Page 1

LUDLUM MODEL 52-1 FAMILY

PORTABLE SCINTILLATION PORTAL MONITORS

July 2018

Serial Number 210041 and Succeeding

Serial Numbers

Page 2

LUDLUM MODEL 52-1 FAMILY

PORTABLE SCINTILLATION PORTAL MONITORS

July 2018

Serial Number 210041 and Succeeding

Serial Numbers

Page 3

Page 4

STATEMENT OF WARRANTY

Ludlum Measurements, Inc. warrants the products covered in this manual to be free of

defects due to workmanship, material, and design for a period of twelve months from

the date of delivery. The calibration of a product is warranted to be within its

specified accuracy limits at the time of shipment. In the event of instrument failure,

notify Ludlum Measurements to determine if repair, recalibration, or replacement is

required.

This warranty excludes the replacement of photomultiplier tubes, G-M and

proportional tubes, and scintillation crystals which are broken due to excessive

physical abuse or used for purposes other than intended.

There are no warranties, express or implied, including without limitation any implied

warranty of merchantability or fitness, which extend beyond the description of the

face there of. If the product does not perform as warranted herein, purchaser’s sole

remedy shall be repair or replacement, at the option of Ludlum Measurements. In no

event will Ludlum Measurements be liable for damages, lost revenue, lost wages, or

any other incidental or consequential damages, arising from the purchase, use, or

inability to use product.

RETURN OF GOODS TO MANUFACTURER

If equipment needs to be returned to Ludlum Measurements, Inc. for repair or calibration, please

send to the address below. All shipments should include documentation containing return shipping

address, customer name, telephone number, description of service requested, and all other necessary

information. Your cooperation will expedite the return of your equipment.

LUDLUM MEASUREMENTS, INC.

ATTN: REPAIR DEPARTMENT

501 OAK STREET

SWEETWATER, TX 79556

800-622-0828 325-235-5494

FAX 325-235-4672

Page 5

Page 6

Page 7

Model 52-1 Family Technical Manual

Table of Contents

Introduction 1

Specifications 2

User Operation 3

Assembly Instructions 3-1

Operational Check 3-3

Personnel Monitoring 3-3

Description of Controls and Functions 4

Front Panel 4-1

AC Panel 4-3

Parameters and Functions 4-3

RS-232 Port 4-5

Water Resistant Sleeve 4-6

Theory of Background Management 4-6

Safety Considerations 5

Environmental Conditions for Normal Use 5-1

Cleaning Instructions and Precautions 5-1

Electrical Safety Precautions 5-2

Warning Markings and Symbols 5-3

Maintenance and Recalibration 6

Maintenance 6-1

Recalibration 6-1

Checkout Procedure 7

General 7-1

Equipment Required 7-1

Checkout Procedure 7-1

Page 8

Model 52-1 Family Technical Manual

Recycling 8

Parts List 9

Models 52-1, 52-1-1, 52-5, 52-5-1, 52-6 and 52-6-1 Portable Scintillation Porta Monitors 9-1

