Right choice for ultimate yield

LSIS strives to maximize customers' profit in gratitude of choosing us for your partner.

Programmable Logic C ontroller

XGB Ethernet/IP IF Module

User’s Manual

Read this manual carefully before

installing,

wiring, operating, servicing

or inspecting this equipment.

Keep this manual within easy reach

for quick reference.

XBL-EIPT

XGT Series

http://www.lsis.com

Safety Instruction

Before using the product …

For your safety and e ffective oper ation, pl ease read the safety ins tructions t horoughly be fore using t he product.

► Safety Instructions should always be observed in order to prevent accident or risk with the safe and

proper use the product .

► Instructions are divided into “Warning” and “Caution”, an d the mea ning of the ter ms is as f ollows.

This symbol indicates the possibility of serious injury or death if some applicable

instruction is violate d

This symbol indicates the possibility of severe or slight injury, and property

damages i f some appli cable instr uction is v iolated

Moreover, even classified events under its caution category may develop into serious accidents relying on

situations. Ther efore we strongly adv ise users to observe al l precautio ns properly just like war nings.

► The marks displayed on the pr oduct and in the user ’s manual have t he following meanings .

Be careful! Danger m ay be expecte d.

Be careful! Electric shock may occur.

► The user’s manual even after r ead shall b e kept avai lable and access ible to

any user of the product.

Warning

Caution

Safety Instruction

Safety Instructions for design process

Please install a protection circuit on the exterior of PLC so that the whole system may

operate safely regardless of failures from external power or PLC. Any abnormal output or

operation from PLC may cause ser ious proble ms to safety in whole sy stem.

- Install protection units on the exterior of PLC like an interlock circuit that deals with opposite

operations such as emer g ency s top, pr otection circuit, and forward/rever s e rot ati on or install an

interlock circuit that deals wi th high/low limit under its position co ntrols.

- If any system error (watch-dog timer error, module installation error, etc.) is detected during

CPU operation in PLC, all output signals are designed to be turned off and stopped for safety.

However, there are cases when out put signals remai n active due t o device fail ures in Relay and

TR which can’t be det ected. Thus , y ou are recommended to install an addi tion ci rcui t to monitor

the output status for those cri tical outputs which may cause significant problems.

Never overload more than rate d current of output modul e nor allow to have a short circuit.

Over current for a long period time m aycause a fire .

Never let the external power of the output circuit to be on earlier t han PLC power, which may

cause accid ents from abnormal outp ut oroperation.

Please install interlock circuits in the sequence program for safe operations in the system

when exchange data with PLC or modify operation modes using a computer or other

external equipments

Read specific instructions thoroughly when conducting control operations

with PLC.

Warning

Safety Instruction

Safety Instructions for design process

Safety Instructions on inst allation proces s

I/O signal or communication line shall be wired at least 100mm away from a high-voltage

cable or power line. Fail to follow this

Caution

Use PLC only in the environment specified in PLC manual or general standard of data

sheet. I f not, electr ic shock, fir e, abnormal operation o f the product may be caus ed.

Before install or remove the module, be sure PLC power is off. If not, electric shock or damage

on the product may be c aused.

Be sure that every module is securely attached after adding a module or an extension

connector. If the product is installed loosely or incorrectly, abnormal operation, error or dropping

may be caused. In addit

ion, contact failures under poor cable installation will be causing

malfunctions as well.

Be sure that screws get tighten securely under vibrating environments. Fail to do so will put

the product under dir ect vibrat ions which w ill cause electric shock, fire and abnormal operati on.

Do not come in contact with conducting parts in each module, which may cause electric

shock, malfunctions or abnormal op eration.

Caution

Safety Instruction

Safety Instructions for wiring process

Prior to wiring works, make sure that every power is turned off. If not, electric shock or

damage on the product may be caused.

A fter wiring process is d one, make sur e that term inal covers are inst alled properly before

its use. Fail to i nstall the cover may cause electric shocks.

Warning

Check rated voltages and terminal arrangements in each product prior to its wiring

process. Applying incorrect voltages other than rated voltages and misarrangement among

terminals may cause fire or malfunctions.

Secure terminal screws tightly applying with specified torque. If the screws get loose, short

circuit, fire or abnormal operation may be caused.

Securing screws too tightly will cause

damages to the module or malfuncti ons, short ci rcuit, an d dropping .

Be sure t o earth to the ground using Class 3 wires for FG terminals which is exclusively

used for PLC. If the terminals not grounded correctly, abnormal operation or electric shock

may be caused.

Don’t let any foreign materials such as wiring waste ins ide the module while wiring,

which may cause fire, damage on th e product or a bnormal operation.

Make sure that pressed terminals get tighten following the specified torque. External

connector type shall be pressed or soldered using proper equipments.

Caution

Safety Instruction

Safety Instructions for test-operation and maintenance

Don’t touch the terminal when powered. Electric shock or ab normal operati on may oc cur.

Prior to cleaning or tightening the terminal screws, let all the external power off including

PLC power. If not, elect ric shock or a bnormal o peration may occur.

Don’t let the battery recharged, disassembled, heated, short or soldered. Heat, explosion

or ignition may cause inj uries or fire.

Warning

Do not make modifications or disassemble each module. Fire, electric shock or abnormal

operation may occur.

Prior to installing or disassembling the module, let all the external power off including

PLC power. If not, elect ric shock or a bnormal operation may occur.

Keep any wireless equipment such as walkie-talkie or cell phones at least 30cm away

from PLC. If not, abnormal oper ation may be caused.

When making a modification on progr ams or using run to modify functions under PLC

operations, read and comprehend all contents in the manual fully. Mismanagement will

cause damages to produ cts and ac cidents .

Avoid any physical impact to the battery and prevent it from dropping as well. Damages

to battery may c ause l eakag e from it s fluid. When bat tery was drop ped or expos ed under strong

impact, never reuse the batte

ry again. Moreover skilled workers are needed when exchanging

batteries.

Caution

Safety Instruction

Safety Instructions for waste disposal

Product or battery waste shall be processed as industrial waste. The waste may discharge

toxic materials or explode itself.

Caution

Revision History

Revision History

Version Date Contents Revised position

V 1.0 ’10.11 First edition -

V 2.0 ’17. 4 Add servic e setting by tag

XG5000 V4.0 UI updated

CH6

Entire

※ The number of User’s manual is indicated right part of the back cover.

ⓒ 2010 LSIS Co., Ltd All Rights Reserved.

About User’s Manual

About User’s Manual

Congratulations on purchasing PLC of LSIS Co., Ltd.

Before use, make sure to carefully read and understand the User’s Manual about the functions,

performances, installation and programming of the product you purchased in order for correct use and

importantly, let the end user and maintenance administrator to be provided with the User’s Manual.

The User’s Manual describes the produc t. If necessary, you may refer to the following description and order

accordingly. In addition, you may connect our website (http://www.lsis.com/

) and download the information

as a PDF file.

Relevant User’s Manuals

Title Description

No. of User’s

Manual

XG5000 User’s

Manual

It describes how to use XG5000 sof tware especially about online

functions such as programming, printing, monitoring and

debugging by using XGT series products.

10310000512

XGK/XGB Series

Instruction &

Programming

It describes how to use the instructions for programming using

XGK/XGB series. 10310000510

XGB Hardware

User’s Manual

It describes how to use the specification of power/input

/output/expansion modules, system configuration and built-in

High-speed counter for XGB basic unit.

10310000926

XGB Analog

User’s Manual

It describes how to use the specification of analog input/analog

output/temperature input module, system configuration and built-

in PID control for XGB basic unit.

10310000920

XGB Position

User’s Manual

It describes how to use built-in positioning function for XGB unit.

10310000927

XGB Cnet I/F

User’s Manual

It describes how to use built-in comm unication function for XGB

basic unit and external Cnet I/F module.

10310000816

XGB Fast Ethernet

I/F User’s Manual

It describes how to use XGB FEnet I/F module.

10310000873

About User’s Manual

Current XBL-EIPT manual is written based on the following version.

Related OS version list

Product name OS version

XGB-XBCH

V2.80

XGB-XBCS

V1.90

XGB-XBCU

V1.70

XGB-XBMH V1.10

XGB-XBMS V3.80

XGB-XECH

V2.20

XGB-XECS

V1.80

XGB-XECU V1.70

XG5000 V4.21

Contents

◎ Contents ◎

Chapter 1 Overview

1.1 Overview ------------------------------------------------------------------------------------------------------------------------------------------- 1-1

1.2 Features -------------------------------------------------------------------------------------------------------------------------------------------- 1-2

1.3 Product Components ----------------------------------------------------------------------------------------------------------------------------- 1-3

1.3.1 Indication of T ype Na mes ------------------------------------------------------------------------------------------------------------ 1-3

1.4 Software for Using Products ------------------------------------------------------------------------------------------------------------------- 1-4

1.4.1 Confirms for Software ----------------------------------------------------------------------------------------------------------------- 1-4

1.4.2 XG5000 ----------------------------------------------------------------------------------------------------------------------------------- 1-4

1.4.3 Confirmation of Versions ------------------------------------------------------------------------------------------------------------- 1-5

1.5 Compatibility by OS version of XGB EtherNet/IP I/F module --------------------------------------------------------------------------- 1-6

1.5.1 Version information available with communication service by Tag ------------------------------------------------------ 1-6

1.5.2 Operation compatibility according to O/S version ----------------------------------------------------------------------------- 1-6

Chapter 2 Specification

2.1 General S pecification ---------------------------------------------------------------------------------------------------------------------------- 2-1

2.2 Performance Specification --------------------------------------------------------------------------------------------------------------------- 2-2

2.3 Name of Each Part ------------------------------------------------------------------------------------------------------------------------------ 2-3

2.4 Cable S tandards ---------------------------------------------------------------------------------------------------------------------------------- 2-5

2.4.1 UTP Cable ------------------------------------------------------------------------------------------------------------------------------- 2-5

Chapter 3 Instal lation and Trial- Run

3.1 Installation Environment ------------------------------------------------------------------------------------------------------------------------ 3-1

3.2 Cautions when Handling ----------------------------------------------------------------------------------------------------------------------- 3-2

3.3 The Order for Setting up Products till Running -------------------------------------------------------------------------------------------- 3-3

3.4 Available device area ----------------------------------------------------------------------------------------------------------------------------- 3-4

3.5 Installation of Products -------------------------------------------------------------------------------------------------------------------------- 3-6

