Page 1

Ludlum Model 2350

DATA LOGGER

Revised: July 1993

Serial No. 106622 and Succeeding

Serial Numbers

Software Version # 37102n16

.

I!!!

cl

LUDLUM

501

OAK ST., P.O.

svuEmTER,Tx78558

9l-FAx:9lW3!%672

MEASUREMENB,

60X

INC.

810

Page 2

f

1

WAND

71.1

I’

15.3

18: 44 DET#O2

uR/hr

0

60 SEC

UR

218 MIN DOS

#OO

0 *o

RAT

’

Et

DOS

1

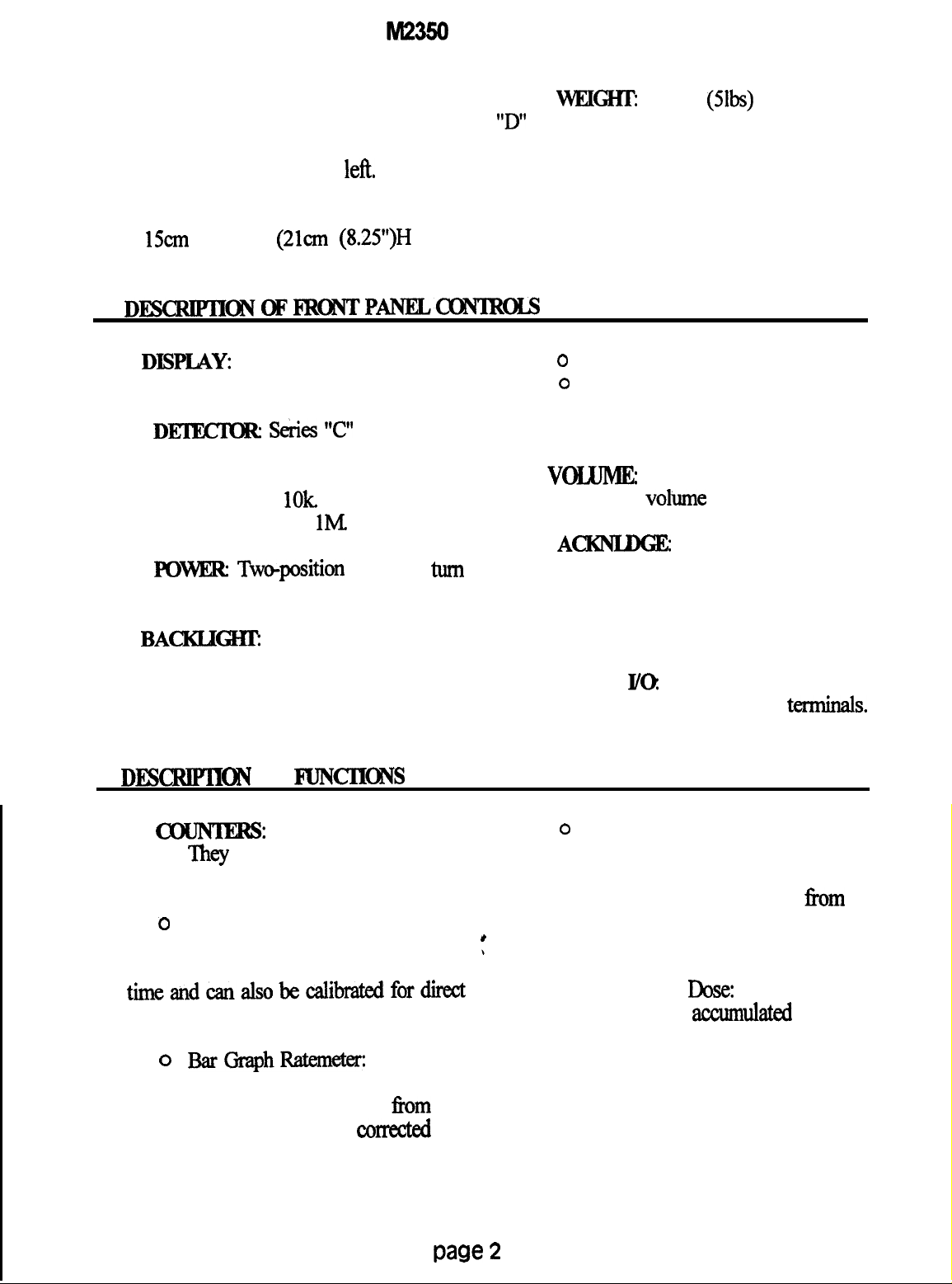

MODEL 2350

DATA LOGGER

SERIAL I/O

(/@zqJ)

o o

I

AUDIO

DIVIDE

ACKNLDGE

1oo

VOLUME

xxxxx

J

1

@

Page 3

Ludlum

of defects due to workmanship, materials, and design for a period of twelve months from the date

of delivery, with the exception of photomultiplier tubes and geiger tubes, which are warranted

ike

for 90 days.

misuse,

In the event of instrument failure, notify Ludlum Measurements, Inc. for repair or replacement.

Liability of this warranty is limited to the purchase price of the insWment.

Be sure to verify that the shipping carton is received in good condition with no visible damage,

Should the instrument be received in a damaged condition, save the shipping container and the

packing material and request an immediate inspection by the carrier.

If equipment needs to be returned to Ludlum Measurements, Inc. for repair or calibration, please

send to the address below. All shipments should include documentation containing return shipping

address, customer name, telephone number, description of service requested, and all other necessary

information. Your

Measurements,

This warranty is voided in instances of improper installation abuse, mishandling,

fkight

damage, or repair by unqualified persons.

uqXration

Inc.

warmnts the,products

RECEMNG CONDITION EXAMINATION

RETURNOFGOOIISToMANuFAcllJRER

will expedite the return of your equipment.

covered in this instruction manual to be

thee

d&ct-

’

:

5olOAKS~

SWEEIWA’IE& TX 79556

91~23~5494

FAX

915-235-4672

Page 4

M2350 Data Logger

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. DESCRIPTION OF FRONT PANEL CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . .

4. DESCRIPTION OF FUNCTIONS . . . . . . . . . . . . . . . .

l

. . . . . . . . . . . . . . . . . . . .

5. OPERATINGPROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1Installingbatteries.. ...........................................

5.2operatingtheinstrurnent

........................................

5.3P~orminga”coldstart” ........................................

6. DESCRIPTION OF DISPLAY MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Normal display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2ParameWs-d&play..

6.3Detectordisplay

...........................................

..............................................

6.4Alarmdisplay.. ...............................................

6.5Loggeddatadisplay ............................................

6.6Recycledatadisplay

6‘7

Recycle setup display

...........................................

........................................... 9

1

1

2

2

5

5

5

5

6

6

6

7

7

8

8

7. DESCRIPTION OF COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1setcommands

7.2control~~

7.3Readcommands

8.

COMMANDUSAGE

8.1

Scanthrou~thedisplaymodes

8.2Setvariousdetectorsettings

8.3Readvariousdetectorsettings

9. APPLICATIONS

9.1 General M2350 setup

9.2CountratemeterwithaNaIscintillator

9.3Micro-RmeterwithaNaIscintillator..

9.4SurveymeterwithaG-Mdetector..

9.5Lqgingreadhgswithmultipleprobes

9.6Viewloggedreadings

...............................................

............................................

.............................................

............................................

..................................

......................................

.......

..................

j..

..........................

.

..................

.

.........

..........................................

.............................

.............................

...............................

..............................

..........................................

10

11

12

14

18

19

20

21

22

22

22

24

26

27

31

page i

Page 5

10.

SPECIAL,

OPEBA’I’@G MODES _ .i:t, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34

10.1 Recyclemade

10.2 Dead time calibration

IO;3

CMibration constant

11.

12.

PAR’TSL,IST

EIANDHEL,DTERMINALOPERATION

11.1Terminalsetup

11.2TerminaIoperatibn;.

OPTICALWANDOPERATION..

12.1

Optidtiuse

12.2Barcode generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . ..A.....................~

