This User's Manual is aimed at……

This User's Manual is aimed at……

Option Module Guide

Describing specification, installation, operation, function, and

maintenance of SV-iS7 series inverter provided for the users

who are familiar with and having basic experience in the inverter.

Be sure to understand function, performance, installation, and

operation of the product by reading through this User's Manual

completely prior to your use of SV-iS7 series inverter that you

have purchased. In addition, you are required to have this User's Manual properly delivered to the end-user and maintenance manager.

The following Option Module Guides will be provided when you

purchase the applicable Option Module. In addition, if you access

our homepage http://www.lsis.biz/ [Support & Service] - [Download Center], you can download it in PDF file.

IS7 PLC Card Option Module Guide

IS7 Encoder Card Option Module Guide

IS7 Profibus-DP Card Option Module Guide

IS7 Modbus-TCP Card Option Module Guide

IS7 LonWorks Card Option Module Guide

IS7 DeviceNet Card Option Module Guide

IS7 I/O Extension Card Option Module Guide

IS7 Built-in RS-485 & Modbus-RTU Option Module Guide

IS7 CANopen Card Option Module Guide

IS7 Ethernet Card Option Module Guide

IS7 CC-Link Card Option Module Guide

Safety Instructions

Remark

WARNING

T o prevent injury and property damage, follow these instructions.

Incorrect operation due to ignoring instructions will cause harm or

damage.

The seriousness of which is indicated by the following symbols.

Symbol Meaning

Even if the instructions are indicated as ‘Caution’, it can cause a serious

result according to the kind of operation and the environment.

The meaning of each symbol in this manual and on your equipment

is as follows.

Symbol Meaning

After reading this manual, keep it in the place that the user always

can contact easily.

This manual should be given to the person who actually uses the

products and is responsible for their maintenance.

Do not remove the cover while power is applied or the unit is in

operation.

Otherwise, electric shock could occur.

Do not run the inverter with the front cover removed.

Otherwise, you may get an electric shock due to high voltage terminals or

charged capacitor exposure.

This symbol indicates the possibility of death or

Warning

serious injury.

This symbol indicates the possibility of injury or

Caution

damage to property.

This is the safety alert symbol.

Read and follow instructions carefully to avoid

dangerous situation.

This symbol alerts the user to the presence of

“dangerous voltage” inside the product that might

cause harm or electric shock.

Safety Instructions

i

Safety Instructions

WARNING

CAUTION

Do not remove the cover except for periodic inspections or wiring,

even if the input power is not applied.

Otherwise, you may access the charged circuits and get an electric shock.

Wiring and periodic inspections should be performed at least 10

minutes after disconnecting the input power and after checking the

DC link voltage is discharged with a meter (below DC 30V).

Otherwise, you may get an electric shock.

Operate the switches with dry hands.

Otherwise, you may get an electric shock.

Do not use the cable when its insulating tube is damaged.

Otherwise, you may get an electric shock.

Do not subject the cables to scratches, excessive stress, heavy

loads or pinching.

Otherwise, you may get an electric shock.

Install the inverter on a non-flammable surface. Do not place

flammable material nearby.

Otherwise, fire could occur.

Disconnect immediately the input power if the inverter gets

damaged.

Otherwise, it could result in a secondary accident and fire.

After the input power is applied or removed, the inverter will remain

hot for a couple of minutes.

Otherwise, you may get bodily injuries such as skin-burn or damage.

Do not apply power to a damaged inverter or to an inverter with parts

missing even if the installation is complete.

Otherwise, electric shock could occur.

Do not allow lint, paper, wood chips, dust, met allic chips or other

foreign matter into the drive.

Otherwise, fire or accident could occur.

ii

Safety Instructions

Caution for Use

Transportation and Installation

Be sure to carry inverter in a proper way suitable for its weight, or it may

result in damage to inverter.

Be sure to use heat-treated wooden crate when you adopt wooden

packaging for the product.

Do not pile up inverters above allowable limit.

Be sure to install the inverter as directed in this instruction manual.

Do not turn off the power supply to the damaged inverter.

Do not open the front cover while carrying the inverter.

Do not place the heavy material on the inverter.

The direction of installation should be observed properly as criterions

specified in this manual show.

Make sure that you should not put screw, metal material, water, oil and the

inflammable something else.

Keep in mind that inverter is very vulnerable to drop from the mid air and

strong shock.

Don't let the inverter exposed to rain, snow, fog, dust, etc.

Do not cover, nor block, the ventilating system having cooling fan. It may

cause the inverter overheated.

Be sure to check the power is off when installing the inverter.

To prevent the risk of fire or electric shock, keep the connected wire in a

sound condition. Use the wire that meets the standard in a recommended

length.

Be sure to ground the inverter. (Under 10 ȳ to 200V class, Under 100Gȳ to

400V class)

iii

Safety Instructions

Wiring

Warning

Be certain to use the inverter under the following conditions.

Environment Description

Ambient

Temperature

Ambient Humidity Below 90% RH (Dewdrop should not be formed)

Storage

Temperature

Ambient

Condition

Altitude/Vibration Below 1000m above sea level, Below 5.9m/sec² (=0.6g)

Ambient Air

Pressure

- 10 ~ 40 ϸ (Non-frozen)

(Less than 80% load is recommended at 50ϸ.)

-20 ~ 65ϸ

Free of corrosive gas, inflammable gas, oil sludge and

dust, etc

70 ~ 106 kPa

Caution

A professional installer should have done the wiring and checking.

Do wiring after installing the inverter body.

Do not connect phase-leading capacitors, surge filter, radio noise filter to the

output of inverter.

Output terminals (terminals named U, V, W respectively) should be

connected in a proper phase sequence.

Make sure that there is not any short circuit terminal, wrong wiring. It may

cause spurious operation or failure.

Refrain from using a cable other than the cable shielded when you connect

control circuit wiring.

Adopt the shielded wire only when wiring the control circuit. It may cause the

failure of inverter in its operation. Use the twisted pair shield wire for the

ground terminal of the inverter.

To prevent an electric shock, be sure to check if MCCB and MC are

switched OFF before wiring

Otherwise, it may cause an electric shock.

iv

Safety Instructions

Adjustment before starting trial operation

How to Use

Do not supply the excessive range of voltage displayed in the user manual to

the each terminal. It may cause damage to the inverter.

Current hunting can be occurred in the low speed territory during testing. It

occurs where the capacity is above 110kW with no-load and the axis is not

connected.

The current hunting has a gap according to the motor characteristic. It will be

disappeared when the load is connected and it is not the indication of

abnormal condition.

If the hunting is occurred seriously, please stop the testing and operates with

the load.

Be sure to check relevant parameters for the application before starting trial

operation.

Be sure not to approach the machine when retry function is selected. The

machine may start working suddenly.

Stop key on the keypad should be set to be in use. For safety, additional

emergency stop circuit should be required.

Inverter restarts if alarm condition is cleared while FX/RX signal is on.

Therefore, be sure to operate the alarm reset switch after checking if FX / RX

signal is off.

Never modify the inverter for inappropriate use.

When a magnetic contactor is installed on the power source, do not

frequently start or stop using this magnetic contactor. It may cause the failure

of inverter.

Noise filter should be used for the minimization of troubles by electro-

magnetic noise. Electronic equipments close to the inverter should be

protected against the damage caused by troubles.

Be sure to install the AC reactor at the input of inverter in case of input

voltage unbalance. Otherwise, generator or phase-leading capacitors may

be destroyed by the harmonic current from inverter.

If 400V class motor is used with the inverter, insulation-enforced motor

should be used or countermeasures against the suppression of micro-surge

voltage generated by the inverter should be carried out.

Otherwise, micro-surge voltage is generated across input terminal for the

motor and this voltage lowers allowable insulation break-down voltage and

then, may cause the destruction of the motor.

v

Safety Instructions

Countermeasure against malfunction troubles

Maintenance, inspection and parts replacement

Disposal

Be sure to set the parameters once more, in case of initialization of

parameters, all values of parameters is set to values of factory setting.

High speed operation can be set easily, therefore be sure to check the

performance of motor or machine before changing parameter value.

DC braking function cannot produce a zero-servo torque. If required,

additional equipment should be installed.

When inverter trip or emergency stop (BX) occurs without keypad connected,

LED on the control board will blink by the interval of 0.5 sec. But LED will

blink by 1 sec when keypad is connected. This function displays which trip

will be occurred according to the connection of keypad.

Do not change wiring, nor disconnect connector or option card during the

operation of inverter.

Do not disconnect the motor wiring while the voltage of inverter is output.

Mishandling may cause damage to the inverter.

Be sure to handle the inverter and option care in the order recommended in

the Electro Static Discharge (ESD) Countermeasure. Mishandling may lead

to damage to the circuit on the PCB caused by ESD.

If inverter is damaged and then gets into uncontrollable situation, the

machine may lead to the dangerous situation, therefore to avoid this situation,

be sure to install the additional equipments such as brake.

Do not perform the megger (insulation resistance check) test on the control

board.

Please refer to intervals for parts replacement on Chapter 8.

Handle the inverter as an industrial waste when disposing of it.

Our inverter contains the raw material of value that can be recycled from the

aspect of energy and resource preservation. All the package materials and

metal parts are recyclable. Plastics are also recyclable, but may be burnt

under the controllable environment depending on the local regulation.

vi

Safety Instructions

General Instruction

Cleaning

Storage

Caution

The drawing in this user manual is represented the details of the inner

inverter, so, the drawing is described without cover part and circuit breaker .

But, cover and circuit breaker should be mounted before the operation

following to the instruction of user manual.

Turn off the power of inverter when the inverter is not used.

Be sure to operate the inverter under a clean condition.

When cleaning the inverter, be sure to check the inverter is off. St art cleaning

it with all the plugs connected with the inverter socket removed.

Never clean the inverter using wet cloth or water. Wipe the stained area softly

using the cloth completely wet with a neutral detergent or ethanol.

Never use the solution such as acetone, benzene, toluene, alcohol, etc.

They may cause the coating on the surface of the inverter to peel off. In

addition, do not clean LCD display, etc. using detergent or alcohol.

Be sure to keep the inverter under the following conditions if you

don't use it for a long period of time.

Make sure that you satisfy the recommended storage environment. (See

page v.)

If the storage period exceeds 3 months, be sure to keep it at the ambient

temperature of -10 ~ +30ȋC to preventϩDeterioration by TemperatureϪof

electrolytic condenser.

Be sure to keep it in a proper package to prevent moisture, etc. Put the

desiccant (Silica Gel), etc., in the package so that the relative humidity in the

package can be maintained at 70% or less.

When it is exposed to moisture or dust (mounted on theϩSystemϪ or

ϩControl PanelϪ, etc. installed at the construction site), remove it and then

keep it under the environmental condition specified in the page v.

If the inverter has been left long with electric current not charged, the

nature of electrolytic condenser can be deteriorated. So be sure to

have it plugged in for 30 ~ 60 minutes once a year. Do not perform

wiring and operation of the output side (secondary side).

vii

Safety Instructions

Introduction to the Manual

z This manual describes the specifications, installation, operation,

functions and maintenance of SV-iS7 series inverter and is for the

users who have basic experience of using an inverter.

z It is recommended you read carefully this manual in order to use

SV-iS7 series inverter properly and safely.

z The manual consists as follows.

Chapter Title Contents

Describes the precautions and basic items

1 Basics

which should be learned before using the

Inverter.

2 Specifications

3 Installation

4 Wiring

How to Use

5

Keypad

The control specifications, ratings and

types of the input and output.

Information on the use environment and

installation method.

Wiring information for the power supply and

signal terminals.

Descriptions on the display and operation

keys on the main body of the Inverter.

Descriptions on the basic functions

6 Basic Functions

including frequency setting and operation

command.

Checking and

7

Troubleshooting

Table of

8

Functions

Descriptions on the failures and anomalies

which may occur during operation.

Brief summarize of functions.

viii

Contents

Chapter 1 Basics

1.1 What Y ou Should Know before Use - - - - - - - - - - - - - - - 1-1

1.1.1 Check of product - - - - - - - - - - - - - - - 1-1

1.1.2 Parts - - - - - - - - - - - - - - - 1-2

1.1.3

Preparation of device and Parts for

operation

- - - - - - - - - - - - - - - 1-2

1.1.4 Installation - - - - - - - - - - - - - - - 1-2

1.1.5 Distribution - - - - - - - - - - - - - - - 1-2

1.2 Names and Uses of Parts - - - - - - - - - - - - - - - 1-3

1.2.1 End product (less than 75 kW) - - - - - - - - - - - - - - - 1-3

1.2.2 When the front cover is removed ( less than

75kW)

- - - - - - - - - - - - - - - 1-3

1.2.3 End product (more than 90kW) - - - - - - - - - - - - - - - 1-4

1.2.4 When the front cover is removed (more than

90kW)

- - - - - - - - - - - - - - - 1-4

Chapter 2 Specifications

2.1 Specifications - - - - - - - - - - - - - - - 2-1

2.1.1 Rated Input and Output :

Input voltage of 200V class (0.75~22kW)

2.1.2 Rated Input and Output :

Input voltage of 200V class (30~75kW)

2.1.3 Rated Input and Output :

Input voltage of 400V class (0.75~22kW)

2.1.4 Rated Input and Output :

Input voltage of 400V class (30~160kW)

2.1.5 Rated Input and Output :

Input voltage of 400V class (185~375kW)

- - - - - - - - - - - - - - - 2-1

- - - - - - - - - - - - - - - 2-1

- - - - - - - - - - - - - - - 2-2

- - - - - - - - - - - - - - - 2-2

- - - - - - - - - - - - - - - 2-3

ix

Contents

2.1.6 Other commons - - - - - - - - - - - - - - - 2-3

Chapter 3 Installation

3.1 Installation - - - - - - - - - - - - - - - 3-1

3.1.1 Cautions before installation - - - - - - - - - - - - - - - 3-2

3.1.2 Exterior and Dimension

(UL Enclosed T ype 1, IP21 T ype)

3.1.3 External dimension

(UL Enclosed Type12, IP54 Type)

3.1.4 Dimension and Weight of frame

(UL Enclosed T ype 1, IP21 T ype)

3.1.5 Dimension and Weight of Frame

(UL Enclosed T ype 12, IP54 T ype)

3.1.6 Installation Guide

(UL Enclosed Type12, IP54 Type)

