Introduction

Introduction

Hello. Thank you for choosing LS Mecapion L7 Series.

This user manual describes how to use the product and what precautions to take.

Failure to comply with guidelines may cause injury or product damage. Be sure to read this

user manual before you use the product and follow all guidelines.

The contents of this manual are subject to change without prior notice depending on software

versions.

No reproduction of part or all of the contents of this manual in any form, by any means or for any

purpose, shall be permitted without the explicit written consent of LS Mecapion.

The patent, trademark, copyright and other intellectual property rights in this user manual are

reserved by LS Mecapion. No use for purposes other than those related to the product of LS

Mecapion shall be authorized.

i

Safety Precautions

Precautions

Definition

Danger

Caution

Safety Precautions

Safety precautions are categorized as either Danger or Caution, depending on the

seriousness of the precaution.

Danger

Caution

Certain conditions that are listed as Caution may also result in serious injury .

Failure to comply with guidelines may cause death or seriou s injury.

Failure to comply with guidelines may cause injury or property damage.

Electric Shock Precautions

Before wiring or inspection tasks, turn off the power. Wa it 15 minu tes until the charg e lamp

goes off, and then check the voltage.

Be sure to ground both the servo drive and the servo motor.

Only specifically trained professional engineers are permitted to perform wiring tasks.

Perform wiring tasks after you install both the servo drive and the servo motor.

Do not operate the device with wet hands.

Do not open the servo drive cover while in operation.

Do not operate the device with the servo drive cover removed.

Even if the power is off, do not remove the servo drive cover.

Fire Prevention Precautions

Install the servo drive, the servo motor, and the regenerative resistance on non-combustible

material.

In case of servo drive malfunction, disconnect the input power.

ii

Safety Precautions

Environment

Conditions

Servo Drive

Servo Motor

Caution

Installation Precautions

Store and use the product in an environment as follows:

Usage temp. 0 ~ 50 ℃ 0 ~ 40 ℃

Storage temp. -20 ~ 65 ℃ -20 ~ 60 ℃

Usage

humidity

Storage

humidity

Altitude Below 1000 m

Spacing

Others

Below 90% RH (non-condensing)

When installing 1 unit:

More than 40 mm space at the top and

bottom of the control panel

More than 10 mm space at the left and

right sides of the control panel

When installing 2 or more units:

More than 100 mm space at the top of

the control panel

More than 40 mm space at the bottom

of the control panel

More than 30 mm space at the left and

right sides of the control panel

More than 2 mm between units

Refer to "2.2.2 Installation Inside the

Control Panel."

Install in a location free from iron, corrosive gas, and combustible gas.

Install in a location free from vibration or shock.

Below 80% RH

Below 90% RH

Make sure that the installation orientation is correct.

Do not drop the product or expose it to excessive shock.

Install in a location that is free from water, corrosive gas, combustible gas, or flammable

material.

Install in a location that can support the weight of the product.

Do not stand on the product or place heavy objects on top of it.

Be sure to maintain the specified spacing when you install the servo drive.

Be sure not to get conductive or flammable debris inside either the servo drive or the servo

motor.

Firmly fix the servo motor onto the machine.

Be sure to install a servo motor with a gearbox in the specified direction.

Do not touch the rotating unit of the servo motor while you operate the machine.

Do not apply excessive shock when you connect a coupling to the servo motor shaft.

Do not place a load on the servo motor shaft that is heavier than specified.

iii

Safety Precautions

Caution

Caution

Caution

Wiring Precautions

Be sure to use AC 200-230 V for the input power of the servo drive.

Be sure to connect the servo drive ground terminal.

Do not connect commercial power directly to the servo moto r.

Do not connect commercial power directly to the U, V, W output terminal of the servo drive.

Directly connect U, V, W output terminals of the servo drive and U, V, W input terminals of the

servo motor, but do not instal l a magnetic contactor between the wiring.

Be sure to use a pressurized terminal with an insulation tube when you connect the power

terminal for the servo drive.

When wiring, be sure to separate the U, V, and W cables for the servo motor power and

encoder cable.

Be sure to use robotic cable if the motor requires movement.

Before you perform power line wiring, turn off the input power of the servo drive, and then wait

until the charge lamp goes off completely.

Be sure to use shielded twisted-pair wire for the pulse command signal (PF+, PF-, PR+, PR-),

speed command signal (SPDCOM), and torque command signal (TRQCOM).

Precautions for I nit ial Operation

Check the input voltage (AC 200-230 V) and power unit wiring before you turn on the power.

The servo must be in the OFF mode when you turn on the power.

Before you turn on the power, check the motor's ID and the encoder pulse for L7 □A □□□A.

Set the motor ID ([P0-00]) and the encoder pulse ([P0-02]) for L7 □A □□□A first after you

turn on the power.

After you complete the above settings, set the drive mode for the servo drive that is connected

to the upper level controller to [P0-03].

Refer to Chapter 1.2 "System Configuration" to perform CN1 wiring for the servo drive

according to each drive mode.

You can check the ON/OFF state for each input terminal of CN1 at [St-14].

Precautions for Handling and Operation

Check and adjust each parameter before operation.

Do not touch the rotating unit of the motor during operation.

Do not touch the heat sink during operation.

Be sure to attach or remove the CN1 and CN2 connectors when the power is off.

Extreme change of param eters may cause system instability.

iv

Safety Precautions

Caution

Caution

Caution

Caution

Caution

Precautions for Use

Install an emergency s top circuit on the outside to immediately stop operation if necessary.

Reset the alarm when the servo is off. Be warned that the system restarts immediately if the

alarm is reset while the servo is on.

Minimize electromagnetic interference by using a noise filter or DC reactor. Otherwise, adjacent

electrical devices may malfunction bec aus e of the inter fer en c e.

Use only the specified combinations of servo drive and servo motor.

The electric brake on the servo motor keeps the mortor at a standstill. Do not use it for ordinary

braking.

The electric brake may not function properly depending on the brake lifespan and mechanical

structure (for example, if the ball screw and servo motor are combined via the timing belt).

Install an emergency stop device to ensure me cha nic al safe t y.

Malfunction Precautions

For potentially dangerous situations that may occur during emergency stop or device

malfunction, use a servo motor with an electric brake, or separately install a brake system on

the outside.

In case of an alarm, solve the source of the problem. After you solve the problem and ensure

safety, deactivate the alarm and start operation again.

Do not get close to the machine until the problem is solved.

Precautions for Repair/Inspection

Before performing servicing tasks, turn off the power. Wait 15 minutes until the charge lamp

goes off, and then check the voltage. Voltage may remain in the condenser even after you turn

off power and may cause an electric shock.

Only authorized personnel are permitted to perform repair, inspection or replacement of parts.

Do not modify the product.

General Precautions

This user manual is subject to change upon prod uct mod ifi ca tion or st and ards change s. In cas e

of such changes, the user m anual will be issued with a new product number.

Product Application

This product is not designed or manufactured for machines or systems that are used in

situations related to human life.

This product is manufactured under strict quality control. However, be sure to install safety

devices when applying the product to a facility where a malfunction in the product might cause

a major accident or signific ant loss.

v

Safety Precautions

Caution

EEPROM Lifes pan

EEPROM is rewritable up to 1 million times for the purpose of, among others, recording

parameter settings. The servo drive may malfunction dependi ng on the lifespan of EEPROM

when the total counts of the following tasks exceed 1 million.

EEPROM recording as a result of parameter changes

EEPROM recording as a result of alarm trigger

Respondi ng to international regulations

L7 Series responds to international regulations with standard models.

Model(Note1) Low Voltage Directive EMC Directive

L7SA001X

L7SA002X

L7SA004X

L7SA008X

EN61800-5-1 EN61800-3

L7SA010X

L7SA020X

L7SA035X

Note1) X = A or B : A = Quadr atur e Enco der Type, B = Serial Encoder Type.

※1 : For more information, please feel free to ask LS Mecapion.

※2 : Please follow the regulations of destination when exporting.

vi

Table of Contents

Table of Contents

Introduction ...................................................................................................................... i

Safety Precautions .......................................................................................................... ii

Ta b le of Contents .......................................................................................................... vii

1. Product Components and Signals ................................................................... 1-1

1.1 Product Components ..................................................................................................... 1-1

1.1.1 Product Verification ........................................................................................ 1-1

1.1.2 Part Names .................................................................................................... 1-3

1.2 System Configurat ion .................................................................................................... 1-8

1.2.1 Overview ........................................................................................................ 1-8

1.2.2 Wiring Diagram of the Entire CN1 Connector ............................................... 1-10

1.2.3 Example of Posit ion Operation Mode Wiring ................................................ 1-11

1.2.4 Example of Speed Operation Mode Wi ring ................................................... 1-12

1.2.5 Example of Torque Operation Mode Wiring .................................................. 1-13

1.2.6 Examples of Speed / Position O peration Mode Wiri ng ................................. 1-14

1.2.7 Example of Speed/Torque Operation Mode Wiring ....................................... 1-15

1.2.8 Example of Posit ion/Torque Operation Mode Wiring .................................... 1-16

1.3 Signals ........................................................................................................................ 1-17

1.3.1 Digital Input Contact S ignal .......................................................................... 1-17

1.3.2 Analog Input Contact Signal ......................................................................... 1-18

1.3.3 Digital Output Contact S ignal ........................................................................ 1-18

1.3.4 Monitor Output Signal and Output Power ..................................................... 1-19

1.3.5 Pulse Train Input Signal ................................................................................ 1-19

1.3.6 Encoder Output Si gnal ................................................................................. 1-20

2. Installation .......................................................................................................... 2-1

2.1 Servo Motor ................................................................................................................... 2-1

2.1.1 Usage Environment ........................................................................................ 2-1

2.1.2 Prevention of Excessive Shock ...................................................................... 2-1

2.1.3 Motor Connecti on ........................................................................................... 2-1

2.1.4 Load Device Connection ................................................................................ 2-2

2.1.5 Cable Installation ............................................................................................ 2-2

2.2 Servo Drive.................................................................................................................... 2-3

2.2.1 Usage Environment ........................................................................................ 2-3

2.2.2 Installation Inside the Control Panel ............................................................... 2-4

2.2.3 Power Wiring .................................................................................................. 2-5

3. Wiring Method .................................................................................................... 3-1

3.1 Internal Block Diagram .................................................................................................. 3-1

3.1.1 L7 Drive Block Diagram [L7SA001□ - L7SA004□] .......................................... 3-1

3.1.2 L7 Drive Block Diagram [L7SA008□ - L7SA035□] .......................................... 3-2

3.1.3 L7 Drive Block Diagram [L7SA050□ ] ............................................................. 3-3

3.2 Power Wiring ................................................................................................................. 3-4

3.2.1 L7 Drive Wiring Diagram [L7SA001□ - L7SA035□] ......................................... 3-4

3.2.2 L7 Drive Wiring Diagram [L7SA050□] ............................................................. 3-5

3.2.3 Dimensions for Pow er Circuit Electr ical Parts ................................................. 3-6

vii

Table of Contents

3.3 Timing Diagram ........................................................................................................... 3-10

3.3.1 Timing Diagram During Power Input ............................................................. 3-10

3.3.2 Timing Diagram at the Time of Alarm Trigger .................................................3-11

3.4 Control Signal Wiring ................................................................................................... 3-12

3.4.1 Contact Input Signal ..................................................................................... 3-12

3.4.2 Contact Output Signal .................................................................................. 3-13

3.4.3 Analog Input/Output Signals ......................................................................... 3-14

3.4.4 Pulse Train Input Signal................................................................................ 3-15

3.4.5 Encoder Output Si gnal ................................................................................. 3-16

3.5 Quadrature Encoder S ignaling Unit ( C N 2) Wiring ........................................................ 3-17

3.5.1 APCS-EAS Cable .................................................................................. 3-17

3.5.2 APCS-EBS Cable .................................................................................. 3-17

3.6 Serial Encoder Signaling Unit (CN2) Wiring ................................................................ 3-18

3.6.1 APCS-ECS Cable .................................................................................. 3-18

3.7 Multi Turn Encoder signal unit(CN2) wiring .................................................................. 3-20

3.7.1 APCS-ECS1 Cable ................................................................................ 3-20

3.7.2 APCS-EDS1 Cable ................................................................................ 3-20

3.7.3 APCS-EES1 Cable ................................................................................ 3-21

3.8 Transmission of Absolute Encoder Data ...................................................................... 3-22

3.8.1 Transmission of Absolute Encoder Data ....................................................... 3-22

4. Parameters .......................................................................................................... 4-1

4.1 How to Use the Loader .................................................................................................. 4-1

4.1.1 Names and Functions of Each Parts .............................................................. 4-1

4.1.2 Status Summary Display ................................................................................ 4-2

4.1.3 Parameter Handli ng ....................................................................................... 4-4

4.1.4 Data Display ................................................................................................... 4-8

4.1.5 External Input Contact Signal Display [ St-14] ............................................... 4-10

4.1.6 External Input Signal and Logic Definition .....................................................4-11

4.1.7 External Output Contact Signal Display [St-15]............................................. 4-19

4.1.8 External Output Signal and Logic Definition ................................................. 4-20

4.2 Parameter Description ................................................................................................. 4-26

4.2.1 Parameter System ........................................................................................ 4-26

4.2.2 Operation Status Display Parameter ............................................................ 4-27

4.2.3 System Setting Par am eter ............................................................................ 4-30

4.2.4 Control Setting Parameter ............................................................................ 4-34

4.2.5 Input/Output Setting Parameter .................................................................... 4-37

4.2.6 Speed Operation Setting Parameter ............................................................. 4-40

4.2.7 Position Operation Setting Parameter .......................................................... 4-42

4.2.8 Operation Handling Parameter ..................................................................... 4-45

4.3 Operation Status Display ............................................................................................. 4-49

4.3.1 Status Display [St-00] ................................................................................... 4-49

4.3.2 Speed Display .............................................................................................. 4-49

4.3.3 Position Display ............................................................................................ 4-49

4.3.4 Torque and Load Display .............................................................................. 4-49

4.3.5 I/O Status Display ......................................................................................... 4-50

4.3.6 Miscellaneous Status and Data Di splay ........................................................ 4-50

4.3.7 Version Display............................................................................................. 4-51

4.4 Parameter Setting ....................................................................................................... 4-52

viii

Table of Contents

4.4.1 System Parameter Setting ............................................................................ 4-52

4.4.2 Control Parameter S etting ............................................................................ 4-55

4.4.3 Analog Input/Output Parameter Setting ........................................................ 4-59

4.4.4 Input/Output Contact Point Parameter Setting .............................................. 4-61

4.4.5 Speed Operation Parameter Setting ............................................................. 4-63

4.4.6 Position Operation Parameter Setting .......................................................... 4-64

4.5 Alarms and Warnings .................................................................................................. 4-66

