The Best Choice for the Most Benefit!

At LS Mecapion, we are committed to providing premium benefits to all of

LSIS always tries its best to bring the greatest benefit to its customers.

our customers.

AC SERVO DRIVE

AC Servo User Manual

XGT Servo

L7NH Series

XDL-L7NH Series User Manual

400

(400V)

Safety Precautions

Read all safety precautions before using this product.

After reading this manual, store it in a readily accessible

location for future reference.

Introduction

Introduction

Hello. Thank you for choosing LSIS XDL-L7NH Series.

This user manual describes how to use this product safely and efficiently.

Failure to comply with the guidelines outlined in this manual may cause personal injury or damage to

the product. Be sure to read this manual carefully before using this product and follow all guidelines

contained therein.

The contents of this manual are subject to change without notice.

The reproduction of part or all of the contents of this manual in any form, by any means or for

any purpose is strictly prohibited without the explicit written consent of LSIS.

LSIS retains all patents, trademarks, copyrights and other intellectual property rights to the

material in this manual. The information contained in this manual is only intended for use with

LSIS products.

Safety precautions are categorized as either Warnings or Cautions, depending on the severity

of the precaution.

Precautions Definition

Danger

Caution

Precautions listed as Cautions may also result in serious injury .

Failure to comply with these guidelines may cause serious injury or death.

Failure to comply with these guidelines may cause personal injury or property

damage.

Electric Safety Precautions

Danger

Before wiring or inspection tasks, turn off the power. Wait 15 minutes until the charge

lamp goes off, and then check the voltage.

Ground both the servo drive and the servo motor.

Only specially trained technicians may perform wiring on this product.

Install both the servo drive and servo motor before performing any wiring.

Do not operate the device with wet hands.

Do not open the servo drive cover during operation.

Do not operate the device with the servo drive cover removed.

Even if the power is off, do not remove the servo drive cover.

Fire Safety Precautions

Caution

Install the servo drive, the servo motor, and the regenerative resistor on non-

combustible materials.

Disconnect the input power if the servo drive malfunctions.

iii

Introduction

Installation Precautions

Store and operate this product under the following environmental conditions.

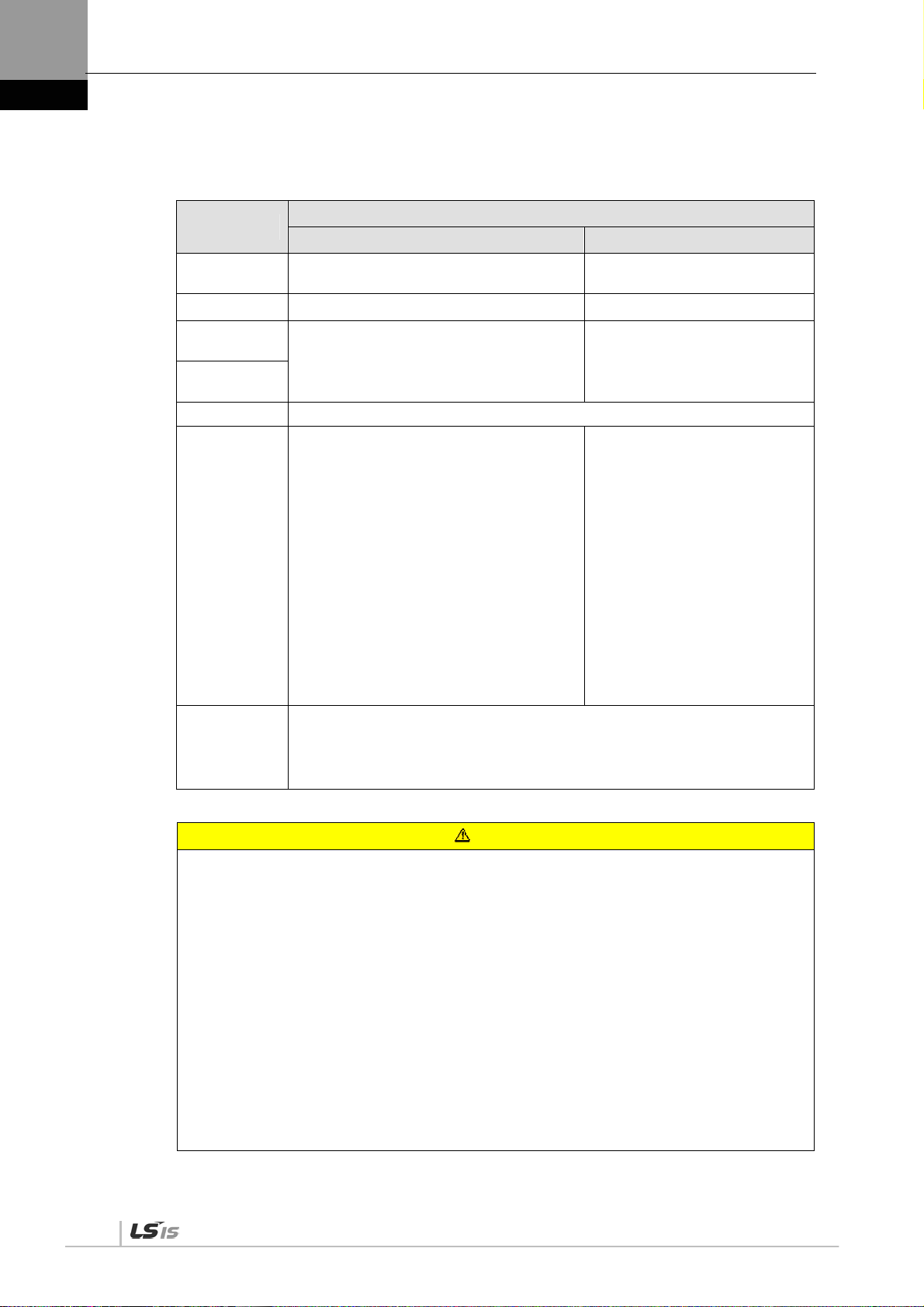

Environment

Conditions

Servo drive Servo motor

Operating

temp.

Storage temp. -20 ~ 65 ℃ -10 ~ 60 ℃

Operating

humidity

Storage

humidity

Altitude 1000 m or lower

0 ~ 50 ℃ 0 ~ 40 ℃

Below 90% RH (no condensation) 20~80% RH(no condensation)

When installing 1 unit:

More than 40 mm at the top and

bottom of the control panel

More than 10 mm on the left and right

sides of the control panel

When installing 2 or more units:

Spacing

More than 100 mm at the top of the

control panel

More than 40 mm at the bottom of the

control panel

More than 30 mm on the left and right

sides of the control panel

More than 2 mm between units

Refer to Section 2.2.1, "Wiring the

Control Panel."

Ensure the installation location is free from dust, iron, corrosive gas,

Other

and combustible gas.

Ensure the installation location is free from vibrations or the potential

for hard impacts.

Caution

Install the product with the correct orientation.

Do not drop the product or expose it to hard impact.

Install this product in a location that is free from water, corrosive gas, combustible

gas, or flammable materials.

Install this product in a location capable of supporting the weight of this product.

Do not stand on the product or place heavy objects on top of it.

Always maintain the specified spacing when installing the servo drive.

Ensure that there are no conductive or flammable debris inside the servo drive or the

servo motor.

Firmly attach the servo motor to the machine.

Install the servo motor with a correctly oriented decelerator.

Do not touch the rotating unit of the servo motor during operation.

Do not apply excessive force when connecting the couplings to the servo motor shaft.

Do not place loads on the servo motor shaft that exceed the specified amount.

iv

Introduction

Wiring Precautions

Caution

Always use an AC 380-480 V power input for the servo drive.

Always connect the servo drive to a ground terminal.

Do not connect commercial power directly to the servo motor.

Do not connect commercial power directly to the U, V, W output terminals of the servo

drive.

Connect the U, V, W output terminals of the servo drive directly to the U, V, W input

terminals of the servo motor, but do not install magnetic contactors between the wires.

Always use pressurized terminals with insulation tubes when connecting the servo

drive power terminal.

When wiring, be sure to separate the U, V, and W cables for the servo motor power

and encoder cable.

Always use the robot cable if the motor moves.

Before you perform power line wiring, turn off the input power of the servo drive, and

then wait until the charge lamp goes off completely.

Startup Precautions

Caution

Check the input voltage (AC 380-480 V) and power unit wiring before supplying power

to the device.

The servo must be in the OFF mode when you turn on the power.

Before you turn on the power, check the motor's ID and the encoder pulse for XDL-

L7NHB .

Set the motor ID[0x2000], encoder type[0x2001] and the encoder pulse [0x2002] for

XDL-L7NHB first after you turn on the power.

After you complete the above settings, set the drive mode for the servo drive that is

connected to the upper level controller in [0x6060].

Refer to Chapter 1.4 "System Configuration" to perform I/O wiring for the servo drive

according to each drive mode.

You can check the ON/OFF state for each input terminal of I/O at [0x60FD].

Handling and Operating Precautions

Caution

Check and adjust each parameter before operation.

Do not touch the rotating unit of the motor during operation.

Do not touch the heat sink during operation.

Be sure to attach or remove the I/O and ENCODER connectors when the power is off.

Extreme change of parameters may cause system instability.

v

Introduction

Usage Precautions

Caution

Install an emergency cut-off switch which immediately stops operation in an

emergency.

Reset the alarm when the servo is off. Be warned that the system restarts

immediately if the alarm is reset while the servo is on.

Use a noise filter or DC reactor to minimize electromagnetic interference. This

prevents nearby electrical devices from malfunctioning due to interference.

Only use approved servo drive and servo motor combinations.

The electric brake on the servo motor stops operation. Do not use it for ordinary

braking.

