Right choice for ultimate yield

LSIS strives to maximize customers' profit in gratitude of choosing us for your partner.

Programmable Logic C ontroller

XGB Cnet I/F

User’s Manual

Read this manual carefully before

installing,

wiring, operating, servicing

or inspecting this equipment.

Keep this manual within easy reach

for quick reference.

XGT Series

http://www.lsis.com

Main Unit

Built

-in Cnet

S TYPE

E TYPE

S TYPE

SU TYPE

H TYPE

Cnet I/F

module

XBL-C41A

XBL

-C21A

XBM

XBC

/XEC

XBC

/XEC

XBC

/XEC

XBC

/XEC

Safety Instruction

Before using the product …

For your safety and effective operation, please read the safety instructions

thoroughly before using the product.

► Safety Instructions should always be observed in order to prevent accident

or risk by using the product properly and safely.

► Precautious measures can be categorized as “Warning” and “Caution”, and

each of the meanings is as follows.

This symbol indicates the possibility of serious injury

or death if some applicable instruction is violated

This symbol indicates the possibility of severe or

slight injury, and damages in products if some

applicable instruction is violated

Moreover, even classified events under its caution category may develop into

serious accidents depending on situations. Therefore we strongly advise users

to observe all precautions in a proper way just like warnings.

► The marks displayed on the product and in the user’s manual have the

following meanings.

Be careful! Danger may be expected.

Be careful! Electric shock may occur.

After reading this user’s manual, it should be stored in a place that is visible

to product users.

Warning

Caution

Safety Instruction

Safety Instructions when designing

Please, install protection circuit on the exterior of PLC to protect

the whole control system from any error in external power or PLC

module. Any abnormal output or operation may cause serious problem

in safety of the whole system.

- Install applicable protection unit on the exterior of PLC to protect

the system from physical damage such as emergent stop switch,

protection circuit, the upper/lowest limit switch, forward/reverse

operation interlock circuit, etc.

- If any system error (watch-dog timer error, module installation error,

etc.) is detected during CPU operation in PLC, the whole output is

designed to be turned off and stopped for system safety. However,

in case CPU error if caused on output device itself such as relay or

TR can not be detected, the output may be kept on, which may

cause serious problems. Thus, you are recommended to install an

addition circuit to monitor the output status.

Never connect the overload than rated to the output module nor

allow the output circuit to have a short circuit, which may cause a

fire.

Never let the external power of the output circuit be designed to

be On earlier than PLC power, which may cause abnormal output or

operation.

In case of data exchange between computer or other external

equipment and PLC through communication or any operation of

PLC (e.g. operation mode change), please install interlock in the

sequence program to protect the system from any error. If not, it

may cause abnormal output or operation.

Warning

Safety Instruction

Safety Instructions when designing

Safety Instructions when designing

I/O signal or communication line shall be wired at least 100mm

away from a high-voltage cable or power line. If not, it may cause

abnormal output or operation.

Caution

Use PLC only in the environment specified in PLC manual or

general standard of data sheet. If not, electric shock, fire, abnormal

operation of the product or flames may be caused.

Before installing the module, be sure PLC power is off. If not,

electric shock or damage on the product may be caused.

Be sure that each module of PLC is correctly secured. If the

product is installed loosely or incorrectly, abnormal operation, error or

dropping may be caused.

Be sure that I/O or extension connecter is correctly secured. If

not, electric shock, fire or abnormal operation may be caused.

If lots of vibration is expected in the installation environment,

don’t let PLC directly vibrated. Electric shock, fire or abnormal

operation may be caused.

Don’t let any metallic foreign materials inside the product, which

may cause electric shock, fire or abnormal operation..

Caution

Safety Instruction

Safety Instructions when wiring

Prior to wiring, be sure that power of PLC and external power is

turned off. If not, electric shock or damage on the product may be

caused.

Before PLC system is powered on, be sure that all the covers of

the terminal are securely closed. If not, electric shock may be caused

Warning

Let the wiring installed correctly after checking the voltage rated

of each product and the arrangement of terminals. If not, fire,

electric shock or abnormal operation may be caused.

Secure the screws of terminals tight ly with specified torque when

wiring. If the screws of terminals get loose, short circuit, fire or abnormal

operation may be caused.

*

Surely use the ground wire of Class 3 for FG terminals, which is

exclusively used for PLC. If the terminals not grounded correctly,

abnormal operation may be caused.

Don’t let any foreign materials such as wiring waste inside the

module while wiring, which may cause fire, damage on the product

or abnormal operation.

Caution

Safety Instruction

Safety Instructions for test-operation or repair

Safety Instructions for waste disposal

Don’t touch the terminal when powered. Electric shock or abnormal

operation may occur.

Prior to cleaning or tightening the terminal screws, let all the

external power off including PLC power. If not, electric shock or

abnormal operation may occur.

Don’t let the battery recharged, disassembled, heated, short or

soldered. Heat, explosion or ignition may cause injuries or fire.

Warning

Don’t remove PCB from the module case nor remodel the module.

Fire, electric shock or abnormal operation may occur.

Prior to installing or disassembling the module, let all the external

power off including PLC power. If not, electric shock or abnormal

operation may occur.

Keep any wireless installations or cell phone at least 30cm away

from PLC. If not, abnormal operation may be caused.

Caution

Product or battery waste shall be processed as industrial waste.

The waste may discharge toxic materials or explode itself.

Caution

Revision History

V

ersion Date Remark Page

V 1.0 2006.6

1. First Edition -

V 1.1 2007.7 1. Position and Special function contents separated

(1) Position function contents separated

(position part published)

(2) PID control and Ch. 12 Analog IO module contents

separated

2. Contents added

(1) Naming standard added

(2) Caution when selecting IO module added

(3) Installation and wiring contents added

3. Content modified

(1) Safety instruction modified

(2) System Configuration modified

(3) High speed counter function modified

(4) External dimension modified

-

-

2-3 ~ 2-6

7-1 ~ 7-6

10-1 ~ 10-18

1 ~ 6

2-7 ~ 2-10

8-6 ~ 8-8

App. 2-1 ~ 2-4

V 1.2 2008.3 1. XGB compact type ‘H’ type added

2. Built-in communication content separated

(1) Ch.9 built-in communication function separated

(Cnet I/F user manual)

-

Ch. 9

V 1.3 2010.3 1. XEC compact type added -

V 1.4 2010.5

1. Standard format applied

2. Modbus protocol added

3. Contents changed

(1) Ch. 5 Communication function

→ Ch. 6 Server function and P2P service

(2) Ch. 6 Remote connection → Ch. 5 Remote connection

-

Ch. 8

Ch. 5, Ch. 6

V 1.5 2013.4

1. Main unit added

(1) XBC/XEC ‘E’ type

(2) XBC/XEC ‘S/SU’ type

(3) XBC/XEC ‘H’ type

2. Contents added

(1) ‘NOTE’ for XGT Dedicated Protocol

2-4 ~ 2-7

7-6

V 1.6 2014.3

1. LS Bus Protocol added

2. Ch.8 ~ Ch.12 → Ch.9 ~ Ch.13

3. Applicable device revised

Ch.8

Ch.9 ~ Ch.13

Ch.7

※ The number of User’s manual is indicated the right side of the back cover.

Copyrights ⓒ 2006 LSIS Co., Ltd All Rights Reserved.

About User’s Manual

About User’s Manual

Congratulations on purchasing PLC of LSIS Co.,Ltd.

Before use, make sure to carefully read and understand the User’s Manual about the functions,

performances, installation and programming of the product you purchased in order for correct use and

importantly, let the end user and maintenance administrator to be provided with the User’s Manual.

The Use’s Manual describes the product. If necessary, you may refer to the following description and order

accordingly. In addition, you may connect our website(http://eng.lsis.biz/

) and download the information as a

PDF file.

Relevant User’s Manual

Title Description

No. of User

Manual

XG5000 User’s

Manual

It describes how to use XG5000 software especially about

online functions such as programming, printing, monitoring

and debugging by using XGT series products.

10310000512

XGK/XGB Series

Instruction &

Programming

It describes how to use the instructions for programming

using XGK/XGB series.

10310000510

XGB Hardware

User’s Manual

It describes how to use the specification of power/input

/output/expansion modules, system configuration and built-in

High-speed counter for XGB basic unit.

10310000926

XGB Analog

User’s Manual

It describes how to use the specification of analog

input/analog output/temperature input module, system

configuration and built-in PID control for XGB basic unit.

