Original operating instructions

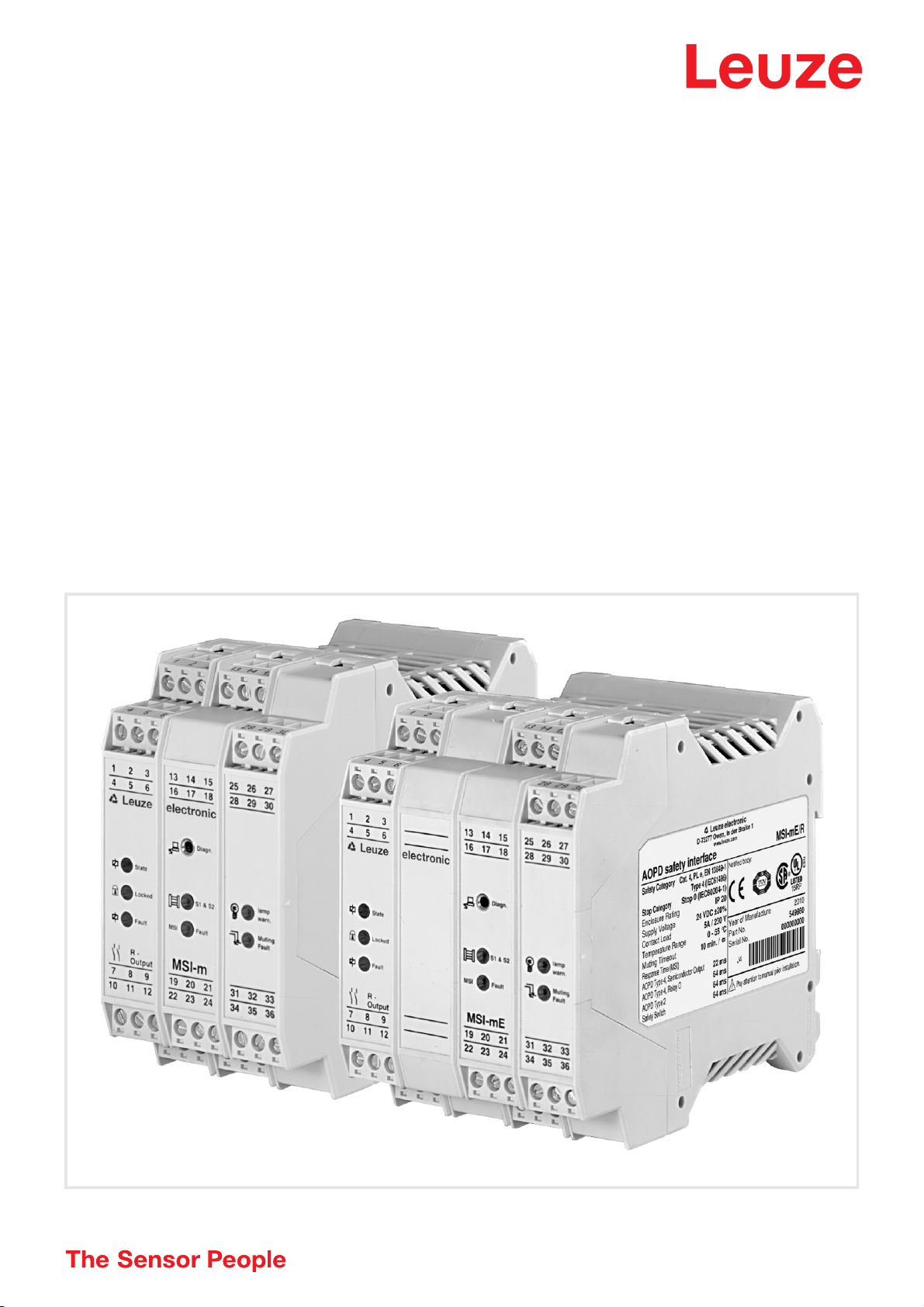

MSI-m/R

MSI-mE/R

Modular safety interface

We reserve the right to make technical changes

EN • 2020-07-22 • 603501

© 2020

Leuze electronic GmbH & Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

info@leuze.com

Leuze electronic GmbH + Co. KG MSI-m(E)/R 2

1 About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 System overview and range of applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Nomenclature MSI-m(E)/R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Intended use and foreseeable misuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Competent personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Responsibility for safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Connection of E-STOP buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.6 Additional safety notices for the special function "Muting" . . . . . . . . . . . . . . . . . . . . . . . . 11

4 System design and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 System design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 DIP switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 MSI-m module DIP switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 I/O-m module DIP switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Operating modes and functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.1 Operating modes – interlocking and contactor monitoring functions. . . . . . . . . . . . . . . 13

4.3.1.1 Operating mode: with start/restart interlock – with dynamic contactor monitoring. . . . . 14

4.3.1.2 Operating mode: with start/restart interlock – with static contactor monitoring . . . . . . . 14

4.3.1.3 Operating mode: with start/restart interlock – without contactor monitoring . . . . . . . . . 14

4.3.1.4 Operating mode: without start/restart interlock – without contactor monitoring. . . . . . . 15

4.3.1.5 Operating mode: with start/without restart interlock – without contactor monitoring . . . 15

4.3.2 Muting function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.2.1 Sequential muting, connections at M1 to M4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.2.2 Parallel muting (2.5 s), connections M2 and M3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.2.3 Parallel double muting – with extended version MSI-mx(E)/Rx only . . . . . . . . . . . . . . . 16

4.3.2.4 Testable and non-testable muting sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.2.5 Muting display function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.2.6 Muting restart while transport material is located in the muting area . . . . . . . . . . . . . . 17

4.3.2.7 Muting time limit - 10 minutes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.2.8 Example: Sequential muting, non-testable muting sensors. . . . . . . . . . . . . . . . . . . . . . 18

4.3.2.9 Example: Sequential muting, testable muting sensors . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.2.10 Example: Parallel muting, non-testable muting sensors . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.2.11 Example: Parallel muting, testable muting sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.5 Signal outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 Diagnostics function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 Power supply requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Connecting AOPDs, type 4 or type 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 Connecting to the machine control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Connection examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Leuze electronic GmbH + Co. KG MSI-m(E)/R 3

7 Technical data and order guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1 MSI-m(E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2 /R output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.3 Dimensioned drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.4 Order guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Leuze electronic GmbH + Co. KG MSI-m(E)/R 4

About this document

1 About this document

These connecting and operating instructions contain information on the approved purpose and use of MSI

safety interfaces.

ATTENTION!

All information provided in the connecting and operating instructions, especially the Safety

Notices, must be observed.

Safety and warning notices are marked with the symbol.

These connecting and operating instructions must be kept in a safe place. It must be available during the

mission time of the MSI safety interfaces.

Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use. Knowledge of these

connecting and operating instructions is considered an element of proper use.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 5

System overview and range of applications

2 System overview and range of applications

2.1 General information

The Modular Safety Interface (MSI) serves as a link between one or more active optoelectronic protective

devices (AOPD), type 2, type 3 or type 4, and the machine control. All MSI safety components include start/

restart interlock and contactor monitoring functions that can be activated and deactivated. They are also

equipped with a series of signal outputs and LED indicators as well as a diagnostic interface to a PC.

In addition, MSI-m(E)/R offers a muting function to suppress the protective function of an AOPD, e.g. when

transporting materials through the protective field. Special safety regulations for muting are described in

chapter 3.6 below.

Leuze electronic offers a range of additional MSI safety interfaces with standard and special function, e.g.

muting (intentional suppression of the safety function) or cycle control (single cycle, two cycle).

