• SV-iS7 is the official name for the iS7 series inverters.

• This operation manual is intended for users with basic knowledge of electricity and electric

devices.

• Keep this manual near the product for future reference whenever setting change, maintenance

or service is required.

• Ensure that the field operators and service engineers can easily access this manual.

• For detailed information about the optional extension boards, including the specifications and

the requirements for installation and operation, refer to the instruction manuals that are

supplied with the products.

Safety Information

Indicates an imminently hazardous situation which, if not avoided, will result in severe injury or

death.

Indicates a potentially hazardous situation which, if not avoided, could result in injury or death.

Indicates a potentially hazardous situation which, if not avoided, could result in minor injury or

property damage.

• Do not open the cover of the equipment while it is on or operating. Likewise, do not operate the

inverter while the cover is open. Exposure of the high voltage terminals or the charging area to

the external environment may result in an electric shock. Do not remove any covers or touch

the internal circuit boards (PCBs) or electrical contacts on the product when the power is on or

during operation. Doing so may result in serious injury, death, or serious property damage.

• Do not open the cover of the equipment, even when the power supply to the inverter has been

turned off, unless it is necessary for maintenance or regular inspection. Opening the cover may

result in an electric shock even when the power supply is off.

• The equipment may hold a charge long after the power supply has been turned off. Use a

multi-meter to make sure that the remaining voltage is below 30 VDC before working on the

inverter, motor, or motor cable.

Safety Information

Read and follow all safety instructions in this manual precisely to avoid unsafe operating

conditions, property damage, personal injury, or death.

Safety symbols in this manual

Safety information

iii

Safety Information

• This equipment must be grounded for safe and proper operation.

• Do not supply power to a faulty inverter. If you find that the inverter is faulty, disconnect the

power supply and have the inverter professionally repaired.

• The inverter becomes hot during operation. Avoid touching the inverter until it has cooled to

avoid burns.

• Do not allow foreign objects, such as screws, metal chips, debris, water, or oil, to get inside the

inverter. Allowing foreign objects inside the inverter may cause the inverter to malfunction or

result in a fire.

• Do not operate the inverter with wet hands. Doing so may result in electric shock.

• Do not modify the interior workings of the inverter. Doing so will void the warranty.

• Do not use cables with damages or cracks on the protective insulation when wiring the inverter.

Damaged insulation may cause misoperation, an electric shock or a fire.

• Do not place heavy objects on top of electric cables. Doing so may damage the cable and result

in an electric shock.

Note

The maximum allowed prospective short-circuit current at the input power connection is defined in

IEC 60439-1 as 100 kA. The drive is suitable for use in a circuit capable of delivering not more than

100 kA RMS at the drive’s maximum rated voltage.

1

Table of contents

Table of Contents

1

About the Product ........................................................................................................ 1

1.1

Preparing for Installation and Operation .......................................................... 1

1.1.1

Identifying the Product ................................................................................. 1

1.1.2

Checking the Product for Defects or Damage .......................................... 3

1.1.3

Preparing the Product for Installation and Operation ........................... 3

1.1.4

Installing the Product .................................................................................... 3

1.1.5

Connecting the Cables ................................................................................... 3

1.2

Part Names .............................................................................................................. 4

1.2.1

Interior and Exterior View (IP 21 Model Types Less than 22 kW [200 V]

/ Less than 75 kW [400 V]) ............................................................................ 4

1.2.2

Interior and Exterior View (IP 54 Model Types Less than 22 kW

[200/400 V]) ..................................................................................................... 5

1.2.3

Interior and Exterior View (Model Types 30 kW and up [200 V] / 90

kW and up [400 V]) ........................................................................................ 6

2

Technical Specifications .............................................................................................. 7

2.1

Input and Output Specifications 200 V Class (0.75–22 kW) ........................... 7

2.2

Input and Output Specifications 200 V Class (30–75 kW)............................... 8

2.3

Input and Output Specifications 400 V Class (0.75–22 kW) ........................... 9

2.4

Input and Output Specifications 400 V Class (30–160 kW) .......................... 10

2.5

Input and Output Specifications 400 V Class (185–375 kW) ........................ 11

2.6

Product Specification Details ............................................................................. 12

2.6.1

Control ........................................................................................................... 12

2.6.2

Operation ...................................................................................................... 12

2.6.3

Protection Function ..................................................................................... 14

2.6.4

Structure and Operating Environment Control .................................... 14

3

Installing the Inverter .............................................................................................. 16

3.1

Installation Considerations ................................................................................ 16

3.2

Selecting and Preparing a Site for Installation ............................................... 17

3.3

Exterior and Dimensions (UL Enclosed Type 1, IP21 Type) ......................... 21

3.4

Exterior and Dimensions (UL Enclosed Type 12, IP54 Type) ....................... 35

3.5

Frame Dimensions and Weight (UL Enclosed Type 1, IP 21 Type) ............. 39

3.6

Frame Dimensions and Weight (UL Enclosed Type 12, IP54 Type)............ 41

3.7

Installation Procedures for UL Enclosed Type12 and IP54 Type Products

42

Table of contents

2

3.7.1

Disassembling the Keypad Cover and Keypad ...................................... 42

3.7.2

Disassembling the IP54 Front Cover ....................................................... 43

3.7.3

Mounting the Inverter ................................................................................ 44

3.7.4

Connecting the Power Cables ................................................................... 45

3.7.5

Reassembling the IP54 Front Cover and the Keypad .......................... 46

4

Connecting the Cables.............................................................................................. 48

4.1

Removing the Front Cover for Cable Connection.......................................... 48

4.1.1

IP 21 Type Products ..................................................................................... 48

4.1.2

IP 54 Type Products ..................................................................................... 50

4.1.3

90–375 kW, 400 V and 30–75 kW, 200 V Products ................................ 51

4.2

Activating and Deactivating the Built-in EMC Filter ....................................... 52

4.2.1

Up to 7.5 kW Inverters ................................................................................ 52

4.2.2

11–22 kW Inverters...................................................................................... 54

4.3

Precautions for Wiring the Inverter .................................................................. 56

4.4

Ground Connection ............................................................................................. 57

4.5

Terminal Wiring Diagram ................................................................................... 58

4.5.1

Up to 7.5 kW Inverters ................................................................................ 58

4.5.2

11–22 kW Inverters...................................................................................... 58

4.5.3

30–75 kW Inverters...................................................................................... 58

4.5.4

90–160 kW Inverters ................................................................................... 58

4.5.5

185–220 kW Inverters ................................................................................. 59

4.5.6

280–375 kW Inverters ................................................................................. 59

4.6

Connecting Cables to the Power Terminal Block .......................................... 60

4.6.1

0.75–22 kW (200 V/400 V) ........................................................................... 60

4.6.2

30–75 kW (200 V/400 V) .............................................................................. 61

4.6.3

90–160 kW (400 V)........................................................................................ 62

4.6.4

185–220 kW (400 V) ..................................................................................... 63

4.6.5

280–375 kW (200 V/400 V) .......................................................................... 64

4.7

Specifications of the Power Terminal Block and Exterior Fuse ................... 65

4.7.1

Cable Length between the Inverter and the Motor ............................. 66

4.7.2

Protective Measures for the Inverter and the Motor ........................... 67

4.8

Control Terminal Wiring for iS7 Inverters Rated for Up To 22 kW ............. 68

4.8.1

NPN Mode (Sink) .......................................................................................... 69

4.8.2

PNP Mode (Source) ..................................................................................... 69

4.8.3

0.75–22 kW (Basic I/O) ................................................................................ 70

4.9

Control Terminal Wiring for iS7 Inverters Rated for 30 kW or More ......... 71

4.10

Terminal Inputs for Inverter Operation........................................................... 72

4.11

Cable Specifications for Control Block Wiring ................................................ 74

3

Table of contents

4.12

Setting the Built-in Surge Filter .......................................................................... 75

4.13

Activating or Deactivating the Surge Filter ..................................................... 76

4.13.1

iS7 30–75KW (400 V) Inverters .................................................................. 76

4.13.2

iS7 90–375 kW (400V) Inverters ................................................................ 76

4.14

Post-Installation Checklist................................................................................... 78

4.15

Test Run .................................................................................................................. 79

4.15.1

Entering Easy Start Mode ........................................................................... 79

4.15.2

Setting the Basic Parameters in Easy Start Mode ................................. 80

4.15.3

Checking the Inverter Operation ............................................................. 81

5

Using the Keypad ....................................................................................................... 82

5.1

About the Keypad ................................................................................................. 82

5.1.1

Dimensions ................................................................................................... 82

5.1.2

Key Functions ............................................................................................... 83

5.1.3

Display Items ................................................................................................ 84

5.1.4

Display Item List ........................................................................................... 84

5.2

Menu Items ........................................................................................................... 87

5.2.1

Parameter Mode .......................................................................................... 88

5.2.2

User & Macro Mode .................................................................................... 89

5.3

Navigating Modes ................................................................................................ 90

5.3.1

Mode Navigation at the Factory Default ................................................. 90

5.3.2

Mode Navigation with User/Macro Mode and Trip Mode .................. 91

5.4

Navigating Modes and Parameters ................................................................. 93

5.4.1

Group Navigation in Parameter mode ................................................... 93

5.4.2

Group Shift in User & Macro Mode .......................................................... 95

5.5

Navigating through Codes (Function Items) .................................................. 96

5.5.1

Code Navigation in Monitor Mode .......................................................... 96

5.5.2

Code Navigation (function items) in Other Modes and Groups ........ 97

5.5.3

Code Navigation Using Jump Code.......................................................... 98

5.6

Setting Parameters ............................................................................................ 100

5.6.1

Parameter Settings in Monitor Mode.................................................... 100

5.6.2

Parameter Settings in Other Modes and Groups ............................... 101

5.7

Monitoring Operating Status ........................................................................... 102

5.7.1

Using Monitor Mode ................................................................................. 102

5.7.2

Monitoring Items ....................................................................................... 103

5.7.3

Using the Status Display........................................................................... 104

5.8

Monitoring Faults ............................................................................................... 105

5.8.1

Faults during Inverter Operation ........................................................... 105

5.8.2

Multiple Faults at a Time during Inverter Operation ......................... 106

Table of contents

4

5.8.3

Saving and Monitoring the Fault Trip History ...................................... 106

5.9

Initializing Parameters ...................................................................................... 108

6

Basic Functions ......................................................................................................... 110

6.1

Setting Frequency References ......................................................................... 110

6.1.1

Keypad as the Source (KeyPad-1 setting) ............................................. 111

6.1.2

Keypad as the Source (KeyPad-2 setting) ............................................. 111

6.1.3

V1 Terminal as the Source ....................................................................... 111

6.1.4

Setting a Frequency Reference Using an I/O Expansion Module

(Terminal V2/I2) ........................................................................................ 121

6.1.5

Setting a Frequency with Pulse Input (with an optional encoder

module) ...................................................................................................... 123

6.1.6

Setting a Frequency Reference via RS-485 Communication............. 125

6.2

Frequency Hold by Analog Input .................................................................... 126

6.3

Changing the Displayed Units (Hz↔Rpm) .................................................... 127

6.4

Setting Multi-Step Frequency........................................................................... 127

6.5

Command Source Configuration .................................................................... 130

6.5.1

The Keypad as a Command Input Device ............................................ 130

