r

K200S

MASTER-K

Programmable Logic Controlle

z

Read this manual carefully before installing,

wiring, operating, servicing or inspecting this

equipment.

z

Keep this manual within easy reach for

quick reference.

K300S

K1000S

Chapter 1 Introduction

1 Introduction.........................................................................................................1-1

1.1 Guide to the user’s manual....................................................................................... 1-1

1.2 Features....................................................................................................................1-2

1.3 Terminology...............................................................................................................1-3

Chapter 1 Instruction MASTER-K

1 Introduction

1.1 Guide to the user’s manual

This user’s manual contains specifications, performance, and handling instructions for each of

unit of MASTER-K 200S/300S/1000S series PLC system.

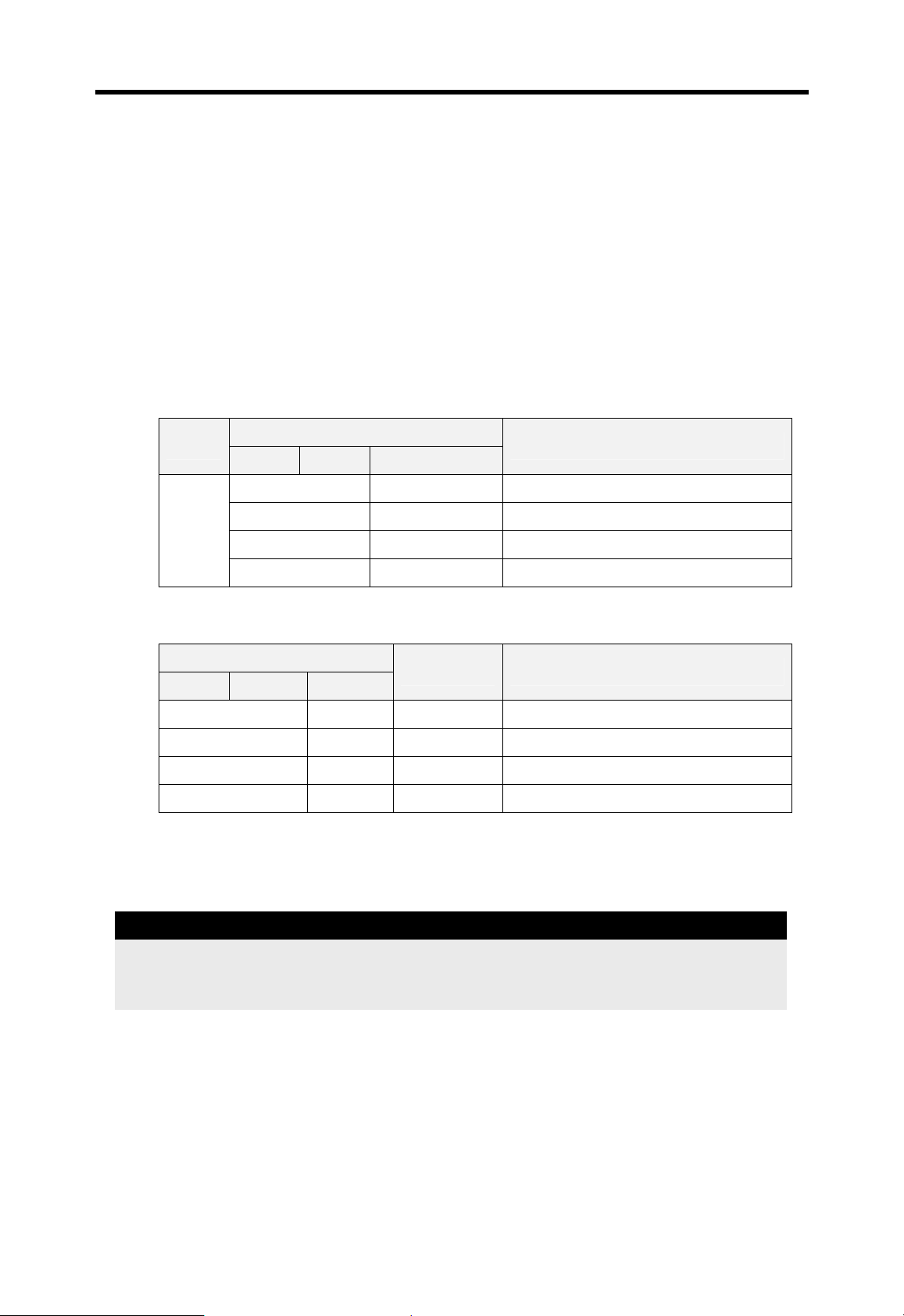

The following table shows the configuration of this user’s manual.

Chapter Item Description

1 Instruction

2 System configuration

3 Specifications

4 CPU module

5 Battery

6 Memory module

7 Digital I/O module

8 Power supply module

9 Base and cable

10 Installation and wiring

11 Maintenance

12 Troubleshooting

Describes configuration of this manual, modules

features and terminology.

Describes available modules and system

configurations in the MASTER-K200S/300S/1000S

series.

Describes general specifications of various modules

used in the MASTER-K200S/300S/1000S series.

Describes the performance, specifications and

functions of the CPU module.

Describes the specifications and handling instructions

for other modules except for the CPU module.

Describes installation, wiring and handling instructions

for reliability of the PLC system.

Describes the check point and method for

maintenance of the PLC system.

Describes various operation errors and corrective

actions.

13

14

15 PID function of K200S

16

Appendix 1 Flag list Describes types and contents of various flags

Appendix 2 Dimension

Remark

In this manual, it is not described that the hardware information and programming of

special/communication modules. Please refer the user’s manual of each module for details.

RS232C communication

for K200S

RS422 communication

for K200S

High speed counter of

K200S

Describes the RS-232C communication function of

K200S A and C type

Describes the RS422 communication functions of

K200S B type

Describes the PID control function of K200S B and C

type

Describes the HSC function of K200S C type

Shows dimensions of CPU, I/O modules and base

unit

1-1

Chapter 1 Instruction MASTER-K

1.2 Features

The features of MASTER-K 200S/300S/1000S series are as following;

1) Program compatibility with previous MASTER-K series

2) Support various and easy-to-use programming devices

① KGL-WIN : Graphic loader for Windows 95 / 98

② KLD-150S : Hand-held loader

3) Open network by supporting communication protocol complying with international

standard.

4) Fast processing speed (operation dedicated processor is mounted)

① K200S : 0.5 μsec / step

② K300S / K1000S : 0.2 μsec / step

5) Various special modules that enlarge the application range of PLC

6) Enhanced self-diagnosis functions

The MASTER-K 200S/300S/1000S series provides more detail error codes that make the

cause of error can be found more easily.

7) Debug function

On-line debugging is available by changing the operation mode as RUN Æ Debug. The

MASTER-K 200S/300S/1000S series provides following debugging functions;

① Execution by one instruction

② Execution by break point setting

③ Execution by the device status

④ Execution by specified scan times

8) Various program types

The MASTER-K 200S/300S/1000S series supports various program types such as timedriven interrupt (TDI), process-driven interrupt (PDI), and subroutine program.

1-2

Chapter 1 Instruction MASTER-K

1.3 Terminology

The following table shows the definition of terms used in this manual.

Terms Definition Remark

A standard element that has a specified function which

Module

Unit

PLC system

KGL-WIN

KLD-150S

I/O image area

FAM

Fnet Fieldbus network

Cnet Computer network (RS-232C, RS-422/485)

configures a system. Devices such as CPU or I/O, which

mounted on the base board or base unit.

A single mod ule or group of modules that performs an

independent operation as a part of PLC system.

A system that con sists of PLC and peripheral devices that

are controlled by user program.

A computer software for Windows 95 / 98 used for write,

editing, and debugging of user program of MASTER-K

series.

A hand-held loader used for write, editing, and debugging

of user program of MASTER- K series

Internal memory area of CPU module that holds the I/O

status during PLC operation.

Abbreviation of the ‘Factory Automation Monitoring S/W’. It

is used to call software for process supervisio n.

Example)

CPU module,

Power module,

I/O module, etc.

Example)

main unit,

expansion unit

Pnet ProfiBus Network

Enet Ethernet Network

RTC

Watchdog timer

Abbreviation of ‘Real Time Clo ck’. It is used to call general

ICs that contains clock function.

An internal timer used for supervising program execution

time. It gives a warning when the execution time exceeds

the preset time.

1-3

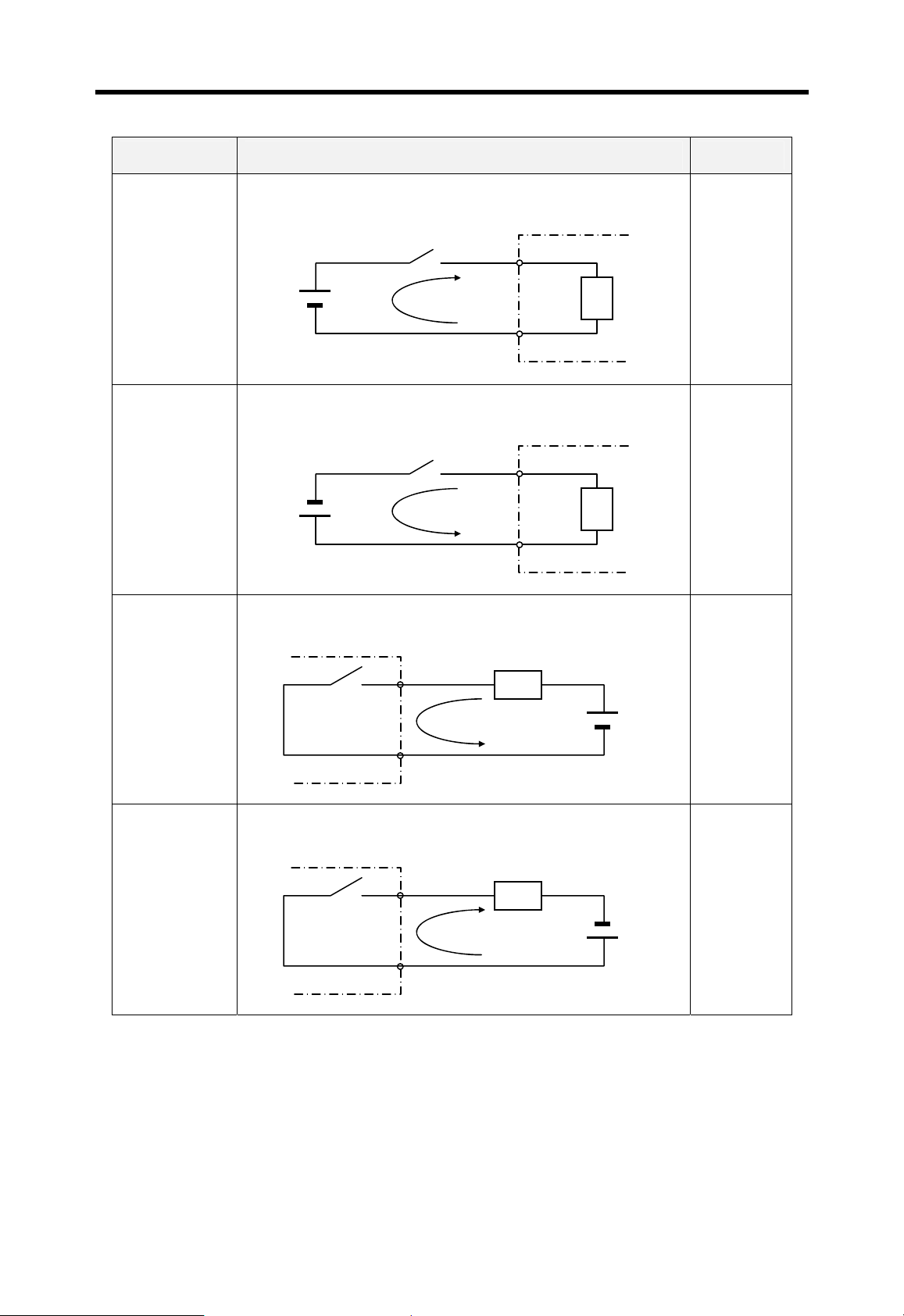

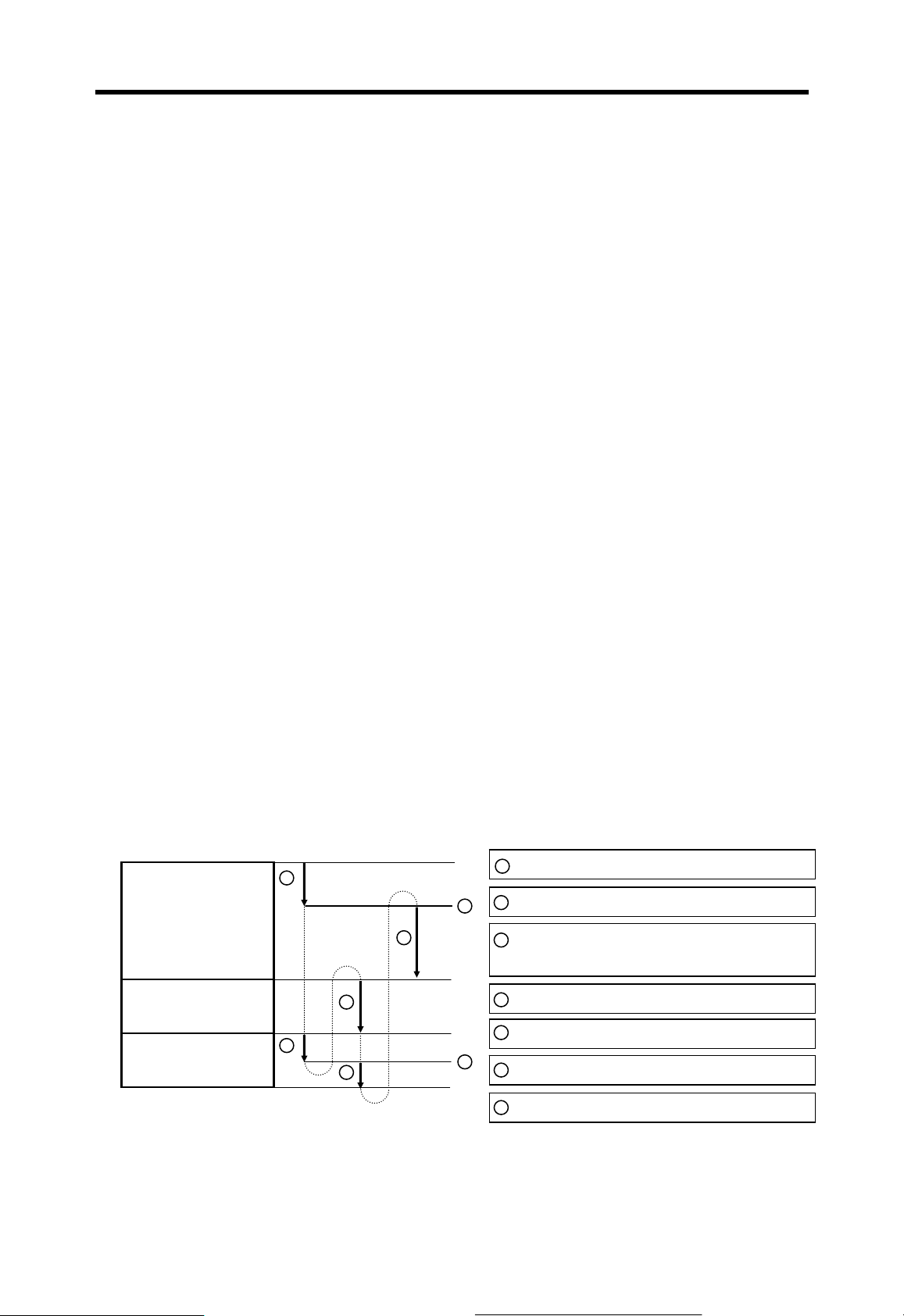

Chapter 1 Instruction MASTER-K

y

y

Terms Definition Remark

Current flows in from the input switch to the input terminal of

PLC when an input signal is turned on.

