LUDLUM MODELS 375 (INCLUDING SERIES ONE),

375/1, 375/2 AND 375/4

DIGITAL WALL-MOUNT AREA MONITORS

May 2017

Serial Number 278020 and Succeeding

Serial Numbers

LUDLUM MODELS 375 (INCLUDING SERIES ONE),

375/1, 375/2 AND 375/4

DIGITAL WALL-MOUNT AREA MONITORS

May 2017

Serial Number 278020 and Succeeding

Serial Numbers

Ludlum Measurements, Inc. May 2017

STATEMENT OF WARRANTY

Ludlum Measurements, Inc. warrants the products covered in this manual to be free of

defects due to workmanship, material, and design for a period of twelve months from

the date of delivery. The calibration of a product is warranted to be within its

specified accuracy limits at the time of shipment. In the event of instrument failure,

notify Ludlum Measurements to determine if repair, recalibration, or replacement is

required.

This warranty excludes the replacement of photomultiplier tubes, G-M and

proportional tubes, and scintillation crystals which are broken due to excessive

physical abuse or used for purposes other than intended.

There are no warranties, express or implied, including without limitation any implied

warranty of merchantability or fitness, which extend beyond the description of the

face there of. If the product does not perform as warranted herein, purchaser’s sole

remedy shall be repair or replacement, at the option of Ludlum Measurements. In no

event will Ludlum Measuremen ts be liable for damages, lost revenue, lost wages, or

any other incidental or consequential damages, arising from the purchase, use, or

inability to

use product.

RETURN OF GOODS TO MANUFACTURER

If equipment needs to be returned to Ludlum Measurements, Inc. for repair or calibration, please send to the address below. All shipments should include

documentation containing return shipping address, customer name, telephone number, description of service requested, and all other necessary

information. Your cooperation will expedite the return of your equipment.

ATTN: REPAIR DEPARTMENT

501 OAK STREET

SWEETWATER, TX 79556

Ludlum Measurements, Inc. May 2017

LUDLUM MEASUREMENTS, INC.

800-622-0828 325-235-5494

FAX 325-235-4672

Table of Contents

Introduction 1

Getting Started 2

External Detector (Option) 2-1

Power Up 2-1

Radiation Units 2-2

Checking Parameters 2-2

*Model 375 Series One 2-3

Setting Alarm Points 2-3

Operational Check 2-4

Return for Repair and Calibration 2-5

Specifications 3

Operator Controls and Setup 4

Calibration Controls 4-1

Dipswitch (under calibration cover) 4-2

RS-232 Output 4-3

9-Pin Remote Data Connector 4-3

9-Pin Relays Connector 4-4

Typical Internal Detector Setups 4-4

Common Options and Modifications 5

Relay Options 5-1

Ethernet Interface Option 5-5

Time and Date Stamp Option 5-5

Printer DIP Switch Settings 5-6

Sigma Alarm Modification Option 5-7

4 to 20 mA Isolated Output Driver Option 5-8

Safety Considerations 6

Environmental Conditions for Normal Use 6-1

Cleaning Instructions and Precautions 6-1

Warning Markings and Symbols 6-2

Electrical Safety Precautions 6-3

Replacement of Main Fuse 6-4

Ludlum Measurements, Inc. May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4

