LUDLUM MODEL 2241-3 & 2241-3i

SURVEY METER

January 2016

Serial Number 299171 and Succeeding

Serial Numbers

LUDLUM MODEL 2241-3 & 2241-3i

SURVEY METER

January 2016

Serial Number 299171 and Succeeding

Serial Numbers

STATEMENT OF WARRANTY

Ludlum Measurements, Inc. warrants the products covered in this manual to be free of

defects due to workmanship, material, and design for a period of twelve months from the

date of delivery. The calibration of a product is warranted to be within its specified

accuracy limits at the time of shipment. In the event of instrument failure, notify Ludlum

Measurements to determine if repair, recalibration, or replacement is required.

This warranty excludes the replacement of photomultiplier tubes, G-M and proportional

tubes, and scintillation crystals which are broken due to excessive physical abuse or used

for purposes other than intended.

There are no warranties, express or implied, including without limitation any implied

warranty of merchantability or fitness, which extend beyond the description of the face

there of. If the product does not perform as warranted herein, purchaser’s sole remedy

shall be repair or replacement, at the option of Ludlum Measurements. In no event will

Ludlum Measurements be liable for damages, lost revenue, lost wages, or any other

incidental or consequential damages, arising from the purchase, use, or inability to

product

.

use

RETURN OF GOODS TO MANUFACTURER

If equipment needs to be returned to Ludlum Measurements, Inc. for repair or calibration, please send to

the address below. All shipments should include documentation containing return shipping address,

customer name, telephone number, description of service requested, and all other necessary information.

Your cooperation will expedite the return of your equipment.

ATTN: REPAIR DEPARTMENT

501 OAK STREET

SWEETWATER, TX 79556

LUDLUM MEASUREMENTS, INC.