The electric brake may malfunction if the brake degrades or if the mechanical

structure is improper (for example, if the ball screw and servo motor are combined via

the timing belt). Install an emergency stop device to ensure mechanical safety.

Malfunction Precautions

Caution

Install a servo motor with an electric brake or separate the brake system for use

during emergencies or device malfunctions.

If an alarm occurs, solve the underlying cause of the problem. After solving the

problem and ensuring safe operation, deactivate the alarm and resume operation.

Do not approach the machine until the problem is solved.

Repair/Inspection Precautions

Caution

Before performing servicing tasks, turn off the power. Wait 15 minutes until the charge

lamp goes off, and then check the voltage. Enough voltage may remain in the

condenser after the power is off to cause an electric shock.

Only authorized personnel may repair and inspect the device or replace its parts.

Do not modify this device in any way.

General Precautions

Caution

This user manual is subject to change due to product modification or changes in

standards. If such changes occur, we issue a new user manual with a new product

number.

Product Application

Caution

This product is not designed or manufactured for machines or systems intended to

sustain human life.

This product is manufactured under strict quality control conditions. Nevertheless,

install safety devices if installing the device in a facility where product malfunctions

may result in a major accident or a significant loss.

vi

Introduction

EEPROM Lifespan

Caution

The EEPROM is rewritable up to 4 million times for the purpose of recording

parameter settings and other information. The servo drive may malfunction if the total

number of the following tasks exceeds 4 million, depending on the lifespan of the

EEPROM.

EEPROM recording as a result of parameter changes

EEPROM recording as a result of an alarm

vii

Table of Contents

Table of Contents

1. Product Configuration ....................................................................................... 1-1

1.1 Product Verification .......................................................................................................... 1-1

1.2 Product Specifications ..................................................................................................... 1-2

1.3 Part Names ...................................................................................................................... 1-4

1.3.1 Servo Drive Parts ............................................................................................. 1-4

1.3.2 Servo Motor Parts ............................................................................................. 1-9

1.4 System Configuration Example ..................................................................................... 1-10

2. Wiring and Connection ...................................................................................... 2-1

2.1 Installation of Servo Motor ............................................................................................... 2-1

2.1.1 Operating Environment .................................................................................... 2-1

2.1.2 Preventing Impact............................................................................................. 2-1

2.1.3 Motor Connection ............................................................................................. 2-1

2.1.4 The Load Device Connection ........................................................................... 2-2

2.1.5 Cable Installation .............................................................................................. 2-2

2.2 Installation of Servo Drive ................................................................................................ 2-3

2.2.1 Installation and Usage Environment ................................................................ 2-3

2.3 Internal Block Diagram of Drive ....................................................................................... 2-4

2.3.1 XDL-L7NH Drive Block Diagram (XDL-L7NHB010U~ XDL-L7NHB035U) ...... 2-4

2.3.2 XDL-L7NH Drive Block Diagram (XDL-L7NHB050U~ XDL-L7NHB075U) ...... 2-5

2.3.3 XDL-L7NH Drive Block Diagram (XDL-L7NHB150U) ...................................... 2-6

2.4 Power Supply Wiring ....................................................................................................... 2-7

2.4.1 Power Supply Wiring Diagram ......................................................................... 2-8

2.4.2 Power Circuit Electrical Components .............................................................. 2-11

2.4.3 Regenerative Resistor Options ...................................................................... 2-17

2.5 Wiring for Input/Output Signals ...................................................................................... 2-18

2.5.1 Names and Functions of Digital Input/Output Signals ................................... 2-18

2.5.2 Names and Functions of Analog Input/Output Signals .................................. 2-20

2.5.3 Examples of Connecting Input/Output Signals .............................................. 2-22

2.5.4 Examples of Connecting Input/Output Signals .............................................. 2-24

2.6 Wiring of Encoder Signal (ENCODER) .......................................................................... 2-25

2.6.1 Quadrature Encoder Signaling Unit Wiring .................................................... 2-25

2.6.2 Serial Encoder Signaling Unit Wiring ............................................................. 2-26

2.6.3 Multi-Turn Encoder Signaling Unit Wiring ...................................................... 2-28

2.6.4 Tamagawa Encoder Signaling Unit Wiring ..................................................... 2-29

2.6.5 EnDat 2.2 Encoder Signaling Unit Wiring ...................................................... 2-30

2.7 Wiring for Safety Function Signals (STO) ...................................................................... 2-31

2.7.1 Names and Functions of Safety Function Signals ......................................... 2-31

2.7.2 Example of Connecting Safety Function Signals ........................................... 2-32

2.7.3 Bypass Wiring of Safety Function Signal ....................................................... 2-33

2.8 Wiring for EtherCAT Communication Signals ................................................................ 2-34

2.8.1 Names and Functions of EtherCAT Communication Signals ......................... 2-34

2.8.2 Example of Drive Connection ......................................................................... 2-35

3. EtherCAT Communication ................................................................................. 3-1

3.1 Structure of CANopen over EtherCAT ............................................................................. 3-1

viii

Table of Contents

3.1.1 EtherCAT State Machine ................................................................................... 3-2

3.2 Status LED ........................................................................................................................ 3-3

3.3 Data Type .......................................................................................................................... 3-5

3.4 PDO assignment ............................................................................................................... 3-5

3.5 Synchronization Using the DC (Distributed Clock) ........................................................... 3-8

3.6 Emergency Messages ...................................................................................................... 3-9

4. CiA402 Drive Profile ........................................................................................... 4-1

4.1 State machine ................................................................................................................... 4-1

4.2 Operation Modes .............................................................................................................. 4-3

4.3 Position Control Modes ..................................................................................................... 4-5

4.3.1 Cyclic Synchronous Position Mode ................................................................... 4-5

4.3.2 Profile Position Mode ........................................................................................ 4-8

4.4 Velocity Control Mode .....................................................................................................4-13

4.4.1 Cyclic Synchronous Velocity Mode .................................................................4-13

4.4.2 Profile Velocity Mode .......................................................................................4-16

4.5 Torque Control Modes ....................................................................................................4-19

4.5.1 Cyclic Synchronous Torque Mode ...................................................................4-19

4.5.2 Profile Torque Mode ........................................................................................4-21

4.6 Homing ............................................................................................................................4-23

4.6.1 Homing Method ...............................................................................................4-24

4.7 Touch Probe Function ....................................................................................................... 4-2

5. Drive Application Functions.............................................................................. 5-1

5.1 Drive Front Panel .............................................................................................................. 5-1

5.1.1 7-Segment for indicating servo status ............................................................... 5-1

5.2 Input/Output Signals Setting ............................................................................................. 5-4

5.2.1 Assignment of Digital Input Signals ................................................................... 5-4

5.2.2 Assignment of Digital Output Signals ................................................................ 5-6

5.2.3 Use of User I/O .................................................................................................. 5-8

5.3 Electric Gear Setup .........................................................................................................5-15

5.3.1 Electric Gear ....................................................................................................5-15

5.3.2 Example of Electric Gear Setup ......................................................................5-16

5.4 Settings Related to Speed Control .................................................................................5-17

5.4.1 Smooth Acceleration and Deceleration ...........................................................5-17

5.4.2 Servo-lock Function .........................................................................................5-18

5.4.3 Signals Related to Speed Control ...................................................................5-18

5.5 Settings Related to Position Control ...............................................................................5-19

5.5.1 Position Command Filter .................................................................................5-19

5.5.2 Signals Related to Position Control .................................................................5-21

5.6 Settings Related to Torque Control .................................................................................5-22

5.6.1 Speed Limit Function .......................................................................................5-22

5.7 Positive/Negative Limit Settings .....................................................................................5-23

5.8 Setting the Brake Output Signal Function ......................................................................5-24

5.9 Torque Limit Function .....................................................................................................5-26

5.10 Gain switching function ...................................................................................................5-29

ix

Table of Contents

5.10.1 Gain group switching ...................................................................................... 5-29

5.10.2 P/PI Control Switching .................................................................................... 5-31

5.11 Dynamic brake ............................................................................................................... 5-33

5.12 Regenerative resistance setting .................................................................................... 5-34

5.12.1 Use of Internal Regenerative Resistor ........................................................... 5-35

5.12.2 Use of External Regenerative Resistor .......................................................... 5-37

5.12.3 Other Considerations ..................................................................................... 5-38

5.13 Configuration of Drive Node Address (ADDR) .............................................................. 5-39

6. Safety Functions ................................................................................................ 6-1

6.1 Safe Torque Off (STO) Function ...................................................................................... 6-1

6.2 External Device Monitor (EDM) ....................................................................................... 6-4

6.3 Example of Using Safety Function .................................................................................. 6-5

6.4 How to Verify Safety Function .......................................................................................... 6-5

6.5 Precautions for Using Safety Function ............................................................................ 6-6

7. Tuning .................................................................................................................. 7-1

7.1 Auto Gain Tuning ............................................................................................................. 7-1

7.2 Manual Gain Tuning ......................................................................................................... 7-2

7.2.1 Gain Tuning Sequence ..................................................................................... 7-3

7.3 Vibration Control .............................................................................................................. 7-5

7.3.1 Notch Filter ....................................................................................................... 7-5

7.3.2 Adaptive Filter ................................................................................................... 7-6

7.4 Analog Monitor ................................................................................................................. 7-7

8. Procedure Function ........................................................................................... 8-1

8.1 Manual JOG Operation .................................................................................................. 8-1

8.2 Programmed Jog Operation ............................................................................................ 8-2

8.3 Deleting Alarm History ..................................................................................................... 8-3

8.4 Auto Gain Tuning ............................................................................................................. 8-5