4.5.1 Servo Alarm Status Summary Display List .................................................... 4-66

4.5.2 Servo Warning Status Summary Display Li st ................................................ 4-68

4.6 Motor Type and ID (to be continued on the next page) ................................................ 4-69

5. Handling and Operation .................................................................................... 5-1

5.1 What to Check Before Operation ................................................................................... 5-1

5.1.1 Wiring Check .................................................................................................. 5-1

5.1.2 Drive Signal (CN1) Wiring Check ................................................................... 5-1

5.1.3 Surrounding Environment Check .................................................................... 5-1

5.1.4 Machine Status Check .................................................................................... 5-1

5.1.5 System Parameter Check ............................................................................... 5-2

5.2 Handling ........................................................................................................................ 5-3

5.2.1 Manual JOG Operation [Cn-00] ...................................................................... 5-3

5.2.2 Program JOG Operat ion [Cn-01] .................................................................... 5-5

5.2.3 Alarm Reset [Cn-02] ....................................................................................... 5-6

5.2.4 Reading Alarm History [Cn-03] ....................................................................... 5-7

5.2.5 Alarm History Reset [Cn-04] ........................................................................... 5-8

5.2.6 Auto Gain Tuning [Cn-05] ............................................................................... 5-9

5.2.7 Phase Z Search Operation [Cn-06] .............................................................. 5-10

5.2.8 Input Contact Forced O N/OFF [Cn-07] ......................................................... 5-11

5.2.9 Output Contact Forc ed O N/OFF [Cn-08] ...................................................... 5-13

5.2.10 Param eter Reset [Cn-09] .............................................................................. 5-15

5.2.11 Autom atic Speed Command Offset Correction [Cn-10] ................................. 5-16

5.2.12 Automatic Torque Command Offset Cor rection [Cn-11] ................................ 5-17

5.2.13 Manu al Speed Command Offset Correction [Cn-12] .................................. 5-18

5.2.14 Manual Torque Command Offset Cor rection [Cn-13] ................................. 5-19

5.2.15 Abs olute Encoder Reset [Cn-14] .................................................................. 5-20

5.2.16 Instantaneous Maximum Load Factor Initialization [Cn-15]........................... 5-21

5.2.17 Param eter Lock[Cn-16] ................................................................................ 5-22

5.2.18 Current Offset[Cn-17] ................................................................................... 5-23

6. Communication Protocol .................................................................................. 6-1

6.1 Overview and Communi cation Specifications ................................................................ 6-1

6.1.1 Overview ........................................................................................................ 6-1

6.1.2 Communication Specifications and Cable Access Rate .................................. 6-2

6.2 Communication Protocol Base Structure ....................................................................... 6-3

6.2.1 Sending/Receiving Packet Structure .............................................................. 6-3

6.2.2 Protocol Command C odes ............................................................................. 6-5

6.3 L7 Servo Drive Commu nication Address Table ............................................................ 6-10

6.3.1 Operation Status Parameter Communication Address Table ........................ 6-10

6.3.2 System Parameter Communication Address Table ....................................... 6-12

6.3.3 Control Parameter C om munication Address Table ....................................... 6-14

6.3.4 Input/Output Parameter Communication Address T able ............................... 6-16

6.3.5 Speed Operation Parameter Communication Address Table ........................ 6-17

ix

Table of Contents

6.3.6 Position Operation Parameter Communication Address T able...................... 6-18

7. Product Specifications ...................................................................................... 7-1

7.1 Servo Motor ................................................................................................................... 7-1

7.1.1 Product Features ............................................................................................ 7-1

7.1.2 Outline Drawing ............................................................................................ 7-22

7.2 Servo Drive ................................................................................................................. 7-34

7.2.1 Product Features .......................................................................................... 7-34

7.2.2 Outline Drawing ............................................................................................ 7-36

7.3 Options and Peripheral Devices .................................................................................. 7-38

8. Maintenance and Inspection ............................................................................. 8-1

8.1 Maintenance and I nspection .......................................................................................... 8-1

8.1.1 Precautions .................................................................................................... 8-1

8.1.2 What to Inspect .............................................................................................. 8-1

8.1.3 Parts Replacement Cycle ............................................................................... 8-2

8.2 Diagnosis of Abnormality and Troubleshooting .............................................................. 8-3

8.2.1 Servo Motor .................................................................................................... 8-3

8.2.2 Servo Drive .................................................................................................... 8-4

9. Appendix ............................................................................................................. 9-1

9.1 Motor Type and ID (to be continued on the next page) .................................................. 9-2

9.2 Test D rive Procedure ..................................................................................................... 9-5

Quality Assurance .......................................... 오류! 책갈피가 정의되어 있지 않습니다.

User Manual Revision History ...................... 오류! 책갈피가 정의되어 있지 않습니다.

x

Table of Contents

xi

1. Product Components and Signals

L7 S A 004 A AA

1. Product Components and Signals

1.1 Product Components

1.1.1 Produc t Verification

1. Check the name tag to verify that the product matches the model you ordered.

Does the format of the servo drive's name tag match?

Does the format of the servo motor's name t ag match?

2. Check the product and options.

Are the type and length of the cables correct?

Does the regenerative resistance conform to the standard?

Is the shape of the shaft end correct?

Is there any abnormality when the oil seal or brake is mounted?

Are the gearbox and the gear ratios correct?

Is the encoder format correct?

3. Check the exterior.

Is there any foreign substance or humidity?

Is there any discoloring, contamination, damage or disconnection of wires?

Are the bolts at joints fastened sufficiently?

Is there any abnormal sound or excessive friction during rotation?

Servo Drive Product Format

Series

Name

Servo

Series

Communication

Type

S: Standard I/O

type

N: Network type

1-1

Voltage

A: 220 VAC

B: 400 VAC

Input

Capacity Encoder Type Option

001: 100 W 050: 5.0 kW

002: 200 W 075: 7.5 kW

004: 400 W 110: 11.0kW

008: 750 W 150: 15.0kW

010: 1.0 kW

020: 2.0 kW

035: 3.5 kW

A: Quadrature

(Pulse type)

B: Serial

(communication

type)

Exclusive

Option

1. Product Components and Signals

Encoder Type

Servo Motor

Motor Capacity

Motor Shape

Flange Size

Rated RPM

Shaft Cross-section

sided round

Oil Seal and Brake

existent: None

Gearbox

Gearbox

APM – S B 04 A E K 1 G1 03

Servo Motor Product Format

S: Solid Shaft

H: Hollow Shaft

B: Assembly

F: Flat Type

A : 40 Flange

B : 60 Flange

C : 80 Flange

D : 100 Flange

E : 130 Flange

F : 180 Flange

G : 220 Flange

H : 250 Flange

J : 280 Flange

R3 : 30[W]

R5 : 50[W]

01 : 100[W]

02 : 200[W]

03 : 300[W]

04 : 400[W]

05 : 450[W]

06 : 550/600[W]

07 : 650[W]

08 : 750/800[W]

09 : 850/900[W]

10 : 1.0[kW]

·

·

150 : 15.0[kW]

220 : 22.0[kW]

300 : 30.0[kW]

370 : 37.0[kW]

A: 3000 [RPM]

D: 2000 [RPM]

G: 1500 [RPM]

M: 1000 [RPM]

Quadrature(pulse type)

A: Inc. 1024 [P/R]

B: Inc. 2000 [P/R]

C: Inc. 2048 [P/R]

D: Inc. 2500 [P/R]

E: Inc. 3000 [P/R]

F: Inc. 5000 [P/R]

G: Inc. 6000 [P/R]

Serial BISS

(communication type)

N : 19bit S-Turn Abs.

M : 19bit M-Turn Abs.

(18bit SA M-Turn Abs.)

N: Straight

K: Onekey (standard)

D: D Cut

T: Tapering

R: Double-sided

round key

H: Hollow Shaft

Classification

03: 1/3

10: 1/10

Specifications

Non-existent:

No gearbox

G1: For general industrial

purposes (Foot Mount)

G2: For general industrial

purposes (Flange Mount)

G3: Precise Gearbox

Nonattached

1: Oil Seal attached

2: Brake attached

3: Oil Seal and Brake

attached

1-2

1. Product Components and Signals

Shaft

1.1.2 Part Names

Servo Motor

80 Flange or below

Motor Power

Motor

Connector

Cable

Encoder

Connector

Encoder

Cable

Bearing Cap

80 Flange or below(Flat Type)

130 Flange or higher

Shaft

Flange

Motor

Connector

Frame

Flange

Housing

Power connector

Frame

Mold Housing

Encoder

Cover

Encoder connector

Encoder Cover

Encoder

Connector

Encoder

Cover

Shaft

Housing

Bearing Cap

Flange

Frame

1-3

1. Product Components and Signals

B+ and B terminals

connector

connector

Servo Drive

L7SA 001□, L7SA 002□, L7SA 004□

Display

Operation keys

(Mode, Up, Down, Set)

Main power connector (L1,

L2, L3)

DC reactor connector

(PO, PI)

Short circuit when not used

CN5:

USB connector

CN4:

RS-422 communication

CN3:

RS-422 communication

Regenerative resistanc e

connector (B+, B, BI)

When basic installation

is in use short circuit B

and BI terminals

When installing external

resistance install in the

Control power connector

(C1, C2)

Motor power cable

connector (U, V, W)

Heat sink

CN1:

Control signal connector

CN2:

Encoder signal connector

Front cover

Ground

1-4

1. Product Components and Signals

connector

B+ and B terminals.

L7SA 008□, L7SA 010□

Display

Operation keys

(Mode, Up, Down, Set)

Main power connector

(L1, L2, L3)

DC reactor connector

(PO, PI)

Short circuit when not used

CN5:

USB connector

CN4:

RS-422 communication

connector

CN3:

RS-422 communication

Regenerative resistanc e

connector (B+, B, BI)

When basic installation

is in use short circuit B

and BI terminals.

When installing external

resistance install in the

Control power connector

(C1, C2)

Motor power cable

connector (U, V, W)

CN1:

Control signal connector

CN2:

Encoder signal connector

Front cover

Heat sink

Ground

1-5

1. Product Components and Signals

connector

connector

L7SA 020□, L7SA 035□

Operation keys

(Mode, Up, Down, Set)

Main power connector

(L1, L2, L3)

DC reactor connector

(PO, PI)

Short circuit when not used

Regenerative resistanc e

connector (B+, B, BI)

When basic installation

is in useshort circuit B

and BI terminals.

When installing external

resistance install in the

B+ and B terminals.

Display

CN5:

USB connector

CN4:

RS-422 communication

CN3:

RS-422 communication

CN1:

Control signal connector

Control power connector

(C1, C2)

Motor power cable

connector (U, V, W)

Heat sink

CN2:

Encoder signal connector

Front cover

Ground

1-6

1. Product Components and Signals

“NC” hole on the case.

connector

Ground

(Mode, Up, Down, Set)

L7SA 050□

Operation keys

CN4:

RS-422 Communication

connector

Display

CN5:

USB Connector

Control power connector

(C1, C2)

DC reactor connector

(PO, PI)

Short circuit when not used

*Not used(N)

CN3:

RS-422 Communication

CN1:

Control signal connector

CN2:

Encoder signal connector

Front cover

Main power connector

(L1, L2, L3)

1-7

Regenerative resistanc e connector (B+, B)

When basic installation is in use,

leave it.

When installing external resistance,

install in the B+ and B terminals after

attaching wires of internal resistance to

Motor power cable

connector (U, V, W)

1. Product Components and Signals

Position

Controller

Speed

Controller

Change

Position

Command

Pulse

Position

Controller

Speed

Controller

Current

Controller

Position Controller

Upper Level Controller

Servo Drive

Servo Motor

Motor

Encoder

Position Feedback

Position

Controller

Speed

Controller

Change

Speed

Command

Speed

Controller

Current

Controller

Speed Command

Upper Level Controller Servo Drive Servo Motor

Motor

Encoder

Position Feedback

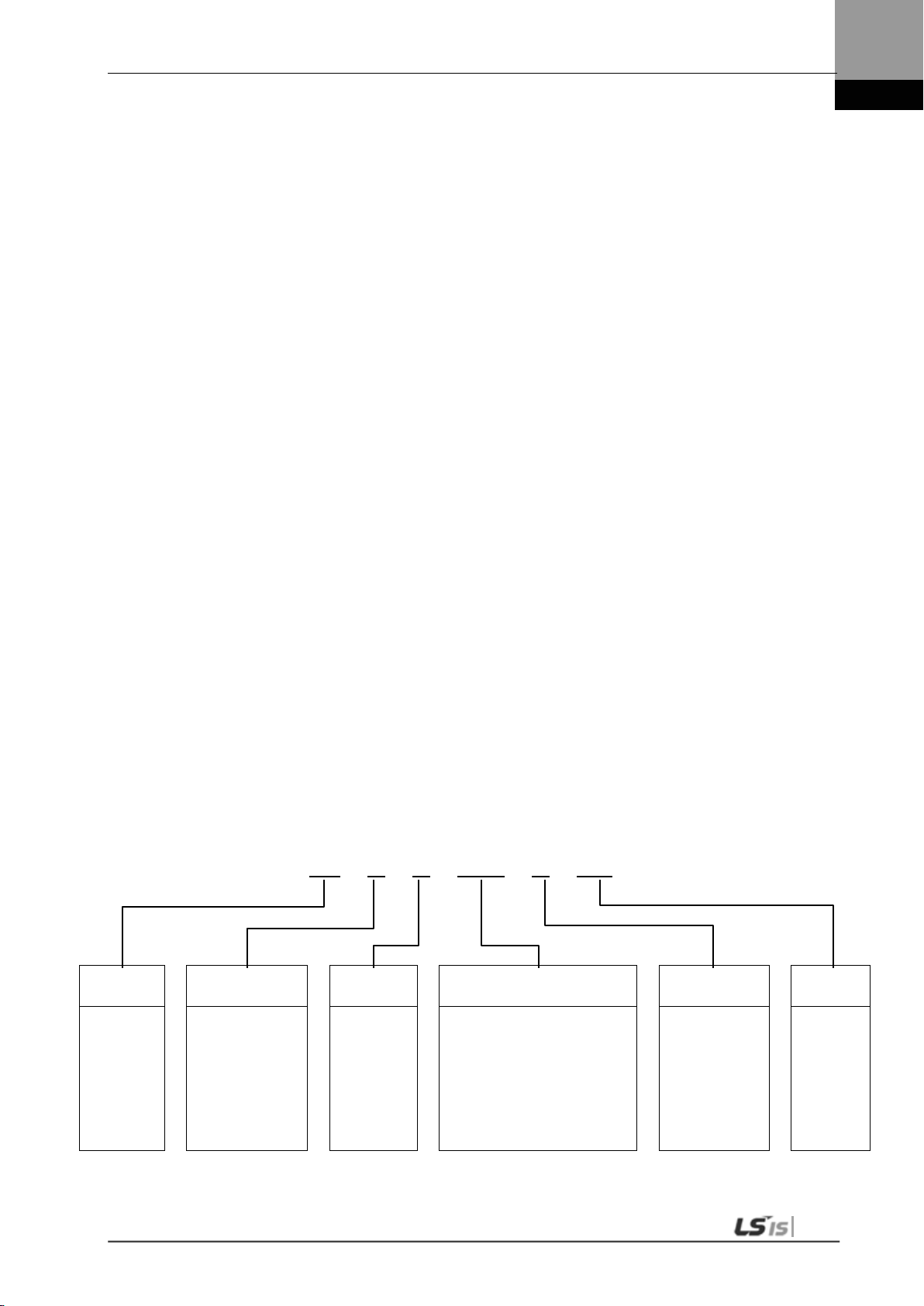

1.2 System Configuration

1.2.1 Overview

The L7 servo system can be configured in various ways depending on its interface with the

upper level controller.