- - - - - - - - - - - - - - - 3-5

- - - - - - - - - - - - - - - 3-30

- - - - - - - - - - - - - - - 3-34

- - - - - - - - - - - - - - - 3-36

- - - - - - - - - - - - - - - 3-37

Chapter 4 Wiring

4.1 Wiring

4.1.1

4.1.2

How to separate front cover when wiring

How to separate front cover when wiring

(90~375 kW 400V, 30~75kW 200V)

4.1.3 Built-in EMC Filter

4.1.4 Wiring precaution

4.1.5 Grounding

4.1.6

Terminal wiring diagram

(Power terminal block)

4.1.7 Terminals of main circuit

Specifications of power terminal block and

4.1.8

Exterior fuse

- - - - - - - - - - - - - - - 4-1

- - - - - - - - - - - - - - - 4-3

- - - - - - - - - - - - - - - 4-5

- - - - - - - - - - - - - - - 4-6

- - - - - - - - - - - - - - - 4-9

- - - - - - - - - - - - - - - 4-9

- - - - - - - - - - - - - - - 4-10

- - - - - - - - - - - - - - - 4-12

- - - - - - - - - - - - - - - 4-14

x

Contents

Control terminal line diagram

4.1.9

(Basic I/O terminal block below 22kW)

4.1.10 Control terminal line diagram

(Insulated I/O terminal block above 30kW)

4.1.11

Control circuit terminal

4.1.12 Specifications of signal terminal block

distribution

4.2 Operation Checking

4.2.1 Easy start

4.2.2 Easy start operation

4.2.3 Checking for normal working

- - - - - - - - - - - - - - - 4-17

- - - - - - - - - - - - - - - 4-21

- - - - - - - - - - - - - - - 4-23

- - - - - - - - - - - - - - - 4-24

- - - - - - - - - - - - - - - 4-26

- - - - - - - - - - - - - - - 4-26

- - - - - - - - - - - - - - - 4-26

- - - - - - - - - - - - - - - 4-27

Chapter 5 How To Use Keypad

5.1 How T o Use Keypad

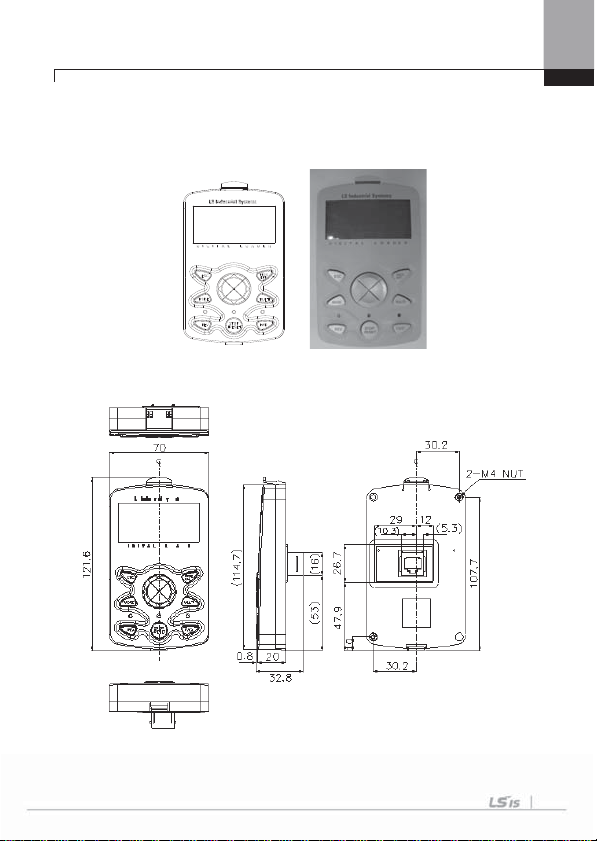

5.1.1 Standard KEYP AD appearance and

description (Graphic keypad)

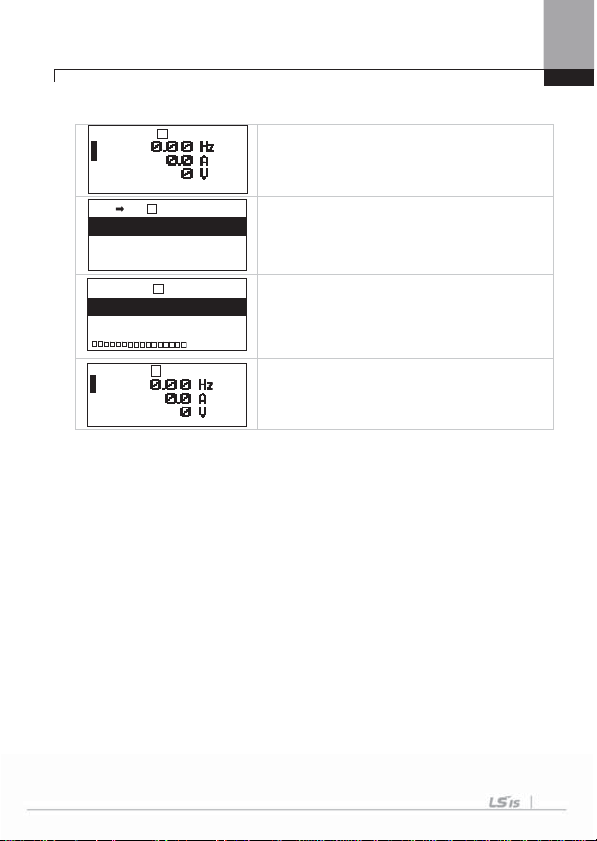

5.1.2 Menu composition

5.1.3 Mode shift

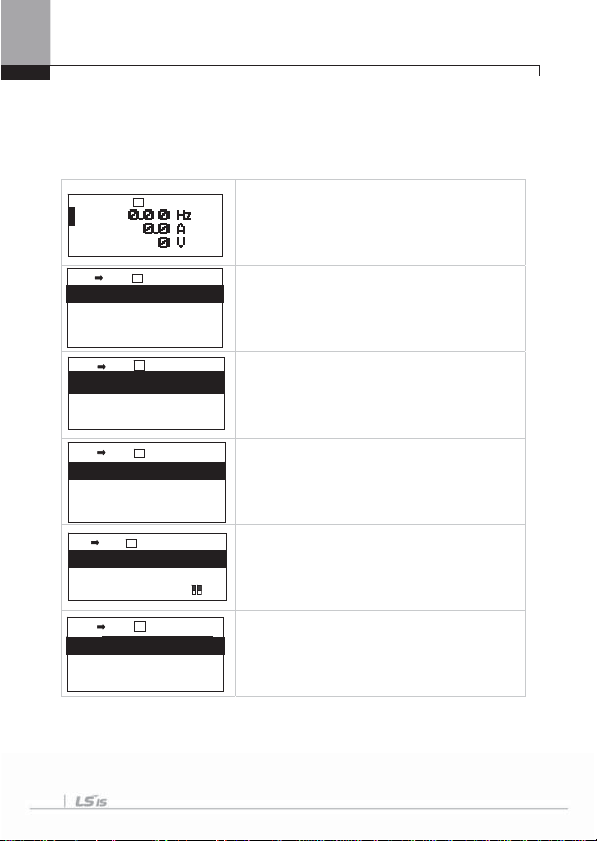

5.1.4 Group shift

5.1.5 Code (Function item) shift

5.1.6 Parameter setting

5.1.7 Operating status monitoring

5.1.8 Failure status monitoring

5.1.9 How to initialize parameter

- - - - - - - - - - - - - - - 5-1

- - - - - - - - - - - - - - - 5-1

- - - - - - - - - - - - - - - 5-6

- - - - - - - - - - - - - - - 5-9

- - - - - - - - - - - - - - - 5-10

- - - - - - - - - - - - - - - 5-11

- - - - - - - - - - - - - - - 5-12

- - - - - - - - - - - - - - - 5-13

- - - - - - - - - - - - - - - 5-15

- - - - - - - - - - - - - - - 5-17

Chapter 6 Basic Functions

6.1 Basic Functions - - - - - - - - - - - - - - - 6-1

6.1.1 How to set frequency - - - - - - - - - - - - - - - 6-1

6.1.2 Analog command frequency fixation - - - - - - - - - - - - - - - 6-10

6.1.3 Changing frequency to revolution - - - - - - - - - - - - - - - 6-11

xi

Contents

6.1.4 Sequential frequency setting - - - - - - - - - - - - - - 6-11

6.1.5 Operating command setting method - - - - - - - - - - - - - - 6-12

6.1.6 Prevention of forward or reverse rotation:

Run Prevent

6.1.7 Run Immediately with power on: Power-on

Run

6.1.8 Setting of accelerating/decelerating time and

pattern

- - - - - - - - - - - - - 6-14

- - - - - - - - - - - - - - - 6-14

- - - - - - - - - - - - - - - 6-15

6.1.9 Motor output voltage adjustment - - - - - - - - - - - - - - - 6-19

Chapter 7 Checking and Troubleshooting

7.1

Checking and troubleshooting - - - - - - - - - - - - - - - 7-1

7.1.1

Protective functions - - - - - - - - - - - - - - - 7-1

7.1.2 Alarm functions - - - - - - - - - - - - - - - 7-4

7.1.3 Troubleshooting - - - - - - - - - - - - - - - 7-6

7.1.4 Replacement of cooling fan - - - - - - - - - - - - - - - 7-9

7.1.5 Daily and regular checkup list - - - - - - - - - - - - - - - 7-1 1

Chapter 8 Table of Functions

8.1 T able of Functions - - - - - - - - - - - - - - - 8-1

8.1.1 Parameter mode – DRV group (ÎDRV) - - - - - - - - - - - - - - - 8-1

8.1.2 Parameter mode – Basic function group

(ÎBAS)

8.1.3 Parameter mode – Extended function group

(PARÎADV)

8.1.4 Parameter mode – Control function group

(ÎCON)

8.1.5 Parameter mode – Input terminal block

function group (ÎIN)

- - - - - - - - - - - - - - - 8-3

- - - - - - - - - - - - - - - 8-6

- - - - - - - - - - - - - - - 8-11

- - - - - - - - - - - - - - - 8-16

xii

Contents

8.1.6 Parameter mode – Output terminal block

function group (ÎOUT)

8.1.7 Parameter mode – Communication function

group (ÎCOM)

8.1.8 Parameter mode – Applied function group

(ÎAPP)

8.1.9 Parameter mode – Auto sequence operation

group (ÎAUT)

8.1.10 Parameter mode – Option card function

group (ÎAPO)

8.1.11 Parameter mode – Protective function group

(ÎPRT)

8.1.12 Parameter mode – 2nd motor function

group (ÎM2)

- - - - - - - - - - - - - - - 8-20

- - - - - - - - - - - - - - - 8-25

- - - - - - - - - - - - - - - 8-28

- - - - - - - - - - - - - - - 8-32

- - - - - - - - - - - - - - - 8-36

- - - - - - - - - - - - - - 8-38

- - - - - - - - - - - - - - - 8-41

8.1.13 Trip mode (TRP Current (or Last-x)) - - - - - - - - - - - - - - - 8-42

8.1.14 Config mode (CNF) - - - - - - - - - - - - - - - 8-42

8.1.15 User/Macro mode – ÎMC1 - - - - - - - - - - - - - - - 8-45

8.1.16 User/Macro mode – Traverse operation

function group (ÎMC2)

- - - - - - - - - - - - - - - 8-46

Chapter 9 Peripheral Devices

9.1 Peripheral Devices - - - - - - - - - - - - - - - 9-1

9.1.1 Composition of peripheral devices - - - - - - - - - - - - - - - 9-2

9.1.2 Specifications of wiring switch, Electronic

contactor and Reactor

9.1.3

Dynamic breaking unit (DBU) and Resistors - - - - - - - - - - - - - - - 9-5

9.1.4

IS7 Remote cable options - - - - - - - - - - - - - - - 9-12

- - - - - - - - - - - - - - - 9-3

Chapter 10 Functional Safety

xiii

Contents

10.1 Functional Safety - - - - - - - - - - - - - - - 10-1

10.1.1 Safety Standard product - - - - - - - - - - - - - - - 10-1

10.1.2 Safety function description and wiring

diagram

- - - - - - - - - - - - - - - 10-1

Chapter 11 Classification Product

11.1 Classification Product - - - - - - - - - - - - - - - 11-1

11.1.1 Classification Standard - - - - - - - - - - - - - - - 11-1

11.1.2 Classification standard qcquisition - - - - - - - - - - - - - - - 11-1

11.1.3 Classification Model SV-iS7 Products - - - - - - - - - - - - - - - 11-1

xiv

Chapter 1 Basics

1.1 What Y ou Should Know before Use

1.1.1 Check of product

T ake the inverter out of the box, check the rating shown on a side of the product body

and whether the inverter type and rated output are exactly what you ordered. Check

also whether the product has been damaged during delivery.

