Page 1

Operators and Safety Manual

Model

644B

10709799

May 1997

ANSI

Page 2

Page 3

CONTENTS

Section Page No.

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INSTRUMENTS AND CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

BEFORE OPERATING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 9

GENERAL OPERATING PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FLUID AND LUBRICANT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SERVICE/LUBRICATION SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SAMPLE LOAD CHART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SAFETY ALERT SYMBOL

This Safety Alert Symbol means:

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

When you see this symbol, be alert to the possibility of personal

injury or death. Follow the instructions in the safety message.

Three Reasons Why Safety is Important to You:

1. Accidents disable and kill.

2. Accidents cost.

3. Accidents can be avoided.

W1027

i

Page 4

INTRODUCTION

INTRODUCTION

You are about to operate one of the finest forklifts available on the market today. To ensure that your forklift will

provide years of safe dependable service, only trained and authorized persons should operate and service the

forklift. It is the responsibility of the operator to read, fully understand and follow all operational and safety related

instructions contained in this manual. Do not operate the forklift until you have read and fully understand these

instructions. Remember, al ways use good safety practices to protect yourself and those around you.

REGISTRATION

The Warranty Registration card must be filled out by the dealer and returned to the

“Warranty Administrator” indicating the date the machine went into

service. The Pre-Delivery Inspection Form must be signed by the customer when the machine is delivered.

IMPORTANT

This operators man ual must remain with the machine at all times!

®

LULL

However, because of owner requirements, equipment and control variations may exist between machines. I n

addition, due to LULL

between machines and the descriptions and information contained herein.

LULL

obligation. LULL

Copyright © 1997 LULL INTERNATIONAL, INC., St. Paul, MN. All rights reserved. This document may

not be duplicated, including electronic digitization, in whole or in part without the expressed written consent of

LULL INTERNATIONAL, INC.

has made every effort to provide information as complete and accurate as possible for its forklifts.

®

policy of continually st ri ving to improve its products, occasional discrepancies may exist

®

reserves the right to make changes and improvements to its products at any time without public notice or

®

also reserves the right to discontinue manufacturing any product at its discretion at any time.

ii

Page 5

W1038

SAFETY

SAFETY STANDARD

The ASME/ANSI B56.6 safety standard for rough

terrain forklift trucks defines safety requirements

relating to the design, operation, and maintenance of

these vehicles. For a copy of this standard write to:

W

CAUTION, WARNING, & DANGER:

WHAT THEY MEAN

Hazards are identified by the “Safety Alert Symbol” and

followed by a signal word: Caution, Warning, or Danger.

CAUTION

CAUTION

hazardous an d MAY result in persona l injury if

not avoided.

CAUTION

practices.

means that a situation COULD be

is also used to alert against unsafe

The American Society of Mechanica l Engine ers

United Engineering Center

345 East 47th Street

New York, NY 10017

DECALS

The decals on the machine provide instructions for safe

and correct operation.

Never make modif ications affecting safe operation or

capacity without the expressed written approval of

LULL

When LULL

user is responsible for seeing that appropriate decals,

load charts, and instructions are changed.

All plates and decals must be in place and legible at all

times.

®

.

®

approved modifications are made, the

ROLL OVER PROTECTIVE

WARNING

W ARNING

hazardous and M AY result in ser ious inj ury or

death if not avoided.

means that a situation COULD be

DANGER

DANGER

means that a situation

HAZARDOUS AND WILL

injury or death if not avoided.

IS

result in serious

STRUCTURE (ROPS) &

FALLING OBJECT PROTECTIVE

STRUCTURE (FOPS)

This machine is equipped with a Roll-Over Protective

Structure (ROPS) to guard the operator if the machine

tips over. The Falling Object Protective Structure

(FOPS) is built into the ROPS. The FOPS protects the

operator from falling objects.

Despite the protection of the ROPS/FOPS, it cannot

protect the operator f rom every possible hazard. Do not

consider the ROPS/FOPS a substitute for safe

practices and good common sense.

Any modification to a ROPS/FOPS, such as welding or

drilling holes in the structural members for mount ing

brackets, will affect the ROPS/FOPS capability to

provide the required protection.

Any modification or repair without the specific written

approval of LULL INTERNATIONAL, INC.

will void the ROPS/FOPS certif ic at io n. Contact your

authorized LULL INTERNATIONAL, INC.

dealer before making any modifications or repairs.

Failure to do so may v oid the ROPS/FOPS certification.

1

Page 6

SAFETY

REFUELING SAFETY

Never smoke near the machine during refueling.

Do not permit anyone to be on the machine during

refueling.

Spilled fuel must be completely absorbed or

evaporated before starting the engine.

Make sure the fuel cap is in place before starting

the engine.

Never use an open flame when checking the f uel

level in the ta nk .

Never fill the fuel tank with the engine running.

Make sure you have adequate ventilation during

fueling.

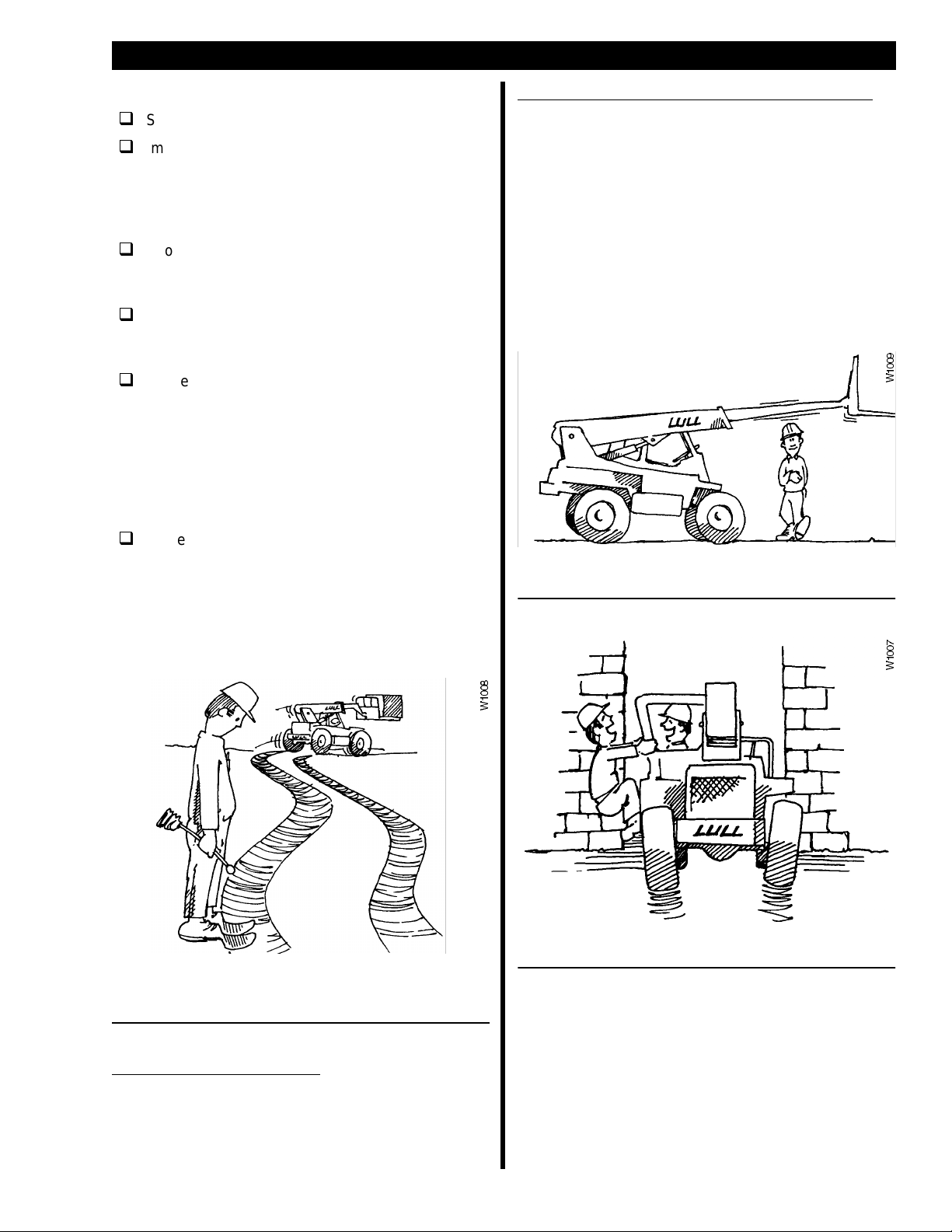

OPERATOR QUALIFICATIONS AND

TRAINING

Only trained and authorized persons should

operate and service the mac hine. To be qualified,

you must understand the written instructions

supplied by t he manufacturer, have training

(including actual operation of this machine) and

know the safety rules and regulations for the

jobsite. A self-training course available from the

Mason Contractors Association of America is

highly recommended.

LULL

video that i s available on VHS tape. Thi s video

shows safe operating and maintenance prac tices

for your forklift. Contact your LULL

dealer to obtain a copy of this video.

Do not operate the machine until you fully

understand the function of all controls, indicators

and instruments.

®

has produced an operational safety

®

authorized

Avoid entanglement hazards. Do not wear

clothing or jewelry that could catch on machinery.

Keep your hands, hair, feet and clothing away

from moving parts. Always keep your hands and

feet inside the cab.

Know the pinch points and rotating parts on the

machine.

Always know where to get assistance in ca se of

an emergency. Know how to use a first aid kit and

fire extinguisher.

MACHINE STABILITY

Your LULL® rough terrain forklift is proven to be stable

when properly operated. However, improper operation,

faulty maintenance, unauthorized modifications, or poor

housekeeping may cause instability.

Some Conditions that Affect Stability:

•

Ground and surface conditions.

•

Surface grade.

•

Weight and configuration of the attachment.

•

Improper tire inflation and ballast content.

•

Operator judgement.

•

Excessive tilting of the fork carriage or other

attachments with an elevated load can cause

machine instability. The amount of allowable tilt is

governed by conditions such as boom elevation,

weight of load, and terrain.

PERSONAL SAFETY

Wear all the protective clothing and personal safety

devices issued to you or called for by job conditions.