3.5.1 Installation of XBL-EIPT -------------------------------------------------------------------------------------------------------------- 3-6

3.6 Trial- Run ------------------------------------------------------------------------------------------------------------------------------------------- 3-8

3.6.1 Directions when Configuring Systems -------------------------------------------------------------------------------------------- 3-8

Chapter 4 System Configuration

4.1 Configuration of a Usable System ----------------------------------------------------------------------------------------------------------- 4-1

4.1.1 System Configuration using a Switch --------------------------------------------------------------------------------------------- 4-1

4.1.2 System Configuration not using a Switch ---------------------------------------------------------------------------------------- 4-1

4.2 Configuration of an unusable System ------------------------------------------------------------------------------------------------------- 4-2

4.2.1 System Configuration using a Switch ---------------------------------------------------------------------------------------------- 4-2

4.2.2 Configuration of a Ring System (Configuration of a XGL-EIPT Ring) ---------------------------------------------------- 4-2

Chapter 5 Instal lation of Sof t ware and Communicat ion Parameters

5.1 Installation and Execution of Software ------------------------------------------------------------------------------------------------------ 5-1

5.1.1 Installation of XG5000 ---------------------------------------------------------------------------------------------------------------- 5-1

5.1.2 Installation of USB Device Drive ---------------------------------------------------------------------------------------------------- 5-4

Contents

5.1.3 Confirmation on the Installation of USB Device Driver ------------------------------------------------------------------------ 5-7

5.2 How to Register Communication Modules ----------------------------------------------------------------------------------------------- 5-15

5.2.1 In case of Offline ----------------------------------------------------------------------------------------------------------------------- 5-15

5.2.2 In case of Online ---------------------------------------------------------------------------------------------------------------------- 5-17

5.2.3 In case of Reading Parameter stored in PLC ---------------------------------------------------------------------------------- 5-19

5.2.4 How to Set-up Modules ------------------------------------------------------------------------------------------------------------- 5-20

5.2.5 Menu bar and shortcut of XG5000 ------------------------------------------------------------------------------------------------- 5-21

Chapter 6 EIP Serv ice

6.1 EtherNet/IP Communication Method -------------------------------------------------------------------------------------------------------- 6-1

6.1.1 EtherNet/IP T erms --------------------------------------------------------------------------------------------------------------------- 6-1

6.1.2 EDS File ---------------------------------------------------------------------------------------------------------------------------------- 6-1

6.1.3 Periodic Communication (Implicit) System -------------------------------------------------------------------------------------- 6-2

6.1.4 Aperiodic Communication (Explicit) System ------------------------------------------------------------------------------------- 6-4

6.2 EIP Service ---------------------------------------------------------------------------------------------------------------------------------------- 6-7

6.3 T ag setup -------------------------------------------------------------------------------------------------------------------------------------------- 6-8

6.3.1 XBC/XBM --------------------------------------------------------------------------------------------------------------------------------- 6-8

6.3.2 XEC --------------------------------------------------------------------------------------------------------------------------------------- 6-9

6.3.3 Supported Device by Main Unit --------------------------------------------------------------------------------------------------- 6-10

6.4 Setup of Periodic/Non-periodic Communication Service ------------------------------------------------------------------------------ 6-11

6.4.1 Periodic Client Communication Service ----------------------------------------------------------------------------------------- 6-11

6.4.2 Set-up of Aperiodic Client Communication Service --------------------------------------------------------------------------- 6-18

6.4.3 Periodic Server Communication Service ---------------------------------------------------------------------------------------- 6-20

6.4.4 Aperiodic Server Communication Service -------------------------------------------------------------------------------------- 6-22

6.4.5 Tag naming rule for aperiodic communication services ----------------------------------------------------------------------- 6-22

6.5 Examples ----------------------------------------------------------------------------------------------------------------------------------------- 6-25

6.5.1 Communication with Rockwell 1756-ENBT Communication Module --------------------------------------------------- 6-25

Chapter 7 Diagnosis Function

7.1 System Diagnosis -------------------------------------------------------------------------------------------------------------------------------- 7-1

7.2 System Diagnosis Items and Contents ----------------------------------------------------------------------------------------------------- 7-2

7.3 Troubleshooting ---------------------------------------------------------------------------------------------------------------------------------- 7-8

7.3.1 Check-out through LED in Communication Module --------------------------------------------------------------------------- 7-8

7.3.2 Check out of Module Errors through XG5000 ---------------------------------------------------------------------------------- 7-9

7.3.3 Check-out on Module Errors through System Log --------------------------------------------------------------------------- 7-10

7.4 Remote Communication control -------------------------------------------------------------------------------------------------------------- 7-12

7.4.1 Introduction ------------------------------------------------------------------------------------------------------------------------------- 7-12

7.4.2 Setting and Connection --------------------------------------------------------------------------------------------------------------- 7-13

Appendix

A.1 Terms ------------------------------------------------------------------------------------------------------------------------------------------- A-1

A.2 Flag List ---------------------------------------------------------------------------------------------------------------------------------------- A-5

A.2.1 Special Relay (F) List ------------------------------------------------------------------------------------------------------------- A-5

A.2.2

Network Register (N) List -------------------------------------------------------------------------------------------------------- A-11

A. 3 External Dimension ---------------------------------------------------------------------------------------------------------------------- A-12

A.4 Action when changing OS version from V1.x to V2.0 ------------------------------------------------------------------------------ A-13

Chapter 1 Overview

1

-1

Chapter 1 Ov erv iew

1.1 Overview

This user guide is made out to describe Ether Net/I P I/F module ( Referr ed to as “EIP Module”) amon g XGB PLC s ystem

networks. EtherNet/IP is the protocols where Common Industrial Protocol (CIP: industrial protocols used in common, such

as Device Net , C ontrolNet, CompoNet , etc ) has been l aid on an upper layer of open prot oco l Ethern et. Thus, EtherNet/I P

allows Device Net, Cont rolNet, a nd CompoN et devel opers to s ecure th e i

nteroperability between multi-band and lower network

devices by

applying the same obj ects and prof iles. EIP m odu l e provides two Ether net Ports ( Ether net Port) a nd th e s witch

function requir ed for the existing STAR system is built in and it is the module for transmitt ing data between PCCs or

between PLC and EtherNet/IP I/F IO module.

T o use the communication service by T ag, the following version is necessary .

1) XBL-EIPT: V2.0 or above

2) XBC Series: SU(V1.90 or above), H(V2.80 or above), U(V1.70 or above)

3) XEC Series: SU(V1.80 or above), H(V2.20 or above), U(V1.70 or above)

4) XBM Series: S(V3.80 or above), H(V1.10 or above)

5) XG5000 Software: V4.21 or above

Chapter 1 Overview

1-2

1.2 Features

XGB EtherNet/IP I/F Module have the following features.

(1) Communication Methods: Extensive Client Messaging Support

▶ Encapsulated Messages, UCMM Explicit Messaging

▶ Class 3 Connected Explicit Messaging(Server Only)

▶ Class 1 Connected Implicit(IO) Messaging(Cyclic I/O Service Only)

(2) Compa tibili ty: XGT Ether Net/IP I/F meet EtherNet/IP Conformance Test Suite V ersion 2.10

(3) 100BASE-TX media is provided and 100Mbps/ (Full Duplex) are supported.

(4) It is possible t o be e qu ip ped wit h 24 u nits p er CPU and installation to bas ic b ase and extension base is availab le.

However, only installation to base is possible in XGR system. .

(5) With the bu ilt - in switch , t here is no need to install a separat e switch and hub a nd wirin g is saved and f le xibility in

installation is provided.

(6) As Auto Cross Over- function is p rovided, cabling jo b is conven ient.

(7) A variety of diagnose functions, the states information of modules and networks are provided.

▶ The state of a communication module

▶ The state of a communication service(EIP, Non-circular server)

▶ Auto Scan-function providing an information of own corporation’s and other corporations’ modules

connected into network

▶ The kinds of packets and the quantity of data received by communication module (Network load – prediction

is available)

▶The diagnosis function through network is available

Chapter 1 Overview

1

-3

1.3 Product Components

1.3.1 Indication of T y pe Names

Components of XGB EtherNet/IP I/F module product are described.

Type Name

Components

Remarks

XBL-EIPT

Electric 2 –port EtherNet/IP Module

More than category 5

Chapter 1 Overview

1-4

1.4 Software for Using Products

The following ex plains main programming tools and other production software for usi ng EIP module. For more exact

application of programs and communication, refer to the contents below and apply it to systems.

1.4.1 Confirms for Software

Segment

Component Products

Communication Set-up T ool

XBL-EIPT Communication Module for XGB XG5000

Notice

1) To use the above program, downl oad f rom the curr ent webs ite you are visiting. In case you can not use the

internet, visit near agencies and ask for CD-ROM for installation.

Internet Web - address: http://www.lsis.com

2) To program XG5000, us e RS-232C port and USB of CPU module. For cable, refer to the XGB catalogue.

(USB-301A, PMC-310S)

1.4.2 XG5000

XG5000 is the software for ded icatedly using all comm unication m odules including Ethernet/IP I/F module for basic

parameter set-up, frame make-up, module and network diagnosis.

The following illustration shows the initial screen of XG5000.

[Figure 1.4.1] XG5000 – Initial Screen

Chapter 1 Overview

1

-5

1.4.3 Confirmation of Versions

Check out the version of the module before using XGB EtherNet/IP I/F.

1) Confirmation through XG5000

T o read the information of a communication module, access to the communication module.

.

If interface is normally maintained with CPU, the information like the following illustration can be got.

(1) Execute XG5000

(2) Connect with CPU via access through [Online]-[Connect] on menu.

(3) When connected with CPU, execute the diagnosis of XG5000.

(4) Locate the mouse to the communication module in system diagnosis screen of online menu.

(5) Double-click the communication module or click right button of mouse and select Detailed Module Information.

`

[Figure 1.4.2] Confirmation of Versions through XG5000

2) Confirmation of Versions through Case Label of Products

In each module, the information of the module product is attached to the exterior case.

In case there is no connect or with PC a nd it is impossibl e to check out online, c onfirmatio n is avai lable after you

remove the mod ule in case. The label attached to the back side of a pr oduct and t he type nam e and the vers ion

information is marked.

Chapter 1 Overview

1-6

1.5 Compatibility by OS version of XGB EtherNet/IP I/F module

XGB EtherNet/I P I/F module change d from OS V2.0 to Tag communication. To use the communication ser vice by Tag,

refer to the following description.