10310000920

XGB Position

User’s Manual

It describes how to use built-in positioning function for XGB

unit.

10310000927

XGB Cnet I/F

User’s Manual

It describes how to use built-in communication function for

XGB basic unit and external Cnet I/F module.

10310000816

XGB Fast Ethernet I/F

User’s Manual

It describes how to use XGB FEnet I/F module.

10310000873

◎

Contents

◎

Chapter 1 General---------------------------------------------------------------------------------------------- 1-1 ~ 1-2

1.1 General --------------------------------------------------------------------- 1-1

1.2 Characteristic--------------------------------------------------------------- 1-2

Chapter 2 Specification -------------------------------------------------------------------------------------- 2-1 ~ 2-9

2.1 General Specification ------------------------------------------------------------------------- 2-1

2.2 Performance Specification -------------------------------------------------------------------- 2-3

2.3 Name and Function of each part ---------------------------------------------------------- 2-5

Chapter 3 System Configuration--------------------------------------------------------------------------3-1~ 3-10

3.1 XGB System Configuration ------------------------------------------------------------- 3-1

3.1.1 “H” type system configuration --------------------------------------------------- 3-1

3.1.2 “S” type System Configuration ---------------------------------------------------- 3-2

3.2 Available System Configuration ------------------------------------------------------------ 3-3

3.2.1 1:1 Connection between PC (HMI) (No modem) -------------------------------------- 3-3

3.2.2 1:1 Dedicated modem c onnection with PC (HMI) ---------------------------------------- 3-6

3.2.3 Modem conn ect ion w i th PC an d c om munication between Cnet I/F modules -------- 3-7

3.2.4 Dedicated communication with PC (HMI) and different type RS-422 communication ---- 3-8

3.2.5 Optical modem communication for moving material communication ------------------- 3-9

3.2.6 Wireless modem communication for communication between revolution bodies --------------- 3-10

Chapter 4 Basic Setting -------------------------------------------------------------------------------------- 4-1 ~ 4-8

4.1 Setting Sequence of Product --------------------------------------------------------- 4-1

4.2 PLC Type Setting an d Ho w t o Register Communication Module --------------------------------- 4-2

4.2.1 Making new project ---------------------------------------------------- 4-2

4.2.2 In case of off line, method on Cnet I/F module registration -------------------- 4-2

4.2.3 How to register Cnet I/F module in case of online ---------------------- 4-3

4.3 How to Set Basic Parameter ------------------------------------------------------- 4-5

4.3.1 Setting item ------------------------------------------------------------- 4-6

4.2.2 Setting method ------------------------------------------------------------ 4-7

Chapter 5 Remote Connection -------------------------------------------------------------------------- 5-1 ~ 5-12

5.1 Server Modbus Service ----------------------------------------------------------------- 5-1

5.1.1 General ---------------------------------------------------------------------------- 5-1

5.1.2 XG5000 remote connection -------------------------------------------------------- 5-2

5.1.3 Remote connection between Cnet I/F modules-------------------------------- 5-8

Chapter 6 Server function and P2P service---------------------------------------------------------- 6-1 ~ 6-12

6.1 Server Modbus Service----------------------------------------------------------------------------- 6-1

6.1.1 General ------------------------------------------------------------------------------------ 6-1

6.1.2 XGT dedicated server------------------------------------------------------------------- 6-2

6.1.3 Modbus server ----------------------------------------------------------------------- 6-2

6.2 P2P Service ---------------------------------------------------------------------------- 6-4

6.2.1 General ------------------------------------------------------------------------------------------------- 6-4

6.2.2 P2P param eter configuration -------------------------------------------------------------------- 6-5

6.2.3 Channel inform ation -------------------------------------------------------------------------------- 6-5

6.2.4 Block information -------------------------------------------------------------------------------- 6-7

6.2.5 User defined frame information ----------------------------------------------------------------- 6-11

6.2.6 P 2P service operatio n ---------------------------------------------------------------------------- 6-21

Chapter 7 XGT Dedicated Protocol -------------------------------------------------------------------- 7-1 ~ 7-19

7.1 XGT Dedicated Protocol ---------------------------------------------------------- 7-1

7.1.1 General ---------------------------------------------------------------------------- 7-1

7.1.2 Frame structure ----------------------------------------------------------------- 7-2

7.1.3 List of commands ----------------------------------------------------------------- 7-3

7.1.4 Data type ----------------------------------------------------------------------- 7-4

7.1.5 Detail of instruction ---------------------------------------------------------- 7-6

Chapter 8 LS Bus Protocol ------------------------------------------------------------------------------- 8-1 ~ 8-6

8.1 LS Bus Protocol -------------------------------------------------------------------------------- 8-1

8.1.1 Frame structure ---------------------------------------------------------------------------- 8-1

8.1.2 List of commands ------------------------------------------------------------------------ 8-2

8.2 Detail of instruction -------------------------------------------------------------------------------- 8-1

8.2.1 Continuous wr iting to inverter dev ice (W) ----------------------------------------------------- 8-3

8.2.2 Inverter continuous r eading (R) ----------------------------------------------------------------- 8-5

Chapter 9 Modbus Communication -------------------------------------------------------------------- 9-1 ~ 9-15

9.1 General ------------------------------------------------------------------------------------------------ 9-1

9.2 Modbus Protocol -------------------------------------------------------------------------------------- 9-1

9.2.1 Kind of modbus protocol------------------------------------------------------------------- 9-1

9.2.2 Structure of modbus protocol------------------------------------------------------------------ 9-1

9.3 Structure of Frame --------------------------------------------------------------------------------------- 9-3

9.3.1 Structure of Frame in the ASCII mode -------------------------------------------------------- 9-3

9.3.2 Frame structure in the RTU mode ----------------------------------------------------- 9-3

9.3.3 Data and expression of address -------------------------------------------------------- 9-4

9.4 Modbus Protocol------------------------------------------------------------------------------------ 9-6

9.4.1 Reading data of bit t ype a t t he bit o utput (01) ------------------------------------------------ 9-6

9.4.2 Read Input Status (02) ----------------------------------------------------------------------- 9-7

9.4.3 Read Ho lding Regist ers (03)---------------------------------------------------------------------- 9-8

9.4.4 Read Input R egisters ( 04) ------------------------------------------------------------------------- 9-9

9.4.5 Force Single Coil (05) ----------------------------------------------------------------------------- 9-10

9.4.6 Preset Single R egiste r (06) ----------------------------------------------------------------------- 9-11

9.4.7 Force Multip le Coils (0F) ------------------------------------------------------------------------- 9-12

9.4.8 Preset Multi ple Regis ters (10) ------------------------------------------------------------------ 9-14

Chapter 10 Example Program------------------------------------------------------------------------- 10-1 ~ 10-25

10.1 Setting of Cnet I/F module in the XG-PD ------------------------------------------ 10-1

10.1.1 In case of acting as server ------------------------------------------------- 10-1

10.1.2 In case of acting as P2P service (client) -------------------------------- 10-3

10.2 Dedicated Communication Example ------------------------------------------------------- 10-6

10.2.1 Settings of XGT server ---------------------------------------------------- 10-7

10.2.2 Settings of XGT client ---------------------------------------------------- 10-8

10.2.3 Checking the operation ------------------------------------------------------ 10-11

10.3 Modbus Communication Example ----------------------------------------------------- 10-12

10.3.1 Modbus RT U ser ver setting ------------------------------------------------------------------ 10-13

10.3.2 Setting of Modbus RTU client ----------------------------------------------------------- 10-15

10.4 User defined Comm unicat ion Exam ple ------------------------------------------------------------- 10-20

10.4.1 User define d c om m unication example syst em configuration ------------------------ 10-20

10.4.2 User definition com munic ation fram e structure ----------------------------------------- 10-21

10.4.3 User def initi on com m unication paramet er setti ng -------------------------------------- 10-22

Chapter 11 Diagnosis ------------------------------------------------------------------------------------- 11-1 ~ 11-8

11.1 Diagnosis F unction of XG-PD -------------------------------------------------------------------------- 11-1

11.1.1 Check ing status of main unit ------------------------------------------------------------------- 11-2

11.1.2 Communication m odule information --------------------------------------------------------- 11-2

11.1.3 Frame monitor ------------------------------------------------------------------------------------- 11-3

11.1.4 Status by service ---------------------------------------------------------------------------------- 11-4

11.2 Trouble Shooting by Error ------------------------------------------------------------------------------ 11-6

11.2.1 Trouble shooing when P2P parameter setting error occurs in case of XG5000

connection -------------------------------------------------------------------------------------------11-6

