User’s Manual

○○○○○○ Series

XGB Hardware (IEC)

Programmable Logic C ontroller

XGT Series

XEC-

DR32H

XEC-

DN32H

XEC-

DP32H

XEC-

DR64H

XEC-

DN64H

XEC-

DP64H

XEC-

DR32H/D1

XEC-

DR64H/D1

Safety Instruction

Before using the product …

For your safety and effective operation, please read the safety instructions

thoroughly before using the product.

► Safety Instructions should always be observed in order to prevent accident

or risk with the safe and proper use the product.

► Instructions are separated into “Warning” and “Caution”, and the meaning of

the terms is as follows;

This symbol indicates the possibility of serious injury

or death if some applicable instruction is violated

This symbol indicates the possibility of slight injury

or damage to products if some applicable instruction

is violated

► The marks displayed on the product and in the user’s manual have the

following meanings.

Be careful! Danger may be expected.

Be careful! Electric shock may occur.

► The user’s manual even after read shall be kept available and accessible to

any user of the product.

Warning

Caution

Safety Instruction

Safety Instructions when designing

Please, install protection circuit on the exterior of PLC to protect

the whole control system from any error in external power or PLC

module. Any abnormal output or operation may cause serious problem

in safety of the whole system.

- Install applicable protection unit on the exterior of PLC to protect

the system from physical

damage such as emergent stop switch,

protection circuit, the upper/lowest limi

t switch, forward/reverse

operation interlock circuit, etc.

- If any system error (watch-dog timer error, module installation error,

etc.) is detected during CPU operation in PLC, the whole output is

designed to be turned off and stopped for system safety. However,

in case CPU error if caused on output device itself such as relay or

TR can not be

detected, the output may be kept on, which may

cause serious problems. Thus, you are recommended to install an

addition circuit to monitor the output stat us .

Never c onnect the overload than rated to the output module nor

allow the output circuit to have a short circuit, which may cause a

fire.

Never let the external power of the output circuit be designed to

be On earlier than PLC power, which may cause abnormal output or

operation.

In case of data exchange between computer or other external

equipment and PLC through communication or any operation of

PLC (e.g. operation mode change), please install interlock in the

sequence program to protect the system from any error. If not, it

may cause abnormal output or operation.

Warning

Safety Instruction

Safety Instructions when designing

Safety Instructions when designing

I/O signal or communication line shall be wired at least 100mm

away from a high-voltage cable or power line. If not, it may cause

abnormal output or operation.

Caution

Use PLC only in the environment specified in PLC manual or

general standard of data sheet. If not, electric shock, fire, abnormal

operation of the product or flames may be caused.

Before installing the module, be sure PLC power is off. If not,

electric shock or damage on the product may be caused.

Be sure that each module of PLC is correctly secured. If the

product is installed loosely or incorrectly, abnormal operation, error or

dropping may be caused.

Be sure that I/O or extension connecter is correctly secured. If

not, electric shock, fire or abnormal operation may be caused.

If lots of vibration is expected in the installation environment,

don’t let PLC directly vibrated. Electric shock, fire or abnormal

operation may be caused.

Don’t let any metallic foreign materials inside the product, which

may cause electric shock, fire or abnormal operation..

Caution

Safety Instruction

Safety Instructions when wiring

Prior to wiring, be sure that power of PLC and external power is

turned off. If not, electric shock or

damage on the product may be

caused.

Before PLC system is powered on, be sure that all the covers of

the terminal are securely cl osed . If not, electric shock may be caused

Warning

Let the wiring installed correctly after checking the voltage rated

of each product and the arrangement of terminals. If not, fire,

electric shock or abnormal operat ion may be caused.

Secure the screws of terminals tightly with specified torque when

wiring. If the screws of terminals get loose, short circuit, fire or abnormal

operation may be caused.

*

Surely use the ground wire of C lass 3 for FG terminal s, which is

exclusively used for PLC. If the terminals not grounded correctly,

abnormal operation may be caused.

Don’t let any foreign materials such as wiring waste inside the

module while wiring, which may cause fire, damage on the product

or abnormal operation.

Caution

Safety Instruction

Safety Instruct ions for test-operation or repair

Safety Instructions for waste disposal

Don’t touch the terminal when powered. Electric shock or abnormal

operation may occur.

Prior to cleaning or tightening the terminal screws, let all the

external power off including PLC power.

If not, electric shock or

abnormal operation may occur .

Don’t let the battery recharged, disassembled, heated, short or

soldered. Heat, explosion or ignition may cause injuries or fire.

Warning

Don’t remove PCB from the module case nor remodel the module.

Fire, electric shock or abnormal operation may occur.

Prior to installing or disassembling the module, let all the external

power off including PLC power. If not, electric shock or abnormal

operation may occur.

Keep any wireless installations or cell phone at least 30cm away

from PLC. If not, abnormal operatio n may be caused.

Caution

Product or battery waste shall be processed as industrial waste.

The waste may discharge toxic materials or explode itself.

Caution

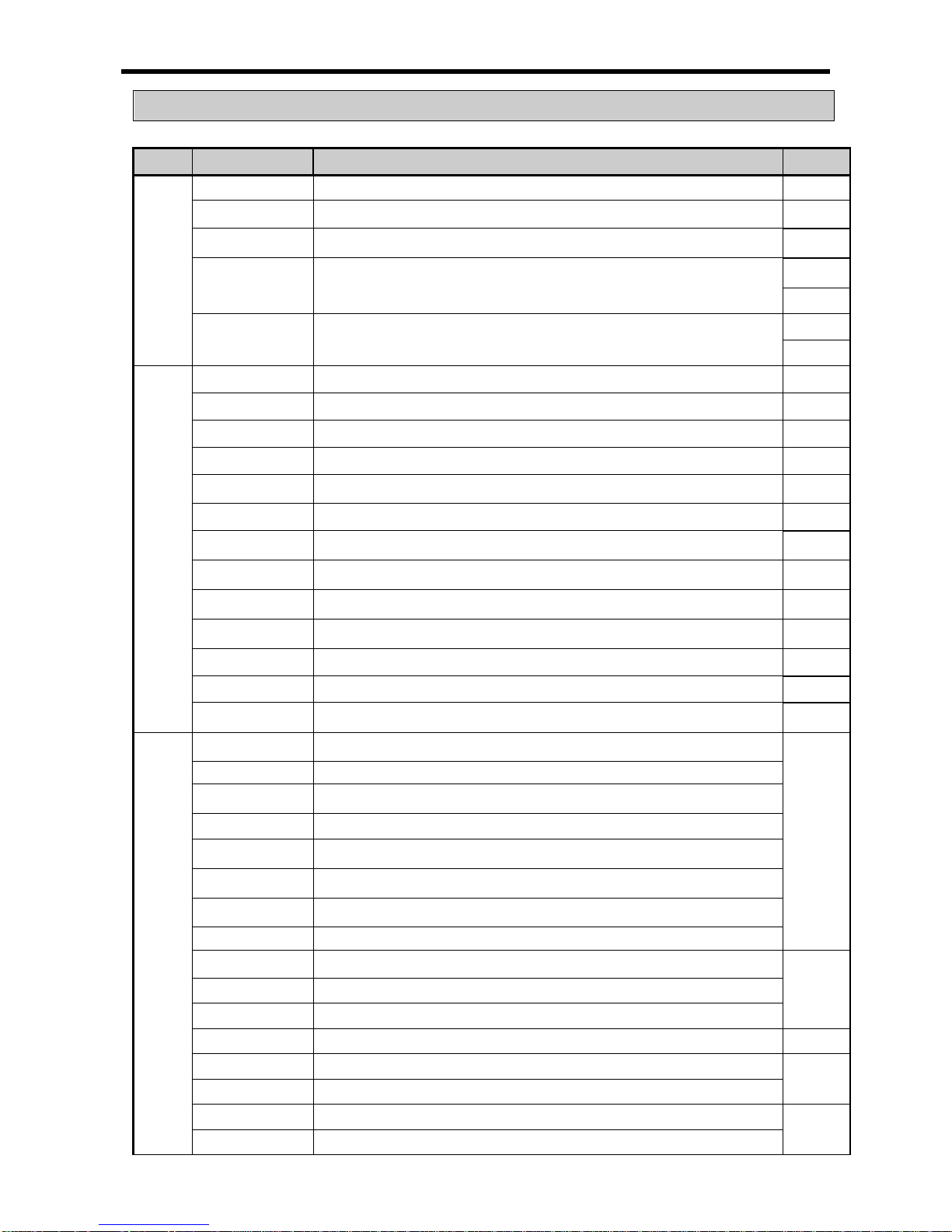

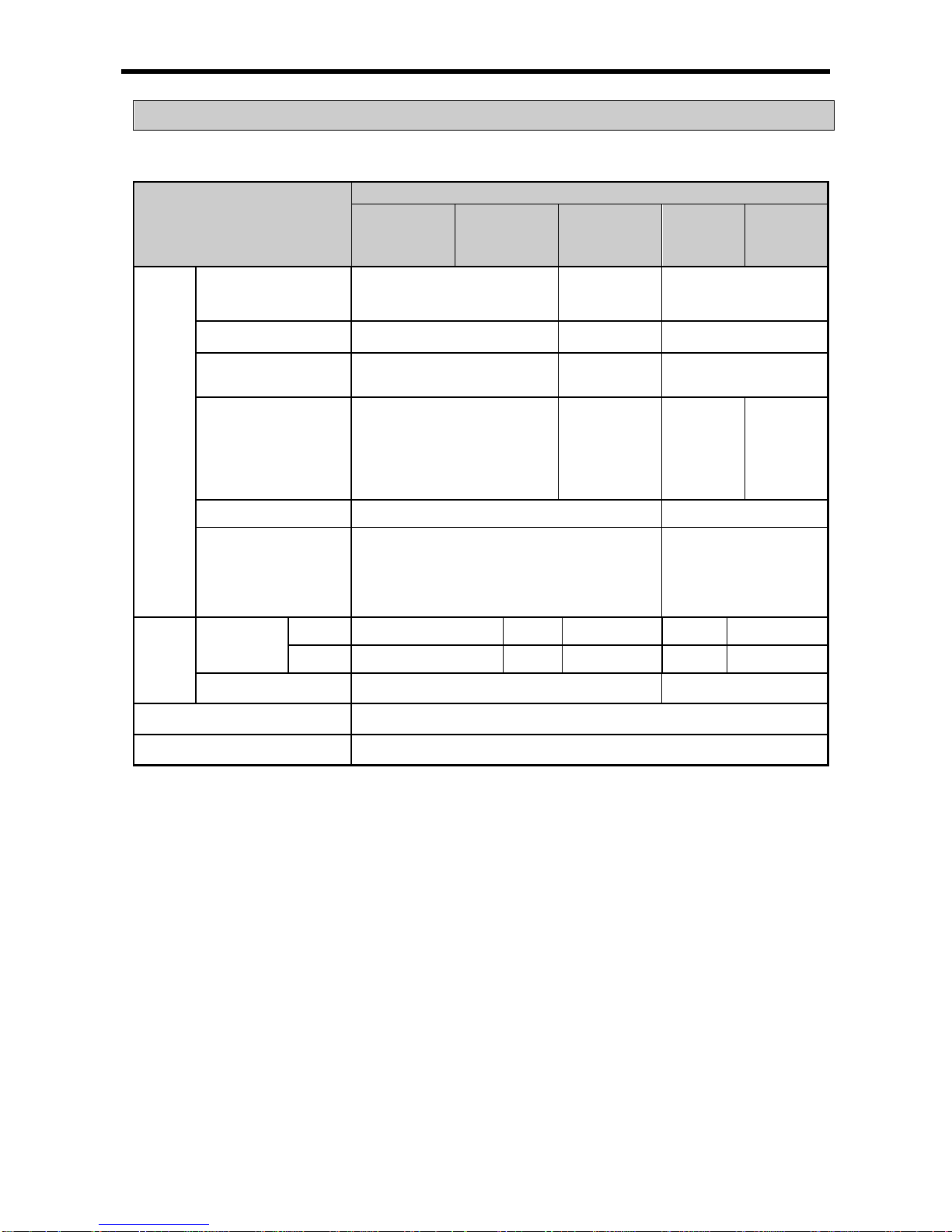

Revision History

V

ersion Date Remark Chapter

V 1.0 2009.2

1. First Edition -

V 1.1 2009.6

1. Add detailed description on High Speed Counter

specification

Ch8.1.1

V 1.2 2009.10

1. Add DC power unit

Ch2.1, Ch2.2

Ch4.1, Ch4.3

Ch7.2.1, Ch7.2.2

Ch8.1.1, Ch8.1.2

Appendix2

V1.5 2010.10

1. Add new module

2. Error in consumption current calculation fixed

3. Error in Momentary power failure and watch dog

fixed

4. Error in program execution fixed

5. Error in memory unit fixed

6. Error in remote function fixed

7. RTC flag, setting method modified

8. Input speciation of main unit fixed

9. Contents related with XGI deleted

10. Voltage reference fixed

11. Contents related with STOP LED deleted

12. APM_SSSB modified

13. XEC-DP32H/DP64H added

Ch2.1, Ch2.2,

Ch2.3.1, Ch4.1

Ch4.3, Ch4.4

Ch5.1.2, Ch5.1.4

Ch5.2.2

Ch5.4.1

Ch6.4

Ch6.12

Ch7.2.1, Ch7.2.2

Ch10.2

Ch10.3

Ch.11

Appendix4

Ch4.1, Ch4.3

Ch7.3.4, Ch7.3.6

Appendix2

V1.6 2014.2

1. Domain Of Homepage Changed

2. Add XEC-DN32H/DC

Front/Back

Cover

Ch2.1, Ch2.2

Ch4.1, Ch4.3

Ch7.2.1, Ch7.3.3

Ch8.1.1

Appendix2

V1.7 2015.7

1. Address & phone number changed

2. Add new module

3. Vibration Specification modified

Back Cover

Ch2.1, Ch2.2,

Ch2.3.3, Ch2.3.4

Ch3.1

The number of User’s manual is indicated the right side of the back cover.

ⓒ LSIS Co. ,Ltd. 2009 All Rights Reserved.

About User’s Manual

About User’s Manual

Thank you for purchasing PLC of LSIS Co.,Ltd.

Before use, make sure to carefully read and understand the User’s Manual about the functions,

performances, installation and programming of the product you purchased in order for correct use and

importantly, let the end user and maintenance administrator to be provided with the User’s Manual.

The Use’s Manual describes the product. If necessary, you m ay refer to the following description and order

accordingly. In addition, you m ay connec t our website(http://eng.lsis.biz/

) and downlo ad the information as a

PDF file.

