LUDLUM MODEL 19

MICRO R METER

February 2012

Serial Number 207422 and Succeeding

Serial Numbers

LUDLUM MODEL 19

MICRO R METER

February 2012

Serial Number 207422 and Succeeding

Serial Numbers

Table of Contents

Introduction 1

Getting Started 2

Unpacking and Repacking 2-1

Battery Installation 2-1

Operational Check 2-2

Maintenance 2-3

Recalibration 2-3

Batteries 2-3

Specifications 3

Identification of Contr ols and Functions 4

Safety Considerations 5

Environmental Conditions for Normal Use 5-1

Warning Markings and Symbols 5-1

Cleaning and Maintenance Precautions 5-2

Troubleshooting 6

Troubleshooting Electronics which utilize a Scintillation Detector 6-1

Technical Theory of Operat ion 7

Detector 7-1

Input 7-1

Amplifier 7-1

Discriminator 7-1

Audio 7-2

Scale Ranging 7-2

Digital Analog Converter 7-2

Meter Drive 7-2

Fast/Slow Time Constant 7-2

Low Voltage Supply 7-2

High Voltage Test 7-2

High Voltage Supply 7-3

Ludlum Measurements, Inc. February 2012

Model 19 MICRO R METER Technical Manual

Recycling 8

Parts List 9

Model 19 Micro R Meter 9-1

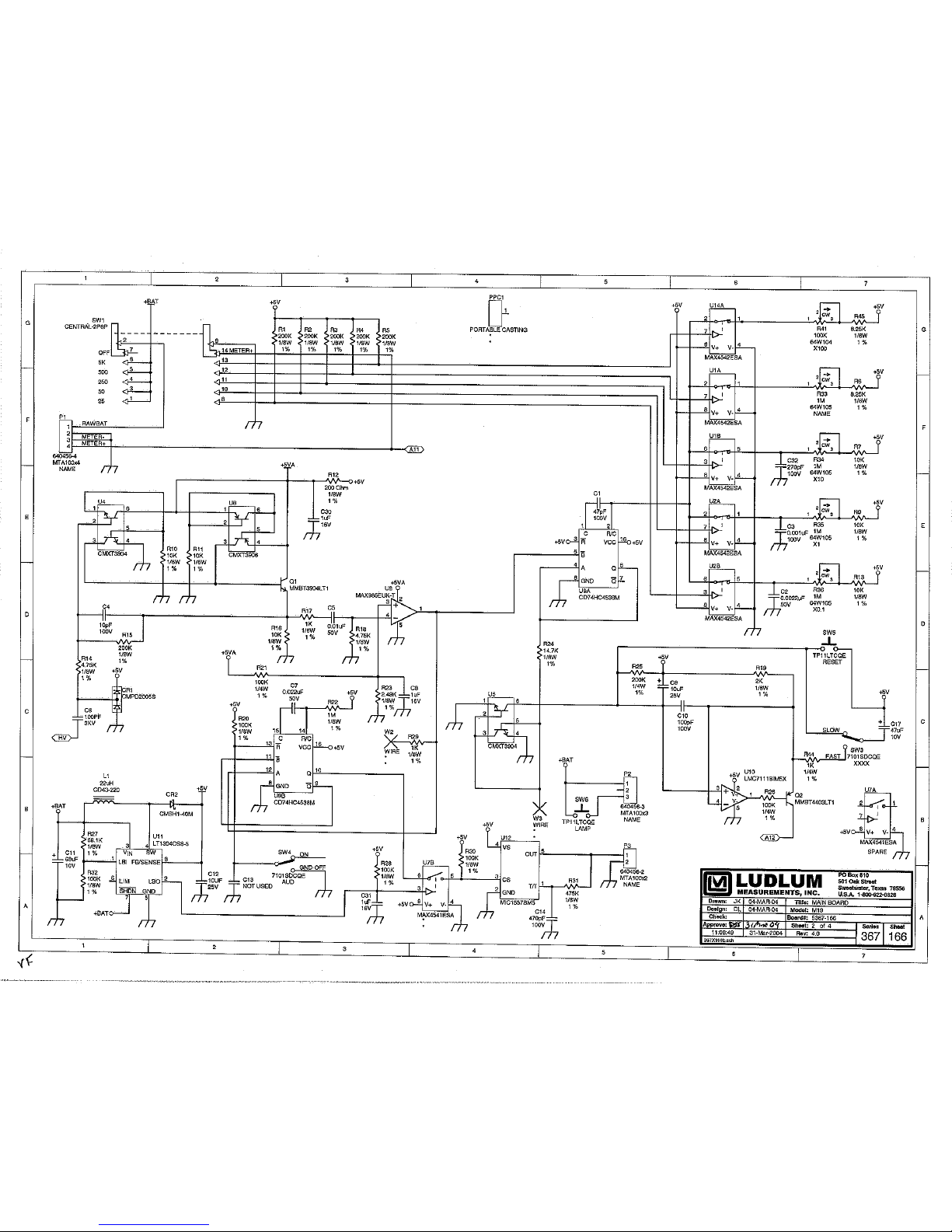

