Page 1

Operating Instructions

OPUS20E

For external sensors

BA-OP20E-01-EN

Page 2

Table of Contents

Please read this manual carefully. These instructions are designed to ensure

that your data logger is used for the purpose for which it was intended and to

guarantee that you get the maximum benefit from your product.

Contents Page

1. Safety Instructions 2

2. Intended Purpose and Use 2

3. Features 3

4. Scope of Delivery 4

5. Preparations Prior to Use 4

5.1. Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5.1.1. Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . .4

5.1.2. Installing the SmartGraph Software . . . . . . . . . . . . . . . . .4

5.1.3 Preparing the Data Logger Configuration . . . . . . . . . . . . .4

6. Operating the Data Logger 4

6.1. Powering ON / OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

6.2. Basic Settings and Operating Modes . . . . . . . . . . . . . . . . . . . . . . .4

6.2.1. The Four Operating Modes . . . . . . . . . . . . . . . . . . . . . . . .5

6.2.2. Network Function (M51) . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.2.3. Factory Setting (M52) . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.2.4. Acoustic Function (M53) . . . . . . . . . . . . . . . . . . . . . . . . . .5

7. Connecting and Configuring External Sensors 6

7.1 BUS Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

7.1.1 Connecting BUS Sensors . . . . . . . . . . . . . . . . . . . . . . . . .6

7.1.2 Configuring BUS Sensors (M6x) . . . . . . . . . . . . . . . . . . . .6

7.1.3 Logging off BUS Sensors (M7x) . . . . . . . . . . . . . . . . . . . .6

7.2 Connecting Analog Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

7.2.1 Voltage Measurement Sensors: 0 - 1V . . . . . . . . . . . . . . .7

7.2.2 Voltage Measurement Sensors:

2-wire 4 - 20 mA and 3-wire 0 - 20 mA . . . . . . . . . . . . . .7

7.2.3 Pt100 Sensors in 3-wire and 4-wire Circuit . . . . . . . . . . .7

7.2.3 Thermocouples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

7.3 Configuring Analog Sensors (M81) . . . . . . . . . . . . . . . . . . . . . . . .7

8. Measurement Value Display and Data Logging 8

8.1. Channel Groups and Measurement Channels . . . . . . . . . . . . . . . .8

8.2 Calculation Channels for Measurement Conversion . . . . . . . . . . .10

8.3. Displaying Measurement Values . . . . . . . . . . . . . . . . . . . . . . . . .10

8.4. Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

9. Alarm Function 10

9.1. Alarm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

9.2. Alarm Symbol on the Display . . . . . . . . . . . . . . . . . . . . . . . . . . .10

9.3. Acoustic Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

9.4. Using the Alarm Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

10. Cleaning and Maintenance Instructions 11

10.1. Replacing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

10.2. Installation During Mobile Operation . . . . . . . . . . . . . . . . . . . . . .11

10.3. Mounting the Logger on a Wall . . . . . . . . . . . . . . . . . . . . . . . . . .11

10.4. Changing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

11. Technical Data 12

12. Error Codes 13

These operating instructions describe the functions of the hardware.

There is also a separate software manual available. This manual shows you

how to configure your data logger and how to use the software. The manual

can be accessed using the Help function as soon as it has been installed.

Your new data logger was designed and manufactured in line with the latest

technological advancements and complies with the requirements as laid down

in existing European and national guidelines. Conformity has been certified. The

relevant declarations and documents are in the possession of the manufacturer.

As the user you must read and adhere to the following safety instructions in

order to ensure that this condition is maintained and that no danger results

from the use of this device:

1. Safety Instructions

We do not accept any liability for any damages which might occur as a result of

improper use or the non-observance of these instructions. The guarantee expires

with immediate effect in any such case.

These instructions must be read in full before this measuring

device is put into operation for the first time.

For reasons of safety and CE compliance you may on no account carry out any

changes or modifications on either the device itself or any other components

which may be used in connection with this measuring device.

The following instructions must be adhered to before

the device is taken into use :

• Do NOT carry out measurements on live components.

• Please observe the sensor measuring range.

• Please observe the operating and storage conditions.

• The user is solely responsible for determining whether he or she

considers the measurement results to be valid and for any conclusions that

are reached or any measures that are taken as a result thereof. We can

neither guarantee the validity of any measurement results nor can we

accept liability for any such results. We are on no account able to accept

liability for any damage which may be caused as a consequence of

the use of these measurement results.

2. Intended Purpose and Use

Data logger OPUS20E is used to detect and log various measurement variables

which the measuring instrument collects using connected external sensors.

The measurement data can be logged, called up or saved to a connected PC at

randomly selectable intervals.

This measuring device may only be used within the specified technical specifications for the purpose for which it was intended.

Any other use is considered to be improper and constitutes a violation of these

conditions.

This product should not be disposed of in your general waste. Please

ensure that it is disposed of in an orderly manner in accordance with

existing regulations.

This publication replaces all previous publications. No part of this publication may be reproduced, processed using

electronic systems, replicated or distributed in any way without our prior written authorisation. Subject to technical

modifications. All rights reserved. Names of goods are used without guarantee of free usage and used for the most part

according to the manufacturers syntax. The names of goods used are registered and should be considered as such.

We reserve the right to modify the design in the interest of ongoing product improvement, such as shape and colour

modifications. The scope of delivery may vary from that in the product description. All due care has been taken

in compiling this document. We accept no liability for any errors or omissions.