You may need…

•

A hard hat

•

Safety shoes

•

Safety glasses, goggles, or face shield

•

Heavy gloves

•

Hearing protection

•

Reflective clothing

•

Wet weather gear

•

Respirator or filter mask

2

STARTING SAFETY

Before Starting the Engine…

Important:

1. Check underneath and around the machine and

make sure all personnel are clear.

2. Be properly seated.

3. Set the park brake.

4. Make sure shift selector is locked in the

NEUTRAL position.

5. Apply the brakes.

Warn all others in the area that you are

going to start the forklift.

Page 7

SAFETY

OPERATION SAFETY

Safe operation is the responsibility of the operator.

Improper use of the machine can lead to

dangerous situations for yourself, those around

you, the machine and the work area. You must

have safe worki ng habits and be aware of

hazardous working c onditions.

Thoroughly read and understand this entire

manual. Follow all safety rules and practices

explained in this manual.

The machine must be checked every day or at the

start of each shift. See “Check The Equipment” on

page 19.

To meet the requirements of different operating

conditions, LULL

packages for your machine. Do not operate the

machine if it is not equipped with lights when

conditions require them. If your machine is not

equipped with the proper lights, contact your

authorized LULL

packages.

If operating in an enclosed or partially enclosed

environment, make sure there is enough

ventilation. Engine exhaust fumes can be deadl y

to you and those around you if precautions are not

taken. Questions about the air quality in the

working environment and sampling methods

should be directed to a qualified person.

®

offers optional lighting

®

dealer for available lighting

Before Leaving the Machine Unattended…

•

Stop the engine.

•

Block the wheels if parked on an incline.

•

Lower the boom.

The machine is considered “attended” when the

operator is less than 25 feet from the machine and it

remains in the operat or’s view.

The machine is considered “unattended” when the

operator is 25 feet or more from the machine and the

machine is in the operator’s view, or whenever the

machine is not in the operator’s view.

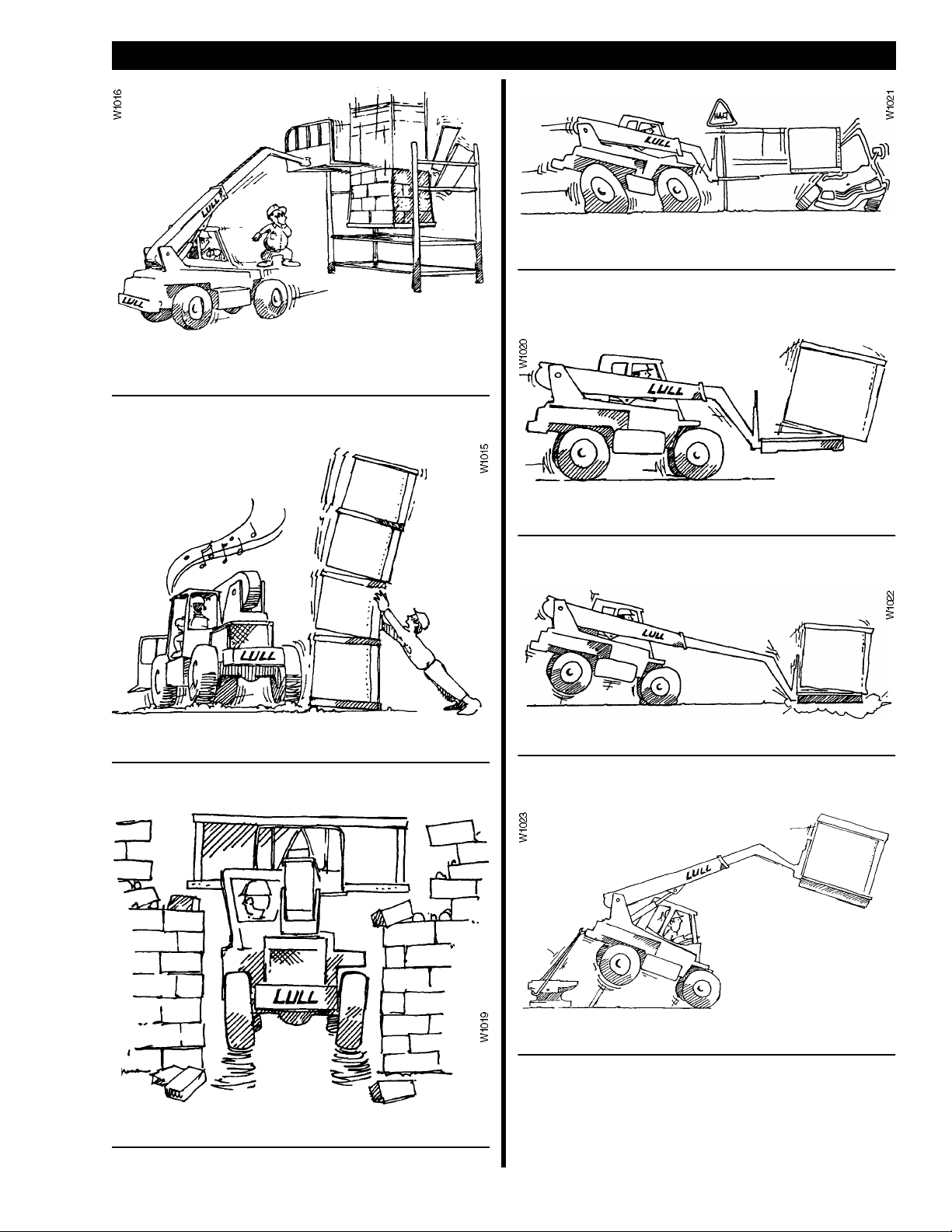

Never stand or walk under a raised boom. Do not allow

others to do so.

Never operate the machine controls while you are

outside the cab. You must be properly seated in the

cab before operating any controls.

Before Leaving the Cab…

•

Bring the machine to a full stop.

•

Apply the park brake.

•

Lower the boom.

Never allow passengers on the machine.

3

Page 8

SAFETY

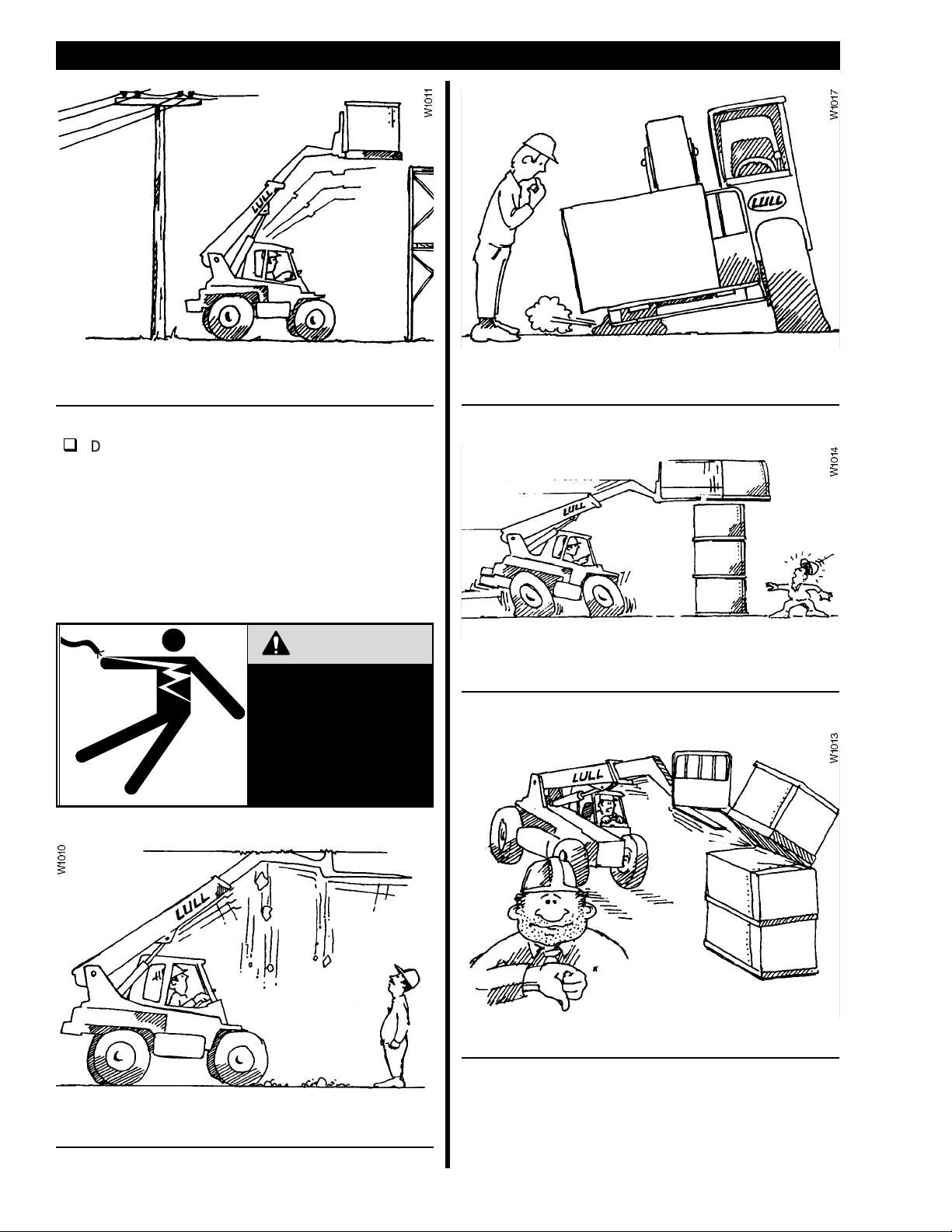

Always check clearances under power lines and

overhead structures before driving under them.

DO NOT operate the machine near energized

power lines. Always contact the electrical power

company when operating near power lines. The

lines should be moved, insulated, disconnected,

or de-energized and grounded before operating in

the area. Keep all parts of the machine at leas t 50

feet away from power lines. Contacting electrical

power lines WILL result in serious personal injury

or death!

DANGER

KEEP ALL PARTS OF

MACHINE AT LEAST 50

FEET FROM POWER

LINES. CONTACTING

ENERGIZED POWER

LINES WILL CAUSE

SERIOUS PERSONAL

INJURY OR DEATH!

Ensure that correct tire pressure and tire ballast levels

are maintained.

Never attempt to discharge a load by stopping the

forklift suddenly.

Always check for enough overheard clearance for the

boom.

4

Never lift a load using one fork.