All MSI safety modules are equipped with relay outputs.

All information also applies to UL compliant version MSI-mE/R, provided that nothing to the contrary is

stated.

2.2 Certifications

Europe

EC Type Examination

TÜV SÜD

2.3 Terminology

AOPD Active Optoelectronic Protective Device

Diagn. Diagnosis Function

EDM External Device Monitoring

ESPE Electro-sensitive Protective Equipment

Fault Relay error

I/O-m module Input/Output module

Lamp Warn. Muting Indicator Failure Warning

Locked Start/Restart Interlock active

MSI Fault MSI error

Muting

Fault/Failure

Contactor monitoring

Muting error

M1 - M4 Muting Input 1 - 4

Muting Indicators Muting indicators

Muting Sensors Muting sensors

N.O. Normally Open Contact

OSSD Safety-related switching output

Reset Start/Restart Interlock Initiator

RS 232 Interface RS 232

S1, S2 Safety input 1, 2

Leuze electronic GmbH + Co. KG MSI-m(E)/R 6

System overview and range of applications

S1 & S2 Indication protective fields free/interrupted

Safety Switches Safety Switches

State Status

Test Test Signal Outputs

T1, T2 Test signal output 1, 2

Warn.

Warning muting indicator defective

(I/O-m module)

2.4 Nomenclature MSI-m(E)/R

MSI Modular Safety Interface

m With muting function

This version offers the following standard functions for either 1 AOPD, type 4, or up to 2 AOPDs,

type 2:

• Start/restart interlock

• Contactor monitoring

• Diagnostics function

and the following special functions for 1 AOPD type 4 or 1 AOPD type 2:

• Sequential muting

• Parallel muting (2.5 s)

/R Relay output with the following functions:

• Two safety-related normally open contacts, OSSD 1 and OSSD 2

• Status indicators and signal outputs

(E) UL compliant version

• Additional empty housing for convection

Leuze electronic GmbH + Co. KG MSI-m(E)/R 7

Safety

3 Safety

Before using the safety interface, a risk assessment must be performed according to valid standards (e.g.

EN ISO 12100, EN ISO 13849-1, EN 62061). The result of the risk assessment determines the required

safety level of the safety interface (see table in chapter 3.1.1). For mounting, operating and testing, document "MSI-m(E)/R Modular Safety Interface" as well as all applicable national and international standards,

regulations, rules and directives must be observed. Relevant and supplied documents must be observed,

printed and handed to the affected personnel.

Before working with the safety interface, completely read and understand the documents applicable to

your task.

In particular, the current version of the following national and international legal regulations apply for

commissioning, technical tests and handling of safety sensors:

• Machinery Directive

• Low Voltage Directive

• Electromagnetic compatibility

• Use of Work Equipment Directive

• OSHA

• Safety regulations

• Accident-prevention regulations and safety rules

• Ordinance on Industrial Safety and Health and employment protection act

• Product Safety Law (ProdSG)

NOTE

Local agencies can also provide safety-relevant information (e.g. occupational safety and

health inspectorate, employer's liability insurance association, labor inspectorate, OSHA).

3.1 Intended use and foreseeable misuse

ATTENTION!

A running machine can cause severe injuries!

Make certain that, during all conversions, maintenance work and inspections, the system is

securely shut down and protected against being restarted.

3.1.1 Intended use

• The safety interface may only be used after it has been selected in accordance with the respectively

applicable instructions and relevant standards, rules and regulations regarding labor protection and

safety at work, and after it has been installed on the machine, connected, commissioned, and

checked by a competent person.

• When selecting the safety interface it must be ensured that its safety-related capability meets or

exceeds the required Performance Level PL

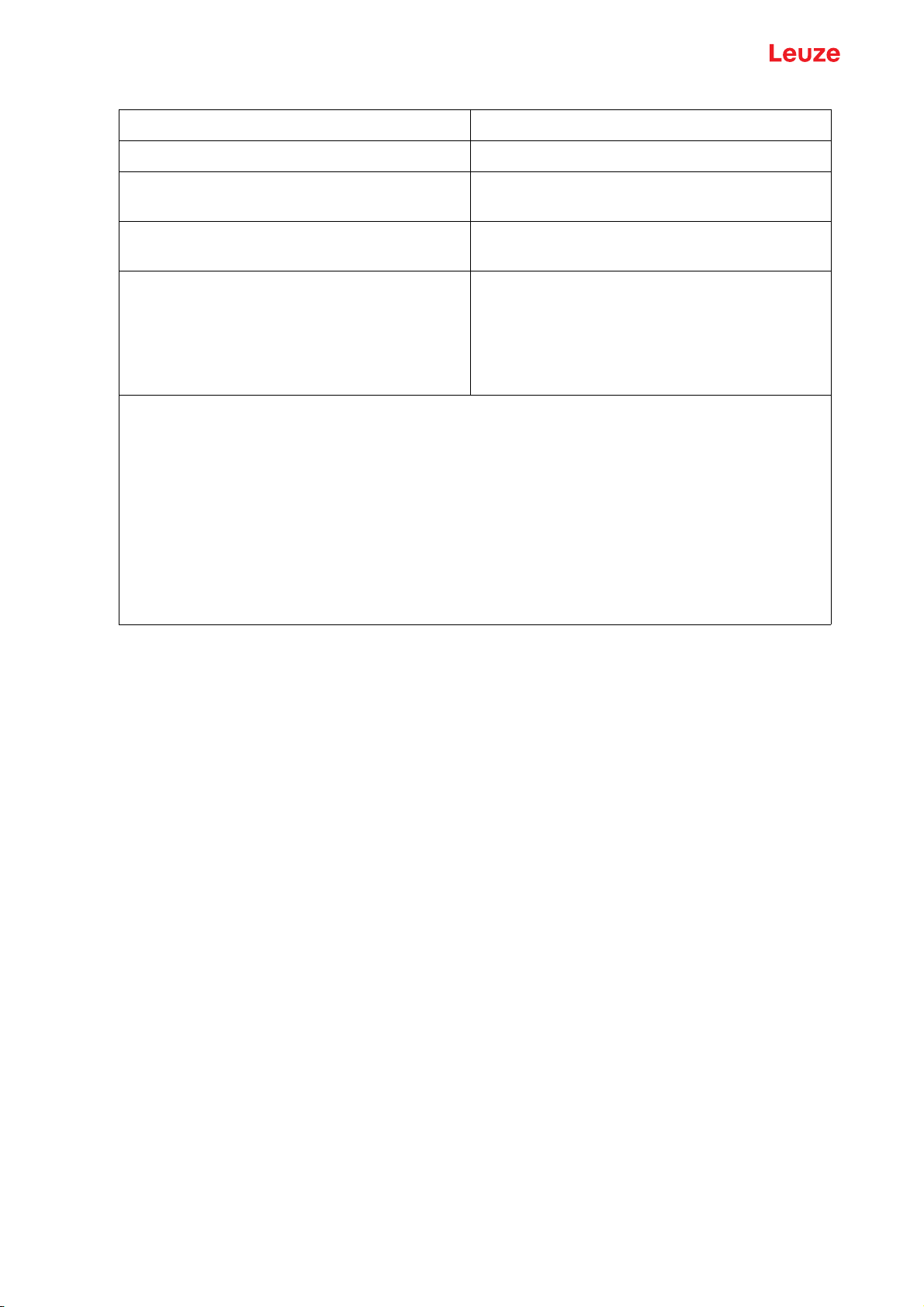

The following table shows the safety-related characteristic parameters of the MSI-m(E)/R modular safety

interfaces.