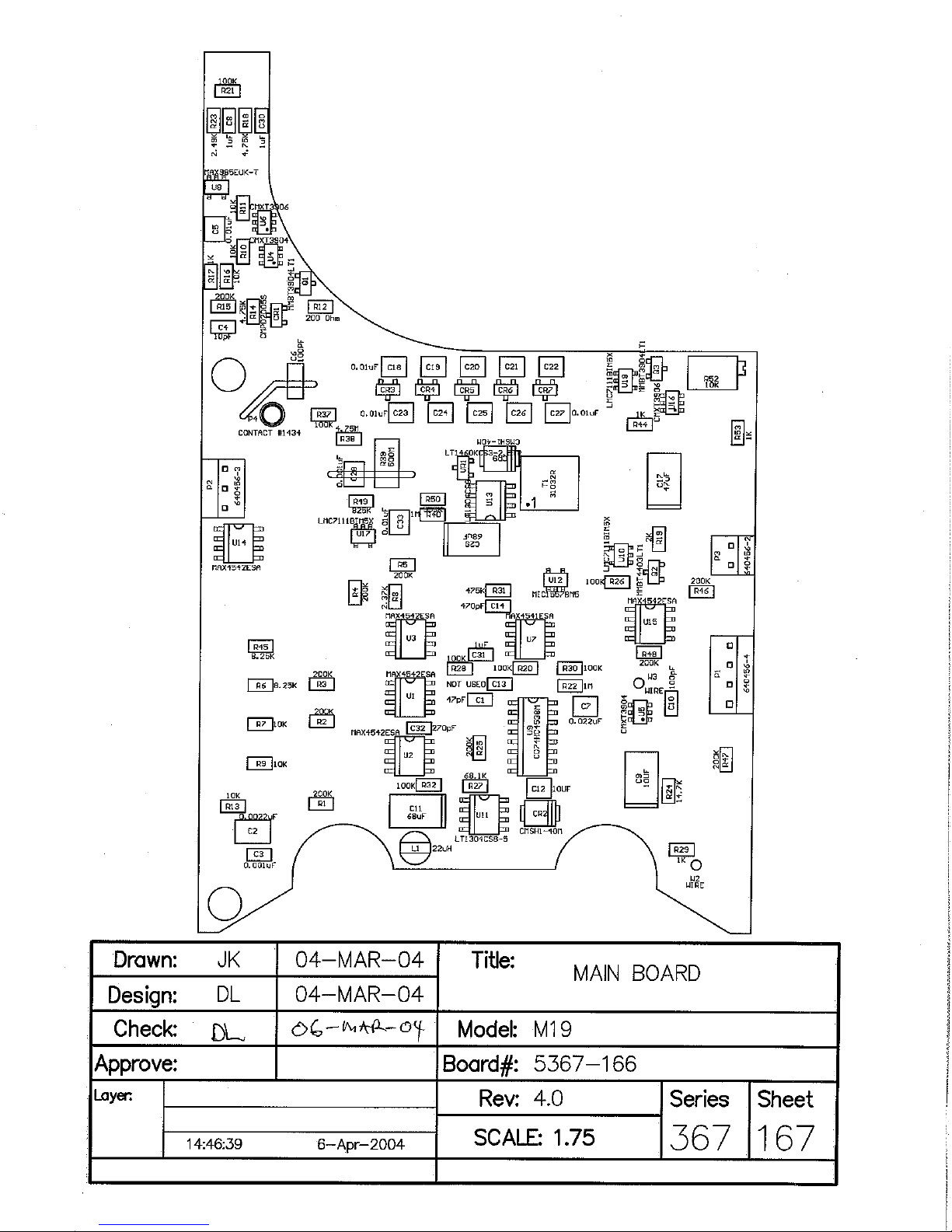

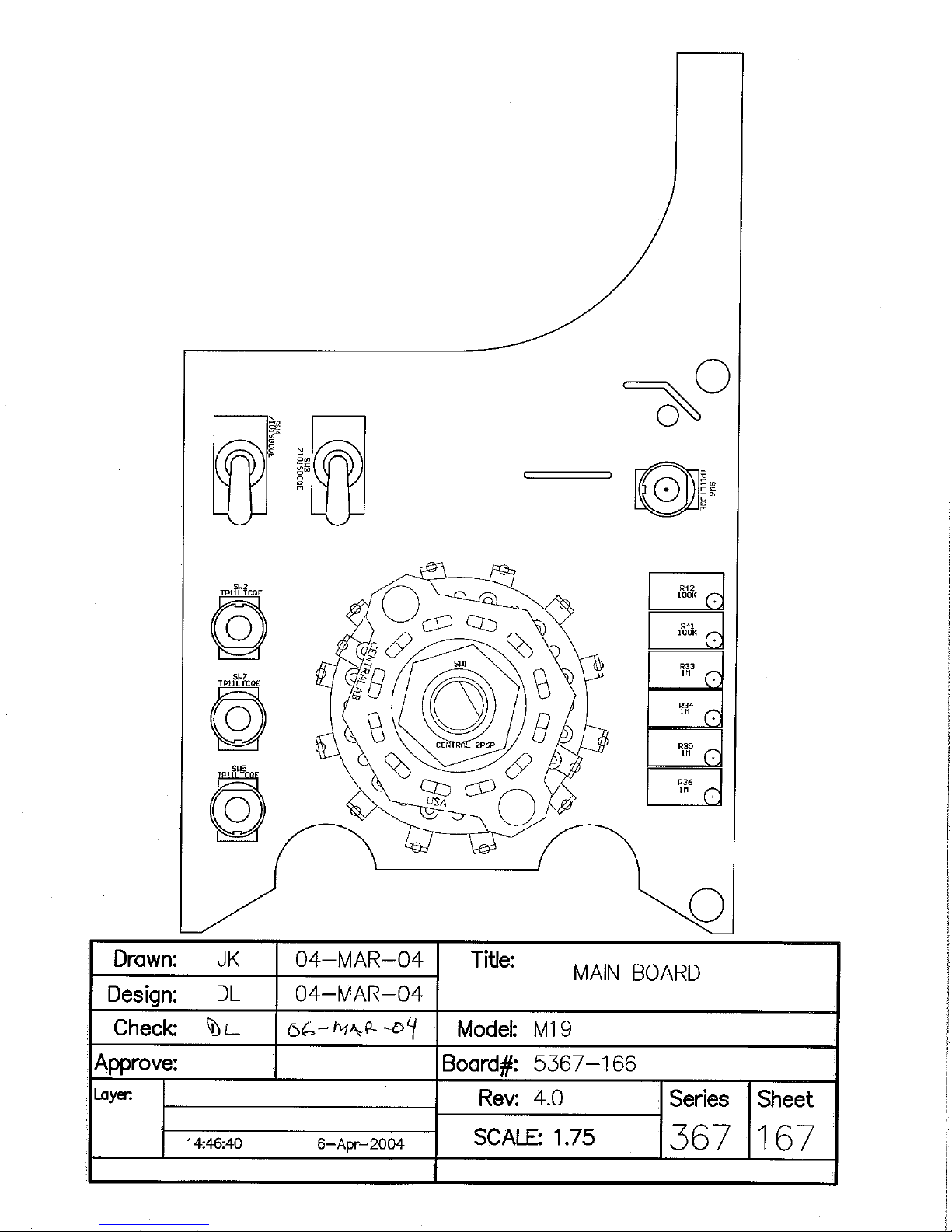

Main Board, Drawing 367 × 166 9-1

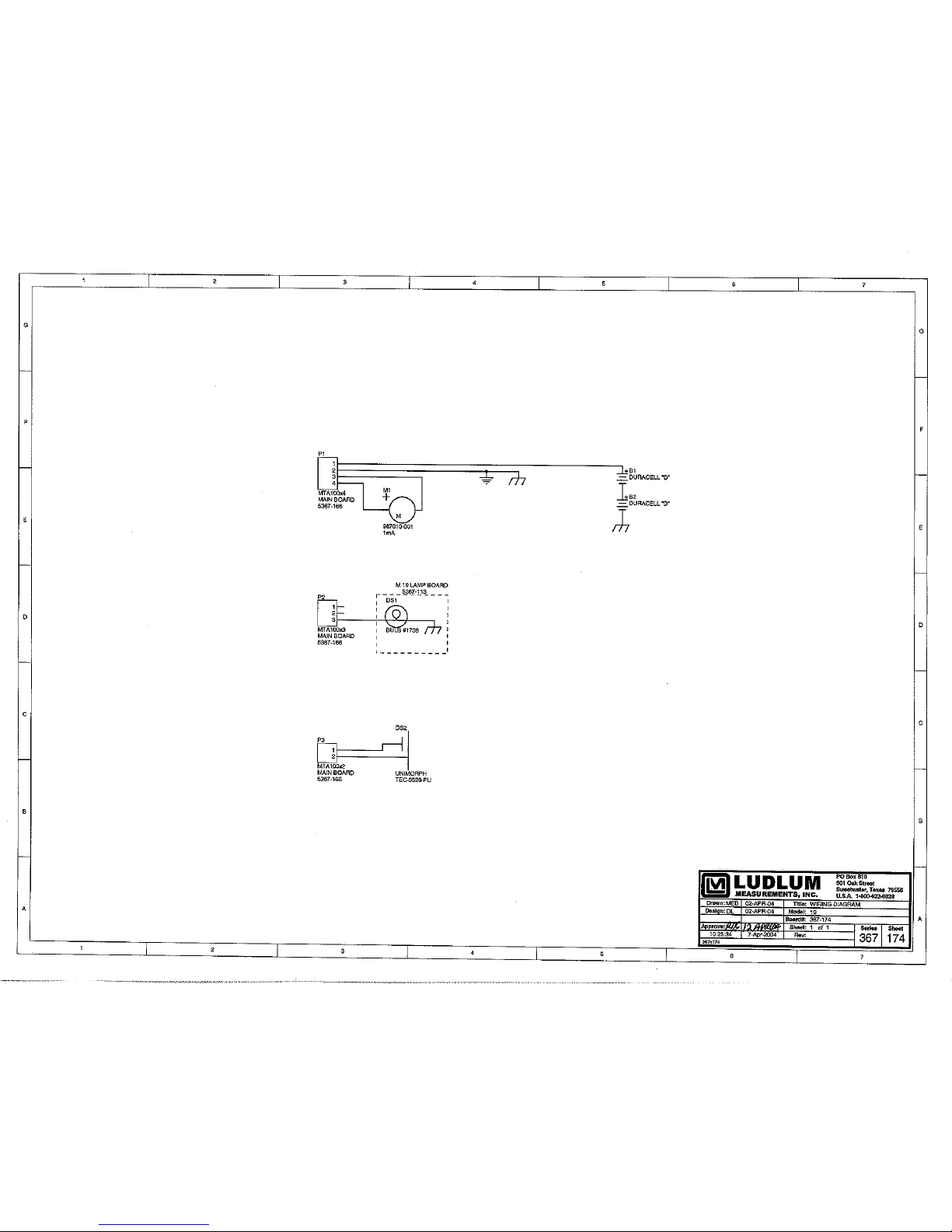

Wiring Diagram, Drawing 367 × 174 9-4

Drawings and Diagrams 10

Ludlum Measurements, Inc. February 2012

Model 19 MICRO R METER Technical Manual Section 1

Section

1

T

Introduction

he Ludlum Model 19 Micro R Meter utilizes an internally-mounted

2.5 x 2.5 cm (1 × 1 in.) NaI(T1) scintillator for optimum

performance in locating and measuring low-level (near background)

gamma radiation.