PLC

Z: Input

Z

impedance

Sink input

Switch

+

Power

Current

Input

terminal

Source input

Sink output

Common

Current flows out from the input terminal of PLC to the input

switch when an input signal is turned on.

Switch

–

Power

+

Current

Input

terminal

Common

PLC

Z

Current flows in from the external load to the output terminal of

PLC when an output signal is turned on.

PLC

Output

rela

Output

terminal

Common

Z

+

Power

Current

Source output

Current flows out from the output terminal of PLC to the

external load when an output signal is turned on.

PLC

Output

rela

Output

terminal

Common

Current

Z

–

Power

+

1-4

Chapter 2 System configuration

2 System configuration ...........................................................................................2-1

2.1 Overall configuration................................................................................................2-1

2.1.1 K200S series..........................................................................................................2-1

2.1.2 K300S / 1000S series............................................................................................2-2

2.2 Product list................................................................................................................2-3

2.2.1 K200S.................................................................................................................... 2-3

2.2.2 K300S.................................................................................................................... 2-5

2.2.3 K1000S.................................................................................................................. 2-8

2.3 System configuration types................................................................................... 2-11

2.3.1 Basic system configuration.................................................................................. 2-11

2.3.2 Computer link system..........................................................................................2-12

2.3.3 Network system...................................................................................................2-13

Chapter 2 System configuration MASTER-K

2 System configuration

The MASTER-K 200S/300S/1000S series has various modules suitable to configuration from

the basic to a large network system. This chapter describes the configuration and features of

each systems.

