LUDLUM MODEL 3030 & 3030E SERIES

ALPHA-BETA SAMPLE COUNTER

November 2017

Serial Number 185762 and Succeeding

Serial Numbers

LUDLUM MEASUREMENTS, INC.

501 OAK STREET, P.O. BOX 810

SWEETWATER, TEXAS 79556

325-235-5494, FAX: 325-235-4672

LUDLUM MODEL 3030 & 3030E SERIES

ALPHA-BETA SAMPLE COUNTER

November 2017

Serial Number 185762 and Succeeding

Serial Numbers

STATEMENT OF WARRANTY

Ludlum Measurements, Inc. warrants the products covered in this manual to be free

of defects due to workmanship, material, and design for a period of twelve months

from the date of delivery. The calibration of a product is warranted to be within its

specified accuracy limits at the time of shipment. In the event of instrument failure,

notify Ludlum Measurements to determine if repair, recalibration, or replacement is

required.

This warranty excludes the replacement of photomultiplier tubes, G-M and

proportional tubes, and scintillation crystals which are broken due to excessive

physical abuse or used for purposes other than intended.

There are no warranties, express or implied, including without limitation any implied

warranty of merchantability or fitness, which extend beyond the description of the

face there of. If the product does not perform as warranted herein, purchaser’s sole

remedy shall be repair or replacement, at the option of Ludlum Measurements. In no

event will Ludlum Measurements be liable for damages, lost revenue, lost wages, or

any other incidental or consequential damages, arising from the purchase, use, or

inability to use product.

RETURN OF GOODS TO MANUFACTURER

If equipment needs to be returned to Ludlum Measurements, Inc. for repair or calibration, please

send to the address below. All shipments should include documentation containing return shipping

address, customer name, telephone number, description of service requested, and all other necessary

information. Your cooperation will expedite the return of your equipment.

LUDLUM MEASUREMENTS, INC.

ATTN: REPAIR DEPARTMENT

501 OAK STREET

SWEETWATER, TX 79556

800-622-0828 325-235-5494

FAX 325-235-4672

Table of Contents

INTRODUCTION ............................................................................................................. 1

GETTING STARTED ...................................................................................................... 3

Unpacking and Repacking .......................................................................................................................................... 3

Software Installation ................................................................................................................................................... 4

External Counter HV Connector (3030E only) ......................................................................................................... 4

Start-up ................................................................................................ ................................................................ ......... 4

SPECIFICATIONS .......................................................................................................... 6

Model 3030 ONLY .............................................................................................................................................. 6

Model 3030E ONLY ............................................................................................................................................ 6

Common Specifications ....................................................................................................................................... 7

DESCRIPTION OF CONTROLS AND FUNCTIONS ...................................................... 8

Front Panel ................................................................................................................................................................... 8

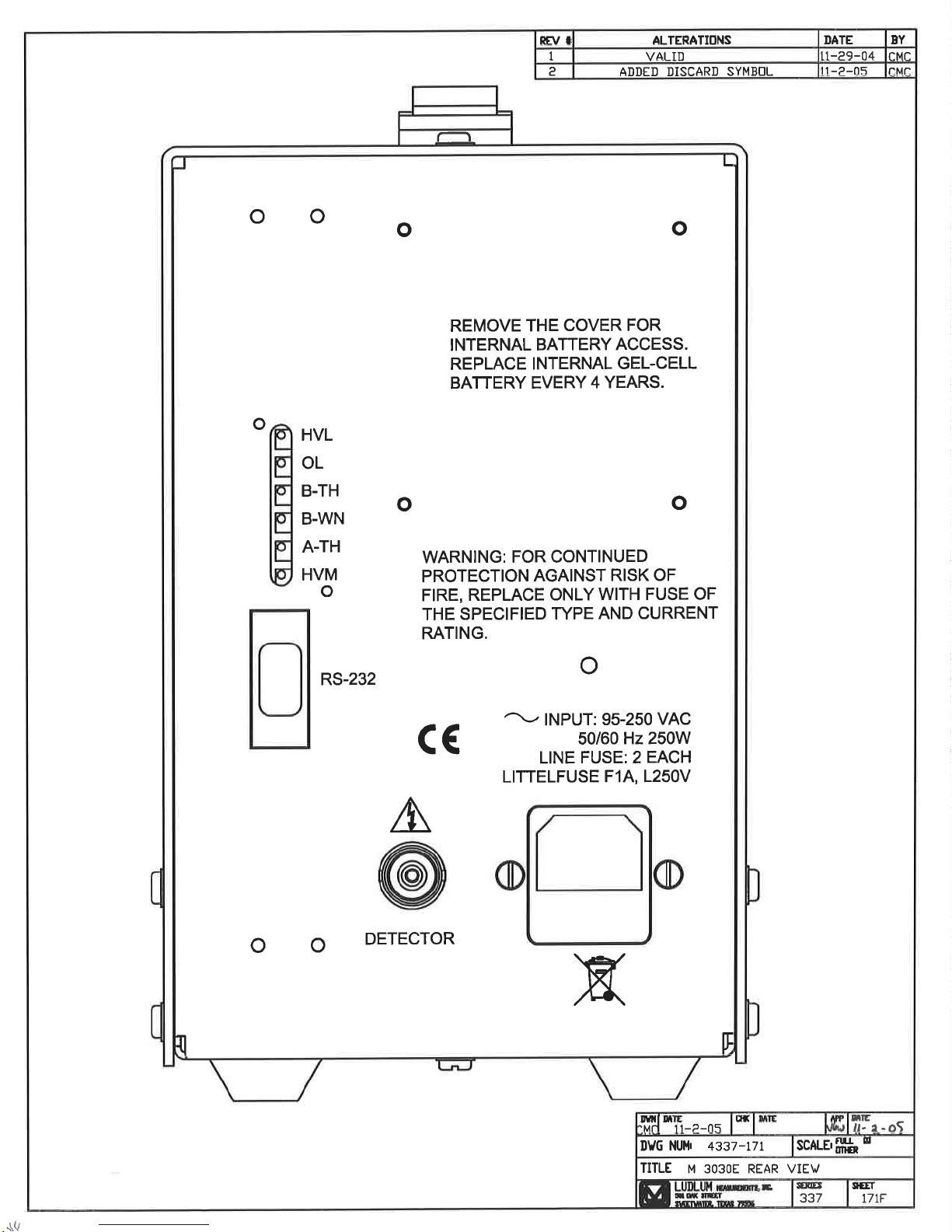

Back Panel .................................................................................................................................................................... 9

Internal Controls ....................................................................................................................................................... 10

SAFETY CONSIDERATIONS ....................................................................................... 11

Environmental Conditions for Normal Use ............................................................................................................. 11

Cleaning Instructions and Precautions .................................................................................................................... 11

Warning Markings and Symbols ............................................................................................................................. 12

Replacement of Main Fuse (Back Panel) ................................................................................................................. 13

CALIBRATION AND MAINTENANCE ......................................................................... 14

Calibration ................................................................................................................................................................. 14

Recommended Sources ............................................................................................................................................ 14

Calibration Procedure ............................................................................................................................................... 14

Maintenance ................................ ................................................................ ............................................................... 18

COMPUTER SOFTWARE ............................................................................................ 20

Parameters ................................................................................................................................................................. 22

QC Check ................................................................................................................................................................... 25

HV Plateau ................................................................................................................................................................. 29

MDA Calculations ..................................................................................................................................................... 32

Data Logging .............................................................................................................................................................. 33

RS-232 Communication ............................................................................................................................................ 34

COMMANDS ............................................................................................................................................................. 34

Bn – Background Subtract Status ............................................................................................................................. 34

Cn – Count ............................................................................................................................................................... 35

Dn – Display Mode .................................................................................................................................................. 35

F – Firmware ............................................................................................................................................................ 35

Ln – Logging Mode .................................................................................................................................................. 35

Pn .............................................................................................................................................................................. 35

Qx ............................................................................................................................................................................. 35

RA – Read Next Sample Number............................................................................................................................. 36

RBn – Read Background Subtract ............................................................................................................................ 36

RC – Read Calibration Due Date ............................................................................................................................. 36

RD – Read Current Date and Time .......................................................................................................................... 36

REn – Read Efficiency ............................................................................................................................................. 36