EN

Operating Instructions OPUS20E For external sensors

2

Page 3

3. Features

Battery compartment

Battery compartment lid

USB micro B port

RJ45 network connection

Mounting rail

LCD display :

Measurement value line 1

Measurement value line 2

Measurement value line 3

Display symbol acoustic signal active

Display symbol network connection active

Display symbol USB connection active

Display symbol power supply via mains

Display symbol power supply via USB

Display symbol battery capacity

Display symbol mode marker

Display symbol logging active

Display symbol logging inactive

Date display

Time display

Mode selection key

Data logger for connecting external sensors

5-pin circular connector M12 for connecting up to

four digital bus-compatible sensors:

Pin 1: Sensor power supply (output)

Pin 2: Data 1

Pin 3: Data 2

Pin 4: GND (reference potential)

Pin 5: n.c. (not connected)

10-pin connector with two independent input channels

for connecting up to two analog sensors:

Pin 1: Terminal +24V (input, external power supply OPUS20E (24 V)

for stationary operation)

Pin 2: Terminal GND (supply voltage GND)

Pin 3: Terminal A1

Pin 4: Terminal B1

Pin 5: Terminal C1

Pin 6: Terminal D1

Pin 7: Terminal A0

Pin 8: Terminal B0

Pin 9: Terminal C0

Pin 10: Terminal D0

EN

Operating Instructions OPUS20E For external sensors

3

Page 4

4. Scope of Delivery

he following components are contained in the standard scope of delivery:

T

• Data logger

• USB cable

• CD-ROM with operating instructions, SmartGraph software

and software manual

• 4 x AA batteries

• Factory certificate

5. Preparations Prior to Use

5.1. Software

Start the SmartGraph software. The program recognises the connected data

logger automatically and adds the data logger to the existing data logger list.

The data logger can now be configured using the software.

You will find more detailed information on the software in the software

manual which you can call up using the Help function of your

SmartGraph software.

Functions of the Professional Version

You will find information on the possibility of upgrading your SmartGraph software

o the professional version (Device Licence Upgrade) in the software manual.

t

6. Operating the Data Logger

The SmartGraph PC software forms the central configuration interface for your

data logger. All further changes to the configuration or display can only be

carried out using the software.

5.1.1. Installation Requirements

Your SmartGraph software has to be installed on to a PC that fulfils the following

requirements in order for you to be able to configure your data logger and read

out the measurement results that have been recorded.

Supported operating systems:

• Windows XP from Service Pack 3 (32 bit or 64 bit version)

• Windows Vista (32 bit or 64 bit version)

• Windows 7 (32 bit or 64 bit version)

Hardware requirements:

• Processor speed: at least 1.0 GHz

• CD ROM drive

• USB or RJ45 network connection

• At least 512 MB main storage

• At least 4 GB free hard disk storage

• Adobe Acrobat Reader software

5.1.2. Installing the SmartGraph Software

Place the CD ROM in the drive of your PC and follow the instructions of the

installation assistant to install the software.

5.1.3 Preparing the Data Logger Configuration

First of all, connect the external sensors as required for measurement purposes

to the external connections on your data logger.

You will find information about connecting and configuring appropriate

sensors in chapters 7 and 11. To connect external sensors, first follow

the instructions in chapter 7 and then return to this section to continue

commissioning.

The next step is to connect the data logger to your PC using the USB cable provided as part of the delivery. The SmartGraph software detects the measuring

instrument automatically.

Alternatively, if a network function is enabled you can also configure your data

logger via a LAN connection on your local network. You will find more information

about the network function in chapter 6.2.2.

You can use the mode selection keys on your data logger

to carry out basic settings directly.

You can also use the software to lock the mode selection keys. In such a case

the data logger cannot be configured via the mode selection keys.

6.1. Powering ON / OFF

The data logger cannot be switched off completely when connected to a functioning power supply. It can, however, be switched to a low-energy power mode

(M1) which allows it to consume as little power as possible. The data logger is

inactive in this mode and therefore unable to carry out measuring or logging or

display any values. You will find an overview of the four different modes in the

following chapter.