2.1 Overall configuration

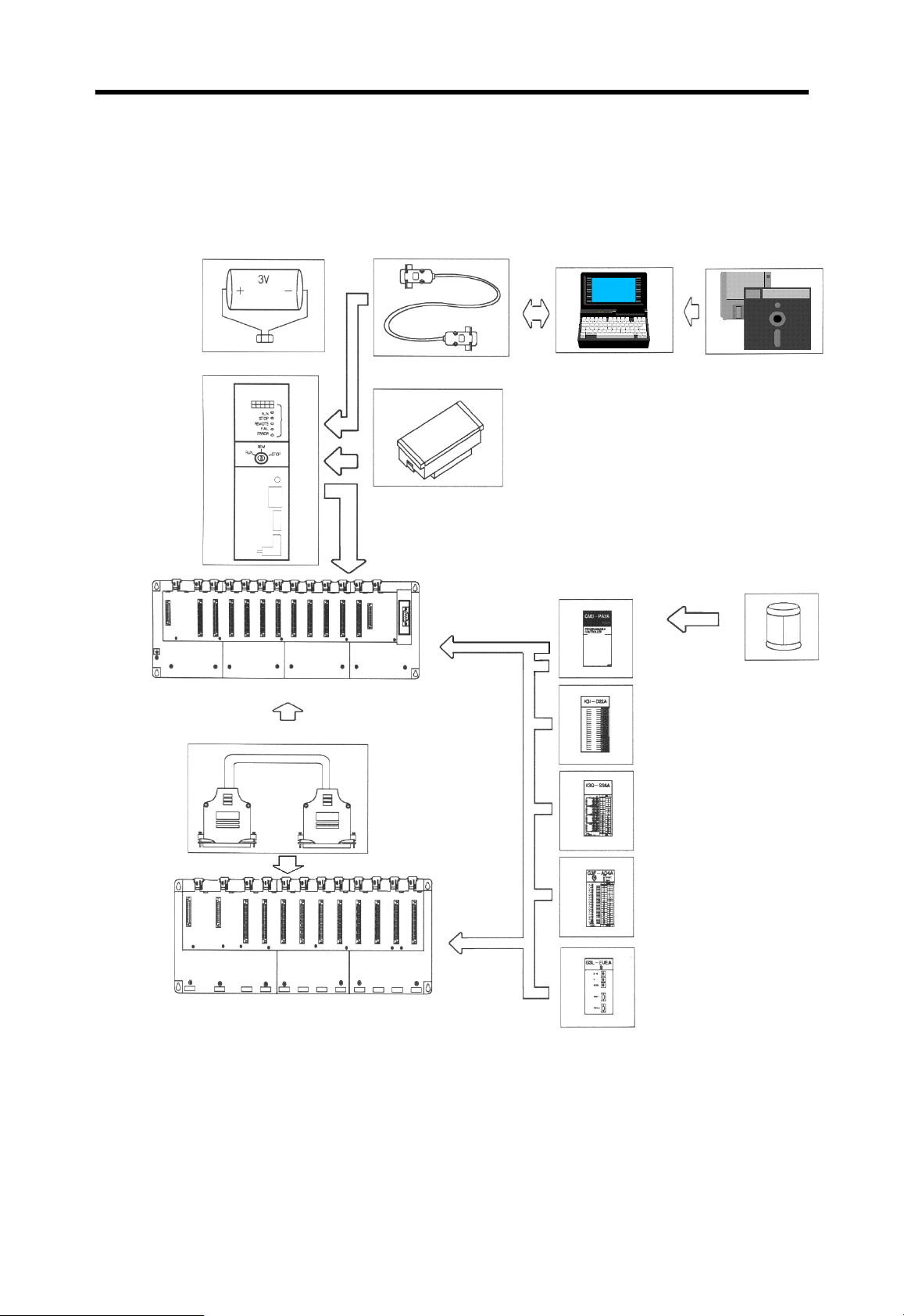

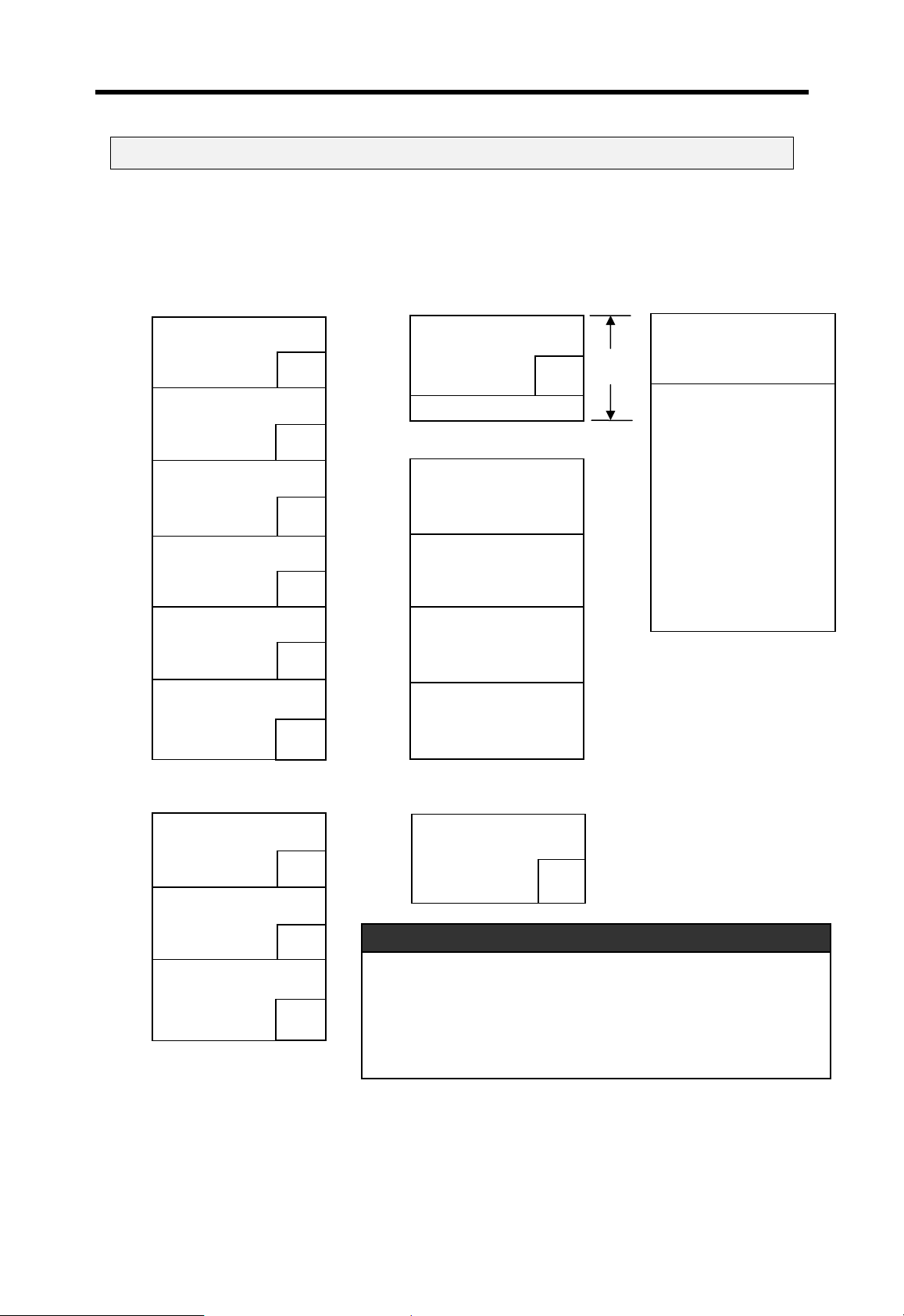

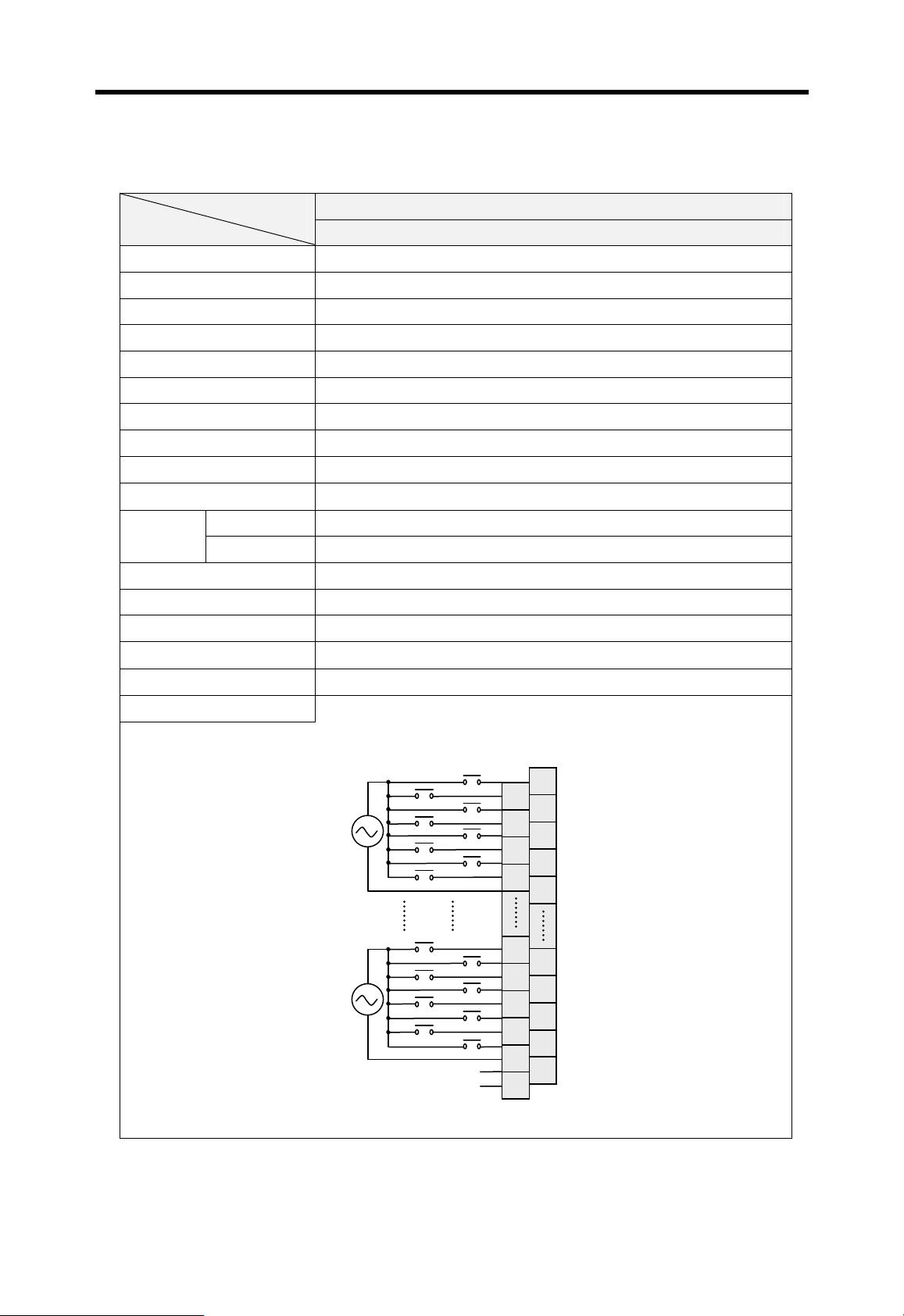

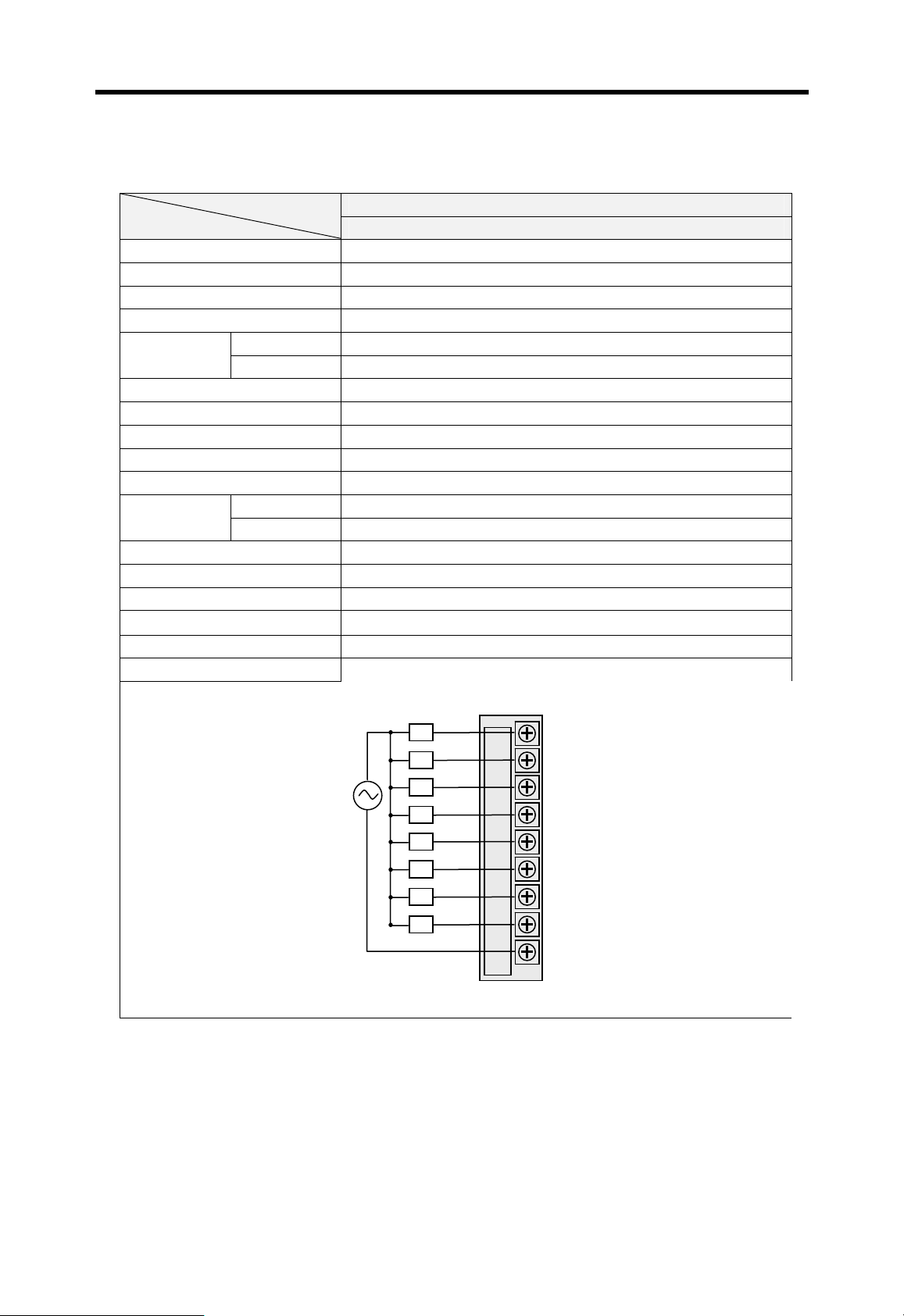

2.1.1 K200S series

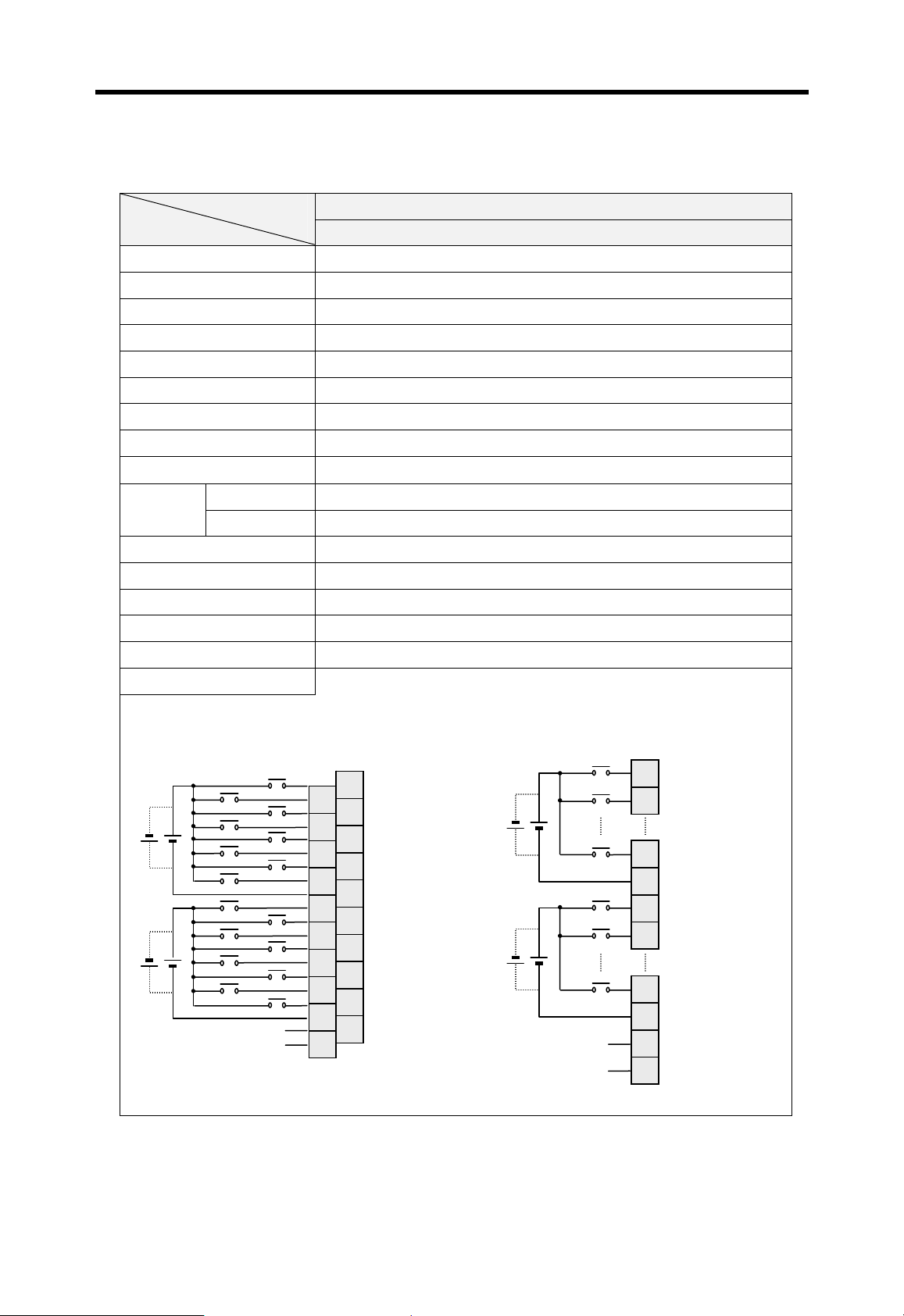

The overall system configuration of K200S series is as following;

Battery

POWER O

K3S-301S

Power Supply

Module

(K3S-□□□S)

K3P-07AS

RUN

PAU/RE

M

CPU Module

KGL-WIN

RS-232C

Cable

IBM

compatible PC

Base board(GM6 – B □□M)

KGL-WIN S/W

G6I-D22A

G6Q-RY2A

G6F-AD2A

G6L-FUEA

(G6I-□□□S)

Input Module

Output Module

(G6Q-□□□S)

Special Module

(G6F-□□□□)

Communication

Module

(G6L-□□□□)