Detector Connector 6-4

Battery Replacement 6-4

Calibration 7

High Voltage 7-1

Calibration Parameters 7-1

Analog Output 7-2

Discriminator 7-2

Battery Charge 7-2

Recycling 8

Parts List 9

Model 375 Digital Wall-Mount Area Monitor without Detector 9-1

Model 375/1 Digital Wall-Mount Area Monitor 9-1

Model 375/2 Digital Wall-Mount Area Monitor 9-1

Model 375/4 Digital Wall-Mount Area Monitor 9-1

Model 375 Series One without Detector 9-1

Model 375/2 Series One 9-1

Model 375/4 Series One 9-1

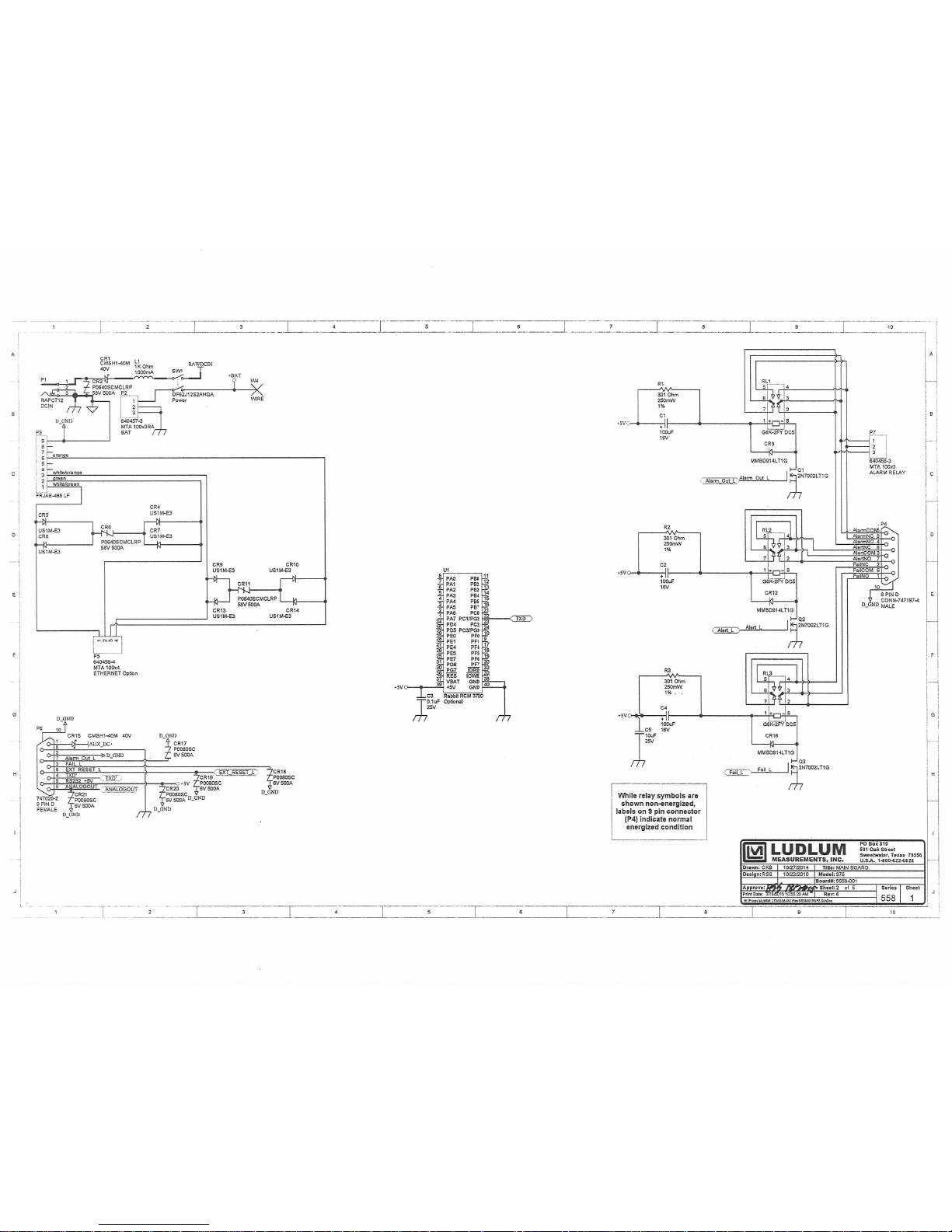

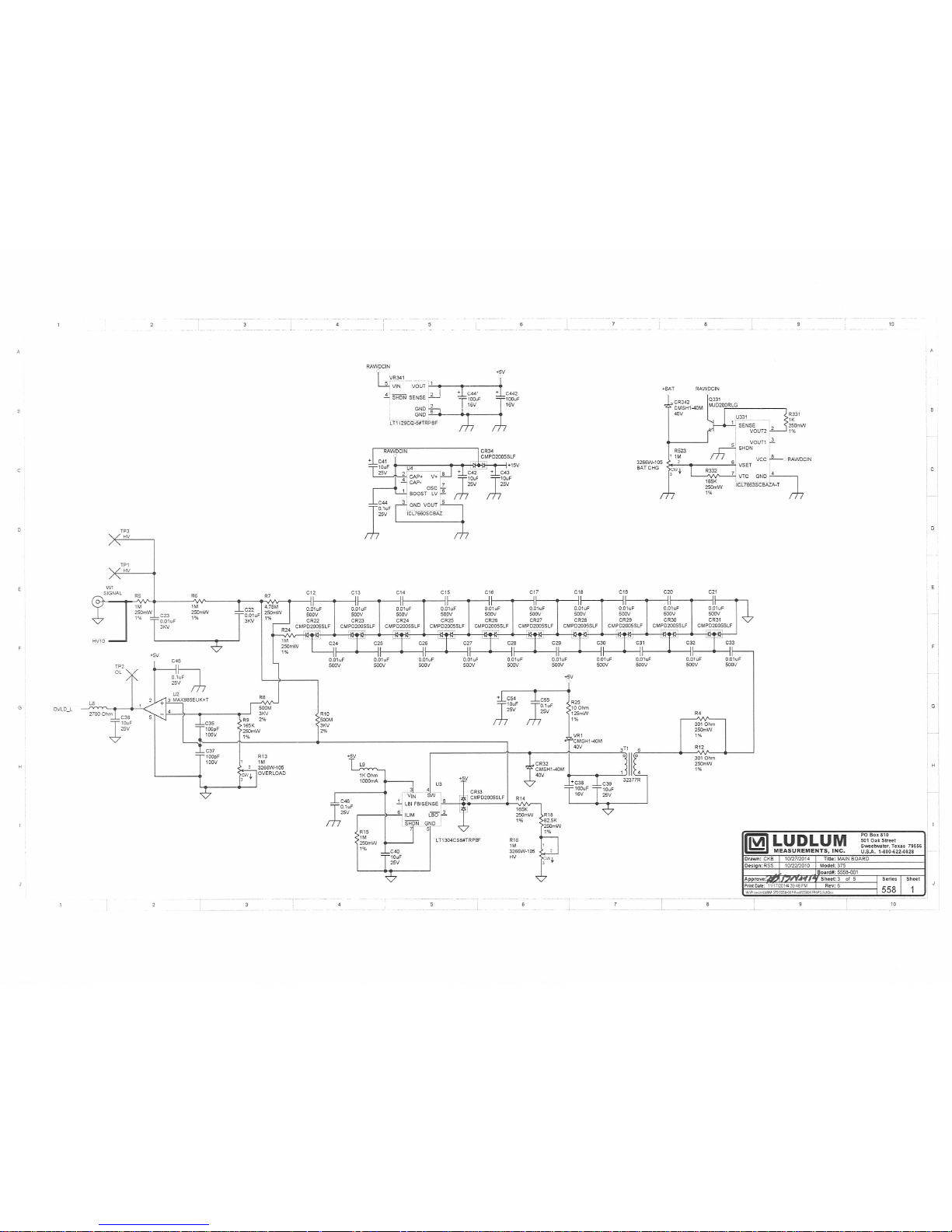

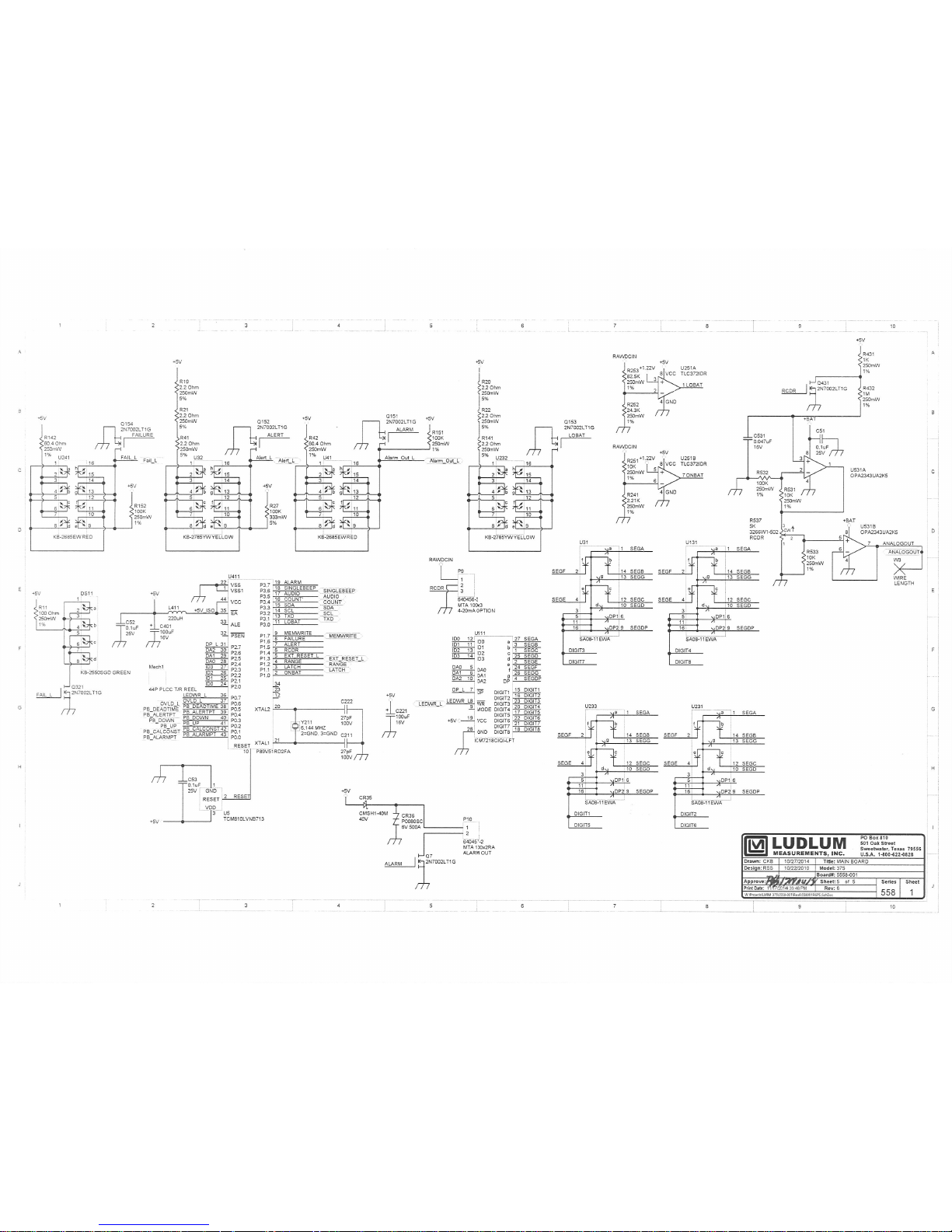

Main Board, Drawing 558 x 1 9-1

Wiring Diagram, Drawing 558 x 136 9-6

Internal Detectors 9-6

Drawings and Diagrams 10

Ludlum Measurements, Inc. May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 1

Section

1

Introduction

he Model 375 Digital Wall-Mount Area Monitor is designed for

visibility and ease of use. Featuring a wall-mount chassis, the Model

T

radiation alarm (red), instrument failure (red), and low battery (yellow). A green

status light is a positive indication of instrument operation.

Parameters are protected under a calibration cover. Calibration is easily

accomplished by moving the cal dipswitch to the right, and using the

pushbuttons to increment or decrement the calibration constant, dead time

correction, and alarm point parameters. Parameters are stored in non-volatile

memory (retained even with power disconnected).

A five-decade logarithmic analog output is provided. A battery backup provides

48 hours of additional use after the primary power is removed. Depending on

the needs of the customer, the Model 375 comes equipped with an internal

detector or a connector for use with an external detector. The Model 375/1

comes equipped with an internal CsI scintillator detector. The Model 375/2

and 375/4 come equipped with internal, energy-compensated GM detectors.

375 has a four-digit LED display that is readable from 9.1 m (30 ft)

away. Backlit indicators warn of low-radiation alarm (yellow), high-

The Ludlum Model 375 Series One is a Model 375 with modified firmware.

Changes include certain display values in decimal points and units. Details can

be found in sections “Getting Started” and “Specifications.”

Ludlum Measurements, Inc. Page 1-1 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 2

Section

2

Getting Started

he Model 375 Digital Wall-Mount Area Monitor is designed for

ease of use. This section of the manual is designed to help the first-

T

manual provide more detailed information.

External Detector (Option)

The Model 375 comes equipped with either an internal detector or a

connector for use with an external detector. If your Model 375 is equipped

with a connector on the bottom side of the chassis, an external detector is

required. If you have an external detector, use the cable provided to connect

it to the Model 375.

time user get started. Initial power-up and basic features of the

Model 375 will be discussed in this section. Other sections of the

Warning!

Potential electrical shock hazard - Do not touch the center

pin of the detector connector unless the unit has turned off

and power has been removed for at least one minute.

Power Up

Plug the wall-mount 9 Vdc power supply into a suitable wall (Mains) outlet.

Ludlum Measurements, Inc. Page 2-1 May 2017

Note:

Splicing or re-terminating cables must be done carefully.

Improper termination will result in the “shorting out” of the

detector voltage, a DET FAIL, and/or blown-fuse condition.

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 2

If the RS-232 feature is used, plug in a suitably wired 9-pin

connector cable. (See Page 4-4 for the pin assignment of the 9-pin

connector.) Turn power ON with the left side panel switch. Do

not turn power OFF unless the unit is to be removed from service.

Read and then remove the sticker (illustrated to the left) from the

instrument calibration cover. Checking and setting of the alarm

point(s) is discussed in detail below and on pages 2-3 and 7-1 of

this manual.

Initial power-up will momentarily activate the internal front-panel lights,

sound the audio, and display "8888" on the 4-digit LED display. The

firmware version number (396Nyy) is then displayed as "396" and "xxyy"

(where xx and yy represents the current version number).

When the instrument has finished measuring background, it will display the

current radiation reading and begin checking for an alarm condition.

Radiation Units

The Model 375 may be calibrated for almost any desired radiation units of

measure. Common units of measure include mR/hr, µR/hr, R/hr, mSv/h,

µSv/h, cps, cpm, and kcpm. In each case, the unit of measure is indicated

underneath the four-digit display. Throughout the rest of this manual, the

notation <units> will be used as a substitute.

Checking Parameters

Check the low alarm point setting by pressing the LOW ALARM button. The

low alarm point will be displayed as long as the button is pressed. The low

alarm point is in units of <units>. The low alarm point can be set from 0.1

<units> to 9999 <units>*.

Check the high alarm point setting by pressing the HIGH ALARM button. The

high alarm point will be displayed as long as the button is pressed. The

highalarm point is in units of <units>. The high alarm point can be set from

0.1 <units> to 9999 <units>*.

Check the calibration constant by pressing the

calibration constant will be displayed as long as the button is pressed. The

calibration constant is in units of cpm (counts per minute) per <units>*.

The calibration constant can be set from 0.1 cpm/<units> to 9999

cpm/<units>*.

CAL CONST button. The

Ludlum Measurements, Inc. Page 2-2 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 2

Check the detector dead time correction by pressing down on the DEAD

TIME

button. The dead time correction will be displayed as long as the

button is pressed. The dead time correction is in units of microseconds*.