800-622-0828 325-235-5494

FAX 325-235-4672

Table of Contents

Introduction 1

Information on Model 2241-3i 1-2

Getting Started 2

Unpacking and Repacking 2-1

Battery Installation 2-1

Connecting a Detector 2-2

Operational Check 2-2

Specifications 3

Removable Switchboard Adjustable Parameters 3-2

Internal Detector Specifications for Model 2241-3i 3-4

Identification of Controls and Functions 4

Display 4-1

Display Status Definitions 4-1

Front Panel Controls 4-2

Front Panel Calibration Controls 4-3

Main Board Controls 4-4

Switch Board Controls 4-5

Safety Considerations 5

Environmental Conditions for Normal Use 5-1

Detector Connector 5-1

Warning Markings and Symbols 5-1

Maintenance 6

Operational Check 6-1

Recalibration 6-1

Batteries 6-3

Technical Principle of Operation 7

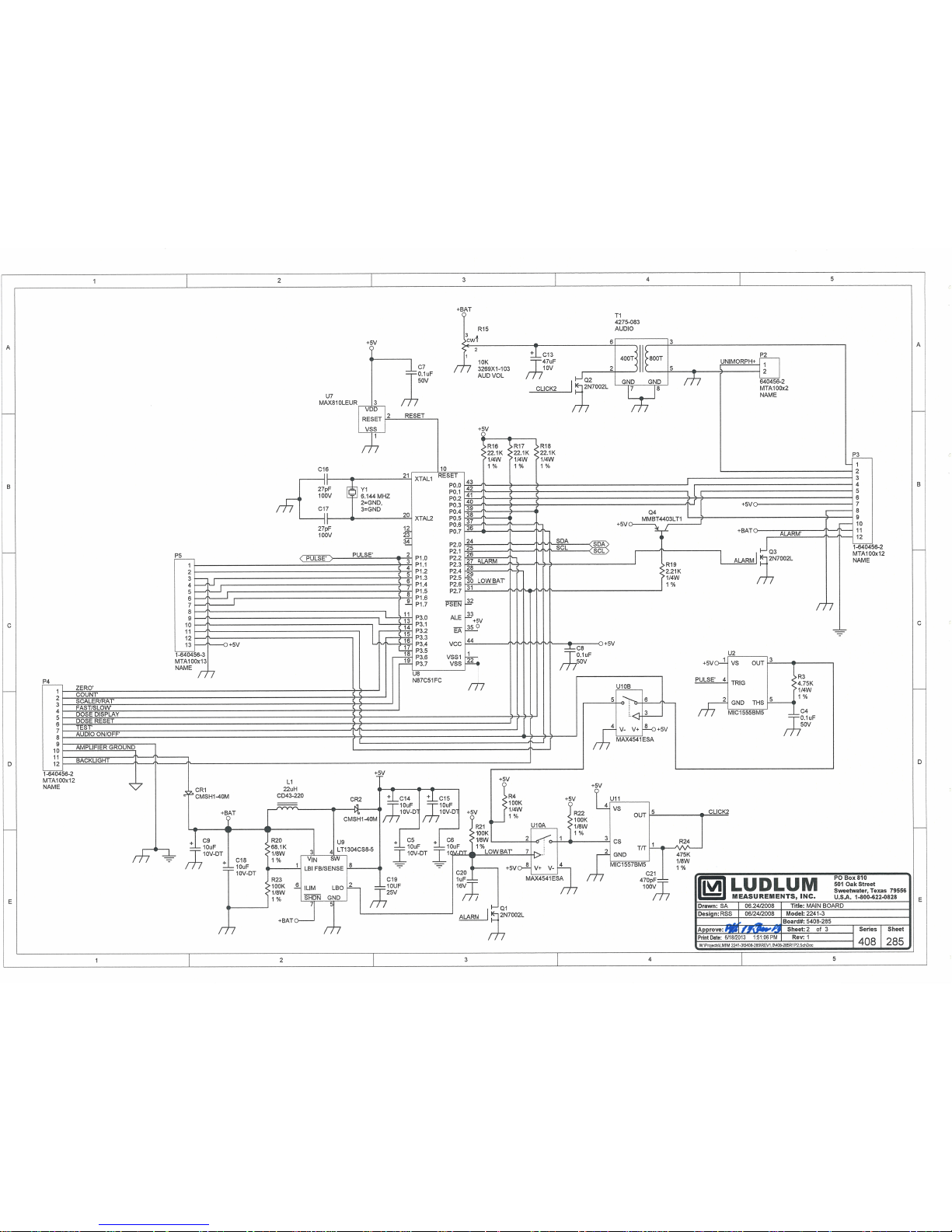

Main Board 7-1

Switch Board 7-2

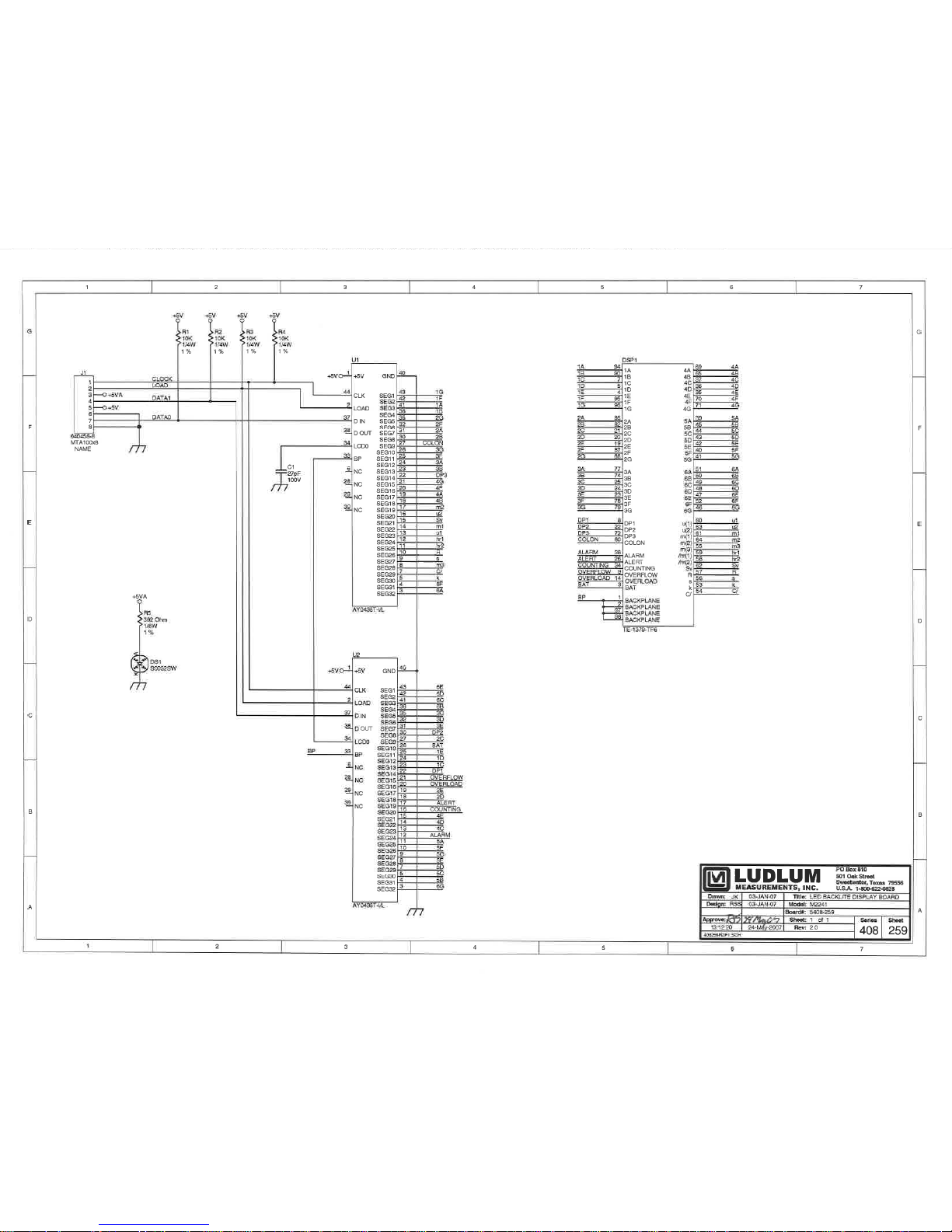

Display Board 7-3

Ludlum Measurements, Inc. January 2016

Model 2241-3 & 3i Technical Manual

Instrument Setup & Calibration 8

Entering or Changing Switch Board Parameters 8-1

Loading Default Parameters 8-1

The Function Switch 8-2

Function Switch Position Descriptions and Variables 8-2

Calibration 8-7

General Detector Setup Information 8-8

Counts per minute (C/m) Calibration 8-9

R/hr Calibration 8-11

Determining CC and DTC 8-12

Software License Agreement 8-19

Recycling 9

Parts List 10

Model 2241-3 Survey Meter 10-1

Main Circuit Board, Drawing 408 × 285 10-1

Calibration Board, Drawing 408 × 98 10-3

Display Board, Drawing 408 × 259 10-4

Switch Board, Drawing 408 × 45 10-5

Chassis Wiring Diagram, Drawing 408 × 101 10-5

Drawings and Diagrams 11

RS-232 Output Formats - Appendix A A

Binary Output Format A-1

ASCII Output Format A-4

Ludlum Measurements, Inc. January 2016

Model 2241-3 & 3i Technical Manual Section 1

Section

1

Introduction

he Model 2241-3 is a portable microprocessor-based digital Scaler/

Ratemeter designed for use with scintillation, Geiger-Mueller (GM),

T

mode) Liquid Crystal Display (LCD) with moving decimal point. A toggle

switch labeled SCA/RATE selects the desired operating mode for the

instrument. A five-position switch labeled ˝OFF/DET 1/DET 2/DET 3/DET

4˝ allows for a quick change of operating parameters when changing out

detectors.

Programmable display units (RATEMETER mode only) can be represented in

R/hr, Sv/h, cpm, or cps with multipliers of micro (µ) or milli (m) for R/hr

and Sv/h and kilo (k) for cpm or cps. The display units are auto-ranging,

enabling the readout to display a broad range of radiation levels. The display

also offers lower limit capability. For example, the display can be set to show

only values that are greater than or equal to1 µR/hr.

and proportional-type detectors for measurement of ionizing

radiation. Data is presented on a four-digit (six digits in the scaler

This instrument incorporates independent adjustable alarms for RATEMETER

and SCALER operating modes. The RATEMETER mode has two alarm

indicators. The first-level alarm is indicated by display of the word ˝

on the LCD. The second-level alarm is indicated by display of the word

˝ALARM˝ and by the emitting of a continuous audible tone. The SCALER

alarm condition will also display the word ˝

audible tone. Both audible alarms may be silenced (acknowledged) by

depressing the RESET switch. All alarms are concurrent.

Other features include: 1) Dead Time Correction (DTC) to compensate for

detector dead time; 2) audible click-per-event with programmable 1, 10, 100,

and 1000 divide-by; 3) LCD backlight with programmable ON time; 4)

programmable fixed or variable response time; and 5) count overflow visual

alarm, indicative of the counting circuitry nearing the maximum counting

capability.

Ludlum Measurements, Inc. Page 1-1 January 2016

ALARM˝ and produce the same

ALERT˝

Model 2241-3 & 3i Technical Manual Section 1

All of the features described above may be programmed manually using the

internal switch board or by computer through the RS-232 port. Four

different detector operating parameters may be stored in non-volatile

memory. The switch board can be removed after entering or changing

parameters to prevent tampering with setup parameters.

A regulated high-voltage power supply, four independent set-point controls

adjustable from 400 to 2500 volts, and adjustable discrimination levels, add

versatility to the instrument. This supports operation for a broad range of

detectors and connecting cable lengths. All of the calibration controls are

covered to prevent any inadvertent adjustment to the detector operating

parameters.

The instrument is powered by two standard ˝D˝ cell batteries. The unit body

is made of cast-and-drawn aluminum with beige powder coating, which aids

in the decontamination of surfaces.

The Model 2241-3i is identical to the Model 2241-3 except for the

following:

The five-position selector switch located on the front panel has been

modified to provide for selection of an internal detector. When selected, the

INT position (formerly DET4) switches detector operation to an internal,

energy-compensated Geiger-Mueller detector. Appropriate wiring changes

to accommodate the internal detector have been made; however, physical

dimensions are the same as for a Model 2241-3.

A drawing of the front-panel of the 2241-3i is included at the beginning of

this manual. A wiring diagram for the instrument is included in the back of

the manual with the other drawings. The internal detector specifications can

be found at the end of Section 3 of this manual.

Ludlum Measurements, Inc. Page 1-2 January 2016

Model 2241-3 & 3i Technical Manual Section 2

Section

2

Getting Started

Unpacking and R epacking

Remove the calibration certificates and place them in a secure location.

Remove the instrument, detectors, and accessories (batteries, cable, etc.), and

ensure that all of the items listed on the packing list are in the carton. Check

individual item serial numbers and ensure calibration certificates match. The

Model 2241-3 serial number is located on the front panel below the battery

compartment. Most Ludlum Measurements, Inc. detectors have a label on

the base or body of the detector for model and serial number identification.

Important!

If multiple shipments are received, ensure that the detectors

and instruments are not interchanged. Each instrument is

calibrated to specific detectors, and are therefore, not

interchangeable.

To return an instrument for repair or calibration, provide sufficient packing

material to prevent damage during shipment. Also provide appropriate

warning labels to ensure careful handling. Include detector(s) and related

cable(s) for calibration.

Every returned instrument must be accompanied by an Instrument Return

Form, which can be downloaded from the Ludlum website at

www.ludlums.com. Find the form by clicking the “Support” tab and

selecting “Repair and Calibration” from the drop-down menu. Then choose

the appropriate Repair and Calibration division where you will find a link to

the form.

Battery Installation

Ensure the OFF/DET 1/DET 2/DET 3/DET 4 switch is in the OFF position.

Open the battery lid by turning the quarter-turn thumb screw counter-

Ludlum Measurements, Inc. Page 2-1 January 2016

Model 2241-3 & 3i Technical Manual Section 2

clockwise. Install two ˝D˝ size batteries in the compartment. Note the (+)

and (–) marks inside the battery door. Match the battery polarity to these

marks. Close the battery box lid.

Note:

The center post of “D” size battery is positive.

Connecting a Detector

Caution!

The detector operating voltage (HV) is supplied to the detector

by way of the input connector. A mild electric shock may

occur if contact is made with the center pin of the input

connector. Switch the Model 2241-3 to the OFF position

before connecting or disconnecting the cable or detector.

Connect a detector to the Model 2241-3 by using the cable provided; firmly

pushing the connectors together while twisting clockwise until the connector

latches (1/4 turn). The diagram to the left illustrates how this is done. Next,

place the detector selector switch in the appropriate position.

Operational Check

Place the SCA/RATE (scaler/ratemeter) switch in the RATE

position. Notice that the display goes through an initialization

sequence. The display will show all “8”s with decimal points.

Check to make sure all segments display, as illustrated in the

diagram to the left.

The LCD then displays the firmware number in the format

“P-XX YY.” The “XX” is the firmware number, and the “YY”

is the firmware version. (The figure to the left is for example

only; to illustrate location of display.)

The minimum displayable value (for example 00.0 µR/hr) should

be shown. When switched to the SCA position, a single “0” will

be displayed.

Ludlum Measurements, Inc. Page 2-2 January 2016

Model 2241-3 & 3i Technical Manual Section 2

The display will auto-range to the current level (see figure at left).

When auto-ranging down, the Model 2241-3 uses multiples of 5.

This technique keeps the decimal point from jumping between

numbers when viewing values around multiples of 10.

Check for a proper background reading:

If using a Ludlum Model 44-9 detector, a typical reading would be 25-50

cpm or 8-15 µR/hr.

If using a Ludlum Model 44-2 detector, a typical reading would be 1.4-2.6

kcpm or 8-15 µR/hr.

If using a Ludlum Model 133-7 detector, a typical reading would be 0 cpm

or 8-15 µR/hr.

A reference reading (or readings) with a check source should be obtained

with the detector(s) in a constant and reproducible manner at the time of

calibration or at the time the instrument is received in the field.

If at any time the instrument fails to read within 20% of the reference

reading when using the same check source, it should be sent to a calibration

facility for recalibration and/or repair. If desired, multiple readings may be

taken at different distances and/or with different sources so that other

ranges or scales are checked.

Switch the

AUD ON/OFF switch to the ON position and confirm that the

external unimorph speaker produces an audible click for each event detected

(audio divide-by 1 parameter). The AUD ON/OFF switch will silence the

clicks if in the OFF position, however, an audible alarm condition will still be

heard.

Increase the source activity or lower the alert and alarm points to initiate an

ALERT and ALARM condition. (Refer to Section 8, Subsection “Entering or

Changing Switchboard Parameters.”) Depress the RESET switch to

acknowledge the audible alarm. Decrease the radiation activity below the

ALERT and ALARM threshold and depress the RESET switch to clear the alarm

conditions. If an alarm condition is not present, depressing the RESET switch

the first time will reset the alert condition and zero the ratemeter.

