LUDLUM MODEL 2929

DUAL-CHANNEL SCALER

January 2016

Serial Number 248597 and Succeeding

Serial Numbers

LUDLUM MODEL 2929

DUAL-CHANNEL SCALER

January 2016

Serial Number 248597 and Succeeding

Serial Numbers

Shown with a Model 43-10-1

STATEMENT OF WARRANTY

Ludlum Measurements, Inc. warrants the products covered in this manual to be free of

defects due to workmanship, material, and design for a period of twelve months from the

date of delivery. The calibration of a product is warranted to be within its specified

accuracy limits at the time of shipment. In the event of instrument failure, notify Ludlum

Measurements to determine if repair, recalibration, or replacement is required.

This warranty excludes the replacement of photomultiplier tubes, G-M and proportional

tubes, and scintillation crystals which are broken due to excessive physical abuse or used

for purposes other than intended.

There are no warranties, express or implied, including without limitation any implied

warranty of merchantability or fitness, which extend beyond the description of the face

there of. If the product does not perform as warranted herein, purchaser’s sole remedy

shall be repair or replacement, at the option of Ludlum Measurements. In no event will

Ludlum Measurements be liable for damages, lost revenue, lost wages, or any other

incidental or consequential damages, arising from the purchase, use, or inability to

product

.

use

RETURN OF GOODS TO MANUFACTURER

If equipment needs to be returned to Ludlum Measurements, Inc. for repair or calibration, please send to

the address below. All shipments should include documentation containing return shipping address,

customer name, telephone number, description of service requested, and all other necessary information.

Your cooperation will expedite the return of your equipment.

ATTN: REPAIR DEPARTMENT

501 OAK STREET

SWEETWATER, TX 79556

LUDLUM MEASUREMENTS, INC.

800-622-0828 325-235-5494

FAX 325-235-4672

Model 2929 Scaler Technical Manual

Table of Contents

Introduction 1

Specifications 2

Controls and Functions 3

Front Panel 3-1

Rear Panel 3-2

Safety Considerations 4

Environmental Conditions for Normal Use 4-1

Cleaning Instructions and Precautions 4-1

Warning Markings and Symbols 4-1

Recycling 5

Operating Procedures 6

Calibration Procedures 6-1

High Voltage Adjustment Procedures 6-2

Data Output 7

Function Identification 7-1

Function Source 7-1

Output Signals 7-1

Removing Data from the Model 2929 7-2

Optional Equipment 8

Model 264 Printer 8-1

Model 464 RS-232 Interface 8-1

Model 464-2 Two-Channel Counter 8-2

Parts List 9

Model 2929 Dual-Channel Scaler 9-1

Power Supply Board 9-1

Amplifier/Discriminator Board 9-2

Ludlum Measurements, Inc. January 2016

Model 2929 Scaler Technical Manual

Scaler Board 9-4

Clock/Logic Board 9-5

Dual Audio Board 9-6

6-Digit Readout Board 9-6

Mother Board 9-6

Preamp Board 9-7

Wiring Diagram 9-8

Drawings and Diagrams 10

Ludlum Measurements, Inc. January 2016

Model 2929 Scaler Technical Manual Section 1

Section

1

Introduction

he Model 2929 is a dual-channel scaler designed for use with

“Phoswich” and/or proportional detectors. A pulse height

T

The Model 2929 is powered by a 95 to 250 Vac wall transformer with an

output of 24 Vdc. It has a built-in detector high voltage power supply

with front panel readout, as well as adjustable count time periods

ranging from 0.1 to 990 minutes. It also has a click-per-event audio for

each of the two channels. The unit will operate two printing calculators

(Ludlum Model 264) by way of data connectors located on the rear

chassis. The amplifier circuitry consists of a three-stage amplifier fed

directly to the discriminator circuit. All discriminator controls are

located internally and are easily accessible internally on the right-hand

side of the chassis.

The Model 2929 is generally used in conjunction with a Model 43-10-1

Alpha/Beta Sample Counter.

analyzer is employed to provide information to the two

independent counters.

Ludlum Measurements, Inc. Page 1-1 January 2016

Model 2929 Scaler Technical Manual Section 2

Section

2

Specifications

0

Power: 95 to 250 Vac wall transformer with 24 Vdc output, 50-60 Hz

single phase (typically less than 100 mA)

Input Senstivity: Beta-gamma lower threshold is adjustable from 4 mV,

beta-gamma upper threshold is adjustable from 25 mV to 100 mV, and

alpha threshold is adjustable from 175 mV.

High Voltage (HV): fully adjustable from 200 to 2500 V ±100 V with

the capability of supporting 60-megohm scintillation loads to 1500 V

HV Meter: 6.4 cm (2.5 in.) panel analog meter readout

HV Meter Accuracy: ±10% of reference value

Audio: click-per-event type with volume control for each of the two

channels

Count Time: 0-99 minutes with multiplier of 0.1, 1.0 and 10; external

position for use with an external clock source

Timer Accuracy: The time base for the scaler is crystal-controlled and

has a timer accuracy of ±0.2% of the thumbswitch setting.

Scaler Readout: six-digit, light-emitting diode readout for each of the

two channels

Scaler Accuracy: ±2% of reference value

Size: 24.4 x 37.1 x 25.1 cm (9.6 x 14.6 x 9.9 in.) (H x W x L)

Weight: 5.5 kg (12.1 lb), including detector

Finish: beige powder coat with anodized front panel and silk-screened

nomenclature

Temperature Range: -20 to 50 °C (-4 to 122°F); may be certified for

operation for -40 to 65 °C (-40 to 150 °F)

Ludlum Measurements, Inc. Page 2-1 January 2016

Model 2929 Scaler Technical Manual Section 3

Section

3

Controls and Functions

Front Panel

High Voltage:

V to 2500 V. It provides a linear adjustment of the detector voltage supply.

Changing the detector voltage will cause the detector gain to change. A

linear change in voltage will cause an exponential change in detector gain.

The instrument will support 60-megohm scintillation loads to 1500 V.

HV Meter: a 6.4 cm (2.5 in.) panel meter displaying the high-voltage setting

continuously.

HV: a 10-turn dial used to adjust the detector high voltage.

ON/OFF: a toggle switch used to apply power to the instrument when in the

“ON” position.

Count Lamp: a red light indicating that the scaler is in the count cycle.

Count Switch: resets and starts the counting cycle. This switch will also

reset the two counters when depressed.

HOLD Switch: stops the count cycle without resetting the scaler display.

The counters will hold the value present at the time this button is depressed.