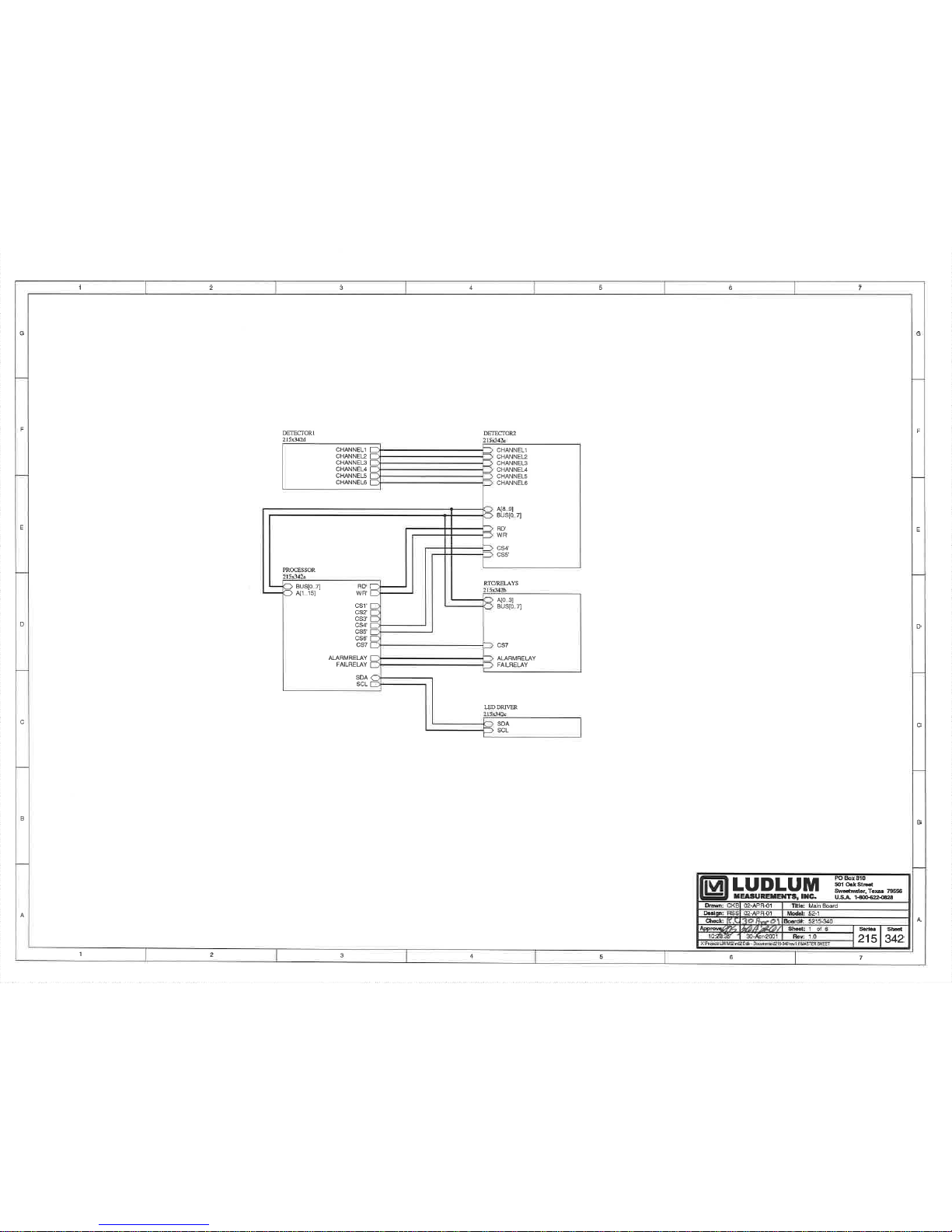

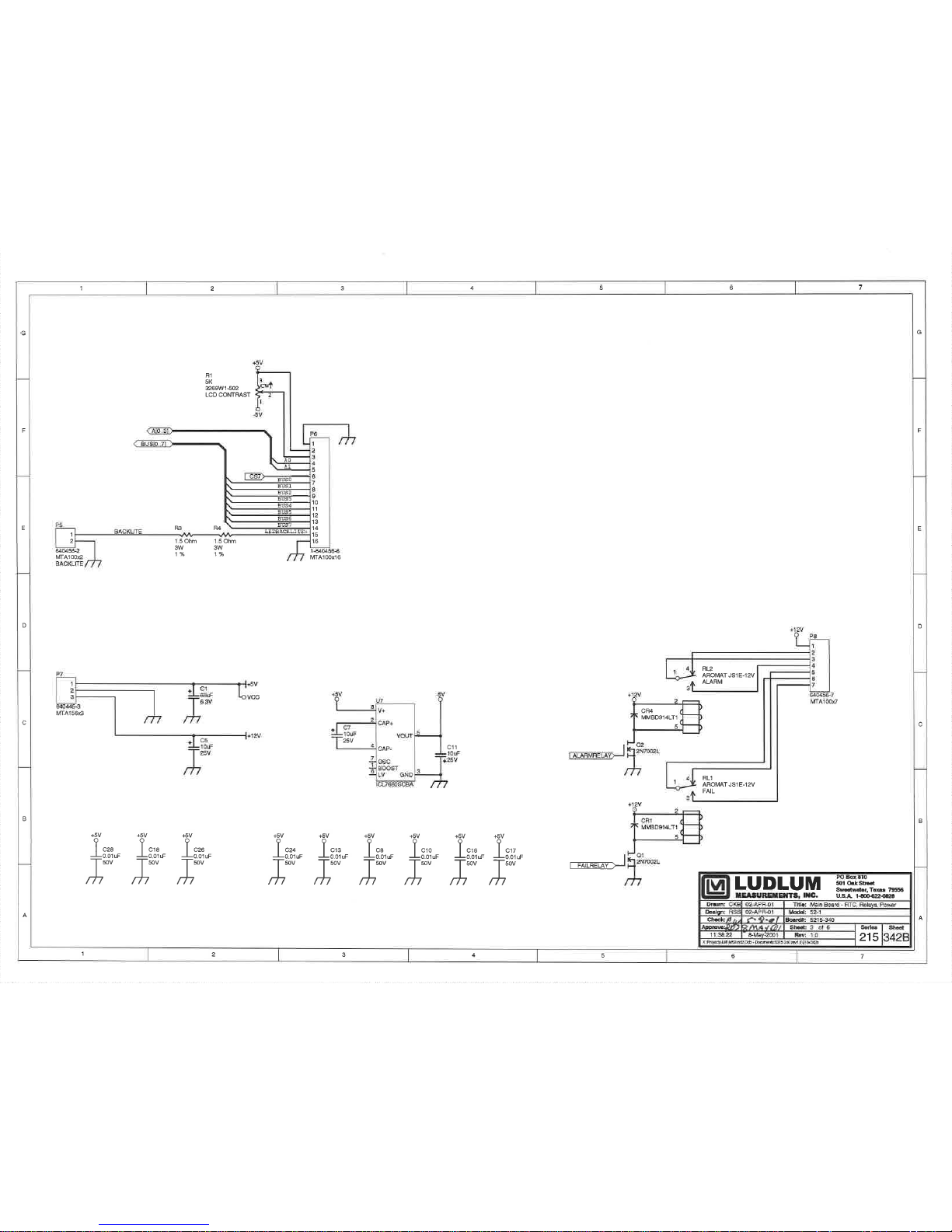

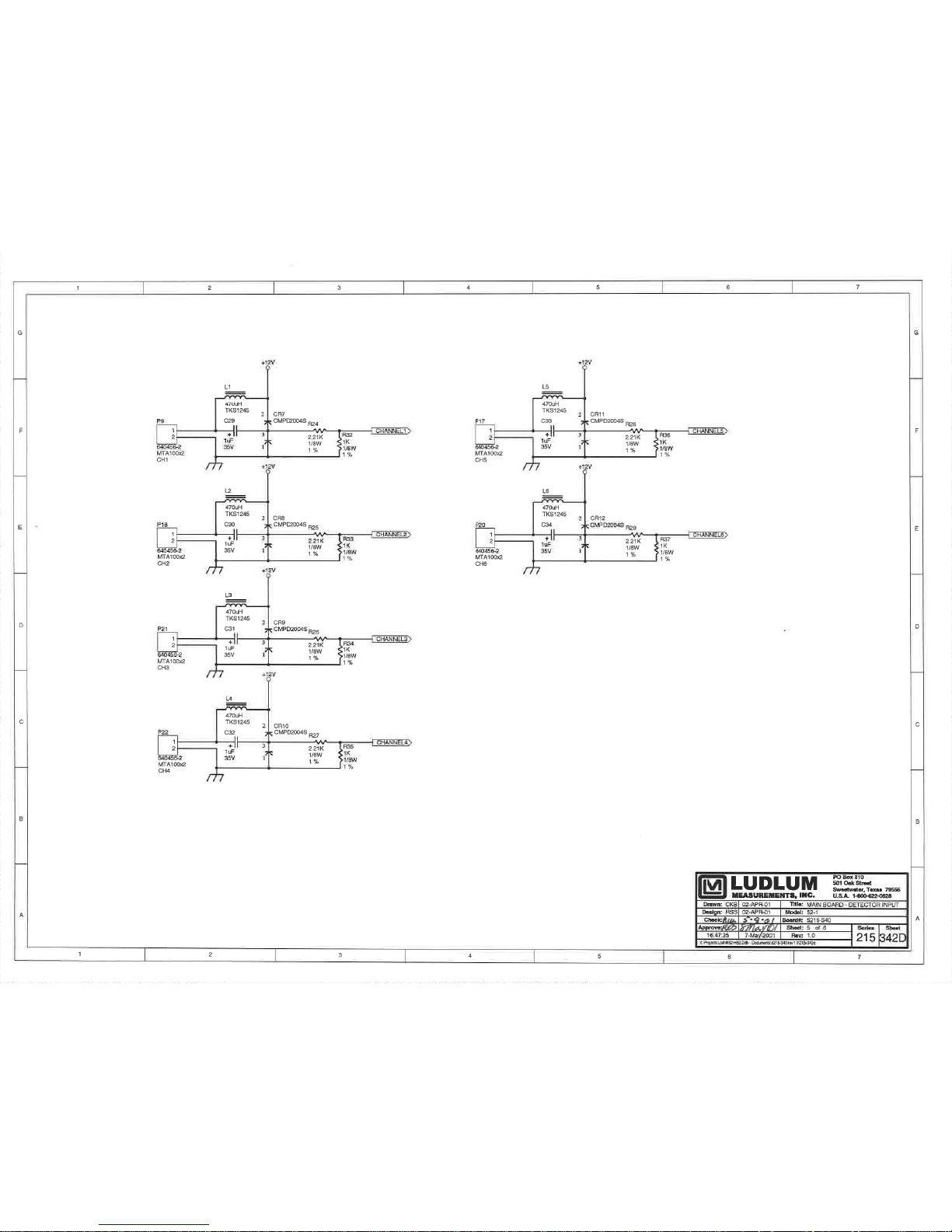

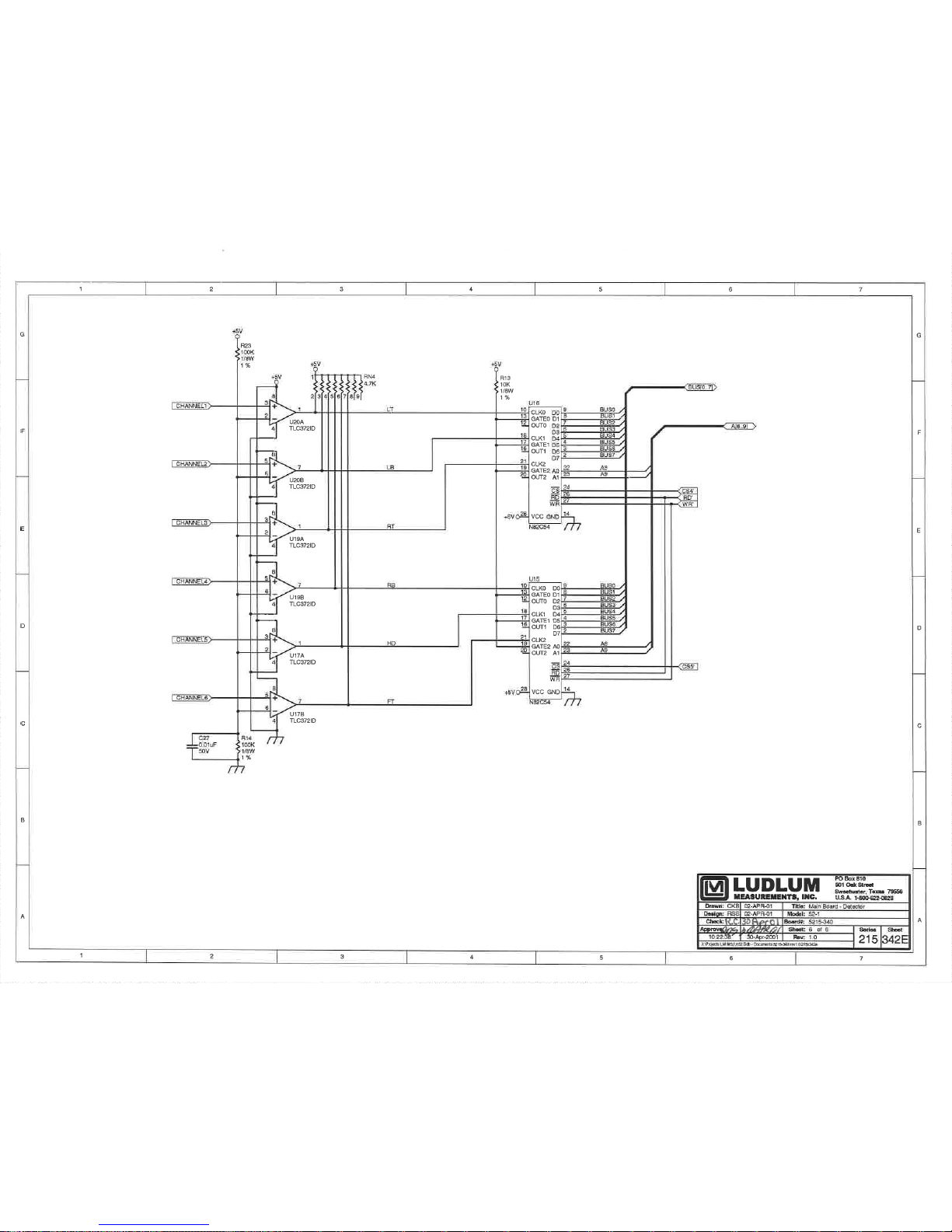

Main Board, Drawing 215 x 342-342E 9-1

Detector Interface Board, Drawing 215 x 347 9-4

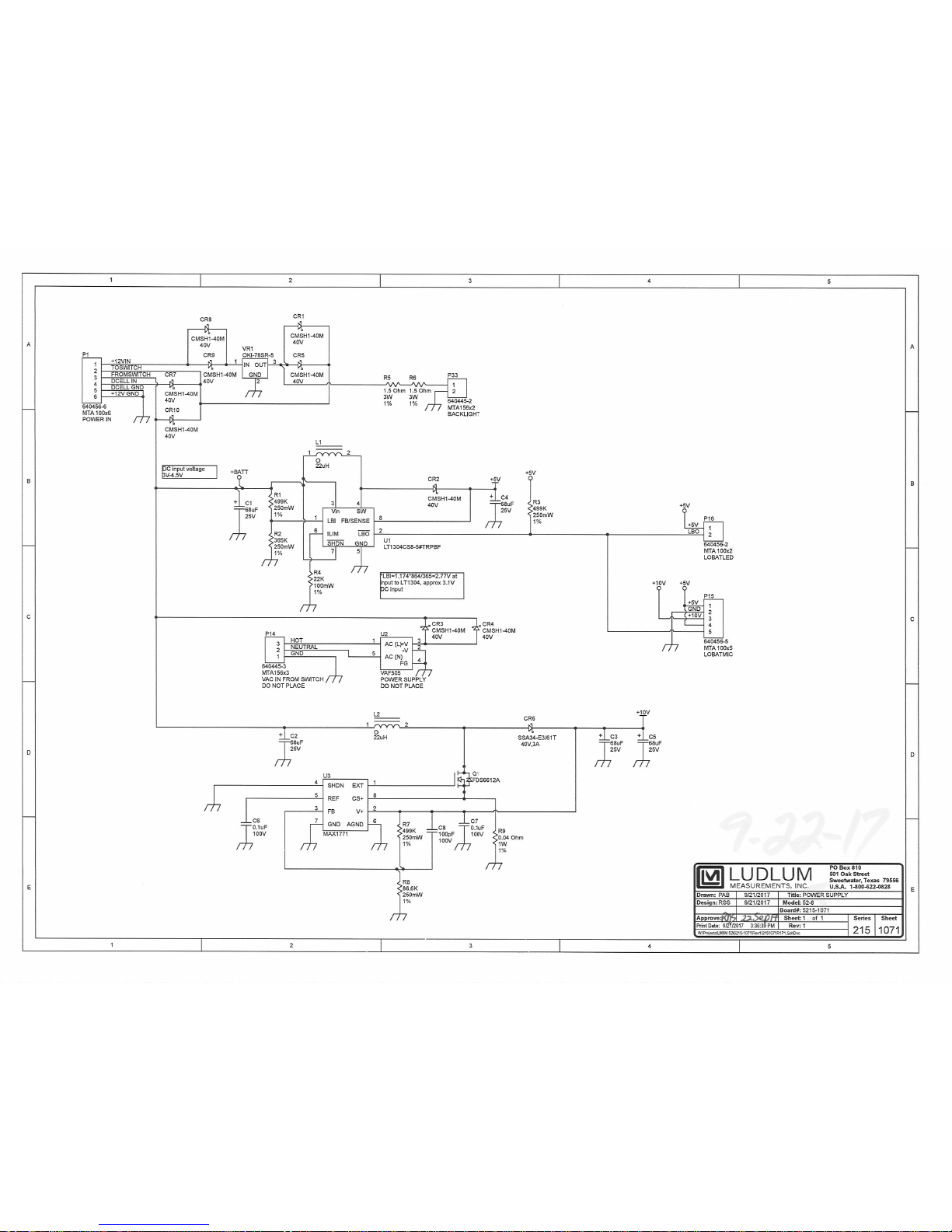

Power Supply, Drawing 215 x 1072 9-5

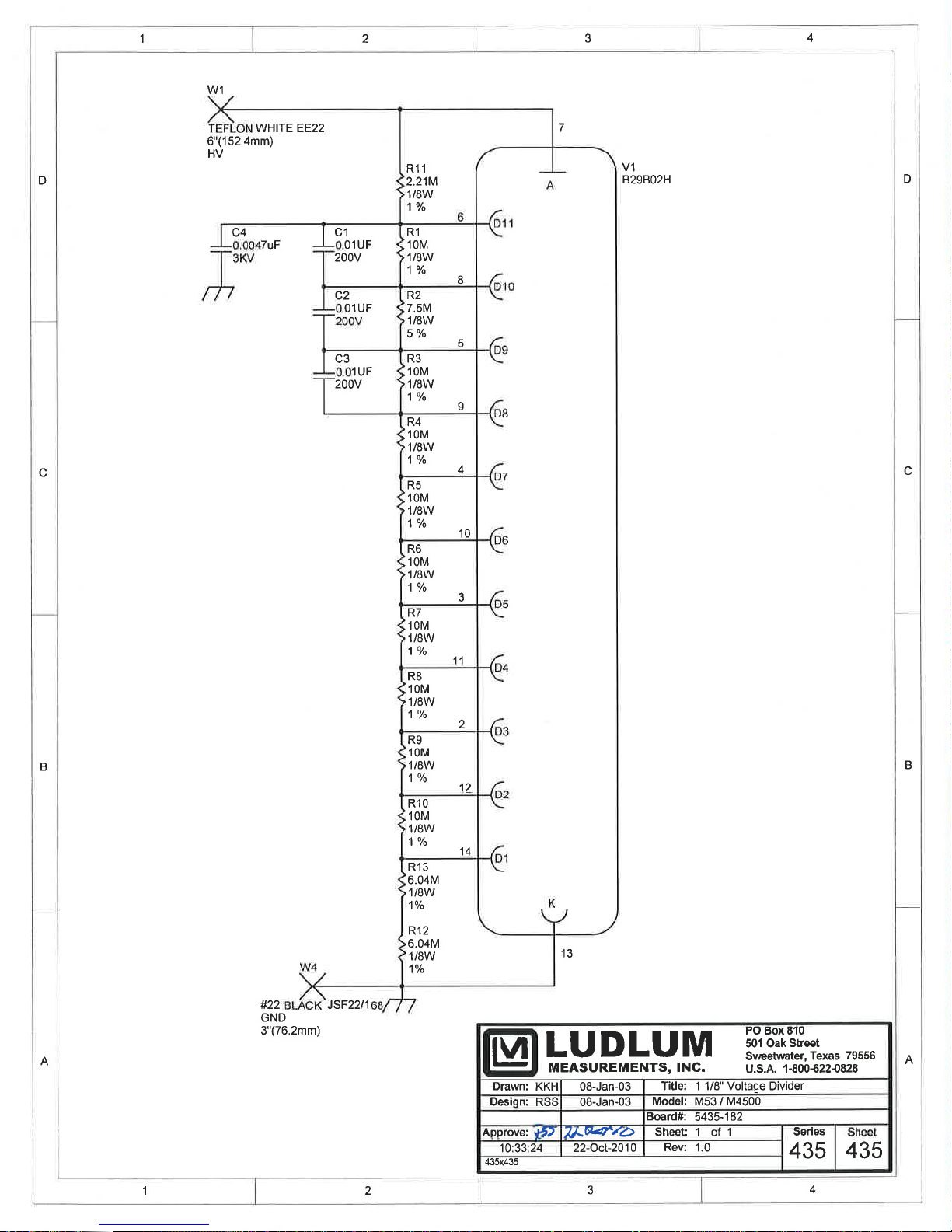

1 1/8 inch Voltage Divider, Drawing 435 x 435 9-6

Resistor Board, Drawing 215 x 782 9-7

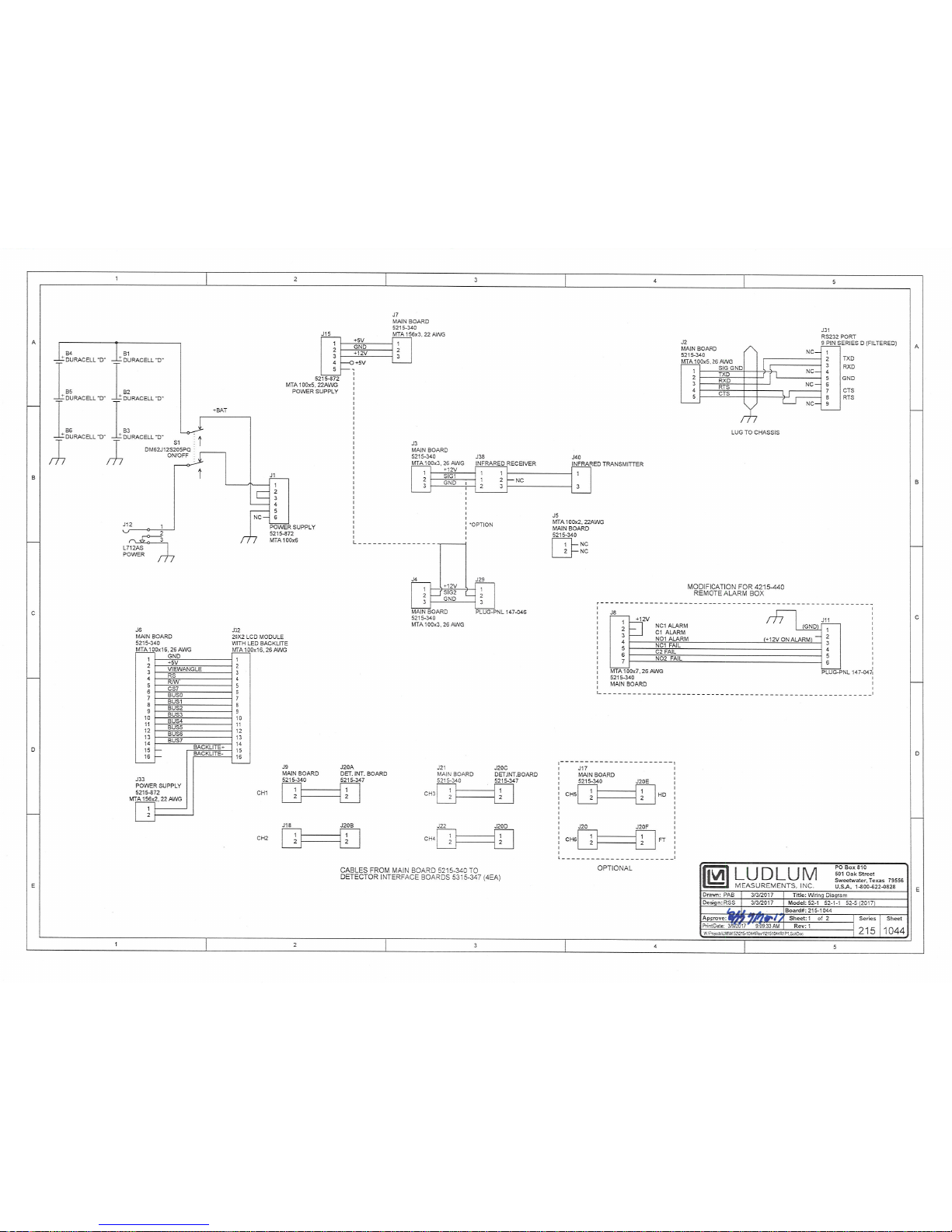

Wiring Diagram, Drawing 215 x 1044 9-7

Retrofit Miscellaneous 9-8

Drawings and Diagrams 10

Page 9

Model 52-1 Family Technical Manual Section 1

Model

# of Detectors

Inside Width

Volume (Total)

52-1

4

24 inches

672 in

3

52-1-1

4

32 inches

672 in3

Model

# of Detectors

Inside Width

Volume (Total)

52-5

5

24 inches

780 in3

52-5-1

5

32 inches

780 in3

52-6

6

24 inches

888 in

3

52-6-1

6

32 inches

888 in3

Section

1

Introduction

The Model 52-1 family includes the Model 52-1, 52-5, and 52-6 series of

instruments. They are Portable Scintillation Portal Monitors, which are

used for beta/gamma personnel radiation monitoring. They are

designed to detect very low levels of radiation coming from personnel

who walk through the portal.

Model 52-1 and 52-1-1