(1) Position Opera ti on System

The servo is run by pulse commands. You can change the location of the servo motor by

changing command pulses based on a certain transfer unit.

Advantage: The structure of the upper level controller is simple because pulse input is linked to

transfer units.

Disadvantages:

Fast rotation is compromised w hen a precise transfer unit is used.

Response is low because multiple levels of control lers are us ed.

(2) Speed Operation System

The servo is run by speed commands. There are two types of speed commands: analog

voltage command and digital speed command.

Advantages:

The servo responds quickly.

Precision control is easy.

Disadvantage: The upper level controller is complex.

1-8

1. Product Components and Signals

Position

Controller

Torque

Controller

Change

Torque

Command

Torque

Controller

Current

Controller

Torque Command

Upper Level Controller

Servo Drive Servo Motor

Motor

Encoder

Position Feedback

Operation Mode

System Configuration

(3) Torque Operation System

The servo is run by torque commands. Analog voltage-based commands are used.

Advantages:

The servo responds quickly.

Precision control is easy.

Disadvantage: The upper level controller is complex.

(4) Operation Mode

The L7 servo drive can be run in torque, speed, and position modes, depending on its

interface with the upper level controller. The operation modes can be switched by

parameters or digital input contact point.

0 The servo is run on the torque operation system.

1 The servo is run on the speed operation system.

2 The servo is run on the position operation system.

3

4

5

The servo is run with the speed and position operation systems as points of

contact.

The servo is run with the speed and torque operation systems as points of

contact.

The servo is run with the position and torque oper ation systems as points of

contact.

1-9

1. Product Components and Signals

STOP 48

EMG

18

CWLIM 19

CCWLIM

20

DIR 46

ALMRST 17

SPD

3 21

SPD

2

22

SPD

1 23

SVON

47

ALARM+

38

ALARM-

39

READY+

40

READY-41

ZSPD43

BRAKE44

INPOS

45

50

+24V IN

GND24

24

ALO0

16

ALO115

ALO2

14

GND2425

SPDCOM 27

GND 8

TRQCOM 1

GND 8

Digital Input

Digital Output

Command Pulse Input

Analog Input

DC 24V

3.3kΩ

Line Driver

Open Collector

CN1

-10V ~ +10V

Upper Level

Controller

-10V ~ +10V

Analog Speed

Command/Limit

Analog Torque

Command/Limit

Note 1)

(DIA)

(DI9)

(DI8)

(DI7)

(DI6)

(DI5)

(DI4)

(DI3)

(DI2)

(DI1)

(DO1)

(DO2)

(DO3)

(DO4)

(DO5)

Note 1)

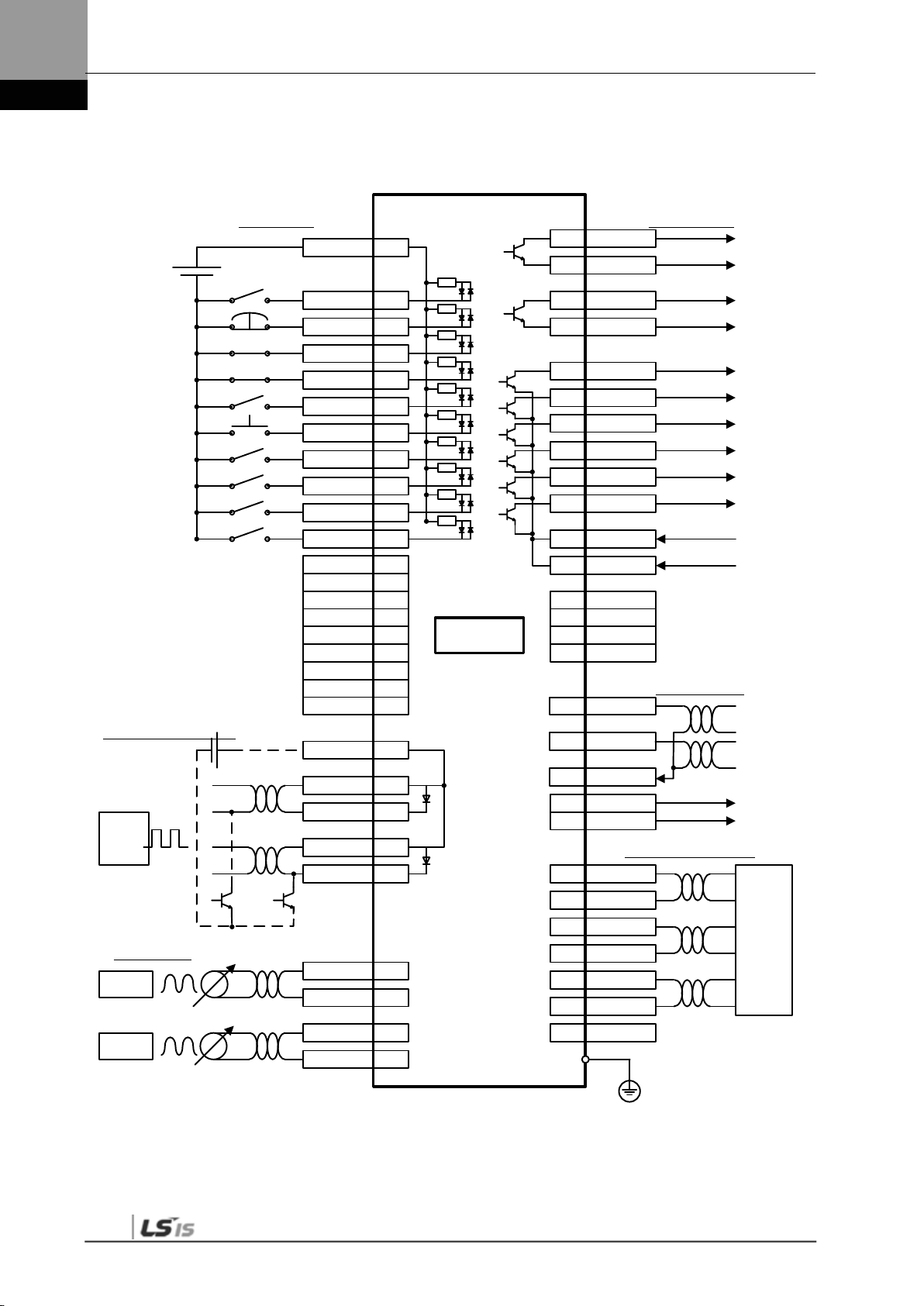

Note 1) Input signals DI1 to DIA and output signals DO1 to DO5 are default signals allocated by the factory.

Note 2) ** These are non-allocated signals. You can change their allocation by setting parameters. For more

information, refer to “4.1.6 External Input Signal and Logic Definition” and “4.1.8 External Output Signal and

Logic Definition.”

VLMT**

TLMT**

Note 2)

WARN**

INSPD**

EGEAR1 **

EGEAR2 **

PCON **

GAIN2

**

P_CLR

**

T_LMT **

Note 2)

MODE **

ABS_RQ

**

ZCLAMP

**

MONIT128

MONIT229

GND37

AO32

/AO33

BO30

/BO31

ZO4

/ZO5

SG36

Analog Output

Encoder Pulse Output

Connect to Connector Case

-10V ~ +10V

-10V ~ +10V

Upper Level

Controller

+12VA34

-12VA35

PULCOM 49

PF+ 9

PF- 10

PR+

11

PR- 12

1.2.2 Wiring Diagram of the Entire CN1 Connector

1-10

1. Product Components and Signals

STOP

48

EMG 18

CWLIM

19

CCWLIM 20

DIR

46

ALMRST 17

SPD

3 21

SPD2 22

SPD1 23

SVON 47

ALARM

+38

ALARM

-39

READY+40

READY-41

ZSPD43

BRAKE44

INPOS

45

50

+24

V IN

GND

2424

MONIT1

28

MONIT2

29

GND37

AO32

/AO

33

BO30

/BO31

ZO4

/ZO5

ALO

0

16

ALO115

ALO2

14

GND2425

PULCOM

49

PF+ 9

PF- 10

PR+

11

PR-

12

TRQCOM 1

GND

8

SG36

Digital Input

Digital Output

Analog Output

Command Pulse Input

Encoder Pulse Output

Analog Input

Connect to Connector Case

DC 24V

3.3kΩ

Line Driver

Open Collector

CN1

-10V ~ +10V

-10V

~ +10V

-10V ~

+10V

Upper

Level

Controller

-10V ~ +10V

Analog

Torque

Limit

Upper

Level

Controller

EGEAR1

**

EGEAR

2

**

PCON

**

GAIN2 **

P_CLR

**

T_LMT **

VLMT**

TLMT**

Note 1)

Note 2

)

Note 2)

(DIA)

(

DI9)

(

DI

8)

(DI7)

(DI6)

(DI

5)

(

DI4

)

(DI3)

(

DI

2)

(

DI1)

(DO1)

(DO

2)

(DO3

)

(DO4)

(

DO5

)

Note 1)

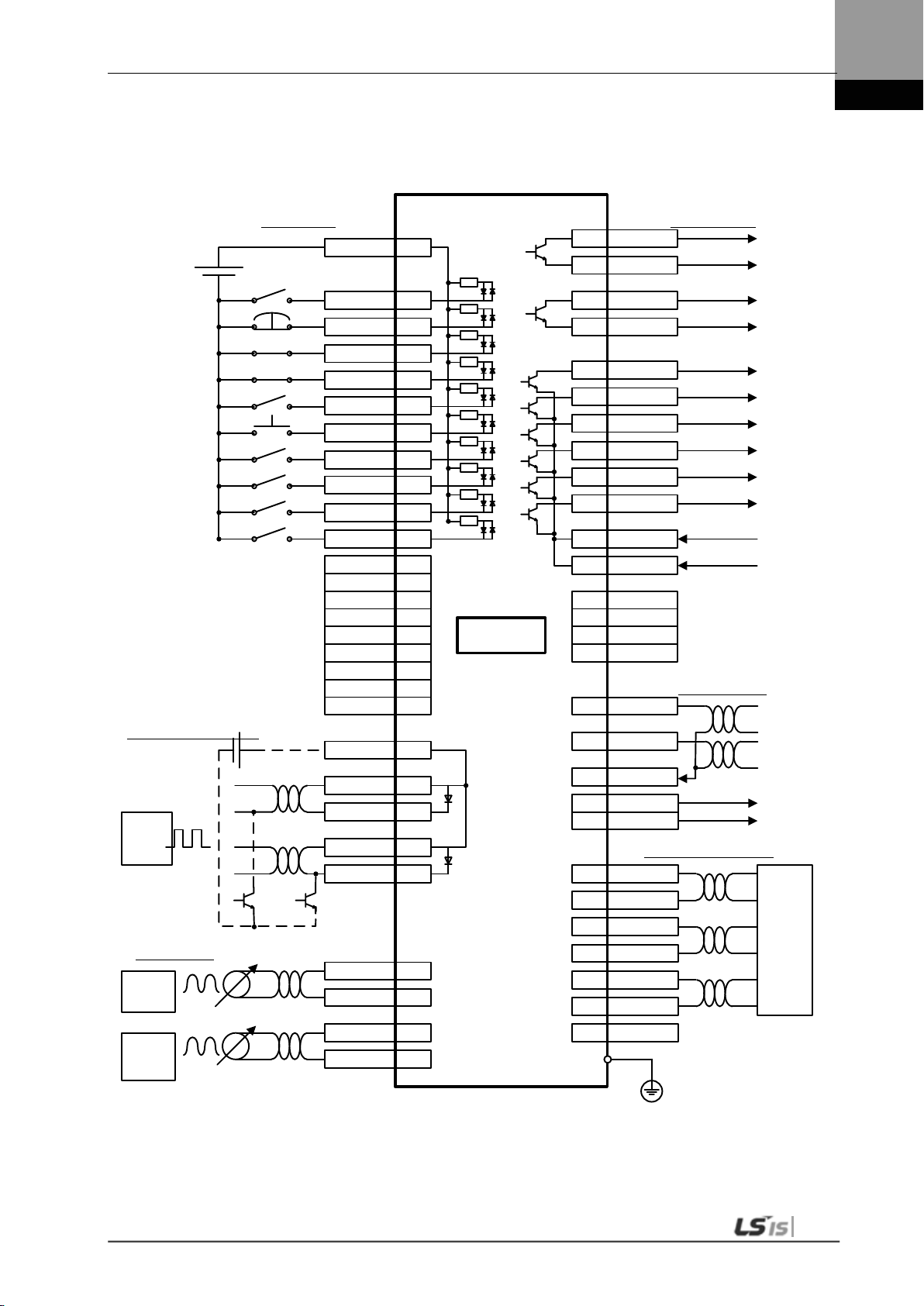

Note 1) Input signals DI1 to DIA and output signals DO1 to DO5 are default signals allocated by the factory.

Note 2) ** These are non-allocated signals. You can change their allocation by setting parameters. For more

information, refer to “4.1.6 External Input Signal and Logic Definition” and “4.1.8 External Output Signal and

Logic Definition.”

