TS210SL

210mm Table Saw With Side Extensions

TS210SL

ORIGINAL INSTRUCTIONS

SAFETY AND OPERATING MANUAL

TS210SL

TABLE OF CONTENTS

Welcome to Lumberjack!

Dear customer, Congratulations on your purchase. Before using the

product for the first time please be sure to read these instructions for use.

They provide you with all information necessary for using the product safely and to

ensure its long service life.

Closely observe all safety information in these instructions!

General Power Tool Safety Warnings………………………………….…......01

Symbols & Cable Rating Chart ……….…………………………………….………06

Machine Details and Product Features……….…………………………….….07

Assembly……………………………………………………………………………………..09

Operation……………………………………….…………………………………………..13

Maintenance and Service……………………………..……………………………..15

Lumberjack Guarantee………….…………………………………………………….17

Declaration of Conformity……………………………………………………………19

Parts List…………..………………………………………………………………………...20

Parts Diagram………………………………………………………………………………23

TS210SL 01

GENERAL POWER TOOL SAFETY WARNINGS

WARNING Read all safety warnings and

all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for

future reference. The term "power tool" in

the warnings refers to your electric (corded)

power tool or battery-operated (cordless) power

tool.

1. Work area safety

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with grounded power tools.

Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with grounded surfaces,

such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk

of electric shock.

3. Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off position before connecting to

power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

finger on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

TS210SL 02

GENERAL POWER TOOL SAFETY WARNINGS

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes,

jewellery or long hair can be caught in moving

parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused

by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking

into account the working conditions and the work

to be performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

5. Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

b) If the replacement of the supply cord is

necessary, this has to be done by the

manufacturer or its agent in order to avoid a

safety hazard.

TS210SL 03

GENERAL POWER TOOL SAFETY WARNINGS

6 . Additional Safety and Working

Instructions

a) Dusts from materials such as lead-containing

coatings, some wood types, minerals and

metals can be harmful to one’s health and

cause allergic reactions, leading to respiratory

infections and/or cancer. Materials containing

asbestos may only be worked by specialists.

Observe the relevant regulations in your country

for the materials to be worked.

b) Prevent dust accumulation at the workplace.

Dusts can easily ignite.

7. Safety Warnings for Dust Extractors

a) Do not vacuum materials that are harmful to

one’s health, e. g. dust from beech or oak

wood, masonry dust, asbestos. These materials

are considered carcinogenic.

b) Take care that the blade guard operates

properly and can move freely. Always adjust

the blade guard in such a manner that it face

loosely against the work piece when sawing.

Never clamp the blade guard when it is open.

c) Never reach behind the saw blade in order to

hold the work piece, remove saw dust/wood

chips or for any other reason. The clearance of

your hand to the rotating saw blade is too small.

d) Guide the work piece against the saw blade

only when the machine is switched on.

Otherwise there is damage of kickback, when

the saw blade becomes wedged in the work

piece.

e) Keep handles dry, clean, and free from oil

and grease. Greasy, oily handles are slippery

causing loss of control.

f) Operate the power tool only when the work

area to the work piece is clear of any adjusting

tools, wood chips, etc. Small pieces of wood or

other objects that come in contact with the

rotating saw blade can strike the operator with

high speed.

g) Only saw one work piece at a time. Work

pieces placed on top or aside of each other can

cause the saw blade to jam or the work pieces to

move against each other while sawing.

h) Always use the parallel guide or the angle

guide. This improves the cutting accuracy and

reduces the possibility of saw blade binding.

i) Use the machine for grooving or rebating only

with an appropriately suitable protective device

(e. g. a tunnel blade guard).

j) Do not use the machine for cutting slots

(stopped grooves).

k) Use the machine only for cutting the materials

listed under Intended Use. Otherwise, the

machine can be subject to overload.

l) If the saw blade should become jammed,

switch the machine off and hold the work piece

until the saw blade comes to a complete stop. To

prevent kick back, the work piece may not be

moved until after the machine has come to a

complete stop. Correct the cause for the jamming

of the saw blade before restarting the machine.

m) Do not use dull, cracked, bent or damaged

saw blades. Unsharpened or improperly set saw

blades produce narrow kerfs causing excessive

friction, blade binding and kickback.

TS210SL 04

GENERAL POWER TOOL SAFETY WARNINGS

n) Always use saw blade with correct size and

shape (diamond versus round) of arbour hole.

Saw blade that do not match the mounting

hardware of the saw will run eccentrically,

causing loss of control.

o) Do not use high speed steel (HSS) saw blade.

Such saw blades can easily break.

p) Do not touch the saw blade after working

before it has cooled. The saw blade becomes

very hot while working.

q) Never operate the machine without the

insert plate. Replace a defective insert plate.

Without flawless insert plates, injuries are

possible from the saw blade.

r) Check the cable regularly and have a

damaged cable repaired only through an

authorised customer service agent. Replace

damaged extension cables. This will ensure that

the safety of the power tool is maintained.

s) Store the machine in a safe manner when not

being used. The storage location must be dry

and lockable. This prevents the machine from

storage damage, and from being operated by

untrained persons.

t) Never leave the machine before it has come

to a complete stop. Cutting tools that are still

running can cause injuries.

u) Never use the machine with a damaged

cable. Do not touch the damaged cable and pull

the main plug when the cable is damaged while

working. Damaged cables increase the risk of an

electric shock.

8. Safety Warnings for Lasers

The mitre saw has a built-in laser light. The laser is

CLASS 2. These lasers do not normally present an

optical hazard. However, DO NOT stare at the

beam, as this can cause flash blindness.

a) Do not remove or deface any product labels.

Removing product labels increases the risk of

exposure to laser radiation.

b) The laser beam can be harmful to the eyes.