The Model 52-1 and 52-1-1 have four side detectors. The only

difference between the Model 52-1 and the Model 52-1-1 is in the width

of the portal monitor. The 52-1-1 is 8 inches wider.

Model 52-5, 52-5-1, 52-6, and 52-6-1

The Model 52-5 and 52-6 have the same width dimensions as the Model

52-1. The Model 52-5 is about an inch taller due to the addition of a

detector in the base. It has 5 detectors. The Model 52-6 uses 6 detectors,

with another additional detector located at the top. Both the 52-5-1 and

the 52-6-1 have 8 inches more width in the portal monitor than the 52-5

and 52-6 have.

These instruments all meet the Federal Emergency Management

Agency (FEMA) standard for Emergency Response Portal Monitoring

Ludlum Measurements, Inc. Page 1-1 July 2018

Page 10

Model 52-1 Family Technical Manual Section 1

(FEMA-REP-21). They are designed to be disassembled for ease of

transportation and storage, and can be assembled in five minutes or

less without tools. All parameters are stored in non-volatile memory,

which requires no battery backup. These parameters allow easy

operation with minimal setup by minimally trained personnel. The

parameters are pre-set at the factory to detect a 1.0 µCi (37.5 kBq)

source in a 10 µR/hr (0.1 µSv/h) background field, in accordance with

the FEMA standard.