1.5.1 Version information available with commun ication service by Tag

1) XBL-EIPT : V2.0, EDS: V er2.10

2) XG5000: V4.21 XG5000 Software: V4.21 or above

3) XBC Series: SU(V1.90 or above), H(V2.80 or above), U(V1.70 or above)

4) XEC Series: SU(V1.80 or above), H(V2.20 or above), U(V1.70 or above)

5) XBM Series: S(V3.80 or above), H(V1.10 or above)

1.5.2 Operation compatibility according to O/S version

Communication Service

O/S version

Action

Client

Server

Implicit message

V2.0 V1.x O

V1.x V2.0 O

Explicit message (Tag Read/Write)

*2)

V2.0 V1.x X

*1)

V1.x V2.0 O

Explicit message (Read/Write)

*2)

V2.0 V1.x O

V1.x V2.0 O

*1) V1.x suppo rts on ly Multi ple Server an d V2.0 sup ports on ly Single Client

*2) Explicit message (T ag Read/Write): Select this to read/write the Tag registered to the external device.

Explicit message (Read/Write): Select this to read / write the CIP Object of the external device.

It should know service code, class, Instance, and Attribute of CIP Object.

Notice

If you are upgrading the OS of XGB EtherNet/IP I/F module from V1.x to V2.0 or replacing V1.x product with V2.0

product, please refer to [A.4 Action when changing OS version from V1.x to V2.0].

<V1.x>

<V2.0>

Chapter 2 Specification

2

-1

Chapter 2 Specification

2.1 General Specification

The general specification of XGT series is as follows.

No. Items Specifications Related st andards

1

Ambient

temperature

0 ~ 55 °C

2

Storage

temperature

−25 ~ +70 °C

3

Ambient

humidity

5 ~ 95%RH (Non-condensing)

4 Storage humidity 5 ~ 95%RH (Non-condensing)

5

Vibration

resistance

Occasional vibration -

Frequency Acceleration Amplitude How many times

IEC61131-2

5≤f< 8.4㎐ - 3.5mm

10 times each

directions

(X , Y and Z)

8.4≤f≤150㎐

9.8㎨

-

Continuous vibration

Frequency Acceleration Amplitude

5≤f< 8.4㎐

-

1.75mm

8.4≤f≤150㎐ 4.9㎨(0.5G) -

6

Shock

resistance

• Peak acceleration: 147 m/s2(15G)

• Duration: 1 1ms

•

Half-sine, 3 times each direction per each axis

IEC61131-2

7 Noise resistance

Square wave

Impulse noise

AC: ±1,500 V

DC: ±900 V

LSIS standa rd

Electrostatic discharge 4kV (Contact discharge)

IEC61131-2

IEC61000-1-2

Radiated electromagnetic field noise 80 ~ 1,000 MHz, 10V/m

IEC61131-2,

IEC61000-1-3

Fast transient/bust

noise

Segment

Power supply

module

Digital/analog input/output

communication interface

IEC61131-2

IEC61000-1-4

Voltage 2kV 1kV

8 Environment Free from corrosive gasses and excessive dust

9 Altitude Up to 2,0 00 m

10

Pollution

degree

Less than equal to 2

11 Cooling Air-cooling

Notice

1) IEC (International Electrote chnical Commission):

An international nongovernmental organization which promotes internationally cooperated standardization in

electric/electronic field, publishes i nternational stand ards and manages applicable estimation system re lated with.

2) Pollution degree:

An index indicating pollution degree of the operating environment which decides insulation performance of the devices. For instance, Pollution

degree 2 indi cates the state generally that only non-conductive pollution

occurs. However, this state contains temporary conduction due to dew

produced.

Chapter 2 Specification

2-2

2.2 Performance Specification

The following table describes the specification of system configuration in accordance with EtherNet/IP I/F module’s media.

When you configure systems, refer to the below table.

Item Standard

Transmission

Standard

Transmission Speed 100Mbps

Transmission Method Base Band

Maximum Extension Distance

between Nodes

100m

Communication Zone Excess

Method

CSMA/CD

Frame Error – Checking

Method

CRC 32 = X

32

+ X26 + X23+ ,,,,, + X2 + X + 1

Topology Line , Star

Diagnosis Function

Module Information , Service S tate , Media Information ,

Auto Scan, Ping T est

Service

Periodic Cline t Implicit IO Client

Aperiodic Client UCMM Client

Periodic Server Implicit IO Server

The Number of

Connections

(Client/Server)

TCP 16/32

CIP(IO Communication) 32/64

The Number of Maximum Services (P2P count) 2

The Number of Maximum Installments 2

Max. setting data

size per block

Periodic client 500 byte

Aperiodic client 512 byte

Media UTP/STP Category 5

Basic Standards

Dimension (mm) 90(H) X 27(W) X 60(D)

Consumption Current (mA)

290

Weight (g)

102

Chapter 2 Specification

2

-3

2.3 Name of Each Part

The name in each module is as follows.

[Figure 2.3.1] The Front View for Module PLC

▶ LED Names and Contents

Silk Mark

LED State

Contents

RUN

ON

Power -on and Process normally operating

OFF

Power –off and Process abnormally operating

I/F

OFF

I/F operating normally with CPU

Flicker/OFF

I/F operating abnormally with CPU

P2P

ON

In case of stetting up P2P Service

OFF

In case of canceling P2P Service

PADT

ON

XG5000 being connected via rem ote control

OFF

XG5000 remote c onnection has been released

SVR

ON

When exterior client has been con nected, Light ON

OFF

When there is no exter ior client connection, Light OFF

MS

Green Light ON

When normal operating

Green Light flickers

When configuration for device is not over

Red Light flickers

In case of wrong set-up or restorable errors happened

Red Light ON

When errors which are impossible to restore have been made

Red Green Light flickers

When self-diag nosis is proceeding

NS

Green Light flickers

When there is no connection of a device

Green Light ON

When there is connection more than 1 with a devic e at least

Red Light flickers

When Timeout with a device more than 1 unit happened

Red Light ON

When repeated IP addr ess has been detected

Red / Green Light

flickers

When self-diag nosis is preceding

n ACT Flicker In case of frame – transmitted and received (n=1,2)

n LNK

ON

When network link has been form ed (n=1,2)

OFF

When network link has not been fo rmed (n=1,2)

LED Display

IP Set-up Switch

LOG Switch

Connector 1

Connector 2

Chapter 2 Specification

2-4

▶ Log Switch

In case of reading Log in communication module and needing to store the Log, if you push it for more than 1 second, it is

stored into Flash area from Memory area. The Log in the memory area is the one erased when power is supplied again

and the Log in Flash area is the one which is maintained when power is supplied again.

▶ IP Set-up Switch (1~90, 94~99)

When IP address has not been inserted via XG5000 within 10 seconds after power was supplied, IP is set up as

‘192.168.250.switch value’.

▶ IP Set-up Switch (91, 92, 93 )

This switch is designed for setting up the inside of communication. If you change it arbitrary, it may cause problems.

▶ IP Set-up Switch (99)

This switch f unctions to configur e the system into a ring form and wh en set-up is not finished, norm al operation is

impossible. It is possible to form a ring system in terms of appearance by supporting 2 connectors but actual ring system

is not supported.

Chapter 2 Specification

2

-5

2.4 Cable Standards

2.4.1 UTP Cable

UTP cable is classified into the 3 types according to the following standards.

▶ With or without Shield: 3 Types (UTP, FTP, STP)

▶ Used - frequency Band: 7 Categories (Category 1 ~ Category 7)

▶ Inflammable Grade: 4 Grades (CMX, CM, CMR, CMP)

1) Kinds of Cables with or without Shield

Classification

Details

Use

UTP(or U.UTP) Unshielded Cables for Hi gh S peed – Signals

Maximum 200MHz

Voice +Information (Data)+ Low grade Video Signal

FTP(or S.UTP)

1 Layer Shield, Cable Core only shielded

* Shield Materi als: AL /Plastic Complex Foil

Or Copper Braid

Maximum 100MHz

Electro Magnetic Interference (EMI)

and Electric Stability

is considered

Voice + Information (Data) + Low grade Video Signal

STP(or S.STP)

Dual - shielded Cons truction,

Pair Shielded Cabl es or

Core Shielded Cables

* Pair - shielded Materials : AL/Plastic Complex Foil

* Core - shielded Materi als : AL/Plastic Complex Foil

or

Copper Braid

Maximum 500MHz

Voice + Information (Data)+ Video Signal

An Alternative to 75Ω – Coaxial Cable

Notice

1) UTP : Unshielded Twisted Paired Copper Cable

FTP : (Overall) Foiled Twisted Paired Copper Cable

STP : (Overall ) Shiel ded(and Shi elded I ndividua lly Pair)Twisted Paired Copper Cable

2) Patch Cable(or Patch Cord)

Instead of S olid Con duct ors, Stranded C on duct ors m a y be used f or the pur pos e of im prov ing the Flex ibil ity of a UT P

4Pair Cable. The materials and sizes of strands used are regulated in accordance with UL444, and representative sizes

and materials are Un-coated AWG 24 (7/0203A).

In other words, diam eter of unshielded wire is 0.203mm and wires ar e stranded in 1+6 str ucture. The materials are

annealed coopers.

UTP

STP

FTP

Chapter 2 Specification

2-6

2) Classification by Frequencies used

Classification Frequency used (MHz)

Transmission

Speed(Mbps)

Uses

Category 1

Voice Frequency

1

T elephone Network (2 Pair)

Category 2

4

4

Multi- Pair Communication Cable

Category 3 16 16

T elephone Network + Computation

Network

Category 4 20 20

1) Computation Network – Transmission

Speed Up

2)Low-loss Communication Cable

Category 5 and

Enhanced

Category 5

100 100

1)Digital Telephone Network +

Computation Network

2)Low Loss, Wideband Cable

Notice

1) The classification c urrently applied at home and abroad is Category 3, 5, Enhanced Ca te gor y 5, and Ca te gor y

6. Category 4 is not now used as Category 5 appears. Category 7 is in STP structure and it is at a

development st age ove r the wo rld.