Position a check source to produce a ratemeter reading of 100 to 2000

counts per minute or 10-100 µR/hr. While observing the ratemeter

fluctuations, select between the fast and slow response time (

F/S) positions

to observe variations in the display. The S position should respond

Ludlum Measurements, Inc. Page 2-3 January 2016

Model 2241-3 & 3i Technical Manual Section 2

approximately five times slower than the F position (for fixed response

mode) and three times slower when in variable response mode. The slow

response position is normally used when the Model 2241-3 is displaying low

numbers, which require a more stable display. The fast response position is

used at high count levels.

Place the SCA/RATE switch to the SCA position. Depress the COUNT switch

located in the end of the carrying handle in order to initiate a count cycle.

The word “COUNTING” should be flashing on the LCD during the count

cycle and should disappear at the end of the predetermined count time. If a

scaler ALARM condition occurs, the RESET switch can be depressed to

acknowledge the alarm; however, the COUNT switch must be depressed to

clear the visual ALARM and to restart the count cycle.

Depress and release the

LIGHT switch. The backlight located behind the

LCD should illuminate (for pre-programmed ON time). Select the desired

F/S, AUD ON/OFF, and RATE/SCA parameters and proceed to use the

instrument.

Ludlum Measurements, Inc. Page 2-4 January 2016

Model 2241-3 & 3i Technical Manual Section 3

Section

3

Specifications

0

Linearity: Readings are within 10% of true value with a detector connected.

Display: a four-digit Liquid Crystal Display (LCD) with digits 1.3 cm (0.5

in.) in height. Two additional 0.5 cm (0.2 in.) high digits are used for the

overflow counter (SCALER mode) and exponential powers (parameter setup).

Enunciators are provided for display units, ALERT, ALARM, low battery,

detector OVERLOAD (not used), counting OVERFLOW, and scaler COUNTING.

Warm-up Time: Unit may be used immediately after the LCD initialization

sequence is completed (approximately five seconds after power-up).

RATEMETER: Depending upon how the instrument was calibrated, the

RATEMETER can display in either R/hr, Sv/h, cpm, or cps when the control

switch is in the RATEMETER position.

SCALER: activated by pushbutton in handle when the three-position switch

is in the SCALER position. Count time is adjustable.

Calibration Controls: accessible from the front of the instrument

(protective cover provided). These controls are preset at the factory or

calibration lab and should not be adjusted by field personnel.

Discriminator / Input Sensitivity: adjustable from 2 to 100 mV;

negative pulse response

High Voltage: four independent controls, each adjustable from

400-2500 volts; four separate set points for each detector setup-

HV 1, HV 2, HV 3, and HV 4, regulated within 0.2% at 1000 Vdc;

maximum load of 50 µA.

RESET: a pushbutton for zeroing the display, acknowledging

and/or resetting the alarm.

Ludlum Measurements, Inc. Page 3-1 January 2016

Model 2241-3 & 3i Technical Manual Section 3

Note:

The RESET button only silences the alarm in the current mode

that the instrument is in. For example, the RESET button will

not affect the scaler alarm if the instrument is in the

ratemeter mode.

Light: display backlight activated by pushbutton

Audio: built-in audio speaker (unimorph) with AUD ON/OFF switch; at

maximum volume > 60 dB at 2 feet; internal adjustable volume

Alert/Alarm: indicated by either an ALERT or ALARM enunciator on the

display (RATEMETER mode only) and by an audible tone

Power: two each, ˝D˝ cell batteries housed in an externally accessible sealed

compartment. Current draw is approximately 35 mA with the backlight OFF.

Minimum battery voltage is 2.2 ±0.1 Vdc.

Battery Dependence: Meter readings vary by less than 3% from fully

charged batteries until the battery symbol appears, indicating the need for

recharge or replacement.

Battery Life: typically 200 hours with alkaline batteries (display indicates

low-battery condition). Instrument will operate for approximately 24 hours

after the battery symbol first appears.

Size: 16.5 x 8.9 x 21.6 cm (6.5 x 3.5 x 8.5 in.) (H x W x D)

Weight: 1.6 kg (3.5 lb), including batteries.

Removable Switchboard Adjustable Parameters:

Backlight ON Time

: 5, 15, 30, 60, 90, 120, 180, or 240 seconds for the

backlight to stay on when activated by the pushbutton; factory set at 5.

Set Minimum Display: allows lower limit of the auto-ranging display to be

fixed. For example, the display can be set to only show values above or

equal to 1 µR/hr.

Ludlum Measurements, Inc. Page 3-2 January 2016

Model 2241-3 & 3i Technical Manual Section 3

RS-232 Data Dump Mode: enables or disables dump mode to the RS-232

port (˝D˝ type connector). When enabled, the data will be dumped every

two seconds.

RS-232 Detector Setup Mode: allows for input of detector parameters via

the RS-232 port

Baud Rate: selects either 150, 300, 600, 1200, 2400, 4800, 9600, or 19200

bps

Detector Dead Time Compensation (DTC): adjustable from 0 to 9999

microseconds

Calibration Constant: adjustable from 0.001 to 280 × 10

9

counts/display

unit

Display Units: can display in R/hr, Sv/h, cpm, or cps

Time Base: can display in seconds or minutes

Audio Divide: 1, 10, 100, or 1000 events per click

Response Time: variable or fixed ratemeter response (All stated times

correspond to a range of 10% to 90% of the final reading). Factory default

is variable so that the instrument will automatically adjust the response time

to the best setting for the current count rate.

Variable Response: dependent on the number of counts

present, typically 4 to 25 seconds for FAST, and 4 to 60 seconds

for SLOW

Fixed Response: The parameter is adjustable from 1-25

seconds resulting in a FAST response from approximately 2-50

seconds. The SLOW response is approximately 10-250 seconds.

For MDA-type measurements, the fixed response mode is

recommended.

Ratemeter Alert/Alarm: set at any point corresponding to the pre-selected

ratemeter range

Scaler Alarm: adjustable from 1 to 999999 counts

Scaler Count Time: adjustable from 1 to 9999 seconds

Ludlum Measurements, Inc. Page 3-3 January 2016

Model 2241-3 & 3i Technical Manual Section 3

Internal Detector Specifications for Model 2241-3i:

Operating Voltage

Input Sensitivity: -30 mV ±10 mV

Dead Time: typically 80 microseconds

Energy Reponse: within ±15%

Tube: 30 mg/cm

Size: 2.3 x 10.2 (0.9 x 4 in.) (Dia x L)

Temperature Range: -20 to 50 °C (-4 to 122 °F)

: recommended 550 volts

2

stainless steel (Halogen quench) GM

Ludlum Measurements, Inc. Page 3-4 January 2016

Model 2241-3 & 3i Technical Manual Section 4

Section

Identification of Controls and

4

Functions

Display

The Model 2241-3 utilizes a four-digit liquid crystal display (LCD) with a

two-digit overflow (SCALER mode) and moving decimal point. The two

smaller digits located in the lower right corner of the display indicate

counter OVERFLOW when in the scaler counting mode (equivalent to a

six-digit scaler) or exponential power when in the parameter setup

mode. The upper right corner of the LCD displays units and

multiplier(s) - R/hr, mR/hr, or µR/hr; Sv/h, mSv/h or µSv/h; C/m,

kC/m, C/s or kC/s. The bottom part of the readout displays the

ALARM, ALERT, OFLOW, OVERLOAD (not used) enunciators and the

low-battery icon. COUNTING indicates that the scaler mode has been initiated

and is in the counting process.

Display Status Definitions

ALARM: Ratemeter or scaler count has increased above the preset alarm

threshold. An audible continuous tone will accompany the latching ALARM

condition. Depressing RESET will acknowledge the audible ratemeter and/or

scaler alarm. Depressing RESET a second time will reset the ratemeter

reading and ratemeter alarm. To reset the scaler ALARM, depress the COUNT

switch located in the carrying handle to re-initiate the scaler count cycle.

ALERT: Ratemeter count has increased above the preset alert threshold. To

reset an ALERT condition, press RESET once if in the non-alarm condition

and twice if in an alarm condition. (The first depression in the alarm

condition acknowledges the audible alarm.) The ratemeter will reset to the

minimum displayable reading each time the alert is reset.

OFLOW (Overflow) [RATEMETER mode]: Indicates that the incoming count

exceeds the capability to display stable or reliable readings corresponding to

the radiation level being measured. The overflow symbol will appear when

the ratemeter exceeds 100 kcps or if the dead time correction is greater than

OFLOW will appear in the SCALER mode when the six-digit display

75%.

(four digits display and two overflow digits in right corner) reaches

“999999” and starts to roll over again.

Ludlum Measurements, Inc. Page 4-1 January 2016

Model 2241-3 & 3i Technical Manual Section 4

Low Battery icon: indicates that the batteries have decreased to the

minimum operating voltage of 2.2 ±0.1 Vdc. Instrument will continue to

operate for approximately 24 hours thereafter.

COUNTING: indicates that the scaler COUNT switch has been depressed and

that the scaler is accumulating counts for the pre-determined count time

Front Panel Controls

OFF/DET 1/DET 2/DET 3/DET 4 Switch: a five-position rotary switch that

applies power to the instrument and selects the desired set of detector

parameters

SCA/RATE (Mode) Switch: a protected (locking) toggle switch that toggles

between ratemeter or scaler counting modes. The user pulls up and then

over to change modes.

AUD ON/OFF Switch: The click-per-event audio may be silenced or enabled

via this front-panel toggle switch. The audible alarm is independent of the

AUD ON

audible alarm can only be silenced by depressing the RESET button.

/OFF switch and will override the audible click-per-event. An

F/S (Fast/Slow) Response Switch: a two-position toggle switch that selects

fast or slow counting response time

Variable Response: The F position allows the time constant (TC) to vary

from 1 to 10 seconds, while the S position varies from 1 to 30 seconds. The

response time is automatically adjusted in proportion to the incoming count

rate between the

Fixed Response: The F position corresponds to the selected fixed response

F/S TC variables.

time - TC. The S position is five times slower than the selected fast TC.