Model235ODataLogger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

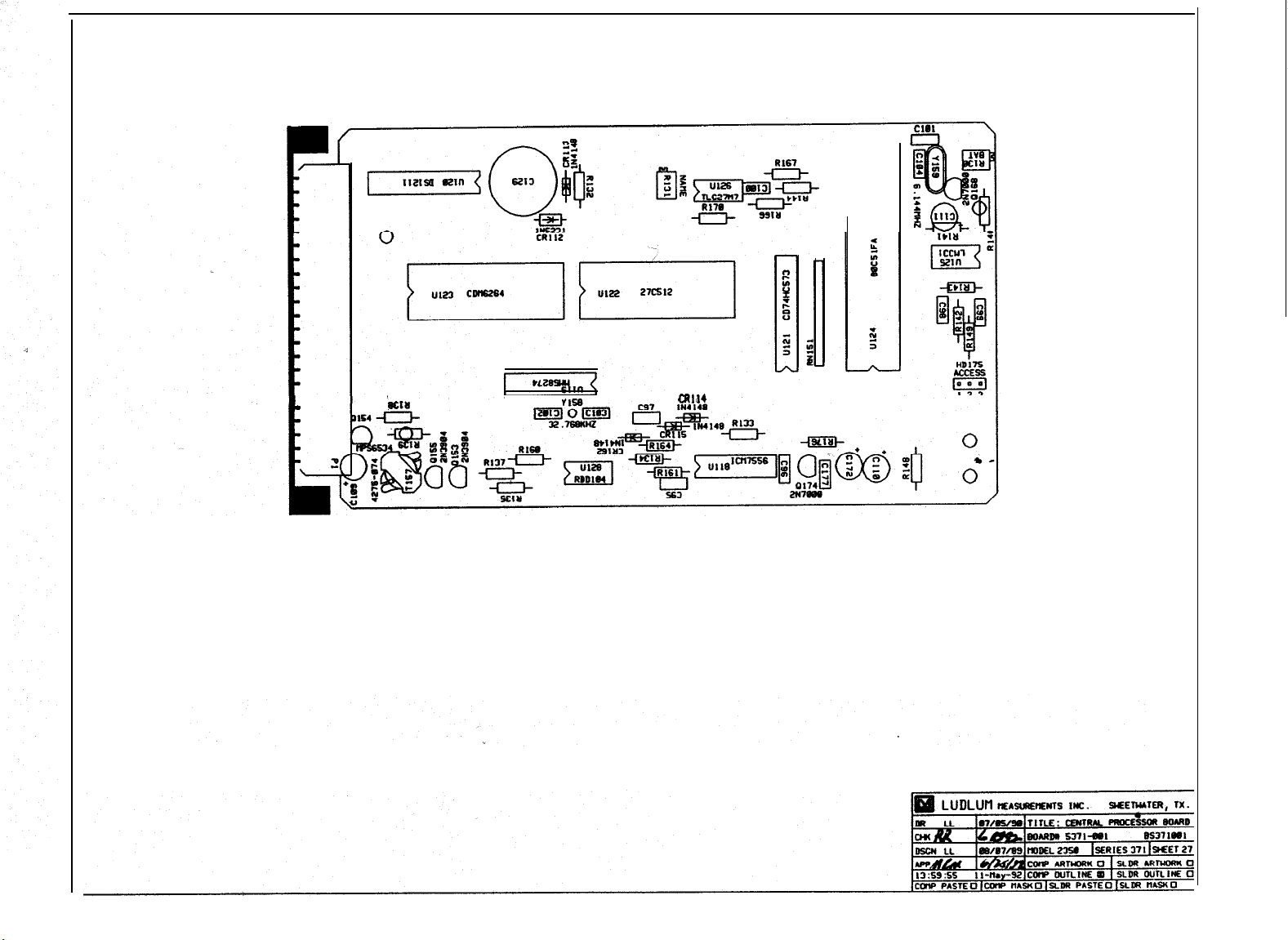

celltral~Board,~g371x1

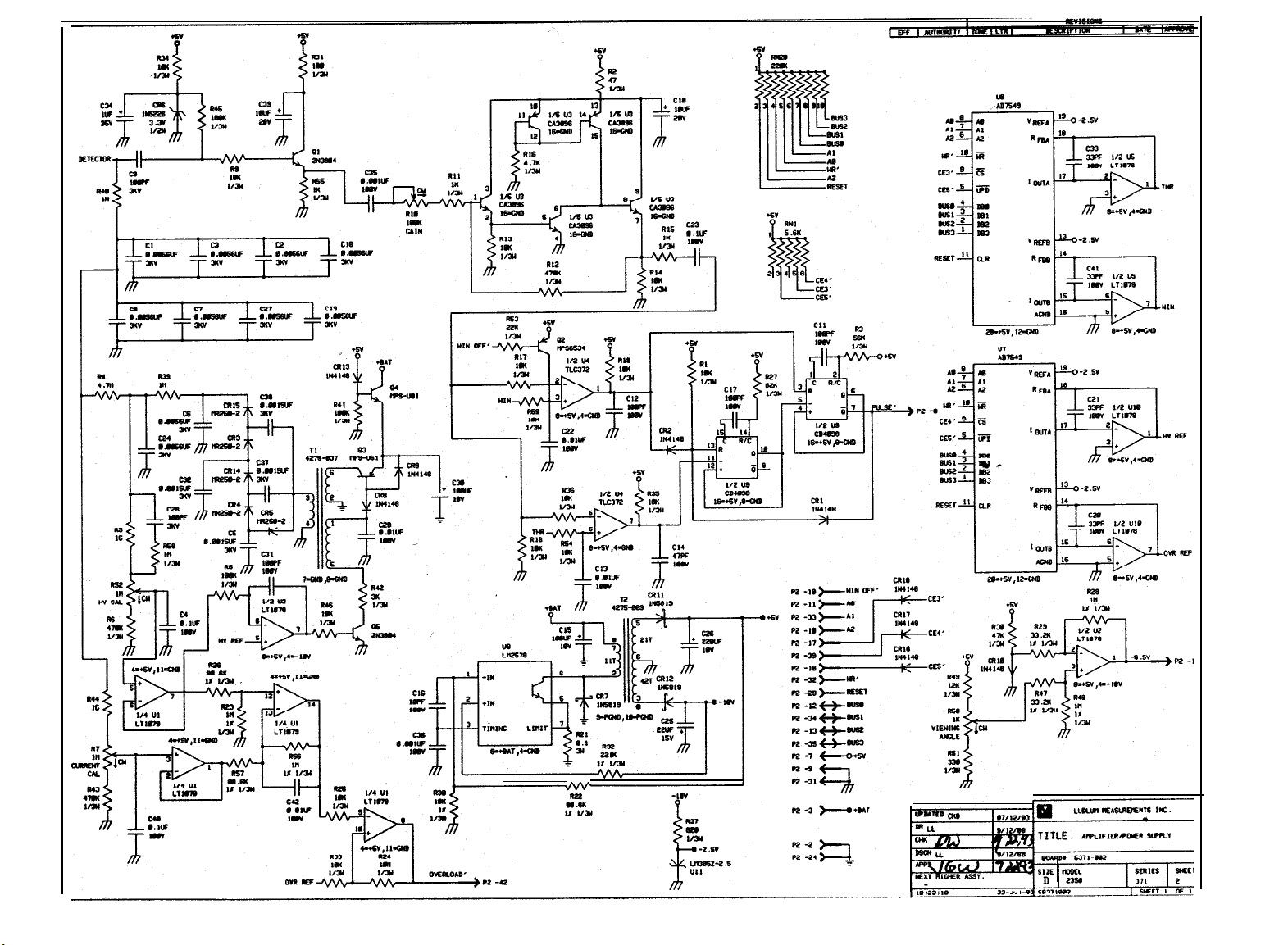

Am@PowrsupplyBoard,~~g371x2

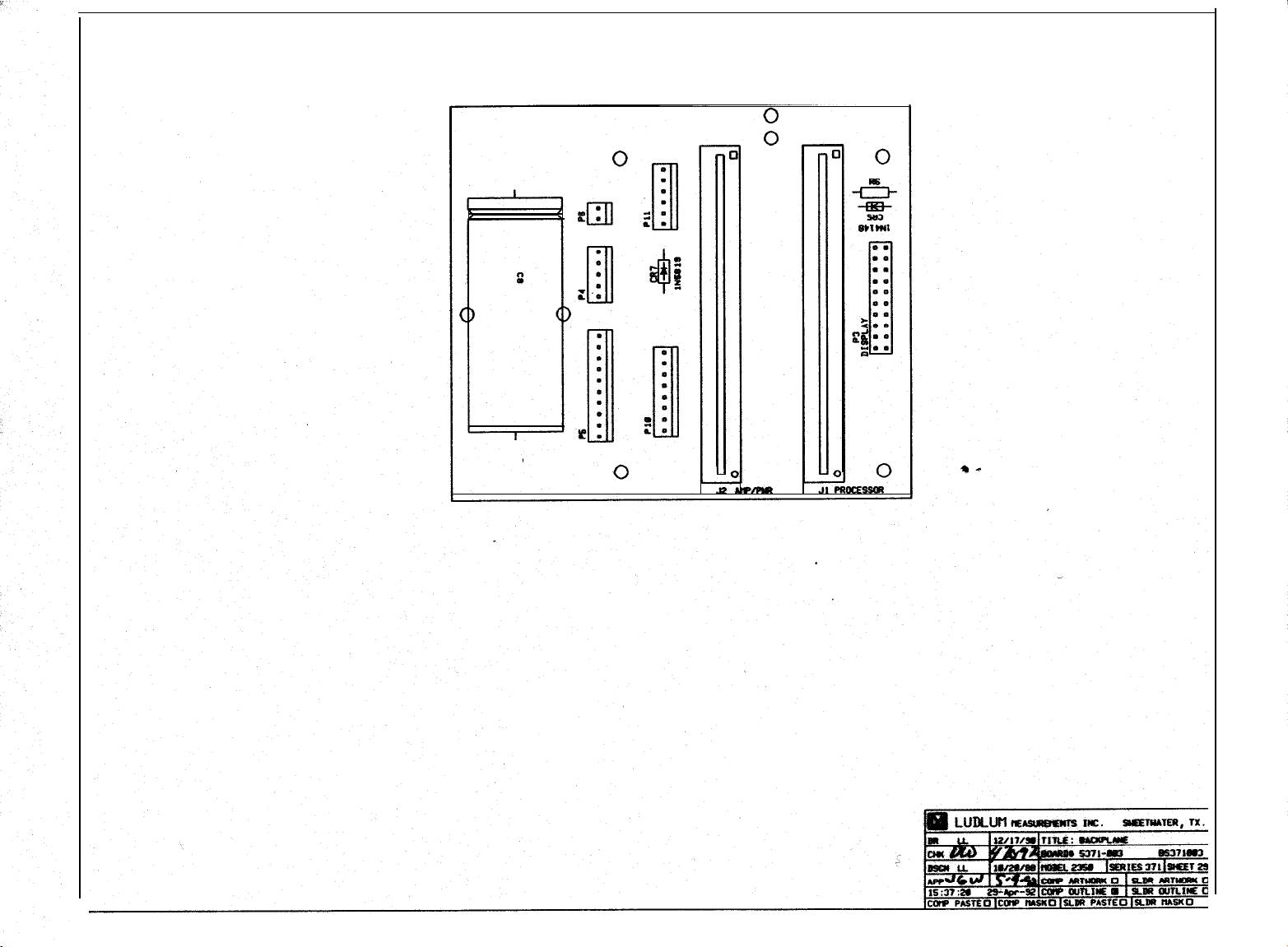

Back@w~Dr&ng371

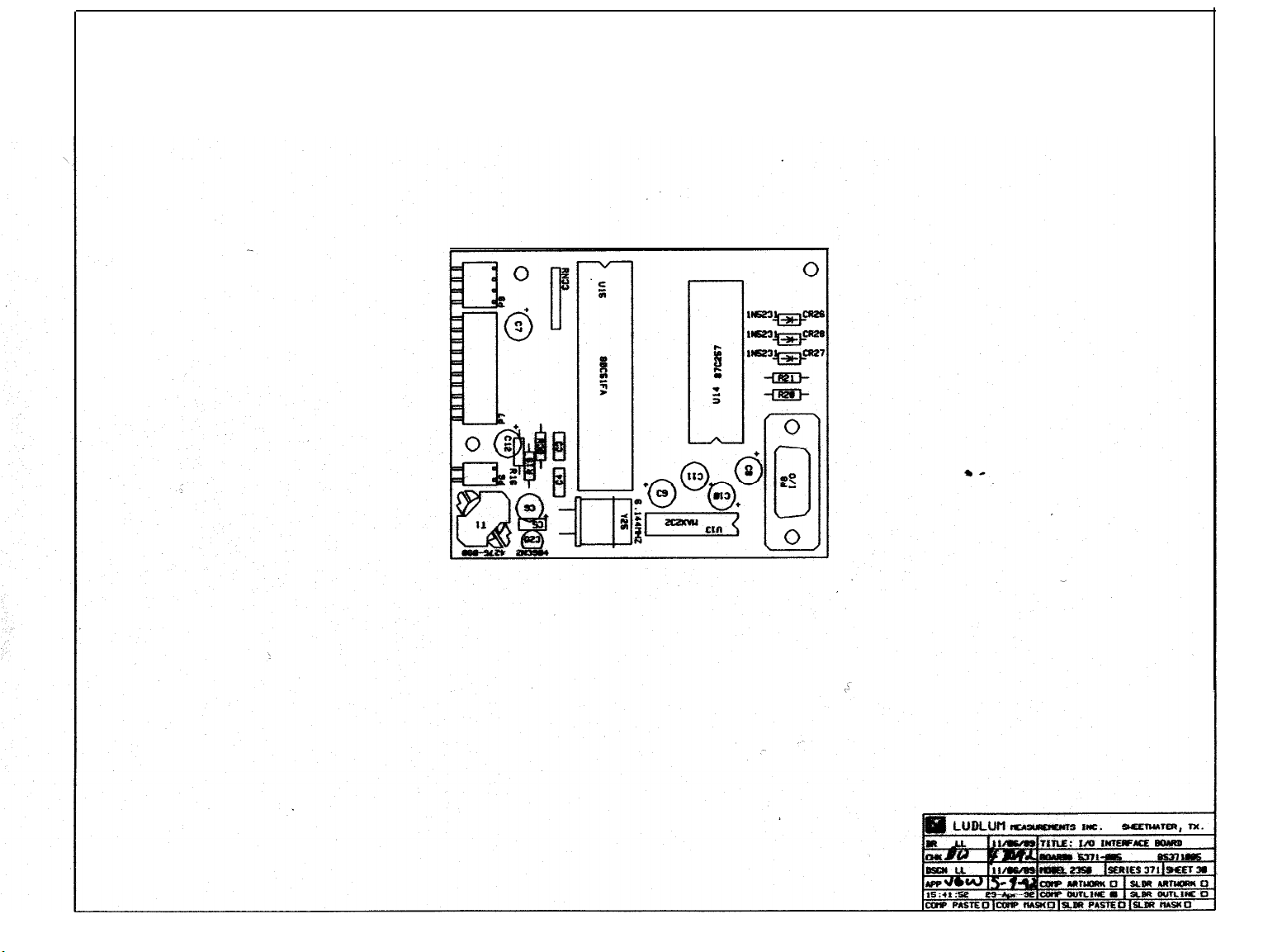

I/Oh~~I>rawving371

WkingDiagfmqIhwing371x4

. .

...............................................

.........................................

..........................................

...........................

...........

........;.........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

t...:Y; .:.

.....

x3 . . . . . . . . . . . . . . . . . .;‘. . . . . . . , . . . . .I 48

x5

. . . . . . . . . . . . . . . . . . . . . . . . .

...........................

.......................

.:

,*’

;;.

;......;

I’.

.

.......

. . .

‘;‘.......

.

.....

. . . . . . . . . . . . . . . . . . . . ...*...

. . . . . . . . l . . . . . . ...’ . . . . . . . .

. . . . .

.

.....

.;.

. . . . . . . . . .

.-.;

. . .

.‘.

. . . . .

..

34

36

38

41

41

41

42

42

42

43

43

43

45

48

50

,i

PageJi ,.

.

Page 6

M2350 Data Logger

1.

GENmAJJ

The Ludlum Model 2350 Data Logger is

a self contained counting instrument designed

for operation with scintillation, proportional,

or G-M detectors.

The M2350

is complete

with a voltage-sensitive amplifier, single

channel analyzer, detector high voltage power

supply, detector overload sensing circuitry,

and data logging memory all under micropro

cessor control. The settings can be changed

through the bar code reader or the RS-232

serial

I/o

port.

‘The M2350 provides four different types

of data readout.

‘Ihey

are 1) a digital

ratemeter, 2) a five decade. log bar graph

ratemeter, 3) a timed counter, and 4) an

integrated dose counter and timer. All four

readouts operate from the same count input.

The

count displays can be cone&d for

detector dead time.

The digital ratemeter and integrated dose

counter can also have a calibration constant

applied to them to allow direct readout in user

selected units (ie. R/hr,

dpm

cps, etc.). All

readout displays can be individually turned on

or off except for the bar graph display, which

is always displayed. The counters will

continue to function even when the counter

display is turned off.

audio output with a programmable AUDIO

DIVIDE selector switch to increase its

usefulness with sensitive detectors. There is

also a five decade analog output available on

the backplane.

readings

sixteen different detectors. The logged reading

contains the count

detector number, location code, sample

number, status, time, and type of reading.

detector setup memory contains the settings

for the detector calibration constant, detector

dead time, detector high voltage, detector

model number, detector serial number, display

range multiplier, display time base, display

units, integrated dose alarm setting, overload

current,

setting, scaler count time, threshold, and

window.

batteries even when the M2350 is turned

In addition, there is a backup capacitor that

keeps the memory powered for about thirty

minutes when the batteries are removed to

allow time to replace weak batteries.

The

M2350

provides a click per event

The data logging memory can store the

fi-oin

250 samples and the setups for

da&

count time, date,

‘Ihe

ratemeter alarm

&tin&

scaler alarm

The memory is powered by the M2350

off.

l

HEH

. SmsrxlWIYz

adjustable from

calibrated to

l

INPUTIMPEDANCE 1Ok

l Dl!XlEKR

II 11

C.

l DISPUW8lineby15chamcterLCD

WJLTAGEz

With threshold at 100,

1.5mV

1OmV.

cKBNEKR

0

to 2500 volts.

to

35mV,

display with EL backlight.

f&ory

Zkries

paw 1

l

AUDIa

Click per event through built

in unimorph speaker with adjustable volume

and selectable divide by 1, 10, or 100.

l

*

’

all calibrations done through the bar

CAUBMTION

CZCINMU:

None;

code

input or RS-232 serial I/O.

l

BA’lJERIE

batteries in

separate

Four

“D”

cell flashlight

externally accessible

compartment.

l

BATJJRY HFE

hours with Duracell MN1300

From 50 hours to 90

batteries

Page 7

M2350

Data Logger

dependiig upon use of EL backlight. 4.4

volts is considered the end point of the battery

“D”

life. When the batteries reach this point’ there

is about two to four hours use left.

enamel with black silk-screened nomenclature.

.

SIZE 1 lcm (4.25”) W x 22cm (8.75”)

L x

15~x11

(6”) H

(21~x1 (8.25”)H

with

handle).

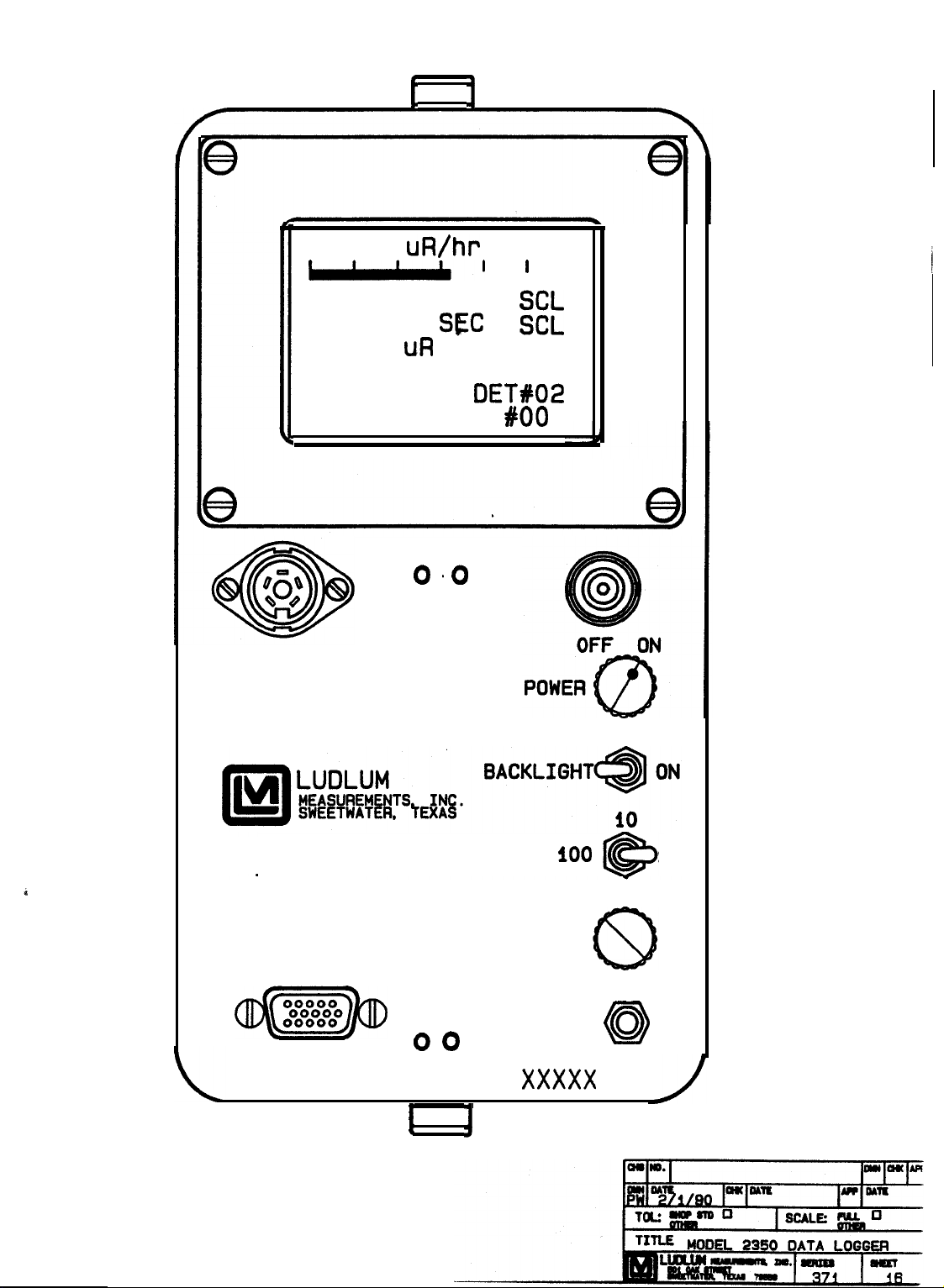

3.

DESQUETIONOFFlRONTPAN]E3L~

l

DISPIAYz

backlit liquid crystal

l

DFLEcI[1DR: seiies “C”

8 line by 15 character

display.

connector for

detector.

0 Impedance:

o Ballast resistor:

l

F0WERz Twoposition switch to turn

1ok.

1M

used to adjust the vohune of the speaker.

to acknowledge and silence the alarms.

power to instrument on or off.

l

BACKLZGHF

Turns LCD backlight

used to read “3 of 9” code bar codes.

on or off.

l AUDIO DIVIDE Three-position

signals to interface to computers or ternGnals.

switch used to control audio divide by:

l

WEIGHR 2.3 kg (Sibs) including four

cells.

l

FINISH Computer beige polyurethane

o

1: Provides 1 click per event

.

o 10: Provides 1 click per 10 events

o

100: Provides 1 click per 100

events

l

VOUTME:

l

ACKNUKEz

l WAND: Connector for optical wand

l SERIAL

One-turn potentiometer

Pushbutton switch used

IlO:

Connector for RS-232

4. DEERFIlOl’T OF

l

cJlxmmm:

available.

They

all use the same input but

FuNcIIc)INS

l-here are four counters

provide different types of readouts.

0 Digital Ratemeter:

Provides a

digital readout of the detector count rate.

‘Ibis readout is corrected for detector dead

timeandcanalsobecalibmtedfordirect

readout in the desii units and timebase.

o

BarGraph-:

Provides a

five-decade log readout of the detector

count rate in counts per second Tom one

cps to 100 kcps that is

corrected

for

detector dead time.

page

o

Scaler: Providesatimedcounter

for accumulating the detector counts far a

preset time. The count range is up to

999,999 counts with count times

second to 65,535 seconds in one-second

r

increments.

0 Integrated

Dose:

readout of the total accunmlated dose and

the accumulation time in minutes. This

readout is also corrected for detector dead

time and displays in the same units as the

digital ratemeter.

2

f.?om

1

Provides a

Page 8

M2350

Data

Log&r

l CIDCKTheM2350hasarealtime

clock that keeps the time (24hour format) and

programmable up to 2500 volts in one-volt

increments.

date.

l

USER

cation code that can be used to identity each

instrument. The characters can be numbers or

letters.

l

DEIKI0R

sixteen different detector setups can be loaded

into the M2350. Once the setups are loaded a

single

co-d

ID: A fifteen-character identifi-

SELKIlaS:

Up to

is all that is required to

function allows the detector settings to include

the model number of the detector. The model

can be up to nine

include both numbers and letters.

function allows the detector serial number to

be saved so there will be a record of which

detector took which data.

change setups to a different detector. The

following items are stored for each detector

setup:

The digital ratemeter can be programmed to

auto-range or be forced into using a multiplier

of micro,

o Detector calibration constant

0 Detectordeadtime

0

Detector high voltage

0 Detector model number

0 Detectorserialnumber

except

ratemeter can have a time base of seconds,

mini,

0 Display range multiplier

o Display time base

0 Display units

o

Integrated

dose alarm setting

0 overload current

0 Ratemeter alarm setting

0 scaler alarm setting

0

Scaler count time

ratemgrammed

oad, @MY9 NW9 (W, 09, -mg),

@)isintegratioion, (C)aunts, (Ci/cn?),

wcti.

o Threshold

o Window

almns for the digital

integrated dose. When a level is equal to or

l DETECTOR CALIBRATION

CXWSTANT

me digital ratemeter and

integrated dose can be calibrated to read

directly in the desired units. This is

accomplished by dividing the dead

t$ne

corrected ratemeter or integrated dose by the

calibration constant.

exceeds the alarm

turned on and a status message is displayed in

the appropriate display line. The audio output

can be turned off by pressing the

NLDGE button

continue to display the alarm message until

the alarm condition is no longer present.

l DEIlZIORMODElLNUMB~This

characters

l

DEIKTORSEEUALNUMB~UMBER:s

.

DJSPLAY

milli,

l

DISPLAY

Ci/d

or

l DISPLAY

RANGE

none, or kilo.

TIME

and

hours.

UNlTS: The

and integrated dose can be

long and can

MMlXIPLWt

BASE:

For all units

E%q/cn?, the

digital

digital

$ro-

to readout in the following units:

or

l

ALf!RMS:

There are programmable

ratemeter,

setting

the audio output is

scaler, and

ACK-

‘Ihe

status message will

l DETEcroR DEAD

M2350 allows for the correction of dead time

1OsseS.

‘Ills The

detect when the detector is drawing excessive

current and the output

not be accurate. It is programmable up to 40.0

l

DEIlXXX

HIM

VOLTAGE:

Supplies the bias voltage to the detector. It is

p4 in 0.1

disabled if desired.

page 3

l

OlvBImD

/LA

increments. It also can be

CURRENTP.

fi-om

the detector may

used to

Page 9

l

0-W

M23!50

If the count rate is

Data Logger

high enough for 75% dead time conection, the

digital ratemeter will display the message

‘OVER RANGE!’

.

sm

alum

mm

This

provides the preset time the scaler counts. It

can be set from 1 to 65,535 seconds in

one-second increments.

.

sINGLJ3m

ANALYzEFt

The SCA can be disabled to allow for gross

counting or enabled to allow energy discrimination. Both the threshold and window are

rrosle

up to 1000 in integer

.

l

LQGGlNG MEMORY:

samples may be stored

inthe

Up to 250

internal logging

memory and be retrieved later. The following

data is saved:

0

Count data: This is the value of the

counter that was logged. The counter is

either the digital ratemeter, scaler, or

integrated dose.

0

Count time: This is the count time

of the reading. For the digital ratemeter, it

is 0. For the scaler, it is the number of

allows the readout of a specified data sample

without requiring the complete memory to be

dumped.

seconds the scalar counted for. For the

integrated dose, it is the number of

minutesthattheintegrateddosehasbeen

accumulating.

mode where automated logging can-be

pe~%ornxd

f?om

0

Date: The date is stored as month,

day, yf=*

of the 6 logging cycles can be setup to log the

digital

and then wait from 1 to 65,535 seconds before

0 Detector

number:

This is the

number of the detector (from 0 to 15)

whose settings were loaded into the data

loggeratthetimethereadingwastaken.

karting the next logging

mode can be programmed to continue until the

data logger memory is full or for a set number

of recycles.

0

Location code: This is the location

code the user enters. It can be up to ten

characks

long and can be a combination

of numbers and letters. The location code

does not need to be unique for each

readiig since the sample number is

unique.

1

0 Sample number: This is the unique

sample number of the logged reading and

will be

fkom

0 to 249.

0

Status: This records the

IV2350

status at the time of the reading. It contains the alarm,

ov&ad,

and over-range

conditions.

0

Time: The time is stored as

hours,minutes

and is in the 24 hour

format.