Always avoid direct expose to eyes. Do not project

the laser beam directly into the eyes or at any

object other than the work piece.

c) Do not look directly into the laser-beamoutput aperture during operation.

d) Turn the laser on only when making cuts. The

laser on the mitre saw is not a toy. Always keep it

out of the reach of children. The laser light

emitted from this device should never be directed

toward any person for any reason.

e) Always turn the laser beam off when it is not in

use. Leaving the tool will increase the risk of

someone inadvertently staring into the laser’s

beam.

f) Be sure that the laser beam is aimed at a work

piece (such as wood or a rough-coated surface)

that does not have a reflective surface.

g) Do not use on materials that have shiny,

reflective surfaces, such as sheet metal. The

reflective surface could reflect the beam back at

the operator. Be aware that laser light reflected

off of a mirror or any other reflective surfaces can

also be dangerous.

TS210SL 05

GENERAL POWER TOOL SAFETY WARNINGS

h) Always wear laser-protective eyewear when

working on or near reflective surfaces.

i) Do not attempt to activate the laser when the

tool housing is removed.

j) The laser is activated by means of a button

switch that is independent of the main switch

for the saw.

k) Do not replace the laser light assembly with a

different one. Any repairs must be carried out by

the laser manufacturer or an authorized service

agent.

l) Do not attempt to repair the laser guide by

yourself.

m) Do not attempt to change any parts of the

laser guide.

TS210SL 06

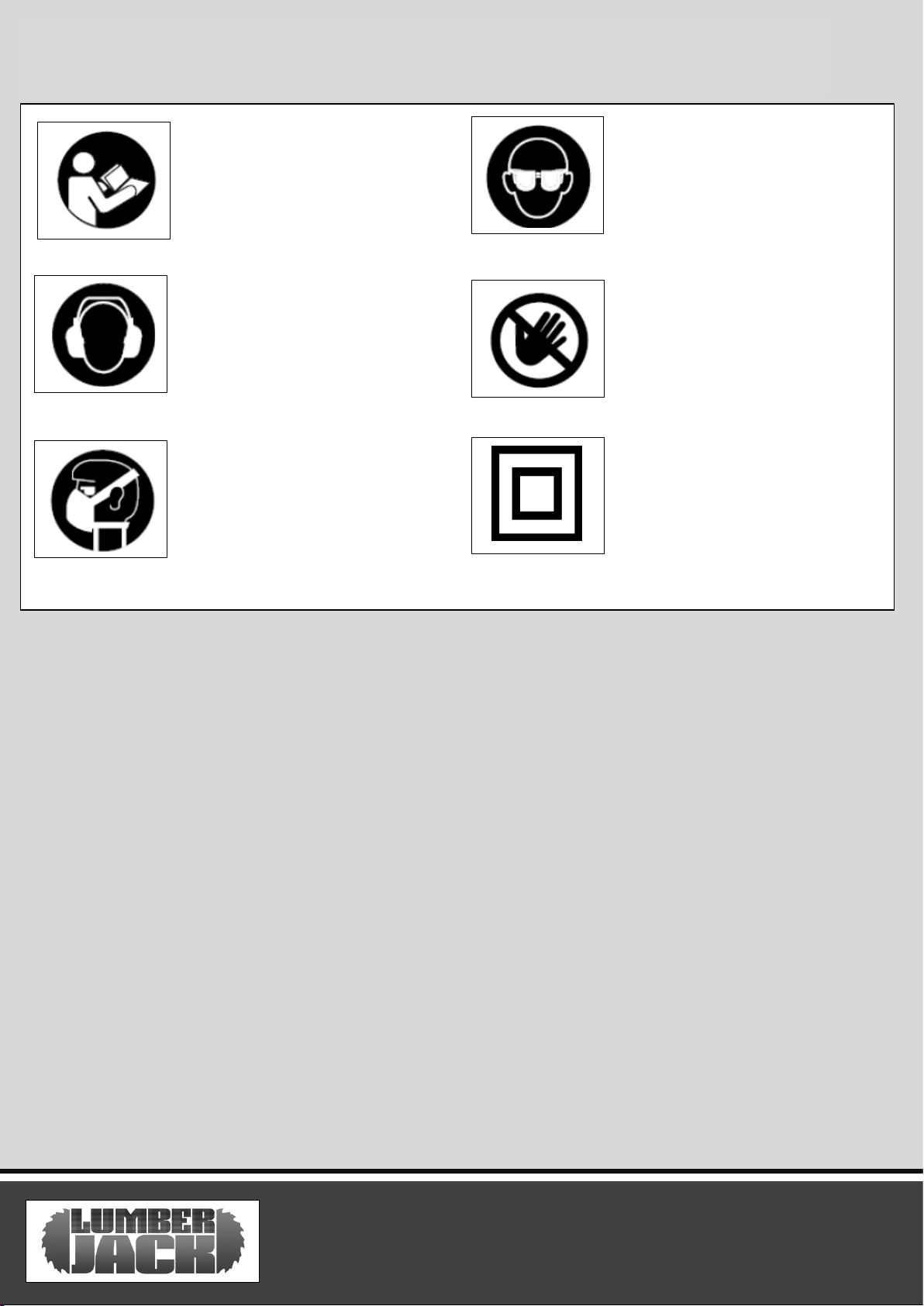

SYMBOLS AND POWER RATING CHART

Danger! – Read the operating

instructions to reduce the risk of

injury.

Caution! Wear safety goggles.

Caution! Wear ear defenders. The

impact of noise can cause

damage to hearing.

Caution! Risk of Injury! Do

not reach into the running

saw blade.

Caution! Wear a dust mask.

Class II Double Insulated

Loading...

Loading...