Right choice for ultimate yield

LSIS strives to maximize customers' profit in gratitude of choosing us for your partner.

Human Machine Interface

XGT Panel

User’s Manual

Read this manual carefully before

installing,

wiring, operating, servicing

or inspecting this equipment.

Keep this manual within easy reach

for quick reference.

XGT Panel Series

http://eng.lsis.biz

XP30-

BTE

XP30-

BTA

XP30-

TTE

XP30-TT

A

XP40-

TTE

XP40-

TTA

XP50-

TTE

XP50-

TTA

XP70-

TTA

XP80-

TTA

XP90-

TTA

Safety Precautions

1

Before using the product…

To use the product safely and effectively, please read this instruction manual thoroughly before use.

► Please keep to the safety precaution, for it is to prevent accidents and potential danger from

occurring.

► Safety precaution is classified into ‘Warning’ and ‘Caution’ and their meanings are as follows.

Violating the instruction may result in serious personal injury or death.

Violating the instruction may result in slight personal injury or product

damage.

► The indicated illustrations on the product and in the manual have the following meanings.

Be cautious, for danger may be present.

Be cautious, for there is a possibility of an electric shock.

► After reading the instruction manual, keep it handy for quick reference.

Warning

Caution

Safety Precautions

2

Design Precautions

Design Precautions

Installation Precautions

Install a safety circuit external to the HMI to protect the whole control system in case of

external power supply trouble.

Serious trouble may occur to the entire system due to erroneous output/operation of the HMI.

Warning

In/output signal or communication cable should be at least 100mm apart from

High-voltage/power wires.

Otherwise, it may cause erroneous output/operation.

Use the HMI in an environment that meets the general specification contained in this

manual or datasheet.

Otherwise, it could result in electric shock, fire, erroneous operation or deterioration.

In case of much vibration in the installed environment, be sure to insulate the HMI from

direct vibration.

Otherwise, it could result in electric shock, fire or erroneous operation.

Be sure not to let foreign substances such as conductive debris inside the product.

Otherwise, it could result in electric shock, fire or erroneous operation.

Caution

Caution

Safety Precautions

3

Wiring Precautions

Be sure to turn off the HMI and external power before wiring.

Otherwise, it may result in an electric shock or damage to the product.

Wire correctly by checking each of the product’s rated voltage and terminal layout.

Otherwise, it may result in fire, electric shock or erroneous operation.

Tighten terminal screws with specified torque when wiring.

If terminal screws are loose, it may result in short circuits, fire or erroneous operation.

Use the exclusive HMI 3-type grounding for the FG terminal.

If not grounded, it may result in erroneous operation.

Be sure not to let any foreign substances such as wiring debris inside the module.

Such debris may cause fire, damage or erroneous operation.

Cautio

n

Warning

Safety Precautions

4

Startup and Maintenance Precautions

Disposal Precaution

Do not touch the terminals while power is on.

Otherwise, it may cause electric shock or erroneous operation.

Turn off the PLC and external power when cleaning or tightening the terminal.

Otherwise, it may cause electric shock or erroneous operation.

Do not charge, disassemble, heat, short circuit, solder, etc. the battery.

Mishandling the battery may cause overheating, crack, fire and may result in injury or fire.

Do not disassemble PCB from the product case or modify the product.

Otherwise, it may result in fire, electric shock or erroneous operation.

Use cellular phone or walky-talky at least 30cm away from the PLC.

Otherwise, it may result in erroneous operation.

When disposing of this product or battery, treat it as industrial waste.

Otherwise, it may cause poisonous pollution or explosion.

Warning

Caution

Caution

Revision History

Revision History

Version Date Contents Revised location

V1.0 ‘07.4 First Edition -

V2.0 ’09.10 1. Initial screen changed (horizontal bar -> square box type)

2. Menu name of initial screen changed

(Download From USB -> Storage Download)

3. Selecting one project file among many project files is available

4. Sending project file by CF card is available

5. File backup function by external storage equipment added

6. Format of backup file is changed into CSV format

7. New module XP80-TTA/AC added

8. Project upload function by external storage equipment added

9. Update function by external storage equipment added

10. XP30-BTE interface added

11. Figure and name of each part for XP30-BTE added

12. Specification of XP30-BTE added

13. Aux diagnosis function added

14. Dimension of XP30-BTE added

15. Specification of XP90-TTA/AC, XP70/80-TTA/DC added

16. Dimension of XP90-TTA/AC, XP70/80-TTA/DC added

17. PLC communication setting option in device menu added

18. Multi-Touch function in environment setting added

CH4, CH5, CH6, CH8

CH7.1

CH7

CH7

CH9

CH9

CH3, CH12, APP2

CH7

CH7

CH1

CH2

CH3

CH5

APP2

CH3, CH10

APP2

CH6.7

CH4.1

V2.1 ’10.06 1. XP30-TTE/DC added

2. Clear Data function in Environment Setting added

CH2.1, CH3.2, CH10

CH4.7

V2.2 ’11. 06 1. XP50-TTE/DC added

CH2.1, CH3.2, CH10

V2.3 ’12. 06 1. XP40-TTE(TTA)/DC added

2. Important User Information added

(about protection sheet and using ferrite core)

3. CE Standard Certification updated

CH2,CH3.2,CH5,CH10

CH10.1, CH10.2

CH12.1

※

The number of User’s manual is indicated the right side of the back cover.

LS Industrial Systems Co

ⓒ

., Ltd 2006 All Rights Reserved.

Contents

8

Chapter. 1 General Introduction ..................................................................................... 1-1~1-6

1.1 Usage of User Manual ................................................................................................................................................. 1-1

1.2 Feature .......................................................................................................................................................................... 1-2

1.3 Terminology ................................................................................................................................................................... 1-6

Chapter. 2 System Configuration ..................................................................................... 2-1~2-6

2.1 Name and Function of Each Part ................................................................................................................................ 2-1

2.2 System Configuration ................................................................................................................................................... 2-5

Chapter. 3 Standard Specification ................................................................................. 3-1~3-7

3.1 General Standards ........................................................................................................................................................ 3-1

3.2 Function Standards ....................................................................................................................................................... 3-3

Chapter. 4 System Configuration .................................................................................. 4-1~4-6

4.1 Touch Calibration .......................................................................................................................................................... 4-1

4.2 Backlight Setting ........................................................................................................................................................... 4-2

4.3 Date Time Setting ......................................................................................................................................................... 4-3

4.4 PC Connection Setting ................................................................................................................................................. 4-3

4.5 Ethernet Setting ............................................................................................................................................................ 4-4