Page 9

Never place loads that exceed scaffold capacity or

subject scaffold to unnecessary “shock” loads.

SAFETY

Drive carefully and avoid sudden stops and changes of

direction.

Ensure that the load is stable and secure. Check to see

that there are no loose articles that may fall off the fork.

Never stack a load on uneven ground.

Always be aware of load width.

Always check the load charts before picking up a load.

Never add unauthorized counterweights.

5

Page 10

SAFETY

Always pick up the load at its center of gravity.

The machine can be levelled side to-side a total of

12.5° in each direction (22% grade). Any slope or

grade that exceeds this is considered excessively

steep.

Avoid parking on slopes. If it is necessary to park on a

slope, set the parking brake and block the wheels.

When Traveling On Inclines…

•

Tilt the attachment back and raised only

enough to clear the ground.

•

Avoid turning. If it cannot be avoided, turn

slowly and with ext reme caution.

•

Travel straight up and down grades.

•

When loaded and traveling up or down

grades, travel only with the load uphill.

•

When unloaded, tr avel only with the forks or

attachment downhill.

•

Proceed slowly and with extreme caution.

•

Do not travel across excessively steep

slopes.

Drive slow and carry the load as low as possible.

When Traveling on Roadways…

•

Make sure the machi ne is equipped with all

necessary lights and safety signs required

for traveling on roadways.

•

Observe all t ra ffic law s and spe e d limits.

•

Keep to the correct side of the roadway.

•

Keep a safe dist ance from other vehicles.

•

Maintain control of the machine at all times.

•

Yield the right-of-way to pedestrians and

emergency vehicles.

•

Do not pass another vehicle at intersections,

blind spots, or other dangerous locations.

•

Avoid running over loose objects and debris.

6

Page 11

Additional Safety Instructions:

•

Maneuver the machine carefully. Do not cause t he

load to shift or t he machine to tip.

•

Slow down for wet and slippery surfaces and

changes in terrain.

•

Turn the steering wheel smoothly and slow down

when turning.

•

Do not make sharp turns at high speeds.

•

Take special care when traveling without a load.

The machine is more suscept ible to tipping over on

its side.

•

Do not continue to operate the machine if an

unsafe condition i s found. Stop the machine and

report the condition to the designated authority.

•

Never make repairs or adjustments unless you are

authorized to do so.

•

Always keep your hands and feet inside the cab,

especially when in or around structures.

SAFETY

•

Never reach into the boom or attachments.

•

Understand the limitations of the machine and

drive safely.

•

Watch for pedestrians, especially when backing up

or turning and where pedestrians may step into the

path of the machine.

•

The machine may add to the overall sound level of

the work area. Give consideration to the sound

exposure of those working around you.

•

If a fuel leak is found, do not operate the machine

until the problem is fixed.

•

When approaching areas where vision is

obstructed, always slow down and sound the horn.

•

Report all accidents involving personnel, building

structures, and equipment to your supervisor or as

directed.

•

Use caution when operat ing on ramps, platforms,

trenches, and other similar surfaces.

•

Keep a clear view of the terrain and where the

machine is heading. Watch out for other vehicles,

people, and structures.

•

If the load blocks your forward view, then carefully

travel in reverse and use a signalman to guide you

if necessary.

•

Do not block access to fire lanes or fire equipment.

7

Page 12

INSTRUMENTS AND CONTROLS

GAUGES

REAR

OSC

LOCK

P

PARK BRAKE

BRAKE

1

240

190

160

130

100

80

60

40

20

0

2

WATER FUEL

°F

OIL BATT.

psi

F

3/4

1/2

1/4

E

16

14

12

10

V

5

TRANSMISSION

DECLUTCH

Gauges

Note: Gauges and indicat or lights operate only when

the ignition switch is in the ON position.

(1)Engine Water Temperature

100 to 240 ° F. Normal operating temperature is

180 to 185 °F.

(2)

Fuel Level

(3)

Transmission Oil Temperature

from 140 to 320 °F with Celsius equivalents. If

the temperature rises above 230 °F (1 10 °C) stop

the vehicle immediately, shift to ne utral and run

the engine at half throttle. The temperature

should drop quickly. If the temperature does not

drop, shut off engine and investigate.

(4)

Engine Oil Pressu re

oil pressure. Gauge registers from 0 to 80 PSI .

Normal operating pressure is 55 to 60 PSI.

—Shows fuel level in fuel tank.

—Shows operating engine

3

°F

280

240

115

138

140

°C

160

60

TRANS

QUARTZ

0000

0

HOURS

64

H1042

—Registers fro m

—Registers

320

1

10

INDICATOR LIGHT S

1

WATER FUEL

240

190

160

130

°F

100

OIL BATT.

80

60

40

20

psi

0

TRANSMISSION

DECLUTCH

REAR

OSC

LOCK

3

P

PARK BRAKE

BRAKE

2

Indicat or Li gh t s

(1)

Park Brake

—Red lamp lights to show when park

brake is applied and goes out when park brake is

released.

(2)

Low Brake Pressure

buzzer sounds when service brake hydraulic

system pressure drops below the safe operating

level. Under normal conditions, the light and

buzzer will go out quickly aft er engine start. If the

light or buzzer does not go out or comes on

during machine operation, shut off engine

immediately, investigate, and repair before

operating. Do not operate machine when low

brake pressure light or buzzer is on.

(3)

Rear Oscillation Lock

light will come on when the boom angle i s above

40°.

F

3/4

1/2

1/4

E

16

14

12

V

10

—Red lamp lights and

—The rear oscillation lock

140

60

TRANS

0000

240

115

QUARTZ

HOURS

°F

280

138

320

°C

160

1

10

0

H1042

(5)

Voltmeter

—Indicates system voltage. Gauge

registers from 10 to 16 volts. Normal operating

voltage range is 14.5 to 15 volts. With ignition in

ON position and engine off, battery voltage is

indicated. This should normally be 12.6 volts.

(6)

Hourmeter

—

Registers total hours of machine

operation.

8

Page 13

INSTRUMENTS AND CONTROLS

H1009

H1009

IGNITION SWITCH

Ignition Swit c h Loc a tion

(1)

The ignition switch

right side.

is located on the dash, near the

Note: The starter will not engage unless the shift

selector is placed in the NEUTRAL position.

THROTTLE

1

H1007

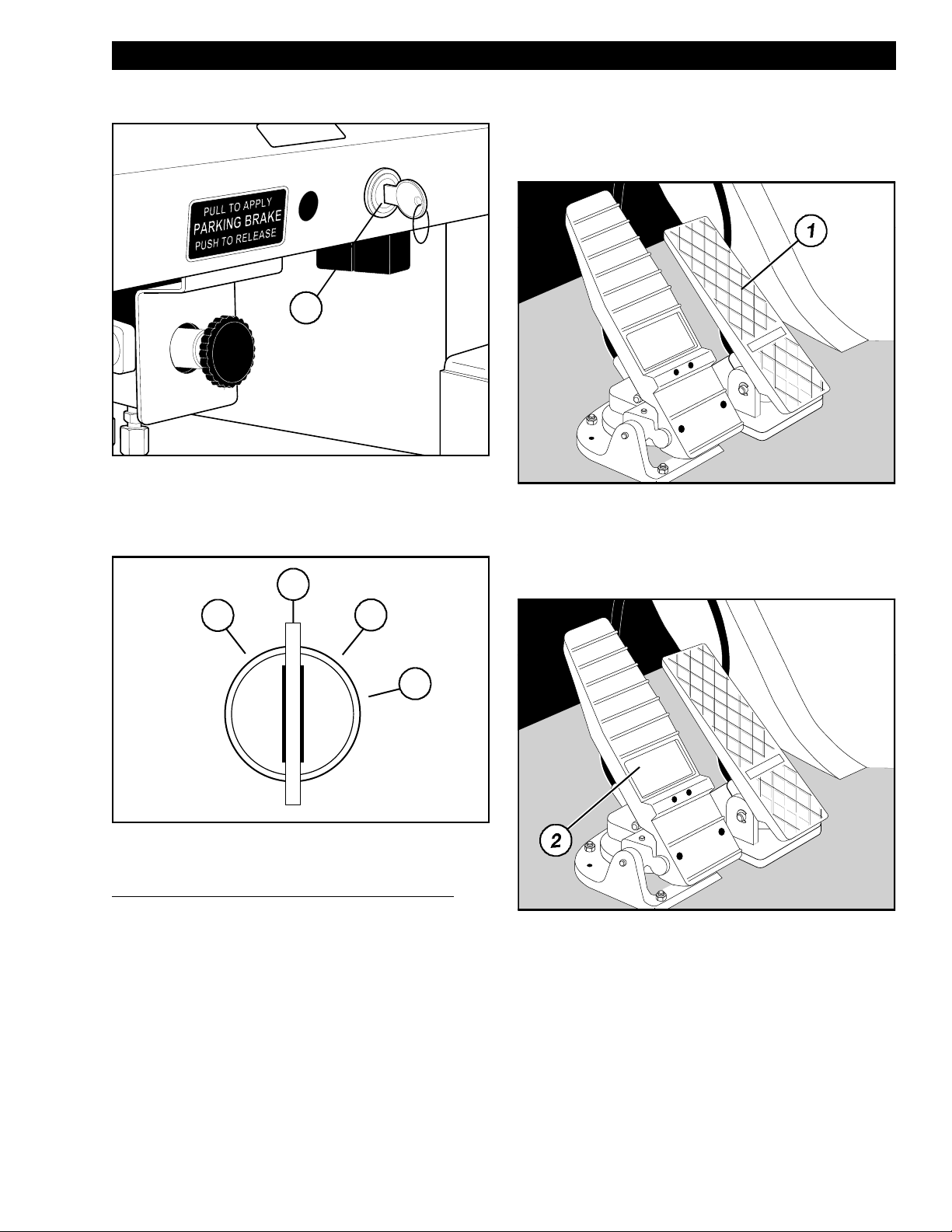

Engine Throttle Pedal

Push throttle pedal

(1)

down to increase engine speed.

1

4

2

3

Ignition Switch Posi tions

The ignition switch has four positions:

(1)

(2)

: The key may be removed or inserted only

OFF

at this position. The engine and all electrical

circuits except the horn circuit are shut down at

this position.

: All electrical circuits except the engine

ON

starter circuit are operational.