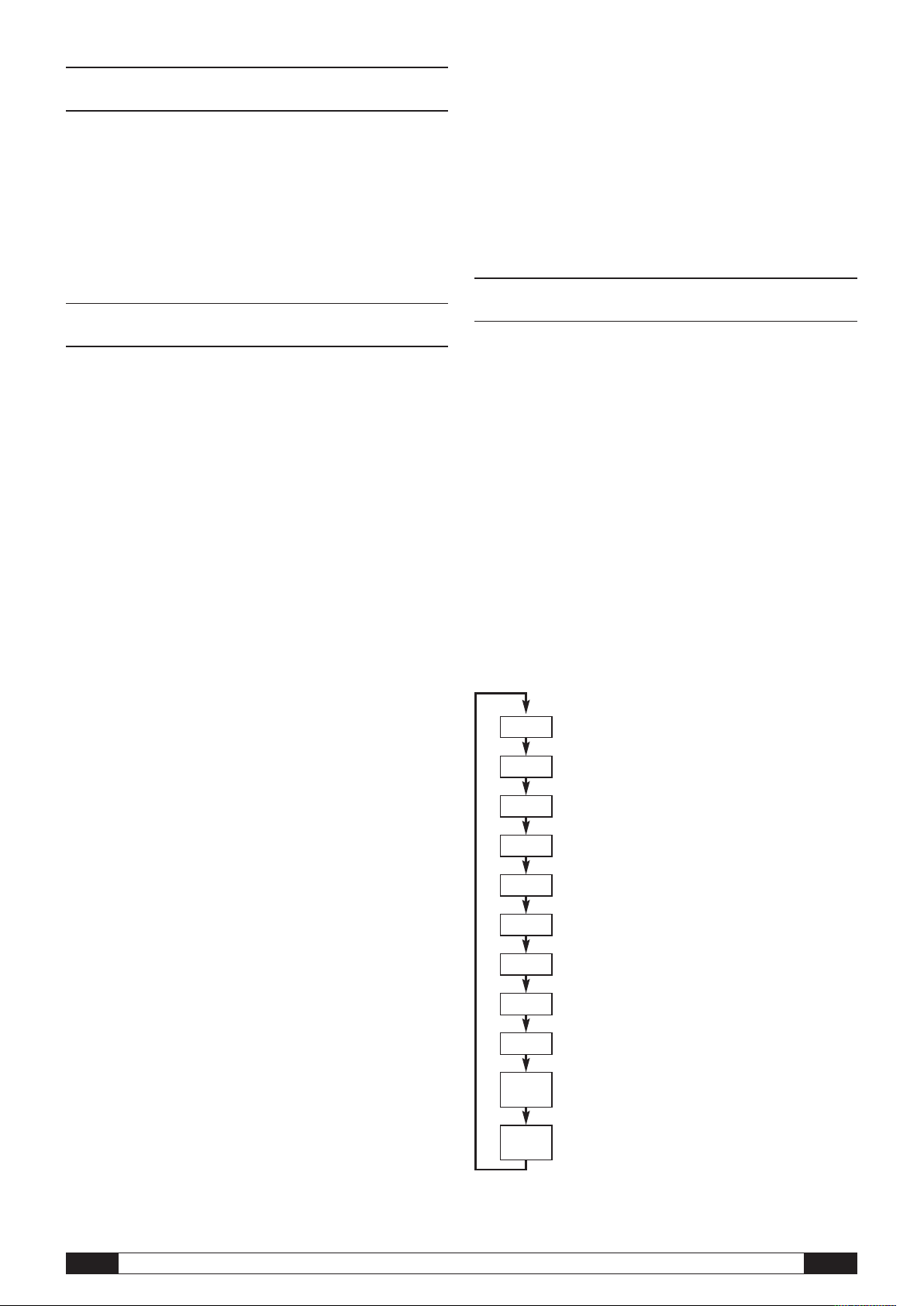

6.2. Basic Settings and Operating Modes

The mode selection key on the data logger can be used to

M1

M2

M3

M4

M51

M52

M53

M6x

M7x*

M81

An 0

M81

An 1

configure eleven basic settings as follows: four basic operating

modes, network function, global settings reset, acoustic function and various settings for configuring external sensors.

Press the mode selection key briefly to access the settings

level which you have currently selected.

Press the mode selection key again to navigate from one setting mode to another.

The selected mode will appear on the display for a maximum

of four seconds. During this time the mode can be selected.

During this time, the mode marker (M1, M2, M3, M4, M51,

M52, M53, M6x, M7x, M81 (An0), M81 (An1)) flashes in the

lower left corner of the display.

Press the mode selection key longer (approx. 1 second) to

confirm your selection.

The data logger will then change into the selected mode.

If you do not confirm your selection within this four-second

period, then the device will leave the settings level and return

to the mode that had previously been selected.

* The function is only available if a BUS sensor

is logged on before (M61)

EN

Operating Instructions OPUS20E For external sensors

4

Page 5

.2.1. The Four Operating Modes

6

Operating mode M1

Select operating mode M1 Display operating mode M1

The logging function is inactive. The word “OFF” appears in measurement value

line 1. The “STOP” symbol is active.

In this mode (data logger factory setting), the energy consumption is low, because

there are not yet any measurement values which could be called up or displayed.

Operating Mode M2

No values are displayed in any of the three lines that normally display measurements. Up to a total of 20 measurement channels, which have all been previously

selected using the SmartGraph software, can be saved into the measurement

memory. The message “REC” (data logging active) appears where the saved

easurement values are normally displayed.

m

6.2.2. Network Function (M51)

Select network function M51 Display example of the network function M51

If the data logger is connected to a local network and the network function is active, then the software can be configured and the data can be read out from the

data logger via this network.

A signal transmitted by the data logger via UDP enables the SmartGraph software to find the data logger in the local network automatically.

When the data logger is connected to the network for the first time (add network

device), you may have to use the SmartGraph software to adapt the data logger

network settings to conform with the existing network configuration. The factory

setting is DHCP.

Select operating mode M2 Display example for operating mode M2

The measuring function is active. The measurement values that were configured

using the SmartGraph software are displayed in all three measurement value

lines together with the previously selected sampling rate.

The logging function is not active in this operating mode. The displayed values

are not saved into the memory. The word “STOP” (data logging inactive) appears

where the saved measurement values are normally displayed.

Operating Mode M3

Select operating mode M3 Display example for operating mode M3

The measuring and logging functions are active. The measurement values that

were configured using the SmartGraph software are displayed in all three measurement value lines together with the previously selected sampling rate.

In addition a total of 20 measurement channels that have all been previously selected using the SmartGraph software can be saved into the measurement

memory. The message “REC” (data logging active) appears where the saved

measurement values are normally displayed.

You will find more detailed information on the software in the software

manual which you can call up using the Help function of your SmartGraph

software.

The professional version of the SmartGraph software also allows you to call up

and log current measurements and measurement values that have been saved

in the data logger at random intervals via the network.

Use and Power Supply in Network Operation

If you intend to use the network card over a longer period, the data logger must

be mounted on a wall.

The data logger consumes more power when the integrated network card is used.

When the network function has been activated, the data logger checks the network status automatically at regular intervals.

If an active local network cannot be identified, the data logger deactivates the

network function independently after 12 minutes.