4.6 Contrast Setting (only for XP30-BTA/DC) ................................................................................................................... 4-5

4.7 Environment Setting ..................................................................................................................................................... 4-5

Chapter. 5 Diagnostics .................................................................................................... 5-1~5-6

5.1 Screen Diagnosis ......................................................................................................................................................... 5-1

5.2 Touch Diagnosis ........................................................................................................................................................... 5-2

5.3 Backup Memory Diagnosis .......................................................................................................................................... 5-2

5.4 Flash Memory Diagnosis Function .............................................................................................................................. 5-3

5.5 CF Card Diagnosis ....................................................................................................................................................... 5-3

5.6 Serial Communication Diagnosis ................................................................................................................................. 5-4

5.7 LED Diagnosis .............................................................................................................................................................. 5-6

5.8 Aux Diagnosis ............................................................................................................................................................... 5-6

Chapter. 6 Viewing Information of PLC Connection Status ..................................... 6-1~6-8

Contents

9

6.1 Connection Information ................................................................................................................................................ 6-2

6.2 PLC Information ............................................................................................................................................................ 6-3

6.3 History of PLC Error .................................................................................................................................................... 6-4

6.4 History of PLC Mode Conversion .............................................................................................................................. 6-5

6.5 History of PLC Power ................................................................................................................................................. 6-6

6.6 History of PLC System ............................................................................................................................................... 6-7

6.7 PLC Communication Configuration Settings ............................................................................................................ 6-8

Chapter. 7 Storage Function................................................................................................... 7-3

7.1 General Introduction ................................................................................................................................................... 7-1

7.2 Downloading Project through the Storage Equipment ............................................................................................... 7-2

7.3 Uploading Project through the Storage Equipment .................................................................................................... 7-2

7.4 Updating the Device through Storage Equipment ...................................................................................................... 7-3

Chapter. 8 XGT Panel S/W Update ......................................................................................... 8-1

8.1 General Introduction ................................................................................................................................................... 8-1

Chapter. 9 File Backup through External Storage Equipment .......................................... 9-5

9.1 Path Structure in case of File Backup .......................................................................................................................... 9-1

9.2 Operation setting when there is no Space for Backup ................................................................................................ 9-3

9.3 Monitoring Connection Status of External Storage Equipment .................................................................................. 9-4

Chapter. 10 Installation and Wiring .......................................................................... 10-1~10-10

10.1 Installation ................................................................................................................................................................. 10-1

10.1.1 Installation environment ................................................................................................................................. 10-1

10.1.2 Notice in handling ........................................................................................................................................... 10-2

10.1.3 Notice in installing the panel .......................................................................................................................... 10-2

10.2 Wiring ........................................................................................................................................................................ 10-6

10.2.1 Power wiring ................................................................................................................................................... 10-6

10.2.2 Ground wiring ............................................................................................................................................... 10-10

Chapter. 11 Maintenance ............................................................................................. 11-1~11-3

11.1 Maintenance............................................................................................................................................................... 11-1

11.2 Daily Maintenance ..................................................................................................................................................... 11-1

11.3 Periodical Maintenance ............................................................................................................................................. 11-2

Contents

10

Chapter. 12 EMC Standard Certification ................................................................. 12-1~12-2

12.1 Requirement for EMC Standard Certification ........................................................................................................ 12-1

12.1.1 CE standard certification .............................................................................................................................. 12-1

12.1.2 MIC standard certification ............................................................................................................................ 12-2

12.2 Requirement for Low Voltage Command Suitability ............................................................................................... 12-2

12.2.1 Standard applied for XGT Panel ................................................................................................................... 12-2

12.2.2 Selection of XGT Panel ............................................................................................................................... 12-2

Appendix 1. Troubleshooting ..................................................... Appendix1-1~Appendix1-18

1. Type of Problem .............................................................................................................................................. Appendix 1-1

2. Problem when Starting ................................................................................................................................... Appendix 1-1

3. Reaction Problem when touching .................................................................................................................. Appendix 1-2

4. Display Problem of Figure and Object ........................................................................................................... Appendix 1-2

5. Communication Problem ................................................................................................................................ Appendix 1-5

6. CF/USB Removal of Memory Card ............................................................................................................... Appendix 1-6

7. Error Message during Execution of Program ................................................................................................ Appendix 1-7

Appendix 2. Dimension ............................................................... Appendix 2-1~ Appendix 2-4

Chapter 1. General Introduction

1-1

Chapter 1. General Introduction

1.1 Usage of User Manual

This manual provides information of each product’s specification, usage and so on. This is necessary to use XGT Panel for medium

and large HMI system.

The user manual’s configuration is as follows.

Sequence Category Contents

Chapter 1 General Introduction It describes this manual’s configuration, product’s feature and term.

Chapter 2 System Configuration It describes feature and system configuration of each XGT Panel.

Chapter 3 Standard Specification It describes XGT Panel’s general and function specification.

Chapter 4 System Configuration It describes XGT Panel’s system configuration.

Chapter 5 Diagnostics It describes XGT Panel’s self-diagnosis.

Chapter 6

Viewing information of

PLC Connection Status

It describes the way on connection status information of PLC which is

connected with XGT Panel.

Chapter 7

Transmission of Project

from USB Storage Device

It describes the way to execute the project by using USB storage device.

Chapter 8 XGT Panel S/W Update It describes the way to update engine at XGT Panel.

Chapter 9

Backup files by using

Storage Devices

It describes the way to backup recipe, logging and etc. files by using

storage devices.

Chapter 10 Installation and Wiring It describes an installation, wiring and caution for reliability of PLC system.

Chapter 11 Maintenance

It describes inspection category and method for long normal operation of PLC

system.

Chapter 12 EMC Standard It describes system configuration for EMC standard.

Appendix 1 Troubleshooting It describes a variety of error contents and measure.

Appendix 2 Dimension It describes the dimension of XGT Panel.

Appendix 3

Warranty and

Environment Policy

-

Remark

This manual doesn’t describe connection with XP-Builder and PLC. For their own function, Please refer to the related

manuals.

Chapter 1. General Introduction

1-2

1.2 Feature

XGT Panel has the following features.

(1)

Diverse external interface

(a) It maximizes custom’s use by providing diverse external interface including USB, CF card and Ethernet.

(b) It can be connected with control device such as PLC, INVERTER.

• It can be connected by RS-232C, RS-422/485, Ethernet (10/100 BASE-T).

Ethernet

Open network

• Inverter

• Inverter

CF card

Memory Interface

Logging data

Image/font data

Expansion connector

USB host

E

tc.