H1021

BRAKE PEDAL

Service Brak e Pedal

Push brake pedal

(2)

down to slow or stop machine.

(3)

START

key is released the switch will return to the ON

position and remain there.

(4)

This position is reserved for future use and

currently has no function.

: Activates the engine starter. When the

9

Page 14

INSTRUMENTS AND CONTROLS

PARK BRAKE CONTROL

H1007

Park Brake Control

Pull knob

Important:

(1)

out (toward you) to engage the park brake.

Always stop the machine with service

brakes before engagi ng park brake. Do

not use the park brake to slow or stop

the machine EXCEPT in an emergency.

Note: When park brake is engaged, transmission will

default to NEUTRAL, regardless of shift selector

position.

SHIFT SELECTOR

REVERSE (R): Move the lever fully rearward to select

reverse machine movement.

Speed Range Selection

The transmission has three speed ranges in forward or

reverse. To select different transmission speed ranges,

rotate the selector handle to t he desired position. Speed

ranges may be selected while the vehicle is moving in

forward or reverse.

Note: The transmission requires 3 seconds

immediately after engine start for

self-diagnostics. Always wait at least 3 seconds

after engine start before engaging transmission.

The following table shows the maximum travel speed

for each position on the selector:

ZF 3WG-100 Speeds

POSITION SPEED

1 2.5 mph

2 5.9 mph

3 13.2 mph

4(See Note)

Note: The Model 644B is not equipped with a fourth

speed. If fourth is selected, the transmission will

remain in third speed.

F

1

2

3

4

N

N

R

H1022

Shift Selector

The shift selector is located on the steering wheel

column. It controls machine travel direction and

transmission speed range.

Direction Control

Machine travel direction is controll ed by moving the shi ft

lever to one of three positions:

FORWARD (F): Move the lever fully forwar d to se lect

forward machine mo vement.

NEUTRAL (N): Move the lever to the center posi tion to

disengage the transmission. The engine may be started

only when the transmission is in NEUTRAL.

10

Page 15

INSTRUMENTS AND CONTROLS

psi

40

20

0

TRANSMISSION

DECLUTCH

H1043

1

Neutral Lock

1

2

3

4

N

F

N

R

1

ND

H1023

H1023

Neutral Lock

The shift selector is equipped with a neutral lock.

To lock the sh if t lev er in the NEUTRAL position:

1. Place the lever in the NEUTRAL position

2. Move the neutral lock lever to the (N) NEUTRAL

LOCK position.

To unlock, move the neut ral lock lever to the (D) DRIVE

position.

TRANSMISSION DECLUTCH

SWITCH

Transmission Declutch Switch

The transmission declutch switch

lighted rocker switch. Pressing the forward side of the

switch activates the transmission declutch feature when

the foot brake pedal is applied.

This feature eliminates the need to shift to NEUTRAL

before operating the hydraulic system at high engine

speeds. When the transmission is declutched, the

drivetrain is disconnected and t he hydraulic system has

full engine power.

To use the Transmission Declutch Feature:

1. The transmission must be in first or second

speed range, forward or reverse. The declutch

feature will not operate when the transmission is

in third speed range.

is an internally

(1)

2. Press the forward side of the transmission

declutch switch.

3. Press the service brake pedal or pull the park

brake knob.

4. The switch will illuminate to show the

transmission clutch has disengaged.

Press the rear si de of the switch to deactivat e the

declutch feature.

11

Page 16

INSTRUMENTS AND CONTROLS

STEER MODE SELECTOR

1

2

FRONT WHEEL STEER

3

There are three steer modes available on your machine:

1)

Oblique Ste er (Cra b S teer)

(

2)

Front Wheel Steer (2-Wheel Steer)

(

3)

Round Steer (4-Wheel Steer)

(

To select a steer mode, turn the steer mode selector so

the handle aligns with a selection on the adjac ent plate.

You will feel the sel ector slip into a detent, or “catch,”

when the desired mode is selected.

ROUND STEER OBLIQUE STEER

H1044

Steer Mode Selector

Front Wheel Steer Mode

V1002

Front Wheel Steer Mode

Front Wheel Steer mode, also known as “2-Wheel

Steer” mode, al l ows the operator to steer the machine

in a conventional manner. The front wheels of the

machine steer and the rear wheels remain in posi tion.

Use this mode when traveling on flat surf aces at hi gher

speeds. Front Wheel Steer mode should not be used in

confined and congested areas.

Important:

Synchronize (straighten and align) the

wheels before engaging Front Wheel

Steer mode.

Round Steer Mode

CAUTION

Never change steer modes while the

machine is moving. The wheels can

become misaligned and cause loss of

control.

Always stop the machine completely and synchronize

(straighten and align) the wheels before changing steer

mode. See “Synchronizing (Straightening) the Wheels”

on page 13.

V1004

Round Ste er Mo de

Round Steer mode, also known as “4-Wheel Steer”

mode, allows the front and rear wheels to steer in

opposite directions.

Use Round Steer when tight turning is required. This

mode is very useful on job sites.

12

Page 17

Oblique Steer Mode

V1010

V1011

V1012

INSTRUMENTS AND CONTROLS

V1003

Oblique Steer Mode

Oblique Steer mode, also known as “Crab Steer” mode,

enables steering of the front and rear wheels in the

same direction.

It is generally used to angle the machine in tight areas.

Oblique Steer mode moves the machine to the side

while moving forward or reverse.

Synchronizing (Straightening) the Wheels

As different steer modes are selected, it is possible for

the wheels to become misaligned. It i s also possible for

the wheels to drift out of alignment when traveling over

long distances or rough terrain.

To synchronize (straighten and align) the wheels:

1. Select ROUND steer mode.

Step 4

4. Turn the steering wheel to t he left about one turn.

5. Select ROUND steer mode.

6. Turn the steering wheel to the right until it

reaches the stop. T his makes sure the rear

wheels are fully against right stop.

7. Select FRONT WHEEL steer mode.

Step 8

Step 2

2. Turn the steering wheel to the right until it

reaches the stop.

3. Select FRONT WHEEL steer mode.

8. Turn the steering wheel to the right until it

reaches the stop.

9. Select ROUND steer mode.

V1009

Step 10

10. Turn the steering wheel to the left until wheels

are pointed straight ahead.

13

Page 18

INSTRUMENTS AND CONTROLS

V1013

Step 11

11. Drive the machine forward a short distance to

check wheel tracking.

12. S t op the machine and select the desired steer

mode.

Note: The above procedure can also be done to the

left side.

Joysticks can be moved in any direction and are not

limited to front/back, left/right movement. Moving a

joystick in a diagonal direction will cause a combination

of actions.

Front Joystick

The front joystick controls transfer carriage extension

and attachment tilt.

An auxiliary function is also available by pressing the

button on top of the handle. See “Auxiliary Joystick

Controls” on page 16 for further information.

STANDARD JOYSTICK CONTROLS

General Description — Joysticks

Joystick

Tilting Attachment Up

Pulling back on the front joystick tilts the attachment

upwards.

The joysticks control hydraulic flow to the associated

cylinders.

Control is proportional: The more joystick movement,

the greater the acti on.The speed of cylinder action is

also affected by engine/hy draulic pump speed. Action is

quicker at higher engine speeds.

14

Page 19

Tilting Attachment Down

Pushing forward on the front joystick tilts the attachm ent

downwards.

INSTRUMENTS AND CONTROLS

Retracting the Transfer Carriage

Moving the front joystick to the left retracts the transfer

carriage.

Extending the Transfer Carriage

Moving the front joystick to the right extends the transfer

carriage

Rear Joystick

The rear joystick controls boom elevation and

extension. An auxiliary function is included on the rear

joystick. This auxiliary function is reserved for future

attachment designs and is not activated on current

Model 644B machines.

Lowering the Boom

Moving the rear joystick forward lowers the boom.

15

Page 20

INSTRUMENTS AND CONTROLS

Raising the Boom

Pulling back on the rear joystick rais es the boom .

Retracting the Boom

Moving the rear joystick to the left retracts the boom.

AUXILIARY JOYSTICK CONTROLS

General Description — Auxiliary Joystick

Controls

Auxiliary Joystick Control

Extending the Bo om

Moving the rear joystick to the right extends the boom.

16

A switch is located on the top of the front joystick, under

a protective rubber cap. Pressing this switch down with

your thu mb act iv a te s t he au x iliary function.

Hold the switch down while moving the joystick left and

right. Functions for specif ic attachments are shown

below.

Releasing the switch while moving the joystick

Note:

left or right changes the function of the joystick

back to transfer carriage control.

Page 21

Tilting Carriage Control

-20

0

40

20

60

80

-20

0

20

40

60

80

DEGREES

H1045

INSTRUMENTS AND CONTROLS

Rotating Tilt Carriage to Left

Holding the button down and moving the front joystick to

the left rotates an opti onal tilting carriage to the

operator’s left.

Rotating Tilt Carri age t o Ri ght

Holding the button down and moving the front joystick to

the right rotates an optional tilting carriage to the

operator’s right.

BOOM ANGLE INDICATOR

Boom Angle Indicator

The Boom Angle I ndicator shows the angle of t he boom

relative to level ground. Use this indicator with the Boom

Extension Indicator, T ransfer Carriage Extension

Indicator, and machine Load Chart to determine correct

boom lifting capacities.

17

Page 22

INSTRUMENTS AND CONTROLS

FRAME LEVEL INDICATOR

10

5

0

Frame Level Indicato r

The Frame Level Indicator shows the lateral

(side-to-side) angle of the frame relative to level ground.

Indicator range is from 0° to 10° left or right, in

increments of one degree. When the ball is centered

(0°), the machine is laterally level. The frame tilt feature

may be used to correct machine angles up to 12.5° to

the left or right. See “Frame Tilt Control” below.

W1040

10

5

H1004

WARNING

ALWAYS LEVEL

MACHINE BEFORE

RAISING BOOM. NEVER

TILT FRAME WITH THE

BOOM RAISED.

MACHINE MAY TIP AND

CAUSE SERIOUS

PERSONAL INJURY OR

DEATH!

(1)

The control lever

prevent unintentional operation. Lift the lock ring

is equipped with a safety lock to

(2)

to

unlock the lever and allow it to be moved left or ri ght.

Return the control l ever to center position and release

lock ring to secure lever.