RHn – Read Header .................................................................................................................................................. 36

RL – Read Loss of Count Timer .............................................................................................................................. 36

RNn – Read MDA .................................................................................................................................................... 36

RP – Read the PC Time ............................................................................................................................................ 37

RQn .......................................................................................................................................................................... 37

RR – Read Count ...................................................................................................................................................... 37

RS – Read Samples .................................................................................................................................................. 38

RT – Read Current Count Time ............................................................................................................................... 38

RU – Read Comment ............................................................................................................................................... 38

RV – Read High Voltage .......................................................................................................................................... 38

RXn – Read the Crosstalk ........................................................................................................................................ 38

RY – Read Recycle Mode Status ............................................................................................................................. 38

Rn – Read the Alarm Set Points ............................................................................................................................... 38

Xn – Set Crosstalk Mode .......................................................................................................................................... 39

SBnxxxxxx – Set Background Subtract ................................................................................................................... 39

SCmmddyyyy – Set Calibration Date ...................................................................................................................... 39

SDmmddyyyyz – Set Date ....................................................................................................................................... 39

SEnxxx – Set Efficiency ........................................................................................................................................... 39

SHnxxxxxxxxxxxxxxx – Set Header ....................................................................................................................... 39

SLyyyyy.y – Set Loss of Count Timer ..................................................................................................................... 39

SNnyyyyyy – Set MDA............................................................................................................................................ 39

SPxxxxx.x ................................................................................................................................................................ 40

SQnn – Set QC parameters ....................................................................................................................................... 40

SR – Reset All Samples ............................................................................................................................................ 40

SThhmm – Set Time ................................................................................................................................................. 40

SUxxxxxxxxxx – Set Command .............................................................................................................................. 40

SVxxxx – Set High Voltage ..................................................................................................................................... 40

SXnyyy – Set Crosstalk ............................................................................................................................................ 41

SYn – Set Recycle Mode .......................................................................................................................................... 41

Snxxxxxx – Set Alarm ............................................................................................................................................. 41

Sample Printouts........................................................................................................................................................ 41

Software License Agreement .................................................................................................................................... 43

RECYCLING ................................................................................................................. 46

PARTS LIST ................................................................................................................. 47

Model 3030 & Model 3030E Alpha-Beta Sample Counters .............................................................................. 47

Amplifier / Processor Board, Drawing 337 × 189 .............................................................................................. 47

Display Board, Drawing 337 × 88 ..................................................................................................................... 50

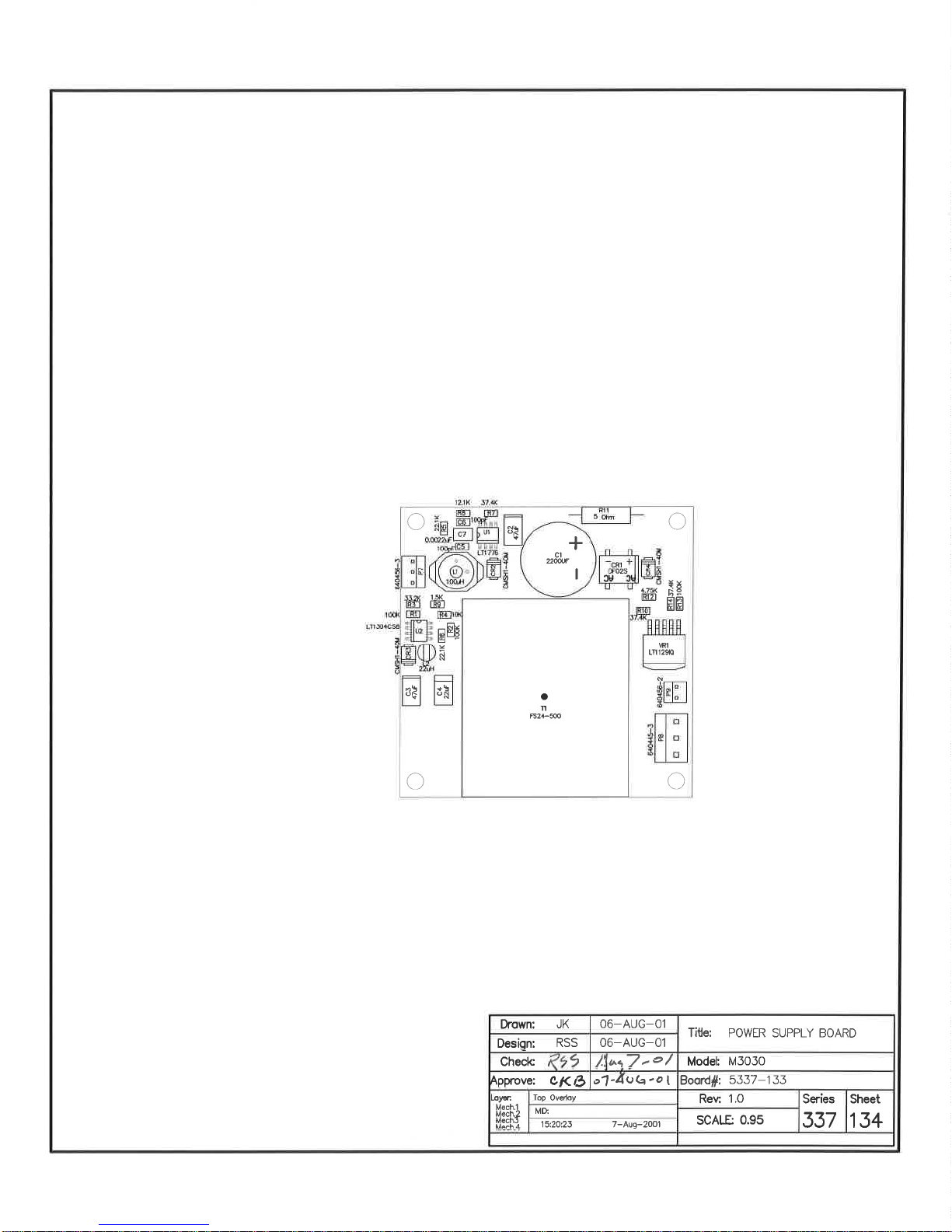

Power Supply Board, Drawing 337 × 133 ......................................................................................................... 51

Wiring Diagram, Drawing 337 × 182 ................................................................................................................ 51

Model 3030 ONLY ............................................................................................................................................ 52

DRAWINGS AND DIAGRAMS ..................................................................................... 53

MODEL 3030-2 ........................................................................................................... A-1

Model 3030 & 3030E Series Technical Manual Section 1

Section

1

T

Introduction

he Model 3030 and 3030E are dual-channel counters designed for

simultaneous alpha and beta sample measurement. The Model 3030

has a built-in scintillation detector with a shielded chamber and

chrome-plated brass sample tray that can accept a maximum sample

size of 5.1 cm (2 in.) in diameter. The Model 3030E utilizes an external, side

mounted sample counter. Common external counters are: the alpha-only,

Model 43-10, or the alpha-beta, Model 43-10-1. Throughout this manual, the

term “3030” will be used to refer to both instruments unless otherwise

noted.

The Model 3030 is powered by main supply of 95-250 Vac. The instrument

features a built-in detector, high-voltage power supply, adjustable count time

periods, and a click-per-event audio with adjustable volume. A pulse height

analyzer is employed to provide information to the two independent

counters. The Model 3030 also features an internal trickle-charged gel-cell

battery for providing up to eight hours of use without mains supply. The

two independent LCDs (liquid crystal displays) feature six 1.3 cm (0.5 in.) tall

digits, which are backlit for improved visibility.

The instrument may be operated as a traditional scaler (counts per count

time) with a manually adjustable high voltage, or may be enabled to operate

with advanced features. The 9-pin RS-232 connector on the back of the

instrument allows attachment to a computer or printer. Software is provided

to allow the setup of several advanced features.

The counts per minute (CPM) or disintegrations per minute (DPM) modes

may be enabled to allow the count to be converted (automatically, in real

time) to cpm or dpm. The background radiation count may be subtracted

automatically in either mode. Crosstalk correction, alpha or beta alarms, and

time/date may also be set. Parameters are stored in non-volatile memory.

Time and date are maintained with an internal lithium battery.