6.5.2

The Terminal Block as a Command Input Device (Fwd/Rev run

commands) ................................................................................................ 131

6.5.3

The Terminal Block as a Command Input Device (Run and Rotation

Direction Commands) ............................................................................. 132

6.5.4

RS-485 Communication as a Command Input Device ....................... 133

6.6

Forward or Reverse Run Prevention .............................................................. 133

6.7

Power-on Run ...................................................................................................... 134

6.8

Setting Acceleration and Deceleration Times .............................................. 135

6.8.1

Acc/Dec Time Based on Maximum Frequency .................................... 135

6.8.2

Acc/Dec Time Based on Operation Frequency .................................... 137

6.8.3

Multi-Step Acc/Dec Time Configuration ................................................ 138

6.8.4

Configuring Acc/Dec Time Switch Frequency ...................................... 139

6.9

Output Voltage Setting ..................................................................................... 141

7

Troubleshooting and Maintenance .................................................................... 142

7.1

7.2

7.3

7.4

Protection Functions .......................................................................................... 142

7.1.1

Protection from Output Current and Input Voltage .......................... 142

7.1.2

Abnormal Circuit Conditions and External Signals ............................. 143

7.1.3

Keypad and Optional Expansion Modules ........................................... 145

Warning Messages ............................................................................................ 146

Troubleshooting Fault Trips ............................................................................. 147

Replacing the Cooling Fan ................................................................................ 150

5

Table of contents

7.4.1

Products Rated below 7.5 kW ................................................................. 150

7.4.2

Products Rated at 11-15 kW 200 V/400 V and 18.5-22 kW 400 V ..... 150

7.4.3

Products Rated at more than 30 kW (200 V) / 90 kW (400 V), and 18.5–

22 kW (200 V) / 30–75 kW (200/400 V) .................................................. 151

7.5

Daily and Regular Inspection Lists .................................................................. 152

8

Table of Functions ................................................................................................... 155

8.1

Parameter Mode – DRV Group (DRV) ........................................................ 155

8.2

Parameter Mode – Basic Function Group (BAS) ...................................... 158

8.3

Parameter Mode – Expansion Function Group (PARADV) ..................... 162

8.4

Parameter Mode – Control Function Group (CON) ................................. 166

8.5

Parameter Mode – Input Terminal Block Function Group (IN) ............ 172

8.6

Parameter Mode – Output Terminal Block Function Group (OUT) ..... 176

8.7

Parameter Mode – Communication Function Group (COM) ................ 180

8.8

Parameter Mode – Applied Function Group (APP) .................................. 183

8.9

Parameter Mode – Auto Sequence Operation Group (AUT) ................. 186

8.10

Parameter Mode – Option Module Function Group (APO) ................... 189

8.11

Parameter Mode – Protective Function Group (PRT) ............................. 192

8.12

Parameter Mode – 2nd Motor Function Group (M2) ............................. 195

8.13

Trip Mode (TRP Current (or Last-x)) ................................................................ 196

8.14

Config Mode (CNF) ............................................................................................. 196

8.15

User/Macro Mode – Draw Operation Function GroupMC1 .................. 199

8.16

User/Macro mode – Traverse Operation Function Group (MC2) ........ 200

9

Peripheral Devices ................................................................................................... 201

9.1

Wiring Switch, Electronic Contactor, and Reactor Specifications ............. 202

9.1.1

Wiring Switch, Short Circuit Switch, and Electronic Contactor ......... 202

9.1.2

Reactors ....................................................................................................... 204

9.1.3

Dynamic Braking Unit (DBU) and Resistor ........................................... 207

9.1.4

DB Unit Dimensions .................................................................................. 211

9.1.5

Indicators on the DB unit ......................................................................... 217

9.1.6

DB Resistors ................................................................................................ 217

9.1.7

DB Resistor Dimensions ........................................................................... 219

9.1.8

Keypad Extension Cable for Remote Control (Optional) ................... 221

10

Safety Funtion STO(Safe Torque Off) .................................................................. 224

10.1

Safety Standard Product ................................................................................... 224

10.2

About the Safety Function ................................................................................ 224

10.2.1

Safety Function Wiring Diagram ............................................................ 225

Table of contents

6

10.2.2

Installing the Safety Board to 0.75–160 kW Product .......................... 226

10.2.3

Installing the Safety Board to 185–375 kW Product ........................... 226

10.2.4

Safety Function Terminal Description ................................................... 227

10.2.5

Cable Specification for Signal Terminal Block Wiring ......................... 227

11

Marine Certification ................................................................................................ 228

11.1

DNV (Det Norske Veritas) Marine Certification Details .............................. 228

11.2

Bureau Veritas (Marine & Offshore Division) Marine Certification Details

228

11.3

ABS Marine Certification Details...................................................................... 228

11.4

Marine Certification Models for SV-iS7 Products ......................................... 229

12

Using a Single Phase Power Source .................................................................... 231

12.1

Single Phase Rating ........................................................................................... 231

12.2

Power(HP), Input Current and Output Current ........................................... 232

12.3

Input Frequency and Voltage Tolerance ....................................................... 233

12.4

Wiring and Peripheral Device .......................................................................... 234

12.5

Other Considerations ........................................................................................ 237

Product Warranty ............................................................................................................ 238

Index ................................................................................................................................... 241

About the Product

About the

Product

1

1 About the Product

This chapter provides details on product identification and part names. To install the inverter

correctly and safely, carefully read and follow the instructions.

1.1 Preparing for Installation and Operation

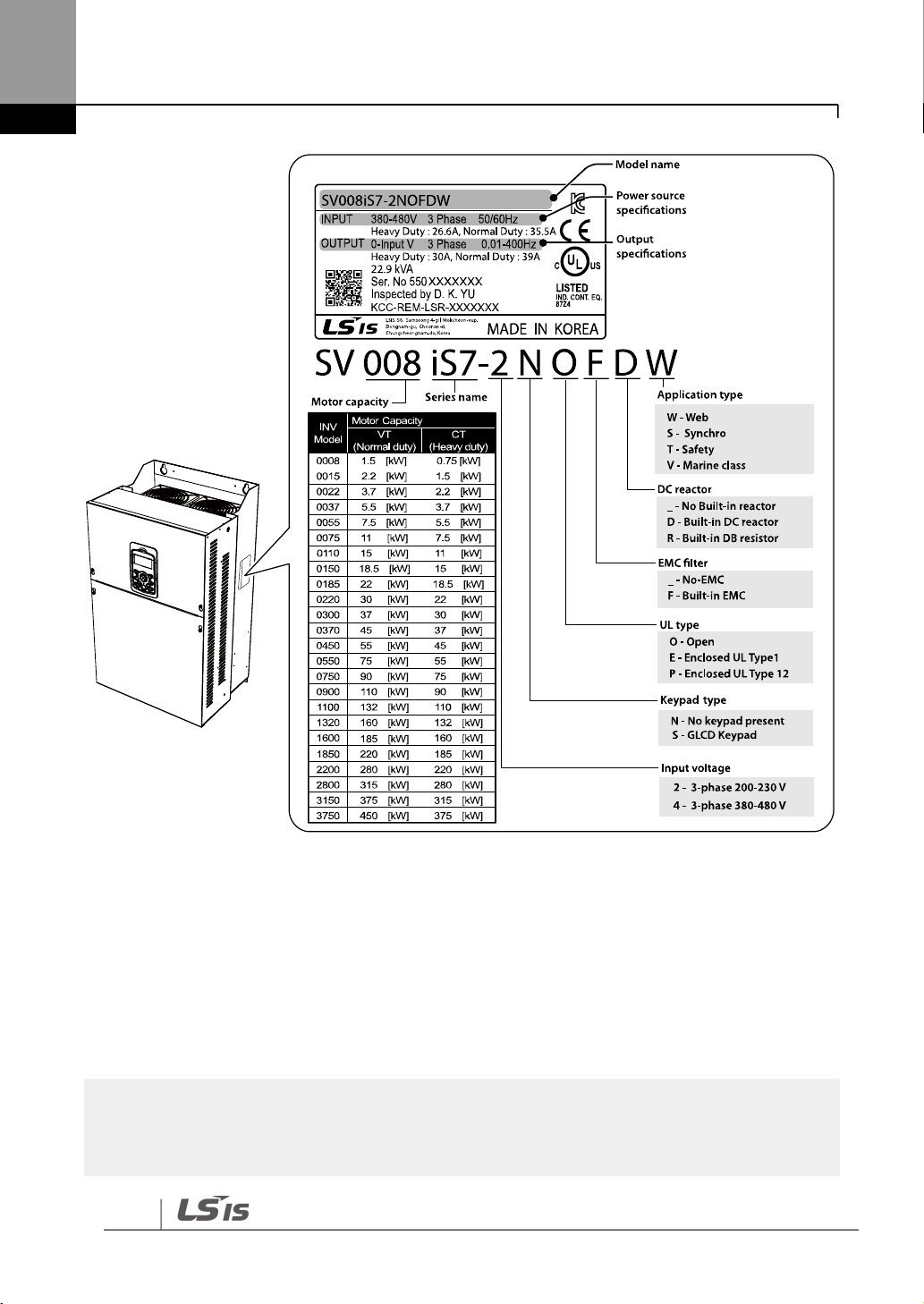

1.1.1 Identifying the Product

Check the product name, open the packaging, and then confirm that the product is free from

defects. Contact your supplier if you have any issues or questions about your product.

The iS7 inverter is manufactured in a range of product groups based on drive capacity and

power source specifications. The product name and specifications are detailed on the rating

plate. Check the rating plate before installing the product and make sure that the product

meets your requirements.

2

About the Product

Note

The iS7 75/90 kW, 400 V inverters satisfy the EMC standard EN61800-3 without the installation of

optional EMC filters.

Note1) Optional conduit parts are available for the Enclosed UL Type 1 models (0.75–75 kW

products).

Note2) Optional built-in DCR is available for the Web application models (0.75–375 kW / type

2/4 products).

Note3) To use safety function, please buy 0.75-160kW product including safety option. However

185-375kW product users have to buy safety option and apply to standard products because

safety option is not included.

About the Product

About the

Product

3

1.1.2 Checking the Product for Defects or Damage

If you suspect that the product has been mishandled or damaged in any way, contact the LSIS

Customer Support center with the phone numbers listed on the back cover of this manual.

1.1.3 Preparing the Product for Installation and Operation

Preparation steps for installation and operation may slightly vary by product type and

application. Refer to the manual and prepare the product accordingly.

1.1.4 Installing the Product

Refer to the installation section of this manual and install the product correctly considering the

installation and operating conditions at the installation location, such as installation clearances,

to prevent premature deterioration or performance loss.

1.1.5 Connecting the Cables

Connect the power input/output and signal cables to the terminal block according to the

instructions provided in this manual. Ensure that all the cables are connected correctly before

supplying power to the product. Incorrect cable connections may damage the product.

4

About the Product

1.2 Part Names

The illustration below displays part names. Details may vary between product groups.

1.2.1 Interior and Exterior View (IP 21 Model Types Less than 22 kW

[200 V] / Less than 75 kW [400 V])

About the Product

About the

Product

5

1.2.2 Interior and Exterior View (IP 54 Model Types Less than 22 kW

[200/400 V])

6

About the Product

Note

Refer to the installation manual provided with the optional module products before installing

communication modules in the inverter.