8.5 Index Pulse Search .......................................................................................................... 8-5

8.6 Absolute encoder reset .................................................................................................... 8-6

8.7 Instantaneous Maximum Torque Initialization .................................................................. 8-6

8.8 Phase current offset tuning .............................................................................................. 8-7

8.9 Software reset .................................................................................................................. 8-8

8.10 Commutation .................................................................................................................... 8-8

9. Object Dictionary ................................................................................................ 9-1

9.1 General Objects ............................................................................................................... 9-1

9.2 Manufacturer Specific Objects ....................................................................................... 9-17

9.3 CiA402 Objects .............................................................................................................. 9-68

10. Product Specifications .................................................................................... 10-1

10.1 Servo Motor ................................................................................................................... 10-1

10.1.1 Product Characteristcs ................................................................................... 10-1

10.1.2 Outline Diagram ........................................................................................... 10-19

x

Table of Contents

10.2 Servo Drive ...................................................................................................................10-29

10.2.1 Product Characteristics .................................................................................10-29

10.2.2 Outline Diagram ............................................................................................10-32

10.3 Options and Peripheral Devices ...................................................................................10-35

11. Maintenance and Inspection ......................................................................... 11-43

11. 1 Maintenance and Inspection ......................................................................................... 11-43

11.1.1 Precautions ................................................................................................... 11-43

11.1.2 What to Inspect ............................................................................................. 11-43

11.1.3 Replacing Parts ............................................................................................. 11-44

11. 2 Diagnosing and Troubleshooting Abnormalities ........................................................... 11-45

11.2.1 Servo Motor ................................................................................................... 11-45

11.2.2 Servo Drive .................................................................................................... 11-46

12. Test Drive ........................................................................................................ 11-54

12.1 Preparation for Operation ...............................................................................................12-3

12.2 Test Drive Using TwinCAT System Manager ..................................................................12-4

12.3 Test Drive Using LSIS PLC (XGT + PN8B) ..................................................................12-12

13. Appendix ......................................................................................................... 13-19

13.1 Firmware Update ..........................................................................................................13-19

13.1.1 Use of USB OTG ...........................................................................................13-19

13.1.2 Use of FoE (File access over EtherCAT) ......................................................13-21

13.1.3 Use of Drive CM ............................................................................................13-25

xi

1. Product Configuration

1. Product Configuration

1.1 Product Verification

1. Check the name tag to verify that the product received matches the model ordered

Does the servo drive's name plate match?

Does the servo motor's name plate match?

2. Check the product components and options.

Are the type and length of cables correct?

Does the regenerative resistor conform to the required standard?

Is the shape of the shaft correct?

Are there any abnormalities after mounting the oil seal or brake?

Are the gearbox and the gear ratios correct?

Is the encoder format correct?

3. Check the exterior of the device.

Are there any foreign substances or humidity in the device?

Is there any discoloration, contaminant, damage or disconnected wire?

Are the bolts tightly fastened to the joints?

Is there any abnormal sound or excessive friction during operation?

1-1

1. Product Configuration

1.2 Product Specifications

XDL-L7NH Series Product Type

XDL-L7 NH B 010 U AA

Series Name

L7 Series

L7 Series

Communication

/Drive Type

NH : Network type

All-in-One Type

Input voltage

A: 200Vac

B: 400Vac

Capacity

001 : 100W

002 : 200W

004 : 400W

008 : 750W

010 : 1kW

020 : 2kW

035 : 3.5kW

050 : 5.0kW

075 : 7.5kW

110 : 11.0k W

150 : 15kW

Encoder

U: Universal

Option

Black:

Standard

Marked:

Dedicated use

1-2

1. Product Configuration

S

e

Servo Motor Product Format

APM – S E P 10 D E K 1 G1 03

ervo Motor

Servo Motor

Motor Shape

Motor Shape

S: 실축형

S: Real Axis

H: Hollow Shaft

H: 중공축형

B: Assembly

B: 조립형

Flange Size

A: 40 Flange

B: 60 Flange

C: 80 Flange

D: 100 Flange

E: 130 Flange

F: 180 Flange

G: 220 Flange

Input

Input

Blank: 200[Vac]

P: 400[Vac

Motor

Motor

R3: 30[W]

R5: 50[W]

01: 100[W]

02: 200[W]

03: 300[W]

04: 400[W]

06: 550/600[W]

07: 650[W]

08: 750/800[W]

10: 1[kW]

15: 1.5[kW]

20: 2[kW]

35: 3.5[kW]

50: 5[kW]

75: 7.5[kW]

150: 15[kW]

220: 22[kW]

300: 30[kW]

370: 37[kW]

Encoder Type

Encoder Type

Quadrature(Pulse type)

A: Inc. 1024[ppr]

B: Inc. 2000[ppr]

C: Inc. 2048[ppr]

D: Inc. 2500[ppr]

E: Inc. 3000[ppr]

F: Inc. 5000[ppr]

G: Inc. 6000[ppr]

Serial

Com mu nication t ype

BiSS(

N : 19bit SingleTurn

M : 19bit MultiTurn

Rated RPM

A: 3000[rpm]

D: 2000[rpm]

G: 1500[rpm]

M: 1000[rpm]

Shaft Shape

N: Straight

One-sided round key

K: 한쪽 둥근키(표준)

(standard)

C: C Cut

D: D Cut

T: Taper 형상

Tape r sh ap e

R: 양쪽 둥근키

Double-sided

H: Hollow Shaft

Oil Seal, Brake Existence

Non-existen t: None included

Non-existent: None included

1: Oil Seal attached

1: Oil Seal attached

)

2: Brake attached

2: Brake attached

3: Oil Seal and Brak

3: Oil Sea l and B rake

Gearbox

Classification

03: 1/3

10: 1/10

Gearbox Sp ec.

Non-existent: No

gearbox

G1: For general

industrial purposes

G2: For general

industrial purposes

G3: Precise

Gearbox

1-3

1. Product Configuration

1.3 Part Names

1.3.1 Servo Drive Parts

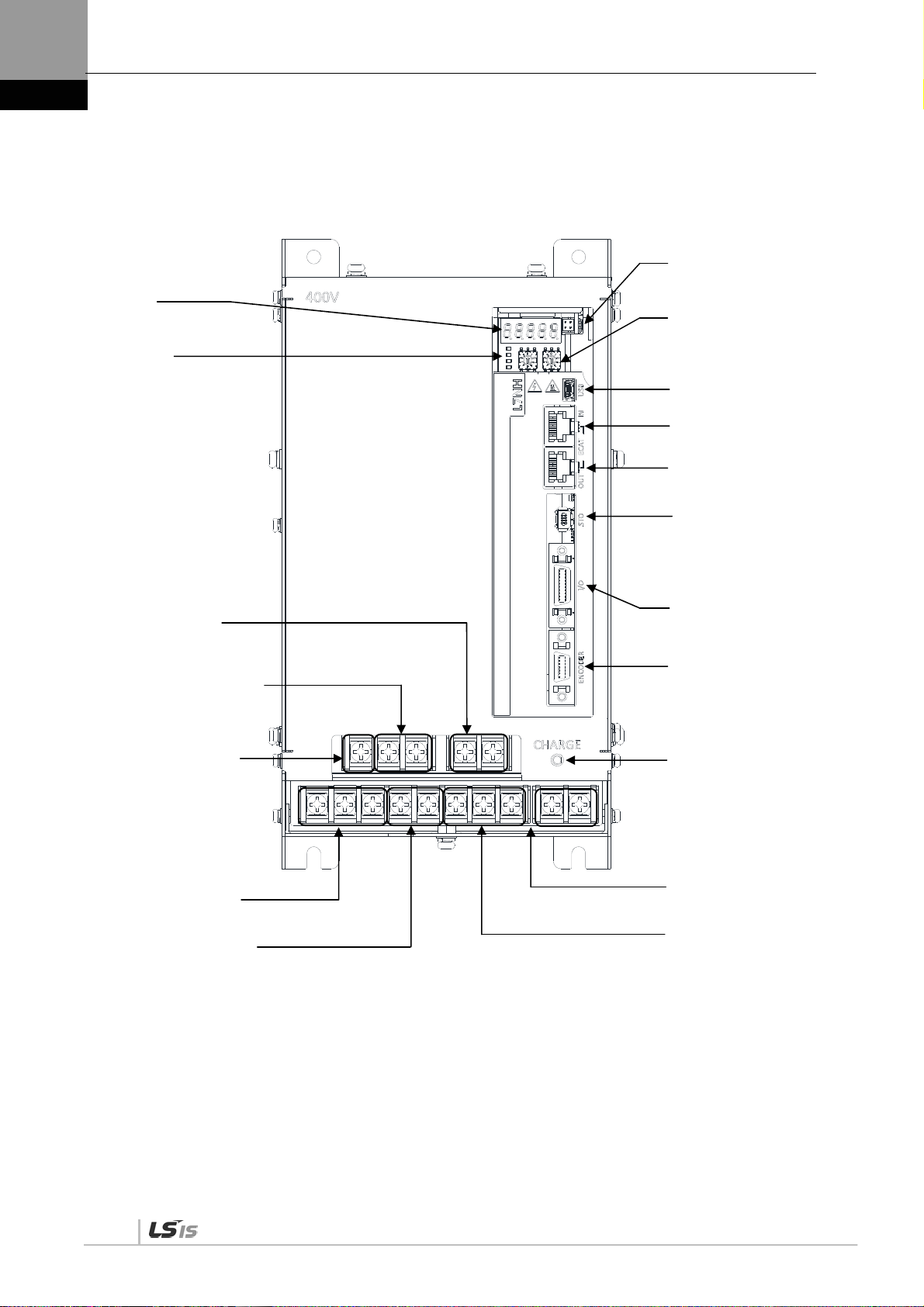

XDL-L7NH Drive (1KW)

Display

It shows drive status, alarms, etc.