11.2.2 Trouble shooting when communication is not done after P2P client setting - 11-6

11.2.3 Trouble shooting when response frame is missed in case of acting as client and

using RS-485 ----------------------------------------------------------------------------------------------- 11-7

11.2.4 Two response fram e are deal t with as unk no wn when ex ecuting f ram e m onitor --11-7

11.2.5 Una ble to anal yze TRX fr ame ----------------------------------------------------------------- 11-7

11.2.6 Unab le to know which one is reason of error, client or server ------------------------ 11-7

11.2.7 Communication is not normal or communication is not executed repeatedly

-------------------------------------------------------------------------------------------------11-8

Chapter 12 Installation and Wiring ------------------------------------------------------------------ 12-1 ~ 12-24

12.1 Safety Instruction ------------------------------------------------------------------------------------------- 12-1

12.1.1 Fail safe circuit -------------------------------------------------------------------------- 12-3

12.1.2 PLC heat calculation -------------------------------------------------------------- 12-6

12.2 Attachment/Detachment of Modules -------------------------------------------------------- 12-8

12.2.1 Attachment/Detachment of modules ------------------------------------------------ 12-8

12.2.2 Caution in handling -------------------------------------------------------------------- 12-12

12.3 Wire -------------------------------------------------------------------------------------------------- 12-13

12.3.1 Power wiring --------------------------------------------------------------------------- 12-13

12.3.2 I/O Device wiring ----------------------------------------------------------------- 12-16

12.4 Channel Operation during Normal Run -------------------------------------------------- 12-17

12.5 Communication Interface Connection Method ------------------------------------------------ 12-18

12.5.1 RS-232C Interface (XBL-C21A) ---------------------------------------------------- 12-18

12.5.2 RS-422/485 interface (Built-in communication) ------------------------------- 12-20

12.5.3 RS-422 interface (XBL-C41A) ---------------------------------------------------- 12-21

12.6 Cable Specifications --------------------------------------------------------------------------- 12-23

12.6.1 Electrical characteristic ------------------------------------------------------------- 12-23

12.5.2 External characteristic ------------------------------------------------------------ 12-23

12.7 Terminal Resistance -------------------------------------------------------------------------- 12-24

Chapter 13 Maintenance --------------------------------------------------------------------------------- 13-1 ~ 13-2

13.1 Maintenance and Inspection -------------------------------------------------------------- 13-1

13.2 Daily Inspection ------------------------------------------------------------------------------ 13-1

13.3 Periodic Inspection --------------------------------------------------------------------------------- 13-2

Appendix ------------------------------------------------------------------------------------------------------- A-1 ~ A-17

Appendix 1 Definition of Terms ------------------------------------------------------------------ A-1

Appendix 1.1 General Terms --------------------------------------------------------------------------- A-1

Appendix 1.2 Serial Communication Terms ----------------------------------------------- A-2

Appendix 2 Communication Relay List (L) -------------------------------------------------------------- A-8

Appendix 2.1 Communication Relay (L) List ---------------------------------------------- A-8

Appendix 2.2 Network Register (N) List -------------------------------------------------- A-11

Appendix 3 Communication Error Code ------------------------------------------------------------- A-12

Appendix 3.1 XGT Server Error Code -------------------------------------------------- A-12

Appendix 3.2 Modbus Server Error Code --------------------------------------------- A-13

Appendix 3.3 P2P Client Error Code ------------------------------------------------------------- A-13

Appendix 4 Dimension (Un it: mm) -------------------------------------------------------------------------- A-14

Chapter 1 General

1-1

Chapter 1 General

1.1 General

This user manual provides the information of Cnet I/F among XGB PLC system network about

specification/performance and how to operate.

Configuration of user manual is as follows.

Chapter Item Content

1 General Describes configuration of manual, product characteristic and term

2 Specification

Indicates general specification and performance specification of each m odule

used XGB PLC.

3 System configuration Describes basic communication parameter setting.

4 Basic setting Describes basic communication setting

5

Communication

function

Describes server for data communication between PLC and P2P parameter

setting.

6 Remote connection

Describes CPU connection method by communication chann el through

XG5000, XG-PD.

7

XGT dedicated

protocol

Describes XGT dedicated communication frame structure.

8 Example program Describes example program for communication test.

9 Diagnosis function Describes about self diagnosis by XG-PD.

10

Installation and

wiring

Describes installation and wiring.

11 Maintenance Describes maintenance.

App.1 Term Describes term used in this manual

App.2 Flag list Describes parameter setting N area, flag L related with Cnet I/F.

App.3

Communication error

code

Describes XGT server, modbus server, P2P error code.

App.4 Dimension Describes dimension of communication module.

Chapter 1 General

1-2

1.2 Characteristic

(1) By using XG-PD operated in window environment, since the user can write communication speed,

communication mode (protocol), connection with external device is easy.

(2) RS-232C 1 port, RS-485 1 port as main unit built-in Cnet is supported. Two type of Cnet I/F

module as extension, RS-232C 1 port (XBL-C21A), RS-422(485) 1port (XBL-C41A) is provided.

(3) It operates independently according to channel, since protocol data written by user is managed by

main unit, in case communication module is changed other than communication module,

additional setting/download is not necessary.

(4) Device read/write by using XGT dedicated/modbus/user defined protocol is available.

(5) It provides communication function in which multidrop, up to 32 connection is available in case of

using RS-422/485.

(6) Setting of diverse communication speed is available.

(1200,2400,4800,9600,19200,38400,57600,115200bps)

(7) 1:1 and 1:N communication are available.

(8) With abundant self-diagnosis, trouble diagnosis is simple.

(9) It supports dedicated server/client, modbus server/client, user defined communication function.

(10) In case of XBL-C21A module, modem communication is provided, by which controlling remote

PLC is available.

Chapter 2 specification

2-1

Chapter 2 Specification

2.1 General Specification

General specification of XGB PLC is as follows.

No. Item Specification Related specifications

1

Operating

temp.

0℃∼+55℃

2 Storage temp. -25℃∼+70℃

3

Operating

humidity

5∼95%RH, no dew allowed

4

Storage

humidity

5∼95%RH, no dew allowed

5

Vibration

proof

For discontinuous vibration

Frequency Acceleration Amplitude Number

IEC 61131-2

10≤f< 57㎐ - 0.075mm

Each 10 times

in X,Y,Z

directions

57≤f≤150㎐ 9.8㎨ -

For continuous vibration

Frequency Acceleration Amplitude

10≤f< 57㎐ - 0.035mm

57≤f≤150㎐ 4.9㎨(0.5G) -

6 Impact proof

* Max. impact acceleration: 147㎨(15G)

* Authorized time: 11㎳

* Pulse wave : Sign half-wave pulse

(

Each 3 times in X,Y,Zdirections

)

IEC 61131-2

7 Noise proof

Square wave impulse noise AC:±1,500V, DC: 500 V

Test spec of LS

Industrial Systems

Static electric discharging

Voltage: 4 kV

(contact discharging),

8 kV (air discharging)

IEC 61131-2,

IEC 61000-4-2

Radiation electromagnetic 80 ~ 1,000MHz, 10 V/m

IEC 61131-2,

IEC 61000-4-3

Fast

Transient

/burst

noise

Class

Power

module

Digital/

Analog I/O

communication interface

IEC 61131-2,

IEC 61000-4-4

Voltage 2kV 1kV

8

Ambient

conditions

No corrosive gas or dust

9

Operating

height

2000m or less

10 Pollution level 2 or less

11 Cooling type Natural air cooling

Chapter 2 specification

2-2

[1] IEC (International Electro technical Commission):

An international nongovernmental organization which promotes internationally cooperated

standardization in electric/electronic fields, publishes international standards and manages applicable

estimation system related with.

[2] Pollution level: An index indicating pollution level of the operating environment which decides

insulation performance of the devices. For instance, Pollution level 2 indicates the state generally that

only non-conductive pollution occurs. However, this state contains temporary conduction due to dew

produced.

Notes

Chapter 2 specification

2-3

2.2 Performance Specification

(1) Built-in Cnet performance specification

Performance specification of XGB built-in Cnet is as follows.