LIGHT (LCD Backlight): A pushbutton switch, when depressed, illuminates

the LCD for a pre-programmed time. The backlight ON time can be selected

between 5 and 240 seconds during the parameter setup.

Ludlum Measurements, Inc. Page 4-2 January 2016

Model 2241-3 & 3i Technical Manual Section 4

RESET Pushbutton: In the non-alarm condition, depressing the RESET

switch resets the ratemeter display to the minimum display readout. In an

alarm condition (ratemeter or scaler), depressing

audible alarm. Depressing RESET a second time will reset the ratemeter

alarm and/or alert condition. The scaler alarm can only be reset by

depressing the scaler count switch located in the end of the Model 2241-3

handle.

Note:

The RESET button only silences the alarm in the current mode

that the instrument is in. For example, the RESET button will

not affect the scaler alarm if the instrument is in the

ratemeter mode.

RESET will silence the

Scaler Count Switch: pushbutton switch located in the end of the Model

2241-3 carrying handle, which when depressed, initializes the start of the

scaler count accumulation for the preset scaling time. The SCA/RATE switch

must be in the SCA position to initiate the counting cycle. The scaler display

uses the two digits in the lower right-hand corner for the two most

significant digits of the six-digit readout. Scaling time can be set from 1 to

9999 seconds in the parameter setup by way of the switch board. Depressing

the Count switch after a scaler alarm will reset the scaler display to 0,

resetting the alarm condition.

F ront P anel Calibration Controls

Note:

Remove the front-panel calibration cover to expose the

following calibration controls:

DISC (Discriminator): a multi-turn potentiometer (approximately 20

revolutions) used to vary the detector pulse-counting threshold from 2 to

100 millivolts. A Ludlum Model 500 Pulser or equivalent should be used in

checking or adjusting the pulse discrimination parameter.

Ludlum Measurements, Inc. Page 4-3 January 2016

Model 2241-3 & 3i Technical Manual Section 4

Note:

When making adjustments to the HV potentiometers, make

note of the following precautions: Use a Ludlum Model 500

Pulser or high-impedance voltmeter with a high-voltage probe

to measure the high voltage at the detector connector. If a

Ludlum Model 500 Pulser is not available, ensure that the

impedance of voltmeter used is 1000 megohms or greater.

HV1, HV2, HV3, HV4: multi-turn potentiometers (approximately 20

revolutions) that vary the detector voltage from 400 to 2500 volts. The

maximum high-voltage output is adjusted by the HV LIMIT potentiometer

located on the internal main board.

Main Board Controls

Note:

To access the internal circuit boards, unlatch the latches at

each end of the Model 2241-3. Carefully separate the top

chassis from the bottom cover (referred to as a can). The can

has the audio speaker (unimorph) with a two-conductor cable

attached to the main board. The audio plug may be

disconnected during the internal control adjustments.

HV LIMIT (R027): A multi-turn potentiometer (approximately 20

revolutions) sets the maximum HV limit with the front-panel

adjusted to the maximum clockwise position. It is adjustable from 1250 to

2500 Vdc.

VOLUME (R002): A multi-turn potentiometer (approximately 20

revolutions) varies the audible click-per-event and alarm audio. Adjust the

control to the maximum clockwise position for maximum volume. If the

VOLUME control is adjusted to the maximum counterclockwise position, the

clicks-per-event, or the audible alarm(s), will not be audible when active.

HV control

Ludlum Measurements, Inc. Page 4-4 January 2016

Model 2241-3 & 3i Technical Manual Section 4

Switch Board Controls

The switch board utilizes a 16-position rotary switch (FUNCTION) to select

the 16 setup parameters. (Refer to schematics and component layout

drawing near the end of the manual.) All of the setup parameters are stored

in the non-volatile EEPROM, which will retain data even after the Model

2241-3 batteries are removed. After the parameters are entered, the switch

board can be removed and the Model 2241-3 will continue to operate from

the previously programmed information. Changing parameters and

information on switchboard controls are covered in detail in Section 8 of

this manual.

Ludlum Measurements, Inc. Page 4-5 January 2016

Model 2241-3 & 3i Technical Manual Section 5

Section

5

Safety Considerations

Environmental Conditions for Normal Use

Indoor or outdoor use

No maximum altitude

Temperature range of –20 to 50 °C (-4 to 122 °F)

Maximum relative humidity of less then 95% (non-condensing)

Pollution Degree 3 (as defined by IEC 664). (Occurs when conductive

pollution or dry nonconductive pollution becomes conductive due to

condensation. This is typical of industrial or construction sites.)

Detector Connector

Caution!

The detector operating voltage (HV) is supplied to the detector

by way of the input connector. A mild electric shock may

occur if contact is made with the center pin of the input

connector. Switch the Model 2241-3 to the OFF position

before connecting or disconnecting the cable or detector.

Warning Markings and Symbols

Ludlum Measurements, Inc. Page 5-1 January 2016

Caution!

The operator or responsible body is cautioned that the

protection provided by the equipment may be impaired if the

equipment is used in a manner not specified by Ludlum

Measurements, Inc.

Model 2241-3 & 3i Technical Manual Section 5

Caution!

Verify instrument voltage input rating before connecting to a

power converter. If the wrong power converter is used, the

instrument and/or power converter could be damaged.

The Model 2241-3 Survey Meter is marked with the following

symbols:

CAUTION, RISK OF ELECTRIC SHOCK (per ISO 3864, No. B.3.6):

designates a terminal (connector) that allows connection to a voltage

exceeding 1 kV. Contact with the subject connector while the instrument is

on or shortly after turning off may result in electric shock. This symbol

appears on the front panel.

CAUTION (per ISO 3864, No. B.3.1): designates hazardous live voltage

and risk of electric shock. During normal use, internal components are

hazardous live. This instrument must be isolated or disconnected from the

hazardous live voltage before accessing the internal components. This

symbol appears on the front panel.

Warning!

The operator is strongly cautioned to take the following

precautions to avoid contact with internal hazardous live parts

that are accessible using a tool:

1. Turn the instrument power OFF and remove the batteries.

2. Allow the instrument to sit for one minute before accessing

any internal components.

The “crossed-out wheelie bin” symbol notifies the consumer that the

product is not to be mixed with unsorted municipal waste when discarding.

Each material must be separated. The symbol is placed on the battery

compartment. See Section 9, “Recycling,” for further information.

The “CE” mark is used to identify this instrument as being acceptable

for use within the European Union.

Ludlum Measurements, Inc. Page 5-2 January 2016

Model 2241-3 & 3i Technical Manual Section 6

Section

6

Maintenance

Instrument maintenance consists of keeping the instrument clean and

periodically checking the batteries and the calibration. The Model 2241-3

may be externally cleaned with a damp cloth (using only water as the wetting

agent). Do not immerse the instrument in any liquid. Observe the following

precautions when cleaning:

1. Turn the instrument OFF and remove the batteries.

2. Allow the instrument to sit for one minute before performing

any external cleaning or accessing internal components for

maintenance.

Operational Check

An instrument operational check should be performed prior to each use by

exposing the detector to the supplied check source, confirming the proper

reading on each scale. See Section 2, Subsection “Operational Check,” for

further details.

Recalibration

Recalibration should be accomplished after any maintenance or adjustment

of any kind has been performed on the instrument. Battery and cable

replacements (of same length) and exterior cleanings do not normally require

the instrument be recalibrated.

Ludlum Measurements, Inc. Page 6-1 January 2016

Note:

Ludlum Measurements, Inc. recommends recalibration at

intervals no greater than one year. Check the appropriate local

state and federal regulations to determine required recalibration

intervals.

Model 2241-3 & 3i Technical Manual Section 6

Ludlum Measurements offers a full-service repair and calibration

department. We not only repair and calibrate our own instruments, but most

other manufacturers’ instruments as well.

See Section 8 “Instrument Setup & Calibration,” for further details on

instrument calibration.

Batteries

The batteries should be removed and the battery contacts cleaned of any

corrosion at least every three months. If the instrument has been exposed to

a very dusty or corrosive atmosphere, more frequent battery servicing should

be used. Use a spanner wrench to unscrew the battery contact insulators,

exposing the internal contacts and battery springs. Removing the handle will

facilitate access to these contacts.

Note:

Never store the instrument over 30 days without removing the

batteries. Although this instrument will operate at very high

ambient temperatures, battery seal failure can occur at

temperatures as low as 38 °C (100°F).

Ludlum Measurements, Inc. Page 6-2 January 2016

Model 2241-3 & 3i Technical Manual Section 7

Section

7

Refer to the Main

Board schematic

for the following:

T echnical Principle of Operation

Detector Input/Amplifier

Negative-going detector pulses are coupled from the detector through C021

to amplifier U021. R024 and CR021 protect the input of U021 from

inadvertent shorts. Self-biased amplifier U021 provides gain in proportion to

R022, divided by R025. Transistor pins 4, 5, and 6 of U021, provide

amplification. Pins 10-15 of U021 are coupled as a constant current source

to pin 6 of U021. The output is self-biased to 2 Vbe (approximately 1.4

volts) at pin 7 of U021. This provides just enough bias current through pin 6

of U021 to conduct all of the current from the constant current source.

Positive pulses from pin 7 of U021 are coupled to the discriminator (U011)

through R031 and C012.