2-1

Chapter 2 System configuration MASTER-K

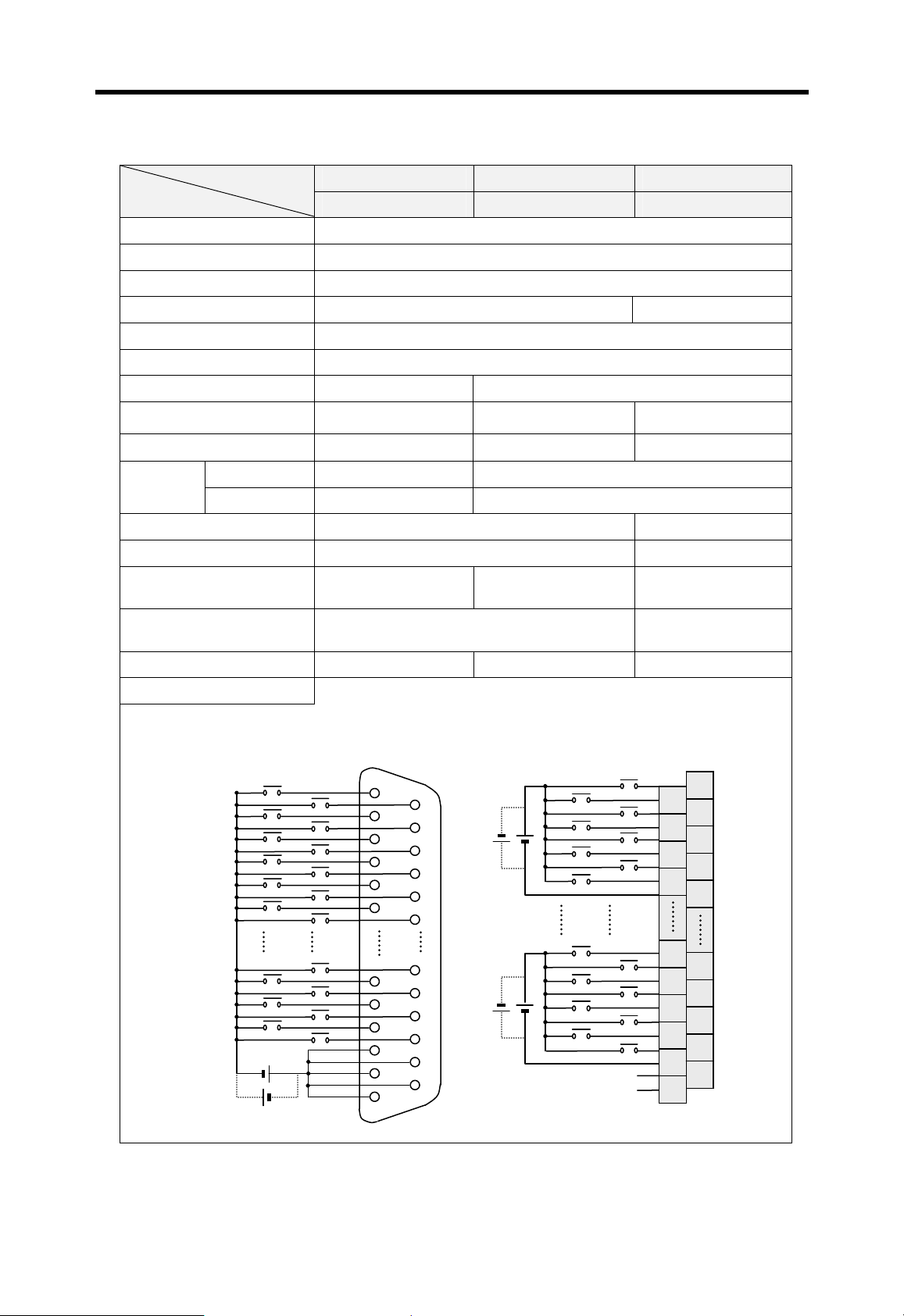

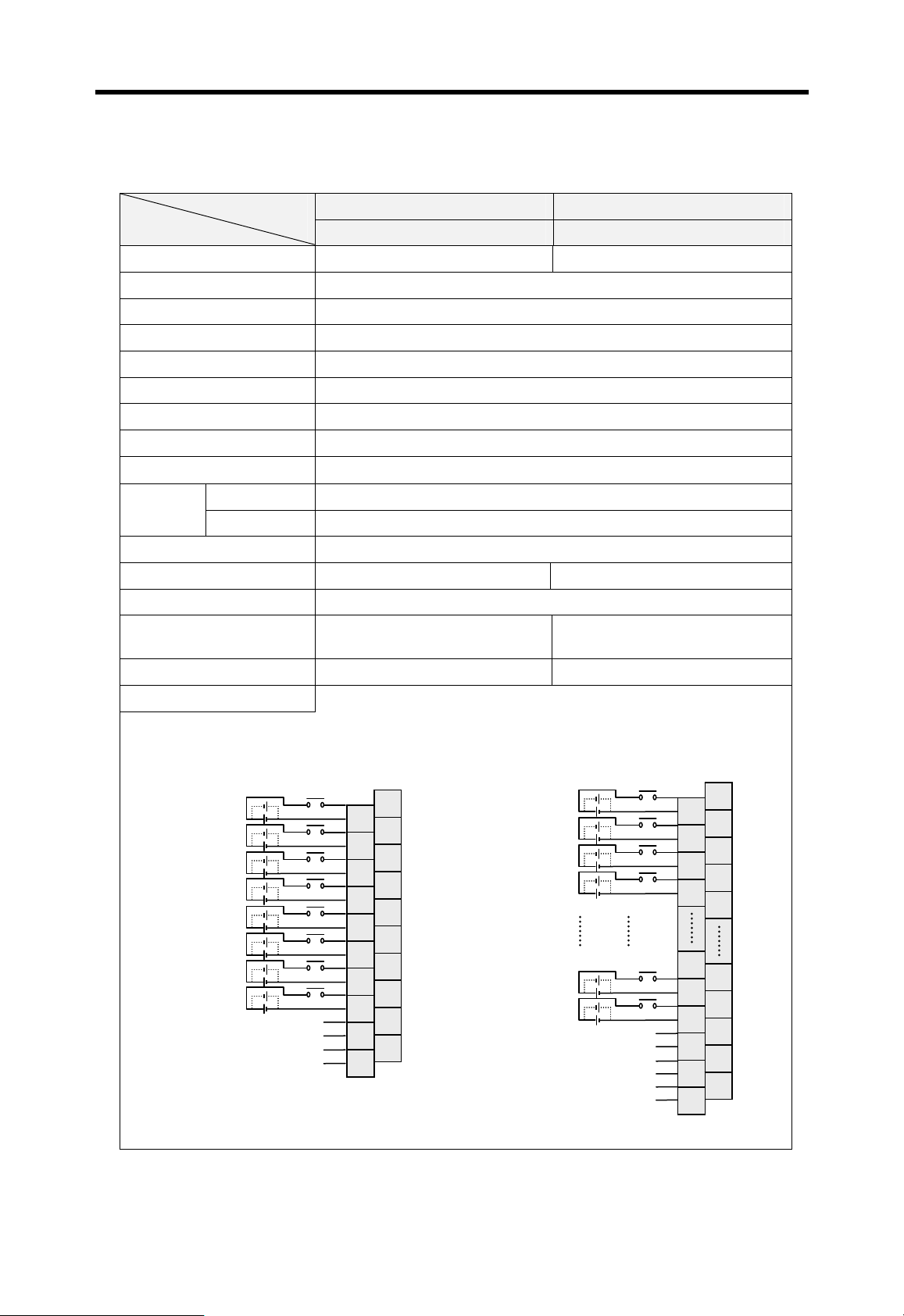

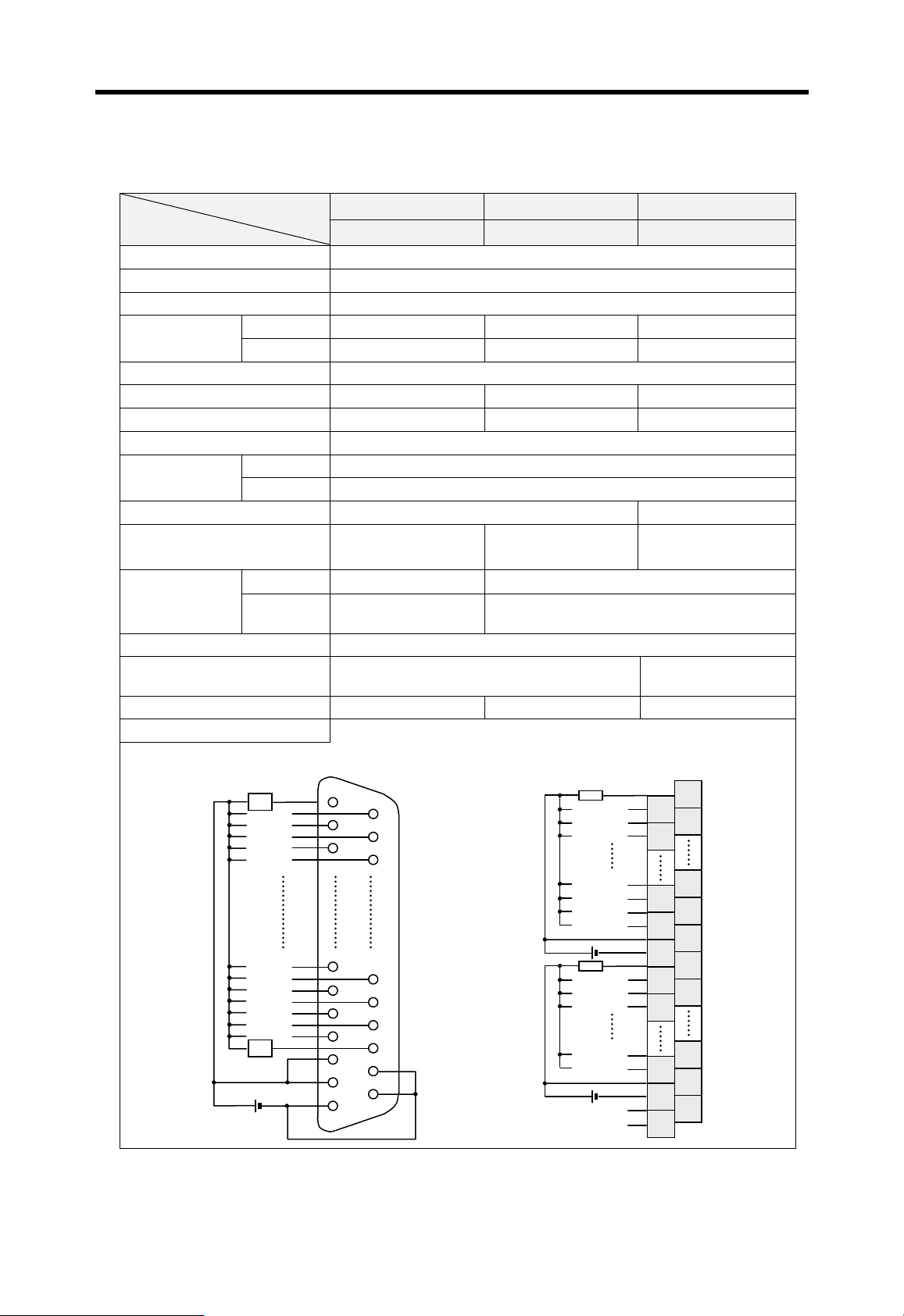

2.1.2 K300S / 1000S series

The overall system configuration of K300S/1000S series is as following;

CPU Module

Battery

-

Main Base

Memory Module

IBM compatible PC RS232-C Cable

MASTER-K

Power Supply

Module

Input Module

KGL-WIN

Fuse

Expansion Cable

Expansion Base

Output Module

Special Function Module

Communication Module

2-2

Chapter 2 System configuration MASTER-K

2.2 Product list

The product list of K200S/300S/1000S are as following;

2.2.1 K200S

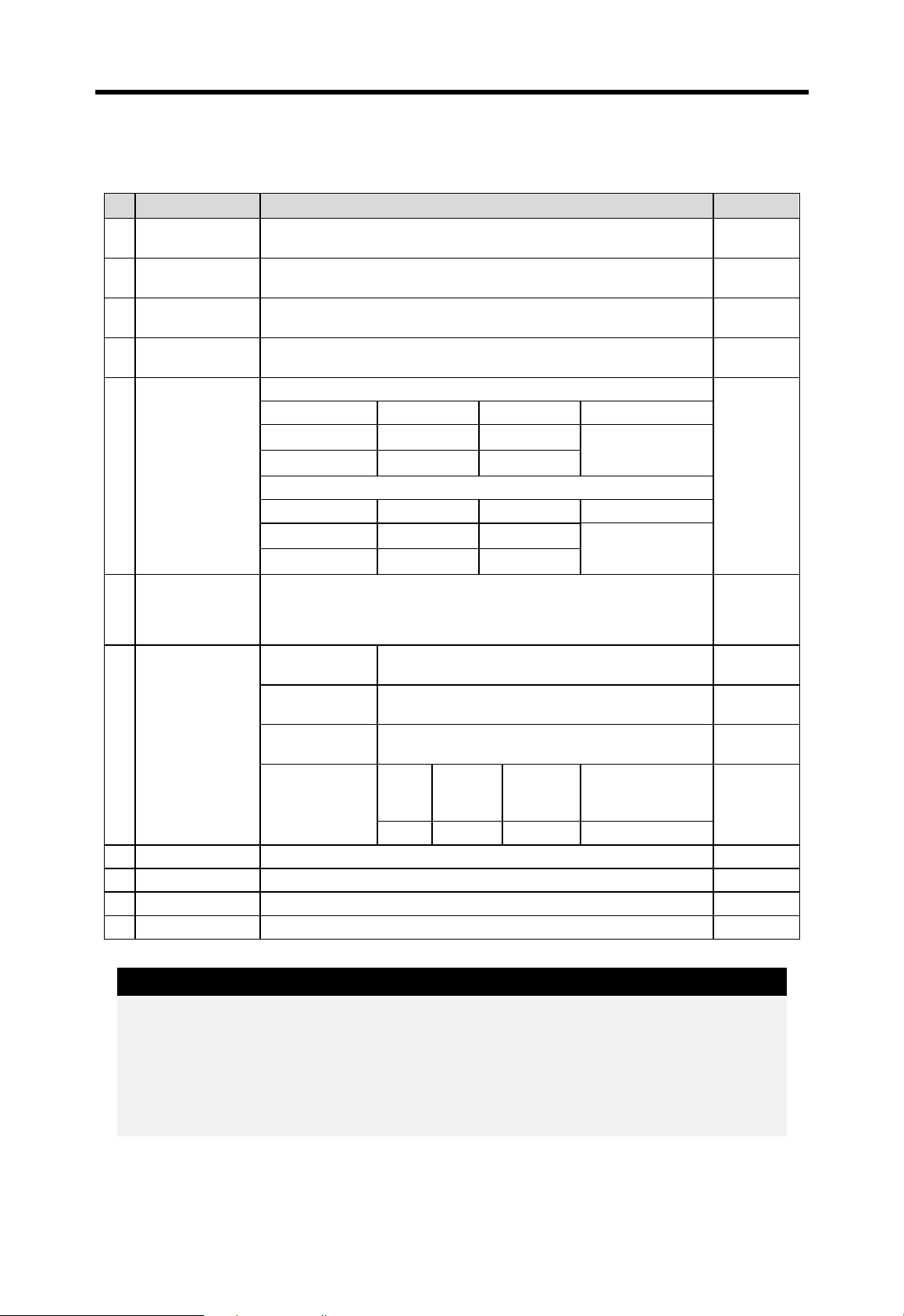

Items Model No. Description Remark

Max. I/O points : 512 points

Special functions : RS-232C

Max. I/O points : 512 points

Special functions : RS-422/485, RTC, PID control

Max. I/O points : 512 points

Special functions : RS-232C, RTC, HSC, PID control

12/24VDC input, 8 points (source/sink)

Relay output, 8 points, 2A/point

100 ~

240VAC

5VDC (3.5A), 24VDC (0.3A)

12 ~

24VDC

5VDC (3A), +15VDC (0.5A), -15VDC (0.2A)

CPU

modules

Digital

input

modules

Digital

output

modules

Digital I/O

hybrid

module

Main

bases

Power

supply

modules

K3P-07AS

K3P-07BS

K3P-07CS

G6I-D21A 12/24VDC input, 8 points (source/sink)

G6I-D22A 12/24VDC input, 16 points (source/sink)

G6I-D22B 24VDC input, 16 points (source)

G6I-D24A 12/24VDC input, 32 points (source/sink)

G6I-D24B 24VDC input, 32 points (source)

G6I-A11A 110VAC input, 8 points

G6I-A21A 220VAC input, 8 points

G6Q-RY1A Relay output, 8 points, 2A/point 1points/com

G6Q-RY2A Relay output, 16 points, 2A/point

G6Q-TR2A Transistor output, 16 points, 0.5A/point (sink)

G6Q-TR2B Transistor output, 16 points, 0.5A/point (source)

G6Q-TR4A Transistor output, 32 points, 0.1A/point (sink)

G6Q-TR4B Transistor output, 32 points, 0.1A/point (source)

G6Q-SS1A Triac output, 16 points, 1A/point

G6H-DR2A

GM6-B04M 4 module

GM6-B06M 6 module

GM6-B08M 8 module

GM6-B12M 12 module

GM6-PAFA 5VDC (2A), 24VDC (0.3A)

GM6-PAFB 5VDC (2A), +15VDC (0.5A), -15VDC (0.2A)

GM6-PAFC

GM6-PDFA 5VDC (2A)

GM6-PDFB

2-3

Chapter 2 System configuration MASTER-K

(continued)

Items Model No. Description Remark

A/D conversion

modules

D/A conversion

modules

High speed

counter module

Special modules

Positioning

module

Thermocouple

module

Fnet modules

Cnet modules

DeviceNet

module

ProfiBus module

Network modules

Dust-cover GM6-DMMA Dust-protector for unused slot

G6F-AD2A

G6F-DA2V

G6F-DA2I

G6F-HSCA

G6F-POPA Pulse output, 2 axes control

G6F-TC2A

G6L-FUEA

G6L-RBEA

G6L-CU2A Cnet I/F module (RS-232C)

G6L-CU4A Cnet I/F module (RS-422/485)

G6L-DUEA DeviceNet I/F module

G6L-PUEA ProfiBus I/F module

G6L-PUEB ProfiBus I/F module

Voltage / Current input, 4channels

1 ~ 5VDC / 0 ~ 10VDC / -10 ~ 10VDC

DC 4 ~ 20mA

Voltage output, 4 channels

-10 ~ 10VDC

Current output, 4 channels

DC 4 ~ 20mA

Counting range ( 0 ~ 16,777,215 : binary 24 bits)

50kHz, 1 channel

Sensor type : 7 types (K, J, E, T, B, R, S)

Input channel : 4 channels

Fnet I/F module

1Mbps base band, Twisted pair cable

Fnet remote I/F module

1Mbps base band, Twisted pair cable

2-4

Chapter 2 System configuration MASTER-K

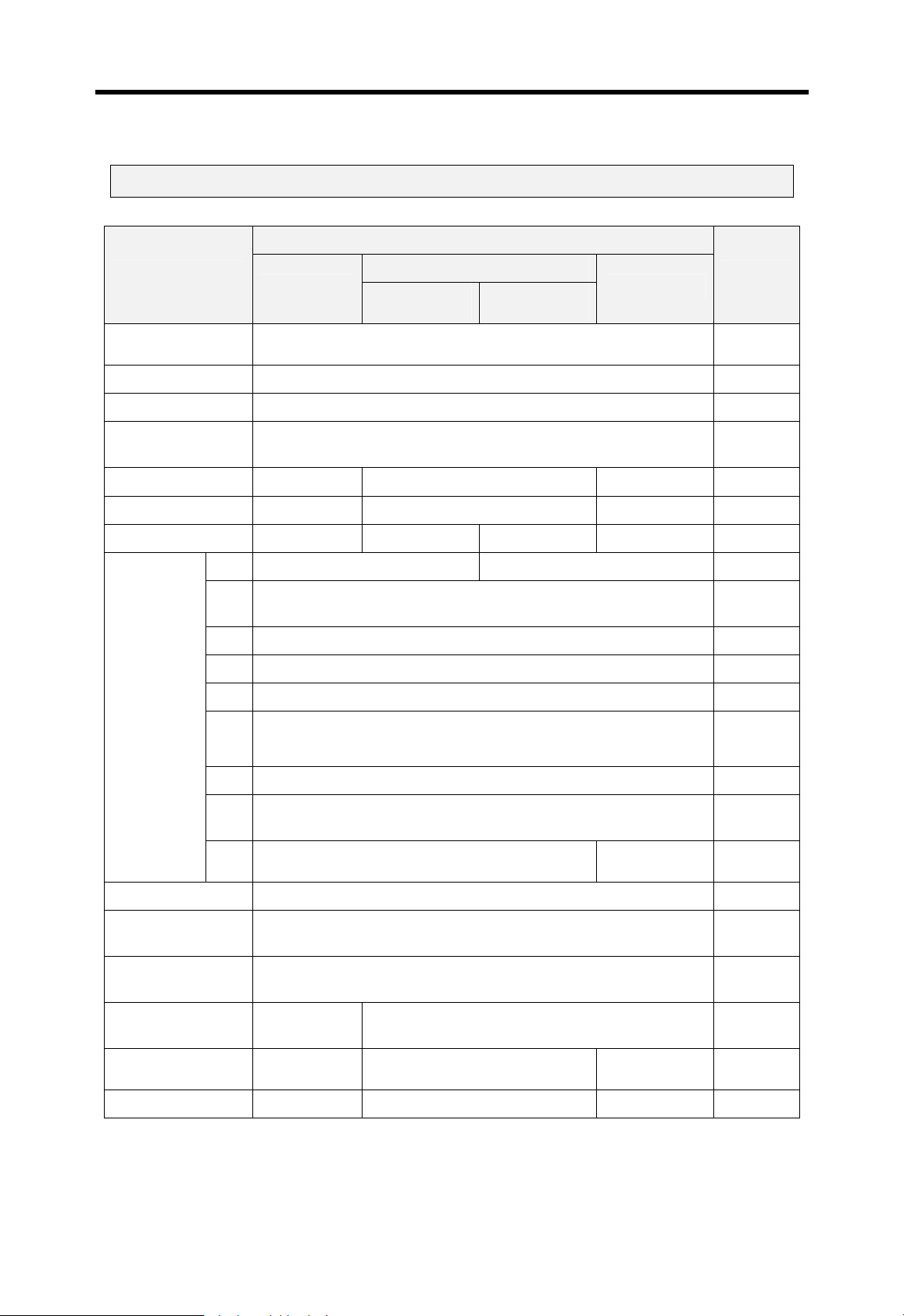

2.2.2 K300S

Items Model No. Description Remark

CPU

modules

Digital

input

modules

Digital

output

modules

Main base

boards

Expansion

base

boards

Expansion

cables

K4P-15AS Max. I/O points : 512 points

G4I-D22A 12/24VDC input, 16 points (source/sink)