These instruments also comply with the applicable European Standards

required for CE marking of the instruments.

The electronics are microprocessor-based for ease of setup and

reliability. Status LEDs indicate count cycle status. Audible signals

(which may be turned off to avoid alarming the occupants) accompany

the LEDs for additional indication. Audio levels can also be controlled

by rotating the baffle at the front of the audio device. Detector counts,

background, and all parameters may be viewed on the Liquid Crystal

Display (LCD). All setup is accomplished by way of push buttons

located below the LCD.

These portal monitors can be operated in a walk-through basis with a

quick scan occurring while a person is positioned within the portal. In

this mode, checking is performed every 200 milliseconds while the

portal is occupied, 600 milliseconds before, and 600 milliseconds after

the portal is occupied. The portal monitor can also monitor in a stopand-count mode, allowing for a more sensitive scan. In stop-and-count

mode, the fixed count time may be set from 1 to 20 seconds.

These instruments have automatic background update and dynamic

alarm setting capabilities. On startup, the instrument will take a

background count and calculate alarm levels for each detector. Selfdiagnostic routines check the background count and warn if the

background becomes either too high or too low. Alarms are calculated

with a user-adjustable sigma parameter and the current background

count. During setup, the user can also specify individual alarms only,

sum alarm only, or both individual and sum alarms. The sum alarms

combine the results of the top detectors and of the bottom detectors.

All four models are able to operate from 85-250 Vac 50/60Hz. They

may also be operated from three or six “D” cell batteries using a

supplied power supply or from the supplied cigarette lighter adapter

cable. Battery lifetime is approximately 28 hours.

137

Cs

Ludlum Measurements, Inc. Page 1-2 July 2018

Page 11

Model 52-1 Family Technical Manual Section 2

Section

2

Specifications

Display (Setup): 2 line-by-20-character LCD, backlit when operated from

AC power

Display (User): five large status LEDs on one side of portal, and detector

LEDs to show alarm location

Detector High Voltage: 700-1200 V

Detector Threshold: -4 mV

Count Time: adjustable from 0 to 20 seconds (“0” indicates walk-through

mode)

Power: can be powered from either a 85-250 Vac, 50/60 Hz, using a

supplied 12 Vdc wall adapter; supplied 12 Vdc cigarette lighter adapter

cable; or from three or six D cell batteries. Typical battery life is 69 hours

using six fresh alkaline batteries and 28 hours using three fresh batteries.

Output: RS-232 and dry contacts for radiation alarm and failure

conditions

Sensitivity: 1 µCi (37.5 kBq)

µSv/h) background field

Energy Response: 30 keV to 3 MeV

Audio: an alarm with an adjustable baffle for portal entry and incomplete

audio, and a continuous beeping for radiation alarm and instrument failure

audio. The "AUDIO ON?" parameter in setup mode (default Yes or

enabled) can be changed to NO to disable the audio.

137

Cs in walk-though mode in 10 µR/hr (0.1

Ludlum Measurements, Inc. Page 2-1 July 2018

Page 12

Model 52-1 Family Technical Manual Section 2

Outside Dimensions (when set up):

For Model 52-1: 211 x 81.3 x 45 cm (83 x 32 x 17.5 in.) (H x W x L)

For Model 52-1-1: 211 x 102 x 45 cm (83 x 40 x 17.5 in.) (H x W x L)

For Model 52-5: 213 x 81.3 x 48 cm (84 x 32 x 19.3 in.) (H x W x L)

For Model 52-5-1: 213 x 102 x 49 cm (84 x 40 x 19.3 in.) (H x W x L)

For Model 52-6: 217 x 81.3 x 49 cm (85.3 x 32 x 19.3 in.) (H x W x L)

For Model 52-6-1: 217 x 102 x 49 cm (85.3 x 40 x 19.3 in.) (H x W x L)

* With the optional stabilizer legs, add 91.4 cm (36 in.) in length to all

models.

Inside Dimensions (when set up):

For Model 52-1: 206 x 61 cm (81 x 24 in.) (H x W)

For Model 52-1-1: 206 x 81 cm (81 x 32 in.) (H x W)

For Model 52-5: 206 x 61 cm (81 x 24 in.) (H x W)

For Model 52-5-1: 206 x 81 cm (81 x 32 in.) (H x W)

For Model 52-6: 206 x 61 cm (81 x 24 in.) (H x W)

For Model 52-6-1: 206 x 81 cm (81 x 32 in.) (H x W)

Case Dimensions: 122 x 61 x 30.5 cm (48 x 24 x 12 in.) (H x W x D)

(Same case is used for all four models.)

Detector Size: Each of the four side detectors has 2753 cm

3

(168 in3) of

plastic scintillator. The foot (base) and head detectors in the Model 52-5,

52-5-1, 52-6, and 52-6-1 all have 1770 cm3 (108 in3) of plastic scintillator.

Weight:

Models 52-1 and 52-1-1: approximately 32 kg (70 lb), 45 kg (100 lb) in

case

Models 52-5 and 52-5-1: approximately 36 kg (80 lb), 50 kg (110 lb) in

case

Models 52-6 and 52-6-1: approximately 41 kg (90 lb), 54 kg (120 lb) in

case

Ludlum Measurements, Inc. Page 2-2 July 2018

Page 13

Model 52-1 Family Technical Manual Section 3

Section

3

T

User Operation

0

his section gives instructions how to set up and use the instrument to

monitor a person for radiation.

Assembly Instructions

This section gives instructions on how to assemble these instruments

and get them ready for use.

The portal monitor comes in a container that can be used for shipping

and storage. The pieces and quantities that make up the system are:

1 - Base

1 – Bottom Left (Section L1)

1 – Top Left (Section L3)

1 - Top Section

1 - Electronics Section

1 - Power Cord

1 - Remote electronics extension cable (optional)

2 – Stabilizer Legs (optional)

Unpack the container and inventory to ensure that all pieces are present.

Any of the four models of the portal monitor can be assembled without

tools. All connections are made with latches. To connect a latch, lift up

the bottom tab, hook the top cross bar into the hook on the piece that

you are attaching, and push tab back down until it snaps into place.

Ludlum Measurements, Inc. Page 3-1 July 2018

Caution!

Exercise care when unlatching pieces, as the latches can spring

open violently.

Page 14

Model 52-1 Family Technical Manual Section 3

To unlatch, lift up the tab and unhook the top cross bar.

Set the BASE on the ground with the rectangular tubes pointing up.

If optional stabilizer legs are provided, attach to the BASE, front and

rear, with screws provided.

Insert the male end of the Bottom Right section into the female side

bracket of the base marked RIGHT SIDE BASE and attach the

latches. The detector screens must be facing the middle of the portal.

Insert the male end of the Top Right section into the female end of the

Bottom Right section and attach the latches.

Repeat the process for the LEFT side.

Insert the TOP into the tops of the side sections and attach the latches.

The top can be installed in either direction. It does not matter which

end goes to the right.

Plug the connector end onto the back of the Bottom Left section with

the blank end facing down. First, engage the black connectors. Then

ensure that the pin on the back of the Bottom Left section goes into the

hole on the electronics. Attach the latches. If you are using the optional

Remote Electronics Extension Cable, connect one end of the cable to

the Bottom Left section and the other end to the Electronics. Locate

the electronics as desired.

If you have line voltage available, plug the POWER CORD into the

connector on the bottom of the electronics marked INPUT. If not,

install 3 “D” Cell batteries into the battery compartment. The power

cord and batteries may both be installed at the same time, but the portal

monitor does not charge the batteries.

Turn on the POWER switch located on the bottom of the electronics

and allow the instrument to finish updating. If the preprogrammed

settings are acceptable, it is ready for use. Proceed to the next section.

If the settings need to be changed or checked, proceed to Parameter

Setup, Section 4.

Disassembly is reverse of assembly.

Ludlum Measurements, Inc. Page 3-2 July 2018

Page 15

Model 52-1 Family Technical Manual Section 3

Operational Check

To ensure that these instruments are functioning correctly, an operational

check should be performed routinely or before using the instrument. This

check verifies that the instrument is turned on, that the settings are

appropriate, and that the system alarms when the detectors are exposed to

excess radiation (above background level). Ludlum Measurements suggests

that this operational check be performed after setup and before use. As long

as the system passes the operational check, no calibration or other checks are

necessary. If the response or any function of the portal monitor changes,

the instrument should be checked and brought into compliance with the

manufacturer’s original specifications.

Check each of the detectors for sensitivity to beta/gamma radiation. Verify

that you get a RADIATION ALARM, using the check source supplied with

the instrument (normally a

In walk-through mode, simply walk through the portal, holding the source in

proximity to a detector. This action should cause the portal to enter the

RADIATION ALARM status until the alarm time parameter is complete.

In stop-and-count mode, you should stand in the portal for the duration of

the count time. At the end of the count time, the portal should enter the

RADIATION ALARM status until the alarm time parameter is complete.

137

Cs, 1 µCi or 37.5 kBq activity source.

Repeat alarm checks for all four sections to confirm that all detectors are

functioning.

To also provide assurance that the instrument meets the FEMA emergency

response criteria prior to operation of this portal, do the following: Pass the

1 µCi (37.5 kBq)

137

Cs checksource through the center of the portal at several

points between 15.2 and 168 cm (0.5 and 5.5 ft) from the floor of the portal

and verify that the alarm is triggered each time. If the portal does not alarm

each time, the user may need to adjust the count time, the alarmpoints, or

move the portal to a location with lower background radiation.

Personnel Monitoring

A count starts when someone blocks the infrared beam. A count can

only be started when the system is in the ENTER mode. Do not enter

the portal while the yellow UPDATING status LED is flashing.

Prior to personnel monitoring, the monitor must be allowed to update the

background count. This mandatory update occurs just after power-up, and

takes one minute. New background data is compared to the low and high

Ludlum Measurements, Inc. Page 3-3 July 2018

Page 16

Model 52-1 Family Technical Manual Section 3

background setpoints that have been programmed into the unit. If the

setpoints have been exceeded, an INSTRUMENT FAILURE alarm is

given, and the unit attempts to update background. The instrument will

continue to update the background until the alarm condition has been

corrected; that is, when the background goes down or failed detectors are

repaired. Please note, however, that high levels of external radiation can

cause the INSTRUMENT FAILURE alarm.

