luceco LBH214K, LBH154K, LBH214K3M, LBH214KMW, LBH154KMW Installation & Operating Instructions Manual

...

>

Installation & Operating Instructions

Installation & Operating Instructions

Installation & Operating Instructions

TECHNICAL INFORMATION

Code Rated Voltage Power PF

LBH154K 220-240V~ 50Hz 14W >0.7 N/A N/A 1250Lm

LBH154KMW 220-240V~ 50Hz 15W >0.7 N/A N/A 1250Lm

LBH154K3M 220-240V~ 50Hz 15W >0.7 3 hour

LBH154KMW3M 220-240V~ 50Hz 16W >0.7 3 hour

LBH214K 220-240V~ 50Hz 24W >0.9 N/A N/A 2100Lm

LBH214KMW 220-240V~ 50Hz 26W >0.9 N/A N/A 2100Lm

LBH214K3M 220-240V~ 50Hz 26W >0.9 3 hour

LBH214KMW3M 220-240V~ 50Hz 27W >0.9 3 hour

Emergency

Duration

Battery

Li-ion

2200mAh 3.7V

Li-ion

2200mAh 3.7V

Li-ion

2200mAh 3.7V

Li-ion

2200mAh 3.7V

Lumens with

diffuser

1250Lm

1250Lm

2100Lm

2100Lm

ADDITIONAL INFORMATION -

COMPONENT REPLACEMENT

• The luminaire contains no user replaceable components

other than the battery pack contained in Emergency versions

Ø317 60

EMERGENCY LIGHTING TESTING

Months 1 to 11 inclusive – Function Test, interrupt the permanent/UnSwitched supply and check the luminaire operates in Emergency

mode at reduced output

Month 12 (Annual) – As months 1 to 11 but for a full 3 hr duration

Luminaire Ref / Location: ........................................ In Case of difficulty, contact the Installation Engineers:- Tel: .........................................................

LBHxx4Kxx Duration 3 hr Lamp Type - LED

INITIAL USE AND ROUTINE TESTING

From initial install the downlight will require up to 24 hr for the batteries to be fully charged and provide the rated 3hr duration in

Emergency mode. Then following subsequent Emergency use, from full discharge will take approx. 14hr to fully recharge batteries.

It is important that the luminaire is routinely tested to ensure the batteries are conditioned and also to fully comply with BS5266.

A function test should be conducted every month with an annual test of the full 3hr duration. Records can be kept on the adjacent table.

It is recommended that batteries are replaced every 4 years to ensure the optimum charging cycle is maintained.