There is also an optionally available PoE model. This model can be powered

directly from the mains.

6.2.3. Factory Setting (M52)

This function allows you to reset all

the settings of your device to the factory settings.

Operating Mode M4

Select operating mode M4 Display operating mode M4

The measuring and logging functions are active.

The display is deactivated.

EN

Operating Instructions OPUS20E For external sensors

Select reset function M52

6.2.4. Acoustic Function (M53)

The data logger has an acoustic signal which can be turned on or off by

activating or deactivating the acoustic function. A symbol appears on the display

when the acoustic function is activated.

5

Page 6

When the acoustic function is activated, an alarm signal alerts the user when

an alarm incident occurs. The alarm for one or more than one measurement

must have been previously set using the SmartGraph software.

elect acoustic function M53 Display example of the acoustic function M53

S

When the acoustic function is activated, the data logger also emits a tone each

time the mode selection key is pressed while navigating through the individual

levels or when a specific mode is selected.

The data logger also emits a tone when you leave the settings level without a

previous selection having been made.

7. Connecting and Configuring

External Sensors

The data logger has a 5-pin, circular connector (M12) for connecting digital,

bus-compatible sensors (BUS sensors) and a 10-pin connector with two independent input channels for connecting up to two analog sensors.

7.1 BUS Sensors

7.1.1 Connecting BUS Sensors

Attach the BUS sensor to the 5-pin circular connector on the data logger (see

, chapter 3). The sensor is powered via the connector.

The last two digits represent the sensor number and are assigned automatically

according to the log on sequence - from 01 for the first logged on sensor to 04

for the fourth logged on sensor.

Once the sensor has been logged on, a message indicating the BUS ID is also

shown for your information – the message symbol flashes in the lower right corner of the display. You can close this message display by briefly pressing the

mode selection key.

Tip: For future measurements, make a note of the

R

BUS ID directly on the sensor.

isplay example: Select log on function

D

M61 to log on the first BUS sensor (n1).

If several sensors are to be used, in accordance with this procedure each individual sensor must first be connected to the data logger, logged on and registered

with a BUS ID.

Alternatively, you can also configure the BUS sensors directly

using the SmartGraph software.

You will find more detailed information on the software-related aspects

concerning the configuration of BUS sensors in the software manual which

you can call up using the Help function of your SmartGraph software.

isplay example: Message display

D

indicating the BUS ID (71.01) for the first

ogged on BUS sensor.

l

7.1.3 Logging off BUS Sensors (M7x)

By using up to three Y-junctions (option), up to four digital

BUS sensors can be connected to the data logger.

You will find more information about the BUS sensors

that are currently available in the technical data

in chapter 11.

7.1.2 Configuring BUS Sensors (M6x)

In order to use BUS sensors with the data logger, each BUS sensor first has to

be individually logged on to the data logger.

The configuration process is only available when the data logger is not

in the logging mode (M3 or M4).

You can configure BUS sensors on the data logger as described below. Alternatively, you can also do this directly using the SmartGraph software. You will

find more detailed information about configuring sensors using the software

in the software manual, which you can call up using the Help function of

your SmartGraph software.

To configure on the data logger, connect the first BUS sensor to be logged on to

the 5-pin circular connector of the data logger and then - as described in

chapter 6.2 - use the mode selection key to navigate to configuration mode

M6x. The option to register the BUS sensor is shown on the display (n1 for the

first sensor to n4 for the fourth sensor).

You can initiate the registration of the BUS sensor by briefly pressing the mode

selection key. The display then switches to the scan mode and the connected

BUS sensor is automatically detected and identified.

Display example: Select log off function

M70 to log off the first logged on sensor.

To log off a BUS sensor that was previously logged on to the data logger, use

the mode selection key to navigate to configuration mode M7x. The option to remove the first BUS sensor is displayed.

It is not necessary to connect the sensor to the device in order to log off.

If several BUS sensors were logged on earlier and you want to remove a sensor

other than the first one, press the mode selection key repeatedly until the

BUS ID of the sensor to be removed is displayed.

You can now initiate the logging off of the BUS sensor by briefly pressing the

mode selection key. Once the sensor has been logged off, a message indicating

the BUS ID is also shown for your information – the message symbol flashes in

the lower right corner of the display. You can close this message display by

briefly pressing the mode selection key.

Display example: Message display

indicating the BUS ID (71.01) of the

logged off BUS sensor.

7.2 Connecting Analog Sensors

The data logger has a 10-pin connector with two independent input channels

for connecting up to two analog sensors. Input channel 1 with pins 1, 3, 5, 7

and 9 and input channel 2 with pins 2, 4, 6, 8 and 10 (see , chapter 3).

On identification the sensor is given a four digit BUS ID. The first two digits of

this ID represent the sensor type (for example 71 for TFF sensors).

EN

Operating Instructions OPUS20E For external sensors

Each of the two input channels supports the sensor configurations detailed

in the following sub-sections.

6

Page 7

D0 / D1

B0 / B1

C0 / C1

Pt100

D0 / D1

B0 / B1

A0 / A1

C0 / C1

Pt100

TC+

TC(-)

B0 / B1

A0 / A1

Sensor

.2.1 Voltage Measurement Sensors: 0 - 1V

Ri

+-

S

ensor

B

0/B1

A0 / A1

GND

Sensor: 4 … 20 mA

External voltage source

A0 / A1

+24V

Sensor

GND

Sensor: 0/ 4 … 20 mA

External voltage source

A0 / A1

+24V

Sensor

7

The positive pole of the voltage source is connected to terminal B and the

negative pole is connected to terminal A, as shown in the diagram:

Important: The voltage input is a true differential input. If the sensor

is connected to the data logger by means of cables of excessive

length, it may be necessary to connect the sensor using shielded cables.