To check someone for radiation, follow the steps below:

The green ENTER light must be illuminated in order to use the

instrument. A yellow UPDATING light may be flashing,

indicating that a background update is taking place. When the

UPDATING light is flashing, the system should not be used,

and all people to be checked should remain at least 1.8 m (6 ft)

away until the ENTER light is illuminated.

The subject steps into the portal, breaking the infrared beam,

and the green READY light will start flashing, indicating that

the portal is now CHECKING. A soft, low-pitched beep will

also occur.

In walk-through mode, the subject may simply continue walking

through the portal. In stop-and-count mode, the yellow

INCOMPLETE light will illuminate if the subject leaves the

portal before the count is complete. A soft, low-pitched beeping

will also warn the subject to return to the portal to finish the

count.

When the count is complete, the green ENTER light or the red

RADIATION ALARM light will be illuminated. In stop-and-

count mode, a second soft, low-pitched beep will occur.

The subject then steps out of the portal.

During operation, a buffer zone of at least 3 m (9.8 ft) (in all directions)

should be established around the monitor, to reduce the possibility of

measurement interferences from external sources. Subjects waiting to be

measured should remain outside the buffer zone until it is their turn to be

measured.

If a measurement results in an alarm, the subject should walk through the

monitor a second time from the opposite direction (and possibly a third

time) to validate the alarm. This alarm validation process minimizes the

Ludlum Measurements, Inc. Page 3-4 July 2018

Page 17

Model 52-1 Family Technical Manual Section 3

possibility the alarm was caused by a momentary, coincidental highbackground event.

Once an alarm has been validated after one (or two) confirming

measurements, the subject can be moved away (>10 m) from the monitor,

and a secondary scan with a hand-held meter can be performed to identify

the location(s) of the contamination or point source.

Note:

The red detector alarm light LEDs will offer guidance as to the

probably location(s) of the radioactivity on the subject.

Ludlum Measurements, Inc. Page 3-5 July 2018

Page 18

Model 52-1 Family Technical Manual Section 4

Section

4

Description of Controls and

Functions

Front Panel

Readout: Liquid Crystal Display (LCD), 2-line, 20-character

alphanumeric display. Background and alarm data is displayed.

Increment (Up Arrow ) Button: increases or changes a parameter

when in setup mode. To enter setup mode, press and hold the Up

Arrow button while turning ON the instrument at the switch under the

control box. Instrument parameters may only be changed while in the

setup mode.

Decrement (Down Arrow ) Button: decreases or changes a parameter

when in setup mode. During instrument operation, pressing this key

will show the number of alarms and the number of passages since

power-up.

Enter Key: selects or advances display. If the ENTER key is pressed

while turning the instrument ON, the instrument is loaded with a set of

default parameters. The parameters that are set are:

Default Value

Language English

Month 1 (January)

Day 2

Year 00

Hour 8

Minute 15

Count Time 0 sec

Alarm Time 15 sec

Incomplete Time 10 sec

RDA Size 500

Low Bkgnd (background) 20

High Bkgnd (background) 2000

Sigma 4.5

LT Active Y

LB Active Y

Ludlum Measurements, Inc. Page 4-1 July 2018

Page 19

Model 52-1 Family Technical Manual Section 4

RT Active Y

RB Active Y

*HD Active Y (* for Models 52-5 and 52-6 only)

*FT Active Y (* for Models 52-5 and 52-6 only)

Individual Alarms Y

Sum Alarms Y

# of Samples 2

Bkgnd Update 8

LT Attenuation 0.0%

LB Attenuation 0.0%

RT Attenuation 0.0%

RB Attenuation 0.0%

*HD Attenuation 0.0% (* for Models 52-5 and 52-6 only)

*FT Attenuation 0.0% (* for Models 52-5 and 52-6 only)

Audio On Y

The default condition is for all detectors to be active.

Detector LEDs: indicate location of radiation alarm (see front panel

drawing in front of manual for LED layout).

Status LEDs (side of portal): (see front panel drawing in front of manual

for LED layout).

Enter/Checking green LED: normally illuminated prior to any personnel

entry, indicating that the system is ready to take a count. It flashes to

indicate the system is checking for excess radiation. It stops flashing at

the end of the count time in stop-and-count mode or whenever the user

leaves the portal in walk-through mode.

Incomplete/Updating yellow LED: indicates that a count was in progress

and the subject stepped out of the portal before the count was complete.

The INCOMPLETE LED stays on for the incomplete time or until the

subject steps back into the portal. An INCOMPLETE resets the count

time.

If no one steps back into the portal during the incomplete time, the portal

monitor goes back to the ready state, illuminating the ENTER LED.

This LED also indicates UPDATING background while flashing. Do

not enter or allow personnel within 1.8 m (6 ft) while the unit is updating

background.

Radiation Alarm red LED: indicates that the system has detected

radiation levels above background.

Instrument Failure red LED: indicates that the system has detected a

high- or low-background condition. If there is a background problem, the

UPDATING LED will also be illuminated.

Ludlum Measurements, Inc. Page 4-2 July 2018

Page 20

Model 52-1 Family Technical Manual Section 4

Low Battery red LED: indicates the batteries are low and must be

replaced immediately.

AC Panel

Line Fuse: fuses to limit current from the AC outlet. The

fuses are Littlefuse F-1A or equivalent.

Input: line voltage input, 85-250 Vac, 50/60 Hz, 250 W

RS-232: RS-232 port so that instrument can be connected to

a printer or a computer

Batteries: instrument may be powered using three or six

each “D” cell batteries

Relay: 6-pin connector to connect internal relays

Relay pinouts:

P1 Alarm Normally Closed

P2 Alarm Common

P3 Alarm Normally Open

P4 Instrument Fail Normally Closed

P5 Instrument Fail Common

P6 Instrument Fail Normally Open

EXT Switch: 3-pin connector for an external activation

switch. External switch can be a passive push-button switch,

or can be an NPN-transistor output infrared sensor.

Parameters and Functions

This section lists the different parameters of these instruments and their

functions. To enter setup mode, press and hold the Increment (Up Arrow)

Button while turning ON the instrument at the switch under the control

box. This will allow the user to change the parameters.

Language: The language is set to English.

Month: adjustable from 1 to 12, which indicates the month.

Day: represented by one number, from 1 to 7.

Year: represented by two numbers.

Count Time: adjustable from 0 to 250 seconds, where 0 sets the portal in

the walk-through mode.

Ludlum Measurements, Inc. Page 4-3 July 2018

Page 21

Model 52-1 Family Technical Manual Section 4

Alarm Time: adjustable from 1 to 255 seconds. This parameter controls

the duration of the RADIATION ALARM and is indicated by a steady

tone from audio.

Incomplete Time: adjustable from 1 to 255 seconds. This parameter

controls the duration of INCOMPLETE, which is indicated by a lowpitched, beeping sound.

RDA Size: This number, in nCi, indicates the size of the source used

during the automatic RDA calculation. (The Model 52-1 does not utilize

the automatic RDA feature, and the RDA size is set to 500.)

Low Background (BKGND) Alarm: This parameter sets the number of

counts per 0.2-second interval that the background should not fall below

in normal operation. If background falls below this level, an

INSTRUMENT FAILURE alarm will occur. This alarm indicates if a

detector has failed or is not connected. This alarm will also indicate if the

ambient background has decreased significantly.

High Background (BKGND) Alarm: This alarm is the opposite of the

LOW BACKGROUND alarm. This alarm will indicate that background

radiation has increased or that a detector has failed.

Sigma: This parameter sets the number of standard deviations above

background that it takes to set off an alarm. A standard deviation is

assumed to be equal to the square root of the background count. As a

simple example, a 3-sigma alarm of a detector with a background count

rate of 100 counts is calculated as 3.0 times the square root of 100, or 30.

In this simple example, a sudden count of 130 counts would cause an

alarm.

Detector Activity: This parameter notifies the user whether or not the

detector is active, indicated with a “Y” for “yes” or an “N” for “no.”

Individual Alarms: An alarm can be set individually for each detector.

This parameter indicates whether one is set and informs the user with a

“Y” for “yes” or an “N” for “no.”

Sum Alarms: This parameter informs the user whether a sum alarm, a

contribution from multiple detectors, is set, indicated with a “Y” for

“yes” or an “N” for “no.”

# of Samples: In walk-through mode, this number determines how many

0.2-second samples to group for each alarm calculation.

BKG Update: This number, adjustable from 1 to 9, adjusts how fast the

background is updated while the portal is unoccupied. The BKG

UPDATE number, multiplied by 18 seconds, gives the response time of

the internal background accumulation.

Ludlum Measurements, Inc. Page 4-4 July 2018

Page 22

Model 52-1 Family Technical Manual Section 4

Attenuation: This parameter is used in the stop-and-count mode to

compensate for the shielding effect of a human body inside the portal.

This parameter will vary depending on local background radiation.

Typical setpoints might be 0.5% to 2.0%. To determine this parameter,

find the percentage decrease in background with an average-sized person

inside the portal. Alternatively, measure the percentage decrease of

several different people, and then determine the average decrease.

Although the shielding effect is slight, this parameter is very useful for

highest sensitivity applications. If not being used, this parameter should

be set to 0.0%.

AUDIO ON (Y/N): "Yes" enables the audio, "No" disables the audio

RS-232 Port

The RS-232 port allows the instrument to be connected to a printer or a

computer so that a record can be kept of the activity of the instrument.

When connected to a printer - When the instrument is first turned on,

the printer will print the parameter settings. From then on, when an

alarm occurs, the printer will print out the time and date, the

background counts, and the number of sigma above background for all

channels. See the example below.

When connected to a computer - The instrument will send the same

data to a computer that it sends to a printer (see above).

The RS-232 port operates at 9600 baud, 8 data bits, 1 stop bit, no parity

(9600,8,N,1).

An example print-out from the Model 52-1 RS-232 port after power-on is

shown here:

LUDLUM MODEL 52-1 PORTAL

02-JAN-00 14:52

SETUP REPORT

SIGMA= 4.5

COUNT TIME=000

ALARM TIME= 015

INCOMPLETE= 010

RDA SOURCE = 500

LOW BKG= 20

HIGH BKG= 2000

ACTIVE DET: LT LB RT RB

IND. ALARM=Y

SUM ALARM= Y

# OF SAMPLES=2

BKG UPDATE=8

Ludlum Measurements, Inc. Page 4-5 July 2018

Page 23

Model 52-1 Family Technical Manual Section 4

An example print-out from the Model 52-5 and the 52-5-1 RS-232 port

after a complete count is shown in the following paragraphs. Note that

the BKG column is expressed in counts per 0.2-second intervals, while

the COUNT column is expressed in terms of sigma above background.