Fifth Year

Signed Date

Month Tes t

1 Function

2 Function

3 Function

4 Function

5 Function

6 Function

7 Function

8 Function

9 Function

10 Function

11 Function

12 Function

First Year

Signed Date

Second Year

Signed Date

Third Year

Signed Date

Fourth Year

Signed Date

LED IP65

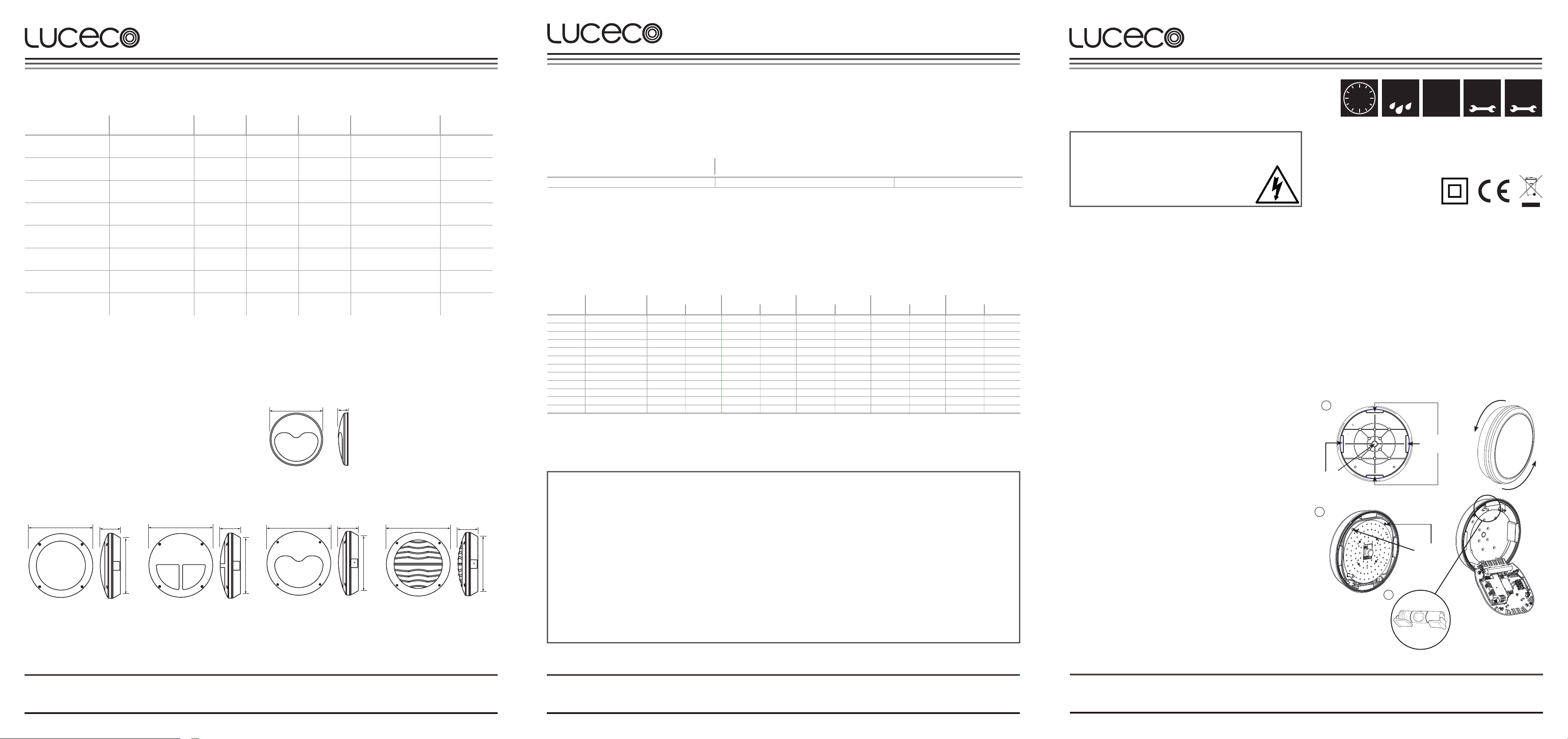

ATLAS BULKHEAD

NOTE – To comply with regulations, installation must be carried out by suitably

qualified competent person and in accordance with the current IEE Wiring

Regulations (BS7671) and Building Regulations. A copy of the instructions must

be left for the user/maintenance engineer for future reference.

For non-UK, please refer/consult local requirements

ENSURE ELECTRICAL SUPPLY IS DISCONNECTED/

ISOLATED BEFORE COMMENCING INSTALLATION

ASSEMBLY AND INSTALLATION

• Suitable for use with mains voltage 220-240V AC

• This product must be disconnected before insulation resistance

testing of the lighting circuit

• Check for electrical cables and pipes before installation

SUGGESTED METHOD OF INSTALLATION

The bulkhead is designed for mounting in any of the

following options: –

• Surface Wall Mounting

• Surface Ceiling Mounting

• Semi-recessed Ceiling Mounting

year

3

standard

WARRANTY

50,000

HOURS

IP65

RATED

CRI

80

year

1

on site

WARRANTY

UK ONLY

• To maintain the IP65 rating of the bulkhead, a suitable 20mm

cable gland should be used in conjunction with rubber insulated

cable to ensure the supply cable is sealed in the gland. Failure

to use a gland and/or rubber insulated cable may result

in water ingress

Surface mounted options may use rear cable entry for flush

mounting or there is facility for surface Conduit ‘besa’ box

mounting or side conduit entry. Semi-recessed Mounting utilises

the metal bracket included but may require access to the ceiling

void during installation

1

• The battery has a 4year service life provided it is operated

and maintained by regular testing, as detailed in this

document. Failure to maintain or change the battery may

result in reduced duration in Emergency mode

• Battery specification - Li-ON 2200mAh 3.7V

LBH154AMS - Metal split eyelid LBH154AMG - Metal grilleLBH154AMP - Metal standard LBH154AME - Metal eyelid