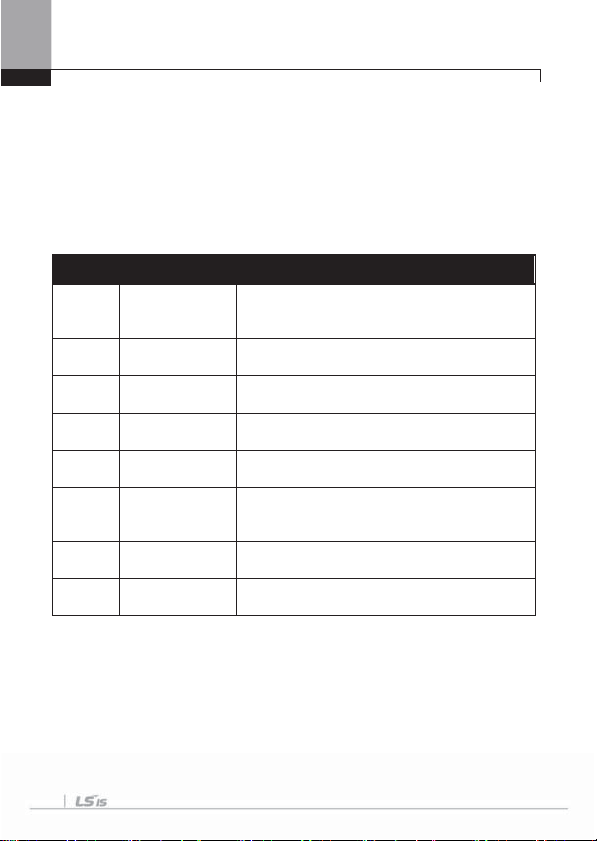

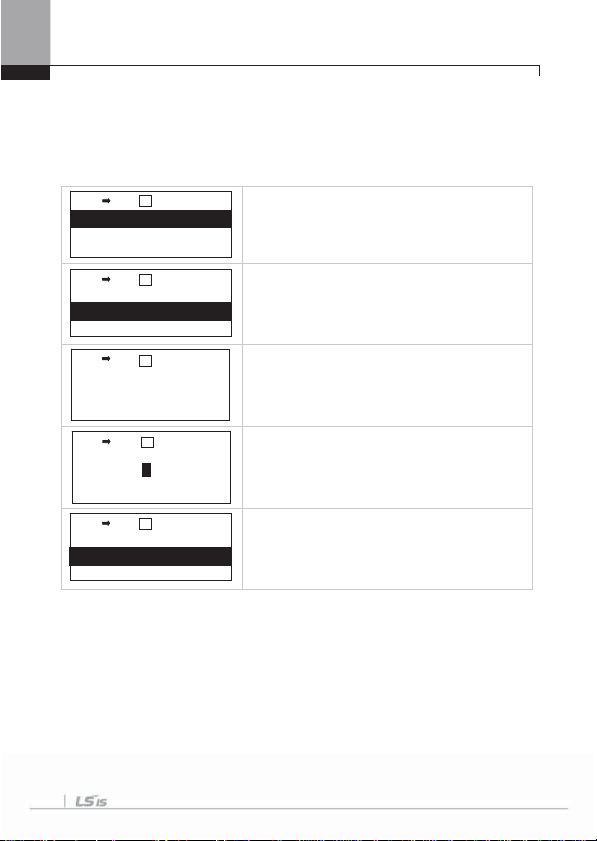

SV 008 iS7 - 2 N O F D

Capacity of Applied

Motor

Series

Name

Input

Keypad UL EMC DCR

Voltage

0008 0.75 [kW]

0015 1.5 [kW]

0022 2.2 [kW]

0037 3.7 [kW]

0055 5.5 [kW]

0075 7.5 [kW]

0110 11 [kW]

0150 15 [kW]

0185 18.5 [kW]

0220 22 [kW]

0300 30 [kW]

0370 37 [kW]

0450 45 [kW]

L S Inverter

2:

3-Phase

200~230[V]

4:

3-Phase

380~480[V]

-

N:

NON

S:

GLCD

(Graphic

Loader)

O:

OPEN

E:

Enclosed

UL

note1)

Type1

P:

Enclosed

UL Type 12

Blank:

NonEMC

F:

EMC

Blank:

Non-DCR

D:

DCR

R

:DB

Resistor

(Inner

Mounted)

0550 55 [kW]

0750 75 [kW]

Wide-Use Inverter

0900 90 [kW]

1100 110 [kW]

1320 132 [kW]

1600 160 [kW]

1850 185 [kW]

2200 220 [kW]

2800 280 [kW]

3150 315 [kW]

3750 375 [kW]

Note1)

Enclosed UL Type 1 has the conduit option addtionally at 0.75 to 75 kW products.

Note2)

DB Resistor of IS7 Product is the option of WEB product. Applicable capacity is from 0.75 to 375 kW of IS7

products.

1-1

Chapter 1 Basics

1.1.2 Parts

If you have any doubt about the product or found the product damaged, call our

company’s branch offices (see the back cover of the manual).

1.1.3 Preparation of device and Parts for operation

Preparation for operation might slightly vary. Prep are parts according to the use.

1.1.4 Installation

Make sure you install the product correctly considering the place, direction or

surroundings in order to prevent decrease in the life and performance of the

inverter.

1.1.5 Distribution

Connect the power supply, electric motor and operating signals (control

signals) to the terminal block. If you fail to connect them correctly, the inverter

and peripheral devices might be damaged.

1-2

1.2 Names and Uses of Parts

p

1.2.1 End product (less than 75 kW)

Chapter 1 Basics

Keypad

Screw to fix the

front

Ground terminal

1.2.2 When the front cover is removed (less than 75 kW)

Keypad

connection

Encoder option

Wiring bracket

Front cover:

Remove it when wiring

Wiring bracket

Cooling FAN

Communication

option

connection

Inverter condition

display BAR

PLC, extension I/O,

communication

tion connection

o

I/O board and terminal

Power terminal

1-3

Chapter 1 Basics

pp

p

play

(

)

1.2.3 End Product (more than 90kW)

Screw to fix

Keypad

upper front

cover (left side)

Screw to fix lower

front cover (left side)

Lower front cover

Power input

1.2.4 When the front cover is removed (more than 90kW)

SCR snubber circuit

Communication option

board connection

Encoder option board

Keypad connection

terminal

I/O board and

terminal

Safety option board

(Selectable function)

Cooling fan

Upper front cover

Screw to fix

u

er front

Screw to fix the

lower front cover

(right side)

Signal input

Ground

FAN SMPS

circuit

Main SMPS

circuit

Inverter condition

LED

dis

PLC, Extension I/O,

Communication

tion Connection

o

Shield plate

Power Busbar

R/S/T , U/V/W, P/N

Remark

Please refer to option board manual for option board information.

1-4

Chapter 2 SpecificationsG

)

ۡ

2.1 Specifications

2.1.1 Rated Input and Output : Input voltage of 200V class (0.75~22kW)

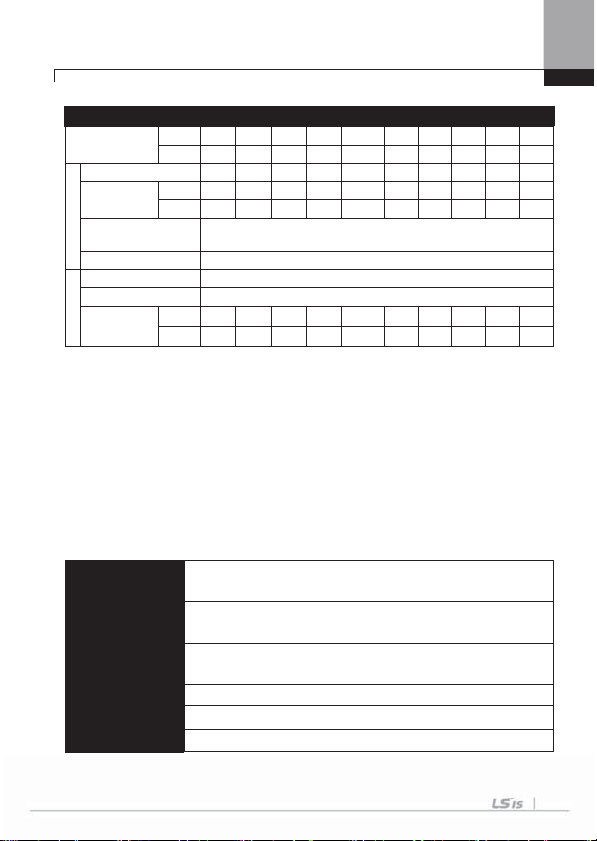

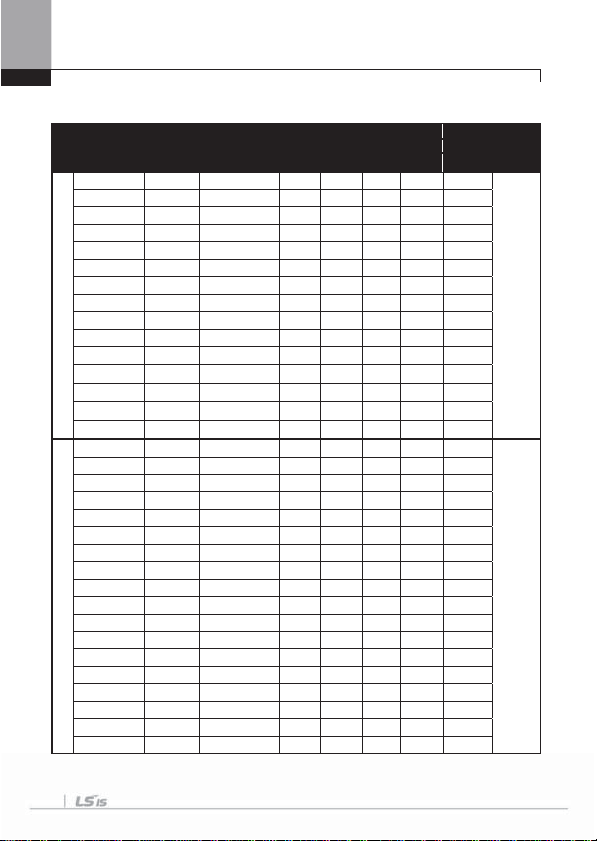

Type : SV xxx iS7 – 2x 0008 0015 0022 0037 0055 0075 0110 0150 0185 0220

1)

Motor

Applied

2

Current[A]

Output Frequency

Rated Output

[HP] 1 2 3 5 7.5 10 15 20 25 30

[kW] 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22

Rated Capacity

[kVA]

3)

Rated

1.9 3.0 4.5 6.1 9.1 12.2 17.5 22.9 28.2 33.5

CT 5 8 12 16 24 32 46 60 74 88

VT 8 12 16 24 32 46 60 74 88 124

4)

0 ~ 400 [Hz]

(Sensorless-1: 0~300Hz, Sensorless-2,Vector: 0~120Hz)

Output Voltage [V] 5)3-phase 200 ~ 230V

Available Voltage [V] 3-phase 200 ~ 230 VAC (-15%,+10%,)

Input Frequency 50 ~ 60 [Hz] (r5%)

Rated

Rated Input

Current [A]

* Non DCR products are provided warranty service when used in CT (Heavy duty) load

rating only.

2.1.2 Rated Input and Output : Input voltage of 200V classۡ(30~75kW)

CT 4.3 6.9 11.2 14.9 22.1 28.6 44.3 55.9 70.8 85.3

VT 6.8 10.6 14.9 21.3 28.6 41.2 54.7 69.7 82.9 116.1

Type : SV xxx iS7 – 2x 0300 0370 0450 0550 0750 - - - - -

1)

Motor Applied

2)

Rated Capacity

3)

Rated

Current[A]

Output Frequency

Rated Output

Output Voltage [V] 5) 3-phase 200 ~ 230V

[HP] 40 50 60 75 100 - - - - -

[kW] 30 37 45 55 75 - - - - -

[kVA]

46 57 69 84 116 - - - - -

CT 116 146 180 220 288 - - - - -

VT 146 180 220 288 345 - - - - -

4)

0 ~ 400 [Hz]

(Sensorless-1: 0~300Hz, Sensorless-2,Vector:0~120Hz)

Available Voltage [V] 3-phase 200 ~ 230 VAC (-15%~+10%)

Input Frequency 50 ~ 60 [Hz] (r5%)

Rated

Rated Input

Current [A]

* Non DCR products are provided warranty service when used in CT (Heavy duty) load

rating only.

G

CT 121 154 191 233 305 - - - - -

VT 152 190 231 302 362 - - - - -

2-1

Chapter 2 SpecificationsG

)

)

2)

4)

2.1.3 Rated Input and Output : Input voltage of 400V class (0.75~22kW)

Type : SV xxx iS7 – 4x 0008 0015 0022 0037 0055 0075 0110 0150 0185 0220

1)

Motor Applied

2

Rated Capacity

3)

Current[A]

Output Frequency

Rated Output

[HP] 1 2 3 5 7.5 10 15 20 25 30

[kW] 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22

[kVA]

Rated

1.9 3.0 4.5 6.1 9.1 12.2 18.3 22.9 29.7 34.3

CT 2.5 4 6 8 12 16 24 30 39 45

VT 4 6 8 12 16 24 30 39 45 61

4

0 ~ 400 [Hz]

(Sensorless-1:0~300Hz, Sensorless-2,Vector:0~120Hz)

Output Voltage [V] 5)3-phase 380 ~ 480V

Available Voltage [V] 3-phase 380 ~ 480 VAC (-15%~+10%)

Input Frequency 50 ~ 60 [Hz] (r5%)

Rated

Rated Input

Current [A]

* Non DCR products are provided warranty service when used in CT (Heavy duty) load

rating only.

CT 2.2 3.6 5.5 7.5 11.0 14.4 22.0 26.6 35.6 41.6

VT 3.7 5.7 7.7 11.1 14.7 21.9 26.4 35.5 41.1 55.7

2.1.4 Rated Input and Output : Input voltage of 400V class (30~160kW)

Type : SV xxx iS7 – 4x 0300 0370 0450 0550 0750 0900 1100 1320 1600 -

1)

Motor Applied

Rated Capacity [kVA]

3)

Rated

Current[A]

Output Frequency

Rated Output

Output Voltage [V] 5)3-phase 380 ~ 480V

[HP] 40 50 60 75 100 120 150 180 225 [kW] 30 37 45 55 75 90 110 132 160 -

46 57 69 84 116 139 170 201 248 CT 61 75 91 110 152 183 223 264 325 VT 75 91 110 152 183 223 264 325 370 -

0 ~ 400 [Hz]

(Sensorless-1:0~300Hz, Sensorless-2,Vector:0~120Hz)

Available Voltage [V] 3-phase 380 ~ 480 VAC (-15%, +10%)

Input Frequency 50 ~ 60 [Hz] (r5%)

Rated Input

Current[A]

Rated

CT 55.5 67.9 82.4 102.6 143.4 174.7 213.5 255.6 316.3 VT 67.5 81.7 101.8 143.6 173.4 212.9 254.2 315.3 359.3 -

* Non DCR products are provided warranty service when used in CT(Heavy duty) load

rating only.

G

2-2

Chapter 2 SpecificationsG

2)

4)

2.1.5 Rated Input and Output : Input voltage of 400V class (185~375kW)

Type : SV xxx iS7 – 4x 1850 2200 2800 3150 3750 - - - - -

1)

Motor Applied

Rated Capacity [kVA]

3)

Rated

Current[A]

Output Frequency

Rated Output

Output Voltage [V] 5)3-phase 380 ~ 480V

[HP] 250 300 375 420 500 - - - - [kW] 185 220 280 315 375 - - - - -

286 329 416 467 557 - - - - CT 370 432 547 613 731 - - - - VT 432 547 613 731 877 - - - - -

0 ~ 400 [Hz]

(Sensorless-1:0~300Hz, Sensorless-2,Vector:0~120Hz)

Available Voltage [V] 3-phase 380 ~ 480 VAC (-15%, +10%)

Input Frequency 50 ~ 60 [Hz] (r5%)

Rated

Rated Input

Current[A]

1) Motor Applied indicates the maximum capacity applied to use of a standard 4 pole standard motor.