Discriminator

Positive pulses from amplifier U021 are coupled to pin 2 of U011

comparator. The discrimination level is set by the DISC control connected

to pin 3 of U011. As the positive pulses at pin 2 of U011 increase above

DISC reference at pin 3, pin 1 goes low, producing a low pulse. Pin 1 of

U011 is normally held high (+5 volts) by R014.

The low pulse from pin 1 of U021 is coupled to univibrator U001. U001

shapes and fixes the pulse width to approximately 10 µs. The univibrator is

configured in the non-retriggerable mode. Negative pulses from pin 9 of

U001 are coupled to the µP for counting.

Low V oltage Supply

Battery voltage is coupled to DC-DC converter U231. U231 and related

components provide +5 V to power the µP, op-amps, and logic circuitry.

R135 and R136 provide voltage division for low-battery detection. Pin 6 of

U231 provides a low signal when the battery voltage decreases to +2.2 ±0.1

Vdc. U121 provides the +2.5 Vdc reference for the HV and DISC control

references.

Ludlum Measurements, Inc. Page 7-1 January 2016

Model 2241-3 & 3i Technical Manual Section 7

High V oltage Supply

High voltage is developed by blocking oscillator Q241, T141, and C244 and

rectified by voltage multiplier CR041-CR043, C041-C043, and C141. High

voltage increases as current through R241 increases, with maximum output

voltage with Q241 saturated.

High voltage is coupled back through R034 to op-amp pin 2 of U131.

Resistor network R027, R132 completes the HV division circuit to ground.

R027 provides HV limit from 1250-2400 when the HV control on the

calibration board is at maximum. The regulated HV output is controlled by

the HV1 and HV2 potentiometers located under the CAL cover on the

front panel. This control provides the reference for comparator pin 3, U131.

During stable operation, the voltage at pin 2 of U131 will equal the voltage

at pin 3 of U131. Pin 1 of U131 will cause conduction of Q141 to increase

or decrease until the HV finds a level of stability.

Microprocessor (µP)

U111 controls all of the data, control inputs, and display information. The

clock frequency is crystal-controlled by Y221 and related components at

6.144 MHz. The µP incorporates internal memory (ROM), storing the

program information. U1 resets the µP at power-up to initiate the start of

the program routine. During the program loop, the µP looks at all the input

switches for initiation or status changes and responds accordingly.

U122 is a 256 x 8 bit EEPROM used to store the setup parameters. The

information is transferred serially from the µP. The EEPROM is

non-volatile, meaning it retains memory even after power is removed.

Audio

Click-per-event, divide-by, and alarm audio pulse frequency is generated by

the µP and coupled to Q101. Q101 then inverts the pulses and drives the

bottom of T101. Bias voltage is provided by the volume control (R002) to

the top of T101.

Refer to the Switch

Board schematic for

the following:

Ludlum Measurements, Inc. Page 7-2 January 2016

S1 (FUNCTION)

S1 is a 16-position binary rotary switch, which selects the programmable

parameters for the Model 2241-3. The switch selects the parameters using

the hexadecimal numbering system via buss lines SW1-SW4.

Model 2241-3 & 3i Technical Manual Section 7

S2-S4

S2-S4 are pushbutton switches which enter/change the variables for each of

the 16 parameters.

U1

U1 is a +5 V powered RS-232 driver/receiver used to interface the Model

2241-3 to a computer.

Refer to Display

Board schematic

for the following:

LCD Driv e

U111 and U211 are serial input 32-bit LCD drivers. The data is loaded

serially into the 32-bit shift registers (internal) via the “D” IN input. The

LOAD input instructs the shift register to receive data while the CLOCK input

shifts the data through the 32-bit registers. After all the data is loaded, the

LOAD line is pulsed by the µP, instructing the registers to transfer the data to

the LCD drivers. The backplane (BP) signal from U211 provides the

reference signal (approximately 125 Hz at 5 Vdc) to the LCD (DSP1) BP

connection. When a segment is illuminated, the signal to that segment will

be out-of-phase with the BP signal. If the segment is OFF, the signal will be

in-phase with the BP signal.

Backlight Driv e

Depressing the LIGHT button instructs the µP to set the BACKLIGHT line, pin

31 on µP, "low" for the predetermined backlight ON time. (Refer to main

board schematic for details.) A "low" condition on pin 31 causes Q212 to

conduct sending +3 V to P8-3 on the display board with +3 V at P8-3

(refer to display board schematic). Backlight oscillator Q011, T011, and

related components start to oscillate, producing a 2.5 kHz, sine wave signal.

The signal is amplified by T011 to 150 volts peak-to-peak to drive the LCD

backlight.

Ludlum Measurements, Inc. Page 7-3 January 2016

Model 2241-3 & 3i Technical Manual Section 8

Section

8

Instrument Setup & Calibration

Entering or Changing Switch Board

Parameters

On the switch board, select the desired parameter to enter or change by

using the corresponding FUNCTION switch position. Depress the ENTER

button, and a character on the LCD will start to flash. The flashing character

indicates that the program is in the parameter change mode.

To change the character, press the UP button until the desired variable is

reached. To shift to another character, increment the LEFT pushbutton until

the desired character is reached. The LEFT pushbutton switch enables the

operator to sequence through all the characters on the LCD associated with

a particular parameter.

Once the desired data is entered, depress the ENTER button. The LCD

characters should stop flashing and the new parameter data should display.

Note:

Loading Default Parameters

To load the default parameters for all detector setups, hold down the UP

pushbutton on the switch board while turning the instrument on until DEF is

displayed on the LCD. The table on the following page shows the default

values.

Ludlum Measurements, Inc. Page 8-1 January 2016

The DETECTOR SELECT switch allows the Model 2241-3 to

have four sets of operating parameters.

Model 2241-3 & 3i Technical Manual Section 8

Model 2241-3 Cpm uR/hr R/Hr mR/hr

Setup 01 Setup 02 Setup 03 Setup 04

Dead Time

Cal Const 100e-2 105e+8 108e+4 198e+6

Rate Alarm 50.0 kcpm 50 µR/hr 5 R/hr 5 mR/hr

Scaler Alarm 85000 85000 85000 85000

Count Time 12 s 12 s 12 s 12 s

Time Base Minutes Seconds Seconds Seconds

Units cpm R/hr R/hr R/hr

Audio Divide-By 1 1 1 1

Response 0 0 0 0

Check Source 0 0 0 0

Percent CS 0 0 0 0

Rate Alert 20.0 kcpm 20 µR/hr 2 R/hr 2 mR/hr

Minimum Display 0.00 cpm

Baud Rate 9600

LCD Time Off 5 s

Detector 0

0 µs0 µs0 µs 0 µs

00.0

µR/hr

00.0

µR/hr

00.0

µR/hr

The Function Switch

FUNCTION Switch: a 16-position rotary switch labeled “0-9” and “A-F.”

This switch selects a parameter setup mode for the Model 2241-3. If the

board is not installed, the normal operation mode (counting mode) is

selected. If the switch board is installed, the selector switch must be set to

the 0 position for normal instrument operation. The following may be

changed using the switch board, and are discussed in detail in this section:

Detector parameters

Durrent detector setup in use

RS-232 communication baud rate

RS-232 data dump mode

RS-232 detector parameters set/read mode

Function Switch P osition Descriptions and

Variables

POSITION 0: NORMAL OPERATION places the Model 2241-3 in the normal

(counting) operating mode. Unplugging the switch board from the Model

2241-3 main board defaults to the normal operating mode.

Ludlum Measurements, Inc. Page 8-2 January 2016

Model 2241-3 & 3i Technical Manual Section 8

POSITION 1: DEAD TIME (µs) allows changing the detector dead time

correction for the current detector setup. Setting this parameter to “0”

disables dead time correction. The dead time adjusts from 0 to 9999

microseconds (µs). The incoming counts are adjusted for dead time using

the following formula:

n =

1-m

cps x time base

CC =

m

rate

Where,

n = corrected counts per second

m = incoming count per second

= system dead time

POSITION 2: calibration constant allows changing the calibration constant

for the current detector setup. The calibration constant (CC) adjusts from

0.001 to 280 × 109. The calibration constant converts counts/time base to

units/time base. The CC must be set to 1 to readout in cps (counts per

second) or cpm (counts per minute).

CC CONVERSION TABLE

Conversion Rate Multiply by to get CC

cps/µR/hr 3.6 x 109

cps/mR/hr 3.6 x 106

cps/R/hr 3.6 x 103

cpm/µR/hr 6.0 x 107

4

cpm/mR/hr 6.0 x 10

cpm/R/hr 6.0 x 101

cps/µSv/h 3.6 x 107

cps/mSv/h 3.6 x 104

cps/Sv/h 3.6 x 101

cpm/µSv/h 6.0 x 105

cpm/mSv/h 6.0 x 102

cpm/Sv/h 0.6

Ludlum Measurements, Inc. Page 8-3 January 2016

Example:

The Model 44-9 GM detector produces approximately 3300

cpm/mR/hr for

137

Cs: 6.0 x 104 x 3300 = 198 x 106 for

CC.

Model 2241-3 & 3i Technical Manual Section 8

POSITION 3: DISPLAY UNITS selects the display units for the associated

detector setup number. The Model 2241-3 and detector may be calibrated in

either exposure rate (R/hr or Sv/h) by entering the appropriate Calibration

Constant (position 2) and Dead Time correction (position 1). The Model

2241-3 will automatically convert to the correct reading when switching

between R and Sv.

The time base for count “C” is set independently in position 4.