The lever can be moved either left or right, tilting the

frame accordingly. To level the f rame, move the lever in

the direction you want the ball in the frame level

indicator to move.

FRAME TILT CONTROL

1

2

H1005

Frame Tilt Control

The frame t ilt cont r ol is u se d to le v el the machine

laterally (side-to-side) up to 12.5°, left or right. The

lateral angle of the machine, relative to level ground, is

shown on the frame level indicator (see “Frame Level

Indicator” above). The control is functional only while

the engine is running.

18

Page 23

CHECK THE EQUIPMENT

KEEP ALL PARTS OF

MACHINE AT LEAST 50

FEET FROM POWER

LINES. CONTACTING

ENERGIZED POWER

LINES WILL CAUSE

SERIOUS PERSONAL

INJURY OR DEATH!

DANGER

Note: Before you begin your workday, take time to

)

check

good operational condition.

your forklift a nd have all syst e ms in

9

(

BEFORE OPERATING THE MACHINE

9

Remove or put away tools, lunch buckets, chains,

hooks or any other loose objects that could

interfere with operation.

KNOW THE WORK AREA

Check the following:

9

Warning decals, special instructions and operators

manuals. Make sure they are legible and stored in

the proper location. NEVER operate without a

legible load chart.

9

Engine oil level. Add oil as required.

9

Radiator coolant level. Add coolant as required.

9

Hydraulic fluid level. Add hydraulic fluid as

required.

9

Hydraulic hoses and hose connections for wear or

leaks. Repair or replace any damaged hoses or

connections.

9

Transmission oil cooler and engine radiator for dirty

fins.

9

Back-up alarm and horn.

9

Forks for welded repairs, cracks, wear and

misalignment.

WARNING

Never repair forks by welding. Never use

forks with welded repairs. Forks may break

and falling load or forks may cause serious

injury or death.

9

Tires for cuts, bulges, correct tire pressure and

proper ballast content.

9

All wheel lugs.

9

Service and park brakes for proper operation.

9

All instruments, gauges and indicator lights.

9

The steering, left and right.

9

All control levers for proper operation.

9

Keep engine and radiat or clean and free of dirt and

flammable material.

9

The condition and operation of the seat belt and its

mounts.

9

Steps, pedals, and non-ski d surfaces. Make sure

they are clean and free of dirt, grease, oil, snow

and ice.

9

Placement and operation of doors, guards and

covers.

9

Cleanliness and operation of mirrors, window

wipers and work lights.

Note: If there is any indication that faulty equipment

exists, shutdown safely, inform the proper

authority and DO NOT operate the forklift until

the problem has been fixed.

Learn as much as poss ible about the work area before

operation. Walk around the worksite and inspect the

terrain th a t yo u w ill be tra ve lling on.

Make a not e of surfaces to be avoided, including…

•

Holes & Drop-offs.

•

Obstacles.

•

Soft mud & standing water.

•

Oil spills & slippery surfaces.

Note: I f any of the above conditions exist in the work

area, correct the condition before operating. If

the condition cannot be corrected, avoid

operation in the problem area.

When operating on docks, ramps or floors, check for

weak spots. Clear away trash and debris. Pick up

anything that could puncture a tire. When required,

check the forklift's maximum fully loaded ground

pressure weight if operating on a hollow floor system.

Watch for condit ions that could cause…

•

Loss of control.

•

A collision.

•

Tipover.

Check overhead clearances. Know the size of

doorways and canopies. Know exactly how much

clearance you have under power lines and telephone

lines.

All local, state/provincial and federal regulations must

be met before approaching power lines, overhead or

underground cables or other power sources with any

part of your forklift. Do not operate the machine near

energized power lines. Always contact the electrical

power company when operating near power lines. The

lines should be moved, insulated, disconnected, or

de-energized and grounded before operating in the

area. Keep all parts of the machine at least 50 feet away

from power lines.

19

Page 24

BEFORE OPERATING THE MACHINE

PLAN YOUR WORK

Before you operate, know how and where you will

travel, turn and pickup, lift and place loads.

Choose a smooth level route to prevent possible tipover

or loss of load.

If possible, avoid cro ssi n g…

•

Ruts.

•

Ditches.

•

Curbs.

•

Exposed railroad tracks.

Note: When these conditions cannot be avoided, keep

the load as low as possible and travel very

slowly and with extreme caution.

Know where there are any blind corner conditions on

the worksite. Before t urning a blind corner, stop, sound

your horn, and proceed slowly.

Always maintain safe dist ances between your forklift

and other equipment that may be on the worksit e.

Know the weights of all loads you may be expected to

transport before attempting to lift them. Avoid loads of

loose material if possible. Check that loads ar e properly

banded or strapped together.

If you will be placing l oads at high elevations, remember

your depth perception is decreased because of

distance. Use a signal person near the point where the

load is to be landed.

Insure that adequate clearance is provided between

both rear tail swing and front fork swing of the forklift to

avoid injury to personnel or damage to nearby

equipment.

An operator must not use drugs or alcohol which can

affect his alertness and coordination. An operator on

prescription or over-the-counter drugs needs medical

approval to safely operate these machines.

KNOW THE RULES

Most employers have rul es governing proper operation

and maintenance of equipment. Before you start work at

a new location, check with your supervisor or the safety

coordinator. Ask about rules you may be expected to

obey.

Make sure you understand the rules covering traf fic at

your jobsite. Make sure you recognize and understand

the meaning of all signs, flags, and markings. Make

sure you understand all hand, flag, whistl e, siren, or bell

signals. Make sure you know when to use lights, turn

signals, flashers and horn.

PROTECT YOURSELF

Wear all the protective clothing and personal saf ety

devices issued to you or called for by job conditions.

You may need:

•

A hard hat.

•

Safety shoes.

•

Safety glasses, goggles, or face shield.

•

Heavy gloves.

•

Hearing protection.

•

Reflective clothing.

Know where you will be expect ed to park your forklift at

the end of the work day, preferably in a level area out of

traffic. If the area i s on a slope or incline, posi tion the

forklift at right angles to the slope, set the parking brake,

lower the boom to the ground, and block the wheels.

Remember…

•

Be alert - know that conditions can change.

•

Use common sense - show that you are a

responsible operator.

•

Be a defensive operat or - prevent accidents before

they happen.

SAFE MACHINE OPERATION

For safe operation of this rough terrain forklift you must

be a qualified and authorized operator. To be qualified,

you must understand the written instructions supplied

by the manufacturer, have training (including actual

operation of this m achine) and know the safety rules

and regulations for the jobsite.

20

•

Wet weather gear.

•

Respirator or filter mask.

MOUNT AND DISMOUNT

PROPERLY

Always use “Three Point Contact” when mounting or

dismounting the machine. “Three Point Contact” means

that three out of four arms and legs are in contact with

the machine at all times during mount and dismount.

Clean your shoes and wipe y our hands before mount ing

machine. Always use hand-hold and step when

mounting.

Never use control levers as a hand-hold when mounting

or dismounting the machine. Never step on foot controls

when mounting or dismounting the machine.

Never attempt to mount a moving machine.

Page 25

GENERAL OPERATING PROCEDURES

CAUTION

STARTING PROCEDURES

Before operating, walk completely around the machine.

Make certain no one is under it, on it or cl ose to it. Let

all other workers and bystanders know you are

preparing to start the machine.

until everyone is clear.

DO NOT

To start engine...

1. Be properly seated.

2. Set park brake.

3. Move shift selector to NEUTRAL positio n. Place

the neutral lock lever to NEUTRAL LOCK

position.

4. Apply brakes.

5. Turn ignitio n switch clockw ise, cranking the

engine. (Do not crank the engine longer than 20

seconds. Wait 2 minutes to allow starter to cool

down before trying again.)

6. Allow engine to warm up.

The transmission requires 3 seconds

Note:

immediately after engine start for

self-diagnostics. Always wait at least 3 seconds

after engine start before engaging transmission.

7. In cold weather operation, progressively move

each function a small distance back and forth

until full cycle has been accomplished.

start machine

SHUTDOWN PROCEDURES

Correct shutdown is important to the safe operation of

the machine.

Always follow these steps:

1. Come to a full stop.

2. Set the park brake.

3. Lower boom to the ground.

operator’s compartment while the machine is

supporting a load.

4. Place transmission shift selector in NEUTRAL

position. Place the neutral lock lever to

NEUTRAL LOCK position.

5. Idle engine for 1–3 minutes for gradual cooling.

This is especially important for turbocharged

engines.

6. Shut off engine.

7. After the engine is shut off, move all hydraulic

levers. If any machine movement is detected, a

problem

be advised immediately.

machine into service until the problem has been

fixed.

8. Remove ignition key.

9. Lock anti-vandalism covers and closures.

10. Dismount.

exist and your supervisor should

MAY

DO NOT

DO NOT

leave the

put the

To make sure warm oil reaches the rear carriage

tilt cylinders, slowly raise and lower the boom

several times. Failure to cycle the rear carriage

tilt cylinders during cold machine start-up can

damage the cylinders and structure.

8. Level machine, move frame tilt full to the right,

then full to the left, then back to level.

9. Raise boom full up and full down. Extend inner

boom full out and retract full in.

10. Tilt attachment full down and full back.

1 1. Move transfer carriage ful l forward and full back.

It is your responsibility to evaluate working

Note:

conditions and adjust your operation of the

forklift accordingly.

1 1. Block wheels if on a slope or incline.

TRAVEL I NG

When traveling over rough terrain, soft

ground, or wet/ icy surfaces, slow dow n and

shift to a lower gear.

Travel only at speeds that permit stopping

in a safe manner.

When traveling, keep forks as low as

possible while maintaining safe clearance

with the ground.

Start and stop machine to check brakes.

Check park brake by holding on hill.

Check the three steering modes:

Round

Front Wheel

Oblique

21

Page 26

GENERAL OPERATING PROCEDURES

FOLLOW SAF E OPERATING

PROCEDURES

WARNING

ALWAYS LEVEL

MACHINE BEFORE

RAISING BOOM. NEVER

TILT FRAME WITH THE

BOOM RAISED.

MACHINE MAY TIP AND

CAUSE SERIOUS

PERSONAL INJURY OR

DEATH!

ALWAYS

machine before lifting a load. Lift only within the

capacity of the machine as shown by the load

chart.

Never tilt the frame when the boom is raised.