Minutes: a two-decade thumb-wheel switch used for presetting count time.

This switch is used in conjunction with the multiplier switch.

Multiplier: a rotary switch allowing selection of count time mulitpliers of

0.1, 1, 10 or an EXT position for timing using external clock sources.

Detector Input Connection: a series “C” coaxial connector used to supply

the detector with its bias voltage and also to return the signal from the

detector. (Other connectors are available upon request.)

a 10-turn potentiometer control for adjusting HV from 200

Ludlum Measurements, Inc. Page 3-1 January 2016

Model 2929 Scaler Technical Manual Section 3

Beta-Gamma Vol: a rotary control used to vary the audio output of the

beta-gamma channel from off to full volume.

Alpha Vol: a rotary control used to vary the audio output of the alpha

channel from off to full volume.

Alpha Count: a six-digit LED readout indicating counts received in the

alpha counting channel.

Beta-Gamma Count: a six-digit LED readout indicating counts received in

the beta channel.

Rear P anel

Amp Out: a BNC connector that provides access to the final amplifier stage. The

pulse is positive-going with a maximum amplitude of approximately 22 V.

Alpha Out: a 15-pin D type connector used as a data output for the alpha

counter. (Refer to Section 7 for a listing of pin numbers and their functions.)

Beta-Gamma Out: a 15-pin D type connector used as a data output for the beta-

gamma counter. (Refer to Section 7 for a listing of pin numbers and their

functions.)

Fuse: Use of a 1-Amp, fast-blowing fuse provides protection to the instrument

in case of internal electrical failure.

110 Vac: a connector used to apply line power to the instrument

Ludlum Measurements, Inc. Page 3-2 January 2016

Model 2929 Scaler Technical Manual Section 4

Section

4

Safety Considerations

Environmental Conditions for Normal Use

Indoor use only

No maximum altitude

Temperature range of -20 to 50°C (-4 to 122 °F); may be certified for

operation from -40 to 65 °C (-40 to 150 °F)

Maximum relative humidity of less than 95% (non-condensing)

Pollution Degree 2 (as defined by IEC 664).

Cleaning Instructions and Precautions

The Model 2929 may be cleaned externally with a damp cloth, using only

water as the wetting agent. Do not immerse the instrument in any liquid.

Observe the following precautions when cleaning:

1. Turn instrument OFF and disconnect the instrument power

cord.

2. Allow the instrument to sit for one minute before cleaning.

Warning Markings and Symbols

Caution!

The operator or responsible body is cautioned that the

protection provided by the equipment may be impaired if the

equipment is used in a manner not specified by Ludlum

Measurements, Inc.

Ludlum Measurements, Inc. Page 4-1 January 2016

Model 2929 Scaler Technical Manual

Caution!

Verify instrument voltage input rating before connecting to a

power converter. If the wrong power converter is used, the

instrument and/or power converter could be damaged.

The Model 2929 is marked with the following symbols:

DIRECT CURRENT (DC) (IEC 417, No. 5032): designates an input

receptacle that accommodates a power cord intended for connection to DC

voltages. This symbols appears on the back panel.

CAUTION, RISK OF ELECTRICAL SHOCK (per ISO 3864, No.

B.3.6): designates a terminal (connector) that allows connection to a voltage

exceeding 1 kV. Contact with the subject connector while the instrument is

on or shortly after turning off may result in electric shock. This symbol

appears on the front panel.

Section 4

CAUTION (per ISO 3864, No. B.3.1): designates hazardous live voltage

and risk of electric shock. During normal use, internal components are

hazardous live. This instrument must be isolated or disconnected from the

hazardous live voltage before accessing the internal components. This

symbol appears on the front panel. Note the following precautions:

Warning!

The operator is strongly cautioned to take the following

precautions to avoid contact with internal hazardous live parts

that are accessible using a tool:

1. Turn the instrument power OFF and disconnect the power

cord.

2. Allow the instrument to sit for one minute before accessing

internal components.

The “crossed-out wheelie bin” symbol notifies the consumer that the

product is not to be mixed with unsorted municipal waste when discarding;

each material must be separated. The symbol is placed near the DC

receptacle. See section 5, “Recycling” for further information.

Ludlum Measurements, Inc. Page 4-2 January 2016

Model 2929 Scaler Technical Manual

Section

Section 5

5

Recycling

udlum Measurements, Inc. supports the recycling of the electronics

products it produces for the purpose of protecting the environment

L

recycling systems. To this end, Ludlum Measurements, Inc. strives to supply

the consumer of its goods with information regarding reuse and recycling of

the many different types of materials used in its products. With many

different agencies – public and private – involved in this pursuit, it becomes

evident that a myriad of methods can be used in the process of recycling.

Therefore, Ludlum Measurements, Inc. does not suggest one particular

method over another, but simply desires to inform its consumers of the

range of recyclable materials present in its products, so that the user will

have flexibility in following all local and federal laws.

The following types of recyclable materials are present in Ludlum

Measurements, Inc. electronics products, and should be recycled separately.

The list is not all-inclusive, nor does it suggest that all materials are present in

each piece of equipment:

and to comply with all regional, national, and international agencies

that promote economically and environmentally sustainable

Batteries Glass Aluminum and Stainless Steel

Circuit Boards Plastics Liquid Crystal Display (LCD)

Ludlum Measurements, Inc. products that have been placed on the market

after August 13, 2005 have been labeled with a symbol recognized

internationally as the “crossed-out wheelie bin.” This notifies the consumer

that the product is not to be mixed with unsorted municipal waste when

discarding; each material must be separated. On the Model 2929, the symbol

will be placed on the rear panel.

The symbol appears as such:

Ludlum Measurements, Inc. Page 5-1 January 2016

Model 2929 Scaler Technical Manual Section 6

Section

6

Operating Procedures

Once the Model 2929 is calibrated for use with a specific detector, the highvoltage operating point must be determined. See HV adjustment procedures

below for details on selecting the proper operating voltage.

Count time: Selection should be based on the count rates being

observed and the desired statistical accuracy.

Volume Controls: Adjust to desired levels. Note that audio is operating

whether a count cycle is in process or not.

Detector: Connect the detector to the instrument using the cable

supplied with the instrument. Note that a cable length change can cause

a shift in calibration.

Printer: When operating two Model 264 printers and a recycle is

required, be sure that only one printer has its recycle switch “ON.”

