Right choice for ultimate yield

LSIS strives to maximize customers' profit in gratitude of choosing us for your partner.

Programmable Logic C ontroller

Cnet I/F Module

User’s Manual

Read this manual carefully before

installing,

wiring, operating, servicing

or inspecting this equipment.

Keep this manual within easy reach

for quick reference.

XGL-

CH2A

XGL-

C22A

XGL-C24A

XGT Series

http://eng.lsis.biz

Safety Instructions

Before using the product …

For your safety and effective operation, please read the safety instructions

thoroughly before using the product.

► Safety Instructions should always be observed in order to prevent accident

or risk with the safe and proper use the product.

► Instructions are divided into “Warning” and “Caution”, and the meaning of

the terms is as follows.

This symbol indicates the possibility of serious injury

or death if some applicable instruction is violated

This symbol indicates the possibility of severe or

slight injury, and property damages if some

applicable instruction is violated

Moreover, even classified events under its caution category may develop into

serious accidents relying on situations. Therefore we strongly advise users to

observe all precautions properly just like warnings.

► The marks displayed on the product and in the user’s manual have the

following meanings.

Be careful! Danger may be expected.

Be careful! Electric shock may occur.

► The user’s manual even after read shall be kept available and accessible to

any user of the product.

Warning

Caution

Safety Instructions

Safety Instructions for design process

Please install a protection circuit on the exterior of PLC so that the

whole system may operate safely regardless of failures from

external power or PLC. Any abnormal output or operation from PLC

may cause serious problems to safety in whole system.

- Install protection units on the exterior of PLC like an interlock circuit

that deals with opposite operations such as

emergency stop,

protection circuit, and forward/reverse rotation or install an interlock

circuit that deals with high/low limit under its position controls.

- If any system error (watch-dog timer error, module installation error,

etc.) is detected during CPU operation in PLC, all output signals are

designed to be turned off and stopped for safety. However, there

are cases when output signals remain active due to device failures

in Relay and TR which can’t be detected

. Thus, you are

recommended to install an addition circuit to monitor the output

status for those critical outputs which may cause significant

problems.

Never overload more than rated current of output module nor

allow to have a short circuit. Over current for a long period time may

cause a fire .

Never let the external power of the output circuit to be on earlier

than PLC power, which may cause accidents from abnormal output or

operation.

Please install interlock circuits in the sequence program for safe

operations in the system when exchange data with PLC or modify

operation modes using a computer or other external equipments

Read specific instructions thoroughly when conducting control

operations with PLC.

Warning

Safety Instructions

Safety Instructions for design process

Safety Instructions on installation process

I/O signal or communication line shall be wired at least 100mm

aw ay from a high-voltage cable or power line. Fail to follow this

instruction may caus e mal funct ions from noise

Caution

Use PLC only in the environment specified in PLC manual or

general standard of data sheet. If not, electric shock, fire, abnormal

operation of the product may be caused.

Before install or remove the modul e, be sure PLC power is off. If

not, electric shock or damage on the product may be caused.

Be sure that every module is securely attached after adding a

module or an extension connector.

If the product is installed

loosely or incorrectly, abnormal operation, error or dropping may be

caused. In addition, contact failures under poor cable installation will

be causing malfunctions as well.

Be sure that screws get tighten securely under vibrating

environments.

Fail to do so will put the product under direct

vibrations which will cause electric shock, fire and abnormal

operation.

Do not come in contact with conducting parts in each module,

which may cause electric shock, malfunctions or abnormal operation.

Caution

Safety Instructions

Safety Instructions for wiring process

Prior to w iring works, make sure that every power is turned off. If

not, electric shock or damage on the product may be caused.

After wiring process is done, make sure that terminal covers are

installed properly before its use. Fail to install the cover may cause

electric shocks.

Warning

Check rated voltages and terminal arrangements in each product

prior to its wiring process.

Applying incorrect voltages other than

rated voltages and misarrangement among terminals may cause fire

or malfunctions.

Secure terminal screws tightly applying with specified torque. If

the screws get loose, short circuit, fire or abnormal operation may be

caused. Securing screws too tightly will cause damages to the module

or malfunctions, short circuit, and dropping.

*

Be sure to earth to the ground using Class 3 wires

for FG

terminals which is exclusively used for PLC. If the terminals not

grounded correctly, abnormal operation or electric shock

may be

caused.

Don’t let any foreign materials such as wiring waste inside the

module while wiring, which may cause fire, damage on the product

or abnormal operation.

Make sure that pressed terminals

get tighten following the

specified torque. External connector type shall be pressed or

soldered using proper equipments.

Caution

Safety Instructions

Safety Instructions for test-operation and

maintenance

Don’t touch the terminal when powered. Electric shock or abnormal

operation may occur.

Prior to cleaning or tightening the terminal screws, let all the

external power off including PLC power.

If not, electric shock or

abnormal operation may occur .

Don’t let the battery recharged, disassembled, heated, short or

soldered. Heat, explosion or ignition may cause injuries or fire.

Warning

Do not make modifications or disassemble each module. Fire,

electric shock or abnormal operation may occur.

Prior to installing or disassemb

ling the module, let all the

external power off including PLC power.

If not, electric shock or

abnormal operation m ay occur .

Keep any wireless equipment such as walkie-talkie or cell phones

at least 30cm away from PLC.

If not, abnormal operation may be

caused.

When making a modification on programs or using run to modif y

functions under PLC operations,

read and comprehend all

contents in the manual fully. Mismanagement will cause damages to

products and accide nts.

Avoid any physical impact to the battery and prevent it from

dropping as well.

Damages to battery may cause leakage from its

fluid. When battery was dropped or exposed under strong impact,

never reuse the battery again. Moreover skilled workers are needed

when exchanging batteries.

Caution

Safety Instructions

Safety Instruct ions for waste disp osal

Product or battery waste shall be processed as industrial waste.

The waste may discharge toxic materials or explode itself.

Caution

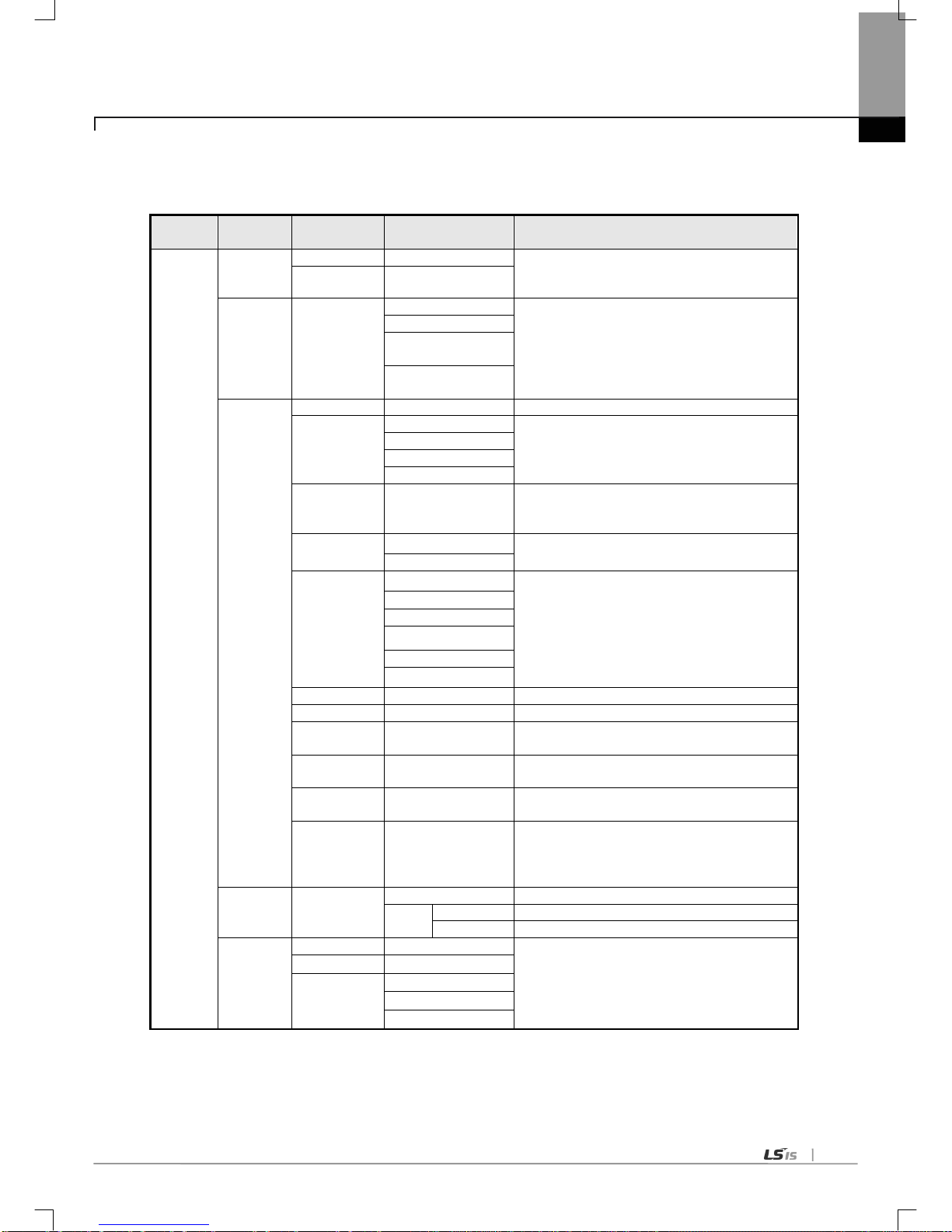

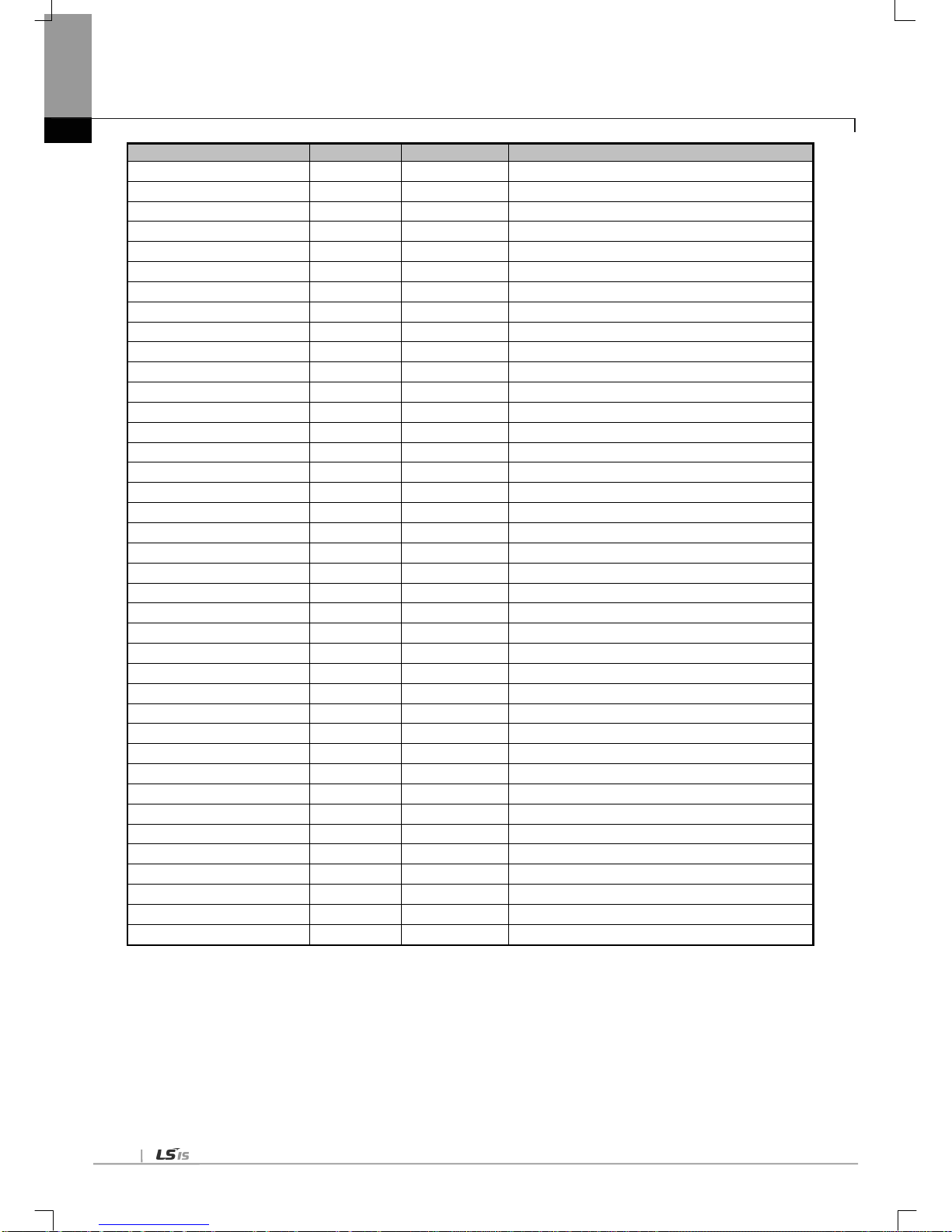

Revision History

2

Revision History

Version

Data

Remark

Page

V 1.0 ’05.03 First Edition

-

V1.1 ’05.05.19 Add function description

-

V1.2 ’05.19.12 Change available CPU device address

-

V2.0 ’07.01.15 Change XG-PD description

-

V 2.1 ’08.02

1. Adding contents

(1) Production Configuration

(2) Software to use the product

(3) Operation Sequence

(4) I/O assignment and Device Information

(5) General of Communication Parameter

(6) Transmission Standard

(7) How to set transmission Standard

(8) Menu bar and shortcut of XG-PD

(9) Operation Start

(10) Diagnosis Function of XG-PD

<Ch.7 XGT Dedicated Communication>

(11) Summary of Protocol

(12) Frame Structure

(13) XGT Communication Function

(14) Remote Connection

(15) Modem Communication

(16) Communication Command

<Ch.8 Modbus Communication>

(17) General

(18) Modbus Protocol

(19) Structure of Frame

(20) Modbus Server

(21) Modbus RTU/ASCII Client

(22) Frame Monitor

<Ch.9 User-defined Communication>

(23) General

(24) Structure of user definition frame

(25) Frame Monitor

(26) Trouble shooting

1-3

1-4 ~ 1-5

4-3

4-6 ~ 4-13

6-1

6-2

6-25

6-27 ~ 6-28

6-35 ~ 6-37

6-42 ~ 6-48

7-1 ~ 7-47

8-1 ~ 8-31

9-1 ~ 9-11

11-9 ~ 11-11

Revision History

3

Version Data Remark Page

(27) User interface using Visual Basic

(28) Dimension

(29) Index

2. Fixing the contents

(1) Introduction

(2) Characteristics

(3) Performance Specifications

(4) Designation of Parts

(5) Cable Specifications

(6) Terminal Resistance

(7) Channel Operation during Normal Run

(8) Method of Serial Interface

(9) P2P setting parameter

(10) Available System Configurations

(11) Unavailable System Configurations

(12) Communication Module Registration

(13) Safety Instructions

A-18 ~ A-29

A-30

A-31 ~ A-32

1-1

1-2

2-2

2-3

2-4

2-5

3-2

3-4

4-5

5-1~ 5-6

5-7 ~ 5-8

6-20 ~ 6-24

V2.2

’08.07

1. Head office address change

Back cover

2. Adding contents

(1) How to configure XGR basic system

4-8

(2) Available device area per CPU

4-12

3. Fixing the contents

(1) Introduction

1-1,1-3

(2) Product Specification

2-3

(3) Installation and Test Operation

4-4, 4-9

(4) Communication Parameter

6-1, 6-47

(5) XGT dedicated communication

7-3, 7-5

(6) Modbus communication

8-18, 8-24

(7) User defined communication

9-3

(8) Example program

10-7

(9) Diagnosis

11-4

(10) Standard setting window modification

Entire

V2.3

’10.03

1. Characteristics modified

Ch1.2

2. CPU added

Ch1.3.2

3. Content on the remote connection modified

Ch7.4.2

4. Figure and figure number of modem

communication modified

Ch7.5

Revision History

4

V2.4 ’10.06.17 1. 2.1 Change general specification

2. 3.4.1 (2) Change Null modem connection cable

3. Back address change and delete

2-1

3-4

Back cover

V2.5

’11.05

1. How to enable link through flag added

CH6.7.2

V2.6 ’14.01.10

1. Change typographical error

2. Delete XGR main base module description

3. Change RS-485 communication cable direction

4. Not usable system configuration

5. add parity bit Ignore function

6. Change delay time setting typographical error

7. Change direct variable write typographical error

8. Change Modbus RTU typographical error

9. add UDATA instruction description

10. Add example UDATA function

Entire

CH1.3.2, CH2.2,

CH4.5.1

CH3.4.2

CH5.2.1

CH6.1.1, CH6.2.1

CH6.1.1

CH7.2.3

CH8

CH9.5

CH10.6

V2.7 ’14.04.19

Change system configuration Entire

V2.8

’14.11

XG5000 V4.0 UI Updated

Entire

※ The number of User’s manual is indicated right part of the back cover.

Copyright ⓒ 2005 LSIS Co., Ltd All Rights Reserved.

About User’s Manual

1

Congratulations on purchasing PLC of LSIS Co.,Ltd.

Before use, mak e s ure t o c aref u l l y rea d an d u nd er s tand the Us er’s Manual about the functions, perform anc es, instal lat ion and

programming of the product you purchased in order for correct use and importantly, let the end user and maintenance

administrator to be provided with the User’s Manual .

The User ’s Manual describes the product. If necessary, you may refer to the following description and order accordingly. In

addition, you may conne ct our websi te (http://eng.lsis.biz/

) and download the information as a PDF file.

Relevant User’s Manuals

Title Description

XG5000 User’s Manual

XG5000 software user manual describing online function such as

programming, print, m onitoring, deb ugging by using XG K, XGB

CPU

XG5000 User’s Manual

(for XGI, XGR)

XG5000 software us er manual describin g online function such

as programming, print, monitoring, debugging by using XGI,

XGR CPU

XGK/XGB Instructions & Programming

User’s Manual

User’s manual for programming

to explain how to use

instructions that are used PLC system with XGK, XGB CPU.

XGI/XGR Instructions & Programming

User’s Manual

User’s manual for programming

to explain how to use

instructions that are used PLC system with XGI, XGR CPU.

XGK CPU User’s Manual

(XGK-CPUU/CPUH/CPUA/CPUS/CPUE)

XGK-CPUU/CPUH/CPUA/CPUS/CPUE user manual describing

about XGK CPU module, power module, base, IO module,

specification of extension cab le and system configuration, E MC

standard

XGI CPU User’s Manual

(XGI-CPUU/D,CPUU,CPUH,CPUS,CPUE)

XGI-CPUU/D,CPUU,CPUH,CPUS,CPUE user manual

describing about XGI CPU module, power module, base, IO

module, specification of extension cable and system

configuration, EMC standard

XGR redundant series User’s

Manual

XGR- CPUH/F, CPUH/T user manual describing about XGR

CPU module, power module, extension drive, base, IO module,

specification of extension cable and system configuration, EMC

standard

Current user manual of XGL-CH2A, C42A, C22A is written based on the following version.