1.2.3 Interior and Exterior View (Model Types 30 kW and up [200 V]

/ 90 kW and up [400 V])

Technical Specifications

Technical

Specifications

7

Model SV xxx iS7–2x

0008

0015

0022

0037

0055

0075

0110

0150

0185

0220

Applied

Motor

Normal load

HP 2 3 5 7.5

10

15

20

25

30

40

kW

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

Heavy load

HP 1 2 3 5

7.5

10

15

20

25

30

kW

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

Rated

output

Rated Capacity (kVA)

1.9

3.0

4.5

6.1

9.1

12.2

17.5

22.9

28.2

33.5

Rated

Current

(A)

Normal

load

8

12

16

24

32

46

60

74

88

124

Heavy

load

5 8 12

16

24

32

46

60

74

88

Output Frequency

0–400 Hz (Sensorless-1: 0–300 Hz, Sensorless-2, Vector: 0.1–120

Hz)

Output Voltage (V)

3-Phase 200–230 V

Rated

input

Working Voltage (V)

3-Phase 200–230 VAC (-15%–+10%)

Input Frequency

50–60 Hz (5%)

Rated

Current

(A)

Normal

load

6.8

10.6

14.9

21.3

28.6

41.2

54.7

69.7

82.9

116.1

Heavy

load

4.3

6.9

11.2

14.9

22.1

28.6

44.3

55.9

70.8

85.3

2 Technical Specifications

2.1 Input and Output Specifications 200 V Class (0.75–

22 kW)

• Only the heavy duty ratings apply to model types without a built-in DC resistor (NON-DCR).

• The standard used for 200 V inverters is based on a 220 V supply voltage.

• The rated output current is limited based on the carrier frequency set at CON-04.

• The output frequency is limited to 0–300 Hz if DRV-09 (control mode) is set to “3

(Sensorless-1),” and to 0–120 Hz if DRV-09 (control mode) is set to “4 (Sensorless-3).”

• The maximum output voltage cannot exceed the input voltage of the power source.

Technical Specifications

8

Model SV xxx iS7–2x

0300

0370

0450

0550

0750

Applied

Motor

Normal load

HP

50

60

75

100

120

kW

37

45

55

75

90

Heavy load

HP

40

50

60

75

100

kW

30

37

45

55

75

Rated

output

Rated Capacity (kVA)

46

57

69

84

116

Rated

Current

(A)

Normal

load

146

180

220

288

345

Heavy

load

116

146

180

220

288 Output Frequency

0–400 Hz (Sensorless-1: 0–300 Hz, Sensorless-2, Vector: 0.1–120

Hz)

Output Voltage (V)

3-Phase 200–230 V

Rated

input

Working Voltage (V)

3-Phase 200–230 VAC (-15%–+10%)

Input Frequency

50–60 Hz (5%)

Rated

Current

(A)

Normal

load

152

190

231

302

362

Heavy

load

121

154

191

233

305

2.2 Input and Output Specifications 200 V Class (30–

75 kW)

• The standard motor capacity is based on a standard 4-pole motor.

• The standard used for 200 V inverters is based on a 200 V supply voltage.

• The rated output current is limited based on the carrier frequency set at CON-04.

• The output frequency is limited to 0–300 Hz if DRV-09 (control mode) is set to “3

(Sensorless-1),” and to 0–120 Hz if DRV-09 (control mode) is set to “4 (Sensorless-3).”

• The maximum output voltage cannot exceed the input voltage of the power source.

Technical Specifications

Technical

Specifications

9

Model SV xxx iS7–2x

0008

0015

0022

0037

0055

0075

0110

0150

0185

0220

Applied

Motor

Normal load

HP 2 3 5 7.5

10

15

20

25

30

40

kW

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

Heavy load

HP 1 2 3 5

7.5

10

15

20

25

30

kW

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

Rated

output

Rated Capacity

(kVA)

1.9

3.0

4.5

6.1

9.1

12.2

18.3

22.9

29.7

34.3

Rated

Current

(A)

Normal

load

4 6 8

12

16

24

30

39

45

61

Heavy

load

2.5 4 6 8 12

16

24

30

39

45

Output Frequency

0–400 Hz (Sensorless-1: 0–300Hz, Sensorless-2, Vector: 0.1–120Hz)

Output Voltage (V)

3-Phase 380–480 V

Rated

input

Working Voltage (V)

3-Phase 380–480 VAC (-15%–+10%)

Input Frequency

50–60 Hz (5%)

Rated

Current

(A)

Normal

load

3.7

5.7

7.7

11.1

14.7

21.9

26.4

35.5

41.1

55.7

Heavy

load

2.2

3.6

5.5

7.5

11.0

14.4

22.0

26.6

35.6

41.6

2.3 Input and Output Specifications 400 V Class (0.75–

22 kW)

• Only the heavy duty ratings apply to model types without a built-in DC resistor (NON- DCR).

• The standard motor capacity is based on a standard 4-pole motor.

• The standard used for 400 V inverters is based on a 440 V supply voltage.

• The rated output current is limited based on the carrier frequency set at CON-04.

• The output frequency is limited to 0-300 Hz if DRV-09 (control mode) is set to “3 (Sensorless-

1),” and to 0-120 Hz if DRV-09 (control mode) is set to “4 (Sensorless-3).”

• The maximum output voltage cannot exceed the input voltage of the power source.

Technical Specifications

10

Model SV xxx iS7–2x

0300

0370

0450

0550

0750

0900

1100

1320

1600

Applied

Motor

Normal load

HP

50

60

75

100

120

150

180

225

250

kW

37

45

55

75

90

110

132

160

185

Heavy load

HP

40

50

60

75

100

120

150

180

225

kW

30

37

45

55

75

90

110

132

160

Rated

output

Rated Capacity

(kVA)

46

57

69

84

116

139

170

201

248

Rated

Current

(A)

Normal

load

75

91

110

152

183

223

264

325

370

Heavy

load

61

75

91

110

152

183

223

264

325 Output Frequency

0–400 Hz (Sensorless-1: 0–300 Hz, Sensorless-2, Vector: 0.1–120

Hz)

Output Voltage (V)

3-Phase 380–480 V

Rated

input

Working Voltage (V)

3-Phase 380–480 VAC (-15%–+10%)

Input Frequency

50–60 Hz (5%)

Rated

Current

(A)

Normal

load

67.5

81.7

101.8

143.6

173.4

212.9

254.2

315.3

359.3

Heavy

load

55.5

67.9

82.4

102.6

143.4

174.7

213.5

255.6

316.3

2.4 Input and Output Specifications 400 V Class (30–

160 kW)

• The standard used for 400 V inverters is based on a 440 V supply voltage.

• The rated output current is limited based on the carrier frequency set at CON-04.

• The output frequency is limited to 0–300 Hz if DRV-09 (control mode) is set to “3

(Sensorless-1),” and to 0–120 Hz if DRV-09 (control mode) is set to “4 (Sensorless-3).”

• The maximum output voltage cannot exceed the input voltage of the power source.

Technical Specifications

Technical

Specifications

11

Model SV xxx iS7–2x

1850

2200

2800

3150

3750

Applied

Motor

Normal load

HP

300

375

420

500

600

kW

220

280

315

375

450

Heavy load

HP

250

300

375

420

500

kW

185

220

280

315

375

Rated

output

Rated Capacity

(kVA)

286

329

416

467

557

Rated

Current

(A)

Normal

load

432

547

613

731

877

Heavy

load

370

432

547

613

731

Output Frequency

0–400 Hz (Sensorless-1: 0–300 Hz, Sensorless-2, Vector: 0–120 Hz)

Output Voltage (V)

3-Phase 380–480 V

Rated

input

Working Voltage (V)

3-Phase 380–480 VAC (-15%–+10%)

Input Frequency

50–60 Hz (5%)

Rated

Current

(A)

Normal

load

463

590

673

796

948

Heavy

load

404

466

605

674

798

Note

The maximum allowed prospective short circuit current at the input power connection is defined in

IEC 60439-1 as 100 kA. The drive is suitable for use in a circuit capable of delivering not more than

100 kA RMS at the drive’s maximum rated voltage.

2.5 Input and Output Specifications 400 V Class (185–

375 kW)

• The standard motor capacity is based on a standard 4-pole motor.

• The standard used for 400 V inverters is based on a 440 V supply voltage.

• The rated output current is limited based on the carrier frequency set at CON-04.

• The output frequency is limited to 0–300 Hz if DRV-09 (control mode) is set to “3

(Sensorless-1),” and to 0–120 Hz if DRV-09 (control mode) is set to “4 (Sensorless-3).”

• The maximum output voltage cannot exceed the input voltage of the power source.

Technical Specifications

12

Items

Description

Control

Control modes

V/F control, V/F PG, slip compensation, sensorless vector-1,

sensorless vector-2, vector control

Frequency

settings resolution

Digital command: 0.01 Hz

Analog command: 0.06 Hz (maximum frequency: 60 Hz)

Frequency

accuracy

Digital command: 0.01% of maximum output frequency

Analog command: 0.1% of maximum output frequency

V/F pattern

Linear, square reduction, user V/F

Overload capacity

Rated current for heavy duty operation: 150% for 1 min

Rated current for normal duty operation: 110% for 1 min

Torque boost

Manual torque boost, automatic torque boost

Items

Description

Operation

Operation types

Select from keypad, terminal strip, or network communication

operation.

Frequency

settings

Analog type: -10–10 V, 0–10 V, 0–20 mA

Digital type: keypad

Operation

function

• PID control

• 3-wire operation

• Frequency limit

• Second function

• Reverse rotation prevention

• Inverter bypass

• Flying start

• Power braking

• Leakage reduction

• Up-down operation

• DC braking

• Frequency jump

• Slip compensation

• Automatic restart

• Automatic tuning

• Energy buffering

• Flux braking

• MMC

2.6 Product Specification Details

2.6.1 Control

• Only the heavy load ratings apply to 0.75-22 kW model types without a built-in DC resistor

(NON-DCR).

2.6.2 Operation

Technical Specifications

Technical

Specifications

13

Items

Description

• Easy start

Input

Multifunction

terminal

(8 EA)

P1–P8*

Select NPN (Sink) or PNP (Source) mode.

• Forward direction operation

• Reset

• Emergency stop

• Multi-step speed frequency-

high/med/low

• DC braking during stop

• Frequency increase

• 3-wire operation

• Acceleration/deceleration/stop

• Operation by keypad input

during an operation by

network communication

• Reverse direction

operation

• External trip

• Jog operation

• Multi-step acc/dec-

high/med/low

• Second motor

selection

• Frequency reduction

• Transition from PID

to general operation

• Analog command

frequency fix

Output

Multifunction

open

collector

terminal

Fault output and inverter operation

status output

Less than DC 26 V, 100 mA

Multifunction

relay

terminal

N.O.: Less than AC 250 V

1A, DC 30 V, 3A

N.C.: Less than AC 250 V

1A, DC 30 V 1A

Analog

output

DC 0–10 V, 0–20 mA: Select output type from frequency, current,

voltage, or DC voltage.

* Set the Input Group codes IN-65 through IN-72 to configure the multi-function terminal functions.