Relevant User’s Manual

Title Description

No. of User

Manual

XG5000 User’s

Manual

(XGI/XGR/XEC)

It describes how to use XG5000 software especially about

online functions such as programming, printing, monitoring

and debugging by using XGB (IEC language)

10310000512

XGI/XGR/XEC Series

Instruction &

Programming

It describes how to use the instructions for programming

using XGB (IEC language) series.

10310000510

XGB Hardware

User’s Manual (IEC

language)

It describes how to use the specification of power/input

/output/expansion m odules, system configuration and built-in

High-speed counter for XGB main unit.

10310000983

XGB Analog

User’s Manual

It describes how to use the specification of analog

input/analog output/temperature input module, system

configuration and built-in PID control for XGB main unit.

10310000920

XGB Position

User’s Manual

It describes how to use bu ilt-in positioning function for XGB

main unit.

10310000927

XGB Cnet I/F

User’s Manual

It describes how to use built-in communication function for

XGB main unit and external Cnet I/F module.

10310000816

XGB Fast Ethernet I/F

User’s Manual

It describes how to use XGB FEnet I/F module.

10310000873

◎

Contents

◎

Chapter 1 Introduction ...................................................................... 1-1~1-5

1.1 Guide to Use This Manual ...................................................................................... 1-1

1.2 Features ................................................................................................................ 1-2

1.3 Terminology ........................................................................................................... 1-4

Chapter 2 System Configuration ........................................................... 2-1~2-11

2.1 XGB System Configuration .................................................................................. 2-1

2.2 Product List .......................................................................................................... 2-2

2.3 Classification and Type of Product Name ............................................................. 2-4

2.3.1 Classification and type of main unit .......................................................................... 2-4

2.3.2 Classification and type of expansion module ........................................................... 2-5

2.3.3 Classification and type of special module ................................................................. 2-6

2.3.4 Classification and type of communication module ..................................................... 2-7

2.3.5 Classification and Type of Option Module ................................................................ 2-7

2.4 System Configuration ........................................................................................... 2-8

2.4.1 Cnet I/F system .......................................................................................................... 2-8

2.4.2 Ethernet system ........................................................................................................ 2-11

Chapter 3 General Specifications ................................................................. 3-1

3.1 General Specifications ........................................................................................... 3-1

Chapter 4 CPU Specifications ................................................................. 4-1~4-9

4.1 Performance Specifications .................................................................................. 4-1

4.2 Names of Part and Function ................................................................................. 4-3

4.3 Power Supply Specifications ................................................................................ 4-4

4.4 Calculation Example of Consumption Current/Voltage ........................................... 4-6

4.5 Battery ................................................................................................................. 4-8

4.5.1 Battery specification ................................................................................................... 4-8

4.5.2 Notice in using ............................................................................................................ 4-8

4.5.3 Life of battery .............................................................................................................. 4-8

4.5.4

How to change the battery ......................................................................................... 4-9

Chapter 5 Program Configuration and Operation Method .................. 5-1~5-28

5.1 Program Instruction .............................................................................................. 5-1

5.1.1 Program execution methods .................................................................................... 5-1

5.1.2 Operation processing during momentary power failure ........................................... 5-2

5.1.3 Scan time .................................................................................................................. 5-3

5.1.4 Scan Watchdog timer ............................................................................................... 5-4

5.2 Program Execution ............................................................................................... 5-5

5.2.1 Configuration of program .......................................................................................... 5-5

5.2.2 Program execution methods ...................................................................................... 5-5

5.2.3 Interrupt . .................................................................................................................... 5-7

5.3 Operation Mode ................................................................................................. 5-19

5.3.1 RUN mode .............................................................................................................. 5-19

5.3.2 STOP mode ............................................................................................................ 5-20

5.3.3 DEBUG mode ......................................................................................................... 5-20

5.3.4 Change operation mode ......................................................................................... 5-24

5.4 Memory ................................................................................................................ 5-25

5.4.1 Program memory .................................................................................................... 5-25

5.4.2 Data memory ............................................................................................................ 5-26

5.4.3 Data retain area setting .......................................................................................... 5-26

5.4.4 Data Memory Map .................................................................................................... 5-28

Chapter 6 CPU Functions ...................................................................... 6-1~6-24

6.1 Type Setting ......................................................................................................... 6-1

6.2 Parameter Setting ................................................................................................ 6-2

6.2.1 Basic parameter setting ............................................................................................ 6-2

6.2.2 I/O parameter setting ................................................................................................ 6-3

6.3 Self-diagnosis Function ........................................................................................ 6-4

6.3.1 Saving of error log .................................................................................................... 6-4

6.3.2 Troubleshooting ........................................................................................................ 6-4

6.4 Remote Functions .................................................................................................. 6-6

6.5 Forced Input/Output On and Off Function .............................................................. 6-7

6.5.1 Force I/O setup ......................................................................................................... 6-7

6.5.2 Processing time and method of Forced Input/Output On and Off ............................ 6-8

6.6 Direct Input/Output Operation ................................................................................ 6-9

6.7 Diagnosis of External Device ...............................................................................

6-10

6.8 Allocation of Input/Output Number .......................................................................

6-11

6.9 Online Editing ......................................................................................................

6-13

6.10 Reading Input/Outpu t Information ...................................................................... 6-16

6.11 Monitoring ........................................................................................................ 6-17

6.12

RTC function ...................................................................................................... 6-22

6.12.1 How to use ............................................................................................................ 6-22

Chapter 7 Input/Output Specifications ............................................... 7-1~7-31

7.1 Introduction .......................................................................................................... 7-1

7.2 Digital Input Specifications of Main Unit ................................................................ 7-7

7.2.1 XEC-DR32H / XEC-DN32H input unit (Source/Sink type) ......................................... 7-7

7.2.2 XEC-DR64H / XEC-DN64H input unit (Source/Sink Type) ........................................ 7-8

7.3 Digital Output Specification of Main Unit ............................................................... 7-9

7.3.1 XEC-DR32H output unit ............................................................................................. 7-9

7.3.2 XEC-DR64H output unit ........................................................................................... 7-10

7.3.3 XEC-DN32H output unit (Sink type) ......................................................................... 7-11

7.3.4 XEC-DP32H output unit (Source type) .................................................................... 7-12

7.3.5 XEC-DN64H output unit (Sink type) ......................................................................... 7-13

7.3.6 XEC-DP64H output unit (Source type) .................................................................... 7-14

7.4 Digital Input Module Specification ....................................................................... 7-15

7.4.1 8 point DC24V input module (Source/Sink type) .................................................... 7-15

7.4.2 16 point DC24V input module (Sink/Source type) .................................................. 7-16

7.4.3 32 point DC24V input module (Source/Sink type) ................................................... 7-17

7.5 Digital Output Module Specifications .................................................................. 7-18

7.5.1 8 point relay output module ...................................................................................... 7-18

7.5.2 16 point relay output module .................................................................................... 7-19

7.5.3 8 point transistor output module (Sink type) ............................................................ 7-20

7.5.4 16 point transistor output module (Sink type) .......................................................... 7-21

7.5.5 32 point transistor output module (Sink type) .......................................................... 7-22

7.5.6 8 point transistor output module (Source type) ........................................................ 7-23

7.5.7 16 point transistor output module (Source type) ...................................................... 7-24

7.5.8 32 point transistor output module (Source type) ...................................................... 7-25

7.6 Combined Module Digital Input Specification ....................................................... 7-26

7.6.1 8 point DC24V input part (Source/Sink type) ........................................................... 7-26

7.7 Combined Module Digital Output Specification ..................................................... 7-27

7.7.1 8 point relay output part ........................................................................................... 7-27

7.8 IO Wiring by Using Smart Link Board ................................................................... 7-28

7.8.1 Smart link board ..................................................................................................... 7-28

Chapter 8 Built-in High-speed Counter Function .............................. 8-1~8-32

8.1 High-speed Counter Specifications ........................................................................ 8-1

8.1.1 Performance specifications ...................................................................................... 8-1

8.1.2 Designation of parts .................................................................................................. 8-2

8.1.3 Counter Function ........................................................................................................ 8-4

8.2 Installation and Wiring ........................................................................................ 8-21

8.2.1 Precaution for wiring ............................................................................................... 8-21

8.2.2 Example of wiring ................................................................................................... 8-21

8.3 Internal Memory ................................................................................................. 8-22

8.3.1 Special area for High-speed counter ...................................................................... 8-22

8.3.2 Error code ............................................................................................................... 8-27

8.4 Examples: Using High-speed Counter ................................................................ 8-28

Chapter 9 Installation and Wiring ........................................................ 9-1~9-18

9.1 Safety Instruction ................................................................................................. 9-1

9.1.1 Fail safe circuit .......................................................................................................... 9-3

9.1.2 PLC heat calculation .................................................................................................. 9-6

9.2 Attachment/Detachment of Modules ..................................................................... 9-8

9.2.1 Attachment/Detachment of modules ....................................................................... 9-8

9.2.2 Caution in handling .................................................................................................. 9-13

9.3 Wire ..................................................................................................................... 9-14

9.3.1 Power wiring ............................................................................................................. 9-14

9.3.2 I/O Device wiring ...................................................................................................... 9-17

9.3.3 Grounding wiring ...................................................................................................... 9-17

9.3.4 Specifications of wiring cable ................................................................................... 9-18

Chapter 10 Maintenance .................................................................... 10-1~10-2

10.1 Maintenance and Inspection ............................................................................. 10-1

10.2 Daily Inspection ................................................................................................ 10-1

10.3 Periodic Inspection ........................................................................................... 10-2

Chapter 11 Troubleshooting ............................................................ 11-1~11-12

11.1 Basic Procedure of Troubleshooting ................................................................. 11-1

11.2 Troubleshooting .................................................................................................. 11-1

11.2.1 Troubleshooting flowchart used with when the PWR(Power) LED turns Off. ........ 11-2

11.2.2 Troubleshooting flowchart used with when the ERR(Error) LED is flickering ....... 11-3

11.2.3 Troubleshooting flowchart used with when the RUN,STOP LED turns Off. ......... 11-4

11.2.4 Troubleshooting flowchart used with when the I/O part doesn’t operate norm all y..11-5

11.3 Troubleshooting Questionnaire ......................................................................... 11-7

11.4 Troubleshooting Examples ............................................................................... 11-8

11.4.1 Input circuit troubles and corrective actions ......................................................... 11-8

11.4.2 Output circuit and corrective actions ...................................................................... 11-9

11.5 Error Code List .................................................................................................. 11-11

Appendix 1 Flag List ............................................................. App. 1-1~App.1-8

Appendix 1.1 Special Relay (F) List ..................................................................... App. 1-1

Appendix 1.2 Communication Relay (L) List ........................................................ App. 1-5

Appendix 1.3 Network Register (N) List .............................................................. App. 1-8

Appendix 2 Dimension ............................................................. App.2-1~App.2-4

Appendix 3 Compatibility with GLOFA ................................... App.3-1~App.3-7

Appendix 4 Instruction List ................................................... App.4-1~App.4-13

Appendix 4.1 Basic Function ................................................................................. App.4-1

Appendix 4.2 MK(MASTER-K) Function ............................................................. App.4-10

Appendix 4.3 Array Operation Function ............................................................. App.4-10

Appendix 4.4

Basic Function Block................................................................... App.4-11

Chapter 1 Introduction

Chapter 1 Introduction

1.1 Guide to Use This Manual

This manual includes specifications, functions and handling instructions for the XGB series PLC.

This manual is divi ded up into chapters as follows.

No. Title Contents

Chapter 1 Introduction

Describes configuration of this manual, unit’s features and

terminology.

Chapter 2 System Configurations

Describes available units and system configuration in the XGB

series.

Chapter 3 General Speci ficati on s

Describes general specifications of units used in

the XGB

series.

Chapter 4 CPU Specifications

Describes performances, specifications and operations.

Chapter 5

Program

Configuration and

Operation Method

Chapter 6 CPU Module Functions

Chapter 7 Input/Output Specifications Describes operation of basic and input/output.

Chapter 8

Built-in High-speed Cou nter

Function

Describes built-in high-speed counter functions.

Chapter 9 Installation and Wiring

Describes installation, wiring and handling instructions for

reliability of the PLC system.

Chapter 10

Maintenance

Describes the check items and method for long-

term normal

operation of the PLC system.

Chapter 11

Troubleshooting Describes various operation errors and corrective actions.

Appendix 1 Flag List Describes the types and contents of various flags.

Appendix 2 Dimension Shows dimensions of the main units and expansion modules.

Appendix 3

Compatibility with

GLOFA

Describes the compatibility with GLOFA.

Appendix 4 Instruction List Describes the special relay and instruction list.

1-1

Chapter 1 Introduction

1.2 Features

The features of XGB system are as follows.

(1) The system secures the following high performances.

(a) High Processing Speed

(b) Max. 384 I/O control supporting small & mid-sized system implement ation

Item Specification Reference

Operation processing

speed

83ns / Step -

Max IO contact point 384 points

Program capacity 200KB -

Max. no. of expanded

base

10 stages -

(c) Enough program capacity

(d) Expanded appli cation s with the suppo rt of float ing poi nt.

(2) Compact : the smallest size comparing to the same class model of competitors.

(a) Compact panel realiz ed thr ough the smallest size.

Item Type Size (W * H * D)

Reference

Main unit

XEC-Dx32H 114 * 90 * 64

XEC-Dx64H 180 * 90 * 64

Extension module XBE-,XBF-,XBL- 20 * 90 * 60 Basis of minimum size

(3) Easy attachable/extensible system for improved user convenience.

(a) Easy attachable to European terminal board and convenient-to-use MIL connector method improving

convenient wirin g. (“S” type main unit and expanded module)

(b) By adopting a removable terminal block connector (M3 X 6 screw), convenience of wiring may be

increased.

(c) By adopting connector coupling method, modules may be easily connected and separated.

(4) Improved maintenance ability with kinds of regis ter, built-in RTC (“H” type), comment backup and etc

(a) Convenient programmin g envir onment by p rovidin g analogu e regi ster, array and structure.

(b) Improved maintenance ability by operating plural programs and task program through module program.

(c) Built-in Flash ROM enabling permanent backup of program without any separate battery.

(d) Improved mainte nance ability by ty pes o f comme nt ba ckup.

(e) Built-in RTC function enabling convenient history and schedul e manage ment

1-2

Chapter 1 Introduction

(5) Optimized communication environment.

(a) With max. 2 channels o f built-in COM (excl. lo ade r) , up to 2 channel communication is available withou t

any expanded of module.