0

Logging mode:

Ibis

is the

identifier that records the type of reading

whether it was the digital ratemeter,

scaler, or integrated dose.

l luxx;ED DATA

l

RECYCIE The M2350

DISPLAYz This

has a

recvcle

The recycle cycle can consist of

1 to 6 logging cycles per recycle. Each

rakmekr,

scaler, or integrated dose

cycle.

The recycle

page

4

Page 10

lM23!50

5.OPER4'IlNGl'RCXXDuREs

Data Logger

5Mnstallingbatteries

To install the batteries,unscrewthebattery

door latch and insert four

“D”

cell batteries in

the battery compartment. The correct position

of the batteries is marked on the bat&y door.

Refasten battery door.

5.2Ope1atingtheimtn1ment

Switch the

power ON/OFF

switch to the ON

position. The

display should

turn all blue afkr

about one second.

The blue will

remain on for two

$llle

seconds and then self

be replaced with

the display in Figure 1. After two seconds, the

display will then be replaced with the last

display that was active before the power was

turned off. If the display appeam abnormal, a

cold start needs to be done.

After the power up cycle is completed,

select the desired diilay mode and the

desired detector parameters and proceed with

the

instmmnt

operation.

37102N16

MEMORY TEST OK

CJ?UTESTOK

1.

check.

M235O's

removed long enough for the memory to be

lost or if the user desires to reset the memory

before setting up for specific detectom.

the hand held knninal or

The display should turn all blue afler about

one second The blue display will remain on

for two seconds and then be replaced with the

display in Figure 2.

This will be dis-

played for two

seconds and then

‘the

resume operation

with all settings

set to their default

Values.

*

,

5.3

Performing a ‘kold statt”

NOTE

A cold start wil clear all detectors

P

and also clear the logging memory.

OncedoneJhedata~be

recoVered.

A cold start is needed to clear the

memory if the batteries have been

To do a cold start, enter

IV2350

will

MEMORY TEST OK

SSRwith

the

optical wand

mu TEST

either

OK

COLDINITIALJZE

Cold

Start

Execute.

Page 11

MZ350 Data Logger

6. DESCFUPIlm OFDISPLAY MODES

There are seven different display modes.

‘Ihey are described below.

displayed here. The ‘SCL’ message is always

on and indicates that this is the scaler timer.

6.1 Nomal display

When the scaler is not counting the time

displayed is the count time for the scaler. If

The normal display mode displays all four

counters,

the time, the detector number,

the scaler is counting, the time displayed is

the time remaining until the count is done.

thelocation code and the number of samples

stored in the logging memory. The display is

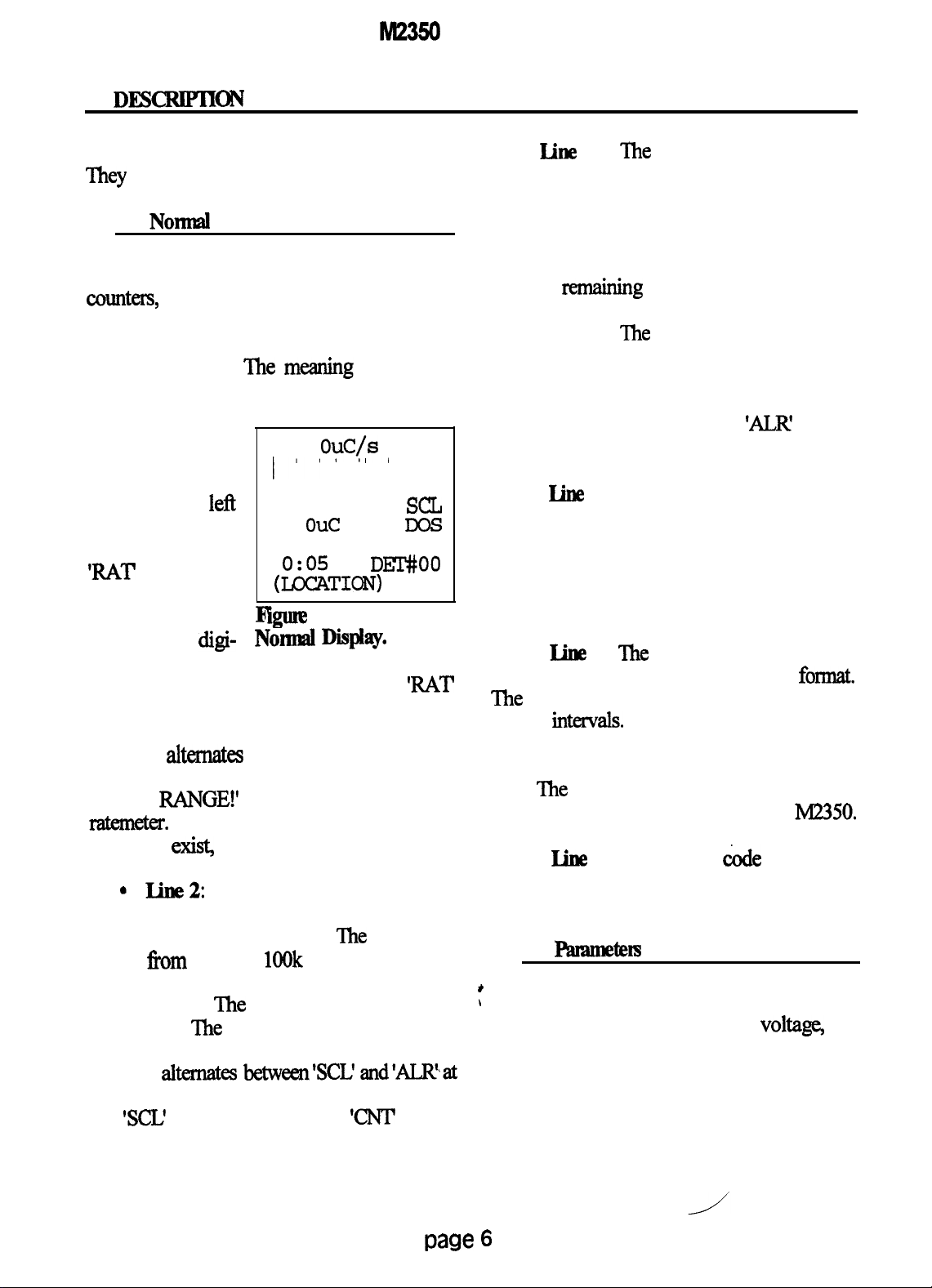

shown in Figure 3. ‘Ihe meanjng of each line

follows:

l Line 1:

The digital

ratemeter is dis-

played in the

left

part of the line.

The message

‘RAT

indicates

that this is the

digital ratemeter.

If there is a digi-

0.

I'(

OuC!s

"

RAT

0

10

SEC

0.

out

4MIN DOS

0:05

(IXXTION)

iIgure

3.

DEX'#OO

#000

NOrmal DisplaY,

sa

SCL

tal ratemeter

alarm, the message alternates between ‘RAT

and ‘AIR at one-second intervals. If there is

a detector overload, the message ‘OVER

LOAD!’

reading. If there is an overrange, the message

‘OVER RANGE!’ alternates with the digital

ratemem.

alternata

with the digital ratemeter

If both overload and overrange

displayed on this line. The message ‘DOS’

indicates that this is the integrated dose. If

thee is an integrated dose alarm, the message

alternates between ‘DOS’ and

second intervals.

is displayed here. ‘The ‘DOS’ message is

always on and indicates that this is the

integrated dose timer. ‘The time displayed is

the elapsed time in minutes since the integrat-

ed dose started accumulating.

the left side of this line in the 24 hour format.

‘Ibe

second intexvals. If the battery voltage is 4.4

volts or lower, the message ‘LO BAT

alternates with the time at one second intervals. The right part of the line shows which

detector settings are beiig used by the M2350.

conditions exist, the overload message is used.

* Iine2:

Thefivedecadelogbargraph

is displayed on this line. The count rate is

always in counts per second

covers f?om 1 cps to

1OOk

cps.

‘Ihe

bar graph

in this line. The number of logged readings is

displayed at the right side of this line.

*

l

Line 3: The scaler readout is displayed

on this line. The message ‘SCL’ indicates that

this is the scaler. If there is a scaler alarm, the

message

al-

between’SCL’

and’ALR%at

one-second intervals. Between the scaler and

the ‘XL! message, the message ‘CNT appears

\

ratemeters, the scaler, the high

window, the battery voltage, the threshold, the

time, the date and the user identification

number. The display is shown in Figure 4.

The meaning of each line follows:

when the scaler is counting.

l

Line

4:

Tbe

scaler count time is

l

Line 5:

l

Line

l

Iine

‘Ihe

integrated dose readout is

‘ALR’

at one

6:

The integrated dose count time

7:

The

clock time is displayed at

colon blinks on and off at one-half

l Iine

8: The location

&de

is displayed

6.2 I’amneten display

The parameters display mode displays both

voltas

the

paw

6

Page 12

MZ350

Data Logger

l Lines 1

thmgh 4:

‘Ihe

same as in the

normal display

(section 6.1)

l Line 5:

The detector high

voltage and Gindow are displayed

on this line. If the

window is off, the window setting is replaced

by the message ‘OFF’.

0.

OuC/s

1 I I l I I

RAT

0

sa

10 SEC sa

0 W= OFF

E;=5.5

T= 100

0:05 l/01/90

(USER ID)

Rgure 4,

I%EUE&XS DI@~~Y.

?he detector serial

number is displayed on this

line.

The

this line displays

the code for the

display units. The

middlepartofthis

line displays the multiplier

l Iine 6: The battery voltage and

threshold

are

displayed on this line. If the

part of this line displays the code for the

display time base.

battery voltage is 4.4 volts or lower, the

message ‘LOW replaces the bat&y voltage.

high voltage and window setting. If the

l

Line 7: The clock time is displayed at

the left side of this line. It is in the 24 hour

format.

second

“Ihe

colon blinks on and off at l/2

intervals. If the battery

voltage is 4.4

volts or lower, the message ‘LO BAT

alternates with the time at 1 second intervals.

window is off, then the window setting is

replaced by the message ‘OFF’.

count time in seconds and the

setting.

‘Ihe right part of the line shows the date as

.rnonth

day, year.

bration constant used by the digital ratemeter

l

Une 8: The user identification code is

displayed on this line.

and the integrated dose.

is kept in counts per second internally and is

divided by the caIibration constant to provide

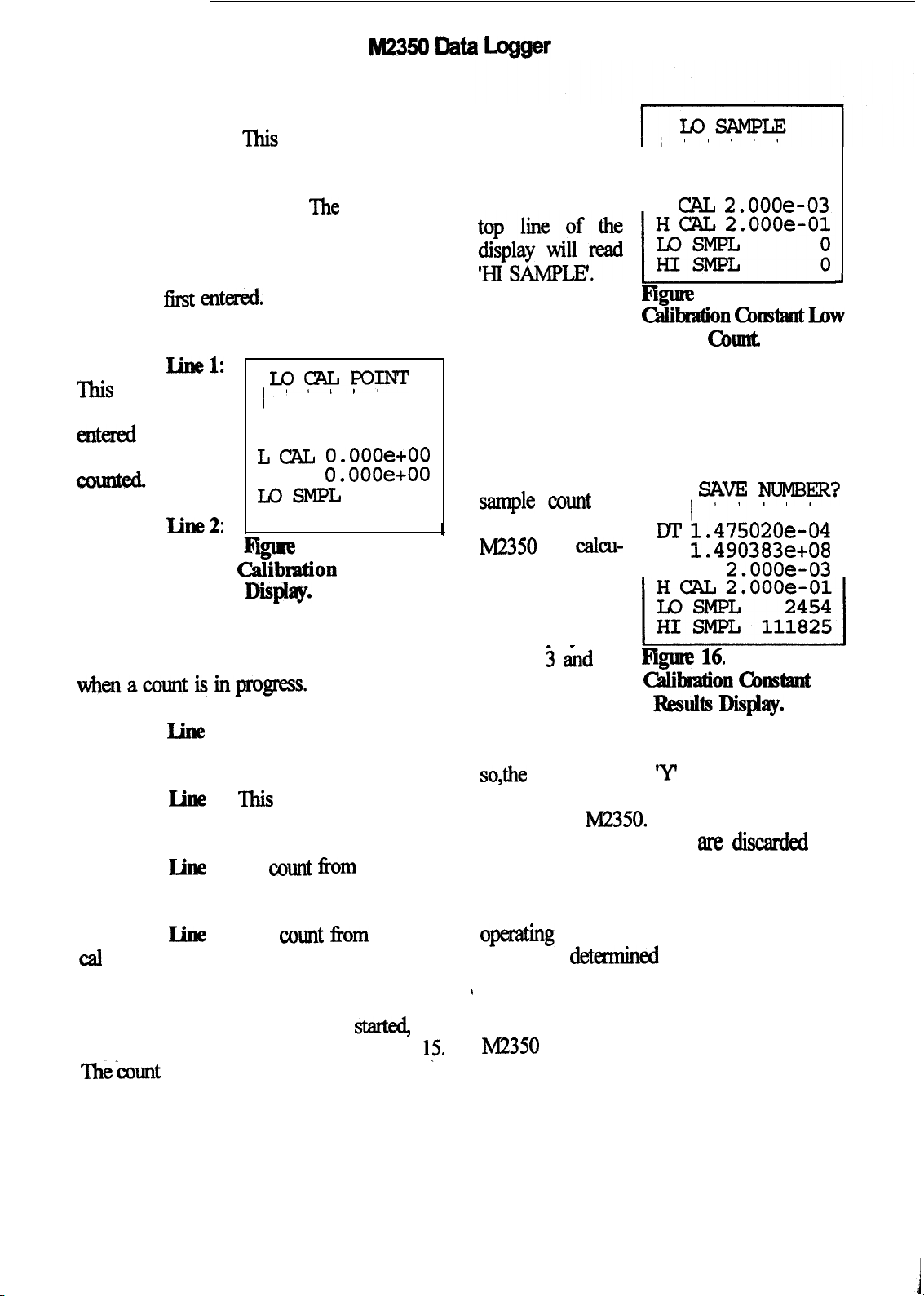

6.3

Detectordisplay

the actual readout.

l Line 3:

D)ZX'EmR

#00

MODEL

SER.#

U=7

M=O TB=O

HV=

0 w= OFF

CT= 10 T= 100

CC=1.000000e+00

9

Line 4:

lefi

part of

LT=O.000000e+00

Qlne

5.

ktector Display.

code.

The right

l

Line 5: This line displays the detector

l

Line

6:

This

line displays the

scaler

threshold

l

Line 7: This

line displays the

‘Ihe

digital ratemeter

cali-

The detector display mode displays the

current detector selection, the detector model

and serial numbers, display setup, high

voltage, window count time, threshold,

calibration constant, and detector dead time.

The display is shown in Figure 5. The mean-

deadtime.Thisnumb&susedtocorrectfor

dead time losses caused by the detector and

the M2350 dead time.

*

,

ing of each line follows:

l

Iine 1: This

line displays the current

detector whose settings are bemg used.

alarm and overload settings. The display is

shown in Figure 6. The meaning of each line

follows:

l

Line 2: The detector model number is

displayed on this line.

detector whose settings are being

paw

7

l

Line 8: This line displays the detector

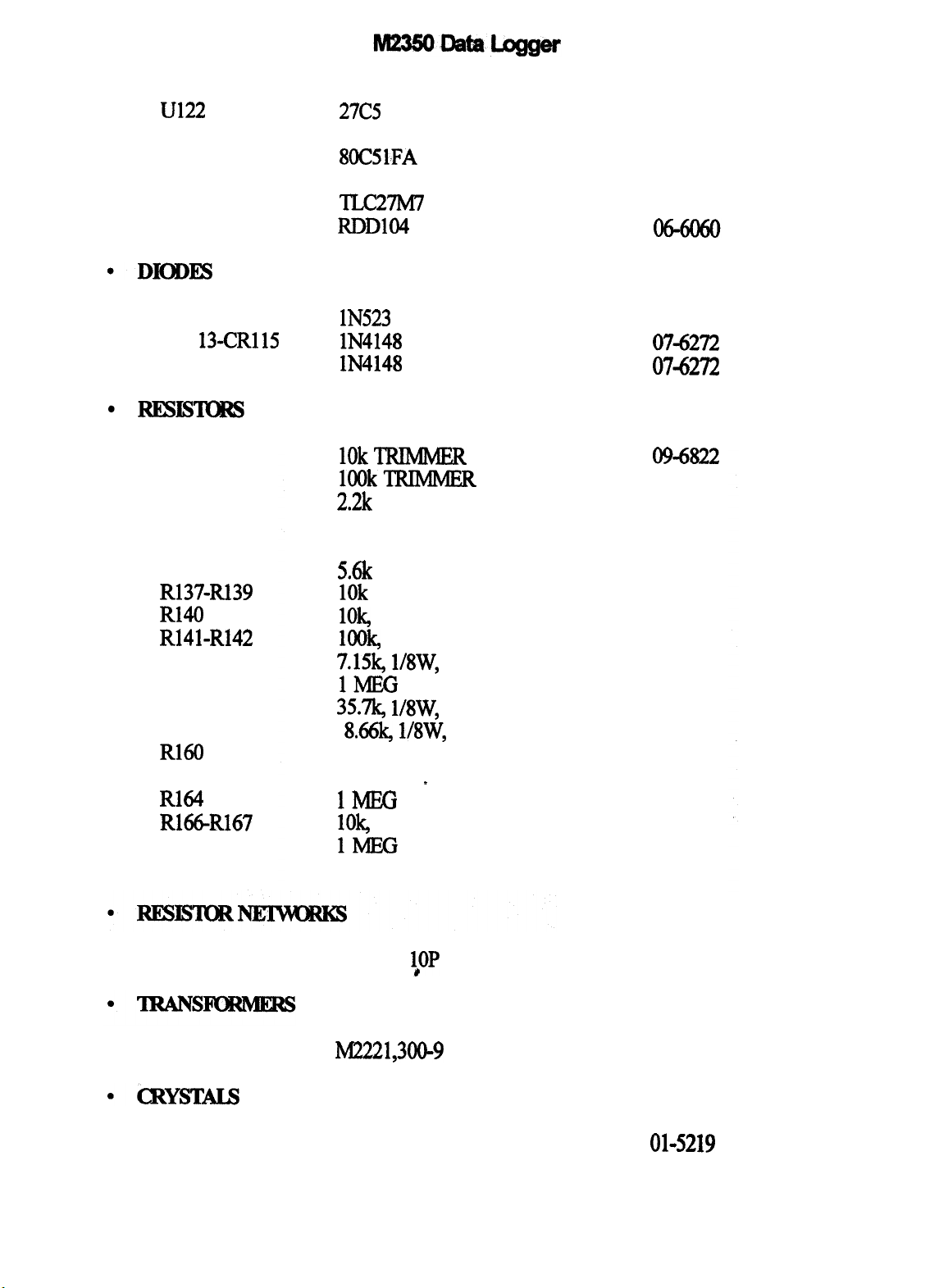

6.4

Ahum disdav

The Alarm display mode displays the

l

Line

1: This

line displays the

curnznt

e

Page 13

M23!50

Data Logger

l Line 2:

This line shows

that the alarm settings are being

displayed.

l Line 3:

DEX'ECIQR

RAT LOOOe+09

Sal 999999

DOS

OVEiF!LOAD=

The digital

mtemeter

setting

alarm

is &+

Ggure

AhIlllDiSplrlly.

played on this

line.

l line

4: The

scaler alarm setting is dis-

played on this line.

l Iine

5: The

integrated dose alarm is

displayed on this line.

l Iine

6: This line is blank.