Operate the controls smoothly–don't jerk the

hydraulic controls or steering wheel.

Avoid sudden stops, starts, turns or changes in

direction.

Never “cowboy” or play games with a forklift.

check the load chart mounted in the

REAR OSCILLATION LOCK SYSTEM

The Rear Oscillation Lock System provides safety and

stability by prevent i ng the frame from rotating on the

rear axle.

The rear oscillation lock will be operational when any or

all of the following conditions apply:

1. When the boom angle exceeds 40°.

2. When the service brakes are applied.

3. If a system component fails.

When the boom angle is above 40°, the following

conditions apply:

1. Rear axle cylinder locks, preventing the frame

from rotating on the rear axle.

2. Transmission is disengaged.

3. Frame tilt function is disengaged.

Note: When the frame tilt function is disengaged, it

CANNOT be overridden by the operator unless

the boom angle is below 40°.

When the service brakes are depressed, the following

conditions apply:

Operate machine controls only while seated in the

operator's compartment.

Never leave the operator's seat without first

lowering the boom to the ground, setting the park

brake, and placing transmission in NEUTRAL.

WARNING

Keep all parts of your body inside the

operators compa rtme nt while oper ating the

rough terrain forklift.

DO NOT

boom, lift mechanism or transfer carriage areas.

DO NOT

the boom, lift mechanism or transfer carriage.

STAY ALE RT!

loose, or fail to operate on your machine, stop

work, shut down the machine and alert your

supervisor immediately.

touch, lean on, or reach through the

permit others to do so. Never climb on

Should something break, come

1. Rear axle cylinder locks preventing the frame

from rotating on the rear axle.

2. The rear oscillation lock cylinder can be unlocked

by the frame tilt function when the boom is below

40 °.

WARNING

ALWAYS LEVEL

MACHINE BEFORE

RAISING BOOM. NEVER

TILT FRAME WITH THE

BOOM RAISED.

MACHINE MAY TIP AND

CAUSE SERIOUS

PERSONAL INJURY OR

DEATH!

Lower the boom or release the service brake to

deactivate the rear oscillation lock system. If the system

does not deact ivate, a problem exists and must be

investigated.

22

Page 27

LIFT THE LOAD SAFELY

WARNING

GENERAL OPERATING PROCEDURES

Important:

1. If possible, plan to load, unload and turn on flat

level ground. If not level, use frame tilt (See

“Frame Tilt Control” on page 18) to level

machine. Level indicator

sure there is enough cl earance overhead and all

around for lifting and traveling. Watch the front

and rear clearances when turning.

2. If loads are to be handled several times, place

stacking blocks under l oads.

3. For sideshift equipped forklifts, center the forks

and carriage before lifting.

4. Inspect load to be lifted. Approach the load

slowly and squarely wi th fork tips straight and

level. Ad jus t pa llet for k s as ne ce s s ar y.

5. Engage the load by moving the transfer carriage

slowly forward until the load touches the fork

carriage backrest.

6. Tilt the forks back to position the load for travel,

then lift the load only enough to clear obstacles.

7. Fully retract the transfer carriage.

ALWAYS

in the machine before lifting a load. Lift

only within the capacity of the machine

as shown by the load chart.

check the load chart mounted

be centered. Be

MUST

TRANSPORT THE LOAD SAFELY

When transporting the load…

Keep the forks ti lted back with boom retract ed and

the load close to the ground.

When traveling over inclines, slopes or

ramps

…

Tilt the attachment back and raised only

enough to clear the ground.

Avoid turnin g. If it cannot be avoided, tu rn

slowly and with extreme caution.

Travel straight up and down the grades.

When loaded and traveling up or down

grades, travel with the load uphill.

When unloaded, tr avel only with the fo rks

or attachment downhill.

Proceed slowly and wit h ext reme cau t ion.

Do not travel across excessively steep

slopes or unstable surfaces.

Failure to follow these instructions may

result in serio us personal in jury or deat h.

Reduce speed and sound horn at blind

intersections, exits and when approaching

pedestrians.

Slow down for turns, ramps, dips, uneven or

slippery surfaces and in congested areas.

Avoid driving over loose objects and holes in

roadway surfaces to prevent losing the load or

tipping the machine.

Keep the load as low as possible. Never carry the

load above eye level.

Where the load will obst ruct the operator's visi on,

it is recommended that the forklift be operated i n

REVERSE

travel. Travel at a slower speed and get someone

to direct you.

Avoid excessively steep slopes or unstable

surfaces.

machine, keep the load low and proceed with

extreme caution.

circumstances, drive across excessive ly steep

slopes.

The machine can be levelled side -to-side a total

of 12.5° in each direction (22% grade). Any slope

or grade that exceeds this is considered

excessively steep.

If a slope is too steep to allow the frame to be

leveled, do not raise the boom. The frame must

always be level before raising the boom.

, looking backwards in the direction of

If you must drive on a slope, level the

DO NOT

, under any

23

Page 28

GENERAL OPERATING PROCEDURES

Avoid crossing ditches, curbs or exposed railroad

tracks. If crossing cannot be avoided, keep the

load as low as possible, travel very slowly, and

proceed with cauti on.

Avoid panic braking. Apply brakes smoothly for a

controlled stop to prevent toppling the load.

SAFELY PLACING THE LO AD

Elevated or Overhead Placement

Important:

When stacking or placing a load to a

high landing use extreme caution! There

may be other workers in the immediate

area you cannot see. Make sure that all

bystanders are away from the area

where the load could tip or fall.

W1042

4. Level the machine using frame tilt

load is raised. (See “Frame Tilt Control” on page

18)

DO NOT

forks are tilted to one side. If the forklift cannot be

positioned so the l oad is level before lifting,

reposition the forklift. The likelihood for forklift

tipover is greatly increased if the load is not level

before lifting.

raise the load for placement if the

BEFORE

WARNING

ALWAYS LEVEL

MACHINE BEFORE

RAISING BOOM. NEVER

TILT FRAME WITH THE

BOOM RAISED.

MACHINE MAY TIP AND

CAUSE SERIOUS

PERSONAL INJURY OR

DEATH!

5. Slowly and carefully raise the load. I f there is any

indication of instability during the lift (i.e.

movement, leaning, swaying), stop immediately,

lower the load, move the forklift to a more stable,

level position. As lift height increases, your depth

perception decreases. Placing the load safely at

a high elevation may require a signalman to

guide you.

6. When the load is slightly higher than the landing

point,

SLOWLY

.

stop the lift.

the

1. Be sure the landing point can safely support the

weight of the l oad. The chosen landing location

should be level , both front-to-back and

side-to-side.

You should know or be able to estimate the

weight and load center of the load that you will

be lifting. If you are unsure of the weight and load

center of the load, check with your supervisor or

with the supplier of the material.

the load chart mounted in the machine before

lifting a load. Lift only within the capacity of the

machine as shown by the load chart.

2. Drive as close as possible to the landing

location. Approach very slowly with the load as

low as possible.

3. Tilt carriage rearward to cradle the load.

ALWA YS

check

WARNING

Do not ram the hydraulic lift cylinder to the

end of its stroke. The jolt could spill the lo ad

resulting in serious person al injury or death.

24

Page 29

7. Use the transfer carriage to place the load

directly over the landing point. The transfer

carriage allows safe and easy placement of the

load without moving the machine. (Consult load

charts for transfer capacity.) Forks should be

level and parallel to the landing surface so that

they may be easily retracted from under the load.

Before retracting the forks, check landing point

for any excessive bowing, cracking noises or

other indications of overloading.

.

GENERAL OPERATING PROCEDURES

If there is any indication that the landing surface

cannot handle the weight of the load, place the

load at a different location that you know can

handle the weight. If the landing surface cannot

handle the weight of the load, pick the load back

up, lower it to the ground and lift a lighter load.

8. Lower the load slowly to place it and relieve the

weight from the forks. Retract the transfer

carriage until the forks are clear of the load.

Lower and retract the boom

the machine.

9. The forklift can now be moved from the landing

location to continue work.

BEFORE

moving

LIFTIN G PERSONNEL

LULL

the rough terrain forklift as a personnel lift. It is designed

for material handling ONLY. If personnel MUST be

lifted, lift only in accordance with ASME/ANSI B56.6

1992 , Para. 5.15 and with a properly designed work

platform.

®

strongly recommends that you DO NOT use

25

Page 30

FLUID & LUBRICANT SPECIFICATIONS

GENERAL FLUID AND LUBRICANT

SPECIFICATIONS

General Fluid & Lubricant Specifications

System or

Component

Fuel System

Hydra u lic

System

Engine Cooling

System

Engine Oil

Transmission See “Transmission Oil

Differential

(Front & Rear)

Planetary Hub Use 58 oz. SAE 90 API GL-5 and 4

1

1

1

Fluid or

Lubrica nt

See “Fuel Requirements”

Heavy Duty

Hydraulic Fluid

Ethylene Glycol/

Pure Water Mix

with additives.

See “Engine Oil Specifications”

Specifications”

Gear Lubricant SAE 90 API GL-5

oz. Friction Modifier, LULL

Specification

Amoco Rykon

MV or equiv.

Low silicate

Ethylene Glycol

ASTM D5345

ASTM D4985

®

P26720

ENGINE OIL SPECIFICATIONS

John Deere Engines

Use the table below to select the oil viscosit y based on

expected air temperature range during the period

between oil changes. Consult the John Deere

Operator’s Manual for additional information.

New John Deere engines use special break-in oil

Note:

for the initial period of operation. Consult engine

Operator’s Manual for additional information.

Engine Oil Selection Chart, John Deere

Engine Oil, John Deere

Oil Grade

SAE 5W-30 -22 to +86 °F -30 to + 30 °C

SAE 10W-30 -4 to +86 °F -20 to +30 °C

SAE 15W-40 +5 to 122 °F -15 to 50 °C

SAE 30W +32 to +86 °F 0 to +30 °C

SAE 40W +50 to +104 °F +10 to +40 °C

Arctic Oil (e.g.

MIL-L-46167B)

Approved Engine Oil Specifications

Temperature

Range °F

Below -22 °F Below -30 °C

Temperature

Range °C

Grease Points Grease Lithium-based

1. Consult engine manufacturer’s Operator’s

Manual for additional information.