(b) Supporting various p rotocol s to improv e the conveni en ce (leaseddedicated, Modbus, user-defined

communication)

(c) Communication module may b e addi tio nal ly in c rea sed by ad di ng modules (up to 2 rackstages such as

Cnet, Enet and etc).

(d) Convenient network-diagnostic function through network & communication frame monitoring.

(e) Convenient networking to upper systems through Enet or Cnet.

(f) High speed p rogr am upload and download by USB P or t

(6) Applications expanded with a variety of I/O modules.

(a) 8, 16, 32 points modules provided (if relay output, 8/16 points module).

(b) Single input, single output and combined I/O modules supported.

(7) Applications expanded through analogue-exclusive dedicated register de sign and ful l attachable

mechanism.

(a) All analogue modules can be attachable on extension base. (H type: up to 10 racks stages available)

(b) W ith anal ogue exclusive dedicated re gister(U) and monitor ing exclusive dedicated function, convenient

use for I /O is maximize d (can design ate operations using eas y programming of U area and moni toring

function)

(8) Integrated programming environment

(a) XG 5000: intensified progr am conveni en ce, diver se monito ring, dia gnosi s and editin g functi on

(b) XG - PD: COM/network parameters setting, frame monitoring, protocol analysis function

(9) Built-in high speed counter function

(a) Providing high High-speed counter 1phase, 2phase and more additional func tions.

(b) Providing parameter setting, diverse moni tori ng and diagno sis fun ction using XG500 0.

(c) Moni torin g func tio n in X G500 0 ca n insp ect w ith out pro gram , ins pect ing ex ter nal w iring, data sett ing a nd

others.

(마침표)

(10) Built-in position control function

(a) Supporting max 100Kpps 2 axes.

(b) Providing parameter setting, operation data collection, diverse monitoring and diagnosis by using

XG5000.

(c) Commissioning by monitoring of XG5000, without program, inspecting external wiring and operation data

setting.

1-3

Chapter 1 Introduction

(11) Built-in PID

(a) Supporting max. 16 loops.

(b) Setting parameters by using XG5000 and supporting loop status monitoring conveniently with trend

monitor.

(c) Control constant setting through the improved automatic Auto-tuning function.

(d) With many other additional functions including PWM output, ∆MV, ∆PV and SV Ramp, improving the

control preciseness.

(e) Supporting types of cont rol m odes suc h as for ward/ back ward m ix ed o perat ion, 2-stage SV PID control,

cascade control and etc .

(f) A variety of warning functions such as PV MAX and PV variation warning securing the safety.

1.3 Terminology

The following table gives defin ition o f terms u sed in this manu al.

Terms Definition Remark

Module

A standard element that has a specifie d function which configures

the system . Devices suc h as I/O b oard, whic h inserted onto the

mother board.

Example)

Expansion module,

Special module,

Communication

module

Unit

A single module or group of modules that perform an

independent operation as a part of PLC systems.

Example)

Main unit,

Expansion unit

PLC System

A system which consists of the PLC and peripheral devices.

A user program can control the system.

-

XG5000

A program and debugging tool for the MAS TER-K series.

It executes program creation, edit, compile and debu gging.

(PADT: Programming Added De bugging Tool)

-

XG - PD

Software to execute descrip tion, ed ition of basic par ameter, high

speed link, P2P parameter, and function of communication

diagnosis

-

I/O image area

Internal m emor y area of the CPU m odule wh ich used to hold I/O

status.

Cnet Computer Network FEnet Fast Ethernet Network Pnet Profibus-DP Network Dnet DeviceNet Network -

RTC

Abbreviation of ‘Real Time Clock’. It is used to call general IC that

contains clock function.

-

Watchdog Timer

Supervisors t he pre-set execut i on times of progr ams and warns if

a program is not competed within the pre-set time.

-

1-4

Chapter 1 Introduction

Terms Definition Remark

Sink Input

Current flows from the switch to the PLC input terminal if a in put

signal turns on.

Z: Input

impedance

Source Input

Current flows from the PLC input terminal to the switch after a

input signal turns on.

-

Sink Output

Current flows from the load to the output terminal and the PLC

output turn on.

-

Source Output

Current flows from the output term inal to the load and the PLC

output turn on.

-

−

Output

Contact

1-5

Chapter 2 System Configuration

Chapter 2 System Configuration

The XGB series has suitable to configuration of the basic, computer link and network systems.

This chapter describes the configuration and features of each system.

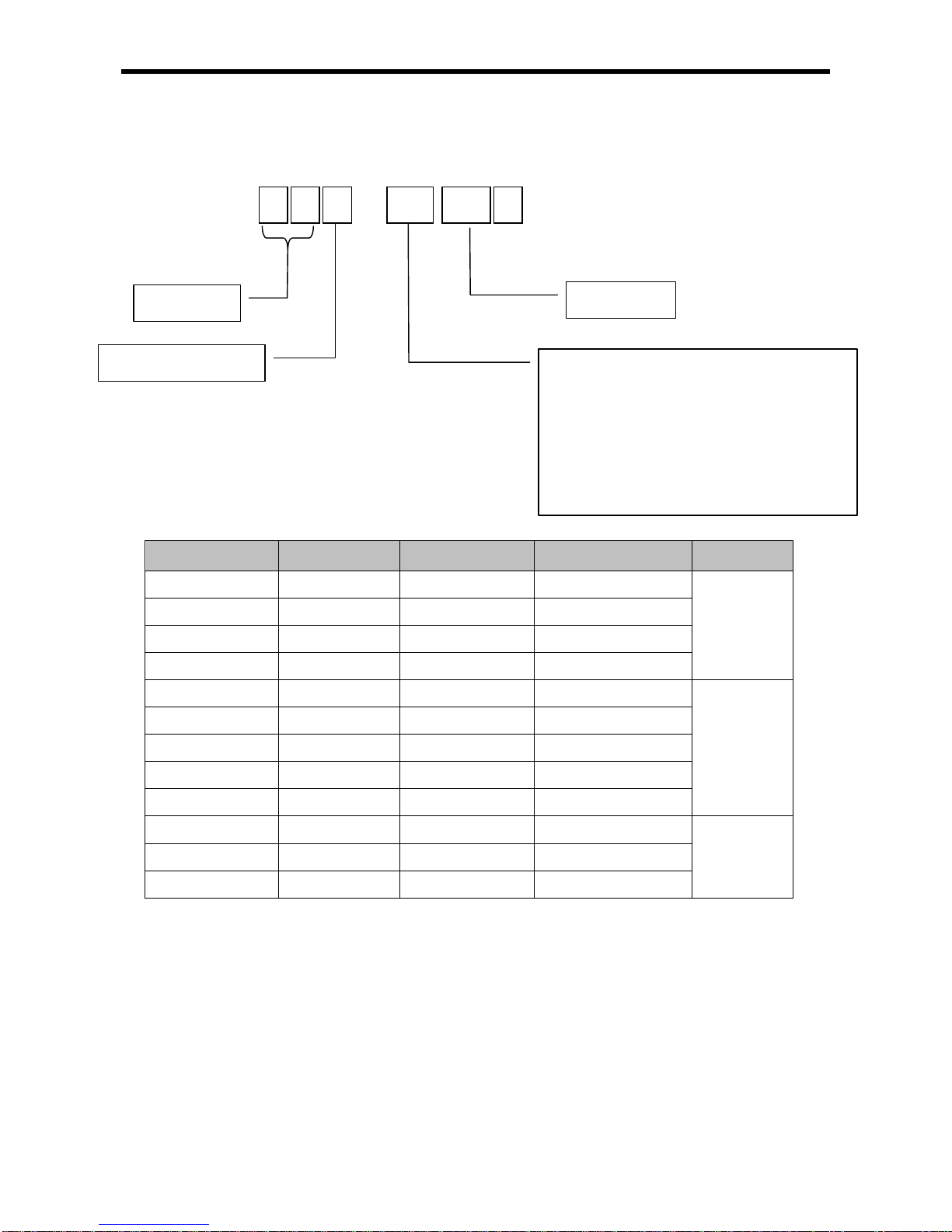

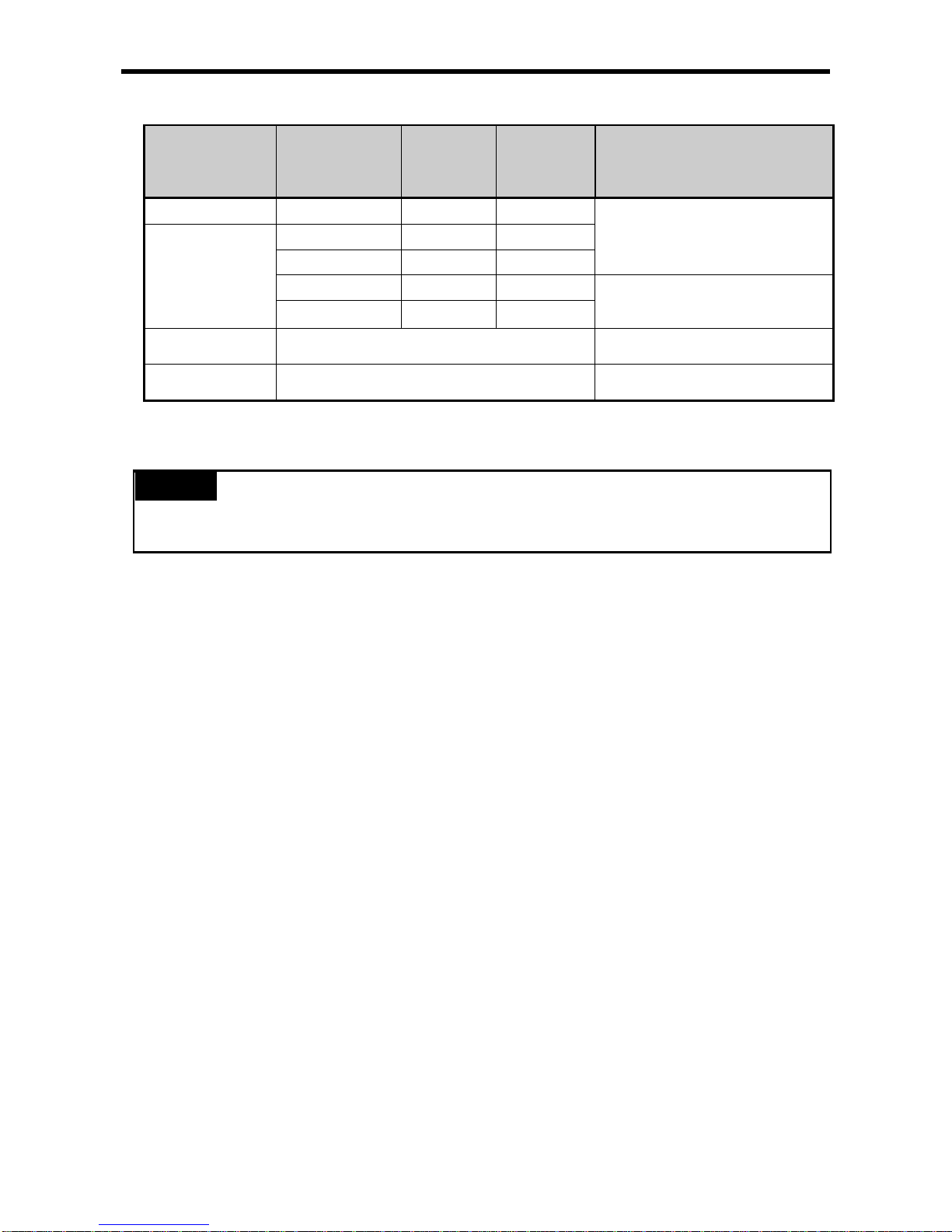

2.1 XGB System Configuration

XGB series System Conf iguration is as f ollows. Expanded I/O module an d special module are available to

connect maximum 7 stages for “S” type and 10 stag es for “H” type. Expanded communication m odule is

available to connect maximum 2 stages.

Item Description

Total I/O points

• XEC-DxxxH : 32~384 points

Maximum number of

expansion

modules

Digital I/O module

•

Max. 10

Special module

•

Max. 10

Comm. I/F module

•

Maximum 2

Items

Main unit

• refer to 2.2 Product List

Expansion

module

Digital I/O module

Special module

Communication I/F

module

Option

module

Memory module

* XG5000 V3.0 or above is required for XEC

Main Unit

I/O Module

Special Module

Communication Module

2-1

Chapter 2 System Configuration

2.2 Product List

XGB series’ product list is as follows.

Types Model Description Remark

Main Unit

XEC-DR32H AC 100V~220V power, DC24V input 16 points, relay output 16 points

-

XEC-DN32H AC 100V~220V power, DC24V input 16 points, TR output 16 points

-

XEC-DN32H/DC DC 24V power, DC24V input 16 points, TR output 16 points

XEC-DR64H AC 100V~220V power, DC24V input 32 points, relay output 32 points

-

XEC-DN64H AC 100V~220V power, DC24V input 32 points, TR output 32 points

XEC-DR32H/D1 DC 12/24V power, DC12V input 16 points, relay output 16 points

XEC-DR64H/D1 DC 12/24V power, DC12V input 32 points, relay output 32 points

Digital I/O module

XBE-DC08A DC24V Input 8 point

-

XBE-DC16A DC24V Input 16 point

-

XBE-DC32A DC24V Input 32 point

-

XBE-RY08A Relay output 8 point

-

XBE-RY08B Relay output 8 point (independent point)

XBE-RY16A Relay output 16 point

-

XBE-TN08A Transistor output 8 point

-

XBE-TN16A Transistor output 16 point

-

XBE-TN32A Transistor output 32 point

-

XBE-TN64A Transistor output 64 point (sink type)

-

XBE-TP16A Transistor output 16 point (source type)

-

XBE-TP32A Transistor output 32 point (source type)

-

XBE-DR16A DC24V Input 8 point, Relay output 8 point

-

Special Module

XBF-AD04A Current/Voltage input 4 channel

Analog

ln/Out

XBF-AD04C Current/Voltage input 4 channel, High resolution

XBF-AD08A Current/Voltage input 8 channel

XBF-DC04A Current output 4 channel

XBF-DC04C Current output 4 channel, High resolution

XBF-DV04A Voltage output 4 channel

XBF-DV04C Voltage output 4 channel, High resolution

XBF-AH04A Current/Voltage input 2 channel, Current/Voltage output 2 channel,

XBF-RD04A RTD (Resistance Temperature Detector) input 4 channel

Temperat

ure

XBF-RD01A RTD (Resistance Temperature Detector) input 1 channel

XBF-TC04S TC (Thermocouple) input 4 channel

XBF-PD02A Position 2Axis, Line Drive type Position

XBF-HD02A High Speed Counter 2 channel, Line Drive Type

Counter

XBF-HO02A High Speed Counter 2 channel, Open Collector Type

XBF-TC04RT

Temperature controller module (RTD input, 4 roof)