Another advanced feature, which may be enabled or disabled, is the QC

Ludlum Measurements, Inc. Page 1 November 2017

(Quality Control) check function. When enabled, the user must perform

Model 3030 & 3030E Series Technical Manual Section 1

measurements on known sources (and background) and receive acceptable

numbers in order for the instrument to be used that day. Twenty-four hours

later, the QC LED (light emitting diode) is turned on, indicating the need for

another QC check. This feature ensures that the instrument is tested daily

and that measurements are valid.

The Model 3030-2 is a variant of the Model 3030 that allows the count to be

displayed in units of Bq or CPS (counts per second). In order to do this, the

status light for overload (OL) is changed to a green indicator, and the

overload condition is instead displayed as "OL" on both LCD displays. The

final change is that, when placed into Bq or CPS units, the alpha and beta

LCD displays are changed to having a second decimal point, ie. in the

format xxxx.xx to allow for lower-level measurements. The Model 3030-2

does have a distinctly different front panel that has the model number

"3030-2" prominently displayed. A detailed summary of these changes are

found in Appendix A, starting with page A-1.

The Model 3030E-2 is like the Model 3030-2, but with an external detector

like the Model 3030E.

Ludlum Measurements, Inc. Page 2 November 2017

Model 3030 & 3030E Series Technical Manual Section 2

Section

2

Getting Started

Unpacking and Repacking

Caution

The Model 3030 Alpha-Beta Scaler weighs approximately 13.2

kg (29 lb). Take necessary precautions when lifting the

instrument to prevent personal injury or strain.

Remove the calibration certificate and place it in a secure location. Remove

the instrument and accessories (batteries, cable, etc.) and ensure that all of

the items listed on the packing list are in the carton. Check individual item

serial numbers and ensure calibration certificates match. The Model

3030/3030E serial number is located on the back panel, lower left-hand

corner. Most Ludlum Measurements, Inc. detectors have a label on the base

or body of the detector for model and serial number identification.

Important!

If multiple shipments are received, ensure that the detectors

and instruments are not interchanged (particularly in the case

of the Model 3030E). Each instrument is calibrated to a

specific detector(s), and is therefore not interchangeable.

To return an instrument for repair or calibration, provide sufficient packing

material to prevent damage during shipment. Also provide appropriate

warning labels to ensure careful handling.

Every returned instrument must be accompanied by an Instrument Return

Form, which can be downloaded from the Ludlum website at

www.ludlums.com. Find the form by clicking the “Support” tab and

selecting “Repair and Calibration” from the drop-down menu. Then choose

the appropriate Repair and Calibration division where you will find a link to

the form.

Ludlum Measurements, Inc. Page 3 November 2017

Model 3030 & 3030E Series Technical Manual Section 2

Software Installation

Interface software supplied with the instrument will need to be installed if

access to advanced features is desired. User must comply with the software

license agreement found in Section 7 of this manual.

Install the Model 3030 interface software before making any connections

between the instrument and a computer.

Note:

Uninstall any previous version of the Model 3030 interface

software prior to installing this version.

Place the CD in the computer CD drive. The software will automatically

install. If desired, double-click “setup.exe” to manually install the software.

After the automatic installation program begins, follow the prompts. Take

note of the directory to which the executable file is saved. After completion

of the installation, the program may be accessed through the directory in

which it was saved.

External Counter HV Connector (3030E only)

Caution!

The external counter operating voltage (HV) is supplied to the

counter via the counter input connector. A mild electric shock

may occur if bodily contact is made with the center pin of the

input connector. Switch to OFF before connecting or dis-

connecting the cable or counter.

Connect one end of a counter cable to the counter by firmly pushing the

connectors together while twisting clockwise a quarter of a turn. Repeat the

process in the same manner with the other end of the cable and the

instrument.

Start-up

Before using the instrument for the very first time, determine whether or not

a computer interface is desired. If the computer interface is desired, revert to

the previous subsection, “Software Installation,” before continuing, and then

connect the instrument to the computer using the RS-232 cable provided.

Ludlum Measurements, Inc. Page 4 November 2017

Model 3030 & 3030E Series Technical Manual Section 2

Connect the instrument to mains power using the power cable provided and

then turn the instrument on “|” using the front panel power switch (lower

left corner).

Upon power-up, the LCD displays become backlit, front panel indicators

(LEDs) illuminate, and the alpha display shows all eights (888888). Then the

firmware version is displayed. Parameters will display before initialization

completes if the “Show Parameters during power-up” box is checked in

“General Settings” within the interface program. After initialization is

complete, both displays are blanked, and all front-panel indicators (LEDs)

are turned off.

If using the computer interface, start the interface program from the

appropriate directory and set the desired operating parameters described in

detail in Section 6 of this manual

Perform a QC check by following the directions imprinted on the

instrument front panel if available, ensuring the tray latch switch (Model

3030) is placed in the TRAY UNLATCHED position before attempting to pull

out the tray. Once the tray is slid out, place the check source in the center,

slide the tray back in place, and place the tray latch switch in the TRAY

LATCHED position. See Section 6 of this manual for further details on “QC

Check.”

The COUNT TIME MINUTES switch should be set based on the count rates

being observed and the desired statistical accuracy. Set the VOLUME control

to the desired level of audio.

Proceed to use the instrument. For further information on instrument

controls or functions, consult Sections 4 and 7 of this manual.

Ludlum Measurements, Inc. Page 5 November 2017

Model 3030 & 3030E Series Technical Manual Section 3

Section

3

Model 3030 ONLY

Model 3030E ONLY

Specifications

Detector: ZnS(Ag) adhered to a plastic scintillation material

Tube: 5.1 cm (2 in.) diameter, magnetically shielded photomultiplier

Window: 0.4 mg/cm

Active and Open Area: 20.3 cm

Sample Holder: brass housing with chrome-plated brass sample tray,

capable of holding 2.5 or 5.1-centimeter (one or two-inch) diameter samples,

up to 1 cm (0.4 in.) thick

Shielding Thickness: 19 mm (0.75 in.)

Efficiency (4π geometry):

Alpha: 32% for

Beta: 8% for

Background:

Alpha: 3 cpm or less

Beta Gamma: 50 cpm or less (10 µR/hr field)

Size: 29.2 x 19.1 x 26.7 cm (11.5 x 7.5 x 10.5 in.) (H x W x D)

14

2

aluminized Mylar

2

230

Th; 39% for

C; 27% for 99Tc; 29% for

238

U; 37% for

239

Pu

137

Cs; 26% for 90Sr/90Y

Ludlum Measurements, Inc. Page 6 November 2017

Weight: 13.2 kg (29 lb)

Finish: gray powder coating with subsurface-printed membrane front panel

Counter Connector: series “C” for connection to an external counter

Size: 24.1 x 13.5 x 25.4 cm (9.5 x 5.3 x 10.0 in) (H x W x D)

Model 3030 & 3030E Series Technical Manual Section 3

Common

Specifications

Weight: 2.7 kg (6 lb)

Finish: beige powder coating with subsurface-printed membrane front panel

Input Sensitivity: Beta-gamma lower threshold is adjustable from 2 mV to

10 mV. Beta-gamma upper threshold is adjustable from 25 mV to 100 mV.

Alpha threshold is adjustable from 150 mV to 500 mV. Normally the beta

channel is set for input pulses from 4 mV to 50 mV, and the alpha channel

is set for input pulses above 120 mV.

Beta Threshold: -4 mV

Alpha Threshold: -120 mV

Beta Window: 50 mV

High Voltage (HV): manually or digitally adjustable from 200 to 2500 Vdc

with the capability of supporting 60-megohm scintillation loads to 1500 volts

Audio: dual tone (one for each channel), “click-per-event” type with volume

control

Data Output: 9-pin RS-232 port

Status Indicators: backlit indicators for QC-daily QC check needed; OL-

scintillation detector is in overload condition; CPM/DPM- counting in CPM or

DPM mode; αAL/βAL-count has exceeded the alarm set point

Count Time: Select 0.1, 0.5, 1, 2, 5, 10, 60 minutes or the user-defined PC

setting, which is defined during setup using the RS-232 port. User-defined

count time may be set from 0.1 to 546.1 minutes.