The display units may be set to:

R/hr (Roentgens per hour)

Sv/h (Sieverts per hour)

C/time base (Counts per time)

The display is auto-ranging with the appropriate multiplier

symbol appearing in front of the “R,” “Sv,” or “C,” indicating

the range:

µR/hr, mR/hr, R/hr

µSv/h, mSv/h, Sv/h

C/s, kC/s, C/m, kC/m

POSITION 4: (TIME BASE) CPS or CPM selects the display time base for the

current detector setup. This time base only applies if the units are set to C/

(Counts/time). The time base for R/hr and Sv/h is fixed in “hr.” For

“true” reading (pulser calibration) cpm or cps calibrations, set the

Calibration Constant (CC, parameter 2) to read “1.” For geometry

calibrations, the detector efficiency can be entered for CC.

Example:

For alpha scintillation detector with 25% 2π efficiency; enter

“250 10-3” in the CC parameter setup.)

The display time base may be set to:

seconds (s)

minutes (m)

Ludlum Measurements, Inc. Page 8-4 January 2016

Model 2241-3 & 3i Technical Manual Section 8

POSITION 5: AUDIO DIVIDE-BY selects the audible click-per-event division

rate for the current detector setup. If the AUD ON/OFF switch is in the OFF

position, no audible click-per-event will be heard.

This parameter ranges from:

0 = Divide By 1

1 = Divide By 10

2 = Divide By 100

3 = Divide By 1000

POSITION 6: RESPONSE TIME allows changing the time constant (TC) for

the current detector setup. If the response is set to 0, the Model 2241-3

automatically calculates (for variable mode) the time constant based on the

incoming cps. If a variable of 1-199 is entered for TC, the response time

becomes fixed.

Variable Response - Response time is varied in proportion to

the incoming count rate. The two-position F/S (Fast/Slow)

toggle switch selects the maximum time constant (TC) for the

variable mode. The fast position varies the TC from 4-25

seconds, and the slow position varies from 4-60 seconds.

Fixed Response - The Fast (F) response position is

programmable from 2-50 seconds, and the slow response is 5

times slower than the fast TC. For MDA-type measurements,

the fixed response time mode is recommended.

POSITION 7: RATEMETER ALARM/ALERT allows changing the ratemeter

alarm for the current detector setup. The units of this alarm are the same as

the units for the ratemeter display. The fifth push of the left button allows

the decimal point to be moved. The ratemeter alarm adjusts from 1 to 999

R/hr (or Sv/h) or 1 to 999 kcpm or 1 to 100 kcps. The units of the alarm

are determined by the units for the ratemeter.

POSITION 8: SCALER ALARM/COUNT TIME sets the scaler alarm variable

from 1-999999, corresponding to the accumulated scaler count. After the

scaler alarm variable is entered, the scaler count time is prompted. The scaler

count time is adjustable from 1-9999 seconds.

POSITION 9: NOT USED

Ludlum Measurements, Inc. Page 8-5 January 2016

Model 2241-3 & 3i Technical Manual Section 8

POSITION A: NOT USED

POSITION B

backlight will stay on after pressing the front panel switch labeled LIGHT.

This value is stored in EEPROM.

POSITION C: SET MINIMUM DISPLAY sets the ratemeter minimum

displayable reading. Depressing the RESET button displays the minimum

ratemeter units. The readout will auto-range up to the maximum displayable

but will display 0 for ratemeter readings below the user-programmed

minimum variable.

: LCD Backlight ON TIME is the amount of time that the LCD

Available values are:

5 seconds

30 seconds

60, 90 seconds

180, 240 seconds.

Minimum displayable values are:

00.0 µ, 000 µ, 0.00 m, 00.0 m, 000 m, 0.00, 00.0, 000 R/hr

.000 µ, 000 µ, 00.0 m, 000 m, 0.00, 00.0, 000 Sv/h

0.00, 00.0, 000, 0.00 k, 00.0 k, 000 kcpm, or cps

POSITION D: RS-232 DATA DUMP MODE allows the RS-232 port to dump

ratemeter data every two seconds. The Model 2241-3 is fully functional

during RS-232 data dump with the exception of the audio function. The

LCD will alternate between display of the ratemeter and the word “dUP”

(representing "dump").

POSITION E: RS-232 DETECTOR PARAMETERS SETUP MODE allows the RS-

232 port to accept/send a string of parameters corresponding to the current

detector setup values.

POSITION F: BAUD RATE configures the RS-232 port for the following baud:

150, 300, 600, 1200, 2400, 4800, 9600, and 19200. The data is eight data bits,

one stop bit with no parity bit. This value is stored in EEPROM. The baud

rate can only be programmed through the switch board.

Ludlum Measurements, Inc. Page 8-6 January 2016

Model 2241-3 & 3i Technical Manual Section 8

RS-232 PORT CONNECTOR: This nine-pin “D” type connector is designed

as a DCE port. A straight wire cable (extension cable) connects the Model

2241-3 to a computer’s nine-pin RS-232 port.

RS-232 CONNECTOR PIN OUT:

PIN FUNCTION

1 NC (No Connection)

2 DATA OUT

3 DATA IN

4 NC

5 NC

6 NC

7 HANDSHAKING IN

8 HANDSHAKING OUT

9 NC

Note:

Ludlum Measurements, Inc. offers a PC compatible software

program, which incorporates the read/write commands

necessary to communicate between the PC and the Model

2241-3. The program also incorporates an algorithm to

calculate the detector Calibration Constant and Dead Time

Constant. The software is offered in a DOS version (part

number 1370-025) or a WINDOWS version (part number

1370-024). Read the Software License Agreement at the end of

this section before installing any LMI software.

Calibration

The Model 2241-3 calibration routine consists of entering detector

parameters into memory by way of the switch board and adjusting the CAL

controls (HV and DISC) for the specific detector operating requirements.

The first subsection of calibration will give a general overview of detector

setup, including the determination of various detector operating voltages

(HV) and the adjustment of counter input sensitivity (DISC).

The next subsection deals with pulse generator counts-per-minute

calibration. The counts-per minute-parameter setup is used in the initial

Ludlum Measurements, Inc. Page 8-7 January 2016

Model 2241-3 & 3i Technical Manual Section 8

instrument checkout procedure and the variables are saved under detector

setup number “1” when shipped from Ludlum Measurements, Inc.

The following subsection deals with exposure rate calibration. The detector

Calibration Constant (CC) and Dead Time Correction (DTC) are the two

primary parameters used in the exposure rate calibrations (R/hr and Sv/h).

These two constants are alternately varied to achieve linearity at the detector

non-linear operating regions. An example of the Ludlum Model 44-9 GM

detector calibration is given at the end of this section to illustrate the

algorithm used in determining the CC and DTC variables.

G

ENERAL DETECTOR SETUP INFORMATION

The operating point for the instrument and probes is established by setting

the probe voltage and instrument sensitivity (HV and DISC). The proper

selection of this point is the key to instrument performance. Efficiency,

background sensitivity, and noise are fixed by the physical makeup of the

given detector and rarely vary from unit to unit. However, the selection of

the operating point makes a marked difference in the apparent contribution

of these three sources of count.

In setting the operating point, the final result of the adjustment is to establish

the system gain so that the desirable signal pulses (including background

radiation) are above the discrimination level and the unwanted pulses from

noise are below the discrimination level and are therefore not counted.

The total system gain can be controlled by adjusting either the instrument

sensitivity or the high voltage.

HV controls the gain of the detector; and DISC

(Discriminator) controls the instrument counting threshold (sensitivity).

In the special case of GM detectors, a minimum voltage must be applied to

establish the Geiger-Mueller characteristic. Further changes in

HV will have

little effect on this type of detector.

GM Detectors: The output pulse height of the GM detector is not

proportional to the energy of the detected radiation. Adjusting DISC will

have minimal effect on observed count rate unless the DISC setting is so low

that the instrument will double-pulse.

Ludlum Measurements, Inc. Page 8-8 January 2016

Model 2241-3 & 3i Technical Manual Section 8

For most GM detectors, set DISC for 30-40 millivolts and adjust HV to the

GM detector recommended high voltage. Most GM detectors operate at

900 volts, although some miniature detectors operate at 450-550 volts. If a

recommended setting is unavailable, plot count rate versus HV to produce a

plateau graph. Adjust the HV for 25-50 volts above the knee or start of the

plateau. For mixed detector use, both sensitivity and high voltage may be

tailored for other detectors as long as the GM detector is operated within

the recommended voltage range. Caution must be observed in lowering the

input sensitivity to ensure that the counter does not double or multi-pulse.

Alpha Air-Proportional Detectors: For air proportional alpha detectors, set

the DISC for 2 millivolt discrimination. Adjust HV until the detector just

breaks down (shown by a rapid increase of count rate without a source

present). Measure the HV output, then decrease the

100 volts below breakdown.

Proportional Detectors: For proportional detectors, set the DISC control for

2-millivolt discrimination (near maximum clockwise). Expose the detector

to a check source and plot count rate versus HV, similar to the one in the

figure below. Refine the HV adjustment for optimum source efficiency with

a minimum acceptable background count.

HV setting to operate

Scintillators: Set the DISC for 10 millivolts. Plot background and

source counts versus HV to produce a plateau graph similar to the

one in the figure. Adjust the HV to 25-50 volts above the knee or

start of the plateau. This provides the most stable operating point

for the detector.

COUNTS PER MINUTE (C/M) CALIBRATION

This procedure will set up the Model 2241-3 for the Counts/minute (C/m)

mode of operation. Refer to Section 8, (Page 8-2 and following) for more

information on setup parameter variables.

A Ludlum Model 500 Pulser or equivalent is required. If the pulser does not

have a high-voltage display, use a high-impedance voltmeter with at least

1000 megohms input resistance to measure the detector high voltage.

Ludlum Measurements, Inc. Page 8-9 January 2016

Model 2241-3 & 3i Technical Manual Section 8

Switch the SCA/RATE switch to the RATE position. Select

position DET1 on the detector selector switch located on the

front panel.