Ø341 110

Ø294

Ø341 110

Tech Help Line

UK -

0330 0249 279

Non UK -

LBH.JH.10.2016

+44 (0)1952 238 100

Ø341 110

Ø294

Supplied by

LUCECO

Stafford Park 1 TF3 3BD ENGLAND

Ø341 110

Ø294

Page 5

Visit our website at

www.luceco.com

Ø294

United Kingdom Warranty

For other territories and for further information, please see www.luceco.com for details

Products are protected by guarantee for a period of 3 year warranty, from date of purchase against defects in material and workmanship (unless otherwise stated). Should

a product fail to perform as described within the warranty period it will be repaired or replaced with the same or equivalent product by Luceco, free of charge provided

that you: (1) return the product to us with shipping charge prepaid, (2) provide us with proof of the original date of purchase and (3) quote our return authorization number.

Repaired or replaced products will be returned to you with shipping charges prepaid. Replacement products may be refurbished or contain refurbished materials. If in our

sole discretion, we are unable to repair or replace a defective product, we will refund the purchase price of the product.

This warranty will not apply if in our judgment, the product fails due to damage in shipment, handling, storage, accident, abuse or misuse, or if it has been used in a

manner not conforming to our product instructions, has been modified in any way, or has any serial number removed or defaced. Repair or attempted repair will void this

warranty. Our maximum liability under the terms of this warranty is limited to the purchase price of the product covered by the warranty.

The warranty is given under English Law. If any part of this warranty is deemed unenforceable (including any provision in which we exclude our liability to you) the

enforceability of any other parts of the warranty will not be affected. These terms do not reduce your statutory rights.

For Non-UK please contact Local Luceco Office for details. THESE TERMS AND CONDITIONS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

Eventually, you may want to replace this fitting;

Environmental Protection W.E.E.E (Wheelie Bin Symbol for EU ONLY)

This symbol is known as the “crossed-out” wheelie Bin Symbol”. When this symbol is marked on a product or battery, It means that it should not be disposed of

with your general household waste. Some chemicals contained within electrical/electronic products or batteries can be harmful to health and the environment.

Only dispose of electrical/electronic/battery items in separate collection schemes, which cater for the recovery and recycling of materials contained within. Your

co-operation is vital to ensure the success of these schemes and for the protection of the environment.

UK -

0330 0249 279

Non UK -

LBH.JH.10.2016

+44 (0)1952 238 100

Tech Help Line

Supplied by

LUCECO

Stafford Park 1 TF3 3BD ENGLAND

Visit our website at

www.luceco.com

1. With the method of mounting chosen, remove the front

Diffuser and Trim Bezel, by twisting them in a Anti-clockwise

direction to the base. (1)

2. To drop the Driver tray, loosen two screws shown then lower

the gear tray. (2 - Gear tray and drop tray)

3. Incorporated within the base is a spirit level to help align the

bulkhead for wall mounting, in such applications the level

should be at the top. (3)

UK -

0330 0249 279

Non UK -

LBH.JH.10.2016

+44 (0)1952 238 100

Tech Help Line

Stafford Park 1 TF3 3BD ENGLAND

Supplied by

cable entry

points

cable entry

points

2

loosen

screws here

3

Page 1 Page 6

Visit our website at

LUCECO

www.luceco.com

N SL CF L

N SL CF L N SL CF LN LSL N LSL

Installation & Operating Instructions Installation & Operating Instructions Installation & Operating Instructions