API CD/ CE

CCMC Specification D4, D5

SAE 5W-30

SAE 10W-30

SAE 15W-40

SAE 30W

SAE 40W

MIL-L-46167B

26

Page 31

FLUID & LUBRICANT SPECIFICATION S

TRANSMISSION OIL

SPECIFICATIONS

The following table shows approved lubricants and

associated temperature ranges for use with ZF 3WG

and 4WG series transmissions.

Transmission Oil Selection Chart

ZF 3WG-100 & 4WG-100 Transmissions

Min. Oil

Oil Grade

Temperatu re

for Starting

Engine

Engine Oils

SAE 20W-20 +14 °F (-10 °C) +41 °F (+5 °C)

SAE 15W-40 +5 °F (-15 °C) +32 °F (0 °C)

SAE 10W,

10W-30,

10W-40

Automatic Transmission Fluid (ATF)

ATF -22 °F (-30 °C) +14 °F (-10 °C)

Approved Lubricants (Engine Oils)

API CD/ CE/ CF/ SF/ SG

MIL-L-2104 C/ D/ E

MIL-L-46152 C/ D/ E

SAE 10W

SAE 10W-30

SAE 10W-40

SAE 15W-40

SAE 20W-20

-4 °F (-20 °C) +23 °F (-5 °C)

Min. Oil

Temperature

for Engaging

Transmission

FUEL REQUIREMENTS

General

Diesel fuels are blended to meet the local temperature

requirements. The standard grades are:

1. 1D for temperatures -22 to +86 °F

(-30 to +30 °C).

2. 2D for temperatures +14 to +122 °F

(-10 to +50 °C)

There are two main classifications of diesel fuel in

general use:

1. Low-sulphur, “on-highway” diesel fuel.

2. Medium-sulfur, “off -highway” diesel fuel. This fuel

contains blue dye.

The engine manufacturer specifies the diesel fuel

requirements. Additional information can be found

below and in the engine manufacturer’s Operator’s

Manual.

Consult your local fuel distributor for the properties of

the diesel fuels available in your area.

John Deere Engines

Use of regular-sulfur “off-highway” diesel fuel is

recommended.

If low-sulfur “on-highway” diesel fuel is used, John

Deere Diesel Fuel Conditioner (TY22030) must be

added.

Use of low-sulfur fuel without the specified conditioner

may cause premature fai lure of the engine’s f uel system

components and void the warranty.

Automatic Trans mission Fluid (A TF) may on ly be used

at ambient temperatures below +14 °F (-10 °C)

27

Page 32

SERVICE/LUBRICATION SCHEDULE MODEL 644B-37

22 23242423 22 22 22

79

19

12

19 19

6

17

16

20

22 2324

252423 22

8

15 10

2222

12

1115 16 16

R1014

2821

14

28

16

13

26

2028

25

8

18

26

27

26

3

54

27

13

26

21

18

2

1

R1015

Page 33

SERVICE/LUBRICATION SCHEDULE MODEL 644B-37

SYSTEM CAPACITIES AND PRESSURES

HYDRAULIC SYSTEM & RESERVOIR 65 GALS PLANETARY HUB (EACH) 62 OZ (SEE NOTE 1)

FUEL TANK 40 GALS ACCUMULATOR (NITROGEN PRECHARGE) 400–425 PSI

COOLING SYSTEM 18 QTS TIRES — 13.00 X 24 PER TIRE

ENGINE CRANKCASE — JOHN DEERE 14 QTS PRESSURE 55 PSI

TRANSMISSION — DRAIN/REFILL (APPROX.) 11 QTS SODIUM CHLORIDE 115 LBS

DIFFERENTIAL 13 QTS WATER 33 GALS

HOURS OF OPERATION

# DESCRIPTION DAILY WEEKLY 20 50 100 200 500 1000 2000 REMARKS

1 ENGINE OIL C *CF CF SEE ENGINE MANUAL

2 ENGINE OIL FILTER *R R SEE PARTS BOOK

3 FUEL FILTER/WATER SEP. C R SEE PARTS BOOK

4 TRANSMISSION FLUID C *CF CF SEE OTHER SIDE OF CARD

5 TRANSMISSION FILTER *R R SEE PARTS BOOK

6 HYD. RESERVOIR FLUID C CF SEE OTHER SIDE OF CARD

7 HYD. RETURN FILTER C *R R SEE PARTS BOOK

8 HYD. PRESSURE FILTER C *R R SEE PARTS BOOK

9 HYD. TANK BREATHER CLN R SEE PARTS BOOK

10 AIR CLEANER C CLN R SEE PARTS BOOK

11 ENGINE COOLANT C CF SEE OTHER SIDE OF CARD

12 AXLE DIFFERENTIAL *CF C CF SAE 90 API-GL-5 LUBE

13 PLANETARY HUBS *CF C CF SEE NOTE 1

14 BOOM PIVOT LUBE 2 GREASE FITTINGS

15 HOIST PIVOTS LUBE 4 GREASE FITTINGS

16 TILT CYLINDER PIVO TS LUBE 6 GREASE FITTINGS

17 QUICK ATTACH PIV OT LUBE 1 GREASE FITTINGS

18 TRANSFER ROLLERS LUBE 4 GREASE FITTINGS

19 OSCILLATION PIVOTS LUBE 4 GREASE FITTINGS

20 FRAME TILT CYLINDER LUBE 2 GREASE FITTINGS

21 REAR AXLE LOCK CYLINDER LUBE 2 GREASE FITTINGS

22 STEER CYLINDERS LUBE 8 GREASE FITTINGS

23 STEER SPINDLES LUBE 8 GREASE FITTINGS

24 TIE ROD ENDS LUBE 4 GREASE FITTINGS

25 PARK BRAKE BELLCRANK LUBE 1 GREASE FITTINGS

26 DRIV E SHAFT U-JOINTS LUBE 4 GREASE FITTINGS

27 DRIVE SHAFT S LIP YOK ES LUBE 2 GREASE FITTINGS

28 BOOM PADS LUBE 2 FITTINGS + SLIDES

NOTES:

1) USE 58 OZ. SAE 90 API GL-5 & 4 OZ. FRICTION MODIFIER, LULL

®

P26720.

* FIRST HOURS OF OPERATION

C= CHECK, SERVICE AS NECESSARY

CF= CHANGE FLUID

R= REPLACE

CLN= CLEAN CAREFULLY

SHORTEN SERVICE INTERVALS

ACCORDINGLY WHEN OPERATING

UNDER DUSTY OR SEVERE

CONDITIONS.

INSPECT ALL FLUID SYSTEMS AND

CHANGE FLUID WHEN FLUID SHOWS

TRACES OF CONTAMINATION OR HIGH

TEMPERATURES, EVIDENCED BY

STRONG ODOR, DISCOLORATION, OR

SEPARATION.

R1013

29

Page 34

SERVICE/LUBRICATION SCHEDULE MODEL 644B-42

22 23242423 22 22 22

79

19

12

19 19

6

17

16

16

20

20

13

26

22 2324

252423 22

8

28

25

8

18

26

15 10

26

2222

13

3

12

1115 16 16

21

1

R1020

2821

14

18

2

30

27

26

27

54

R1021

Page 35

SERVICE/LUBRICATION SCHEDULE MODEL 644B-42

SYSTEM CAPACITIES AND PRESSURES

HYDRAULIC SYSTEM & RESERVOIR 65 GALS PLANETARY HUB (EACH) 62 OZ (SEE NOTE 1)

FUEL TANK 40 GALS ACCUMULATOR (NITROGEN PRECHARGE) 400–425 PSI

COOLING SYSTEM 18 QTS TIRES — 13.00 X 24 PER TIRE

ENGINE CRANKCASE — JOHN DEERE 14 QTS PRESSURE 55 PSI

TRANSMISSION — DRAIN/REFILL (APPROX.) 11 QTS SODIUM CHLORIDE 115 LBS

DIFFERENTIAL 13 QTS WATER 33 GALS

HOURS OF OPERATION

# DESCRIPTION DAILY WEEKLY 20 50 100 200 500 1000 2000 REMARKS

1 ENGINE OIL C *CF CF SEE ENGINE MANUAL

2 ENGINE OIL FILTER *R R SEE PARTS BOOK

3 FUEL FILTER/WATER SEP. C R SEE PARTS BOOK

4 TRANSMISSION FLUID C *CF CF SEE OTHER SIDE OF CARD

5 TRANSMISSION FILTER *R R SEE PARTS BOOK

6 HYD. RESERVOIR FLUID C CF SEE OTHER SIDE OF CARD

7 HYD. RETURN FILTER C *R R SEE PARTS BOOK

8 HYD. PRESSURE FILTER C *R R SEE PARTS BOOK

9 HYD. TANK BREATHER CLN R SEE PARTS BOOK

10 AIR CLEANER C CLN R SEE PARTS BOOK

11 ENGINE COOLANT C CF SEE OTHER SIDE OF CARD

12 AXLE DIFFERENTIAL *CF C CF SAE 90 API-GL-5 LUBE

13 PLANETARY HUBS *CF C CF SEE NOTE 1

14 BOOM PIVOT LUBE 2 GREASE FITTINGS

15 HOIST PIVOTS LUBE 4 GREASE FITTINGS

16 TILT CYLINDER PIVO TS LUBE 6 GREASE FITTINGS

17 QUICK ATTACH PIV OT LUBE 1 GREASE FITTINGS

18 TRANSFER ROLLERS LUBE 4 GREASE FITTINGS

19 OSCILLATION PIVOTS LUBE 4 GREASE FITTINGS

20 FRAME TILT CYLINDER LUBE 2 GREASE FITTINGS

21 REAR AXLE LOCK CYLINDER LUBE 2 GREASE FITTINGS

22 STEER CYLINDERS LUBE 8 GREASE FITTINGS

23 STEER SPINDLES LUBE 8 GREASE FITTINGS

24 TIE ROD ENDS LUBE 4 GREASE FITTINGS

25 PARK BRAKE BELLCRANK LUBE 1 GREASE FITTINGS

26 DRIV E SHAFT U-JOINTS LUBE 4 GREASE FITTINGS

27 DRIVE SHAFT S LIP YOK ES LUBE 2 GREASE FITTINGS

28 BOOM PADS LUBE 4 FITTINGS + SLIDES

NOTES:

1) USE 58 OZ. SAE 90 API GL-5 & 4 OZ. FRICTION MODIFIER, LULL

®

P26720.