MODE **

ABS_RQ **

ZCLAMP ** WARN**

INSPD**

+

12VA34

-12VA35

1.2.3 Example of Position Operation Mode Wiring

1-11

1. Product Components and Signals

STOP

48

EMG

18

CWLIM 19

CCWLIM 20

DIR 46

ALMRST

17

SPD3 21

SPD

2 22

SPD

1 23

SVON 47

ALARM

+38

ALARM

-39

READY

+40

READY-

41

ZSPD

43

BRAKE

44

INPOS

45

50+24

V IN

GND2424

ALO016

ALO115

ALO214

GND2425

SPDCOM 27

GND 8

TRQCOM 1

GND 8

Digital Input Digital Output

Command Pulse Input

Analog Input

DC

24V

3

.

3

k

Ω

Line Driver

Open Collector

CN1

-10

V ~ +10V

Upper

Level

Controller

-10V ~

+10V

Analog

Speed

Command

Analog

Torque Limit

Note 1

)

(DIA)

(DI9)

(

DI8

)

(

DI7

)

(

DI

6)

(DI

5)

(

DI4)

(DI3)

(DI2)

(

DI

1

)

(DO1)

(DO2)

(DO

3

)

(

DO

4)

(

DO

5)

Note

1)

Note 1) Input signals DI1 to DIA and output signals DO1

to DO5 are default signals allocated by the factory.

Note 2) ** These are non

-allocated signals. You can change their allocation by setting parameters. For more

in

formation, refer to “4.1.6 External Input Signal and Logic Definition” and “4.1.

8 External Output Signal and

Logic Definition.”

VLMT**

TLMT**

Note 2)

WARN**

INSPD

**

EGEAR

1 **

EGEAR

2 **

PCON **

GAIN2 **

P_CLR **

T_LMT **

Note

2)

MODE **

ABS_RQ **

ZCLAMP

**

MONIT128

MONIT

229

GND37

AO32

/

AO33

BO30

/BO31

ZO4

/ZO5

SG36

Analog Output

Encoder Pulse Output

Connect to Connector Case

-10

V ~

+10V

-10V ~ +

10V

Upper

Level

Controller

+

12VA

34

-

12VA35

1.2.4 Example of Speed Operation Mode Wiring

1-12

1. Product Components and Signals

STOP

48

EMG 18

CWLIM 19

CCWLIM 20

DIR 46

ALMRST

17

SPD3 21

SPD

2 22

SPD1 23

SVON 47

ALARM

+38

ALARM-39

READY+40

READY-

41

ZSPD

43

BRAKE44

INPOS

45

50+24V IN

GND2424

ALO016

ALO115

ALO214

GND24

25

SPDCOM 27

GND 8

TRQCOM 1

GND 8

Digital Input

Digital Output

Command Pulse Input

Analog Input

DC 24V

3

.

3

kΩ

Line Drive

r

Open Collector

CN1

-10V ~

+10V

Upper

Level

Controller

-10V

~ +10V

Analog

Speed Limit

Analog

Torque

Command

Note 1)

(DIA)

(DI

9)

(

DI

8)

(

DI

7)

(

DI

6)

(

DI

5)

(DI4)

(DI3)

(

DI

2)

(

DI

1)

(DO1)

(DO2)

(

DO3

)

(

DO4

)

(

DO5)

Note 1

)

Note 1) Input signals DI1

to DIA and output signals DO1 to DO5 are default signals allocated by the factory.

Note 2) ** These are non-allocated signals. You can change their allocation by setting parameters. For more

information, refer to “4.1.6 External Input Signal and Logic Definition” and “4.1

.8 External Output Signal and

Logic Definition.”

VLMT**

TLMT

**

Note 2)

WARN**

INSPD**

EGEAR

1 **

EGEAR2 **

PCON **

GAIN2 **

P_

CLR **

T

_LMT

**

Note 2)

MODE **

ABS

_RQ

**

ZCLAMP **

MONIT

128

MONIT2

29

GND37

AO32

/

AO33

BO30

/BO31

ZO4

/ZO5

SG36

Analog Output

Encoder Pulse Output

Connect to Connector Case

-10

V ~

+10V

-10V ~

+10V

Upper

Level

Controller

+12

VA34

-12

VA35

1.2.5 Example of Torque Operation Mode Wiring

1-13

1. Product Components and Signals

STOP

48

EMG

18

CWLIM

19

CCWLIM

20

DIR

46

ALMRST

17

SPD3

21

SPD2

22

SPD1

23

SVON

47

ALARM+

38

ALARM-

39

READY+

40

READY-

41

ZSPD

43

BRAKE

44

INPOS

45

50

+24V IN

GND24

24

ALO0

16

ALO1

15

ALO2

14

GND24

25

PULCOM

49

PF+

9

PF-

10

PR+

11

PR-

12

SPDCOM

27

GND

8

TRQCOM

1

GND

8

Digital Input

Digital Output

Command Pulse Input

Analog Input

DC 24V

3.3kΩ

Line Driver

Open Collector

CN1

-10V ~ +10V

Upper

Level

Controller

-10V ~ +10V

Analog

Speed

Command

Analog

Torque

Limit

Note 1)

(DIA)

(DI9)

(DI8)

(DI7)

(DI6)

(DI5)

(DI4)

(DI3)

(DI2)

(DI1)

(DO1)

(DO2)

(DO3)

(DO4)

(DO5)

Note 1)

Note 1) Input signals DI1 to DIA and output signals DO1 to DO5 are default signals allocated by the factory.

Note 2) ** These are non-allocated signals. You can change their allocation by setting parameters. For more

information, refer to “4.1.6 External Input Signal and Logic Definition” and “4.1.8 External Output Signal and

Logic Definition.”

Note 3) Input Contact Mode = ON: Speed Control Mode, Mode = OFF: Position Operation Mode

VLMT

**

TLMT

**

Note 2)

WARN

**

INSPD

**

EGEAR1

**

EGEAR2

**

PCON

**

GAIN2

**

P_CLR

**

T_LMT **

Note 2)

MODE

**

ABS_RQ

**

ZCLAMP

**

MONIT1

28

MONIT2

29

GND

37

AO

32

/AO

33

BO

30

/BO

31

ZO

4

/ZO

5

SG

36

Analog Output

Encoder Pulse Output

Connect to Connector Case

-10V ~ +10V

-10V ~ +10V

Upper

Level

Controller

+12VA

34

-12VA

35

Note 3)

1.2.6 Examples of Speed / Position Operation Mode Wiring

1-14

1. Product Components and Signals

STOP

48

EMG

18

CWLIM

19

CCWLIM

20

DIR 46

ALMRST 17

SPD

3 21

SPD

2 22

SPD

1 23

SVON 47

ALARM

+

38

ALARM

-

39

READY+40

READY-41

ZSPD

43

BRAKE

44

INPOS

45

50+

24

V IN

GND

2424

ALO016

ALO115

ALO214

GND2425

SPDCOM 27

GND 8

TRQCOM 1

GND 8

Digital Input Digital Output

Command Pulse Input

Analog Input

DC

24

V

3.3kΩ

Line Driver

Open Collector

CN1

-10V

~ +10V

Upper

Level

Controller

-10V ~

+10V

Analog

Speed

Command/

Limit

Analog

Torque

Limit/

Command

Note

1)

(DIA

)

(

DI

9

)

(

DI

8

)

(

DI

7

)

(

DI

6

)

(

DI

5

)

(DI4)

(DI3)

(DI2)

(DI

1)

(

DO

1

)

(

DO2

)

(

DO

3

)

(

DO

4

)

(DO

5

)

Note

1

)

Note 1) Input signals DI1

to DIA and output signals DO1 to DO5 are default signals allocated by the factory.

Note 2) ** These are non-

allocated signals. You can change their allocation by setting parameters. For more

information, refer to “4.1

.6 External Input Signal and Logic Definition” and “4.

1.8 External Output Signal and

Logic Definition.”

Note 3

) Input Contact Mode = ON: Speed Control Mode, Mode = OFF:

Torque Operation Mode

VLMT

**

TLMT

**

Note

2)

WARN

**

INSPD**

EGEAR

1

**

EGEAR2 **

PCON

**

GAIN

2

**

P_

CLR **

T_LMT **

Note

2)

MODE **

ABS

_

RQ **

ZCLAMP **

MONIT

128

MONIT2

29

GND

37

AO32

/

AO33

BO30

/BO31

ZO4

/ZO5

SG36

Analog Output

Encoder Pulse Output

Connect to Connector Case

-10V

~ +

10

V

-

10

V ~ +10V

Upper

Level

Controller

+12VA34

-

12VA

35

Note 3)

1.2.7 Example of Speed/Torque Operation Mode Wiring

1-15

1. Product Components and Signals

STOP

48

EMG

18

CWLIM

19

CCWLIM

20

DIR

46

ALMRST

17

SPD3

21

SPD2

22

SPD1

23

SVON

47

ALARM+

38

ALARM-

39

READY+

40

READY-

41

ZSPD

43

BRAKE

44

INPOS

45

50

+24V IN

GND2424

ALO0

16

ALO1

15

ALO2

14

GND24

25

PULCOM

49

PF+

9

PF-

10

PR+

11

PR-

12

SPDCOM

27

GND

8

TRQCOM

1

GND

8

Digital Input

Digital Output

Command Pulse Input

Analog Input

DC 24V

3.3kΩ

Line Driver

Open Collector

CN1

-10V ~ +10V

Upper

Level

Controller

-10

V ~ +10V

Analog

Speed

Limit

Analog

Torque

Limit/

Command

Note 1)

(DIA)

(DI9)

(DI8)

(DI7)

(DI6)

(DI5)

(DI4)

(

DI3)

(DI2)

(DI1)

(DO1)

(DO2

)

(DO3)

(DO4)

(DO5)

Note 1)

Note 1) Input signals DI1 to DIA and output signals DO1 to DO5 are default signals allocated by the factory.

Note 2) ** These are non

-allocated signals.

You can change their allocation by setting parameters. For more

information, refer to “4.1.6 External Input Signal and Logic Definition” and “4.1.8 External Output Signal and

Logic Definition.”

Note 3) Input Contact Mode = ON: Position Control Mode, Mode = OFF: Torque Operation Mode

VLMT

**

TLMT

**

Note 2)

WARN

**

INSPD

**

EGEAR1

**

EGEAR2 **

PCON

**

GAIN2

**

P_CLR

**

T_LMT

**

Note 2)

MODE

**

ABS_

RQ

**

ZCLAMP

**

MONIT1

28

MONIT2

29

GND

37

AO

32

/AO

33

BO

30

/BO

31

ZO

4

/ZO

5

SG

36

Analog Output

Encoder Pulse Output

Connect to Connector

Case

-10V ~ +10

V

-10V ~ +10V

Upper

Level

Controller

+12VA

34

-12VA

35

Note 3)