Temperat

ure

XBF-TC04TT

Temperature controller module (TC input, 4 roof)

2-2

Chapter 2 System Configuration

Types Model Description Remark

Communication

Module

XBL-C21A Cnet (RS-232C/Modem) I/F XBL-C41A Cnet (RS-422/485) I/F -

XBL-EMTA Enet I/F -

XBL-EIMT RAPIEnet I/F 2 UTP cable

-

XBL-EIPT EtherNet I/P Module

XBL-CMEA CANopen MasterI/F -

XBL-CSEA CANopen Slave I/F -

XBL-PMEC Pnet I/F -

Option

module

XBO-M1024A Memory module -

Download

Cable

PMC-310S

Connection cable (PC to PLC), 9pin(PC)-6pin(PLC) -

USB-301A Connection cable (PC to PLC), USB -

Download Cable (PMC-310S) Diagram

Note

2-3

Chapter 2 System Configuration

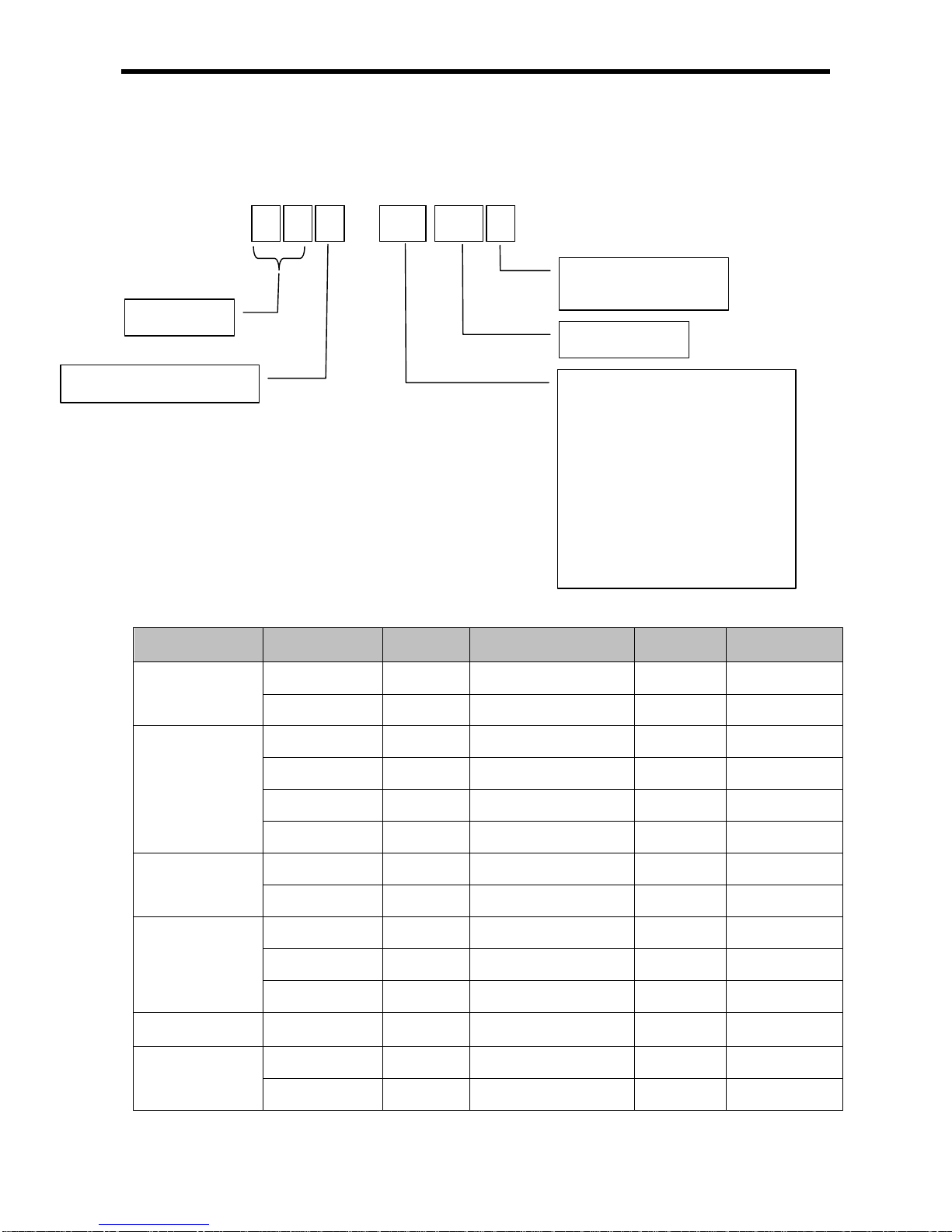

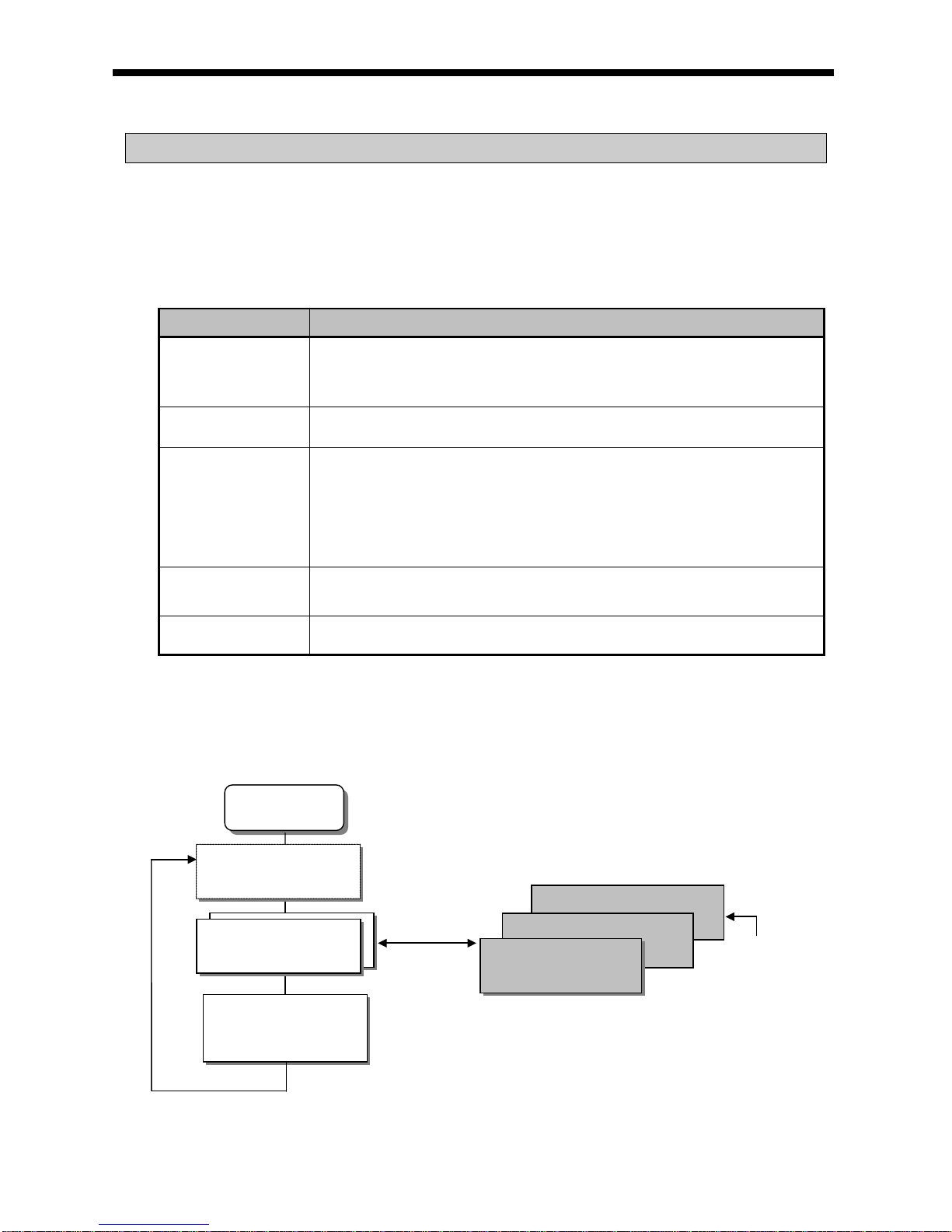

2.3 Classification and T ype of Product Name

2.3.1 Classification and type of main unit

Name of main unit is classified as follows.

Classification Name DC input Relay output Transistor output Power

Module type

Main unit

XBM-DR16S 8 point 8 point None

DC24V

XBM-DN16S 8 point None 8 point

XBM-DN32S 16 point None 16 point

Compact type

Main unit

(MK language)

XBC-DR32H 16 point 16 point None

AC110V~220V

XBC-DN32H 16 point None 16 point

XBC-DR64H 32 point 32 point None

XBC-DN64H 32 point None 32 point

XBC-DR32H/DC 16 point 16 point None

DC24V

XBC-DN32H/DC 16 point None 16 point

XBC-DR64H/DC 32 point 32 point None

XBC-DN64H/DC 32 point None 32 point

Compact type

main unit

(IEC language)

XEC-DR32H

16 point 16 point None

AC110V~220V

XEC-DN32H

16 point None 16 point

XEC-DR64H

32 point 32 point None

XEC-DN64H

32 point None 32 point

XEC-DP32H

16 point None 16 point

XEC-DP64H

32 point None 32 point

XEC-DR32H/D1

16 point 16 point None

DC 12/24V

XEC-DR64H/D1

32 point 32 point None

X B M

-

D R X X S

Relay output (R)

Sink type transistor output (N)

Source type transistor output (P)

No. of IO point

XGB PLC standard (S)

XGB PLC High-end type (H)

XGB PLC

Module type main unit (M)

Compact type main unit(C)

DC input

MK language supported (B)

IEC language supported (E)

2-4

Chapter 2 System Configuration

2.3.2 Classification and type of expansion module

Name of expansion module is classified as follows.

Name DC input Relay output Transistor output Reference

XBE-DC08A

8 point None None

XBE-RY08A/B

None 8 point None

XBE-TN08A

None None 8 point (Sink type)

XBE-TP08A

None None 8 point (Source type)

XBE-DC16A/B

16 point None None

XBE-RY16A

None 16 point None

XBE-TN16A

None None 16 point (Sink type)

XBE-TP16A

None None 16 point (Source type)

XBE-DR16A

8 point 8 point None

XBE-DC32A

32 point None None

XBE-TN32A

None None 32 point (Sink type)

XBE-TP32A

None None 32 point (Source type)

X B E

-

DC X X A

Relay output(RY)

Transistor output (TN/TP)

Digital input (DC)

Digital input+ sink type transistor output (DN)

Digital input+ source type transistor output (DP)

Digital input + relay output (DR)

No. of IO point

XGB series

I/O expansion module

2-5

Chapter 2 System Configuration

2.3.3 Classification and type of special module

Special module is classified as follows.

Classification Name

No. of

input ch.

Input type

No. of

output ch.

Output type

Analog input

XBF-AD04A 4 Voltage/Current None XBF-AD08A 8 Voltage/Current None

Analog output

XBF-DC04A None - 4 Current

XBF-DC04B None - 4 Current

XBF-DV04A None - 4 Voltage

XBF-AH04A 2 Voltage/Current 2 Voltage/Current

RTD input

XBF-RD04A 4 PT100/JPT100 None XBF-RD01A 1 PT100/JPT100 None -

TC input

XBF-TC04S 4 K, J, T, R None -

XBF-TC04RT 4 PT100/JPT100 4 Transister

XBF-TC04TT 4 K, J, T, R 4 Transister

Positioning

module

XBF-PD02A - Line Driver 2 Voltage

High Speed

Counter

XBF-HD02A 2 Line Driver

XBF-HO02A 2 Open Collector

X B F

-

AD X X A

Analog input (AD)

Analog voltage output (DC)

Analog current output (DV)

Analog combined module (AH)

RTD input (RD)

Thermocouple input (TC)

Line driver positioning module (PD)

No. of IO point

XGB series

Expansion special module

Non-insulation type (A)

Insulation type (S)

2-6

Chapter 2 System Configuration

2.3.4 Classification and type of communication module

Name of communication module is classified as follows.

Classification Name Type

Cnet Comm. Module

XBL-C21A RS-232C, 1 channel

XBL-C41A RS-422/485, 1 channel

FEnet Comm. Module XBL-EMTA Electricity, open type Ethernet

RAPIEnet Comm. Module

XBLEIMT/EIMF/EIMH

Comm. Module between PLCs, electric media,

100 Mbps industrial Ethernet supported

EtherNet Comm. Module XBL-EIPT Open EtherNet I/P

CANopen Comm. Module

XBL-CMEA CANopen Master

XBL-CSEA CANopen Slave

Pnet Comm. Module XBL-PMEC Profibus-DP

2.3.5 Classification and Type of Option Module

Name of option module is classified as follows.

Classification Name Type

Memory module XBO-M1024A Memory module : 1,024 KB

X B L - C21A

Cnet 1 channel (RS-232C): C21A

Cnet 1 channel (RS-422/485): C41A

FEnet 1 channel: EMTA

RAPIEnet 1 channel: EIMT

XGB series

Expansion communication module

X B O - M1024A

Memory module : 1,024 KB

XGB series

Option module

2-7

Chapter 2 System Configuration

2.4 System Configuration

2.4.1 Cnet I/F system

Cnet I/F System is used for communication between the main unit and external devices using RS-

232C/RS-422 (485) Int erface. The XGB ser ies has a built-in RS-232C port, R S-485 port and has also

XBL-C21A for RS-232C , XBL-C4 1A for R S-422/485. I t is pos sible to c onstruct c omm unication s ystems

on demand.

(1) 1:1 communication system

(a) 1:1 communication of an external device (computer) with main unit using a built-in port

(RS-232C/RS-485)

(b) 1:1 communication wit h main unit using a built-in RS-485 port

(In case of built-in RS-232C,it is for connecting to HMI device.)

Built-in RS-232C Connection

PADT

connection

Built-in RS-485 Connection

RS-232C / RS-485

XEC-DR32H

XEC-DR32H

XEC-DR32H

XP30-TTA

2-8

Chapter 2 System Configuration

(c) 1:1 RS-232C Communication with remote device via modem by Cnet I/F modules

(d) 1:1 communication of an external device (monito ring unit) with main unit using a built-in RS-

232C/485 port.