3) Classification by Non-flammable Grades(Base on UL Certification )

Segment

Induced

Calorie

Induced Time

Combustion

Length

Smoke

Regulation

Remarks

CMP 88(kW) 20 minutes

Less than

73m/min

Regulated

• For Installing ceilings without duct

• Plenum Cable

• UL 910 (Plenum Test)

CMR 150(kW) 30 minutes

Less than

3.6m

Not

Regulated

• V ertical Installation Type

• Non-Plenum Cable

• UL 1666(Riser Test)

CM 21(kW) 20 minutes

Less than

2.4m

Not

regulated

• Gene ral Ty pe

• Non-Plenum Cable

• UL 1581(VTFT T est)

CMX 1(kW) 1 minute

Less than

0.5m

Not

regulated

• Restrictive Use

• Non-Plenum Cable

• UL 1581 (VW-1 T est)

Notice

1) CMG is located in the middle grade between CM and CMR, but generally it is not applied to LAN Cable

such as UTP Cable.

Example) CMG: CAS FT4 (VTFT T est), similar to CM of UL 1581.

→Burner Angle (Horizontality → 45 degree – Upward) a nd S ample Conditions (1/2 interval arra ngem ent

→ A Bundle of 6 ones x 6 units) are different.

Chapter 2 Specification

2

-7

4) An Example (CTP-LAN5) of Category - 5 Twisted Pair Cable(UTP)

Items

Units

Values

Conductor Resistance

(Maximum)

Ω/km 93.5

Insulation Resistance

(Minimum)

MΩ/km 2500

Anti- voltage

V/minute

AC 500

Characteristic

Impedance

Ω(1~100MHz) 100 ± 15

Attenuation Less than dB/100m

10MHz

6.5

16MHz

8.2

20MHz

9.3

Near End Cross-talk

Attenuation

Less than dB/100m

10MHz

47

16MHz

44

20MHz

42

Chapter 3 Installation and Trial-Run

3

-1

Chapter 3 Installation and Trial- Run

3.1 Installation Environment

This product is very reliable regardless of installation environments, but to guaranty the reliability and stability of the system,

pay attention to the following items.

1) Environment Conditions

(1) Install in the control board where waterproof and dustproof are possible.

(2) The places where constant impacts or vibrations are imposed.

(3) The places where direct rays are not directly exposed .

(4) The places where dew is not formed by the rapid change in temperature.

(5) The places where surrounding temperature is maintained to be at 0-55℃.

2) Installation Constructions

(1) Make sure wiring leavings are not inserted inside the PLC when you process screw holes or do wiring jobs.

(2) Install the places where it is easy to control.

(3) Do not install into the same panel as high press machine.

(4) Make sure the distance to the duct and the surrounding module is maintained to be more than 50㎜.

(5) Put to earth where surrounding noise environment is good.

Over 100mm

Over 50mm

Over 50mm

Chapter 3 Installation and Trial-Run

3-2

3.2 Cautions when Handling

Observe the following directions when you configure the system using EtherNet/IP I/F module.

1) Do not drop or impose strong impact.

2) Do not separate PCB from the case. It may cause malfunctions.

3) Make sure foreign objects are not put into the upper area of the module while you do wiring jobs.

4) If foreign objects are entered, remove them.

5) Do not remove the module when light is ON.

6) Use standard cables and install within maximum distance.

7) Make sure comm unication lines ar e not affected by sur ges and induct ive noises that may occur fr om alternating

current or current parts.

8) In case the machinery or the substances that may generate high temperature are nearby you or when wires directly

come into contact oil and other things for a long time when you do wiring jobs, it may cause a short cut, damage, or

malfunctions.

9) When you do wirings during pipe arrangement, it is necessary to put to earth to pipes.

Chapter 3 Installation and Trial-Run

3

-3

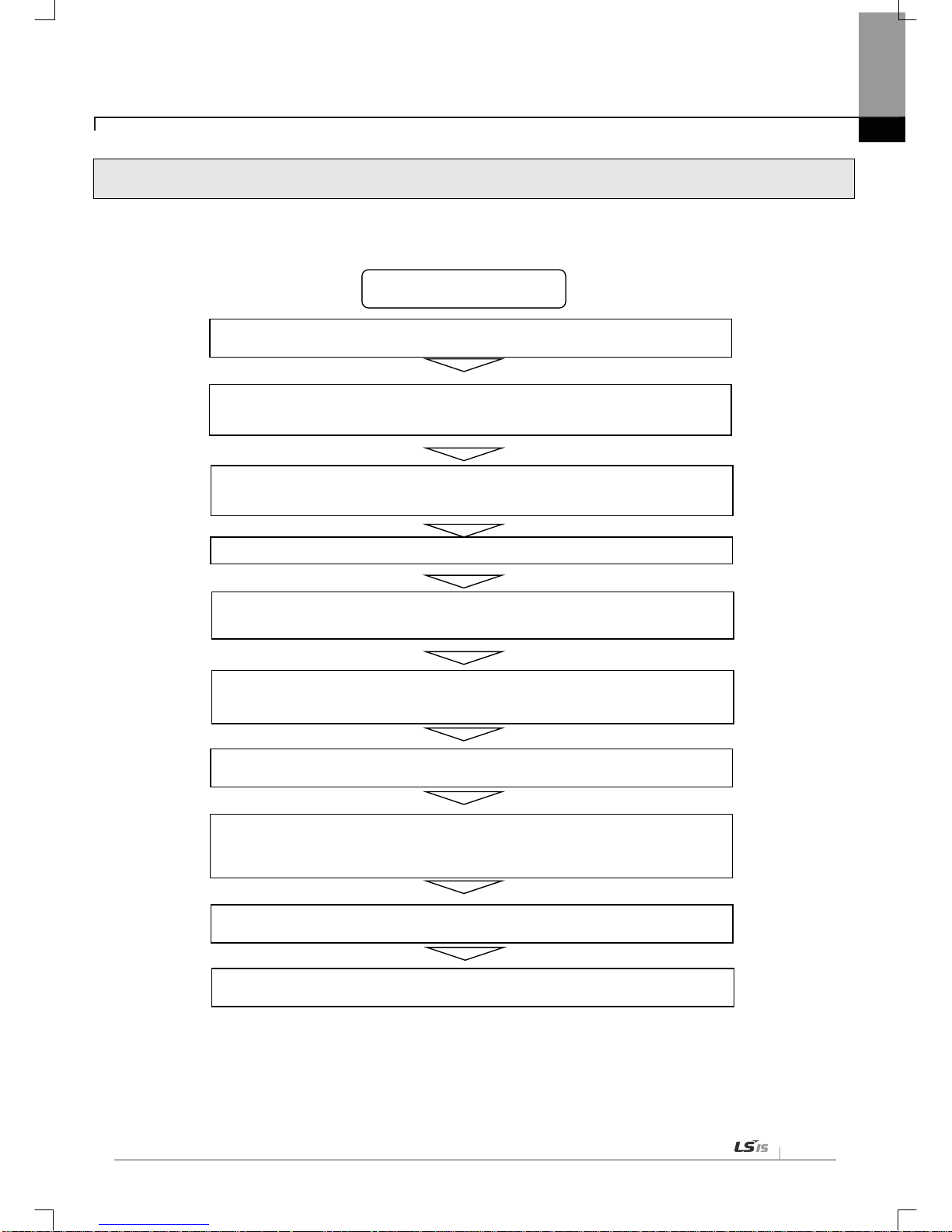

3.3 The Order for Setting up Products till Running

The following describes the order of installing or setting up products. Install the system and setting up the parameter so that

they can operate in order.

Start

● Check out the sizes and standards to be used

● Install the module to the base

● Check out the location of the base and the slot

● Check out the LED state of a communication module after power is authorized. (RUN:

Green)

● Connect to CPU using XG5000

● Carry out “I/O Sync” in XG5000

● The module appears in project window after executing “I/O Sync”

● Set up the basic parameter

▶ IP Address, Subnet Mask, Gateway

● Install the necessary EDS file

● Set up EIP parameter

▶ Channels, Functions, Starting Conditions, Data Sizes and Areas, Ty pes

● Execute “Write Parameter” and “Enable Link”

● Execute EIP communication

Chapter 3 Installation and Trial-Run

3-4

3.4 Available device area

Available device areas for each basic unit are as follows

CPU type Area Range

Size

(word)

Reference

XBC/

XBM

P

P0~P127 128 Read/Write/Monitor available, XBMS

P0~P1023 1024 Read/Write/Monitor available, XBCH, XBCS, XBMH

P0~P2047 2048 Read/Write/Monitor available, XBCU

M

M0~M255 256 Read/Write/Monitor available, XBMS

M0~M1023 1024 Read/Write/Monitor available, XBCH , XBCS, XBMH

M0~M2047 2048 Read/Write/Monitor available, XBCU

K

K0~K2559 2560 Read/Write/Monitor available, XBMS

K0~K4095 4096 Read/Write/Monitor available, XBCH , XBCS, XBMH

K0~K8191 8192 Read/Write/Monitor available, XBCU

F

F0~F255 256 Read/ Monitor avail able, XBMS

F0~F1023 1024 Read/ Moni tor avail able, XB CH, XBCS, XBMH

F0~F2047 2048 Read/ Monitor avail able, XBCU

T

T0~T255 16 Read/Write/Monitor available, XBMS

T0~T1023 64 Read/Write/Monitor available, XBCH, XBCS, XBMH

T0~T2047 128 Read/Write/Monitor available, XBCU

C

C0~C255 16 Read/Write/Monitor available, XBMS

C0~C1023 64 Read/Write/Monitor available, XBCH, XBCS, XBMH

C0~C2047 128 Read/Write/Monitor available, XBCU

L

L0~L1279 1280 Read/Write/Monitor available, XBMS

L0~L2047 2048 Read/Write/Monitor available, XBCH, XBCS

L0~L4095 4096 Read/Write/Monitor available, XBCU, XBMH

N

N0~N3935 3936 Read/Write/Monitor available, XBMS

N0~N5119 5120 Read/Write/Monitor available, XBCH

N0~N10239 10240 Read/Write/Monitor available, XBCU, XBMH

D

D0~D5119 5120 Read/Write/Monitor available, XBMS

D0~D10239 10240 Read/Write/Monitor available, XBCH, XBCS, XBMH

D0~D19999 20000 Read/Write/Monitor available, XBCU

Chapter 3 Installation and Trial-Run

3

-5

U

U0~U255 256 Monitor available, XBMS

U0~U351 352 Monitor available, XBCH , XBCS

U0~U383 384 Monitor available, XBCU

Z Z0~Z127 128 Read/Write/Monitor available

R

R0~R10239 10240 Read/Write/Monitor available, XBCH , XBCS

R0~R16383 16384 Read/Write/Monitor available, XBCU

XEC

I IW0.0.0~IW15.15.3 1024 Read/Write/Monitor available

Q QW0.0.0~QW15.15.3 1024 Read/Write/Monitor available

M

MW0~MW8191 8192 Read/Write/Monitor available, XECH, XECS

MW0~MW16383 16384 Read/Write/Monitor available, XECU

R

RW0~RW10239 10240 Read/Write/Monitor available, XECH, XECS

RW0~RW16383 16384 Read/Write/Monitor available, XECU

W

WW0~WW10239 10240 Read/Write/Monitor available, XECH, XECS

WW0~WW32767 32768 Read/Write/Monitor available, XECU

U

UW0.0.0~UW0.11.31 384 Monitor available, XECU

UW0.0.0~UW0.15.31 512 Monitor available, XECH, XECS

Notice

1) F Device: Writeable address is F220 or later .