Tool port (RS

-

232C): XP

-

Builder

Printer

USB Storage

Device

Keyboard,

Mouse

Communication

Module

Chapter 1. General Introduction

1-3

(c) XP30-BTE(TTE), economic type, is not supported for Ethernet, expansion connector and CF card.

(2)

Based on Windows CE

(a) Adoption of Microsoft Company’s Windows CE

• Windows CE 5.0

(b) Advantage

• It provides stable software capacity by using Microsoft Company’s platform.

• It can process diverse function simultaneously.

• It provides diverse interface including Ethernet, USB, and CF card.

• The user interface including mouse and keyboard can be connected.

• It has high flexibility like computer software.

• Fast reaction is available when adding new equipment.

• Wide data sharing and management with upper system is available. (Later)

(3)

Improvement of project transmission time

(a) It provides Ethernet which is faster than RS-232C.

(b) It provides the transmission function from USB storage device.

(4)

High quality screen

(a) It provides the high quality screen and clearness by high quality LCD.

Download

Upload

Data change

RS232C

RS422/RS485

Terminal Block Type

Battery Cover

USB Port

Chapter 1. General Introduction

1-4

• It adopts TFT LCD which supports the 65,536 colors. (XP30-BTE/DC and XP30-BTA/DC adopts STN Mono LCD.)

(b) It provides diverse graphic type.

• It is available to express precisely and actually.

• It provides the simple moving function with GIF support.

(5)

Analog touch Panel

(a) It adopts analog (resistor film method) Touch Panel.

• Visibility is improved without the grids.

(b) It provides high touch resolution.

• It can control Touch Panel precisely.

(6)

Multilingual and diverse font

(a) It supports the multilingual function.

• It transmits the Windows/User font used in computer to XGT Panel.

• Additional language development is not necessary.

• Multilingual language is an advantage of Windows CE.

(b) It can express four kinds of language simultaneously.

• It can express 8 kinds of language simultaneously.

• Language switching is available by using special switch during operation.

(c) It can provide the various fonts.

• Various expressions are available by using the Windows/User font.

• Font size and type can be adjusted freely.

Chapter 1. General Introduction

1-5

(7)

Advanced function

(a) Alarm function

• The History alarm can be classified alarm group and alarm list and selected alarm can be expressed by alarm search.

• The Flow alarm indicates current or the latest alarm at the bottom of screen.

• The System alarm indicates the important problems from operation.

(b) Logging function

• It provides conditional logging according to device condition and continuous periodic logging which operates periodically

according to time and device status.

• It provides 255Kbyte areas for backup.

• Backup into CF card or USB storage device is available.

• Backup data’s type is stored in Excel, it is easy to use.

(c) Recipe function

• It provides READ/WRITE function.

• A recipe provides Max. 100 DWORDs and 16 blocks.

• Backup into the CF card or USB storage device is available.

• Backup data’s type is stored in Excel, it is easy to use.

(d) Scheduler function

• It can be set up to Max. 32.

(e) Print function

• It provides a Screen/Alarm print function.

• It can be printed by USB printer.

(f) Script function

• It provides more flexible function by user Script.

• It can be diversely applied to such as including Global/Object/Screen indication and so on.

(8)

Stable product suitable for international standards

(a)

CE, KC standard acquisition

(b) UL(cUL) standard acquisition

Chapter 1. General Introduction

1-6

1.3 Terminology

It describes terms used in this manual.

Term Definition Example

Module

A standard element that has a specified function which configures the system.

Devices such as I/O board, which inserted onto the mother board or base unit.

Ex.) CPU module

Power module,

I/O module

Unit

A single module or group of modules that perform an independent

operation as a part of PLC system.

Ex.) Basic unit,

Extension unit

PLC system

System consisted of PLC and peripheral device which can be controlled by

user program.

-

XP-Builder Software used to write and edit the project. -

Cnet module

Computer Link

-

FEnet module Fast Ethernet Network -

RTC

Abbreviation of ‘Real Time Clock’. It is used to call general IC that contains

clock function.

-

Chapter 2. System Configuration

2-1

Chapter 2. System Configuration

Here describes the feature of XGT Panel and system configuration.