The dead time correction can be set from 0.1 microseconds to 9999 microseconds*.

* Model 375 Series One: In the special case of the Model 375 Series One,

make note of the following changes resulting from firmware modification:

With the RANGE dipswitch in the left position, two decimal places will

be displayed.

With the

RANGE dipswitch in the right position, no decimal place will be

displayed.

Calibration constant will be displayed in cps per unit, instead of cpm per

unit.

Dead Time Correction will display in 10

ths

of microseconds (i.e. 0.50

µsec instead of 5 µsec).

Setting Alarm Points

The LOW ALARM and HIGH ALARM points can only be changed while the

instrument is in calibration mode. Switch the top dipswitch CAL MODE

(behind the calibration cover) to the right to place the instrument into

calibration mode.

Changing alarm points is done by holding down the corresponding

parameter key and pressing the up or down arrow buttons. Alarm points can

be set in the range of 0.1 to 9999*. When an alarm point is changed, the

instrument will sound an audible beep to confirm the saving of the

parameter, and will then return to displaying the current radiation level.

Ludlum Measurements, Inc. Page 2-3 May 2017

Note:

Once the alarm point(s) is set, it is important to remember to

switch the CAL MODE switch back to the left. This action

protects the parameters from inadvertent changes.

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 2

Operational Check (optional)

The operational check is an important assurance that the radiation detector

and electronics are working correctly.

Note:

Ludlum Measurements suggests that an operational check be

performed on a regular basis. Local procedures may

supersede this suggestion.

For an operational check, it is necessary to use a radiation check source (not

included, but available). When not being used, store the check source in a

secure area.

Note:

LMI check sources present very minimal risks and are

therefore unlicensed (Exempt Quantity Sources reference:

10 CFR 30.71 Schedule B). The radioactive element is sealed

(permanently bonded or fixed inside a capsule) so you need

not wash your hands after handling. Radiation exposure

while handling this source is very minimal with no identified

long or short term risks. Although the amount of radiation

given off by exempt sources is so low that it presents no

significant hazard, they should be handled with care and

respect. Time, distance, and shielding are the best ways to

control exposure.

1. Taking the source in hand, place it so that it is located on or near

the center (same location each time) of the detector. (For

internal detector models, a metal plate on the bottom of the

chassis identifies the location of the internal detector.) Hold it

there for approximately five seconds or until the reading

stabilizes. Take note of the displayed level of radiation.

2. Verify that the reading is within 20% of the last reading

obtained. Remove the source from the detector.

Ludlum Measurements, Inc. Page 2-4 May 2017

3. If an alarm is activated, ensure that all visual and audible devices

(if applicable) work correctly.

Models 375 (Including Series One), 375/2, 375/4 & 375WT Technical Manual

Return for Repair and Calibration

To return an instrument for repair or calibration, provide sufficient packing

material to prevent damage during shipment.

Every returned instrument must be accompanied by an Instrument Return

Form, which can be downloaded from the Ludlum website at

www.ludlums.com. Find the form by clicking the “Support” tab and

selecting “Repair and Calibration” from the drop-down menu. Then choose

the appropriate Repair and Calibration division where you will find a link to

the form.

Ludlum Measurements, Inc. Page 2-5 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 3

Section

3

Specifications

Compatible Detectors: GM, proportional, and scintillation

Display: four-digit LED display with 2 cm (0.8 in.) character height

Display Range: 000.0-9999 (Series One: 00.00-9999)

Display Units: can be made to display in µR/hr, mR/hr, R/hr, µSv/h,

mSv/h, Sv/h, µrem/hr, mrem/hr, rem/hr, cpm, cps, and others

Linearity: readings within 10% of true value with detector connected

Operating Range: depends upon the type of detector used. The

operating range of the 375/2 is from 1 µSv/h to 10 mSv/h (0.1 mR/hr

to 1 R/hr). The operating range of the 375/4 is from 0.01 mSv/h to 100

mSv/h (1 mR/hr to 10 R/hr). External detectors will have different

operating ranges.

Response: typically 3 seconds from 10% to 90% of final reading

Status (green light): indicates the instrument is functioning properly

Low Alarm: indicated by a yellow light and slow beep (1 per second)

audible tone (can be set at any point from 0.0-9999 {00.00-9999 for

Series One})

High Alarm: indicated by a red light and a fast beep (4 per second)

audible tone (can be set at any point from 0.0-9999 {00.00-9999 for

Series One})

Ludlum Measurements, Inc. Page 3-1 May 2017

Note:

Audible indicators can be configured as a single beep by

dipswitch if desired. Audio intensity is controlled by rotating

the baffle on the audio device. Audio intensity may also be

adjusted by moving an internal connector.

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 3

DET Fail: indicated by a red light and an audible tone greater than 68 dB

at 6.1 ft (2 m) for conditions of detector overload, no count from

detector or instrument failure

Low Bat: indicated by a yellow light, beginning when two hours of

battery life remain

Connector: series ˝C˝ (others available)

Ethernet (optional): 10 Base-T connection for use with Ludlum software

Calibration Controls: accessible from the front of instrument (protective

cover provided)

High Voltage: adjustable from 450-2500 volts

Dead Time: adjustable to compensate for dead time of the detector and

electronics (can be read on the display)

Overload: a display reading of -OL- and audible FAIL alarm indicate

detector saturation. It is normally set to initiate just above the highest

range of the detector.

Over-range: A display reading of ˝----˝ and activated low and high alarms

indicate that the radiation field being measured has exceeded the counting

range of the instrument (or when dead time correction accounts for more

than 75% of the displayed reading).

Data Output: A 9-pin connector with female sockets provides five-

decade log output, RS-232 output, signal ground connection,

HIGH ALARM signals (current sink), and direct connection to battery and

FAIL and

ground

Relays: A 9-pin connector with male pins provides connection to three

fail-safe form C relays, activated by the LOW ALARM (alert) High

ALARM, and instrument FAIL. These contacts are potential-free (nonpowered), but can handle 125 Vac at 0.3 A or 30 Vdc at 1 A.

RS-232 Output: a 2-second dump for computer data logging

Remote (optional): Ludlum Model 271 or 272 remote units

Ludlum Measurements, Inc. Page 3-2 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 3

Audio: Intensity can vary from approximately 68 dB to 100 dB through

operation of the external rotary baffle and the internal voltage

connection. Frequency is approximately 3 kHz.

Power: 9 Vdc wall-mount adapter, handles any mains voltage in the

world, supplied with four sets of prongs for almost any style wall

receptacle

Battery Life: typically 48 hours in non-alarm condition; 12 hours in alarm

condition

Battery Charger: battery is continuously trickle charged when the

instrument is connected to line power and turned on

Warning!:

Only certified technician or calibration personnel should

replace battery.

Environmental Rati ng: NEMA (National Electrical Manufacturers

Association) rating of 1; IP (Ingress Protection) rating of 40. (Protective

enclosures are available for harsher environments.)

Construction: aluminum housing with ivory powder-coat finish

Size: 18.7 x 24.6 x 6.4 cm (7.4 x 9.7 x 2.5 in.) (H x W x D)

Weight: 2.1 kg (4.7 lb)

Ludlum Measurements, Inc. Page 3-3 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 4

Section

4

Operator Controls and Setup

Calibration Controls

Remove the calibration cover to expose the calibration controls.

Warning!

Do not touch the circuit board in the calibration window

due to potential for electric shock.

The calibration controls include the up/down buttons, five calibration

potentiometers, and the option dipswitch (detailed in the following

subsection). The five potentiometers are detailed below.

ANALOG: used to adjust the logarithmic analog voltage output. Adjusted

in calibration mode to the full-scale voltage reading or adjusted to a

known point at some given reading.

Ludlum Measurements, Inc. Page 4-1 May 2017

HV: used to set the high voltage required for detector operation.

Adjustable from 450-2500 Vdc. The high voltage required will depend

on the type of detector used. Internal GM detectors typically require 550

Vdc. Be sure to check the high voltage with a high impedance (1000Mohm impedance) voltmeter only. A high-voltage checkpoint is located

next to the

DISC: internal discriminator used to set negative pulse threshold for

counting pulses from the detector. Pad allows direct measurement of

threshold voltage. Utilize a Ludlum Model 500 Pulser or equivalent to

inject pulses of the desired threshold size. The pulse height threshold is

adjustable from 2.0 mVdc to 100 mVdc.

BAT CHARGE: used to set the backup battery trickle charging voltage. It

is set to 6.9 Vdc while the battery is disconnected.

HV potentiometer.

OVERLOAD: used to set the detector current overload point. When

excessive radiation causes the detector to overload, this set point will

cause the FAIL light to engage, and the display will be forced to -OL-.

Dipswitch (under calibration cover)

When the calibration cover is removed, a four-pole dipswitch is accessible

that can activate or deactivate options. These four options are CAL MODE,

LATCH ALARM, RANGE, and SINGLE BEEP.

Dipswitch 1: Switching the top CAL MODE switch to the right places the

instrument into calibration mode. Parameters can only be changed while

the instrument is in calibration mode. Calibration mode also changes the

analog output to full-scale so that the full-scale voltage may be set by the

ANALOG potentiometer. Calibration mode also slows the response time

of the display and increases the accuracy. If the display seems too erratic,

leaving this switch in the calibration mode during operation will help.

Moving the CAL MODE switch back to the left locks the parameters and

disables any further changes.

Dipswitch 2: The second switch, LATCH ALARM, changes the high

alarm to a latching alarm. This switch does not affect the low alarm,

which is always non-latching. When switched to the left, the high alarm

is non-latching; the alarm automatically turns off when the radiation

level drops below the alarm point. When switched to the right, the high

alarm light and audio signals are latched until either the LOW ALARM or

HIGH ALARM button is pressed.

* See note on page 2-3 regarding Model 375 Series One.