CHARGE lamp

This turns on when the main circuit power is on.

Status LED

It indicates the current state of EtherCAT

communication.

Main power connectors (L1, L2, and L3)

These terminals connect to the main circuit power

input.

DC reactor connector (PO, PI)

These terminals connect to the DC reactor to

suppress high-frequency power.

-If the DC reactor is not used, be sure to shortcircuit this connector.

Regenerative resistance connector (B+, B, BI)

These terminals connect to the external regenerative resistor.

-For basic installations : Short-circuit B and BI terminals.

-For external resistor installations : Install to B+ and B terminals.

Control power terminals (C1 and C2)

These terminals connect to the control power input.

Connector for analog monitors

It is a connector for checking the analog output

signal.

Node address setting switch

This switch is to set the node address of the drive.

You can set the node addresses from 0 to 99.

USB connector (USB)

This connector is to communicate with a PC.

EtherCAT communication input port (ECAT IN)

EtherCAT communication output port (ECAT

OUT)

Safety connector (STO)

This connector connects safety devices.

-If a safety device is not used, be sure to install the

safety jump connector before use.

Input/output signal connector (I/O)

This connector is for sequence input/output signals.

Servo motor connection terminals (U,V,W)

These terminals connect to the main circuit cable

(power cable) of the servo motor.

Ground terminal

It is a ground terminal to prevent electric shock.

1-4

Encoder connector (ENCODER)

This connector connects to the encoder

installed in the servo motor.

1. Product Configuration

XDL-L7NH Drive (2KW, 3.5KW)

Display

It shows drive status, alarms, etc.

CHARGE lamp

This turns on when the main circuit

power is on.

Status LED

It indicates the current state of

EtherCAT communication.

Main power connectors

(L1, L2, and L3)

These terminals connect to the main

circuit power input.

DC reactor connector (PO, PI)

These terminals connect to the DC

reactor to suppress high-frequency

power.

-If the DC reactor is not used, be sure to

short-circuit this connector.

Regenerative resistance connector

(B+, B, BI)

These terminals connect to the external

regenerative resistor.

-For basic installations : Short-circuit B

and BI terminals.

-For external resistor installations:

Install to B+ and B terminals.

Control power terminals (C1 and C2)

These terminals connect to the control power

input.

Servo motor connection terminals (U,V,W)

These terminals connect to the main circuit cable

(power cable) of the servo motor.

Connector for analog monitors

It is a connector for checking the analog output

signal.

Node address setting switch

This switch is to set the node address of the

drive.

USB connector (USB)

This connector is to communicate with a PC.

EtherCAT communication input port (ECAT IN)

EtherCAT communication output port

(ECAT OUT)

Safety connector (STO)

This connector connects safety devices.

-If a safety device is not used, be sure to install

the safety jump connector before use.

Input/output signal connector (I/O)

This connector is for sequence input/output

signals.

Encoder connector (ENCODER)

This connector connects to the encoder

installed in the servo motor.

Ground terminal

It is a ground terminal to prevent electric

shock.

1-5

1. Product Configuration

*

XDL-L7NH Drive (5KW)

Connector for analog monitors

It is a connector for checking the analog

Display

It shows drive status, alarms,

etc.

Status LED

It indicates the current state of

EtherCAT communication.

output signal.

Node address setting switch

This switch is to set the node address of the

drive. You can set the node addresses from 0

to 99.

USB connector (USB)

This connector is to communicate with a PC.

EtherCAT communication input port

(ECAT IN)

EtherCAT communication output port

(ECAT OUT)

Safety connector (STO)

This connector connects safety devices.

-If a safety device is not used, be sure to

install the safety jump connector before use.

Control power terminals (C1 and C2)

These terminals connect to the control

power input.

DC reactor connector (PO, PI)

These terminals connect to the DC reactor

to suppress high-frequency power.

-If the DC reactor is not used, be sure to

short-circuit this connector.

It is not a connector for

connection (N)

Main power connectors (L1, L2, and L3)

These terminals connect to the main circuit

power input.

Regenerative resistance connector (B+, B)

These terminals connect to the external

regenerative resistor.

-For basic installations : Short-circuit B+ and B

terminals.

-For external resistor installations : After

attaching internal resistor wiring to the internal

resistor fixing hole “NC” of the case, connect

the external resistor to B+ and B terminals.

Input/output signal connector (I/O)

This connector is for sequence

input/output signals.

Encoder connector (ENCODER)

This connector connects to the encoder

installed in the servo motor.

CHARGE lamp

This turns on when the main circuit power

is on.

Ground terminal

It is a ground terminal to prevent electric

shock.

Servo motor connection terminals (U,V,W)

These terminals connect to the main circuit

cable (power cable) of the servo motor.

1-6

1. Product Configuration

*

XDL-L7NH Drive (7.5KW)

Connector for analog monitors

It is a connector for checking the analog

output signal.

Display

It shows drive status,

alarms, etc.

Status LED

It indicates the current state of

EtherCAT communication.

Node address setting switch

This switch is to set the node address of

the drive. You can set the node addresses

from 0 to 99.

USB connector (USB)

This connector is to communicate with a

PC.

EtherCAT communication input port

(ECAT IN)

EtherCAT communication output port

(ECAT OUT)

Safety connector (STO)

This connector connects safety

devices.

-If a safety device is not used, be sure

to install the safety jump connector

before use.

CHARGE lamp

This turns on when the main

circuit power is on.

It is not a connector

for connection (N)

DC reactor connector (PO, PI)

These terminals connect to the DC reactor to

suppress high-frequency power.

-If the DC reactor is not used, be sure to short-circuit

this connector.

Main power connectors (L1, L2,

and L3)

These terminals connect to the

main circuit power input.

* NC

Input/output signal connector (I/O)

This connector is for sequence

input/output signals.

Encoder connector

(ENCODER)

This connector connects to the

encoder installed in the servo

Control power terminals (C1 and C2)

These terminals connect to the control

power input.

Servo motor connection terminals

(U,V,W)

These terminals connect to the main

circuit cable (power cable) of the servo

motor.

Ground terminal

It is a ground terminal to prevent electric shock.

Regenerative resistance connector (B+, B)

These terminals connect to the external regenerative resistor.

-For basic installations : Short-circuit B+ and B terminals.

-For external resistor installations : After attaching internal resistor

wiring to the internal resistor fixing hole “NC” of the case, connect

the external resistor to B+ and B terminals.

1-7

1. Product Configuration

*

XDL-L7NH Drive (15KW)

Connector for analog monitors

Display

It shows drive status,

alarms, etc.

Status LED

It indicates the current state of

EtherCAT communication.

It is a connector for checking the analog

output signal.

Node address setting switch

This switch is to set the node address of the

drive. You can set the node addresses from 0

to 99.

USB connector (USB)

This connector is to communicate with a PC.

EtherCAT communication input port

(ECAT IN)

Control power terminals

(C1 and C2)

These terminals connect to

the control power input.

CHARGE lamp

This turns on when the

main circuit power is on.

Main power connectors (L1,

L2, and L3)

These terminals connect to the

main circuit power input.

It is not a connector for

connection (N)

DC reactor connector (PO, PI)

These terminals connect to the DC reactor to

suppress high-frequency power.

-If the DC reactor is not used, be sure to shortcircuit this connector.

Z

EtherCAT communication output port

(ECAT OUT)

Safety connector (STO)

This connector connects safety devices.

-If a safety device is not used, be sure to

install the safety jump connector before use.

Input/output signal connector (I/O)

This connector is for sequence

input/output signals.

Encoder connector (ENCODER)

This connector connects to the encoder

installed in the servo motor.

Servo motor connection terminals

(U,V,W)

These terminals connect to the main circuit

cable (power cable) of the servo motor.

Ground terminal

It is a ground terminal to prevent electric shock.

Regenerative resistance connector (B+, B)

These terminals connect to the external

regenerative resistor.

-Install external regenerative resistance

1-8

1. Product Configuration

1.3.2 Servo Motor Parts

80 Flange or below

130 Flange or higher

1-9

1. Product Configuration

1.4 System Configuration Example

The figure below shows an example of system configuration using this drive.

Power

전원

Three-phase AC380V

Molded case circuit

breaker

It is used to protect

배선용 차단 기

power line.

It turns the circuit OFF

전원라인을 보호하기

if overcurrent flows.

위하여 사용합니다.

과전류가 흐르면

회로를 OFF합니다.

Noise filter

노이즈 필터

It protects power line

전원라인으로부터의

from external noise.

외부 노이즈를

막습니다.

삼상 AC380V

R S T

Electromagnetic

전자 접촉 기

contactor

It turns servo

서보전원을 ON /

power ON / OFF.

OFF로 합니다.

Oscilloscope

오실로스코프

Analog monitor cable

아날로그 모니터 케이블

Servo Drive

서보 드라이브

DAQ

Upper device

상위 장치

XGT

EtherCAT 통신케이블

EtherCAT communication cable

Node address setting switch

Node 주소 설정 스위치

0

0

5

5

ADDR

Connect a

회생 저항 연결

regenerative resistor.

1.기본 장착 사용 시

1.When using basic

- 단락(B, B I)

installations

2.외부 저항 장착 시

-Short-circuit (B, BI)

- 장착(B, B +)

2.When installing

external resistance

-Install it (B, B+)

DC reactor connection

DC 리액터 연결

-미사용 시 단락(PO, PI)

-Short-circuit if not used

(PO, PI)

모터 케이 블

Motor cable

Servo Motor

서보모터

I/O Cable

3M

10314

Encoder cable

엔코더 케이 블

3M

10314

Safety cable

안전 케이 블

1.If the safety function

is not used : Install the

1. 안전기능 을

safety jump connector.