The cable shield must be connected to the GND terminal.

To log on and configure voltage measurement sensors on the data logger,

follow the instructions in chapter 7.3.

7.2.2 Voltage Measurement Sensors:

2-wire 4 - 20 mA and 3-wire 0 - 20 mA

The circuit supports voltage measurements in 2-wire and 3-wire operation.

The prerequisite for 2-wire operation is that the reference potential of the

power supply to the sensor and the power supply to the OPUS20E must be identical. In 2-wire and 3-wire operation, the power supply to the sensor is fed

via terminal A0/A1.

.2.3 Pt100 Sensors in 3-wire and 4-wire Circuit

7

In the case of the 3-wire circuit, the Pt100 sensor is connected to the measurement circuit using 3 wires. The measuring current is fed into the sensor via line

D0/D1. The resistance of the Pt100 sensor is determined from the terminal voltages B0/B1, C0/C1 and D0/D1:

mportant: The OPUS20E is capable of compensating line

I

resistances of up to 10 Ω. Compensation typically reduces the

effect of the line resistance by a factor of 100.

In the case of the 4-wire circuit, the Pt100 sensor is connected to the measurement circuit using 4 wires. The measuring current is fed into the sensor via

lines D0/D1 and C0/C1. The resistance of the Pt100 sensor is determined from

the terminal voltages B0/B1 and A0/A1:

Connection diagram for voltage measurement

using the 2-wire technique:

The sensor current is converted into a voltage at a burden resistor in the

OPUS20E. The burden resistor has a resistance of <50 Ω. Both the sensor and

the OPUS20E can be powered via an external voltage source.

Connection diagram for voltage measurement

using the 3-wire technique:

For precise temperature measurement, the 4-wire circuit is preferable.

To log on and configure Pt sensors on the data logger,

follow the instructions in chapter 7.3.

7.2.3 Thermocouples

The data logger supports the connection of type J, K and S thermocouples. The

positive pole of the thermocouple is connected to terminal B and the negative

pole is connected to terminal A:

Important: Pay attention to polarity when

connecting thermocouples.

To log on and configure thermocouples on the data logger,

follow the instructions in chapter 7.3.

This circuit is used for sensors with power consumption greater than 4 mA,

for example heated gas sensors.

To log on and configure voltage measurement sensors on the data logger, follow

the instructions in chapter 7.3.

EN

Operating Instructions OPUS20E For external sensors

7.3 Configuring Analog Sensors (M81)

In order to use analog sensors with the data logger, the specification of the

analog sensors must be correctly configured on the data logger.

The configuration process is only available when the data logger is not in

the logging mode (M3 or M4).

To configure the specification of a sensor for the first input channel, use the

mode selection key as described in chapter 6.2 to navigate to configuration

mode M81 (AN0); or to configure the specification of a sensor for the second

input channel, use the mode selection key to navigate to configuration mode

M81 (AN1). The option to configure the first analog sensor is shown on the

display.

7

Page 8

No sensor assignment is pre-set during initial commissioning at the factory. In

the case of subsequent configurations, the last pre-set specification is assigned.

By holding down the mode selection key, you can now switch to the configuration

menu for the analog sensor specification.

Press the mode selection key repeatedly until the desired sensor specification

is displayed. Finally, confirm the desired sensor specification by holding down

the mode selection key.

Once the sensor has been logged on, a message indicating the selected

sensor configuration is also shown for your information – the message

symbol flashes in the lower right corner of the display. You can close

this message display by briefly pressing the mode selection key.

Sample LCD displays: Sensor specification for logging on an analog

sensor to the first input channel (AN0):

election of a Pt100 sensor using the

S

4-wire technique.

Selection of a type K thermocouple. Status display showing that a type K

tatus display showing that a Pt100

S

sensor using the 4-wire technique is

ogged on to the first input channel.

l

hermocouple is logged on to the first

t

input channel.

Selection to specify no sensor assignment

n the first input channel.

o

Selection of a voltage measurement

sensor 0 - 1 V.

Selection of a current measurement

sensor using the 2-wire technique.

Status display showing that no sensor is

ogged on to the first input channel.

l

Status display showing that a voltage

measurement sensor 0 - 1 V is logged on

to the first input channel.

Status display showing that a current

measuring sensor using the 2-wire technique is logged on to the first input channel.

election of a type J thermocouple

S

on the first input channel.

Selection of a type S thermocouple

on the first input channel.

tatus display showing that a type J

S

thermocouple is logged on to the first

nput channel.

i

Status display showing that a type S

thermocouple is logged on to the first

input channel.

8. Measurement Value Display and

Data Logging

8.1. Channel Groups and Measurement Channels

Each measurement variable captured by a connected sensor - in the defined

unit of measurement - represents one channel group.

Selection of a current measurement

sensor using the 3-wire technique.

Selection of a Pt100 sensor using the

3-wire technique.

EN

Status display showing that a current

measuring sensor using the 3-wire technique is logged on to the first input channel.

Status display showing that a Pt100

sensor using the 3-wire technique is

logged on to the first input channel.

Operating Instructions OPUS20E For external sensors

For example, a temperature sensor with defined units of measurement in °C or

°F represents two channel groups (temperature in °C and temperature in °F).

The number of channel groups which a BUS sensor can measure depends on

the sensor type. For example, the type TFF BUS sensor can measure seven different channel groups.

Analog sensors for measuring voltage or current can only measure one channel

group; analog sensors for measuring temperature can measure two channel

groups (°C and °F).