2) Rated capacity : the input capacity of a 200V class is based on 220V and that of a 400V class is based

on 440V. The current rating is based on CT current.

3) The output of rated current is limited according to setting of the carrier frequency (CON-04).

4) In case of Sensorless-1, you can set the frequency at up to 300Hz by selecting 3 as the control mode

(DRV-09 Control Mode). In case of Sensorless-2, you can set the frequency at up to 120Hz by selecting

4 as the control mode (DRV-09 Control Mode).

5) The maximum output voltage does not go up over the supplied power voltage. You can select the output

voltage as you want below the supplied power voltage.

CT 404 466 605 674 798

VT 463 590 673 796 948

- - - - -

- - - - -

2.1.6 Other commons

1) Control

Control Method

Frequency Setting

Resolving Power

Frequency Degree

V/F Pattern

Overload Capacity

Torque boost

V/F control, V/F PG , slip compensation, sensorless vector-1,

sensorless vector-2, vector control

Digital command : 0.01 Hz

Analog command : 0.06 Hz (maximum frequency : 60Hz)

Digital command operation : 0.01% of the maximum frequency

Analog command operation : 0.1% of the maximum frequency

Linear, double reduction, user V/F

CT current rating :150% for 1 min., VT current rating :1 10% for 1 min.

Manual torque boost, Automatic torque boost

* Non DCR products are provided warranty service when used in CT (Heavy duty) load rating only .

2-3

Chapter 2 SpecificationsG

2) Operation

Operating Method

Frequency Setting

Selectable among keypad/ terminal block/

communication operation

Analog : 0 ~ 10[V], -10 ~ 10[V], 0 ~ 20[mA]

Digital : keypad

PID control, up-down operation, 3-wire operation, DC break,

Frequency limit, Frequency jump, Second function, Slip

Operating Function

compensation, Reverse rotation prevention, Auto restarting,

Inverter By-pass, Auto tunning Flying Start, Energy buffering,

Power breaking, Flux breaking, Leakage current reduction,

MMC, Easy Start

NPN (Sink) / PNP (Source) selectable

Function: forward operation, reverse operation, reset, external

trip, emergency stop, jog operation, sequential frequency-

Multi-function

Terminal

(8 points)

Input

P1 ~ P8

high/medium/low, multi - level acceleration and deceleration –

high/medium/low, D.C. control during stop, selection of a second

motor, frequency increase, frequency decrease, 3-wire

1)

operation, change to general operation during PID operation,

Main inverter body operation during option operation, analog

command frequency fixation, acceleration and deceleration stop

selectable

Multi-function

Open Collector

Ter min al

Multi-function

Relay Terminal

Output

Analog Output

1) The Functions for Multi-function terminal available according to IN-65~72 parameter

setting of IN Group.

G

G

G

Failure output and inverter

operation output

0 ~ 10 Vdc (below 20mA) : selectable from frequency, current,

voltage, direct current voltage

Below DC 26V, 100mA

Below (N.O., N.C.) AC250V 1A,

Below DC 30V 1A

2-4

G

3) Protective Function

y

Over voltage, Low voltage, Over current, Earth current detection,

Inverter overheat, Motor overheating, Output imaging, Overload

Trip

protection, Communication error, Frequency command loss,

Hardware failure, Cooling fan failure, Pre-PID failure, No motor trip,

External break trip, etc.

Alarm

Stall prevention, Overload, Light load, Encoder error, Fan failure,

Keypad command loss, Speed command loss.

Below CT class 15 msec (below VT class 8 msec) : Operation

Instantaneous

Interruption

continues (within rated input voltage, rated output)

2)

Above CT class 15 msec (above VT class 8 msec) : Availble

automatic restarts

2) Operation at the CT (Heavy Duty) current rating

4) Structure and Use Environment

Cooling Method

Forced cooling : 0.75~15kW (200/400V class), 22kW (400V class)

Inhalation cooling : 22~75kW (200V class), 30~375kW (400V class)

- 0.75~22kW(200V), 0.75~75kW(400V): Open type IP 21 (default),

Protection

Structure

UL enclosed type 1 (Option)

- 30~75kW (200V), 90~375kW(400V): Open type IP 00 (default),

UL enclosed type 1 (Option)

- 0.75~22kW-2/4 and etc.: Enclosed IP54 type, UL enclosed type 12

- CT (Heavy Duty) load : - 10 ~ 50 (without ice or frost)

Ambient

Temperature

- VT (Normal Duty) load : - 10~ 40 (without ice or frost)

(It is recommended that you use less than 80% load when you use

VT load at 50.)

- IP54 product: -10~40 (without ice or frost)

Preservation

Temperature

Surrounding

Humidit

Altitude, Vibration

Environment

-20qC ~ 65qC

Below 90% RH of relative humidity (with no dew formation)

Below 1,000m, below 5.9m/sec

There should be no corrosive gas, flammable gas, oil mist or dust.

(Pollution degree 2 Environment)

3) UL Enclosed type 1 with conduit box installed.

Chapter 2 SpecificationsG

3)

3)

2

(0.6G)

2-5

Chapter 2 SpecificationsG

2-6

G

Chapter 3 Installation

3.1 Installation

Be sure to check mechanical and electrical installation environment before you start the

inverter. Read through the checking list below. Be sure to read through the Caution for

Safety on this User's Manual prior to the operation of inverter.

Checking List

Mechanical Installation Checking List

y Be sure to check the surrounding environment is allowed for operation. (Read through

the ‘Caution on Installation’)

y Inverter is a heat-generating device. Be sure to sufficiently secure the surrounding

space to prevent thermal saturation phenomenon.

y Be sure to check air is circulated in a normal condition.

y Be sure to check motor and drive system are ready to start.

Electrical Installation Checking List

y Make sure that the protective grounding is properly done.

y Replace the condenser with new one if it lasted longer than two years.

y Set the input voltage to the nominal input voltage of the inverter.

y Check if the input voltage connected with R, S, T and then fasten them tightly using an

accurate torque wrench.

y Check if input power fuse and circuit breaker are properly installed.

y Install the motor cable away from the other cable.

y Check if the ext. input/output is properly connected.

y Check if the input voltage is properly connected with the output terminal of inverter.

3-1

Chapter 3 Installation

r

3.1.1 Cautions before installation

Be careful so that the plastic parts of the inverter may not be damaged. Do not

move the product holding the cover only. Do not install the product where there i

s vibration, a press or truck. Life of the inverter greatly influenced by the surround

ing temperatures, make sure that the surrounding temperature does not exceed th

e permitted temperature (-10 ~ 50qC).

The life of the inverter is affected by ambient temperature. Place that inverter inst

alled in of ambient temperatures should not exceed the following allowable temper

ature.

When the inverter is installed inside the panel, panel temperature must not excee

d the following allowable temperature. In other word, the ambient temperature insi

de or outside of the panel, regardless of the installation, needs to be measured a

round 5cm of the inverter.

㟝GGGhG{G

jSGGGGGGG

{G

j{OoGkPGaGTGXWG¥G\WG G

}{OuGkPaGTGXW¥G[WG G

OoSG}{OuGkPG G \WSGG G _WLG

GGGGPG

pw\[GwGaGTXWG¥[WG

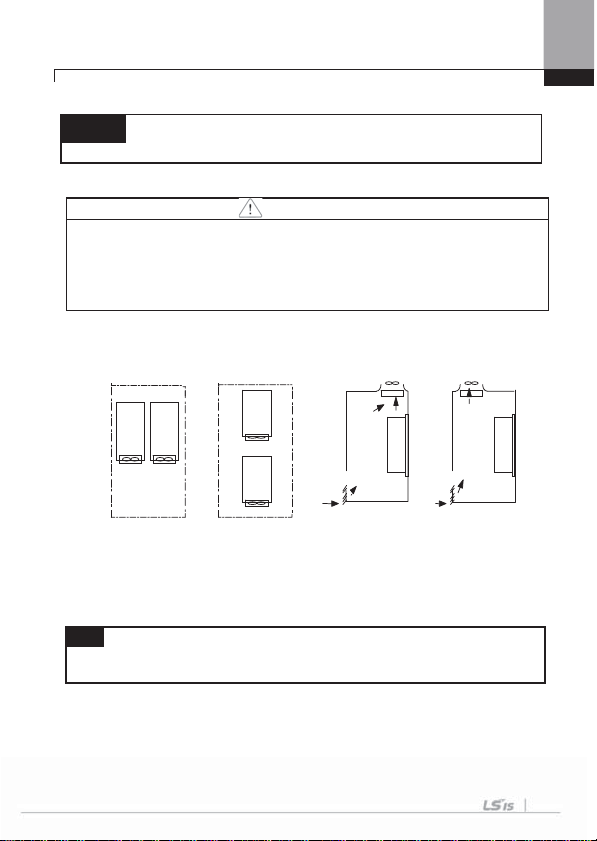

<Measurement Points of Surrounding T emperature>

Install the inverter on an inflammable surface because its temperature rises high

during operation.

Sufficient space is required to prevent heat saturation because the inverter emits

heat.

Enough space is

required for the

distribution duct not to

block the cooling air.

Cooling ai

Built-in cooling fan

(In case of

inhalation air

cooling type)

over

5cm

B

A: over 10cm

Inverte

B

over

5cm

A: over10cm

3-2

Built-in cooling fan

(In case of forced

air cooling type)

Chapter 3 Installation

Built-i

Remark

Over 50cm, B : over 20cm is necessary when you install an inverter above 30kW.

Caution

Avoid direct rays of light or a warm and humid place.

Install the inverter in a closed panel or clean place free from foreign substances such as

oil mist and fiber dust.

In order to meet the EMC standard, 200V 30~75kW and more than 90kW product should

be installed inside a metal cabinet or panel.

If you install two or more inverters inside the panel, be careful about the location

of the ventilation fan and inverter. See the figure below.

Inverte

Inverter

Inverter

r

Inverter

Ventilation

Ventilation

I

nverter

n coolingfan

(O)

Acceptable

When two or more units are installed

Inverter

Unacceptable

(X)

Acceptable

(O)

Unacceptable

Where the ventilation fan is installed

(X)

Install the inverter upright using screws or bolts so that the inverter does not move.

Note

Arrange the panels in order to the hot air generated by the heating of the inverter should

be released.

3-3

Chapter 3 Installation

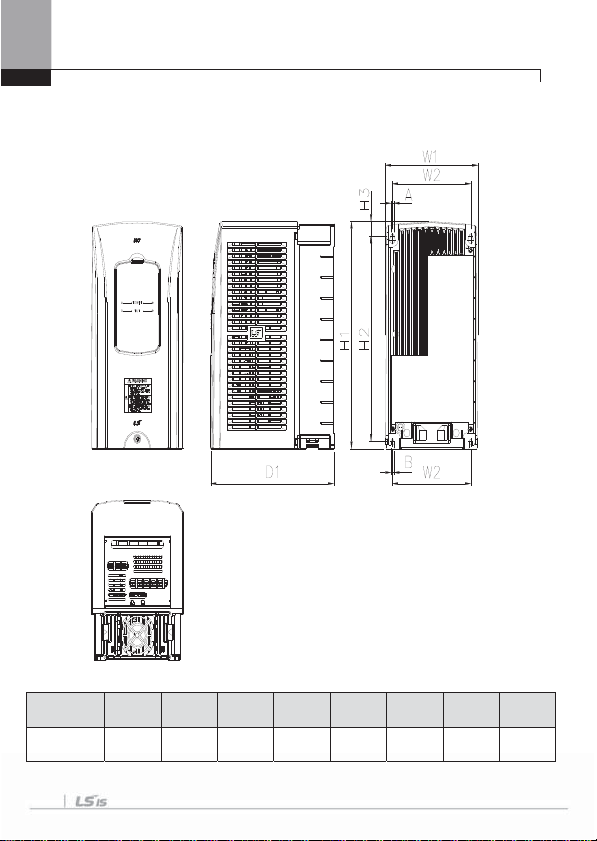

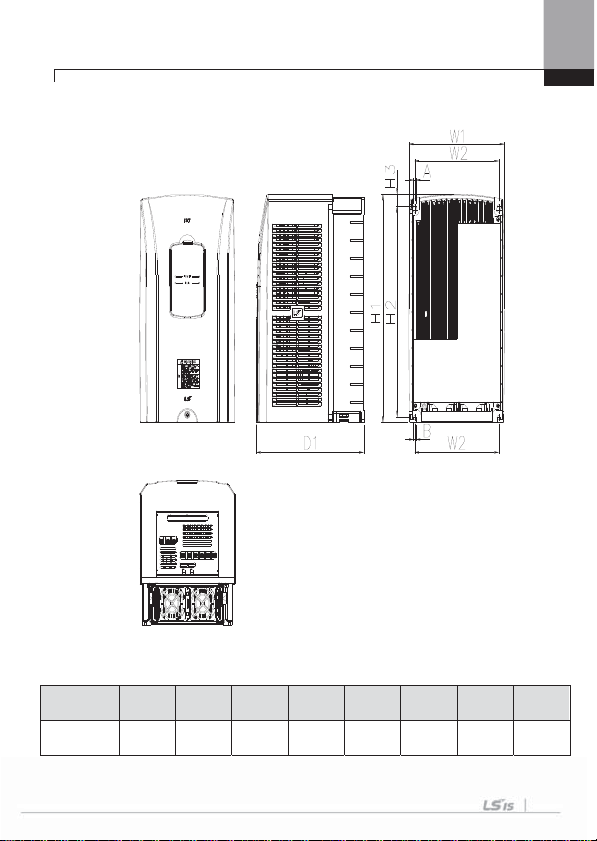

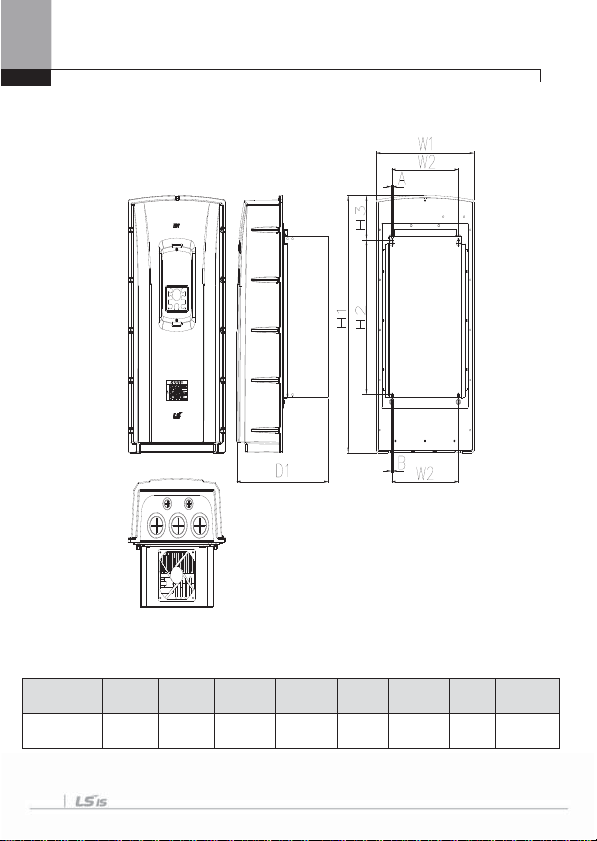

3.1.2 Exterior and Dimension (UL Enclosed T ype 1, IP21 Type)

1) SV0008-0037iS7 (200V/400V)