Modem

Modem

XBL-C21A

XEC-DR32H

XBL-C21A

XEC-DR32H

Modem

Modem

XBL-C21A

XEC-DR32H

Built-in RS-232C/485 connection

XP30-TTA

XEC-DR32H

2-9

Chapter 2 System Configuration

(2) 1:n Communication system

(a) Using RS-485 built-in function can connect between one computer and multiple main units for up

to 32 stations.

(b) Using RS-485 built-in function/expansion Cnet I/F module can be connect for up to 32 stations.

1) Refer to ‘XGB Cnet I/F user manual’ for details

Note

Max. 32 stations available

PADT connection

Built-in RS-232C connection

XEC-DN32H

Max. 32 stations available

XEC-DN32H

PADT connection

Built-in RS-232C connection

XBL-C41A

XEC-DN32H

XBL-C41A

XEC-DN32H

Max. 32 stations available

Max. 32 stations available

2-10

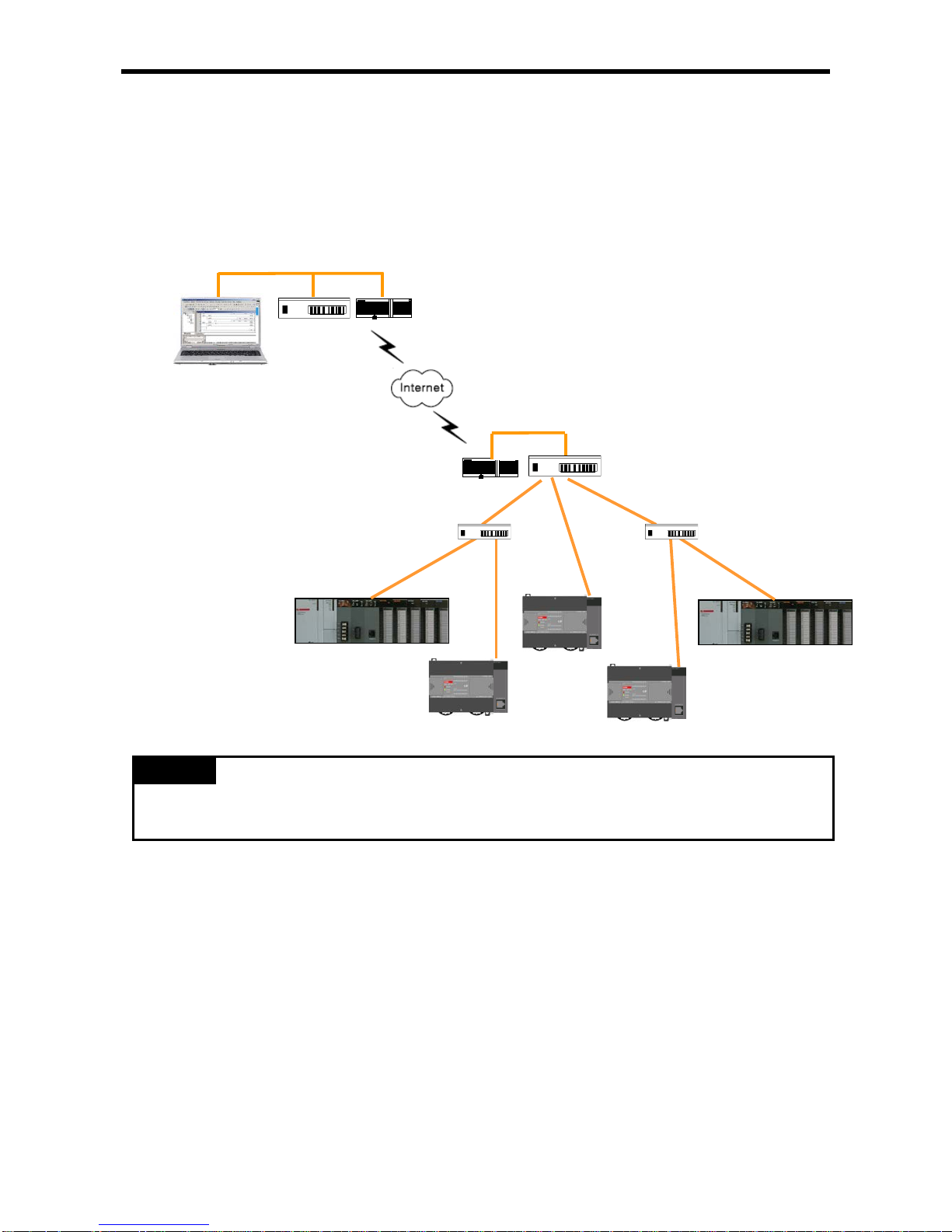

Chapter 2 System Configuration

Hub

Hub

Hub

Hub

Router or

Gateway

Router or

Gateway

Public line

2.4.2 Ethernet system

Ethernet made b y cooperation of Xerox, Intel, DEC is standard LAN c onnection method (IEEE802.3) ,

which is network connection system using 1.5KB packet with 100Mbps transmission ability. Since

Ethernet can combine a variety of computer by network , it is called as standard specification of LAN and

diverse products. By adopting CSMA/CD m ethod, it is easy to configure the network and collect large

capacity data.

1) Refer to ‘XGB FEnet I/F user manual’ for details

Note

100Base-TX

M

HMI

HMI

H

2-11

Chapter 3 General Specifications

Chapter 3 General Specifications

3.1 General Specifications

The General specification of XGB series is as below.

No. Items Specifications Related standards

1

Ambient

temperature

0 ~ 55 °C

-

2

Storage

temperature

−25 ~ +70 °C

3

Ambient

humidity

5 ~ 95%RH (Non-condensing)

4

Storage

humidity

5 ~ 95%RH (Non-condensing)

5

Vibration

resistance

Occasional vibration

-

Frequency

Acceleration

Amplitude

times

IEC61131-2

5 ≤ f < 8.4Hz

−

3.5mm

10 times each

directions

(X, Y and Z)

8.4 ≤ f ≤ 150Hz

9.8m/s2 (1G)

−

Continuous vibration

Frequency

Acceleration

Pulse width

5 ≤ f < 8.4Hz

−

1.75mm

8.4 ≤ f ≤ 150Hz

4.9m/s2 (0.5G)

−

6

Shock

resistance

• Peak acceleration: 147 m/s

2

(15G)

• Duration: 11ms

•

Half-sine, 3 times each direction per each axis

7

Noise

resistance

Square wave

Impulse noise

AC: ±1,500 V

DC: ±900 V

LSIS standard

Electrostatic

discharge

4kV (Contact discharge)

IEC61131-2

IEC61000-4-2

Radiated

electromagnetic

field noise

80 ~ 1,000 MHz, 10V/m

IEC61131-2,

IEC61000-4-3

Fast

transient/bust

noise

Segment

Power

supply

module

Digital/analog input/output

communication interface

IEC61131-2

IEC61000-4-4

Voltage

2kV

1kV

8

Environment

Free from corrosive gasses and excessive dust

9

Altitude

Up to 2,000 ms

10

Pollution

degree

2 or less

11

Cooling

Air-cooling

1) IEC (International Electrotechnical Commission)

:

An international civil community that promotes international cooperation for standardization of

electric/ electro technology, publishes international standard and operates suitability assessment

system related to the above.

2) Pollution Degree

:

An index to indicate the pollution degree of used environment that determines the insulation

performance of the device. For example, pollution de gree 2 means the state to occur the pollution of

non-electric conducti vity generally, but the state to occ ur temporary electric conductio n according to

the formation of dew.

Notes

3-1

Chapter 4 CPU Specifications

Chapter 4 CPU Specifications

4.1 Performance Specifications

The following table shows the general specifications of the XGB main module type

Items

Specifications

Remark

XECDR32H(/D1)

XECDR64H(/D1)

XECDN32H(/DC)

XECDN64H

XECDP32H

XECDP64H

Numb

er of

instruc

tions

Operator 18

Basic function 136 + Real number operation function

Basic function block 43

Dedicated function

block

Special function dedicated function

Processing speed

Basic instruction : 0.083 ㎲/step

Program memory capacity 200KB (XEC 200KB corresponds to XGI 110KB)

Max. I/O points 352 384 352 384 352 384

Data

memory

Automatic variable

(A)

32KB (Max. 16KB retain set ting avai lable )

Input variable (I) 2 KB (%IX15.15.63)

Output variable (Q) 2 KB (%QX15.15.63)

Direct

variable

M 16KB (Max. 8KB retain setting available)

R 20KB (1block)

W 20KB Same area with R

Flag

variable

F 2KB System flag

K 8KB Built-in special flag

L 4KB High speed link flag

N 10KB P2P flag

U 1KB Analog flag

Flash area 20KB, 2 block R device used

Timer No limit to the number of point (time range: 0.001s ~ 4,294,967,295s)

20 byte automatic

variable area

occupied per r point

Counter No limit to the number of point (count range: 64 bit expression range)

Operation mode RUN, STOP, DEBUG

Restart mode Cold, Warm

Total number of program

block

128

Task

Initialization 1

Fixed period 8

External input 8 (%IX0.0.0 ~ %IX0.0.7)

Internal devi ce 8

Self diagnosis Detecting operation delay , memory error, I/O error

Data reserved in case of

power cut

Setting retain area at basic parameter

Number of max. extension

stage

10 stage

Internal consumption

current

660mA 1,040mA 260mA 330mA 300mA 380mA

Weight 600g 900g 500g 800g 500g 800g

4- 1

Chapter 4 CPU Specifications

Items Specifications Remark

Built-in function

PID control function

Controlled by instructions, Auto-

tuning, PWM output, Manual output,

Adjustable operation scan time, Anti Windup, Delta MV function, SV-

Ramp function

-

Cnet I/F function

Dedicated protocol support

MODBUS protocol support RS-232C 1 port

User defined protocol support RS-485 1 port

High-speed counter

Capacity

AC

type

1 phase: 100 kHz 4 channel, 20kHz 4 channel

2 phase: 50 kHz 2 channel, 10kHz 2 channel

D1

type

1 phase : 100 kHz 4 channel, 10 kHz 4 channel

2 phase : 50 kHz 2 channel, 5 kHz 2 channel

Counter

mode

4 different counter modes according to input pulse and

addition/subtraction method

• 1 phase pulse input: addition/subtraction counter

• 1 phase pulse input: a

ddition/subtraction counter by B

phase

• 2 phase pulse input: addition/subtraction counter

• 2 phase pulse input: addition/subtraction by

phase differences

Additional

function

• Internal/External preset function

• Latch counter function

• Comparison output function

• Revolution number per unit time function

Positioning function

Basic function

No. of control axis: 2 axes

Control method: position/speed control

Control unit: pulse

Positioning data: 80 data/axis

(operation step No. 1~80)

Operation mode: End/Keep/Continuous

Operation method: Single, Repeated operation

TR output type

support

Positioning

function

Positioning method: Absolute / Incremental

Address range: -2,147,483,648 ~ 2,147,483,647

Speed: Max. 100Kpps(setting range 1 ~ 100,000pps)

Acceleration / Deceleration method : trapezoidal method

Return to Origin

Origin detection when approximate origin turns off

Origin detection when approximate origin turns on

Origin detection by approximate origin.

JOG operation

Setting range: 1~100,00 0 ( Hi gh / Low spee d )

Additional

function

Inching operation, Speed synchronizing operation, Position

synchronizing operation, linear interpolation operation etc.

Pulse catch

10㎲ 4 points (%IX 0.0.0~%IX0.0.3), 50㎲ 4points ( %IX0.0.4

~ %IX0.0.7)

-

External interrupt

10㎲ 4points (%IX 0.0.0~%IX0.0.3), 5 0㎲ 4 points (%I X0.0.4

~ %IX0.0.7)

Input filter Select among 1,3,5,10,20,70,100 ㎳ (Adjustable)

4- 2

Chapter 4 CPU Specifications

4.2 Names of Part and Function

XGB Compact type main unit (IEC language)

No. Name Description

①

Input indicator LED

▪ Input indicator LED

②

PADT connecting

connector

▪

PADT connecting USB (USB 1.1 supported) 1 channel,

RS-232C 1 channel connector

③

Input connector and

terminal block

▪ Input connector and terminal block

④

Output connector and

terminal block

▪ Output connector and terminal block

⑤

Key switch

▪

RUN / STOP Key switch

In case of STOP mode, Remote mode changeable.

⑥

Output indicator LED ▪ Output indicator LED

⑦

Status indicator LED

It indicates CPU module’s status.

▪ PWR(Red): Power status

▪ RUN(Green): RUN status

STOP mode: Off/ RUN mode : On

▪

Error(Red): In case of error, it is flickering.

⑧

8-1

Built-in RS-232C

/ RS-485

Connecting

connector

Built-in RS-485 connecting connector

“+” , “-“ terminal connecting connector in RS-485 communication

▪ Built-in RS-232C connecting connector

“TxD” , “RxD“ , “GND” connecting connector in RS-232C

8-2

Power supply

connector

▪ AC100~240V power supply connector

⑨

Battery holder

▪ Battery (3V) holder

⑩

Mode switch

▪ Program mode and O/S download mode select switch

①

②

④

⑤

⑥

③

⑦

8-1

8-2

⑨

⑩

4- 3

Chapter 4 CPU Specifications

4.3 Power Supply Specificat ions

Describes power specification of main unit

Items

Specification

XEC-DR32H

XEC-DN32H

XEC-DP32H

XEC-DR64H

XEC-DN64H

XEC-DP64H

XEC-

DN32H/DC

XEC-

DR32H/D1

XEC-

DR64H/D1

Input

Rated voltage

(UL warranty voltage)

AC 100 ~ 240 V DC24V DC 12/24V

Input voltage range

AC85~264V(-15%, +10%)

DC19.2~28.8V

(-20%,+20%)

DC 9.5~30V

Inrush current 50APeak or less

50APeak

or less

50APeak or less

Input current

AC 220V : 0.5A or less,

AC 110V : 1A or less

0.7A or less

DC 12V :

1.4 A or

less

DC 24V :

0.7 A or

less

DC 12V :

2.1 A or

less

DC 24V :

1.0 A or

less

Efficiency

65% or more

60% or more

Permitted momentary

power failure

Less than 10 ㎳

DC 12V : less than 2

㎳

DC 24V : less than 10

㎳

Output

Rated

output

DC5V

2A

3A

2A

2A

3A

DC24V

0.4A

0.6A - -

-

Output voltage ripple

DC5V (±2%) DC4.9~5.15V

Power supply status indication

LED On when power supply is normal

Cable specification

0.75 ~ 2 mm2

* Use the power supply which has 4 A or more fuse for protecting power supply.