사용하지 않을 경우 :

안전점프 커넥터 설치

2.If the safety

2. 안전기능을 사용

function is used

할 경우 :

안전 기기

Safety device

Mini USB

미니 USB

케이블

cable

U

S

B

Mini USB

cable

미니 USB

케이블

Mini USB

미니 USB

adaptor

젠더

POTNOT HOME

1-10

2. Wiring and Connection

2. Wiring and Connection

2.1 Installation of Servo Motor

2.1.1 Operating Environment

Item Requirements Notes

Ambient

temperature

Ambient

humidity

External

vibration

0 ∼ 40[℃]

80% RH or lower Do not operate this device in an environment with steam.

Vibration acceleration

19.6 ㎨ or below on both

the X and Y axis.

Consult with our technical support team to customize the product if

temperatures in the installation environment are outside this range.

Excessive vibrations reduce the lifespan of the bearings.

2.1.2 Preventing Impact

Impact to the motor during installation or handling may damage the encoder.

Caution

2.1.3 Motor Connection

If the motor is directly connected to commercial power, it may be burned. Be sure to connect with

the specified drive before using it.

Connect the ground terminals of the motor to either of the two ground terminals inside the drive,

and attach the remaining terminal to the type-3 ground.

U – U

V - V

W – W

- F.G

Connect the U, V, and W terminals of the motor in the same way as the U, V, and W terminals of

the drive.

Ensure that the pins on the motor connector are securely attached.

In order to protect against moisture or condensation in the motor, make sure that insulation

resistance is 10 ㏁ (500 V) or higher before installation.

2-1

2. Wiring and Connection

2.1.4 The Load Device Connection

For coupling connections: Ensure that the motor shaft and load shaft are aligned within the tolerance

range.

Load

shaft

0.03 ㎜ or below (peak to peak)

0.03 ㎜ or below (peak to peak)

Motor

shaft

For pulley connections:

Flange

40 148 15 39 4

60 206 21 69 7

80 255 26 98 10

130 725 74 362 37

180 1548 158 519 53

220 1850 189 781 90

Lateral Load Axial Load

N kgf N kgf

Notes

Nr: 30 ㎜ or below

Lateral load

Axial load

2.1.5 Cable Installation

For vertical installations, make sure that no oil or water flows into the connecting parts.

Do not apply pressure to or damage the cables. Use robot cables to prevent swaying when the

motor moves.

2-2

2. Wiring and Connection

2.2 Installation of Servo Drive

2.2.1 Installation and Usage Environment

Item

Ambient

temperature

Ambient

humidity

External

vibration

Ambient

conditions

Environmental

conditions

0∼50[℃]

90% RH or lower

Vibration

acceleration 4.9

㎨ or lower

Caution

Install a cooling fan on the control panel to maintain an

appropriate temperature.

Caution

Condensation or moisture may develop inside the drive during

prolonged periods of inactivity and damage it. Remove all

moisture before operating the drive after a prolonged period of

inactivity.

Excessive vibration reduces the lifespan of the machine and

may cause malfunctions.

Notes

Do not expose the device to direct sunlight.

Do not expose the device to corrosive or combustible gases.

Do not expose the device to oil or dust.

Ensure that the device receives sufficient ventilation.

2-3

2. Wiring and Connection

035

r

t

t

t

p

p

2.3 Internal Block Diagram of Drive

2.3.1 XDL-L7NH Drive Block Diagram

(XDL-L7NHB010U~ XDL-L7NHB035U)

3-phase power

3상 전원

AC380~480V

Control Power Phase

Loss Detection Circuit

Single-phase power

단상 전원

AC380V~480V

입력

제어전원결상

검출회로

Input

입력

C1

C2

0

1

9

2

8

3

7

4

6

5

x10

Input

L1

L2

L3

ECAT IN/OUT

0

1

9

8

7

4

6

5

x1

S

M

P

S

2

3

Diode

Thermistor

써미스터

Main Power Phase

주전원결상

Loss Detection

Circuit

검출회로

USB

010 : Thermistor

EtherCAT

EtherCAT

Communication

통신

USB

USB

communication

통신

안전기능입력

Safety Function Inpu

(2점)

(2 Points)

Note 1)

주1) 주2)

써미스터

: Resistor

Chage

Lamp

B

B+

회생저항

Regenera tive

Resisto

Thermistor

써미스터

PI

PO

T1

Main 제어

DC전압

DC Voltage

Detection Circuit

검출회로

내부온도

Internal

Temperature

검출회로

Detection Ci rcuit

U,V Curren

U,V전류

DC Voltage

DC전압

Relay

driving circuit

구동회로

Main Control POWER circuit connection

A/D Conversion

A/D 변환

ESC

USB OTG FS

P/C 절연 I/F

P/C Insulation I/F

안전기능출력

Safety F unction Outpu

(1점)

(1 Point)

Digital input

디지털입력

(8점)

oints)

(8

Note 2)

BI

T2

회생제동

Regenera tive

Brake Drive

Circuit

구동회로

POWER 회로 접속

MCU / FPGA

IGBT온도

IGBT Temperature

검출회로

Detection Circuit

Digital Output

디지털출력

(4점)

(4

oints)

IGBT

Current sensor

전류 센서

PWM신호

PWM Signal SC

Detection Circuit

SC검출회로

아날로그 입력

Analog Input (1 Point)

(1점)

U,V전류

U and V Current

Detection Ci rcuit

검출회로

BiSS-C

Quadrature

TAMAGAWA

EnDat

Analog output

(2 points)

Note 3)

U

V

W

엔코더

Encoder Input

아날로그출력

(2점)

주3)

DB

DB Drive Circuit

구동회로

입력

M

E

ENCODER

2-4

Safety device c onnection (STO)

안전기기 연결(STO)

Input/output connection (I/O)

입/출력 연결(I/O)

Analog output connection

아날로그 출력 연결

Note 1) If using a DC reactor, connect the PO and PI pins.

Note 2) If using an external regenerative resistor, remove the B and BI short-circuit pins and

connect the B+ and B pins.

Note 3) XDL-L7NHB010U~ XDL-L7NHB035U Model is cooled by a DC 24 V cooling fan.

2. Wiring and Connection

t

(

t

(

)

p

(4 p

)

(2 p

g

r

2.3.2 XDL-L7NH Drive Block Diagram

(XDL-L7NHB050U~ XDL-L7NHB075U)

3-phase power

3상 전원

AC380~480V

제어전원결상

Control Power Phase

Loss Detection Circuit

Single-phase power

단상 전원

AC380V~480V

검출회로

Input

입력

C1

C2

0

9

8

7

6

5

x10

입력

1

2

3

4

Input

L1

L2

L3

ECAT IN/OUT

0

9

8

7

6

5

x1

1

2

3

4

Main Power Phase

주전원결상

Loss Detection

S

M

P

S

USB

Diode

Thermistor

써미스터

Circuit

검출회로

EtherCAT

Communication

USB

communication

EtherCAT

통신

USB

통신

Note 4)

주1) 주5)

써미스터

Resistor

Chage

Lamp

Internal

내부온도

Temperature

Detection Ci rcuit

검출회로

U,V전류

U,V Current DC

DC전압

Volt a

e

Relay

driving circuit

구동회로

Main 제어

Main Control

A/D Conversion

A/D 변환

DC전압

DC Voltage

Detection Circuit

검출회로

BB+

Regenera tive

PI

PO

ESC

USB OTG FS

P/C Insulation I/F

P/C 절연 I/F

Note 5)

회생저항

Resisto

Thermistor

써미스터

T1

T2

Regenera tive

회생제동

Brake Drive

Circuit

구동회로

POWER 회로 접속

POWER circuit connection

MCU / FPGA

IGBT

IGBT온도

IGBT Temperature

Detection Circuit

검출회로

전류 센서

PWM신호

PWM Signal SC

Detection Ci rcuit

SC검출회로

Current sensor

U and V Current

Detection Ci rcuit

BiSS-C

Quadrature

TAMAGAWA

EnDat

U,V전류

검출회로

Note 6)

주6)

U

V

W

DB Drive Circuit

입력

엔코더

Encoder Input

DB

구동회로

M

E

ENCODER

안전기능입력

Safety Function Inpu

(2점)

2 Points)

Safety device c onnection (STO)

안전기기 연결(STO)

안전기능출력

Safety Function Outpu

(1점)

1 Point

Digital input

디지털입력

(8점)

(8

oints)

Digital Output

디지털출력

(4점)

oints

입/출력 연결(I/O)

아날로그 입력

Analog Input (1 Point)

(1점)

Analog output

아날로그출력

(2점)

oints)

Analog output connection Input/output connection (I/O)

아날로그 출력 연결

Note 4) If using a DC reactor, connect the PO and PI pins.

Note 5) If the external regenerative resistor is used, after attaching internal resistor wiring to the

internal resistor fixing hole “NC” of the case, connect the external regenerative resistor to

B+ and B terminals.

Note 6) XDL-L7NHB050U ~ XDL-L7NHB075U models are cooled by a DC 24 V cooling fan.