#00

l.OOOe+09

OFF

6.

l Line 4:

The type of data

logged is

played here

dis-

DEX'FCIOR

#00

RA-

(ratemeter, scaler,

integrated

i&e).

l Line 5:

The count that

0:05 l/01/90

I

figune

7.

W~~Di@aY.

I

was logged is displayed here.

l

Iine6:

logged, this line is blank.

Iftheratemeterreadingwas

Ifthe

scaler reading

was logged this line is the scaler count time

in seconds. If the integrated dose reading was

logged, this line displays the accumulated time

in minutes since the

intern

dose was

started.

l line

of

p.A

is

disabled,

7:

The overload setting in tenths

is displayed on this line. If the overload

the setting is replaced with the

time (24 hour format) and the date (month,

day, year) that the reading was taken.

message ‘OFF.

l Iine

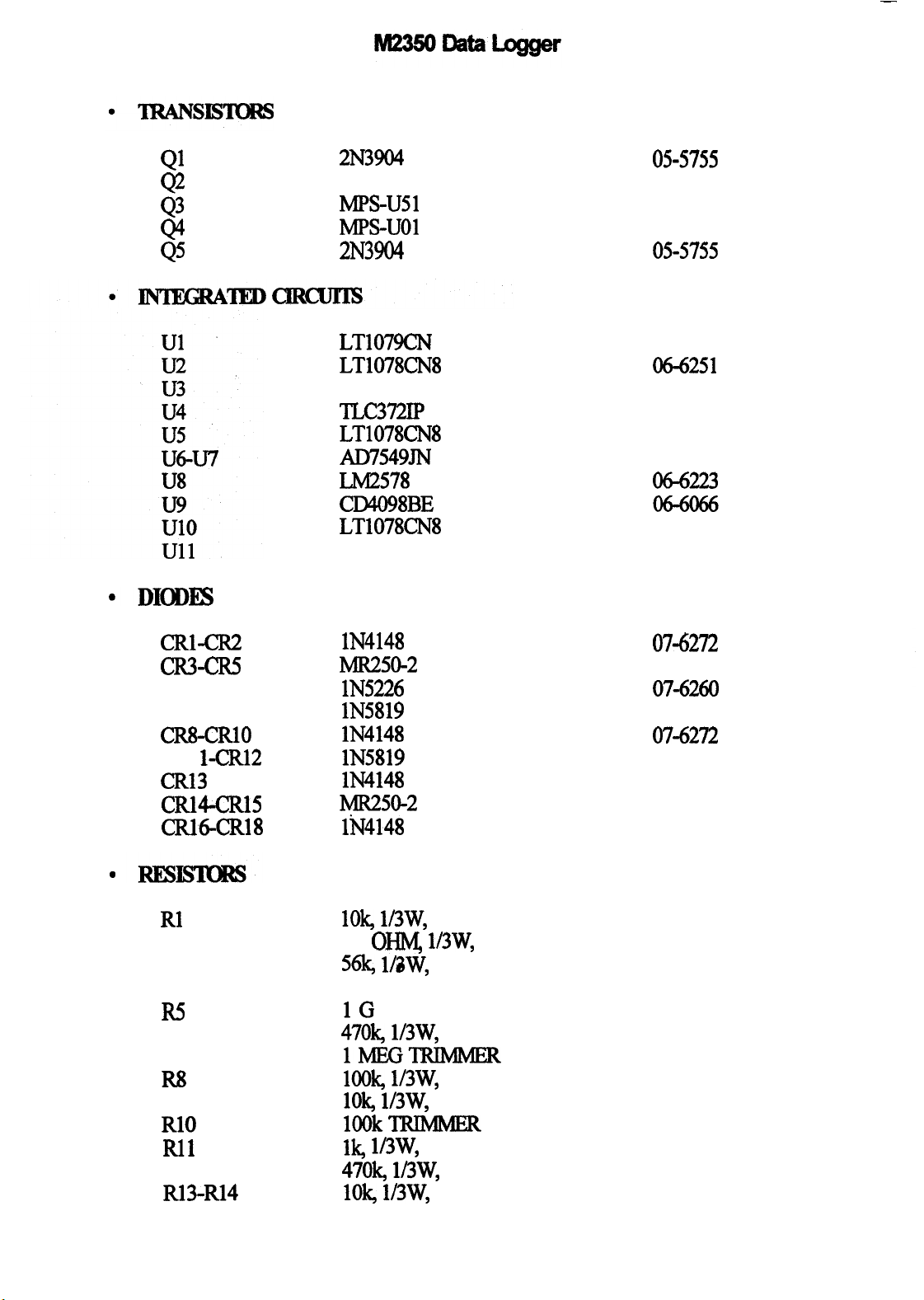

6.5 Lagged

8:

Jhis

daba dispiay

line is blank.

specified has not

beenusedfordata

Tbe lo&

logged data

data display mode displays the

tirn

the

selected

sample. The

logged data consists of the sample number,

the location

code,

the detector

USBCS,

the

logging yet, the

display looks like

Figure 8.

logging mode, the count, the count time, the

time, and the date. ‘Ihe display is shown in

Figure 7.

l Iine 1: The sample number is dis-

‘Ihe

meaning of each line follows:

*

,

played in this line.

.

W

in this line.

2: The location code is displayed

both ratemeters, the scaler, the recycle count

status, the

Joggion code and the number of samples

l Iine3:Thedetectorwhosesettings

were used to log the data is displayed here.

stored in the logging memory. The display is

shown in Figure 9.

follows:

l Iine

l LineWIhislineisblank.

7: This

line displays the clock

If the location

!~!!!!111111111

. . . . .

*...

INVALID

IK24TION

lllllllllllllll

. ..*...........

Flgm

8.

hvalidI.malionDisplay.

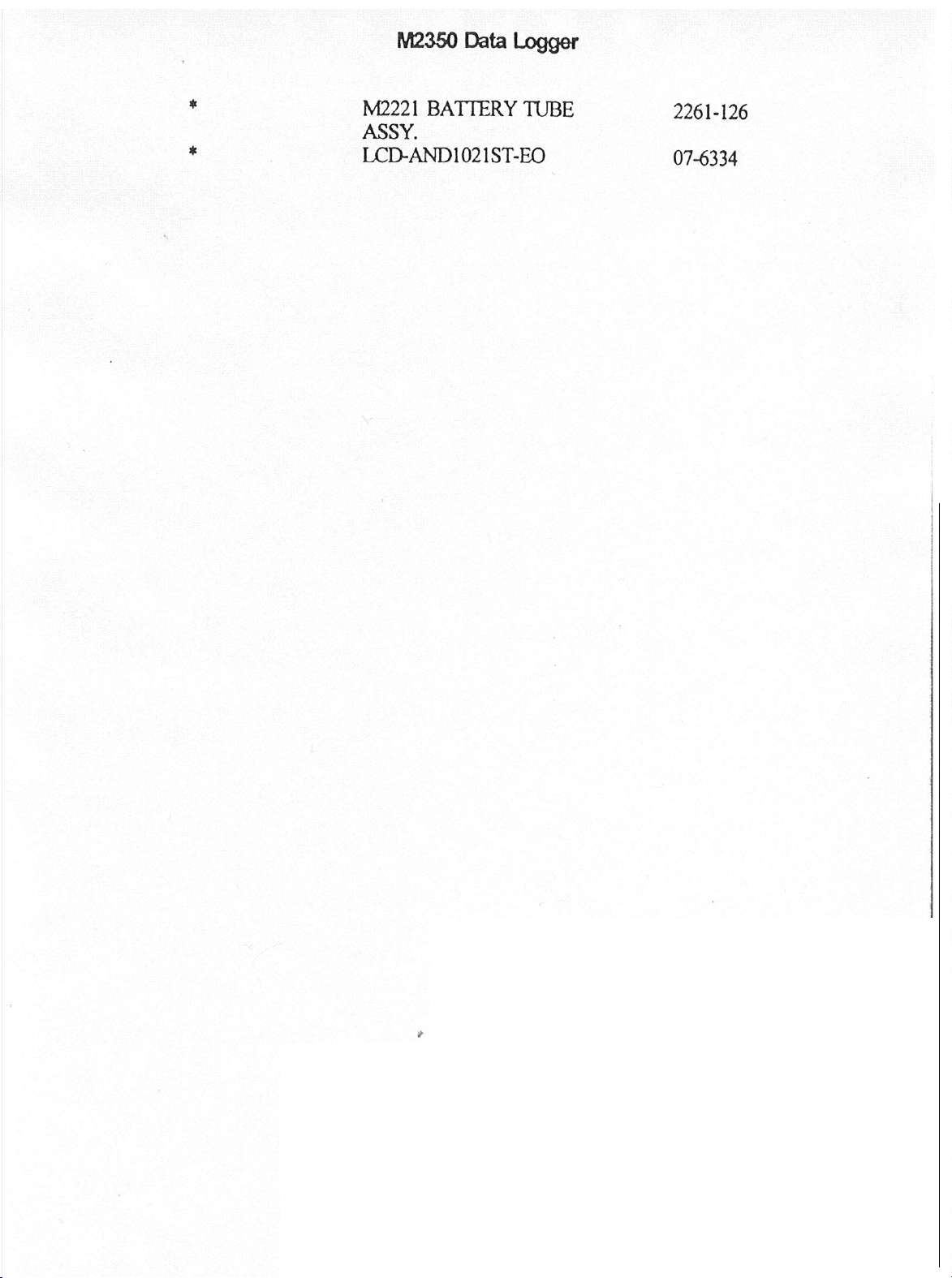

6.6 Recycle data

display

The recycle data display mode displays

tinq

the detector number, the

‘Ihe

meaning of each line

Page

8

Page 14

lVt2350 Data Logger

l Lines 1

thmugh

4: The

same as in the

normal display

(section 6.1).

l Line 5:

This line displays

the

current cycle

that is active, the

?. OuC/s

, I

I

0

RAT

SCL

10 SEC SCL

CYC 1 OF 1 ROOO

DELAY

0:05

60 SEC

(DFT #)

(UICATI~N) #ooo

F@un2

Recycle Dab

9.

Display.

the setup information for the recycle counts.

This consists of the number of cycles enabled,

the detector each cycle will use, the delay

time before the data is logged, the logging

mode, and the number of recycles. The

display is shown in Figure 11. The meaning

of each line follows:

number of cycles

in each recycle, and the number of recycles

that have been completed.

This

that the recycle

l Iine 6:

time left. before the next cycle is started.

l

Line 7: The clock time is displayed at

the lefi side of this line. It is in the 24 hour

format. The colon blinks on and Off at

one-half second intervals. If the battery

voltage 4.4 volts or below, the message ‘LO

BAT

alternates

intervals. The right part of the line shows

which detector setting is being used by the

M2350.

‘Ihis

line displays the delay

with the time at 1 second

countsetupdatais

beiig displayed.

‘Ihis

the setup informa-

tion for cycle 1.

The cycle number

is displayed fust. Next is the detector used by

this cycle. The next number is the delay time

before the data is logged. The last number on

this line is the logging mode that will be used.

6.7 Recycle setup display

‘The recycle setup display mode displays

l Line 1:

line shows

3NmENABLED

4NurEwmwD

5NmExaBm

l Line 2:

line shows

figure

10.

WcIe Sebup Display.

l

Line 8: The location code is displayed

in this line. The number of logged readings is

displayed at the right side of this line.

tbe same information as line 2. If the particular cycle is not enabled, the message ‘NOT

ENABLD

If the recycle mode is disabled, lines 5 and

information.

6 will display the message ‘RECYCLE

DISABLED’.

allowed is displayed here.

l Iines

3 thmugh 7:

?Ihese

lines display

is displayed instead of the cycle

l Iine 8: The number of recycles

paw 9

Page 15

M23!50 Data Logger

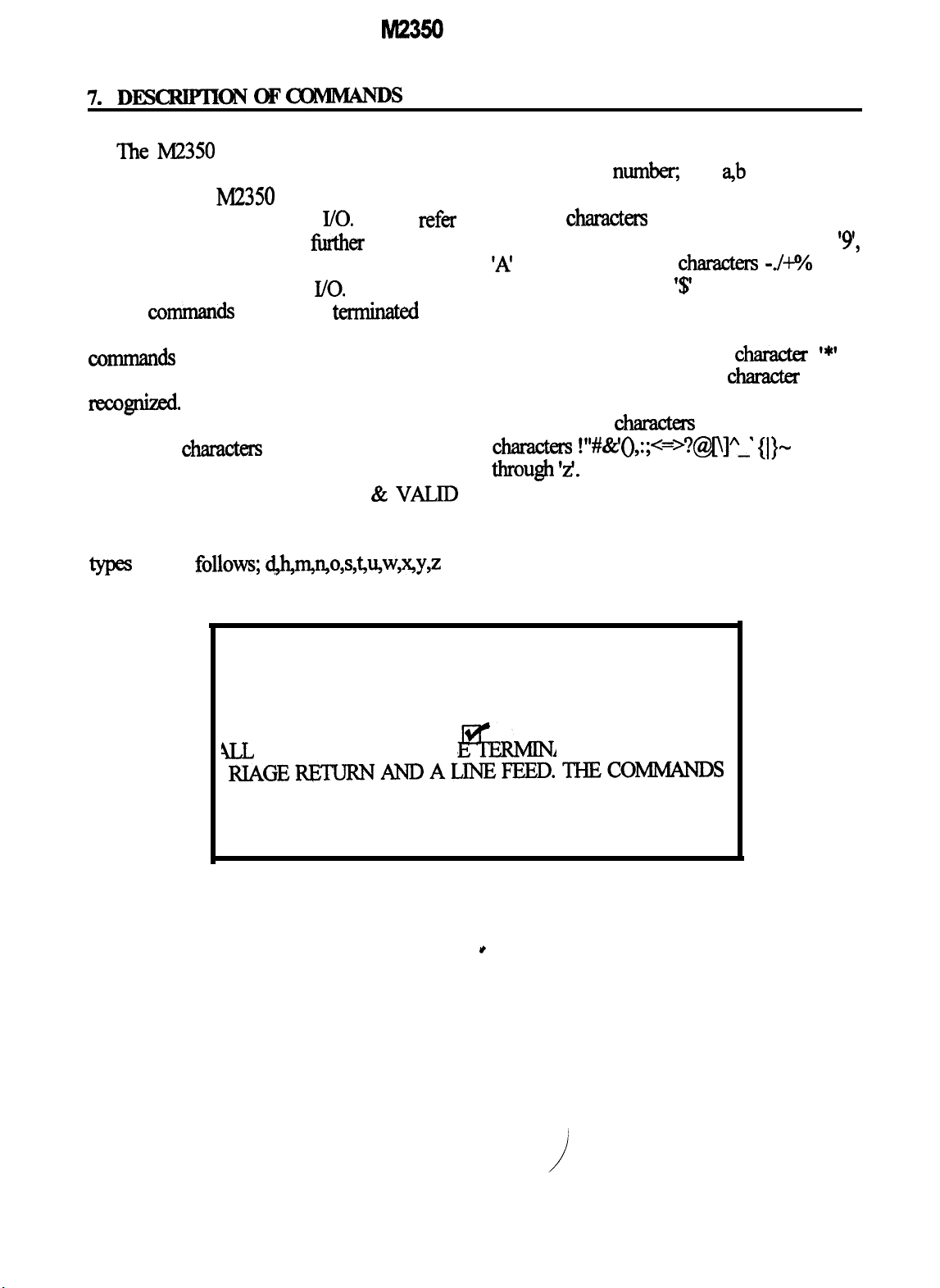

‘Ihe M2350

is controlled by either the

optical wand or the serial I/O. All commands

to control the

either the wand or the serial

M2350

can be executed by

I/O.

Please refer

to Sections 11 and 12 for fbrther information

regarding the setup and operation of the

optical wand and the serial

All

wnmands

need to be

I/O.

termhted

with

a carriage return and then a line feed. The

tzanmands are all upper case. If lower case

commands are used, they will not be

Ilzcow.

In the command descriptions below, the

lower case characters in the COMMAND line

are supplied by the user. The lower case

letters under the RESPONSE &

VALID

are integer values; f is a single precision

floating point

meric string. With the alphanumeric string, the

following

serial I/O and the optical wan& ‘0’ through

‘A’

space. The character

when multiple commands are to be sent at one

time or as the separator code when dumpmg

the logged readings. The

reserved as the start and stop charackr for the

bar codes. If only the serial I/O is to be used,

the following

charades

tllrougll ‘2.