Scalers: two each (one per channel), six-digit LCD displays with backlights

providing a range of 0-999999 counts (started by the COUNT button)

Scaler Linearity: reading within 2% of true value

Count Timer: adjustable from 0.1 to 30 minutes (PC setting is user-defined

via PC software)

Power: 250 watts at 95-250 Vac, 50-60 Hz single phase; internal 12 Vdc,

1.2A/hr, trickle-charged battery provides power for eight hours

Ludlum Measurements, Inc. Page 7 November 2017

Model 3030 & 3030E Series Technical Manual Section 4

Section

4

Description of Controls and

Functions

Front Panel

ON/OFF: a rocker switch used to apply power to the instrument when in the

ON position

COUNT Button: resets and starts the counting cycle, also resets the two

counters when depressed

QC CHECK Button: starts the QC (Quality Control) Check cycle, also resets

the two counters when depressed. Pressing this button during a QC Check

will restart the process. Press the COUNT Button to advance to the next

step.

COUNT TIME (MINUTES): a rotary switch, allowing selection of count times

of 0.1, 0.5, 1, 2, 5, 10, 60 or a PC position that selects the user-defined count

time

VOLUME: a rotary control used to vary the audio output from off to full

volume

Tray: a slide-out tray is used to hold the sample during a count cycle. The

tray will hold samples, which are up to 1 centimeter (0.4 inches) thick by

either 2.5 or 5.1 centimeters (one or two inches) in diameter. The tray insert

is held in place by a set screw (left side) and is reversible (by loosening the set

screw) for selection of sample diameter.

Tray Switch (Model 3030 only) (Marked TRAY LATCHED and TRAY

UNLATCHED): a 90° rotary control used to lift the sample tray into position

and block all extraneous light from the detector. Tray switch should always

be in the LATCHED position while counting.

Ludlum Measurements, Inc. Page 8 November 2017

Model 3030 & 3030E Series Technical Manual Section 4

ALPHA: A six-digit backlit LCD readout indicates counts received in the

alpha counting channel.

BETA: A six-digit, backlit LCD readout indicates counts received in the beta

counting channel.

QC: A red LED indicator illuminates whenever QC is needed. When a valid

QC check is performed, the QC indicator turns off. Additionally, the QC

indicator is turned off when the QC check feature is disabled (during setup).

OL: A red LED indicator illuminates whenever the internal circuitry detects a

current overload to the detector. This warning usually indicates an open

sample tray or a torn window on the front of the internal detector.

Instrument will not count while this indicator is illuminated.

CPM: A green LED indicator illuminates whenever CPM mode is

established (during setup).

DPM: A green LED indicator illuminates whenever DPM mode is

established (during setup).

αAL: A red LED indicator illuminates whenever the alpha count exceeds the

alarm level established during setup.

βAL: A red LED indicator illuminates whenever the beta count exceeds the

alarm level established during setup.

Back Panel

Detector Input Connection (Model 3030E only): a series "C" coaxial

connector; other connectors are available upon request

RS-232: a 9-pin D-connector for connection to printer or computer

CAL: a cover for the calibration potentiometers, which should only be

adjusted by trained and authorized personnel during calibration

INPUT: line or mains power receptacle and fuse holder. Use of two

one-amp, fast-blowing fuses provides protection to the instrument in case of

internal electrical failure.

Remove the calibration (cal) cover plate to access the following

calibration potentiometers:

A-TH: a multi-turn potentiometer used to vary the alpha pulse discriminator

from 40 to 700 mV, normally set at 120 mV

Ludlum Measurements, Inc. Page 9 November 2017

Model 3030 & 3030E Series Technical Manual Section 4

B-WN: a multi-turn potentiometer used to vary the upper beta pulse

discriminator from BT setting to AT setting, normally set at 50 mV

B-TH: a multi-turn potentiometer used to vary the lower beta pulse

discriminator from 2 to 15 mV, normally set at 4 mV

OL: a multi-turn potentiometer that provides a means to vary the detector

current overload set point

HVL: a multi-turn potentiometer used to calibrate the digital high voltage

HVM: a multi-turn potentiometer used to manually adjust the high voltage

when digital control is not desired

Internal Controls

The following dipswitches and jumpers are located on the

amplifier/processor board and are only accessible when the cover is

removed.

Dipswitch 1: When in the OFF position, the Model 3030 is locked into Scaler

mode only. The default position is ON.

Dipswitch 2: When in the ON position, the calibration date is disabled. The

default position is ON.

HV Jumper: When shunt is on the two outside pins, the HV is adjusted

manually with the HVM potentiometer. The normal shunt position is on the

two inside pins.

Ludlum Measurements, Inc. Page 10 November 2017

Model 3030 & 3030E Series Technical Manual Section 5

Section

5

Safety Considerations

Environmental Conditions for Normal Use

Indoor use only

No maximum altitude

Temperature range of -20 to 50 °C (-4 to 122 °F)

Maximum relative humidity of less than 95% (non-condensing)

Mains supply voltage range of 95-250 Vac, 50/60Hz single phase,

250W

Maximum transient voltage of 1500 Vac

Installation Category II (Overvoltage Category as defined by IEC

1010-1)

Pollution Degree 2 (as defined by IEC 664): Normally only

nonconductive pollution occurs. Temporary conductivity caused by

condensation is to be expected.

Cleaning Instructions and Precautions

The Model 3030 Alpha-Beta Sample Counter may be cleaned externally with

a damp cloth, using only water as the wetting agent. Do not immerse the

instrument in any liquid. Observe the following precautions when cleaning:

1. Turn the instrument OFF and disconnect the instrument power

cord.

2. Allow the instrument to sit for one minute before cleaning.

Ludlum Measurements, Inc. Page 11 November 2017

Model 3030 & 3030E Series Technical Manual Section 5

Warning Markings and Symbols

Caution!

The operator or responsible body is cautioned that the

protection provided by the equipment may be impaired if the

equipment is used in a manner not specified by Ludlum

Measurements, Inc.

Caution!

Verify instrument voltage input rating before connecting to a

power converter. If the wrong power converter is used, the

instrument and/or power converter could be damaged.

The Model 3030 Alpha-Beta Sample Counter is marked with the following

symbols:

ALTERNATING CURRENT (AC) (IEC 417, No. 5032) - designates an

input receptacle that accommodates a power cord intended for connection

to AC voltages. This symbol appears on the back panel.

PROTECTIVE CONDUCTOR TERMINAL (per IEC 417, No. 5019)

– designates the central grounding point for the safety ground. This symbol

is visible inside the chassis.

CAUTION (per ISO 3864, No. B.3.1) – designates hazardous live voltage

and risk of electric shock. During normal use, internal components are

hazardous live. This instrument must be isolated or disconnected from the

hazardous live voltage before accessing the internal components. This

symbol appears on the front panel. Note the following precautions:

Ludlum Measurements, Inc. Page 12 November 2017

Model 3030 & 3030E Series Technical Manual Section 5

Warning!

The operator is strongly cautioned to take the following

precautions to avoid contact with internal hazardous live parts

that are accessible using a tool:

1. Turn the instrument power OFF and disconnect the power

cord.

2. Allow the instrument to sit for one minute before accessing

internal components.

CAUTION, RISK OF ELECTRIC SHOCK (per ISO 3864, No. B.3.6)

– designates a terminal (connector) that allows connection to a voltage

exceeding one kV. Contact with the subject connector while the instrument

is on or shortly after turning off may result in electric shock. This symbol

appears on the rear panel of the Model 3030E only.

The “crossed-out wheelie bin” symbol notifies the consumer that the

product is not to be mixed with unsorted municipal waste when discarding;

each material must be separated. The symbol is placed near the AC

receptacle. See section 8, “Recycling,” for further information.

Replacement of Main Fuse (Back Panel)

Warning!

For continued protection against risk of fire, replace only with

fuse of the specified type and current rating!

Ludlum Measurements, Inc. Page 13 November 2017

Model 3030 & 3030E Series Technical Manual Section 6

Section

6

Calibration and Maintenance

Calibration

The following calibration procedure is applicable to the Model 3030.

Adjustments are necessary if this procedure is used with the Model 3030E.

Where applicable, those changes will be noted with regard to the most

common external detector used – the Model 43-10-1. Other instrument

detector combinations are not covered in this manual. Consult the individual

detector manual for the needed specifications.