Inverter

capacity

SV0008~0037

iS7 - 2/4

3-4

mm ( inches )

W1 W2 H1 H2 H3 D1 A B

150(5.90) 127(5.00) 284(11.18) 257(10.11) 18(0.70) 200(7.87) 5(0.19) 5(0.19)

2) SV0055-0075iS7 (200V/400V)

)

Chapter 3 Installation

Inverter

capacity

SV0055~0075

iS7 - 2/4

mm ( inches )

W1 W2 H1 H2 H3 D1 A B

200(7.87) 176(6.92) 355(13.97

327(12.87)19(0.74) 225(8.85) 5(0.19) 5(0.19)

3-5

Chapter 3 Installation

)

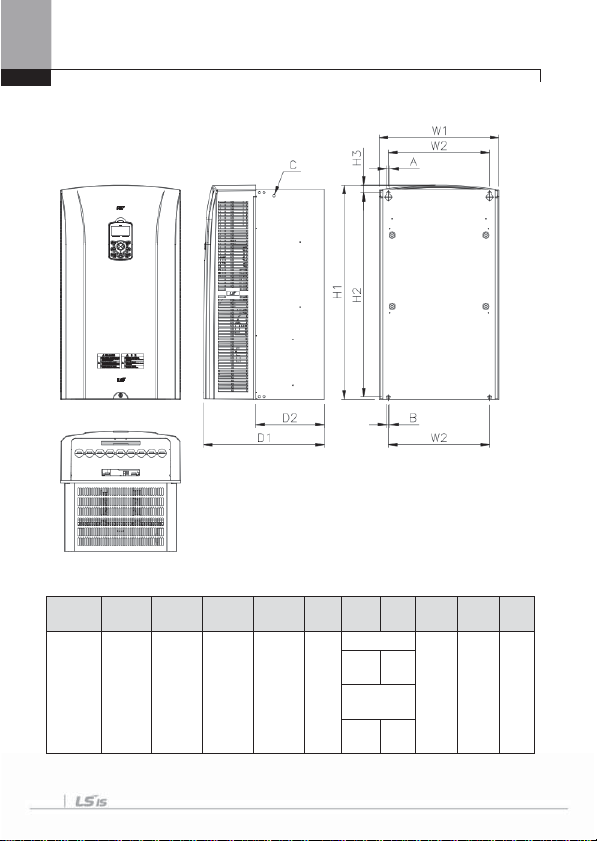

3) SV0110-0150iS7 (200V/400V)

Inverter

capacity

SV0110~0150

iS7- 2/4

3-6

mm ( inches )

W1 W2 H1 H2 H3 D1 A B

250(9.84) 214.6(8.44

385(15.15) 355(13.97) 23.6(0.92 284(11.18) 6.5(0.25) 6.5(0.25)

4) SV0185-0220iS7 (200V/400V)

4

Chapter 3 Installation

Inverter

capacity

SV0185~0220

iS7- 2/4

mm ( inches )

W1 W2 H1 H2 H3 D1 A B

280(11.02) 243.5(9.58)

61.6(18.17)445(17.51) 10.1(0.39)298(11.73) 6.5(0.25)6.5(0.25)

3-7

Chapter 3 Installation

5) SV0300-iS7 (200V, IP00 Type)

3-8

Inverter

capacity

SV0300

iS7-2

W1 W2/W3 H1 H2 H3 D1 A B

300

190

570

552

10

265.2

(11.81)

(7.48)

(22.44)

(21.73)

(0.39)

(10.44)

10

(0.39)

mm ( inches )

C

10

M8

(0.39)

6) SV0370-0450iS7 (200V, IP00 Type)

Chapter 3 Installation

Inverter

capacity

SV0370~04

50

iS7-2

mm ( inches )

W1 W2/W3 H1 H2 H3 D1 A B

370

270

630

609

11

281.2

(14.5

6)

(10.63)

(24.8)

(23.97)

(0.43)

(11.07)

10

(0.39)

10

(0.39)

C

M10

3-9

Chapter 3 Installation

7) SV0300-0450iS7 (400V)

mm ( inches )

Inverter

capacityW1 W2 H1 H2 H3 D1 D2 A B C

SV300~

450

iS7-4

3-10

300.1

(11.81)

242.8

(9.55)

594.1

(23.38)

562

(22.12)

DCR Type

303.2

(11.93)

161

(6.33)

24.1

(0.94)

Non-DCR Type

271.2

129

(10.67(

(5.78)

10

(0.39)

M8

10

(0.39)

8) SV0550-0750iS7 (200V, IP00 Type)

Chapter 3 Installation

Inverter

capacity

SV0550~0

750

iS7-2

mm ( inches )

W1 W2/W3 H1 H2 H3 D1 A B

465

381

750

723.5

15.5

355.6

(18.3)

(15.0)

(29.52)

(28.48)

(0.61)

(14.0)

11

(0.43)

11

(0.43)

C

M16

3-11

Chapter 3 Installation

)

)

9) SV0550-0750iS7 (400V)

Inverter

capacity

SV0055~

W1 W2 H1 H2 H3 D1 D2 A B

370.1

(14.57)

312.8

(12.31)

0075

iS7-4

663.5

(26.12)

631.4

(24.85)

24.1

(0.94)

DCR Type

373.3

(14.69

Non-DCR

Type

312.4

(12.29

211.5

(8.32)

150.6

(5.92)

mm ( inches )

10

(0.39)

10

(0.39)

C

M8

3-12

10) SV0900-1100iS7 (400V, IP00 Type)

Chapter 3 Installation

Inverter

capacity

SV0900~

1100

iS7-4

mm ( inches )

W1 W2 W3 H1 H2 H3 D1 A B

510

381

350

783.5

759

15.5

422.6

(20.07)

(15.0)

(13.77)

(30.84)

(29.88)

(0.61)

(16.63)

11

(0.43)

11

(0.43)

C

M16

3-13

Chapter 3 Installation

11) SV1320-1600iS7 (400V, IP00 Type)

Inverter

mm ( inches )

capacityW1 W2 W3 H1 H2 H3 D1 A B

SV1320

~1600

iS7-4

510

(20.07)

381

(15.0)

350

(13.77)

861

(33.89)

836

(32.93)

15.5

(0.61)

422.6

(16.63)

11

(0.43)

3-14

11

(0.43)

C

M16

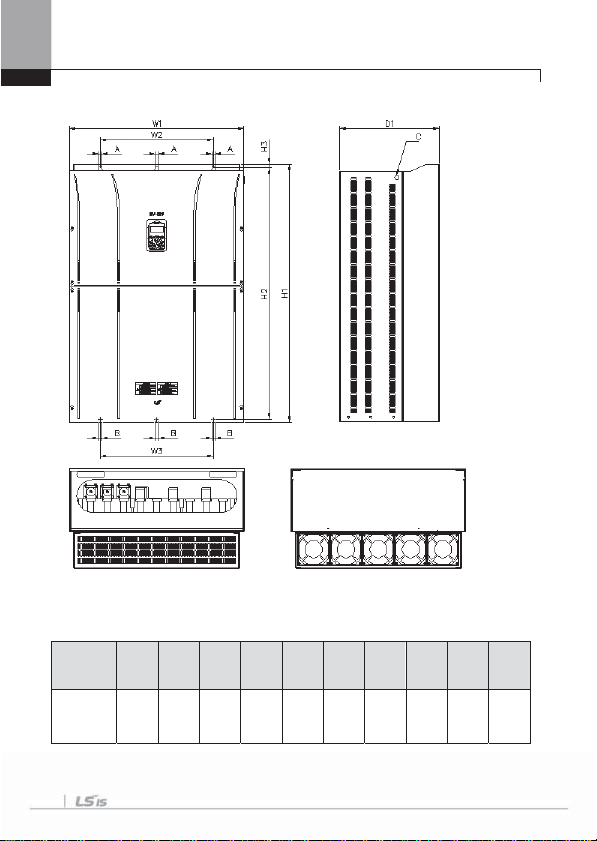

12) SV1850-2200iS7 (400V, IP00 TYPE)

G

G

G

Chapter 3 Installation

Inverter

capacity

z}X_\WVG

YYWWz^T[G

W1GW2GW3GH1GH2GH3GD1GAGB

]`WG

\_XG

\Y_G

XW^_

XW[ZU\

Y\U\G

OY^UX]PG

OYYU_^PG

OYWU^`P

O[YU[[P

O[XUW_P

OXUWWP

[\WG

OX^U^YPG

mm ( inches )

X[G

X\G

OWU\\PG

OWU\`PGtYW

C

3-15

Chapter 3 Installation

G

GOGGPG

G

G

13) SV2800iS7 (400V, IP00 TYPE )

Inverter

capacity

z}Y_WWz^

W1GW2GW3GH1GH2GH3GD1GAGB

G

^^XG

\WWG

T[G

OZWUZ\PG

OX`U]`PG

\WWG

OX`U]`P

O[[U_WP

XXZ_

XXXW

O[ZU^WP

X\G

OWU\`P

[[WG

OX^UZYP

XZG

OWU\XPG

XZG

OWU\XPG

C

G

tX]G

3-16

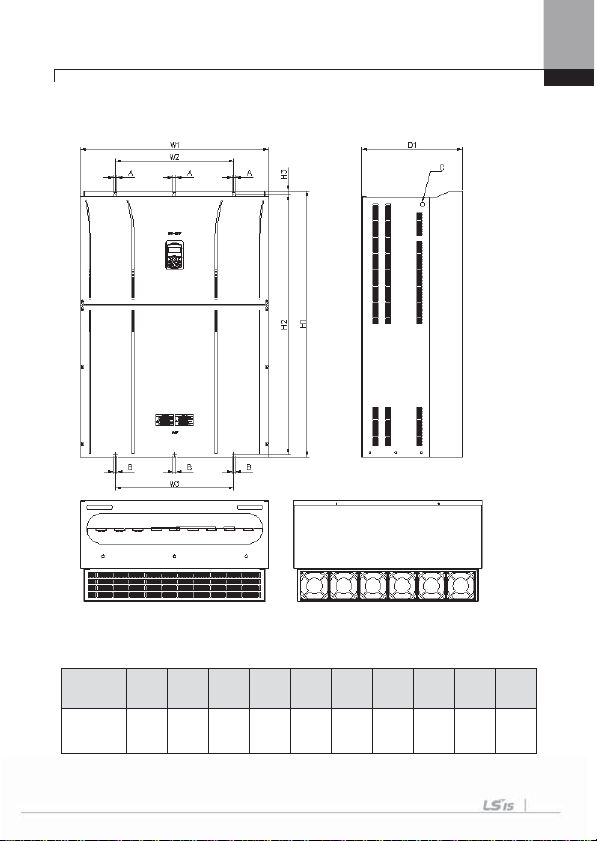

14) SV3150-3750iS7 (400V, IP00 TYPE )

G

G

~XG ~YG ~ZG oXG oYG oZG kXG hG iG

G

jG

Chapter 3 Installation

Inverter

capacity

SV3150/

3750iS7-4

922

580

580

1302.5

1271.5

15

(36.30)

(22.83)

(22.83)

(51.28)

(50.06)

(0.59)

495

(19.49)

(0.55)

14

mm ( inches )

14

M16

(0.55)

3-17

Chapter 3 Installation

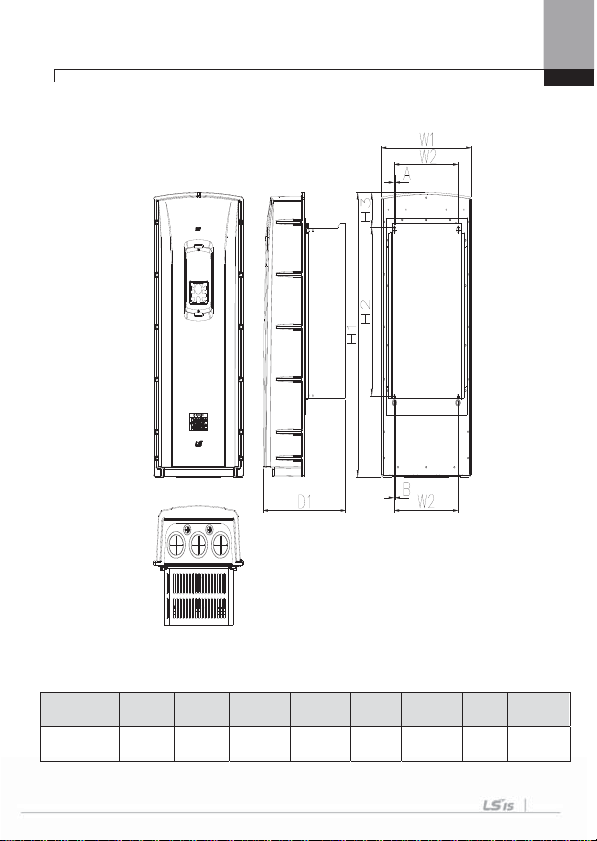

3.1.3 External dimension (UL Enclosed Ty pe12, IP54 Type)

1) SV0008-0037iS7 (200V/400V)

Inverter

capacity

SV0008~0037

iS7-2/49

3-18

mm ( inches )