CHARACTERS are the values returned in

response to the read commands. The variable

types

are as

follow 4hmQo,s,6Qw,%,y,z

numb,

charactw

and

a,b

are alphanu-

are valid for use with the

‘9’,

through ‘Z’, and the characters -./+?4 and a

‘$’

is reserved for use

chamcter ‘*I

characters

are also valid; the

!“#&‘(),:;<=>?@o]A-’ {I}-

is

and ‘a’

NOTE

ILL COMMANDS MUST B

ATEDWITHACAR

RIAGE~TURNANDALJNEFEED.‘IHECOMh’IANDS

MUST BE UPPER CASE

NOTE

i

page10

Page 16

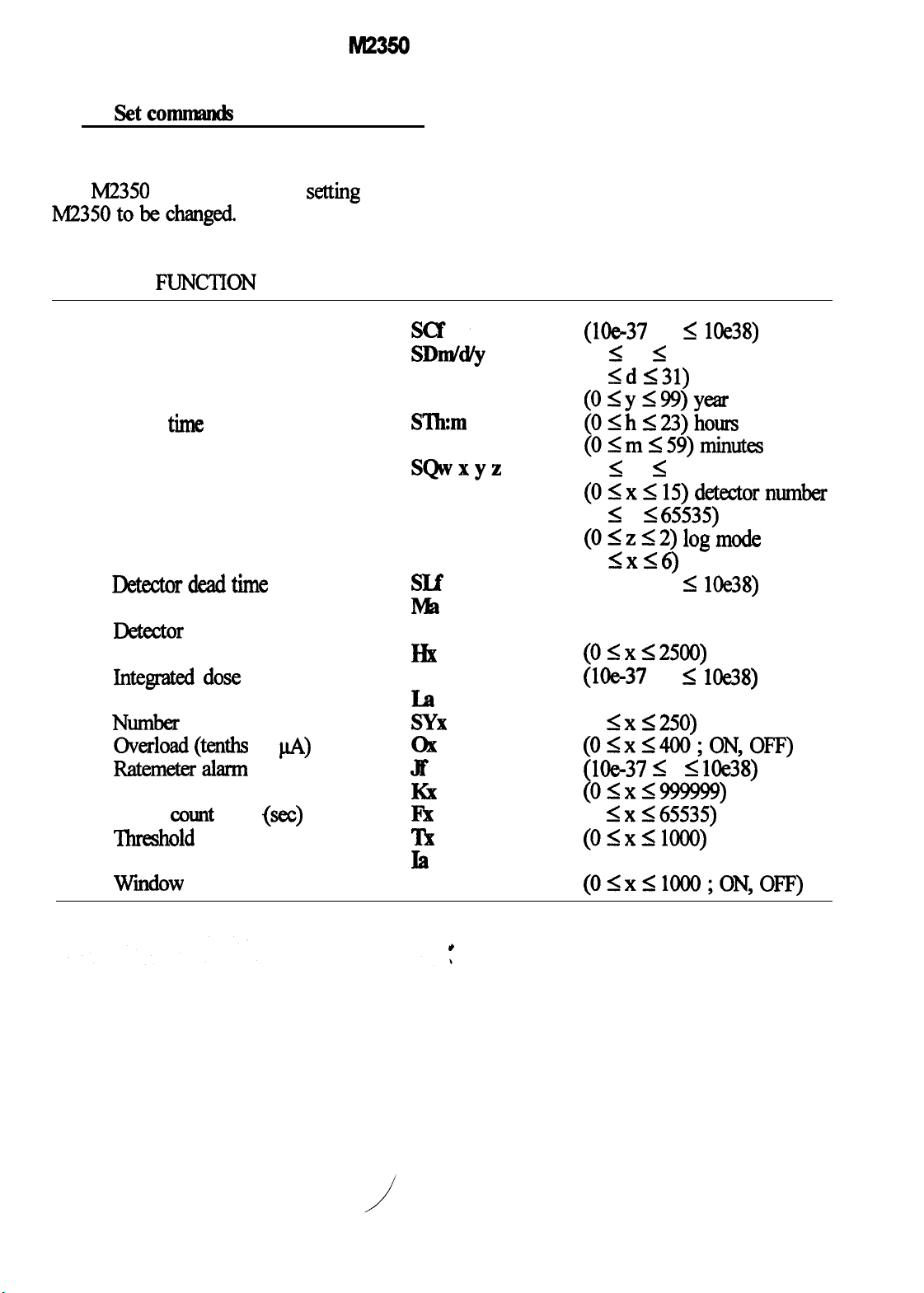

M2350

7.1 !ktconlnmKk

This type of command will send data to

the

M2350

M235otobechanged.

which allows a

SET FUNC’IION COMMAND VALID CHARACTERS

setting

in the

Data Logger

Calibration constant

Clock date

Clock time

Cycle count

Cycles per recycle

Detectordeadtime

Detector model

Detector serial number

High voltage

Integrated dose alarm

Location code

Numher of recycles

o-&Tx&g(m~ of

scaler alarm

Scaler

‘Ihreshold

User I.D. number

wmdow

c43unt

time

pA)

@cc)

Slkm

SQWXYZ

SRX

SLf

lb

Na

Hx

Pf

I.2

SYX

ox

Jf

Ki

I%

TX

Ii

wx

(Me-37

(1 I m I 12) month

(1 Sd

(OIyI99)year

(OIh123)hours

(O,<mI59)minutcs

(1 I w 5 6) cycle number

(OIxI15)detectornumber

(0 I y

(OIz<2)

(1

(Me-37 If <

(alphanumeric, 9 char)

(alphanumeric, 9 char)

(05x52500)

(l&37

(alphanumeric, 10 char)

(1

(OIxUOO;ON,OF’F)

(lb37

(OSx999999)

(0

(01x~lOOO)

(alphanumeric, 15 char)

(O1x51OOO;ON,OF’F)

If I

531)

day

265535)

logmode

IXG)

If I

5xs250)

< f I

5x165535)

lOe38)

seconds delay

lOe38)

lOe38)

lOe38)

page 11

Page 17

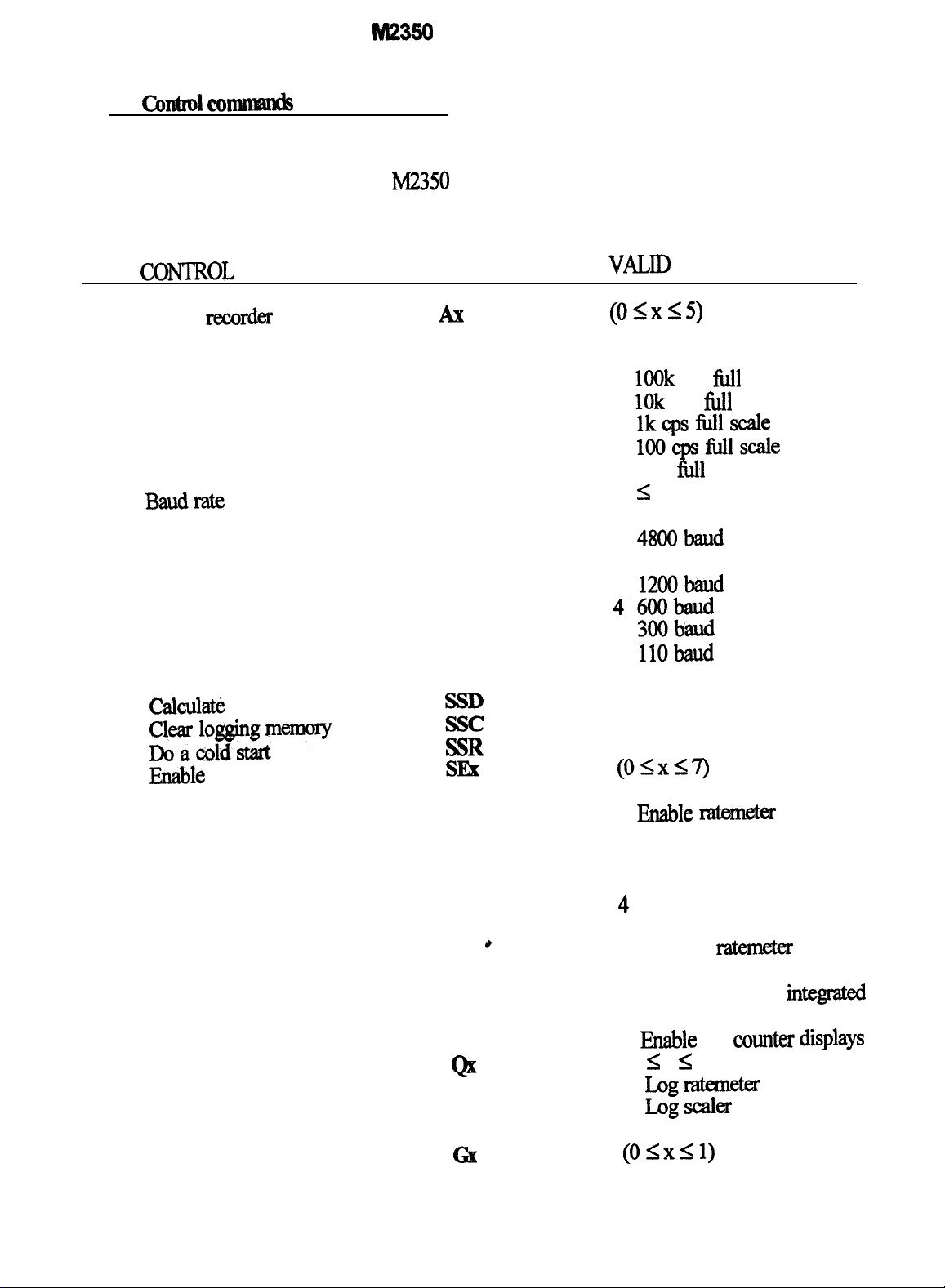

MB!30 Data Logger

7.2 Contml

commands

This type of command may or may not

require data with it and will cause the M2350

to do something.

cmTRoL

Analog

FUNCTION

recorder

mode

Baudrate

Calculate cal constant

Calculati:

dead time

COMMAND

Ax

Bx

SSK

~=r~$n”y

Enable

counter displays

Logareading

Ratemeter response

S!3R

SEX

Gix

VALID CHARACTERS

(05x15)

0 5 decade log

1

1OOk

cps

111

scale

2

1Ok

cps

111

scale

3

lkcpsfblhcale

4 1OOcpsfbllscale

5

10 Ml scale

cps

(0 1. x 5.6)

0

96oobaud

1

48OObaud

2 24OObaud

3

12OObaud

46oobaud

5

3oobaud

6 11Obaud

(OSxS7)

0 All counter displays off

1 Ehble

ratema

display

2 Enable scaler display

3 Enable ratemeter and scaler

display

4 Enable integrated dose

display

5 Enable

ratemeter

and in-

tegrated dose display

6 Enable scaler and

integmted

dose display

7

l&able

all

counm displays

(0 5 x I 2)

0 LQgI-tmeer

1

Logscaler

2 Log integrated dose

(05x51)

page12

Page 18

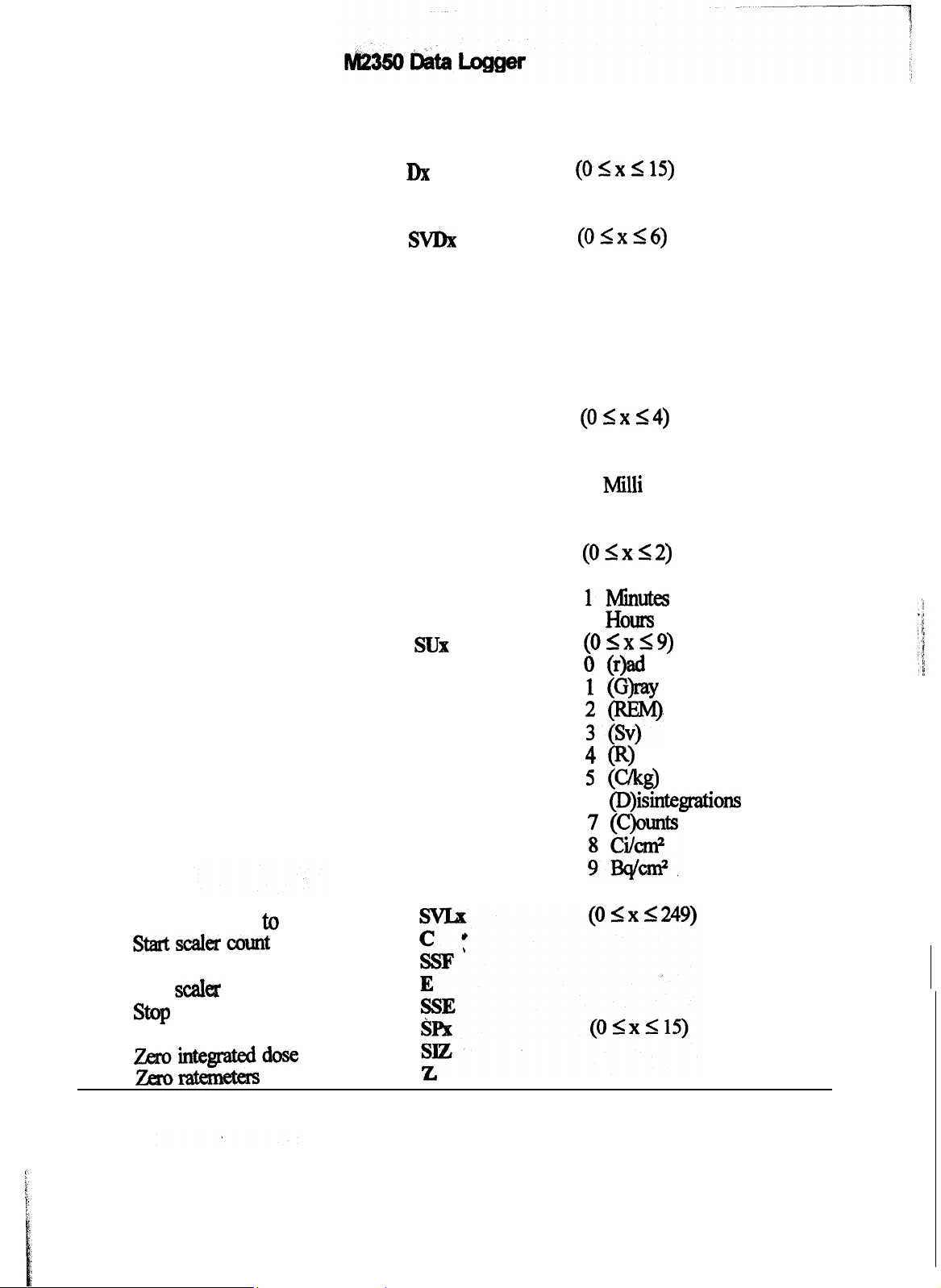

Recall detector settings

Reset alarms

Dx

X

0 slow response

1 fast response

(OlxIlS)

Select display mode

Select display multiplier

Select display time base

Select display units

SVDX

SMX

SBX

!3UX

(OIxS6)

0 Normal display

1

Parameters display

2

Detector display

3

Alarm display

4 Logged data display

5 Recycle data display

6

Recycle setup display

(OIx14)

0 Autorange

1

Micro

Milli

2

3

none

Kilo

4

(OIxS2)

Seconds

0

ll%lW

2

Hours

(OSxS9)

(r)ad

0

1

@WY

set log location to view

startscalercoutnt

Start the recycle

stop

Scala

count

Stop

the

recycle

store detector settings

zerointegrateddose

zero-

ip

4

0

5

uu

6

(D)isintegrations

;: LEE?@

9Ek+n.

Y

page 13

Page 19

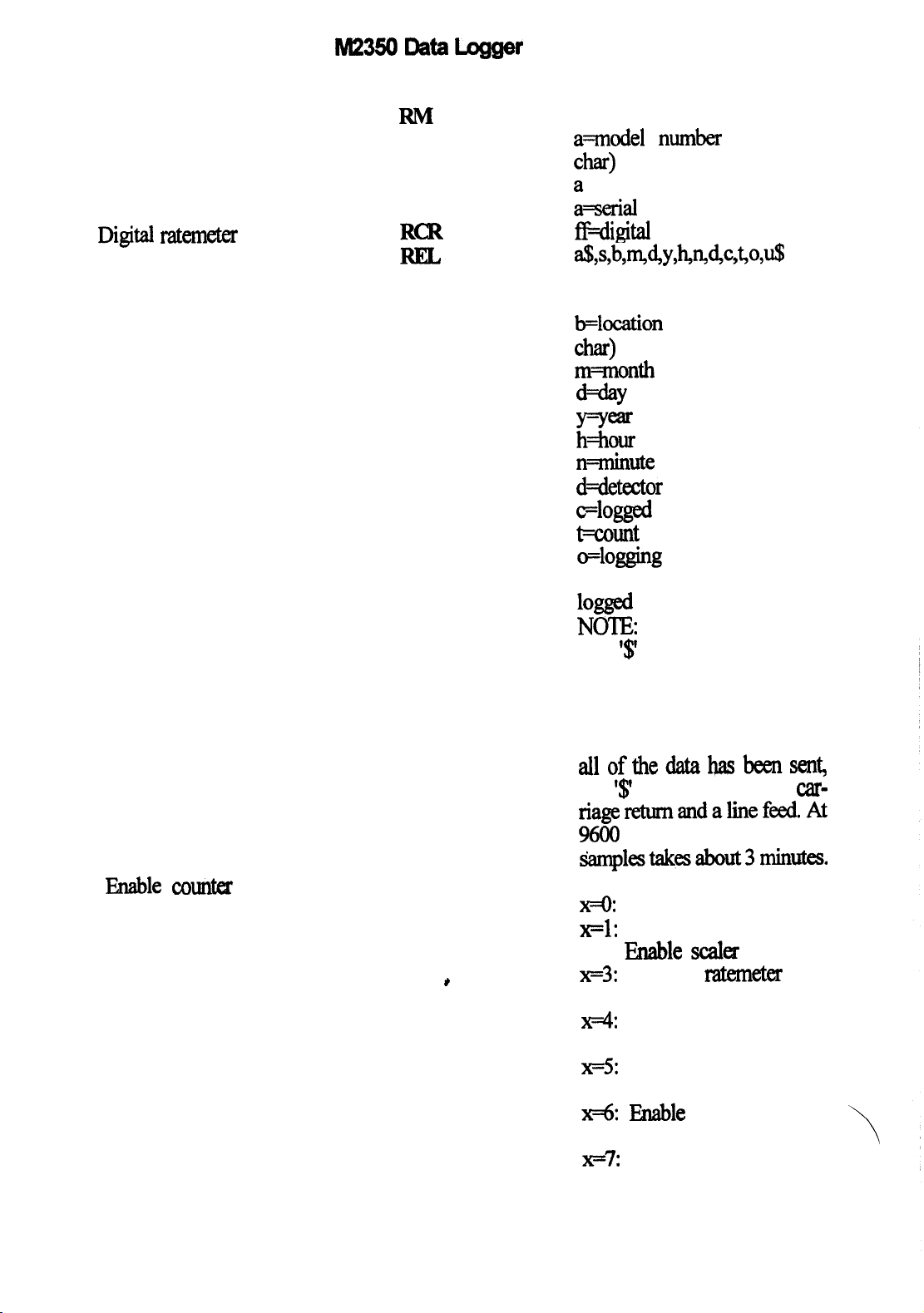

7.3 Read commands

lid2350

Data Logger

‘These

commands

will cause the desired

datatobesentout~serialvo.

READFUNCTION

Analog recorder

mode

Bar graph ratemeter

Baud rate

Battery voltage

calibration constant

Clock date

Clock time

Cycle

Cycles per recycle

Detector dead time

counf

COMMAND

RA

RT3

RST

RSL

RESPONSE & VALID

CHARACTERS

k0: 5

decade log

x=1: 1OOk

~2:

x=3:

x74:

x=5:

cps

1Ok

cps

111

lk cps

Ml

100 cps

10 cps

111

@ll

scale

scale

111

scale

scale

scale

f

Margraphratem~

X

?FOZ%OObUd

x==l: 4800 baud

~2:

~3:

2400

1200

baud

baud

X4:6OOlXUd

x3:

300 baud

x76: 1lObaud

f

f!4xaay

f

+calibration

voltage

constant

Q4Y

m=mMh

WY

y-year

4m

h==hours

nmlinw

(1 SwW6)cyclenumber

%YJ

x=+&ctor numbzr

y=seconds

delay

Flog mode

x

x=number

of cycles per

If”y”1”

Head

time

page 14

Page 20

M2350 Data Logger

Detector model

Detector Serial number

Digital ratemeter

Dump logging memory

Enable uxn&x displays

RN

RSE

a

a=model number

(up to 9

Char)

FLserial

ff4igital

number (up to 9 char)

ratemeter

dWwvWwAc,co,~

a=I.D number (up to 15 char)

s-sample number

b=location

code (up to 10

Char)

m==month

sample logged

d=day sample logged

y=year sample logged

h=hour sample logged

mnimte

d==detector

Flogged

+count

sample logged

number

count data

time of logged data

o=logging mode

FM2350 status when data

logsed

NOTE:

The

‘$’

character signifies that

a logging location% data has

been sent. The variable string

except for ‘a’ is repeated for

each logging location. When

alloflhedatahasbeensen~

the

‘$’

is followed by a

carriagereturnandalinefeed.At

9600

baud, dumping all 250

&implestak~about3minutes.