Calibration Procedures

The following procedures apply to the Model 2929 when used in

conjunction with the Model 43-10-1 scintillator

NOTE: The following settings are normally:

Ludlum Measurements, Inc. Page 6-1 January 2016

Beta Threshold (B-G THS) = 4 mV

Beta Window (B-G WIN) = 50 mV

Alpha Threshold (ALPHA THS) = 175 mV

Amp/Disc Board

Apply a negative pulse of 10 mV amplitude to the DETECTOR

input of the Model 2929. A count rate greater than 25,000 cpm

should be used.

Model 2929 Scaler Technical Manual Section 6

Adjust the GAIN control located internally and to the right-hand

side of the instrument for a positive pulse amplitude of 200 mV (at

the AMP OUT connector).

This completes the amplifier gain calibration. The optimum amplifier

gain should be approximately 20.

Apply a negative pulse of 200 mV amplitude.

Attach an oscilloscope probe to pin 7 of U5 ad adjust B-G THS

WIDTH (R6) for a five-microsecond wide negative 5 V pulse.

Move the oscilloscope to pin 9 of U6 and apply a negative pulse of

4 mV amplitude.

Adjust B-G THS (R3) until negative 5-volt pulses appear.

Apply a negative pulse of 50 mV amplitude and adjust B-G WIN

(R2) until negative 5-volt pulses just disapper.

Apply a negative pulse of 175 mV amplitude and adjust ALPHA

THS (R4) until a 5-volt positive pulse appears at pin 6 of U6.

High Voltage Power Supply

With a high-voltage meter of at least 1000 megohm input

impedance, adjust the front-panel HV control for 1000 Vdc at the

detector connector.

Adjust R6 for a front-panel meter reading of 1 kV.

NOTE: If adjustment is necessary, a 10-pin extender board will be required.

With no detector attached, turn the HV dial to maximum (fully

clockwise) and adjust R13 for 1500 V. (Higher limits may be

necessary, depending upon the type of detector being used.

High V oltage Adjustment Procedures

High Voltage: Selection of an operating voltage is determined by the plateau

method. With this method, a graph of high-voltage settings versus counts

received from each channel is generated (source counts and background

counts). LMI uses

239

Pu as the alpha source; and 99Tc or 14C as beta sources.

Ludlum Measurements, Inc. Page 6-2 January 2016

Model 2929 Scaler Technical Manual Section 6

The following procedures describes the determination of the operating

voltage for a Model 43-10-1 detector, which is commonly used with the

Model 2929 dual channel scaler. Note that certain criteria must be met for

the background counts, source efficiencies, and crosstalk.

1. Connect the Model 43-10-1 to the counting instrument with proper

cable.

2. Place a calibrated

99

Tc source in the sample holder. Close and lock

the sample drawer.

3. Adjust the counting instrument HV until it receives at least 27% 4π

efficiency

4. Decrease HV by 25 volts.

5. Record the HV.

6. Record the

99

Tc source count and beta crosstalk in the alpha

channel.

7. Remove the

99

Tc source and record the background count in the

alpha and beta channels.

8. Place a calibrated

239

Pu source in the sample holder. Close and lock

the sample drawer.

9. Record the

239

Pu source count and the alpha crosstalk in the beta

channel.

10. Increase the HV by 25 volts.

Ludlum Measurements, Inc. Page 6-3 January 2016

11. Repeat Steps 5-10 until one or more of the following conditions

happen:

a. Beta background exceeds 80 cpm

b. Alpha background d exceeds 3 cpm

exc14eeds

c. Alpha crosstalk in the beta channel

10%

d. Beta crosstalk in the alpha channel exceeds 1%.

12. The operating voltage should be selected at a point where:

99

a.

Tc efficiency greater than or equal to 27%.

239

b.

Pu efficiency greater than or equal to 37%

Model 2929 Scaler Technical Manual Section 6

c. Alpha crosstalk in beta channel less than or equal to 10%

d. Beta crosstalk in alpha channel is less than or equal to 1%

e. Beta background is less than or equal to 80 cpm

f. Alpha background is less than or equal to 3 cpm.

Ludlum Measurements, Inc. Page 6-4 January 2016

Model 2929 Scaler Technical Manual Section 7

Section

7

Data Output

Function Identification

PIN FUNCTION

1 Count Complete

2 Printer Ready

3 Load Printer

4 Printer Clock

5 Ground

6 Count

7 Hold

8 +5 Vdc

9 Alpha Pulse Out

10 Beta/Gamma Pulse Out

11 Blanking

12 Bit 1

13 Bit 2

14 Bit 3

15 Bit 4

Function Source

All functions are from Model 2929 to accessory except:

PIN 2 Printer Ready

PIN 6 Count

PIN 7 Hold

Output Signals

Output signals are CMOS with LO = GROUND and HI = VOLTAGE

on Pin 8.

Pin 2 Printer Ready: Signal should be of the same voltage swing as the

signals from the Model 2929.

Ludlum Measurements, Inc. Page 7-1 January 2016

Model 2929 Scaler Technical Manual Section 7

6 Count: Signal should be pulled low to start counting.

Pin 7 Hold: Signal should be pulled low to stop counting.

Remo ving Data from the Model 2929

When the Model 2929 has timed out and counting stops, a HI pulse appears

on pin 1 (count complete). This pulse is approximately 2 milliseconds wide

and is used to signal the accessory unit that data is ready to be transmitted.

When the accessory unit is ready to accept the data, Pin 2 (printer ready) is

pulsed HI for a minimum of 2 milliseconds. When this Pin goes LO, data is

unloaded from the Model 2929 as follows:

The most significant digit appears first. This is valid at the negative eduge of

the first clock pulse and position continues until all digits have been read out.

At this time, Pin 3 (load printer) goes LO, signaling completion of data

transfer.

NOTE: Count Complete (Pin 1) and Printer Ready (Pin 2) are tied together.

The data is presented as BCD data on Pins 12 (BIT 1), 13 (BIT 2), 14 (BIT

3), and (BIT 4).

Figure 1

Ludlum Measurements, Inc. Page 7-2 January 2016

Model 2929 Scaler Technical Manual Section 7

To start the Model 2929 again, Pin 6 (count)

may be brought LO for a minimum of 100

milliseconds. The suggested circuit for this is

shown in Figure 2.

Pins 9 and 10 are +5 V pulses and are present

even if the Model 2929 is not in a count cycle.

Figure 2

Ludlum Measurements, Inc. Page 7-3 January 2016

Model 2929 Scaler Technical Manual Section 8

Section

8

Optional Equipment

Model 264 Printer

The LMI Model 264 accessory printer is offered as an option for the

Model 2929 Scaler.