Related OS version list

Product name OS version

XGK-CPUU, CPUH, CPUA, CPUS, CPUE V2.0

XGI-CPUU/D, CPUU, CP UH, CP US, CPUE V2.1

XGR-CPUH/F, CPUH/T, CPUH/S V1.1

XG5000 V4.0

Contents

1

◎ Contents ◎

Chapter 1 Overview

1.1 Introduction------------------------------------------------------------------------------------------------------------------------------------------------- 1-1

1.2 Characteristics-------------------------------------------------------------------------------------------------------------------------------------------- 1-2

1.3 Product Configuration----------------------------------------------------------------------------------------------------------------------------------- 1-3

1.3.1 Type name indication----------------------------------------------------------------------------------------------------------------- 1-3

1.3.2 Equip-able number per CPU------------------------------------------------------------------------------------------------------------- 1-3

1.4 Software to use the product-------------------------------------------------------------------------------------------------------------------- 1-4

1.4.1 Software check point------------------------------------------------------------------------------------------------------------------- 1-4

1.4.2 XG5000 ---------------------------------------------------------------------------------------------------------------------------------------- 1-4

1.4.3 Check of version----------------------------------------------------------------------------------------------------------------------------- 1-5

Chapter 2 Product Specifications

2.1 General Specifications------------------------------------------------------------------------------------------------------------------------------------ 2-1

2.2 Performance Specifications----------------------------------------------------------------------------------------------------------------------------- 2-2

2.3 Names of Parts--------------------------------------------------------------------------------------------------------------------------------------- 2-3

2.4 Ca ble Specifications-------------------------------------------------------------------------------------------------------------------------------------- 2-4

2.5 Terminal Resis tance-------------------------------------------------------------------------------------------------------------------------------------- 2-5

Chapter 3 Performance Sp ecifications

3.1 Operat ion M ode Setting--------------------------------------------------------------------------------------------------------------------------------- 3-1

3.2 Channe l Op er at i on during Norm a l Ru n ----------------------------------------------------------------------------------------------------------- 3-2

3.3 Channel Operation in Diagnosis Mode (Loop-Back) ------------------------------------------------------------------------------------------ 3-3

3.4 Method of Serial Interface------------------------------------------------------------------------------------------------------------------------------- 3-3

3.4.1 RS-232C interface----------------------------------------------------------------------------------------------------------------------------- 3-3

3.4.2 RS-422/485 interface-------------------------------------------------------------------------------------------------------------------------- 3-5

Chapter 4 Instal lation and Test Operation

4.1 Installation Environment -------------------------------------------------------------------------------------------------------------------------------- 4-1

4.2 Precautions for Handling-------------------------------------------------------------------------------------------------------------------------------- 4-2

4.3 Operation Sequence--------------------------------------------------------------------------------------------------------------------------- 4-3

4.4 Contents of Parameter Setting in the XG5000-------------------------------------------------------------------------------------------- 4-4

4.4.1 Basic setting parameter ------------------------------------------------------------------------------------------------------------------ 4-4

4.4.2

P2P setting paramet er

--------------------------------------------------------------------------------------------------------------------------- 4-5

4.5 I/O Assignment and Device Information------------------------------------------------------------------------------------------------------------ 4-6

4.5.1 I/O assignment ---------------------------------------------------------------------------------------------------------------------------------- 4-6

4.5.2 Device information---------------------------------------------------------------------------------------------------------------------------- 4-9

4.5.3 Available device area per series---------------------------------------------------------------------------------------------------------- 4-12

Contents

2

Chapter 5 System Configuration

5.1 Available System Configurations

------------------------------------------------------------------------------------------------------------------- 5-1

5.1.1 1:1 connection (no modem) to PC (HMI) ------------------------------------------------------------------------------------------------ 5-1

5.1.2 1:1 dedicated modem connection to PC (HMI) --------------------------------------------------------------------------------------- 5-1

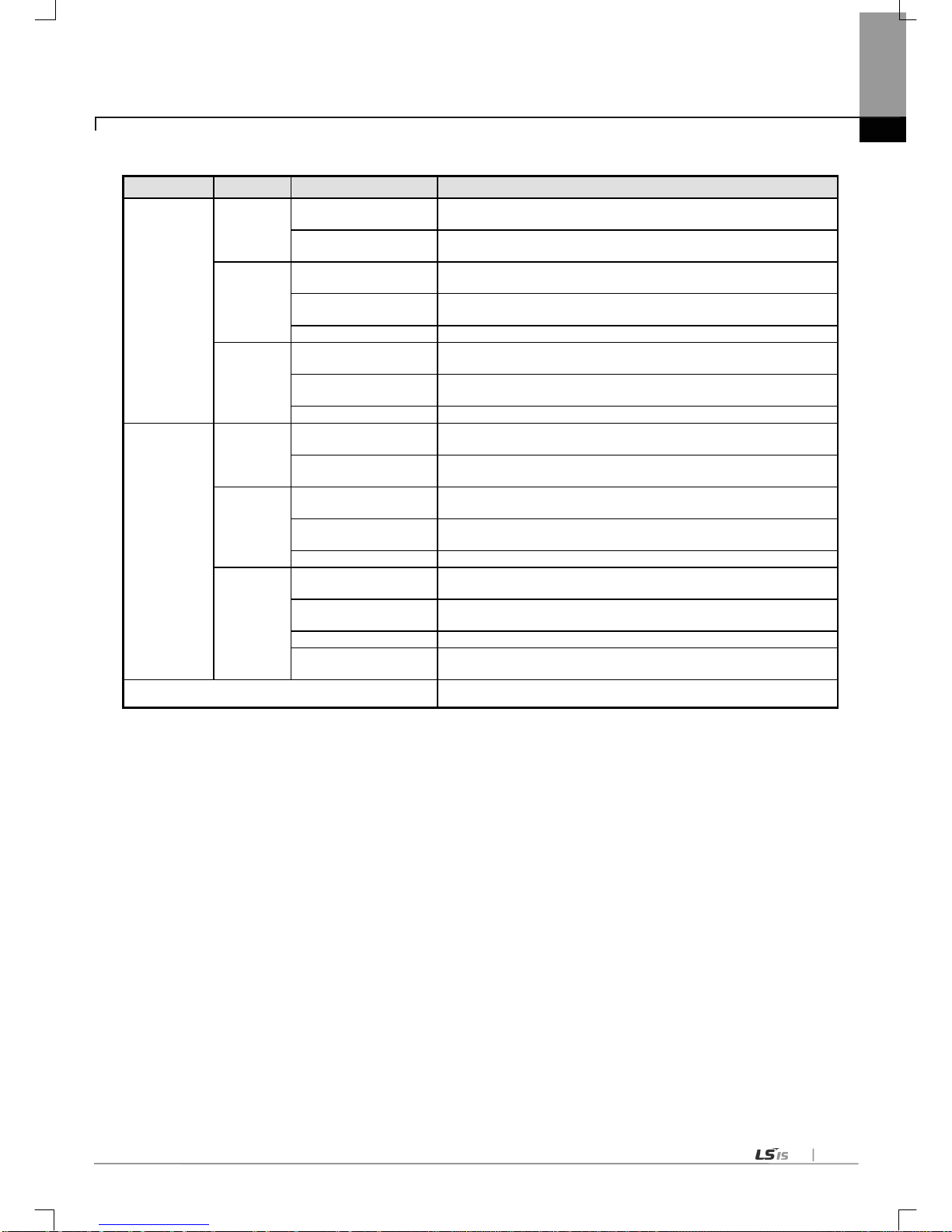

5.1.3 Modem connection to PC & Communication between Cnet I/F modules----------------------------------------------------- 5-2

5.1.4 Dedicated communication with PC (HMI) & Other company’s RS-422 communication --------------------------------- 5-3

5.1.5 Optical modem communication for mobile communication ----------------------------------------------------------------------- 5-4

5.1.6 Wireles s modem commu n icat io n f or communication be t wee n r e v olution bodies ---------------------------------------- 5-5

5.1.7 TM/TC communication system ------------------------------------------------------------------------------------------------------------- 5-6

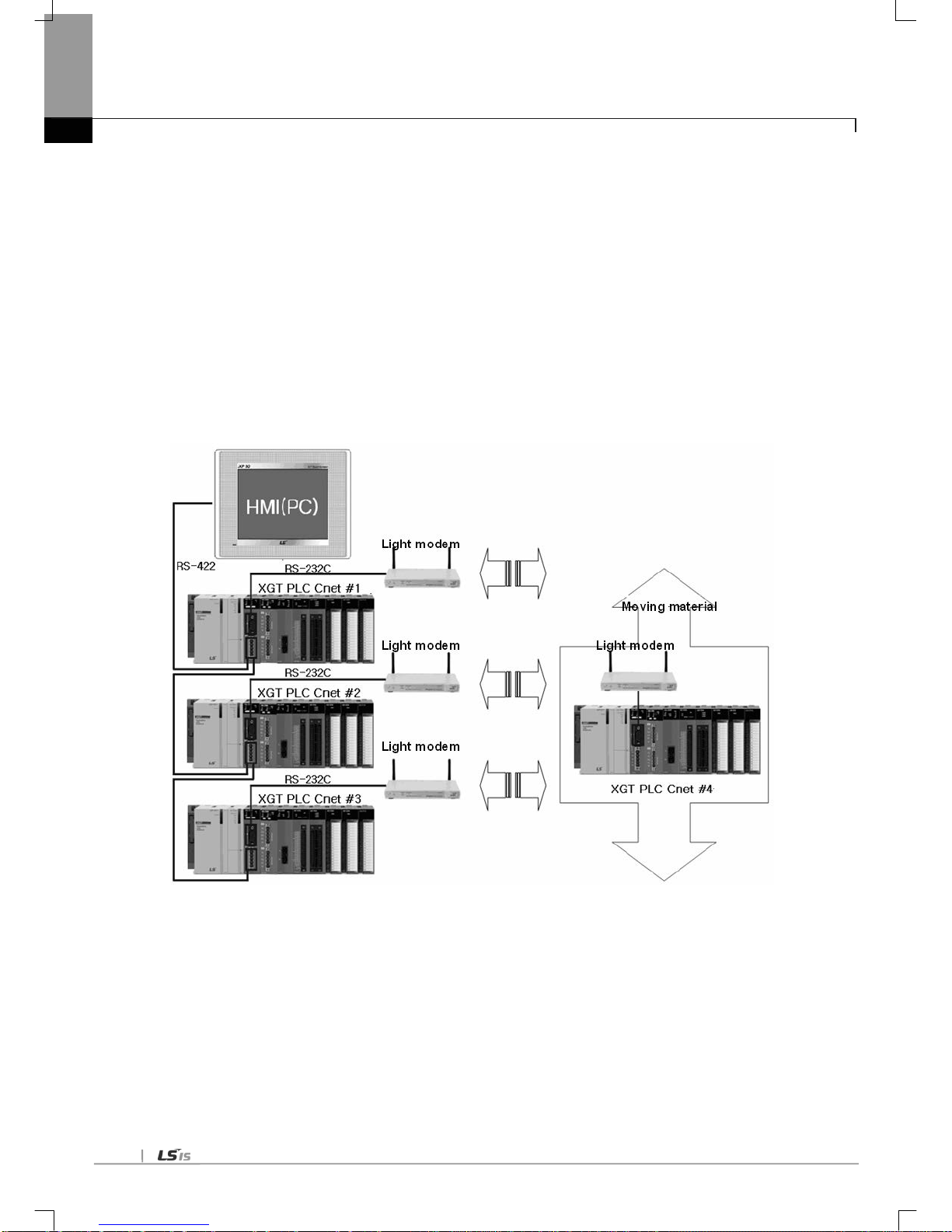

5.2 Unavailable System Configurations -------------------------------------------------------------------------------------------------------------- 5-7

5.2.1 Dial-up modem communication between Cnet I/F modules ---------------------------------------------------------------------- 5-7

5.2.2 XG5000 connection using RS-422 channel of Cnet I/F module ----------------------------------------------------------------- 5-8

Chapter 6 Communication Parameter

6.1 General -------------------------------------------------------------------------------------------------------------------------------------------------- 6-1

6.1.1 Basic setting parameter ---------------------------------------------------------------------------------------------------------------------- 6-1

6.1.2 P2P setting parameter ------------------------------------------------------------------------------------------------------------------- 6-3

6.2 Transmission Standard -------------------------------------------------------------------------------------------------------------------------------- 6-4

6.2.1

Setting item --------------------------------------------------------------------------------------------------------------------------------------- 6-4

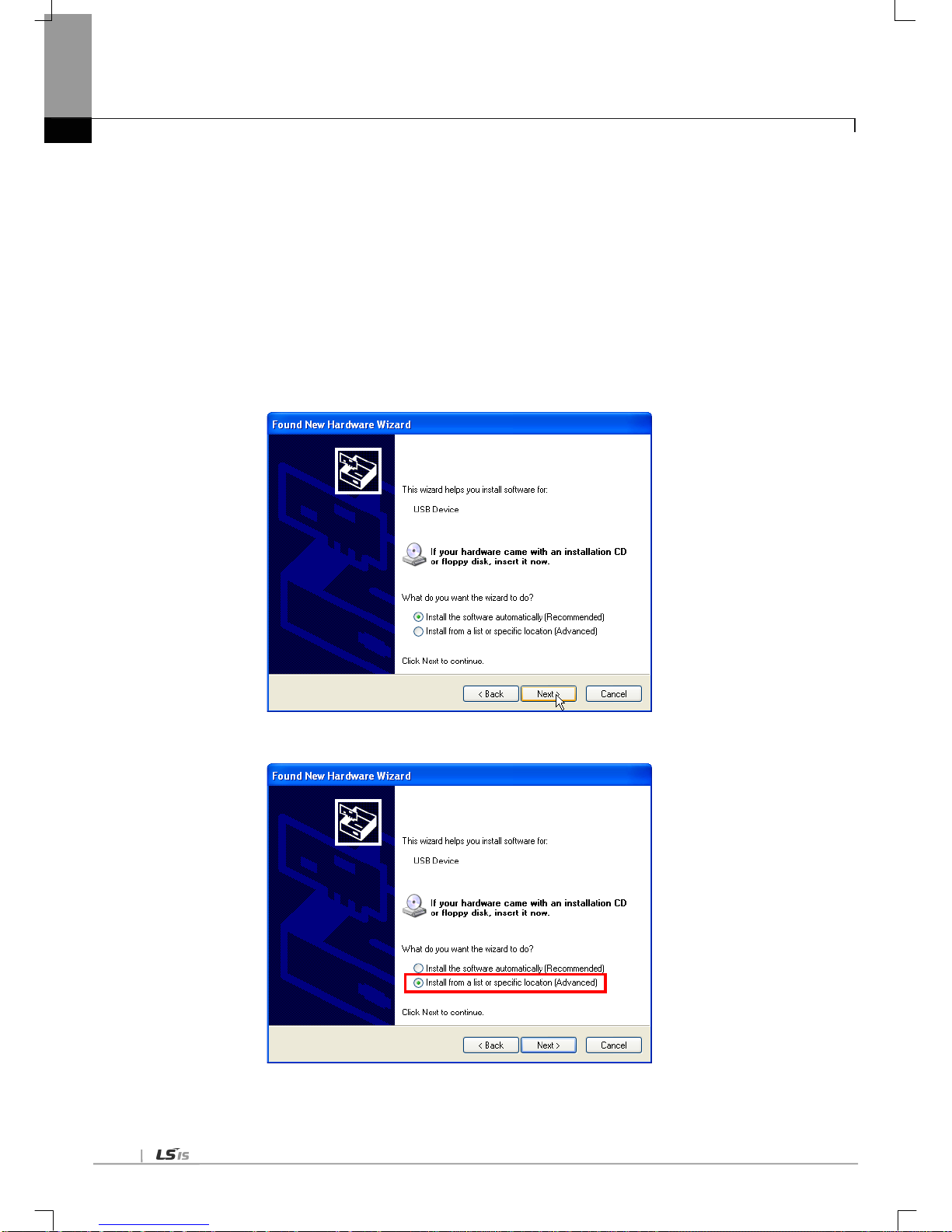

6.3 Installation and Execution of Software ------------------------------------------------------------------------------------------------------------ 6-6

6.3.1 XG5000 installation ---------------------------------------------------------------------------------------------------------------------------- 6-6