Ludlum Measurements, Inc. Page 4-2 May 2017

Dipswitch 3: The third switch, RANGE, selects the range of the

instrument. To select the 0.1 <units> - 999.9 <units>* range, switch the

RANGE switch to the left. To select the 1 <units> - 9999 <units>*

range, switch the RANGE switch to the right.

Dipswitch 4: Switching the fourth switch to the right places the

instrument into SINGLE-BEEP mode. This option limits the audio

output to a single half-second beep on LOW ALARM and HIGH ALARM.

DET FAIL audio output (steady tone) is not limited.

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 4

RS-232 Output

With the CAL MODE dipswitch in the left position, the Model 375 dumps RS232 data onto pin 4 of the 9-pin connector every two seconds.

The RS-232 data includes the

current radiation readings and the

current condition of the status

lights. The data is presented in the

following format:

BYTE1 0 x

BYTE2 x x

BYTE3 x OR x

BYTE4 x x

BYTE5 . .

BYTE6 x 0

BYTE7 Audio Status =1=on

BYTE8 High Alarm Status =1=on

BYTE9 Low Alarm Status =1=on

BYTE10 Over Range Status=1=on

BYTE11 Monitor Status =1=on

BYTE12 Error Code

BYTE13 Carriage Return (ODH)

BYTE14 Line Feed (0AH)

9-Pin Remote Da ta Connector

(female sock ets)

The 9-pin connector provides output signals from the instrument and

input voltage to the instrument. The pin assignments are:

pin1- +BATTERY

pin2- GND IN

pin3- FAIL_L

pin4- RS232 DUMP

pin5- ANALOG OUT

pin6- CHASSIS GND

pin7- HIGH ALARM_L

pin8- EXT RESET_L

pin9- +5VDC OUT

The FAIL and HIGH ALARM digital signal outputs are open drain 2N7002

outputs, able to sink about 50 mA each.

Ludlum Measurements, Inc. Page 4-3 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 4

9-Pin Relays Connector (male pins)

The 9-pin relay connector provides a Form C (common, normally open, and

normally closed) contact for the three fail-safe relays of LOW ALARM

(alert), HIGH ALARM, and FAIL.

The pin assignments are (shown energized):

pin1- FailNO

pin2- FailNC

pin3- AlertCOM

pin4- AlarmNO

pin5- AlarmCOM

pin6- FailCOM

pin7- AlertNO

pin8- AlertNC

pin9- AlarmNC

Typical Internal Detector Setups

Model 375/2

Typical response and set points for the model 375 with internal energycompensated LND 71210 GM detector is as follows:

Operating Voltage: 550 Vdc

Threshold: 100 mVdc

Calibration Constant: 1000 cpm/mR/hr

Dead Time Correction: 30 µsec-150 µsec

Linear Range with DTC: 0.1 mR/hr - 1 R/hr

Typical Checkpoints:

1 mR/hr

2 mR/hr * set calibration constant

8 mR/hr

20 mR/hr

80 mR/hr

200 mR/hr * set dead time correction

800 mR/hr

1000 mR/hr

Ludlum Measurements, Inc. Page 4-4 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 4

Model 375/4

Typical response and set points for the model 375 with internal energycompensated LND 71412 GM detector is as follows:

Operating Voltage: 550 Vdc

Threshold: 100 mVdc

Calibration Constant: 100 cpm/mR/hr

Dead Time Correction: 30 µsec-150 µsec

Linear Range with DTC: 1 mR/hr - 8 R/hr

Typical Checkpoints:

2 mR/hr

8 mR/hr

20 mR/hr * set calibration constant

80 mR/hr

200 mR/hr

800 mR/hr

2,000 mR/hr

8,000 mR/hr * set dead time correction

Ludlum Measurements, Inc. Page 4-5 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 5

Section

Common Options and

5

Modifications

Relay Options

Internal Circuit-Board-Mounted Relays

A 9-pin connector with male pins provides connection to three fail-safe

form C relays, activiated by the LOW ALARM (alert), HIGH ALARM, and

instrument FAIL. These contacts are potential-free (non-powered), but can

handle 125 Vac at 0.3 A or 30 Vdc at 1 A.

For additional flexibility, additional relay options are available at extra cost:

Form C Relay (3 pin connector added) PN45 58-036:

This option allows the user to access the fail-safe form C contacts

(normally open, normally closed, and common), which activate upon

HIGH ALARM. This is achieved by using an additional 3-pin connector

with male pins, located at the bottom of the instrument, wired in

parallel with the 9 pin D male pin connector. These contacts are

potential-free (non-powered), but can handle 125 Vac at 0.3 A or 30

Vdc at 1 A.

RL1 Relay

The added 3-pin connector has the following connections

(shown energized):

Pin 1- normally open (NO) (ORG)

Pin 2- common (BRN)

Pin 3- normally closed (NC) (RED)

Ludlum Measurements, Inc. Page 5-1 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 5

External Mains (120 or 240 VAC) Alarm Rela y Out (usin g 3 pin

connector) PN4558-038:

Allows the use of the 9-pin D female connector for RS-232 or remote use

and does not interfere with the internal form C relays.

This option includes a small enclosure connected to the Model 375 via a

short cable, that accepts a standard mains power cord (conduit option is

4558-038-1). In an ALARM condition, the mains voltage is relayed to a

set of terminals. Only a licensed electrician should install this option.

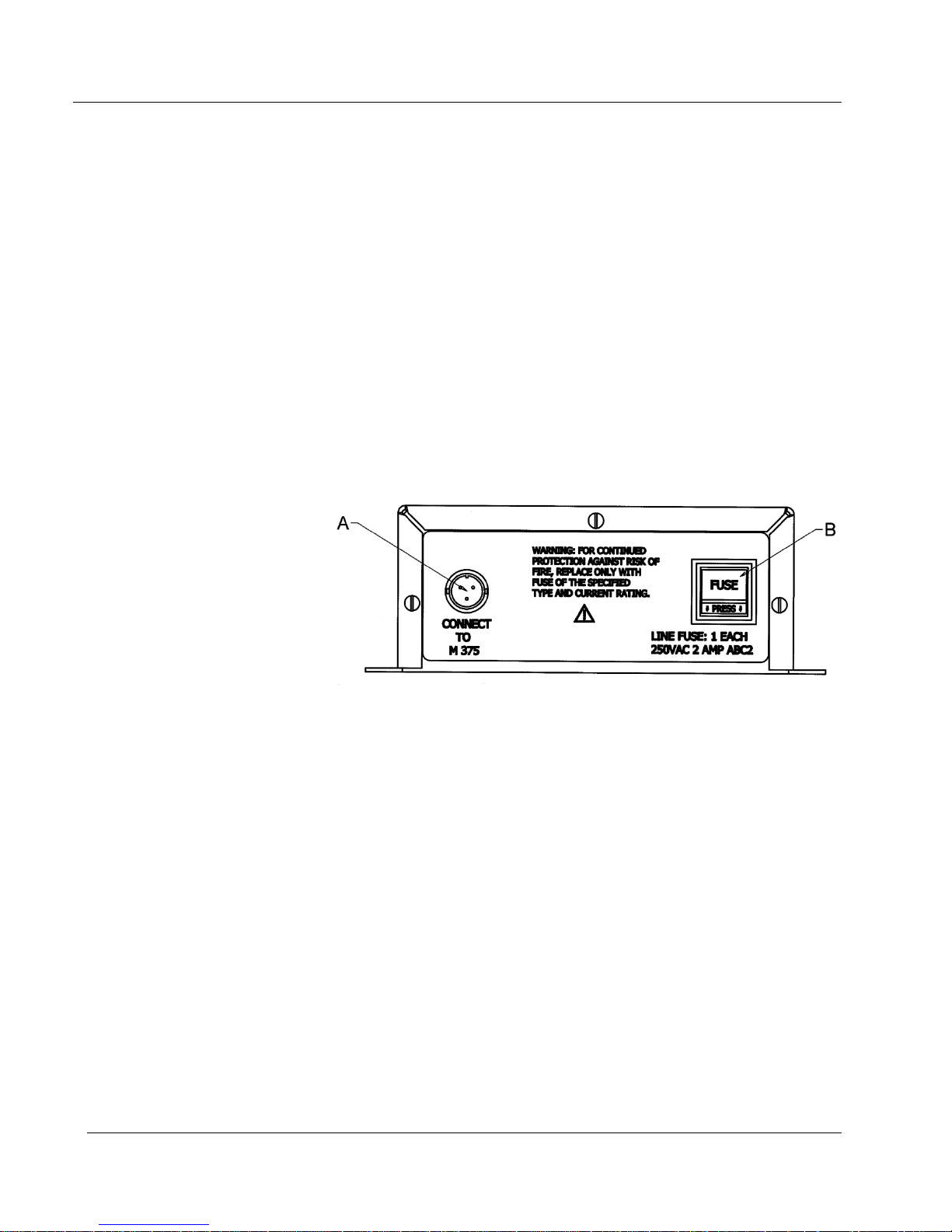

Figure 1. Mains Relay Box Back Panel.

See below for description of noted parts in drawing above.

A – connector for cable (Part # 8303-879) that connects the

mains relay box to the Model 375.

B – Use fuse that is noted in drawing above.