Item

Specification

Channel 1

Channel 2

Serial communication

method

RS-232C RS-485

Modem connection

function

- -

Operation

mode

(Operation

define by

channel)

P2P

Act as communication client

- XGT dedicated protocol client

- Modbus ASCII/RTU client

- User defined communication

- LS Bus Client

Notes 1)

Server

- XGT dedicated protocol server

- Modbus ASCII/RTU server

Data

type

Data bit

7 or 8

Stop bit

1 or 2

Parity

Even/Odd/None

Synchronization type

Asynchronous type

Transmission speed

(bps)

1200/2400/4800/9600/19200/38400/57600/115200 bps available

Station No. setting

Setting range: 0~255

Max. station No. available: 32 stations

Transmission

distance

Max. 15m Max. 500m

Diagnosis function Check available by XG-PD diagnosis service

Notes

Notes 1) < LS Bus Client applicable version>

Series XBM XBCH XBCSU XBCS XBCE XG5000

Version V3.40 or above V2.30 or above V1.40 or above V1.30 or above V1.20 or above V3.69 or above

Series XBCEX XBCEB XECH XECSU XECE -

Version V1.01 or above V1.01 or above V1.70 or above V1.30 or above V1.10 or above

-

Chapter 2 specification

2-4

(2) Extension Cnet performance specification

XGB extension Cnet communication module performance specification is as follows

Item

Specification

XBL-C21A

XBL-C41A

Serial communication

channel

RS-232C 1 channel RS-422(485) 1 channel

Modem connection

function

External modem connection available -

Operation

mode

(Operation

definition

by port)

P2P

Operates as communication client

- XGT dedicated protocol client

- Modbus ASCII/RTU client

- User defined communication

- LS Bus Client

Server

- XGT dedicated protocol server

- Modbus ASCII/RTU server

Data

type

Data bit

7 or 8

Stop bit

1 or 2

Parity

Even/Odd/None

Synchronization type

Asynchronous type

Transmission speed

(bps)

1200/2400/4800/9600/19200/38400/57600/115200 bps available

Station No. setting

Setting range: 0~255

Max. station No. available: 32 stations

Transmission

distance

RS-232C: 15m

(Extension available in c ase of using

modem)

RS-422/485: max 500m

Diagnosis function Check available by LED and XG-PD diagnosis service

Consumption current

120mA

120mA

Weight

56g

56g

Chapter 2 specification

2-5

2.3 Name and Function of each part

XBM “S” Type

No. Name Purpose

①

Input indication LED Input indication LED

②

PADT connection

connector

PADT connection connector

③

Input connector and

terminal block

Input connector and terminal block

④

Output connector and

terminal block

Output connector and terminal block

⑤

Key switch

RUN / STOP key switch

- In case key switch is STOP, remote mode change available

⑥ Output indication LED Output indication LED

⑦

Status indication LED

Indicates operation status of CPU module

- PWR(Red): Power status indication

- RUN(Green): RUN status indication

STOP mode: Off / RUN mode : On

- Error(Red): Flicker in case error occurs

⑧

8-1

Built-in RS-485

Connection

connector

Built-in RS-485 connection connector

- “+”, “-“ terminal connection connector ofRS-485 communication

8-2

Built-in RS-232C

connection

connector

Built-in RS-232C connection connector

-“TD”, “RD”, “SG” terminal connection connector of RS-232C

communication

8-3 Power connector DC24V power connector

①

②

④

⑤

⑥

③

⑦

③

⑧

8-1

8-2

④

①

②

⑤

⑥

⑦

XBM-DR16S

XBM-DN16/32S

8-3

Chapter 2 specification

2-6

XBC/XEC “E” type

No. Name Purpose

①

Input indication LED Input indication LED

②

PADT connection

connector

PADT connection RS-232C 1 channel connector

③

Input terminal block Input connector and terminal block

④

Output terminal block

Output connector and terminal block

⑤

Key switch RUN / STOP key switch

-In case key switch is STOP, remote mode change available

⑥

Output indication LED Output indication LED

⑦

Status indication LED Indicates basic unit’s operation status

- PWR(Red) : power status indication

- RUN(Green) : RUN status indication

- STOP mode : Off / RUN mode : On

- Error(Red): flicker in case error occurs

⑧

Built-in RS-232C/

RS-485 Connection

terminal block

Built-in RS-485 connection terminal block

- “+”,”-“ terminal connection terminal block of RS-485

communication

- “TD”,”RD”,”SG” terminal connection terminal block of

RS-232C communication

Power terminal AC100~240V power terminal block

Notes

Notes 1) XBC/XEC main units of "E” type are not able to use XGB expansion module.

XBC-DR10E

XBC-DN10E

XBC-DP10E

XBC-DR14E

XBC-DN14E

XBC-DP14E

XBC-DR20E

XBC-DN20E

XBC-DP20E

XBC-DR30E

XEC-DN10E

XEC-DN14E

XEC-DN20E

XEC-DN30E

XEC-DP10E

XEC-DP14E

XEC-DP20E

XEC-DP30E

XEC-DR10E

Chapter 2 specification

2-7

XBC/XEC “S/SU” type

No. Name Purpose

①

Input indication LED Input indication LED

②

PADT connection

connector

PADT connection USB(USB 1.1 supported) 1 channel,

RS-232C 1 channel connector

Notes 1)

③

Input terminal block Input connector and terminal block

④

Output terminal block

Output connector and terminal block

⑤

Key switch RUN / STOP key switch

-In case key switch is STOP, remote mode change available

⑥

Output indication LED Output indication LED

⑦

Status indication LED Indicates basic unit’s operation status

- PWR(Red) : power status indication

- RUN(Green) : RUN status indication

- STOP mode : Off / RUN mode : On

- Error(Red): flicker in case error occurs

⑧

Built-in RS-232C/

RS-485 Connection

terminal block

Built-in RS-485 connection terminal block

- “+”,”-“ terminal connection terminal block of RS-485

communication

- “TD”,”RD”,”SG” terminal connection terminal block of

RS-232C communication

Power terminal AC100~240V power terminal block

Notes

Notes 1) The S-type of XBC/XBC doesn’t provide a usb port.

XBC-DN20S(U)

XBC-DR20SU

XBC-DN30S(U)

XBC-DR30SU

XBC-DN40SU

XBC-DR40SU

XBC-DN60SU

XEC-DN20SU

XEC-DN30SU

XEC-DN40SU

XEC-DN60SU

XEC-DR20SU

XEC-DR30SU

Chapter 2 specification

2-8

XBC/XEC “H” type

No. Name Purpose

①

Input indication LED Input indication LED

②

PADT connection

connector

PADT connection USB(USB 1.1 supported) 1 channel,

RS-232C 1 channel connector

③

Input terminal block Input connector and terminal block

④

Output terminal block

Output connector and terminal block

⑤

Key switch RUN / STOP key switch

-In case key switch is STOP, remote mode change available

⑥

Output indication LED Output indication LED

⑦

Status indication LED Indicates basic unit’s operation status

- PWR(Red) : power status indication

- RUN(Green) : RUN status indication

- STOP mode : Off / RUN mode : On

- Error(Red): flicker in case error occurs

⑧

Built-in RS-232C/

RS-485 Connection

terminal block

Built-in RS-485 connection terminal block

- “+”,”-“ terminal connection terminal block of RS-485

communication

- “TD”,”RD”,”SG” terminal connection terminal block of

RS-232C communication

Power terminal AC100~240V power terminal block

XEC-DN32H

XEC-DN64H

XEC-DP32H

XEC-DP64H

XEC-DR32H

XEC-DR64H

XBC-DR32H

XBC-DN32H

XBC-DR64H

XBC-DN64H

Chapter 2 specification

2-9

Extension Cnet module

No. Name Purpose

①

LED indication Operation status indication

②

RS-422/RS-485

connector

Connector for connection with external device

③

RS-232C connector Connector for connection with external device

LED name LED indication content LED status LED status content

RUN Operation status indication

On Normal operation

Off Abnormal operation

I/F

Interface with main unit status

indication

Flicker Normal operation

Off Abnormal operation

TX Indication during frame transmission

Flicker Transmitting frame

Off Frame transmission completion

RX Indication during frame receiving

Flicker Receiving frame

Off Frame reception completion

ERR Frame error indication

On Frame error

Off Normal frame

[Table 2.3.1] LED indication content

①①

②③

XBL-C41A

XBL-C21A

Chapter 3 System Configuration

3-1

Chapter 3 System Configuration

XGB PLC is having diverse product suitable for main syst em, computer lin k and network system conf iguration

This chapter describes configurati on method and ch aracteristi c.

3.1 XGB System Configuration

System configuration of XGB PLC is as follows. Extension I/O module, in case of spe cial module, in “S” type, up

to 7 step connection and in “H” type, up to 10 step connection is available. In communication module, up to 2 step

extensions is available.