A recycle switch on the Model 264 is provided for continuous cycling, if

desired. \When the counting time has reached the preset selection, the

count is printed, and the scaler and timer are reset to 0 to begin again.

The preset time is variable from 6 seconds up to 990 minutes.

The calculator may be used for any normal calculation function as long

as the keys are not activated at the same time the scaler is feeding its

information to the printer.

NOTE: When operating two Model 264 printers and a recycle is required,

be sure that only one printer has its recycle switch ON.

Model 464 RS-232 Interface

The LMI Model 464 RS-232 interface connects to the Model 2929,

allowing communication between the scaler and a device with an RS232c I/O (Input/Output), such as a personal computer (PC).

A command input through the RS-232 port to the interface is interpreted

and action is taken accordingly. The scaler can be started, stopped and have

data extracted by way of commands sent to the interface. The timed count

may be controlled by the scaler front panel, interface internal timer or by a

timer in the controlling device. The interface internal timer is programmable

to 4.5 days.

Other commands allow the user to read the interface timer, read the

current count, start a timed count using the interface internal timer, and

ask the interface if the timer has timed out.

Ludlum Measurements, Inc. Page 8-1 January 2016

Model 2929 Scaler Technical Manual Section 8

The interface is powered by the scaler and is reset when the scaler is

turned off.

Model 464-2 Two-Channel Counter

The Model 2929 with modified data output connector may be connected

to a Model 464-2 two-channel counter with a single cable for display on

a PC by way of a serial port.

Every 0.5 seconds, the counts are collected from the counter boards and

sent to the RS-232 port. The supplied software allows the user to

specify count time, alarms, and to log counts to disk.

NOTE: The Model 464-2 accumulates counts independently from the

Model 2929 and its internal timer. Pulses are sent to the Model 464-2

counters, regardless of the status of the Model 2929 control board. This

allows the user to take timed counts at the Model 2929 without affecting

the serial port operation.