Ludlum Measurements, Inc. Page 5-2 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 5

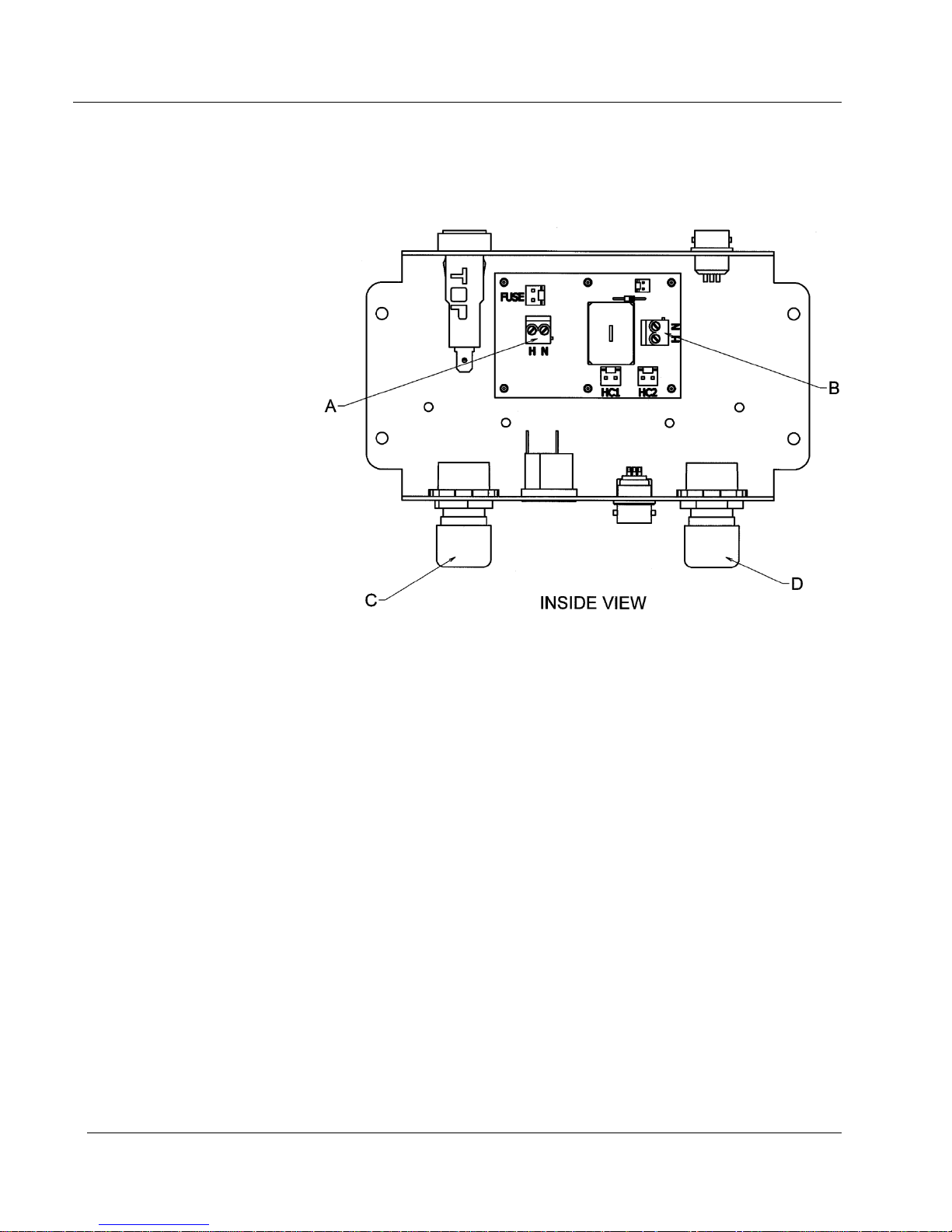

Figure 2. Mains Relay Box Front Panel.

See below for description of noted parts in drawing above.

A – conduit connector to the box if necessary.

B – AC receptacle (removed if using conduit).

C – mains relay output 3-pin connectors.

D – optional extra output.

E – relay output for conduit if necessary.

Ludlum Measurements, Inc. Page 5-3 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 5

Figure 3. Mains Relay Box Inside View.

See below for description of noted parts in drawing above.

A – 110/220 Vac conduit AC input. “H” = hot and “N” =

neutral. For 220 Vac, H = L1 and N = L2.

B – relay output. “H” = hot and “N” = neutral. For 220 Vac, H

= L1 and N = L2.

C – optional conduit connector input.

D – optional relay output for conduit.

Strobe lights and/or horns are also available through Ludlum

Measurements.

Ludlum Measurements, Inc. Page 5-4 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 5

Ethernet Interface Option

A 10-BaseT Ethernet interface may be added internally for network

reporting, using Ludlum software:

4558-098 LMI “Ethernet” Hardware Interface

4558-105 LMI “Webpage” Hardware Interface

Either the Ethernet software (1370-055) or the Webpage software (1370-

077) must be purchased separately (site-licensed).

Time and Date Stamp Option

Description:

When an alarm or failure occurs, the Model 375 will print the current

reading, date, time, and either ALARM or FAIL to the RS-232 port. The Model

375 will print once every 30 seconds as long as the alarm or fail condition is

present.

Setup:

You will need the following: a Model 375 instrument, a CBM-910 40-

column printer, and a cable (8558-142).

The printer should be configured at 2400 bps (baud), no parity, 8 data

bits, 1 stop bit, and no handshaking. See printer manual for proper setup

instructions.

Setting the date and time:

Check the month and day (MMDD) by pressing the

HIGH ALARM buttons simultaneously. The month and day will be

LOW ALARM and

displayed as long as those buttons are pressed. The month and day can be

set from 0101 to 1231.

Check the year (YYYY) by pressing the LOW ALARM and CAL CONST

buttons simultaneously. The year will be displayed as long as those

buttons are pressed. The year can be adjusted from 0000 to 9999.

Check the hours and minutes (HHMM) by pressing the

DEAD TIME buttons simultaneously. The hours and minutes will be

displayed as long as those buttons are pressed. The hours and minutes

can be adjusted from 0000 to 2359.

Ludlum Measurements, Inc. Page 5-5 May 2017

LOW ALARM and

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 5

RS-232 Data Format:

The data will be sent to the RS-232 port as:

Byte 1 0 x Byte 18 Space (20H)

Byte 2 x x Byte 19 H

Byte 3 x OR x Byte 20 H

Byte 4 x x Byte 21 :

Byte 5 . . Byte 22 M

Byte 6 x 0 Byte 23 M

Byte 7 Space (20H) Byte 24 :

Byte 8 Space (20H) Byte 25 S

Byte 9 Space (20H) Byte 26 S

Byte 10 M Byte 27 Space (20H)

Byte 11 M Byte 28 A Space

Byte 12 / Byte 29 L F

Byte 13 D Byte 30 A OR A

Byte 14 D Byte 31 R I

Byte 15 / Byte 32 M L

Byte 16 Y Byte 33 Carriage Return (0DH)

Byte 17 Y Byte 34 Line Feed (0AH)

Example Output:

0642.1 04/21/95 16:56:24 ALARM

0000.0 04/21/95 08:32:16 FAIL

Printer DIP Switch Settings

Citizen Dot Matrix Printer Model C BM-910 Type II

Please refer to page 32 of the printer user’s manual for the location of the

DIP Switches. Switches 2, 3, and 6 should be in the ON position (toward the

back of the printer). Switches 1, 4, 5, 7, and 8 should be in the OFF position

(toward the front of the printer).

Ludlum Measurements, Inc. Page 5-6 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 5

Sigma Alarm Modification Option

With this option, special firmware allows the Model 375 to have a sigmabased alarm point in addition to a regular fixed alarm point. This sigmabased alarm point allows the user to have a floating alarm point that will stay

at “x” sigma above the radiation background. As the background changes,

the sigma alarm also changes. The sigma alarm, when activated, activates a

rapid beeping and activates the HIGH ALARM indicator on the front panel of

the Model 375.

To set the sigma alarm, one first needs to consult a probability table showing

one-sided sigma values. If the sigma alarm (read or set by the

button) is set to 3.0, that setting statistically means that 99.87% of normal

background readings would be less than the alarm point. To look at the false

alarm rate, it means that 0.13% or 1 out of 769 comparisons would result in

a false alarm. Since comparisons are made every second, a setting of 3.0 will

result in a false alarm about every 13 minutes. Similarly, a setting of 5.0

would result in a false alarm every 38 days. To actually calculate the sigma

alarm point, it is necessary first to determine the background radiation level

in cps (counts per second). The sigma alarm point is then BKGND + (x

sigma × square root of BKGND).

LOW ALARM

The HIGH ALARM has not been changed; it is still a fixed alarm point and will

be activated when the radiation level exceeds that setpoint. This feature

allows the sigma alarm to trigger quickly if a small amount of radiation is

present and allows the fixed alarm to warn that the background radiation is

too high. Since the sigma alarm is allowed to rise if the background rises, the

HIGH ALARM is necessary to have an absolute value or ceiling for the

radiation level. The time constant for the background radiation level and the

displayed radiation reading is 20 seconds. The sigma alarm is not activated

until 60 seconds after the Model 375 is turned ON, in order to allow the

Model 375 to accumulate a stable background radiation reading.

Two other changes were made to the Model 375. The first change was to

deactivate the

LOW ALARM button) and the fixed alarm (HIGH ALARM button) trigger the

HIGH ALARM indicator. The second change was to lower the detector loss-

LOW ALARM indicator. Both the sigma-based alarm (set by the

of-count time frame to 15 seconds. This change means that the DET FAIL

indicator is activated if no pulses are received from the radiation detectors in

15 seconds. Since the sigma alarm is most useful for scintillation detectors

that have several hundred pulses per minute, this change allows a faster

determination of detector failure.