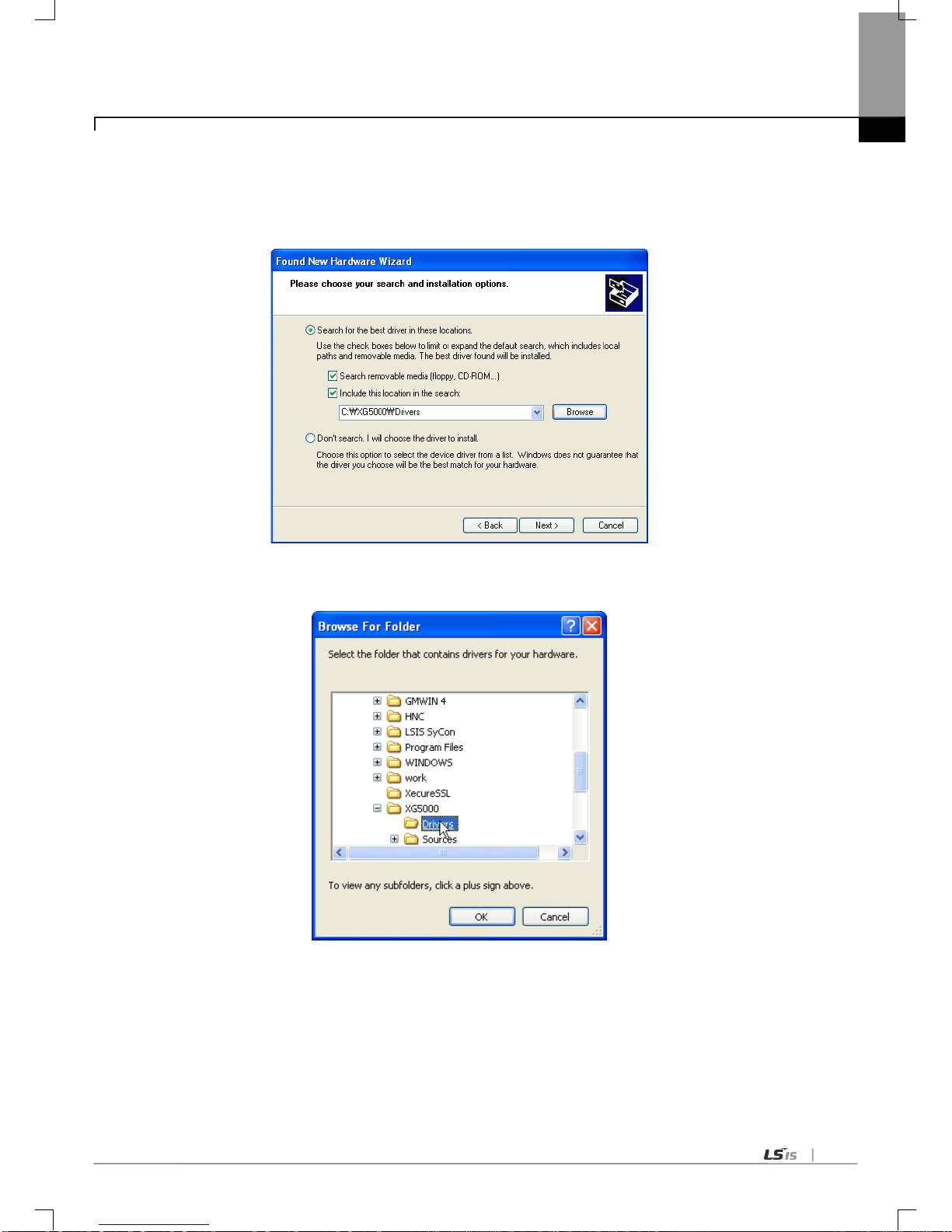

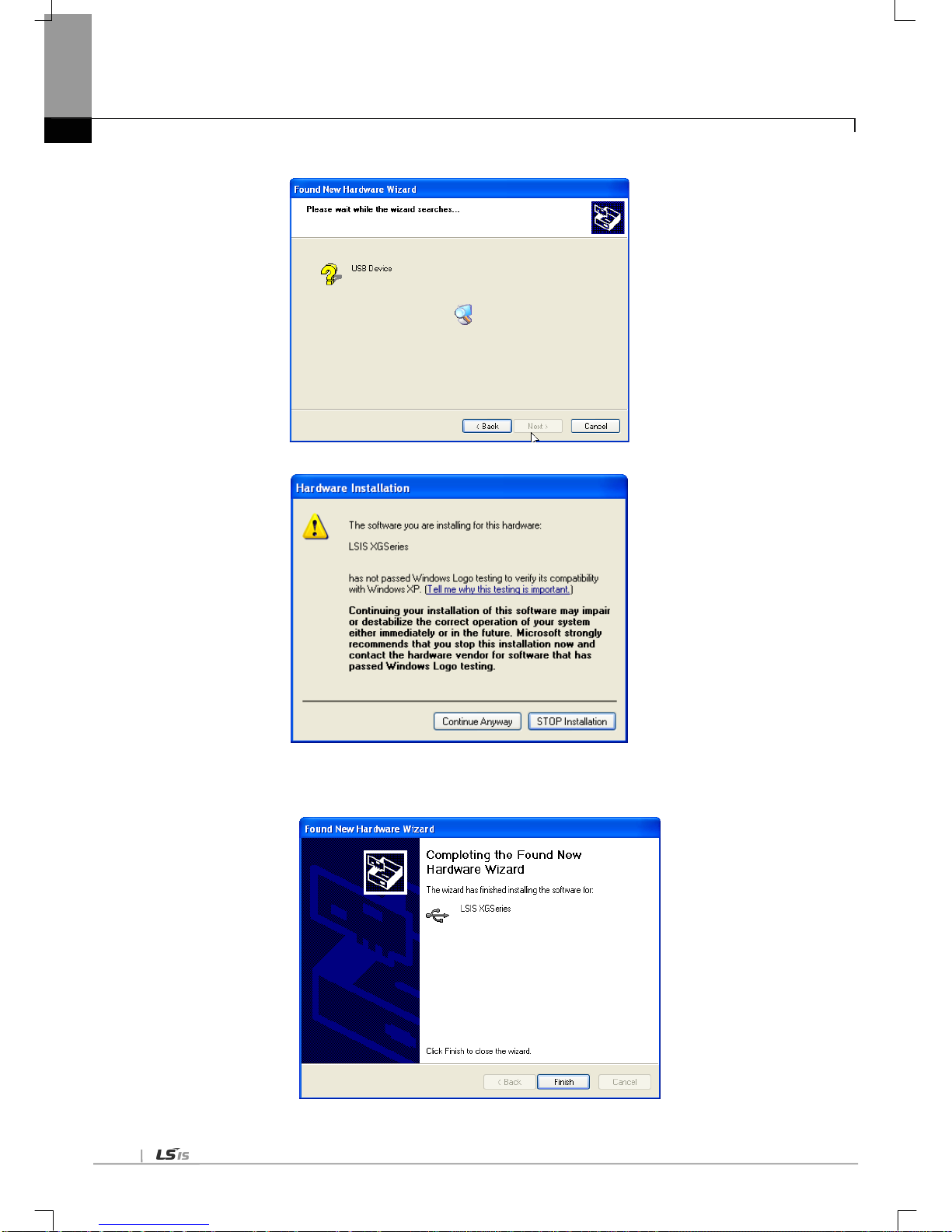

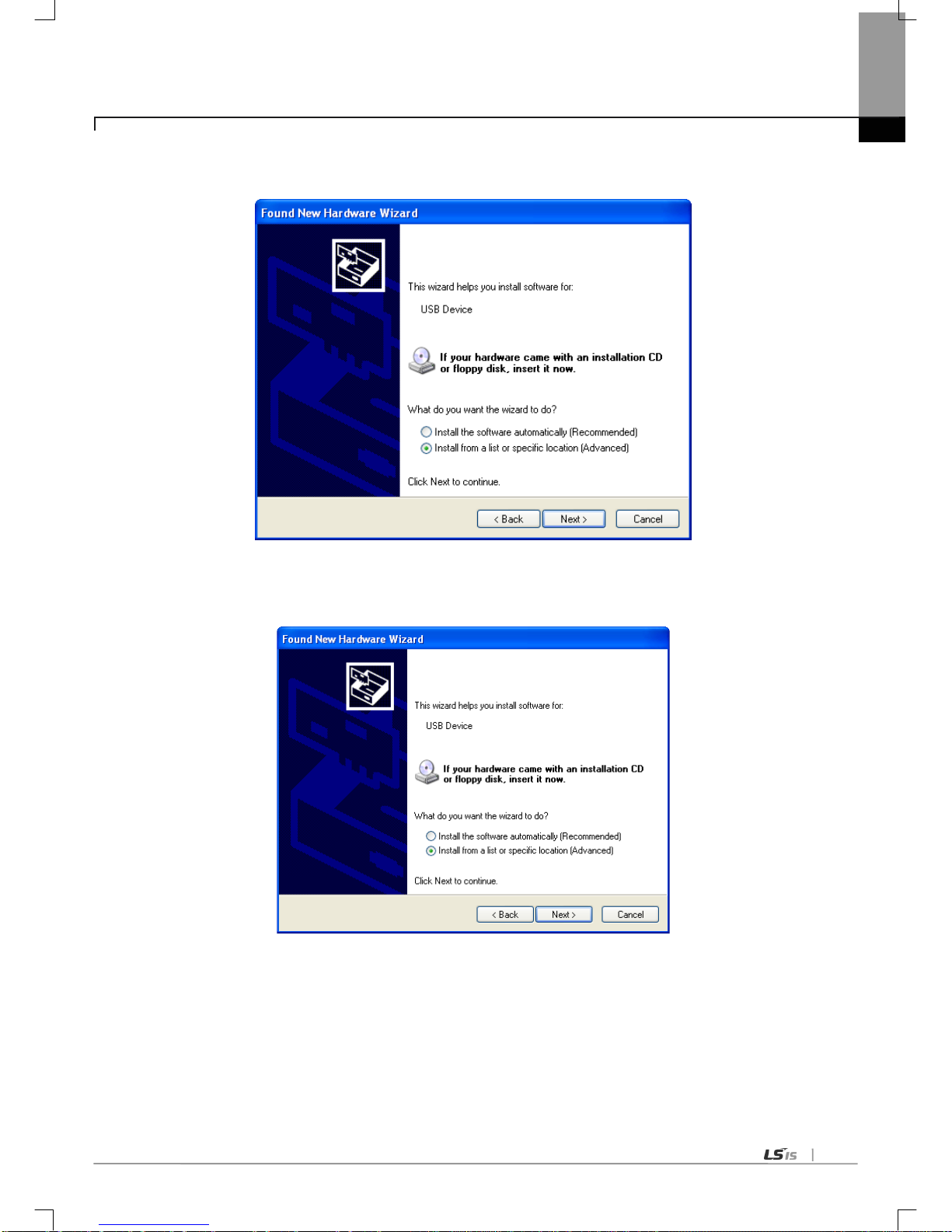

6.3.2 US B device driver installation ---------------------------------------------------------------------------------------------------------- 6-10

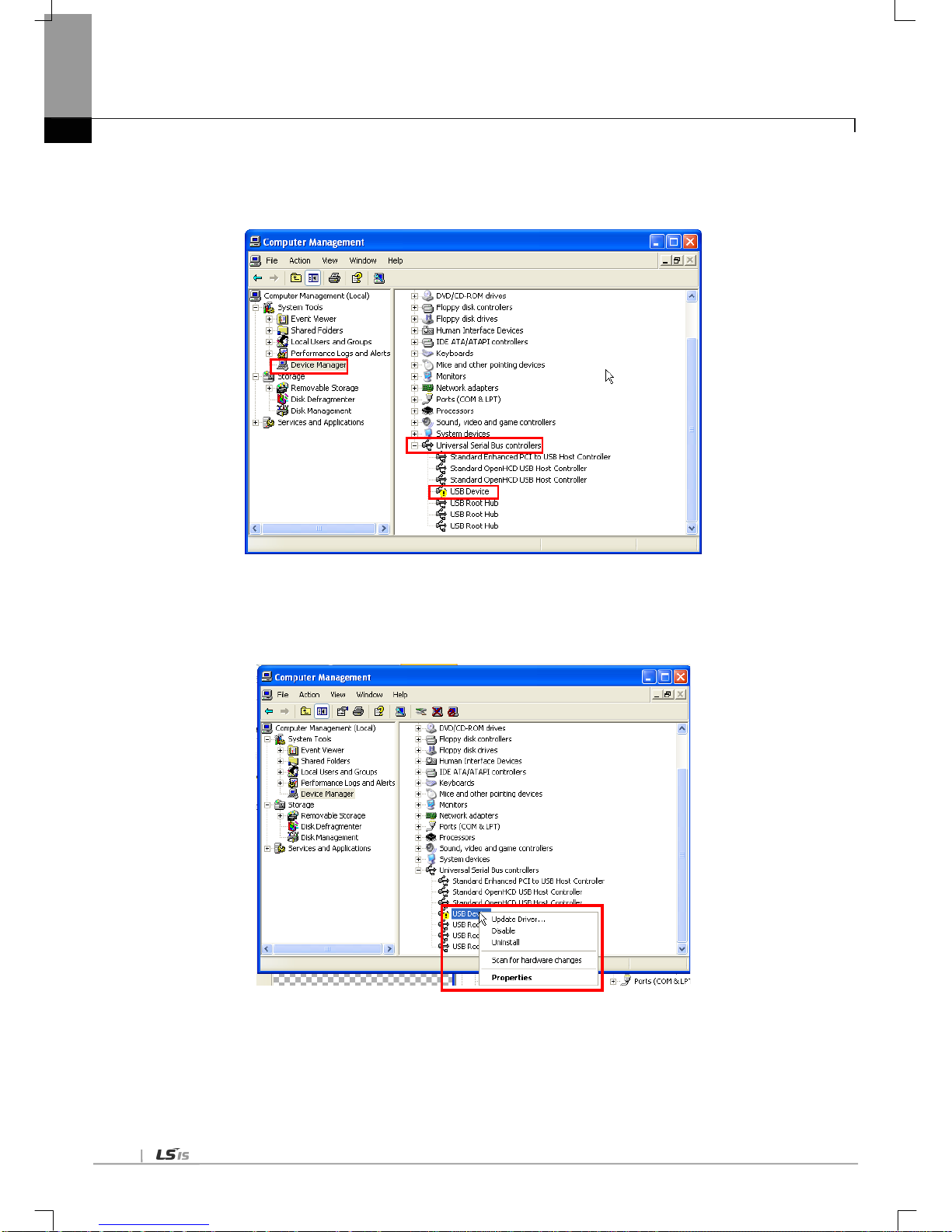

6.3.3 Confirmation of installed USB device driver ------------------------------------------------------------------------------------------ 6-13

6.4 Communication Module Registration ----------------------------------------------------------------------------------------------------------- 6-20

6.4.1 Off-line registration of Cnet I/F module ------------------------------------------------------------------------------------------------- 6-20

6.4.2 Online registration of Cnet I/F module -------------------------------------------------------------------------------------------------- 6-21

6.4.3 How to read the p aramet er saved in t he PLC --------------------------------------------------------------------------------------- 6-23

6.5 How to set the Transmission Standard --------------------------------------------------------------------------------------------------------- 6-24

6.5.1 How to s et -------------------------------------------------------------------------------------------------------------------------------------- 6-24

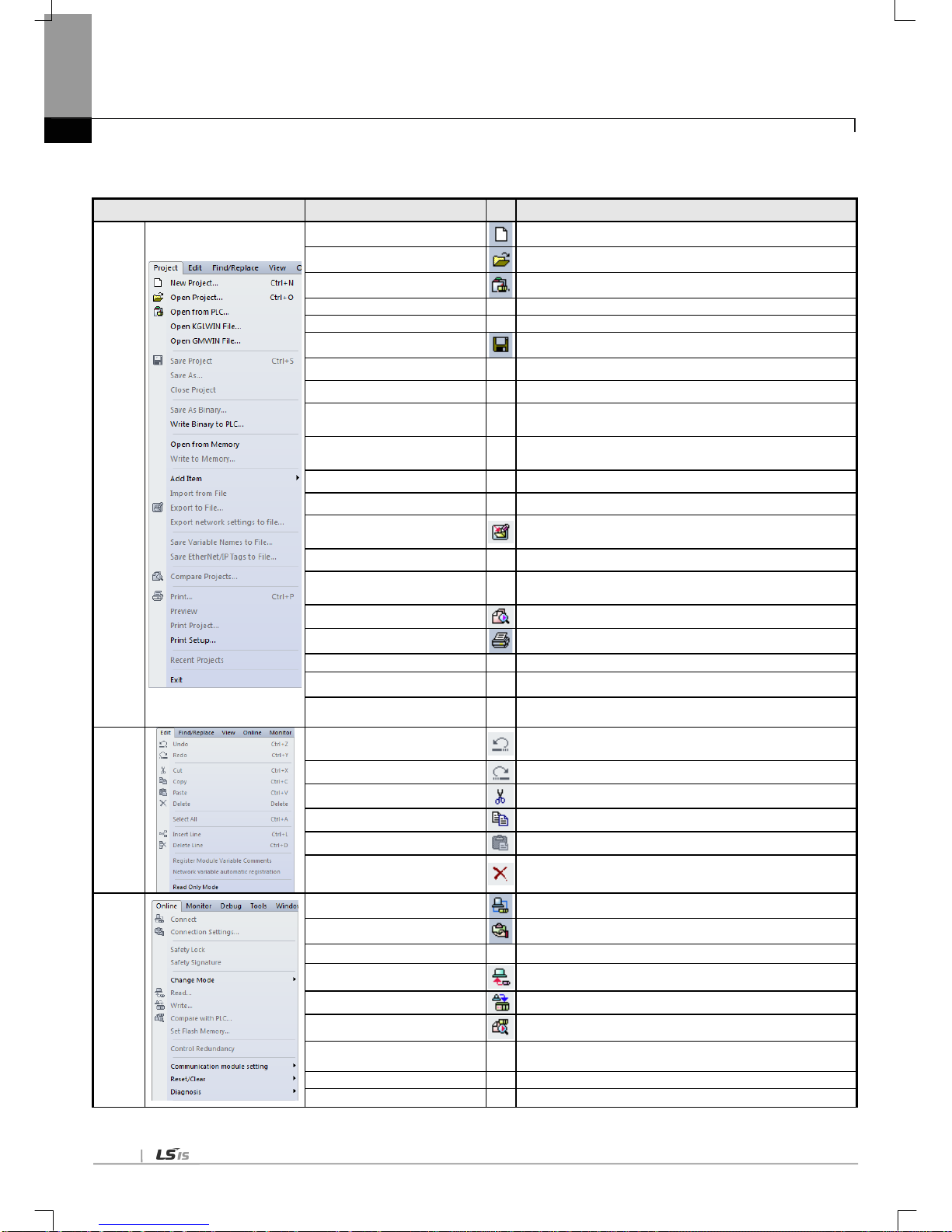

6.5.2 Menu bar and shortcut of XG5000 ---------------------------------------------------------------------------------------- 6-26

6.6 How to set the Parameter according to Service --------------------------------------------------------------------------------------------- 6-28

6.6.1 Exclusive Serv ice

----------------------------------------------------------------------------------------------------------------------------- 6-28

6.6.2 P2P service ----------------------------------------------------------------------------------------------------------------------------------- 6-31

6.7 Operation Start ----------------------------------------------------------------------------------------------------------------------------------------- 6-35

6.7.1 In case of acting as server ----------------------------------------------------------------------------------------------------------------- 6-35

6.7.2 In case of acting as P2P service (client) ----------------------------------------------------------------------------------------------- 6-38

6.8 Diagnosis Function of XG5000 ------------------------------------------------------------------------------------------------------------------- 6-44

6.8.1 Type of diagnosis function ----------------------------------------------------------------------------------------------------------------- 6-44

6.8.2 Checking the CPU status ------------------------------------------------------------------------------------------------------------------ 6-45

6.8.3 Communication module information ---------------------------------------------------------------------------------------------------- 6-45

6.8.4 Frame m onitor

------------------------------------------------------------------------------------------------------------------------------- 6-46

6.8.5 Loop back test

----------------------------------------------------------------------------------------------------------------------------- 6-48

6.8.6 St atus by service ------------------------------------------------------------------------------------------------------------------------------ 6-49

Contents

3

Chapter 7 XGT Dedicated C ommunication

7.1 Summary of Protocol ----------------------------------------------------------------------------------------------------------------------------------- 7-1

7.1.1 Summary ---------------------------------------------------------------------------------------------------------------------------------------- 7-1

7.2 Frame Structure ----------------------------------------------------------------------------------------------------------------------------------------- 7-2

7.2.1 Frame structure --------------------------------------------------------------------------------------------------------------------------------- 7-2

7.2.2 Instruction list ----------------------------------------------------------------------------------------------------------------------------- 7-4

7.2.3 Writing the single direct variable (W(w)SS)---------------------------------------------------------------------------------------------- 7-6

7.2.4 Reading single direct variable (R(r)SS) -------------------------------------------------------------------------------------------------- 7-8

7.2.5 Writing the direct variable continuously (W(w)SB)---------------------------------------------------------------------------------- 7-11

7.2.6 Reading direct variable continuously (R(r)SB) --------------------------------------------------------------------------------------- 7-13

7.2.7 Registration and execution of monitor variable

-------------------------------------------------------------------------------------- 7-15

7.2.8 Error code of XGT communication ------------------------------------------------------------------------------------------------------ 7-18

7.3 XGT Communication Function -------------------------------------------------------------------------------------------------------------------- 7-19

7.3.1 General ------------------------------------------------------------------------------------------------------------------------------------------ 7-19

7.3.2 Parameter setting when PLC acts as XGT server --------------------------------------------------------------------------------- 7-19

7.3.3 Parameter setting in case of XGT client

-------------------------------------------------------------------------------------- 7-22

7.3.4 Frame monitor ----------------------------------------------------------------------------------------------------------------------------- 7-29

7.3.5 Example of parameter setting ------------------------------------------------------------------------------------------------------------ 7-30

7.4 Remote connection

----------------------------------------------------------------------------------------------------------------------------------- 7-31

7.4.1

Summary of remote connection --------------------------------------------------------------------------------------------------------- 7-31

7.4.2 Limit of remote connection between Cnet I/F modules --------------------------------------------------------------------------- 7-31

7.4.3 Remote 1 co nnection ----------------------------------------------------------------------------------------------------------------------- 7-32