Ludlum Measurements, Inc. Page 8-2 January 2016

Model 2929 Scaler Technical Manual Section 9

Section

9

Model 2929 DualChannel Scaler

Power Supply Board,

Drawing 337 x 27

CAPACITORS

TRANSISTORS

INTEGRATED

CIRCUITS

Parts List

Reference Description Part Number

UNIT Completely Assembled

Model 2929 48-1426

BOARD Assembled Power Supply

5337-031

C1 100pF, 3kV 04-5532

C2 2.2µF, 20V, DT 04-5508

C3 100µF, 10V, DT 04-5576

C4 0.1µF, 35V, DT 04-5574

C5 1µF, 35V, DT 04-5575

C6-C7 0.0056µF, 3kV, C 04-5522

C8-C9 0.01µF, 2kV, C 04-5525

C10 0.0056µF, 3kV, C 04-5522

C11 0.1µF, 100V, C 04-5521

C12 0.0056µF, 3kV, C 04-5522

C13 0.1µF, 100V, C 04-5521

Q1 MPSW51 05-5765

Q2 2N3904 05-5755

U1 LM358 06-6024

U2 LM385z-1.2 05-5808

Ludlum Measurements, Inc. Page 9-1 January 2016

Model 2929 Scaler Technical Manual Section 9

Reference Description Part Number

DIODE

RESISTORS

TRANSFORMERS

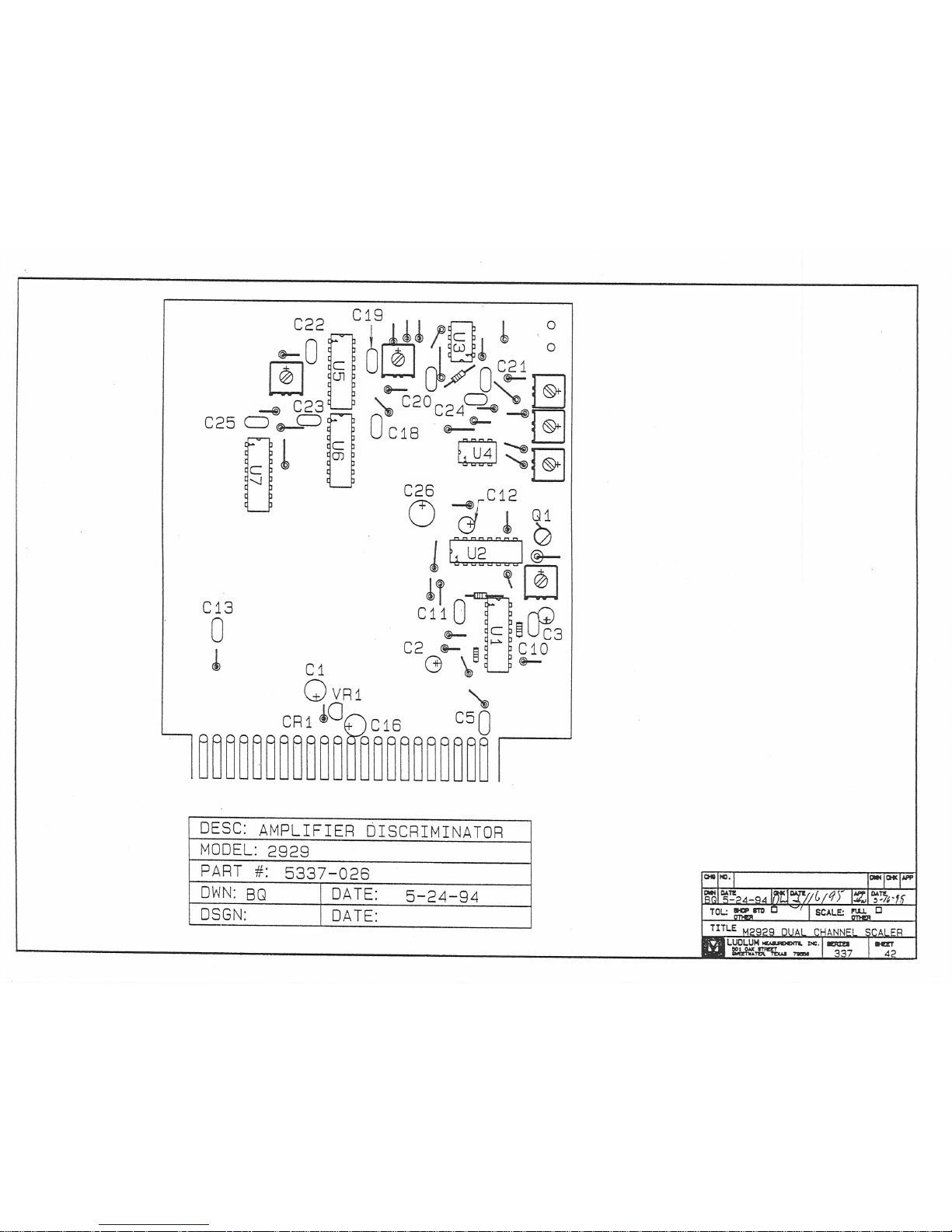

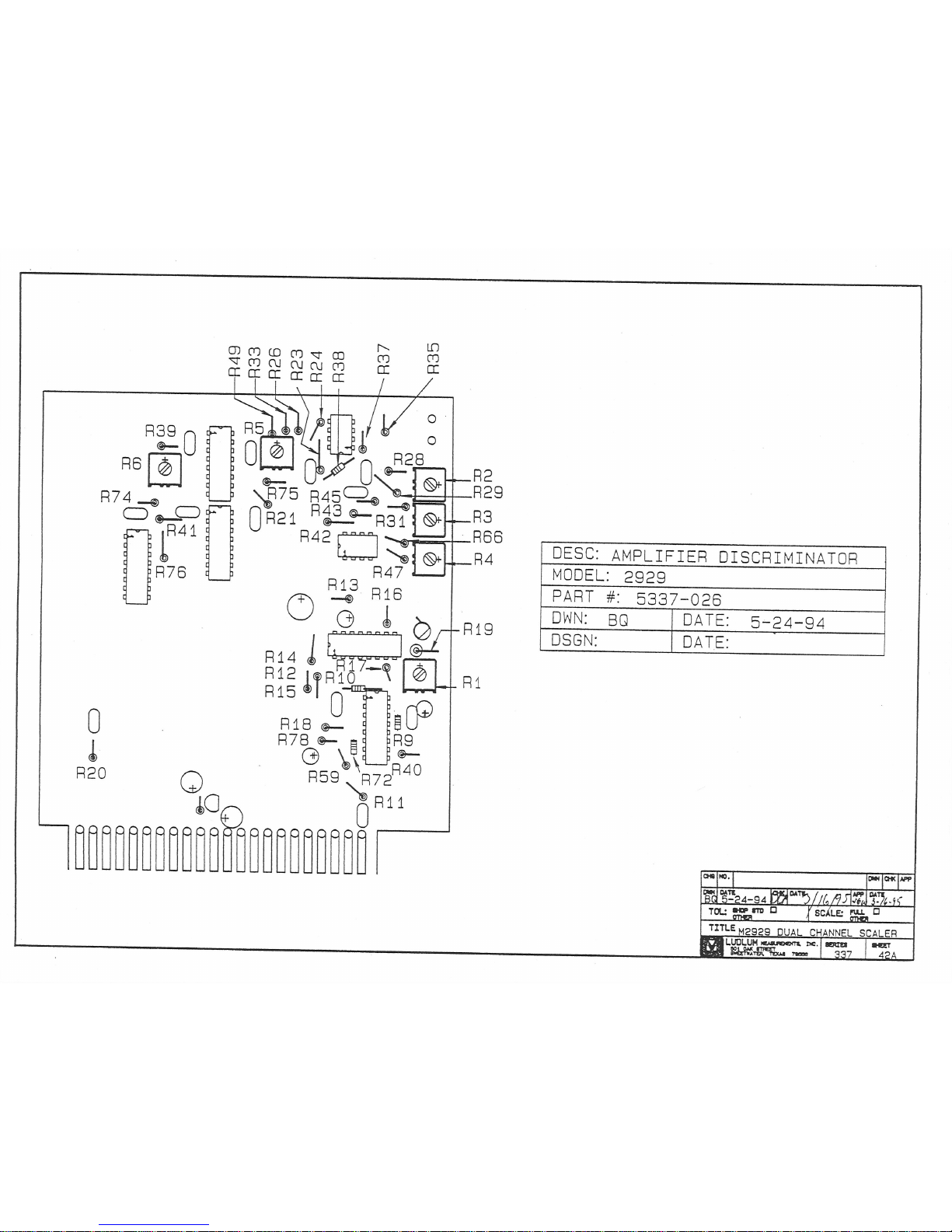

Amplifer/

Discriminator,

Drawing 337 x 19

CAPACITORS

CR1 1N4148 07-6272

CR2-CR5 GI250-2 07-6266

THERM-RL 1006 07-6322

THERM-RL 1006 07-6322

R1 220K, 1/4W, 5% 10-7066

R2-R3 1G, FHV-1, 2% 12-7686

R4 1M, 1/4W, 5% 10-7028

R5 301 OHM, 1/8W, 1% 12-7677

R6 2K TRIMMER 09-6798

R7 820K, 1/4W, 5% 10-7063

R8-R9 10K, 1/4W, 5% 10-7016

R10 1.5K, 1/4W, 5% 10-7065

R11 200 OHM, 1/4W, 5% 10-7006

R12 10M, 1/4W, 5% 10-7031

R13 500K TRIMMER 09-6792

R14 1M, 1/4W, 5% 10-7028

T1 L8050 X 50 40-0902

BOARD Assembled Discriminator 5337-026

C1 10µF, 20V, DT 04-5592

C2-C3 1µF, 35V, DT 04-5575

C5 0.1µF, 100V, C 04-5521

C10 47pF, 100V, C 04-5533

C11 0.1µF, 100V, C 04-5521

C12 1µF, 35V, DT 04-5575

C13 0.01µF, 100V 04-5523

C16 22µF, 35V, DT 04-5594

C18-C19 100pf, 100V, C 04-5527

C20-C21 0.01µF, 100V 04-5523

C22-C23 100pf, 100V, C 04-5527

C24 0.01µF, 100V 04-5523

C25 100pf, 100V, C 04-5527

C26 22µF, 35V, DT 04-5594

Ludlum Measurements, Inc. Page 9-2 January 2016

Model 2929 Scaler Technical Manual Section 9

V

Reference Description Part Number

TRANSISTORS

INTEGRATED

CIRCUITS

DIODE

OLTAGE REGULATORS

Q1 2N3904 05-5755

U1-U2 CA3096 06-6023

U3-U4 CA3290 06-6140

U5-U7 CD4098 06-6066

CR1 1N4148 07-6272

VR1 LM78L05 05-5815

R1-R4 10K TRIMMER 09-6794

R5 200K TRIMMER 09-6791

R6 50K TRIMMER 09-6790

R9 12K, 1/4W, 5% 10-7048

R10 10K, 1/4W, 5% 10-7016

R11 4.7K, 1/4W, 5% 10-7014

R12 22K, 1/4W, 5% 10-7070