A Ludlum Model 500 Pulser or equivalent is required. If the pulser does not

have a high-voltage readout, use a high-impedance voltmeter with at least

1000 megohm input resistance to measure the detector voltage. Calibrated

sources are also required.

Recommended Sources

The recommended sources for use with the Model 3030 are plated

alpha and 99Tc beta sources. These sources are 3.2 cm (1.3 in.) disks with an

active diameter of 2.5 cm (1 in.). These disks are then mounted in a

protective ring with an outside diameter of 4.8 cm (1.9 in.). We feel that this

type of source construction protects those vital dpms. The recommended

size is as large as possible. Keep in mind that you want good statistics, and to

do that you want large numbers in a short amount of time. If you want to

count for 60 seconds, than a source size of about 20,000 dpm will generally

result in counts (given a 15% 4π efficiency) of 3000 counts. Counting this

size source in a tenth of a minute will result in a count of only about 300

above background, and your percentage error will be greater. Increasing the

size of the source to 200,000 dpm gives you better statistics, while allowing

you to keep the count time short.

Calibration Procedure

Perform mechanical checks, such as switch function and

illumination of digital readouts.

239

Pu

Ludlum Measurements, Inc. Page 14 November 2017

Model 3030 & 3030E Series Technical Manual Section 6

Remove the outside cover of the Model 3030. Measure battery

voltage and ensure voltage is 13 volts or greater.

Connect the Model 3030 to the computer and load the default

settings. Make sure that the jumper on the amplifier/processor

board is on the inside two (2) pins. Ensure that both dipswitches are

in the ON position.

Connect the Model 500 Pulser to the Model 3030 with the

appropriate cable. (Computer may stay connected.)

Adjust the pulser for 400,000 cpm and adjust the pulse amplitude to

4 mV (negative amplitude).

Adjust the beta threshold (B-TH) and beta window (B-WN) for the

appropriate set points: B-TH at 4 mV and B-WN at 50 mV. The

pulser counts should be detected on the Model 3030 beta display

above 4 mV and should shut off above 50 mV.

Pulses in the beta channel should be audible. Ensure that the

VOLUME control works correctly.

Set the Model 500 Pulser amplitude switch to 200 mV. With the

Model 500 Pulser set to 120 mV, adjust the alpha threshold (A-TH)

control for 120 mV.

Pulses in the alpha channel should be audible.

Set the HV to 800 Vdc. Using a high-voltage meter, measure the high

voltage and adjust the HVL potentiometer on the amplifer/processor

board until the high voltage reads 800 Vdc ±2 Vdc.

Change the voltage (using the computer) to 500 Vdc and 1500 Vdc.

In each case, verify that the high voltage is within ±5% of the

correct value.

Change the shunt on the jumper (amplifier/processor board) to the

manual side (outside two [2] pins from the edge of the board).

Adjust the HVM potentiometer to manually adjust the high voltage to

800 Vdc. Place shunt back to the automatic side (inside two [2]

pins).

Ludlum Measurements, Inc. Page 15 November 2017

Set the LCD count time for 0.1 minute (6 seconds). Adjust the

pulser count rate to 400,000 cpm and pulse amplitude to 20 mV.

Model 3030 & 3030E Series Technical Manual Section 6

Press the COUNT button. When count cycle is complete, multiply the

β BETA LCD reading by 10 and confirm that this reading is within

±2% of the incoming count rate. Repeat this step with 200 mV

pulses and check the α-ALPHA LCD reading.

The objective of the next steps is to find an operating voltage for the

detector that will yield the detector’s stated efficiency while not over-

counting the background radiation field. The 2π efficiency (Eff) is

calculated as:

Instrument Count Rate

×100% = Eff

cpm of Source

In addition, “cross talk” must be considered for determining

the optimum operating voltage and is defined as:

Alpha “cross talk” =

αSourceCβ - BackCβ

×100%

αNetCα

and

Beta “cross talk” =

βSourceCα – BackCα

×100%

βNetCβ

where

αSourceCβ = α source count in β channel

BackCβ = background count in β channel

αNetCα = Net α source count in α channel

βSourceCα =β source count in α channel

BackCα = background count in α channel

βNetCβ = Net β source count in β channel

For the alpha/beta scintillation detector, applicable 4π efficiencies

are:

Ludlum Measurements, Inc. Page 16 November 2017

Model 3030 & 3030E Series Technical Manual Section 6

27% for 99Tc,

37% for

239

Pu.

Acceptable background count rates (in a 10µR/hr field ) are:

alpha: 3 cpm or less

beta: typically 50 cpm or less

(Model 3030E with 43-10-1: 50-80 cpm)

Acceptable “crosstalk” values (in a 10µR/hr field) are:

alpha “crosstalk”: 10% or less

beta “crosstalk”: 1% or less.

Using the computer interface software, perform a high voltage

plateau in 25-volt increments from about 500 to 650 Vdc. Print the

results and keep the printout with the calibration certificate.

Find the optimum operating voltage, which gives the greatest alpha

and beta source efficiencies and acceptable background (cpm), while

maintaining acceptable values for “crosstalk” between channels.

Set the unit in DPM mode with efficiencies, background subtract,

and crosstalk correction numbers from the high voltage plateau.

Set the count time to one minute and print out an MDA chart from

the interface software.

Ludlum Measurements, Inc. Page 17 November 2017

Model 3030 & 3030E Series Technical Manual Section 6

Note:

The detector operating voltage must be determined and set

before the overload (OL) adjustment is performed. If the

detector operating voltage is readjusted, the OL setting must be

readjusted.

Adjust the OL control to the maximum counterclockwise position.

To simulate a light leak, expose the photomultiplier tube (PMT) to

light by pulling the tray out. Adjust the OL control until the overload

LED just begins to flicker. Confirm that the overload LED turns off

when the tray is latched closed.

Maintenance

Instrument maintenance consists of keeping the instrument clean and

periodically checking the battery and calibration.

An instrument QC Check should be performed prior to each use by

exposing the detector to a known source and confirming the proper reading

on each scale.

Recalibration should be accomplished after any maintenance or adjustment

has been performed on the instrument. Ludlum Measurements recommends

recalibration at intervals no greater than one year. Local regulations may

have precedence over this recommendation.

To maintain the life of the internal battery it is recommended that the

instrument be constantly connected to line power with the power switch in

the ON position, even when the instrument is not in use. This will keep the

internal battery fully charged.

When the instrument is used without line power, adequate charge time must

be allowed for the internal battery to recharge. If possible, leave the

instrument on with line power applied overnight and weekends. At a

minimum, allow one hour of charge time for each hour of use. If the battery

is inadvertently allowed to fully discharge, and is left in that state, constant

charging for 500 hours (three weeks) may be required for battery recovery.

Ludlum Measurements, Inc. Page 18 November 2017

Model 3030 & 3030E Series Technical Manual Section 6

Note:

The ON-OFF switch must be in the ON position to charge the

batteries. If the unit is out of service for extended periods of

time, charge the battery every six months.

It is recommended that the internal gel-cell battery be replaced every four

years.

Ludlum Measurements, Inc. Page 19 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

Section

7

T

Computer Software

he Model 3030 Control Software allows the user to set all

parameters, view QC Check settings, run high voltage plateaus,

perform MDA (Minimum Detectable Activity), and retrieve the

sample data saved to the logging memory. Certain parameters can

be protected by a password to prevent changes that could affect the

calibration of the instrument.

When the software is started, a dialogue is displayed allowing the user to

manually select the Comm port or to have the software select it

automatically. The software will only search Comm ports 1-16. After the

Model 3030 is found, the parameters are downloaded from the instrument

and the main screen is displayed. The main screen consists of a tabbed

interface separating the various functions and include General Settings, QC

Check, HV Plateau, MDA Calculation, and Data Logging.

Ludlum Measurements, Inc. Page 20 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

The following parameters require a password: Calibration Date, Date, Time,

High Voltage, Background Subtract On/Off, Alpha Background Subtract,

Beta Background Subtract, Alpha Efficiency, Beta Efficiency, Crosstalk

On/Off, Alpha Crosstalk, and Beta Crosstalk. Running an HV Plateau is

also password protected.

