position Phoenix

AC Input Power

Interface 15 pin “D” female 15 pin “D” male

Connector DMKDS2.5

#10-32 stud for ground

At least 14AWG wire

Optional 4-pin

Interface

HV Output

* Note: other connectors or flying lead configuration also available,

contact Lumina Power for any interface changes.

• Ventilation: This unit is forced air cooled via internal DC fans. A clearance of

2” should be maintained at either side of the power supply the fan end of the

power supply as well as the grill side of the power supply. Hot air exits the grill

side and should be ducted out of the system. Do not let the hot air exhaust

recirculate to the power supply air inlet. Fully sealed systems should implement a

heat exchanger system to maintain the environmental conditions list in section 3

CCPF-500/750-XX Specifications on page 5.

Molex connector

70553-003

MHV Female

Amphenol 27000

*See note below

AC Input wires should be at least #14 AWG,

mating housing use Molex 50-57-9404

MHV Male and coax cable rated for at

least 150% of maximum rated output

voltage of unit

Page 16

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 16 of 17

8. Product Limited Warranty

Lumina Power, Inc., as Seller, warrants that each Product sold by it is free of defects in materials and

workmanship. Duration of warranty is as follows:

a. All Chassis enclosed products are covered for twenty four (24) months from date of shipment. Products

included but are not limited t o the following product families: CCPF, CCHP, LDY, LDYHC, LDQCW,

XLB (exclud ing XLB-300), and MLB. Custom fully enclosed products may be covered for the same 24

months. Please consult factory for specific terms.

b. All Open Frame products are covered for 12 months from date of shipment. Open frame power supplies

are defined as any product that is not enclosed in a metal or plastic enclosure. Products included but are not

limited to the following produc t families: LDPC, LDQPC, XLB-300 and any open frame custom products.

c. All products returned for repair are covered for a period of 6 month or the balance of the original

warranty, whichever is longer.

Warranty is not transferable t o parties outside of original Buyer's corporate or educational organization.

Seller will have sole discretion in making de termination of validit y of warranty if the Pr oduct is transferred

to a different user group than the or iginal Buyer.

Normal wear and tear and items expendable in normal use are not covered by this warranty. All warranty

repair or replacement of parts shall be limited to Product malfunct ions, which, in the sole opinion of Seller,

are due or traceable to defects in original materials or workmanship. Such determination will be made when

the Product is returned to the Seller's factory, transportation prepaid by the Buyer, within the warranty

period.

All obligations under this warranty shall cease immediately in the event of abuse, accident, alteration,

misuse, or neglect of the Product. Use and service of the Product in a manner not in accordance with the

Owner's Manual (if furnished) will likewise cause all obligations under this warranty to cease. Repaired or

replacement parts are warranted only for the remaining unexpired portion o f the original warr anty period

for the Product. After expiration of the applicable warranty period, Buyer shall be charged at the then

current prices for parts, labor and transportation.

Seller has no responsibility under this warranty for the cost of any work (material, labor, and/or other

expenses) performed by or incurred by Buyer or any third party for modification or repair of the Product

unless specifically authorized in advance in writing by Seller.

Reasonable care must be used to avoid hazards. Seller expressly disclaims responsibility for loss or damage

caused by use of its Products other than in accordance with proper operation procedures. Other than those

expressly stated herein, there are no other warranties of any kind, expressed or implied, and specifically

included but not by way of limitation are the implied warranties of fitness or merchantability for a

particular purpose.

It is understood and agreed the seller’s liability whether in contract, in tort, under any warranty, in

negligence or otherwise shall not exceed the return of the amount of the purchase price paid by the

purchaser and under no circumstance shall seller be liable for special, indirect, incidental or consequential

damages. The price stated for the product is a consideration in limiting seller's liability. No action,

regardless of form, arising out of the transactions of this agreement may be brought by purchaser more than

one year after the cause of action has accrued.

Seller’s maximum liability sh all not exceed and buyer's remedy is limited to either (i) repair or replacement

of the defective part of product, or at seller's option (ii) return of the product and refund of the purchase

price, and such remedy shall be the buyer's entire and exclusive remedy.

Page 17

02100005 Rev 1

CCPF-500 CCPF-750 User Manual

Page 17 of 17

9. Service

Rev

ECO

Description

Doc Ctrl

Date

App

1

7706

Initial Release

MJ

8/28/2017

EK

This unit contains no user serviceable parts.

performed only by qualified personnel from Lumina Power, Inc. For more

information contact

Email: sales@luminapower.com Web site: www.luminapower.com

Service and repair should be

Lumina Power, Inc.

26 Ward Hill Ave.,

Bradford, MA 01835

Ph: 978-241-8260

Fx: 978-241-8262

Loading...

Loading...