G4I-D22B 12/24VDC input, 16 points (source)

G4I-D22C 24VDC input, 16 points (source/sink)

G4I-D24A 12/24VDC input, 32 points (source/sink)

G4I-D24B 12/24VDC input, 32 points (source)

G4I-D24C 24VDC input, 32 points (source/sink)

G4I-D28A 12/24VDC input, 64 points (source/sink)

G4I-A12A 110VAC input, 16 points

G4I-A22A 220VAC input, 16 points

G4Q-RY2A Relay output, 16 points, 2A/point

G4Q-TR2A Transistor output, 16 points, 0.5A/point (sink)

G4Q-TR2B Transistor output, 16 points, 0.5A/point (source)

G4Q-TR4A Transistor output, 32 points, 0.1A/point (sink)

G4Q-TR4B Transistor output, 32 points, 0.1A/point (source)

G4Q-TR8A Transistor output, 64 points, 0.1A/point (sink)

G4Q-SS2A Triac output, 16 points, 1A/point

G4Q-SS2B Triac output, 16 points, 0.6A/point

GM4-B04M 4 module

GM4-B06M 6 module

GM4-B08M 8 module

GM4-B12M 12 modules No expansion

GM4-B04E 4 modules

GM4-B06E 6 modules

GM4-B08E 8 modules

G4C-E041 Length : 0.4m

G4C-E121 Length : 1.2m

G4C-E301 Length : 3.0m

Memory

module

Power

supply

modules

GM4-M032 Flash memory, 32k steps

GM4-PA1A 110VAC

GM4-PA2A 220VAC

GM4-PA1B 110VAC

GM4-PA2B 220VAC

GM4-PD3A 24VDC

5VDC : 5A, 24VDC : 0.7A

5VDC : 3A, 24VDC : 0.5A,

5VDC : 4A, 24VDC : bypass

2-5

Chapter 2 System configuration MASTER-K

(continued)

Items Model No. Description Remark

Voltage / Current input, 4channels

-5 ~ 5VDC / -10 ~ 10VDC

DC -20 ~ 20mA

Voltage / Current input, 8channels

1 ~ 5VDC / 0 ~ 10VDC

DC 4 ~ 20mA

Voltage / Current output, 2 channels

-10 ~ 10VDC, DC4 ~ 20mA

Voltage output, 4 channels

-10 ~ 10VDC

Current output, 4 channels

DC 4 ~ 20mA

Voltage output, 8 channels

-10 ~ 10VDC

Current output, 8 channels

DC 4 ~ 20mA

A/D

conversion

modules

D/A

conversion

modules

G4F-AD2A

G4F-AD3A

G4F-DA1A

G4F-DA2V

G4F-DA2I

G4F-DA3V

G4F-DA3I

High

speed

counter

module

Special modules

Positioning

module

Thermoco

uple input

module

RTD

module

PID control

module

Analog

timer

module

Interrupt

module

G4F-HSCA

G4F-POPA Pulse output, 1 axis control

G4F-POPB Pulse output, 2 axes control

G4F-TC2A

G4F-RD2A

G4F-PIDA Max. 8 loops control

G4F-AT3A

G4F-INTA 8 channels

Counting range ( 0 ~ 16,777,215 : binary 24 bits)

50kHz, 1 channel

Sensor type : 7 types (K, J, E, T, B, R, S)

4 channels

Sensor type : Pt100, JPt100

4 channels

8 analog timers

Setting range : 0.1 ~ 1.0sec / 1 ~ 10sec

10 ~ 60sec / 60 ~ 600sec

Each channel

can be set

independently

2-6

Chapter 2 System configuration MASTER-K

(continued)

Items Model No. Description Remark

Fnet I/F module

1Mbps base band, Twisted pair cable

Fnet I/F module

1Mbps base band, Twisted pair cable

Fnet remote I/F module

1Mbps base band, Twisted pair cable

Fnet single I/F module

12 / 24VDC input, 16 points

Fnet single I/F module

Relay output, 1A/point, 16 points

Fnet single I/F module

12 / 24VDC input, 8 points

Relay output, 1A/point, 16 points

Install to the IBM

compatible PC

Fnet

modules

G4L-FUEA

G0L-FUEA

G4L-RBEA

G0L-SMIA

G0L-SMQA

G0L-SMHA

G0L-FREA Repe ater for Fnet

Converter

Network modules

Active

coupler

Cnet

modules

DeviceNet I/F

module

Profibus-DP

I/F module

Pseudo

input

switch

Others

Dust cover

G0L-FOEA

G0L-FAPA Power module for active coupler

G0L-FABA Base board for active coupler

G0L-FACA Active coupler

G0L-FADA Dummy card for active coupler

G4L-CUEA Cnet I/F module (RS-232C)

G4L-DUEA

Optical ↔ Electrical converter

DeviceNet I/F module

G4L-PUEA Profibus-DP master module (I/O : 1K)

G4L-PUEB

G4S-SW16 Pseudo input switch, 16 po ints

GM4-DMMA Dust protector for unused slot

Profibus-DP master module (I/O : 7K)

In 3.0 or higher

CPU O/S version

and 3.2 or higher

KGL-WIN version

2-7

Chapter 2 System configuration MASTER-K

2.2.3 K1000S

Items Model No. Description Remark

CPU

modules

Digital

input

modules

Digital

output

modules

Main base

boards

Expansion

base

boards

Expansion

cables

K7P-30AS Max. I/O points : 1,024 points

G3I-D22A 12/24VDC input, 16 points (source/sink)

G3I-D24A 12/24VDC input, 32 points (source/sink)

G3I-D24C 24VDC input, 32 points (source/sink)

G3I-D28A 12/24VDC input, 64 points (source/sink)

G3I-A12A 110VAC input, 16 points

G3I-A22A 220VAC input, 16 points

G3I-A14A 110VAC input, 32 points

G3I-A24A 220VAC input, 32 points

G3Q-RY2A Relay output, 16 points, 2A/point

G3Q-RY4A Relay output, 32 points, 1A/point

G3Q-TR2A Transistor output, 16 points, 2A/point (sink)

G3Q-TR4A Transistor output, 32 points, 0.5A/point (sink)

G3Q-TR4B Transistor output, 32 points, 0.5A/point (source)

G3Q-TR8A Transistor output, 64 points, 0.1A/point (sink)

G3Q-TR8B Transistor output, 64 points, 0.1A/point (source)

G3Q-SS2A Triac output, 16 points, 2A/point

G3Q-SS4A Triac output, 32 points, 1A/point

GM3-B04M 4 module

GM3-B06M 6 module

GM3-B08M 8 module

GM3-B04E 4 modules

GM3-B06E 6 modules

GM3-B08E 8 modules

G3C-E061 Length : 0.6m

G3C-E121 Length : 1.2m

G3C-E301 Length : 3.0m

Memory

module

Power

supply

modules

G3M-M064 Flash memory, 64k steps

GM3-PA1A 110VAC

GM3-PA2A 220VAC

GM1-PA1A 110VAC

GM1-PA2A 220VAC

GM3-PD3A 24VDC

5VDC : 7A, 24VDC : 1.5A

5VDC : 13A, 24VDC : None

5VDC : 4A, 24VDC : bypass

2-8

Chapter 2 System configuration MASTER-K

(continued)

Items Model No. Description Remark

Voltage / Current input, 16 channels

-5 ~ 5VDC / -10 ~ 10VDC

DC -20 ~ 20mA

Voltage / Current input, 16 channels

1 ~ 5VDC / 0 ~ 10VDC

DC 4 ~ 20mA

Voltage / Current input, 8 channels

1 ~ 5VDC / 0 ~ 10VDC

DC 4 ~ 20mA

Voltage output, 16 channels

-5 ~ 5VDC / -10 ~ 10VDC

Current output, 16 channels

DC 4 ~ 20mA

Voltage output, 8 channels

0 ~ 10VDC

Current output, 8 channels

DC 4 ~ 20mA

+15VDC : 0.5A

-15VDC : 0.1A

Counting range ( 0 ~ 16,777,215 : binary 24 bits)

50kHz, 2 channels

Sensor type : 7 types (K, J, E, T, B, R, S)

16 channels

Sensor type : Pt100, JPt100

8 channels

16 analog timers

Setting range : 0.1 ~ 1.0sec / 1 ~ 10sec

10 ~ 60sec / 60 ~ 600sec

For A/D & D/A

modules

Each channel

can be set

independently

A/D

conversion

modules

D/A

conversion

modules

Power

supply

module

High speed

counter

module

Positioning

module

Thermocou

ple input

module

RTD

module

PID control

module

Analog

timer

module

Interrupt

module

G3F-AD4A

G3F-AD4B

G3F-AD3A

G3F-DV4A

G3F-DI4A

G3F-DV3A

G3F-DI3A

G3F-PA1A 110VAC

G3F-PA2A 220VAC

G3F-HSCA

G3F-POPA Pulse output, 1 axis control

G3F-POAA Analog output, 2 axes control

G3F-TC4A

G3F-RD3A

G3F-PIDA Max. 32 loops control

G3F-AT4A

G3F-INTA 16 channels

2-9

Chapter 2 System configuration MASTER-K

(continued)

Items Model No. Description Remark

Fnet I/F module

1Mbps base band, Twisted pair cable

Fnet I/F module

1Mbps base band, Optical fiber cable

Fnet I/F module

1Mbps base band, Twisted pair cable

Fnet remote I/F module

1Mbps base band, Twisted pair cable

Fnet remote I/F module

1Mbps base band, Optical fiber cable

Fnet single I/F module

12 / 24VDC input, 16 points

Fnet single I/F module

Relay output, 1A/point, 16 points

Fnet single I/F module

12 / 24VDC input, 8 points

Relay output, 1A/point, 16 points

Install to the IBM

compatible PC

Fnet

modules

Network modules

G3L-FUEA

G3L-FUOA

G0L-FUEA

G3L-RBEA

G3L-RBOA

G0L-SMIA

G0L-SMQA

G0L-SMHA

G0L-FREA Repe ater for Fnet

Converter

Active

coupler

Cnet

modules

Profibus-DP

I/F module

Pseudo

input

switch

Others

Dust cover

G0L-FOEA

G0L-FAPA Power module for active coupler

G0L-FABA Base board for active coupler

G0L-FACA Active coupler

G0L-FADA Dummy card for active coupler

G3L-CUEA Cnet I/F module (RS-232C:1ch / RS422:1ch)

Optical ↔ Electrical converter

G3L-PUEA Profibus-DP master module (I/O : 1K)

G3L-PUEB

G3S-SW32 Pseudo input switch, 32 po ints

G3F-DMMA Dust protector for unused slot

Profibus-DP master module (I/O : 7K)