The unit features a push-button, lighted meter and was designed to be

moisture and dust resistant. The meter is housed in a rugged aluminum bezel

with waterproof seals. All controls, including a calibration potentiometer for

each range, are located on the front panel. Front-panel switches are rubberbooted to seal out moisture and dust. A high-voltage (HV) test control is

provided to allow rapid plateau testing of the detector.

Five range divisions are provided in the 0-5000 micro R/hr spectrum. The

meter face is made up of two scales, 0-50 and 0-25, plus battery test. The 050 scale corresponds to the 50, 500 and 5000 positions on the range selector

switch. The 0-25 scale corresponds to the 25 and 250 positions on the range

selector switch.

The instrument is capable of using either standard "D" cell flashlight

batteries or nickel-cadmium rechargeable batteries. However, the Model 19

does not include circuitry for recharging the batteries. The two "D" cell

batteries are located in an isolated compartment, easily accessible from the

front panel.

The Model 19 NaI scintillator is energy sensitive. An energy response curve

is included in section 10 of this manual for further reference.

Ludlum Measurements, Inc. Page 1-1 February 2012

Model 19 MICRO R METER Technical Manual Section 2

Section

2

Getting Started

Unpacki ng and Repac king

Remove the calibration certificate and place it in a secure location. Remove

the instrument and accessories (batteries, cable, etc.) and ensure that all of

the items listed on the packing list are in the carton. Check individual item

serial numbers and ensure calibration certificates match. The Model 19 serial

number is located on the front panel below the battery compartment. Most

Ludlum Measurements, Inc. detectors have a label on the base or body of

the detector for model and serial number identification.

Important!

If multiple shipments are received, ensure that the detectors

and instruments are not interchanged. Each instrument is

calibrated to specific detectors, and therefore, not

interchangeable.

To return an instrument for repair or calibration, provide sufficient packing

material to prevent damage during shipment. Also provide appropriate

warning labels to ensure careful handling. Include detector(s) and related

cable(s) for calibration. Include brief information as to the reason for return,

as well as return shipping instructions:

- Return shipping address

- Customer name or contact

- Telephone number

- Description of service requested and all other necessary

information

Battery Installation

Ensure the Model 19 power switch is in the “OFF” position. Open the

battery lid by pushing down and turning the quarter-turn thumbscrew

counterclockwise a quarter of a turn. Install two "D" size batteries in the

compartment.

Ludlum Measurements, Inc. Page 2-1 February 2012

Model 19 MICRO R METER Technical Manual Section 2

Note the (+) and (-) marks inside the battery door. Match the battery

polarity to these marks. Close the battery box lid, push down and turn the

quarter-turn thumb screw clockwise a quarter of a turn.

Note:

Center post of a flashlight battery is positive. The batteries are

placed in the battery compartment in opposite directions.

Operational C heck

Turn the range selector switch to the “25” position. Depress the “BAT”

pushbutton switch and ensure that the meter needle falls within the “BAT

OK

” marks. Check for a proper background reading. A typical reading would

be: 5-15 uR/hr

Turn the range selector switch to the “5000” position. Expose the

instrument to a check source and verify that the instrument indicates within

20% of the check source reading obtained during the last calibration.

Switch the “AUD ON/OFF” switch to the “ON” position and confirm that the

external unimorph speaker produces an audible click for each event

detected. The “AUD ON/OFF” switch will silence the audible clicks if in the

“OFF” position. It is recommended that the “AUD ON/OFF” switch be kept

in the “OFF” position when not needed in order to preserve battery life.

Turn the range selector switch to the “250” position and increase the source

activity for a meter reading of 10-100 uR/hr. While observing the meter

fluctuations, select between the fast and slow response time (F/S) positions

to observe variations in the display. The "S" position should respond

approximately five times slower than the “F” position.

Note:

The slow response position is normally used when the

instrument is displaying low numbers, which require a

more stable meter movement. The fast response position is

used at high rate levels.

Check the meter reset function by depressing RESET and ensuring the meter

needle drops to “0.”

Ludlum Measurements, Inc. Page 2-2 February 2012

Model 19 MICRO R METER Technical Manual Section 2

Depress the “LAMP” pushbutton switch. Ensure that the meter face

illuminates when the switch is depressed. Proceed to use the instrument.

Maintenance

Instrument maintenance consists of keeping the instrument clean and

periodically checking the batteries and the calibration. The Model 19

instrument may be cleaned with a damp cloth (using only water as the

wetting agent). Do not immerse instrument in any liquid. Observe the

following precautions when cleaning:

1. Turn the instrument off and remove the batteries.

2. Allow the instrument to sit for one minute before accessing

internal components.

Recalibration

Recalibration should be accomplished after any maintenance or adjustment

of any kind has been performed on the instrument. Battery replacements are

not considered maintenance and do not normally require instrument

recalibration.

Note:

Ludlum Measurements, Inc. recommends recalibration at

intervals no greater than one year. Check the appropriate

regulations to determine required recalibration intervals.