1.2.8 Example of Position/Torque Operation Mode Wiring

1-16

1. Product Components and Signals

Pin

Number

of

Factory

Setting

Name

Details

Applicable Modes

Position

Speed

Torque

Speed

/Position

Speed

/Torque

Position

/Torque

1.3 Signals

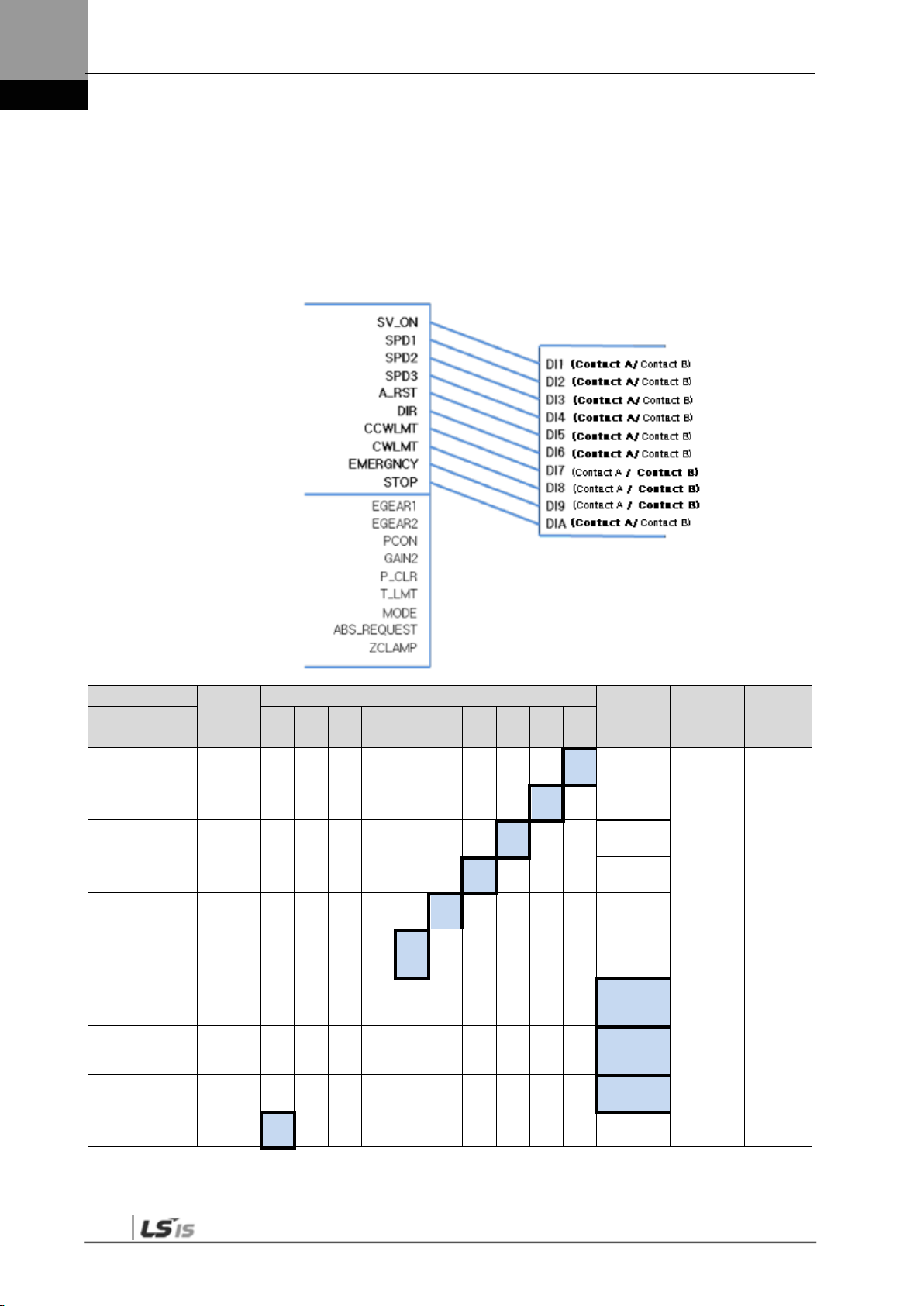

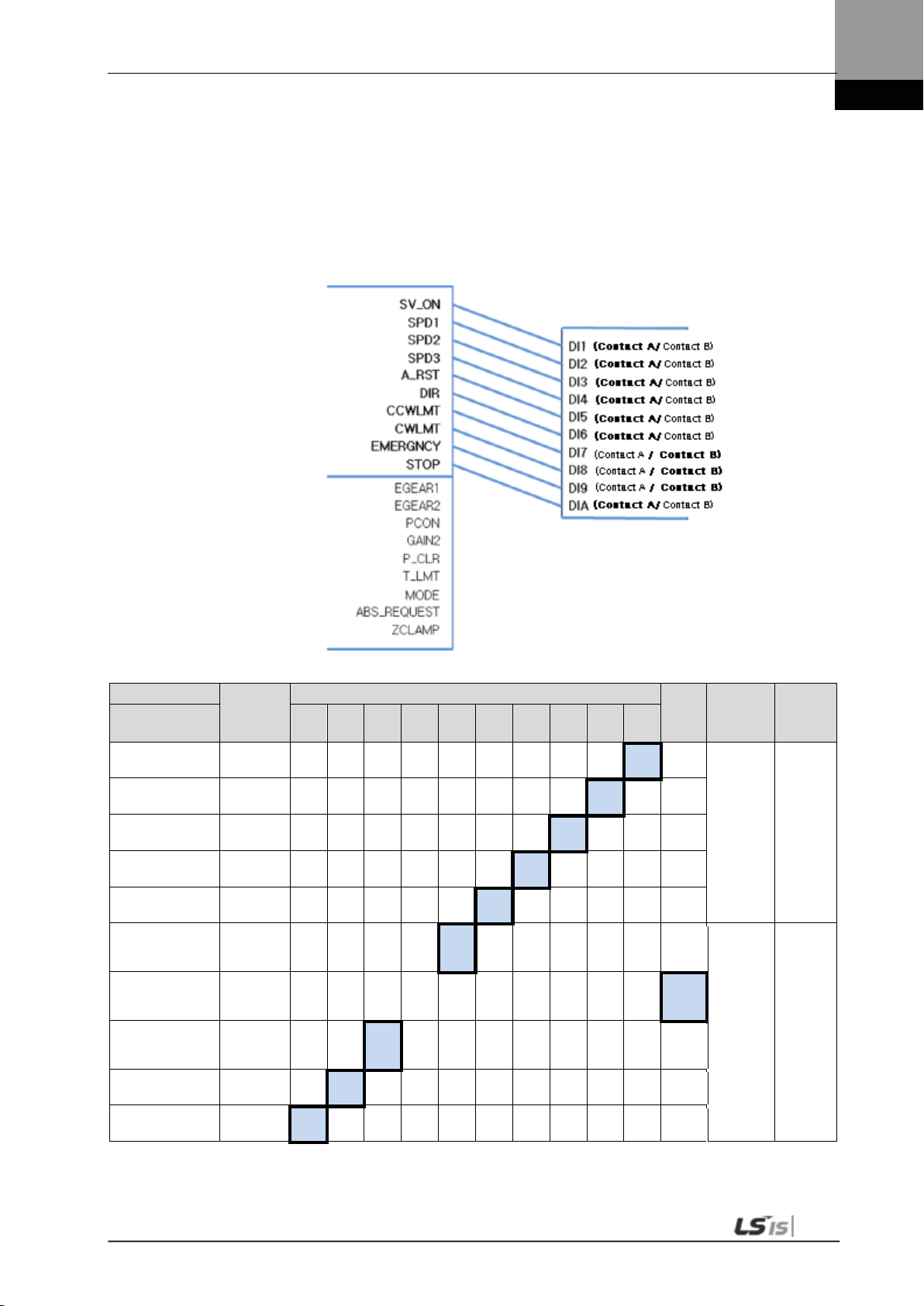

1.3.1 Digital Input Contact Signal

50 +24 V IN

47 SVON Servo ON O O O O O O

23 SPD1 Multi-speed 1 X O X O/X O/X X

22 SPD2 Multi-speed 2 X O X O/X O/X X

21 SPD3 Multi-speed 3 X O X O/X O/X X

17 ALMRST Reset upon alarm O O O O O O

46 DIR

20 CCWLMT

19 CWLMT Clockwise limit O O O O O O

18 EMG Emergency stop O O O O O O

48 STOP Stop X O O O/X O X/O

Allocate EGEAR1 Electronic gear ratio 1 O X X X/O X O/X

Allocate EGEAR2 Electronic gear ratio 2 O X X X/O X O/X

Allocate PCON P control action O O X O O/X O/X

Allocate GAIN2 Select gain 2 O O X O O/X O/X

Input contact +24 [V]

power

Select rotation

direction

Counter-clockwise

limit

O O O O O O

O O O O O O

O O O O O O

Allocate P_CLR Clear error pulse O X X X/O X O/X

Allocate T_LMT

Allocate MODE

Allocate ABS_RQ

Allocate ZCLAMP Zero clamp X O X O/X O/X O

Control torque with

TRQCOM

Change operation

modes

Request absolute

position data

O O O O O O

X X X O O O

O O O O O O

1-17

1. Product Components and Signals

1.3.2 Analog Input Contact Signal

Pin

Number

27 SPDCOM

1 TRQCOM

8

37

Name Description

Analog speed

command (-10-+10 [V])

Analog Speed Limit

(-10-+10 [V])

Analog T orque

Command

(-10-+10 [V])

Analog torque limit

(-10-+10 [V])

GND

Grounding for analog

signals

Position Speed Torque

X O X O/X O/X X

X X O X X/O X/O

X X O X X/O X/O

O O X O O/X O/X

O O O O O O

1.3.3 Digital Output Contact Signal

Pin

Number

of

Factory

Setting

16 ALO0

15 ALO1

14 ALO2

Name Description

Alarm group contact

output 1

Alarm group contact

output 2

Alarm group contact

output 3

Position Speed Torque

O O O O O O

O O O O O O

O O O O O O

Applicable Modes

Speed

/Position

Applicable Modes

Speed

/Position

Speed

/Torque

Speed

/Torque

Position

/Torque

Position

/Torque

38 / 39 ALARM +/- Alarm O O O O O O

40 / 41 READY +/- Ready for operation O O O O O O

43 ZSPD Zero speed reached O O O O O O

44 BRAKE Brake O O O O O O

45 INPOS Position reached O X X X/O X O/X

Allocate TLMT Torque limit O O O O O O

Allocate VLMT Speed limit O O O O O O

Allocate INSPD Speed reached X O X O/X O/X X

Allocate WARN Warning O O O O O O

24

25

GND24

Input/output contact

Grounding of drive

power (24 [V])

O O O O O O

1-18

1. Product Components and Signals

1.3.4 Monitor Output Signal and Output Power

Pin

Number

28 MONIT1

29 MONIT2

8

37

34 +12 V

35 -12 V

Name Description

Analog monitor

output 1

(-10-+10 [V])

Analog monitor

output 2

(-10-+10 [V])

GND

Grounding for analog

signals

Terminal for +12 [V]

power output

Terminal for -12 [V]

power output

Position Speed Torque

1.3.5 Pulse Train Input Signal

Line Driver (5 V)

Pin

Number

9 PF+ F+ pulse input O X X X/O X O/X

Name Description

Position Speed Torque

Applicable Modes

Speed

/Position

O O O O O O

O O O O O O

O O O O O O

O O O O O O

O O O O O O

Applicable Modes

Speed

/Position

Speed

/Torque

Speed

/Torque

Position

/Torque

Position

/Torque

10 PF- F- pulse input O X X X/O X O/X

11 PR+ R+ pulse input O X X X/O X O/X

12 PR- R- pulse input O X X X/O X O/X

49 PULCOM Not for use X X X X X X

Open Collector (24 V)

Pin

Number

9 PF+ Not for use X X X X X X

10 PF- F pulse input O X X X/O X O/X

11 PR+ Not for use X X X X X X

12 PR- R pulse input O X X X/O X O/X

49 PULCOM +24 V power input O X X X/O X O/X

Name Description

Applicable Modes

Position Speed Torque

Speed

/Position

Speed

/Torque

Position

/Torque

1-19

1. Product Components and Signals

1.3.6 Encoder Output Signal

Pin

Number

32

33

30

31

Applicable Modes

Name Description

AO

/AO

BO

/BO

4

5

ZO

/ZO

Outputs encoder signals

received from the m otor as

signals pre-scaled

according to the ratio

defined by [P0-14].

(5 [V] line driver method)

Outputs encoder Z signals

received from the m otor.

(5 [V] line driver method)

Position Speed Torque

O O O O O O

O O O O O O

Speed

/Position

Speed

/Torque

Position

/Torque

1-20

2. Installation

Item

Requirements

Notes

40[℃

2. Installation

2.1 Servo Motor

2.1.1 Usage Environment

Ambient

temperature

Ambient

humidity

External

vibration

0 ∼

80[%] RH or lower Use the product in steam-free places.

Vibration accelerati on

19.6 [㎨] or below in the

X and Y directions

If the temperature at whic h the product will be used is

outside this range, the product must be custom-ordered

with consultation of the technical support team.

Excessive vibration reduces the lifespan of bearings.

2.1.2 Prevention of Excessive Shock

Excessive shock to the motor shaft during installation, or the motor falling during handling,

may damage the encoder.

2.1.3 Motor Connection

The motor might burn out when commercial power is directly connected to it.

Be sure to connect via the specified drive.

Connect the ground terminal of the motor to either of the two ground terminals inside the drive, and

the remaining terminal to the type-3 grounding.

U – U

V - V

W – W

- F.G

Connect the U, V, and W terminals of the motor, just as the U, V, and W terminals of the drive.

Make sure that the pins on the motor connector are securely connected.

In case of moisture or condensation on the motor, make sure that insulation resistance is 10 [㏁]

(500 [V]) or higher before you start installation.

2-1

2. Installation

Flange

Lateral Load

Axial Load

Notes

N

kgf N kgf

below

2.1.4 Load Device Connection

For coupling connection: Make sure that the motor shaft and the load shaft are aligned within

the tolerance.

Load shaft

For pulley connection:

40 148 15 39 4

60 206 21 69 7

80 255 26 98 10

130 725 74 362 37

180 1548 158 519 53

220 1850 189 781 90

0.03 [㎜] or below (peak to peak)

Motor shaft

0.03 [㎜] or below (peak to peak)

Nr: 30 [㎜] or

Lateral load

Axial load

2.1.5 Cable Installation

In case of vertical installation, make sure that no oil or water flows into connection parts.

Do not apply pressure to, or scratch, cables.

In case of moving the motor, be sure to use robotic cables to prevent sway.

2-2

2. Installation

Item

Requirements

Notes

50[

2.2 Servo Drive

2.2.1 Usage Environment

Ambient

temperature

Ambient

humidity

External

vibration

Surrounding

conditions

Caution

0 ∼

90[%] RH or

Vibration

acceleration 4.9

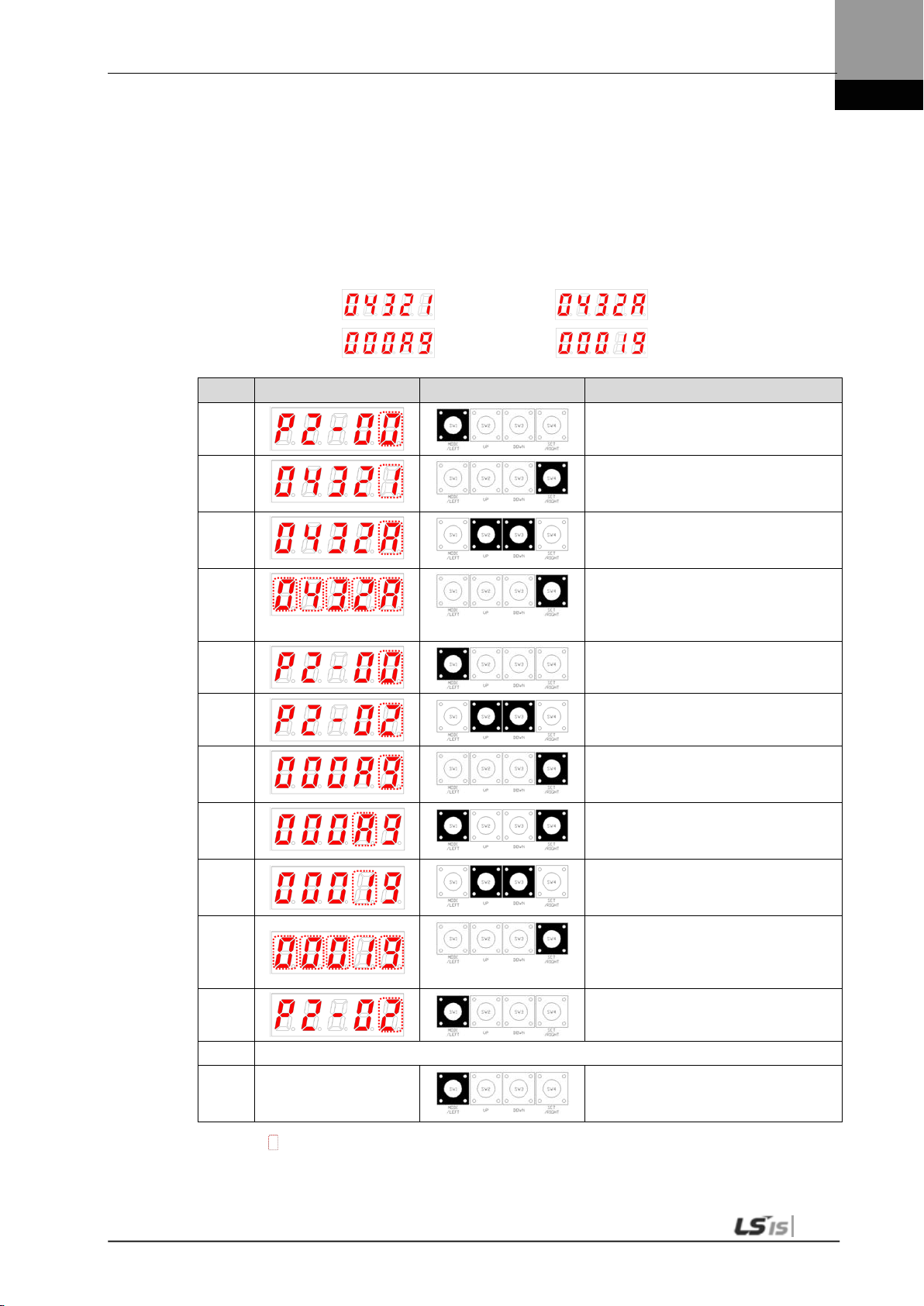

[㎨] or lower

No exposure to direct sunlight.