W1 W2 H1 H2 H3 D1 A B

204.2

127

(8.03)

(5.0)

419

(16.49)

257

(10.11)

95.1

208

(3.74)

(8.18) 5(0.19) 5(0.19)

2) SV0055-0075iS7 (200V/400V)

Chapter 3 Installation

Inverter

capacity

SV0055~0075

iS7- 2/4

mm ( inches )

W1 W2 H1 H2 H3 D1 A B

254

176

(10.0)

(6.92)

460.6

(18.13)

327

(12.87)

88.1

232.3

(3.46)

(9.14) 5(0.19) 5(0.19)

3-19

Chapter 3 Installation

3) SV0110-0150iS7 (200V/400V)

Inverter

capacity

SV0110~0150

iS7-2/4

3-20

mm ( inches )

W1 W2 H1 H2 H3 D1 A B

313.1

214.6

(12.32)

(8.44)

590.8

(23.25)

355

(13.97)

101.7

(4.0)

294.4

(11.59)

6.5

(0.25)

6.5

(0.25)

4) SV0185-0220iS7 (200V/400V)

Chapter 3 Installation

Inverter

capacity

SV0185~0220

iS7-2/4

mm ( inches )

W1 W2 H1 H2 H3 D1 A B

343.2

243.5

(13.51)

(9.58)

750.8

(29.55)

445

(17.51)

91.6

(3.60)

315.5

(12.42)

6.5

(0.25)

6.5

(0.25)

3-21

Chapter 3 Installation

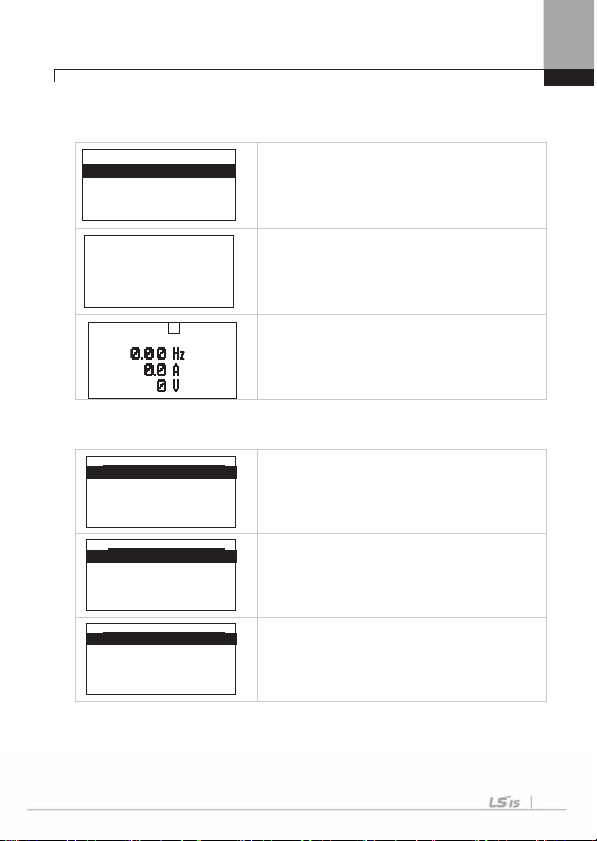

3.1.4 Dimension and Weight of frame (UL Enclosed Type 1, IP 21Type)

Inverter

Capacity W[mm] H[mm] D[mm]

SV0008iS7-2/4 150 284 200 5.5 4.5 5.0 4.5

SV0015iS7-2/4 150 284 200 5.5 4.5 5.0 4.5

SV0022iS7-2/4 150 284 200 5.5 4.5 5.0 4.5

SV0037iS7-2/4 150 284 200 5.5 4.5 5.0 4.5

SV0055iS7-2/4 200 355 225 10 8.4 9.3 7.7

SV0075iS7-2/4 200 355 225 10 8.4 9.3 7.7

SV0110iS7-2/4 250 385 284 20 17.2 16.8 14

SV0150iS7-2/4 250 385 284 20 17.2 16.8 14

SV0185iS7-2 280 461.6 298 30 27 25.9 22.9

SV0220iS7-2 280 461.6 298 30 25.8 25.9 22.9

SV0300iS7-2 300 570 265.2

SV0370iS7-2 370 630 281.2

SV0450iS7-2 370 630 281.2

SV0550iS7-2 465 750 355.6

SV0750iS7-2 465 750 355.6

SV0185iS7-4 280 461.6 298 27.4 23.5 23.3 19.7

SV0220iS7-4 280 461.6 298 27.4 23.5 23.5 20.1

SV0300iS7-4 300.1 594.1 300.4 - - 41 28

SV0370iS7-4 300.1 594.1 300.4 - - 41 28

SV0450iS7-4 300.1 594.1 300.4 - - 41 28

SV0550iS7-4 370 663.4 371. - - 63 45

SV0750iS7-4 370 663.4 371. - - 63 45

SV0900iS7-4 510 783.5 422.6 - - 101 -

EMC&DCL

Weight

Only EMC

[Kg]

Product

weight[Kg]

- - 29.5

- - 44

- - 44

- - 72.5

- - 72.5

Only DCL

Product

weight[Kg]

Non EMC

and DCL

Product

weight[Kg]

3-22

Chapter 3 Installation

Inverter

Capacity W[mm] H[mm] D[mm]

SV1100iS7-4 510 783.5 422.6 - - 101 -

SV1320iS7-4 510 861 422.6 - - 114 SV1600iS7-4 510 861 422.6 - - 114 SV1850iS7-4 690 1078 450 - - -200 SV2200iS7-4 690 1078 450 - - -200 SV2800iS7-4 771 1138 440 - - - 252SV3150iS7-4 922 1302.5 495 - - - -352

SV3750iS7-4 922 1302.5 495 - - - -352

Note

Weight[Kg] above indicates the total weight including EMC FIL TER and DCL. (excluding

box packing) 30 through75 kW (200V) products don’t have an option type. 30 through

160kW(400V) products have only DCL option type. 280 through 375kW (400V) products

have not EMC and DCL option.

EMC&DCL

Weight

[Kg]

Only EMC

Product

weight[Kg]

Only DCL

Product

weight[Kg]

Non EMC

and DCL

Product

weight[Kg]

3-23

Chapter 3 Installation

3.1.5 Dimension and Weight of Frame

(UL Enclosed Type 12, IP54 Type)

Inverter

Capacity W[mm] H[mm] D[mm]

SV0008iS7-2/4 204.2 419 208 8.2 7.2 7.7 6.7

SV0015iS7-2/4 204.2 419 208 8.2 7.2 7.7 6.7

SV0022iS7-2/4 204.2 419 208 8.2 7.2 7.7 6.7

SV0037iS7-2/4 204.2 419 208 8.2 7.2 7.7 6.7

SV0055iS7-2/4 254 460.6 232.3 12.8 10.2 12.1 9.5

SV0075iS7-2/4 254 460.6 232.3 12.9 10.3 12.2 9.6

SV0110iS7-2/4 313.1 590.8 294.4 25.6 22.8 22.4 19.6

SV0150iS7-2/4 313.1 590.8 294.4 25.9 23.1 22.7 19.9

SV0185iS7-2 343.1 750.8 315.5 38.3 34.2 34.1 29.9

SV0220iS7-2 343.2 750.8 315.5 38.3 34.2 34.1 29.9

SV0185iS7-4 343.2 750.8 315.5 34.9 31 31 27.1

SV0220iS7-4 343.2 750.8 315.5 34.9 31 31 27.1

Note

Weight[Kg] above indicates total weight. (excluding packing)

0.75~22 kW products have only IP54 type product.

EMC&DCL

Weight[Kg]

Only EMC

Weight[Kg]

Only DCL

Weight[Kg]

Non

EMC&DCL

Weight[Kg]

3-24

Chapter 3 Installation

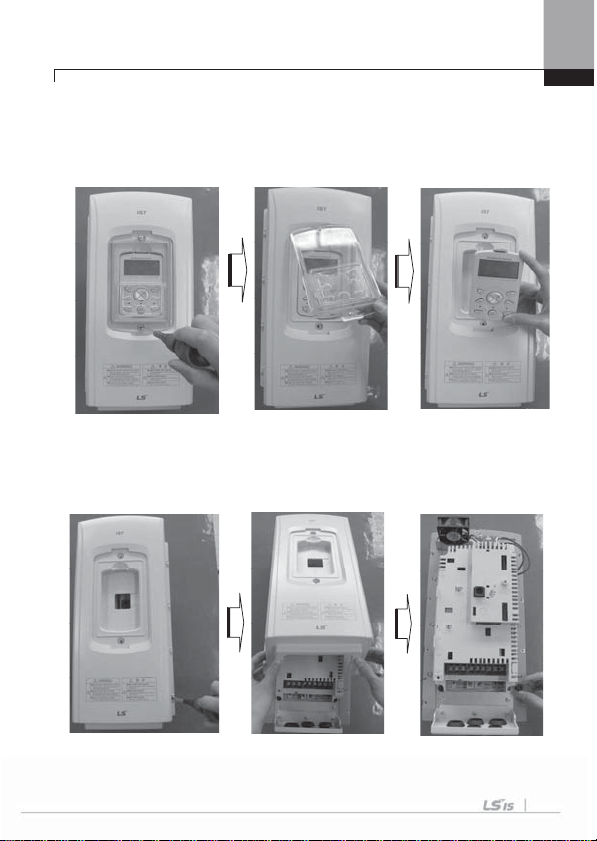

3.1.6 Installation Guide (UL Enclosed Type12, IP54 Ty pe)

1) How to separate IP54 keypad cover and keypad

- Release the upper/lower screw on the transparent keypad cover and then separate

the transparent cover from the inverter.

- Separate the keypad from the inverter.

2) How to separate IP54 front cover

- Loosen the captive screws (nine or thirteen, depending on the size of the frame)

around the edge of the cover.

- Remove the cover.

3-25

Chapter 3 Installation

3) Mounting the inverter

- Remove the four rubber packings on the corner.

- Mount the inverter onto fixing hole on the panel and securely tighten the four screws

or bolts.

- Place the four rubber packings to the each corner.

4) Power cable wiring

- Connects the input/output power cable as followed picture.

- Refer to Chapter 4 Wiring for the detailed wiring.

3-26

Chapter 3 Installation

5 How to attach the IP54 front cover

- Place the front cover matching with plate hole.

- Securely tighten the screw at the corner of front cover.

- Connect the cable to the keypad and then place the front cover on the inverter.

- Place the transparent keypad cover on the keypad and tighten the upper/lower screw .

3-27

Chapter 3 Installation

3-28

Chapter 4 Wiring

4.1 Wiring

Do the wiring of inverter and then check the wiring of main circuit and control circuit

before starting it. Read through the checking list as below.

Checking List

Inverter, Peripherals, Option card

Is the inverter supplied in the form as ordered?

y

Are the type and numbers of peripherals (Resistance, DC reactor, Noise

filter, etc.) supplied as ordered?

y

Is the type of option supplied as supplied?

Place of the inverter to be installed and how to install it

y Is the inverter installed on a right place in a right way?

Power voltage, Output voltage

y Is power voltage within the range of inverter input voltage specified?

y

Does the rated output comply with the inverter output specification?

y

Is the rating done properly?

Main Circuit Wiring

y Is the power input using the circuit breaker?

y

Is the rating of the circuit breaker done properly?

y

Is the power wiring input properly to the inverter input terminal? [If the

input power is connected with the input terminal (U, V, W) it may cause

damage to the inverter]

y

Is the motor wiring connected with the inverter output terminal in a proper

phase sequence? (Otherwise, the motor will be rotated adversely.)

y

Is 600V vinyl insulation wire adopted for the power and motor wires?

y

Is the main circuit wire in a proper size?

Is the ground line installed in a proper way?

y

y

Are the screws of the main circuit terminal and the ground terminal

fastened tightly

y

In the event several motors are operated with one inverter, does each

motor have a overload protecting circuit

y

In the event it adopts braking resistance or braking resistance unit, is an

electronic contactor installed at the inverter power side so as to isolate

the inverter from the power by protecting the resistance from overload

y

Isn't power condenser, surge killer, or radio noise filter connected with the

output side?

?

?

?

4-1

Chapter 4 Wiring

Checking List

Control Circuit Wiring

y Is a twisted pair shielded wire adopted for the inverter control circuit

?

wiring

y

Is the covered wire with shield connected with the ground terminal?

y In the event it is operated in 3-Wire sequence, is the control circuit wiring

done after the parameter of multi-function contact input terminal is

?

modified

Is the wiring of the optional devices done properly?

y

Aren't there any wiring mis-connected?

y

Are the inverter control circuit terminal screws fastened tightly?

y

y

Aren't there any wire fragments or screw left?

Doesn't the remaining wire connected with the terminal contact the

y

terminals nearby

Is the control circuit wiring isolated from the main circuit wiring in the duct

y

or control panel

y

Doesn't the length of wiring exceed 300m ? (In the case of the produce of

3.7kW or less, the entire length of wiring should be 100m or less

y

Doesn't the wiring of safety input exceed 30m?

?

?

)

4-2

Chapter 4 Wiring

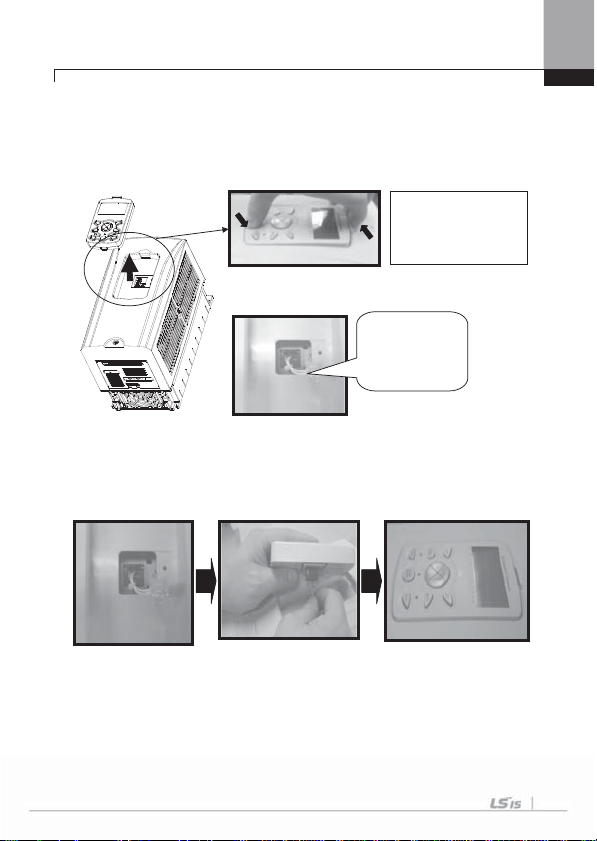

4.1.1 How to separate front cover when wiring

Remove Keypad on the product and release fixed volt of the lower end of up cover.