X

*

All counter displays off

x=1: Enable ratemeter display

x=2:

Wle scak

~3:

t

Enable

display

mtemeter

and

scaler display

x=4 Enable integrated dose

display

~5:

Enable ratemeter and integrated dose display

x=6

F5nable

tegrated dose display

~7%

Enable all counter

scaler and in-

\

displays

page 15

Page 21

High voltage

RH

Ligh

voltage

Integrated dose

Integrated dose alarm

Integrated

do& her

(min)

Locatkh code

Ne

of recycles

Ratemeter alarm

‘Ratemeter;response

Read

display

R&a+lisplay

multiplier

time base

Read display units

R.ecalldetector~gs

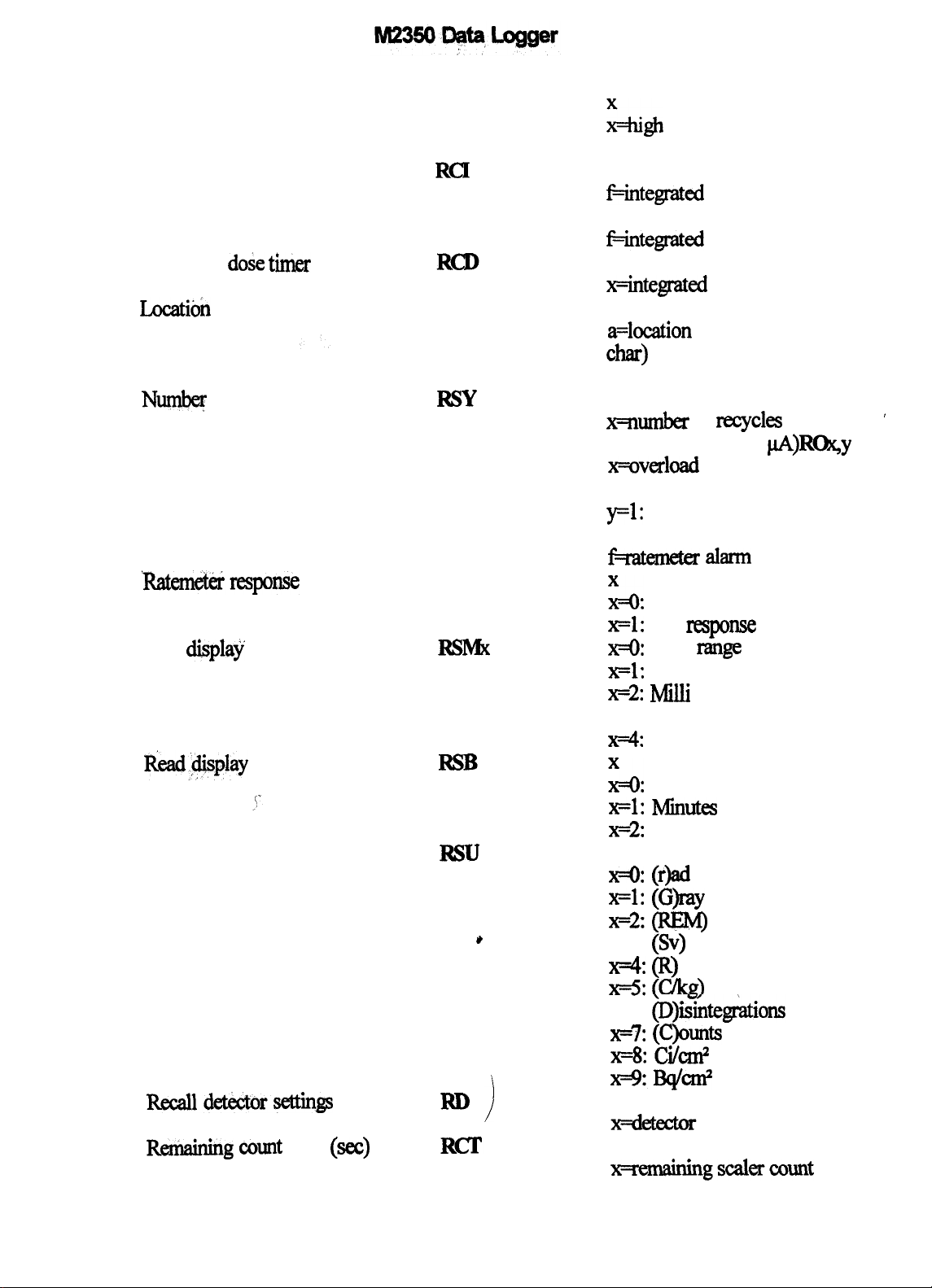

RCI

RP

RL

RSY

RJ

RG

RSMX

RSU

*

RD

!

f

+integrated dose

f

&integrated

dose alarm setting

x

x=integrated

dose timer

a

a=location

code (up to 10

Char)

X

x?ilumber

Overload (tenths of

x=overload

of

ITcycles

setting

allowed

@)R%y

y=o: overload disabled

y=l:

overload enabled

f

jL+amaa alarm

E&o:

slow response

x=1:

fast

response

~0:

Auto

x=1:

Micro

x72: Mllli

x=3:

x74:

Kilo

t=O:

Seconds

x4:

x=2 Hours

X

range

none

Min-

setting

x=0: (r)ad

x=1: (G)ray

x=2(REryl)

x=3: (Sv)

x4 (RI)

XFS:

(ckg)

x=6:

(D)isintegAtions

x=7: (C)aunts

x=8: Ci/d

?F!mqd

X

’

Remaining count

time (set)

X

?FEmaEngscal~count time

page 16

Page 22

SC&

scaler alarm

Scaler count time

Soitware

version

Threshold

User I.D. number

’

Window

IL42350

status

(se@

RCS

RK

RF

RT

RI

RW

X

xwaler contents

X

x=scaler

alarm setting

Xer count time

kersion

number (up to 16

Char)

kthreshold

k1.D. number (up to 15 char)

%Y

x+ndow

y=O:

window off

y=l:

window on

k2350 statlls

8

bit number

defjned

as

follows

Bit 0: n&meter alarm

Bit 1:

scaler alaxm

Bit 2: integrated dose alarm

Bit 3: scaler overflow

Bit 4.: integrated dose

overflow

Bit 5: low battery

Bit 6:

ovenrange

Bit 7: overload

NOTE:

‘Ihe

display is in

decimalf~andmustbe

converted to a bii 6

quivaknt.

the bit is

the bit is “not

If a bii bit is 1,

“seP;

if the bit is 0,

set”.

page

A7

Page 23

READ FUNCTION COMMAND VALID CHARACTERS

8.

tXMMANDUSAGE

M23!50

Data Logger

The M2350

customize

applications. This is done by issuing a series cmmands to configure and use the

ummands allow the user to

the

M2350

for particular

specific operating needs. The following

examples show how to use the

M2350

Ivl2350.

of commands to the M2350 to set it up for the The examples are set up to list the function

desired, the actual M2350 command, and the

M2350

response.

‘Ihe

examples also do not

show the carriage retum and line feed that are

needed at the end of the command. They ate

not shown because their entry method depends

on the type of entry equipment used.

NOTE

ALL COMMANDS

MSJS

Ar

E TERMINATED WITH A

CARRIAGE PETURN AND A LINE FEED. THE COM-

MANDS MUST BE UPPER CASE

NOTE

8.1Scanthroughthedisplaymodes

The following command examples will

show the various display modes of the

M2350.

FUNCTION

Select the normal display mode.

Select the parameters display

mode.

Select the detector display mode. SVD2

Select the alarm display mode.

page 18

For a detailed explanation of the displays,

refa

to section 6.

COMMAND

Svlp

\

SVDl

M2350

The

RESPONSE

M2350

display should

now look like Figure 3.

The

M2350

display should

now look like Figure 4.

The

M2350 display

should

now look like Figure 5.

svD3

The

M2350

display should

Page 24

lM2SODataLogger

Select the logged data display SW4

mode.

Select the recycle data display SW5

mode.

Select the recycle setup display

mode.

8.2

Set various detector settings

SW6

now look like Figure 6.

The

M2350

display should

now look like Figure 7 or

Figure 8.

The

M2350

display should

now look like Figure 9.

The

M2350

display should

now look like Figure 10.

The following command examples will

show the how to set some of the detector

FUNCTlON

Select the

pammeters

display

co-

SvDl

mode.

Set the high voltage to

9OOV.

Set the threshold to 500.

Turn the window on.

Set the window to 50.

Turn the window off.

Set the clock to

Set the date to

11:23.

12W90.

Select the detector display mode.

Set the calibration constant to

1,000,000.

Set the calibration constant to 1.

Setthedeadtimeto25pS.

SetthedeadtimetoOyS.

Set the model to 44-2.

settings. The ccmmands not shown work in

the same fashion.

M2350

The

RESPONSE

M2350

display should

now look like Figure 4.

The high voltage should now

read 9oov.

The threshold should now read

500.

The

window should now be

on and display a number.

The window should now read

50.

The window should now be

Off.

The time should now display

11:23.

The date should now display

12/12/90.

The

NJ2350

display should

now look like Figure 5.

The calibration constant

should now be

1.m.

The calibration constant

should now be

1..

‘Ihe dead time should now be

2.5OOOOOe45.

The dead time should now be

0.

The model should now display

44-2.

page19

Page 25

M23!iO

Data Logger

Set the serial number to

Select the alarm display mode.

Set the ratemeter alarm to Jle4

10,000.

Set the scaler alarm to 5647.

Set the integrated dose alarm to

1223.

N12Z3

svD3

KS47

P2Se5

250,000.

Set the ratemeter alarm to le9.

Set the scaler

Set the integrated dose alarm to

M.

Turn the overload on.

Set the overload to

Twn the overload off.

alann

to 999,999.

5.0@

Jle9

K999999

Ple9

The serial number should now

display

The

now look like Figure 6.

The ratemeter alarm should

now be

The scaler alarm should now

1223.

M2350

display should

1.OOOetO4.

be5647.

‘l’he

integrated dose alarm

should now be

The

ratemeter alarm should

nowbe1.OOOeHB.

The sealer alarm should now

he999999.

The integrated dose alarm

should now be

The overload should now be

on and display a number.

The overload should now read

2.5OOei-05.

1.M.

50.

The overload should now be

Off.

8.3

The following command examples will

show how to read some of the detector

settings. These examples assume a termbal is

being used that can display the data sent

Read

vtious

FUNCTION

Select the parameters display

mode.

Set the high voltage to 500V.

Read the high voltage.

Turn the window on

Set the window to 50.

detector

setiims

COMMAND

SVDl

l%XM?

RH

mN

from the M2350. A command will be given to

set the setting to the desired value and then

the setting will be read to verify the value.

The responses to the read commands

explained in section 7.

M2350

‘Ihe

now look like Figure 4.

The high voltage should now

read

The

‘9oo’outtheserialpoti

The window should now be

on and display a number.

The window should now mad

RESPONSE

M2350

Nov.

M2350

display should

will now send

are

50.

page20

Page 26

M23!50 Data Logger

Read the window setting.

Turn the window

OK

Read the window setting.

The following examples show how to set

RW

WOFI?

RW

set, the user identification number will be pro-

up and use the M2350 in various situations. grammed,

The possible uses range

from

a simple

ratemeter to a data logging system using

cleared. The following settings will be

entd

multiple probes.

0 date

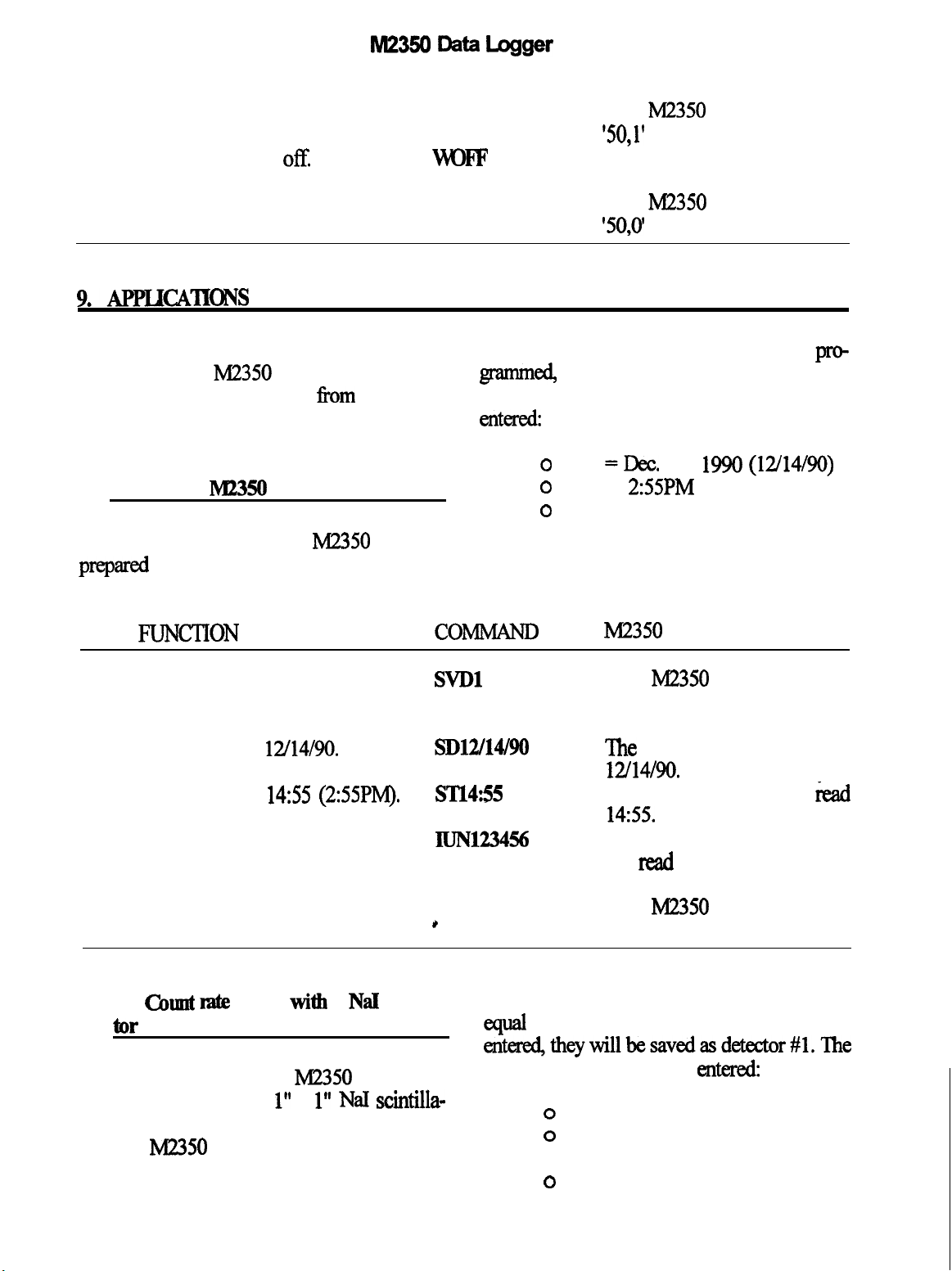

9.1 General

MI2350

setup

o time =

0

In this example, the

M2350

will be

prepared for further set up. The clock will be

The

M2350

will now send

‘50,l’ out the serial port.

The window should now be

Off.

The

M2350

'50,o'

out

will now send

the

serial port.

and the logging memory will be

=Dec.

14,

1990 (12/14/90)

2:55PM

user id = UN123456

FUNCTION

Select the parameters display

co-

SVDl

mode.

Set the date to

Set the time to

12/14/90.

14:55

(2:55PM).

Set the user I.D. number to

m1u14/90

sTl4:55

IUN123456

UN123456,

Select the normal display mode.

9.2

Count mte

meter

witi

a Nal scintilla

for

SVDO

*

,

time correction and the calibration constant

equal

entered,theywillbesavedasdetector#1.The

For this example, the M2350 will be set

following settings will be

up to use an LMI 44-2 1” x 1” NaI scintilla-

tor. This example also assumes

general

MB50

setup has already been done.

that the

The display is in counts per minute with live

M2350

The

RESPONSE

M2350

display should

now look like Figure 4.

‘Ihe

date should now read

12/14/90.

The time should now

read

14:55.

The user identification should

now read UN123456.