ascertained in the risk assessment.

r

Leuze electronic GmbH + Co. KG MSI-m(E)/R 8

Safety

n

op

dophop3600 s/ht

Zyklus

=

Type in accordance with EN 61496-1 Type 4

SIL in accordance with EN 61508 SIL 3

Performance Level (PL) in accordance with

PL e

EN ISO 13849-1:2015

Category in accordance with

Cat. 4

EN ISO 13849-1:2015

Mean probability of a dangerous failure per hour

(PFH

) as a function of the mean number of

d

annual switching cycles of the relay n

op

*

100% Load n

60% Load n

100% Load n

60% Load n

100% Load n

60% Load n

*n

= mean number of annual actuations, see C.4.2 and C.4.3 of EN ISO 13849-1:2015

op

= 4,800: 1.5 x 10

op

= 4,800: 1.2 x 10

op

= 28,800: 3.1 x 10

op

= 28,800: 1.5 x 10

op

= 86,400: 7.4 x 10

op

= 86,400: 2.1 x 10

op

-08

-08

-08

-08

-08

-08

Use the following formula to calculate the mean number of annual actuations:

In doing so, make the following assumptions with regard to the use of the component:

= mean operating time in hours per day

h

op

d

= mean operating time in days per year

op

t

= mean operating time between the start of two successive cycles of the component (e.g switch-

cycle

ing of a valve) in seconds per cycle

1/h

1/h

1/h

1/h

1/h

1/h

• The safety interface is used in combination with one or more multiple light beam safety devices or

safety light curtains to safeguard points of operation or danger zones.

• The control of the machine or system that is to be safeguarded must be electrically influenceable. A

switch-off command initiated by an MSI must result in an immediate shutdown of the dangerous

movement.

• The "Reset" acknowledgment button for unlocking the start/restart interlock must be mounted in such

a way that the entire danger zone can be seen from its mounting location.

• Signal outputs (state output) must not be used for switching safety-relevant signals.

• The safety interface is designed for installation in a cabinet or a protective housing with a degree of

protection of at least IP 54.

• The 24 V DC ±20% power supply must guarantee safe insulation from the mains voltage and be able

to bridge a power outage period of 20 ms.

• Depending on external wiring, dangerous voltages may be present at the switching outputs. In addition to the power supply, these must be switched off and safeguarded against being switched back

on prior to all work on the MSI-m(E)/R.

• These operating instructions must be included with the documentation of the machine on which the

protective device is installed so that they are available to the operator at all times.

• In the event of changes to the MSI-m(E)/R, all warranty claims against the manufacturer of the safety

interface are rendered void.

• The safety distance between the AOPD and the point of operation is to be maintained. It is calculated

according to the formulas for machine-specific C standards or given in the general B1 standard

EN ISO 13855. Both the reaction time of the test monitoring unit and the braking time of the machine

must be taken into account.

• Two switching contacts must always be looped into the switch-off circuit of the machine. To prevent

welding, relay switching contacts must be fused/protected externally according to the technical data.

• The safety interface must be exchanged after a maximum of 20 years. Repairs or the exchange of

wear parts do not extend the mission time.

• The safety interface satisfies the requirements of safety category 4 acc. to EN ISO 13849-1:2015. If,

however, an AOPD of a lower safety category is connected, the total category for the given path of

Leuze electronic GmbH + Co. KG MSI-m(E)/R 9

Safety

the control cannot be higher than that of the connected AOPD.

• Cross-circuits between S1 and S2 are only detected by the MSI safety module if both time-delayed

test signal outputs, T1 and T2, are used for the connected protective device(s) with relay output.

AODPs of type 4 with safety-relevant transistor outputs and their own cross circuit monitoring can be

directly connected to S1 and S2.

3.1.2 Foreseeable misuse Any use other than that defined under the "approved purpose" or which goes beyond that use is consid-

ered improper use!

e.g.,

• Applications in explosive or easily flammable atmospheres

ATTENTION!

Such instances can jeopardize the health and lives of the personnel operating the machinery

and/or may cause damage to property.

3.2 Competent personnel

Prerequisites for competent personnel:

• They have a suitable technical education.

• They know the rules and regulations for labor protection, safety at work and safety technology and

can assess the safety of the machine.

• They know the instructions for the safety interface and the machine.

• They were instructed by the responsible individuals on the mounting and operation of the machine

and of the safety interface.

3.3 Responsibility for safety

Manufacturer and operator must ensure that the machine and implemented safety interface function properly and that all affected persons are adequately informed and trained.

The type and content of all imparted information must not lead to unsafe actions by users.

The manufacturer of the machine is responsible for:

• Safe machine construction

• Safe implementation of the safety interface

• Imparting all relevant information to the operating company

• Adhering to all regulations and directives for the safe commissioning of the machine

The operator of the machine is responsible for:

• Instructing the operating personnel

• Maintaining the safe operation of the machine

• Adhering to all regulations and directives for labor protection and safety at work

• Regular testing by competent personnel (see chapters 3 and 3.2)

3.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• Safety interface is not used as intended.

• Safety notices are not adhered to.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Proper function is not tested.

• Changes (e.g., constructional) are made to the safety interface.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 10

Safety

3.5 Connection of E-STOP buttons

• It must be ensured that the EMERGENCY STOP function is always and immediately effective.

E-STOP buttons must not be connected at sensor inputs which provide for muting or cycle control functions!

Since the MSI-m(E)/R does not provide for additional sensor inputs without special functions, no E-STOP buttons must be connected.

If an E-STOP button is needed, the use of the extended version MSI-mx(E)/

Rx is recommended.

3.6 Additional safety notices for the special function "Muting"

• Muting is the intentional suppression of the safety function of an AOPD. It is used, for instance, to

allow the material flow to pass through the protective field without triggering a switch-off signal.

• During the muting function the protective function of this AOPD is no longer active! For this reason

other measures must be taken to ensure that it is not possible to reach or go into the point of operation. For instance, if the material transport completely fills the access area, or if there is no danger

while muting is active, such as during the return motion of a tool.

• The muting sensors must be positioned in such a way that it is impossible to manipulate them easily.

For example, optical sensors can be mounted so high or so far apart that the operating personnel

cannot cover them either simultaneously or at all. If switches are used, we recommend a concealed

installation.

• The operating personnel must be expressly informed that the protective device offers no protection in

the muting state. Any manipulations of or unauthorized entries into the system present immediate

danger to personnel.

• An additional sign should be put up stating that the safety light grid offers no protection when the

Muting indicator is lit and it is dangerous to reach or walk through the protective field. Muting indicators and sign should be placed in a clearly visible location near the muting area.

• The start button must be positioned so that it cannot be actuated by persons who are located in the

protective field.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 11

System design and functions

DS4 DS3

DS2 DS1

down

up

MU4 MU3

MU2 MU1

down

up

4 System design and functions

4.1 System design

Two microprocessors handle the redundant processing of the signal sequences within the intelligent

modular safety interface MSI. The results of the two processors are continuously compared. If any deviations are found, the safety-related outputs are immediately switched off and the LED indicating an MSI

failure lights up.

Sensor signals at inputs S1 and S2 are checked. Depending on which of the functions (as described

below) are selected, when the protective fields of all connected AOPDs are free, the MSI outputs switch

automatically to the ON state (without start/restart interlock) or remain in the OFF state until the reset

button has been pressed and released (with start/restart interlock = standard operating mode).

On the output side, the MSI-m(E)/R is equipped with two positive-guided, normally open contacts.