4- 4

Chapter 4 CPU Specifications

(1) Consumption current (DC 5V)

Type Model

Consumption current (Unit : ㎃)

Main unit

XEC-DR32H

660

XEC-DR64H

1,040

XEC-DN32H 260

XEC-DN64H

330

XEC-DP32H

300

XEC-DP64H

380

XEC-DR32H/D1 660

XEC-DR64H/D1 1,040

Expansion I/O module

XBE-DC32A 50

XBE-DC16A/B 40

XBE-DC08A 30

XBE-RY16A 440

XBE-RY08A/B 240

XBE-TN32A 80

XBE-TN16A 60

XBE-TN08A 50

XBE-TP32A 80

XBE-TP16A 60

XBE-TP08A 50

XBE-DR16A 250

Expansion special module

XBF-AD04A 120

XBF-DV04A 110

XBF-DC04A 110

XBF-DC04B 110

XBF-RD04A 100

XBF-RD01A 100

XBF-TC04S 100

XBF-PD02A 500

XBF-AH04A 120

XBF-AD08A 105

Expansion communication module

XBL-C21A 120

XBL-C41A

120

XBL-EMTA 300

XBL-EIMT 290

XBL-EIPT 290

Memory module XBO-M1024A 40

4- 5

Chapter 4 CPU Specifications

4.4 Calculation Example of Consumption Current/Voltage

Calculate the consumption current and configure the system not to exceed the output current capacity of

main unit.

(1) XGB PLC configuration example 1

Consumption of current/voltage is calculated as follows.

Type Model Unit No.

Internal 5V

consumption

current

(Unit : ㎃)

Remark

Main unit XEC-DN32H 1 260

In case contact points are On.

(Maximum consumption current)

Expansion

module

XBE-DC32A 2 50

XBE-TN32A 2 80

XBF-AD04A 1 120

All channel is used.

(Maximum consumption current)

XBF-DC04A 1 110

XBL-C21A 1 120

Consumption

current

870 ㎃

-

Consumption

voltage

4.35 W

0.87A ⅹ 5V = 4.35W

In case system is configured as above, since 5V consumption current is total 870 mA and 5V output of XGB

32 points main unit is maximum 2A, normal system configuration is available.

(2) XGB PLC configuration example 2

Type Model Unit No.

Internal 5V

consumption

current

(Unit : ㎃)

Remark

Main unit XEC-DR32H 1 660

In case all contact points are On.

(Maximum consumption current)

Expansion

module

XBE-DR16A 5 250

XBE-TN32A 2 80

XBF-AD04A 1 120

All channel is used.

(Maximum consumption current)

XBL-C21A 1 120

Consumption

current

2,310mA -

Consumption

voltage

11.55W 2.31 * 5V = 11.55W

If system is configured as above, total 5V current consumption is exceeded 2,310mA and it exceeds the 5V

output of XGB 32 points main unit. Normal system configuration is not available. Although we assume the

above example that all contact points are on, please use 64 points main unit which 5V output capacity is

higher than standard type main unit.

4- 6

Chapter 4 CPU Specifications

(3) XGB PLC configuration example 3

Type Model Unit No.

Internal 5V

consumption

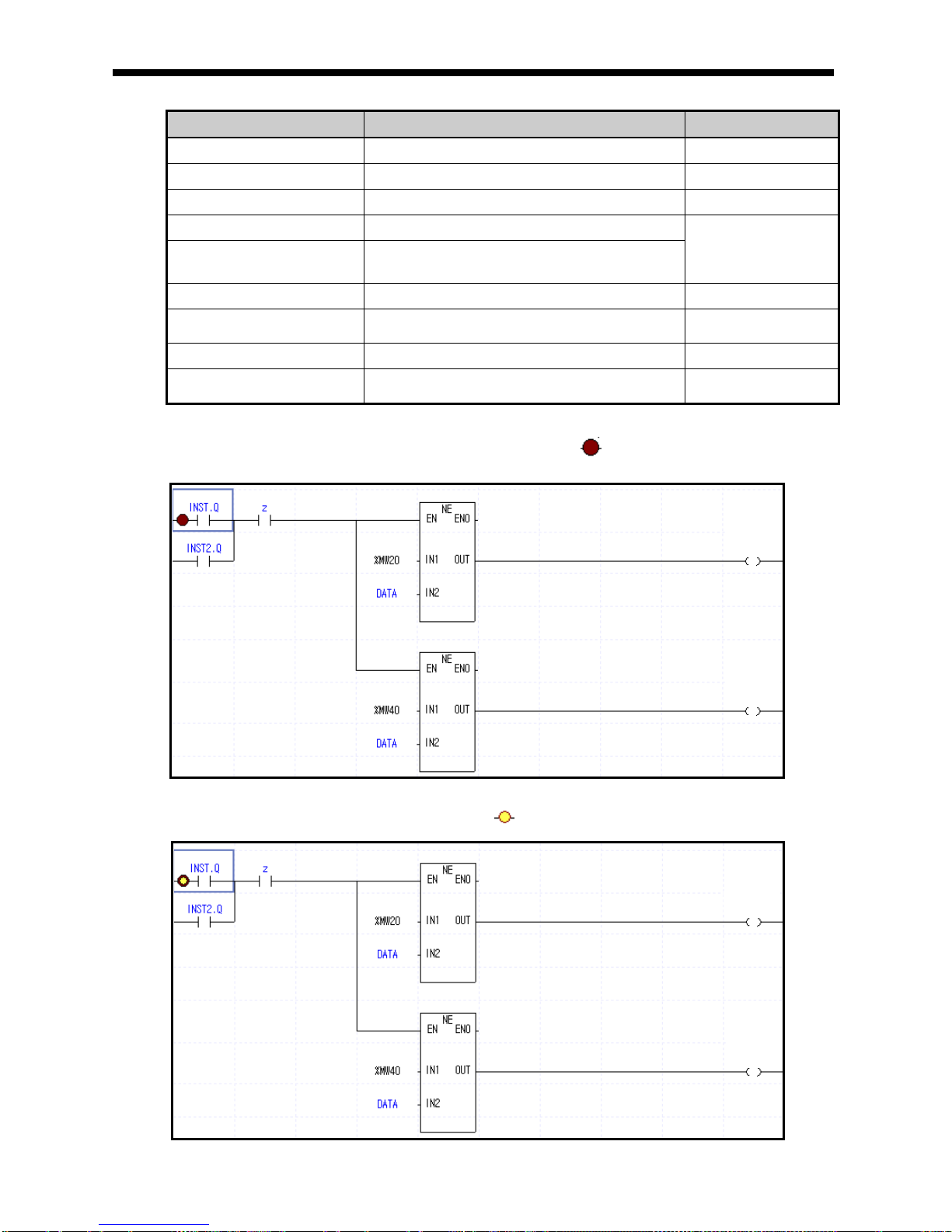

current

(Unit : ㎃)

Remark

Main unit XEC-DR64H 1 1,040

In case of all contact points are

On.

(Maximum consumption current)

Expansion

module

XBE-DR16A 5 250

XBE-TN32A 2 80

XBF-AD04A 1 120

All channel is used.

(Maximum consumption current)

XBL-C21A 1 120

Consumption

current

2,690mA -

Consumption

voltage

13.45W

2.69A ⅹ 5V = 13.45W

The above system is an example using XEC-DR64H, 64 points main unit, about system (2). Unlike (2)

example, 5V output capacity of XEC-DR64H is maximum 3A, normal configuration is available.

Remark

Calculating of consum ption current is based on m aximum consum ption current. In app lication system ,

the consumption current is consumed less than above calc ulat ion.

4- 7

Chapter 4 CPU Specifications

4.5 Battery

Battery is inserted in XGB PLC compact main unit (XEC-DR32/64H, XEC-DN32/64H, XEC-DP32/64H)

4.5.1 Battery specification

Item

Specification

Voltage/Current

DC 3V / 220 mAh

Warranty period

3 years (ambient temp.)

Purpose

Program and data backup,

RTC operation in case of power failure

Specification

Manganese Dioxide lithium battery

Dimension (mm)

φ 20 X 3.2 mm

4.5.2 Notice in using

(1) Do not heat the battery or solder the polarity. ( It may cause the reduction of life.)

(2) Do not measure the voltage or short with tester. (It may cause the fire.)

(3) Do not disassemble the battery.

4.5.3 Life of battery

Life of battery depends on the power failure time and ambient temperature etc..

If battery is getting low, main unit cause the warning, ‘battery voltage low warn ing ’. The user can check it

by error LED, flag and error message of XG5000.

Since battery works properly for long time, after battery voltage low warning, so the user can take the

action after batter y voltage lo w warning occurred.

4- 8

Chapter 4 CPU Specifications

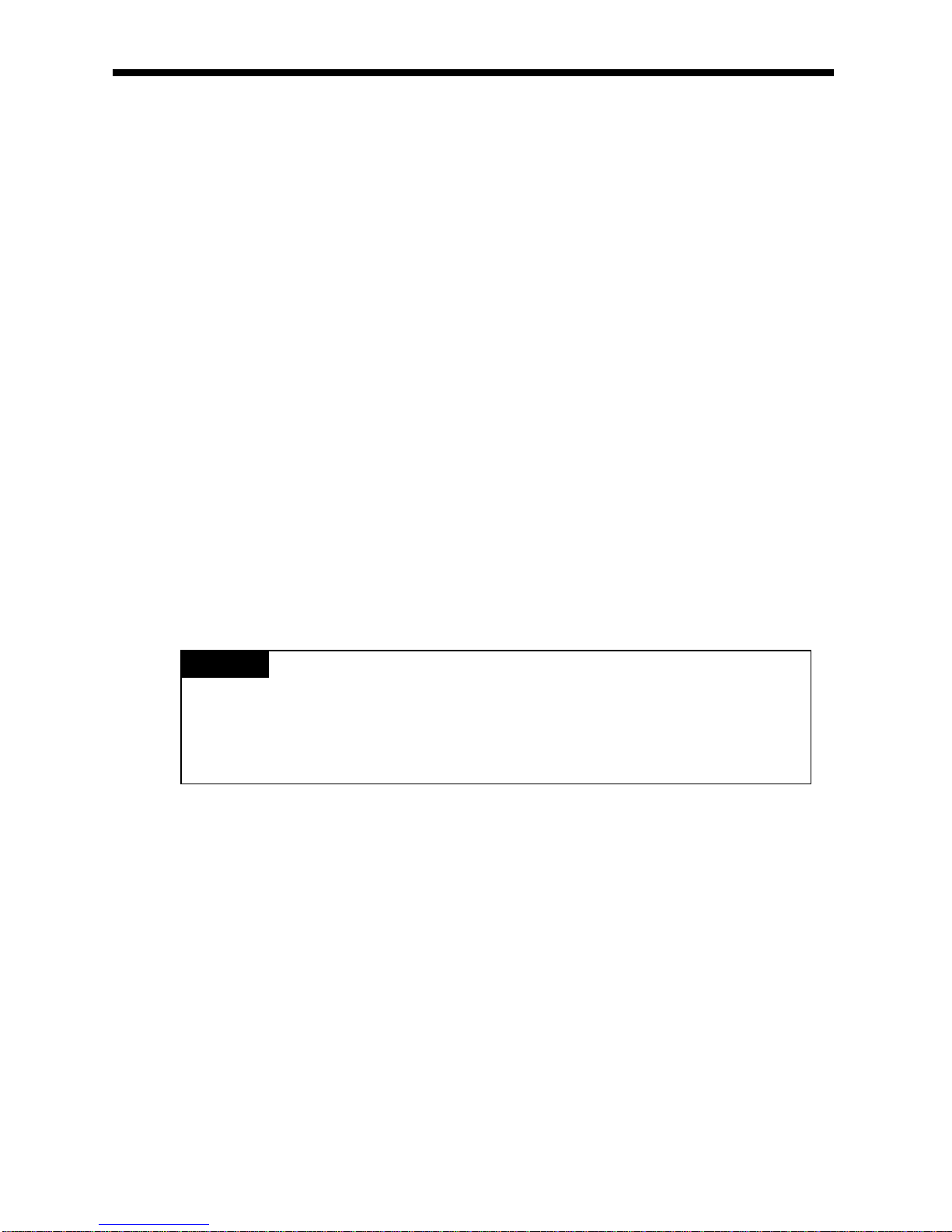

4.5.4 How to change the battery

The user should change the battery used to save the program and backup the data in case of power

failure periodically. Though the user eliminate the battery, it works for 30 minute by super capacitor.

Change the battery as fast as possible.

Sequence changing battery is as follows.

Start of battery change

Open battery cover

Pick up using battery from holder and

disassemble the connector

Insert new battery and connect to

connector with proper direction

Check the LED whether ERR LED is off

ERR LED off?

Battery malfunction

No

Yes

Complete

4- 9

Chapter 5 Program Configuration and Operation Method

Chapter 5 Program Configuration and Operation Method

5.1 Program Instruction

5.1.1 Program execution methods

(1) Cyclic operation method (Scan)

This is a basic program pro ceeding met hod of PLC that perfo rms the oper ation repe atedly for the pr epared

program from the beginning to the last step, which is called ‘program scan’. The series of processing like

this is called ‘cyclic operation method’. The processing is divided per stage as below.

Stage Processing description

-

A s tage to start the scan processing which is executed once

when power is applied or Reset is executed, as below.

Self-diagnosis execution

Data clear

Address allocation of I/O module and type register

If initializing task is designated, Initializing program is executed.

Reads the state of input module and saves it in input image

area before starting the operation of program.

Perform s the operation in order fr om the program start to las t

step.

Performs the operation in order from the program start to last step.

A processing stage to return to the first step after CPU module

completes 1 scan processing an d the processing p erformed is as

below.

Update the current value of t imer and co unter et c.

User event, data trace service

Self-diagnosis

High speed link, P2P e-Service

Check the state of key switch for mode setting

Start

Initialization processing

Input image area refresh

Program operation processing

Program start

Program last step

Output image area refresh

END

5 - 1

Chapter 5 Program Configuration and Operation Method

(2) Interrupt operation (Cycle time, Internal device)

This is the method that stops the program operation in proceeding temporarily and carries out the

operation processing which corresponds to interrupt program immediately in case that there occurs the

status to process emergently during PLC program execution.

The signal to inform this kind of urgent status to CPU module is called ‘interrupt signal’. There is a Cycle

time signal that operates program every appointed time and external interrupt signal that operates program

by external contact point (%IX0.0.0~%IX0.0.7). Besides, there is an internal devi ce start prog ram that

starts according to the state change of device assigned in si de .