Password operation can be enabled in the Parameters menu. Selecting the

"Password Protect" menu item will enable password protection. A

checkmark next to this menu item will indicate if password protection is on

or off. The password is required to change this.

The default password is blank until it is changed by the user using the

Change Password menu item. The password can contain the following

characters: a-z, A-Z, 0-1, !@#$%^&*() and cannot exceed eight characters

in length.

Ludlum Measurements, Inc. Page 21 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

The user is prompted for the password when clicking in the Update button

after changing any of the password protected parameters. If the password

given is correct, the parameters are changed and the instrument is updated.

If the password is incorrect and the user cancels the password prompt, the

previous values for the parameters are restored, with no parameters sent to

the instrument. Clicking in the Start button under the HV Plateau tab will

prompt the user for the password. The password will not be asked for again

until a different tab is selected to allow the user to run multiple plateaus

without having to enter the password every time.

Parameters

The “Update” button at the bottom of the window will save all changes to

the instrument.

File Menu/Load Defaults: This menu item loads the file, “default.cfg,” and

saves the settings to the instrument.

Parameters/Update (Ctrl-U): This menu item is the same as clicking on the

“Update” button.

Parameters/Load from File (Ctrl-O): This menu item loads in settings from

a user-defined text file.

Parameters/Save to File (Ctrl-S): This menu item will save the current

settings to a user-defined file.

Parameters/Reload All Data (Ctrl-R): This menu item will reload all data

from the instrument.

Parameters/Print Parameters (Ctrl-P): This menu item will print out a

report of all parameters to a printer.

Parameters/Password Protect: When this is checked, certain functions

require a password.

Ludlum Measurements, Inc. Page 22 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

Parameters/Change Password: This selection changes the current

password.

Headers 1–6: These are six user-defined fields to place general information.

These are limited to 15 characters.

Calibration Due Date: This date is checked when instrument is turned on. If

current date is past this date, “OUTCAL” is displayed on the instrument.

Setting Dipswitch 2 to the “ON” position will disable this feature.

3030 Date/Time: This is the current date and time from the last time data

was read from the instrument.

User Defined Time (min): In addition to the seven preset count times, there

is a user-defined count time that can be set from the PC. This is the count

time that will be used when the instrument is switched to the “PC” position.

Alpha, Beta, Alpha + Beta Alarms: These are the alarm settings. A value of

999999 will disable the alarm. If the unit is in CPM, the alarms are in CPM.

If the instrument is in DPM, the alarms are in DPM. It is up to the user to

make sure that the alarms are set accordingly to the count mode.

High Voltage: This field displays the current high-voltage setting. The high

voltage may be adjusted from 0 to 2000 Vdc.

Loss of Count Timer: If the detector receives no counts on the beta channel

after the time expires, the display will show “LOC FAIL” and will not

operate until reset. This timer is reset whenever a count is received.

Count Mode: The model 3030 can display the readings in raw scaler counts,

CPM, or DPM. If dipswitch 1 is “OFF,” the unit is always in scaler mode.

The Ludlum Model 3030 can operate as a traditional radiation scaler,

displaying measurements in terms of CPM (counts per minute). It can also

be programmed to automatically adjust and display the measurements in

DPM (disintegrations per minute). By knowing what the efficiency is for

alpha and beta particles, the Model 3030 is able to divide measurements by

the known efficiency and display in DPM. The DPM mode may be easier

for users, since many regulations and limits are expressed in terms of DPM.

In raw scaler mode, the count obtained is the actual counts received during

that count time. In CPM mode, the counts are adjusted for the count time.

In DPM mode, the counts are adjusted for count time and efficiency. For

example:

Ludlum Measurements, Inc. Page 23 November 2017

Count Time = 0.1 minutes (6 seconds)

Model 3030 & 3030E Series Technical Manual Section 7

Efficiency = 25%

Input = 1000 DPM

CPM = 250 counts per minute (no background subtract or crosstalk

calculations)

DPM = 400 disintegrations per minute (no background subtract or

crosstalk calculations)

Alpha/Beta Efficiency: These values are only available when unit is in DPM

count mode. This is used to calculate the DPM reading and is expressed as a

percent. The QC mode has a function to update the efficiency with values

calculated from the QC check.

Activate Background Subtract: This is only available when count mode is

CPM or DPM. It turns on/off the background subtract and will subtract the

background from each channel and display the net count.

Alpha/Beta Background Subtract: These values will be subtracted while the

instrument is counting. For example, in CPM mode with an input of 2000

CPM and a background subtract value of 1000, the reading will display

“1000.” The QC mode has a function to update the background subtract

with values calculated from the QC check.

Activate Crosstalk Correction: This is only available when count mode is

CPM or DPM. This control turns on/off the crosstalk correction.

% Alpha to Beta Crosstalk: This is the percent of alpha counts that are seen

by the beta channel. Setting this number to 2% subtracts 2% of the received

alpha counts from the beta channel.

% Beta to Alpha crosstalk: This is the percent of beta counts that are seen

by the alpha channel. Setting this number to 2% subtracts 2% of the

received beta counts from the alpha channel.

Show Parameters during power-up: When enabled, the following are

displayed to the LCD display during power up: firmware version, date, time,

high voltage, user-defined count time, and alarms.

Ludlum Measurements, Inc. Page 24 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

QC Check

The Ludlum Model 3030 has a “QC Check” function that allows the user to

determine whether the instrument is operating within predetermined limits.

This function is optional and does not have to be enabled. There is also an

option to update the background every 24 hours. This background update

does not validate the received reading with any of the limits set on this

screen. It simply takes a background count and stores that reading in the

instrument. When the QC check is enabled, every day the user must perform

the QC check procedure and receive acceptable values in order to utilize the

instrument for normal use. After 24 hours, the instrument will light the red

indicator marked “QC,” and not allow normal use until the next QC check.

The predetermined limits are:

1. The instrument counts a specific alpha source with a known activity

and receives a specified standard efficiency, plus or minus a specified

percentage.

2. The instrument counts a specific beta source with a known activity

and receives a specified standard efficiency, plus or minus a specified

percentage.

3. The instrument counts background (no source inside the tray) and

receives results that are within the upper and lower limits specified.

Ludlum Measurements, Inc. Page 25 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

QC Off/Normal QC/Background Update Only/Manual QC Only: If enabled,

24 hours after the last QC check, the QC LED turns on and a QC check

must be run before the normal operation can resume. The “Normal QC”

check takes both an alpha and beta source count and a background count.

The “Background Update Only” takes only background counts and replaces

the current background subtract values with the new values. In the

“Background Update Only” mode the display shows the counts in CPM

with one decimal place. Manual mode allows the QC button to start a QC

test but does not automatically require one after 24 hours. Manual QC

option only available with firmware 39013N31 or higher.

If the QC mode is disabled then a QC test cannot be started with the QC

button.

Update Efficiency: If enabled, the efficiencies calculated during the QC

check will replace the efficiencies used for the DPM calculation. This option

is only available in the Normal QC check mode.

Update Background Subtract: If enabled, the background readings

received during the QC check will replace the current background subtract

values. This option is only available in the Normal and Background Only

QC check modes.

Override Count Time: If enabled, the count times set by the count time

switch on the front of the instrument are overridden using the values in the

alpha, beta, and background QC count times.

Last QC Performed: This is the last date and time a successful QC check

was performed.

Last Alpha/Beta Efficiency: The last time a QC check was run, this was the

computed efficiency.

Standard Alpha/Beta Efficiency: These are the values that the QC check

will use to determine pass/fail. If the calculated efficiency is outside the

Standard Efficiency by the Allowable QC Efficiency %, the QC will fail.

Allowable QC Efficiency ± %: This is the range for how close the computed

efficiency must be to the standard. A standard of 25% with an allowable

range of 5% specifies that to pass the QC check, the efficiency must be in

the range of 20% to 30% to pass.

Source Size: The DPM value of the source size is saved to the instrument

and is used to determine the efficiency during a QC check.

Ludlum Measurements, Inc. Page 26 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

Alpha QC Source Count Time (min): This is the alpha source count time in

minutes used when the Override Count Time function is enabled.

Beta QC Source Count Time (min): This is the beta source count time in

minutes used when the Override Count Time function is enabled.

Background QC Count Time (min): This is the background count time in

minutes used when the Override Count Time function is enabled.