Select FUNCTION switch positions 1-6 and adjust for the

following parameters:

Switch Pos. Parameter Function

1 0000 s-6 Dead Time

2 0100 -2 Calibration Constant

3 c/ Display Units

4 m Timebase

5 1 Audio Divide-by

6 000 s Response Time

Position 7 selects the desired ratemeter

ALERT and ALARM trip points.

If the parameters are undetermined, arbitrarily choose “0050

kC/m” for the alarm and “0045 kC/m” for the alert to confirm

operation of the alert/alarm function.

Position 8 selects the scaler alarm parameter and the scaler count time.

If the values are unknown, set the scaler alarm to “4500

ALARM00

”

and the count time to “0060” (60 second count time).

Position 9 is not used, and position A is not used.

Switch to position B and enter “15” for a 15-second backlight

ON time.

Switch to position C and enter “00.0 C/m” for the minimum

displayable value.

Select position 0 to return to normal operation.

Connect the Model 500 Pulser to detector input and adjust HV and DISC to

the specific detector operating parameters.

Ludlum Measurements, Inc. Page 8-10 January 2016

Model 2241-3 & 3i Technical Manual Section 8

Adjust the pulser amplitude to 1.5 times the Model 2241-3

discrimination level.

Adjust the pulser output to 800 cpm and confirm that the Model

2241-3 reads 800 cpm ±10% on the ratemeter setting.

Adjust the pulser output to 200 cpm and confirm that the Model

2241-3 reads 200 cpm ±10% on the ratemeter setting.

Adjust the pulser output to 800 cpm, take a one minute count and

confirm that the digital scaler readout displays 800 cpm ±2%.

Adjust the pulser output to 200 cpm, take a one minute count and

confirm that the digital scaler readout displays 200 cpm ±2%.

Confirm that the 20% and 80% readings for the upper decades are

within the pulser input by decading the pulser count output.

Confirm that the scaler readout is within 2% of the pulser input rate.

Ensure that the ALERT and ALARMs function by inputting the preset

alarm levels as to initiate the alert and alarm conditions.

R/hr CALIBRATION

The following calibration procedure assumes that detector Calibration

Constant (CC) and Dead Time Constant (DTC) are already known. If these

constants must be determined, reference the following subsection,

“Determining CC and DTC.”

Switch the toggle switch to

DET2. Detector setup number “1” is usually

reserved for the Counts/minute parameter calibration. Rotate the

FUNCTION switch counterclockwise to position 1 and enter the detector

Dead Time in µs. Rotate to position 2 and enter the Calibration Constant.

Enter the desired parameters for positions 3-F. Switch to position 0 for

normal operation.

Expose the detector to calibrated radiation fields extending from the lower

to the upper operating range of the detector. Confirm that the linearity is

within 10% of each respective reading. If the readings are off on the lower

detector operating region, vary CC. If the readings are off at the upper end

of the detector operating region, adjust DTC.

Ludlum Measurements, Inc. Page 8-11 January 2016

Model 2241-3 & 3i Technical Manual Section 8

DETERMINING CC AND DTC

This procedure contains the algorithm (hi-lo method) for determining the CC

(Calibration Constant) and the DTC (Dead Time Correction). An example

of the Ludlum Model 44-9 GM detector calibration is used in conjunction

with the algorithm calculations to aid in solving the equations.

Note:

Ludlum Measurements, Inc. offers a PC-compatible software

program, which incorporates the read/write commands

necessary to communicate between a PC and the

Model 2241-3. The program also incorporates the algorithm to

calculate the detector CC and DTC. The software is offered in

a DOS version (part number 1370-025) or a WINDOWS

version (part number 1370-024). Read the Software License

Agreement at the close of this section prior to installing any

LMI software.

Hi-Lo Method

: The hi-lo method refers to the placement of the detector in a

radiation field using a two-point (CC and DT) calibration to make linear the

detector response, even in the non-linear operating regions of the detector.

The low-radiation field (CC) should be a field that yields from 2 to 5 %

count loss. The high radiation field (DT) should be a field that yields from

30 to 60 % count loss. The algorithm ignores background counts, and

therefore, the low field must be at least ten times the background count.

The following summary lists the calibration constraints.

Calibration and Dead Time Calibration Constraints

FIELD CONSTRAINT

BACKGROUND *10 times less than low field

LOW FIELD Yields from 2 to 5 % count loss

HIGH FIELD Yields from 30 to 60 % count loss

* This constraint only applies when using two sources (two fields) or a

radiation range calibrated without background consideration.

Ludlum Measurements, Inc. Page 8-12 January 2016

Model 2241-3 & 3i Technical Manual Section 8

T

Preliminary CPS Setup

Refer to Section 8, Subsection “Function Switch Position Descriptions and

Variables,” for cps readout variables.

Equation 1

LO

LO

2%

5%

CPS

Equation 2

CPS

Select position

DET1 on the detector selector switch located on the front

panel. Starting with FUNCTION switch position 1, enter the following

variables:

SWITCH POS. PARAMETER FUNCTION

1 0000s-6 Dead Time

2 0100 -2 Calibration Constant

3 C/ Display Units

4 m Timebase

5 N/A Audio Divide-By

6 N/A Response Time

7 N/A Ratemeter Alm./Alert

8 0060 s ScalerAlm./Count Time

9 Not Used

1

=

DT x 49

A Not Used

B N/A LCD Backlight

C 000 C/s Set Minimum Display

D-F N/A RS-232 Parameters

1

=

DT x 19

Equation 3

CPS

HI

30%

=

1

Equation 4

60%

=

1.5

D

CPS

HI

Ludlum Measurements, Inc. Page 8-13 January 2016

The equations to the left (Equations 1-4) determine the hi and lo radiation

fields used to acquire counts for the CC and DTC algorithm. These

calculations require an unknown variable, DT (Dead Time). Typical dead

DT x 2.3333

times for some of the standard LMI detectors are referenced in the table at

the end of this section. The lo count field should be a field that yields

between 2 and 5% count loss. The hi count field (CPS

that yields between 30 and 60% count loss.

HI

) should be a field

Model 2241-3 & 3i Technical Manual Section 8

Reference the table at the end of this section to determine the cps/exposure

rate (cps/ER). The conversion can be determined by placing the detector in

a radiation field, which produces from 50

cps

= cps/ER

to 200 cps. Calculate the count/exposure

rate using the equation to the left.

radiation field in exposure rate units

For example, exposing an LMI Model 44-

9 to a 2 mR/hr

137

Cs field yields approximately 110 cps so that:

cps 110

mR/hr 2

Abbreviations used:

cps/mR/hr 55 =

The typical dead time for a Model 44-9 is approximately 85 µs. Therefore,

using 85 µs for “DT” in equations 1-4, the lo field should be between 240

and 619 cps, and the hi field is between 5040-17,650 cps. Dividing the cps

values by the 55 cps/mR/hr conversion equates to between 4-11 mR/hr for

the lo field and 91-320 mR/hr for the hi field.

Select a calibrated field between the lo and hi data points determined above:

lo (CALlo) = 8 mR/hr

hi (CALhi) = 200 mR/hr

The following procedure outlines the hi-lo method

units = Sv, R, counts.

CALlo = lo field calibration point.

CALhi = hi field calibration point.

CORRlo = recorded field at low calibration point.

CORRhi = recorded field at high calibration point.

DT = dead time constant entered into Model 2241.

CC = calibration constant entered into Model 2241.

fd and ad are intermediate steps in calculating DT.

f

is an intermediate step in calculating CC.

cal

Ludlum Measurements, Inc. Page 8-14 January 2016

Model 2241-3 & 3i Technical Manual Section 8

e

s

60

m 60

h

CC and DTC Algorithm

Equations (5) and (6) convert units per time (R/hr Display Units) to units

per second:

units

tim

Equation 5

CAL

Equation 6

CAL

(0.008 =

lo

(0.200 =

hi

units

second

R

( x )

h

R

( )x

Insert the cps lo data point (8 mR/hr for the Model 44-9 example)

determined from equations (1) and (2):

h 1

m 60

m 1

( x )

s60

x 2.22 = )

10

6

s

Insert the cps hi data point (200 mR/hr for the Model 44-9 example)

determined from equations (3) and (4):

h 1

m 1

( )x

x 55.6 =)

10

6

s

Place the detector in the low field and enter the counts per second:

Equation 7

CORR

lo

SAMPL

=

=

counts

s

Note:

lo

time count

The low field count sample should be 3000 counts. Use the

scaler and adjust the count time to accumulate count 3000.