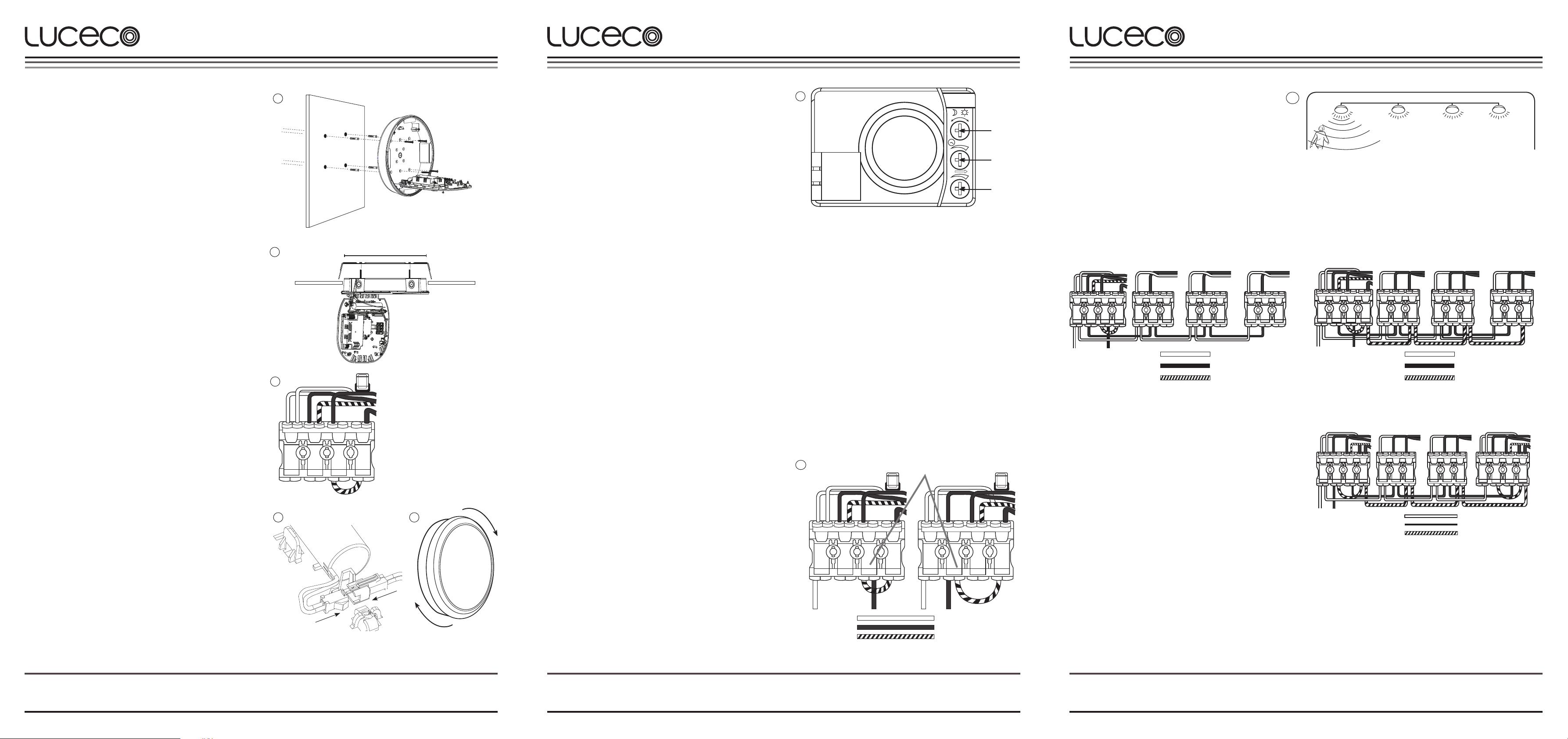

SURFACE MOUNTING

LBHxx4K can be mounted on ceilings and Vertical walls. Ensure

the mounting surface is suitable for installation. Once Mounting

points are decided, drill out mounting holes and any cable entry

points needed

If using a side cable entry the Lower trim needs to be cut also for

a flush finish (4)

SEMI-RECESSED MOUNTING

The LBHxx4K can also be recessed mounted into ceilings.