Technical Specifications

14

Items

Description

Protection

function

Trips

• Over voltage

• Low voltage

• Over current

• Earth current detection

• Inverter overheat

• Motor overheat

• Output imaging

• Overload protection

• Network

communication error

• Lost command

• Hardware failure

• Cooling fan failure

• Pre-PID failure

• No motor trip

• External trip

• Other safety functions

Alarms

• Stall prevention

• Overload

• Light load

• Encoder error

• Fan failure

• Keypad command loss

• Speed command loss

Instantaneous

blackout

Less than 15 ms (CT) [Less than 8 ms (VT)]: Continue

operation (must be within the rated input voltage and rated

output range).

Over 15 ms (CT) [Over 8 ms (VT)]: Automatically restart

Items

Description

Structure/

operating

environment

Cooling type

Forced cooling: 0.75–15 kW (200/400 V class),

22 kW (400 V class)

Inhalation cooling: 22–75 kW (200 V class),

30–375 kW (400 V class)

Protection

structure

- 0.75–22 kW (200V), 0.75–75 kW (400 V): Open type IP 21

(default), UL enclosed type 1 (optional)*

- 30–75 kW (200 V), 90–375 kW (400 V): Open type IP 00

- 0.75–22 kW, frame types 2, 4 and others.: Enclosed IP54

type, UL enclosed type 12

Ambient

temperature

• CT load (heavy duty): -10–50℃

• VT load (normal duty): -10–40℃

- No ice or frost should be present.

- Working under normal load at 50℃ (122F), it is

2.6.3 Protection Function

2.6.4 Structure and Operating Environment Control

Technical Specifications

Technical

Specifications

15

Items

Description

recommended that less than 80% load is applied.

• IP54 product: -10–40℃

- No ice or frost should be present.

Storage

temperature.

-20C–65C (-4–149F)

Ambient humidity

Relative humidity less than 90% RH (to prevent condensation

from forming)

Operation altitude

Maximum 1000m above sea level for standard operation.

From 1000 to 4000m, the rated input voltage and rated

output current of the drive must be derated by 1% for every

100m.

Oscillation

Less than 5.9 m/sec2 (0.6 G).

Surrounding

environment

Prevent contact with corrosive gases, inflammable gases, oil

stains, dust, and other pollutants (Pollution Degree 2

Environment).

* UL Enclosed type 1 when an optional conduit box is installed. The 30–75 kW (200 V class) product is

regarded as UL Open type IP 20 when an optional conduit box is installed.

Installing the Inverter

16

Items

Description

Ambient Temperature*

CT load (heavy duty): -10℃–50℃

VT load (normal duty): -10℃–40℃

IP54 model types: -10℃–40℃

Ambient Humidity

90% relative humidity (no condensation)

Storage Temperature

- 4–149F (-20–65℃)

Environmental Factors

An environment free from corrosive or flammable gases, oil residue, or

dust (pollution degree 2)

Altitude/Vibration

Lower than 3,280 ft (1,000 m) above sea level/less than 0.6 G (5.9

m/sec2)

Air Pressure

70–106 kPa

• Do not transport the inverter by lifting with the inverter’s covers or plastic surfaces. The inverter

may tip over if covers break, causing injuries or damage to the product. Always support the

inverter using the metal frames when moving it.

• Hi-capacity inverters are very heavy and bulky. Use an appropriate transport method that is

suitable for the weight. Do not place heavy objects on top of electric cables. Doing so may

damage the cable and result in an electric shock.

• Do not install the inverter on the floor or mount it sideways against a wall. The inverter must be

installed vertically, on a wall or inside a panel, with its rear flat on the mounting surface.

3 Installing the Inverter

3.1 Installation Considerations

Inverters are composed of various precision electronic devices, and therefore the installation

environment can significantly impact the lifespan and reliability of the product. The table below

details the ideal operation and installation conditions for the inverter.

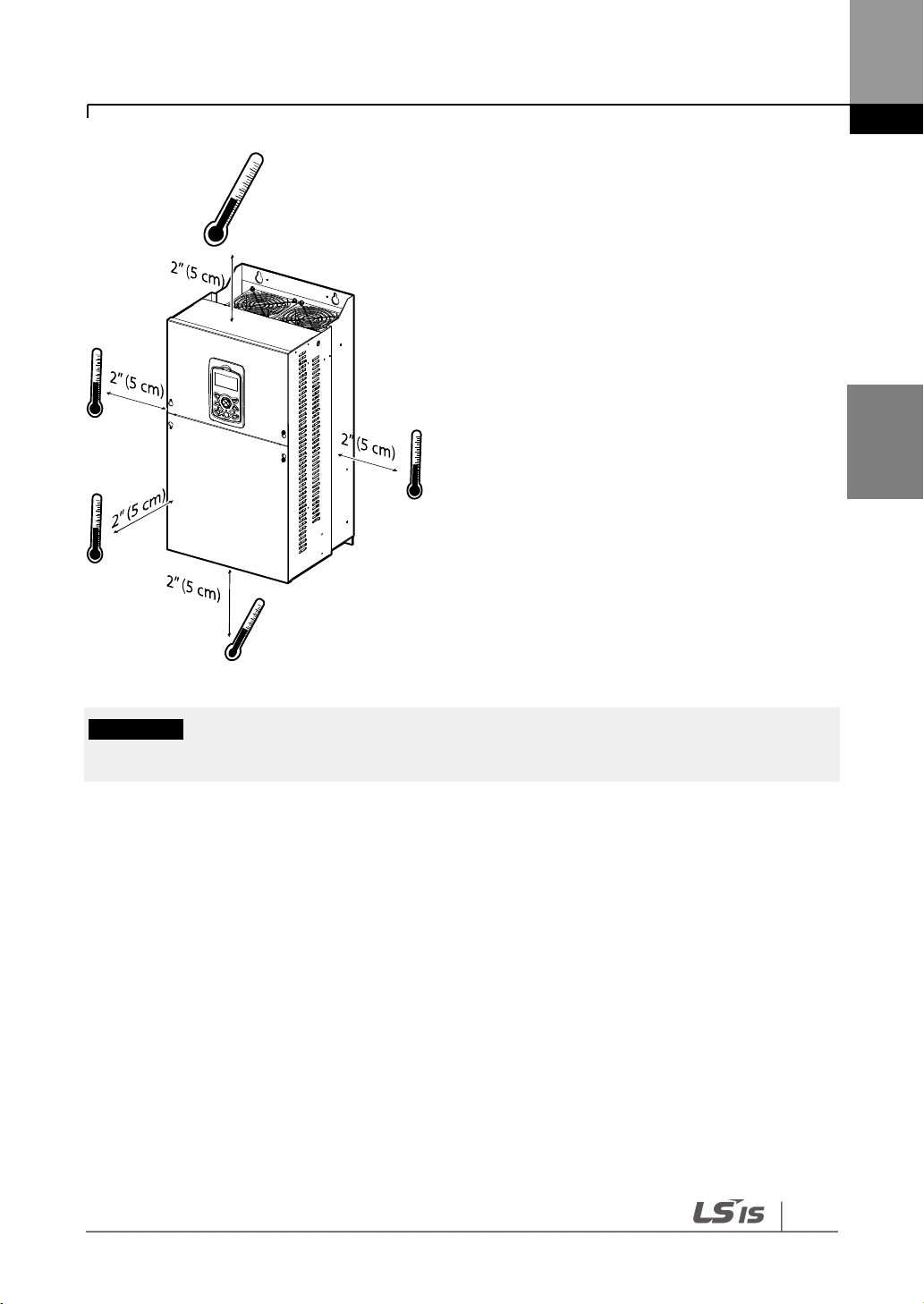

* The ambient temperature is the temperature measured at a point 2” (5 cm) from the surface of the

inverter. No ice or frost should be present.

Installing the Inverter

Installing

the Inverter

17

Do not allow the ambient temperature to exceed the allowable range while operating the inverter.

3.2 Selecting and Preparing a Site for Installation

When selecting an installation location, consider the following requirements:

• The inverter must be installed on a wall that can support the inverter’s weight.

• The location must be free from vibration. Vibrations can adversely affect the operation of

the inverter.

• The inverter can become very hot during operation. Install the inverter on a surface that is

fire resistant or flame retardant with sufficient clearance around the inverter to allow for air

circulation. The illustrations below detail the required installation clearances.

Installing the Inverter

18

Install the inverter on a non-flammable surface, and do not place flammable material near the

inverter. Otherwise, a fire may result.

Note

Model types with capacities of 30 kW or more require a minimum of 8” clearance above and below

the unit.

Installing the Inverter

Installing

the Inverter

19

Note

In order to meet EMC standards, 200 V, 30–75 kW model types and model types with capacities of 90

kW or more should be installed inside a metal cabinet.

• Ensure that the cable conduits do not obstruct the air flow to and from the cooling fan.

• Ensure sufficient air circulation is provided around the inverter when it is installed. If the

inverter is to be installed inside a panel, enclosure, or cabinet rack, carefully consider the

position of the inverter’s cooling fan and vents. The cooling fan must be positioned to

efficiently dissipate the heat generated by the operation of the inverter.

Installing the Inverter

20

• If you are installing multiple inverters of different ratings, provide sufficient clearance to

meet the clearance specifications of the larger inverter. The iS7 inverters rated for up to 30

kW may be installed side by side.

Installing the Inverter

Installing

the Inverter

21

Inverter Capacity

W1

W2

H1

H2

H3

D1 A B

SV0008–0037 iS7 - 2/4

150

(5.90)

127

(5.00)

284

(11.18)

257

(10.11)

18

(0.70)

200

(7.87)

5

(0.19)

5

(0.19)