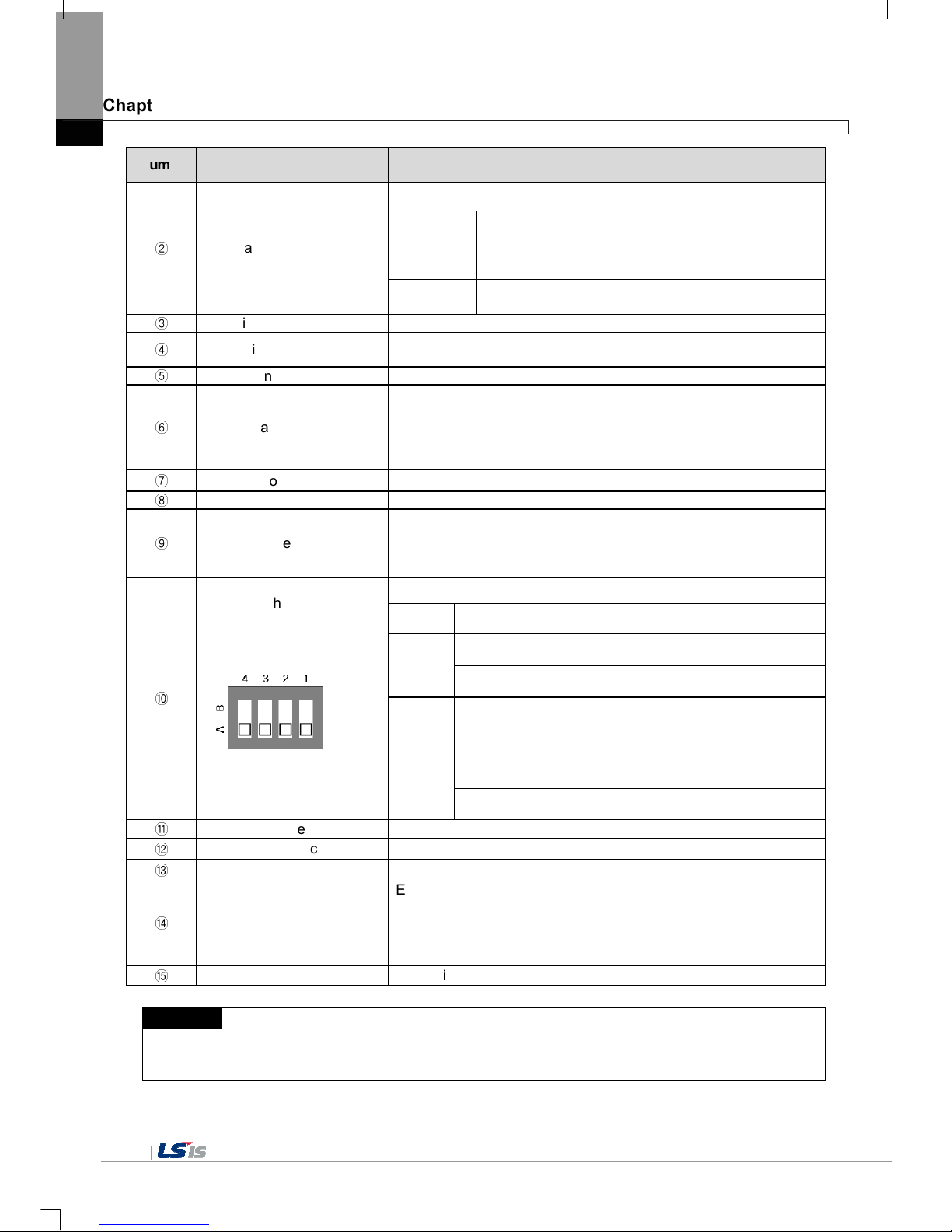

2.1 Name and Function of Each Part

1.

1. 1.

1. XP30-BTA, XP30/50/70/80-TTA

Number

Name Description

①

Front view

1) Analog touch panel: User touch input

2) LCD: screen indication

Chapter 2. System Configuration

2-2

Number

Name Description

②

LED Status

Indicates operation status of device

Green

Normal RUN status

(monitoring, downloading the project data)

Initializing the status when booting

(HMI does not operate)

Red

Error occurs

(communication error, project data error)

③

Panel fixed part XGT Panel is fixed at panel by bracket.

④

CF card interface

1) Logging/recipe/screen data backup

2) Upgrade of windows CE is available.

⑤

Power connection terminal It consists of power input and FG terminal.

⑥

USB interface

It consists of 2 ports.

1) USB memory connection: logging/recipe/screen data backup

2) USB memory connection: project data transmission/backup

3) User interface connection: use of mouse/keyboard

4) Printer connection: printing is available

⑦

Extension port Extension module installation

⑧

Reset switch Hardware reset switch

⑨

TOOL interface

RS-232C interface

1) project data transmission

2) logging/recipe/alarm/screen data backup

3) machine software upgrade

⑩

Setting switch

Device setting switch

No.1 Reserved

No.2

A setting Normal operation (default)

B setting When upgrading Windows CE

No.3

A setting Watchdog On (default)

B setting Watchdog Off

No.4

A setting RS-422/485 Terminal Switch On (120Ω)

B setting RS-422/485 Terminal Switch Off (120Ω)

⑪

Extension module fixation hall Extension module fixation hall

⑫

RS-422/485 connector RS-422/485: PLC/control machine communication

⑬

RS-232C connector RS-232C: PLC/control machine communication

⑭

Ethernet terminal

Ethernet: 10Base-T / 100Base-TX

1) Project data transmission

2) logging/recipe/alarm/screen data backup

3) machine software upgrade

4) PLC/control machine communication

⑮

FG terminal FG terminal hole for extension module

Remark

(1) For details about communication connection, please refer to the communication user manual.

(2) For details about installation, please refer to the Chapter 10

Chapter 2. System Configuration

2-3

When you use the XGT Panel, the prevention tape is installed to prevent battery discharge.

If you remove this prevention tape, backup is available.

In order to remove tape, pull tape downward like the following figure.

2. XP30-BTE, XP30-TTE, XP50-TTE, XP40-TTA(TTE)

Prevention

tape

⑪

⑫

Chapter 2. System Configuration

2-4

Number

Name

Description

①

Front view

1) Analog touch panel: User touch input

2) LCD: screen display

②

LED Status

Indicates operation status of module.

Green

Normal RUN status

(monitoring, downloading the project data)

Initializing mode when booting

(HMI does not Ready)

Red

Error occurs

(communication error, project data error)

③

Panel fixed part XGT Panel is fixed at panel by bracket.

④

Power terminal

cover

Prevention from electric shock

⑤

USB interface

1) USB memory connection: logging/recipe/screen data backup

2) USB memory connection: project data transmission/backup

3) User interface connection: use of mouse/keyboard

4) Printer connection: printing is available

⑥

Communication

interface

RS-232C, RS-422/485: For communication with controller (PLC)

⑦

Reset switch Hardware reset switch

⑧

Battery cover Open or close when replacing the battery

⑨

Tool interface

RS-232C interface

1) Project data transmission

2) Logging/recipe/alarm/screen data backup

3) Machine software upgrade

⑩

Setting switch

Module setting switch

No.1 Reserved

No.2

A setting Normal operation (default)

B setting When upgrading Windows CE

No.3

A setting Watchdog On (default)

B setting Watchdog Off

No.4

A setting RS-422/485 Terminal Switch On (120Ω)

B setting RS-422/485 Terminal Switch Off (120Ω)

⑪

Power terminal It consists of power input and FG terminal

⑫

Ethernet terminal

Ethernet: 10Base-T / 100Base-TX

1) Project data transmission

2) logging/recipe/alarm/screen data backup

3) machine software upgrade

4) PLC/control machine communication

※

Supported on XP40-TTA

Chapter 2. System Configuration

2-5

2.2 System Configuration

In order to use XGT Panel, write project data at the XP-Builder and transmit it to the XGT Panel.

XGT Panel can be basically connected through RS-232C.

Maximum communication speed is 115,200 [bps].

RS-232C communication speed is not fast so it takes long time to transmit project data into XGT Panel.

Project data can be quickly transmitted through Ethernet.

When LAN system is configured like the following figure, you can use it easily and effectively.

In case that LAN system is not configured, it provides 1:1 connection. (LAN cable should be cross cable.)

LAN

Ethernet

Chapter 2. System Configuration

2-6

When communication is not available to transmit project data, USB storage device is available

For details, please refer to the Chapter.7 and XP-Builder user manual.

Remark

1) We recommend Ethernet more than RS-232C.

2) For the Ethernet cable manufacture, please refer to the communication manual.

3) For the project transmission method, please refer to the XP-Builder manual.

4) Ethernet is not supported on XP30-BTE, XP30-TTE, XP50-TTE and XP40-TTE.