R13-R14 10K, 1/4W, 5% 10-7016

R15 820K, 1/4W, 5% 10-7063

R16 330 OHMS, 1/4W, 5% 10-7053

R17 1K, 1/4W, 5% 10-7009

R18 10K, 1/4W, 5% 10-7016

R19 5.6K, 1/2W 11-7275

R20 1K, 1/4W, 5% 10-7009

R21 56K, 1/4W, 5% 10-7021

R23 5.6K, 1/4W, 5% 10-7042

R24 100K, 1/4W, 5% 10-7023

R26 10K, 1/4W, 5% 10-7016

R28 18K, 1/4W, 5% 10-7018

R29 2.7K, 1/4W, 5% 10-7055

R31 150K, 1/4W, 5% 10-7024

R33 820 Ohm, 1/4W, 5% 10-7060

R35 10K, 1/4W, 5% 10-7016

R37 1M, 1/4W, 5% 10-7028

R38-R39 5.6K, 1/4W, 5% 10-7042

R40 10K, 1/4W, 5% 10-7016

R41 56K, 1/4W, 5% 10-7021

R42 5.6K, 1/4W, 5% 10-7042

R43 100K, 1/4W, 5% 10-7023

R45 10K, 1/4W, 5% 10-7016

R47 24K, 1/4W, 5% 10-7059

R49 2.2K, 1/4W, 5% 10-7012

Ludlum Measurements, Inc. Page 9-3 January 2016

Model 2929 Scaler Technical Manual Section 9

R59 330 OHMS, 1/4W, 5% 10-7053

R66 1K, 1/4W, 5% 10-7009

R72 22K, 1/4W, 1% 10-7070

R74-R75 56K, 1/4W, 5% 10-7021

R76 10K, 1/4W, 5% 10-7016

R78 330 OHMS, 1/4W, 5% 10-7053

Scaler Board,

Drawing 167 x 170

CAPACITORS

INTEGRATED

CIRCUITS

RESISTORS

RESISTOR

NETWORK

BOARD Completely Assembled Scaler 5167-235

C1 100µF, 10V, DT 04-5576

C2 0.001µF, 100V, C 04-5519

C3 0.01µF, 10V 04-5523

C4 0.001µF, 100V, C 04-5519

U1 CD4001BE 06-6064

U2 CD4093BE 06-6030

U3 LS7031 06-6114

U4 CD4001BE 06-6064

U5 CD4098BE 06-6066

U6 CD4511BE 06-6065

U7 ULN2003A 06-6073

U8 CA3082 06-6004

R7 560K, 1/4W, 5% 10-7027

R9-R10 560K, 1/4W, 5% 10-7027

R18 4.7K, 1/4W, 5% 10-7014

R19 100K, 1/4W, 5% 10-7023

R20 4.7K, 1/4W, 5% 10-7014

RN1 33 OHM 14P DIP 12-7771

RN2 10K 14P DIP 12-7772

Ludlum Measurements, Inc. Page 9-4 January 2016

Model 2929 Scaler Technical Manual Section 9

Reference Description Part Number

Clock/Logic Board,

Drawing 167 x 363

CRYSTAL

CAPACITORS

TRANSISTORS

INTEGRATED

CIRCUITS

DIODES

RESISTORS

CONNECTORS

BOARD Completely Assembled

Clock/Logic 5167-362

Y1 Micro Xtal X0-43B-1.0 01-5356

C1 0.01µF, 100V 04-5523

Q1 2N3904 05-5755

U1 CD4093 06-6030

U2 CD4001 06-6064

U5-U7 CD4017 06-6001

U8 CD40102 06-6062

U138-U139 RDD104 06-6060

CR142 1N4001 07-6268

R1 22K, 1/4W, 5% 10-7070

R2 220K, 1/4W, 5% 10-7066

R3-R4 22K, 1/4W, 5% 10-7070

R8 560K, 1/4W, 5% 10-7027

R9 1K, 1/4W, 5% 10-7009

R10 560K, 1/4W, 5% 10-7027

R11-R18 56K, 1/4W, 5% 10-7021

JP141 531220-22P 13-8099

103186-1 HEADER 13-8471

Ludlum Measurements, Inc. Page 9-5 January 2016

Model 2929 Scaler Technical Manual Section 9

Dual Audio Board,