7.4.4 Remote 2 co nnection ----------------------------------------------------------------------------------------------------------------------- 7-33

7.5 Modem Communication ----------------------------------------------------------------------------------------------------------------------------- 7-35

7.5.1 Summary ---------------------------------------------------------------------------------------------------------------------------- 7-35

7.5.2 Remote connection through modem --------------------------------------------------------------------------------------------------- 7-35

7.5.3 Communication procedure between PLC and dial up modem ---------------------------------------------------------------- 7-39

7.6 Communication command ------------------------------------------------------------------------------------------------------------------------- 7-40

7.6.1 XGK comm and ------------------------------------------------------------------------------------------------------------------------------- 7-40

7.6.2 XGI command --------------------------------------------------------------------------------------------------------------------------------- 7-45

Chapter 8 Modbus Communication

8.1 General ----------------------------------------------------------------------------------------------------------------------------------------------------- 8-1

8.1.1 Procedure of Modbus communication ------------------------------------------------------------------------------------------------- 8-1

8.2 Modbus Protocol ---------------------------------------------------------------------------------------------------------------------------------------- 8-1

8.2.1 Kind of modbus protocol ---------------------------------------------------------------------------------------------------------------- 8-1

8.2.2 Structure of modbus protocol --------------------------------------------------------------------------------------------------------------- 8-2

8.3 Structure of Frame -------------------------------------------------------------------------------------------------------------------------------------- 8-3

8.3.1 S tructure of frame in the ASCII mode --------------------------------------------------------------------------------------------------- 8-3

8.3.2 Frame structure in the RTU mode ------------------------------------------------------------------------------------------------------- 8-3

8.3.3 Data and expr ession of a ddress ------------------------------------------------------------------------------------------------------- 8-4

8.3.4 Reading data of bit type at the b it output (01) ------------------------------------------------------------------------------------ 8-4

8.3.5 Read Input Status (02) ----------------------------------------------------------------------------------------------------------------------- 8-6

8.3.6 Read Holding Registers (03) -------------------------------------------------------------------------------------------------------------- 8-7

8.3.7 Read Input Registers (04) ------------------------------------------------------------------------------------------------------------------ 8-8

8.3.8 Force Single Coil (05) ------------------------------------------------------------------------------------------------------------------------ 8-9

8.3.9 Preset Single Register (0 6) ---------------------------------------------------------------------------------------------------------------8-10

8.3.10 Force Multiple C oils (0F) ---------------------------------------------------------------------------------------------------------------- 8-11

8.3.11 Preset Multiple Registers (10) ---------------------------------------------------------------------------------------------------------- 8-13

8.4 Modbus Server ----------------------------------------------------------------------------------------------------------------------------------------- 8-15

8.4.1 Setting when CPU is XGK series and Cnet acts as ASCII server

----------------------------------------------------------- 8-15

8.4.2 Setting when CPU is XGI series and Cnet acts as ASCII server ------------------------------------------------------------ 8-18

8.4.3 Setting when CPU is XGK series and Cnet acts as Modbus RTU server------------------------------------------------- 8-21

8.4.4 Setting when CPU is XGI series and Cnet acts as Modbus RTU server ------------------------------------------------- 8-24

Contents

4

8.5 Modbus RTU/ASCII Client ------------------------------------------------------------------------------------------------------------------------- 8-27

8.5.1 S tandard settings in case of Modbus client ----------------------------------------------------------------------------------------- 8-27

8.5.2 Settings in case of Modbus RTU/ASCII client ------------------------------------------------------------------------------------- 8-29

8.5.3 Writing the parameter

--------------------------------------------------------------------------------------------------------------------- 8-31

8.6 Frame Monitor ----------------------------------------------------------------------------------------------------------------------------------------- 8-32

Chapter 9 User-defined Communication

9.1 General --------------------------------------------------------------------------------------------------------------------------------------------------- 9-1

9.1.1 Pr ocedure of user-defined communication ---------------------------------------------------------------------------------------- 9-1

9.2 Structure of us er definition fr ame --------------------------------------------------------------------------------------------------------------- 9-2

9.2.1 Structure of H EAD ------------------------------------------------------------------------------------------------------------------------- 9-2

9.2.2 Structure of TAIL -------------------------------------------------------------------------------------------------------------------------- 9-2

9.2.3 Structure of BODY ------------------------------------------------------------------------------------------------------------------------ 9-3

9.3 Writing of frame ----------------------------------------------------------------------------------------------------------------------------------------- 9-4

9.3.1 S tandard setting for user-defined communication---------------------------------------------------------------------------------- 9-4

9.3.2 Writing transmission frame ---------------------------------------------------------------------------------------------------------------- 9-6

9.3.3 Writing reception frame --------------------------------------------------------------------------------------------------------------------- 9-8

9.3.4 Setting parameter ----------------------------------------------------------------------------------------------------------------------- 9-10

9.3.5 Writing parameter -------------------------------------------------------------------------------------------------------------------------- 9-11

9.4 Frame Monitor ----------------------------------------------------------------------------------------------------------------------------------------- 9-12

9.1 General -------------------------------------------------------------------------------------------------------------------------------------------------- 9-13

9.5.1 XGI Instruction ------------------------------------------------------------------------------------------------------------------------- 9-13

9.5.2 XGK Instructio n ----------------------------------------------------------------------------------------------------------------------------- 9-18

Chapter 10 Program Examples

10.1 Setting of Cnet I/F module in the XG5000 ------------------------------------------------------------------------------------------------- 10-1

10.1.1 In case of acting as server ----------------------------------------------------------------------------------------------------------- 10-2

10.1.2 In case of acting as P2P service (client) ----------------------------------------------------------------------------------------- 10-4

10.2 XGT Dedicated Service ------------------------------------------------------------------------------------------------------------------------- 10-7

10.2.1 XGT Settings of XGT server -------------------------------------------------------------------------------------------------------- 10-8

10.2.2 Settings when acting as XGT client ------------------------------------------------------------------------------------- 10-10

10.2.3 Checking the operation ------------------------------------------------------------------------------------------------------------- 10-14

10.3 Modbus Communication ----------------------------------------------------------------------------------------------------------------------- 10-15

10.3.1 Settings when acting as Modbus RTU server ------------------------------------------------------------------------------- 10-16

10.3.2 Setting when acting as RTU client ----------------------------------------------------------------------------------------------- 10-18

10.4 User - defined Communication --------------------------------------------------------------------------------------------------------------- 10-24

10.4.1 Communication with other producer’s product ------------------------------------------------------------------------------ 10-24

10.4.2 Using P2P flag as conditional flag ----------------------------------------------------------------------------------------------- 10-30

10.5 Communication between HMI and inverter through Cnet I/F module ---------------------------------------------------------- 10-35

10.6 SMS transmission method using the CDMA modem -------------------------------------------------------------------------------- 10-42

10.4.1 SMS transmissi on metho d using the CDMA modem --------------------------------------------------------------------- 10-44

Chapter 11 Diagnosis

11.1 Diagnosis of XG5000 ---------------------------------------------------------------------------------------------------------------------------- 11-1

11.2 Error c ode by p rotoc ol -------------------------------------------------------------------------------------------------------------------------- 11-7

11.3 Trouble Shooting by Error ---------------------------------------------------------------------------------------------------------------------- 11-8

11.3.1 Trouble

shooing when P2P parameter setting error occurs in case of XG5000 connection--------------------- 11-8

11.3.2 Trouble shooting when communication is not done after P2P client setting-------------------------------------------11-8

11.3.3 Trouble shooting when response frame is missed in case of acting as client and using RS-485

------------- 11-8

11.3.4 Two response frame are dealt with as unknown when executing frame monitor----------------------------------- 11-9

11.3.5 U navail able to exec ute individ ual reset ---------------------------------------------------------------------------------------- 11-9

11.3.6 U nable to analyze TRX f rame ---------------------------------------------------------------------------------------------------- 11-9

11.3.7 Unable to know which one is reason of error, client or servers ---------------------------------------------------------- 11-9

11.3.8 Communication is not normal or communication is not executed repeatedly ------------------------------------- 11-10

Contents

5

11.3.9 When error code of Status by Service is “E000”----------------------------------------------------------------------------- 11-10

11.3.10 When error code of Status by Service is “E001”--------------------------------------------------------------------------- 11-10

Appendix

A.1 Definition of Terms ----------------------------------------------------------------------------------------------------------------------- A-1

A.2 Flag List ------------------------------------------------------------------------------------------------------------------ A-7

A.2.1 Special Relays List (F) ------------------------------------------------------------------------------------------------------------------ A-7

A.2.2

Communication Relays List (L) -

-------------------------------------------------------------------------------------------------------- A-15

A.2.3

Link Devices List (N) ---------------------------------------------------------------------------------------------------------------------- A-17

A.3 RS-232C interface through VisualBasic --------------------------------------------------------------------------------------------------- A-19

A.3.1 System configuration ------------------------------------------------------------------------------------------------------------------ A-19

A.3.2

Pin No -

-------------------------------------------------------------------------------------------------------------------------------------- A-19

A.3.3 Mode setting------------------------------------------------------------------------------------------------------------------------------ A-20

A.3.4 Instruction --------------------------------------------------------------------------------------------------------------------------------- A-20

A.3.5 Project

-

------------------------------------------------------------------------------------------------------------------------------------ A-21

A.3.6 Form design------------------------------------------------------------------------------------------------------------------------------ A-21

A.3.7 Make form proce dur e code -------------------------------------------------------------------------------------------------------- A-22

A.3.8 Execute program

-

---------------------------------------------------------------------------------------------------------------------- A-28

A.3 Dimension ------------------------------------------------------------------------------------------------------------------------------------------- A-19

Chapter 1 Overview

1-1

Chapter 1 Overview

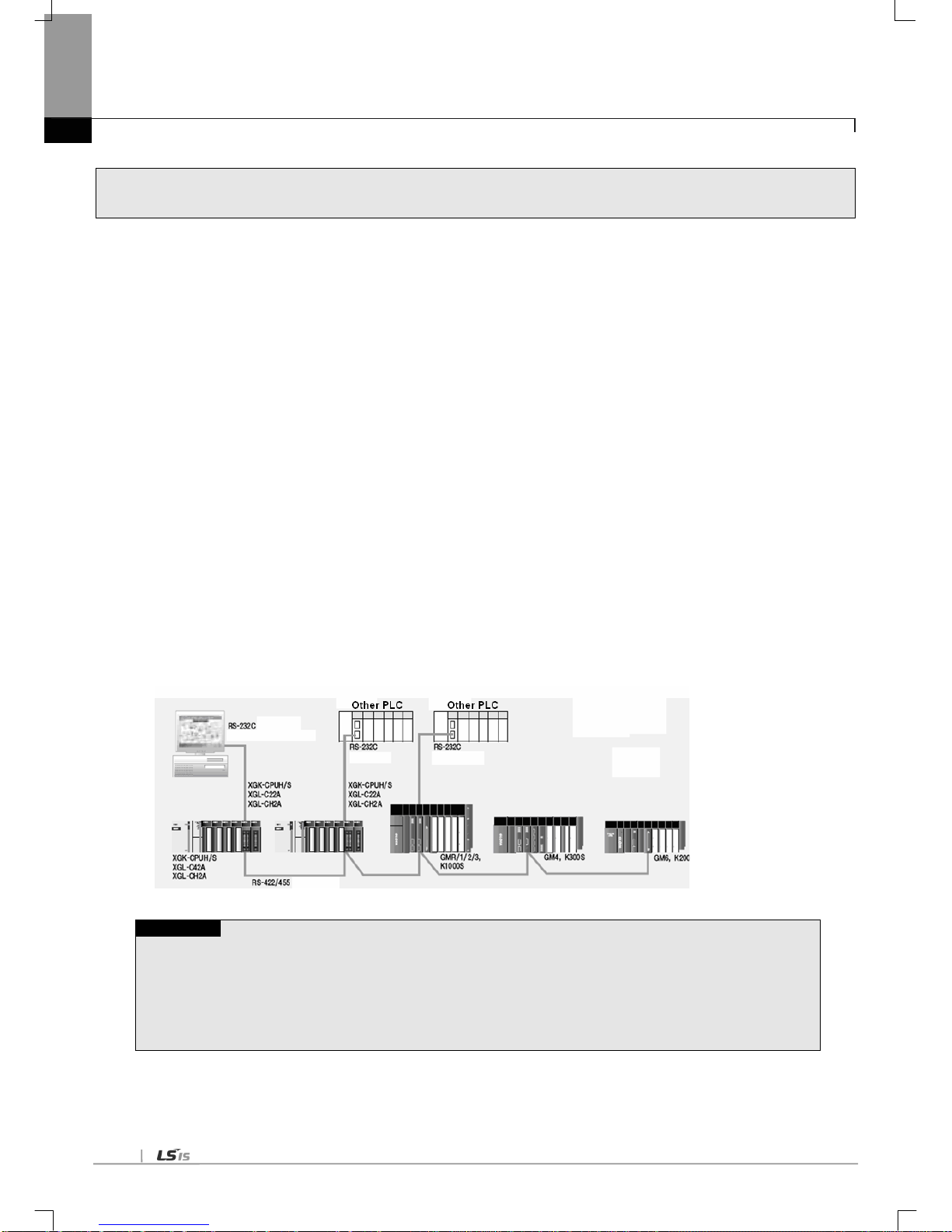

1.1 Introduction

This user’s manual describes the Computer Link I/F module (hereinafter referred to as Cnet I/F module) of XGT PLC system

network. Cnet I/F module has the connection function with different model to communicate with communication devices of

various different type protocols such as other company’s PLC and computer, etc., and the function of modem communication to

control remote PLC.

When programming, refer to the following user manual.

• XG5000 manual

• XGK instruction

• XGK manual

• XGI/XGR instruction

• XGI instruction

• XGI manual

• XGR manual

When configuring the system of the XGT Cnet I/F module, be careful of the followings.

• XG5000: more than V4.0

• XGT Cnet I/F module OS: more than V2.3

Note

1) This manual is written on a basis of XG5000 V4.0

In case of previous version or different version, menu and method how to write a parameter may be different. Be

careful of this.

Chapter 1 Overview

1-2

1.2 Characteristics

The XGT Cnet I/F module is serial communication device supporting the RS-232C and RS-422(485) protocol and has the following

characteristics.

(1) Since the user can write directly, it is easy to connect with other company’s products

(2) Because communication speed and communication mode (protocol) are directly specified by user using XG5000 operative in

Windows environment, connection with other company’s products is easy.

(3) 3 types of Cnet I/F modules are available: RS-232C 2Port, RS-422(485) 2Port, RS-232C 1Port/ RS-422 1Port.

(4) With the separate operation based on each channel, the protocol data specified by user is controlled by CPU module, which

allows the replaced communication module directly to be applied without additional setting or downl oading.

(5) Read/Write is available by using the dedicated protocol.

(6) Dedicated communication function suitable to multi-drop configuration connectable up to 32 units is provided if RS-422/485

channel used.

(7) With modem communication function built-in, remote PLC can be controlled by XG5000 connection, dedicated communication,

and user defined communication.

(8) Various communication speeds can be set

- RS-232C : 300bps ~ 115,200bps / RS-422 : 300bps ~ 1 15,200bps.

(9) 1:1/1:N/N:M communication(if RS-422 channel used) is available.

(10) Communication types of full-duplex (RS-422/RS-232C) and half-duplex (RS-485) are supported.

(11) With satisfactory self-diagnosis function and Loop-Back diagnosis function, diagnosis of errors is easy to make.

(12) Dedicated communication and Modbus Server/Client functions are available.

(13) Remote connection during communication between XGT Cnet I/F modules is available.

Note1)

Note

Note1) Remote connection during communication between XGT Cnet I/F modules is supported when O/S version of

XGT Cnet I/F module is 2.5 or above. Features are as follows.

(1) For communication type, only RS-232C, RS-422 method is supported. In case of remote connection using

RS-485, remote connection is only available when the P2P link on the online menu of XG5000 is disabled.

(2) Remote connection is supported regardless of active mode.

(3) Remote connection during communication is affected according to TRX period and an amount of data

- In case TRX period is short or amount of data is huge, disconnection may occur.

Chapter 1 Overview

1-3

1.3 Product Configuration

1.3.1 Type name indication

Describes on the product configuration of the XGT Cnet module

Type name

Contents

Reference

XGL-C22A

RS-23 2C 2 ports

Twisted-pair shield cab le

XGL-CH2A

RS-23 2C 1 port, RS-422 1 port

XGL-C42A

RS-42 2 2 ports

1.3.2 Equip-able number per CPU

Note1)

The Cnet I/F module can be mounted up to 24 without distinction of basic and extension base. T o realize the

maximum capacity of communication module, if possible, mount the communication module in the basic base.

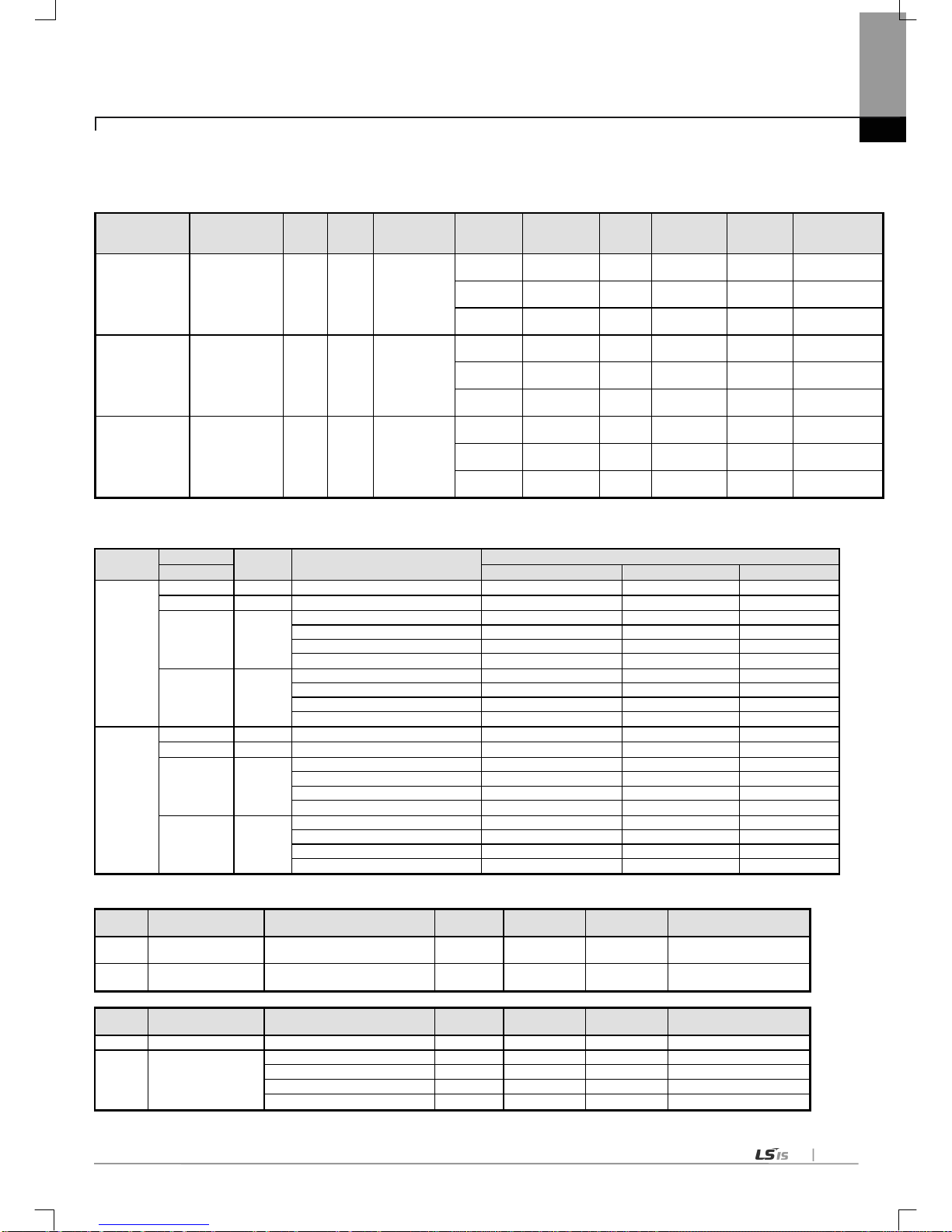

The following table indicates the available service type according to CPU. Apply it when configuring the system.