The MSI safety interface comes in a 52.5/70 mm-wide slide-in housing that holds the MSI-m module, the

I/O-m module and the output module. It is suitable for mounting on a grounded 35 mm standard rail.

4.2 DIP switch settings

4.2.1 MSI-m module DIP switch To reset the DIP switches: cut off the voltage supply to the interface (see chapter "Safety Notices"), loosen

the mounting tabs of the component with the imprint "MSI-m" and pull this module partly out of the housing:

Functions only in conjunction with external wiring, see Chapter 4.3:

DIP switch DS4 DS3 DS2 DS1

Function With-

out

Up Start interlock only Static• - none•• –

Down Start/restart interlock* - none** Dynamic –

Factory setting: all switches down

* See chapter 4.3.1.1 – 4.3.1.3

** See chapter 4.3.1.4

• See chapter 4.3.1.2

•• See chapter 4.3.1.3 – 4.3.1.5

4.2.2 I/O-m module DIP switch To reset the DIP switches: cut off the voltage supply to the interface (see chapter "Safety Notices"), loosen

the mounting tabs of the component and pull the I/O-m module (to the right of the MSI-m module) partly

out of the housing:

Lock Contactor moni-

toring

Without

DIP switch MU4 MU3 MU2 MU1

Function Muting area 1 Muting sensors Muting time limit Muting function

Up S1 only Non-testable Without Without

Down S1 & S2 Testable 10 min Muting area 1

Factory setting: all switches down

Leuze electronic GmbH + Co. KG MSI-m(E)/R 12

System design and functions

4.3 Operating modes and functions

MSI-m(E)/R permits the following operating modes and functions:

• Protective function with the possibility of the following combinations of interlocking function and contactor monitoring function.

• Five operating modes can be selected by means of external wiring and the DIP switches DS2 and

DS3 on the MSI-m module.

• Muting function by way of testable or non-testable muting sensors in sequential or parallel muting

mode. Further details are given in chapter 4.3.2.

4.3.1 Operating modes – interlocking and contactor monitoring functions The following 5 combinations can be selected by externally wiring the MSI safety interface and/or by

changing the settings of the DIP switches DS2 and DS3 in the MSI-m module:

OPERATING MODES

Chapter Type of locking Type of contactor monitoring Muting function

4.3.1.1 With start/restart inter-

With dynamic contactor monitoring Possible

lock

4.3.1.2 With start/restart inter-

With static contactor monitoring Possible

lock

4.3.1.3 With start/restart inter-

Without contactor monitoring Possible

lock

4.3.1.4 Without start/restart

Without contactor monitoring Not permitted

interlock

4.3.1.5 With start/without restart

Without contactor monitoring Not permitted

interlock

ATTENTION!

The MSI safety interface is factory-set for the operating mode "with start/restart interlock and

dynamic contactor monitoring function". If this setting is changed, these functions (i.e. the

appropriate safety level) must be guaranteed by other means.

• Types of interlocking functions

The "start interlock function" ensures that when the system is switched on or when the supply voltage returns, even if the protective field is free, the safety-related output contacts (OSSDs) do not

automatically go into ON state, but only after the reset button has been pressed and released.

The "start/restart interlock function" prevents the OSSDs from automatically entering the ON state

when the protective fields of one or more of the connected AOPDs are released again after an interruption. Here as well, the reset button must be pressed and released to initiate the system.

Cyclic operation and muting are not permissible if there is no locking (and hence no reset button)

since the start button is also used to perform the function of the cyclic and muting reset.

• Types of contactor monitoring

The function "dynamic contactor monitoring" monitors the contactors and relays connected downstream from the MSI safety interface. Each time before the OSSDs switch to the ON state, a check is

made of whether the subsequent circuit elements have closed and reopened. If they have not, the

OSSDs of the MSI safety interface remain in the OFF state.

If the function "static contactor monitoring" is selected, a check is made of whether the subsequent

switching elements are in an open state. If they are, the start/restart interlock can be unlocked.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 13

System design and functions

Start

+24 V

0 V

k2

k1

Start

+24 V

0 V

k2

k1

Start

+24 V

0 V

4.3.1.1 Operating mode: with start/restart interlock – with dynamic contactor monitoring

External wiring requirements:

Terminal 13 "Reset" Connected to 24 V DC supply via a start button

Terminal 14 "EDM" Connected to 0 V via feedback contacts of the positive-

guided downstream relay

Required DIP switch settings in the MSI module (chapter 4.2):

DS3 down DS2 down (factory setting on delivery)

Start/restart interlock is no longer active when the protective fields of all connected

AOPDs are free, the downstream relays have returned to their original state, and the

reset button is pressed and released.

4.3.1.2 Operating mode: with start/restart interlock – with static contactor monitoring

External wiring requirements:

Terminal 13 "Reset" Connected to 24 V DC supply via a start button

Terminal 14 "EDM" Connected to 0 V via feedback contacts of the positive-

guided downstream relay

Required DIP switch settings in the MSI module (chapter 4.2):

DS3 down DS2 up

In this operating mode, if the protective fields are free, a check is made of whether the

downstream switching elements have returned to their original state. If so, a release is

issued by pressing and releasing the reset button.

ATTENTION!

The dynamic monitoring of the downstream relays, which may be required in order to maintain the safety category, must be performed by other means.

4.3.1.3 Operating mode: with start/restart interlock – without contactor monitoring

External wiring requirements:

Terminal 13 "Reset" Connected to 24 V DC supply via a start button

Terminal 14 "EDM" Connected to 0 V

Required DIP switch settings in the MSI module (chapter 4.2):

DS3 down DS2 up

ATTENTION!

The monitoring of the downstream switching elements, which may be required in order to

Leuze electronic GmbH + Co. KG MSI-m(E)/R 14

maintain the safety category, must be performed by other means.

System design and functions

+24 V

0 V

+24 V

0 V

4.3.1.4 Operating mode: without start/restart interlock – without contactor monitoring

Muting operation is not permissible in this operating mode!

External wiring requirements:

Terminal 13 "Reset" Connected to 0 V

Terminal 14 "EDM" Connected to 24 V DC

Required DIP switch settings in the MSI module (chapter 4.2):

DS3 down DS2 up

ATTENTION!

After the supply voltage is applied, the OSSDs immediately go into the ON state if all of the

protective fields of the connected AOPDs are free. The start/restart interlock function and the

monitoring of the downstream switching elements, which may be required in order to maintain

the safety category, must be performed by other means.

4.3.1.5 Operating mode: with start/without restart interlock – without contactor monitoring

Muting operation is not permissible in this operating mode!

External wiring requirements:

Terminal 13 "Reset" Connected to 0 V

Terminal 14 "EDM" Connected to 24 V DC

Required DIP switch settings in the MSI module (chapter 4.2):

DS3 up DS2 up

After the supply voltage is applied, the OSSDs remain in the OFF state even if all of

the protective fields of the connected AOPDs are free.

ATTENTION!

When the protective fields of all connected AOPDs are initially free, the OSSDs first enter the

ON state when the protective field of the AOPD connected at S1 (for type 4: S1 and S2) is

interrupted and released. Only then do the rest of the connected AOPDs respond to the interruption and release of their own protective fields by switching the OSSDs directly to the OFF

and ON states.

The restart interlock function and the monitoring of the downstream switching elements,

which may be required in order to maintain the safety category, must be performed by other

means.

4.3.2 Muting function Muting is the intentional suppression of the protective function. Special safety precautions must be

observed if muting is being used. See special Safety Notices in chapter 3.6.