Recessed mounting uses the supplied metal bracket, but

is installed without the lower trim. When recessed, only the

4 side cable entry points can be used

Access to the ceiling space is recommended for installation

The product is installed into a 290mm Cut out, and can be

mounting into ceilings upto 30mm thick

Choose wiring entry/exit points and drill out cable entry points

prior to installation. Install as shown, with the bracket on the top

side of ceiling, Install with supplied bolts until tight (5)

ELECTRICAL CONNECTIONS

1. With the bulkhead securely fixed in the desired position,

make the electrical connection to the terminal block,

observing the correct polarity. (See also additional

information)

Note – the bulkhead is a class II construction and does not

require an Earth Connection and for Emergency versions, 2no.

Live connections (Switched [SL] and UnSwitched [L] required) (6)

FOR EMERGENCY VERSIONS

The battery requires connecting before use, Connect the two

push connectors between Driver and battery (7)

Once the electrical connections have been made, the gear tray

can be hinged back into position and secured using the 2no.

Fixing screws. If the Bulkhead has a Microwave Sensor, the

sensor settings can be adjusted by the installer/user, please

see additional information below

Re-fit the front diffuser and bezel assembly by placing against

the base and twisting clock-wise. To aid ease of re-fitment, the

diffuser/bezel can be aligned at 90degree intervals. Turn on

power and operate (8)

4

5

6

290mm

N SL CF L

7 8

Page 2

ADDITIONAL INFORMATION -

MICROWAVE SENSOR

• Versions fitted with a MicroWave sensor allow the

bulkhead to be automatically switched ON where

movement is detected

• MicroWave sensors are significantly more sensitive that

Passive Infra Red (PIR) sensors, which only detect changes

in heat against the background. Therefore MicroWave

sensors can be prone to ‘nuisence switching’ in an

exterior application

MICROWAVE SENSOR SETTINGS

• The MicroWave sensor is supplied, pre-set to its optimum

settings and also configured to ‘corridor function’ facility.

This provides a standby mode, where the sensor will switch

the bulkhead off

• By Default the Sensor is set to dim the product to 0% light

output when no presence detected. This can be changed to

10% by changing the wiring layout on the terminal block

• The Bulkhead can be adjusted to switch/dim to 10%, (see

below). Due to the use of LED, the energy used is minimal

in Corridor Function mode and threshold setting prevents

the sensor from operating when there is adequate natural

light in the area (9)

• This low illumination provides security for people in areas

such as corridors and stairwells, that the area is not totally

dark when initially entered. When Set to 10% dimming,

Emergency versions can no longer be switched on/off

• The Sensor Has a LED that will flash to show how the sensor

is set

• Range – The sensor has a maximum range of upto 10M, this

is based on being ceiling mounted at around 2.5M. The range

is based on detecting a person of around 1.6M tall, 1 Flash

–1M, 5 Flashes =5M, 10 Flashes = 10M

• Time -the light can be set to stay ON for any period of time

between approx. 10sec (dial turned fully anti-clockwise)

and a maximum of 30min(dial turned fully clockwise). Any

movement detected during the “on” time will reset the timer.

The number of flashes means the following:

1 flash=10sec, 2 flashes=1 min, 3 flashes=2 min, 4 flashes=

5 min, 5 flashes=8 min, 6 flashes=10 min, 7 flashes=15 min, 8

flashes=20 min,9 flashes=25 min, 10 flashes=30 min

• Ambient Light - The ambient Light level can be set between

2-2000lux. Turn it fully anti-clockwise to select dusk- todawn operation at about 2 Lux. Turn it fully clockwise to

select daylight operation at about 2000lux. The knob must be

turned fully clockwise when adjusting the detection zone and

performing the walk test in daylight

9

3

2

1

1. Detection Range – Recommended Maximum setting

(Approx 10M radius) for optimum sensing

2. Switch Off Time Delay – Min 10seconds and Max 30minutes.

If movement is detected during the set time delay, the delay

resets. This prevents unwanted frequent switching

3. Threshold Setting – This allows the ambient light in the

area to be considered, so the sensor only switches the LED

bulkhead ON when there is low ambient light. Min Setting

2lux, Max 2000lux

To make maximum use of the corridor function, use the

maximum setting

CHANGING 0% DIMMING TO 10% DIMMING

Press the terminal block piano key and remove desired wires.