3.1.1 “H” type system configuration

Item content

I/O configuration point XB(E)C-DxxxH: 32 ~ 384 points

Extension module

connection available no.

Digital I/O module Max. 10

Analog module Max. 10

Communication

module

Max. 2

Product list

Main unit “H” type

XBC-DR32/64H XBC-DN32/64H

XEC-DR32/64H XEC-DN32/64H

Extension

module

Digital I/O module

XBE-DC08/16/32

XBE-TN08/16/32

XBE-TP08/16/32

XBE-RY08/16A

XBE-DR16A

Analog module

XBF-AD04A XBF-RD04A

XBF-DV04A XBF-RD01A

XBF-DC04A XBF-TC04S

Communication

module

XBL-C41A XBL-C21A

XBL-EMTA

Option

module

Memory module XBO-1024A

Main unit

I/O module

Special module

Communication

module

Chapter 3 System Configuration

3-2

3.1.2 “S” type System Configuration

Item Content

I/O configuration point XBM-DxxxS : 16 ~ 352 point

Extension module

connection available

no.

Digital I/O module Max. 7

Analog module Max. 7

Communication module Max. 2

Product

list

Main unit “S” type XBM-DR16S XBM-DN16/32S

Extension

module

Digital I/O module

XBE-DC08/16/32

XBE-TN08/16/32

XBE-TP08/16/32

XBE-RY08/16A

XBE-DR16A

Analog module

XBF-AD04A XBF-RD04A

XBF-DV04A XBF-RD01A

XBF-DC04A XBF-TC04S

Communication module

XBL-C41A XBL-C21A

XBL-EMTA

Option

module

Memory module XBO-1024A

Main unit I/O module Special module Communication module

Chapter 3 System Configuration

3-3

3.2 Available System Configuration

Communication system by using XGB built-in communication function and Cnet module is diverse. In this

chapter, it describes system configuration example.

.

3.2.1 1:1 Connection between PC (HMI) (No modem)

PC (HMI) and Cnet I/F module is connected by RS-232C or RS-422/485 channel, PC (HMI) and PLC is

connected by 1:1 without modem. In most case, PC (HMI) acts as client and Cnet I/F module acts as server which

respond request of PC (HMI). Since there is no modem, in case of using RS-232C channel, communication

distance is max 15m, in case of using RS-422 channel, communication distan ce is max 500m. Ope ration mod e of

Cnet I/F module is set according to PC (HMI)’s communication method. Wiring method and system connection is

applied in case of XGB “S” type built-in communication. In case of using XGB “H” type and external

communication module, refer to 10.5 communication interface connection method.

(1) In case of using 1:1 connection with normal PC

Wiring method

External form of

PC

PC

Connection number and signal

direction

XGB main unit

XGB external

form

Pin no. Pin no.

Signal

name

1

1 485-

2

(RXD)

2

485+

3(TXD) 3 SG

4 4 TX

5(GND) 5 RX

6

7

8

9

In case of using channel 2, connect 485+ and 485- of RS485 terminal.

[Figure 3.2.1] 1:1 communication with PC

XGB main unit built-in

communication

1

2

3

4

5

Female Type

Chapter 3 System Configuration

3-4

(2) In case of using 1:1 connection with monitoring device such as XGT Panel

Wiring method (RS-232C)

XP external form

XP

Connection number and

signal direction

XGB main unit

XGB external

form

Pin no. Pin no.

Signal

name

1 1 4852(RXD) 2 485+

3(TXD) 3 SG

4 4

TX

5(GND) 5

RX

6

7

8

9

Note) In case of PMU, short no.4 and no.6, short no.7 and no.8.

Wiring method (RS-485)

PMU

Connection no. and signal direction XGB main unit

485+ 485+

485-

485-

XP series (LSIS)

XGB main unit

RS-232C I/F

RS-485 I/F

Female Type

1

2

3

4

5

[Figure 3.2.2] 1:1 communication with HMI

Chapter 3 System Configuration

3-5

(3) In case of using 1:1 connection with XGB main unit

Wiring method

XGB external

form

XGB main unit

Connection no. and

signal direction

XGB main unit

Pin no.

Pin

no.

Signal name

1

1

485-

2 2

485+

3 3 SG

4 4 TX

5 5 RX

XGB main unit

XGB main unit

RS-232C I/F

RS-485 I/F

[Figure 3.2.3] 1:1 communication between PLCs

Chapter 3 System Configuration

3-6

3.2.2 1:1 Dedicated modem connection with PC (HMI)

It is 1:1 communication system connected through dedicated modem through RS-232C channel

with PC (HMI). Normally, PC (HMI) acts as client station, Cnet I/F module acts as server station

which respond request of PC (HMI). Since it uses modem, RS-232C channel should be set as

dedicated modem and long distance communication is available. Operation mode of this module

should be set according to communication method of PC (HMI).

[Figure 3.2.4] dedicated modem communication with PC

Modem

Modem

XBL-C21A

XBM-DN32S

XBL-C21A

XBM-DN32S

Chapter 3 System Configuration

3-7

3.3.3 Modem connection with PC and communication between Cnet I/F modules

PC and Cnet #1 station is connected by modem through RS-232C channel

Cnet #1 station ~ N station is communication between Cnet I/F module through RS-422 channel

Cnet #1 station ~ N station is Communication between Cnet I/F modules through RS-422

channel

PC acts as client station of Cnet #1 station

Up to max 32 station connection is available in case of Cnet I/F module (RS-422/485

communication)

It sets station 1 among Cnet I/F module as server station

Dedicate modem or dial-up modem available

[Figure 3.2.5] Dedicated modem communication with PC

Type

Module setting

XBL-C41A Station no.

PLC Cnet #1

P2P

1

XGT client

Cnet #2 ~ #N XGT server 2~N

[Table 3.2.1] module setting table per station

XGB PLC

Cnet # 1 station

XGB PLC

Cnet # N station

XGB PLC

Cnet # 2 station

RS-232C

Communication

RS-422 communication

Chapter 3 System Configuration

3-8

3.2.4 Dedicated communication with PC (HMI) and different type RS-422 communication

Null-modem communication by usin g PC (HMI) and RS-232C channel

PC (HMI) acts as client station, Cnet I/F module acts as server, at this time, module setting acts as

RS-232C XGT server

Cnet I/F module RS-422 channel acts as P2P mode.

It transmits indication data to display module of mosaic panel through RS-422 channel

Reading display transmissi on data from PC

[Figure 3.2.6] 7-Segment operating system for RS-422

Type

Module setting

XBL-C21A XBL-C41A Station no.

PLC Cnet #1 XGT server P2P 1

[Table 3.2.2] Module setting table per station

XGB PLC

Cnet # 1

HMI - PC

(GLOFA VIEW)

RS-232C communication

RS-422 communication

Chapter 3 System Configuration

3-9

3.2.5 Optical modem communication for moving material communication

Optical modem communication system for Cnet communication on material above moving

linearly

P2P communication or dedicated mode communication with monitoring device

RS-232C/RS-422 communication with optical modem

Communication between Cnet I/F mod ule is dedicated server/client communication

Optical modem connected with Cnet I/F module on m obile body can communicate with the

other optical modem only when positioned in communication available

Main application: Parking tower

[Figure 3.2.7] Optical modem communication system

XGB PLC

Cnet # 1

Monitoring

device

RS-232C

communication

RS-422

communication

XGB PLC

Cnet # 3

XGB PLC

Cnet # 2

XGB PLC

Cnet # 4

Optical

modem

Optical

modem

Optical

modem

Moving material

RS-232C communication

RS-232C communication

RS-232C communication

광

모

뎀

Chapter 3 System Configuration

3-10

3.2.6 Wireless modem communication for communication between revolution bodies

RS-232C communication with wireless modem

Communication between Cnet I/F module is dedicated/client communication

RS-232C channel of Cnet I/F module is dedicated modem mode

[Figure 3.2.8] wireless modem communication system

Type

Module setting

RS-232C RS-422 Station

XBL-C21A

Dedicated mode

Not used 2 station

User mode

[Table 3.2.3] setting content table between communication module

RS-232C communication

RS-232C

communication

XGB PLC

Cnet # 2

Wireless modem

Wireless modem

Chapter 4 Basic Setting

4-1

Chapter 4 Basic Setting

4.1 Setting Sequence of Product

It describes installation of product and sequence. Install system by be operated by the following

sequence.