Ludlum Measurements, Inc. Page 5-7 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 5

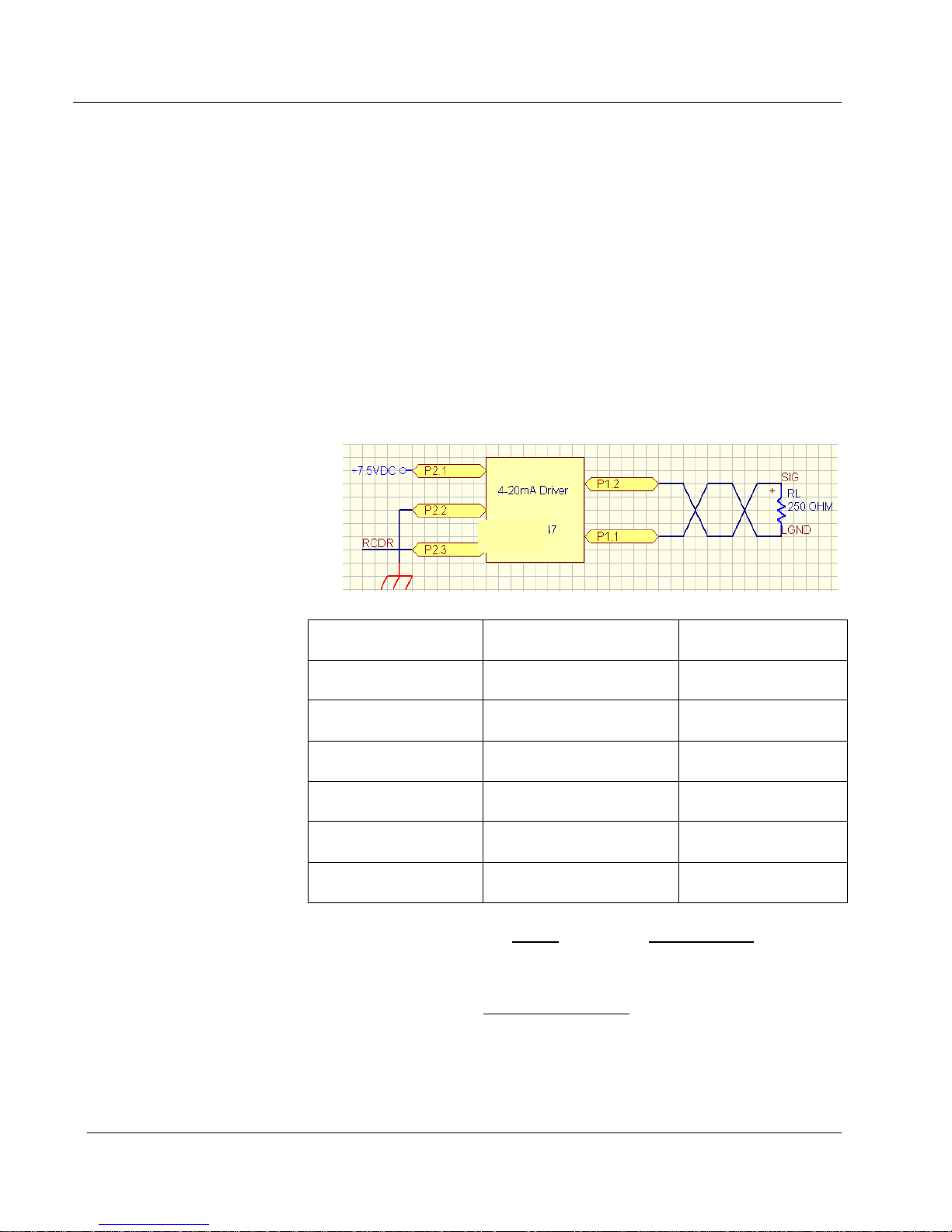

4 to 20 mA Isolated Output Driv er Option

4 to 20 mA Driver (Isolated) Modification Kit Part Number 4558-104

This circuit may be added to replace the Model 375 analog output, providing

an isolated 4 to 20 mA output capability. The circuit board (LMI Part

Number 5396-754) takes the analog output, varying between 0 and 5.00

volts, and converts it to a current output of 4 to 20 mA.

The circuit has an internal loop supply, generating +12 Vdc from the

RAWDC of the Model 375. It is designed for a 2-wire configuration, with

one conductor carrying the 4-20 mA current signal and the second

conductor providing a return (isolated loop ground). See Wiring Diagram,

Figure 4 (below).

Figure 4: Wiring Diagram.

5396-754

Decade “Base” Display mA Value

0 0.1 4 mA

1 1 7.2 mA

2 10 10.4 mA

3 100 13.6 mA

4 1000 16.8 mA

5 10,000 20 mA

mA value = 4

.

3.2log

∗

Display reading = 10

.∗

.

Ludlum Measurements, Inc. Page 5-8 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 5

SPECIFICATIONS

Power Required: 7.5 Vdc at 100 mA; minimum V

maximum Vin= 15 V (connected internally)

Terminating Resistor: 250 ohm

Model 375 4 to 20 mA Isolated Output Connections (3-pin Hirose

connector)

Pin 1 is black (negative).

Pin 2 is white (positive).

Internal Board Header Pinout

P1-1) Loop GND (Isolated)

P1-2) 4-20 current output (Isolated)

P2-1) +7.5 Vdc , RAWDC from main circuit board number 5396-160

(May range from +5.5 to 15 Vdc)

P2-2) GND

P2-3) RCDR voltage in or analog input (0-1.25 Vdc)

= 5.5 V and

in

CALIBRATION

Apply 0 counts or RESET the Model 375.

Check for a voltage of 1.00 V ±5% across Rterm, typically a 250 ohm (V

= 0.004 X Rterm) terminating resistor. The resistor should be placed

between Pin 5 (the 4-20 mA output) and Pin 6 (Loop ground).

Note:

Loop ground is isolated from instrument ground.

Now apply a full-scale meter reading to the analog input, or move the

CAL dipswitch to the right. The voltage at full-scale must be set to 5.00 V

±0.1 V between the analog input and instrument ground.

Note:

Instrument ground is not the same as loop ground.

Adjust the SPAN trimmer, R5, until the voltage across the 250-ohm

terminating resistor is 5 V ±5% (V= .020 X Rtem).

Ludlum Measurements, Inc. Page 5-9 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 6

Section

6

Safety Considerations

Environmental Conditions for Normal Use

Indoor use only

No maximum altitude

Temperature range of -15 to 50 °C (5 to 122 °F); may be certified for

operation from -40 °C (-40 °F)

Maximum relative humidity of less than 95% (non-condensing)

Mains supply voltage range of 100-240 Vac ,

50/60Hz single phase (less than 100 mA typical, 1 amp max) to wallmounted DC adapter supplying 9-12 Vdc

Maximum transient voltage of 1500 Vac

Installation Category II (Overvoltage Category as defined by IEC 1010-1)

Pollution Degree 2 (as defined by IEC 664)

Cleaning Instructions and Precautions

The Model 375 may be cleaned externally with bleach wipes or with a damp

cloth, using water, Lysol or alcohol as a wetting agent. Do not immerse the

instrument in any liquid. Observe the following precautions when cleaning:

1. Turn the instrument OFF and disconnect the instrument power

cord.

2. Allow the instrument to sit for one minute before cleaning.

Ludlum Measurements, Inc. Page 6-1 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 6

Warning Markings and Symbols

Caution!

The operator or responsible body is cautioned that the

protection provided by the equipment may be impaired if

the equipment is used in a manner not specified by Ludlum

Measurements, Inc.

The Model 375 is marked with the following symbols:

CAUTION, RISK OF ELECTRIC SHOCK (per ISO 3864, No. B.3.6)

– designates a terminal (connector) that allows connection to a voltage

exceeding 1 kV. Contact with the subject connector while the instrument is

on or shortly after turning off may result in electric shock. This symbol

appears on the side panel (Applicable for Models with an external detector).

DIRECT CURRENT (DC) (IEC 417, No. 5032) - designates an input

receptacle that accommodates a power cord intended for connection to DC

voltages. This symbol appears on the side panel.

PROTECTIVE CONDUCTOR TERMINAL (per IEC 417, No. 5019)

– designates the central grounding point for the safety ground. This symbol

is visible inside the chassis.

CAUTION (per ISO 3864, No. B.3.1) – designates hazardous live voltage

and risk of electric shock. During normal use, internal components are

hazardous live. This instrument must be isolated or disconnected from the

hazardous live voltage before accessing the internal components. This

symbol appears on the side panel. Note the following precautions:

Caution!

Do no touch the circuit board in the calibration window due

to possible electric shock.

Caution!

Verify instrument voltage input rating before connecting to a

power converter. If the wrong power converter is used, the

instrument and/or power converter could be damaged.

Ludlum Measurements, Inc. Page 6-2 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4

Warning!

Section 6

The operator is strongly cautioned to take the following

precautions to avoid contact with internal hazardous live parts

that are accessible using a tool:

1. Turn the instrument power

OFF

and disconnect the power

cord.

2. Allow the instrument to sit for one minute before accessing

internal components.

The “crossed-out wheelie bin” symbol notifies the consumer that the

product is not to be mixed with unsorted municipal waste when discarding;

each material must be separated. See section 8, “Recycling” for further

information. Also displayed on the side panel.

The “CE” mark is used to identify this instrument as being acceptable for

use within the European Union.

Electrical Safety Precautions

Warning!

Observe the following instructions to avoid a potentially

hazardous situation which, if mishandled, could result in

death or serious personal injury, as well as property damage.

Do not expose the unit to rain or an environment where it may be

splashed by water or other liquids, as doing so may result in fire or

electric shock.

Use the unit only with the voltage specified on the unit. Using a

voltage higher than that which is specified may result in fire or

electric shock.

Do not cut, kink, or otherwise damage nor modify the power supply

cord. IN addition, avoid using the power cord in close proximity to

heaters, and never place heavy objects – including the unit itself –

on the power cord, as doing so may result in fire or electric shock.

Avoid installing or mounting the unit or its power supply in unstable

conditions, such as a rickety table or a slanted surface. Doing so may

Ludlum Measurements, Inc. Page 6-3 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 6

result in the unit falling down and causing personal injury and/or

property damage.