Ludlum Measurements offers a full-service repair and calibration

department. We not only repair and calibrate our own instruments but most

other manufacturers’ instruments. Calibration procedures are available upon

request for customers who choose to calibrate their own instruments.

Batteries

The batteries should be removed any time the instrument is placed into

storage. Battery leakage may cause corrosion on the battery contacts, which

must be scraped off and/or washed using a paste solution made from

baking soda and water. Use a spanner wrench to unscrew the battery contact

Ludlum Measurements, Inc. Page 2-3 February 2012

Model 19 MICRO R METER Technical Manual Section 2

insulators, exposing the internal contacts and battery springs. Removal of the

handle will facilitate access to these contacts.

Note:

Never store the instrument over 30 days without removing the

batteries. Although this instrument will operate at very high

ambient temperatures, battery seal failure may occur at

temperatures as low as 37 °C (100 °F).

Ludlum Measurements, Inc. Page 2-4 February 2012

Model 19 MICRO R METER Technical Manual Section 3

Section

3

Specifications

0

Linearity: reading within 10% of true value

High Voltage: variable from 400 to 1500 Vdc; electronically regulated to

within 1%

Battery Dependence: instrument calibration change less than 3%

within the meter battery check limits

Power: two standard alkaline "D" cell batteries, secured in an isolated

compartment

Battery Life: expected lifetime of approximately 2000 hours with the

“AUD ON/OFF” switch in the OFF position

Audio Output: built-in unimorph speaker and “ON/OFF” switch

provided on the front panel

Counting Ranges: two-scale meter face presenting 0-50 µR/hr with full

scale range positions of 5000, 500 and 50; and 0-25 µR/hr with full scale

range positions of 250 and 25.

Meter: 1 mA, 6.4 cm (2.5 in.) scale, pivot-and-jewel suspension

Detector: photomultiplier coupled to a 2.5 x 2.5 (1 × 1 in.) NaI(Tl)

crystal, mounted inside the instrument housing

Construction: cast-and-drawn aluminum with beige powder-coat finish

and printed membrane front panel

Size: 15.2 x 8.9 x 21.6 cm (6.0 x 3.5 x 8.5 in.), not including instrument

handle

Weight: 2.04 kg (4.5 lb), including batteries

Ludlum Measurements, Inc. Page 3-1 February 2012

Model 19 MICRO R METER Technical Manual Section 4

Section

4

Identification of Controls and

Functions

Range Selector Switch: a six-position switch marked OFF, 5000, 500,

250, 50, and 25. Moving the range selector switch to one of the range

positions (5000, 500, 250, 50, 25) provides the operator with an overall

range of 0-5000 µR/hr. Note that the range positions 5000, 500 and 50

are screened in black and correspond to the meter scale screened in

black. The range positions 250 and 25 are screened in red and

correspond to the meter scale screened in red.

AUD ON-OFF Toggle Switch: In the ON position, the switch operates

the unimorph speaker, located on the left side of the instrument. The

frequency of the clicks is relative to the rate of the incoming pulses. The

higher the rate is, the higher the audio frequency. The audio should be

turned OFF when not required in order to reduce battery drain.

F-S Toggle Switch: provides meter response. Selecting the fast, "F,"

position of the toggle switch provides 90% of full-scale meter deflection

in four seconds. In the slow, "S," position, 90% of full-scale meter

deflection takes 22 seconds. In "F" position, there is fast response and

large meter deviation. The "S" position should be used for slow response

and damped, meter deviation.

BAT Pushbutton Switch: when depressed, this switch indicates the

battery charge status on the meter. The range selector switch must be

out of the OFF position.

RES Pushbutton Switch: When depressed, this switch provides a rapid

means to drive the meter to zero.

LAMP Pushbutton Switch: When depressed, this switch lights the meter

face.

HV Pushbutton Switch: When depressed, the meter reads the detector

high voltage. Each meter division is equivalent to 100 V.

Ludlum Measurements, Inc. Page 4-1 February 2012

Model 19 MICRO R METER Technical Manual Section 4

HV Adjustment: provides a means to vary the high voltage from 400 to

1500 V.

Range Calibration Adjustments: recessed potentiometers located under

the calibration cover on the right side of the front panel. These

adjustment controls allow individual calibration for each range

multiplier.

Ludlum Measurements, Inc. Page 4-2 February 2012

Model 19 MICRO R METER Technical Manual Section 5

Section

5

Safety Considerations

Environment al Conditions for Normal Use

Indoor or outdoor use

No maximum altitude

Temperature range of -20 to 50 °C (-4 to 122 °F)

Maximum relative humidity of less than 95% (non-condensing)

Pollution Degree 3 (as defined by IEC 664) (Occurs when conductive

pollution or dry nonconductive pollution becomes conductive due to

condensation. This is typical of industrial or construction sites.)

Warning Markings and Symbols

Caution!

The operator or responsible body is cautioned that the

protection provided by the equipment may be impaired if

the equipment is used in a manner not specified by Ludlum

Measurements, Inc.

The Model 19 Micro R Meter is marked with the

following symbols:

CAUTION (per ISO 3864, No. B.3.1) – designates hazardous live voltage

and risk of electric shock. During normal use, internal components are

hazardous live. This instrument must be isolated or disconnected from the

hazardous live voltage before accessing the internal components. This

symbol appears on the front panel. Note the following precautions:

Ludlum Measurements, Inc. Page 5-1 February 2012

Model 19 MICRO R METER Technical Manual Section 5

Warning!