Classification

XGK XGI XGR

CPUH CPUU CPUA CPUS CPUE CPUU CPUH CPUS CPUH/T CPUH/F

Max. no. of module

using high speed

link

Not used

Max. no. of module

using P2P

8 EA

Max. no. of module

using dedicated

service

24 EA

Note

Note1) equipment position of Cnet I/F module according to CPU type

- In case of using XGK/XGI, Y ou can install Cnet I/F module at both basic and extension base.

- In case of using XGR CPU, You can install Cnet I/F module at only extension base.

Chapter 1 Overview

1-4

1.4 Soft ware to use the product

Here describe on main programming tool and other software to use the Cnet module. For more specific program

and application of communication, refer to the followings.

1.4.1 Sof tware check point

(1) A pplied at the XGT series

Classification

Connection port

Communication setting to ol

XGL-C22A

RS-23 2C 2 ports

XG5000

XGL-CH2A

RS-23 2C 1 port, RS-422 1 port

XGL-C42A

RS-42 2 2 ports

Note

1) The above program can be downloaded from our website now. In case of not using the internet, visit the near

our company and get the CD.

Internet web address : http://eng.lsis.biz

2) XG5000 is programmable through the RS-23C port of CPU module and USB. For the used cable name, refer

to the XGT catalog item list. (USB-301A, K1C-050A)

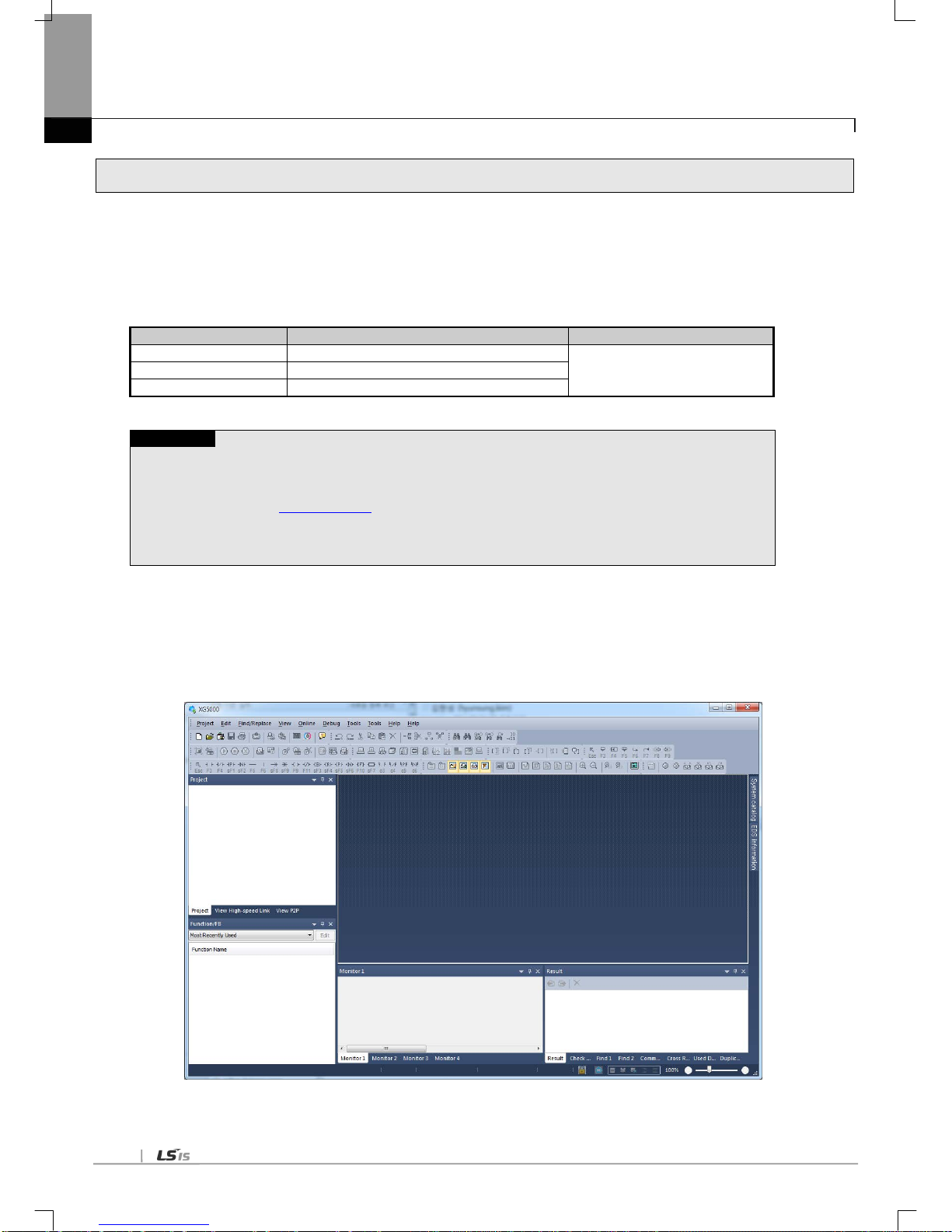

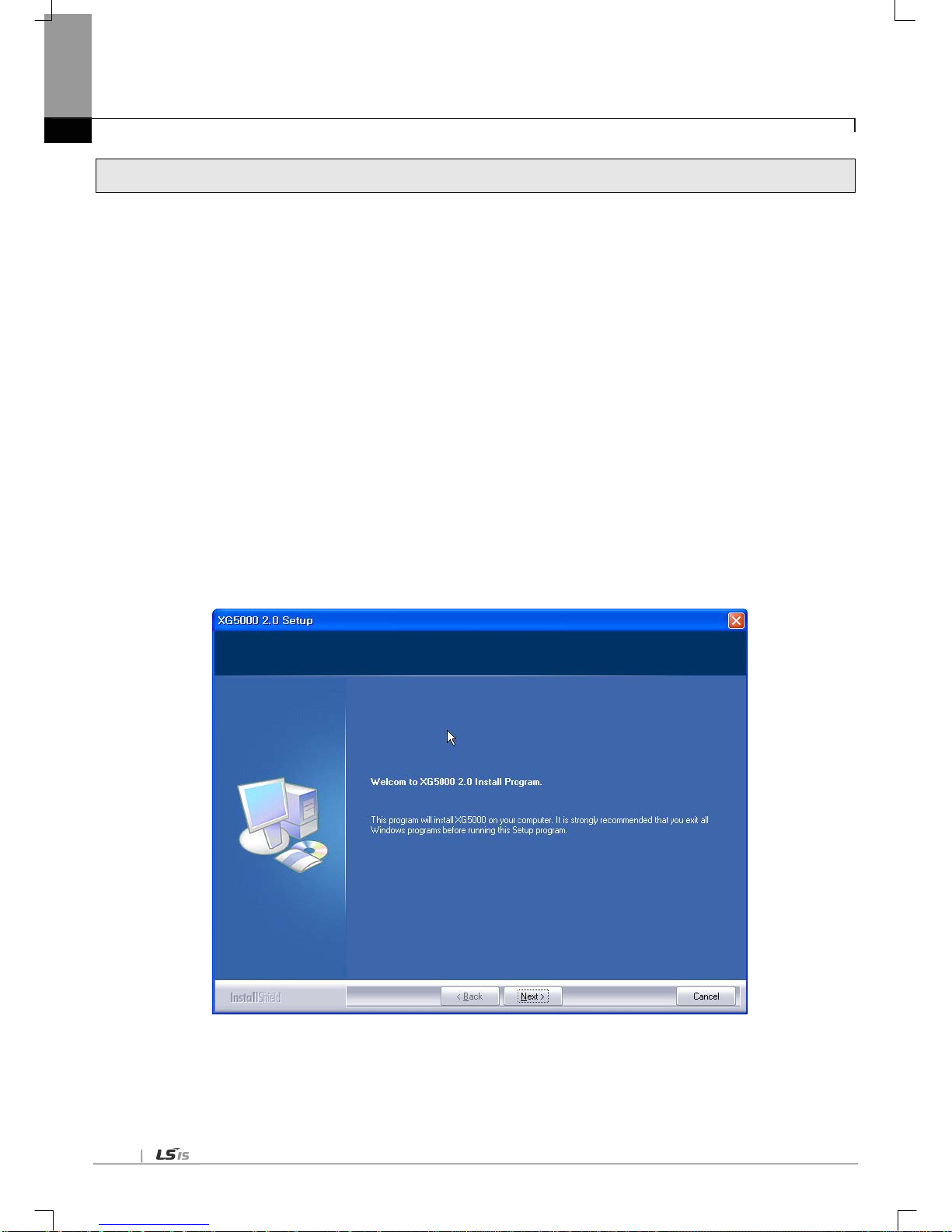

1.4.2 XG5000

XG5000 is dedicated software for setting of basic parameter, writing of frame and diagnosis of all communication

module including the Cnet I/F module.

The following figure is initial screen of XG5000.

[Figure 1.4.1] XG5000 initial screen

Chapter 1 Overview

1-5

1.4.3 Check of version

Before using the Cnet module, check the version of module.

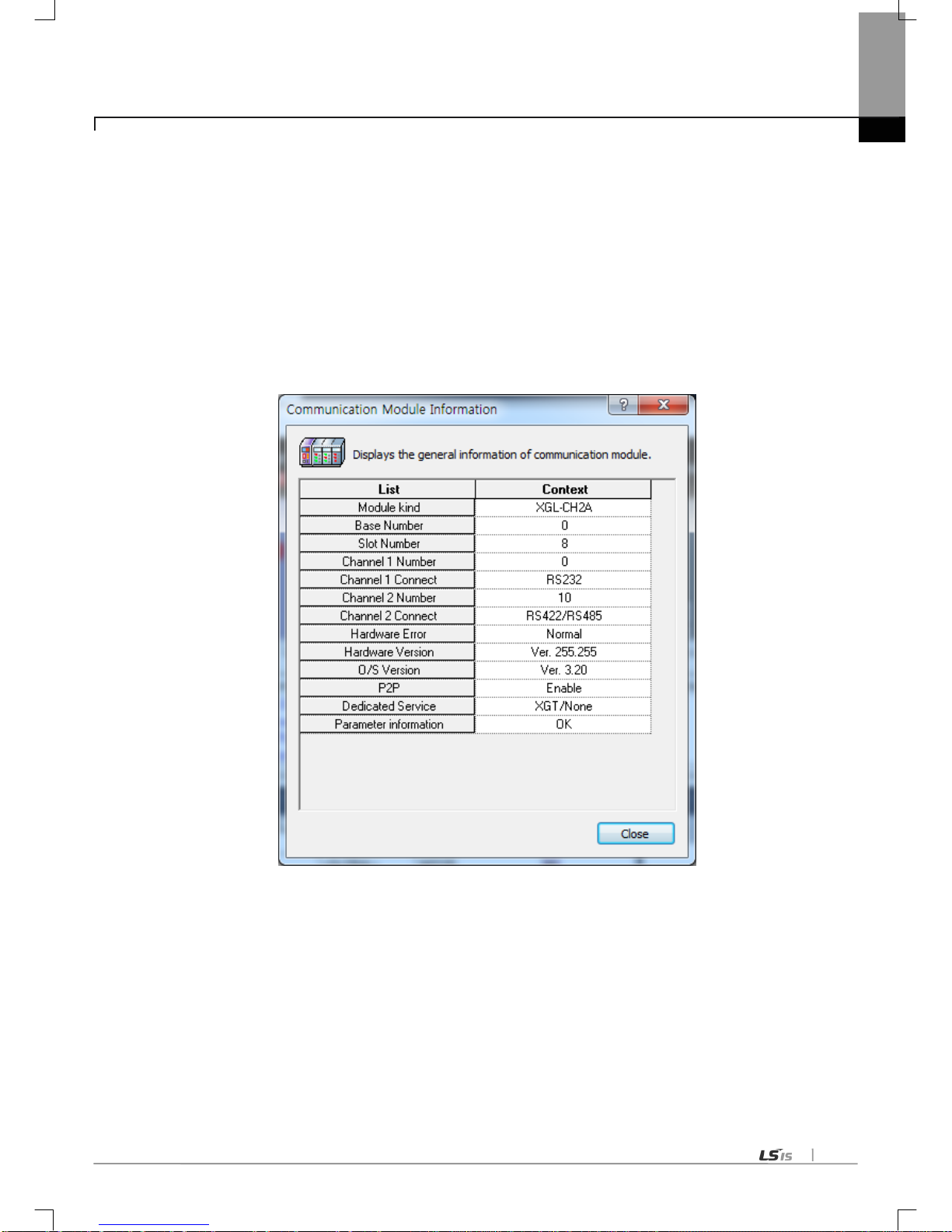

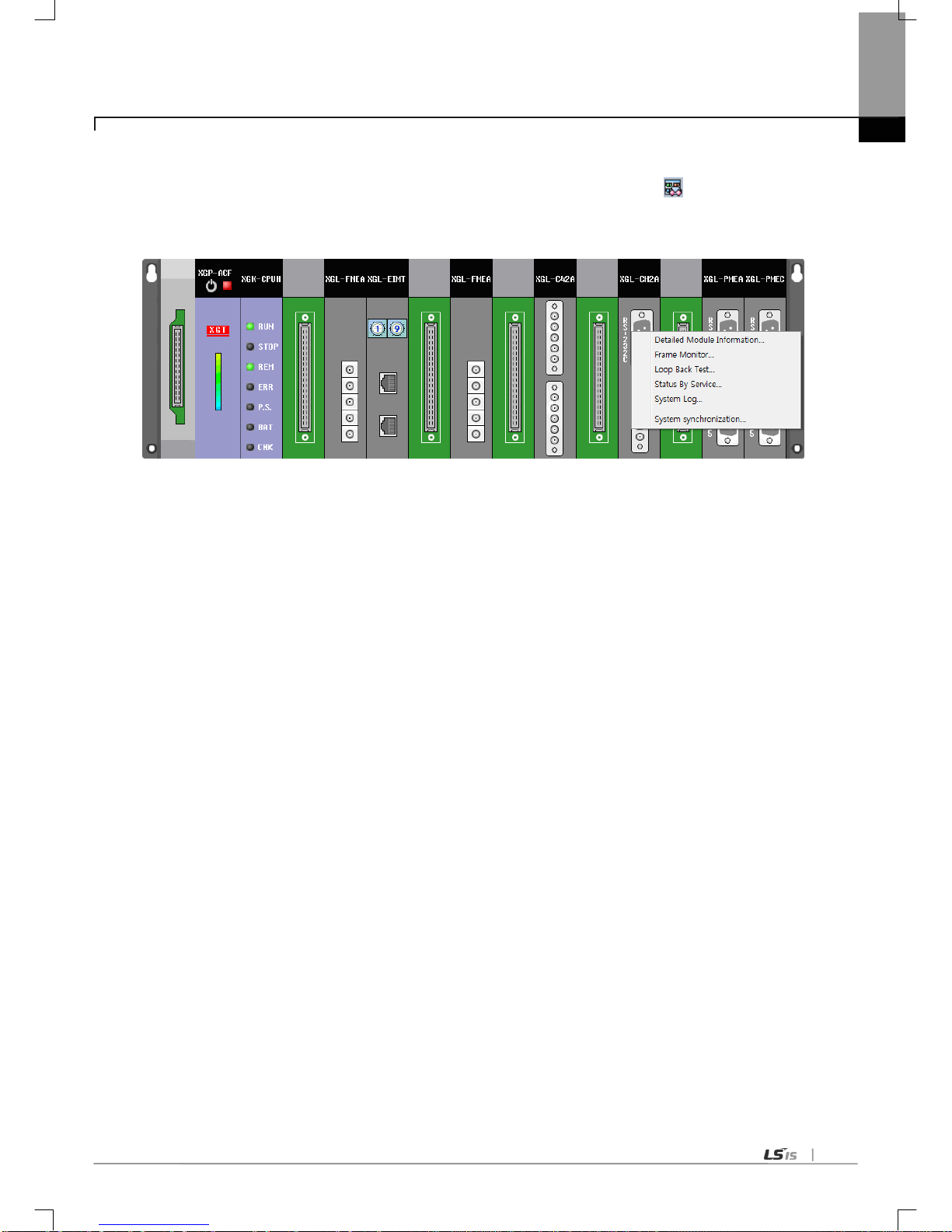

(1) Check through XG5000

Here describes on how to read communication module information by online connection to communication module. If

interface with CPU is normal, it is available to get the following information.

(a) Execute the XG5000.

(b) Connect with CPU through online connection.

(c) If connection with CPU is established, execute the system diagnosis.

(d) Execute the Communication module information in the system diagnosis screen.

(e) Software information shows at the right bottom of screen.

[Figure 1.4.2] Check of version through XG5000

(2) Check version written on the case label of the product

Each communication module has the product information label on the case. If online check is not possible, see

the label on the case after removing it from base.

Label is in the back of the case and type name of product and version information is indicated.

Chapter 2 Product Specifications

2-1

Chapter 2 Product Specifications

2.1 General Specifications

General specifications of XGT series are as follows.