The muting operation is initiated by the connected muting sensors.The MSI-m automatically detects the

muting mode based on which of the muting inputs (M1 to M4) are occupied. For instance, sequential

muting will be performed when all inputs are occupied, and parallel muting takes place when M2 and M3

are occupied. Both of the muting indicators must be connected. See chapter 4.3.2.5.

Special feature for muting AOPDs of type 2

When the DIP switch of the I/O-m module is factory-set (MU4 down), the muting function applies for safety

inputs S1 and S2. If a type 2 AOPD is to be muted, the muting area 1 must be set to "S1 only" via MU4

(up) and the type 2 AOPD to be muted must be connected to S1. For DIP switch settings,

Leuze electronic GmbH + Co. KG MSI-m(E)/R 15

System design and functions

see chapter 4.2.2.

4.3.2.1 Sequential muting, connections at M1 to M4

Sequential muting requires the connection of 4 muting sensors and their damping in a predetermined

sequence. It is preferred when the material being transported (i.e. the transport vehicle) always has consistent dimensions and there is sufficient space available for the material intake. Examples are shown in

chapter 4.3.2.8 and 4.3.2.9.

4.3.2.2 Parallel muting (2.5 s), connections M2 and M3

The muting process is initiated if the two inputs, M2 and M3, switch simultaneously (within 2.5 s of each

other). Parallel muting is used when material of inconsistent size is being conveyed or when there is limited

room in front of the muting station.

Parallel muting can be performed by two photoelectric sensors (separated transmitter and receiver or

retro-reflective photoelectric sensors) whose beam paths intersect behind the protective field but within the

danger zone. Examples of these and other possibilities can be found in chapter 4.3.2.10 and 4.3.2.11.

4.3.2.3 Parallel double muting – with extended version MSI-mx(E)/Rx only

Parallel double muting is not possible with MSI-m. If muting is needed for two independent areas, e.g. the

entrance and exit area of a packaging line, the extended safety interface MSI-mx(E)/Rx takes on this task.

Ask Leuze electronic or its local representatives for further information.

4.3.2.4 Testable and non-testable muting sensors

The following devices are suitable for use as muting sensors:

• Non-testable photoelectric sensors (transmitter/receiver or retro-reflective photoelectric sensors)

with pnp output, dark-switching

• Testable and non-testable reflective diffuse sensors with pnp output, light-switching

• Mechanical position switches

• Inductive proximity switches

• Induction loops if metallic objects move into the path to be muted

ATTENTION!

The cables to the individual muting sensors must be laid separately!

Non-testable muting sensors

Prerequisites: DIP switch MU3 in the I/O-m module must be up

• pnp or switching output must provide 0 V in the non-dampened state

• pnp or switching output must provide 24 V DC in the dampened state

Testable muting sensors

Prerequisites: DIP switch MU3 in the I/O-m module must be down (factory setting)

• Diffuse reflection sensors, light-switching, are suitable; with activation/test input and a reaction time

of 2 to 18 ms.

• Test signal T1 must be used for the muting sensor at M2 (M4).

• Test signal T2 must be used for the muting sensor at M3 (M1).

• pnp output must provide 0 V in the non-dampened state and 24 V DC (plus above-mentioned test

impulses) in the dampened state.

Example: SLS SR8.8/ER8/66-S12, polarized for light switching, from Leuze electronic

Leuze electronic GmbH + Co. KG MSI-m(E)/R 16

System design and functions

4.3.2.5 Muting display function

Single muting for S1/S2, or in the case of type 2 for S1 only

In case of muting, terminal 28 will deliver 24 V DC to muting indicator 1 connected to it to indicate the

muting.

Terminal 29 serves as backup in case that muting indicator 1, which is connected to terminal 28, fails

(broken filament or interrupted supply). Muting indicator 2 must be connected to terminal 29 to serve as

back-up unit to take over the indicating function in case muting indicator 1 (connected to terminal 28) fails,

in order to ensure fault-free operation.

With the automatic change from muting indicator 1 to muting indicator 2, the assigned LED "lamp warn"

on the I/O-m module flashes (1 impulse). If muting indicator 2 should fail (it is monitored constantly, even

if it is not switched on), the LED "lamp warn" will also flash (2 impulses).

In addition to the indication, the impulses (1 or 2) are also directed to output terminal 30. This output will

deliver an active-high signal during fault-free operation. Only if the second indicator fails as well, the

MSI-m(E)/R will enter a fault state and the OSSDs will switch to the OFF state.

4.3.2.6 Muting restart while transport material is located in the muting area

If transport material is in the sensor area when switching on the system after a power interruption, after an

E-Stop release or after termination of the muting function by incorrect sequence or time condition, a muting

restart is always required. If the transport material dampens at least one muting sensor but does not interrupt the protective field of the AOPD that is to be muted, press and release the start button to activate the

transport system. Muting is not activated. As soon as the transport material interrupts the protective field,

the OSSDs switch into the OFF-state and the muting indicators start to blink. Muting restart is now

possible. If the transport material dampens at least one muting sensor and, at the same time, the protective

field of the AOPD that is to be muted when switching on is already interrupted, the OSSDs remain in the

OFF state and the muting indicator flashes immediately. Muting restart is immediately possible. Muting

restart requires pressing the start button two times within 4 s. On the second activation of the start button

the safety circuit is released immediately. On the second release of the start button the MSI-m(E)/R safety

interface checks the muting sensors for a valid state. If the check ascertains a valid muting combination,

the OSSDs will stay in the ON-state. The system takes on normal operation.

ATTENTION!

If an invalid muting combination is detected, the release remains in effect only as long as the

button is pressed. As soon as the button is released, the system comes to a standstill. Thus it

is possible to enable and operate the system as long as a responsible person constantly

observes the process and can interrupt the dangerous movement at any time by letting go of

the start button. In this case, the muting sensors have to be checked for misalignment, contamination or damage. This option assumes that the start button is mounted in a location from

which the entire danger zone can be viewed. See chapter 3.6Additional safety notices for the

special function "Muting".

4.3.2.7 Muting time limit - 10 minutes

Regardless of the selected muting mode, the MSI safety interface reports a muting malfunction when the

duration of a muting exceeds 10 minutes. If a muting sequence is initiated within the 10 minutes, the timer

is reset and the 10 minutes start over again.

ATTENTION!

The muting time limit is mandatory. The muting time limit may only be switched off with DIP

switch MU2 in the I/O-m module in reasonable cases, e.g. for a normally uninterrupted flow of

goods in the muting path and if no persons are thereby endangered.

ATTENTION!

The user assumes responsibility for switching off the muting time monitoring!

Leuze electronic GmbH + Co. KG MSI-m(E)/R 17

System design and functions

M1

M2

M3

M4

w

d

R

T

M1

M2

M3

M4

St

S

E

E

E

E

S

50 ms

each

response time

Danger zone

Muting

-

function

S

S

4.3.2.8 Example: Sequential muting, non-testable muting sensors

• Attention: Non-testable muting sensors. Shift DIP switch MU3 up

• Muting function effects the inputs S1 & S2. Change position of DIP switch MU4, if input S2 should not

be muted. See chapter 4.2.2 DIP switch setting I/O-m module.

T = AOPD transmitter

R = AOPD receiver

Piece = Start/restart, muting restart, must not be reachable out from the danger zone

• M1 to M4, non-testable muting sensors after transmitter/receiver operation deliver 24 V DC in the

dampened state.

