Operating Instructions

LAA

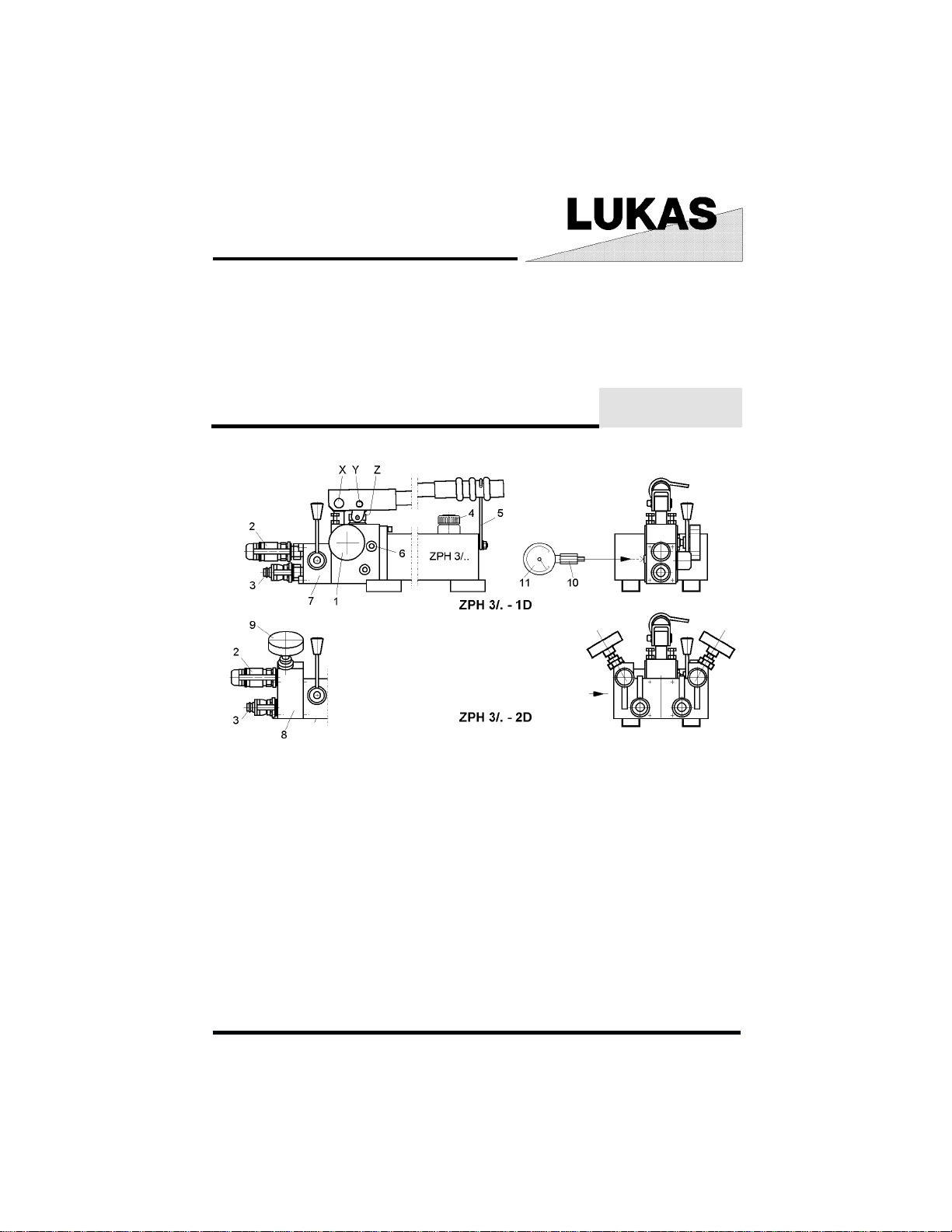

Hand pump ZPH 3 /. - .

1 drain valve Hand pump

2 Quick connect socket StMu-61O

3 Quick connect plug StNi-61

4 Venting- / filling cap

5 Clamp

6 Pressure limiting valve

7 4/2-way valve N4/2W

8 2D block

9 Control valve 2D block

possible accessories

10 pressure gauge connector MA2

11 Pressure gauge

84072/6680-85 GB

Issue 7.99

1

1 Basic operation and designated use of the machine

1.1 The machine has been built in accordance with state-of-the-art standards and the recognized

safety rules. Nevertheless, its use may constitute a risk to life and limb of the user or of third

parties, or cause damage to the machine and to other material property.

1.2 The machine must only be used in technically perfect condition in accordance with its

designated use and the instructions set out in the operation manual, and only by safety-conscious

persons who are fully aware of the risks involved in operating the machine. Any functional disorders,

especially those affecting the safety of the machine/plant, should therefore be rectified immediately!