Again, four measurement channels are available for each channel group for the

purpose of data logging: current measurement (curr), minimum measurement

(min), maximum measurement (max) and mean measurement (mean).

With full sensor assignment and a total of four connected type TFF BUS sensors

and two connected analog Pt100 sensors, the data logger is capable of capturing

measurements from a total of 32 channel groups and 128 measurement channels, as shown in Table 1.

8

Page 9

Table 1: Summary of Channel Groups (Measurement Variables) and Measurement Channels available on the Data Logger

Sensor

assignment

Sensor type Channel group

(measurement

variable)

Unit Calculation

channels

available for

measurement

conversion

Temperature °C – curr min max mean

Temperature °F – curr min max mean

BUS

sensor 1

For example

TFF sensor BUS class 71

Dew point °C – curr min max mean

Dew point °F – curr min max mean

Relative humidity % – curr min max mean

Absolute humidity g/m³ – curr min max mean

Mixing ratio g/kg – curr min max mean

Temperature °C – curr min max mean

Temperature °F – curr min max mean

BUS

sensor 2

(with Yjunction)

For example

TFF sensor BUS class 71

Dew point °C – curr min max mean

Dew point °F – curr min max mean

Relative humidity % – curr min max mean

Absolute humidity g/m³ – curr min max mean

Mixing ratio g/kg – curr min max mean

Temperature °C – curr min max mean

Temperature °F – curr min max mean

BUS

sensor 3

(with Yjunction)

For example

TFF sensor BUS class 71

Dew point °C – curr min max mean

Dew point °F – curr min max mean

Relative humidity % – curr min max mean

Absolute humidity g/m³ – curr min max mean

Mixing ratio g/kg – curr min max mean

Temperature °C – curr min max mean

Temperature °F – curr min max mean

BUS

sensor 4

(with Yjunction)

For example

TFF sensor BUS class 71

Dew point °C – curr min max mean

Dew point °F – curr min max mean

Relative humidity % – curr min max mean

Absolute humidity g/m³ – curr min max mean

Mixing ratio g/kg – curr min max mean

Analog

sensor 1

on input

channel 1

(An0)

Analog

sensor 2

on input

channel 2

(An1)

Voltage measurement 0 - 1 V Voltage V V

Current measurement using 2-wire technique 4 - 20 mA Current strength mA curr min max mean

Current measurement using 3-wire technique 0 - 20 mA Current strength mA curr min max mean

Pt100 temperature measurement using 3-wire technique Temperature °C – curr min max mean

Pt100 temperature measurement using 3-wire technique Temperature °F – curr min max mean

Pt100 temperature measurement using 4-wire technique Temperature °C – curr min max mean

Pt100 temperature measurement using 4-wire technique Temperature °F – curr min max mean

Temperature measurement using type K thermocouple Temperature °C – curr min max mean

Temperature measurement using type K thermocouple Temperature °F – curr min max mean

Temperature measurement using type J thermocouple Temperature °C – curr min max mean

Temperature measurement using type J thermocouple Temperature °F – curr min max mean

Temperature measurement using type S thermocouple Temperature °C – curr min max mean

Temperature measurement using type S thermocouple Temperature °F – curr min max mean

Voltage measurement 0 - 1 V Voltage V V

Current measurement using 2-wire technique 4 - 20 mA Current strength mA curr min max mean

Current measurement using 3-wire technique 0 - 20 mA Current strength mA curr min max mean

Pt100 temperature measurement using 3-wire technique Temperature °C – curr min max mean

Pt100 temperature measurement using 3-wire technique Temperature °F – curr min max mean

Pt100 temperature measurement using 4-wire technique Temperature °C – curr min max mean

Pt100 temperature measurement using 4-wire technique Temperature °F – curr min max mean

Temperature measurement using type K thermocouple Temperature °C – curr min max mean

Temperature measurement using type K thermocouple Temperature °F – curr min max mean

Temperature measurement using type J thermocouple Temperature °C – curr min max mean

Temperature measurement using type J thermocouple Temperature °F – curr min max mean

Temperature measurement using type S thermocouple Temperature °C – curr min max mean

Temperature measurement using type S thermocouple Temperature °F – curr min max mean

Yes,

see

Table 2

Yes,

see

Table 2

Measurement channels

available for data logging

(max. 20 channels storable)

and display (max. 3 channels

displayable)

curr min max mean

curr min max mean

EN

Operating Instructions OPUS20E For external sensors

9

Page 10

Table 2: Available Calculation Channels for Measurement Conversion

Assignable units:

Assignable sensor types:

counts, logic, digits, °C, °F, K, °Cdp, °Fdp, %rH, g/kg, g/m³, µm, mm, cm, dm, m, km, in, mil, ft, mi, m/s, km/h, kts, ppm,

mV, V, mA, A, Hz, kHz, bar, mbar, Pa, mPa, hPa, kPa, m³, l, s, ms, µs, %, °, mm/h, m³/h, l/m², in/h, mil/h, g, kg

Temperature, relative humidity, absolute humidity, dew point, battery voltage, voltage, current, absolute air pressure, relative air pressure,

building moisture, flow velocity, mixing ratio, CO2 concentration, particle 0.1 µm, particle 0.2 µm,

particle 0.3 µm, particle 0.5 µm, particle 1 µm, particle 5 µm, particle 10 µm, particle x µm, particle y µm, particle z µm,

unknown, inactive, cooling limit temperature, global radiation, daylight, precipitation amount, wind speed,

wind direction, analog/digital input, soil moisture, leaf wetness

8.2 Calculation Channels for

Measurement Conversion

Using the SmartGraph software, analog sensors that deliver a current or voltage

value can be used as calculation channels for measurement conversion. Calculation channels allow input variables from analog sensors that deliver a current

or voltage value to be converted into the actual measurement variable. Units of

measurement, conversion parameters and decimal place settings can be specified and assigned to a sensor type (see Table 2).