In 3.0 or higher

CPU O/S version

and 3.2 or higher

KGL-WIN version

2-10

Chapter 2 System configuration MASTER-K

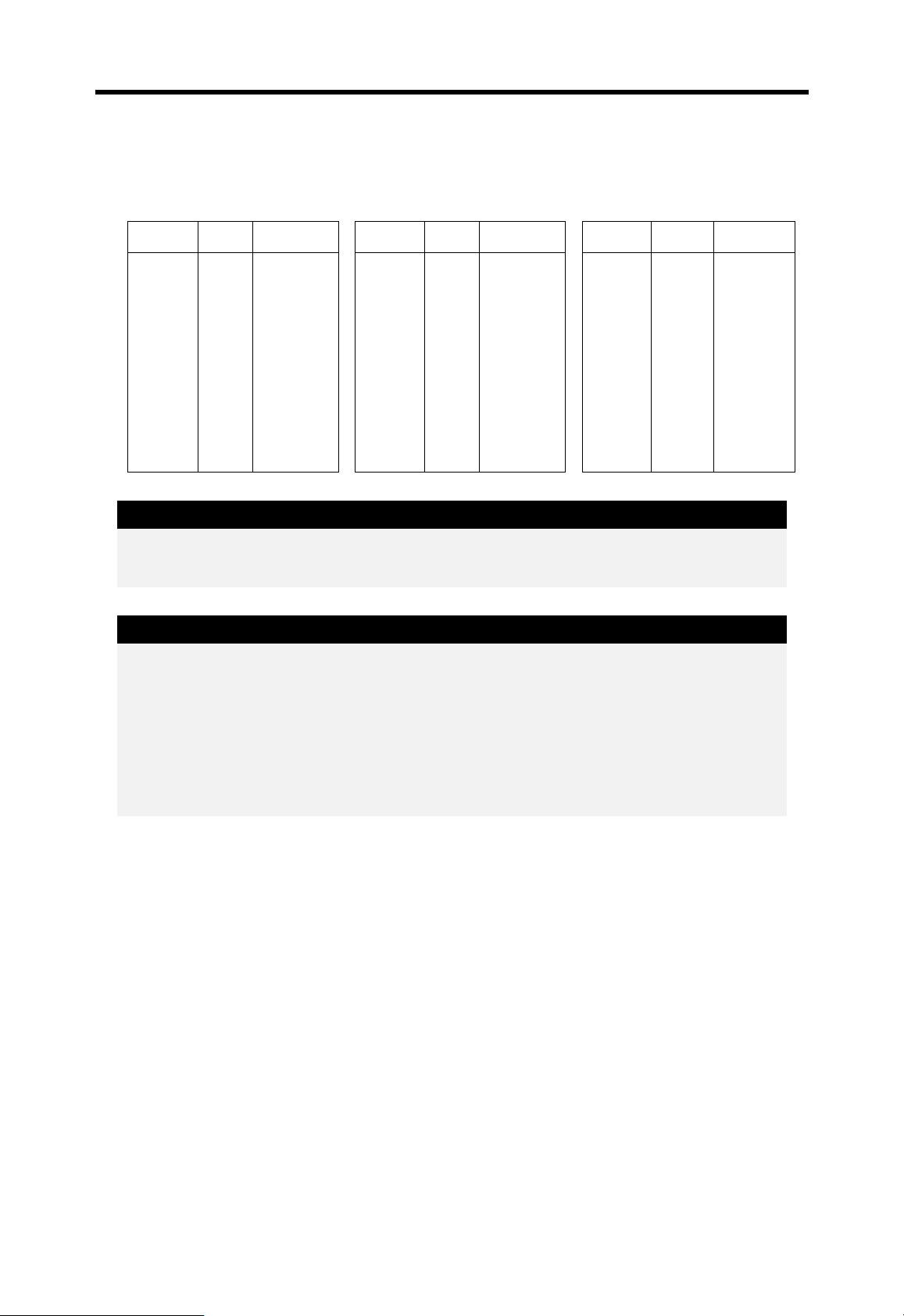

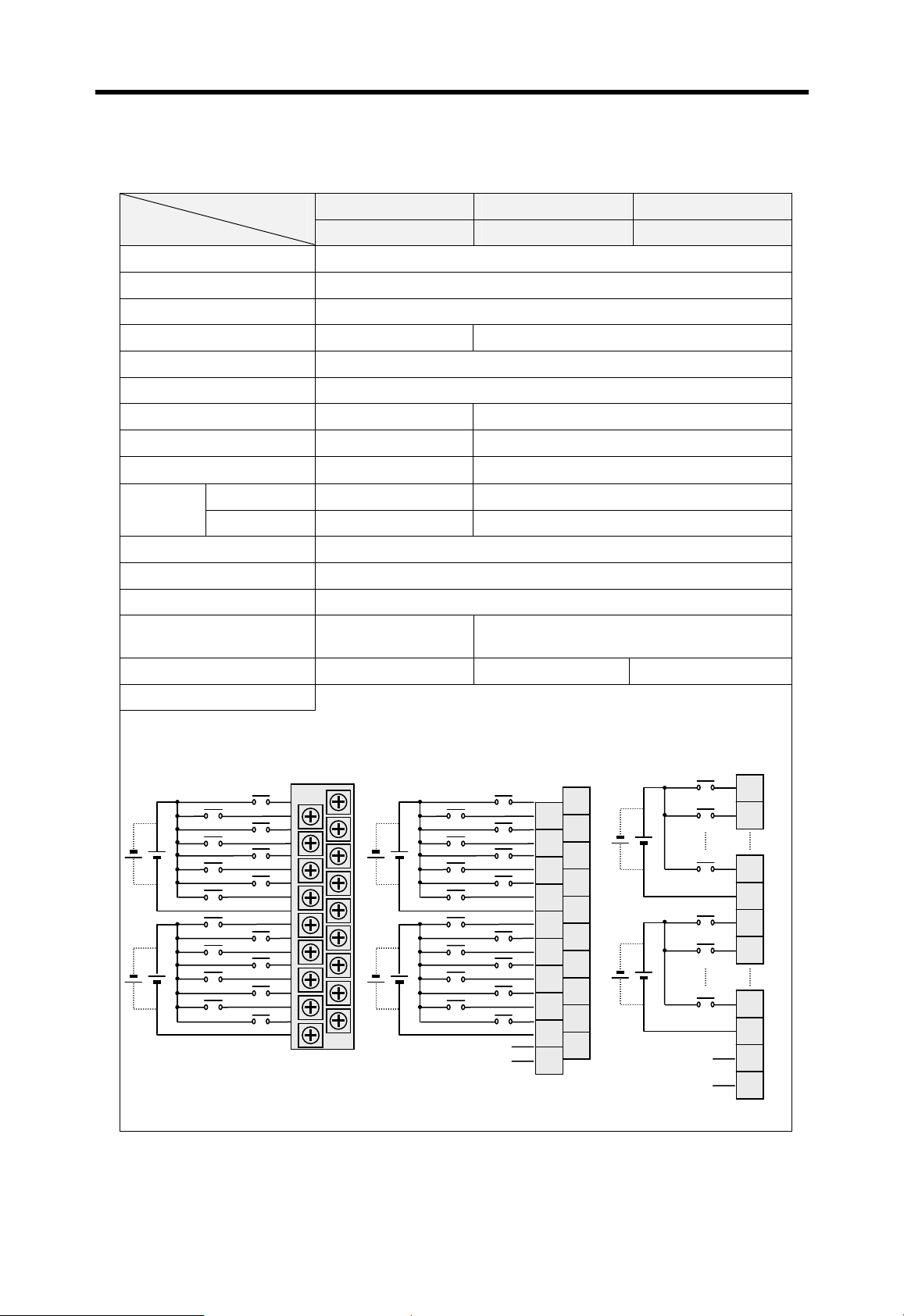

2.3 System configuration types

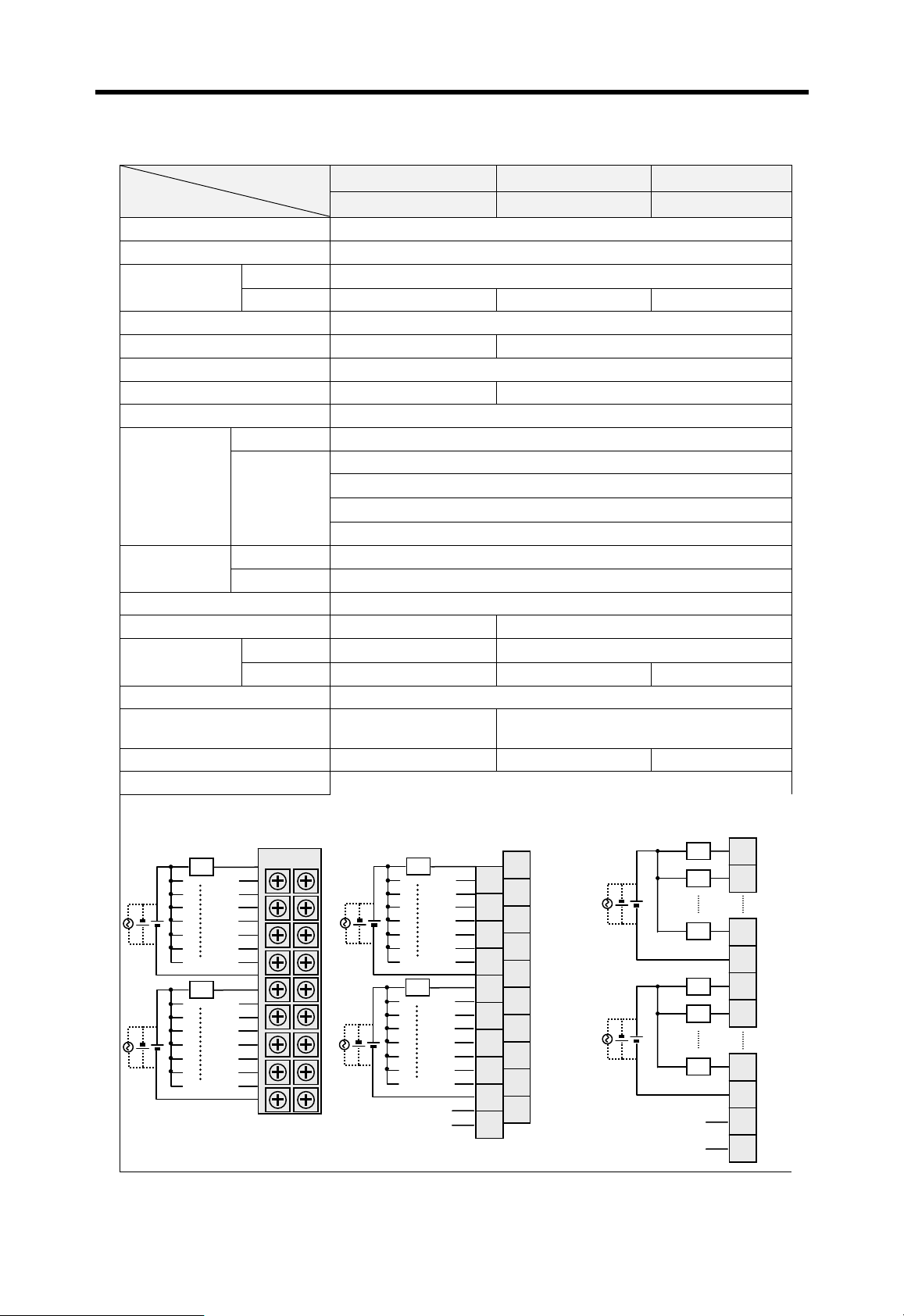

System configuration is classified into 3 types such as basic, computer link, and network system.