* FIRST HOURS OF OPERATION

C= CHECK, SERVICE AS NECESSARY

CF= CHANGE FLUID

R= REPLACE

CLN= CLEAN CAREFULLY

SHORTEN SERVICE INTERVALS

ACCORDINGLY WHEN OPERATING

UNDER DUSTY OR SEVERE

CONDITIONS.

INSPECT ALL FLUID SYSTEMS AND

CHANGE FLUID WHEN FLUID SHOWS

TRACES OF CONTAMINATION OR HIGH

TEMPERATURES, EVIDENCED BY

STRONG ODOR, DISCOLORATION, OR

SEPARATION.

R1019

31

Page 36

SAMPLE LOAD CHART

40

12

INDICATES REAR

11

10

35

30

9

8

25

7

20

6

OSCILLATION LOCK

ENGAGED

TRANSACTION

80" (203 CM)

50°

60°

70°

MAXIMUM BOOM LOAD CAPACITIES AT

24" LOAD CENTER, FOR LIFT AND

REACH POSITIONS IN POUNDS AND

FEET WITH METRIC CONVERSIONS.

MANUFACTURER'S RECOMMENDED

CAPACITIES ARE IN CONFORMANCE

WITH ANSI/ASME B56.6 STABILITY

TESTS USING STANDARD

HOMOGENEOUS CUBES 4' × 4' × 4'.

MANUFACTURER'S RECOMMENDED

LOADS AND ANGLES SHOWN ARE AT

THE HORIZONTAL CENTER OF GRAVITY

OF THE ABOVE CUBE. CAPACITY

ADJUSTMENT MUST BE MADE FOR

EXTENDED LOAD CENTERS AND OTHER

VARIATIONS OF LOAD SIZE, ETC.

RATED LIFT CAPACITIES SHOWN ARE

WITH MACHINE ON A FIRM, LEVEL

SURFACE WITH UNDAMAGED,

PROPERLY INFLATED, BALLAST-FILLED

TIRES.

5

4

3

2

1

0

-1

FEET

METERS

15

10

G

K

K

0

0

5

0

4

9

/

/

S

S

B

B

L

L

0

0

5

0

0

0

0

1

2

G

G

K

0

6

3

1

/

S

B

L

0

0

0

3

0

F

G

H

I

TRANSACTION

80" (203 CM)

J

G

G

K

K

0

0

6

1

2

8

2

1

/

/

S

S

B

B

L

L

0

0

0

0

0

0

5

4

C

D

E

40°

G

K

0

30°

2

7

2

/

20°

S

B

L

10°

0

0

0

6

0°

-5°

A

B

CAPACITIES SHOWN DEPICT FULL BOOM

EXTENSION PRIOR TO TRANSACTION.

051015202530

0123456789

SAMPLE LOAD CHART

CONSULT LOAD CHART MOUNTED IN MACHINE

FOR YOUR MACHINE'S MODEL AND

OPTIONAL ATTACHMENT CAPACITIES

➊

VERTICAL SCALE SHOWS DISTANCE ABOVE AND BELOW GROUND LEVEL.

R1025

➋

HORIZONTAL SCALE SHOWS DISTANCE FROM FRONT WHEELS.

➌

BOOM ANGLE SCALE REPRESENTS THE BOOM ANGLE RELATIVE TO LEVEL GROUND.

➍

LETTERED ARCS SHOW THE AMOUNT OF BOOM EXTENSION AND THE ROTATION OF THE BOOM

AT THESE EXTENSIONS.

➎

LOAD AREAS SHOW MAXIMUM RATED LOAD CAPACITIES.

EACH AREA DEFINES THE CAPACITY THAT MAY BE LIFTED AN D PLA CED .

FOR EASE OF READING, HEAVY LINES AND DIFFERENT COLORS SEPARATE THESE AREAS.

➏

TRANSACTION AREA SHOWS THE ADDI TIONAL 80 INCH AREA THAT MAY BE REACHED BY MOVING

THE TRANSFER CARRIAGE WITH A FULLY EXTENDED BOOM. (Models 644B , 844C, and 1044C only.)

➐

THE AREA FILLED WITH RED DOTS SHOWS WHERE THE REAR AXLE IS LOCKED AND FRAME TILT

AND DRIVE ARE DISABLED. See “Rear Oscillation Lock System” on page 22.

32

Page 37

GENERAL OPERATING PROCEDURES - SUPPLEMENT

DRIVE LOCKOUT OVERRIDE

Important: Read and understand the following

instructions BEFORE using the optional

Drive Lockout Override System!

Theory of Normal Operation

This machine is equipped with a stabilization system

that does several things to increase lateral (side-toside) stability.

When the boom is raised above 20° elevation:

• The transmission is limited to first and second

gears.

• The rear oscillation lock cylinder is limited to slow

(orificed) movement.

• The speed of the frame tilt function is limited.

When the boom is raised above 40° elevation:

• The rear axle stabilization cylinder is locked,

preventing the frame from rotating on the rear axle.

• The transmission is disengaged, stopping drive

capabilities.

These functions help prevent tipover accidents which

can cause serious injuries and death. The

owner/operator manual describes the normal use and

operation of a telescopic handler and tells the operator

to carry the load and forks as low as possible, but not

above eye level.

The Rear Oscillation Lock System stops the machine

from driving when the boom angle is above 40°. Driving

with the boom elevated (loaded or empty) can be very

dangerous, especially on uneven terrain. The

machine’s center of gravity is highest when the boom is

elevated, which makes it less stable laterally as the

boom is raised higher. Improperly driving the machine

introduces dynamics that can add to instability and lead

to a tipover.

Diagram 2: Stability Rectangle (Front and rear

axles locked, preventing frame from rotating)

When the boom angle is below 20° the machine

operates with a freely oscillating rear axle to negotiate

rough terrain. (See Diagram 1)

When the boom angle is above 20°, the rear axle

cylinder is orificed, slowing movement of the frame on

the rear axle. This increases the lateral (side-to-side)

stability.

When the boom angle is above 40°, the rear axle

cylinder locks, preventing the frame rotating on the rear

axle. This changes the stability diagram from a triangle

to a rectangle (when viewed from above) and

substantially increases the machine’s lateral stability.

(See Diagram 2)

General Description, Drive Lockout

Override System

In some special applications, it is not possible to carry

or place the required load unless the machine is driven

with an elevated boom. The Drive Lockout Override

System is designed to allow this and MUST BE USED

WITH EXTREME CARE!

The Drive Lockout Override System does two things

when engaged with the boom angle above 40°:

• Allows the transmission to be engaged in first gear

only.

Diagram 1: Stability Triangle (Front axle locked and

frame free to rotate on rear axle)

Supplement P09836 Origin 1/98 1

• Unlocks the rear oscillation lock cylinder and

allows very slow (orificed) movement. This

increases dynamic lateral stability while the

machine is being driven.

Page 38

GENERAL OPERATING PROCEDURES - SUPPLEMENT

Operation of the Drive Lockout Override

System

To operate the Drive Lockout Override System:

WARNING

WARNING

Failure to follow the instructions in this

supplement and the owner/operator manual

may result in serious personal injury or

death!

Note: These procedures only apply to situations where

the boom is above 40° elevation.

1. Plan your route of travel. The surface must be

firm and as level as possible. Always avoid rough

or steep areas.

2. Level the frame before picking up the load. If

load is suspended (slung load), make sure tag

lines are secure and manned. Never let a slung

load sway, as this may lead to machine tipover or

injury to personnel.

3. With the brakes on, move the shift selector to the

Forward or Reverse position.

4. Using your left foot, press and hold down the

Drive Lockout Override Switch. The drive will

engage in first gear only and the machine may

be moved.

5. Drive the machine very slowly, while carefully

watching the terrain. Make turns smoothly and

slowly.

6. Use the service brakes to stop the machine

slowly and smoothly. Releasing the Drive

Lockout Override Foot Switch will disengage the

drive, but this will not activate the brakes.

ALWAYS LEVEL MACHINE

BEFORE RAISING BOOM.

WHEN DRIVE LOCKOUT

OVERRIDE IS USED TO MOVE

MACHINE WITH BOOM

ELEVATED, FRAME LEVEL CAN

CHANGE WITH CHANGING

TERRAIN. ADJUST FRAME TILT

TO KEEP FRAME AND BOOM AS

LEVEL AS POSSIBLE WHILE

DRIVING. NEVER EXCEED ± 5°

FROM LEVEL.

LEVEL FRAME SLOWLY AND

CAREFULLY.

FAILURE TO FOLLOW THE

INSTRUCTIONS IN THIS

SUPPLEMENT AND THE

OWNER/OPERATOR MANUAL

MAY RESULT IN SERIOUS

PERSONAL INJURY OR DEATH!

2 Supplement P09836 Origin 1/98

Page 39

To: JLG, Gradall, Lull and Sky Trak product owner:

If you now own, but ARE NOT the original purchaser of the product covered by this manual, we would like

to know who you are. For the purpose of receiving safety-related bulletins, it is very important to keep JLG

Industries, Inc. updated with the current ownership of all JLG products. JLG maintains owner information for each

JLG product and uses this information in cases where owner notification is necessary.

Please use this form to provide JLG with updated information with regard to the current ownership of JLG

Products. Please return completed form to the JLG Product Safety & Reliability Department via facsimile (717) 4856573 or mail to address as specified on the back of this form.

NOTE: Leased or rented units should not be included on this form.

Mfg. Model:

Serial Number:

Previous Owner:

Address:

City: State:

Zip: Telephone: ( )

Date Of Transfer:

Current Owner:

Address:

City: State:

Zip: Telephone: ( )

Who in your organization should we notify?

Name:

Title:

JLG Industries, Inc.

TRANSFER OF OWNERSHIP

Thank you,

Product Safety & Reliability Department

JLG IIndustries, IInc.

1 JLG Drive

McConnellsburg, PA 17233-9533

Telephone: (717) 485-5161

Fax: (717) 485-6573

Please cut on the dotted line and fax to 717-485-6573

Page 40

Page 41

Page 42

McConnellsburg PA. 17233-9533

JLG Worldwide Locations

Corporate Office

JLG Industries, Inc.

1 JLG Drive

USA

Phone: (717) 485-5161

Fax: (717) 485-6417

JLG Industries (Australia)