Drawing 337 x 58

CAPACITORS

TRANSISTORS

INTEGRATED

CIRCUITS

RESISTORS

TRANSFORMERS

6-Digit Readout

Board, Drawing

167 x 29

INTEGRATED

CIRCUITS

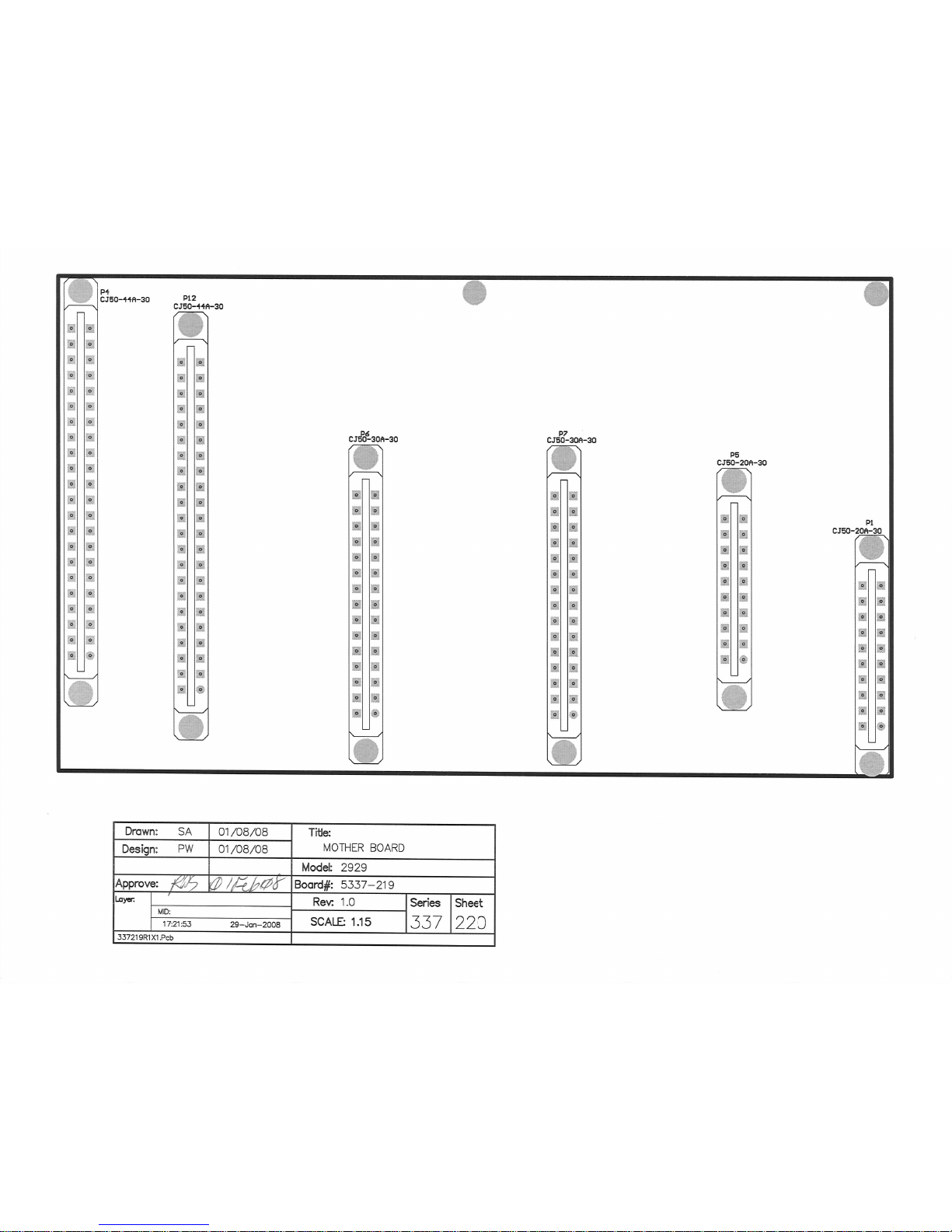

Mother Board,

Drawing 337 x 219

CAPACITORS

Reference Description Part Number

BOARD Assembled Dual Audio 5337-066

C2-C5 0.01µF 04-5523

C6 100µF, 10V, DT 04-5576

Q1-Q2 VN2222LL 05-5816

U1-U2 ICM7555IPA 06-6136

U3 CD4098BE 06-6066

R1 10K, 1/4W, 5% 10-7016

R2 2.2MEG 1/4W, 5% 10-7052

R3 33K, 1/4W, 5% 10-7019

R4-R5 1 OHM, 1% 12-7555

R7 56K, 1/4W, 5% 10-7021

R8-R9 10K, 1/4W, 5% 10-7016

R11 10K, 1/4W, 5% 10-7016

R12 2.2MEG, 1/4W, 5% 10-7052

R13-R14 33 OHM, 1/4W, 5% 10-7001

T1-T2 M177-1 AUDIO 40-0948

BOARD 6-Digit Readout 5167-030-00

U1-U6 LED-HP5082-7653 07-6283

BOARD Assembled Mother Board 5337-219

C1 100µF, 35V 04-5595

C2-C3 10µF, 20V 04-5592

C4 100µF, 35V 04-5595

C5 0.1µF, 100V 04-5521

C6 100µF, 10V 04-5576

C7-C9 10µF, 20V 04-5592

Ludlum Measurements, Inc. Page 9-6 January 2016

Model 2929 Scaler Technical Manual Section 9

Reference Description Part Number

RESISTORS

DIODES

VOLTAGE

REGULATORS

CONNECTORS

INDUCTOR

FUSES

Preamp Board,

Drawing 337 x 22C

CAPACITORS

INTEGRATED

CIRCUITS

R1 560 OHM, 1/4W, 5% 10-7054

R3 10K, 1/4W, 1% 12-7540

R5 560 OHM, 1/4W, 5% 10-7054

CR1 1N5819 07-6306

CR2 1N4001 07-6268

VR1 LM2597-5.0 06-6723

VR2 LM78L12ACZ 05-5812

P1 CJ50-20A-30 13-8050

P2-P3 1-640456-4 MTA 100X14 13-8141

P4 CJ50-44A-30 13-8083

P5 CJ50-20A-30 13-8050

P6-P7 CJ50-30A-30 5167-021-00 13-8052

P9-P10 DB15RA/F-P 13-8576

P11 640456-5 MTA 100X5 13-8057

P12 CJ50-44A-30 5167-362 13-8083

P15 640456-8 MTA 100X8 13-8039

P17 640456-9 MTA 100X9 13-8094

P18 MTA100X11 13-8059

P19-P20 640456-4 MTA 100X4 13-8088

J1 RAPC712 13-8445

J2 BNC-RA-50 OHM 21-8976

L1 DO3308P-154 22-9301

F1 DO3308 THERMAL FUSE 21-9031

BOARD Assembled Preamp 5170-027

C1 100pF, 3kV, C 04-5532

C3 1µf, 35V, DT 04-5575

U1 CA3096E 06-6023

Ludlum Measurements, Inc. Page 9-7 January 2016

Model 2929 Scaler Technical Manual Section 9

RESISTORS

MISCELLANEOUS

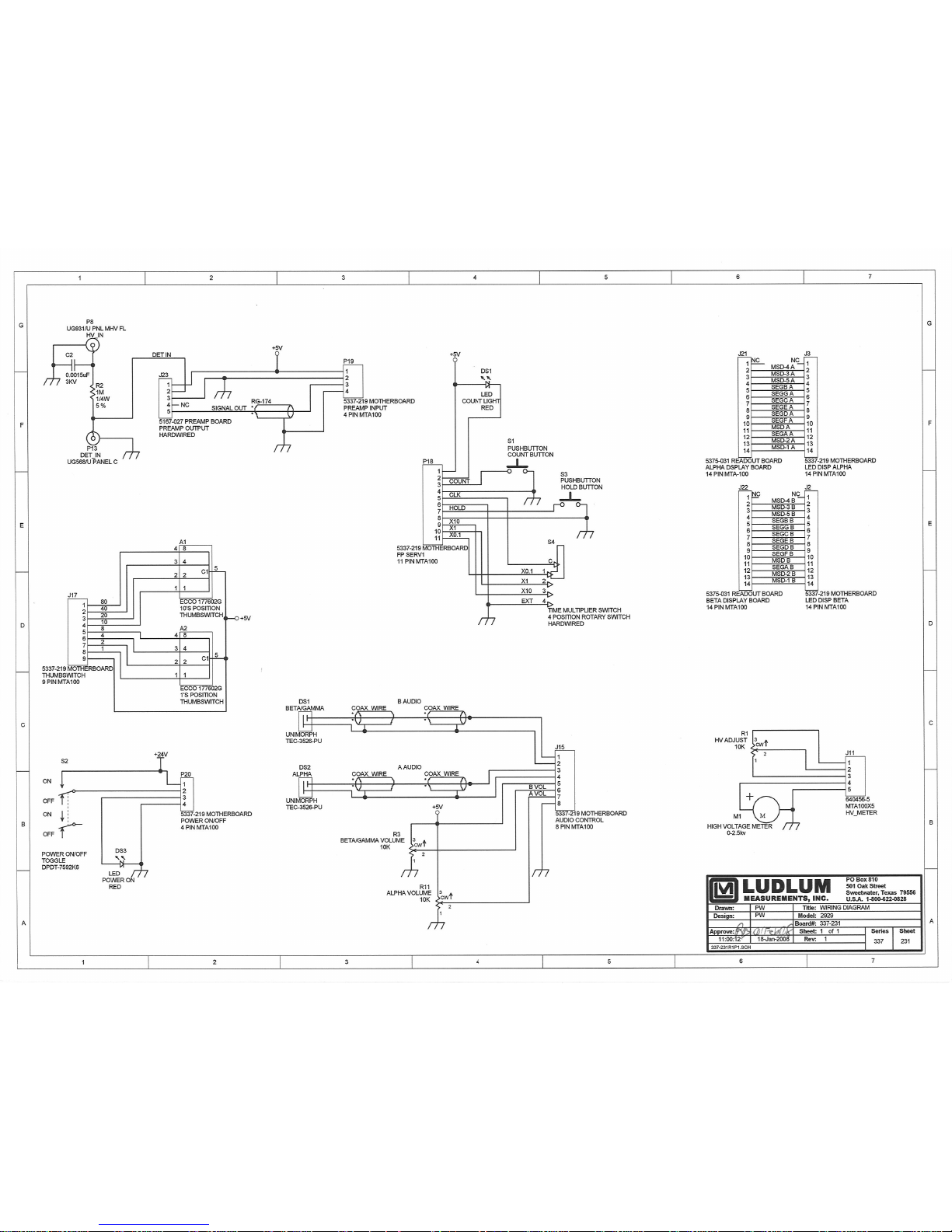

Wiring Diagram,

Drawing 337 x 66

CAPACITORS

CONNECTORS

SWTICHES

DIODES

Reference Description Part Number

R3 22K, 1/4W, 5% 10-7070

R5 22K, 1/4W, 5% 10-7070

R6 10K, 1/4W, 5% 10-7016

R7 33K, 1/4W, 5% 10-7019

R10 330 OHMS, 1/4W, 5% 10-7053

R12 10K, 1/4W, 5% 10-7016

R13 1K, 1/4W, 5% 10-7009