2-5

2. Wiring and Connection

r

g

P/C I

I/F

p

p

p

p

p

2.3.3 XDL-L7NH Drive Block Diagram (XDL-L7NHB150U)

External

regenerative

resistor

Note 7)

Resistor

Note 8)

Note 9)

Control Power Phase

Loss Detection Circuit

Single-phase

Input

9

8

7

DC Voltage

nsulation

Digital input

(8

Regenera tive

Resisto

Thermistor

Regenera tive

oints)

Brake Drive

IGBT Temperature

Circuit

Detection Circuit

POWER circuit connection

Digital Output

(4

oints)

Input/output connection (I/O)

PWM Signal SC

Detection Circuit

Analog Input

(1 Point)

Current sensor

U and V Current

Detection Ci rcuit

Analog output connection

Encoder Input

Analog output

(2

oints)

DB Drive Circuit

Input 3-phase power

Thermistor

Main Power Phase

Loss Detection

Circuit

EtherCAT

Communication

USB

1

1

9

2

2

8

3

3

7

4

4

6

6

communication

Internal

Temperature

Detection Ci rcuit

U,V Current DC

e

Volt a

Safety Function

In

ut (2 Points)

Safety device c onnection (STO)

driving circuit

A/D Conversion

Safety Function

Out

ut (1 Point)

Detection Circuit

2-6

Note 7) If using a DC reactor, connect the PO and PI pins.

Note 8) XDL-L7NHB150U model has no internal regenerative resistance. The external regenerative

resistance is used. When attaching the resistance, connect it to B+ and B terminals.

Note 9) XDL-L7NHB150U Model is cooled by a DC 24 V cooling fan.

2. Wiring and Connection

2.4 Power Supply Wiring

Ensure that the input power voltage is within the acceptable range.

Caution

Overvoltages can damage the drive.

If commercial power is connected to U, V, W terminals of Drive, they may be damaged. Be sure to

connect power to L1, L2, L3 terminals.

Connect short-circuit pins to the B and BI terminals. For external regenerative resistors, remove the

short-circuit pins and use standard resistors for the B+ and B terminals.

Model Resistance

XDL-L7NHB010U

XDL-L7NHB020U

XDL-L7NHB035U

XDL-L7NHB050U

XDL-L7NHB075U

XDL-L7NHB150U

100[]

40[]

27[]

27[]

13.4[]

Standard

Capacity

Built-in 100 W

Built-in 150 W

Built-in 120 W

Built-in 240 W

External 2000 W

* Notes

Caution

For information about resistance during

regenerative capacity expansion, refer to

Section 2.4.3, "Regenerative Resistor

Options.”

Configure the system so that the main power (L1, L2, L3) is supplied after the control power (C1,

C2). (Refer to section 2.4.1, “Power Supply Wiring Diagram.”)

High voltages may remain in the device for sometime even after the main power is disconnected.

Please be careful.

Warnings

After disconnecting the main power, ensure that the charge lamp is off before you start wiring.

Failure to do so may result in electric shock.

Always ground the device over the shortest possible distance. Long ground wires are susceptible to

noise which may cause the device to malfunction.

2-7

2. Wiring and Connection

2.4.1 Power Supply Wiring Diagram

Power Supply Wiring Diagram(XDL-L7NHB010U~ XDL-L7NHB035U)

AC 380~480[V]

RST

Main

OFF

NF

Note 1)

주1)

Main

ON

RA

1Ry1MC

1SK

1MC

Servo Drive

서보드라이브

DC 리액터

DC reactor

PI

P

O

L1

L2

U

V

W

L3

C1

C2

1Ry

+2

4V

RA

Alarm+

Alarm-

17

18

B+

B

BI

Note 2)

I/O

Note 1) It takes approximately one to two seconds until alarm signal is output after you turn on the

E

엔코더

Encoder

외부

External

주2)

회생저항

regenerative

resistor

main power. Accordingly, push and hold the main power ON switch for at least two seconds.

Note 2) Short-circuit B and BI terminals before use, because XDL-L7NHB010U(100[W], 100[]) and

XDL-L7NHB020U~ XDL-L7NHB035U(150[W], 40[]) have internal regenerative resistance. If the

regenerative capacity is high because of frequent acceleration and deceleration, open the

short-circuit pins (B , BI) and connect an external regenerative resistor to B and B+.

Note 3) Remove approximately 7-10 ㎜ of the sheathing from the cables for the main circuit

power and attach crimp terminals. (Refer to Section 2.4.2, "Power Circuit Electrical

Components.”)

Note 4) Use a (-) flathead screwdriver to connect or remove the main circuit power unit wiring.

2-8

2. Wiring and Connection

Power Supply Wiring Diagram(XDL-L7NHB050U~ XDL-L7NHB075U)

Note 1)

Servo Drive

DC reactor

Power Supply Wiring Diagram(XDL-L7NHB150U)

Note 6)

Encoder

External

regenerative

resistor

Note 1)

Servo Drive

DC reactor

Note 7) External

Encoder

regenerative

resistor

2-9

2. Wiring and Connection

Note 5) It takes approximately one to two seconds until alarm signal is output after you turn on the

main power. Accordingly, push and hold the main power ON switch for at least two seconds.

Note 6) Short-circuit B and BI terminals before use, because XDL-L7NHB050U(120[W], 27[]),

XDL-L7NHB075U(240[W], 27[]) have internal regenerative resistance. If the regenerative

capacity is high because of frequent acceleration and deceleration, attach the short-circuit

pins (B+, B) to NC terminal and connect an external regenerative resistor to B+ and B

before use.

Note 7) By default, use external regenerative resistance for XDL-L7NHB150U(2000[W], 13.4[]), and

connect the resistance to B+ and B terminals before use.

Note 8) For the cables for the main circuit and control power unit, you must use crimp terminals

(XDL-L7NHB050U, XDL-L7NHB075U : GP110028_KET, XDL-L7NHB150U : GP110732_KET)

compliant with electrical components.

(Refer to Section 2.4.2, "Power Circuit Electrical Components.”)

XDL-L7NHB050U, XDL-L7NHB075U and XDL-L7NHB150U use terminal block, so use (+) and (-)

screwdrivers to connect or remove the terminals.

2-10

2. Wiring and Connection

2.4.2 Power Circuit Electrical Components

Name

MCCB

Noise Filter (NF)

XDL-

L7NHB010U

30A Frame

10A

(ABE33b/10)

TB6-

B010LBEI

(10A)

XDL-

L7NHB020U

XDL-

L7NHB035U

30A Frame

20A

(ABE33b/20)

TB6-

B020NBDC

(20A)

XDL-

L7NHB050U

30A Frame

30A

(ABE33b/30)

TB6-

B030NBDC

(30A)

XDL-

L7NHB075U

30A Frame

30A

(ABE33b/30)

TB6-

B040A

(40A)

XDL-

L7NHB150U

50A Frame

50A

(ABE53b/50)

TB6-

B060LA

(60A)

DC reactor 10[A] 20[A] 30[A] 30[A] 50[A]

MC

9A / 550V

(GM-12)

18A / 550V

(GM-22)

26A / 550V

(GM-40)

26A / 550V

(GM-40)

38A / 550V

(GM-50)

L1, L2 ,L3,

1)

PO, PI, N

B+, B,

U, V, W

Wire

Note

C1, C2

Crimp terminal

Regenerative

Resistor

(Default)

100[W]

100

AWG14 (2.08 ㎟)

AWG14 (2.08 ㎟)

UA-F4010, SEOIL

(10mm Strip & Twist)

150[W] 40 120[W] 27 240[W] 27

AWG10

(5.5 ㎟)

GP110028

KET

AWG10

(5.5 ㎟)

GP110028

KET

AWG8

(8.0 ㎟)

GP110732

KET

Connector

(Default)

Note 1) When you select a wire, please use 600V, PVC-insulated wire.

BLZ 7.62HP/3/180LR SN OR BX SO

BLZ 7.62HP/11/180LR SN OR BX SO

To comply with UL(CSA) standards, use UL-certified wire (heat resistant temperature 75℃ or

above).

To comply with other standards, use proper wires that meet applicable standards.

For other special specifications, use wires equivalent or superior to those in this section.

2-11

2. Wiring and Connection

XDL-L7NHB010U

Wire strip

~

Weidmuller

SD 0.6x3.5x100

XDL-L7NHB020U / XDL-L7NHB035U

Wire strip

~

M4 : 1.2[N*m]

2-12

Weldmuller

M4 : 1.2[N*m]

SD 0.6x3.5x100

2. Wiring and Connection

For information on wiring to BLZ 7.62HP Series connector, refer to the above procedures.

1) Insert electric wire into insert hole with upper locking screw loosened, and use applicable flathead (-) driver

for each model to fully tighten screw to 0.4-0.5 N·m.

2) Otherwise, insufficient torque of locking screw may cause vibration-induced disconnection, system

malfunction and contact-induced fire accident.

3) After you connect a wire to connector, place the connector as closely to servo drive as possible and use

both locking hooks to fully lock it.

4) Use FG locking screw of M4 size (shown in bottom of product) to tighten it to 1.2 N·m.

5) Insufficient torque of locking screw may cause FG contact failure and even malfunctioning drive.

6) Recommended (-) driver: Use Weidmuller flathead driver (SD 0.6×3.5×100).

2-13

2. Wiring and Connection

XDL-L7NHB050U

TB3

TB2

TB1

NC : Internal Regenerative Resistor

Screw for Fixing Lead Terminal

Terminal signal

TB1

L1 L2 L3 B+ B U V W FG FG

TB2

N PO P1

TB3

C1 C2

Terminal screw: M4

Tightening torque: 1.2 N·m

Terminal screw: M4

Tightening torque: 1.2 N·m

Terminal screw: M4

Tightening torque: 1.2 N·m

1) Otherwise, insufficient torque of locking screw may cause vibration-induced disconnection, system malfunction

and contact-induced fire accident.

2) Use FG locking screw of M4 size (shown in bottom of product) to tighten it to 1.2 N·m.