1.3 The machine is exclusively designed for the use described in the operating manual. Using

the machine for purposes other than those mentioned in the manual, such as driving and controlling

other pneumatic systems, is considered contrary to its designated use. The manufacturer/supplier

cannot be held liable for any damage resulting from such use. The risk of such misuse lies

entirely with the user.

Operating the machine within the limits of its designated use also involves observing the instructions

set out in the operating manual and complying with the inspection and maintenance directives.

2 Organizational measures

2.1 The operating manual must always be at hand at the place of use of the machine!

2.2 In addition to the operating instructions, observe and instruct the user in all other generally

applicable legal and other mandatory regulations relevant to accident prevention and environmental protection.

This also applies for wearing protective clothing, helmet with visor or goggles and protective

gloves.

2.3 In order to avoid innjuries, the machine must only be operated by a specially trained operator

who has undergone a safety training.

2.4 Observe all safety instructions and warnings attached to the machine. Make sure that safety

instructions and warnings attached to the machine are always complete and perfectly legible.

2.5 Never make any modifications, additions or conversions which might affect safety without

the supplier's approval. This also applies to the installation and adjustment of safety devices and

valves.

2.6 Spare parts must comply with the technical requirements specified by the manufacturer.

Spare parts from original equipment manufacturers can be relied to do so. It is only allowed to use

original LUKAS spare parts of LUKAS system components.

2.7 Replace hydraulic hoses at the specified or adequate intervals, even if no defects are detected

which might affect safety. This must be done after 10 years, at the latest!

2.8 Adhere to prescribed intervals or those specified in the operating manual for routine checks

and inspections.

2.9 Make sure to dispose properly of packing material and dismounted parts!

3 General safety instructions

3.1 In the event of malfunctions, stop the machine immediately and lock it. Have any defects rectified

immediately.

2

3.2 Before starting up or setting the machine in motion and during operation of the machine make

sure that nobody is at risk.

3.3 Before transporting the machine always check that the accessories have been safely stowed

away.

3.4 Make sure that there is enough lighting during work.

3.5 Avoid any operation that might be a risk to machine stability.

3.6 Check the machine at least after every operation for obvious damage and defects. Report any

changes (incl. changes in the machine’s working behaviour) to the competent organization /person

immediately. If necessary, stop the machine immediately and lock it. All lines, hoses and screwed

connections have to be checked for leaks and obvious damage. Repair damage immediately.

Splashed oil may cause injury and fire.

3.7 All safety equipment has to be checked for completeness and flawless condition:

- instruction markings and warning signs (safety instructions)

- check safety cover (e.g. motor-safety covers, heat protection etc.) if they are available and if they

are in good condition.

3.8 Working under loads is not allowed if they are only lifted by hydraulic cylinders. If the work is

indispensable sufficient mechanical supports are needed additionally.

3.9 Do not stress hoses mechanically (pulling, buckling etc.).

4 Instructions for maintenance and service

4.1 For the execution of maintenance and service work, tools and workshop equipment adapted

to the task on hand are absolutely indispensable.

Work on the hydraulic system must be carried out only by personnel having special knowledge and

experience with hydraulic equipment.

4.2 Before putting into operation clean the machine, especially connections and threaded unions,

of any traces of oil, fuel or preservatives before carrying out maintenance/repair. Never use

aggressive detergents. Use lint-free cleaning rags and pay attention that the components are

meticulously clean during reassembling after repair.

4.3 During dismantling of machines it is necessary to collect the outrunning hydraulic liquids

completely, so that they cannot reach the ground. They have to be disposed properly according to

the instructions.

4.4 Always tighten any screwed and thread connections that have been loosened during

maintenance and repair. Observe the stipulated torques.

4.5 Work on the electrical system or equipment may only be carried out by a skilled electrician

himself or by specially instructed personnel under the control and supervision of such electrician

and in accordance with the applicable electrical engineering rules.

4.6 The electrical equipment of machines is to be inspected and checked at regular intervals.

Defects such as loose connections or scorched cables must be rectified immediately.

4.7 Aggressive material (acid, lye, solvent, vapour) can damage the machine. It is necessary to

clean the whole machine if it must be exceptionally operated under such conditions or gets into

touch with these materials. Additionally, the machine must be checked as described under 3.6.

3

5 Safety Instructions for Hydraulic hoses

All instructions as to safe use of hydraulic hoses can be found in the booklet HR 1495 35 219

deliverd with the hoses.

6 Intended use

The hand pump ZPH 3/... serves mainly for operation of LUKAS double-acting cylinders. Jt must

be used only in connection with components out of the LUKAS Rerailing System or the Hydraulik

Tools System 50 MPa, resp. 70 MPa.

An operation of cylinders other than LUKAS is possible, but it must be approved by LUKAS in

each individual case.

Warning

The system operating pressure must not exceed the pressure rating of the lowest rated component

in the system.