No corrosive gas or combustible gas.

No oil or dust.

Sufficient ventilation for closed area s.

lower

Install a cooling fan on the control panel in to keep the

surrounding temperature within the required range.

Caution

Condensation or freezing of moisture inside the drive during

prolonged periods of inactivity may damage it.

Remove any moisture completely before you operate the drive

after a prolonged period of inactivity.

Excessive vibration reduces the lifespan of the machine and

causes malfunction.

2-3

2. Installation

Caution

2.2.2 Installation Inside the Control Panel

Comply with the spaces specified in the following images for installation inside the control

panel.

40 mm or

longer

10 mm or

longer

10 mm or

longer

40 mm or

longer

When installing 1 unit:

30 mm or

longer

40 mm or

longer

When installing 2 or more units:

100 mm

or longer

30 mm or

longer

2 mm or longer

Make sure that heat does not affect the drive during the installation of external regenerative

resistance.

When assembling the control panel of the servo drive, make sure that it is sufficiently close to

the wall.

When assembling the control panel, make sure that metal powder caused by drilling does not

enter the drive.

Make sure that oil, water, and metal dust do not enter the drive through gaps or the ceiling.

Protect the control panel with air purge in places where there is a lot of harmful gas or dust.

2-4

2. Installation

Caution

Model

Resistance

Value

Standard

Capacity

* Notes

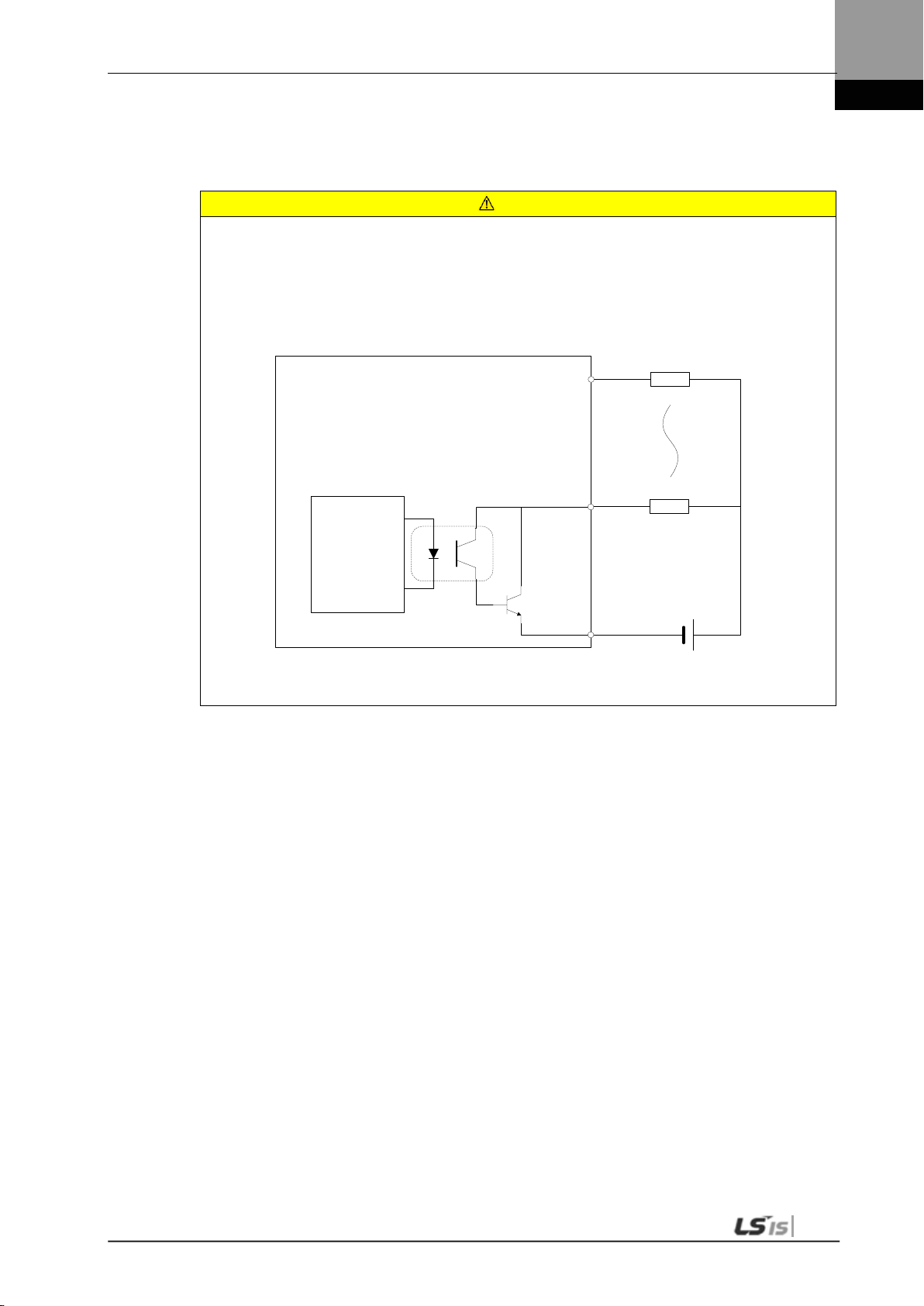

Danger

2.2.3 Power Wiring

Make sure that the input power voltage is within the allowed range.

Overvoltage can damage the drive.

Connection of commercial power to the U, V and W terminals of the drive may cause damage.

Be sure to supply power via terminals L1, L2 and L3.

Connect short-circuit pins to the B and BI terminals. For external regenerative resistance, use

standard resistance for the B+ and B terminals after removing the short-circuit pins.

L7□A001□

L7□A002□

L7□A004□

L7□A08□

L7□A010□

L7□A020□

L7□A035□

L7□A050□

Configure the system in a way that main power (L1, L2, L3) is supplied only after control power (C1,

C2). (Refer to “Chapter 3 Wiring.”)

High voltage remains for a while, even after the main power is disconnected.

After disconnecting the main power, make sure that the charge lamp is off before you start

wiring. There is a risk of electric shock.

Grounding must be done over the shortest distance.

A long ground wire is susceptible to noise and thus causes malfunction.

100 [Ω] Built-in 50 [W]

40 [Ω]

13 [Ω]

6.8[Ω] Built-in 120[W]

Built-in 100

[W]

Built-in 150

[W]

Caution

For more information about resistance for

expanding regenerative capacity, refer to “7.3

Option and Peripheral Device.”

2-5

3. Wiring Method

3. Wiring Method

3.1 Internal Block Diagram

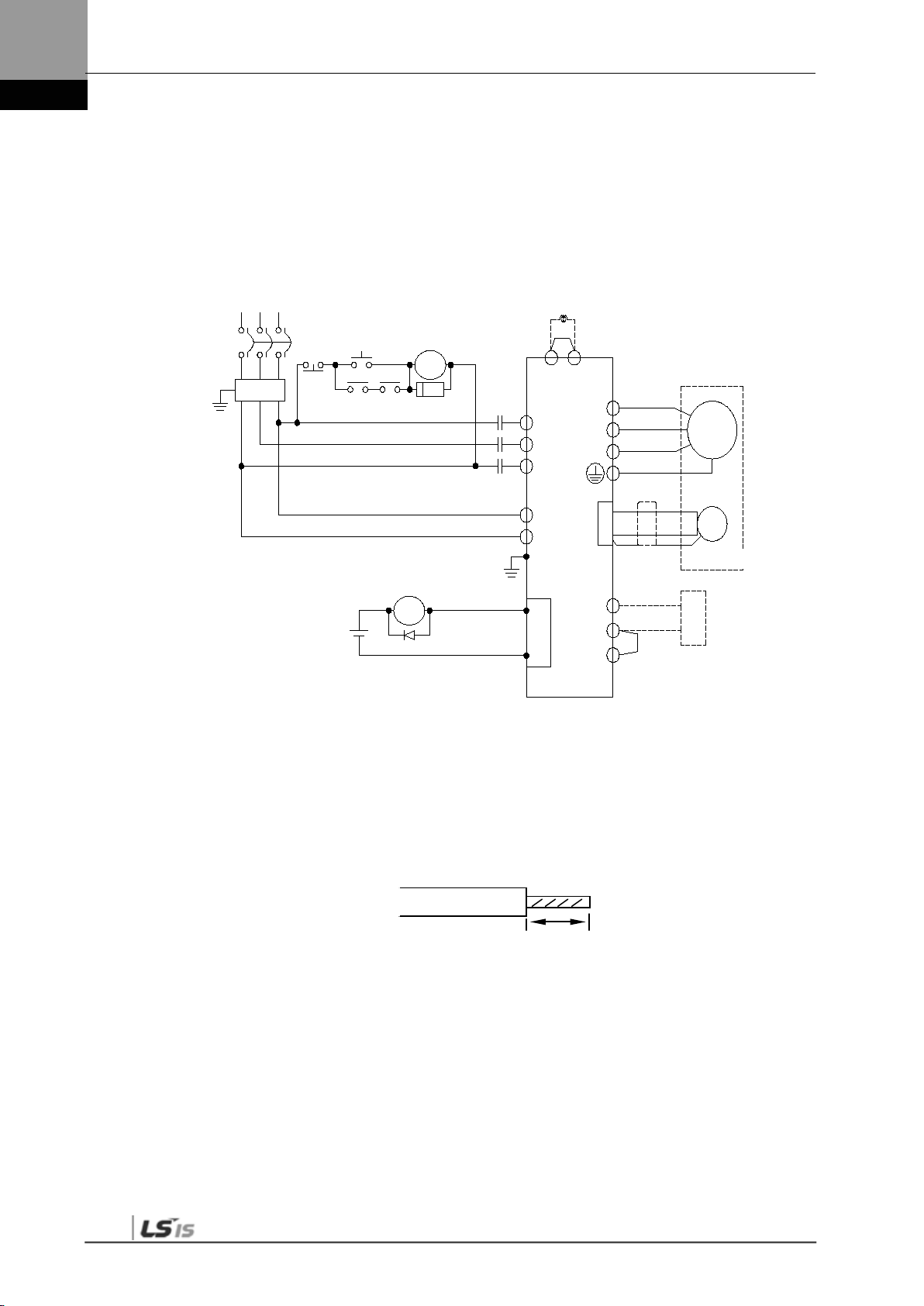

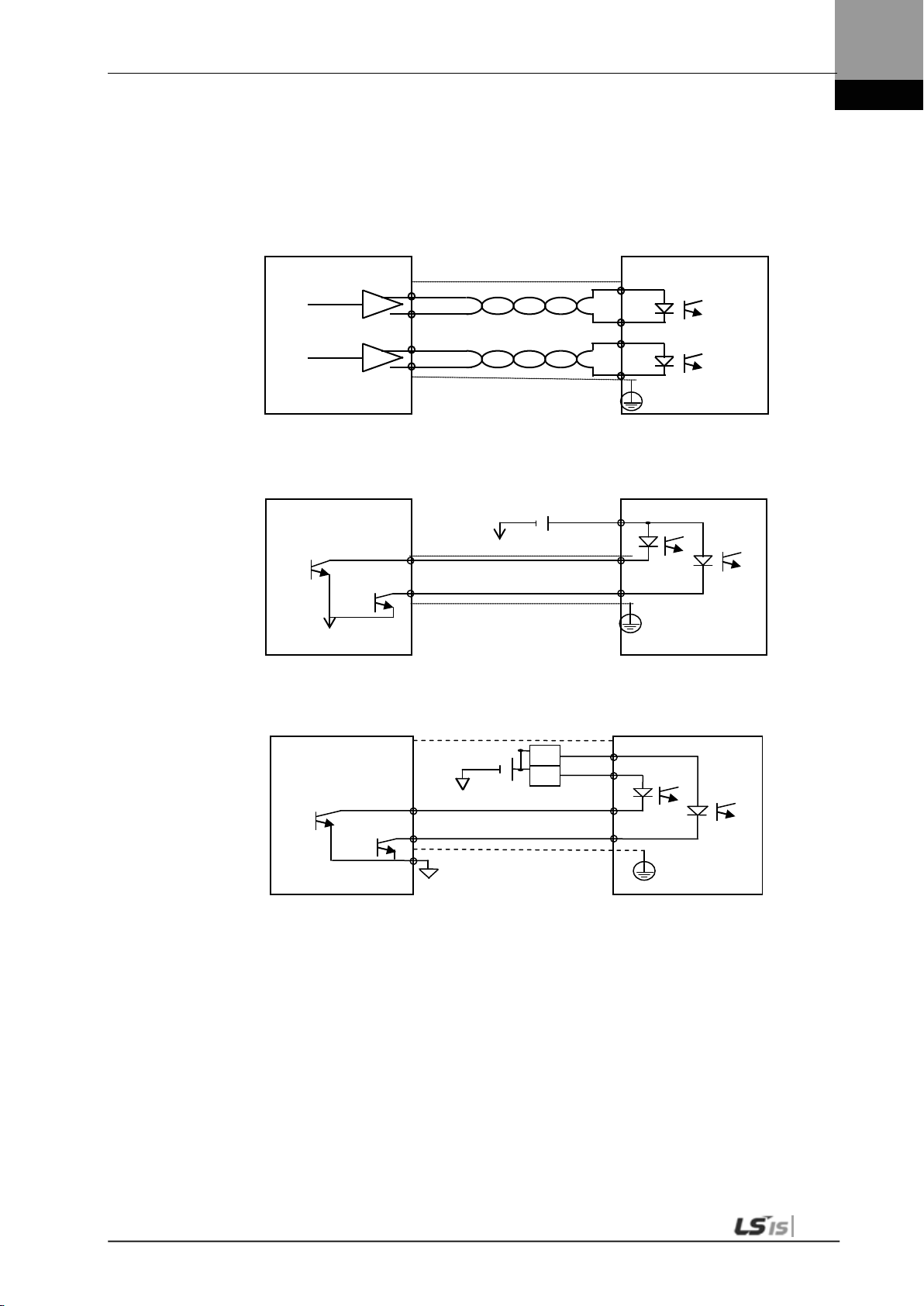

3.1.1 L7 Drive Block Diagram [L7SA001□ - L7SA004□]

NOTE 1) If you use a DC reactor, connect to the PO and PI pins.