• Activation sequence: sequential without time monitoring. But: 10 min. time limit when muting has

started

• w = transport vehicle length, d = distance M1, M4, condition: w > d

• Positioning of M2 and M3 as close as possible to the receiver, but consider 50 ms reaction time

• M1 to M4, symmetrical arrangement

• All muting sensors must be released before M1 (or M4 for reverse travel) is activated again.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 18

System design and functions

M1

M2

M3

M4

R

T

6W

T1

T2

M1

M2

M3

M4

50 ms

each

response time

Danger zone

Muting

-

function

G

w

4.3.2.9 Example: Sequential muting, testable muting sensors

• Attention: Testable muting sensors. DIP switch MU3 down (factory setting)

• Muting function effects the inputs S1 & S2. Change position of DIP switch MU4, if input S2 should not

be muted. See chapter 4.2.2 DIP switch setting I/O-m module.

T = AOPD transmitter

R= AOPD receiver

Piece = Start/restart, muting restart, must not be reachable out from the danger zone

• T1, T2 test signal outputs

• M1 to M4, testable muting sensors according to the diffuse-reflection-sensor principle deliver

24 V DC and test signals in the dampened state.

• Activation sequence: sequential without time monitoring. But: 10 min. time limit when muting has

started

• w = transport vehicle length, d = distance M1, M4, condition: w > d

• Positioning of M2 and M3 as close as possible to the receiver, but consider 50 ms reaction time

• M1 to M4, symmetrical arrangement

• All muting sensors must be released before M1 (or M4 for reverse travel) is activated again.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 19

System design and functions

M2

M3

R

T

St

M2

M3

<2,5 s

<2,5 s

<2,5 s

50 ms

each

response time

Muting

-

function

4.3.2.10Example: Parallel muting, non-testable muting sensors

• Attention: Non-testable muting sensors. Shift DIP switch MU3 up

• Muting function effects the inputs S1 & S2. Change position of DIP switch MU4, if input S2 should not

be muted. See chapter 4.2.2 DIP switch setting I/O-m module.

T = AOPD transmitter

R = AOPD receiver

Piece = Start/restart, muting restart, must not be reachable out from the danger zone

• M2 and M3 = non-testable muting sensors

The two retro-reflective photoelectric sensors with pnp output, dark-switching, provide 24 V DC in

dampened state.

• Condition: Simultaneous activation of M2 and M3 within 2.5 s

• Muting is limited to 10 min. (time limit)

• Short interruptions of less than 2.5 s do not stop the muting function as long as only one muting sensor is affected.

• As soon as both of the muting sensors are falling back to 0 V, the muting function will end.

• Attention: The beams must intersect behind the protective field of the AOPD, i.e. within the danger

zone. Symmetrical arrangement

Leuze electronic GmbH + Co. KG MSI-m(E)/R 20

System design and functions

M2

M3

M2’

M2

M3

M3’

R

T

St

T1

T2

M2

M3

<2,5 s

<2,5 s

<2,5 s

50 ms

each

response time

Muting

-

function

4.3.2.11Example: Parallel muting, testable muting sensors

• Attention: Testable muting sensors. DIP switch MU3 down (factory setting)

• Muting function effects the inputs S1 and S2. Change position of DIP switch MU4, if input S2 should

not be muted. See chapter 4.2.2 DIP switch setting I/O-m module.

T = AOPD transmitter

R = AOPD receiver

Piece = Start/restart, muting restart, must not be reachable out from the danger zone

• T1, T2 test signal outputs

• M2 and M3, M2' and M3' = Testable muting sensors

The four diffuse reflection sensors with pnp output, light-switching, provide 24 V DC in dampened

state.

• Condition: Simultaneous activation of M2, M3 or M2', M3' within 2.5 s

• Muting is limited to 10 min. (time limit)

• Short interruptions of less than 2.5 s do not stop the muting function as long as only one muting sensor is affected.

• As soon as both of the muting sensors are falling back to 0 V, the muting function will end.

• Positioning of M2, M2', M3 and M3' as close as possible to the receiver, but consider 50 ms reaction

time. Symmetrical arrangement.

4.4 Indicators

A number of LEDs of various colors indicate the operating state of the MSI modular safety interface. It is

also possible to show the indicators and input/output states on the PC monitor using the integrated RS 232

interface and diagnostic connector.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 21

System design and functions

lamp

warn.

Muting

Fault

25

26

27

28

29

30

31

32

33

34

35

36

Fault

State

Locked

7

8

9

10

11

12

Output

R-

Leuze

1

2

3

4

5

6

1

2

3

R-Output

Modul

MSI-m

Modul

8

7

I/O-m

Modul

MSI-m

Diagn.

S1 & S2

Fault

MSI

electronic

13

14

15

16

17

18

19

20

21

22

23

24

4

5

6

Fault

State

Locked

7

8

9

10

11

12

Output

R-

Leuze

1

2

3

4

5

6

1

2

3

R-Output

Modul

electronic

lamp

warn.

Muting

Fault

25

26

27

28

29

30

31

32

33

34

35

36

MSI-m

Modul

8

7

I/O-m

Modul

MSI-mE

Diagn.

S1 & S2

Fault

MSI

13

14

15

16

17

18

19

20

21

22

23

24

4

5

6

Konvektions-

gehäuse

Output /R

Position Display/function Icon Status LED Color

1 Switching state

Safety output

2 Start/restart interlock Lock Locked

3 Error in output module Relay Error

Relay On

Off

Not locked

No error

On

On

On

Off

On

Off

Green

Red

Yellow

Red

MSI-m module

Position Display/function Icon Status LED Color

4 Diagnosis, RS 232

See signal outputs

5 Protective field AOPDs

Socket

Diagn.

S1 & S2

N/A N/A N/A

Protective field

free

On

Off

Green

Not free

6 MSI error MSI Fault Error

No error

On

Off

Red

I/O-m module

Position Display/function Icon Status LED Color

7 Muting indicators Broken fil-

ament

8 Muting error Sequence

Leuze electronic GmbH + Co. KG MSI-m(E)/R 22

Shortcircuit

Interruption

error

Defect indicator 1

Defect indicator 2

No defect

Error

No error

Flashes 1x

Flashes 2x

Off

On

Off

Red

Red

Red

System design and functions

T1

T2

S1

S2

AOPDs

Test

+24V

Diagn.

0 V

9

4

15

24

22

23

13

14

20

21

31

32

Muting

Indicators

1

2

Warn.

Reset

EDM

M1

M2

Muting Sensors

State Outputs

S1-S2

Muting

Failure

19

33

30

28

29

Leuze

electronic

MSI-m(E)/R

RS 232

State

7

6

R-Output

M3

M4

11

2

10

1

OSSD2

OSSD1

N.O.

N.O.

4.5 Signal outputs

ATTENTION!

Signal outputs are not allowed to be used as safety-related signals in release circuits (see

also chapter Safety Notices, Operating conditions and approved purpose).

Output /R

Terminal Signaling function Icon Status Signal output

6 Start/restart interlock Lock Locked

Not locked

7 Switching state

Safety output

Relay ON

OFF

Active high

Active low

Active high

Active low

MSI-m module

Terminal Signaling function Icon Status Signal output

Front

socket

19 Protective field(s) S1 - S2 Free

Diagnosis, RS 232

2.5 mm connector

– – Connection to PC with

diagnosis program

Active high

Not (all) free

Active low

Leuze electronic GmbH + Co. KG MSI-m(E)/R 23

System design and functions

Leuze electronic

Leuze electronic

MSI-m(E)/R

I/O-m module

Terminal Signaling function Icon Status Signal output

28* Muting indicators

Lamp Muting on

24 V DC, 5 W max.

29* Muting indicators

Lamp Muting on

24 V DC, 5 W max.

30 Warning

Muting indicator defective

Broken filament

Short-circuit

Interruption

33 Muting error Muting

Failure

*Terminal 29 as backup

4.6 Diagnostics function

Requirements for running the diagnosis system: a standard PC or laptop operating under Windows

(Version 3.1 or higher) and the MSI software, Version 01, as well as a serial connection cable and a 2.5

mm jack plug.