The

M2350

display should

now look like Figure 3.

to 1. After the settings have been

enteredz

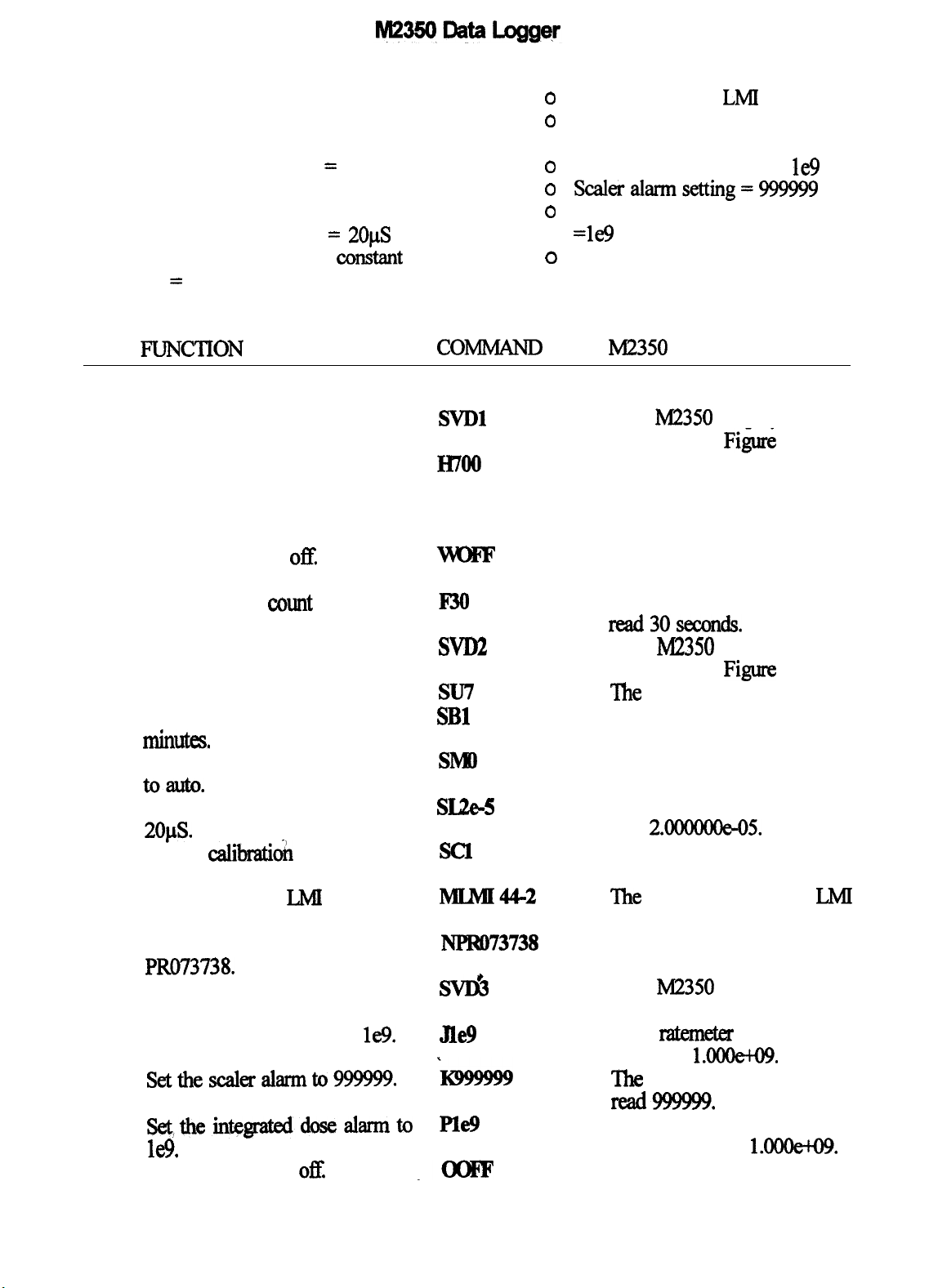

0 High voltage = 700v

o

Threshold = 1003) Window =

Off

o Window = off

page21

Page 27

0

Scaler count time = 30

seconds

0 Display units = counts

o

Display time base = minutes

0 Display range multiplier =

auto

o Detector dead time =

o Detector calibration cunstant

=

1

2OpS

0 Detector model =

0 Detector serial number =

PRO73738

0 Ratemeter alarm setting =

0 scaleralarmsetting=m

0 Integrated dose alarm setting

=le9

0 overload current = off

LMI

44-2

l&

l?‘UNCTION

Select the parameters display

mode.

Set the high voltage to 700V.

Set the threshold to 100.

Turn the window

Set the scaler

seconds.

Select the detector display mode.

offI

count

time to 30

set the readout units to counts.

Set the readout time base to

mill-.

Set the readout range multiplier

toauto.

Set the detector dead time to SUe-5

2o@s.

Set the

Set the model to

Set the serial number to

PRO73738

Select the alarm display mode.

Set the ratemeter alarm to le9.

Setthescaleralarmto999999.

Settheinte~dosealarmto

l&.

Turn the overload

calibrati&

constant to 1.

IMI

44-2.

off.

COMMAND

SVDl

IWO0

Tloo

F30

SVD2

su7

SBl

SMO

SCl

MLMI44-2

Nl?RO7373??

SW&

Jle9

i99!ww

Ple!J

.-

M2350

The

now look like

The high voltage should now

read 700v.

The threshold should now read

100.

The window should now be

RESPONSE

M2350

display should

Fig&

4.

Off.

The count time should now

read3oseJcmds.

The

M2350

now look like Figum 5.

‘Ihe units should now read 7.

‘The time base should now

read 1.

The range multiplier should

now read 0.

The dead time should now

read

2.000000e-05.

The calibration constant

should mad 1.

‘Ihe

model should read

44-2.

The serial number should now

read PR073738.

The

M2350

now look like Figure 6.

‘The rakmekr alarm should

now read

‘Ihe scaler alarm should now

read!299999.

‘The integrated dose alarm

should now read

The overload should now be

display should

LMI

display should

1AMOe-W.

MOOe-KB.

page 22

Page 28

M2350

Data

Save the settings as detector 1. SPl

Select the normal display mode.

Load detector #l settings.

SVDO

Dl

Logger

Off.

The

settings have now been

saved as detector

The IV2350

#l.

display should

now look like Figure 3.

This step is not needed, but is

included to show how to recall

the settings of detector

#l.

The setup of the M2350 for the count rate dose.

meter is now complete. The M2350 can now

beusedasacountratemeterorascaler.~~

following commands will show how to start

not effect the settings saved under detector

because the save

will not be used in the following example.

the scaler, stop the scaler, change the count

time, and zero the ratemeter and integrated

FUNCTION

Select the normal display mode.

Start the scaler counting.

Stop the scaler.

Set the count

the

to 10 seconds.

Start the scaler counting.

zerotherat~.

Reset the integrated dose.

coMM44ND

SVDO

C

E

FlO

C

Z

SlZ The integrated dose and the

*

The

changes made to the count time will

parameta

M.2350

The

M2350

command (SPx)

RESPONSE

display should

now look like Figure 3.

‘The M2350

should now start

cQunting.

lhe

M2350

should stop counting.

‘The

count time should read 10

seconds.

‘The M2350

should now start

counting.

‘Ihe

digital

barograph

both

rateme

ratemeter should

zm

and then resume

and the

normal operation,

integrated dose timer should

zeroandthenresumenormal

operation.

#l

9.3

MicmR

meter with a

NaI t&till&r

provide the direct readout in R per hour.

the settings have

For this example, the

II42350

will be set

up to use an LMI 44-2 1” x 1” NaI scintilla-

tar,

This example also

geneml Me2350

setup has already been done.

assumes

that the

saved as detector

will be entered

The display is in R per hour with live time

correction and the calibration constant is set to

page 23

been en-

#2.

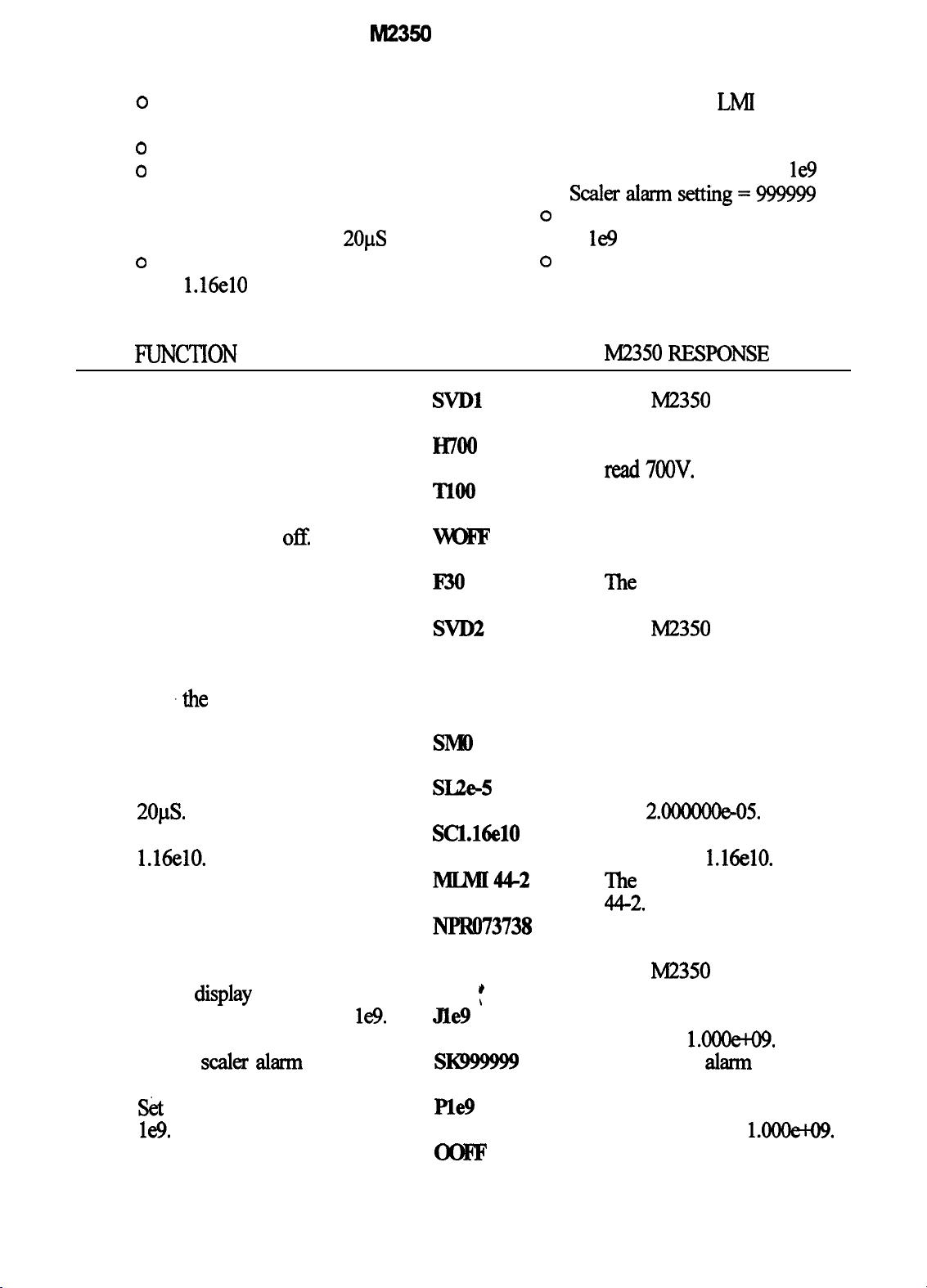

The following settings

0

High voltage =

o

Threshold=1OO

o Window = off

Mer

they will be

7OOv

Page 29

M2350

0

Scaler count time = 30

seconds

o

Display units = R

0 Display time base = hours

o Display range multiplier =

auto

o Detector dead time = 20~s

0 Detector calibration constant

=

1.16elO

Data Logger

0 Detector model = LMI 44-2

0 Detector serial number =

PRO73738

0 Ratemeter alarm setting =

0 scalerdarmsetting=999999

o

Integrated dose alarm setting

= le9

0 overload current = off

le9

FuNCTlON

Select the parameters display

mode.

Set the high voltage to 700V.

Set the threshold to 100.

Turn the window

Set the scaler count time to 30

seconds.

Select the detector display mode.

Set the readout units to R

Set

.the

readout time base to

hours.

Set the readout range multiplier

to auto.

Set the detector dead time to

ofI

2ops.

Set the calibration constant to

1.16elO.

Set the model to LMI 44-2.

Set the serial number to

PR073738.

Select the

alarm display mode.

Set the ratemeter alarm to le9.

Set the scaler

Set the integrated dose alarm to

le9.

Tum the overload off.

ahn

to 999999.

COMMAND

SvDl

Hmo

no0

F30

su4

SB2

sue-5

Scl.16elO

MLlw44-2

svD3

*

Jle9

’

SKgggggg

Ple9

M2350

The

now look like Figure 4.

The high voltage should now

RESPONSE

M2350

display should

read7OOv.

The threshold should now

read 100.

The window should now be

Off.

The

count time should now

read

30

seconds.

The

M2350

now look like Figure 5.

The units should now read 4.

The time base should now

read

2.

The range multiplier should

now read 0.

The dead time should now

read

2.000000s05.

The calibration constant

should read

The model should read LMI

display should

1.16elO.

44-2.

The serial number should now

read PR073738.

The

M2350

now look like Figure 6.

The ratemeter alarm should

now read 1.000&09.

‘The scaler

read999999.

‘l-he integrated dose alarm

should now read

The overload should now be

Off.

display should

ahnn

should now

1.OOOetO9.

page 24

Page 30

M2350

Data Logger

Save the settings as detector 2.

Select the normal display mode.

Load detector #2 settings.

SP2

SVDO

D2

The setup of the M2350 for the micro-R

meter is now complete. The operation of the

M2350

is the same as in the application

above.

9.4

Survey

meter with a GM detector

For this example, the M2350 will be set

up to use an LMI 44-38 G-M detector. This

examplealsoassumesthatthegeneralM235O

setup has already been done. The display is in

R per hour with live time correction and the

calibration constant is set to provide the direct

readout in R per hour. After the settings have

been entered, they will be saved as detector

#3.

The following settings will be

enteredz

The settings have now been

saved as detector

The

M2350

#2.

display should

now look like Figure 3.

‘This step is not needed, but is

included to show how to recall

the settings of detector

0

High voltage = 900v

0

Threshold = 500

0

Window

0

Scaler count time = 6 seconds

0

Readoutunits=R

0

Readout time base = hours

0

Readout range multiplier =

auto

0

Detector dead time =

0

Detector calibration constant

=7.64e7

0

lletector model = LMI 44-38

0

Detector serial number =

= off

lOOuS

PRO73796

0

l3ammx

0

scaler alarm setting = 999999

0

Integrated dose alarm setting

alarm setting = le9

=le9

0

overload culrent = off

#2.

FUNCTlON

Select the

parame&s

display

COMMAND

SVDl

mode.

Se

the high voltage to

9OOV.

Set the threshold to 500.

H900

*-

Turn the window off.

Set the scaler count time to 6

I%

seconds.

Select the detector display mode.

SetthereadoutunitstoR

SVD2

su4

Set the readout time base to SB2

hours.

page25

M2350

The

RESPONSE

M2350

display should

now look like Figure 4.

The high voltage should now

read 9oov.

The threshold should now

Rad500.

The window should now be

Off.

The

count

time should now

read 6

The

seconds.

M2350

display should

now look like Figure 5.

‘The units should now read 4.

‘The time base should now

read 2.

Page 31

MZ350 Data Logger

FUNCTION COMMAND

Set the readout range multiplier

SMO

to auto.

Set the detector dead time to

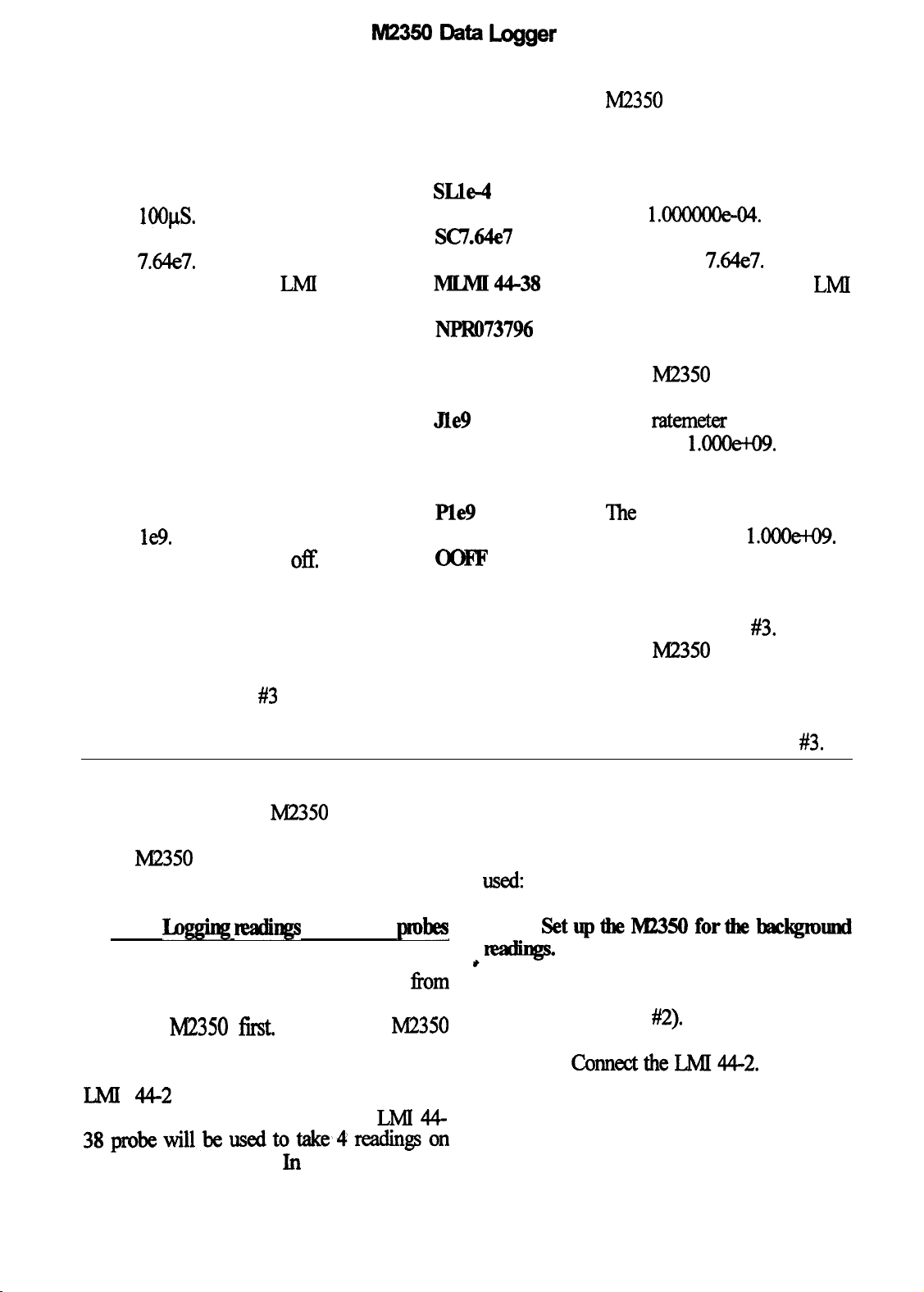

SLIe-4

loops.

Set the calibration constant to

SC7.64e7

7.64e7.

Set the model to LMI 44-38.

Set the serial number to

PR073796.

Select the alarm display mode.

Set the ratemeter alarm to le9.

Set the scaler alarm to 999999. SK999999

Set the integrated dose alarm to

le9.

Turn the overload 0%

Save the settings as detector 3.

Select the normal display mode.

Load detector #3 settings.

MLlw44-38

NPRO73796

svD3

JYle9

Ple9

SF.3

SVDO

D3

Id2350

RESPONSE

The range multiplier should

now read 0.

The dead time should now

read

1.m04.

The calibration constant

should read 764e7.

The model should read LMI

44-38.

The serial number should now

read PR073796.

The

M2350

now look like Figure 6.

The

ratemeter

now read

The scaler alarm should now

read999999.

The

integrated dose alarm

should now read

The overload should now be

Off.

The settings have now been

saved as detector

The

M2350

now look like Figure 3.

This step is not needed but is

included to show how to recall

the settings of detector

display should

alarm should

l.OOOe+O9.

1.m.

#3.

display should

#3.

The setup of the

M2350

for the G-M

reading will be saved as well as the integrated

survey meter is now complete. The operation dose accumulated during the logging proceof the M2350 is the same as in the application

above.

9.5

For this example, the settings

Iqging tt3dhgs

with multiple probes

from

sections 9.1 through 9.4 need to be entered

into

the

M2350

fist.