(3) Constant Scan (Fixed Period)

This is the operation method that performs the scan program every appointed time. This stands by for a

while after performing all the scan program, and starts again the program scan when it reaches to the

appointed time. The di ffe r ence fro m con stan t p r og ram i s t he up dat e o f inp ut /ou tput and t he thi ng to

perform with synchroniz ati on.

At constant operation, the scan time indicates the net program processing time where the standby time is

deducted. In case that scan time is bigger than ‘constant’, %FX92 (_CONSTANT_ER) flag shall be ‘ON’.

5.1.2 Operation processing during momentary power failure

CPU module detects the momen ta ry power fail ure when input power vol tage supp lied to power modu le is lower

than the standard. If CPU module detects the momentary power failure , it carries out the operation processing

as follows.

If momentary power failure within 10 ms is occurred, main unit (CPU) keeps the operation. But, if

momentary power failure a bove 10 ㎳, the operation is stop and t he output is Off. Restart pr ocessing

like at power input shall be performed.

(1) Momentary power failure within 10 ms

(2) Momentary power failure exceeding 10 ms

Remark

1) Momentary power failure?

This means the state that the voltage of supply power at power condition designated by PLC is

lowered as it exceeds the allowable variable range and the short time (some ms ~ some dozens ms)

interruption is called ‘momentary power failure’ ).

Restart processing like at power input shall

be performed.

Input power

Input power

Momentary power failure exceeding 10 ms

Momentary power failure within 10 ms

(1) When momentar y po wer failure occurs, PLC holds

its output status and stop operation.

(2) If momentary power failure is canceled, operation

continues.

(3) Output voltage of power module keeps value is

specification.

(4) Though momentary power failure occurs and

operation stops, timer measurement and timer

measurement for interrupt is conducted normally.

5 - 2

Chapter 5 Program Configuration and Operation Method

5.1.3 Scan time

The processing time from program step 0 to the next step 0 is called ‘Scan Time’.

(1) Scan time calculation expression

Scan time is the sum of the processing time of scan program and interrupt program prepared by the user

and PLC internal time, and i s disting uished by the follow ing fo rmula.

(a) Scan time = Scan program processing time + Interrupt program processing time + PLC internal

processing time

Scan program processing time = processing time of user program not saved as interrupt program

Interrupt program processing time = Sum of interrupt program proceeding time processed during 1 scan

PLC internal processing time = Self-diagnosis time + I/O refresh time + Internal data processing time

+ Communication service processing time

(b) Scan time depends on whether to execute interrupt program and communication processing.

(2) Scan time monitor

(a) Scan time can be monitored 『Online』-『PLC Information』-『Performance』.

(b) Scan time is save in special relay (F) area as follows.

%FW50: max. value of scan time (unit: 0.1 ms)

%FW51: min. value of scan time (unit: 0.1 ms)

%FW52: current value of scan time (unit: 0.1 ms)

5- 3

Chapter 5 Program Configuration and Operation Method

5.1.4 Scan Watchdog timer

WDT (Watchdog Timer) is the function to detect the program congestion by the error of hardware and software of

PLC CPU module.

(1) WDT is the timer used to detect the operation delay by user program error. The detection time of WDT is

set in Basic parameter of XG5000.

(2) If WDT detects the excess of detection setting time while watching the elapsed time of scan

during operation, it stops th e oper ation of PLC im m ediately an d k eeps or cle ars t he outp ut ac cordi ng

to parameter setting

(3) If the excess of Scan Watchdog Time is expected in the program processing of specific part while

performing the user program (FOR ~ NEXT instruction, CALL instruction), clear the timer by using

‘WDT_RST’ Function

‘WDT_RST’ Function initializes the elapsed time of Scan Watchdog Timer and starts the time measurement

from 0 again.

(For further information of WDT_RST Function, please refer to Instruction.)

(4) To clear the erro r state o f watchdog , we can use the fol lowing method : powe r re-supply, PLC reset,

mode conversion to STOP mode.

Remark

1) The setting range of Watchdog Timer is 10 ~ 1000ms (Unit: 1ms).

WDT_RST instruction

execution

0 1 2 3 ….. …8 9

SCAN END

WDT Reset

0 1 2 …

WDT

count(ms)

0 1 2 … …6 7

SCAN END

0 1 2 …

5- 4

Chapter 5 Program Configuration and Operation Method

5.2 Program Execution

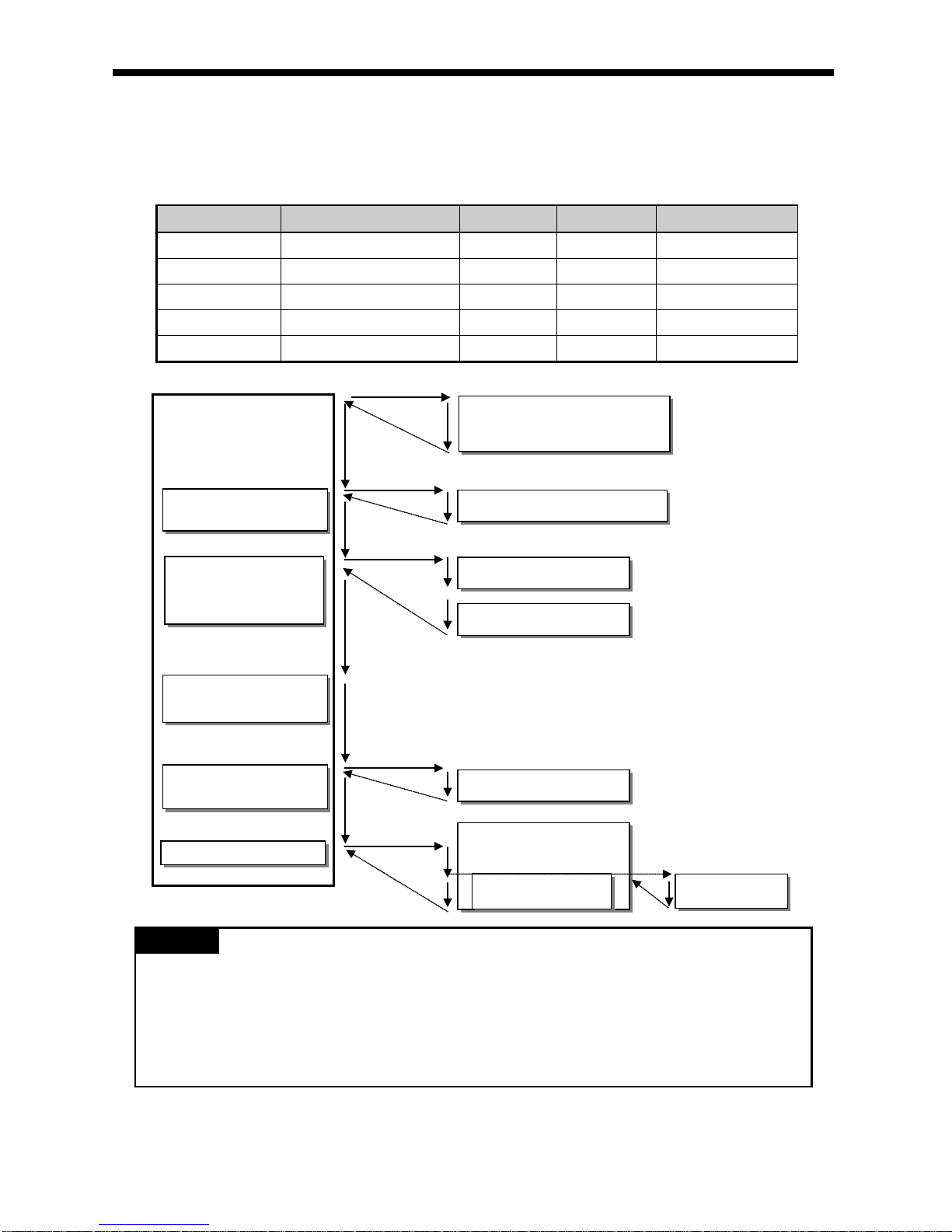

5.2.1 Configuration of program

All functional elements need to execute a certain control process are called as a ‘program’. Program is stored in

the built-i n RAM mounte d on a CPU module or flash memory of a exter nal memory module. The following tabl e

shows the classification of the program.

Program type Description

Initializing program

• It will be executed till the specific Flag ‘INIT_DONE’ is On. And while the

initialization task is executed, several of initializing program is

programmed. (If INIT_DONE instruction is executed, scan program is

executed.)

Scan program

• The scan program is executed regularly in every scan.

Cycle time interrupt

program

• The pr ogram is perf ormed ac cordi ng to t he fixe d tim e interv al in c ase th at the

required processing time condition is as below.

In case that the faster processing than 1 scan average processing time is

required

In c ase that t he longer t ime interv al than 1 sc an averag e process ing time is

required

In case that program is processed with the appointed time interval

External interrupt

program

• The exter nal interrupt program is perform ed process on external interrupt

signal.

Subroutine

program

•

Only when some condition is satisfied.(in case that input condition of CALL

instruction is On)

5.2.2 Program execution methods

Here describes the program proceeding method that is executed when the power is applied o r key swi t ch i s ‘ RUN’.

The program performs the operation processing according to the configuration as below.

Start processing

Scan program

END processing

Subroutine program

External interrupt program

Cycle time program

Only when some

condition is satisfied.

Initializing program

It executes up to execution of INIT_DONE instruction when initializing program is designated.

5- 5

Chapter 5 Program Configuration and Operation Method

(1) Scan program

(a) Function

• This program performs the operation repeatedly from 0 step to last step in order prepared by the program

to process the signal tha t is repeated ly regularly every scan.

• In case that the execution condition of interrupt by task interrupt or external input while executing program

is established, stop the current program in execution and perform the related interrupt program.

(2) Interrupt program

(a) Function

• This program stops the operation of scan program and then processes the related function in prior to

process the internal/external signal occurred periodically/non-periodically.

(b) Type

• Task p rogr a m is di v ide d a s bel ow .

- Cycle time task program: available to use up to 8.

- Internal device ta sk program: available to u se up t o 8.

- I/O (External contact task program): available to use up to 8. (%IX0.0.0~%IX0.0.7)

• Cycle time task program

- Performs the program according to the fixed time internal.

• Internal devi ce task prog ram

- Performs the corresponding program when the start condition of internal device occurs.

- The start cond ition de tection of device shall be performed after processing of scan program.

• I/O (External contact task program)

- Performs the program according to the input external signal (%IX0.0.0~%IX0.0.7).

Remark

(1) Write the interrupt program as s hortl y as poss i ble . I n c as e same interrupt occurs repeatedly

before completion of interrupt, program is not executed and O/S watch dog error may occur.

(2) Though interrupt whic h has lower priority occurs man y times during execution of interrupt

which has higher priority, interrupt which has lower priority occurs only one time.