Warning

NEVER set the relief valve to a higher pressure than the maximum rated pressure of the pump.

Higher settings may result in equipment damage and/or personal injury.

7 Description

All ZPH/ series hand pumps have the two-stage design, i. e. they are working with two different

speeds:

a high speed in the low-pressure range (LP) for fast extension of a cylinder without load and a low

speed in the high-pressure range (HP) for controlled extension of a cylinder with a load resting on

it.

Switch-over from low to high pressure mode is done automatically by a factory-preset switch-over

valve (see also technical data).

8 Putting into Operation

8.1 Preparing the pump

The pump is to be connected to a hydraulic cylinder by means of suitable hydraulic hose pairs.

Permissible hose pairs (red/blue)

- 5m (ref. 84072/1764)

- 10m (ref. 84072/1765)

The hose pair (with quick couplers) is to be connected directly to the quick couplers on the pump

head: red hose to connection A, blue hose to connection B.

Before pumping: Open the oil filter cap (4) by approx. 1/2 rotation (turn left) and swing away the

clamp (5)

8.2 Connection of hose coupling to cylinder and hand pump

Before coupling, remove the dust protection covers and unlock the connect socket with adjusting

ring by turning it. Withdraw the sleeve and connect plug and socket while holding the sleeve in

this position. Release the sleeve and set the showglass to „red“ with the adjusting ring. Now the

parts are connected and locked. Decoupling is done in the reverse order.

4

8.3 Venting the cylinder

Connect the cylinder with the pump. Extend the piston by half its stroke and turn the cylinder so

that the piston is facing downwards. The highest point of the cylinder must be on a lower level

than the pump. Fully extend the piston and retract again so that eventual air bubbles can escape

into the oil container of the pump.

Remark:

The oil filler cap of the pump must be open during bleeding.

9 Operation of one double-acting cylinder

- fully close the hand wheel (1) by turning it clockwise

- switch the hand lever on the 4/2-way (7) valve to position A or B

(extension or retraction).

- activate the cylinder by operating the pump lever. Observe safety

remarks as per para 11.1 !

10 Operation of two double-acting cylinders

- fully close the hand wheel (1) of the hand pump and the

hand wheels (9) on the block 2D by turning it clockwise

- switch the hand lever on the 4/2-way (7) valve to position A or B

(extension or retraction).

- To effect extension resp. retraction of one or both cylinders switch

the hand lever on the 4/2-way (7) valve to position A or B . A synchronism

of both cylinders can be achieved by different opening / closing of the hand wheels.

Observe safety remarks as per para 11.1 !

for Pos. 9 and 10:

The 4/2-way valve (N4/2W) itself does not have such a function.

Load can be sustained when the hand wheel (1) is fully closed. The lever of the N4/2W valve must

thereby stay in position „extending“.

11 Lifting a load

11.1 Safety remarks as to safe use of the hand pump

Caution!

NEVER add extensions to pump handle. Extensions cause unstable pump operation.

Warning!

In certain situations the pump handle can "kick back". Always keep your body to the side of the

pump, away from the line of force of the handle.

Note

To reduce handle effort at high pressure, take short strokes. Maximum leverage is obtained in the

last 5 degrees of stroke.

11.2 Observe „Safety measures prior to and during lifting“ as per separate operating

manual of your LUKAS cylinder.

12 Lowering a load (pressure release)

12.1 Open the oil filling cap (4) on the reservoir a few turns

12.1.1To retract the piston of the cylinder, open the drain valve of the pump carefully (..1D resp.

on the block ..2D) (rotation to the left). Closing the drain valve (rotation to the right) will interrupt the

drain process. By means of fine adjustment of the drain valve, an extremely precise retraction of

the piston of the cylinder is facilitated.

5

12.2 Special function „quick stop“

If you open the drain valve rapidly (rotation to the left), an existent quickstop only for 50 MPa

cylinders StMu61-M (silver) is activated, i.e. a non-return valve, incorporated in the quick-connect

coupling, will prevent the oil from flowing back. While the hose is at zero pressure, the cylinder

remains under pressure. Pump and cylinder can now be separated and the pump can be used

elsewhere.

The "quickstop" also serves as a safety valve if for some reason the hose is damaged. The

quickstop will in this case prevent the load from falling.

In order to release the quickstop, the pressure in the cylinder must be increased with a few pump

slaps. This will re-open the non-return valve in the quick-connect plug StNi 6. The draining can

now be continued.

12.3 Uncoupling pump and cylinder

Before uncoupling the pump from the cylinder, make sure (by opening the drain valve) that there

is no pressure and that the piston is completely retracted.

Remount the protection caps after uncoupling in order to avoid pollution of the coupling parts.

Close the oil reservoir filler cap, so that no oil is spilled during transport.