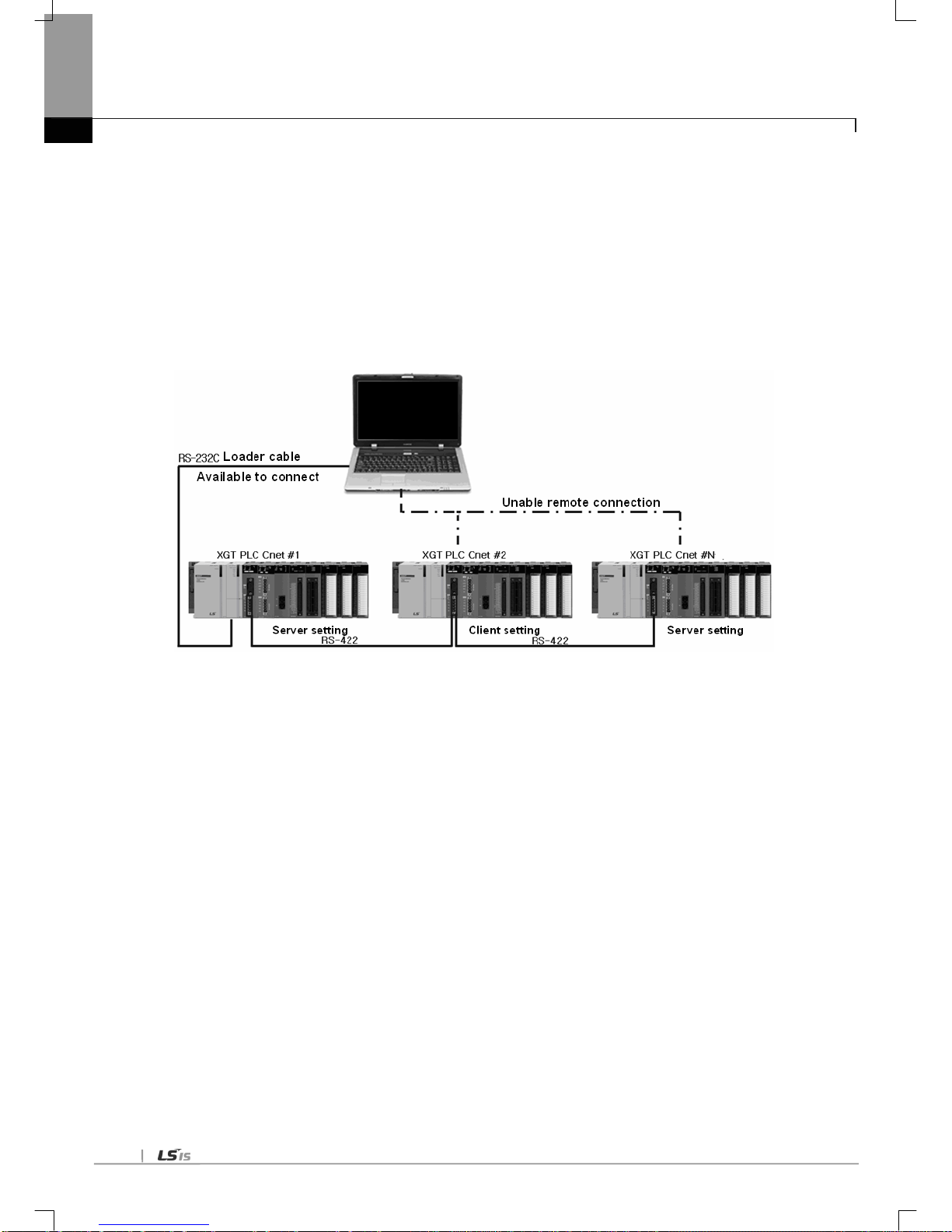

No. Items Specification Reference

1

Ambient T emp.

0 ~ 55 °C

2 Storage T emp. −25 ~ +70 °C

3 Ambient humidity 5 ~ 95%RH (Non-condensing)

4

Storage humidity

5 ~ 95%RH (Non-condensing)

5 Vibration Immunity

Occasional vibration

- Frequency

Acceleration

Pulse width

Times

IEC61131-2

5≤f< 8.4

㎐

- 3.5mm

10 times each

direction (X,Y

and Z)

8.4≤f≤150

㎐

9.8㎨(1G) -

Continuous vibration

Frequency

Acceleration

Pulse width

5≤f< 8.4

㎐

- 1.75mm

8.4≤f≤150

㎐

4.9㎨(0.5G)

-

6 Shocks Immunity

• Peak acceleration : 147 m/s2(15G)

• Duration : 1 1ms

•

Pulse wave type : Half-sine (3 times each direction per each axis)

IEC61131-2

7 Noise Immunity

Square wave

impulse noise

AC : ±1,500V

DC : ±900V

LSIS internal test

spec.

Electrostatic

discharge

Voltage: 4kV (Contact discharge)

IEC61131-2

IEC61000-4-2

Radiated

electromagnetic field

noise

80 ~ 1000 MHz, 10V/m

IEC61131-2,

IEC61000-4-3

Fast transient

/Burst noise

Classificat

ion

Power

supply

Digital/Analog Input/Output,

Communication Interface

IEC61131-2

IEC61000-4-4

Voltage

2kV

1kV

8

Operation ambience

Free from corrosive gases and excessive dust

9 Altitude Less than 2,000m

10 Pollution degree Less than 2

11

Cooling method

Air-cooling

[T able 2.1] General Specifications

Note

1) IEC (International Electrotechnical Commission):

An international nongovernmental organization which promotes internationally cooperated standardization in

electric/electronic field, publishes i nternational stand ards and manages applicable estimation system re lated with.

2) Pollution degree:

An index indicating pollution degree of the operating env ironment which decides in sulation performance of the devices. For instance, Pollution

degree 2 indicates the state generally that only non-conductive pollution occurs. However , this state cont ains temporary conduction due to dew

produced.

Chapter 2 Product Specifications

2-2

2.2 Performance Specifications

Item

Specification

XGL-C22A

XGL-CH2A

XGL-C42A

Serial

communicat

-ion cha nnel

RS-232C

2 channels

1 channel

-

Conforms to RS-232C standard

Line config

1:1

RS-422/485

-

1 channel

2 channels

Conforms to RS-422/485 standards

Line config

1:1, 1:n, n:1, m:n

Modem connection function

Remote communication with external devices is

available vi a publ ic t elepho ne li ne by conne cting exter nal

modem to the module.

-

Operating

mode

(specified

per port)

P2P

Operated by communication client

Protocol client exclusively used for LSIS,

Modbus ASCII/RTU client

Use defined communication available

SEVER

Protocol server exclusively used for LSIS

Modbus ASCII/RTU sever

Data

type

Data Bit

7 or 8

Stop Bit

1 or 2

Parity

Even/Odd/None

Synchronization type

Asynchronous ty pe

Transmission speed (bps)

300/600/1200/2400/4800/7200/9600

/19200/38400/57600/64000/115200 bps available

Station No. setting

Setting range : 0-31

Max. station No. available : 32 stations

Transmission

distance

RS-232C: Max.15m (extendible if modem used)

-

-

RS-42 2: Max. 500 m

Diagnosis function

Checking available through LED and XG-PD diagnosis service

Loop-Back diagnosis

Current consumption

310mA

310mA

300mA

Weight

121g

119g

116g

[T able 2.2] Performance Specifications

Chapter 2 Product Specifications

2-3

2.3 Names of Parts

Names of parts are as follows;

[Fig. 2.3.1] Cnet I/F Module, Front

<Name of each part>

Name

Contents

①

LED

Refer to the LED details

②

RS-232C interface

RS-232C interface to communicate with other device through serial

③ RS-422/485 interface RS-422/485 interface to communicate with other device through serial

<LED details>

LED LED details LED status Details of LED status

RUN

Displays Cnet operation

status

On Operation normal

Off Cnet module abnormal

I/F

Displays interface status

with CPU

On

Operation abnormal during communication

with CPU module

Off

Communication module initializing error

Blinks

Operation normal

TX

Displays fra me being

transmitted

On Frame being transmitted

Off Frame transmitted completely

RX

Displays fra me being

received

On Frame being received

Off Frame received completely

ERR Displays frame error

On

Frame error

Off

Frame normal

①->

②->

③->

①->

②->

③->

Chapter 2 Product Specifications

2-4

2.4 Cable Specifications

When using communication channel, RS-422 or RS-485, twisted pair cable for RS-422 shall be used in consideration of

communication distance and speed. [Table 2.4] describes recommended specifications of cable. Also when using other cable

than recommended, the cable conforming to characteristics in [Table 2.4] shall be used.

(1) Product : Low Capacitance LAN Interface Cable

(2) Type : LIREV-AMESB

(3) Size : 2P X 22AWG(D/0.254 TA)

(4) Manufacturer: LS Cable

Electric

characteristics

T est item

Unit

Characteristics

T est conditions

Conductor resistance

Ω

/km

59 or less

Normal temp.

Withstanding voltage(DC)

V/1min

Withstands for 1 min. at

500V

In air

Insulation resistance

MΩ-km

1,000 or more

Normal temp

Static electricity capacity

pF/M

45 or less

1kHz

Characteristics

impedance

Ω 120 ± 12

10MHz

Characteristics of

appearance.

Item

Single Cable

Conductor

Cores

Pair 2 Size

AWG

22

Composition

NO./mm

1/0.643

Outer dia.

mm

0.643

Insulator

Thickness

mm

0.59

Outer dia.

mm

1.94

[T able 2.4.1] St andard of Tw isted Pair Cable

[Fig. 2.4.1] Structure

Braided

Ground line

AL/MYLER TAPE

Conductor

Insulator

Sheath

Chapter 2 Product Specifications

2-5

2.5 Terminal Resistance

For communication via RS-422/RS-485 channel, terminal resistance from external must be connected. Terminal resistance has the

function to prevent distortion of signal by reflected wave of cable for long-distance communication, and the same resistance (1/2W)

as characteristic impedance of cable must be connected to terminal of network.

When using the recommended cable in 2.4, connect terminal resistance of 120Ω to both ends of cable. Also when using other cable

than recommended, the same resistance (1/2W) as characteristic impedance of cable must be connected to both ends of cable.

▶ T erminal Resistance: 1/2W, 120Ω, tolerance of 5%

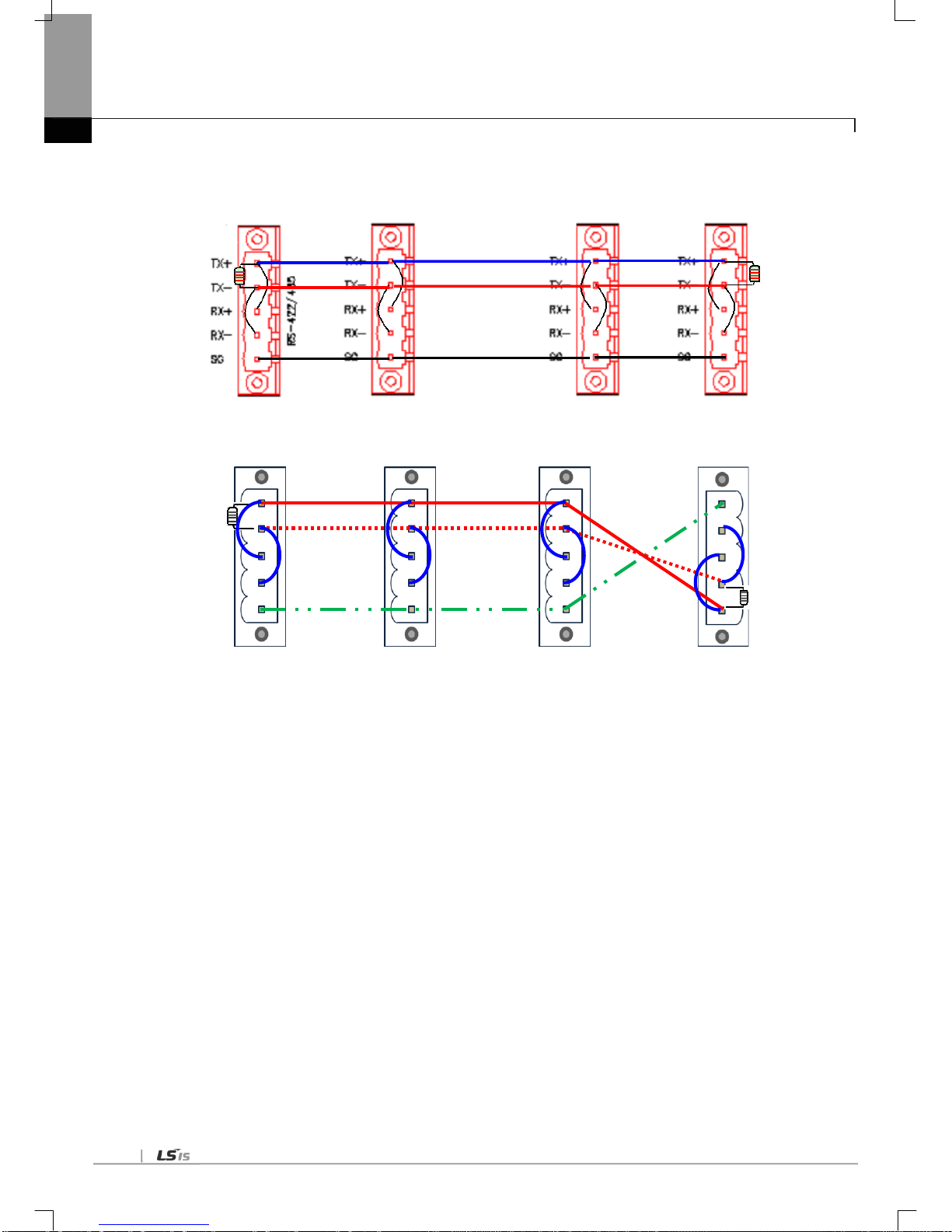

(1) How to connect with terminal resistance, When using RS-422 connection

[Fig. 2.5.1] RS-422 connection with Terminal Resistance

[Fig. 2.5.2] RS-422 connection with Ter minal Resistance by hardware version

TX+

TXRX+

RXSG

TX+

TXRX+

RXSG

TX+

TXRX+

RXSG

SG

RXRX+

TXTX+

(Less then V2.0) (Less then V2.0) (Less then V2.0) (V2.0 or Later)

Chapter 2 Product Specifications

2-6

(2) How to connect with terminal resistance during RS-485 connection

[Fig. 2.5.3] RS-485 connection with Ter minal Resistance

[Fig. 2.5.4] RS-485 connection with Ter minal Resistance by hardware version

TX+

TXRX+

RXSG

TX+

TXRX+

RXSG

TX+

TXRX+

RXSG

SG

RXRX+

TXTX+

(Less than V2.0) (Less than V2.0) (Less than V2.0) (V2.0 or Later)

Chapter 3 Performance Specifications

3-1

Chapter 3 Performance Specifications

3.1 Operation Mode Setting

The operation mode of XGT Cnet is decided by the basic communication parameters. It operates separately from each

communication port with the operation modes available as described below.

(1) Server Mode

Operates as a server in the network. XGT server and Modbus server are optional.

(a) XGT server: dedicated communication protocol supported, memory Read/Write available.

(b) Modbus server: Modbus protocol supported, RTU/ASCII type optional.

(c) Setting necessary for conversion between Modbus protocol memory area and XGT memory area.

(d) XG5000 service (remote 1/2 step connection) functions supported at a time.

(2) P2P (Client) Mode

(a) Operates as a client in the network.

(b) Dedicated communication protocol and Modbus protocol supported.

(c) Up to 64 communication blocks can be specified for 1 Cnet module to define the independent operation.

Chapter 3 Performance Specifications

3-2

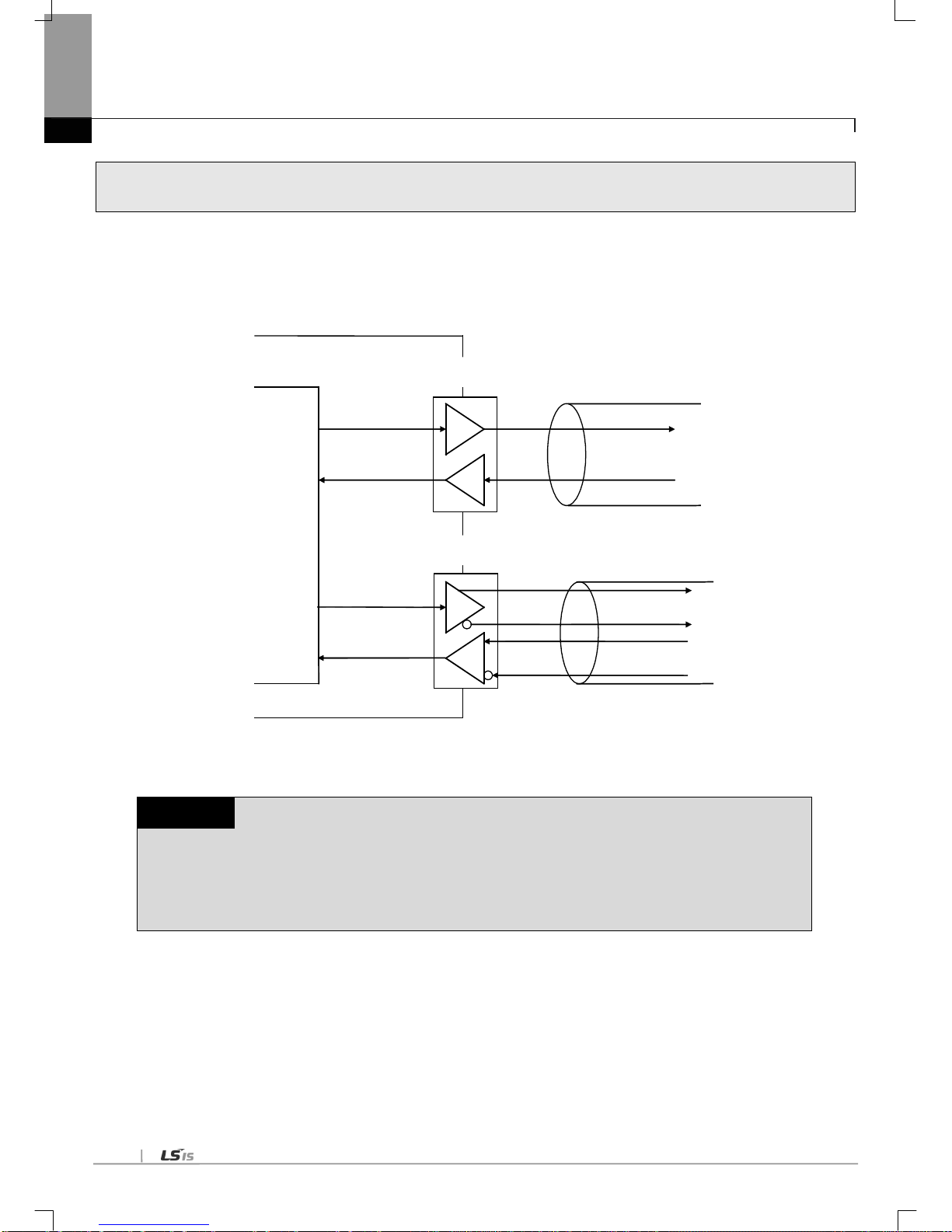

3.2 Channel Operation during Normal Run

Each communication port operates independently to allow simultaneous Tx/Rx in separate transmission specifications.

Therefore, transmission specifications can be set per RS-232C and RS-422 channel, and the operation is started and stopped

according to channels. Data flow of each channel is as below.

RS-422 channel

PLC CPU

TX

RX

RX

TX

RS-232C channel

RS-422 cable

RS-232C cable

[Fig. 3.2.1] Data Flow of Each Channel

Notes

[Note 1] Mode change during operation is unavailable. In order to change the mode, download the basic

communication parameters and reset the communication module.

[Note 2] Cnet I/F module supports only the separate mode.

Chapter 3 Performance Specifications

3-3

3.3 Channel Operation in Diagnosis Mode (Loop-Back)

Loop-Back diagnosis is a function to check if communication channel normally operates by itself without connection with

external devices, which is available when the diagnosis service is executed. For the details of its operation method, see

‘Chapter 11 Diagnosis Function’.

3.4 Method of Serial Interface

3.4.1 RS-232C I nterface

Channel RS-232C uses 9-pin connector (Female) for commun ic at io n with ex ternal devices. The n am es a nd f unc t io ns of pi ns

and dat a directi ons are as shown in the figure bel ow.