2) In case of XBL-EIPT V2.0 or later: XEC type can only use I, Q, M, R, and W devices as EIP v ariable in global variable.

3) T / C is a timer / counter devic e. Bit designation m eans contact v alue and Word designation means current v alue.

4) XBMS, XBMH type does not support R device.

5) In U device, the addre ss of bit area is hexadecimal (Hex) value an d the address of word area is de cimal value.

Chapter 3 Installation and Trial-Run

3-6

3.5 Installation of Products

3.5.1 Installation of XBL-EIPT

[Figure 3.6.1] How t o Install 100BASE-TX

The maximum segment distance of 100BASE-TX reaches 100m. (The distance between modules)

Straight cables and cross cables are used.

If a cross cable is used when connected between these communication modules, the time for connecting links can be

shortened.

This module doesn’t support a ring system.

When configuring a ring form, IP address switch of a module – front view must be set up at ’99.’

Then, a ring system is formed in external aspect, but the service for a ring system will not be supported.

If IP address switch is not set up at 99’after formed in a ring , data burst may happen and modules can not execu te

normal actions.

Pin NO. Signal

Straight Cable between

Cables

1:1 Cross Cable

1

TD+

1-1

1-3

2

TD -

2-2

2-6

3

RD+

3-3

3-1

6

RD-

6-6

6-2

4,5,7,8

Not used - -

Notice

1) 100BASE-TX cable is designed to be weak in cable structure, so only if cables are twisted (Two

wires are stranded) after No.1 (TD+) and No. 2 (TD-) wires are twisted and No. 3 and No. 6 are

twisted with each other. wiring will be strong in strength.

2) For cable terminal treatment and manufacture, consult with professional providers to install

8 Pin - RJ45 Plug

Twist Pair Cable

Chapter 3 Installation and Trial-Run

3

-7

1) How to Inst all UTP

(1) For reliable transmission of 100Mbps signal using UTP cables, Patch Cord, Line Cord, Patch Panel, DVO(Data

Voice Outlet), etc must meet 5 spec (Category 5 Spec.- EIA/TIA-568A).

(2) Make sure the length of patch c ode will be over 7m in cross-connect, If the length exce eds 7m, the length

corresponding to 90m, as much as the allowable value in Horizont al Distri bution Sy stem, must be deducted.

(3) Make sure the length of line cord does not exceed 3m in line cord length. If the length exceeds 3m, as much as

the length corresponding to 90m, the allowable value in Horizontal Distribution System, must be deducted.

(4) Make sure the loose of paired pitch of U IP cable in cas e of disco nnection to patc h panel and D VD does not

exceed the following dimension.

(5) Maximum Paired Pitch – Loose : Category 5 : 13mm, Category 3 : 26mm

(6) Use jumper wires in DC cross-connect system. Then, also the loose of paired pitch must not exceed the above

standards. Es peci a ll y, in case of serio usl y b e nd in g c a bles , pay attention so t ha t d am ag e or s e parati on b etween

pairs does not happen.

(7) Maximum Curvature Diameter : 4 Pair Cable : 4 times the Diameter

Cable more than 25 Pair: 10 times the Diameter

(8) Make sure the maximum tensile force while using does not exceed 110N (11.3Kgf) based on 4 Pair

(9) Make sure jumper cabl es and patch cod es are loos ely disco nnected. W hen tig htly connect ed, the f eatures of

category 5 may low er. When using Tie-wrap, make sure cables are not stressed.

(10) Make sure proper distance is maintained between EMI source and UTP cable when installing cables.

The proper distance in each case is as follows.

Conditions

Minimum Separation Distance

Less than

2.0KVA

2.5 KVA

More than

5.0KVA

In case unshie lded po wer l ines or e lectr ic fac ilit ies are op en

and are in th e state of being closely located nearby non-

metal pipes

127mm 305mm 610mm

In case unshield ed po wer lines or e lectric facilities are in

the

state of being located nearby buried metal pipes

64mm 152mm 305mm

In case buried metal pipes the power line (

or the same

shields)

are in the state of being loca te d ne ar b y bur ie d metal

pipes

- 76mm 152mm

Notice

1) In case voltage reaches 480V and electric power source reaches more than 5KVA, separated calculation is required.

Chapter 3 Installation and Trial-Run

3-8

3.6 Trial- Run

3.6.1 Directions when Configuring Systems

1) To use P2P service including this module, make sure IP Addresses of all stations are different from IP addresses of

all other stations.

2) To use comm unication cables, select the on es in designated si zes. Using cables that have not been designate d

may cause serious communication obstacles.

3) Check out whether cables are disconnected or short-circuited before installing communication cables.

4) Completely tighten the connectors of communication cables so that cable connections can be fixed.

5) Incomplete cable connections may cause serious obstacles to communication.

6) In case of connecting comm unication c ables to a long distanc e, make sur e cables ar e not separated f rom po wer

lines or inductive noises.

7) Coaxial cables are low in f lex ib i li t y, so they must be re-branched lo wering down at least more than 30 cm f rom t he

connector in communication module, and if cables are bent on the square and forcibly transformed, it may cause the

destruction of the connector located in the communication module.

8) In case LED does not normally operate, refer to ‘Chapter 10 Troubleshooting’ and check out causes. If something

is wrong ev en if actions have been taken, contact Warranty Service Center.

Chapter 4 System Configuration

4

-1

Chapter 4 System Configuration

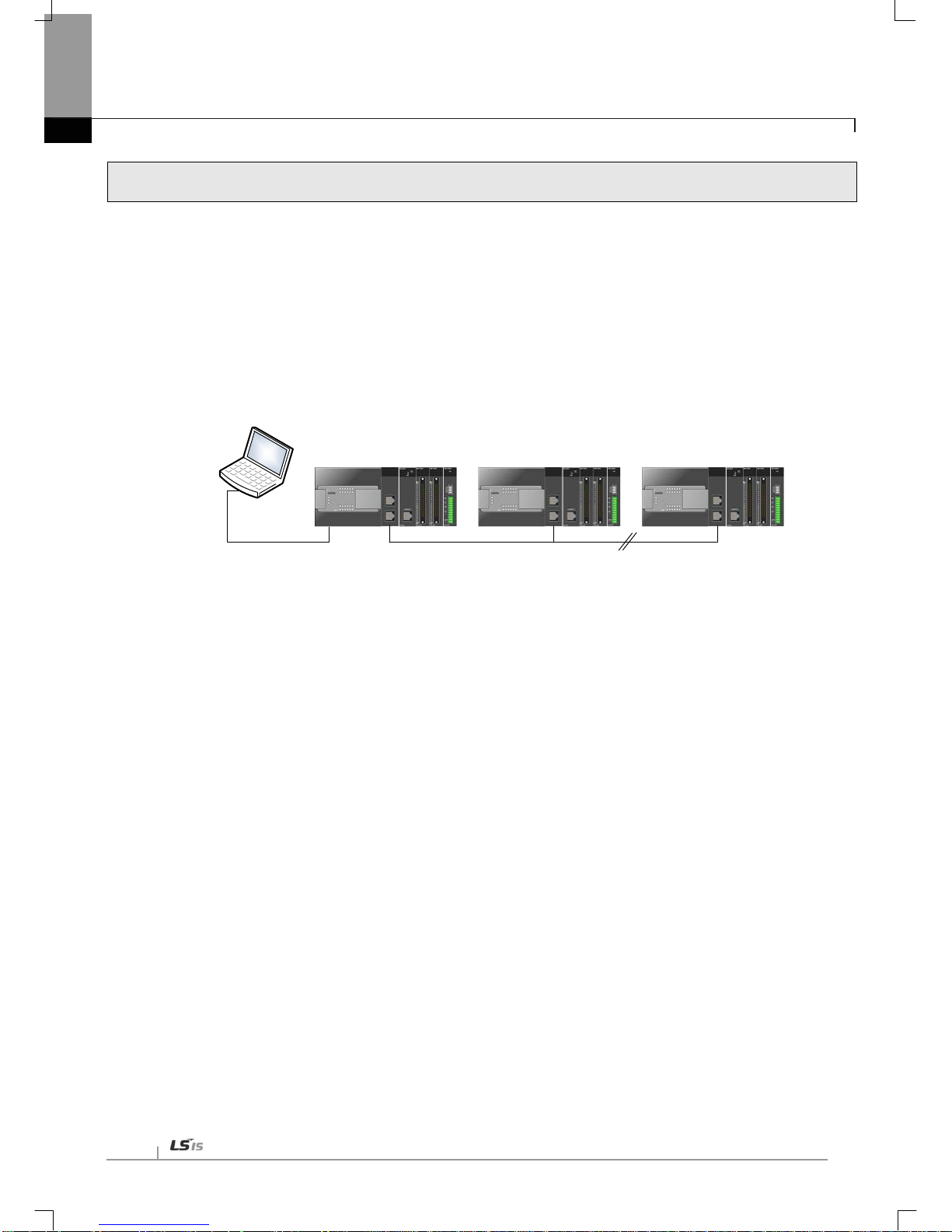

XGB EtherNet/IP I/F modules can be installed on the XBC CPU modules. The number of maximum installments reaches 2 .

It is possib le for the communication system using this modu le to be applied to a variety of configurations. This chapter

describes the examples of the cases w hen system configuration is available and unavailable by applications.

4.1 Configuration of a Usable System

4.1.1 System Configuration using a Switch

4.1.2 System Configuration not using a Switch

Chapter 4 System Configuration

4-2

4.2 Configuration of an unusable System

4.2.1 System Configuration using a Switch

It is impossible for EtherNet/IP I/F module to normally operate as data burst happens when each module is connected

to each switch of 2 communication ports.