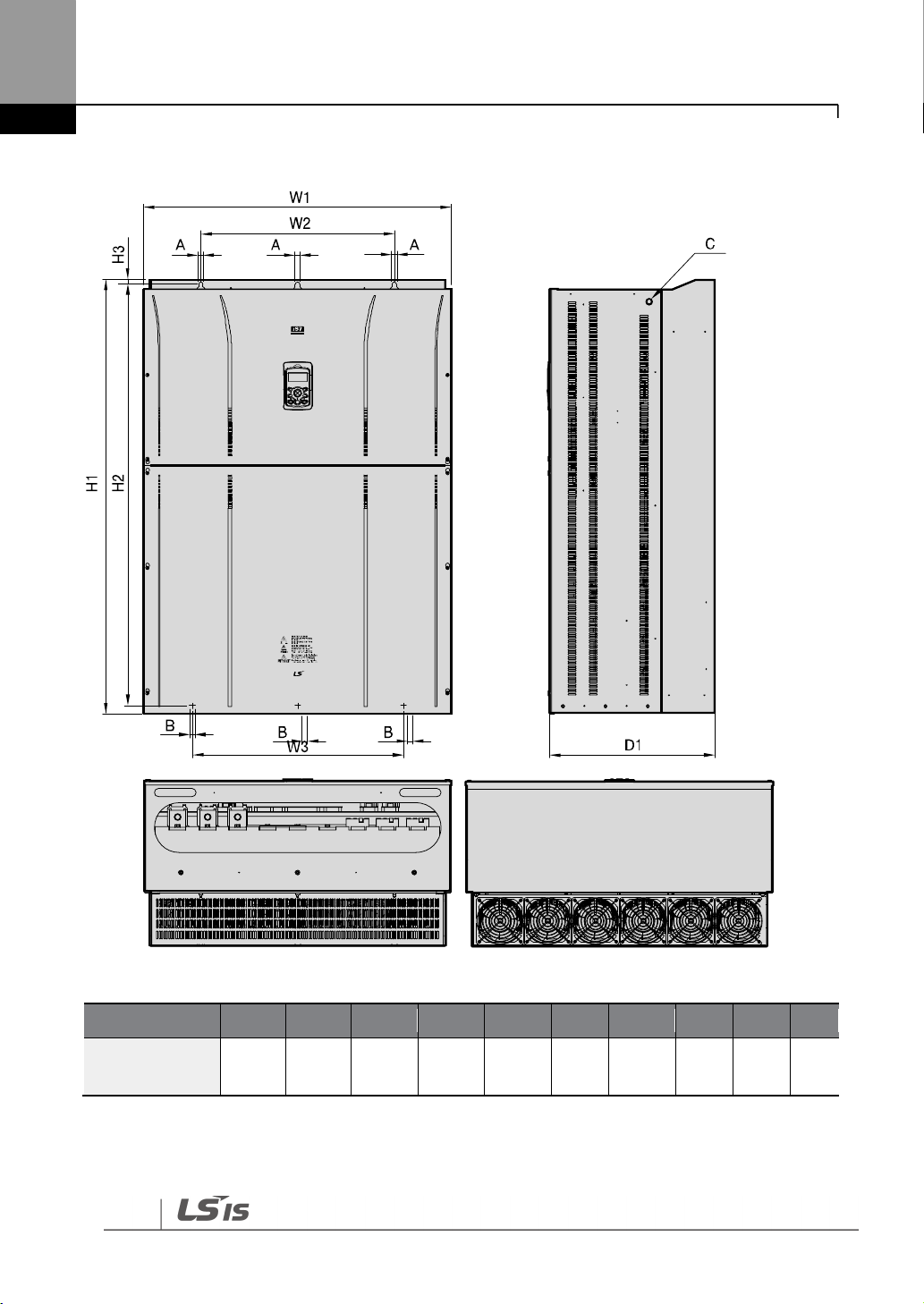

3.3 Exterior and Dimensions (UL Enclosed Type 1, IP21

Type)

SV0008-0037iS7 (200 V/400 V)

Units: mm (inch)

Installing the Inverter

22

Inverter Capacity

W1

W2

H1

H2

H3

D1 A B

SV0055–0075 iS7 - 2/4

200

(7.87)

176

(6.92)

355

(13.97)

327

(12.87)

19

(0.74)

225

(8.85)

5

(0.19)

5

(0.19)

SV0055-0075iS7 (200 V/400 V)

Units: mm (inch)

Installing the Inverter

Installing

the Inverter

23

Inverter Capacity

W1

W2

H1

H2

H3

D1 A B

SV0110–0150 iS7- 2/4

250

(9.84)

214.6

(8.44)

385

(15.15)

355

(13.97)

23.6

(0.92)

284

(11.18)

6.5

(0.25)

6.5

(0.25)

SV0110-0150iS7 (200 V/400 V)

Units: mm (inch)

Installing the Inverter

24

Inverter Capacity

W1

W2

H1

H2

H3

D1 A B

SV0185–0220iS7- 2/4

280

(11.02)

243.5

(9.58)

461.6

(18.17)

445

(17.51)

10.1

(0.39)

298

(11.73)

6.5

(0.25)

6.5

(0.25)

SV0185-0220iS7 (200 V/400 V)

Units: mm (inch)

Installing the Inverter

Installing

the Inverter

25

Inverter Capacity

W1

W2

W3

H1

H2

H3

D1 A B

C

SV0300 iS7-2

300

(11.81)

190

(7.48)

190

(7.48)

570

(22.44)

552

(21.73)

10

(0.39)

265.2

(10.44)

10

(0.39)

10

(0.39)

M8

SV0300-iS7 (200 V, IP00 Type)

Units: mm (inch)

Installing the Inverter

26

Inverter Capacity

W1

W2

W3

H1

H2

H3

D1 A B

C

SV0370–0450

iS7-2

370

(14.56)

270

(10.63)

270

(10.63)

630

(24.8)

609

(23.97)

11

(0.43)

281.2

(11.07)

10

(0.39)

10

(0.39)

M10

SV0370-0450iS7 (200 V, IP00 Type)

Units: mm (inch)

Installing the Inverter

Installing

the Inverter

27

Inverter Capacity

W1

W2

H1

H2

H3

D1

D2 A B

C

SV300–450

iS7-4

300.1

(11.81)

242.8

(9.55)

594.1

(23.38)

562

(22.12)

24.1

(0.94)

DCR type

10

(0.39)

10

(0.39)

M8

303.2

(11.93)

161

(6.33)

Non-DCR type

271.2

(10.67)

129

(5.78)

SV0300-0450iS7 (400 V)

Units: mm (inch)

Installing the Inverter

28

Inverter Capacity

W1

W2

W3

H1

H2

H3

D1 A B

C

SV0550–0750

iS7-2

465

(18.3)

381

(15.0)

381

(15.0)

750

(29.52)

723.5

(28.48)

15.5

(0.61)

355.6

(14.0)

11

(0.43)

11

(0.43)

M16

SV0550-0750iS7 (200 V, IP00 Type)

Units: mm (inch)

Installing the Inverter

Installing

the Inverter

29

Inverter

W1

W2

H1

H2

H3

D1

D2 A B

C

SV0550–0750

iS7-4

370.1

(14.57)

312.8

(12.31)

663.5

(26.12)

631.4

(24.85)

24.1

(0.94)

DCR type

10

(0.39)

10

(0.39)

M8

373.3

(14.69)

211.5

(8.32)

Non-DCR type

312.4

(12.29)

150.6

(5.92)

SV0550-0750iS7 (400 V)

Units: mm (inch)

Installing the Inverter

30

Inverter Capacity

W1

W2

W3

H1

H2

H3

D1 A B

C

SV0900–1100

iS7-4

510

(20.07)

381

(15.0)

350

(13.77)

783.5

(30.84)

759

(29.88)

15.5

(0.61)

422.6

(16.63)

11

(0.43)

11

(0.43)

M16

SV0900-1100iS7 (400 V, IP00 Type)

Units: mm (inch)

Installing the Inverter

Installing

the Inverter

31

Inverter Capacity

W1

W2

W3

H1

H2

H3

D1 A B

C

SV1320–1600

iS7-4

510

(20.07)

381

(15.0)

350

(13.77)

861

(33.89)

836.5

(32.93)

15.5

(0.61)

422.6

(16.63)

11

(0.43)

11

(0.43)

M16

SV1320-1600iS7 (400 V, IP00 Type)

Units: mm (inch)

Installing the Inverter

32

Inverter Capacity

W1

W2

W3

H1

H2

H3

D1 A B

C

SV1850/

2200iS7-4

690

(27.16)

581

(22.87)

528

(20.79)

1078

(42.44)

1043.5

(41.08)

25.5

(1.00)

450

(17.72)

14

(0.55)

15

(0.59)

M20

SV1850-2200iS7 (400 V, IP00 Type)

Units: mm (inch)

Installing the Inverter

Installing

the Inverter

33

Inverter Capacity

W1

W2

W3

H1

H2

H3

D1 A B

C

SV2800iS7-4

771

(30.35)

500

(19.69)

500

(19.69)

1138

(44.80)

1110

(43.70)

15

(0.59)

440

(17.32)

13

(0.51)

13

(0.51)

M16

SV2800iS7 (400 V, IP00 Type)

Units: mm (inch)

For 280 kW model types, I volts are supplied with the product.

Installing the Inverter

34

Inverter Capacity

W1

W2

W3

H1

H2

H3

D1 A B

C

SV3150/

3750iS7-4

922

(36.30)

580

(22.83)

580

(22.83)

1302.5

(51.28)

1271.5

(50.06)

15

(0.59)

495

(19.49)

14

(0.55)

14

(0.55)

M16

SV3150-3750iS7 (400 V, IP00 Type)

Units: mm (inch)

For 315-375 kW model types, I volts are supplied with the product.

Installing the Inverter

Installing

the Inverter

35

Inverter Capacity

W1

W2

H1

H2

H3

D1 A B

SV0008–0037 iS7-2/4

204.2

(8.03)

127

(5.0)

419

(16.49)

257

(10.11)

95.1

(3.74)

208

(8.18)

5

(0.19)

5

(0.19)

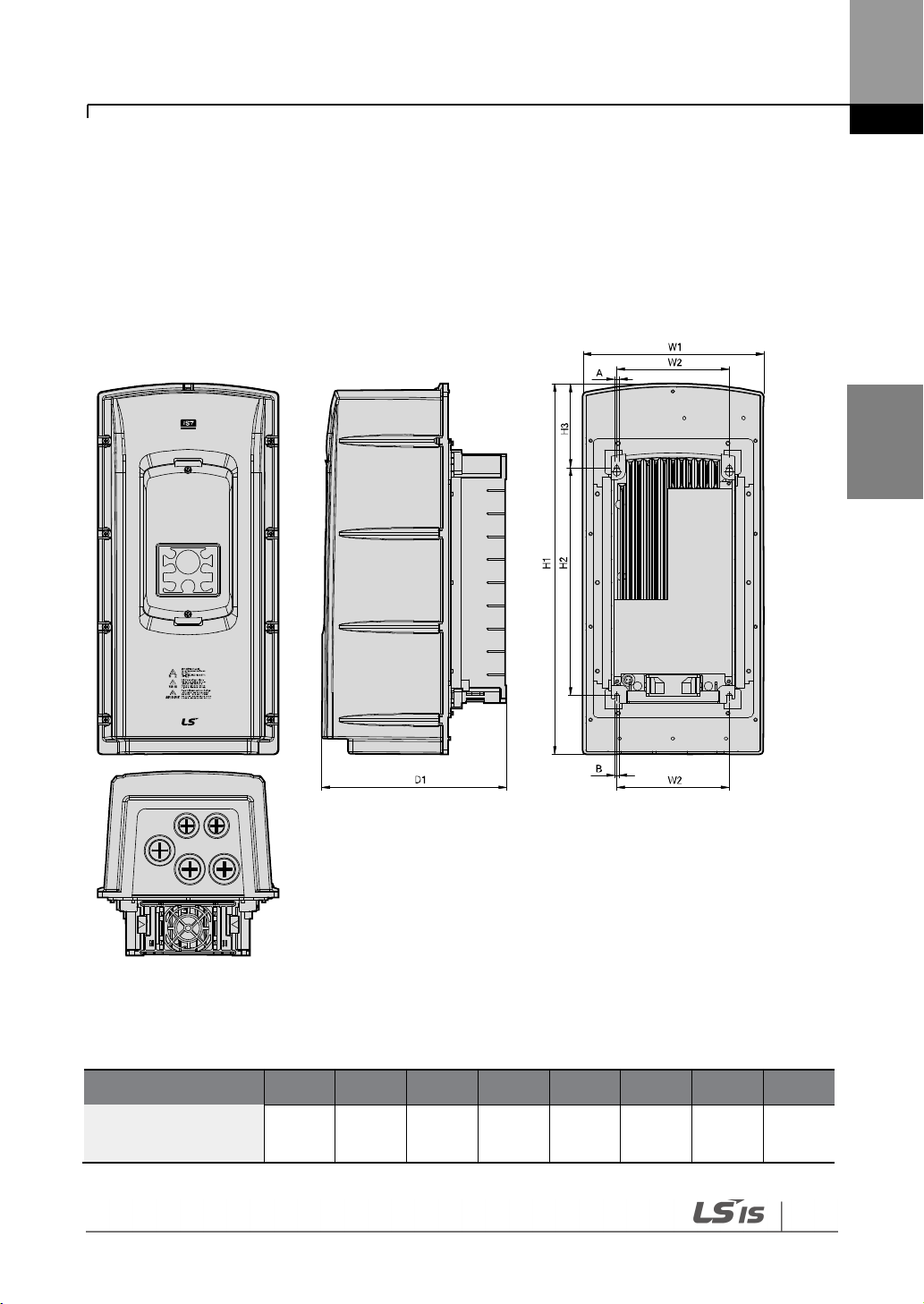

3.4 Exterior and Dimensions (UL Enclosed Type 12,

IP54 Type)