The operator is strongly cautioned to take the following

precautions to avoid contact with internal hazardous live

parts that are accessible using a tool:

1. Turn the instrument power OFF and remove the batteries.

2. Allow the instrument to sit for one minute before accessing

internal components.

The “crossed-out wheelie bin” symbol notifies the consumer that the

product is not to be mixed with unsorted municipal waste when discarding;

each material must be separated. The symbol is placed on the battery

compartment lid. See section 8, “Recycling,” for further information.

The “CE” mark is used to identify this instrument as being acceptable

for use within the European Union.

Cleaning and Maintenance Precautions

The Model 19 may be cleaned externally with a damp cloth, using only water

as the wetting agent. Do not immerse the instrument in any liquid. Observe

the following precautions when cleaning or performing maintenance on the

instrument:

1. Turn the instrument OFF and remove the batteries.

2. Allow the instrument to sit for one minute before cleaning the

exterior or accessing any internal components for maintenance.

Ludlum Measurements, Inc. Page 5-2 February 2012

Model 19 MICRO R METER Technical Manual Section 6

Section

6

O

Troubleshooting

ccasionally, you may encounter problems with your LMI

instrument or detector that may be repaired or resolved in the

field, saving turn-around time and expense in returning the

instrument to us for repair. Toward that end, LMI electronics

technicians offer the following tips for troubleshooting the most common

problems. Where several steps are given, perform them in order until the

problem is corrected. Keep in mind that with this instrument, the most

common problems encountered are: (1) sticky meters; and (2) battery

contacts.

Note that the first troubleshooting tip is for determining whether the

problem is with the electronics or with the detector. A Ludlum Model 500

Pulser is invaluable at this point, because of its ability to simultaneously

check high voltage, input sensitivity or threshold, and the electronics for

proper counting.

We hope these tips will prove to be helpful. As always, please call if you

encounter difficulty in resolving a problem or if you have any questions.

T roubleshooti ng Electronics which utili ze a

Scintilla tion Detector

SYMPTOM

No power (or meter

does not reach BAT

or BAT OK

TEST

mark)

POSSIBLE SOLUTION

1. Check batteries and replace if weak.

2. Check polarity (see marks inside

batter lid). Are the batteries installed

backwards?

Ludlum Measurements, Inc. Page 6-1 February 2012

Model 19 MICRO R METER Technical Manual Section 6

SYMPTOM

No power (or meter

does not reach BAT

TEST

or BAT OK

mark) (continued)

Nonlinear Readings

Meter goes full-scale

or “pegs out”

POSSIBLE SOLUTION

3. Check battery contacts. Clean them

with rough sandpaper or use an

engraver to clean the tips.

4. Check for loose or broken wires,

especially between the main board

and the calibration board.

1. Check the high voltage (HV) by

pressing the HV TEST button. If a

multimeter is used to check the HV,

ensure that one with high impedance

is used, as a standard multimeter

could be damaged in this process.

2. Check for “sticky” meter movement.

Does the reading change when you

tap the meter? Does the meter needle

“stick” at any spot?

3. Check the “meter zero.” Turn the

power OFF. The meter should come

to rest on “0.”

1. Check the HV and, if possible, the

input threshold for proper setting.

2. Check for loose wires, especially

between the main board and the

calibration board.

Ludlum Measurements, Inc. Page 6-2 February 2012

Model 19 MICRO R METER Technical Manual Section 7

Section

7

T echnical Theory of Operation

Detector

The detector consists of a crystal of sodium iodide with Thallium activation

(NaI Tl) that gives off light pulses when penetrated by radiation photons.

The light pulses are converted to electrical pulses by the photo cathode of

the photomultiplier tube. The photomultiplier includes a nine-stage electron

amplifier. This amplifier utilizes an electrostatic field for each stage, adding

up to a required 500 to 1500 V supply.

Input

Detector pulses are coupled from the detector through C6 to the amplifier.

CR1 protects the amplifier from input shorts. R37 couples the detector to

the high-voltage supply.

Amplifier

A self-biased amplifier provides gain in proportion to R15 and C4 divided by

R14. Transistor (pin 3 of U4) provides amplification. U6 is configured as a

current mirror to provide a load for pin 3 of U4. The output self biases to 2

Vbe (approximately 1.4 volts) at emitter of Q1. This provides just enough

bias current through pin 3 of U4 to conduct all of the current from the

current mirror.

Positive pulses at R16 are coupled to the discriminator through C5.

Discriminator

Comparator U8 provides discrimination. The discriminator is set by the

voltage divider, R21 and R23, coupled to pin 3 of U8. U8 output pulses are

coupled to pin 5 of U9A for meter drive and pin 12 of U9B for audio.

Ludlum Measurements, Inc. Page 7-1 February 2012

Model 19 MICRO R METER Technical Manual Section 7

Audio

Discriminator pulses are coupled to univibrator pin 12 of U9B. Front-panel

audio ON-OFF selector controls the reset at pin 13 of U9B. When ON, pulses

from pin 10 of U9B turn on oscillator U12, which drives the can-mounted

unimorph. Speaker tone is set by R31, C14; duration by R22, C7.

Scale Ranging

Detector pulses from the discriminator are coupled to univibrator pin 5 of

U9A. For each scale, the pulse width of pin 6 of U9A is controlled by the

front-panel calibration controls and their related capacitors. This

arrangement allows the same current to be delivered to C9 in proportion to

the meter reading.