4.2.2 Configuration of a Ring System (Configuration of a XBL-EIPT Ring)

EtherNet/IP I/F does no t support a ring system. When you configur e a ring form, it is necessary t o set up the IP

address switc h of the m odule – front vie w at ’99 .’ Then, it is co nfigure d into a ring system in exter nal aspect , but the

service on an actual ring system is n ot supported. In c ase I P addr es s switch is not set up at N O . ‘99’ after configured

into a ring, data burst happens and the module does not normally execute operations.

Chapter 5 Installation of Software and communication Parameters

5-1

Chapter 5 Installation of Software and Communication Parameters

5.1 Installation and Execution of Software

To use software XG5000, it is necessary to i ns tall XG5000. Then, XBL-EIPT V1.x should use X G50 00 V3.1 or later, XBL-

EIPT V2.0 or later should use XG5000 V4.21 or later. The requirements for system needed to execute are as follows.

1) PC and Memory: It is nec es sary to need a computer wit h more than 128MB m em ory and the memor y with more

than 512MB is recommended.

2) Communication Port: RS-232C serial port or USB po rt are req uired.

3) Hard Disk: The area where more than 200MB is possible to use is required.

4) Mouse: A mouse that can be connected with a computer is required.

5) Monitor: The resolution must reach more than 1024 X 768.

6) Window: It is possible to execute in Window 2000/XP/VISTA. However, if several app lications inc luding other

products are executed, XG5000 can be on the blitz due to the restriction to using memories.

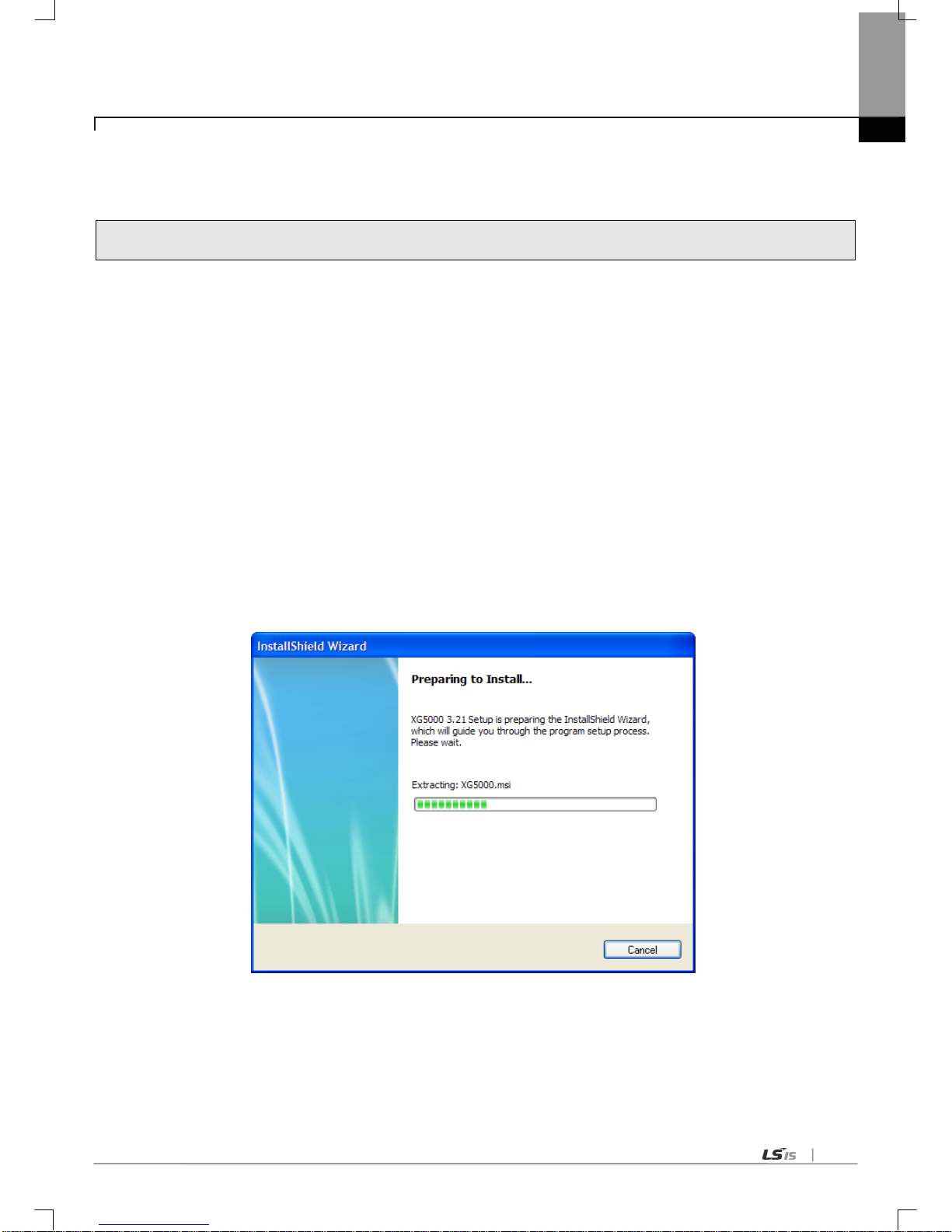

5.1.1 Installation of XG5000

1) Execute the installation file.

2) InstallShield Wizard prepares for installation as follows.

Chapter 5 Installation of Software and communication Parameters

5-2

3) Click [Next] button.

4) Insert a company’s name and press [Next] button.

5) Designate the folder t hat XG5000 wi ll be instal led. If you wan t to change th e folder, click [Browse] and enter or

select new folder. As XG5000 needs installation space of 500MByte, select t he disk with enough room. If the

installation room is not enough, warning message is on and thus, it is impossible to proceed to next step.

6) If you have selected a folder, press [Next] button.

Chapter 5 Installation of Software and communication Parameters

5-3

7) Check out the installation path and p ress [Next] button. Install as follows.

XG5000 USB device drive install screen appears while installing, and soon, installation is completed as follows.

Chapter 5 Installation of Software and communication Parameters

5-4

5.1.2 Installation of USB Device Drive

When you install XG5000 into Window XP for the first time, install USB Device Drive additionally. Even if USB is not

connected, install USB device drive as follows.

However, in Window 2000, USB device drive is automatically installed when XG5000 is installed, and in Window XP, install it

additionally.

1) Check out whether there are driver folders in the folder XG5000 has been installed into. In Drivers folder, there are

two drive files - GmUSBD.sys, GmUSBD.inf. If there is no folder or drive file, install XG5000 again.

2) Turn on PLC power and connect USB connector to PC. When connected, new hardware search Wizard Dialogue

Box appears

3) Order a user to install the device drive.

4) Select [Install from a list or specific location (Advanced)] of the options in new hardware search wizard dialogue box

and press [Next] button.

Chapter 5 Installation of Software and communication Parameters

5-5

5) Select [Search f or the best driver in these locations] of drive searc h options and c heck out [Include this locati on in the

search]

6) Press [Browse] button

Select Drivers Folder where XG5000 has been installed in “Browse for Folder”

Chapter 5 Installation of Software and communication Parameters

5-6

7) Press [Ok] button. The computer searches for the folder you selected.

8) If the computer selects the most suitable device drive, it will ask to install the device driver selected. As USB device driver

stably operates in Window operating system, press the button [Continue].

9) The com pletion of a d evice driver is completed; the dialogue box for installation like this appears. If you press

[Finish] button, driver installation is terminated.

Chapter 5 Installation of Software and communication Parameters

5-7

5.1.3 Confirmation on the Installation of USB Device Driver

If USB is not connected, confirm the installation of device driver as follows.

(1) Click the right button in [My Computer] on the desktop and select menu [Manage].

1) The computer managem ent dialogue box appears like this . In the left tree list of the dialogu e box, extension

proceeds in this order - [Computer Management (Local)] - [System Tool ] - [Device Manager].

2) The items appearing in th e list can differentl y come out with each ot her according to the devices installed in the

computer.

Chapter 5 Installation of Software and communication Parameters

5-8

(1) In case of normal state

If the list [LSIS XGSeries] located in the lower of [Universal Serial Bus controllers] appears, the device driver has

been normally installed.

(2) In case of abnormal state

The following illustration appears, it is the case the device drive has not normally been installed.

In case of not normally installed, reinstall according to the following order.

(3) Click the right button in the device driver where “Exclamation Mark” appears.

(4) Select Menu [Update Driver]