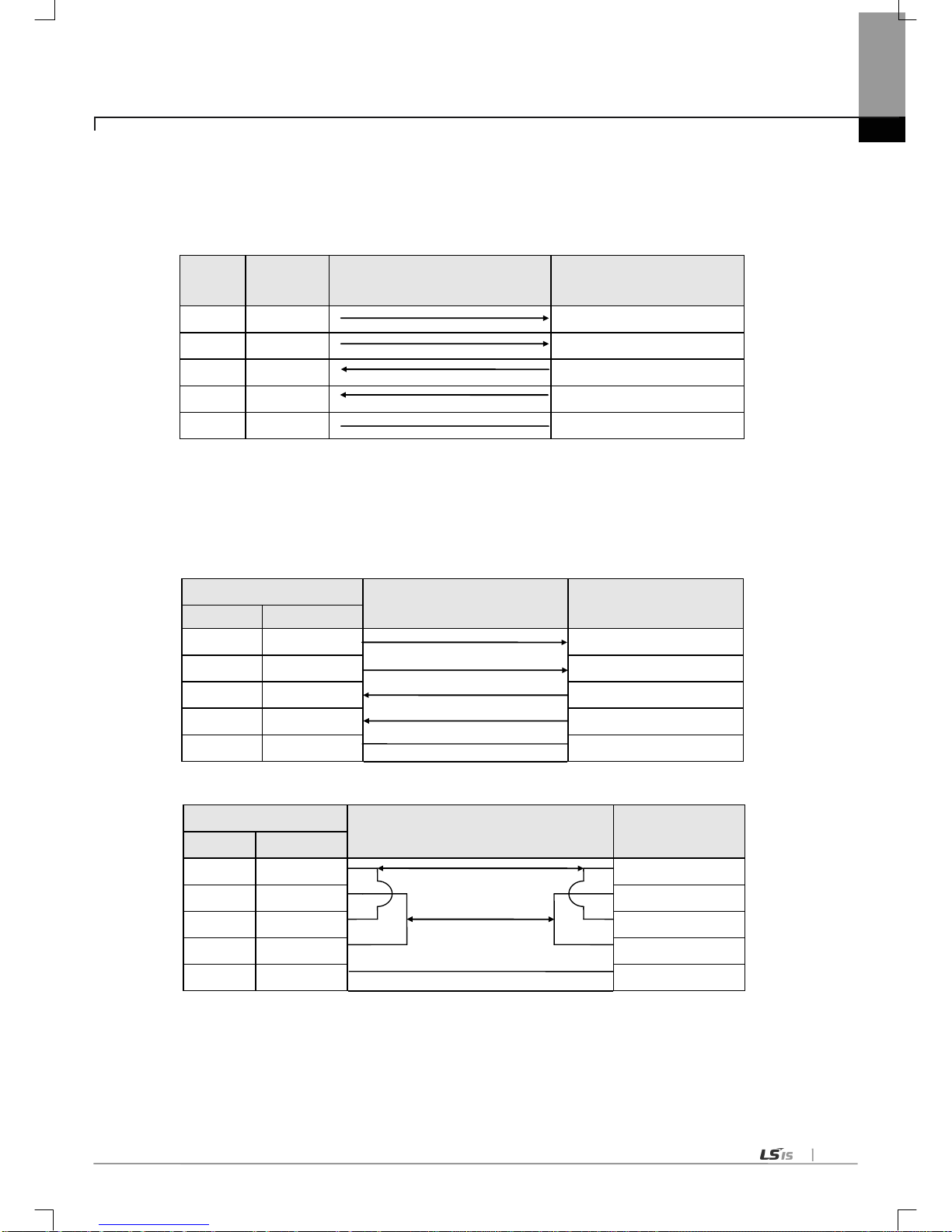

Pin No. Name Contents

Signal Direction

(Cnet I/F module

↔ external device)

Description

1

CD

Carrier Detect

Reports carrier detection of DCE to DTE

2

RxD

Received Data

Received data signal

3

TxD

Transmitted Data

Transmitted data signal

4 DTR

Data Terminal

Ready

Reports ready communication of DTE

Note1

to DCE

Note2

5

SG

Signal Ground

Ground line for signal

6

DSR

Data Set Ready

Reports ready communication of DCE to DTE

7

RTS

Request To Send

DTE asks DCE to send data

8

CTS

Clear To Send

DCE asks DTE to send data

9

RI

Ring Reports ringing tone received from DCE to DTE

[Fig. 3.4.1] RS-232C 9-pin Connector Standard

Channel RS-232C can communicate with external devices directly and also with remote communication devices using modem .

When connecting modem, communication type of RS-232C must be set to ‘modem’ with XG5000, and when not using modem,

it must be set to null modem

Notes

[Note1] DTE: Data Terminal Equipment (Cnet I/F module)

[Note2] DCE: Data Communication Equipment (external modem)

Chapter 3 Performance Specifications

3-4

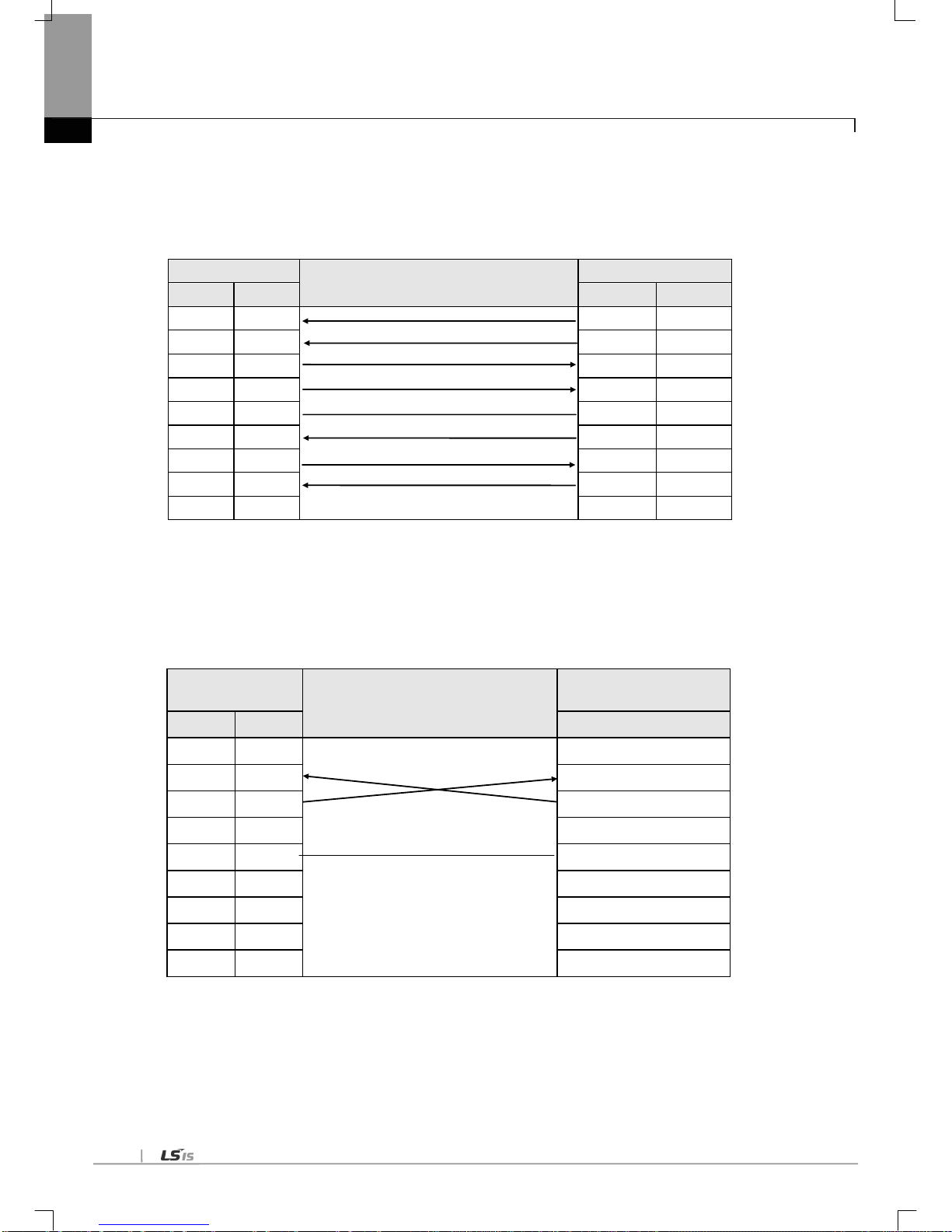

(1) How to connect RS-232C connector during modem connection

This module can communicate with devices of long distance as connected with modem. Modem and RS-232C channel shall

be connected as in [Fig. 3.4.2] below.

Cnet (9-PIN)

Connection No. and signal direction

Modem side (25-PIN)

Pin No.

Name

Name

Pin No.

1

CD CD 8 2

RXD

RXD

3

3

TXD

TXD

2

4

DTR

DTR

20

5

SG

SG

7

6

DSR

DSR 6 7

RTS

RTS

4

8

CTS

CTS

5

9

RI

[Note]

RI

22

[Fig 3.4.2] Cable Connection between RS-232C and Mo dem

[Note] No.9, RI signal is not used in Cnet I/F module.

(2) How to connect connector for RS-232C in null modem mode

In null modem mode, the connector can be connected in 3-line type as below .

Cnet (9-PIN)

Connection No. and signal direction

Computer/communication

devices

Pin No.

Name

Name

1

CD CD

2

RXD

RXD

3

TXD

TXD

4

DTR

DTR

5

SG

SG

6

DSR

DSR

7

RTS

RTS

8

CTS

CTS

9

RI

RI

[Fig. 3.4.3] 3-line Type of Connection (no handshake)

Chapter 3 Performance Specifications

3-5

3.4.2 RS-422/485 interface

Channel RS-422 uses 5-pin connector (Terminal Block) for communication with external devices. The names and functions

of pins and data directions are as shown in [Fig. 3.5] below

Pin No. Name

Signal Direction

(Cnet<--> external device)

Description

1

TX+ Transmitted data (+)

2

TX- Transmitted data (-)

3

RX+ Received data (+)

4

RX- Received data (-)

5

S.G(SG)

Ground line for signal

[Fig. 3.4.4] RS-422 5-pin Connector Standard

Channel RS-422 is designed available to connect RS-422 and RS-485(multi-drop) with external devices. When RS-422

channel is used as multi-drop, set each channel’s communication type to RS-485 on the basic setting menu of XG5000, and

use the terminal of RS-422 connected as shown in [Fig. 3.7].

[Fig. 3.4.5] shows an example of connecting communication cable in RS-422 communication

Cnet(5-Pin)

Signal Direction

(Cnet<---> external device)

External communication

device

Pin No.

Name

1

TX+ RX+

2

TX-

RX-

3

RX+

TX+

4

RX-

TX-

5

S.G(SG)

S.G

[Fig. 3.4.5] RS-422 Connection

Cnet(5-Pin)

Signal Direction

(Cnet<---> external device)

External

communication device

Pin No.

Name

1

TX+ RX+

2

TX-

RX-

3

RX+

TX+

4

RX-

TX-

5

S.G(SG)

S.G

[Fig. 3.4.6] RS-485 Connection

[Fig. 3.4.6] shows how to connect RS-485 multi-drop communication. In case of multi-drop communication, to connect with

external devices, TX+ and RX+, RX- and TX- of RS-422 channel shall be connected with each other. At this time half-duplex

communication is run sharing Tx/Rx line, so the applicable port shall be applied as set to RS-485 in XG5000.

Chapter 4 Installation and Test O peration

4-1

Chapter 4 Installation and Test Operation

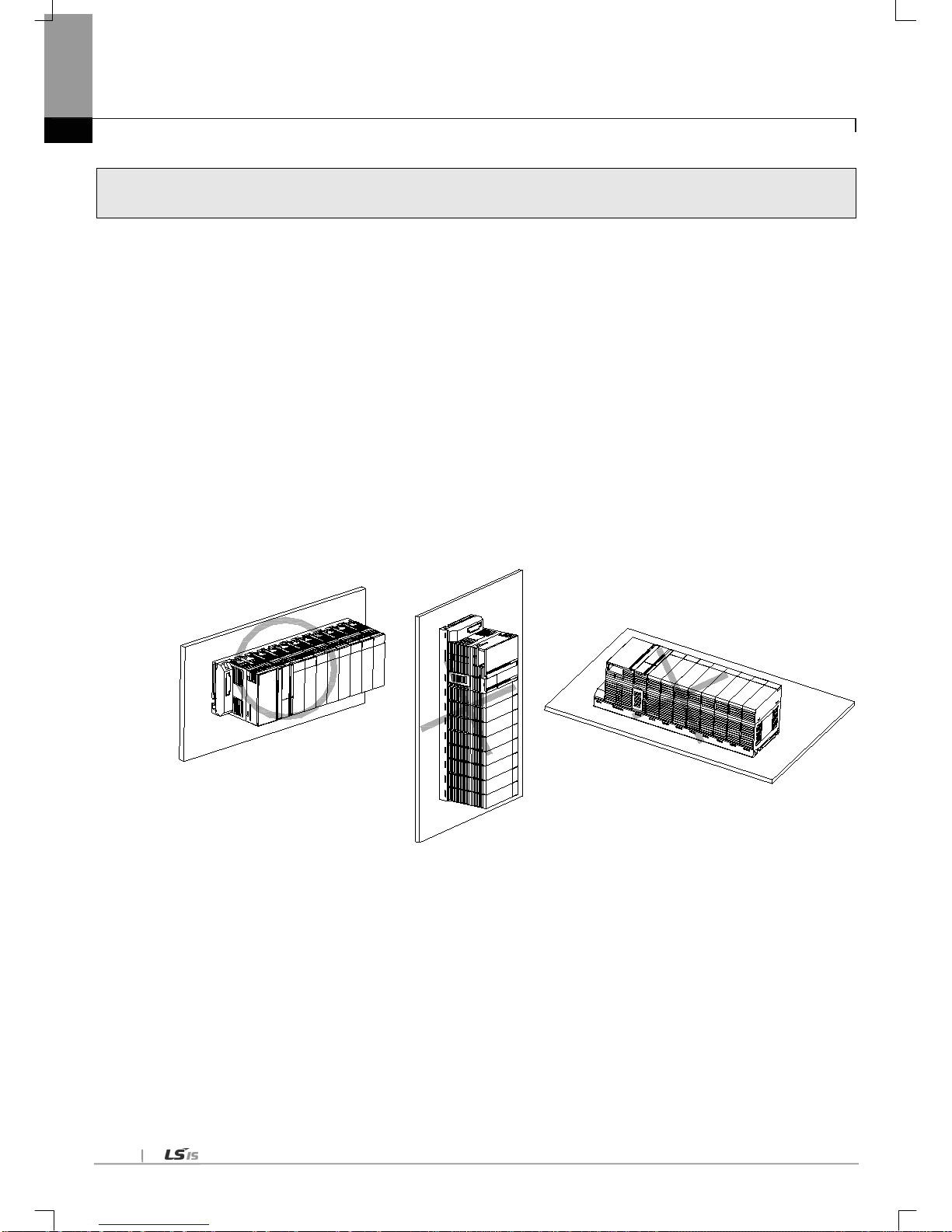

4.1 Installation Environment

This product is of high reliance reg ardless of insta llation environm ent. However, for the sake of relianc e and stabilit y of the

system, please pay attention to those precautions described below.

(1) Environmental Conditions

(a) To be installed on the control panel waterproof and dustproof.

(b) No continuous impact or vibration shall be expected.

(c) Not to be exposed to the direct sunlight.

(d) No dew shall be caused by rapid temperature change.

(e) Ambient temperature shall be kept 0-55 ℃.

(2) Installation Work

(a) No wiring waste is allowed inside PLC when wiring or drilling screw holes.

(b) To be installed on a good location to work on.

(c) Don’t let it installed on the same panel as a high-volta ge devic e is on.

(d) Let it kept at least 50 ㎜ away from duct or near-by module.

(e) To be grounded in an agreeable place free from noise.

Chapter 4 Installation and Test Operation

4-2

4.2 Precautions for Handling

The system configuration with Cnet I/F module shall be performed under the following precautions.

1) Don’t let it dropped or shocked hard.

2) Don’t remove PCB from the case. It will cause abnormal operation.

3) Don’t let any foreign materials including wiring waste inside the top of the module when wiring.

4) Get rid of foreign materials if any.

5) Don’t install or remove the mo dule whil e powered on.

6) Use standard cable only and let it installed within the maximum distance specified.

7) Let the communication cable free from the surge and inductive noise generated by or from the alternating current.

8) D on’t let wiring too clos e to hot device and m aterial or in direct c ontact with oil for lo ng, which will caus e damage or

abnormal operation due to short-circuit.

9) For wiring with pipes, the pipes need grounding.

Chapter 4 Installation and Test O peration

4-3

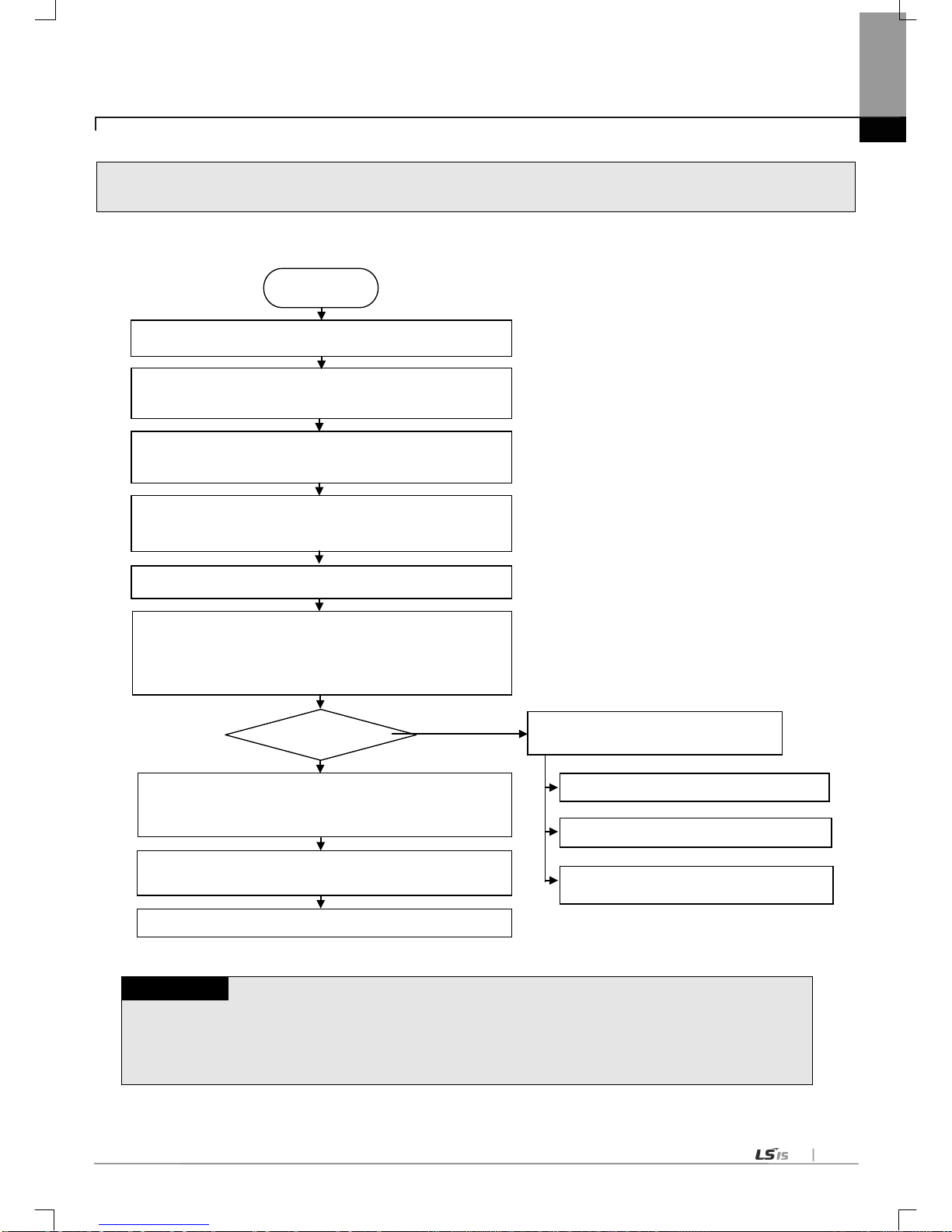

4.3 Operation Sequence

The sequence of t h e pro duc t fr om installation to operation will be described below. After the product installation is complete,

install and configure the system to be operated as specified in the following sequence.