Chapter 3. Standard Specification

3-1

Chapter 3. Standard Specification

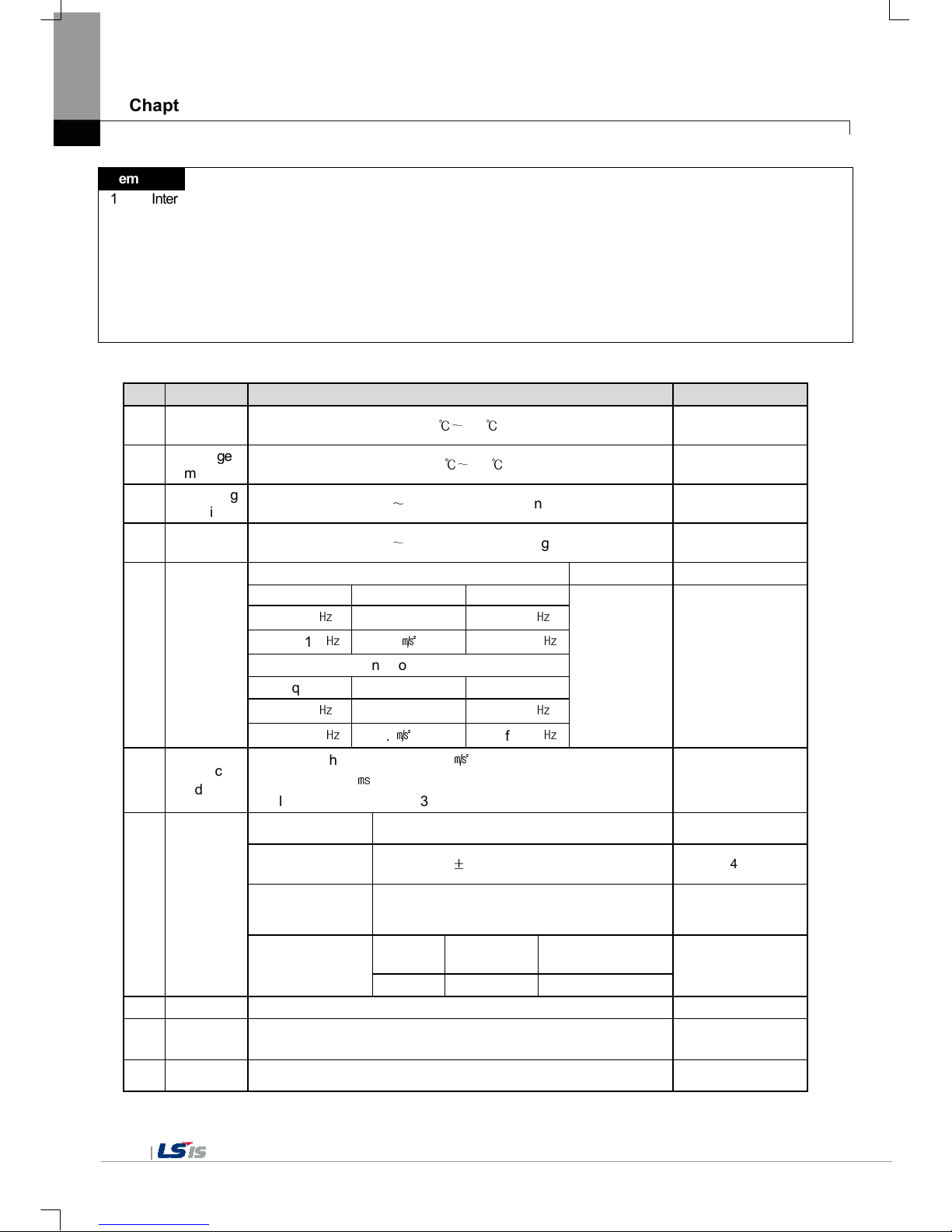

3.1 General Standards

XGT Panel’s general standard is as follows.

No. Category Standard Related standard

1

Ambient

operating

temperature

0℃∼+50℃

-

2

Storage

temperature

-20℃∼+60℃ -

3

Operating

humidity

10∼85%RH, non-condensing. -

4

Storage

humidity

10∼85%RH, non-condensing.

-

5

Vibration

resistance

Occasional vibration count -

Frequency Acceleration Amplitude

10 times for each

X, Y, Z axis

IEC 61131-2

5 ≤ f < 9㎐

- 3.5 mm

9 ≤ f ≤ 150㎐ 9.8㎨

-

Continuous vibration

Frequency Acceleration Amplitude

5 ≤ f < 9㎐

- 1.75 mm

9 ≤ f ≤ 150㎐ 4.9㎨

-

6

Shock

endurance

* Maximum shock acceleration: 147㎨ (15G)

* Duration time: 11㎳

* Pulse wave: half sine pulse (3 shocks per axis, on X, Y, Z axis)

IEC 61131-2

7

Noise

Immunity

Square wave

Impulse noise

AC: ±1,500V

DC: ±1,000V

LSIS

Standard

Electrostatic

discharge Immunity

±

6 kV (Discharge by contact)

IEC 61131-2

IEC 61000-4-2

Radiated

electromagnetic

field noise

80 ~ 1000 MHz, 10 V/m

IEC 61131-2

IEC 61000-4-3

Fast transient &

Burst noise

Category Power module

Communication

interface

IEC 61131-2

IEC 61000-4-4

Voltage 2 kV 1 kV

8 Environment

Free from corrosive gases and excessive dust -

9

Operating

height

Up to 2,000m (6,562 ft) -

10

Pollution degree

Less than 2

-

11

Cooling method

Air-cooling

-

Chapter 3. Standard Specification

3-2

Remark

(1) IEC(International Electro technical Commission)

: International private group facilitating international cooperation of electric/electronic standardization, issuing international

standards and operating the compliance evaluation systems.

(2) Pollution degree

: As an index representing the pollution degree of an environment to determine the insulation of a device, pollution degree 2

generally means the status generating non-conductive contamination. However, it also contains the status generating

temporarily conduction due to condensation.

(3) Radiated electromagnetic field noise for XP30-BTE(TTE) is 80 ~ 1000MHz, 10 V/m

(All others are same as shown on the table)

(1) General Specification for XP40-TTA(TTE)

No. Category

Standard Related standard

1

Operating

Temperature

0℃∼+50℃

-

2

Storage

Temperature

-20℃∼+60℃

-

3

Operating

Humidity

10∼85%RH, non-condensing.

-

4

Storage

Humidity

10∼85%RH, non-condensing.