Operation sequence

Equip Cnet I/F module to XGB system

(It is applied in case of using external Cnet I/F module)

Connect Cnet I/F module with device to communicate

by cable.

Cable wiring and connect terminal resistance.

After power on, check LED status of communication

module

Check whether interface of communication with CPU

is normal or not.

Set P2P parameter and basic setting at XG-PD.

Set parameter according to network configuration at

XG-PD, download parameter

Enable link at XG-PD.

Not enable link act as server.

Operation start

Note

1) In Cnet I/F module, hardware station setting is not necessary.

By using XG-PD, designate station and basic setting necessar y in Cnet communication.

Chapter 4 Basic Setting

4-2

4.2 PLC Type Setting and How to Register Communication Module

To use Cnet I/F function, communication parameter should be written by XGP-PD. To set system

about Cnet I/F module located in temporary position, register each module at XG-PD. Method on

register Cnet I/F module is as follows according to On/Off line status.

4.2.1 Making new project

First, after click File-New File and input project name, select XGB series as PLC series.

About CPU type, in case of “S” type, select “XGB-XBMS”, in case of “H” type, select “XBC-XBCH”.

In case of IEC type, select “XGB-XECH”

[Figure 4.2.1] New project making screen

4.2.2 In case of off line, method on Cnet I/F module registration

In the status PLC is not connected, in case the user set about communication module and write

parameter related with communication, in the “standard settings”, the user select slot location to

register Cnet I/F module and shows “Communication module settings” window. In this window, you

register Cnet I/F module about wanted slot position. If you double-click at the slot position, you can

set communication card. At this time, slot 0 is set as built-in Cnet. In case of using Cnet module other

than built-in Cnet, registration is necessary.

Chapter 4 Basic Setting

4-3

[Figure 4.2.2] Cnet module registration screen

4.2.3 How to register Cnet I/F module in case of online

If you register communication module at online status by using XG-PD, you should connect basic unit.

After [Online]-> [Online] after doing communication setting by using “Connection setting” -> Selecting

“Connection” and doing local connection (or remote 1/2 connection). In case of normal connection,

lower menu of “online” is activated, selecting [Online]-> “Read IO Information”, equipped

communication module is searched automatically.

[Figure 4.2.3] Cnet I/O information read screen

Chapter 4 Basic Setting

4-4

At this time, in case registered module is different with currently connected module or type of

communication module in the previous project, it shows whether it changes or not with the following

message.

[Figure 4.2.4] I/O information change message

If you execute Read IO Information, equipped communication module like the following is indicated

IO module information window.

[Figure 4.2.5] Communication module registration compete screen

Chapter 4 Basic Setting

4-5

4.3 How to Set Basic Parameter

Communication function used in Cnet I/F module is classified as followings.

1) Server mode service

Without other program at PLC, you can read or write information in PLC and data.

It can act as XGT server providing XGT dedicated protocol and Modbus server providing

RTU/ASCII protocol.

2) Client (P2P) service

Cnet I/F module acts as client in network.

In case designated event occurs, you can read or write memory of other station.

It can act as XGT client and Modbus client.

In case of sending/receiving user wanted frame and communicating with other device.

You can define P2P block with max. 32 per one channel acting independently.

3) Loader service

By using remote 1/2, you can monitor/download program about remote PLC.

To use Cnet I/F module, you should set transmission specification such as data type like transmission

speed and data/stop bit.

You should select transmission specification of system to be same with specification of system.

Written standard setting value is saved CPU module of PLC and this value keeps though power goes

off and this value is not changed before writing. Also though Cnet I/F module is changed and new

module is installed, the standard setting value saved at CPU module previously written is applied to

new module automatically. Standard communication setting parameter and P2P, all parameter is

applied if download is complete.

Chapter 4 Basic Setting

4-6

[Figure 4.3.1] Built-in communication standard setting screen

4.3.1 Setting item

When setting Cnet communication parameter, the fact the user should define is as follows [Table 4.3.1]

Item Setting content

Station no.

You can set from station 0 to station 255.

Communicati

on speed

1200, 2400, 4800, 9600, 19200, 38400, 57600,115200 bps available

Data bit

7 or 8 bit available

Parity bit

None, Even, Odd available

Stop bit

1 or 2 bit available

Communicati

on channel

It is fixed as follows according to Cnet type

1) Built-in communication → channel 1 : RS-232C , channel 2 : RS-485

2) XBL-C41A → channel 1 : not used, channel 2: RS-422/RS-485

3) XBL-C21A → channel 1 : not used, channel 2: RS-232C

Delay time

It sets interval of communication frame

Time out

It sets the time waiting respond after requesting data.(100㎳ unit 1~ 65535 available)

[Table 4.3.1] communication parameter setting item

Chapter 4 Basic Setting

4-7

*Parity bit

Cnet I/F module can define three parity bits. Meaning of each parity bit is as follows.

Parity bit type Meaning Reference

None Not using parity bit

Even If the number of 1 in one byte is even, parity bit becomes “0”.

Odd If the number of 1 in one byte is odd, parity bit becomes “1”.

[Table 4.3.2] Parity content table

Operation mode setting

▪ Sets operation mode

Driver type Meaning Reference

P2P

Each port acts as client and executes the communication

by setting P2P parameter.

P2P setting

reference

XGT server

It acts as XGT server supporting XGT dedicated

communication.

Dedicated service

Modbus ASCII server It acts as Modbus ASCII server

Modbus

communication

Modbus RTU server It acts as MOdbus RTU server

Modbus

communication

[Table 4.3.3] operation mode setting item

4.3.2 Setting method

You should do like following to operate Cnet I/F module according to communication specification

defined by user. In case of setting like the followings about XBL-C41A (RS-422/485 1 port) installed

slot 2, setting method is as follows.

(1) Communication specification

Channel 2: RS-422, 38400Bps, 8/1/Odd, Null modem, P2P, 2 station, delay time 10 ㎳

Executing XG-PD, you register communication module Cnet for setting at each slot position. After

Cnet module is registered, if you double-click Cnet module, the following standard setting window

shows.

Chapter 4 Basic Setting

4-8

[Figure 4.3.2] Communication module setting screen

If standard communication parameter setting ends, download Cnet module.

If you select [Online -> connection -> Write parameter], download is executed. After downloading,

parameter is applied shortly.

[Figure 4.3.3] Write Parameter screen

Chapter 5 Remote Connection

5-1

Chapter 5 Remote Connection

5.1 Remote Connection

5.1.1 General

In case PC executing XG500/XG-PD is far from XGB PLC, if you use remote connection function of

Cnet I/F module, you can control remote PLC such as program download, upload, program debugging

and monitor. Especially, in case XG5000 is far from PLC, if you use XG5000 remote connection

function and modem connection function of Cnet I/F module, you can access easily by remote

connection through air line. Remote connection is supported at XGB communication module, FEnet

I/F module and Cnet I/F module. Connection between networks is available and you can contro l

remote PLC through multiple connections. There are two methods for remote connection by using

Cnet I/F module, first, XG5000 is connected with Cnet I/F module of remote PLC through modem,

second, XG5000 and local PLC are connected into CPU through RS-232C, Cnet I/F module of local

PLC communicates with Cent I/F module of remote PLC.

5.1.2 XG5000 remote connection

[Figure 5.1.1] is figure indicating remote connection example where XG5000 and PLC are connected

through modem. Like figure, it is necessary configuration in case PC executing XG5000 is far from

PLC and telephone line and connected by dedicated modem or wireless modem. At this case, you

should connect Cnet I/F module by modem from XG5000 and you should select modem as

connection method at connection option. There are two methods, dedicated modem connection using

dedicated line and dial-up modem connection using public line.

(1) Dial-up modem connection

[Figure 5.1.1] is example using dial-up modem. You can establish remote connection by

connecting dial-up modem to PC and Cnet I/F module (RS-232C). In PC side, you can use external

modem or internal dial-up modem and in Cnet I/F side (RS-232C), you should use external modem.

[Figure 5.1.1] XG5000 remote connection example by dial-up modem

Public line Public line

Tandem center

Chapter 5 Remote Connection

5-2

Remote connection sequence by using dial-up modem is as follows.

(a) Cnet I/F module connected with PLC setting

1) Sets active mode of RS-232C channel of Cnet I/F as XGT server at XG-PD.

2) Sets Modem type of Cnet I/F module (RS-232C) as Dial-up modem and inputs atz in Modem

Initialization.

[Figure 5.1.2] XG-PD setting example

(b) XG5000 setting

1) Execute XG5000 and pop up online settings window by selecting “Onli ne -> Connection

settings”.