5- 6

Chapter 5 Program Configuration and Operation Method

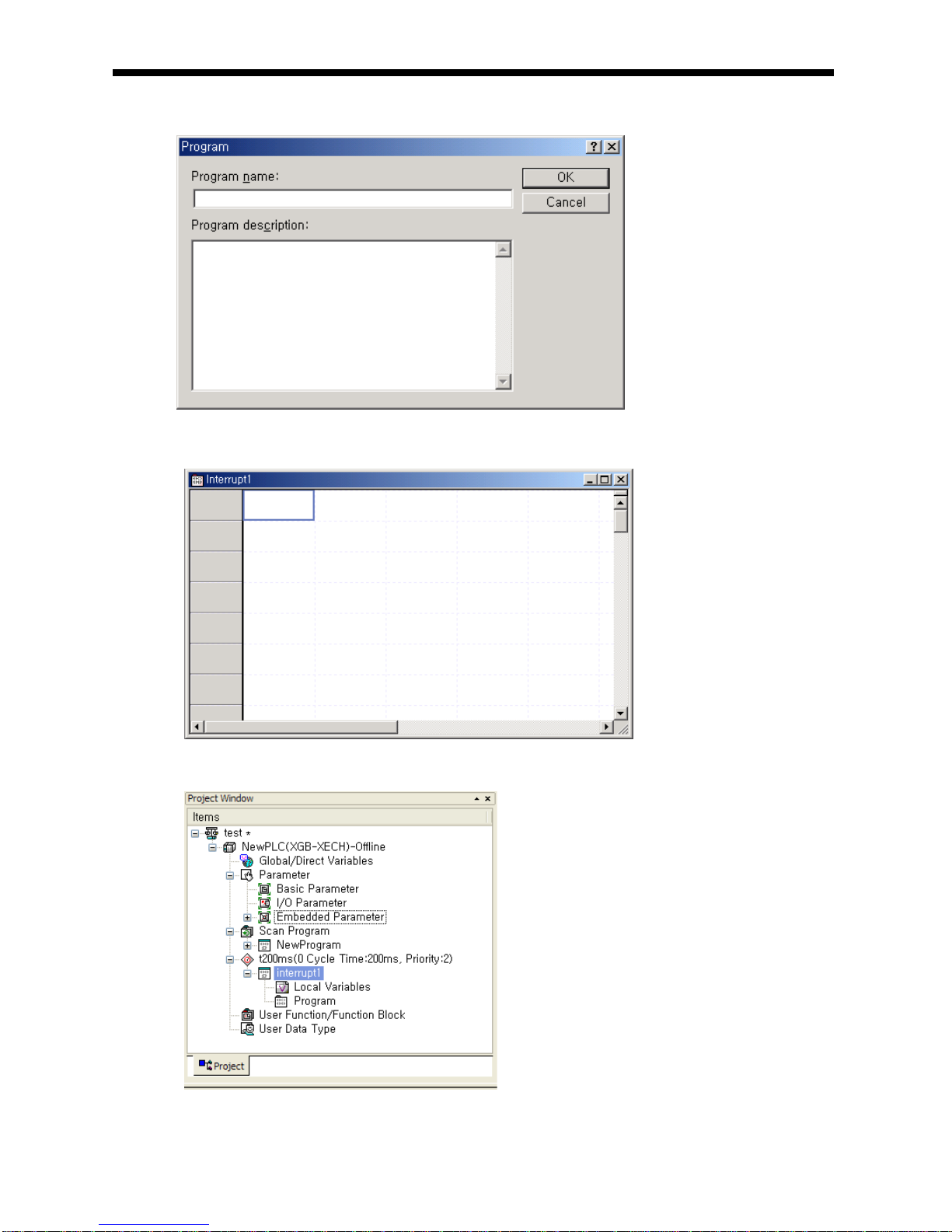

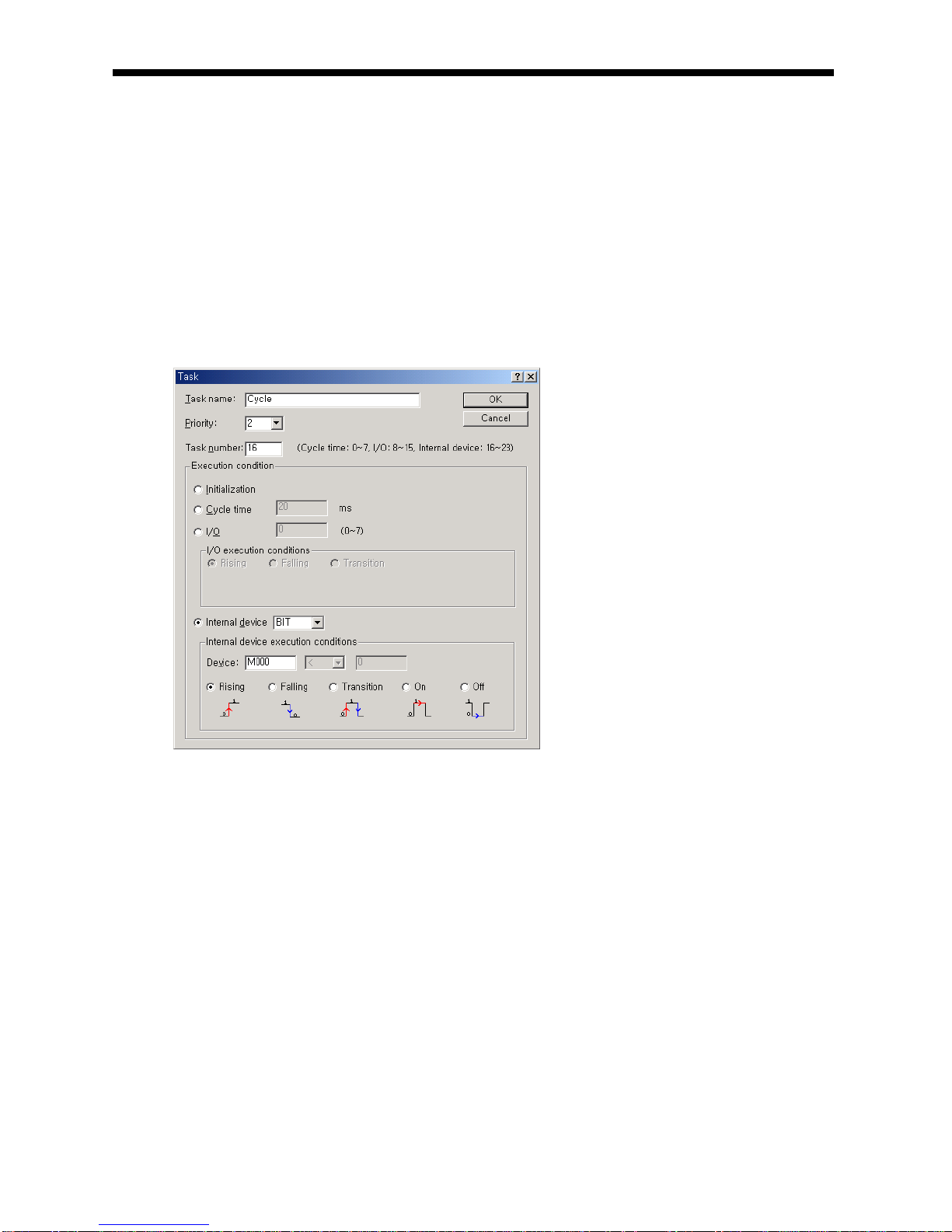

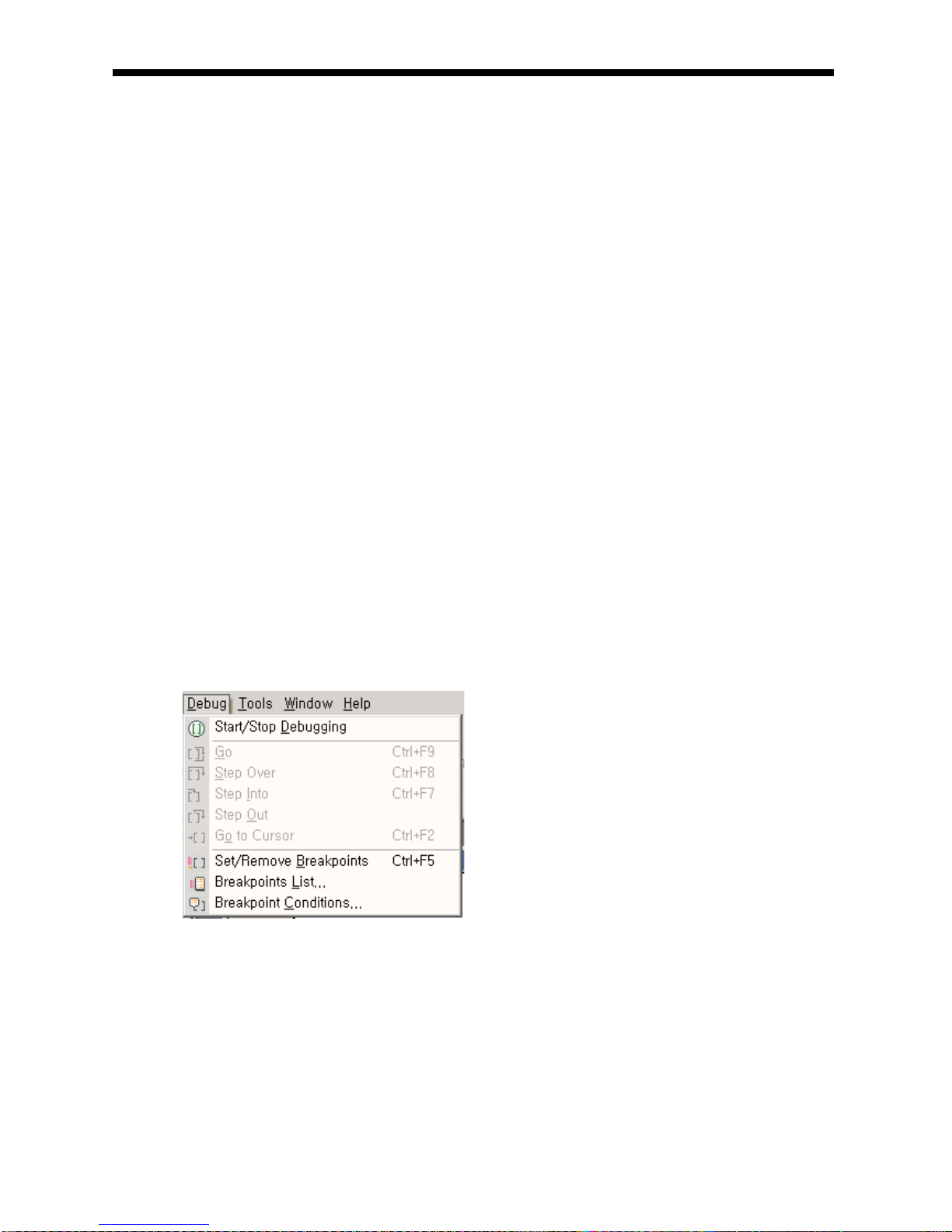

5.2.3 Interrupt

For your understanding of Interrupt function, here describes program setting method of XG5000 which is an XGB

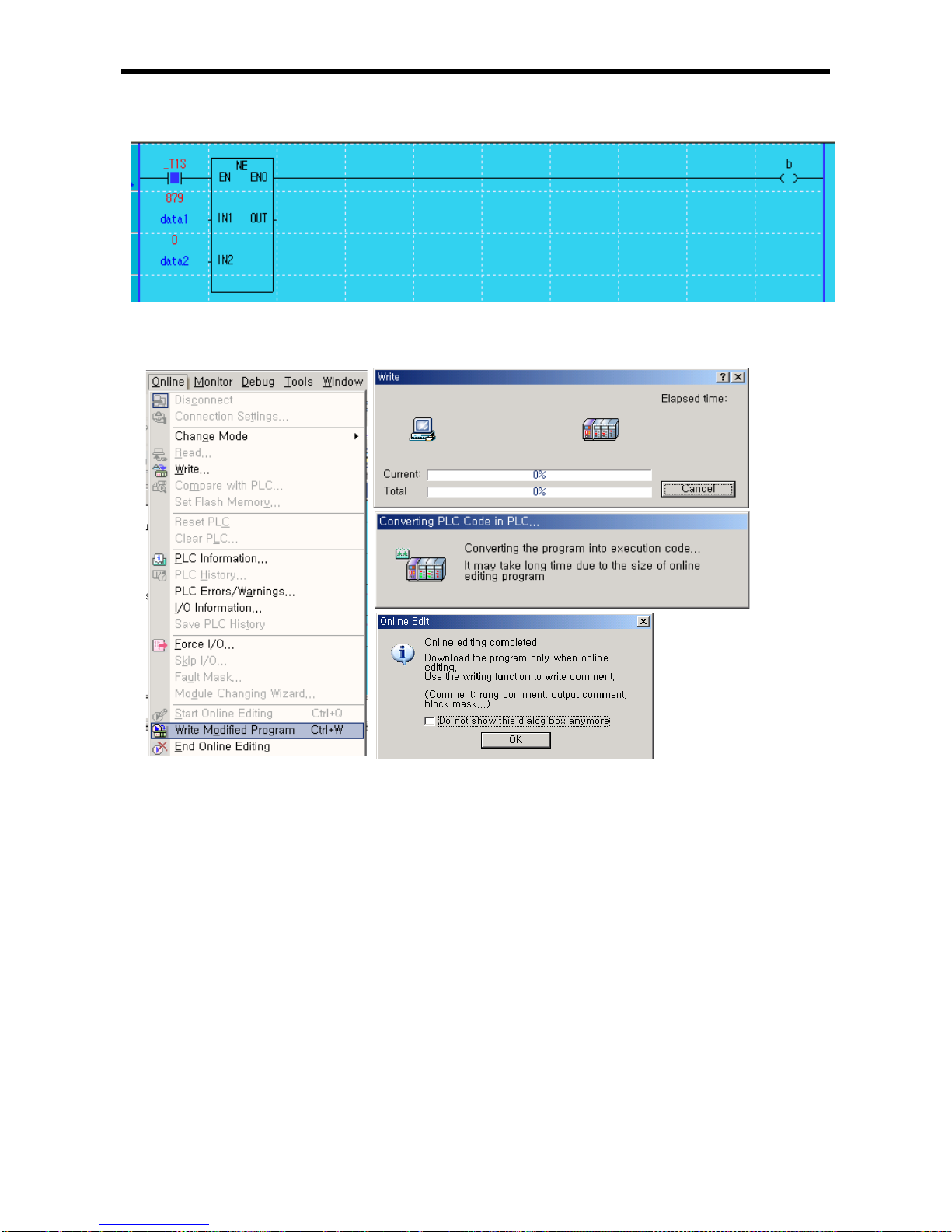

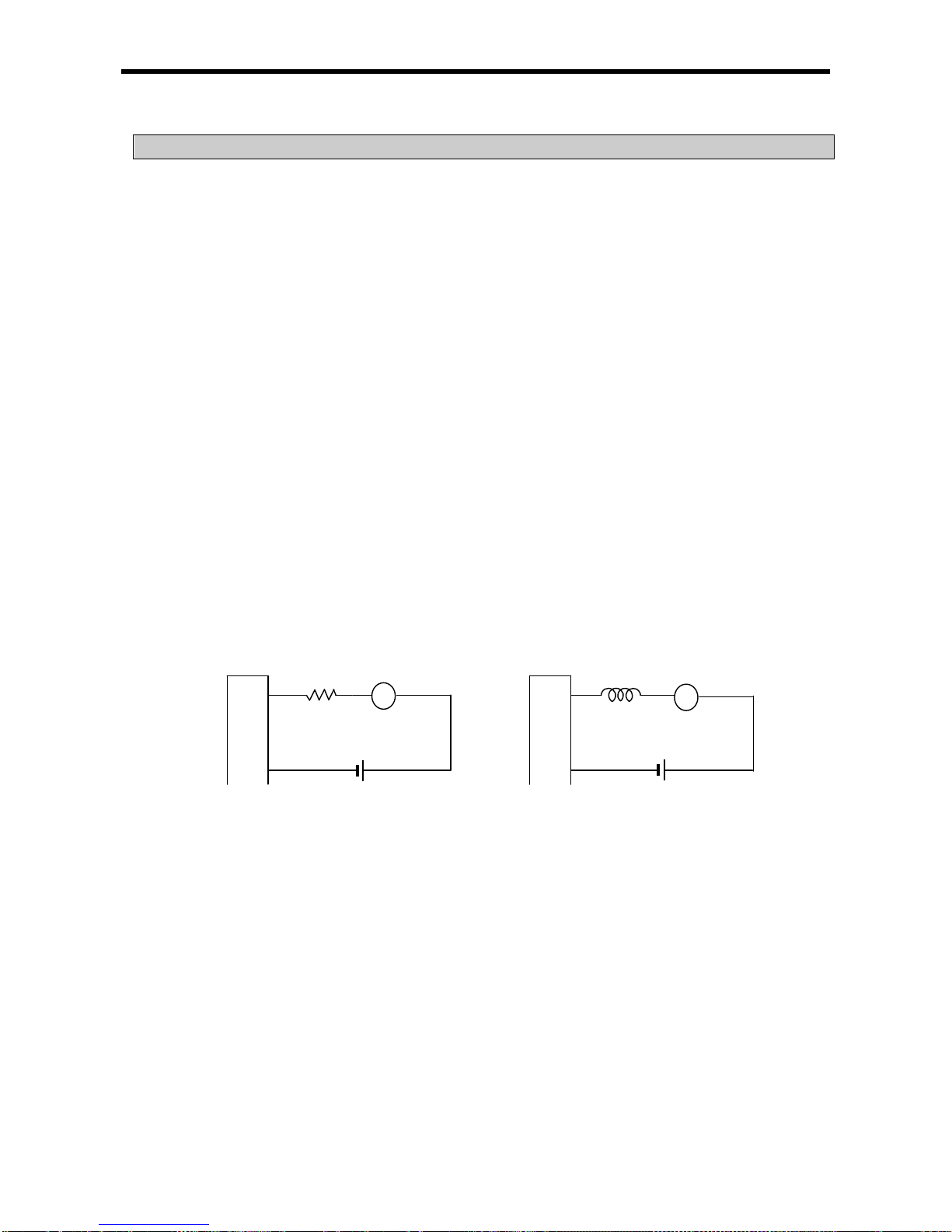

programming S/W. Example of interrupt setting is as shown bellows.