You will find more detailed information on how to use the software to

configure calculation channels in the software manual which you can call up

via the Help function of your SmartGraph software.

8.3. Displaying Measurement Values

One of the channel groups specified in Table 1 can be configured to display

measurement values on each of the three lines provided on the display for this

purpose. The current measurement is always displayed.

8.4. Data Logging

When you select operating mode M3 or M4, the data logger is in the logging

mode (REC) and the measurement values of the measurement channels pre-selected for logging are stored in the device.

Up to 20 of the measurement channels specified in Table 1 can be logged in parallel and stored in the memory of the measuring device.

Logging begins immediately as soon as operating mode M3 or M4 is selected

and is executed in the ring mode. This means that logging does not end when

the memory is full but is permanently ongoing. For this purpose, the oldest

values are continuously overwritten with the most recent data.

Tip: The current, minimum, maximum and mean measurement values

R

of a channel group represent an individual measurement channel in

each case. If you want these measurements to be available for subsequent

documentation and analysis, each of these measurement channels must be

pre-selected for logging at the memory organization level, as subsequent

computation of these measurements is not available on the software side.

Using the software, you can set up the individual specifications for the type,

duration and scope of data logging in the logging mode. You will find detailed

information about this in the software manual.

9. Alarm Function

Please note: The alarm function will only be displayed for the channel groups

of the three measurement channels which have been previously selected to

be displayed and only in the operating modes M2 and M3.

Alarm incidents of further selected measurement channels in logging mode are

saved regardless of whether they have been selected to be displayed or not.

This means that alarm incidents of measurement channels that have not been

selected for display but which have been selected for logging will be saved.

All selected alarm incidents are also recorded when the display has been deactivated in operating mode M4.

9.2. Alarm Symbol on the Display

The alarm will only appear on the display for measurement values which

have been selected to be displayed and

which have been configured with an active alarm function. When an alarm has

been triggered on one of these meas-

Display example for an alarm incident

of the measurement channel displayed

in the first measurement line.

The alarm symbol stops flashing as soon as the measured value is within the selected thresholds. The alarm symbol remains on the display.

This is to show the user that an alarm has been triggered and that an alarm incident has occurred. If the threshold values are exceeded again, then the alarm

symbol starts to blink again.

The alarm symbol disappears when the memory is read out.

Alarm display

Upper alarm

threshold value

Set value

corridor –

“Good sector”

Lower alarm

threshold

value

Flashing

Static

urement channels, an alarm symbol appears next to the measurement value

for this specific channel. The symbol continues to flash until the measurement

value returns to the preset corridor.

Logging mode

Reading out the value memory

9.1. Alarm Configuration

The data logger management can be used to configure an alarm for each individual measuring channel which has been selected for display or logging.

First you must define both an upper and a lower alarm threshold so as to set a

corridor within which the values are deemed to be good. The data logger triggers the alarm as soon as the measured value is outside this corridor, i.e. one

of the thresholds has been exceeded.

EN

Operating Instructions OPUS20E For external sensors

A hysteresis can also be set which switches off the alarm when the measured

value is once again within the corridor.

9.3. Acoustic Alarm

When an alarm is triggered when the acoustic function is active (see chapter

6.2.4. Acoustic Function), an alarm tone sounds in addition to the alarm symbol

on the display. The logger stops emitting the tone when the measured value is

within the corridor.

10

Page 11

.4. Using the Alarm Hysteresis

9

If you use the alarm function with an alarm hysteresis, the alarm will be trig-

ered and recorded every time the alarm thresholds are exceeded.

g

If the corridor between the selected alarm thresholds is very narrow, the alarm

will be triggered more often.

Only use batteries which are permissible according to the technical specifications.

Other battery types can cause faults. Do NOT use rechargeable batteries.

Do NOT dispose of used batteries in your household waste. Do NOT throw into

an open fire or water. Please dispose of these batteries in a proper manner in

accordance with existing regulations.

If, for example, you have selected 24°C as your upper alarm threshold for the

room temperature and 10°C for your lower alarm threshold and the room temperature fluctuates between 23.5 and 25°C during the entire measuring period,

then this would lead to the alarm being triggered and recorded much more often

than would perhaps otherwise be the case during a normal measuring period.

In order to prevent this from happening, you can set an alarm hysteresis. By

doing so you are defining a value which has to be reached in the selected value

corridor, the so-called “good sector” to switch off the alarm.

The alarm hysteresis is set to 1°C in the previous example. This means that the

alarm will be triggered when the measured value has exceeded 24°C and then

switched off again when it reaches 23°C.

pper alarm

U

threshold value

et value

S

orridor –

c

“Good sector”

Lower alarm

threshold

value

Flashing

Static

Upper alarm

threshold value

Alarm display without hysteresis

Logging mode

10.2. Installation During Mobile Operation

The data logger can be placed at any random position during mobile operation.

Please make sure that the permissible ambient conditions are observed

(see Technical Data). Because of its compact size, the data logger can be easily

concealed during mobile operation.

10.3. Mounting the Logger on a Wall

If stationary logging is to be carried out, the data logger can be mounted on a

wall or fixed to a mounting rail. A mounting rail is included in the scope of

delivery.

The wall mount must be used if the logger is being used in

network operation. You will find more information on

network operation in chapter 6.2.2.