Here selects “Connection settings -> Type” as Modem.

[Figure 5.1.3] Modem connection setting screen of XG5000

Chapter 5 Remote Connection

5-3

2) Select settings of “Connection settings” and set detail of modem

[Figure 5.1.4] Modem detail setting screen

Note

Baud rate in modem settings means communication speed between PC and modem,

not communication speed of modem. Baud rate of modem means communication speed

between modem and modem, it is set automatically according to quality of public line

and destination modem’s speed.

For XG5000 remote connection at XGB PLC, you should use RS-232C channel. At

communication standard setting, set “RS-232C dial-up modem” and write it to XGB Cnet

I/F module.

3) Phone number means phone number of modem side connected with Cnet I/F module, in case

of going out from local through extension line, you can use extension number and ‘,’ symbol.

(Ex) In case extension number is ‘9’: set as 9, 0343-398-xxxx

Note

In case modem connected with Cnet I/F module of destination station is through

tandem center, communication is impossible. Namely, there is extension number for

reception station, dial-up modem communication is impossible.

4) In case of selecting connection step as remote 2, like the following, select base and slot

number of remote 1 communication module in detail and communication module station

number of remote 2. Inputs station number set in Cnet I/F module, In case of Cnet channel,

selects communication channel of remote 2.

Chapter 5 Remote Connection

5-4

[Figure 5.1.5] Modem remote 2 setting screen

5) Select connection on online after setting connection option, modem initialization dialog box

shows and modem is initialized.

6) In case setting of COM channel of modem or connection with modem is wrong or, the error

message shows. At this time, check COM channel or modem connection.

Remote 1

Communication

module

Remote 2

Communication

module

Public line Public line

Tandem center

Chapter 5 Remote Connection

5-5

7) If making phone call is complete, XG5000 tries remote connection. In case remote connection

is complete, “Online” menu is activated.

8) This case is same with connection status where connection is established through RS-232C

cable. Here you can use all function of online menu.

Note

After remote connection, you can use online menu of XG5000 like local connection. You

can use program download/upload/monitor function etc. PLC control through modem is

affected by capability of modem and status of telephone line. In case telephone line is bad,

connection may be canceled. At this time, don’t try reconnection instantly, wait for 30s and

retry again from step 1)

9) In case you want to disconnect remote connection, select disconnect at online menu. Then

disconnection menu box shows and remote connection is disconnected.

10) If connection is disconnected, XG5000 quit call automatically and disconnection telephone

connection.

11) If it is success to quit call normally, local and remote modems return to initialization status.

You can establish remote connection through making phone call.

Chapter 5 Remote Connection

5-6

(2) Dedicated modem connection

The following figure indicates that PC and Cent module is connected by dedicated modem through

dedicated line.

[Figure 5.1.6] XG5000 remote connection example by dedicated modem

[Figure 5.1.6] is example of dedicated modem connection by dedicated line. You can use wireless

modem, optical modem other than dedicated modem. For setting method of modem not using public

line, it is same with case of dedicated modem and refer to the followings.

Remote connection sequence by dedicated modem is as follows.

(a) Connects PC with dedicated modem at Cnet I/F module

(b) Cnet I/F module setting connected at remote PLC

1) Sets RS-232C channel of Cnet I/F module as XGT server.

2) Sets RS-232C channel operation of Cnet I/F module as dedicated modem.

(c) XG5000 setting

1) Execute XG5000 and select “Online -> connection settings” and pop up online settings window.

Here set “Connection settings -> Type” as Modem. Press the “Settings” button and set

communication channel and baud rate set in dedicated mode m connected with PC. Baud rate

should be same with communication speed of dedicated modem.

[Figure 5.1.7] dedicated modem setting screen

Dedicated line

Chapter 5 Remote Connection

5-7

2) In case of setting depth as remote 2, set settings related with remote 1, 2 at the “Detail”

window like the followings.

[Figure 5.1.8] dedicated modem remote 2 setting screen

3) After completing setting, if you click connection of connection setting, XG5000 tried remote

connection. In case remote connection is complete, it is same when connection is established

by RS-232C cable. Here you can use all functions of “Online” menu.

Note

After remote connection, you can use online menu of XG5000 like local connection.

You can use program download/upload/monitor etc. PLC control through mode m is affected

by capability of modem and status of telephone line. In case telephone line is bad,

connection may be canceled. At this time, don’t try reconnection instantly, wait for 30s and

retry again from step 1)

(d) In case you want to disconnect remote connection, select disconnect at online menu.

Disconnection menu box shows and remote connection is disconnected.

(e) If disconnection is done normally, Cnet I/F module and XG5000 are switch into initial mode. In

case of reconnection, retry from (b) item to reconnect.

(f) Since for optical modem, wireless modem, only media between modems is different. Connection

method is same.

Chapter 5 Remote Connection

5-8

5.1.3 Remote connection between Cnet I/F modules

(1) Remote connection through dedicated modem

[Figure 5.1.13] indicates that XG5000 and local PLC is connected through RS-232C cable and in

case RS-232C channel of Cnet I/F module equipped at local PLC communicates with Cnet I/F

module of remote PLC through dedicated modem. Figure is example indicating remote connection

with remote PLC. Like figure, XG5000 uses modem communication function between Cnet I/F

modules and control remote PLC by using remote connection.

[Figure 5.1.9] remote connection between Cnet I/F modules

Remote connection sequence by dedicated modem is as follows.

(a) Cnet I/F module setting connected at remote PLC

1) Set RS-232C channel operation of Cnet I/F module at XG-PD as dedicated modem and have it

operate as XGT server.

[Figure 5.1.10] Cnet I/F module XG-PD setting of remote PLC

Remote server

Remote client

Remote connection

Dedicated line

Dedicated modem

Dedicated modem

Chapter 5 Remote Connection

5-9

(b) Cnet I/F module setting connected at local PLC

1) Converts local connected PLC to Stop mode

Note

Basic parameter of remote server connected through XG5000 should be set as server. In

case of remote client, it should be set as P2P client.

In case there are many communications, if you try to remote connection, you may fail. Be

sure to convert local PLC to stop mode and stop communication before remote connection.

2) XG-PD setting

a) Set active mode of RS-232C of Cnet I/F module at XG-PD as Use P2P settings.

b) Set modem type of Cnet I/F module (RS-232C) as dedicated modem.

[Figure 5.1.11] Cnet I/F module XG-PD setting of local PLC

3) XG5000

a) Execute XG5000 and select “Online – Connection Settings” and set connection method.

Select Type as RS-232C and communication channel. This is same in case of local

connection.

[Figure 5.1.12] XG5000 remote connection setting screen

Chapter 5 Remote Connection

5-10

b) Select depth as remote 1 and click “Settings” for detail setting. In the detail window, set

station number. AS for station number, input station number set in Cnet I/F module to

execute remote connection. Figure is case Cnet station number is set as 1.

[Figure 5.1.13] XG5000 remote 1 connection setting screen

c) XG5000 tries remote connection and in case remote connection is complete, online related

function is activated.

d) In this case, remote 1 connection is complete, it is same status with where it is connected by

RS-232C cable. Here you can use all functions of online menu.

(c) In case you want to disconnect remote connection, select disconnect at online menu.

Disconnection menu box shows and remote connection is disconnected.

In case disconnection is done normally, Cnet I/F module and XG5000 are converted into initial

mode. In case of reconnection, retry from (a) for reconnection.

Chapter 5 Remote Connection

5-11

(d) In case of optical modem, wireless modem other than dedicated modem, communication media

is only different, method of remote connection is same.

[Figure 5.1.14] indicates remote connection by wireless modem. As for connection method, it is

same with method of remote connection between Cnet I/F module by using communication. In

case of using wireless modem, 1:N remote connection where there are many Cnet I/F module

is also available.

[Figure 5.1.14] remote connection by using wireless modem

Remote connection

Remote Cent

Wireless modem

Wireless modem

Chapter 5 Remote Connection

5-12

(2) Remote connection by RS-422/485

[Figure 5.1.15] indicates XG5000 and local PLC is connected into CPU module by RS-232C cabl e,

in case RS-422/485 channel of Cnet I/F module connected at local PLC communicate s, it is figure

indicating remote connection example to remote PLC. Like figure, XG5000 can control program of

remote PLC by remote connection through remote connection function between Cnet I/F modules.

[Figure 5.1.15] Remote connection in case of RS-422/485 communication

Note

Basic parameter of remote server connected through XG5000 should be set as server, in case of

remote client, it should be set P2P client.