This sets up the M2350

to allow for background readings as well as

higher readings. This example will use the

LMI

readings outside of a room Then the

44-2

probe to take 4

background

LMI

44-

dure. The following logging procedure will be

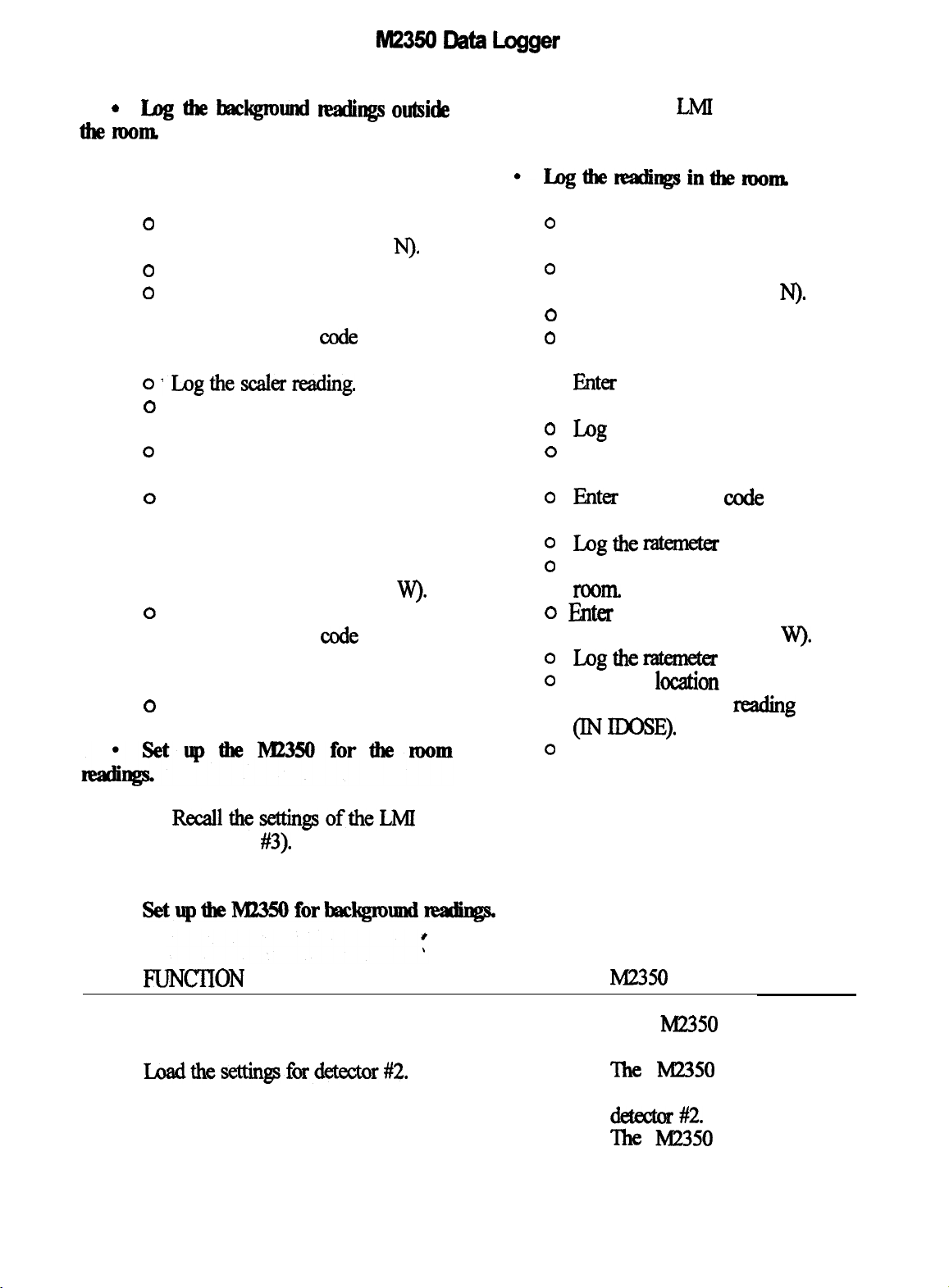

used:

l

SetuptheM235Oforthebackgmund

e-

,

0

Recall the settings of the LMI

44-2

0

Clear the logging memory.

0

ConnecttheM44-2.

0

Clear the integrated dose.

(det #2).

38probewillbeusedtotake4readingson

the inside of the room In both cases, each

page26

Page 32

Mz3!50 Data Logger

. rag

theloom

tin? backgmlmd readings olltside

Move to the north side of the

o

room.

0

Enter the location code for

the 1st reading (OUTSIDE

0

Log the scaler reading.

o

Move to the east side of the

NJ

mom.

0

Enter the location code for

the 2nd reading (OUTSIDE E).

0~Logthescalerreading.

o

Move to the south side of the

room.

Enter the location code for

0

the

3rd

reading (OUTSIDE S).

0

Log the scaler reading.

o

Move to the west side of the

room.

Enter the location code for

0

the

4th

reading (OUTSIDE

0

Log the sealer raiding.

Enter the location code for

0

the integrated dose reading

(OUT DOS).

o

Log the integrated dose.

W).

0 Connect the LMI 44-38.

o Clear the integrated dose.

IkgtbeHngsinthemom

0 Move to the north wall of the

room.

0 Enter the location code for

the 1st reading (INSIDE

Log the ratemeter reading.

0

o

Movetotheeastwallofthe

N).

room.

Enter the location code for

0

the 2nd reading (INSIDE E).

0 Log the ratemeter reading.

0

Move to the south wall of the

room.

0

E&r

the location code for

the

3rd

reading (INSIDE S).

0

Logthe

o

Movetothewestwallofthe

lllbmeb

reading.

ITxm.

0

Enter the location code for

the

4th

reading (INSIDE W).

0

Logthe l-atama

Enter the

0

k&ion

reading.

code for

the integrated dose reading

m IDosE)*

o Log the integrated dose.

o RecallthesettingsoftheLMI

44-38

l SetuptheMZ35Oforlx3ckgmund~

(det #3).

FUNCTlON COMMAND

Select the detector display mode.

SVD2

Loadthesettingsfordet&or#2. D2

Select the normal display mode.

SVDO

page27

M2350

The

RESPONSE

M2350

display should

now look like Figure 5.

The M2350

display should

now show the settings for

de&xtor #2.

'Ihe M2350

display should

now look like Figure 3.

Page 33

M23!5ODataLogger

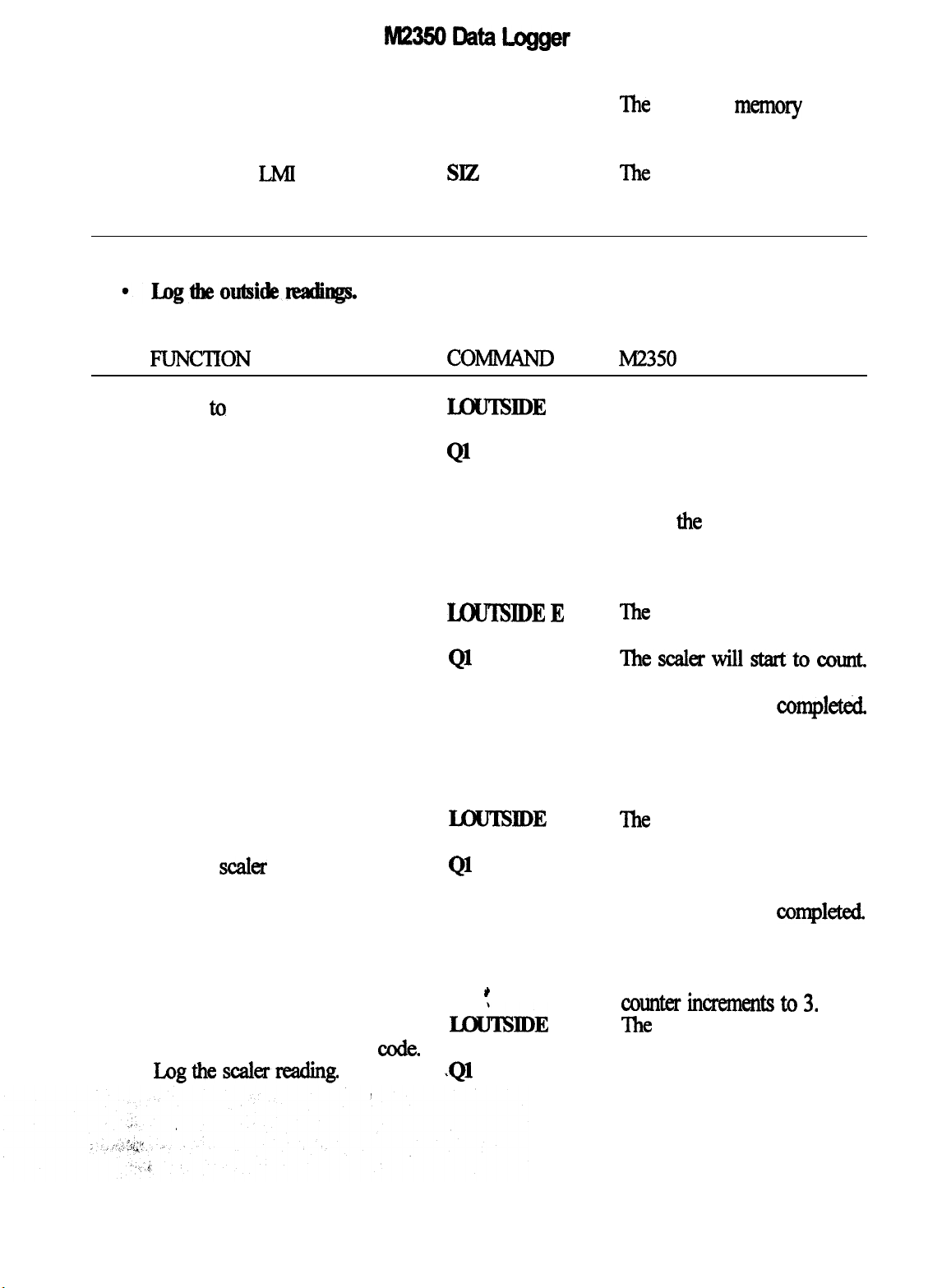

Clear the logging memory to SSC

allow for new data.

Connect the

LMI

44-2 and then

HZ

clear the integrated dose.

F’UNCTION

Move to the north side of the

COMMANJI

UXJ’ISmE N

room and enter the location code.

Log the scaler reading.

Move to the east side of the

Ql

IKW’JBJDEE

room and enter the location code.

Log the scaler reading.

Move to the south side of the

Ql

IDUISIDE S

room and enter the location code.

Log the

scaler

reading.

Ql

*

Move to the west side of the

room and enter the location axle.

Logthescalerreadin~

I&ISIDE

.Ql

W

The

logging

memory

should

be cleared and the sample

number should be 0.

The

integrated dose and the

integrated dose timer should

he 0.

M2350

RESPONSE

The location code should

change to OUTSIDE N.

The scaler will start to count.

Remain at the same position

until the count is completed.

When the scaler stops coun-

ting the reading is saved as

sample 0 and the sample

counter increments to 1.

The

location code should

change to OUTSIDE E.

Thescalerwill~tocount.

Remain at the same position

until the count is cumpleted

When the scaler stops counting, the reading is saved as

sample 1 and the sample

counter increments to 2.

‘The

location code should

change to OUTSIDE S.

The scaler will start to count.

Remain at the same position

until the count is compkted.

When the scaler stops count-

ing the reading is saved as

sample 2 and the sample

counterincrementsto3.

The

location code should

change to OUTSIDE W.

The scaler will start to count.

Remain at the same position

until the count is completed

When the scaler stops counting the reading is saved as

sample 3 and the sample

page28

Page 34

FUNCTION

page29

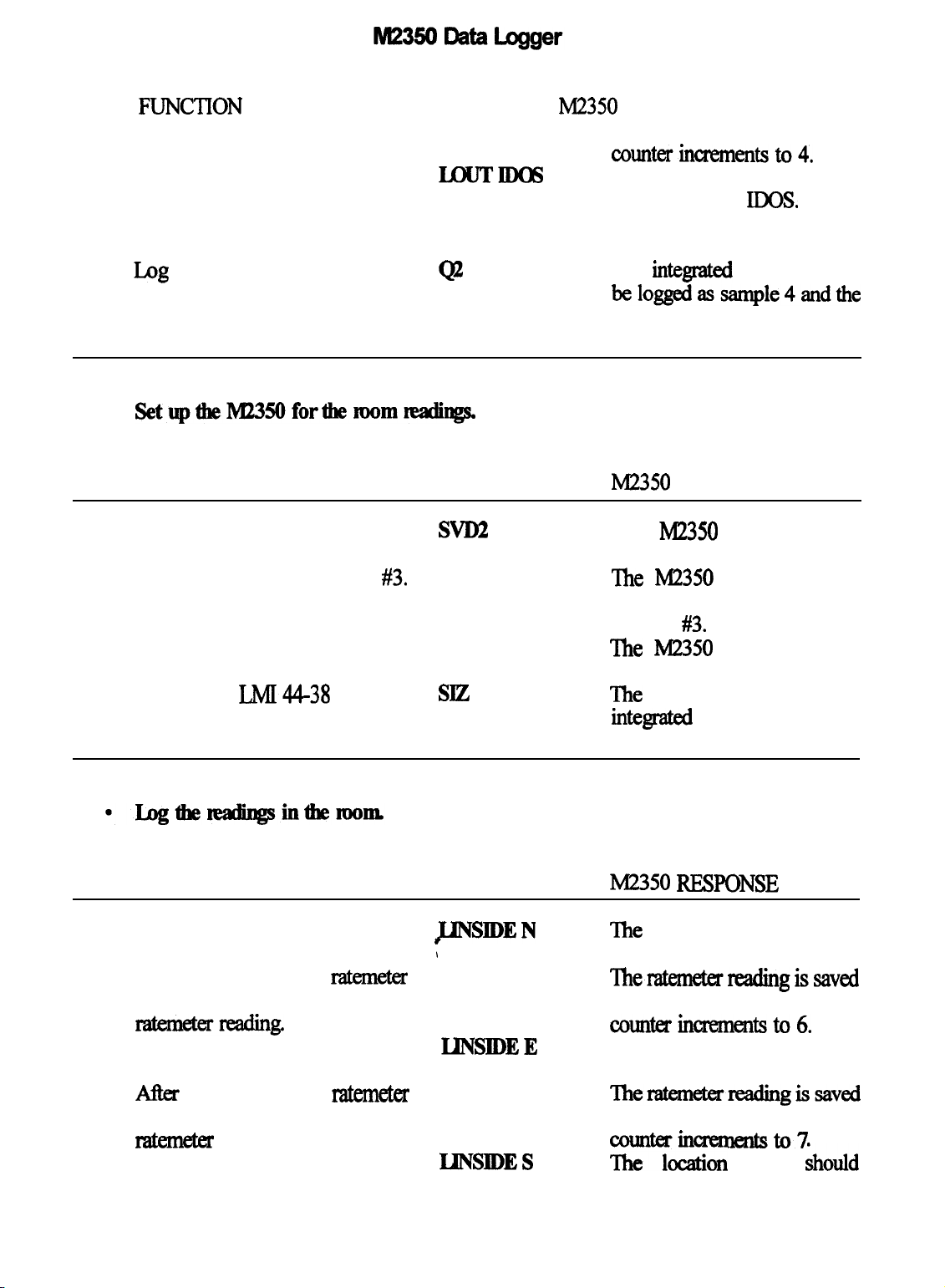

Now set the location code to

indicate the outside integrated

dose.

COMMAND

IBUTIDCB

M2350

txxlnt~in~entsto4.

The location code should

change to OUT

RESPONSE

DOS.

Lag the integrated dose reading.

@

The

intqpted

beloggedassample4andthe

sample counter increments to

5.

l

SetupthelW235Oforthemomnxuliqp.

FUNCTION COMMAND M2350 RESF’ONSE

Select the detector display mode. SVD2

The

M2350

display should

now look like Figure 5.

Load the settings for detector

#3.

D3

‘Ihe M2350

display should

now show the settings for

Select the normal display mode.

SVDO

detector

‘Ihe It42350

#3.

display should

now look like Figure 3.

Connect the LMl44-38 and then SIZ

clear the integrated dose.

The

integrated dose and the

Intel

dose timer should

he 0.

dose will now

FUNCTION COMMAND

Move to the north wall of the JINSIDEN

room and enter the location code.

After waiting for the

ratemeter

b

QO

reading to stabilize, log the

ratemeterreading.

Movetotheeastwallofthe

LINSIDEE

room and enter the location code.

Aiter waiting for the

n&meter

QO

reading to stabilize, log the

ratemeta

Move to the south wall of the

reading.

UNSIDES

room and enter the location code.

M2350

‘Ihe

RTZSPONSE

location code should

change to INSIDE N.

Themkmeterreadingissaved

as sample 5 and the sample

countsin~entsto6.

The location code should

change to INSIDE E.

Theraknderreadingissaved

as sample 6 and the sample

--to7

it?titicm

change to INSIDE S.

code

;;hou.ld

Page 35

FUNCTION

After

waiting for the ratemeter

reading to stabilize, log the

ratemeter IEading.

Move to the west wall of the

room and enter the location code.

After

waiting for the ratemeter

readhg

to stabilize, log the

ratemeterreading.

Now set the location uxle to

indicate the inside integrated

dose.

Log the integrated dose reading.

9.6 View bgged nadings

COMMAND M2350

CP

RESPONSE

The ratemeter reading is saved

as sample 7 and the sample

counterincrementsto8.

IANSIDE

W

The location code should

change to INSIDE W.

Ihe

Qo

.

ratemeter reading is saved

as sample 8

and the sample

counter increment to 9.

LaNlDm The location code should

42

change to IN

The integrated dose will now

DOS.

he logged as sample 9 and the

sample counter incxments to

10.

For this example, the settings

fi-om

sections 9.1 through 9.4 need to be entered

into

the It42350

f.

Then the example in

section 9.5 needs to be done. ‘Ibis will store

the

trcaiings

M2350.

in the logging memory of the

FUNCTION

Select the logged data display

COMMAND M2350

SVIM

mode.

Select the sample to view.

Select the sample to view.

RESPONSE

‘Ihe M2350

display should

now look similar to Figure 7.

In all of the following commands, this display will be

The following data is

displayed.

Location

code:

OUTSIDE N

Detector#:O2

Type of reading: SCALER

Logged count: 1.357ooo&o3

Count time:

30

seconds

Time: 15:21

Date:

12/14&O

User I.D.: UN123456

The following data is

displayed

Location

code:

OUTSIDE E

page 30

Page 36

Select the sample to view.

Select the sample to view.

Select the sample to view.

SW2

SW3

SVIA

*

Selectthesampletoview. ’ SVI5

Detector #: 02

Type of

reading. SCALER

Logged cmlnt: 1.29mooeto3

Count time: 30 seconds

Time: 15:25

Date:

lU14/90

User I.D.: UN123456