Chapter 5 Installation of Software and communication Parameters

5-9

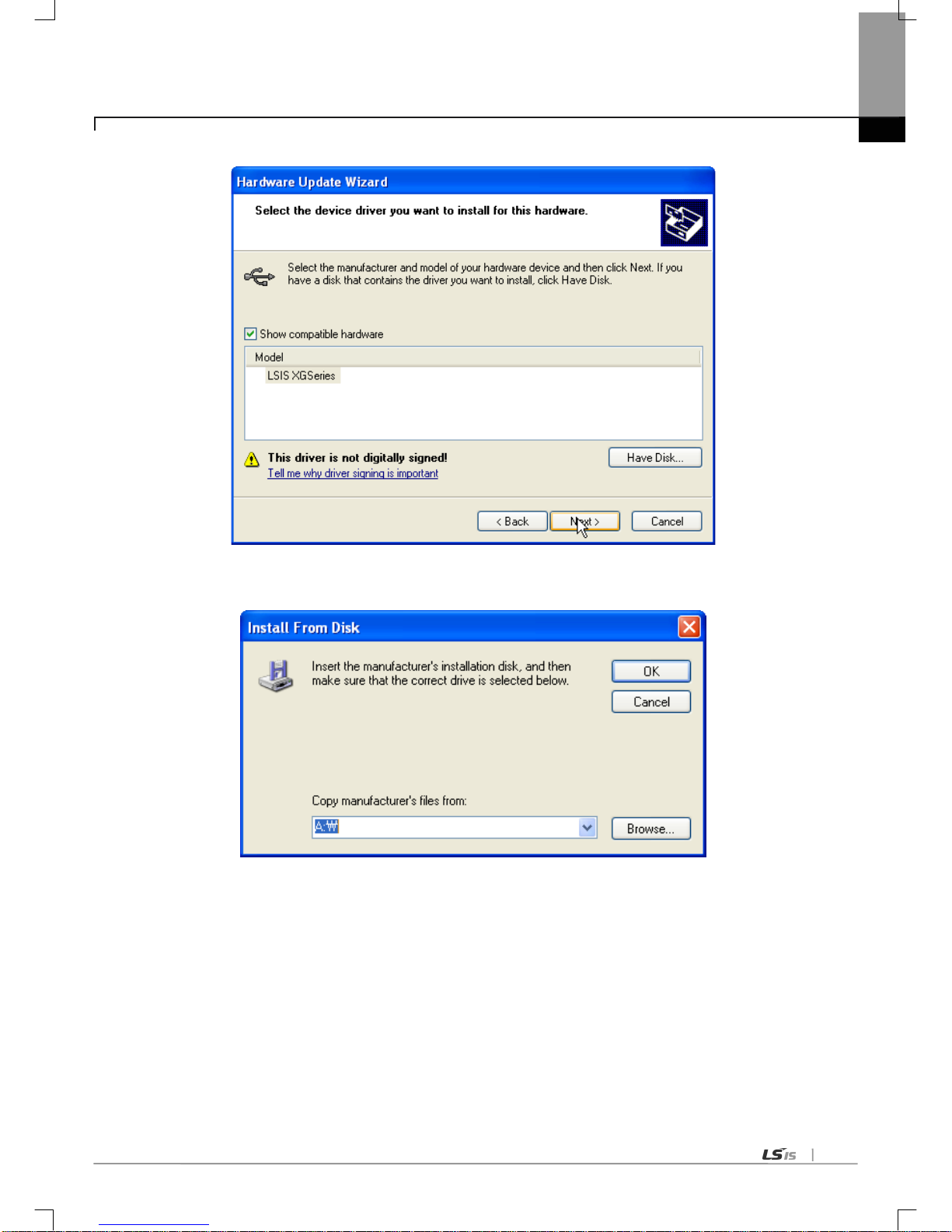

(5) Hardware Update Wizard Dialogue Box appears. Select Option [Install from a list or specific location

(Advanced)] List and press next button. The following procedures are manual and are the same to the installation

of the device driver.

Chapter 5 Installation of Software and communication Parameters

5-10

If not installed, reinstall according to the following order.

(1) In case a device driver has been wrongly installed or is problematic, execute Hardware Update Wizard Start.

(2) Select Option [Installation from a List or a specific location (Advanced)] List and press next button.

(3) On search and installation options, select [Don’t Search. I will choose the driver to install.] an d click [Next].

Chapter 5 Installation of Software and communication Parameters

5-11

(4) Click [Have Disk…] on the Dial og Box below.

(5) If Installation Dialogue Box appears from the disc appears, press button [Browse.]

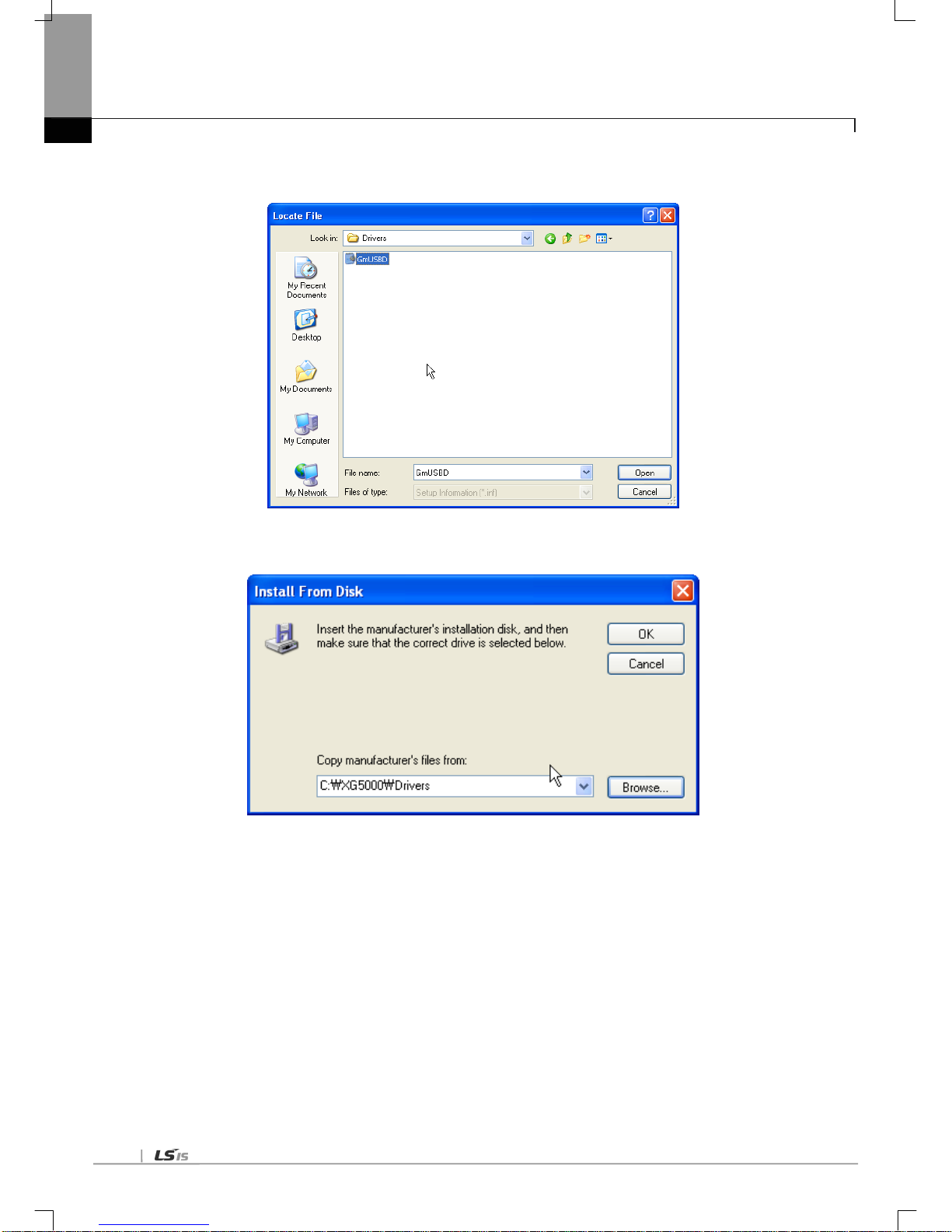

Chapter 5 Installation of Software and communication Parameters

5-12

(6) Move to the folder Fi le XG5000 has been installed f rom File Search Dialog ue Box. If drivers fold select ed,

GmUSBD.inf file appears. Select this file and press button [Open.].

(7)The directory with device driver files appears on the location of the manufacture’s file. Press button [Ok.].

Chapter 5 Installation of Software and communication Parameters

5-13

(8) On the compatible H/W display list of the device driver Select Dialog Box, select “LSIS XGSeries” driver and

then click [Next] button.

(9)The Dialogue Box for Hardware Installation appears. Press button [Continue] and proceed with installation.

Chapter 5 Installation of Software and communication Parameters

5-14

(10)Dialogue Box for Hardware Update Wizard Completed appears. Press button [Finish] and complete the

installation of device drive.

Chapter 5 Installation of Software and communication Parameters

5-15

5.2 How to Register Communication Modules

To use Ethernet/IP I/F modu le, communication parameter m ust be made up in XG5000 and to set up the s ystem on

Ethernet/IP I/F module, the module must be registered to XG5000.

How to register Ethernet/IP I/F module located at discretion is as follows in accordance with the state of on/off line.

5.2.1 In case of Offline

This is the way used in setting up communic atio n modules an d makin g up comm unicatio n related parameters in the

state of not connected with PLC. The execution method is as follows.

1) After execute XG5000, select [Project] [New Project ] o r cli ck ( ).

2) Create the projects that you will store in the project name, and select the names of the projects to be stored and the

CPU types of PLC that you selected.

3) If you register a communication module without connected to PLC, Use a “Communication module setting” window.

If Ethernet/IP is to be registered on base 0 and slot 1, Set it in the following procedure at a project Window.

a) Right click [unspecified Network] -> [add item] -> [Communication module]

[Fig 5.2.4] Select communication module menu

b) Click [Select communication module] -> [Add module]

Chapter 5 Installation of Software and communication Parameters

5-16

[Fig 5.2.5] Add module

c) [Communication module settings] -> select module type, base, slot

[Fig. 5.2.6] Communication module setting

Ethernet/IP module is registered on Slot 1 of Base 0 is as shown below;

[Fig. 5.2.7] Manually register communication module

Chapter 5 Installation of Software and communication Parameters

5-17

5.2.2 In case of Online

To register the communication modu le in online state, using XG 5000, the methods in NO . 1 and NO. 2 are t he s am e

as the one in registering modules of EtherNet/IP in offline state. The execution order afterwards is as follows.

1) If not connected, check out the state of connection with PLC or select [Online ]-> [Connection Set-up], or select the

connection met hod by clicking ic on . As a connection m ethod, there is a m ethod using RS-232C, a m ethod

using USB cables, and a method using Ethernet module and EtherNet/IP module. As a connection method, select

Local in case of directly connecting with PLC. The remote connection steps will be described in 7.4 remote

connection.

2) When normally connected, the lower menus of online menus are activated.

3) To check out the m odules installe d to the curr ent main unit, se lect [Online] [Diagnosis] [I/O information …],

communicatio n modules existing in the main unit are automatically searched for and the information of installation

modules appears on the project window. In case the module r egistered in offline state are different f rom the

information of PLC currently connected or kinds of communication modules, check out whether they have

changed or not with the above message.

4) The list of the communication module installed to a product is created on “Project Window.”

Chapter 5 Installation of Software and communication Parameters

5-18

Chapter 5 Installation of Software and communication Parameters

5-19

5.2.3 In case of Reading Parameter stored in PLC

The method for reading the basic set-up values for the communication module stored in PLC and for reading P2P setup values are in the below order.

1) Select [Project.] [Open from PLC…] or click ( ).

2) It is possible to check out the basic set-up values and P2P set-up values stored in PLC.

Chapter 5 Installation of Software and communication Parameters

5-20

5.2.4 How to Set-up Modules

T o operate EtherNet/IP I/F modules, set up in the following order.

1) Execution Order

(1) Enter in the Project Window

Please refer to 5.2.1 In case of Offline.

(2) I/O Information – Read

Please refer to 5.2.2 In case of Online

2) Operation Check –out

(1) Select [Online] → [Communication module setting] → [System Diagnosis] or click icon ( ).