-

5

Vibration

Resistance

Occasional vibration count -

Frequency Acceleration Frequency

10 times for each

X, Y, Z axis

IEC 61131-2

5 ≤ f < 9㎐

-

5 ≤ f < 9㎐

9 ≤ f ≤ 150㎐ 9.8㎨(1G) 9 ≤ f ≤ 150㎐

Continuous vibration

Frequency Acceleration Frequency

5 ≤ f < 9㎐

-

5 ≤ f < 9㎐

9 ≤ f ≤ 150㎐ 4.9㎨(0.5G) 9 ≤ f ≤ 150㎐

6

Shock

Endurance

* Maximum shock acceleration: 147㎨ (15G)

* Duration time: 11㎳

* Pulse wave: half sine pulse (3 shocks per axis, on X, Y, Z axis)

IEC 61131-2

7

Noise

Immunity

Square wave

Impulse noise

DC: ±800V

-

Electrostatic discharge

Immunity

±

4kV (Contact discharge)

IEC61000-4-2

Radiated

electromagnetic field

noise

80 ~ 1,000 MHz, 10 V/m

IEC61131-2

IEC61000-4-3

Fast transient &

Burst noise

Category Power module

Communication

interface

IEC61131-2

IEC61000-4-4

Voltage

2 kV 1 kV

8 Environment

Free from corrosive gases and excessive dust -

9

Operating

height

Up to 2,000m (6,562 ft) -

10

Pollution

degree

2 or less

-

Chapter 3. Standard Specification

3-3

11

Cooling

method

Air-cooling

-

3.2 Function Standards

XGT Panel’s function standard is as follows.

1. DC type

(1) 5.7 Inches Models

Item XP30-TTE/DC XP30-BTE/DC XP30-BTA/DC XP30-TTA/DC

Display type TFT LCD STN mono LCD TFT Color LCD

Screen size 14 ㎝ (5.7”)

Display Resolution

320 x 240 pixel

Color indication 256 Colors 8 step Gray Scale 65,000 Colors

Indication degree

Left/Right: 80 deg.

Upper: 70 deg.

Lower: 70 deg

Left/Right: 45 deg.

Upper: 20 deg.

Lower: 40 deg

Left/Right: 80 deg.

Upper: 70 deg.

Lower: 70 deg.

Backlight LED Type

Backlight duration

50,000 hours

Contrast - Adjust through touch/parameter -

Brightness 600cd/㎡ 230cd/㎡ 600cd/㎡

Touch panel 4 – Line type, analog

Sound Output Magnetic buzzer

Process ARM920T (32bit RISC), 200MHz

Graphic accelerator Hardware Accelerator

Memory

Flash 16MB 32MB

Operating RAM

32MB 64MB

Backup RAM 128KB 512KB

Backup data Date/Hour data and Logging/Alarm/Recipe data

Battery duration Approx. 3 years (Operating ambient temperature of 25℃)

Ethernet - 1 Channel, IEEE802.3, 10Base-T/100Base-TX

USB Host 1 Channel

2 Channels, USB 2.0

(printer, USB memory stick driver is available)

RS-232C Terminal Block 2 Channels

RS-422/485 Terminal Block 1 Channel,RS-422/485 mode

CF Card - 1 Slot (Compact Flash)

Expansion module

- Option module is available

Multi-language Up to 8 language simultaneously

Animation GIF format is available

Chapter 3. Standard Specification

3-4

Item XP30-TTE/DC XP30-BTE/DC XP30-BTA/DC XP30-TTA/DC

Recipe available

Data logging available

Script executor available

Certifications CE, UL, KC

Protection standard

IP65F

Dimension (mm)

181 x 140 x 56.5 181 x 140 x 66.5

Panel cut (mm) 156 x 123.5 156 x 123.5

Rated voltage DC24V (Actual Range: 19.2 ~ 28.8V)

Power consumption (W)

5 8.5

Weight(Kg) 0.62 0.75

(2) 7 Inches Models

Item XP40-TTE/DC XP40-TTA/DC

Display type TFT Color LCD

Screen size 7” (17.7㎝)

Display Resolution 800 x 480 pixel

Color indication 256 Colors 65,536 Colors

Indication degree

Left/Right: 65 deg.

Upper: 50 deg.

Lower: 60 deg.

Backlight LED (Replaceable)

Backlight duration

Above 30,000 hours

Brightness 280cd/㎡

Touch panel Analog

Sound Output Magnetic Buzzer

Process ARM920T (32bit RISC), 200MHz

Graphic accelerator Hardware Accelerator

Memory

Flash 16MB 32MB

Operating RAM 32MB 64MB

Backup RAM 128KB 512KB

Backup data Date/Hour data and Logging/Alarm/Recipe data

Battery duration Approximately 3 years (Operating ambient temperature of 25℃)

Ethernet - 1 Channel, IEEE802.3, 10Base-T/100Base-TX

USB Host

1 Channels, USB 2.0

(printer, USB memory stick driver is available)

RS-232C Terminal Block

RS-422/485 Terminal Block

Chapter 3. Standard Specification

3-5

Item XP40-TTE/DC XP40-TTA/DC

Multi-language

Up to 8 language simultaneously

Animation GIF format is available.

Recipe Available

Data logging Available

Script executor Available

Certifications CE, UL(cUL), KC

Protection standard IP65F

Dimension (mm) 203.5x153.5x41.5

Panel cut (mm) 192 x 138

Rated voltage DC24V (19.2 ~ 28.8V)