Alpha/Beta Upper & Lower Limits: These determine what range is

acceptable for the background during a QC check. If the background does

not fall within these values, the QC check will fail.

Alpha/Beta Upper & Lower Limits: These determine what range is

acceptable for the background during a QC check. If the background does

not fall within these values, the QC check will fail.

STEPS FOR PERFORMING A QC CHECK

1. To enable the QC mode, click on the box marked “Normal QC” in

the tab marked “QC Settings.”

2. Press the button marked “Reload Last Values” at the bottom of the

screen to see the last values calculated during the last HV

Plateau. The data shown include the “Last QC Performed,” the

“Last Alpha Efficiency,” the “Last Beta Efficiency,” the “Last

Alpha Background,” and the “Last Beta Background.” These

numbers are shown for reference ONLY. The QC check

predetermined limits must be chosen and input by the user.

3. Enter values for the “Standard Alpha Efficiency” and the “Standard

Beta Efficiency.” The values input here should reflect the

average efficiency with the given sources. After entering the

values, press the “Update” button.

4. Enter values for the “Allowable QC Efficiency.” These percentage

values entered allow the instrument to accept efficiencies that

are somewhat higher and lower than the standard efficiency.

For example, if the standard alpha efficiency is 25% and the

allowable QC efficiency is 5%, the acceptable alpha efficiency

will be from 20% to 30%. After entering the values, press the

“Update” button.

5. Enter the “Alpha Source Size” and “Beta Source Size” of the

sources to be used during the QC check. It is preferred to use

the DPM or µCi column wherever possible. Conversion from

Ludlum Measurements, Inc. Page 27 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

CPM to DPM using a factor of 2 may not be correct, depending

on isotope and source material. Note that these source sizes are

completely independent of the source sizes used in the HV

plateau. After entering the values, press the “Update” button.

Enter in upper and lower background limits for both alpha and beta

background. Since alpha background is usually very low, it is acceptable to

use a lower limit of 0. After entering the values, press the “Update” button.

To start a QC check:

1. Press the QC CHECK button on the front of the Model 3030. The

Model 3030 does not need to be connected to a computer for the

QC check to function.

2. If the Normal QC mode is selected, the upper LCD should flash

ALPHA. Unlatch the tray and insert the alpha source. Close and

latch the tray.

3. Press the COUNT button to start the alpha count. At the end of the

count, the LCD will flash between displaying the final readings and

ALPHA. If the QC Check fails, the instrument should be taken out

of service until it can be repaired.

4. Unlatch the tray and remove the alpha source. Insert the beta

source and close and latch the tray.

5. Press the COUNT button to advance to the beta step. The lower

LCD should now flash BETA.

6. Press the COUNT button to start the beta count. At the end of the

count the LCD will flash between displaying the final readings and

BETA. If the QC check fails, the instrument should be taken out of

service until it can be repaired.

7. Unlatch the tray and remove the beta source. Close and latch the

tray.

8. Press the COUNT button to advance to the background count.

Both displays should flash BAC.

9. Press the COUNT button to start the background count. At the

end of the count, the LCD will flash between the readings and BAC.

If the QC check fails, the instrument should be taken out of service

until it can be repaired.

Ludlum Measurements, Inc. Page 28 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

10. Press the COUNT button to exit the QC check mode.

HV Plateau

A high-voltage (HV) plateau is normally run at calibration time in order to

set the proper HV and to determine the operating efficiencies. This routine

is provided to automate the plateau procedure and simplify the calculations.

This screen allows you to enter the starting and ending value, the voltage

increment, and the source size. The background count is always one minute.

The data may be saved in a text file or printed to a printer.

The plateau order can be changed from Alpha, Beta, Background to Beta,

Alpha, Background.

STEPS FOR PERFORMING A HIGH VOLTAGE PLATEAU

1. Turn the Model 3030 on and connect to a computer by way of a

serial port with supplied cable.

2. Run the Model 3030 control software. Software will automatically

detect the instrument and download all parameters.

3. When all the parameters have been downloaded, click on the tab

marked “HV Plateau” at the top of the window.

Ludlum Measurements, Inc. Page 29 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

4. Enter the “Starting High Voltage” and the “Ending High Voltage.”

These parameters define where the plateau will start and end.

5. Enter the “High Voltage Step.” This parameter determines the

increment between steps in the plateau.

6. Enter the “Alpha Source Size” and “Beta Source Size.” There are

three fields for each channel corresponding to CPM, DPM, and

µCi. The user can enter the source size in any field, and the

other fields will automatically show the converted value. It is

preferred to use the DPM or µCi column wherever possible.

Conversion from CPM to DPM using a factor of 2 may not be

correct depending on isotope and source material. Under the

“ISOTOPE” fields, enter the isotope label for the alpha and

beta source.

7. Verify the current count time. The Model 3030 has seven preset

time values and a user-definable “PC” time set by the computer.

The “PC” time is defined in the tab marked “General Settings.”

Enter in the needed time and press “Update.” If a different time

is required, change the time by using the knob on the front of

the instrument and click the “Read” button to refresh the count

time on screen. The background count time is always one

minute.

8. Press the “Start” button to start the plateau. There is a prompt to

insert the alpha source. The Model 3030 will record readings at

each high voltage as determined above. When the alpha plateau

is completed, you are prompted to insert the beta source. Again,

the Model 3030 will record readings at each high voltage. After

the beta plateau is complete, you are prompted to remove the

beta source. Background counts are then taken. The grid

contains the following columns:

1. Alpha source (beta counts shown in parenthesis)

2. Beta source (alpha counts shown in parenthesis)

3. Alpha background in cpm

4. Beta background in cpm

5. % alpha efficiency (4π)

6. % beta efficiency (4π)

Ludlum Measurements, Inc. Page 30 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

7. % alpha to beta crosstalk

8. % beta to alpha crosstalk

9. After the plateau is complete, you can either save the plateau to an

ASCII text file or print the results for later reference.

10. You may choose the operating voltage according to your own

standards. Ludlum Measurements current standards, which may

or may not be appropriate for your use, are listed below:

99

(a)

Tc efficiency (4π) greater than or equal to 27%

239

(b)

Pu efficiency (4π) greater than or equal to 37%

(c) Alpha crosstalk in beta channel less than or equal to 10%

(d) Beta crosstalk in alpha channel less than or equal to 1%

(e) Beta background is less than or equal to 50 cpm

(f) Alpha background is less than or equal to 3 cpm

11. By double-clicking on a row after the plateau has completed, the

user may automatically update the efficiencies, background

subtract, and crosstalk values, or the user can manually enter in

the values to update the instrument.

Manual Entry:

12. Enter the selected operating voltage in the field marked “High

Voltage (Vdc)” and click “Update.” This action stores the

chosen operating voltage inside the Model 3030.

Ludlum Measurements, Inc. Page 31 November 2017

13. Click on “DPM” under the Count Mode area to select DPM mode.

Model 3030 & 3030E Series Technical Manual Section 7

14. Enter in the alpha and beta efficiencies as 4π efficiencies and click

“Update.”

15. You may also choose to utilize the “Background Subtract” function

by entering values to subtract the known constant background

from each measurement. The values may be chosen from the

data gathered above during the plateau. When used, the value

entered is subtracted prior to the conversion to DPM.

16. You may also choose to utilize the “Crosstalk Correction” function

by entering values to correct each measurement for crosstalk.

The values may be chosen from the data gathered above during

the plateau. When used, the crosstalk correction is applied to

measurements after background subtraction (if active) and

before the DPM conversion (if active).

MDA Calculations

This screen shows the calculated MDA values for all count times based on

the current background and efficiency values. The confidence level may be

set at 90%, 95%, or 99%. This screen is only available when the instrument

is in DPM mode. The values are preset according to the current instrument

settings but may be changed here. The data may also be printed to a printer.

Ludlum Measurements, Inc. Page 32 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

Data Logging

The Model 3030 can store 600 samples in its data logging memory. The

following fields are stored with each sample: time, date, alpha reading, beta

reading, count time, count mode, and user-defined comment.

Recycle On: This will activate the recycle function. As soon as the count

completes, another one is started automatically.

Logging Mode: The choices are either Off, Log All, or Log QC only. This

will activate the saving of samples to the instrument’s non-volatile memory.