• Simultaneous display of all input and output states as well as all LED displays on the MSI

With its diagnosis interface, the intelligent modular safety interface MSI offers a convenient way to visualize all of the input and output states simultaneously on the monitor. The connection diagram as well as

display fields in different colors can be shown via the connection terminals. A graphic representation of the

MSI front design with the display elements as described in chapter 4.4 also appears on the screen.

Example:

Muting off

Muting off

Indicator OK

Defect indicator 1

Defect indicator 2

No error

Muting error

Active high

Active low

Active high

Active low

Active high

Impulse 1x

Impulse 2x

Active high

Active low

This enables the sequences at individual screw terminals to be tracked without the use of additional

measuring instruments. The diagnostics function is equipped with online help and can be operated in

either English or German.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 24

Electrical connection

5 Electrical connection

5.1 Installation instructions

ATTENTION!

The general Safety Notices in chapter 3 must be observed. The electrical installation may

only be performed by trained specialists and if there is no voltage applied.

ATTENTION!

In the R/Rx versions, it is possible that high voltages may be applied at the output contacts. A

de-energized state is achieved only when the 24 V DC supply voltage as well as the supply

lines to the switching contacts are safely switched off and secured against being switched on

again.

ATTENTION!

Coded plug-in terminal blocks allow a connection cross-section of up to 2.5 mm

voltage must be externally fused against overcurrent with a fuse of 2.5 A mT. The switching

contacts must also be externally fused against overcurrent with a maximum of 4 A gG. This

prevents the safety-related contacts from welding together if the current load is too high!

2

. The supply

5.2 Power supply requirements

ATTENTION!

The supply voltage of 24 V DC must guarantee safe mains separation and be able to bridge a

voltage dip of 20 ms at full load. The functional earth connection of the MSI is established

when snapped onto the grounded metal mounting rail via the rear clamping device.

The supply line for the supply voltage must be externally fused against overcurrent with a

maximum of 2.5 A mT.

5.3 Connecting AOPDs, type 4 or type 2

The examples below show possibilities for connecting and combining AOPDs of various safety categories

and with various output features (relays, safety-oriented transistor outputs, cross circuit monitoring within

and outside the AOPD).

AOPDs of type 4 with transistor outputs and cross circuit monitoring function can be connected directly to

the safety inputs S1 and S2. See example 1.

AOPDs of type 4 with relay outputs must be connected so that the odd-numbered test signal T1 is directed

via the non-delaying contacts to an odd-numbered sensor input (T1 => S1) and vice versa (T2 => S2). See

example 2.

AOPDs of type 2 are periodically tested using the time-delayed test signals T1 or T2. The even-numbered

test signal must be directed to an odd-numbered safety input via the time-delaying sensor (T2 => S1) and

vice versa (T1 => S2). The sensor response time to a test request must be in a range of 2 to 18 ms. See

example 3.

All available safety inputs must be occupied! In case no components are connected, the remaining sensor input

must be connected to the corresponding test signal using bridges. In doing so, please note that the evennumbered test signal must be connected to the even-numbered sensor input via the non-delaying bridge

(T2 => S2) and vice versa (T1 => S1).See example 4.

If type 2 AOPDs are connected:

• According to EN 61496-1, only a maximum of PL c or SIL CL 1 can be achieved!

• When cables are laid without protection, an error detection time of up to 10 s is possible.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 25

Electrical connection

AOPD

TYP 4

2 x

pnp

Test

AOPDs

Test

AOPDs

AOPD TYP 4

2 x relays

Test

test input

test input

AOPDs

AOPD

TYP 2

1 x

pnp

AOPD

TYP 2

1 x

pnp

Example 1

1 AOPD of type 4 with 2

safety-related transistor

outputs and internal

cross circuit monitoring

function.

Example 2

1 AOPD of type 4 with

2 relay outputs; cross

circuit monitoring of

interconnection cables

by using the test signals

T1 and T2.

Example 3

2 AOPDs of type 2 with

one safety-related

transistor output each;

cross circuit monitoring

between the supply lines

of both AOPDs.

Example 4

1 AOPD of type 2 with

one safety-related

transistor output.

AOPD

TYP 2

1 x

pnp

test input

23

24

T2

22

S2

S1

AOPDs

15

T1

Test

5.4 Connecting to the machine control

ATTENTION!

The safety-related parts of the controls comprise more than the MSI-m(E)/R described above.

They also include successive control elements and even power transmission elements which

must be safely and promptly shut down. Special attention must be given here to the adherence to the required safety category. Important information on this topic can be found in

EN ISO 13849-1:2015.

ATTENTION!

Essential prerequisites for safe operation are the abilities to electrically influence the interruption of the dangerous movement and to bring the machine to a standstill as quickly as possible. These factors, as well as the reaction times of AOPDs and the MSI, must be taken into

consideration when calculating the safety distance.

The reaction times depend on the type of AOPD selected (see chapter 7, Technical data).

Other parameters, such as access speed or additional distance to be added to the safety distance, are dependent on the respective applications and the resolution of the used AOPD.

European standard EN ISO 13855 includes calculation formulas and examples for various

arrangements.

ATTENTION!

Impairment of the protective function due to faulty muting signals with 2-sensor parallel muting!

Note the order of the ground connections! The ground connection of the MSI-m(E)/R (0 V/

terminal 9) must be wired between the ground connections of muting sensors M2 and M3.

For the muting sensors and the safety sensor, a shared power supply unit is to be used. The

connection lines of the muting sensors must be laid separated from one another and protected.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 26

Connection examples

K1*

k2

k1

M1

M2

M3

M4

L+

Ph

LN

K2*

L-NL+

Ph

k1

k1

k2

k2

24 V, 5 W max

24 V, 5 W max

+24 V

0 V

T1

T2

S1

S2

AOPDs

Test

+24V

Diagn.

0 V

9

4

15

24

22

23

13

14

20

21

31

32

Muting

Indicators

1

2

Warn.

Reset

EDM

M1

M2

Muting Sensors

State Outputs

S1-S2

Muting

Failure

19

33

30

28

29

Leuze electronic

MSI-m(E)/R

RS 232

State

7

6

R-Output

M3

M4

11

2

10

1

OSSD2

OSSD1

N.O.

N.O.

gh

** **

f

e

a

b

cd

6 Connection examples

The connection example below shows one wiring suggestion for the MSI-m(E)/R.

Connection example MSI-m(E)/R with one AOPD type 4

a = AOPD type 4 with protective and muting function

b = M1, M2, M3, M4, non-testable muting sensors (i.e. throughbeam photoelectric sen-

sors), sequential muting

c = Command device for release (start/restart interlock)

d = Feedback circuit for contactor monitoring

e = Possible collector cable for warning/error indications

Pin 19 = Signal output "sensor state"

Pin 33 = Signal output "muting error"

Pin 30 = Warning output "Muting indicator defective"

Pin 28/29 = Outputs muting indicators 1 and 2

Pin 7 = Signal output "switching state of safety output "

Pin 6 = Signal output "interlock state"

f = Safety-related switching outputs (OSSDs)

g = Two-channel release circuit

h = One-channel release circuit

* = Use suitable spark extinction circuits

** = Always use both contacts in the release circuit. Only use sequential contactors with

All available safety inputs must be occupied!