Power consumption (W) Less than 4.5 Less than 5

Weight(Kg) 0.80 0.81

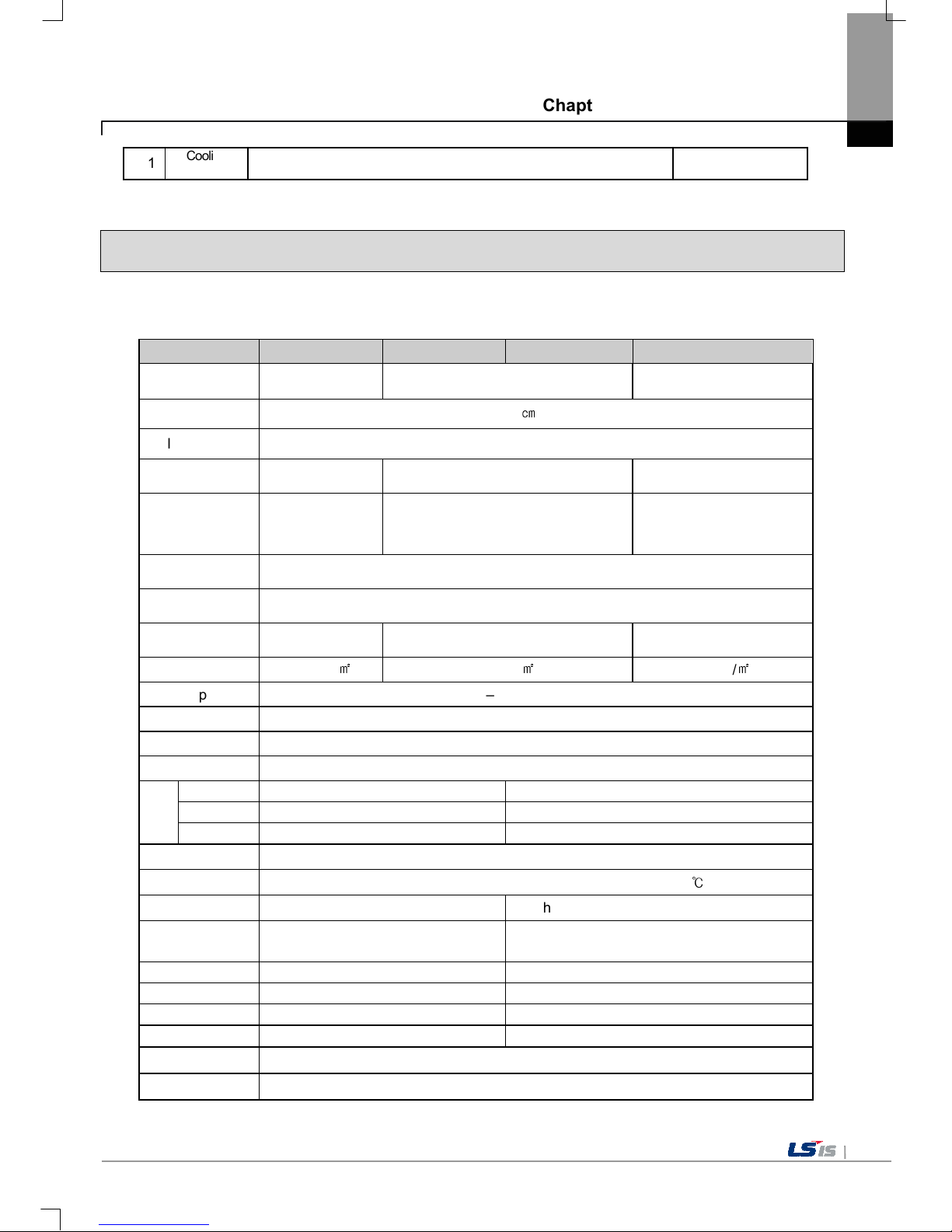

(3) 8.4/10.4/12.1 Inches Models

Item

XP50-TTE/DC

XP50-TTA/DC

XP70-TTA/DC

XP80-TTA/DC

Display type

TFT Color LCD

Screen size

21 ㎝(8.4”) 26 ㎝(10.4”) 31㎝(12.1”)

Display Resolution 640 x 480 pixel 800 x 600 pixel

Color indication

256 Color 65,000 Color

Indication degree

Left/Right: 45 deg.

Upper: 20 deg.

Lower: 20 deg.

Left/Right: 65 deg.

Upper: 50 deg.

Lower: 60 deg.

Left/Right: 65 deg.

Upper: 45 deg.

Lower: 65 deg.

Left/Right: 65 deg.

Upper: 45 deg.

Lower: 75 deg.

Backlight

CCFL (Replacement is available), Supporting automatic On/Off

Backlight duration 50,000 hr.

Brightness 200cd/㎡ 480cd/㎡ 430cd/㎡ 400cd/㎡

Touch panel

8 Line, analog

Sound Output

Magnetic buzzer

Process

ARM920T (32bit RISC), 200MHz

Graphic accelerator Hardware Accelerator

Memory

Flash

16MB 32MB

Operating RAM 32MB 64MB

Backup RAM 128KB 512KB

Backup data

Date/Hour data and Logging/Alarm/Recipe data

Battery duration

Approx. 3 years (Operating ambient temperature of 25℃)

Ethernet

1 Channel, IEEE802.3, 10Base-T/100Base-TX

USB Host 1 Channel 2 Channels, USB 2.0 (printer, USB memory stick driver is available)

RS-232C Terminal Block 2 Channels

Chapter 3. Standard Specification

3-6

Item

XP50-TTE/DC

XP50-TTA/DC

XP70-TTA/DC

XP80-TTA/DC

RS-422/485 Terminal Block 1 Channel, RS-422/485 mode

CF Card - 1 Slot (Compact Flash)

Expansion module - Option module is available

Multi-language

Up to 8 language simultaneously

Animation

GIF format is available

Recipe

available

Data logging

available

Script executor

available

Certifications

CE, UL, KC

Protection standard IP65F

Dimension (mm)

240 x 174 x 63 240 x 174 x 73 317 x 243 x 73

Panel cut (mm)

228.0 x 158.0 294.5 x 227.5

Rated voltage

DC24V (Actual Range: 19.2 ~ 28.8V)

Power

consumption(W)

13 20 27 30

Weight(Kg)

1.2 1.4 2.2 2.4

Remark

(1) Notice in connecting with power

: Connecting AC power to the device using DC power may cause product break or fire. Be careful when connecting

(2) FG connection

: Use ⑤FG terminal (Chapter 2.1) for FG of the device. ⑮FG (Chapter 2.1) is for FG terminal of extension card.

(Except XP30-BTE, XP30-TTE and XP50-TTE)

(3) Prevention tape of Battery discharge

: There is prevention tape is to prevent the battery discharge. In order to use backup, remove the prevention tape.

(4) Battery operation and duration

: Battery is used to reserve backup data and RTC (data/time) when power is off.

Because battery is used when power is off, battery is not consumed when power is on.

(5) LCD Backlight replacement

: XP40-TTA(TTE)/DC, XP50-TTA(TTE)/DC, XP70-TTA/DC, XP80-TTA/DC, LCD backlight is replaceable.

However in XP30-BTE/DC, XP30-TTE/DC, XP30-BTA/DC and XP30-TTA/DC, LCD backlight is not

replaceable because LCD and backlight is all-in-one type.