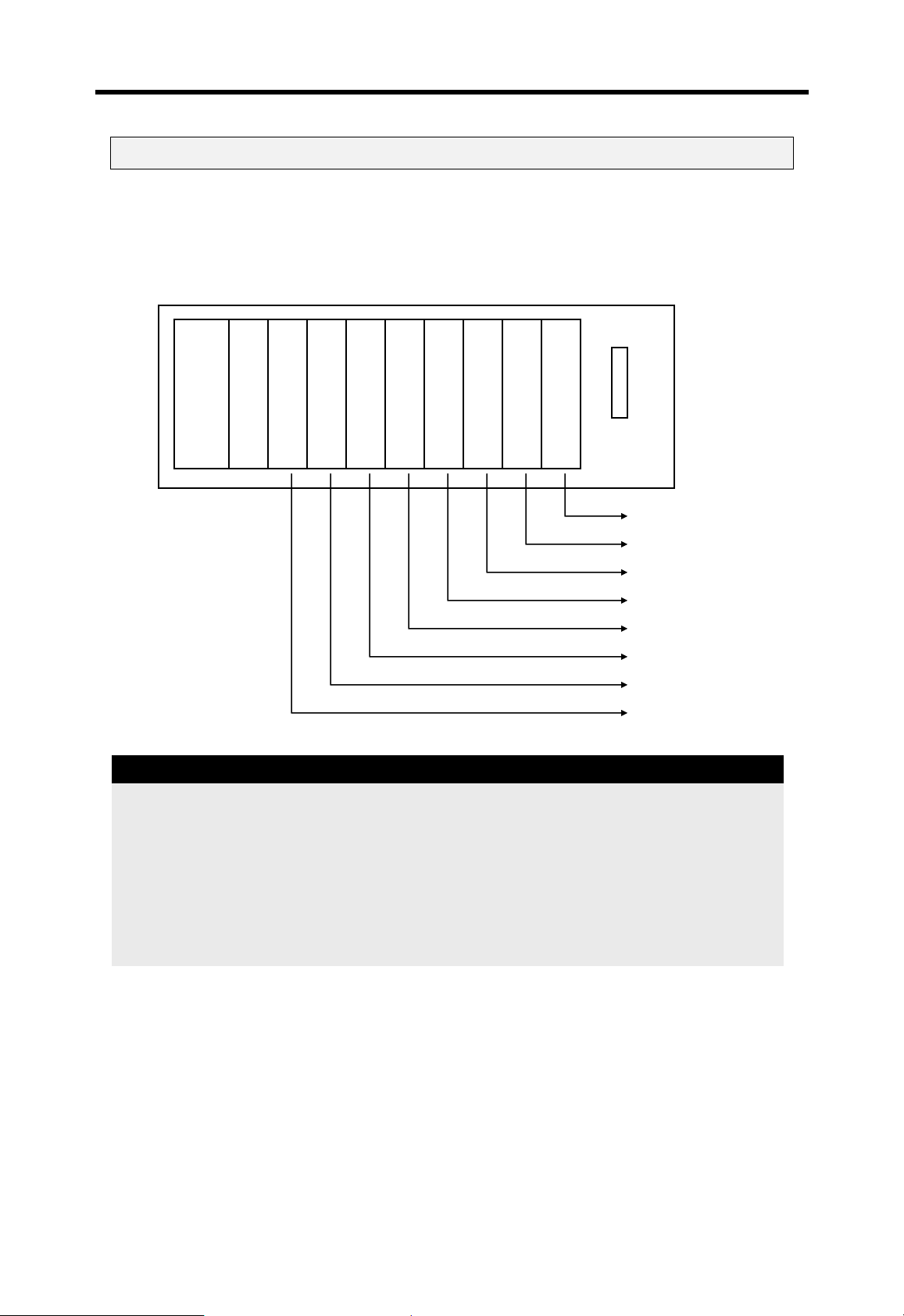

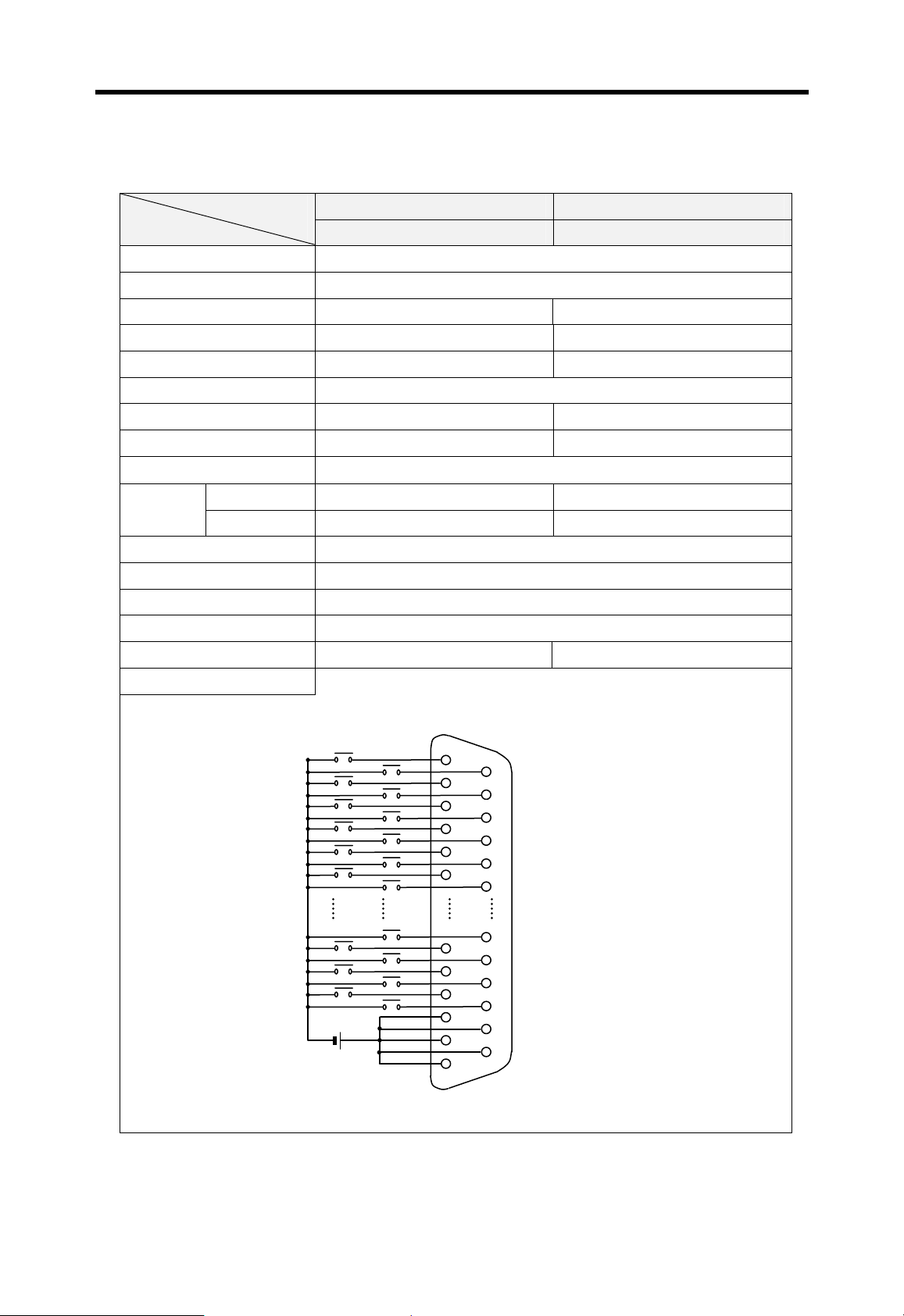

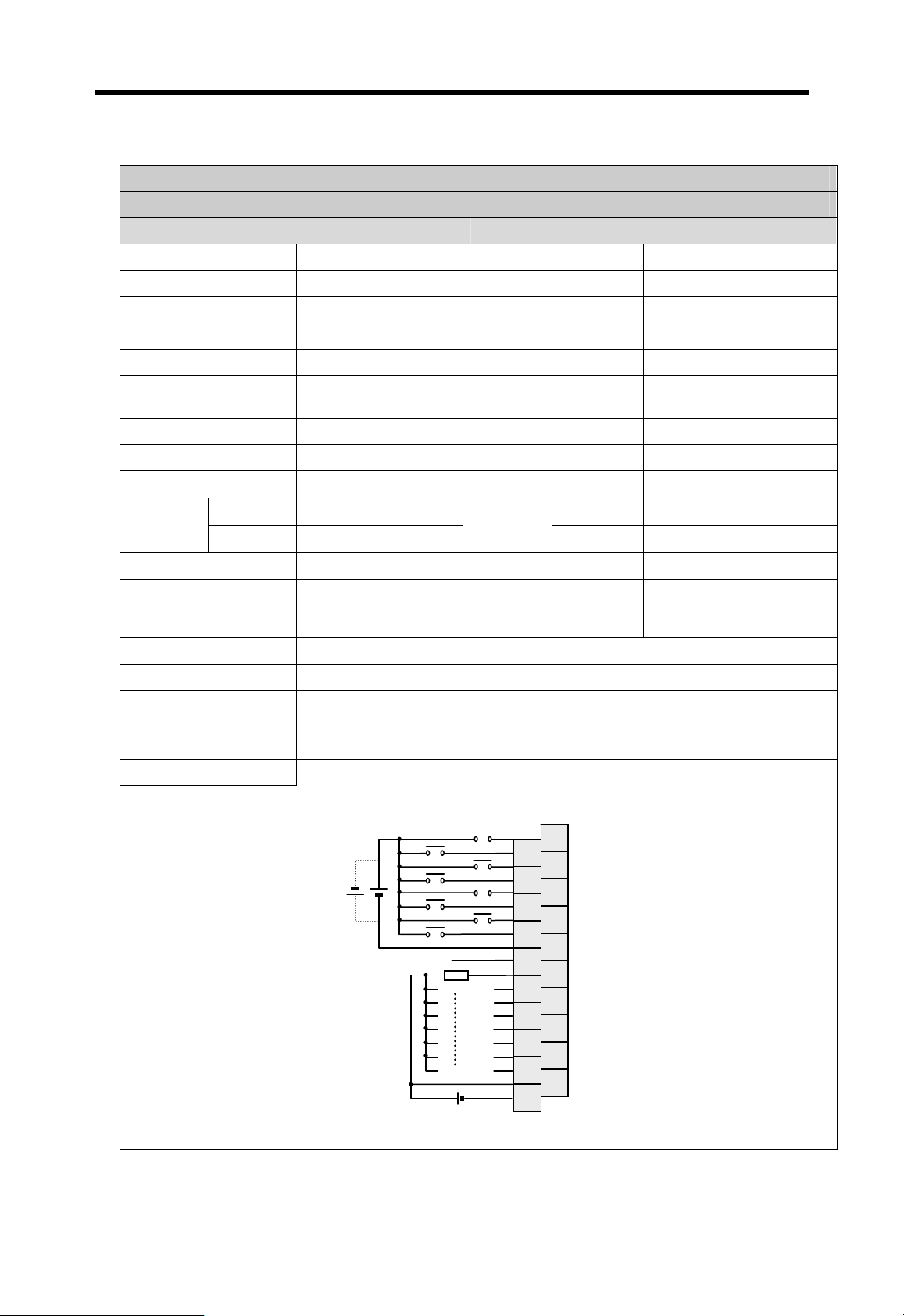

2.3.1 Basic system configuration

The basic system consists of a main base and expansion base(s). The main and expansion

base(s) are connected via expansion cable.

Main base

Expansion

base

Power

CPU

Power

Slot 0

Slot 0

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

Expansion

cable

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

Max. expansion level – 3 levels

Max. distance between bases – 3 m

Max. numbers of I/O module 12 modules 32 modules

Max. I/O points 384 points 512/1,024 points1 1,024 points

CPU K3P-07AS K4P-15AS K7P-30AS

Power supply

Module

type

Main base

Expansion base – GM4-B04/06/08E GM3-B04/06/08E

Expansion cable – G4C-E041/121/301 G3C-E061/121/301

I/O module

Special-function

module

K200S K300S K1000S

GM6-PAFA/B/C

GM6-PDFA/B

GM6B04/06/08/12M

G6I-

G6Q-

G6F-

GM4-PA1A/PA2A

GM4-PA1B/PA2B

GM4-PD3A

GM4-

B04/06/08/12M

G4I-

G4Q-

G4F-

GM3-PA1A/PA2A

GM3-PA1B/PA2B

GM3-PD3A

GM3-B04/06/08M

G3I-

G3Q-

G3F-

I/O number (P00, P01, …) is allocated for each module

I/O number allocation

1

Only in 3.0 or higher CPU O/S version

automatically. A empty slot occupies 16 bits.

Special-functi on modules can be mounted on all bases and

slots with no limit on the number of modules.

2-11

Chapter 2 System configuration MASTER-K

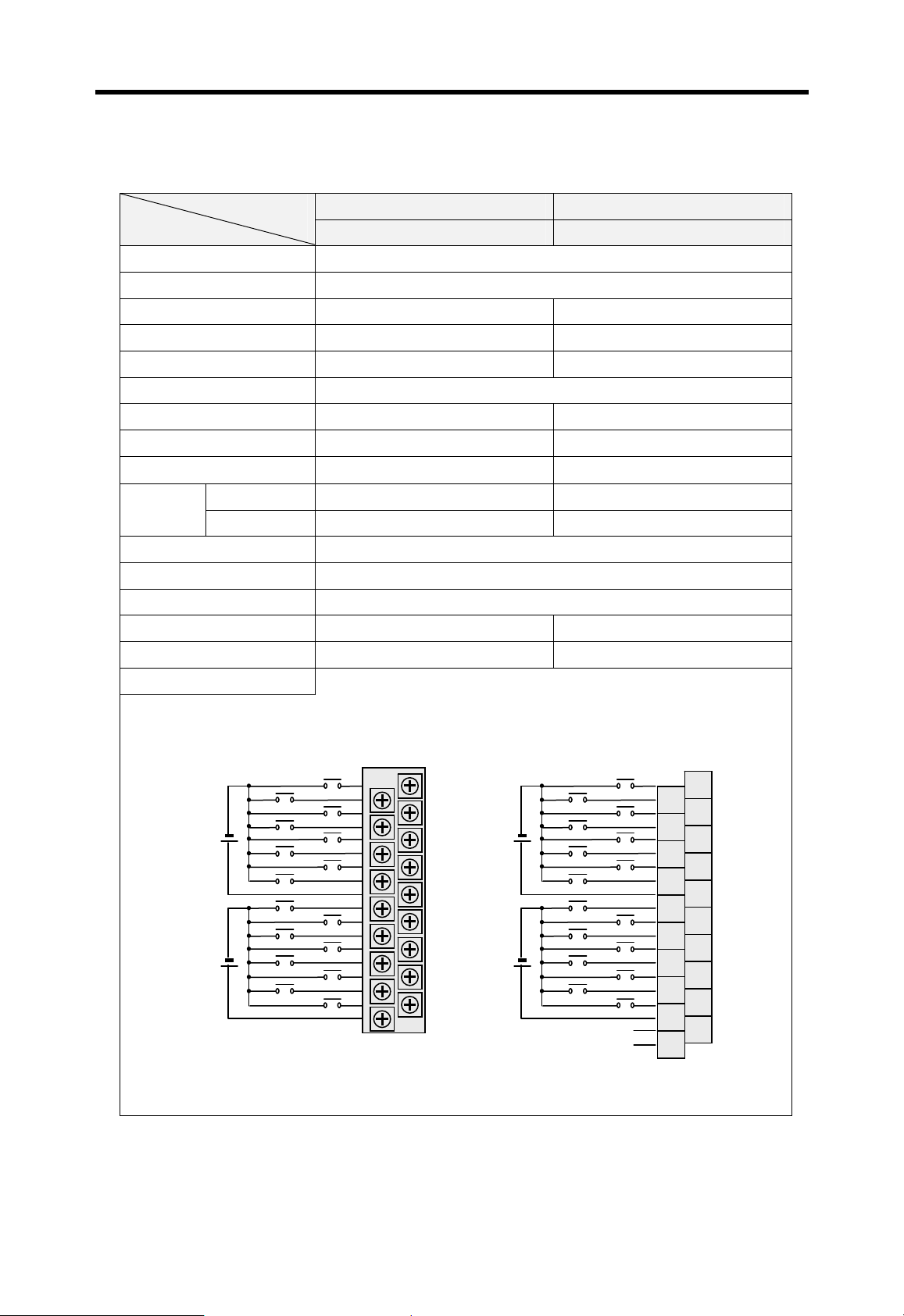

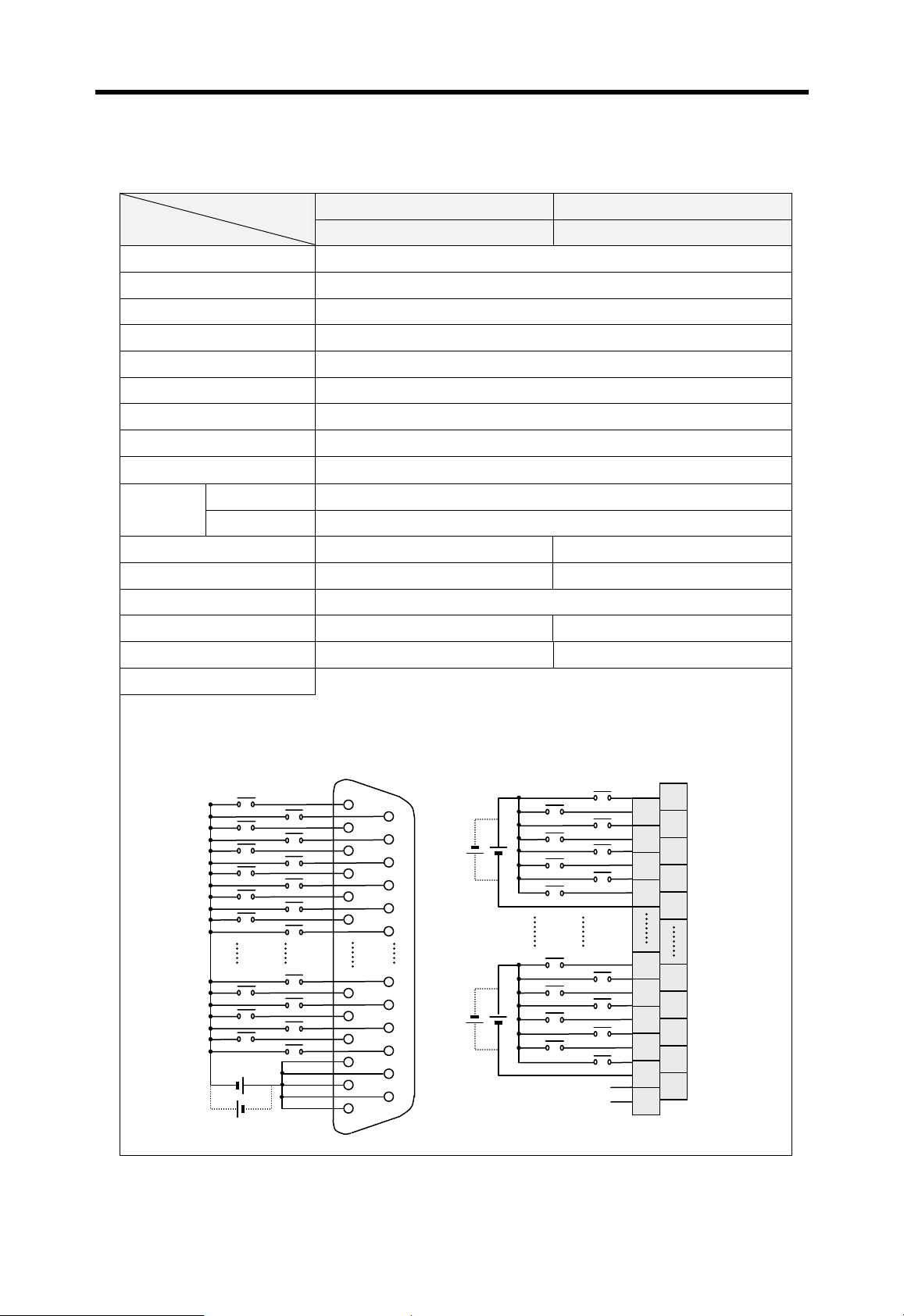

2.3.2 Computer link system

When a CPU module is connected with external devices (such as computer or printer, etc.)

via RS-232C or RS-422/485 protocol by using computer link module, it is called as computer

link system. For details about computer link system, please refer user’s manual of MK

computer link modules.