2-14

2. Wiring and Connection

XDL-L7NHB075U

TB3

TB2

TB1

NC : Internal Regenerative Resistor

Screw for Fixing Lead Terminal

Terminal signal

Terminal screw

Tightening torque

Terminal screw

Tightening torque

Terminal screw

Tightening torque

1) Otherwise, insufficient torque of locking screw may cause vibration-induced disconnection, system malfunction

and contact-induced fire accident.

2) Use FG locking screw of M4 size (shown in bottom of product) to tighten it to 1.2 N·m.

2-15

2. Wiring and Connection

XDL-L7NHB150U

TB2

TB1

Terminal signal

1) Otherwise, insufficient torque of locking screw may cause vibration-induced disconne ction, system malfunction

and contact-induced fire accident.

TB1

L1 L2 L3 N PO PI B+ B U V W

TB2

C1 C2

FG

Terminal screw: M5

Tightening torque: 3.24 N·m

Terminal screw: M4

Tightening torque: 1.2 N·m

Terminal screw: M5

Tightening torque: 3.24 N·m

2) Use FG locking screw of M4 size (shown in bottom of product) to tighten it to 1.2 N·m.

2-16

2. Wiring and Connection

2.4.3 Regenerative Resistor Options

Category

Resistance

Resistance

Product

Name

Braking

resistance

Braking

resistance

Name

IRV300-82

82[]

(300W)

IRV600-

140

70]

(600W *2P)

- Making

under review

Applicable

Drive

XDL-

L7NHB010U

XDL-

L7NHB020U

/ XDL-

L7NHB035U

(2P)

Specifications

Resistance

Resistance

Braking

resistance

Braking

resistance

IRV600-75

25[]

(600W *3P)

IRM2000-

13.4

13.4[]

(2000W)

XDL-

L7NHB050U

/ XDL-

L7NHB075U

(3P)

XDL-

L7NHB150U

2-17

2. Wiring and Connection

2.5 Wiring for Input/Output Signals

I/O Connector Specification : 10120-3000PE (3M)

Analog Monitoring Connector Specification : DF-11-4DS-2C (HIROSE)

2.5.1 Names and Functions of Digital Input/Output

Signals

Names and Functions of Digital Input Signals (I/O Connector)

Pin

Number

6 +24V DC 24V

11 DI1 POT

name assignment Details Function

DC 24V

INPUT

Forward

(CCW)

prohibited

COMMON

The actuator stops the servo motor to

prevent it from moving beyond the

motion range in forward direction.

2-18

Reverse

12 DI2 NOT

7 DI3 HOME Origin sensor

8 DI4 STOP Servo stop

(CW)

prohibited

The actuator stops the servo motor to

prevent it from moving beyond the

motion range in reverse direction.

Connects the origin sensor to return to

the origin.

Stops the servo motor when the contact

is on.

2. Wiring and Connection

13 DI5 PCON

14 DI6 GAIN2

9 DI7 PCL

10 DI8 NCL

** PROBE1

** PROBE2

** EMG

** ARST Alarm reset Resets the servo alarm.

** LVSF1

** LVSF2

Suppression

Suppression

P control

action

Switch from

Gain 1 to 2

Forward

torque limit

Negative

torque limit

Touch

probe 1

Touch

probe 2

Emergency

stop

Vibration

Filter 1

Vibration

Filter 2

When the contact is on, it converts the

mode from PI control to P control.

When the contact is on, it switches the

speed control gain 1 the gain 2

When the contact is on, the forward

torque limit function is activated.

When the contact is on, the negative

torque limit function is activated.

The probe signal to rapidly store the

position value (1)

The probe signal to rapidly store the

position value (2)

Emergency stop when the contact is on.

Depending on the Vibration

Suppression Filter function

setting(0x2515), using filter 1 signal

Depending on the Vibration

Suppression Filter function

setting(0x2515), using filter 2 signal

** SVON Servo On Servo On

Note 1) **Signals not assigned by default as factory setting. The assignment may be changed by

parameter setting. For more information, refer to 「5.2 Input/Output Signals Setting.」

Note 2) Wiring can be also done by using COMMON (DC 24 V) of the input signal as the GND.

Names and Functions of Digital Output Signals

Pin

Number

1 DO1+ BRAKE+

2 DO1- BRAKE-

17 DO2+ ALARM+

18 DO2- ALARM-

3 DO3+ RDY+

4 DO3- RDY-

19 DO4+ ZSPD+

20 DO4- ZSPD-

Name assignment Details Function

Brake Outputs brake control signal.

Servo alarm Outputs signal when alarm occurs.

This signal is output when the main

Servo ready

Zero speed

reached

power is established and the

preparations for servo operation are

complete.

Outputs a signal when the current speed

drops below the zero speed.

** INPOS1

Position

reached 1

Outputs signal when having reached the

command position (1)

2-19

2. Wiring and Connection

** TLMT Torque Limit

** VLMT Speed limit

** INSPD

** WARN

** TGON

** INPOS2

** Unassigned signals. The assignment may be changed by parameter setting. For more

information, refer to 「5.2 Input/Output Signals Setting.」

Speed

reached

Servo

warning

Rotation

detection

Position

reached 2

Outputs signal when the torque is

limited.

Outputs signal when the speed is

limited.

Outputs signal upon reaching the

command speed.

Outputs signal when a warning occurs.

Outputs signal when the servo motor is

rotating above the set value.

Outputs signal when having reached the

command position (2)

2.5.2 Names and Functions of Analog Input/Output

Signals

Names and Functions of Analog Input Signals (I/O Connector)

Pin

Number

15 A-TLMT Analog torque limit

5 AGND AGND (0V) Analog ground

Name Details Function

It applies -10~+10V between A-TMLT(AI1) and

AGND to limit motor output torque. Relationship

between input voltage and limit torque depends on

the value of [0x221C].

Names and Functions of Analog Output Signals (Analog Monitoring

Connector)

Pin

Number

1 AMON1 Analog Monitor 1 Analog monitor output (-10V ~ +10)

2 AMON2 Analog Monitor 2

3 AGND AGND (0V) Analog ground

4 AGND AGND (0V) Analog ground

Note 1) You can change the output variables to be monitored with analog monitor output by parameter

setting.

Name Details Function

Analog monitor output (-10V ~ +10)

2-20

For more information, refer to 「5.2.3 Analog Monitor.」

2. Wiring and Connection

2-21

2. Wiring and Connection

2.5.3 Examples of Connecting Input/Output Signals

Examples of Connecting Digital Input Signals

Caution

1. The input contact can be set to the contact A or the contact B, based on the characteristics of

individual signal.

2. Each input contact can be assigned to 15 functions.

3. For more information on signal assignment and contact change of the input contact, refer to 5.2

Input/Output Signals Setting.

4. The rated voltage is DC 12 V to DC 24 V.

Servo Drive

Internal

Circuit

Internal

Circuit

R1 : 3.3K, R2 : 680

Example of Connecting Digital Output Signals

Caution

1. The output contact can be set to the contact A or the contact B, based on the characteristics of

individual signal.

2. Each output contact can be assigned to 11 output functions.

3. For more information on signal assignment and contact change of the output contact, refer to

5.2 Input/Output Signals Setting.

4. Overvoltages or overcurrents may damage the device because it uses an internal transistor

switch.

5. The rated voltage and current are DC 24 V ± 10% and 120 [㎃].

2-22

2. Wiring and Connection

Servo Drive

Internal

Circuit

Internal

Circuit

Note 1) For DO1~ DO4 output signals, the GND24 terminal is separated.

Example of Connecting Analog Output Signals

Caution

1. For more information on settings and scale adjustment of monitoring signals, refer to 5.2.3

Assignment of Analog output signals.

2. The range of analog output signals is -10V to 10V.

3. The resolution of analog output signal is 12 bits.

4. The maximum load current allowed is 2.5 [mA].

5. The stabilization time is 15 [us].

Servo Drive

2-23

2. Wiring and Connection

2.5.4 Examples of Connecting Input/Output Signals

Analog torque

limit

Digital Input

Analog Input

Digital Output

2-24

Safe function input

Safety function output

Analog Output

Note 1) The input signals DI1 - DI8 and output signals DO1 - DO4 are the factory default signals.

2. Wiring and Connection

2.6 Wiring of Encoder Signal (ENCODER)

ENCODER Connector Specification: 10114-3000VE (3M)

2.6.1 Quadrature Encoder Signaling Unit Wiring

APCS-EAS Cable

Servo Drive Servo Motor

Encoder

2-25

2. Wiring and Connection

APCS-EBS Cable

Servo Motor

Encoder

Servo Drive

2.6.2 Serial Encoder Signaling Unit Wiring

APCS-ECS Cable

Servo Motor

Encoder

Servo Drive

2-26

2. Wiring and Connection

APCS-EDS Cable

Servo Motor

Encoder

Servo Drive

APCS-EES Cable

Servo Motor

Encoder

Servo Drive

2-27

2. Wiring and Connection

2.6.3 Multi-Turn Encoder Signaling Unit Wiring

APCS-ECS1 Cable

Servo Motor

Encoder

Servo Drive

APCS-EDS1 Cable

Servo Motor

Encoder

Servo Drive

2-28

2. Wiring and Connection

APCS-EES1 Cable

Servo Motor

Encoder

Servo Drive

2.6.4 Tamagawa Encoder Signaling Unit Wiring

Servo Motor

Encoder

Servo Drive

2-29

2. Wiring and Connection

2.6.5 EnDat 2.2 Encoder Signaling Unit Wiring

Servo Motor

Encoder

Servo Drive

2-30

2. Wiring and Connection

2.7 Wiring for Safety Function Signals (STO)

2069577-1(Tyco Electronics)

2143658

7

2.7.1 Names and Functions of Safety Function Signals

Pin

Number

1 +12V

2 -12V

3 STO1- DC 24 V GND

4 STO1+ Blocks the current (torque) applied to the motor when the signal is off.

5 STO2- DC 24 V GND

6 STO2+ Blocks the current (torque) applied to the motor when the signal is off.

name Function

For bypass wiring

7 EDM+

8 EDM-

Monitor output signal for checking the status of safety function input

signal

2-31

2. Wiring and Connection

2.7.2 Example of Connecting Safety Function Signals

Caution

1. The rated voltage is DC 12 V to DC 24 V.

2. With the contacts of STO1 and STO2 off, the motor output current is blocked.

24 V power

Driving signal

Blocking

Blocking

Safety Module

2-32

2. Wiring and Connection

2.7.3 Bypass Wiring of Safety Function Signal

This drive provides the Mini I/O Bypass connector which has Bypass wiring to be used for the

convenience of the user when the STO function is not used. To use the Bypass function, connect the

Mini I/O Plug connector as follows.