Printer Mode On: When activated, the instrument will output the count data

to the serial port. No handshaking is active. A serial printer may be

connected to display the data. The date, time, alpha reading, beta reading,

count mode, and count time is output. The count mode is indicated by a

single letter: C = cpm, D = dpm, S = Scaler.

Get Samples: This button reads all sample data from the instrument.

Clear Samples: This button clears the instrument of all samples in memory.

Save Samples: This allows saving the sample data to a user-defined file.

The data is saved in a comma delimited (*.csv) file to allow for importing

into other applications.

Ludlum Measurements, Inc. Page 33 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

Print Samples: Selecting this option prints the sample data to a printer.

RS-232 Communication

The Model 3030 communicates by way of an RS-232 interface. The RS-232

port operates at 9600 baud, 8 data bits, 1 stop bit, no parity, and hardware

(RTS/CTS) flow control.

A standard RS-232 cable with straight-through connections is required.

Following is information for pin-outs of the RS-232 Connector/Cable:

M3030 PC (9-Pin)

2 TXD RXD 2

3 RXD TXD 3

5 GND GND 5

7 CTS RTS 7

8 RTS CTS 8

The Model 3030 uses the line-feed character [LF] to terminate commands.

It is acceptable to terminate commands with a carriage return and a line feed

character. All messages received from the Model 3030 are terminated with a

carriage return and line feed character.

The commands are not case sensitive. Any command not recognized will

return "ERROR-xx" where xx is the first two characters of the unknown

command.

[LF] = line feed character (ASCII value 10)

[CR] = carriage return character (ASCII value 13)

COMMANDS

Bn – Background Subtract Status

Sets background subtract ON/OFF or return background subtract status,

where “n: is a value of 0, 1, or 2.

0 = Sets background subtract OFF.

1 = Sets background subtract ON.

2 = Returns status.

Ludlum Measurements, Inc. Page 34 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

Cn - Count

Performs various count functions. The count time is determined by the

positing of the COUNT TIME SWITCH on the front panel unless

otherwise noted. See command RR for the format of the count results.

1 = Start a count.

2 = Stop a count in progress.

3 = Clear alarms.

4 = Start a count and automatically return the results.

5 = Start a one-minute count and automatically return the results.

Dn – Display Mode

The display can be set to show count data as raw scaler counters, counts per

minute (CPM), and disintegrations per minute (DPM).

0 = Set display mode to scaler.

1 = Set display mode to CPM.

2 = Set display Mode to DPM.

3 = Return display mode (SCA, CPM, or DPM).

F – Firmware

Returns a string containing the firmware version number.

Ln – Logging Mode

Sets how samples are logged to internal memory.

0 = Turn logging OFF.

1 = Turn Logging ON.

2 = Log only QC checks.

3 = Return logging mode (OFF, ON, or QC).

Pn

Sets printer mode On/Off.

0 = Turn printing OFF.

1 = Turn printing ON.

2 = Return printing mode (OFF, ON).

Qx

Sets quick power-on mode. The Model 3030 may be configured to display

certain parameters during power-up.

Ludlum Measurements, Inc. Page 35 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

0 = Show parameters OFF.

1 = Show parameters ON.

2 = Return power-up mode (OFF, ON).

RA – Read Next Sample Number

Reads the next sample number. Subtracts one from this number to get the

total number of samples logged. Returns nnnn.

RBn – Read Background Subtract

Reads the alpha or beta background subtract value. The value returned must

be divided by 10 to get the correct value. Returns nnnnnn.

1 = Read alpha background subtract.

2 = Read beta background subtract.

RC – Read Calibration Due Date

Reads the calibration due date. Returns MMDDYYYY.

RD – Read Current Date and time

Reads the current date and time. Returns HH:MM:SS MM/DD/YYYY.

REn – Read Efficiency

Reads the alpha or beta percent efficiency. The value returned must be

divided by 10 to get the correct value. Returns nnn.

1 = Read alpha percent efficiency.

2 = Read beta percent efficiency.

RHn – Read Header

Reads the 15-character, user-definable header where “n” is a value from 1 to

6. Returns xxxxxxxxxxxxxxx.

RL – Read Loss of Count Timer

Reads the loss of count timer value in seconds. Returns two lines. Line 1

contains the count time as nnnnn.n. Line 2 returns “BETA” if the loss of

count timer has expired. Otherwise, “OK” is returned.

RNn – Read MDA

Reads the Minimum Detectable Activity (MDA). Returns nnnnnn.

Ludlum Measurements, Inc. Page 36 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

1 = Read alpha ratemeter MDA.

2 = Read beta ratemeter MDA.

3 = Read alpha scaler MDA.

4 = Read beta scaler MDA.

RP – Read the PC Time

Reads the PC or user-defined count time in seconds. The PC time is used

when the COUNT TIME SWITCH on the front panel is set to PC.

Returns nnnnn.n.

RQn

Reads the specified QC parameter.

01 = Read QC enabled status. Returns ON or OFF.

02 = Read current alpha efficiency %. Returns nn.

03 = Read current beta efficiency %. Returns nn.

04 = Read standard alpha efficiency %. Returns nn.

05 = Read standard beta efficiency %. Returns nn.

06 = Read alpha source size (cpm). Returns nnnnnn.

07 = Read beta source size (cpm). Returns nnnnnn.

08 = Read alpha efficiency limit %. Returns nn.

09 = Read beta efficiency limit %. Returns nn.

10 = Read alpha background upper limit (cpm). Returns nnnnnn.

11 = Read alpha background lower limit (cpm). Returns nnnnnn.

12 = Read beta background upper limit (cpm). Returns nnnnnn.

13 = Read beta background lower limit (cpm). Returns nnnnnn.

14 = Read last QC date. Returns MM/DD/YYYY.

15 = Read alpha background (cpm). Returns nnnnnn.

16 = Read beta background (cpm). Returns nnnnnn.

17 = Read last QC time. Returns HH:MM.

18 = Read QC Mode. Returns NOR, BKG, or MAN.

19 = Read QC Update Mode. Returns OFF, ON, EFF, or SUB.

20 = Read alpha source count time (secs). Returns nnnnn.n.

21 = Read beta source count time (secs). Returns nnnnn.n.

22 = Read background count time (secs). Returns nnnnn.n.

23 = Read QC override status. Returns OFF or ON.

RR – Read Count

Reads the current alpha and beta counts. Returns HH:MM MM/DD/YY

aaaaaa bbbbbb x tttt.t.

Ludlum Measurements, Inc. Page 37 November 2017

aaaaaa = alpha count

bbbbbb = beta count

x = S (scaler), C (cpm), and D (dpm)

Model 3030 & 3030E Series Technical Manual Section 7

tttt.t = count time in minutes (If count is in progress, this value

shows count time remaining.)

RS – Read Samples

Reads all logged samples from memory. While reading samples, the audio is

stopped and the displays show a scrolling series of dashes along with the

sample number. A "$" marks the end of the samples.

Returns: ssss MM/DD/YY HH:MM:SS aaaaaa bbbbbb ttttt.t x

cccccccccc[CR][LF] - 59 bytes $[CR][LF] - 3 bytes

ssss = sample number

aaaaaa = alpha scaler

bbbbbb = beta scaler

x = S (Scaler), C (cpm), and D (dpm)

ttttt.t = count time in seconds

cccccccccc = user defined comment

RT – Read Current Count Time

Reads the current count time in seconds. Returns nnnnn.n.

RU – Read Comment

Reads the user-defined, 10-character comment field. Returns xxxxxxxxxx.

RV – Read High Voltage

Reads the high voltage set point. Returns nnnn.

RXn – Read the Crosstalk

Reads the beta-to-alpha or alpha-to-beta crosstalk. The value must be

divided by 10 to get the correct value. Returns nnn.

1 = Read beta-to-alpha crosstalk.

2 = Read alpha-to-beta crosstalk.

RY – Read Recycle Mode Status

Reads the status of the recycle mode. Returns OFF or ON.

Rn – Read the Alarm Set Points

Reads the specified alarm set point. Returns nnnnnn.

Ludlum Measurements, Inc. Page 38 November 2017

Model 3030 & 3030E Series Technical Manual Section 7

1 = Read alpha alarm set point.

2 = Read beta alarm set point.