Replacement of Main Fuse (Side Panel)

Warning!

For continued protection against risk of fire, replace only

with fuse of the specified type and current rating.

Detector Connector

Warning!

Potential electrical shock hazard: do not touch the center pin

of the detector connector unless the unit has turned off and

power has been removed for at least one minute.

Battery Replacement

Warning!

Only certified technicians or calibration personnel should

replace battery.

Ludlum Measurements, Inc. Page 6-4 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 7

Section

7

Calibration

High V oltage

The high voltage is adjustable from 450-2500 Vdc using the HV

potentiometer located under the calibration cover. The high voltage required

will depend on the type of detector used. Internal GM detectors usually

require 550 Vdc. Ensure that the high voltage is checked only with a highimpedance (≥1000 megohm) voltmeter. A high-voltage checkpoint is

located next to the HV potentiometer.

Warning!

Do not touch the circuit board in the calibration window

due to potential for electric shock.

Calibration Parameters

The calibration parameters, LOW ALARM, HIGH ALARM, CAL CONST, and

DEAD TIME can only be changed while in calibration mode. Switch the top

dipswitch CAL MODE to the right to switch into calibration mode. Changing

any parameter is done by holding down the parameter key and pressing the

up or down arrow buttons. Any parameter can be set in the range of 0.1 to

9999*. If a parameter is changed, the instrument will beep to confirm the

saving of the parameter, and then return to displaying the current radiation

level.

The calibration constant (

a "low" radiation field. A "low" radiation field in this case is defined as a field

where dead time losses do not exceed 5%. The calibration constant is usually

given for a certain detector. A Ludlum Model 133-4 detector, for example,

has a calibration constant of approximately 100 cpm/mR/hr. Once the

calibration constant is set and checked at a low radiation field, the dead time

correction can be set.

Ludlum Measurements, Inc. Page 7-1 May 2017

CAL CONST) is set when the detector is exposed to

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 7

The dead time correction (DEAD TIME) is set when the detector is exposed to a

"high" radiation field. A "high" radiation field in this case is defined as a field

where dead time losses exceed 30%. The dead time correction will elevate the

ratemeter reading to account for counts arriving at the detector during the

detector's dead time. GM tubes typically have long dead times from 50-150

microseconds. Neutron and scintillation detectors generally have short dead times

of 1-5 microseconds.

Note:

Once parameters are set, it is important to remember to

switch the CAL MODE switch back to the left. This action

protects the parameters from inadvertent changes.

Analog Output

The analog output is a five-decade logarithmic voltage-out. The maximum

voltage-out while under primary power is 6 volts. The maximum voltage-out

while under battery backup power is 4.5 volts. The five decades are:

0.1 <units> - 1.0 <units>*

1 <units> - 10 <units>*

10 <units> - 100 <units>*

100 <units> - 1000 <units>*

1000 <units> - 10000 <units>*

When the CAL MODE dip switch is switched to the right, the analog output

goes to full scale. The analog output goes to full scale during a DET FAIL

condition.

Discriminator

The DISC potentiometer located under the calibration cover is used to set the

threshold for pulses coming from the detector. The desired pulse threshold

depends on the type of detector used. It is adjustable from 2.0 mVdc to 100

mVdc.

Battery Charge

The potentiometer labeled BAT, located under the calibration cover, is used

to set the backup battery trickle-charge voltage. This is typically set to 6.9

Vdc with the battery disconnected.

* See note on page 2-3 regarding Model 375 Series One.

Ludlum Measurements, Inc. Page 7-2 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4

Section 8

Section

8

Recycling

udlum Measurements, Inc. supports the recycling of the electronics

products it produces for the purpose of protecting the environment

L

recycling systems. To this end, Ludlum Measurements, Inc. strives to supply

the consumer of its goods with information regarding reuse and recycling of

the many different types of materials used in its products. With many

different agencies – public and private – involved in this pursuit it becomes

evident that a myriad of methods can be used in the process of recycling.

Therefore, Ludlum Measurements, Inc. does not suggest one particular

method over another, but simply desires to inform its consumers of the

range of recyclable materials present in its products, so that the user will

have flexibility in following all local and federal laws.

The following types of recyclable materials are present in Ludlum

Measurements, Inc. electronics products, and should be recycled separately.

The list is not all-inclusive, nor does it suggest that all materials are present in

each piece of equipment:

and to comply with all regional, national, and international agencies

that promote economically and environmentally sustainable

Batteries Glass Aluminum and Stainless Steel

Circuit Boards Plastics Liquid Crystal Display (LCD)

Ludlum Measurements, Inc. products, which have been placed on the

market after August 13, 2005, have been labeled with a symbol recognized

internationally as the “crossed-out wheelie bin.” This notifies the consumer

that the product is not to be mixed with unsorted municipal waste when

discarding; each material must be separated. The symbol will be placed near

the AC receptacle, except for portable equipment where it will be placed on

the battery lid.

The symbol appears as such:

Ludlum Measurements, Inc. Page 8-1 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 9

Section

9

Model 375 Digital WallMount Area Monitor

without Detector

Model 375/1 Digital WallMount Area Monitor

Model 375/2 Digital WallMount Area Monitor

Model 375/4 Digital WallMount Area Monitor

Model 375 Series One

without Detector

Model 375/2 Series One

Model 375/4 Series One

Main Board,

Drawing 558 x 1

CRYSTAL

CAPACITORS

Parts List

Reference Description Part Number

UNIT Completely Assembled 48-2230

Model 375

UNIT Completely Assembled 48-3831

Model 375/1

UNIT Completely Assembled 48-2410

Model 375/2

UNIT Completely Assembled 48-2411

Model 375/4

UNIT Completely Assembled 48-2676

Model 375 Series One

UNIT Completely Assembled 48-2931

Model 375/2 Series One

UNIT Completely Assembled 48-3007

Model 375/4 Series One

BOARD Completely Assembled Main 5558-001

Circuit Board (common to all)

Y211 6.144 MHZ 01-5262

C1-C2 100µF, 16V 04-5794

C3 0.1µF, 25V 04-5744

C4 100µF, 16V 04-5794

C5-C6 10µF, 25V 04-5728

C7 100µF, 16V 04-5794

C8 10µF, 25V 04-5728

Ludlum Measurements, Inc. Page 9-1 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 9

T

Reference Description Part Number

C9-C11 100µF, 16V 04-5794

C12-C21 0.1µF, 500V 04-5696

C22-C23 0.01µF, 3kV 04-5762

C24-C33 0.1µF, 500V 04-5696

C35 100pF, 100V 04-5743

C36 10µF, 25V 04-5728

C37 100pF, 100V 04-5743

C38 100µF, 16V 04-5794

C39-C40 10µF, 25V 04-5728

C41-C43 10µF, 25V 04-5655

C44-C53 0.1µF, 25V 04-5744

C54 10µF, 25V 04-5655

C55-C56 0.1µF, 25V 04-5744

C57 4.7pF, 200V 04-5787

C201 10µF, 25V 04-5655

C211 27pF, 100V 04-5658

C221 100µF, 16V 04-5794

C222 27pF, 100V 04-5658

C301-C303 10µF, 25V 04-5655

C401 100µF, 16V 04-5794

C441-C442 100µF, 16V 04-5794

C531 0.047µF, 16V 04-5729

C541-542 10µF, 25V 04-5655

C543 2700µF, 35V 04-5621

C611 10µF, 25V 04-5655

C711-C12 10µF, 25V 04-5655

C721 10µF, 25V 04-5655

C722 0.001µF, 100V 04-5659

C731 100pF, 3kV 04-5735

RANSISTORS

VOLTAGE

REGULATOR

Q1-Q3 2N7002L 05-5840

Q4 CMXT3904TRLF 05-5888

Q5 CMXT-3906TRLF 05-5890

Q6 CMXT3904TRLF 05-5888

Q7 2N7002L 05-5840

Q151-Q154 2N7002L 05-5840

Q321-Q322 2N7002L 05-5840

Q331 MJD200RLG 05-5844

Q431 2N7002L 05-5840

VR341 LT1129CQ-5 06-6372

Ludlum Measurements, Inc. Page 9-2 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 9

Reference Description Part Number

INTEGRATED

CIRCUITS

DIODES

U2 MAX985EUK+T 06-6459

U3 LT1304CS8 06-6394

U4 ICL7660SCBAZ 06-6437

U5 TCM810LVNB713 06-6424

U31 SA08-11EWA 07-6389

U32 KB-2785YW 07-6371

U41 KB-2685EW 07-6400

U111 ICM7218CIQI-LFT 06-6311

U131 SA08-11EWA 07-6389

U201 MAX220ESE+T 06-6329

U231 SA08-11EWA 07-6389

U232 KB-2785YW 07-6371

U233 SA08-11EWA 07-6389

U241 KB-2685EW 07-6400

U251 TLC372IDR 06-6290

U321 M24C02-WMN6TP 06-6299

U331 ICL7663SCBAZA-T 06-6302

U411 P89V51RD2FA 06-6303

U521 CD74HC4538M96 06-6297

U531 OPA2343UA2K5 06-6582

U611 MAX985EUK+T 06-6459

U711 LM285DR-1-2 05-5845

CR1 CMSH1-40M 07-6411

CR2 P0640SCMCLRP 21-9028

CR3 MMBD914LT1G 07-6353

CR4-CR5 US1M-E3 07-6530

CR6 P0640SCMCLRP 21-9028

CR7-CR10 US1M-E3 07-6530

CR11 P0640SCMCLRP 21-9028

CR12 MMBD914LT1G 07-6353

CR13-CR14 US1M-E3 07-6530

CR15 CMSH1-40M 07-6411

CR16 MMBD914LT1G 07-6353

CR17-CR21 P0080SC 21-9004

CR22-CR31 CMPD2005SLF 07-6468

CR32 CMSH1-40M 07-6411

CR33-CR34 CMPD2005SLF 07-6468

CR35 CMSH1-40M 07-6411

CR36 P0080SC 21-9004

CR38 US1M-E3 07-6530

CR341-CR342 CMSH1-40M 07-6411

Ludlum Measurements, Inc. Page 9-3 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 9