Note also that the final line item (for “FT”) does not apply to the Model

52-1 or 52-1-1.

LUDLUM MODEL 52-5 PORTAL

02-JAN-00 14:53

RADIATION ALARM

SIGMA=4.5 COUNT TIME= 0

CHAN BKG COUNT ALARM

LT 78 6.2 YES

LB 85 0.0 NO

RT 72 5.0 YES

RB 81 0.0 NO

FT 45 0.8 NO

Water Resistant Sleeve

In order to provide a degree of protection against rain, a water-resistant

sleeve is available for the instrument. To install, simply slide the sleeve over

the bottom R1 section before installing the rest of the sections. After all

detector sections have been installed, stretch the sleeve over all sections. Cut

a hole in the sleeve over the connector for the electronics. Slide a short piece

of sleeving over the electronics, and cut a hole over that connector. Fold the

sleeve over the top of the electronics, and then attach the electronics to the

detector section. Proceed with operation of the instrument.

Theory of Background Measurement

These Ludlum instruments are designed to detect very small increases in

radiation above the ambient “background” radiation. The ambient

background fluctuates due to variations in cosmic radiation, radon gas

buildup, etc. Therefore, these instruments must constantly be aware of what

the background is, in order to decide if any extra radiation is present. So,

measuring the “true” background radiation level is of utmost importance to

determine the baseline for setting an alarm point.

On power-up, the portal monitor takes a 60-second background count

and checks to see if the counts are excessively low or excessively high. If

the background counts are normal, then the instrument calculates the

alarm points, and is ready to monitor personnel. For every six seconds,

if no person is detected in the portal, the instrument takes the

background count from three seconds prior and updates the background

count. Using the three-second prior count ensures that someone walking

up to the monitor or leaving the monitor is at least three seconds away.

When a person is detected in the portal, the background updating

Ludlum Measurements, Inc. Page 4-6 July 2018

Page 24

Model 52-1 Family Technical Manual Section 4

process is stopped immediately and restarted after the person leaves the

portal.

One very important consideration for the background measurement process

is accounting for the shielding effect of a human body. A human body

inside or next to the portal actually lowers the background by several

percent. This drop in background can seriously affect the alarm point, which

can either increase the false alarm rate or decrease the sensitivity.

For example, suppose the alarm point is equivalent to 4% above

background. A large person entering the portal might drop the background

count by 5%. Therefore, if that person had radiation contamination on his

clothes, the contamination would have to be at least 9% above background

to trigger the alarm. Alternatively, suppose the same person is standing next

to the portal when it is updating background at power-up. Next to the

portal, that person might reduce background by 2.5%.

If that person leaves and a smaller person enters the portal, then the

possibility for a false alarm is much higher than normal. These problems

can be avoided by ensuring that people stay back at least two meters

from the portal while it is updating background and by using the

attenuation parameter to compensate for the attenuation of a person

inside the portal. During setup, have an average-sized person stand in

the portal while the initial background is calculated. Figure the average

percentage change in background between unoccupied and occupied

background, and use that number for the attenuation parameter.

During setup, another parameter that can be chosen that affects

background is the Update Background parameter. This number, which

can be set from 1 to 9, controls how fast or slow the background is

updated. Background counts are averaged in order smooth out

background fluctuations. The time required to fully change the

background is the Update Background parameter times 18 seconds.

Thus you can set the Update Background parameter to vary the update

time from 18 to 162 seconds.

There are two modes for checking personnel with these instruments.

The walk-through mode, chosen by setting the CountTime parameter to

0, allows personnel to simply walk through the portal. Checking is

performed every 200 milliseconds while the portal is occupied, 600

milliseconds before, and 600 milliseconds after the portal is occupied.

The stop-and-count mode, chosen by setting the CountTime parameter

to a number of seconds that personnel must stand in the center of the

portal, allows greater sensitivity. The stop-and-count mode also has an

extended count time that extends the original count twice as long in

Ludlum Measurements, Inc. Page 4-7 July 2018

Page 25

Model 52-1 Family Technical Manual Section 4

order to make a determination on questionable counts. For example, an

original count time of two seconds may get extended another four

seconds if the count during the original two seconds is not clearly less

than the alarm point or clearly more that the alarm point. The

requirement for extending a count time is that the count is 2.5 standard

deviations above the background without being above the alarm point.

(The following paragraph gives more information on standard

deviations.)

The alarm parameter Sigma is the number of standard deviations above

background to set the alarm point. The standard deviation is equal to the

square root of the background count for the time period in question.

For example, if the 200-millisecond background count is 300, the

standard deviation for a 2-second count is the square root of 3000, or

54.8. How high the alarm should be set depends on the desired

sensitivity and the nuisance alarm rate. Nuisance alarm rates may be

found by utilizing a statistical table that details the area under the

standard normal curve. An abbreviated table that shows the percentage

of counts above a certain number of standard deviations is shown

below:

1.0 Sigma = 15.87% or 15.87 nuisance alarms in 100 chances

2.0 Sigma = 2.28% or 2.28 nuisance alarms in 100 chances

3.0 Sigma = 0.13% or 13 nuisance alarms in 10,000 chances

3.1 Sigma = 0.10% or 1 nuisance alarms in 1,000 chances

3.7 Sigma = 0.01% or 1 nuisance alarms in 10,000 chances

4.0 Sigma = 0.003% or 3 nuisance alarms in 100,000 chances

5.0 Sigma = 0.00003% or 3 nuisance alarms in 10,000,000 chances

6.0 Sigma = 0.00000001% or 1 nuisance alarm in 1,000,000,000 chances

As can be seen from this table, nuisance alarm rates decrease rapidly as

the Sigma setting increases above 3.0 Sigma. Another factor to consider

is how many chances there are to alarm with each passage through the

portal. In walk-through mode there are five chances to alarm every

second, while in stop-and-count mode there is only one chance per

passage. There is also the number of detectors and sum alarms to

consider. If there are five detectors, and the individual alarms are set,

then there are 25 chances to alarm every second in walk-through mode,

and five chances to alarm in stop-and-count mode for each passage.

Setting both individual alarms and sum alarms means there are 10

chances to alarm in stop-and-count mode, and 50 chances to alarm per

second while in walk-though mode. Note the big difference between

“1/1000 nuisance alarm rate” and 1 nuisance alarm per 1000 passages. It

is important to account for how many chances for alarm are made per

passage.

Ludlum Measurements, Inc. Page 4-8 July 2018

Page 26

Model 52-1 Family Technical Manual Section 5

Section

5

Safety Considerations

Environmental Conditions for Normal Use

Indoor or outdoor use (element weather only)

No maximum altitude

Temperature range of -20 to 50 °C (-4 to 122 °F)

Maximum relative humidity of less than 95% (non-condensing)

Mains supply voltage range 85-265 Vac

Maximum transient voltage of 1500 Vac

Installation Category II (Overvoltage Category as defined by IEC 1010-1)

Pollution Degree 3 (as defined by IEC 664)

Cleaning Instructions and Precautions

The Model 52-1, 52-5, and 52-6 series of instruments may be cleaned

externally with a damp cloth, using only water as the wetting agent. Do not

immerse the instrument in any liquid. Observe the following precautions

when cleaning:

1. Turn the instrument OFF and disconnect the instrument power

cord.

2. Allow the instrument to sit for one minute before cleaning.

Ludlum Measurements, Inc. Page 5-1 July 2018

Page 27

Model 52-1 Family Technical Manual Section 5

Electrical Safety Precautions

Warning!

Please follow the instructions below. If you do not, a

potentially hazardous situation could develop, which could

result in death or serious personal injury.

Do not expose the unit to rain or an environment where it may be

splashed by water or other liquids, as doing so may result in fire or

electric shock.

Use the unit only with the voltage specified on the unit. Using a

voltage higher than that which is specified may result in fire or

electric shock.

Do not cut, kink, otherwise damage nor modify the power supply

cord. In addition, avoid using the power cord in close proximity to

heaters, and never place heavy objects – including the unit itself – on

the power cord, as doing so may result in fire or electric shock.

Avoid installing or mounting the unit or its power supply in unstable

locations, such as a rickety table or a slanted surface. Doing so may

result in the unit falling down and causing personal injury and/or

property damage.

Caution!

Verify instrument voltage input rating before connecting to a

power converter. If the wrong power converter is used, the

instrument and/or power converter could be damaged.

Ludlum Measurements, Inc. Page 5-2 July 2018

Page 28

Model 52-1 Family Technical Manual Section 5

Warning Markings and Symbols

Caution!

The operator or responsible body is cautioned that the

protection provided by the equipment may be impaired if the

equipment is used in a manner not specified by Ludlum

Measurements, Inc.

The Model 52-1, 52-1-1, 52-5, 52-5-1, 52-6, and 526-1 Portable Scintillation Portal Monitors are

marked with the following symbols:

ALTERNATING CURRENT (AC) (IEC 417, No. 5032) - designates an

input receptacle that accommodates a power cord intended for connection

to AC voltages. This appears on AC panel, bottom side.

PROTECTIVE CONDUCTOR TERMINAL (per IEC 417, No. 5019)

– designates the central grounding point for the safety ground. This symbol

is visible inside the chassis.

CAUTION (per ISO 3864, No. B.3.1) – designates hazardous live voltage

and risk of electric shock. During normal use, the stabilizer legs must be

installed to avoid a tip-over of the unit. Without the stabilizer legs, a

substantial impact to the front or back of the unit could cause the unit to tip

and fall. This symbol appears on the side panels near the stabilizer leg

attachment points. Note the following precautions:

Warning!

The operator is strongly cautioned to take the following

precautions to avoid contact with internal hazardous live parts

that are accessible using a tool:

1. Turn the instrument power OFF and disconnect the power

cord.

2. Allow the instrument to sit for one minute before accessing

internal components.

The “CE” mark is used to identify this instrument as being acceptable for

use within the European Union.

Ludlum Measurements, Inc. Page 5-3 July 2018

Page 29

Model 52-1 Family Technical Manual Section 6

Section

6

Maintenance and Recalibration

Maintenance

Instrument maintenance consists of keeping the instrument clean and

periodically checking the calibration. The Model 52-1, 52-5, and 52-6 Series

of instruments may be cleaned externally with a damp cloth, using only

water as the wetting agent. Do not immerse the instrument in any liquid.