2 EA. RECPT-CLOVERLEAF

011-6809 18-8771

C2 0.0015µf, 3KV, C 04-5518

C3 10,000µF, 50V 04-5577

C4 1600µF, 50V 04-5535

C5-C6 0.1µF, 35V, T 04-5501

J1 RECPT-EAC 309 13-7982

P1 EDGE-CJ50-20A-30 10 PIN 13-7852

P2-P3 EDGE-CJ50-30A-30 15 PIN 13-7853

P4 EDGE-CJ50-44A-30 22 PIN 13-7866

P5 EDGE-CJ50-20A-30 10 PIN 13-7852

P6-P7 EDGE-CJ50-30A-30 15 PIN 13-7853

P8 RECPT-UG931/U PANEL MHV 13-7757

P9-P10 “D” RECPT RD15F000V30

15 PIN 13-7789

P11 Hard-Wired

P12 EDGE-CJ50-44A-30 22 PIN 13-7866

P13 RECPT-UG568/U PANEL C 13-7752

P14 CONN-RECPT-UG1094/U

SCREW BNC 13-7753

S1 30-1-PB GRAYHILL 08-6517

S2 TOGGLE 7952-K6 08-6525

S3 30-1-PB GRAYHILL 08-6517

S4 GRAYHILL

55D36-01-2-AJN 08-6514

2 EA. 177602G-ECCO 08-6521

CR1 1N5242 07-6264

CR2-CR3 1N4001 07-6268

CR4 PILOT RED LAMP 21-9299

Ludlum Measurements, Inc. Page 9-8 January 2016

Model 2929 Scaler Pulser Technical Manual Section 9

V

Reference Description Part Number

RESISTORS

TRANSFORMER

REGULATORS

MISCELLANEOUS

OLTAGE

F1 FUSE - #312001 3-AGC-1 21-9277

FUSE HOLDER 341001 21-9269

DS1 UNIMORPH 21-9251

DS2 UNIMORPH 21-9251

DS3 LAMP-IDI 2110A1 21-9296

LAMP-IDI 2110A1 21-9296

M1 METER ASSEMBLY 4167-302

LAMP-CLIP

515-0051 21-9300

LAMP-PLUG

515-0074 21-9301

2 EA. BRIDGE RECT-250JB1L 07-6281

R1 10K, 10-TURN 09-6761

R2 1 MEG, 1/4W, 5% 10-7028

R3 10K TRIMMER 09-6753

R9 10K, 1/4W, 5% 10-7016

R11 10K TRIMMER 09-6753

R13 2.2K, 1/4W, 5% 10-7012

T1 M2929 X5 4275-023

VR1 LM323K 05-5773

VR2 LM340K-24 05-5774

Ludlum Measurements, Inc. Page 9-9 January 2016

Model 2929 Scaler Technical Manual Section 10

Section

10

Drawings

Power Supply Board, Drawing 337 x 27

Power Supply Board Component Layout, Drawing 377 x 35

Amplifier/Discriminator Board, Drawing 337x 19

Amplifier/Discriminator Board Component Layout, 337 x 4-42A

Scaler/Ratemeter Board, Drawing 167 x 170

Scaler/Ratemeter Board Component Layout, Drawing 167 x 176

Clock/Logic Board, Drawing 167 x 363

Clock/Logic Component Layout, Drawing 167 x 364

Dual Audio Board, Drawing 337 x 58

Dual Audio Component Layout, Drawing 337 x 59

6-Digit Readout Board, Drawing 375 x 60 (2 sheets)

Mother Board, Drawing 337 x 219

Mother Board Component Layout, Drawing 337 x 220 (2 sheets)

Preamp Board, Drawing 337 x 22

Preamp Board Component Layout, Drawing 170 x 31

Wiring Diagram, Drawing 337 x 231

Ludlum Measurements, Inc. Page 10-1 January 2016

Loading...

Loading...