SV0008-0037iS7 (200 V/400 V)

Units: mm (inch)

Installing the Inverter

36

Inverter Capacity

W1

W2

H1

H2

H3

D1 A B

SV0055–0075 iS7-2/4

254

(10.0)

176

(6.92)

460.6

(18.13)

327

(12.87)

88.1

(3.46)

232.3

(9.14)

5

(0.19)

5

(0.19)

SV0055-0075iS7 (200 V/400 V)

Units: mm (inch)

Installing the Inverter

Installing

the Inverter

37

Inverter Capacity

W1

W2

H1

H2

H3

D1 A B

SV0110–0150 iS7-2/4

313.1

(12.32)

214.6

(8.44)

590.8

(23.25)

355

(13.97)

101.7

(4.0)

294.4

(11.59)

6.5

(0.25)

6.5

(0.25)

SV0110-0150iS7 (200 V/400 V)

Units: mm (inch)

Installing the Inverter

38

Inverter Capacity

W1

W2

H1

H2

H3

D1 A B

SV0185–0220 iS7-2/4

343.2

(13.51)

243.5

(9.58)

750.8

(29.55)

445

(17.51)

91.6

(3.60)

315.5

(12.42)

6.5

(0.25)

6.5

(0.25)

SV0185-0220iS7 (200 V/400 V)

Units: mm (inch)

Installing the Inverter

Installing

the Inverter

39

Inverter

Capacity

W[mm]

H[mm]

D[mm]

Weight[Kg]

w/ built-in

EMC and DCR

Weight[Kg]

w/ built-in

EMC

Weight[Kg]

w/ built-in

DCR

Weight[Kg]

non-DCR

types

SV0008iS7-2/4

150

284

200

5.5

4.5

5.0

4.5

SV0015iS7-2/4

150

284

200

5.5

4.5

5.0

4.5

SV0022iS7-2/4

150

284

200

5.5

4.5

5.0

4.5

SV0037iS7-2/4

150

284

200

5.5

4.5

5.0

4.5

SV0055iS7-2/4

200

355

225

10

8.4

9.3

7.7

SV0075iS7-2/4

200

355

225

10

8.4

9.3

7.7

SV0110iS7-2/4

250

385

284

20

17.2

16.8

14

SV0150iS7-2/4

250

385

284

20

17.2

16.8

14

SV0185iS7-2

280

461.6

298

30

27

25.9

22.9

SV0220iS7-2

280

461.6

298

30

25.8

25.9

22.9

SV0185iS7-4

280

461.6

298

27.4

23.5

23.3

19.7

SV0220iS7-4

280

461.6

298

27.4

23.5

23.5

20.1

SV0300iS7-2

300

570

265.2

- - -

29.5

SV0370iS7-2

370

630

281.2

- - -

44

SV0450iS7-2

370

630

281.2

- - -

44

SV0550iS7-2

465

750

355.6

- - -

72.5

SV0750iS7-2

465

750

355.6

- - -

72.5

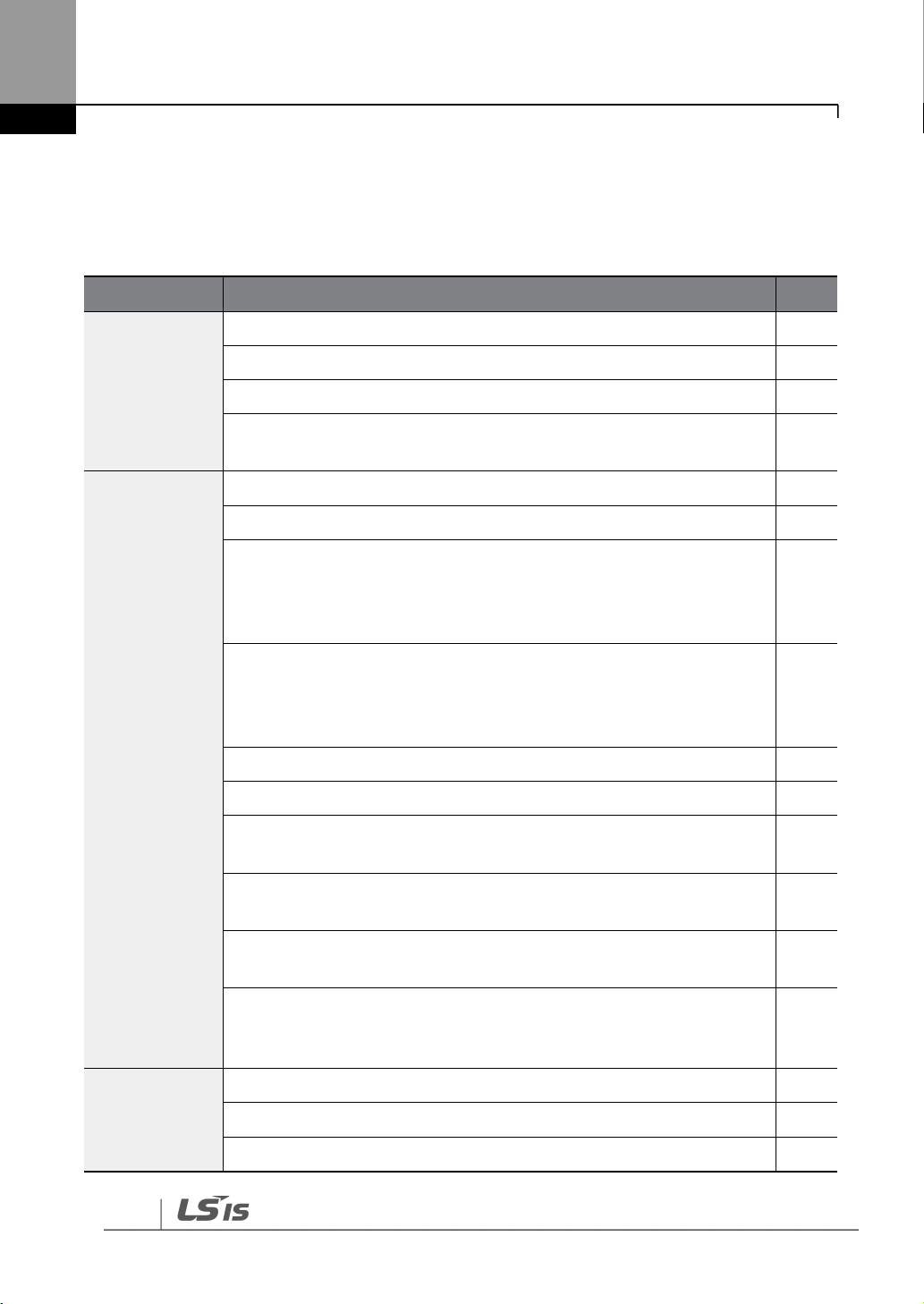

Note

• The weight specified in the table indicates the total weight of the product without packaging,

which includes the built-in parts, such as the EMC filter and DCR.

• The built-in EMC filter and DCR are not available for 30–75 kW (200 V) products.

3.5 Frame Dimensions and Weight (UL Enclosed Type

1, IP 21 Type)

Installing the Inverter

40

Inverter

Capacity

W[mm]

H[mm]

D[mm]

Weight[Kg]

w/ built-in

EMC and DCR

Weight[Kg]

w/ built-in

EMC

Weight[Kg]

w/ built-in

DCR

Weight[Kg]

non-DCR

types

SV0300iS7-4

300

594

300.4

- - 41

28

SV0370iS7-4

300

594

300.4

- - 41

28

SV0450iS7-4

300

594

300.4

- - 41

28

SV0550iS7-4

370

663.4

371 - -

63

45

SV0750iS7-4

370

663.4

371 - -

63

45

SV0900iS7-4

510

784

423 - -

101 - SV1100iS7-4

510

784

423 - -

101 - SV1320iS7-4

510

861

423 - -

114 - SV1600iS7-4

510

861

423 - -

114 - SV1850iS7-4

690

1078

450 - -

200 - SV2200iS7-4

690

1078

450 - -

200 - SV2800iS7-4

771

1138

440 - - - 252

SV3150iS7-4

922

1302.5

495 - - - 352

SV3750iS7-4

922

1302.5

495 - - - 352

Note

• The weight specified in the table indicates the total weight of the product without packaging,

which includes built-in parts, such as the EMC filter and DCR.

• 300-220 kW (400 V) products have built-in DCR only.

• 280-375 kW (400 V) products are provided without a built-in EMC filter and DCR.

Installing the Inverter

Installing

the Inverter

41

Inverter

Capacity

W[mm]

H[mm]

D[mm]

Weight[Kg]

w/ built-in

EMC and DCR

Weight[Kg]

w/ built-in

EMC

Weight[Kg]

w/ built-in

DCR

Weight[Kg]

non-DCR

types

SV0008iS7-2/4

204

419

208

8.2

7.2

7.7

6.7

SV0015iS7-2/4

204

419

208

8.2

7.2

7.7

6.7

SV0022iS7-2/4

204

419

208

8.2

7.2

7.7

6.7

SV0037iS7-2/4

204

419

208

8.2

7.2

7.7

6.7

SV0055iS7-2/4

254

461

232

12.8

10.2

12.1

9.5

SV0075iS7-2/4

254

461

232

12.9

10.3

12.2

9.6

SV0110iS7-2/4

313

591

294

25.6

22.8

22.4

19.6

SV0150iS7-2/4

313

591

294

25.9

23.1

22.7

19.9

SV0185iS7-2

343

751

316

38.3

34.2

34.1

29.9

SV0220iS7-2

34

751

316

38.3

34.2

34.1

29.9

SV0185iS7-4

343

751

316

34.9

31

31

27.1

SV0220iS7-4

343

751

316

34.9

31

31

27.1

Note

• The weight specified in the table indicates the total weight of the product without packaging,

which includes the built-in parts, such as the EMC filter and DCR.

• Only 0.75-22 kW products are available in IP 54 Type specifications.