If you connect +12V to STO2-, -12V to STO1+ and STO1- to STO2+ for wiring of the Mini I/O Plug

connector, you can bypass the safety function signal. Never use this power (+12V,-12V) except for this

purpose.

Mini I/O By-pass Connector

Mini I/O Plug Connector

1971153-1(Tyco Electronics)

2069577-1(Tyco Electronics)

2-33

2. Wiring and Connection

2.8 Wiring for EtherCAT Communication Signals

2.8.1 Names and Functions of EtherCAT

Communication Signals

EtherCAT IN and EtherCAT OUT Connector

Pin

Number

1 TX/RX0 +

2 TX/RX0 -

3 TX/RX1+

4 TX/RX2 -

5 TX/RX2 +

6 TX/RX1 -

7 TX/RX3 +

8 TX/RX3 -

Note 1) EtherCAT only uses signals from No. 1, 2, 3, and 6.

Signal Name Line color

White/Orange

Orange

White/Green

Blue

White/Blue

Green

White/Brown

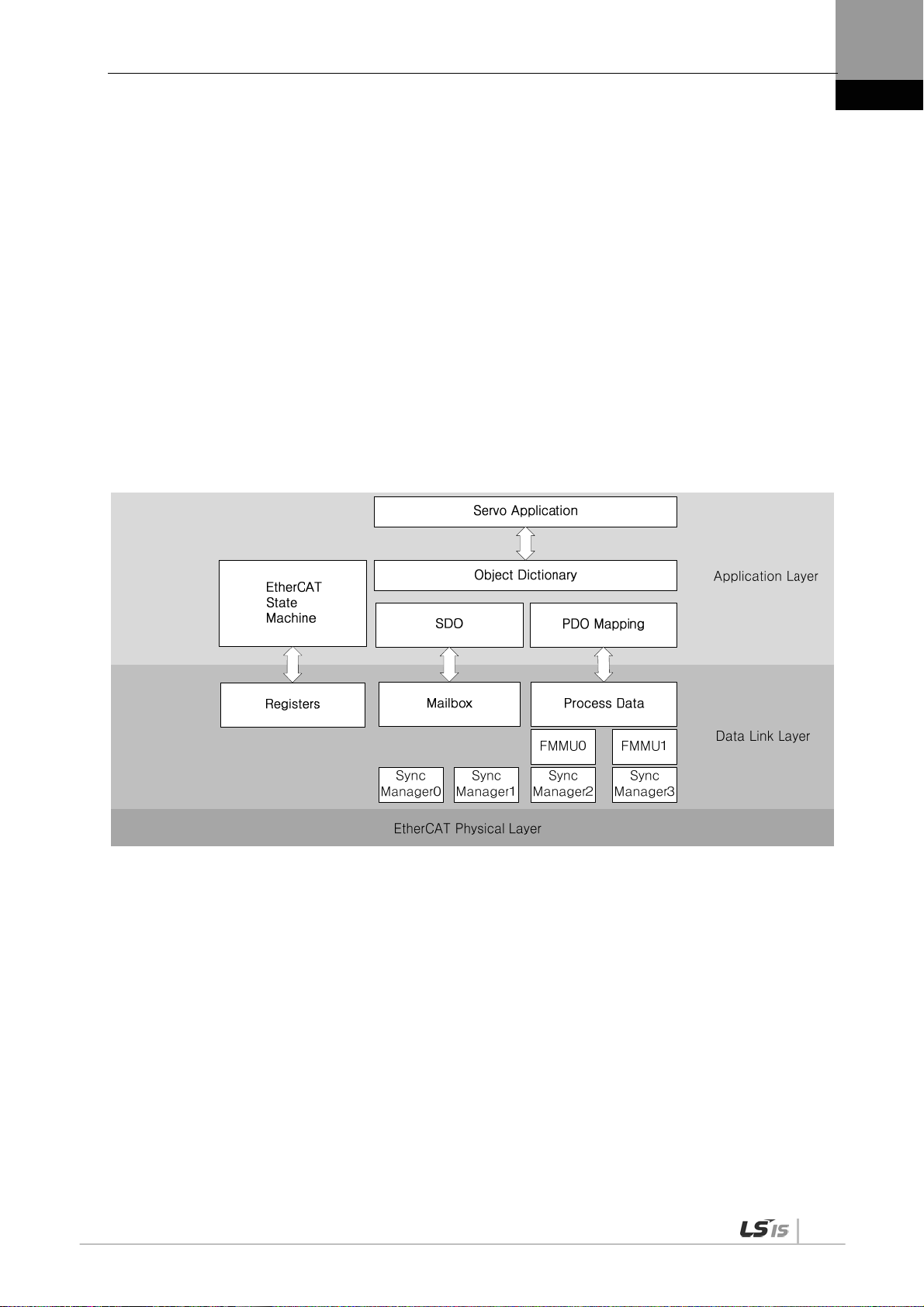

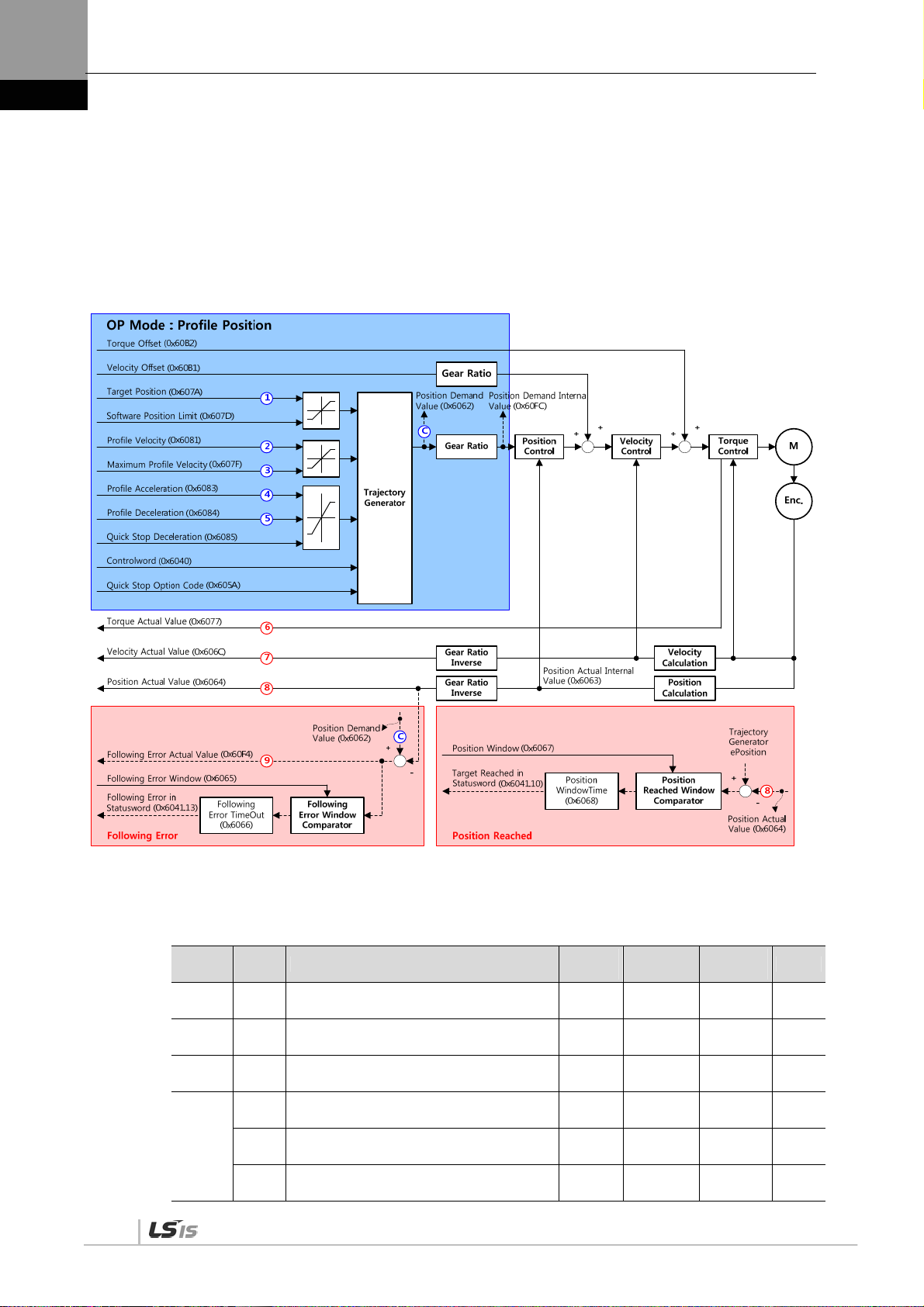

Brown