If you try remote connection when there is many communications, connection may fail. You

should convert PLC as Stop mode and stop communication before remote connection.

Remote connection sequence by using dedicated modem is as follows.

(a) Set basic parameter of remote server as XGT server.

(b) Convert local connected PLC into Stop mode.

(c) Execute XG5000 and select “Online – Connection settings” and set connection method. And

select connection method RS-232C and communication channel. This is same with case of local

connection. At this time, you should set station number of remote server to connect.

Remote server

Remote client

Remote server

Remote server

●

●

●

Chapter 6 Server function and P2P service

6-1

Chapter 6 Server function and P2P service

6.1 Server Modbus Service

6.1.1 General

Dedicated service is built-in service in Cnet I/F module. Without specific program at PLC, you can

read or write information and data from PC and other device. It acts as server at communication

network and if read, write request conforming XGT dedicated protocol or Modbus protocol come, it

responds.

To use dedicated service, select operation mode about channel used as server among channel 1,

channel of Cnet, when setting standard communication setting.

It supports XGT server and Modbus server and Modbus server responds about RTU and ASCII

type.

Since each channel of Cnet I/F module acts independently, you can set as other type server. For

normal operation check and diagnosis of dedicated service, refer to Chapter 9 Diagnosis.

Chapter 6 Server function and P2P service

6-2

6.1.2 XGT dedicated server

It is used in case of communication between our products by our dedicated service, all characters

are configured as ASCII code. In case of using multi drop, up to 32 stations can be connected. In

case of setting station number, duplicated station number should not be set. In case of using multi

drop, communication speed/stop bit/parity bit/data bit of all Cnet I/F module in network should be

same. For more detail protocol, refer to “chapter 7 XGT dedicated protocol”.

6.1.3 Modbus server

It is used in case partner device acts as Modbus client.

ASCII mode and RTU mode of Modbus are all supported. You can define in standard settings

active mode.

[Figure 6.1.1] Modbus server standard settings screen

Modbus instruction and response data max. number which is supported by Modbus RTU/ASCII

driver are as follows.

Other client device should request in the range of the following table.

Chapter 6 Server function and P2P service

6-3

Code Purpose Address

Max. no. of response

data

01 Read Coil Status 0XXXX 2000 Coils

02 Read Input Status 1XXXX 2000 Coils

03 Read Holding Registers 4XXXX 125 Registers

04 Read Input Registers 3XXXX 125 Registers

05 Force Single Coil 0XXXX 1 Coil

06 Preset Single Register 4XXXX 1 Register

15 Force Multiple Coils 0XXXX 1968 Coils

16 Preset Multiple Registers 4XXXX 120 Registers

[Table 6.1.1] Modbus instruction code

About request per above code, you should set area about XGB PLC memory. At ‘Modbus Settings

of Cnet active mode’ window, if you click “Modbu Settings” button which is activated when

selecting Modbus ASCII server/RTU server, the following setting window shows.

[Figure 6.1.2] Modbus server memory settings window

Meaning of each setting item is as follows.

Item Meaning Reference

Bit read area Address Address of XGB relevant to digital Input area Bit address

Bit write area Address Address of XGB relevant to digital output area Bit address

Word read area Address Address of XGB relevant to analog input area Word address

Word write area Address Address of XGB relevant to analog output area Word address

[Table 6.1.2] Modbus area meaning

In case of IEC type, use IEC type address value

Address value of each item is base address of each area.

The setting of above screen is the situation of allocating bit reading are from M0000 (bit)

and Word writing area from D0000 (word).

Base address input value should be in XGB series internal device area.

Chapter 6 Server function and P2P service

6-4

Since address of Modbus 1~9999 (decimal number), size of bit IO area is 9999/8=1249.875 byte

(Namely 1249, byte should be integer unit).

Also size of word IO area is 9999*2=19998 byte.

In case the user set 0 as base address of bit output (0XXXX) area, Modbus bit area 00001

corresponds 0

th

byte 0th bit, 00002 corresponds 0th byte first bit.

6.2 P2P Service

6.2.1 General

P2P service means acting client operation of communication module. P2P instructions available at

Cnet I/F module are 4 (Read/Write/Send/Receive).

Registration and edit of P2P service is executed in XG-PD, each P2P parameter consists of max.

32 P2P block.

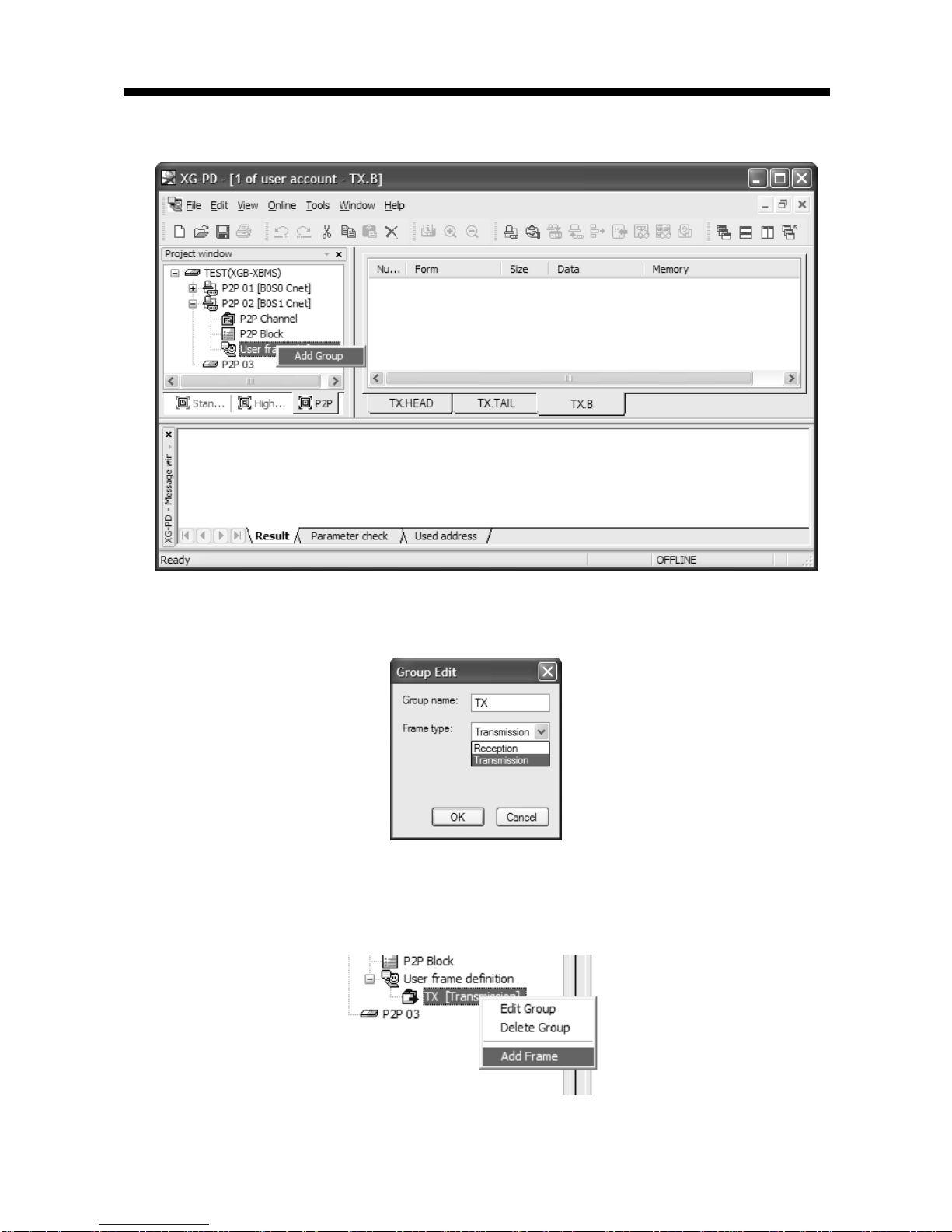

The following figure is example of P2P parameter setting window of XG-PD.

[Figure 6.2.1] P2P parameter setting example

Note

[N1] P2P 01 is fixed allocated at built-in communication, P2P 02 for first communication

module, P2P 03 for second communication. So slot number should be correct.

P2P parameter registration window

Diverse P2P parameter setting about one Cnet I/F module is available.

Each P2P parameter consists of P2P channel, P2P block, user frame definition.

Chapter 6 Server function and P2P service

6-5

6.2.2 P2P parameter configuration