12.4 Adjustment of the maximum pressure (50 MPa)

or if necessary of a lower pressure

Check adjusted pressure with closed drain valve.

Adjust pressure limiting valve (item 6, see cover page) as follows:

- Unscrew the screw plug 6.1 (SW5), with the hexagonal socket-head wrench

(SW4) adjust the nut 6.2 to the intended pressure.

Note:

Rotation to the right = pressure increase; Rotation to the left = pressure relief.

The pressure can be seen on the connected pressure gauge.

Caution: Observe para 6 of this operating manual!

13 Servicing and Maintenance

Oil should be changed once a year. In case of frequent use or operation in particularly dusty

environment, oil should be changed every six months.

13.1 Adding Oil to the Pump

Warning: Always add oil with cylinders fully retracted (extended if pull cylinders) or the system will

contain more oil than the reservoir can hold.

- Remove vent/fill cap from reservoir.

- Fill reservoir only to level mark shown on pump.

- Remove air from system if necessary. See 8.3. Recheck oil level after removing air.

- Return vent/fill cap to proper position.

- Make sure no dirt gets into the oil reservoir or into the pump, as this will cause malfunction.

- To extend pump life and improve performance, lubricate the beam pin X, cross pin Y and

piston head Z regulary, using roller bearing grease (see cover page).

6

14 Trouble shooting

Problem Possible Cause Solution

Cylinder does not

advance,

advances slowy,

or advances in

spurts.

Cylinder

advances, but

does not hold

pressure

Cylinder does not

retract, retracts

part way, or

retracts more

slowly than

normal

If the defects cannot be repaired, contact an authorised LUKAS dealer or the LUKAS service

department. The address:

LUKAS Hydraulik GmbH, Weinstraße 39, 91058 Erlangen, P.O.B. 2560, 91013 Erlangen,

Germany, service phone 09131/698 348; fax 09131/698 353

Oil level in pump reservoir is low. Add oil according to the Maintenance instructions on 12.1

Drain valve open Drain valve closed

Loose hydraulic coupler Check that all couplers are fully tightened

Load is too heavy Do not attempt to lift more than rated tonnage

Air trapped in system Remove air according to the instructions on page 8.3

Cylinder plunger binding

Leaking connection Check that all connections are tight and leak free

Leaking seals

Internal leakage in pump

Drain valve closed Open drain valve

Pump reservoir is over-filled

Loose hydraulic coupler Check that all couplers are fully tightened

Air trapped in system Remove air according to the instructions 8.3

Hose I.D. too narrow Use larger diameter hydraulic hose

Cylinder retraction spring broken

or other cylinder damage

Check for damage to cylinder; have cylinder by a

authorised dealer or LUKAS themselves

Locate leak(s) and have equipment serviced by

authorised dealer or LUKAS themselves

Have pump serviced by a authorised dealer or LUKAS

themselves

Drain oil level to full mark. See 12.1 instructions for

adding oil

Have cylinder serviced by a authorised dealer or LUKAS

themselves

15 T echnical dat a

epyTD1-8/3HPZD1-4/3HPZ

.onredrO0866/270480466/27048

)*aPM(erusserpgnikroW05

)l(yticapaclioelbasU/yticapacliO8/5,014/52,5

)³mc(PH/PLyreviledliOekortsnotsiprep2,4/8,01

)*aPM(revo-hctiwscitamotuA81

)mm(hxwxlsnoisnemiD281x032x519281x031x519

)gk(liohtiwthgieW2,8151

* 10bar = 1 MPa

7

epyTD2-8/3HPZD2-4/3HPZ

.onredrO5866/270488466/27048

)*aPM(erusserpgnikroW05

)l(yticapaclioelbasU/yticapacliO8/5,014/52,5

)³mc(PH/PLyreviledliOekortsnotsiprep2,4/8,01

)*aPM(revo-hctiwscitamotuA81

)mm(hxwxlsnoisnemiD281x062x049

)gk(liohtiwthgieW8,026,71

* 10bar = 1 MPa

15.1 Oil recommendations

For LUKAS hydraulic devices, use mineral oil in accordance with DIN 51 524 and others

Range of oil temperature Viscosity rating Remarks

A - 24... + 30°C HL 5

B - 18... + 50°C HLP 10

C - 8... + 75°C HLP 22

D + 5... + 80°C HLP 32

E - 8... + 70°C HF - E15 biodegradable

Recommended viscosity range: 10 ... 200 mm²/s, delivered with HLP 10 to DIN 51 524

LUKAS Hydraulik GmbH

A Unit of IDEX Corporation

Weinstraße 39, 91058 Erlangen • Germany

Postfach 2560, 91013 Erlangen • Germany

Telefon +49 (0)9131/698-0 • Telefax +49 (0)9131/698-394

84072_6680_e.P65

© Copyright 1999 LUKAS Hydraulik GmbH

8

Loading...

Loading...