1) How to separate Keypad

Under pressing the

lower end of keypad,

pull the upper part of

keypad.

Connection wire

for Loader when

keypad is

disconnected.

2) How to assemble plug when connecting Keypad

As showing figures below, install the keypad after connecting the plug.

4-3

Chapter 4 Wiring

3) How to separate front cover

[IP21 Type]

Separate

front cover

I/O board control

circuit Terminal

releasing

the fixed

bolt.

[IP54 Type]

Separate the transparent keypad cover releasing fixed bolt and then separate keypad.

Separate the front cover releasing fixed bolt.

Before wiring, IP54 product must be installed on the panel.

Power circuit

terminal

4-4

Keypad

cover

fixed

bolt

Front

cover

fixed

bolt

Keypad fixed cover

Keypad

Wiring hole

Built-in

circulation

fan

Chapter 4 Wiring

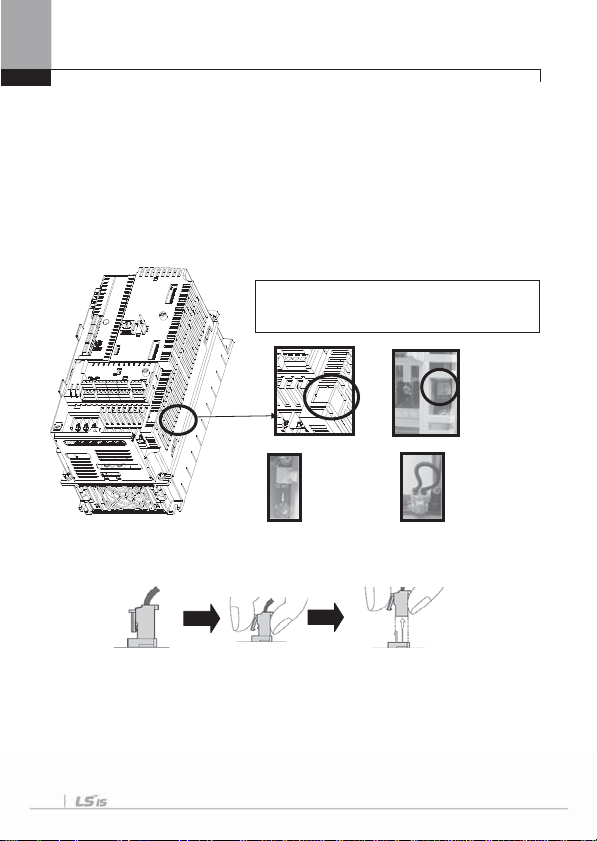

4.1.2 How to separate front cover when wiring

(90~375 kW 400V, 30-75kW 200V)

Releasing the right/left fixed bolt on the lower front cover and get down the lower front

cover and then open it. Now, you can wire power part (R/S/T, P/N, U/V/W) and signal

cable (terminal block, encoder option, communication option, PLC option etc.).

4-5

Chapter 4 Wiring

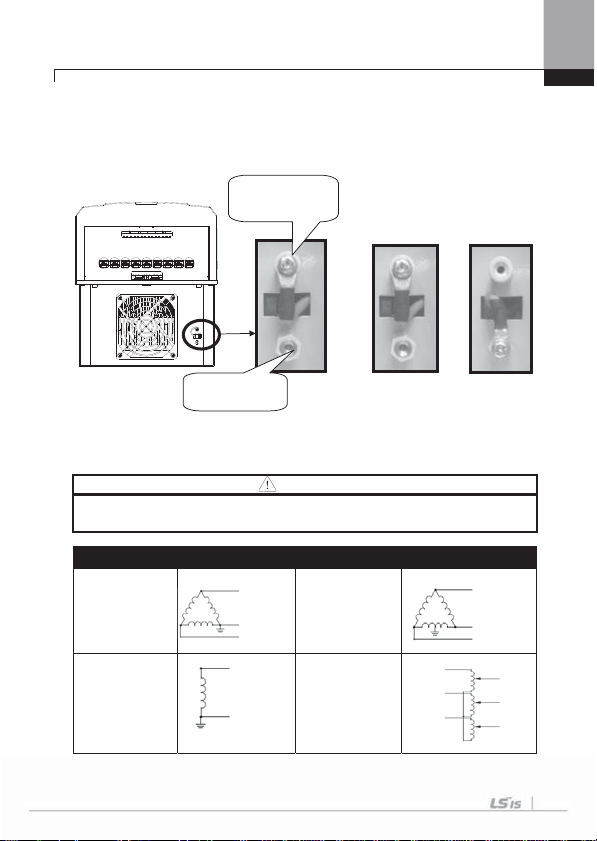

4.1.3 Built-in EMC Filter

The product which has a built-in EMC filter is efficient for reducing conductive and

radiated noise from the input part of inverter. Turns On the On/Off switch of EMC filter to

perform the EMI function if you are select the product which has a built-in EMC filter.

(However, when unable to use EMC filter or due to the asymmetric structure of the

ground to use, EMC filter of on/off swich is set to off

1) How to set EMC Filter functions (Less than 7.5kW Products)

- Cut off plastic cover which marked below.

- If short circuit connector is connected with SW1

which is inside, EMC Filter works.

2) How to remove EMC Filter ON/OFF connector (Less than 7.5kW Product)

EMC filter OFF EMC filter ON

EMC filter ON EMC filter OFF

Check the voltage by a tester in 10minute after cutting the power supply. In case

separate with connector, pull the connector while pressing fixed hasp. When reinstalling,

be sure to hook the hasp of the connector. (If it is hard to separate them, please use

radio pincher or tweezers.)

4-6

Chapter 4 Wiring

3) How to set EMC Filter functions (11~22kW Products)

EMC filter ON/OFF set terminal is located in lower part of the 11~22KW Terminal as

shown figure below. Initial set isON. When the green wire is connected in upper metal

connection terminal, EMC filter is ON and EMC filter is OFF if it is connected in

insulated connection terminal.

Metal terminal for

EMC filter ON

EMC filter has effect in reducing air electronic wave while being used in power source of

symmetrical ground method. Be sure to use EMC filter in symmetrical ground method

such as Y connection.

Insulated

terminal for EMC

EMC filter ON EMC filter OFF

Caution

Leakage current increases while EMC filter is ON. Do not use EMC filter when the

input is asymmetrical way such as Delta connection. It may cause an electric shock.

Asymmetrical Ground structure

1-phase is

grounded in

Delta

connection

Grounded in

1-phase end

R(L1)

S(L2)

T(L3)

L

N

Grounded middle

tap of 1-phase in

Delta connection

Non-grounded

3-Phase

connection

R(L1)

S(L2)

T(L3)

R(L1)

S(L2)

T(L3)

R(L1)

S(L2)

T(L3)

4-7

Chapter 4 Wiring

4.1.4 Wiring precaution

1) The internal circuits of the inverter will be damaged if the incoming power is connected

and applied to output terminals (U, V, W).

2) Use ring terminals with insulated caps when wiring the input power and motor wiring.

3) Do not leave wire fragments inside the inverter. Wire fragments can cause faults,

breakdowns, and malfunctions.

4) For input and output, use wires with sufficient size to ensure voltage drop of less than

2%. Motor torque may drop of operating at low frequencies and a long wire run

between inverter and motor.

5) The cable length between inverter and motor should be less than 150m (492ft). Due to

increased leakage capacitance between cables, overcurrent protective feature may

operate or equipment connected to the output side may malfunction. [But for products

of less than 3.7kW, the cable length should be less than 50m (164ft).]

6) The main circuit of the inverter contains high frequency noise, and can hinder

communication equipment near the inverter. To reduce noise, install line noise filters

on the input side of the inverter.

7) Do not use power factor capacitor, surge killers, or RFI filters on the output side of the

inverter. Doing so may damage these components.

8) Always check whether the LCD and the charge lamp for the power terminal are OFF

before wiring terminals. The charge capacitor may hold high-voltage even after the

power is disconnected. Use caution to prevent the possibility of personal injury.

9) Do not connect with MC at output pare of inverter and make MC On/Off during

operation. It can cause the Trip or damage of inverter.

10) When using a DC common with 30~75kW product, please be careful.

30~75kW product provides P1(+) and P2(+) terminal. In the case of DCR type of

product, P1(+) terminal is before reactor and P2(+) terminal is after reactor.

Therefore When using DC Common, you mush use P2(+) and N.

So, inevitablely to use DC Common, before using that, you muse contact with sales

team in advance. Because various matters need to be considered except for wiring.

Similary, when you connected to an external braking unit, you must use P2(+) and N

terminal.

Otherwise, products can be damaged(ex. Using P1(+) and N Terminal)

4.1.5 Grounding

1) The inverter is a high switching device, and leakage current may flow. Ground the

inverter to avoid electrical shock.

2) The ground impedance for 200V class is 100 ohm or less and 400V class 10ohm or less .

3) Connect only to the dedicated ground terminal of the inverter. Do not use the case or

the chassis screw for grounding.

4) As a minimum, grounding wire should meet the specifications listed below. Grounding

wire should be as short as possible and should be connected to the ground point as

near as possible to the inverter.

4-8

Chapter 4 Wiring

G

S

G

G

r

Inverter Capacity

Grounding wire size ( mm²)

200V class 400V class

0.75 ~ 3.7kW 3.5 2

5.5 ~ 7.5 kW 5.5 3.5

11 ~ 15 kW 14 8

18.5 ~ 22 kW 22 14

30 ~ 45 kW 22 22

55 ~ 75 kW 38 38

90 ~ 110 kW - 60

132 ~ 220 kW - 100

280 ~ 315 kW - 185

375 kW - 240

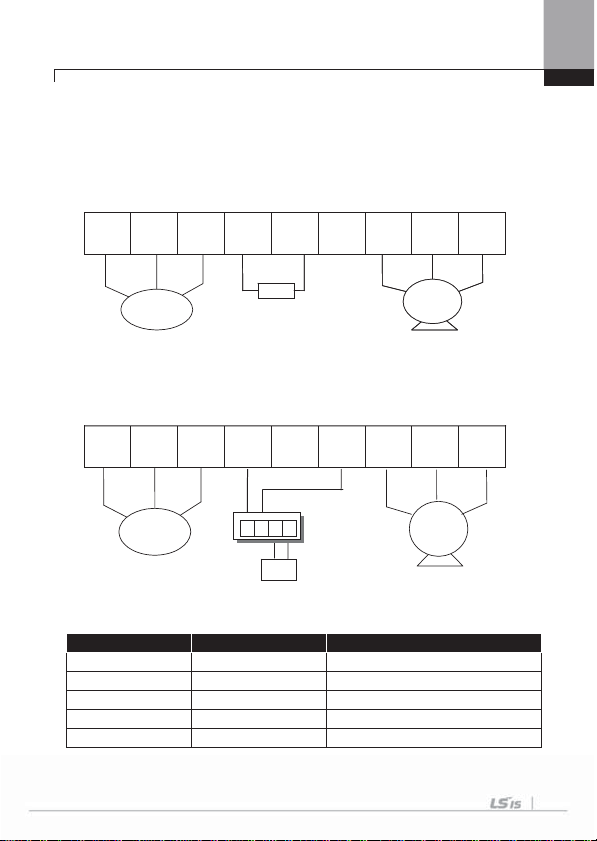

4.1.6 Terminal wiring diagram (POWER terminal block)

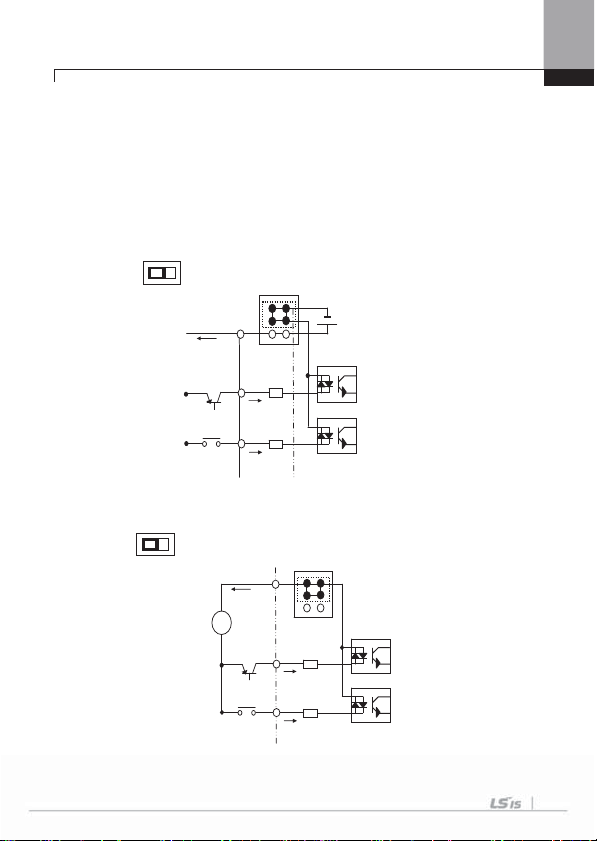

1) Wiring of Inverter below 7.5kW

Ground

terminal

G

R(L1)

(L2)

T(L3)

External

Fuse

2) Wiring of 11~22kW Product

3Phas e

AC

3-phase AC input

power supply

P(+)

BG

N(-)G

Dynamic brake resistor

R(L1) S(L2) T(L3) P(+) B N(-) U V W

3) Wiring of 30~75kW Product

R(L1) S(L2) T(L3) P1(+) P2(+) N(-) U V W

VG WG

IM

Moto

4-9

Chapter 4 Wiring

4) Wiring of 90~160kW Product

R(L1) S(L2) T(L3) P2(+) N(-) U V W

5) Wiring of 185~220kW Product

R(L1) S(L2) T(L3) P2(+) N(-) U V W

6) Wiring of 280~375kW Product

R(L1) S(L2) T(L3) P1(+) P2(+) N(-) U V W

Note

Products over 11kW have a linear arrangement of terminal blocks. Products for

0.75~22kW have built-in DC Reactor, so it does’t necessary any other DC Reactor

connection. Ground terminal must be grounded. Do not use ground to command for

ground cable, welding machine and power machine etc. Ground cable must be wire as

short as possible. If ground terminal of inverter is far from the inverter,electric potential

of inverter terminal ground can be unstable because leakage current of inverter can be

gernerated form inverter.