Ludlum Measurements, Inc. Page 8-15 January 2016

Model 2241-3 & 3i Technical Manual Section 8

As an example, assume a 60-second count sample in a low field of 8

mR/hr:

Example

CORR

Equation 8

CORR

Example

CORR

lo

hi

hi

26,427

=

SAMPL

=

5830

=

60

1

Place detector in the high field and enter the counts per second:

=

counts

hi

time count

Counts/second sample in high field of 200 mR/hr:

C/s 440 =

s

C/s 5830 =

Equation 9

=

f

Example

f

Equation 10

a

Example

a

CAL

d

d

( =

CAL

d

hi

x 55.6 =

10

x

CORR

x (55.6 =

10

Insert the values calculated in equations (5), (6), (7), and (8) and solve for fd:

x

CORR

CORR

6

-

CAL

lo

lohi

x 2.22 x 5830

10

units

=

s

6

440

Solve for ad:

( - )

CAL

x

CORR

x (2.22 - 5830) x

10

= )

hilohihid

x 26.2 =

10

R

6

s

count units

2

s

x 31.1 = 5830) x

10

RCount

266

2

s

Ludlum Measurements, Inc. Page 8-16 January 2016

Model 2241-3 & 3i Technical Manual Section 8

Enter the results of equations (9) and (10) into equation (11) to solve for

DT:

Equation 11

Example

f

d

= DT

= DT

=

a

d

x

102.26

x

101.31

s

count

6

2

seconds

5

x =

104.8

or 84 x 10

-6

sec

count

Equation 12

cal

cal

=

CAL

CORR

= CC

f

Example

f

Equation 13

Example

= CC

f

440

x 2.22 =

cal

10

x 2.14

lo

10

( -

CAL

=

6

Solve for f

x

CORR

x (2.22-

10

:

cal

units

x 84 x 440 x

= DT) x

10

lololo

s

R

6666

x 2.14 = )

10

s

Enter the result of equation (12) into:

count

units

and solve for CC:

counts

6

x 206 =

10

R

Enter the CC and DT values (positions 1 and 2 of the FUNCTION switch),

derived from the equations above. Perform an “R/hr calibration” as

described in the previous subsection in order to ensure that the instrument

and detector have been correctly calibrated.

Ludlum Measurements, Inc. Page 8-17 January 2016

Model 2241-3 & 3i Technical Manual Section 8

Model 44-9 Detector Parameter Setup

FUNCTION PARAMETER

1 0084 s-6

2 0206 06

4 N/A

5-8 as desired

B-C as desired

D-F if applicable

Typical Count Rate and Dead Time for LMI Detectors

DEAD TIME

MODEL & TYPE COUNT RATE in µs (microseconds)

44-6, GM 20 cps/mR/hr 90-110 µs

44-9, GM 55 cps/mR/hr 80-90 µs

44-7, GM 35 cps/mR/hr 240-290 µs

133-2, GM 17.5 cps/mR/hr 40-55 µs

133-4, GM 2 cps/mR/hr 40-55 µs

133-6, GM 0.3 cps/mR/hr 40-55 µs

44-2, Gamma Scint. 2800 cps/mR/hr 8-12 µs*

44-10, Gamma Scint. 15,000 cps/mR/hr 18-20 µs

44-3, Low-Energy Gamma Scint. N/A, operated in Counts/units mode 8-12 µs*

44-21, Beta/Gamma Scint. N/A, operated in Counts/units mode 8-12 µs*

43-5, Alpha Scint. N/A, operated in Counts/units mode 20-28 µs

*The dead time values for these scintillation detectors are due to the dead

time of the Model 2241-3 electronics.

Ludlum Measurements, Inc. Page 8-18 January 2016

Note:

The data represented in the table above is typical. Actual values

may vary among detector and instrument combinations. This

table represents some of the common detectors operated with

the Model 2241-3. Consult the LMI sales department for

information concerning detectors not listed in the table above.

Model 2241-3 & 3i Technical Manual Section 8

Ludlum Measurements, Inc. Page 8-19 January 2016

Model 2241-3 & 3i Technical Manual Section 8

Ludlum Measurements, Inc. Page 8-20 January 2016

Model 2241-3 & 3i Technical Manual Section 8

Ludlum Measurements, Inc. Page 8-21 January 2016

Model 2241-3 & 3i Technical Manual Section 9

Section

9

Recycling

udlum Measurements, Inc. supports the recycling of the electronic

products it produces for the purpose of protecting the environment

L

recycling systems. To this end, Ludlum Measurements, Inc. strives to supply

the consumer of its goods with information regarding reuse and recycling of

the many different types of materials used in its products. With many

different agencies – public and private – involved in this pursuit, it becomes

evident that a myriad of methods can be used in the process of recycling.

Therefore, Ludlum Measurements, Inc. does not suggest one particular

method over another, but simply desires to inform its consumers of the

range of recyclable materials present in its products, so that the user will

have flexibility in following all local and federal laws.

The following types of recyclable materials are present in Ludlum

Measurements, Inc. electronic products, and should be recycled separately.

The list is not all-inclusive, nor does it suggest that all materials are present in

each piece of equipment:

and to comply with all regional, national, and international agencies

that promote economically and environmentally sustainable

Batteries Glass Aluminum and Stainless Steel

Circuit Boards Plastics Liquid Crystal Display (LCD)

Ludlum Measurements, Inc. products, which have been placed on the

market after August 13, 2005, have been labeled with a symbol recognized

internationally as the “crossed-out wheelie bin.” This notifies the consumer

that the product is not to be mixed with unsorted municipal waste when

discarding. Each material must be separated. The symbol will be placed near

the AC receptacle, except for portable equipment where it will be placed on

the battery lid.

The symbol appears as such:

Ludlum Measurements, Inc. Page 9-1 January 2016

Model 2241-3 & 3i Technical Manual Section 10

0

Section

1

Parts List

Reference Description Part Number

Model 2241-3

Survey Meter

Main Circuit Board,

Drawing 408 × 285

CAPACITORS

UNIT Completely Assembled

Model 2241-3 Survey Meter 48-2864

BOARD Completely Assembled

Main Circuit Board 5408-285

C1 0.1µF, 50V 04-5663

C3 0.1µF, 50V 04-5663

C001-C002 47pF, 100V 04-5660

C011 0.001µF, 100V 04-5659

C012 0.1µF, 50V 04-5663

C021 100pF, 3KV 04-5532

C031 0.0047µF, 3KV 04-5547

C032 100pF, 3KV 04-5532

C033 0.0047µF, 3KV 04-5547

C041-C043 0.0047µF, 3KV 04-5547

C101 47uF, 10V 04-5666

C121 47uF, 10V 04-5666

C122-C123 27pF, 100V 04-5658

C131 0.0047µF, 3KV 04-5547

C132-C133 0.1µF, 50V 04-5663

C134 0.01µF, 50V 04-5664

C135 47µF, 10V 04-5666

C136 0.01µF, 50V 04-5664

C137 47µF, 10V 04-5666

C138 100pF, 100V 04-5661

C139 0.001µF, 100V 04-5659

C141 0.0047F, 3KV 04-5547

Ludlum Measurements, Inc. Page 10-1 January 2016

Model 2241-3 & 3i Technical Manual Section 10

Reference Description Part Number

C241 1µF, 35V 04-5656

C242 68µF, 10V 04-5654

C243 0.1µF, 50V 04-5663

C251 68µF, 10V 04-5654

TRANSISTORS

INTEGRATED

CIRCUITS

DIODES

POTENTIOMETERS /

TRIMMERS

RESISTORS

Q101 2N7002L 05-5840

Q141 MMBT3904LT1 05-5841

Q211 2N7002L 05-5840

Q212 MMBT4403LT1 05-5842

Q241 MJD210 RL 05-5843

U1 MAX810LEUR 06-6424

U001 CD74HC4538M 06-6297

U011 TLC372ID 06-6290

U021 CA3096M; 16=GND 06-6288

U111 N87C51FC 06-6303

U121 LM285MX-2.5 06-6291

U122 X24C02S8T5 06-6299

U131 LM358D 06-6312

U231 LT1073CS8-5 05-5852

CR021 MMBD7000LT1 07-6355

CR031 GI250-2 07-6266

CR041-CR044 GI250-2 07-6266

CR231 CXSH-4 EB33 07-6358

CR241 MMBD914LT1 07-6353

CR242 CXSH-4 EB33 07-6358

R002 10K; 3269X1-103, VOLUME 09-6921

R027 1M; 3269X1-105, HV LIMIT 09-6906

R001 100K, 1/4W, 1% 12-7834

R011-R012 10K, 1/4 W, 1% 12-7839

R013 1K, 1/4W, 1% 12-7832

R014 10K, 1/4W, 1% 12-7839

R015 100K, 1/4W, 1% 12-7834

R021 1M, 1/4W, 5% 10-7028

R022 392K, 1/8W, 1% 12-7841

R023 10K, 1/4W, 1% 12-7839

R024-R025 4.75K, 1/4W, 1% 12-7858

Ludlum Measurements, Inc. Page 10-2 January 2016

Model 2241-3 & 3i Technical Manual Section 10

Reference Description Part Number

R026 8.25K, 1/8W, 1% 12-7838

R031 4.75M, 1/4W, 5% 10-7030

R032 1M, 1/4W, 5% 10-7028

R033-R034 1G, FHV-1, 2% 12-7686

R111-R113 22.1K, 1/4W, 1% 12-7843

R121 100Ohm, 1/4W, 1% 12-7840

R122 6.81K, 1/4W, 1% 12-7857

R131 1M, 1/4W, 1% 12-7844

R132 511K, 1/8W, 1% 12-7896

R133 750K, 1/4W, 1% 12-7882

R134 1M, 1/4W, 1% 12-7844

R135 82.5K, 1/8W, 1% 12-7849

R136 10K, 1/4W, 1% 12-7839

R141 22.1K, 1/4W, 1% 12-7843

R211 2.21K, 1/4W, 1% 12-7835

R231 100Ohm, 1/4W, 1% 12-7840

R241 2.21K, 1/4W, 1% 12-7835

R242 200Ohm, 1/8W, 1% 12-7846

CRYSTALS

INDUCTOR

TRANSFORMERS

MISCELLANEOUS

Calibration Board,

Drawing 408 × 98

POTENTIOMETERS

Y221 6.144 MHZ, 2=GND, 3=GND 01-5262

L231 100uH, CTX100-2 21-9740

T101 4275-083, AUDIO 4275-083

T141 L8050 40-0902

P1-P2 1-640456-3, MTA100X13 13-8100

P3 640456-6, MTA100X6 13-8095

P4 640456-2, MTA100X2 13-8073