See chapter 5.3.

positive-guided contacts.

Leuze electronic GmbH + Co. KG MSI-m(E)/R 27

Technical data and order guide

7 Technical data and order guide

7.1 MSI-m(E)

Version, type

Modular Safety Interface

Type in accordance with EN 61496-1 Type 4

SIL in accordance with EN 61508 SIL 3

Performance Level (PL) in accordance with

EN ISO 13849-1:2015

Category in accordance with

EN ISO 13849-1:2015

Mean probability of a dangerous failure per

hour (PFH

number of annual switching cycles of the

relay n

Number of cycles until 10% of the components have a failure to danger (B10

op

) as a function of the mean

d

*

MSI-m(E)

PL e

Cat. 4

100% Load n

60% Load n

100% Load n

60% Load n

100% Load n

60% Load n

= 4,800: 1.5 x 10

op

= 4,800: 1.2 x 10

op

= 28,800: 3.1 x 10

op

= 28,800: 1.5 x 10

op

= 86,400: 7.4 x 10

op

= 86,400: 2.1 x 10

op

-08

-08

-08

-08

-08

-08

1/h

1/h

1/h

1/h

1/h

1/h

400,000: 100% of the max. switching current of

)

d

loading cases AC1, DC1, AC15, DC13

2,500,000: 60% of the max. switching current of

loading cases AC1, DC1, AC15, DC13

20,000,000: 20% of the max. switching current of

loading cases AC1, DC1, AC15, DC13

Mission time (T

)20 years

M

Connectable safety sensors at S1 and S2 1 AOPD of type 4, type 3 or up to 2 AOPDs of type 2

(all in acc. with EN 61496-1)

Test outputs T1 and T2, test interval

Test impulse duration, time-delayed

Reaction time, AOPD of type 2 on test

200 ms

24 ms each

2 to 18 ms

request

Available functions Start/restart interlock

Contactor monitoring

Sequential muting

Parallel muting (2.5 s)

Control input

Start/restart interlock (reset)

Control input

Contactor monitoring (EDM)

Potential-free normally open contact (button or key

switch)

Feedback of positive-guided contacts of sequential contactors (see connection diagram)

Control inputs

Muting sensors M1 to M4

Signal level in dampened state:

(separate connection cables required)

Connection of non-testable muting sensors

Active high, 24 V DC

(dark switching)

Connection of testable muting sensors

Active low, 24 V DC, plus test impulses from T1 or T2

(light switching)

Reaction time of testable muting sensors to

2 to 18 ms

a test request

Leuze electronic GmbH + Co. KG MSI-m(E)/R 28

Technical data and order guide

n

op

dophop3600 s/ht

Zyklus

=

Outputs of muting indicators

For lamp 24 V DC/5 W max.

LED indicators 24 V DC, 0.5 W to 5 W

Signal output

State of protective fields S1 to S2

Signal outputs

MSI error, muting error

Warning output

Muting indicator defective

Safety outputs

(Technical data, see below)

pnp – switching outputs

Muting function on

Active high, 24 V DC,

200 mA max.

Muting function off

Active low

pnp – switching output

All protective fields free

Active high, 24 V DC,

100 mA max.

Not all free

Active low

Push-pull transistor

outputs, each

No error message

Active high, 24 V DC,

60 mA max.

Error message

Active low

Push-pull transistor

output

No warning

Active high, 24 V DC,

60 mA max.

Warning indicator 1

Warning indicator 2

Impulse 1x

Impulse 2x

Relay outputs Via /R output

Supply voltage 24 V DC, ± 20%, external power supply unit (PELV) with

safe mains separation and equalization for 20 ms voltage

dip required

Current consumption Approx. 200 mA without external load

External fuse (power supply) 2.5 A mT

Housing

Degree of protection

IP 20; installation in switch cabinet or housing with degree

of protection of at least IP 54; mounting on 35 mm

standard top-hat rail

Protection class III

Ambient temperature, operation 0 … + 55 °C

Ambient temperature, storage -25 … + 70 °C

Relative humidity 93 % max.

Connection technology (GS-ET-20: 2014) Pluggable, coded screw terminals

Cable cross section min., rigid, flexible: 0.14 mm²

Cable cross section max., rigid, flexible: 2.5 mm²

Cable cross section AWG/kcmil, min./max.: 26/14

Cable cross section UL AWG/kcmil: 30-12

Dimensions See dimensional drawing

*n

= mean number of annual actuations, see C.4.2 and C.4.3 of EN ISO 13849-1:2015

op

Use the following formula to calculate the mean number of annual actuations:

In doing so, make the following assumptions with regard to the use of the component:

h

= mean operating time in hours per day

op

d

= mean operating time in days per year

op

t

= mean operating time between the start of two successive cycles of the component (e.g switch-

cycle

ing of a valve) in seconds per cycle

Leuze electronic GmbH + Co. KG MSI-m(E)/R 29

Technical data and order guide

70 *

)

Output

8 9107

11

R -

12

Fault

Locked

State

Leuze

45

1

2

6

electronic

3

23

20 2119

22

24

31

34

MSI- mE

MSI Fault

S1 & S2

Diagn.

161817 28

141315

25

Fault

32 33

35

36

lamp

warn.

Muting

30

29

26 27

113.6

111

99.0

52.5 *

)

Output

8 9107

11

R -

23

20 211219

22

24

31

34

MSI- m

Fault

Locked

State

MSI Fault

S1 & S2

Diagn.

Leuze

45

1

2

6

161817 28

electronic

143

13

15

25

Fault

32 33

35

36

lamp

warn.

Muting

30

29

26 27

7.2 /R output

OSSD safety outputs

Switching voltage/switching current

Safety outputs protection class II

Rating voltage for safety outputs Overvoltage category 3 / 300 V AC

OSSD external fuse (EN 60269-1) 4 A gG D-fuse

Contact currents (EN 60947-5-1) AC15, 3 A

OSSD reaction time MSI

(without AOPD)

OSSD restart delay time > 100 ms

OSSD-suitable spark extinction via the

coils of the downstream relays

Do not use "Status of switching outputs" signal output for safety circuit!

2 safety-related normally open contacts,

60 V DC, 250 V AC, 5 A max.

Minimum switching current 20 mA

DC13, 2 A

For AOPD type 4, transistor output

For AOPD type 4, relay output

For AOPD type 2

For safety switches

22 ms

64 ms

64 ms

64 ms

(electro-mechanical)

Required

pnp switching output

OSSDs ON state:

Active high,

24 V DC,

100 mA max.

OSSDs OFF state:

Active low

Signal output

"State of start/restart interlock"

7.3 Dimensioned drawing

*) Stringing together without distance possible

pnp switching output

Locked:

Not locked:

Active high,

24 V DC,

100 mA max.

Active low

Leuze electronic GmbH + Co. KG MSI-m(E)/R 30

Technical data and order guide

7.4 Order guide

Type Order no.

MSI-m/R 549904

MSI-mE/R 549980

MSI diagnostic software 549930

Diagnostics cable 3 m 549953

Diagnostics cable 5 m 549955

/R output assembly (replacement

part)

509210

Leuze electronic GmbH + Co. KG MSI-m(E)/R 31

EC Declaration of Conformity

8 EC Declaration of Conformity

Leuze electronic GmbH + Co. KG MSI-m(E)/R 32

EC Declaration of Conformity

Leuze electronic GmbH + Co. KG MSI-m(E)/R 33

EC Declaration of Conformity

Leuze electronic GmbH + Co. KG MSI-m(E)/R 34

Loading...

Loading...