4-10

Chapter 4 Wiring

A

4.1.7 Terminals of main circuit

1) 0.75 ~ 22 kW (200V/400V)

(1) Built-in dynamic braking unit used

Connect P(+) and B terminal of inverter to the dynamic braking unit when built-in

dynamic unit is used.

R(L1) S(L2) T(L3) P(+) B N(-) U V W

Connects P(+) terminal of inverter to P/(+) terminal of the dynamic braking unit and

3 Phase

C Input

(2) Optional dynamic braking unit used

N(-) terminal of inverter to N/(-) terminal of the dynamic braking unit. B terminal of

inverter is not used.

R(L1) S(L2) T(L3) P(+) B N(-) U V W

DBR

Dynamic Brake

Resistor

Motor

ۡ

ۡ

ۡ

ۡ

ۡ

3 Phase

AC Input

P

ۡ

N

B1 B2

DB

Dynamic

Braking Unit

Dynamic Brake

Resistor

Motor

Terminal Symbol Terminal Name Description

R(L1),S(L2),T(L3) AC power supply input Connects normal AC input

P(+) (+) DC voltage terminal (+) DC link voltage terminal

N(-) (-) DC voltage terminal (-) DC link voltage terminal.

P(+),B Dynamic brake resistor Connects dynamic brake resistor.

U,V,W Inverter output Connects the 3 phase induction motor

4-11

Chapter 4 Wiring

2) 30 ~ 75 kW (200V, 400V)

R(L1) S(L2) T(L3) P1(+) P2 N(-) U V W

3 Phase

AC Input

DBU

Terminal Symbol Terminal Name Description

R(L1), S(L2), T(L3) AC power supply input Connects normal AC input

P1(+) (+)DC voltage terminal

P2, N(-)

N(-) (-)DC voltage terminal (-)DC link voltage terminal.

U, V, W Inverter output

1)

When using this terminal as a DC common, special considerations are required.

Dynamic brake unit

connection,

DC common terminal

N

B1

B2

P

Motor

DBR

(+)DC link voltage terminal,

It is located in front of DCL terminal.

Voltage terminal connecting Dynamic

brake unit, DC common terminal

1)

Connects the 3-phase induction

motor.

Be sure to consult with our sales representative.

Remark

Pay close attention when using 30~75W product for DC Common.

Buying DC reactor from the outside, it can not be installed with 30~75kW product. If you

want to use DC reactor of product, please purchase type of 30~75kW product mounted

with DC reactor. P1(+) terminal is at the Reactor’s front end while P2(+) terminal at its

back-end.

In the event of using such other DCR-mounted product for DC Common, you must use

P2(+) and N(-) terminals without fail. When using P1(+) and N(-) terminals for DC

Common, it may casue damage to the product.

Use for DC Common requires several considerations besides wiring. Therefore, in the

event it should be used for DC Common inevitably, be sure to contact our Sales

Department in advance.

Likewise, in the event of connecting with exterial braking unit, you must use P2(+) and

N(-) terminals without fail. When connecting with P1(+) and N(-) terminals, it may cause

damage to the product.

4-12

Chapter 4 Wiring

3) 90 ~ 160 kW (400V)

R(L1) S(L2) T(L3) P2(+) N(-) U V W

4) 280 ~ 375 kW (400V)

3 Phase

AC Input

Terminal Symbol Terminal Name Description

R(L1), S(L2), T(L3) AC power supply input Connects normal AC input

P(+) (+)DC voltage ternimal (+)DC link voltage terminal

N(-) (-)DC voltage terminal ( - )DC link voltage terminal

P(+), N(-)

U, V, W Inverter output

External brake unit

P N B1 B2

connection

Dynamic

brake unit

DBR

Dynamic

brake resistor

Voltage terminal connecting Dynamic

brake unit.

Connects the 3-phase induction

motor.

Motor

R(L1) S(L2) T(L3) P1(+) P2 N(-) U V W

3 Phase

AC Input

DBU

Terminal Symbol Terminal Name Description

R(L1), S(L2), T(L3) AC power supply input Connects normal AC input

P1(+) (+)DC voltage terminal

P2, N(-)

N(-) (-)DC voltage terminal (-)DC link voltage terminal.

U, V, W Inverter output

1)

When using this terminal as a DC common, special considerations are required.

Dynamic brake unit

connection,

DC common terminal

N

B1

B2

P

Motor

DBR

(+)DC link voltage terminal,

It is located in front of DCL terminal.

Voltage terminal connecting Dynamic

brake unit, DC common terminal

1)

Connects the 3-phase induction

motor.

Be sure to consult with our sales representative.

4-13

Chapter 4 Wiring

2)

²

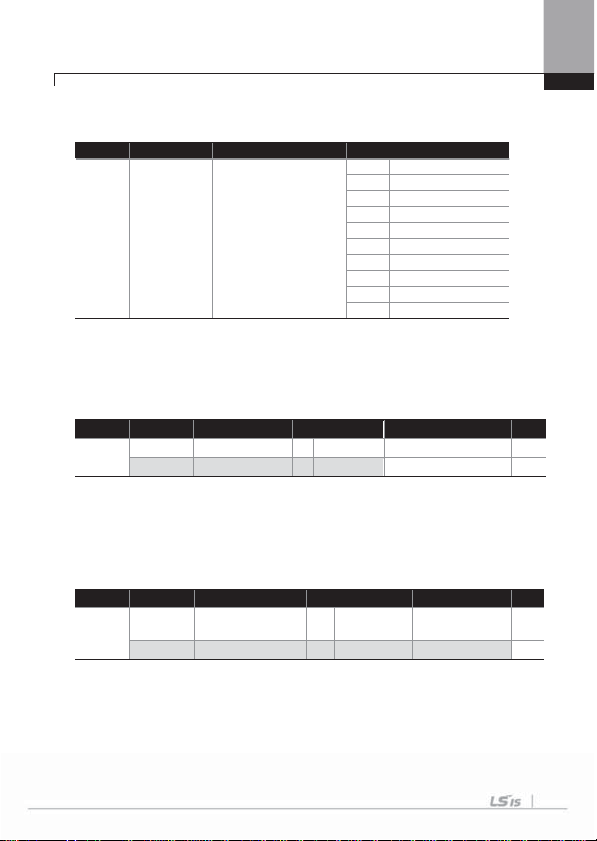

4.1.8 Specifications of power terminal block and Exterior fuse

Inverter applied

Terminal

Screw

size

Screw torque

1)

(Kgf·cm)

Cable

mm

AWG

R,S,T U,V,W R,S,T U,V,W Current Voltage

0.75 kW M4 7.1~12 2.5 2.5 14 14 10A

1.5 kW M4 7.1~12 2.5 2.5 14 14 15A

2.2 kW M4 7.1~12 2.5 2.5 14 14 20A

3.7 kW M4 7.1~12 4 4 12 12 32A

5.5 kW M4 7.1~12 6 6 10 10 50A

7.5 kW M4 7.1~12 10 10 8 8 63A

2

11 kW M6 30.6~38.2 16 16 6 6 80A

0

15 kW M6 30.6~38.2 25 22 4 4 100A

0

18.5 kW M8 61.2~91.8 35 30 2 2 125A

V

22 kW M8 61.2~91.8 35 30 2 2 160A

30 kW M8 61.2 ~ 91.8 70 70 1/0 1/0 200A

37 kW M8 61.2 ~ 91.8 95 95 2/0 2/0 250A

45 kW M8 61.2 ~ 91.8 95 95 2/0 2/0 350A

55 kW M10 89.7 ~ 122.0 120 120 3/0 3/0 400A

75 kW M10 89.7 ~ 122.0 150 150 4/0 4/0 450A

0.75~1.5kW M4 7.1~12 2.5 2.5 14 14 10A

2.2 kW M4 7.1~12 2.5 2.5 14 14 15A

3.7 kW M4 7.1~12 2.5 2.5 14 14 20A

5.5 kW M5 24.5~31.8 4 2.5 12 14 32A

7.5 kW M5 24.5~31.8 4 4 12 12 35A

11 kW M5 24.5~31.8 6 6 10 10 50A

15 kW M5 24.5~31.8 16 10 6 8 63A

18.5 kW M6 30.6~38.2 16 10 6 8 70A

22 kW M6 30.6~38.2 25 16 4 6 100A

4

30~37 kW M8 61.2~91.8 25 25 4 4 125A

0

45 kW M8 61.2~91.8 70 70 1/0 1/0 160A

0

55 kW M8 61.2~91.8 70 70 1/0 1/0 200A

V

75 kW M8 61.2~91.8 70 70 1/0 1/0 250A

90 kW M12 182.4~215.0 100 100 4/0 4/0 350A

110 kW M12 182.4~215.0 100 100 4/0 4/0 400A

132 kW M12 182.4~215.0 150 150 300 300 450A

160 kW M12 182.4~215.0 200 200 400 400 450A

185 kW M12 182.4~215.0 200 200 400 400 620A

Exterior fuse

500V

500V

4-14

Chapter 4 Wiring

2)

²

Inverter applied

Terminal

Screw

size

Screw torque

(Kgf·cm)

1)

mm

Cable

AWG

Exterior fuse

R,S,T U,V,W R,S,T U,V,W Current Voltage

220 kW M12 182.4~215.0 250 250 500 500 800A

280 kW M12 182.4~215.0 325 325 650 650 1000A

315 kW M12 182.4~215.0 2x200 2x200

375 kW M12 182.4~215.0 2x250 2x250

1) : Apply the prescribed torque for the terminal screws. If the screws are loose, it might cause a

failure.

2) : Use 600V 75 copper cable.

The entire cable length should be below 150m. In case of connection of the motor, the entire

length should not exceed 150m because if a motor is connected from a remote location, the

over current protection function might be started by the harmonics caused by the floating

volume increment within the cables or a failure of the device connected to the secondary side

might occur. The entire cable length should be below 150m too when you connect more than

one motor. Do not use a triplex cable in case of distance wiring. (50m when below 3.7KW)

In case of lengthy wiring, Use thick wire in order to reduce line voltage drop and decrease the

carrier frequency or use a micro surge filter.

Line Voltage Drop [V] = (¥3 X wire resistance [mȍ/m]X wire length [m] X Current [A])/1000

Distance between inverter and motor Up to 50 m Up to 100 m Over 100 m

2x40

2x50

0

0

2x400 1200A

2x500 1400A

Permitted carrier frequency Below 15 kHz Below 5 kHz Below 2.5 kHz

Note Short Circuit Rating

Suitable for use on a circuit capable of delivering not more than 5,000 rms Symmetrical

Amperes, 240 or 480 Volts Maximum. When protected by a circuit breaker having an

interrupting rating not less than 100,000 rms symmetrical amperes, Suitable for use on a circuit

capable of delivering not more than 100,000 rms Symmetrical Amperes, 480 Volts Maximum.

4-15

Chapter 4 Wiring

)

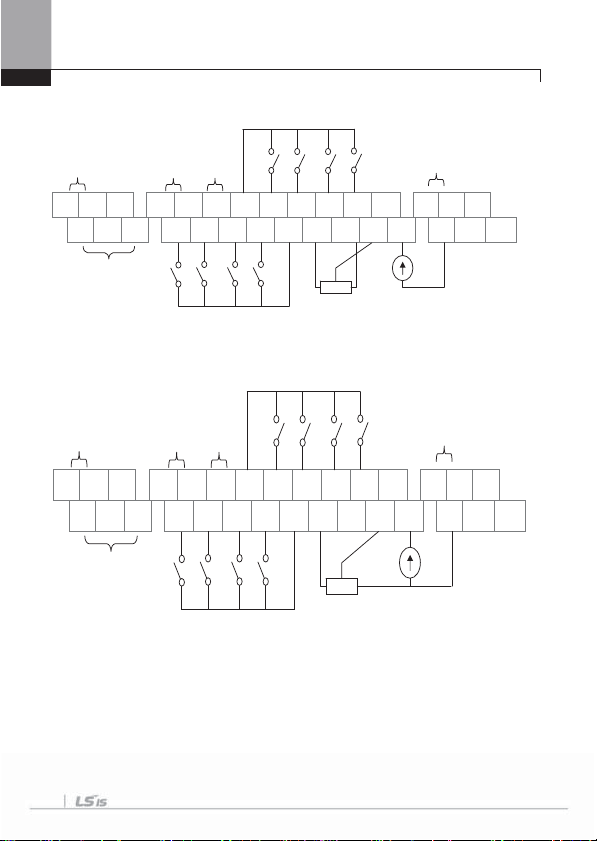

4.1.9 Control terminal line diagram (Basic I/O terminal block, below 22kW)

NPN (Sink)

/PNP (Source) set terminal

I / PTC

set terminal

TR

1) How to set NPN (Sink)/PNP (Source)

iS7 serves 2 sequence input terminals of control circuit: NPN mode (Sink mode)

and PNP mode (Source mode). It is possible to change the logic of input terminal with

NPN mode (Sink mode) and PNP mode (Source mode) by using NPN (Sink)/PNP

(Source) set terminal. Each mode connecting methods are follows.

(1) NPN mode (Sink mode)

Set NPN (Sink)/PNP (Source) switch into NPN. CM (24V GND) is common terminal of

contact point input signal. Initial set of Factory default is NPN mode (Sink mode).

PNP

NPN

NPN mode (Sink mode)

CM (24G)

Inner source (24V)

P1(FX

P2 (RX)

4-16

Chapter 4 Wiring

+

(2) PNP mode (Source mode) – When use inner source

Set NPN (Sink)/PNP (Source) switch into PNP. 24 (24V inner source) is common

terminal of contact point input signal. PNP mode (Source mode) – Set NPN (Sink)/PNP

(Source) switch into PNP When use exterior source.

If you want try to use exterior 24V source, connect exterior source (-) terminal with CM

(24V GND).

PNP

NPN

PNP mode (Source mode) – When using inner source

Inner source (24V)

24(24V)

P1(FX)

P2(RX)

NPN PNP

External

Source (24V)

PNP mode (Source mode) – When using external source

CM (24G)