For MW version, to change to a 10%

1.Swap the red loop wire on user side from CF to SL.

2.Swap the Red Sensor wire on luminaire side from SL to CF.

For MW3M version,

3. Swap the Black wire from CF to SL.

When 10% corridor function, ambient light sensor level must be

set to maximum.

10

0% 10%

Press down this tab

N SL CF LN SL CF L

Neutral (Blue)

Permanent Live (Brown)

Switch Live (Orange)

Page 3

ADDITIONAL INFORMATION -

11

Master Slave Slave Slave

MASTER/SLAVE FUNCTION

The LBHxx4K can be connected for master switching function,

in this mode a sensor at the start and/or end of a corridor can

switch all the lights on together. This Uses the Sensor on one

product as Switched live on the others. For master/slave function, all luminaries must be run on a single Live/ Neutral chain.

For emergency Installations, a separate Single Emergency Live line is required

Sensors can be added at both ends to allow Switching when presence at either end of the Installation

Please note, maximum of 9 fittings can be used for each switching group

Master/slave Function can operate on 0% Dimming or 10% dimming. Only 0% Dimming can be

switched on/off for emergency when used in master/slave function (11)

LBHxx4KMW

LBHxxKMW3M(0%Dim) LBHxx4K LBHxx4K LBHxx4K

N SL CF L N LSL N LSL N LSL

Neutral Unswitch Live

(POWER INPUT)

Neutral (Blue)

Permanent Live (Brown)

Switch Live (Orange)

ADDITIONAL INFORMATION - EMERGENCY

FUNCTION

• Versions fitted with Emergency control gear provide

a reduced light output in the event of a mains power failure

to aid the safe evacuation of the area

• By having a second Live (unswitched/permanent, marked L)

power feed to the bulkhead, it can be switched ON/OFF as

required and also will sense a power failure in the lighting

circuit, regardless of the bulkhead being ON or OFF

• Where a second live is not provided, when the bulkhead is

switched off, the batteries will power the LED array, this will

vastly reduce the life of the batteries and their ability to charge

LBHxx4KMW3M

LBHxx4KMW3M(0%Dim) LBHxx4K3M LBHxx4K3M LBHxx4K3M

N SL CF L N LSL N LSL N LSL

Neutral Unswitch Live

(POWER INPUT)

For 10 % dimming, unswitched master/slave function, the

common Live needs to be taken from CF NOT SL

(unswitch 10%Dim)

Neutral Unswitch Live

(POWER INPUT)

LBHxx4K3M LBHxx4K3M LBHxx4K3MLBHxx4KMW3M

Neutral (Blue)

Permanent Live (Brown)

Switch Live (Orange)

Neutral (Blue)

Permanent Live (Brown)

Switch Live (Orange)

EMERGENCY OPERATION

• From initial installation the integral batteries will require

24hr to reach full charge status

• Following a full discharge, 12-14hr should be allowed for the

batteries to re-charge

• The Green LED charge indicator signifies that the batteries

are charging and will remain illuminated when the bulkhead

is switched off

• The batteries have a rated service life of 4years and should

be checked and considered for replacement at that point

• A record of routine testing should be kept to ensure

Emergency luminaires are maintained and operated

correctly

Page 4

Tech Help Line

UK -

0330 0249 279

Non UK -

LBH.JH.10.2016

+44 (0)1952 238 100

Supplied by

LUCECO

Stafford Park 1 TF3 3BD ENGLAND

Visit our website at

www.luceco.com

UK -

0330 0249 279

Non UK -

LBH.JH.10.2016

+44 (0)1952 238 100

Tech Help Line

Supplied by

LUCECO

Stafford Park 1 TF3 3BD ENGLAND

Visit our website at

www.luceco.com

UK -

0330 0249 279

Non UK -

LBH.JH.10.2016

+44 (0)1952 238 100

Tech Help Line

Supplied by

LUCECO

Stafford Park 1 TF3 3BD ENGLAND

Visit our website at

www.luceco.com

Loading...

Loading...