NOTE 2) If you use external regenerative resistance, connect to the B+ and B pins after removing the B

and BI short-circuit pins.

3-1

3. Wiring Method

3.1.2 L7 Drive Block Diagram [L7SA008□ - L7SA035□]

NOTE 1) If you use a DC reactor, connect to the PO and PI pins.

NOTE 2) If you use external regenerative resistance, connect to the B+ and B pins after you remove the B

and BI short-circuit pins.

NOTE 3) The L7SA008□ and L7SA035□ models are c ooled by a DC 24 [V] cooling fan.

3-2

3. Wiring Method

Main Control

Diode

L3

Three-phase

L1

L2

Lamp

Chage

Output

Encoder

POWER Circuit Access(CN7)

DSP / FPGA

CN2

M

IGBT

W

Current Sensor

U

V

B

B+

E

PO

PI

(Note1)

C1

C2

S

M

P

S

T1

T2

Thermister

AC200~230V

CN5

CN3,CN4

BISS

FAN

(Note3)

USB TO UART

External Regenerative

Resistance(separately Installed)

(Note2)

Resistance

Regenerative

Power Input

Power Input

AC200~230V

One-phase

Main Power

Failure Detection

Circuit

Internal

Temperature

Detection

Circuit

Relay

Operation

Circuit

DC Voltage

Detection

Circuit

Regenerative

Braking

Operation

Circuit

IGBT

Temperature

Detection

Circuit

PWM

Signal

SC Detection

Circuit

U and V

Current

Detection

Circuit

DB

Operation

Circuit

RS422

Communication

USB

Communication

A/D Conversion

D/A Conversion

P/C Insulation I/F

Input

Encoder

Contact Output

(5 points)

(2 points)

Pulse Input

Contact Input

(10 points)

Monitor Output

(10 points)

Analog Input

(2 points)

Upper Level Controller Connection(CN1)

Control Power

Failure Detection

Circuit

Thermister

U,VCurrent

DC Voltage

3.1.3 L7 Drive Block Diagram [L7SA050□ ]

NOTE 1) If you use a DC reactor, connect to the PO and PI pins.

NOTE 2) If you use external regenerative resistance, connect to the B+ and B pins after attac hing wires of

internal regener ative resistance to “NC” hole on the case.

NOTE 3) The L7SA050□ models are cooled by a DC 24 [V] cooling fan.

3-3

3. Wiring Method

U

V

W

L1

L2

L3

C1

C2

B+

B

BI

38

39

CN1

RA

M

E

Alarm-

Alarm+

1Ry

RA

1SK

1Ry1MC

+24V

NF

1MC

R S T

서보드라이브

(200~230V)

Main

OFF

Main

ON

인코더

외부

회생저항

주1)

주2)

PO

PI

DC 리액터

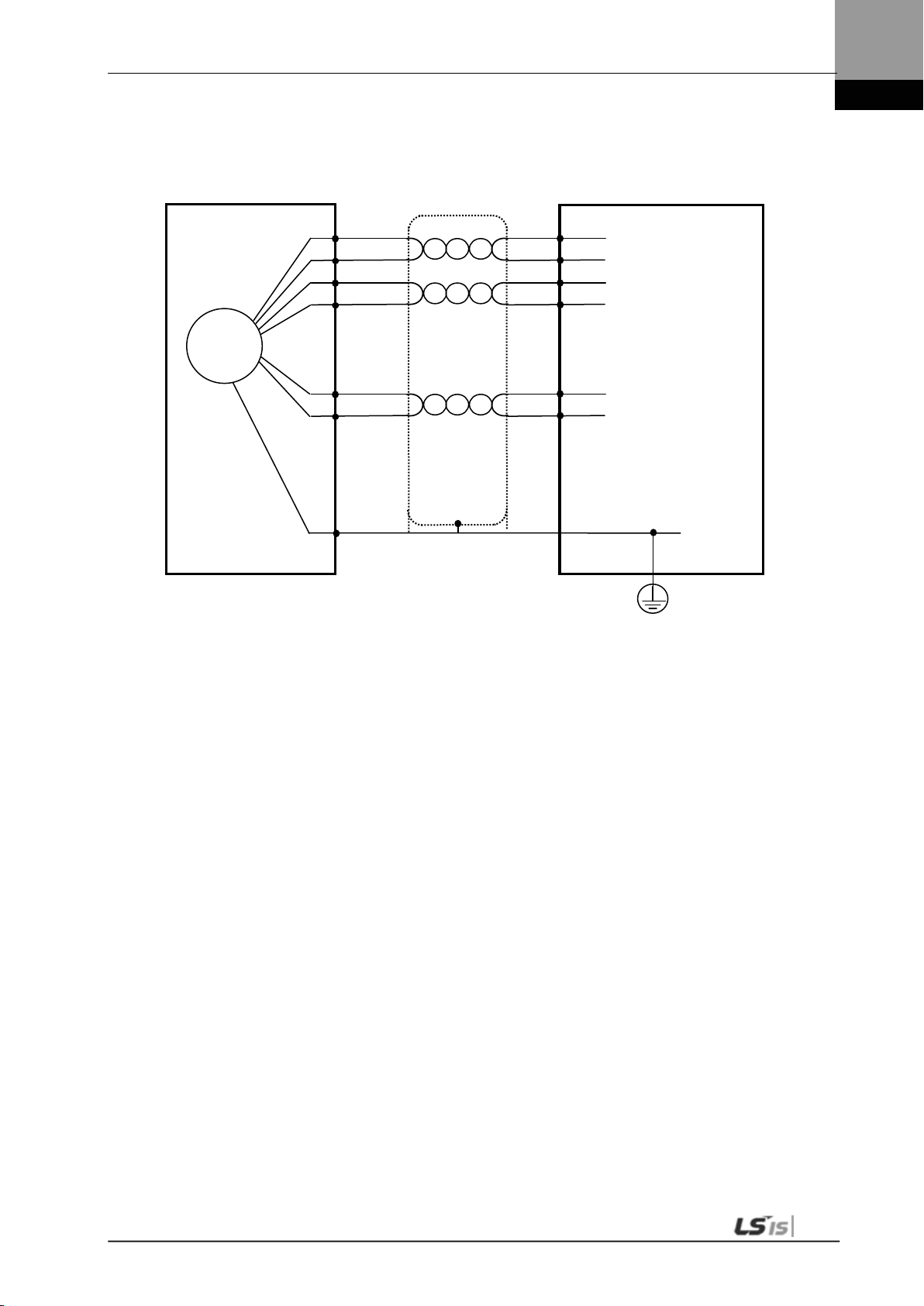

3.2 Power Wiring

3.2.1 L7 Drive Wiring Diagram [L7SA001□ - L7SA035□]

Servo Drive

Note 1)

DC Reactor

Encoder

Note 2) External

Regenerative Resistancer

NOTE 1) It takes approximately one to two sec onds until alarm signal is output after you turn on the main

NOTE 2) Short-circuit B and BI terminals before use. Regenerative resistance of L7SA001□-L7SA004□

NOTE 3) Remove the sheath of cables to be used for the main circ uit power by approximately 7-10 [㎜] and

power. Accordingly, push and hold the main power ON switch for at least two seconds.

(50 [W], 100 [Ω]), L7SA010□ (100 [W], 40 [Ω]), and L7SA035□ (150 [W], 13 [Ω]) exist inside. If

regenerative capacity is high because of frequent acceleration and deceleration, open the shortcircuit pins ( B, BI) and connect external regenerative res istance to B and B+.

use devoted crim p terminals. (Refer to “3.2.2 Power Circuit Electric Sub Assembly Standards.”)

NOTE 4) Connect or remove the main circuit power unit wiring after pushing the button of t he L7SA001□ –

L7SA010□ drive terminal. For drive L7SA 035□, use a (-)slot screw drive for connecti on and

removal.

7~10㎜

3-4

3. Wiring Method

U

V

W

L1

L2

L3

C1

C2

B+

B

38

39

CN1

RA

M

E

Alarm-

Alarm+

1Ry

RA

1SK

1Ry

1MC

+24V

NF

1MC

R

S

T

(200~230V)

Main

OFF

Main

ON

Encoder

(Note1)

(Note2)

PO

PI

DC Reactor

external

regenerative

resistance

Servo Drive

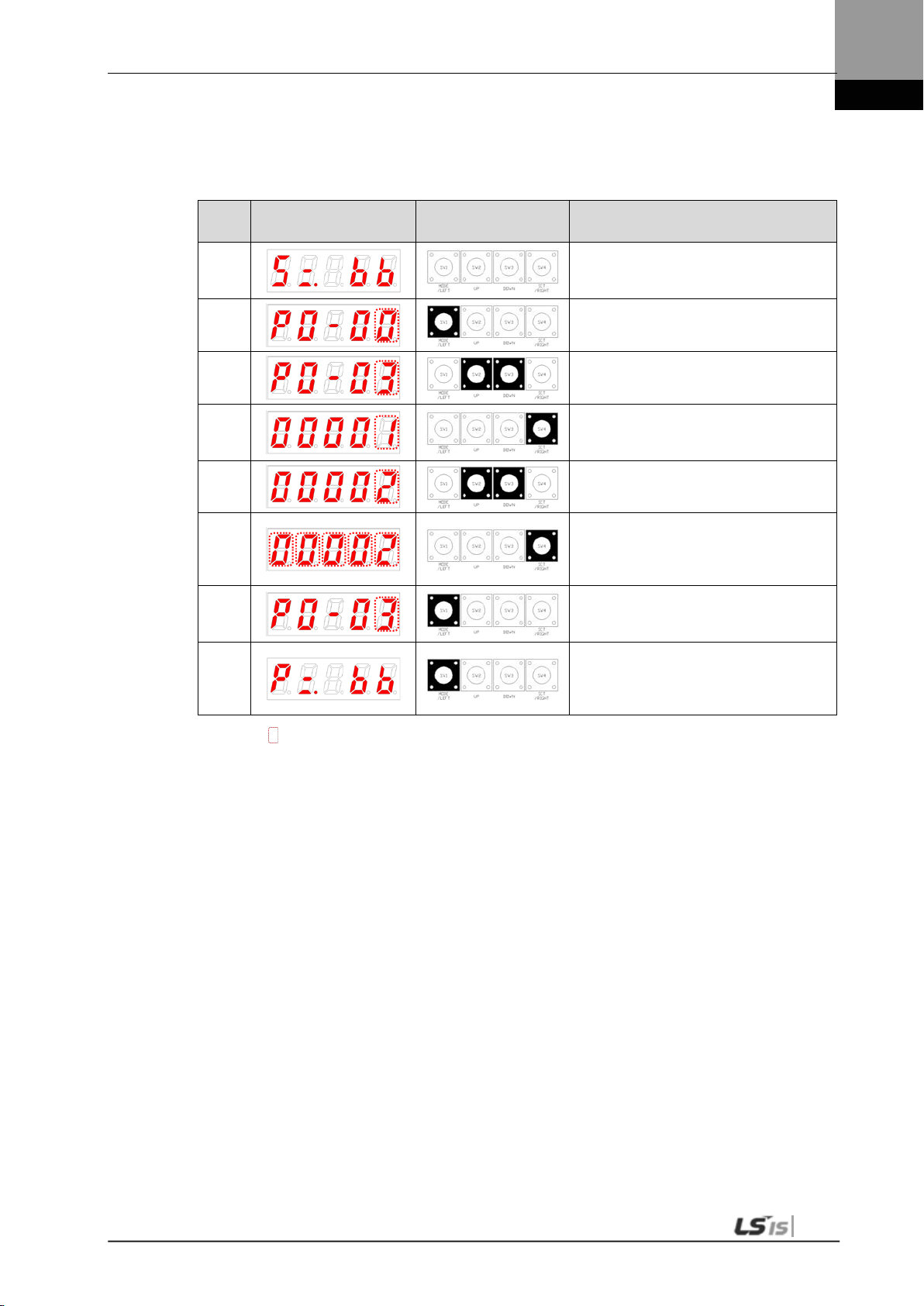

3.2.2 L7 Drive Wiring Diagram [L7SA050□]

NOTE 1) It takes approximately one to two sec onds until alarm signal is output after you turn on the m ain

NOTE 2) Check status of connection of inter nal regenerative res istance(B+, B) before using because

power. Accordingly, push and hold the main power ON switch f or at least two seconds.

L7SA050□ (120[W], 6.8[Ω ]) has internal regenerative resis tance. If value of regener ative voltage

is too high by freq uent dec eler at i on an d ac cel er ati on, i ns tall exter nal r egen er ati ve res i stanc e on B,

B+ terminal after at taching internal regenerative resistance connected B+, B to “NC” hole on the

case.