Observe the following precautions when cleaning:

1. Turn instrument OFF and disconnect the instrument power

cord.

2. Allow the instrument to sit for one minute before cleaning.

Recalibration

Recalibration is required after any repairs or adjustments have been made to

the instrument. Recalibration is not normally required following instrument

cleaning, battery replacement, or detector cable replacement.

Note:

Ludlum Measurements, Inc. recommends recalibration at

intervals no greater than one year. Check the appropriate

regulations to determine required recalibration intervals.

Ludlum Measurements offers a full-service repair and calibration

department. We not only repair and calibrate our own instruments, but most

other manufacturers’ instruments.

Calibration procedures are available upon request for customers who choose

to calibrate their own instruments.

Ludlum Measurements, Inc. Page 6-1 July 2018

Page 30

Model 52-1 Family Technical Manual Section 7

Section

7

Checkout Procedure

General

These models are set for -4 mV sensitivity (pulse height) for their plastic

scintillation detectors.

Equipment Required

1. Ludlum Model 500 Pulser or equal.

2. High-impedance voltmeter for high-voltage measurements (1000

megohm)

3. 8 to 15 Vdc power supply

4. Digital counter or oscilloscope for negative-going 5 Vdc pulses

Checkout Procedure

Checkout of the portal monitor is accomplished by determination of the

pulse threshold and high voltage of each detector interface board located on

each detector of the portal frame. No adjustments are possible to the

threshold voltage level, which is fixed by component values. The design

threshold level is -4 mV and operating high voltage is approximately 7001200 Vdc.

Proper high-voltage setting is determined by completing a high-voltage

plateau with the isotope(s) of interest. The best point of operation may

be selected by calculating a figure of merit (FOM) for each high voltage

point. The FOM can be defined as either the net source counts divided

by the square root of the background, or as the net source counts

squared divided by the background.

Ludlum Measurements, Inc. Page 7-1 July 2018

Page 31

Model 52-1 Family Technical Manual Section 7

Connect the cable from the Model 500 Pulser to one of the

detector interface boards. Apply power to the board by

supplying +12 Vdc and ground on the two-pin connector on the

detector interface board.

Attach the counter or oscilloscope to pin 1 of the TLC372

comparator. Adjust pulser amplitude to approximately -4 mV ±1

mV, until pulses just appear.

Adjust R18 until the Model 500 Pulser reads within 5% of the

correct high voltage. The correct high voltage should be

determined by running a voltage plateau with the detector and

one or more radioactive isotopes.

Ludlum Measurements, Inc. Page 7-2 July 2018

Page 32

Model 52-1 Family Technical Manual Section 8

Section

8

L

Recycling

udlum Measurements, Inc. supports the recycling of the electronics

products it produces for the purpose of protecting the environment

and to comply with all regional, national and international agencies

that promote economically and environmentally sustainable

recycling systems. To this end, Ludlum Measurements, Inc. strives to supply

the consumer of its goods with information regarding reuse and recycling of

the many different types of materials used in its products. With many

different agencies, public and private, involved in this pursuit it becomes

evident that a myriad of methods can be used in the process of recycling.

Therefore, Ludlum Measurements, Inc. does not suggest one particular

method over another, but simply desires to inform its consumers of the

range of recyclable materials present in its products, so that the user will

have flexibility in following all local and federal laws.

The following types of recyclable materials are present in Ludlum

Measurements, Inc. electronics products, and should be recycled separately.

The list is not all-inclusive, nor does it suggest that all materials are present in

each piece of equipment:

Batteries Glass Aluminum and Stainless Steel

Circuit Boards Plastics Liquid Crystal Display (LCD)

Ludlum Measurements, Inc. products which have been placed on the

market after August 13, 2005 have been labeled with a symbol recognized

internationally as the “crossed-out wheelie bin” which notifies the consumer

that the product is not to be mixed with unsorted municipal waste when

discarding; each material must be separated. The symbol will be placed near

the AC receptacle, except for portable equipment where it will be placed on

the battery lid.

The symbol appears as such:

Ludlum Measurements, Inc. Page 8-1 July 2018

Page 33

Model 52-1 Family Technical Manual Section 9

Section

9

Models 52-1, 52-1-1,

52-5, 52-5-1, 52-6,

and 52-6-1 Portable

Scintillation Portal

Monitors

Main Board,

Drawing 215 x

342-342E

CAPACITORS

Parts List

Reference Description Part Number

UNIT Completely Assembled

Model 52-1 Portal Monitor 48-3172

UNIT Completely Assembled

Model 52-1-1 Portal Monitor 48-3258

UNIT Completely Assembled

Model 52-5 Portal Monitor 48-3393

UNIT Completely Assembled

Model 52-5-1 Portal Monitor 48-3571

UNIT Completely Assembled

Model 52-6 Portal Monitor 48-3611

UNIT Completely Assembled

Model 52-6-1 Portal Monitor 48-3603

BOARD Completely Assembled

Main Circuit Board 5215-340

C1 68µF, 6.3V 04-5654

C2-C4 0.1µF, 50V 04-5663

C5 10µF, 25V 04-5655

C6 0.1µF, 50V 04-5663

C7 10µF, 25V 04-5655

C8 0.01µF, 50V 04-5664

C9 27pF, 100V 04-5658

C10 0.01µF, 50V 04-5664

C11 10µF, 25V 04-5655

C12 27pF, 100V 04-5658

C13-C14 0.01µF, 50V 04-5664

C15 10µF, 25V 04-5655

C16-C18 0.01µF, 50V 04-5664

Ludlum Measurements, Inc. Page 9-1 July 2018

Page 34

Model 52-1 Family Technical Manual Section 9

TRANSISTORS

INTEGRATED

CIRCUITS

DIODES

Reference Description Part Number

C21 0.1µF, 50V 04-5663

C22 0.01µF, 50V 04-5664

C24 0.01µF, 50V 04-5664

C25 10pF, 100V 04-5673

C26-C28 0.01µF, 50V 04-5664

C29-C34 1µF, 35V 04-5656

Q1-Q5 2N7002L 05-5840

Q6 MMBT4403LT1 05-5842

Q7 2N7002L 05-5840

Q9 2N7002L 05-5840

Q11-Q21 2N7002L 05-5840

U1 CD74HC138M 06-6339

U2 PCF8593TD 06-6403

U3 CD74HC00M 06-6308

U4 MAX232D 06-6382

U5 27C512-15N DIP28 06-6264

U6 HM62256ALP-10SL 06-6301

U7 ICL7660SCBA 06-6437

U8 24C65ISM 06-6401

U9 N80C51FA 06-6332

U10 CD74HC573M 06-6298

U11 PCF8574TD 06-6402

U15-U16 N82C54 06-6309

U17 TLC372ID 06-6290

U18 PCF8574TD 06-6402

U19-U20 TLC372ID 06-6290

CR1 MMBD914LT1 07-6353

CR2-CR3 CMPD2004S 07-6402

CR4-CR6 MMBD914LT1 07-6353

CR7-CR12 CMPD2004S 07-6402

Ludlum Measurements, Inc. Page 9-2 July 2018

Page 35

Model 52-1 Family Technical Manual Section 9

RESISTORS

RESISTOR NETWORK

CRYSTALS

INDUCTORS

CONNECTORS

MISCELLANEOUS

Reference Description Part Number

R1 5k TRIMMER 09-6918

R2 4.75k 12-7858

R3-R4 1.5 OHM 12-7602

R7 8.25k 12-7838

R8 4.75k 12-7858

R9 10k 12-7839

R10 1k 12-7832

R12-R13 10k 12-7839

R14 100k 12-7834

R23 100k 12-7834

R24-R29 2.21k 12-7835

R32-R37 1k 12-7832

RN1 NETWORK-220k 12-7923

RN2 NETWORK-22k 12-7917

RN3 NETWORK-220k 12-7923

RN4 NETWORK-4.7k 12-7918

Y1 6.144MHZ 01-5262

Y2 32.768Khz 01-5305

L1-L6 470 µH 21-9699

P1-P2 640456-5 MTA 100 13-8057

P3-P4 640456-3 MTA 100 13-8081

P5 640456-2 MTA 100 13-8073

P6 1-640456-6 13-8134

P7 640445-3 MTA 156 13-8125

P8 640456-7 MTA 100 13-8115

P9 640456-2 MTA 100 13-8073

P10 1-640456-0 MTA 100 13-8066

P17-P18 640456-2 MTA 100 13-8073

P19 1-640456-1 MTA 100 13-8059

P20-P22 640456-2 MTA 100 13-8073

B1 BATT-3V LITHIUM 22-9986

Ludlum Measurements, Inc. Page 9-3 July 2018

Page 36

Model 52-1 Family Technical Manual Section 9

Detector Interface

Board, Drawing

215 x 347

CAPACITORS

DIODES

TRANSISTORS

RESISTORS

Reference Description Part Number

BOARD Completely Assembled

Detector Interface Board 5215-347

C1 10µF, 25V 04-5655

C2 4.7µF, 25V 04-5653

C3 0.001µF, 100V 04-5659

C4 10µF, 25V 04-5655

C5 47µF, 10V 04-5666

C6 0.001µF, 10V 04-5659

C7 0.01µF, 50V 04-5664

C8 1µF, 35V 04-5656

C9-C10 0.01µF, 50V 04-5664

C11 0.001µF, 2kV 04-5703

C12 10 pF, 100V 04-5673

C13 0.01µF, 50V 04-5664

C14 0.01µF, 2KV 04-5722

C15 47 pF, 100V 04-5660

C16 10µF, 25V 04-5655

C17 0.01µF, 2kV 04-5722

C18-C22 0.001µF, 2kV 04-5703

C23-C27 0.01µF, 500V 04-5696

CR1 CMSH1-40M 07-6411

CR2-CR8 CNOD2004S 07-6402

Q1 MTD2N50E 05-5855

R1-R4 150 OHM 12-7965

R5-R6 47.5 OHM 12-7966

R7 100k 12-7834

R8 1.82k 12-7030

R9 10k 12-7839

R10 4.75k 12-7858

R11 100 OHM 12-7840

R12 1k 12-7832

R13-R15 10k 12-7839

R16 4.75k 12-7858

Ludlum Measurements, Inc. Page 9-4 July 2018

Page 37

Model 52-1 Family Technical Manual Section 9

INTEGRATED CIRCUITS

VOLTAGE REGULATOR

INDUCTORS

CONNECTORS

LEDs

Power Supply,

Drawing 215 x 1072

CAPACITORS

INTEGRATED

CIRCUITS

DIODES

Reference Description Part Number

R17 392k 12-7841

R18 1 M TRMR 09-6911

R19-R20 1 M 12-7844

R21 1 G 12-7686

R23 1 M 12-7844

U1 ICL7667CBA 06-6510

U2 MAX985EUK-T 06-6459

U3 CA3096M 06-6288

U4 MAX641ACSA-5 06-6388

VR1 LT1460KCS3-2.5TR 05-5867

VR2 LM78L05ACM 05-5864

L1-L2 470 µH 21-9224

P20 640456-2 MTA-100 13-8073

P34 640456-2 MTA-100 13-8073

W1 COAXIAL CONNECTOR 21-9463

DS1 LED-SML-LX1206SRC-TR RED 1206

07-6648

BOARD Completely Assembled

Power Supply 5215-1071

C1-C5 68µF, 25V 04-5828

C6-C7 0.1µF, 100V 04-5792

C8 100pF, 100V 04-5661

U1 LT1304CS8 06-6434

U3 MAX1771 06-6845

CR1-CR5 CMSH1-40M 07-6411

CR6 SSA34-E3/61T 07-6610

CR7-CR10 CMSH1-40M 07-6411

Ludlum Measurements, Inc. Page 9-5 July 2018

Page 38

Model 52-1 Family Technical Manual Section 9

TRANSISTORS

RESISTORS

INDUCTORS

CONVERTER

CONNECTORS

1 1/8 inch Voltage

Divider,

Drawing 435 x 435

CAPACITORS

RESISTORS

Reference Description Part Number

Q1 FDS6612A 05-5742

R1 499k, 250mW 12-7037

R2 365k, 250mW 12-7049

R3 499k, 250mW 12-7037

R4 22k, 100mW 12-7179

R5-R6 1.5Ohm, 3W 12-7602

R7 499k, 250mW 12-7037

R8 86.6k, 250mW 12-8275

R9 0.04Ohm, 1W 12-8276

L1-l2 22µH 21-9208

VR1 OKI-78SR-5 21-8637

P1 640456-6 MTA100X6 13-8095

P15 640456-5 MTA100X5 13-8057

P16 640456-2 MTA100X2 13-8073

P33 640445-2 MTA156X2 13-8098

BOARD Completely Assembled

Voltage Divider 5435-182

C1-C3 0.01µF, 200V 04-5725

C4 0.0047µF, 3KV 04-5547

R1 10M, 1/8W, 1% 12-7996

R2 7.5M, 1/8W, 5% 12-7971

R3-R10 10M, 1/8W, 1% 12-7996

R11 2.21M, 1/8W, 1% 12-7002

R12-R13 6.04M, 1/8W, 1% 12-7071

Ludlum Measurements, Inc. Page 9-6 July 2018

Page 39

Model 52-1 Family Technical Manual Section 9

Resistor Board,

Drawing 215 x 782

CAPACITORS

RESISTORS

CONNECTORS

Wiring Diagram,

Drawing 215 x 1044

CONNECTORS

MISCELLANEOUS

Miscellaneous

Parts

Reference Description Part Number

BOARD Completely Assembled

Model 52-1 Resistor Board 5215-781

C1-C3 0.1 µF, 25V 04-5744

R1 332 OHM 12-7854

R3-R4 150 OHM 12-7062

R5-R12 332 OHM 12-7854

Reference Description Part Number

P100 640456-2 MTA-100 13-8073

P101 640456-7 MTA-100 13-8115

P102 640456-4 MTA-100 13-8088

P103 640456-6 MTA-100 13-8095

P104-P105 640456-2 MTA-100 13-8073

P106 640456-5 MTA-100 13-8057

P107 640456-4 MTA-100 13-8088

P108 640456-7 MTA-100 13-8115

S1 DM62J12S205PQ 08-6715

J12 L712AS 21-8795

J29 RM12BRD-3PH(71)3PM 13-8546

J31 RS-232 9-PIN “D” 13-8556

J38 IR RECEIVER 2310737

J40 IR TRANSMITTER 2310738

B1-B6 BATTERY – “D” 21-9313

FP5 MEMBRANE SWITCH KEYPAD 7215-779

SP1 ALARM-TXC-V86-515-Q 5-15VDC XLOUD

21-8802

Model 52-1 12 Vdc Car Power Cable 8515-819

Model 52-1 +12V Wall Transformer Cable 8303-1029

Ludlum Measurements, Inc. Page 9-7 July 2018

Page 40

Model 52-1 Family Technical Manual Section 10

Section

10

Drawings

Front of Manual

Front Panel, Drawing 215 x 999

AC Panel Assembly, Drawing 215 x 999A

Back of Manual

Boards and Wiring Diagram

Main Board, Drawing (6 sheets), 215 x 342-342E

Main Board Layout, Drawing 215 x 343

Detector Interface Board, Drawing 215 x 347

Detector Interface Board Layout, Drawing 215 x 348A

Power Supply Board, Drawing 215 x 1071

Power Supply Board Layout, Drawing 215 x 1072

1 1/8 inch Voltage Divider, Drawing 435 x 435

1 1/8 inch Voltage Divider Component Layout, Drawing (2 sheets)

435 x 436A

Resistor Board, Drawing 215 x 782

Resistor Board Layout, Drawing 215 x 781A (2 sheets)

Wiring Diagram-Electronics, Drawing 215 x 1044 (2 sheets)

Assembly and Setup

Model 52-1 & 52-5 Series Packing Instructions, Drawing 215 x 225C

Ludlum Measurements, Inc. Page 10-1 July 2018

Model 52-6 Series Packing Instructions, Drawing 215 x 633B

Model 52-1 & 52-5 Series Overall Assembly, Drawing 215 x 225A

Model 52-6 Overall Assembly Drawing 215 x 633A

Page 41

Model 52-1 Family Technical Manual Section 10

Model 52-1 & 52-5 Series Dimensions, Drawing 215 x 225

Model 52-6 Series Dimensions, Drawing 215 x 633

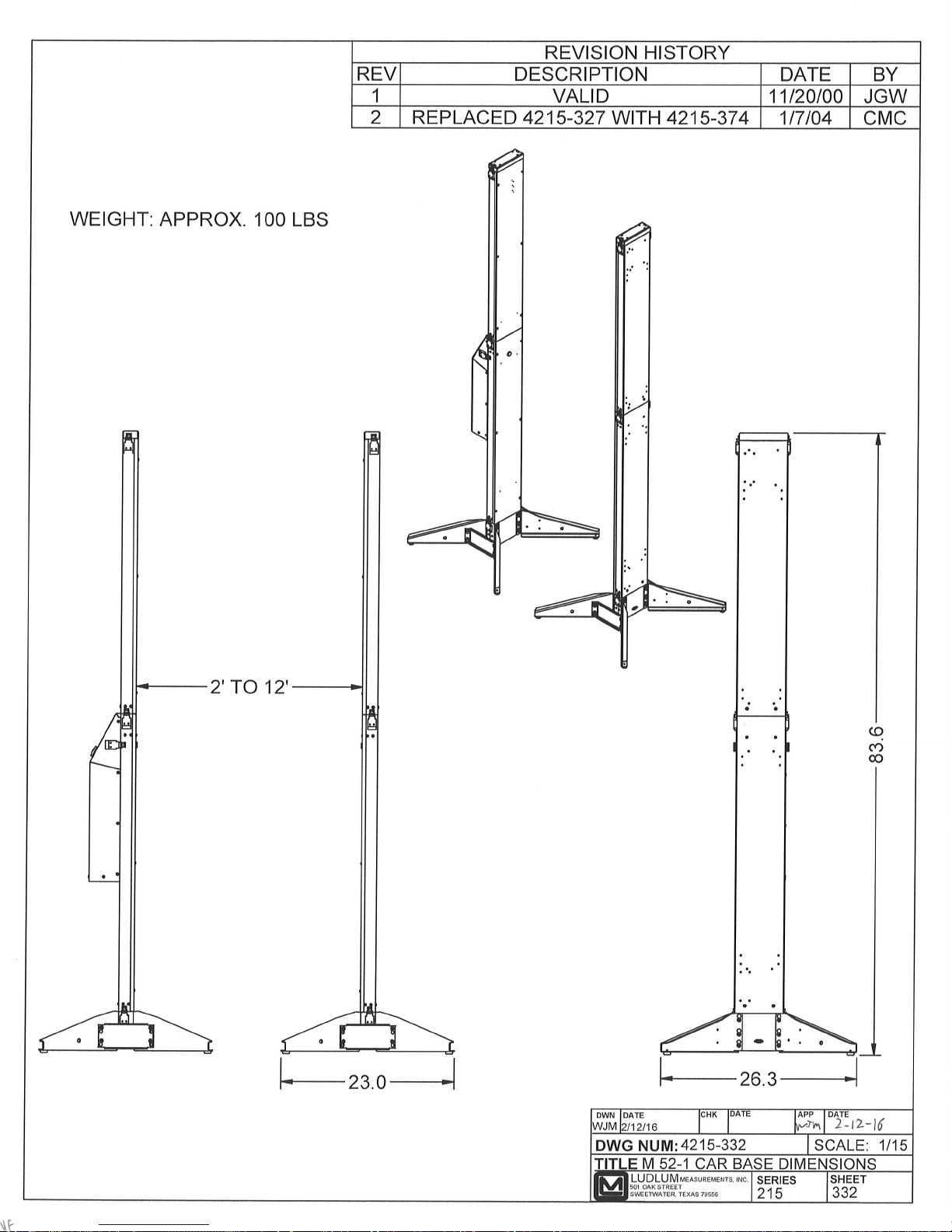

Car Base Assembly, Drawings 215 x 332 & 332A

Car Base Setup, Drawing 215 x 374 & 374B

Ludlum Measurements, Inc. Page 10-2 July 2018

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Page 79

Page 80

Page 81

Page 82

Page 83

Page 84

Page 85

Page 86

Page 87

Page 88

Page 89

Page 90

Page 91

Page 92

Page 93

Page 94

Page 95

Page 96

Page 97

Page 98

Page 99

Loading...

Loading...