3.6 Frame Dimensions and Weight (UL Enclosed Type

12, IP54 Type)

Installing the Inverter

42

3.7 Installation Procedures for UL Enclosed Type12

and IP54 Type Products

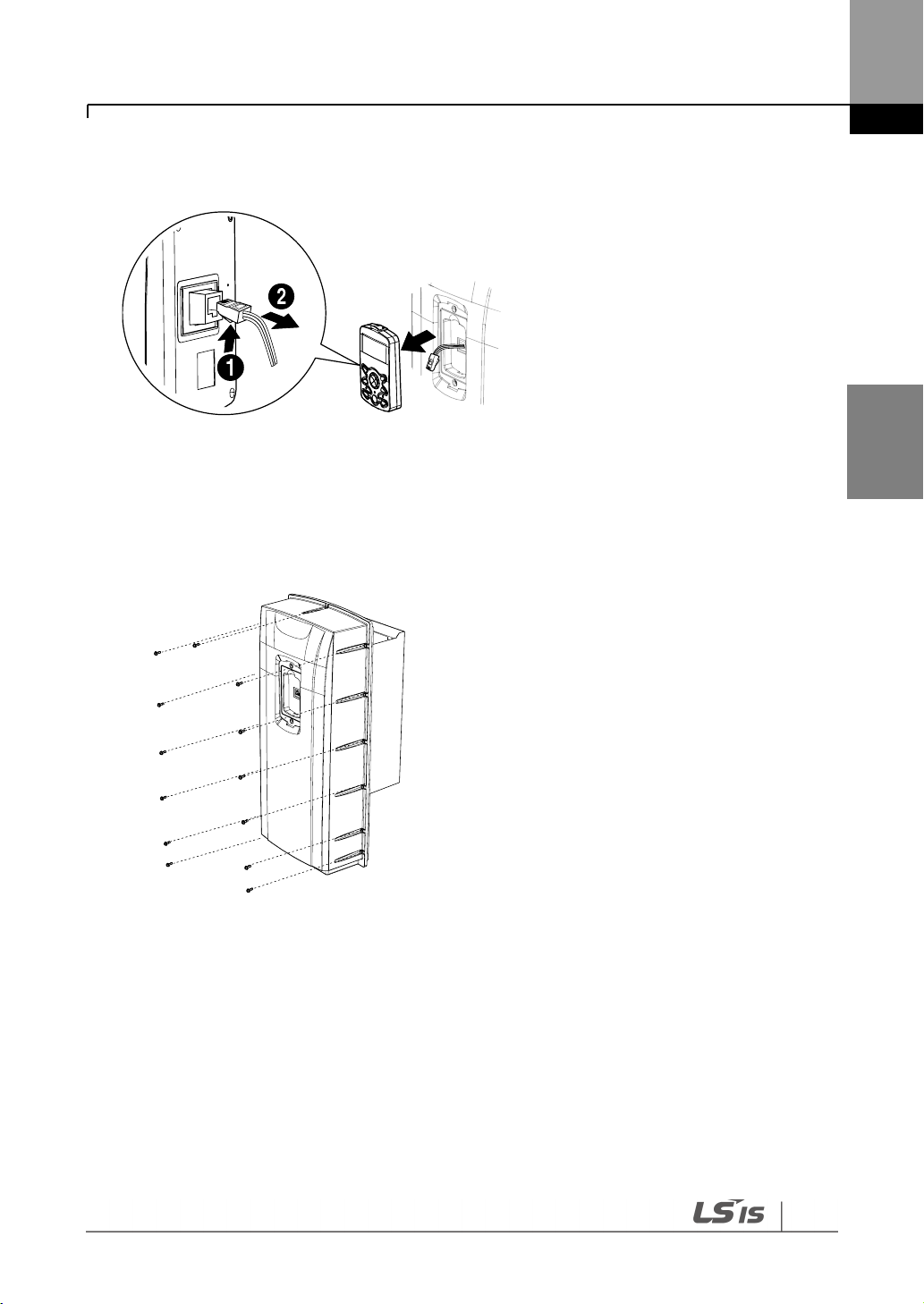

3.7.1 Disassembling the Keypad Cover and Keypad

1 Loosen the screws that secure the keypad cover and remove the keypad cover.

2 Depress the tab at the top of the keypad and gently lift the keypad from the inverter to

remove it. Be careful not to damage the keypad cable.

Installing the Inverter

Installing

the Inverter

43

3 Depress the tab on the keypad cable connector and disconnect the cable from the back of

the keypad.

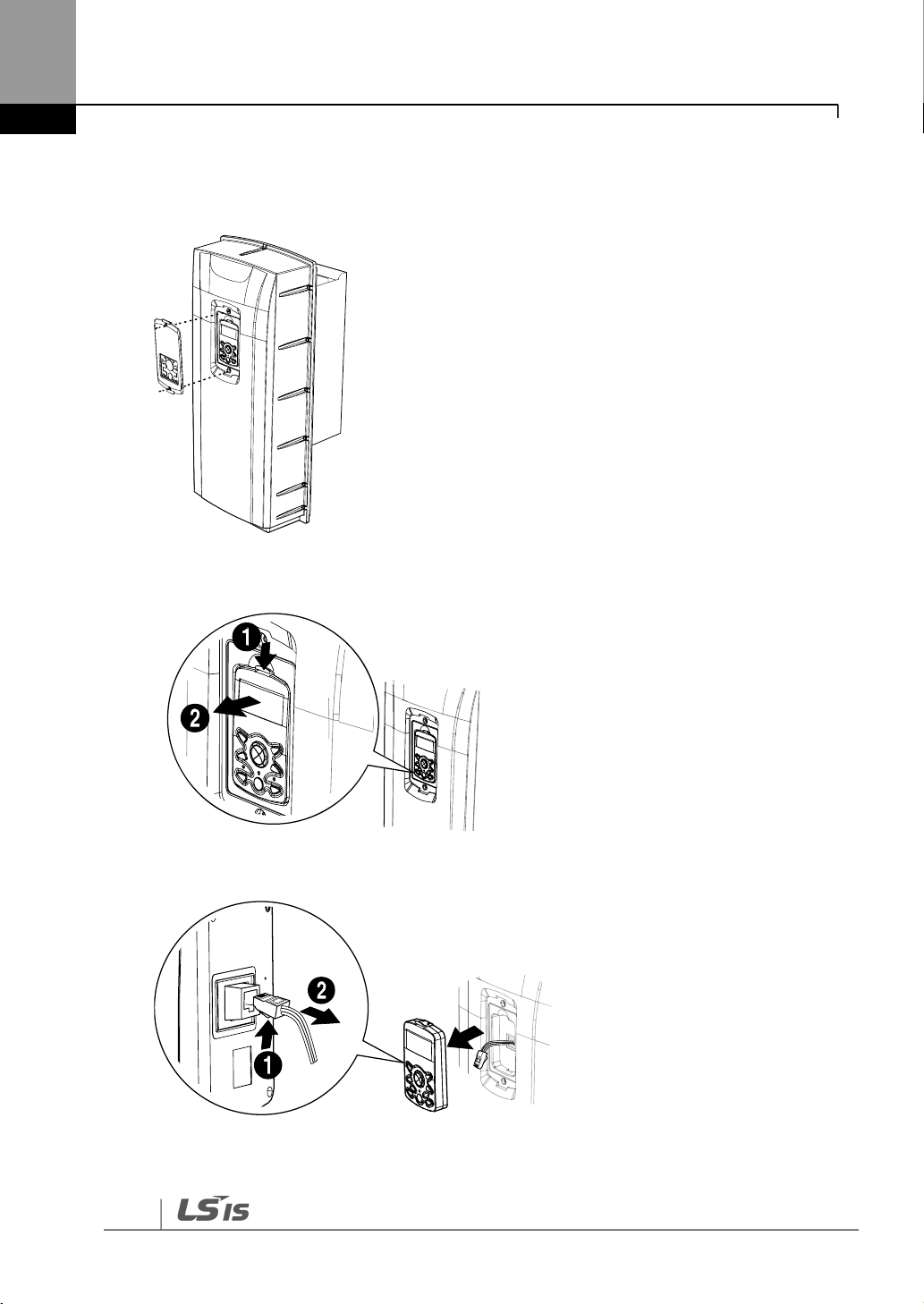

3.7.2 Disassembling the IP54 Front Cover

1 Loosen the screws that secure the front cover to the chassis. There are 9–13 screws on the

cover depending on the model type.

Installing the Inverter

44

2 Remove the cover by lifting it upwards from the bottom.

3.7.3 Mounting the Inverter

1 Remove the 4 rubber feet from the corners.

Installing the Inverter

Installing

the Inverter

45

2 Place the inverter on a flat wall or in a cabinet, and use 4 screws or bolts to securely fix the

inverter to the surface.

3.7.4 Connecting the Power Cables

Connect the power cables to the input (R, S, T) and output (U, V, W) terminals. Then, tighten the

terminal screws.

Refer to 4 Connecting the Cables on page 48 for detailed information.

Installing the Inverter

46

3.7.5 Reassembling the IP54 Front Cover and the Keypad

1 Place the front cover on the chassis and align the screw holes on each side.

2 Insert and tighten the screws. There are 9–13 screws on the cover depending on the model

type.

Installing the Inverter

Installing

the Inverter

47

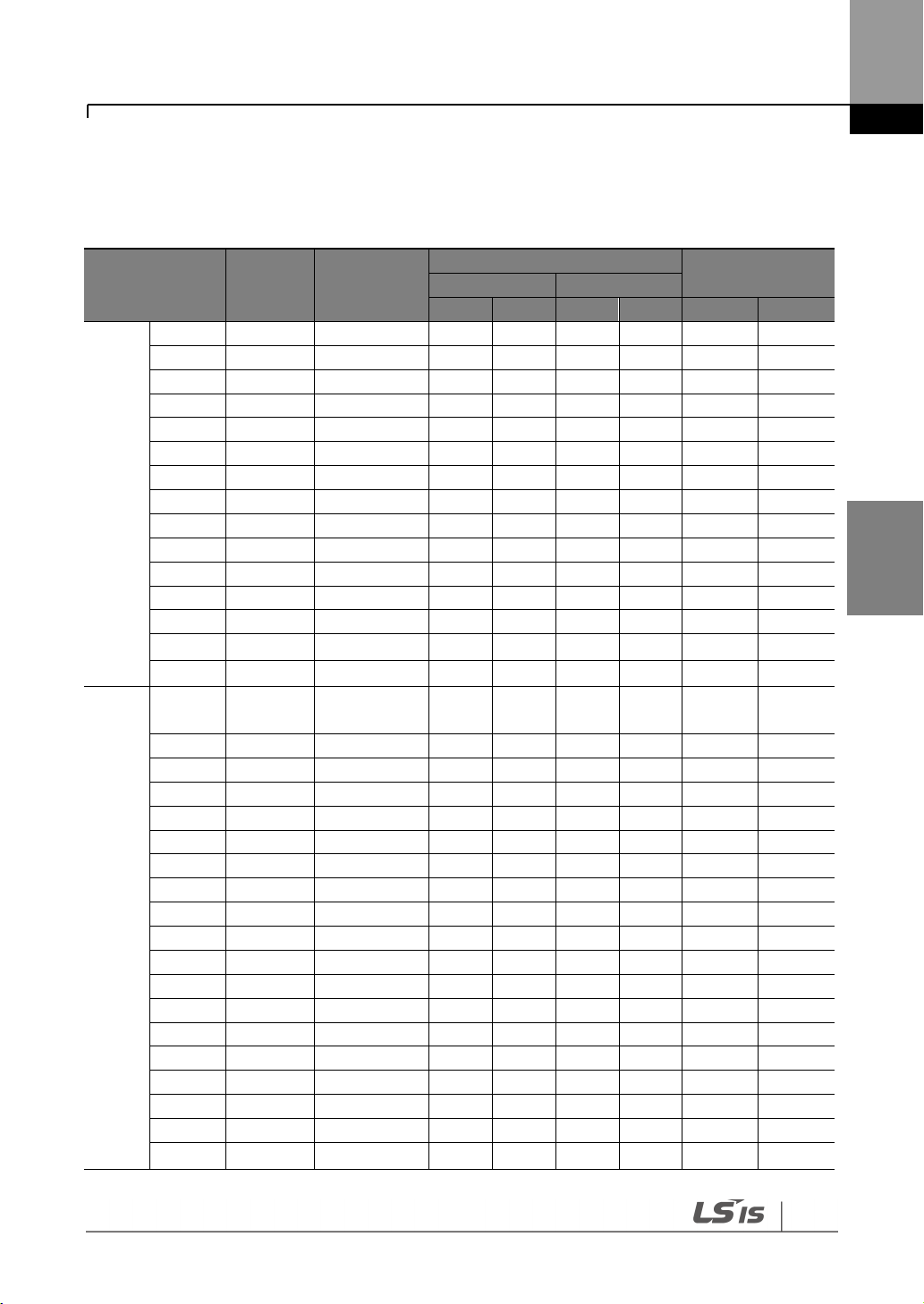

3 Connect the signal cable to the keypad, align the lower part of the keypad to the bottom of

the keypad receptacle, and then push the top part of the keypad into the chassis until the

keypad snaps into place.