3-5

3. Wiring Method

Name

L7SA001□

L7SA002□

L7SA004□

L7SA008□

L7SA010□

L7SA020□

L7SA035□

L7SA050□

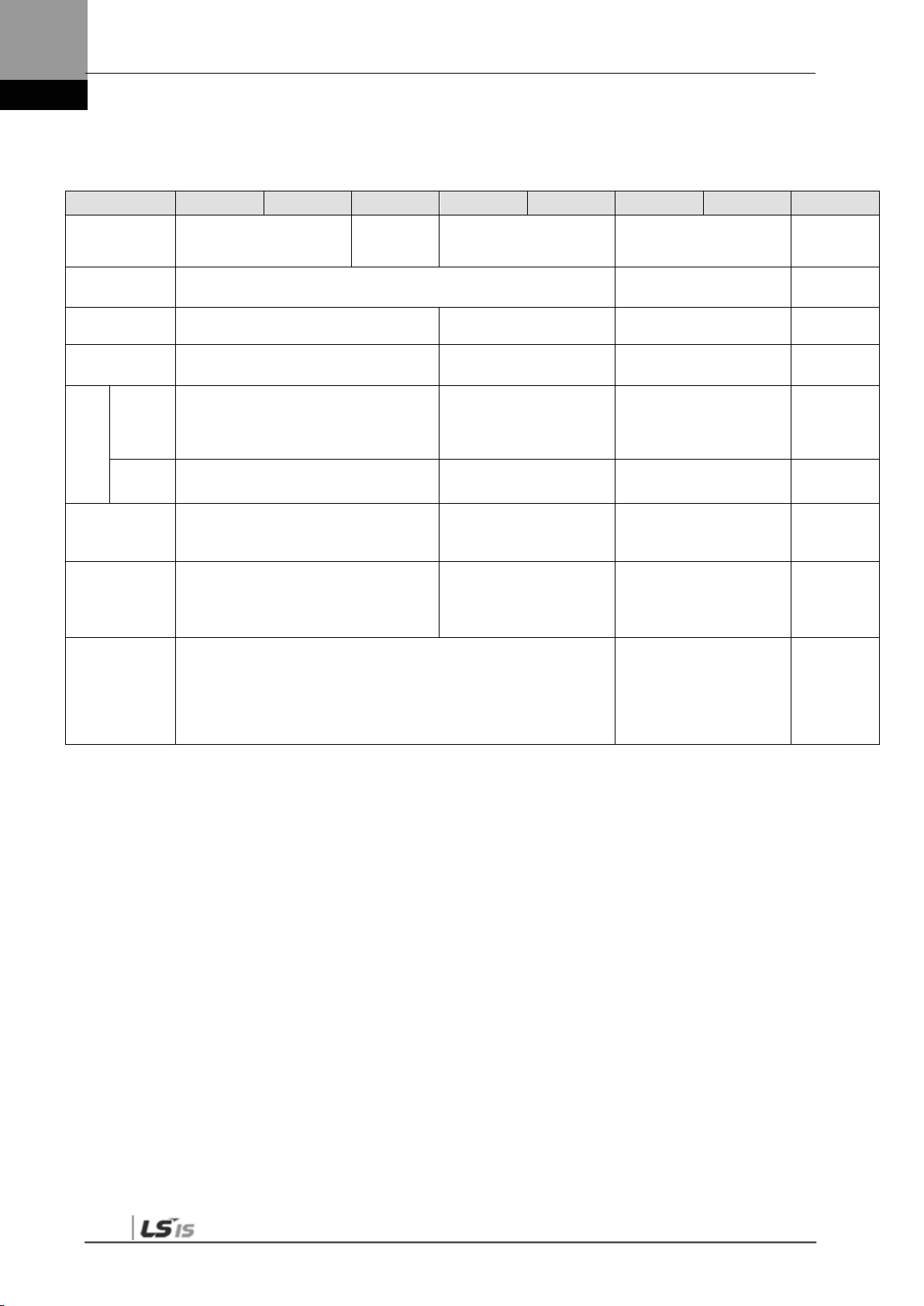

3.2.3 Dimensions for Power Circuit Electrical Parts

MCCB(NFB)

Noise Filter

(NF)

DC reactor

MC

L1,L2,L3

PO,PI,N,

B+,B,BI

Wire

U,V,W

C1

C2

Crimp terminal

Regenerative

resistance

(Provided by

default)

Connector

(L1,L2...U,V,W

)

30A Frame 5A (ABE 33b/5)

AWG16(1.5 ㎟) AWG16(1.5 ㎟) AWG16(1.5 ㎟)

UA-F1510, SEOIL

(10 mm Strip & Twist)

30A Frame

10A

(ABE33b/10)

TB6-B010LBEI(10A) TB6-B030NBDC(30A)

HFN-10 (10 A) HFN-15 (15 A) HFN-30 (30 A)

11A / 240V

(GM□-9)

AWG16

(1.5 ㎟)

50 [W]

100 Ω

• BLF 5.08/03/180F SN BK BX

• BLF 5.08/11/180F SN BK BX

30A Frame 15A (ABE 33b/15) 30A Frame 30A (ABE33b/30)

18A / 240V

(GM□-18)

AWG14

(2.5 ㎟)

UA-F2010, SEOIL

(10 mm Strip & Twist)

100 [W]

40 Ω

• BLZ7.62HP/03/180LR

SN BK BX SO

BLZ7.62HP/11/180LR

SN BK BX SO

32A / 240V

(GM□-32)

AWG12

(4.0 ㎟)

UA-F4010, SEOIL(10 mm

Strip & Twist)

150 [W]

13 Ω

50A Frame

40A(ABE53b

/40)

TB6-

B040A(40A)

HFN-

40(40A)

50A / 240V

(GM□-50)

AWG10 (6.0

㎟)

AWG16(1.5

㎟)

GP110028

KET

120[W]

6.8Ω

Note1) Use 600V-PVC Insulated w ire for wiring.

Use appr oved UL wire(Temp. 60 ℃ or above) for UL(CSA) Regulation.

Use approved wire for any other r egulations.

Use equivalent or above componets compare to components above for any special applications.

3-6

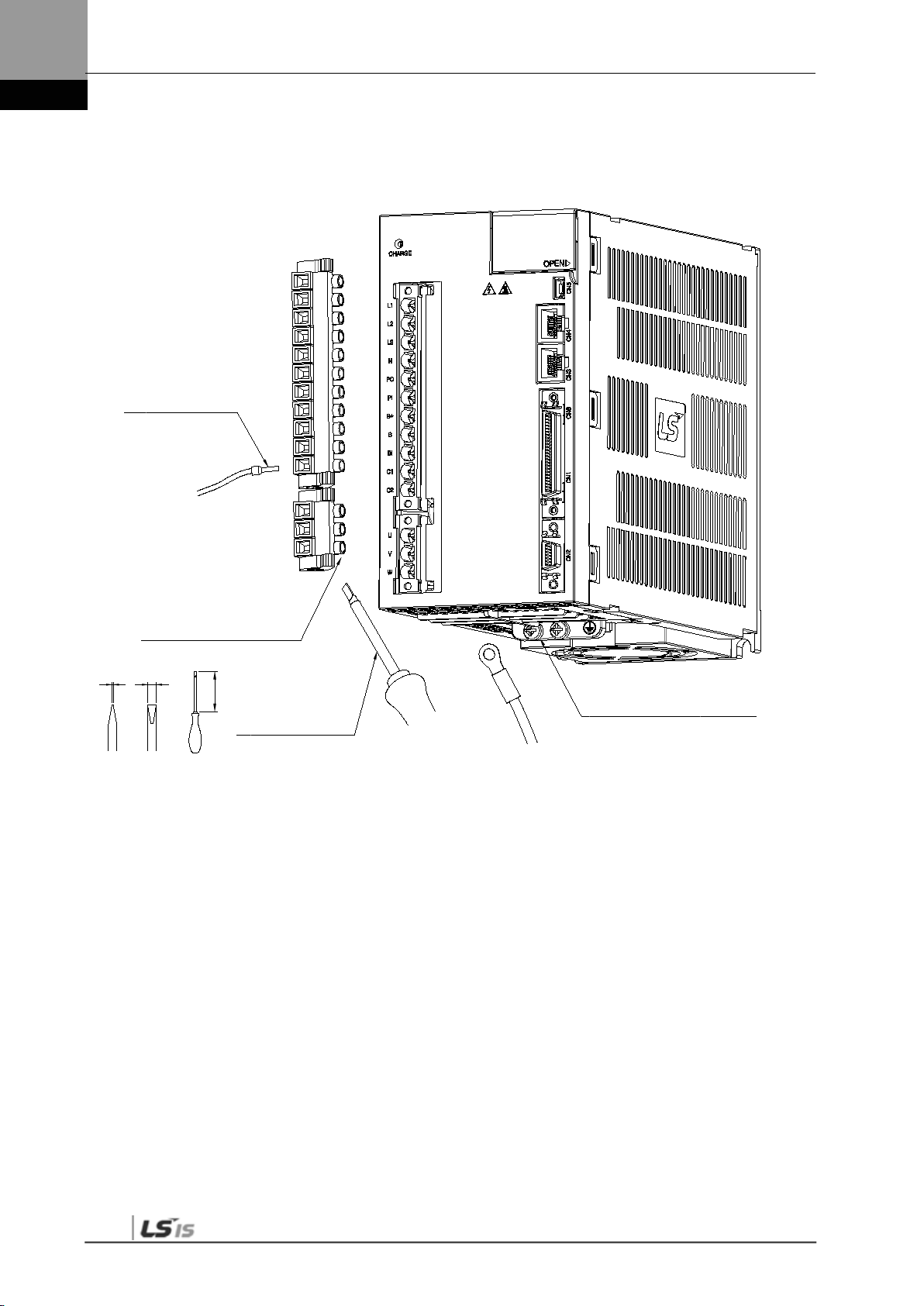

3. Wiring Method

0.6 3.5

100

A

B

C

0.4~0.5[N·m]

SD 0.6x3.5x100

0.4~0.5[N·m]

7~10[㎜]

7~10[㎜]

( L7SA004□ or below)

Length of strip

(L7SA008□ ~ L7SA010□)

Length of strip

Weidmueller’s

SD 0.6x3.5x100

M4 : 1.2[N·m]

Weidmueller’s

M4 : 1.2[N·m]

3-7

3. Wiring Method

A

B

C

0.4~0.5[N·m]

7~10[㎜]

(L7SA020□ ~ L7SA035□)

Length of strip

Weidmueller’s

SD 0.6x3.5x100

M4 : 1.2[N·m]

1) Refer to the drawings above for wiring with BLF 5.08 or BLZ 7.62HP Series connector.

2) Insert wire into wire-hole when upper screw is untightened and then, use appropriate (-) shaped

screwdriver with 0.4 ~ 0.5[N.m] torque to make tight completely.

3) Cut by vibration, malfunction or fire by short could be occurred if torque of screwing was not enough.

4) Make tight completely by using hooks both side when connectors are attached to servo drive after

wiring.

5) FG screw which is located the bottom of servo drive has to be M4 and put on the FG screw with

1.2[N.m] torque.

6) Malfunction of drive could be occurred if torque of screwing was not enough.

7) Recommended (-)shaped screwdriver : Weidmueller’s SD 0.6x3.5x100.

3-8

3. Wiring Method

Terminal Block Signals

TB1

TB2

TB3

NC : 내부 회생저항기

리드 단자 고정용 나사

NC : Internal regenerative resistor

Screw for holding lead terminal

(L7SA050□)

TB1

L1 L2 L3 B+ B U V W FG FG

TB2

N PO P1

TB3

C1 C2

Screw : M4

Screwing torque : 1.2[N·m]

Screw : M4

Screwing torque : 1.2[N·m]

Screw : M4

Screwing torque : 1.2[N·m]

1) Cut by vibration, malfunction or fire by short could be occurred if torque of screwing was not enough.

3-9

3. Wiring Method

establishment

rotation)

3.3 Timing Diagram

3.3.1 Timing Diagram During Power Input

For L7 Series, connect single-phase power to the C1 and C2 terminals to supply power to

the control circuit, and three-phase power to L1, L2, and L3 to supply power to the main

circuit.

The servo signal becomes Ready after the maximum time of 120 [ms] that is required to

reset the inside of the device. If you change the signal to ON, the servo starts operation in 40

[ms].

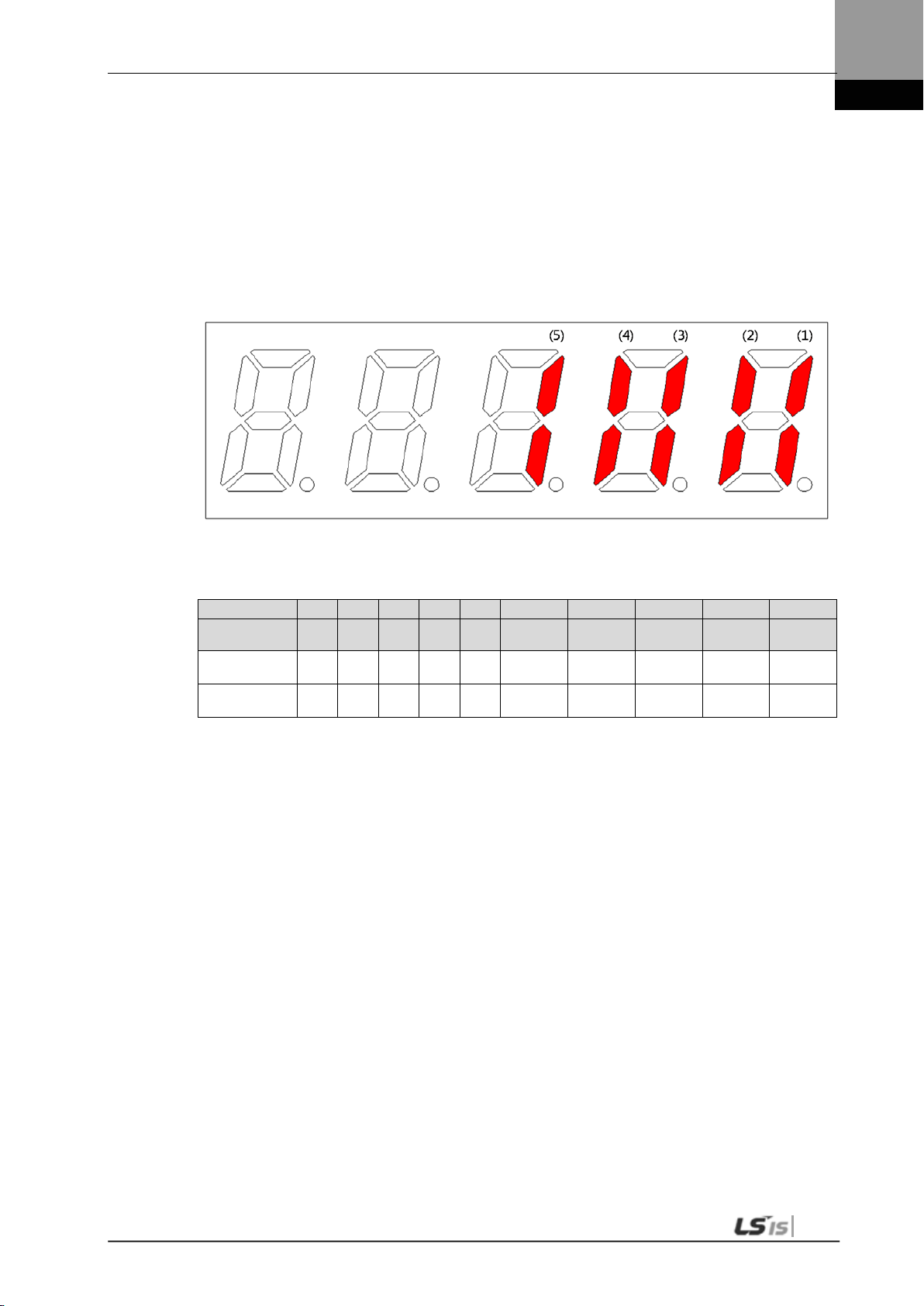

200 ms