LED

SWITCHES

POTENTIOMETER

RESISTORS

DS11 KB-2550SGD 07-6370

S001 ALERT POINT 08-6728

S101 ALARM POINT 08-6728

S201 CALIBRATION CONSTANT 08-6728

S301 DEADTIME CORRECTION 08-6728

S501 DOWN 08-6728

S511 UP 08-6728

S512 OPTION DIPSWITCH 08-6709

SW1 POWER 08-6840

R13 1M, BAT CHG ADJ 09-6778

R16 1M, HV ADJ 09-6778

R523 1M, OVLD ADJ 09-6778

R535 200K, THR ADJ 09-6949

R537 5K, RCDR 09-6849

R1-R4 301ohm, 1%, 250mW 12-7863

R5-R6 1M, 1%, 250mW 11-7251

R7 4.75M, 1%, 250mW 12-7995

R8 500M, 2%, 3kV 12-7031

R9 165K, 1%, 125mW 12-7877

R10 500M, 2%, 3kV 12-7031

R11 100ohm, 1%, 250mW 12-7840

R12 301ohm, 1%, 250mW 12-7863

R14 165K, 1%, 250mW 12-7877

R15 1M, 1%, 250mW 11-7251

R17 2.2ohm, 5%, 250mW 12-7932

R18 82.5K, 1%, 250mW 12-7849

R19-R22 2.2ohm, 5%, 250mW 12-7932

R23 100K, 1%, 250mW 12-7834

R24 1M, 1%, 250mW 11-7251

R25 10ohm, 1%, 125mW 12-7836

R26 100ohm, 1%, 100mW 12-7142

R27 100k, 5%, 333mW 12-7747

R41 2.2ohm, 5%, 250mW 12-7932

R42 60.4ohm, 1%, 250mW 12-7962

R141 2.2ohm, 5%, 250mW 12-7932

R142 60.4ohm, 1%, 250mW 12-7962

R151-R152 100K, 1%, 250mW 12-7834

R201 24.3K, 1%, 250mW 12-7867

R241 2.21K, 1%, 250mW 12-7835

R251 10K, 1%, 250mW 12-7839

R252 24.3K, 1%, 250mW 12-7867

Ludlum Measurements, Inc. Page 9-4 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 9

R253 82.5K, 1%, 250mW 12-7849

R331 1K, 1%, 250mW 12-7832

R332 165K, 1%, 250mW 12-7877

R341 2.2ohm, 5%, 250mW 12-7932

R431 1K, 1%, 250mW 12-7832

R421-R422 100K, 1%, 250mW 12-7834

R432 1M, 1%, 250mW 11-7251

R531 10K, 1%, 250mW 12-7839

R532 100K, 1%, 250mW 12-7834

R533 10K, 1%, 250mW 12-7839

R534 2.21K, 1%, 250mW 12-7835

R611 47.5K, 1%, 250mW 12-7872

R621 4.75K, 1%, 250mW 12-7858

R622 10K, 1%, 250mW 12-7839

R623 1K, 1%, 250mW 12-7832

R631 47.5K, 1%, 250mW 12-7872

R713-R714 10K, 1%, 250mW 12-7839

R721 10K, 1%, 250mW 12-7839

R722 165K, 1%, 250mW 12-7877

R723 1K, 1%, 250mW 12-7832

R724 4.75K, 1%, 250mW 12-7858

R732-R733 100K, 1%, 250mW 12-7834

R735 10K, 1%, 250mW 12-7839

RESISTOR NETWORK

CONNECTOR

RN411 220K 12-7831

P1 RAPC712 13-8445

P2 640457-3 BAT 13-8165

P3 FRJAE-468 LF 21-9007

P4 9 PIN D CONN-747197-4 13-8364

P5 640456-3 MTA 100X4 ETHERNET

13-8088

P6 747020-2 9 PIN D FEMALE 13-8555

P7 640456-3 MTA 100X3 4-20mA 13-8081

P8 640457-4 MTA 100X4RA SONALERT

13-8089

P9 640456-3 MTA 100X3 4-20mA 13-8081

P10 640457-2 MTAX2RA ALARM OUT

13-8147

Ludlum Measurements, Inc. Page 9-5 May 2017

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 9

Reference Description Part Number

INDUCTORS

RELAY

TRANSFORMER

MISCELLANEOUS

Wiring Diagram,

Drawing 558 x 136

AUDIO

FUSE

BATTERY

Internal Detectors

L1 1Kohm 21-9008

L3-L4 2700ohm 21-9009

L8 2700ohm 21-9009

L9 1Kohm 21-9008

L411 220µHY 21-9678

RL1-RL3 G6K-2FY DC5 22-9332

T1 32377R 21-9925

* SOCKET 44P PLCC 06-6613

S2 SHIELD-M4500 PREAMP 7436-142

U1 RABBIT RCM 3700 23110915

W1 COAX, WIRE *

W3-W5 WIRE *

TP1-TP3 COAX, WIRE *

DS1 TXC-V86-515-Q

WARNING DEVICE 218802

F1 RUEF110, 1.1A, 30V 21-8989

B1 BATTERY-PS630 21-9705

* Model 375/2 (only) DET ASSY. 4396-055

* Model 375/4 (only) DET ASSY. 4396-056

Ludlum Measurements, Inc. Page 9-6 May 2017

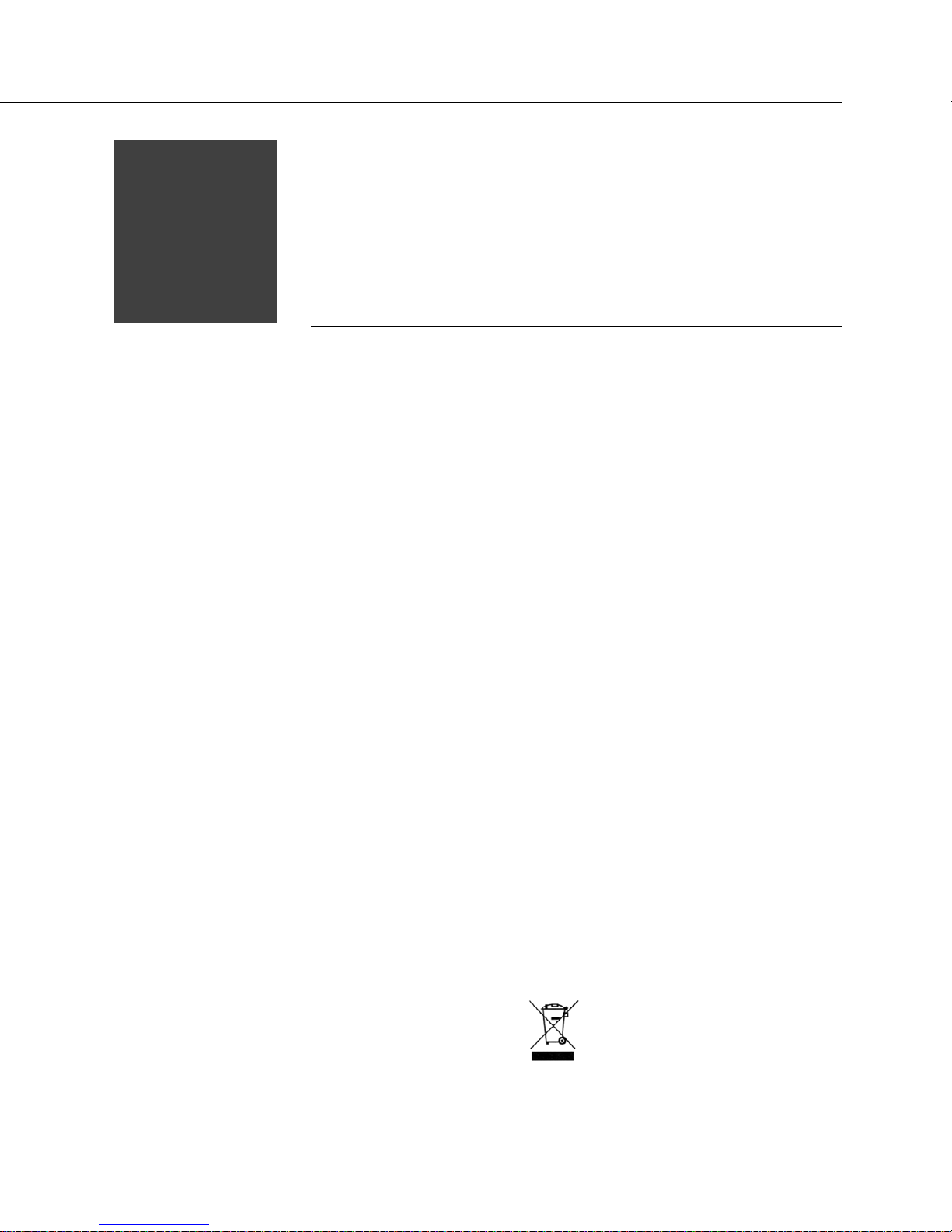

Models 375 (Including Series One), 375/1, 375/2 & 375/4 Section 10

Section

10

Drawings

Main Circuit Board, Drawing 558 x 1 (5 sheets)

Main Circuit Board Component Layout Drawing 558 x 2

Main Circuit Board Component Layout Drawing 558 x 2A

Wiring Diagram, Drawing 558 x 136

Ludlum Measurements, Inc. Page 10-1 May 2017

Loading...

Loading...