Digital Analog C onverter

U5 is configured as a current mirror. For each pulse of current through R24,

an equal current is delivered to C9. This charge is drained off by R25. The

voltage across C9 is proportional to the incoming count rate.

Meter Drive

The meter is driven by the collector of Q2 coupled as a voltage follower in

conjunction with pin 1 of U10.

For the battery test, the voltage follower is bypassed and the meter

movement is directly coupled to the battery through R8.

Fast/Slow Time Const ant

For slow-time constant, C17 is switched from the output of the meter drive

to parallel C9.

Low V oltage Supply

Battery voltage is coupled to U11 and associated components (a switching

regulator) to provide 5 V at pin 8 to power all circuits.

High V oltage T est

A constant current is developed by collector of Q3 in proportion to HV

signal at pin 1 of U17. U16 provides a current mirror to drive the meter

Ludlum Measurements, Inc. Page 7-2 February 2012

Model 19 MICRO R METER Technical Manual Section 7

through analog switch logic circuit U15, U14, and U3.

High V oltage Supply

High voltage is developed by switching regulator U13 and T1. Voltage

multiplier CR3 thru CR7, and associated components, develop the detector

voltage. Voltage feedback is provided by R39 thru U17 to feed back pin 8 of

U13 for voltage regulation. Pin 1 of U17 is proportional to the high voltage,

and its output is also utilized to measure the high voltage. High voltage is

adjusted by varying the feedback current with R42.

Ludlum Measurements, Inc. Page 7-3 February 2012

Model 19 MICRO R METER Technical Manual Section 8

Section

8

L

Recycling

udlum Measurements, Inc. supports the recycling of the electronics

products it produces for the purpose of protecting the environment

and to comply with all regional, national, and international agencies

that promote economically and environmentally sustainable

recycling systems. To this end, Ludlum Measurements, Inc. strives to supply

the consumer of its goods with information regarding reuse and recycling of

the many different types of materials used in its products. With many

different agencies – public and private – involved in this pursuit, it becomes

evident that a myriad of methods can be used in the process of recycling.

Therefore, Ludlum Measurements, Inc. does not suggest one particular

method over another, but simply desires to inform its consumers of the

range of recyclable materials present in its products, so that the user will

have flexibility in following all local and federal laws.

The following types of recyclable materials are present in Ludlum

Measurements, Inc. electronics products, and should be recycled separately.

The list is not all-inclusive, nor does it suggest that all materials are present in

each piece of equipment:

Batteries Glass Aluminum and Stainless Steel

Circuit Boards Plastics Liquid Crystal Display (LCD)

Ludlum Measurements, Inc. products, which have been placed on the

market after August 13, 2005, have been labeled with a symbol recognized

internationally as the “crossed-out wheelie bin.” This notifies the consumer

that the product is not to be mixed with unsorted municipal waste when

discarding; each material must be separated. The symbol will be placed near

the AC receptacle, except for portable equipment where it will be placed on

the battery lid.

The symbol appears as such:

Ludlum Measurements, Inc. Page 8-1 February 2012

Model 19 MICRO R METER Technical Manual Section 9

Section

9

Parts List

Model 19

Micro R Meter

Main Board,

Drawing 367 × 166

CAPACITORS

Reference Description

UNIT Completely Assembled

Model 19 Micro R Meter 48-1615

BOARD Completely Assembled

Circuit Board 5367-166

C1 47pF, 100V 04-5660

C2 0.0022µF, 50V 04-5676

C3 0.001µF, 100V 04-5659

C4 10pF, 100V 04-5673

C5 0.01µF, 50V 04-5664

C6 100pF, 3KV 04-5735

C7 0.022µF, 50V 04-5667

C8 1µF, 16V 04-5701

C9 10µF, 25V 04-5655

C10 100pF, 100V 04-5661

C11 68µF, 10V 04-5654

C12 10µF, 25V 04-5728

C14 470pF, 100V 04-5668

C17 47µF, 10V 04-5666

C18-C27 0.01µF, 500V 04-5696

C28 0.001µF, 2KV 04-5703

C29 68µF, 10V 04-5654

C30-C31 1µF, 16V 04-5701

C32 270pF, 100V 04-5679

C33 0.01µF, 50V 04-5664

Part Number

Ludlum Measurements, Inc. Page 9-1 February 2012

Model 19 MICRO R METER Technical Manual Section 9

VOLTAGE

INTEGRATED

DIODES

SWITCHES

POTENTIOMETERS /

TRANSISTORS

REGULATOR

CIRCUITS

TRIMMERS

Reference Description

Part Number

Q1 MMBT3904LT1 05-5841

Q2 MMBT4403LT1 05-5842

Q3 MMBT3904LT1 05-5841

VR1 LT1460KCS3-2.5TR 05-5867

U1-U3 MAX4542ESA 06-6453

U4-U5 CMXT3904 05-5888

U6 CMXT3906 05-5890

U7 MAX4541ESA 06-6452

U8 MAX985EUK-T 06-6459

U9 CD74HC4538M 06-6297

U10 LMC7111BIM5X 06-6410

U11 LT1304CS8-5 06-6434

U12 MIC1557BM5 06-6457

U13 LT1304CS8 06-6394

U14-U15 MAX4542ESA 06-6453

U16 CMXT3906 05-5890

U17-C18 LMC7111BIM5X 06-6410

CR1 CMPD2005S 07-6468

CR2 CMSH1-40M 07-6411

CR3-CR7 CMPD2005S 07-6468

CR9 CMSH1-40M 07-6411

SW1 RANGE SELECTOR 08-6761

SW2 H.V. PUSHBUTTON 08-6770

SW3 F-S TOGGLE 08-6781

SW4 AUD ON-OFF TOGGLE 08-6781

SW5 RES PUSHBUTTON 08-6770

SW6 LAMP PUSHBUTTON 08-6770

SW7 BAT PUSHBUTTON 08-6770

R33 1M, 64W105 NAME 09-6814

R34 1M, 64W105 X10 09-6814

R35 1M, 64W105 X1 09-6814

R36 1M, 64W105 X0.1 09-6814

R41 100K, 64W104 X100 09-6813

Ludlum Measurements, Inc. Page 9-2 February 2012

Model 19 MICRO R METER Technical Manual Section 9

RESISTORS

CONNECTORS

Reference Description

Part Number

R42 100K, 64W104 HV ADJ 09-6813

R52 10K, 3266X1-103 NAME 09-6822

R1-R5 200K, 1/8W, 1% 12-7992

R6 8.25K, 1/8W, 1% 12-7838

R7 10K, 1/8W, 1% 12-7839

R8 2.37K, 1/8W, 1% 12-7861

R9-R11 10K, 1/8W, 1% 12-7839

R12 200 Ohm, 1/8W, 1% 12-7846

R13 10K, 1/8W, 1% 12-7839

R14 4.75K, 1/8W, 1% 12-7858

R15 200K, 1/8W, 1% 12-7992

R16 10K, 1/8W, 1% 12-7839

R17 1K, 1/8W, 1% 12-7832

R18 4.75K, 1/8W, 1% 12-7858

R19 2K, 1/8W, 1% 12-7926

R20-R21 100K, 1/4W, 1% 12-7834

R22 1M, 1/8W, 1% 12-7844

R23 2.49K, 1/8W, 1% 12-7999

R24 14.7K, 1/8W, 1% 12-7068

R25 200K, 1/4W, 1% 12-7992

R26 100K, 1/4W, 1% 12-7834

R27 68.1K, 1/8W, 1% 12-7881

R28 100K, 1/8W, 1% 12-7834

R29 1K, 1/8W, 1% 12-7832

R30 100K, 1/8W, 1% 12-7834

R31 475K, 1/8W, 1% 12-7859

R32 100K, 1/8W, 1% 12-7834

R37 100K, 1/8W, 1% 12-7834

R38 4.75M, 1/8W, 1% 12-7995

R39 500M, 3KV, 2% 12-7031

R40 1M, 1/4W, 1% 12-7844

R44 1K, 1/4W, 1% 12-7832

R45 8.25K, 1/8W, 1% 12-7838

R46-R48 200K, 1/4W, 1% 12-7992

R49 825K, 1/8W, 1% 12-7005

R50 953K, 1/8W, 1% 12-7950

R53 1K, 1/4W, 1% 12-7832

P1 CONN-640456-4

MTA100x4 NAME 13-8088

Ludlum Measurements, Inc. Page 9-3 February 2012

Model 19 MICRO R METER Technical Manual Section 9

INDUCTOR

TRANSFORMER

AUDIO

CONNECTOR

BATTERY

MISCELLANEOUS

Wiring Diagram,

Drawing 367 × 174

Reference Description

Part Number

P2 CONN-640456-3

MTA100x3 NAME 13-8081

P3 CONN-640456-2

MTA100x2 NAME 13-8073

P4 CONTACT #1434 NAME 18-9124

L1 22µH, CD43-220 21-9808

T1 31032R 21-9925

DS1 Model 19 LAMP BOARD 5367-113

5367-113

DS2 UNIMORPH TEC-3526-PU 21-9251

P1 MTA100x4 MAIN BOARD

5367-166 13-8170

P2 MTA 100x3 MAIN BOARD

5367-166 13-8135

P3 MTA 100x2 MAIN BOARD

5367-166 13-8178

B1-B2 DURACELL "D" 21-9313

* MODEL 19 INTERNAL DETECTOR

47-3426

* TUBE/XTAL ASSY 2004-061

M1 MODEL 19 METER

ASSY 987010-001 1mA 4367-024

* MODEL 19 METERFACE

(202-016) 7367-023

* METER BEZEL W/ GLASS

W/ SCREWS 4363-352-00

* METER MOVEMENT (1mA) 15-8030

* Model 19 BATTERY BOX

LID W/CNTCT 2363-191

* DEEP PORTABLE

CAN ASSY 4363-615

* MODEL 19 CASTING 7367-171

* MODEL 19 MAIN HARNESS 8367-170

Ludlum Measurements, Inc. Page 9-4 February 2012

Model 19 MICRO R METER Technical Manual Section 9

Reference Description

Part Number

* PORTABLE KNOB 08-6613

* SWITCH SEAL (P/B) 08-6611

* UNIMORPH W/WIRES,

O'RING 40-0034

* CAL COVER W/SCREWS 4363-200

* HANDLE- PORTABLE (GRIP) 7363-139

Ludlum Measurements, Inc. Page 9-5 February 2012

Model 19 MICRO R METER Technical Manual Section 10

Section

10

Drawings

Model Board Circuit, Drawing 367 × 166 (4 sheets)

Model Board Component Layouts, Drawings 367 × 167 (2 sheets)

Wiring Diagram, Drawing 367 × 174

Energy Response for Ludlum Model 19

Ludlum Measurements, Inc. Page 10-1 February 2012

Loading...

Loading...