(2) C lick the r ight butto n of the m ouse in the m odule of the ‘System Diagnosis ’ Window and c heck out whether

communication has been in normal state or not after c licking [Detailed Module Information…] or [Status By

Service…].

Chapter 5 Installation of Software and communication Parameters

5-21

5.2.5 Menu bar and shortcut of XG5000

The following is menu bar and short cut of XG5000. (For other menus, refer to XG5000 User’s Manual)

Menu bar

Menu

Icon

Contents

Project

New Project

Creates a new project.

Open Project

Opens the existing project.

Open from PLC

Uploads the pr oject and program stored

in PLC.

Open KGLWIN File

Opens the project file for KGLWIN.

Open GMWIN File

Opens the project file for GMWIN.

Save Project

Saves the project.

Save As

-

Saves the project as a different name.

Close Project

Closes the project.

Save as Binary

Saved as the b inary file that cannot show

the details of the project.

Write Binary to PLC

Writes the binary file with the PLC. You

cannot see the details of the project.

Add Item

Adds a new item to the project.

Import Item from File

Imports a ite m fro m a separated file.

Export to File

Saves the selected items included

opened project as separated file.

Save

Variable Names to

File

Saves variable names to file for using

other programs.

Save EtherNet/IP Tags to

File

Registers Eth er

Net/IP tag and sav es the

established EtherNet/IP tag list to the file.

Compare Projects

Compares two proj ects

stored in PC and

displays its result.

Print

Prints the active window’s details.

Preview

-

Previously displays the screen to be

printed.

Print Project

-

Selects the project item to print

Print Setup

-

Sets the printer options.

Edit

Undo

Cancels the edit on Program Edit Window

to recovers its previous status.

Redo

Recovers the ed it cancel led above.

Cut

Copies the selec ts block to c lipboard an d

deletes the block.

Copy

Copies the selects block to the clipboard.

Paste

Copies from the clipboard onto Edit

Window.

Delete

Deletes the selected block or items.

Chapter 5 Installation of Software and communication Parameters

5-22

Menu bar Menu Icon Contents

Online

Connect/Disconnect

Connects or disconnects with PLC.

Connect Settings

Specifies the c onnection method.

Change Mode Changes PLC mode.

Read

Reads parameter/program/comment from

PLC.

Write

Writes parameter/progr am/comment on PLC.

Compare with PLC

Compares the project to the project saved in

PLC

Set Flash Memory -

Shows the window for setting up the flash

memory.

Communication Module

Setting

Sets up Link-Enable and Upload/Download

EIP Tag

Reset/Clear Reset the PLC or Clear all memory

Diagnosis

Shows up the PLC information or history

windows

Tools

T emperatur e control

Executes the XG-TCON tool.

Position control

Executes the XG-PM tool.

Address calculator Executes the address calculator .

Star t simulator

Starts the simulator.

ASCII Table Displays the ASCII code t able.

Customize Users define tools, commands .

Options -

Can change the XG5000’s environment for a

user.

EDS

Register or delete the EDS file used for

EtherNet/IP module

N Configurator

Executes the N Configurator tool

Chapter 6 EIP Service

6

-1

Chapter 6 EIP Service

6.1 EtherNet/IP Communication Method

The communica nt methods of EtherNet/IP are div ided into Implicit Communica tion Method and Explicit Comm unication

Method and each method is again divided into client and server function. In XGB EtherNet/IP IF module, Implicit

communication m ethod is prov ided by period ic client /period ic server and explicit commu nication metho d is provided b y

aperiodic client/aperiodic server.

The periodic client/server is similar to th e h ig h s pee d link of the existing XGT communication ser vic e, which is the service

used when data is tr ans mitted and recei ve d p er iodically. The aperiodic client/s er v er m eth od is t he communication m eth od

used when particul ar e vents ha pp en . I n XGB EtherNet/IP I/F module these two services ar e inc orporated into EIP ser vice

and provided.

6.1.1 EtherNet/IP Terms

1) Implicit Messaging: Suggestive message, the m essage where t he header information oth er than data has been

implicate d to the min imum (In XGB EtherN et/IP I/F module the m essage is provid ed via client /per iodic server

communication)

2) Explicit Messaging: Clear message, including all information that can translate frames besides data

(In XGB EtherNet/IP I/F module the message is provided via aperiodic client communication)

3) Client: The subject requiring information

4) Server: The subject that provides information at request

5) Producer: The entity that create producers, information

6) Consumer: The entity that receives consumer information and consumes it

7) Tag: Nameplate , Named Variable

8) EDS File: The abbre viation for Electric Data S heets. The file where the inf ormation on the device and on the

communication set –up is recorded

9) RPI: The abbreviation for Requested Packet Interval, meaning the period when Packet will be sent

(In XGB EtherNet/IP I/F module, pac ket is provided at transmission period)

6.1.2 EDS File

Electrical Description Script (EDS) File is a description on devices and it includes the information about a product type

and connect ion, as well as Vendor ID. In Et herN et/I P I/F module it is the b asic pr incip le t o s et up us ing EDS Fi le. To

install EDS Fie, EDS register menu of XG5000 should be set up.

Chapter 6 EIP Service

6-2

6.1.3 Periodic Communication (Implicit) System

Implicit Message provided in periodic communication in XGB EtherNet/IP I/F module means a suggestive and implied

message. As this m essage c ontai ns head er i nform ation to t he m inimum exc ept for t he data in f rame, it als o refer s to

the message which is im poss ible t o see what da ta means. In addit ion, if we trans la te it in differe nt way, this message

means that header information is small in quantity, so the process of translating the frame has been simplified and it is

possible to process data quickly. In EtherNet/IP, connection between client and server is set up with the parameter for

sending this da ta.

Client requires connect ion and it bec om es the object t ha t recei ves an d cons um es data, and s ev er com es to tr ansm it

the said data in tra nsmission period ( Re qu es t ed P acket Interval: RPI) and communication method (Unicast/Multicast)

like the way client wants Thus, client comes to set u p consumed tag and server w ill set up produced tag (XGT

EtherNet/IP IF: Input Only Type).

[Figure 6.1] Client and Server in XGT EtherNet/IP I/F - Module Periodic Communication

Notice

Implicit Server is created also in Implicit Client. Server can set up timeout in the period that client grants according to types.

Using data that client provides, it is possible to output to his own module .

Chapter 6 EIP Service

6

-3

Operating procedure of periodic communication is as follows.

Client

Time

①

Connection request

(

SYN)

Time

②

Connection request

response

(

SYN ACK

)

③

Connection confirm

response

(

ACK

)

④

Request

(PUSH ACK

)

⑤

Request

(

PUSH ACK)

⑨

Disconnection request

(

FIN ACK)

⑩

Disconnection confirm

(

ACK)

⑪

Disconnection

(

RST)

Server

Destination port

:

44818

Connection

Disconnection

Connection

Disconnection

Session register

request

Native Session ID

response

Receiving port:

44818

●

●

●

⑥

Request

(

PUSH ACK)

⑦

Reponse

(PUSH ACK)

ForwardOpen

request

T2

O, O

2T

Connection ID

response

⑧

O2

T IO Data

(O2

T Connection ID)

Source port: 2222

Destination port

:

2222

(

UDP)

⑧

T2O IO Data

(

T2O Connection ID

)

Source port

: 2222

Destination port:

2222

(

UDP)

[Figure 6.2] Operating procedure of periodic communication

Chapter 6 EIP Service

6-4

6.1.4 Aperiodic Communication (Explicit) System

Explicit Messa ge provided in aperiod ic communication from XGB EtherNe t/IP I/F module means clear a nd explicit

message. This mess ag e a ls o m eans t h at all inf ormation which is poss i bl e to tr ans lat e da ta to dat e frame. Thus, even

though it takes some time to translate frame, if the message we want is sent without the process of setting parameter,

frame is translated from server and the response is made.

In general it is utilized as monitoring data to aperiodic data rather than control data.

The following table shows the parameter items set up when XGB EtherNet/IP I/f module is used.

Inferior

Configuration

Set-up Items Set-up Scope

Set-up or Not

Remarks

Periodic

Client

Periodic

Server

Aperiodic

Client

EIP

Configuration

- O X X

Drag & drop from EDS File

EIP Channel

-

0-15 X O

O

Set up other’s IP

EIP Block Channel 0-15

O O O

Enter the channel y ou will use of set up

channels in EIP channel

Operation

Mode

Pursuant to

EIP Channel

O O O

Automatically displayed in accordance

with set up channels

I/O Ty pe Defined in

EDS

O X X

Select I/O type defined in EDS

Connection

Type

Multicast,

Point to Point

O X X

Select one among connection types

defined in EDS

Function Write, Read,

Tag Read,

T ag Write

X X O

Select one among aperiodic client s

Parameter Parameter

item O X O

Set up the parameter defined in ED S

- In case of aperiodic client, only

read/write can be set up for read /writ e

Parameter

Contents

Defined in

parameter

X X -

Display the contents set up in the

Parameter

Mobile

Conditions

Contact Point

X X O

Set up mobile conditions

Transmitting

Period

20-10000

O X X

Period transmitting d ata

Timeout x4/8/16/32/64

/128/256/512

O X X

Transmission Period x Timeout(x4/8/16

/32/64/128/256/512)

Data Ty pe BIT,1/2/4/8

BYTE

O O O

Set up a data type

T ag Set- up/

Local T ag

PLC Device

O O O

The device area of the local axis where

“Write” or “Read” is executed you w ill

T ag Set- up/

Remote T ag

Destination

TAG name

O X O

Designate Other’s T AG

T ag Setup/Size

O O O

Periodic Client/Server : Maximum 500

Byte

Aperiodic Client : Maximum 512 Byte

Chapter 6 EIP Service

6

-5

Notice

1) Data type: The data type is the same as above table for XBL-EIPT V1.x, and the same as the registered tag type for V2.0 or later.

BOOL(BIT), BYTE, WORD, DWORD, LWORD, SINT, INT, DINT, LINT , USINT, UINT , UDINT, ULINT, REAL, LREAL types are av ailable.

The data size in V1.x i

s fixed at 1 for BIT and 2 BYTE in case of periodic server, but in V2.0 and above, size and type are the same as

registered tags.

2) T ag setting / Loc al tag: When XBL-EIPT V2.0 or later is used, tag name can be up to 38 characters for XBC/XBM and up to 46 characters