4 Place the keypad cover on top of the keypad, and secure it using 2 screws.

Connecting the Cables

48

ESD (Electrostatic discharge) from the human body may damage sensitive electronic components on

the PCB. Therefore, be extremely careful not to touch the PCB or the components on the PCB with

bare hands while you work on the I/O PCB.

To prevent damage to the PCB from ESD, touch a metal object with your hands to discharge any

electricity before working on the PCB, or wear an anti-static wrist strap and ground it on a metal

object.

Wait at least 10 minutes before opening the covers and exposing the terminal connections. Before

working on the inverter, test the connections to ensure the DC voltage has been fully discharged.

Personal injury or death by electric shock may result if the DC voltage has not been discharged.

4 Connecting the Cables

Connect cables to the power and signal terminal blocks of the inverter.

4.1 Removing the Front Cover for Cable Connection

4.1.1 IP 21 Type Products

1 Depress the tab at the top of the keypad and gently lift the keypad from the inverter to

remove it. Be careful not to damage the keypad cable.

Connecting the Cables

Connecting

the Cables

49

2 Depress the tab on the keypad cable connector and disconnect the cable from the back of

the keypad.

3 Loosen the screw from the bottom part of the front cover, and then remove the front cover.

Connecting the Cables

50

4.1.2 IP 54 Type Products

1 Loosen the two screws securing the keypad cover, and then remove the keypad cover.

2 Depress the tab at the top of the keypad and gently lift the keypad from the inverter to

remove it. Be careful not to damage the keypad cable.

3 Depress the tab on the keypad cable connector and disconnect the cable from the back of

the keypad.

Connecting the Cables

Connecting

the Cables

51

4 Remove the screws from each side of the front cover, and then remove the front cover.

4.1.3 90–375 kW, 400 V and 30–75 kW, 200 V Products

1 Loosen the two screws on the front cover.

2 Slide the cover downwards and remove it from the inverter.

Connecting the Cables

52

Do not activate the EMC filter if the inverter uses a power source with an asymmetrical grounding

structure, for example a grounded delta connection. Personal injury or death by electric shock may

result if the power source is not grounded properly.

4.2 Activating and Deactivating the Built-in EMC

Filter

Some iS-7 inverter models have built-in EMC filters to reduce conductive and radiational noise

at the inverter input. Refer to 1.1.1 Identifying the Product on page 1 and check your inverter’s

model type and specifications to see if it has a built-in EMC filter.

If your inverter has a built-in EMC filter, refer to the following instructions to activate or

deactivate it.

4.2.1 Up to 7.5 kW Inverters

1 Locate the plastic knockout cap that covers the EMC filter switch (jumper SW1).

2 Remove the knockout cap and locate the jumper switch. The EMC filter will be deactivated

if the two jumper pins are not connected.

Connecting the Cables

Connecting

the Cables

53

3 Connect the two jumper pins using a short circuit connector to activate the EMC filter.

4 To remove the short circuit connector and deactivate the EMC filter, pull the connector

while pressing the latch on the side of the connector. Use pliers or tweezers if you cannot

reach the latch with your fingers.

Connecting the Cables

54

4.2.2 11–22 kW Inverters

1 Locate the EMC filter cable and the ground terminal at the bottom of the inverter.

The EMC filter is deactivated if the EMC filter cable is connected to the insulated stud.

2 Remove the EMC filter cable from the insulated stud and connect it to the ground terminal

An EMC filter prevents electromagnetic interference by reducing radio emissions from the

inverter. Using an EMC filter is not always recommended, as it increases current leakage. If an

inverter uses a power source with an asymmetrical grounding connection, the EMC filter must

be turned off.

Before using the inverter, confirm the power supply’s grounding system. Disable the EMC filter

if the power source has an asymmetrical grounding connection.

<EMC filter is turned OFF>

(metal) to activate the EMC filter.

<EMC filter is turned ON>

Connecting the Cables

Connecting

the Cables

55

Asymmetrical Grounding Connection

One phase of

a delta

connection is

grounded

Intermediate

grounding

point on one

phase of a

delta

connection

The end of a

single phase is

grounded

A 3-phase

connection

without

grounding

Connecting the Cables

56

• Do not connect power to the inverter until installation has been fully completed and the inverter

is ready to be operated. Doing so may result in electric shock.

• Wiring and inspection of wiring must be performed by an authorized engineer.

• Install the inverter before connecting the cables.

• Ensure that no metal debris, such as wire clippings, remain inside the inverter. Metal debris in

the inverter can cause inverter failure.

• Power supply cables must be connected to the R, S, and T terminals. Connecting power cables

to other terminals will damage the inverter.

• Use insulated ring lugs when connecting cables to R/S/T and U/V/W terminals.

• The inverter’s power terminal connections can cause harmonics that may interfere with other

communication devices located near the inverter. To reduce interference, the installation of

noise filters or line filters may be required.

• To avoid circuit interruption or damaging connected equipment, do not install phase-advanced

condensers, surge protection, or electronic noise filters on the output side of the inverter.

• To avoid circuit interruption or damaging connected equipment, do not install magnetic

contactors on the output side of the inverter.

• Make sure that the total cable length does not exceed 495 ft (150 m). For inverters < = 3.7 kW

capacity, ensure that the total cable length does not exceed 165 ft (50 m). Long cable runs can

cause reduced motor torque in low frequency applications due to voltage drop. Long cable runs

also increase a circuit’s susceptibility to stray capacitance and may trigger over-current

protection devices or result in the malfunction of equipment connected to the inverter.

• Route the signal cables away from the power cables. Otherwise, signal errors may occur due to

electric interference.

• Tighten terminal screws to their specified torques. Loose terminal block screws may allow the

cables to disconnect and cause a short circuit or inverter failure. Refer to 4.7 Specifications of the

Power Terminal Block and Exterior Fuse on page 6565 for torque specifications.

• Do not place heavy objects on top of electric cables. Heavy objects may damage the cable and

result in electric shock.

• Use cables with the largest cross-sectional area, appropriate for power terminal wiring, to

ensure that voltage drops do not exceed 2%.

• Use copper cables rated at 600 V, 75℃ for power terminal wiring.

• Use copper cables rated at 300 V, 75℃ for control terminal wiring.

• If you need to rewire the terminals due to wiring-related faults, ensure that the inverter keypad

display is turned off and the charge lamp under the terminal cover is off before working on

wiring connections. The inverter may hold a high-voltage electric charge long after the power

supply has been turned off.

4.3 Precautions for Wiring the Inverter

Connecting the Cables

Connecting

the Cables

57

Install ground connections for the inverter and the motor by following the correct specifications to

ensure safe and accurate operation. Using the inverter and the motor without the specified

grounding connections may result in electric shock.

• Do not use the ground terminal as the signal (control) ground.

• Do not share the ground connection with other machines that consume a large amount of

power, such as a welding machine.

• Connect the ground cable to the nearest earth contact and keep the cable length as short as

possible.

Note

• 200 V products require Class 3 grounding. Resistance to ground must be ≤ 100 Ω.

• 400 V products require Special Class 3 grounding. Resistance to ground must be ≤ 10 Ω.

Inverter Capacity

Grounding wire size ( mm²)

200 V class

400 V class

0.75–3.7kW 4 2.5

5.5–7.5 kW 6 4

11–15 kW

16

10

18.5–22 kW

25

16

30–45 kW

25

16

55–75 kW

35

35

90–110 kW - 60

132–220 kW - 100

280–315 kW - 185

375 kW

-

240

4.4 Ground Connection

Because the inverter is a high-frequency switching device, leakage current may occur during

operation. To avoid the danger of electrocution due to current leakage, the inverter must be

properly grounded. Ground connection must be made to the specified ground terminal on the

inverter. Do not connect ground cables to chassis screws.

The following table lists the minimum ground cable specifications that must be met to properly

ground the inverters.

Connecting the Cables

58

R (L1)

S (L2)

T (L3)

3-phase AC input

P (+)

B

N (-) U V

W

Dynamic brake

resistor

To motor

R (L1)

S (L2)

T (L3)

P (+)

B

N (-) U V

W

R (L1)

S (L2)

T (L3)

P1 (+)

P2 (+)

N (-) U V

W

R (L1)

S (L2)

T (L3)

P2 (+)

N (-) U V

W

4.5 Terminal Wiring Diagram

4.5.1 Up to 7.5 kW Inverters

4.5.2 11–22 kW Inverters

4.5.3 30–75 kW Inverters

4.5.4 90–160 kW Inverters

Connecting the Cables

Connecting

the Cables

59

R (L1)

S (L2)

T (L3)

P2 (+)

N (-) U V

W

R (L1)

S (L2)

T (L3)

P1 (+)

P2 (+)

N (-) U V

W

Note

• Inverters with a rated capacity of 11 kW or more are equipped with linearly arranged terminal

blocks.

• 0.75–22 kW inverters have built-in DC reactors. The installation of an external DC reactor is not

necessary for these inverters.

• The inverter must be properly grounded using the ground terminal.

Note

If the forward command (Fx) is turned on, the motor should rotate counterclockwise when viewed

from the load side of the motor. If the motor rotates in the reverse direction, switch the cables at the

U and V terminals.

Remarque

Si la commande avant (Fx) est activée, le moteur doit tourner dans le sens anti-horaire si on le

regarde côté charge du moteur. Si le moteur tourne dans le sens inverse, inverser les câbles aux

bornes U et V.

4.5.5 185–220 kW Inverters

4.5.6 280–375 kW Inverters

Connecting the Cables

60

Power supply cables must be connected to the R, S, and T terminals. Connecting power cables to

other terminals will damage the inverter.

Note

The motor will rotate in the opposite direction if the U, V, and W terminals are connected in a wrong

phase order.

Terminal Symbol

Terminal Name