Chapter 3. Standard Specification

3-7

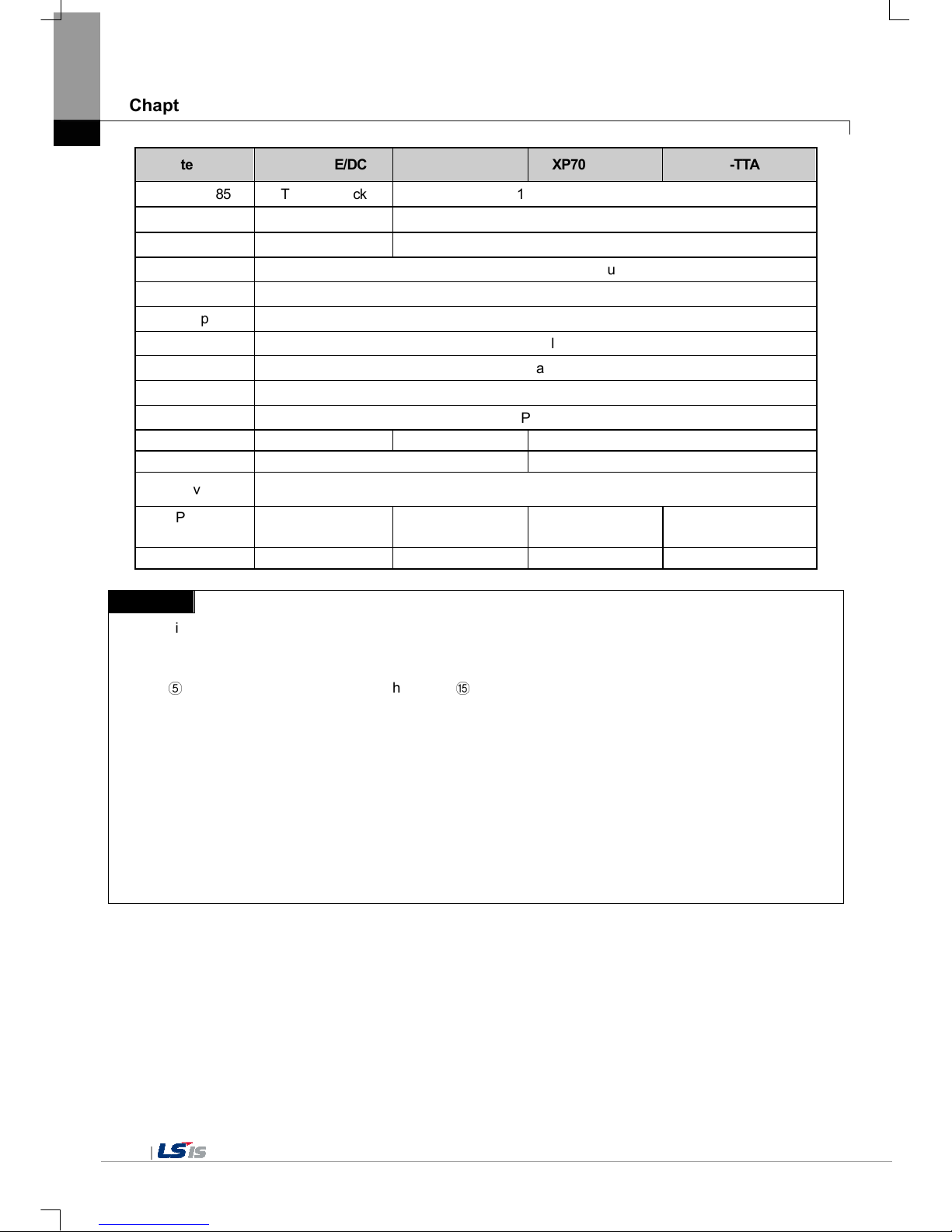

2. AC Type

(1) 10.4/12.1/15 Inches Models

Item XP70-TTA/AC XP80-TTA/AC XP90-TTA/AC

Display type TFT Color LCD

Screen size 26cm (10.4”) 31cm (12.1”) 38cm (15”)

Display Resolution 640 x 480 pixel 800 x 600 pixel 1024 x 768 pixel

Color indication 65,000 Color

Indication degree

Left/Right: 65 deg.

Upper: 45 deg.

Lower : 65 deg.

Left/Right: 65 deg.

Upper: 45 deg.

Lower : 75 deg.

Left/Right: 75 deg

Upper : 50 deg

Lower : 60 deg

Backlight CCFL (Replacement is available), Supporting automatic On/Off

Backlight Duration 50,000 hr.

Contrast -

Brightness 430cd/㎡ 400cd/㎡ 450cd/㎡

Touch Panel 8 Line, analog

Sound Output Magnetic buzzer

Process ARM920T (32bit RISC), 200MHz

Graphic Accelerator Hardware Accelerator

Memory

Flash 32MB 64MB

Operating Ram 64MB 128MB

Backup Ram 512KB

Backup data Date/Hour data and Logging/Alarm/Recipe data

Battery duration Approx. 3 years (Operating ambient temperature of 25℃)

Ethernet 1Channel, IEEE802.3, 10Base-T/100Base-TX

USB Host 2 Channels, USB 2.0 (printer, USB memory stick driver is available)

RS-232C 2 Channels

RS-422/485 1 Channel,RS-422/485 mode

CF Card 1 Slot (Compact Flash)

Expansion Module

Option module is available

Multi-language Up to 4 language simultaneously

Animation GIF format is available

Recipe available

Data logging available

Script executor available

Certification CE, UL, KCC

Protection standard

IP65F

Dimension (mm) 317 x 243 x 73 395 x 294 x 73

Panel cut (mm) 294.5 x 227.5 383.5 x 282.5

Rated voltage AC100~240V

Power consumption (W)

37 40 46

Weight (Kg) 2.2 2.4 3.9

Chapter 3. Standard Specification

3-8

Remark

(1) Notice in connecting with power

: If you connect DC power to the device using AC power, the product doesn’t work. Please be careful when connecting.

(2) FG connection

: Use ⑤FG terminal (Chapter 2.1) for FG of the device. ⑮FG (Chapter 2.1) is for FG terminal of extension card.

(Except XP30-BTE , XP30-TTE and XP50-TTE)

(3) Prevention tape of Battery discharge

: There is prevention tape is to prevent the battery discharge. In order to use backup, remove the prevention tape.

(4) Battery operation and duration

: Battery is used to reserve backup data and RTC (data/time) when power is off.

Because battery is used when power is off, battery is not consumed when power is on.

(5) LCD Backlight replacement

: In XP70-TTA/AC, XP80-TTA/AC, XP90-TTA/AC, LCD backlight is replaceable.

Chapter 4. System Configuration

4-1

Chapter 4. System Configuration

It describes the system configuration including XGT Panel’s time setting, Ethernet connection setting, and connection with

PC and backlight.

If you press [Settings] button in XGT Panel’s basic screen, you can set XGT Panel’s environment as follows.

XGT Panel’s basic screen

XGT Panel’s System Configuration screen

Loading...

Loading...