Notes

1) Station number of Cnet I/F module is not necessary to set due to hardware properties.

Use XG5000 to specify basic settings necessary for station number and Cnet communication.

START

Check the function and specification

Install Cnet I/F module on the base.

→ Check the location of base/slot

Connect the communication device with Cnet I/F module by

means of cable.

With power On, check the LED status of the communication

module. (RUN: RED flicker, I/F: RED)

Connect XG5000 with XGK/XGI/XGR CPU by means of CPU

Perform basic setting in XG5000.

(communicatio n type, co mmunicat ion speed, data ty pe,

modem type, station number, operation mode)

Set the P2P parameter.

(channel, P2P function, start condition, data size, area, type,

destination st ation)

Execute the XGT server communication

Execute the modbus RTU server

Execute the modbus ASCII server

Execute the P 2P co mmunicati on

Operation

Download the parameter and let the link enabled.

Download the parameter and let the link

enabled.

Chapter 4 Installation and Test Operation

4-4

4.4 Contents of Parameter Setting in the XG5000

Contents of parameter setting in XG5000 are as follows.

4.4.1 Basic setting p arameter

Note

(1) Response waiting time: waiting time from sending to receiving

(a) Operation setting: Settable in case operation mode is Use P2P .

(b) basic response waiting time per communication speed

1) 9,600~115,200bps : 100ms+(setting value×100ms)

2) 7,200~2,400bps : 200ms+(setting value×100ms)

3) 1,800~1,200bps : 400ms+(setting value×100ms)

4) 600bps : 800ms+(setting value ×100ms)

5) 300bps : 1,200ms+(setting value×100ms)

(2) Delay time setting: sends frame after delay time set by user

(a) Operation setting: settable in case co mmunicati on type is RS-422/485

(3) Delay time between character: In case of character coming within set time at one frame, it means character

interval between character

(a) Operation setting: settable regardless of operation mode

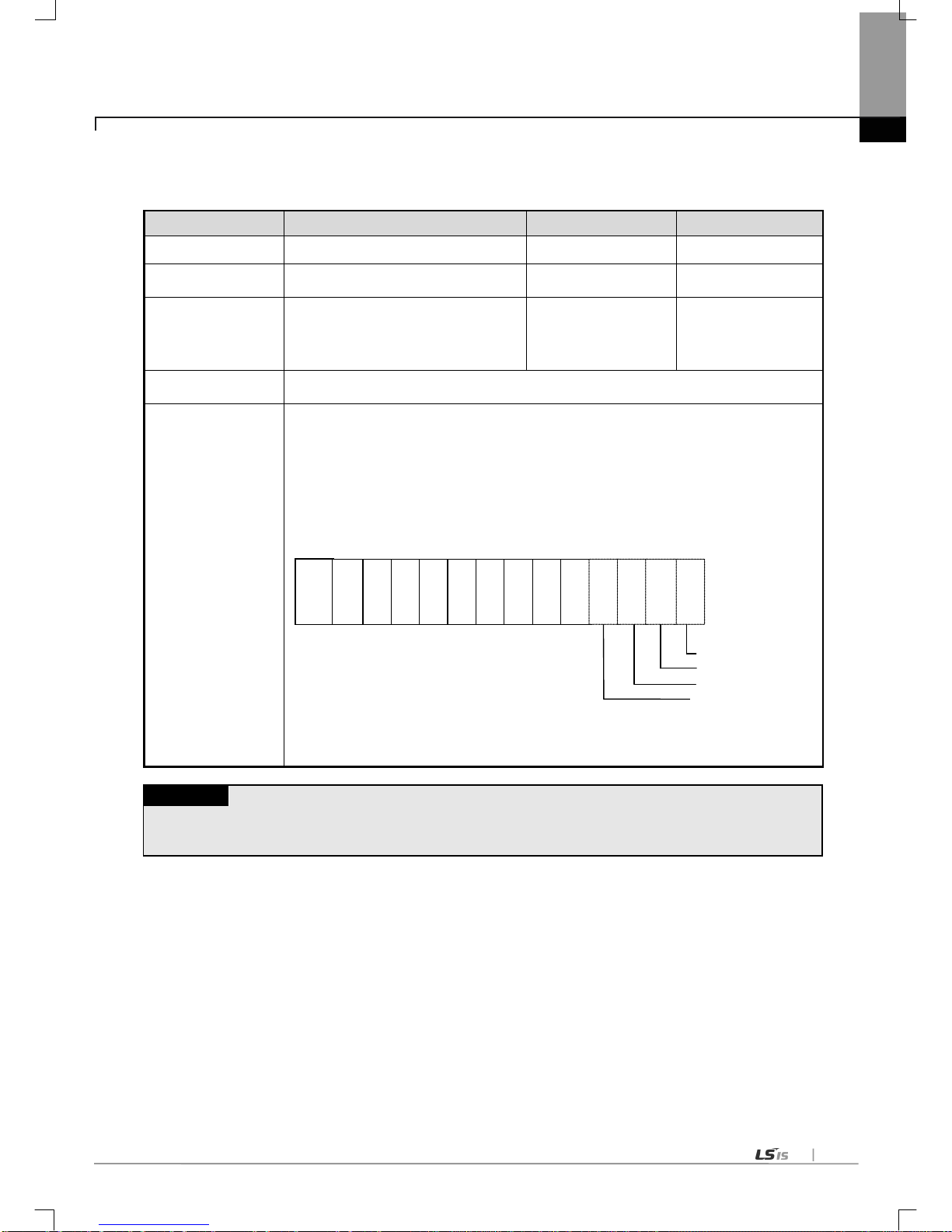

Parameter

Lower

menu

Setting item Setting range

Setting right

Reference

Client Server

Basic

setting

Connection

setting

Communication type

RS-232C

RS-422

RS-485

○ ○

Communication

speed (bps)

300~1,15,200 ○ ○

Data bit 7,8 ○ ○

Modbus ASCII

In case of

modbus,

data bit is 7.

Stop bit

1,2 ○ ○

Parity bit

NONE,ODD,EVEN

○

○

Modem type

Null modem, dedicated

modem, dial up modem

○ ○

Modem initiali zation - ○ ○

Setting available in

case of dial up

modem

STATION 0~31 ○ ○

No meaning i n case

of client

Delay time

0~2550ms ○ -

Used in case of P2P

Time out 0~5000ms ○ - Used in case of P2P

Operation

mode

Use P2P settings

Select one mode

○

-

XGT server

-

○

Modbus ASCII server

-

○

Modbus RTU server

-

○

Chapter 4 Installation and Test O peration

4-5

4.4.2

P2P setting parameter

Parameter Lower menu Setting item

Setting range and

contents

Setting right (client)

XGT

Modbus

ASCII

Modbus

RTU

User

definition

frame

P2P

Communication

module setting

Base

0~7

○ ○ ○ ○ Slot

0~11

○ ○ ○

○

P2P channel P2P driver

User frame definition

- - -

○

XGT client

○ - -

-

Modbus ASCII

Client

- ○ - -

Modbus RTU

Client

- - ○

P2P block

Channel

1, 2

○ ○ ○

○

P2P function

READ

○ ○ ○ - WRITE

○ ○ ○

-

SEND

- - - ○ RECEIVE

- - -

○

Conditional flag

*note 1)

○ ○ ○

○

Command type

Single

○ ○ ○

-

Continuous

○ ○ ○

-

Data type

Bit

○ ○ ○

-

Word

○ ○ ○

-

1 byte

○ - -

-

2 byte ○ - - -

4 byte

○ - -

-

8 byte

○ - -

-

No. of variable

*note2)

○ ○ ○ - Data size

*note2)

○ ○ ○

-

Destination station

○ ○ ○

-

Destination station

no.

○ ○ ○ -

Frame

- - ○ Setting

*note3)

○ ○ ○

○

User definition

frame

Add group

Group name

- - -

Frame type

Transmission

- - -

○

reception - - - ○

Frame

*Note4)

Edit group

Group name

- - - ○ Delete group

- - -

○

Add frame

HEAD

- - - ○ TAIL

- - -

○

BODY

- - -

○

Note

1) Conditional flag can be set when P2P function is ‘SEND’ in case of user definition frame communication.

2) No. of variable and data size can be set when command type is ‘Continuous’ at the XGT client, Modbus ASCII/RTU

client.

3) Setting can be set when selecting the fix sized variable or variable sized variable in case of user definition frame

communication.

4) Frame setting is available after setting the group name and frame type of user definition frame.

Chapter 4 Installation and Test Operation

4-6

4.5 I/O Assignment and Device Information

4.5.1 I/O assignment

(1) When using the XGK CPU

(a) How to configure the basic system

The characteristic of basic system consisting of basic and extension base is as follows. The number of extension

base is different according t o CPU type and there a re fixed ty pe and changeable methods on I/ O assignment.

Classification XGK-CPUE XGK-CPUS XGK-CPUA XGK-CPUH XGK-CPUU

Max. extension no. 1 3 3 7 7

Max. equip-able

I/O module no.

24 48 48 96 96

Max. I/O point

1,536

3,072

3,072

6,144

6,144

Max. extension

distance

15m

(b) Assignment of I/O point (fixed type)

1) 64 I/O points are assigned to each slot regardless of module.

2) 1024 (64*16) I/O points are assigned to each base. Namely no. 1 base’s start number is P00640. (Refer to

2.3.2)

3) The example of I/O assignment of 12 slot base is as follows.

0 1 2 3 4 5 6 7 8 9 10

11

(c) Assignment of I/O point (Changeable type)

1) The point changes according to each module equipped at the slot.

2) If there is no module, designated point is assigned.

3) The slot not designated by I/O parameter is assigned according to the equipped module automatically. (8 points

module is assigned as 16 points.)

4) The empty slot not designated by I/O parameter is assigned as 16 points.

5) It is possible to set the points without designation of module.

6) 16 points is assigned at the slot where special and communication module is equipped.

7) The example of assignment of I/O point for 12 sl ot base is as foll ows.

0 1 2 3 4 5 6 7 8 9 10

11

P

W

R

IO

1

6

IO

1

6

IO

3

2

IO

6

4

IO

1

6

IO

3

2

IO

3

2

IO

6

4

IO

3

2

IO

3

2

IO

1

6

IO

3

2

C

P

U

Slot no.

P

W

R

IO

1

6

IO

1

6

IO

3

2

IO

6

4

IO

1

6

IO

3

2

IO

3

2

IO

6

4

IO

3

2

IO

3

2

IO

1

6

IO

3

2

C

P

U

Slot no.

Chapter 4 Installation and Test O peration

4-7

(2) When using the XGI CPU

(a) How to configure the basic system

Classification XGI-CPUU XGI-CPUS XGI-CPUE

Max. extension no. 7 3 1

Max. equip-able IO

module no.

96 48 24

Max. IO points

• In case of 16 point s module: 1,536 point

• In case of 32 point s module: 3,072 point

• In case of 64 points module : 6,144 point

768 point

1,536 point

3,072 point

384 point

768 point

1,536 point

Max. extension

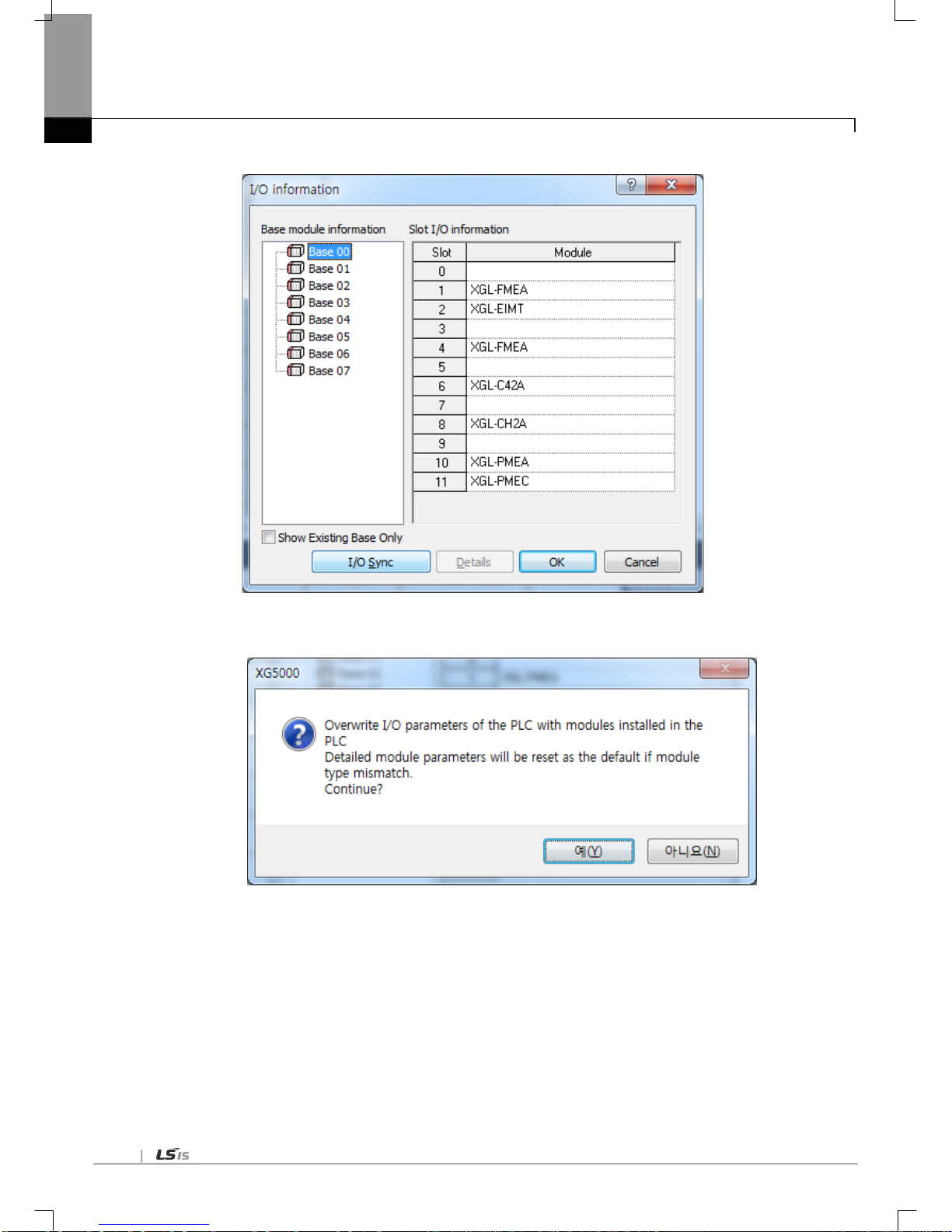

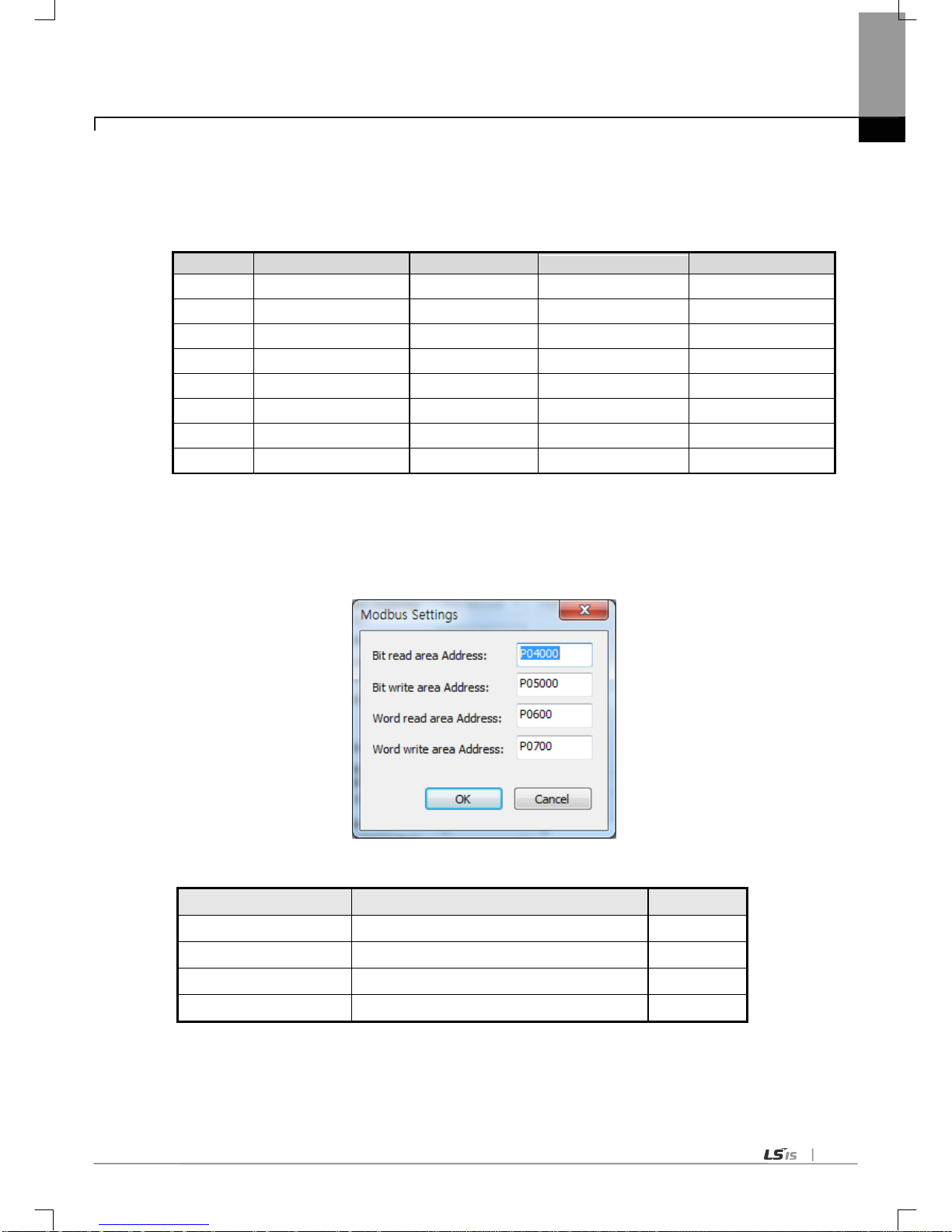

distance