10.4. Changing Locations

A change of location, i.e. from a cold to a warm place (for example when the device has been left in a car overnight before being brought into a warm room for

measuring), can lead to condensation forming on the printed circuit board.

This physical phenomenon, which cannot be avoided through any change in the

construction of such a measuring device, will invariably lead to incorrect readings.

Please wait approximately 5 minutes to give the device enough time to adapt to

its new surroundings before carrying out measuring.

Set value

corridor –

“Good sector”

Lower alarm

threshold

value

Flashing

Static

Alarm display with hysteresis

Logging mode

10. Cleaning and Maintenance

Instructions

10.1. Replacing the Batteries

When the message “LO bAtt” appears on the display,

the batteries have to be replaced.

The data logger cannot log data while the batteries are being

replaced. If you have to interrupt a logging process, please ensure

that the data logger is set to operating mode M1 or M2 before the

batteries are replaced.

Open the battery compartment and remove the used batteries. Place the new

batteries in the battery compartment. Make sure that the poles are properly

aligned.

HYSTERESIS

The clock continues to give the correct time for at least a minute while the

batteries are being replaced.

EN

Operating Instructions OPUS20E For external sensors

11

Page 12

11. Technical Data

Data logger OPUS20E for external sensors

Measuring range 0 … 1 V

Voltage Input

0 - 1 V

Accuracy ±200 µV ± 0.1% of measurement

Resolution < 500 µV

Measuring range 2-wire operation: 4 … 20 mA, 3-wire operation: 0 … 20 mA

Current Measurement

K-type Thermocouple

J-type Thermocouple

S-type Thermocouple

Pt100

Accuracy ± 4 µA ± 0.1% of measurement

Resolution < 5 µA

Burden resistor approx. 50 Ω

Measuring range -200°C … 1,200°C

Accuracy

Resolution < 0.2 °C

Measuring range -200°C … 1,200°C

Accuracy

Resolution < 0.2 °C

Measuring range -50°C … 1,700°C

Accuracy

Resolution < 0.2 °C

Measuring range -200°C … 500°C

Accuracy ± 0.2°C ± 0.1% of measurement

Resolution < 0.02°C

Sampling interval 10 / 30 s, 1 / 10 / 12 / 15 / 30 min, 1 / 3 / 6 / 12 / 24 h

± 1°C ± 0.5% of measurement at -200°C … 0°C,

± 1°C ± 0.2% of measurement at 0°C … 1,200°C

± 1°C ± 0.5% of measurement at -200°C … 0°C,

± 1°C ± 0.2% of measurement at 0°C … 1,200°C

± 1°C ± 0.5% of measurement at -50°C … 0°C,

± 1°C ± 0.2% of measurement at 0°C … 1,700°C

Memory Organization

Equipment and

Dimensions

Power Supply

Permissible Operating/

Ambient Conditions

Scope of Delivery

Storage interval 1 / 10 / 12 / 15 / 30 min, 1 / 3 / 6 / 12 / 24 h

Data storage 16 MB, approx. 3,200,000 measurements

Data logging up to 20 parallel measurement channels

LC display W 90 x H 64 mm

Housing Plastic

Dimensions L 180 x W 32 x H 78 mm

Weight approx. 250 g

Interfaces USB, LAN, RS485 (sensor BUS)

Internal

External

Air temperature -20°C to +50°C

Relative humidity 0 to 95% RH, < 20 g / m³ (non-condensing)

Altitude 10,000 m above sea level

Standard

battery service life > 1 year (dependent on connected sensors and configuration)

connectors for external voltage source for power supply to sensors

Measuring instrument, CD ROM containing SmartGraph 3

PC software for graphic and numeric representation of the measurement data analysis

and operating manual, USB connection cable and batteries

4 x LR6 AA batteries,

USB, LAN (PoE version),

EN

Optional Measuring instrument in PoE version, TFF sensors

Operating Instructions OPUS20E For external sensors

12

Page 13

12. Error Codes

Sensor Status Measuring range Code

Negative polarity approx. < -0.024 V 0x53 (CHANNEL_UNDERRANGE)

Threshold range -0.024 V … 0.000 V Displayed: 0.000V

… 1 V

0

4 … 20 mA

0 … 20 mA

Normal operation 0.000 V … 1.000 V

Threshold range 1.000 V … 1.024 V Displayed: 1.000V

Overvoltage approx. > 1.024 V 0x52 (CHANNEL_OVERRANGE)

Special case: open

Negative polarity approx. < -0.48 mA 0x53 (CHANNEL_UNDERRANGE)

Sensor failure approx. -0.48 mA … 0.30 mA 0x55 (MEAS_UNABLE)

Residual current 0.30 mA … 3.00 mA 0x51 (VALUE_UNDERFLOW)

Threshold range 3.00 mA … 4.00 mA Displayed: 04.00mA

Normal operation 4.00 mA … 20.00 mA

Threshold range 20.00 mA … 20.48 mA Displayed: 20.00mA

Over current approx > 20.48 mA

Negative polarity approx. < -0.48 mA 0x53 (CHANNEL_UNDERRANGE)

Threshold range -0.48 mA … 0.00 mA Displayed: 0.00mA

Normal operation 0.00 mA … 20.00 mA

Threshold range 20.00 mA … 20.48 mA Displayed: 20.00mA

Over current approx > 20.48 mA 0x52 (CHANNEL_OVERRANGE)

Floating input, e.g. CHANNEL_OVERRRANGE, also 0x52

0x52 (CHANNEL_OVERRANGE)

EN

Operating Instructions OPUS20E For external sensors

13

Loading...

Loading...