Remark

The maximum number of Cnet modules that can be mounted simultaneously is as following;

K200S : 2 modules K300S : 4 modules K1000S : 8 modules

Cnet modules can be mounted only main base board. (Not available for expansion base board)

In 3.0 or higher CPU O/S version, Cnet module can be mounted on a main or expansion base

board-

2-12

Chapter 2 System configuration MASTER-K

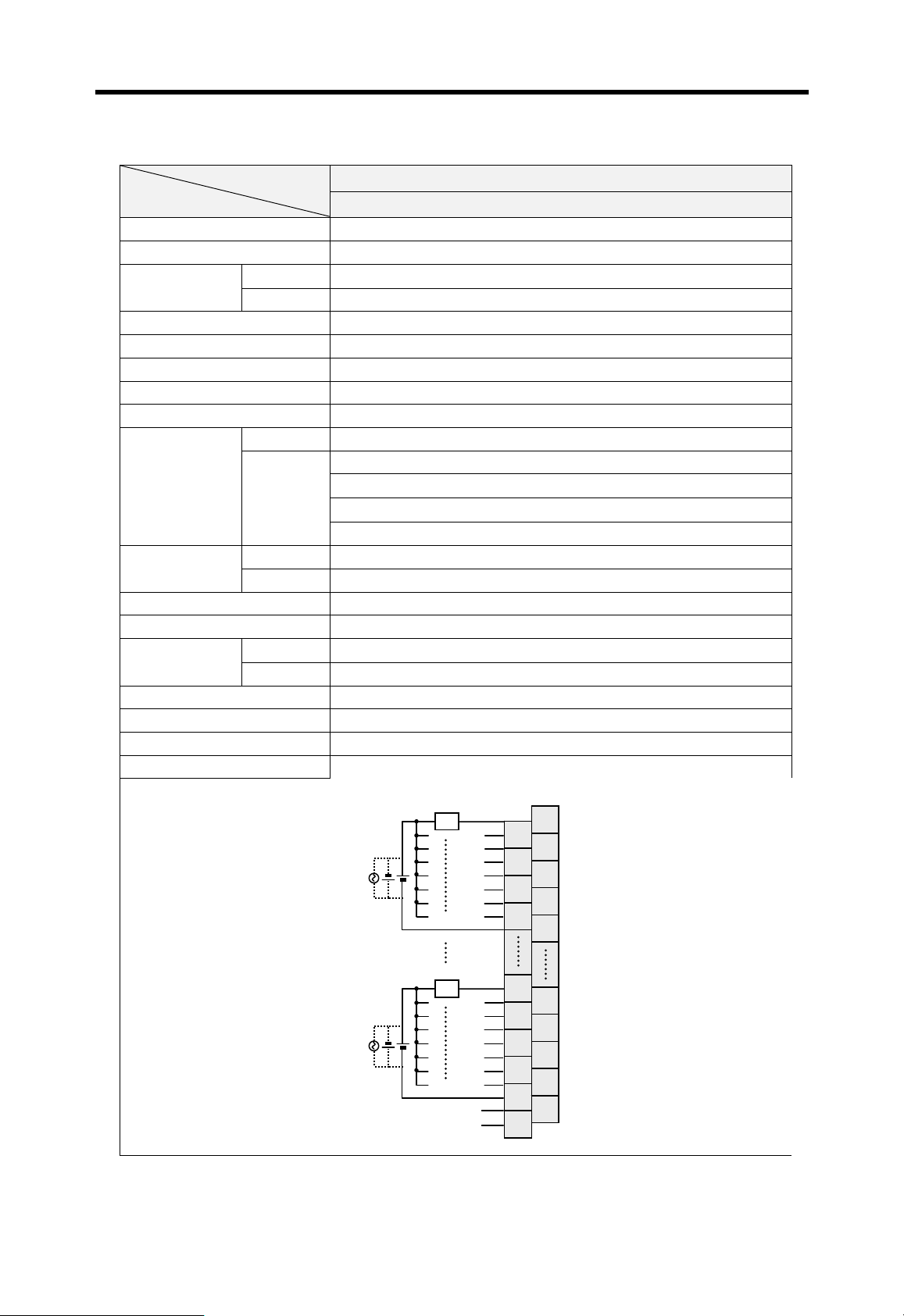

2.3.3 Network system

In network system, user can access and control I/O module of remote station through a

network I/F and remote I/F module. MASTER-K series uses the Fnet system to consist a

network system.

Besides, in 3.0 or higher CPU O/S version and in 3.2 or higher KGL-WIN version, user who want

to use other network system can use the Dnet I/F sy stem or

system. (Dnet I/F syst em or

Profibus I/F system is available for K300S and Profibus I/F system is

Profibus I/F to construct a network

available for K1000S)

Please refer the user’s manual of Fnet network module for details.

Remark

1. Fnet network module can be mounted on main a base board only. It can not be mounted on a

expansion base board

The maximum number of Fnet modules that can be mounted simultaneously is as following;

K300S: 2 modules K1000S : 4 modules

2. In 3.0 or higher K300S/1000S CPU O/S version , high-speed link communication module can

be mounted on a main or expansion base board and the maximum number that can be

mounted simultaneously is 4

3. The remote system has same configuration with a basic system configuration. However, the

following modules can not be used on the remote system which a Fnet remote I/F module is

mounted.

PID control module G4F-PIDA G3F-PIDA

Positioning module G4F-POPA G3F-POPA

G4F-POPB G3F-POAA

Analog timer module G4F-AT3A G3F-AT4A

Fnet I/F module G4L-FUEA G3L-FUEA

Cnet I/F module G4L-CUEA G3L-CUEA

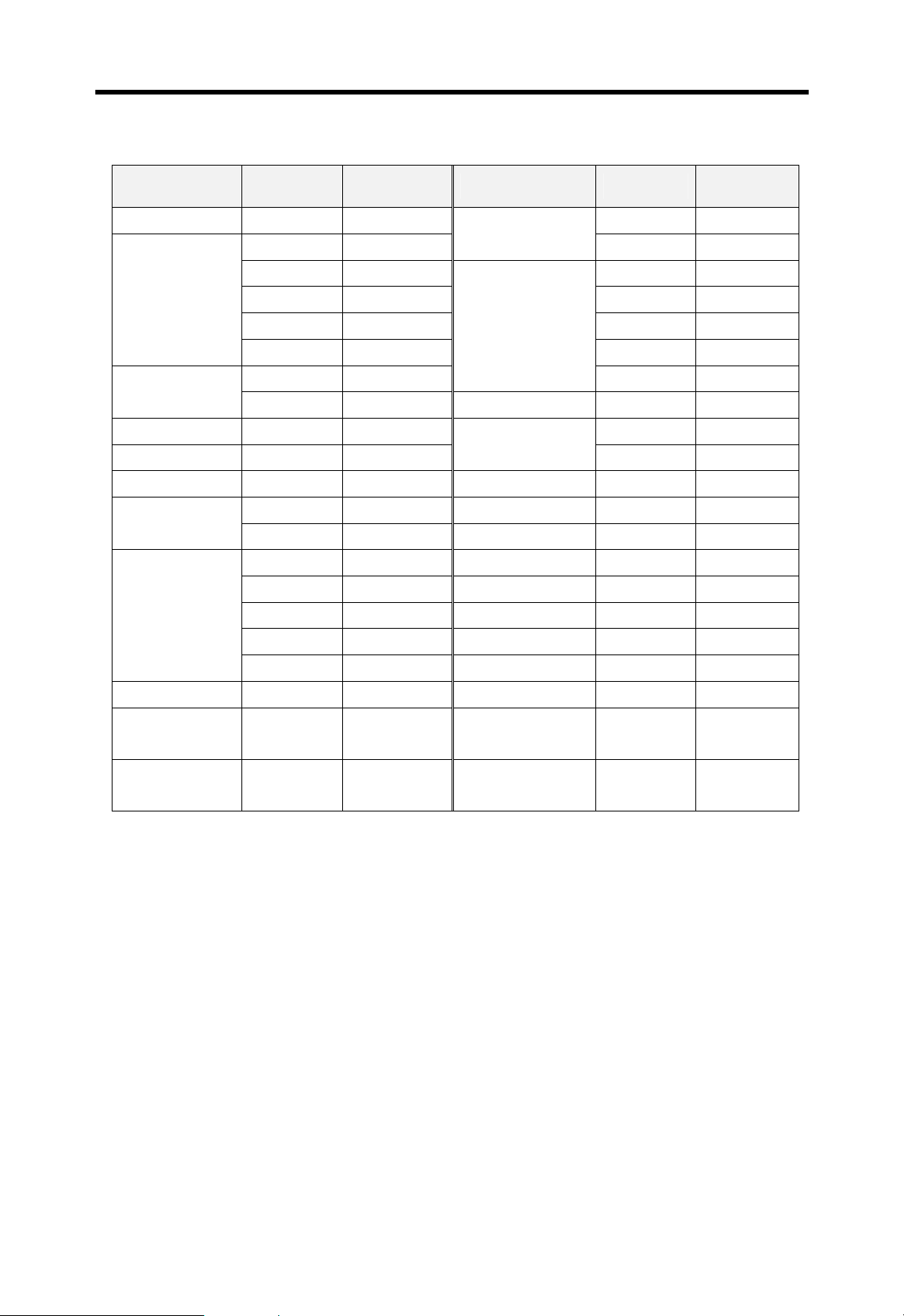

Example) K300S Network system

GM4-PA2A

Fnet I/F module

G4L-FUEA

K4P-15AS

Fnet remote

I/F module

GM4-PA1A

The above modules can not

be mounted on these slots

K4F-RBEA

Main base

2-13

Chapter 3 General specifications

3 General specifications.............................................................................. 3-1

Chapter 3 General specifications MASTER-K

3 General specifications

The following table shows the general specifications of MASTER-K series.

No Item Specifications Remark

Operating ambient

1

temperature

Storage ambient

2

temperature

Operating ambient

3

4

5 Vibration resistance

6 Shock resistance

7 Noise immunity

8 Atmosphere Free of corros ive gases

9 Altitude for use Up to 2,000m ( 6,560ft )

10 Pollution degree 2

11 Cooling method Self-cooling

humidity

Storage ambient

humidity

0 ~ 55℃ (32 ~ 131 °F)

-25 ~ 70℃ (-13 ~ 158 °F)

5 ~ 95%RH, non-condensing

5 ~ 95%RH, non-condensing

Occasional vibration

Frequency Acceleration Amplitude Sweep count

10≤f<57 Hz - 0.075 mm

57 ≤f≤150 Hz 9.8 ㎨ (1G) -

Continuos vibration

Frequency Acceleration Amplitude

10≤f<57 Hz - 0.035 mm

57≤f≤150 Hz 4.9㎨ (0.5G) -

Maximum shock acceleration: 147 ㎨ (15G)

Duration time :11 ms (3 times in each of X, Y and Z directions)

Pulse wave: half sine wave pulse

Square wave

impulse noise

Electrostatic

discharge

Radiated electro-

magnetic field

Fast transient

burst noise

±1,500 V

Voltage :4 kV(contact discharge)

27 ~ 500 MHz, 10 V/m

Severity

Level

Voltage 2 kV 1 kV 0.25 kV

All power

modules

Digital I/O

( Ue ≥ 24 V)

10 times in each

direction for X, Y, Z

10 times in each

direction for X, Y, Z

Digital I/O (Ue<24 V)

Analog I/O

Communication I/O

IEC 1131-2

IEC 1131-2

LGIS ’ s

specification

IEC 1131-2

IEC 801-2

IEC 1131-2

IEC 801-2

IEC 1131-2

IEC 801-4

Remark

1. IEC (International Electrotechnical Commission) : The international civilian organization which

produces standards for electrical and el ectronics industry.

2. Pollution degree : It indicates a standard of operation ambient pollution level. The pollution

degree 2 means the condition in which normally, only non-conductive pollution occurs.

Occasionally, however, a temporary conductivity caused by condensation shall be expected.

3-1

Chapter 4 CPU modules

4 CPU modules............................................................................................. 4-1

4.1 Performance specifications.....................................................................................4-1

4.2 Operation processing of CPU.................................................................................. 4-2

4.2.1 Operation method..................................................................................................4-2

4.2.2 The operation during momentary power failure.....................................................4-3

4.2.3 Scan time...............................................................................................................4-4

4.2.4 Watchdog timer...................................................................................................... 4-4

4.2.5 Timers .................................................................................................................... 4-5

4.2.6 Counter.................................................................................................................. 4-8

4.3 Program structure...................................................................................................4-10

4.3.1 Classification of program.....................................................................................4-10

4.3.2 Processing method..............................................................................................4-10

4.3.3 Interrupt processing............................................................................................. 4-11

4.3.4 Error handling......................................................................................................4-15

4.4 Operation mode ...................................................................................................... 4-16

4.4.1 RUN mode........................................................................................................... 4-16

4.4.2 Stop mode............................................................................................................4-17

4.4.3 PAUSE mode....................................................................................................... 4-18

4.4.4 DEBUG mode...................................................................................................... 4-19

4.4.5 Operation mode change...................................................................................... 4-20

4.5 Special functions of CPU module ......................................................................... 4-22

4.5.1

RTC (Real Time Clock) function .......................................................................... 4-22

4.5.2 Forced I/O setting................................................................................................4-25

4.5.3 Program edit in RUN mode..................................................................................4-26

4.5.4 Self-diagnosis......................................................................................................4-27

4.5.5 Direct I/O refresh..................................................................................................4-28

4.5.6 System error history.............................................................................................4-28

4.6 Memory configuration............................................................................................ 4-29

4.6.1 Memory map of K200S / K300S.......................................................................... 4-29

4.6.2 The memory map of K1000S...............................................................................4-30

4.7 Assign I/O address ................................................................................................. 4-31

4.8 Parts names............................................................................................................. 4-32

Chapter 4 CPU modules MASTER-K

4 CPU modules

4.1 Performance specifications

The performance specification of K200S / 300S / 1000S series is shown as following table;

Specifications

Item

Program control

method

I/O control method Indirect mode (Refresh method), Direct by program command

Program language Mnemonic, Ladder diagram

Numbers of

instructions

Processing speed

Program capacity 7k steps 15k steps 30k steps

Max. I/O points 384 points 512 points 1,024 points 1,024 points

P P000 ~ P31F (512 points) P000 ~ P63F (1,024 points) I/O relay

M M000 ~ M191F (3,072points)

K K000 ~ K31F (512 points) Keep relay

L L000 ~ L63F (1,024 points) Link relay

Memory

device

F F000 ~ F63F (1,024 points) Special relay

T

K200S

Cycle execution of stored program, Time-driven interrupt,

0.5μsec/step 0.2μsec/step 0.2μsec/step

2.X or lower

CPU O/S version

Process-driven interrupt

Basic : 30, Application : 218

100ms : T000 ~ T191 (192 points)

10ms : T192 ~ T255 (64 points)

K300S

3.X or higher

CPU O/S version

K1000S

Remarks

Auxiliary

relay

Timer

C C000 ~ C255 (256 point s) Counter

S

D D0000 ~ D4999 (5,000 words)

Operation modes RUN, STOP, PAUSE, DEBUG

Self-diagnosis

functions

Data back-up

method

Max. expansion

level

Current

consumption

Weight 0.11kg 0.25kg 0.42kg

Detect errors of scan time, memory, I/O, battery, and power supply

None Up to 3 level

170mA (A type)

210mA (B/C type)

S00.00 ~ S99.99 (100×100 steps)

D0000 ~ D9999

(10,000 words)

Battery-back-up

130mA 130mA

4-1

Step

controller

Data

register

Chapter 4 CPU modules MASTER-K

4.2 Operation processing of CPU

4.2.1 Operation method

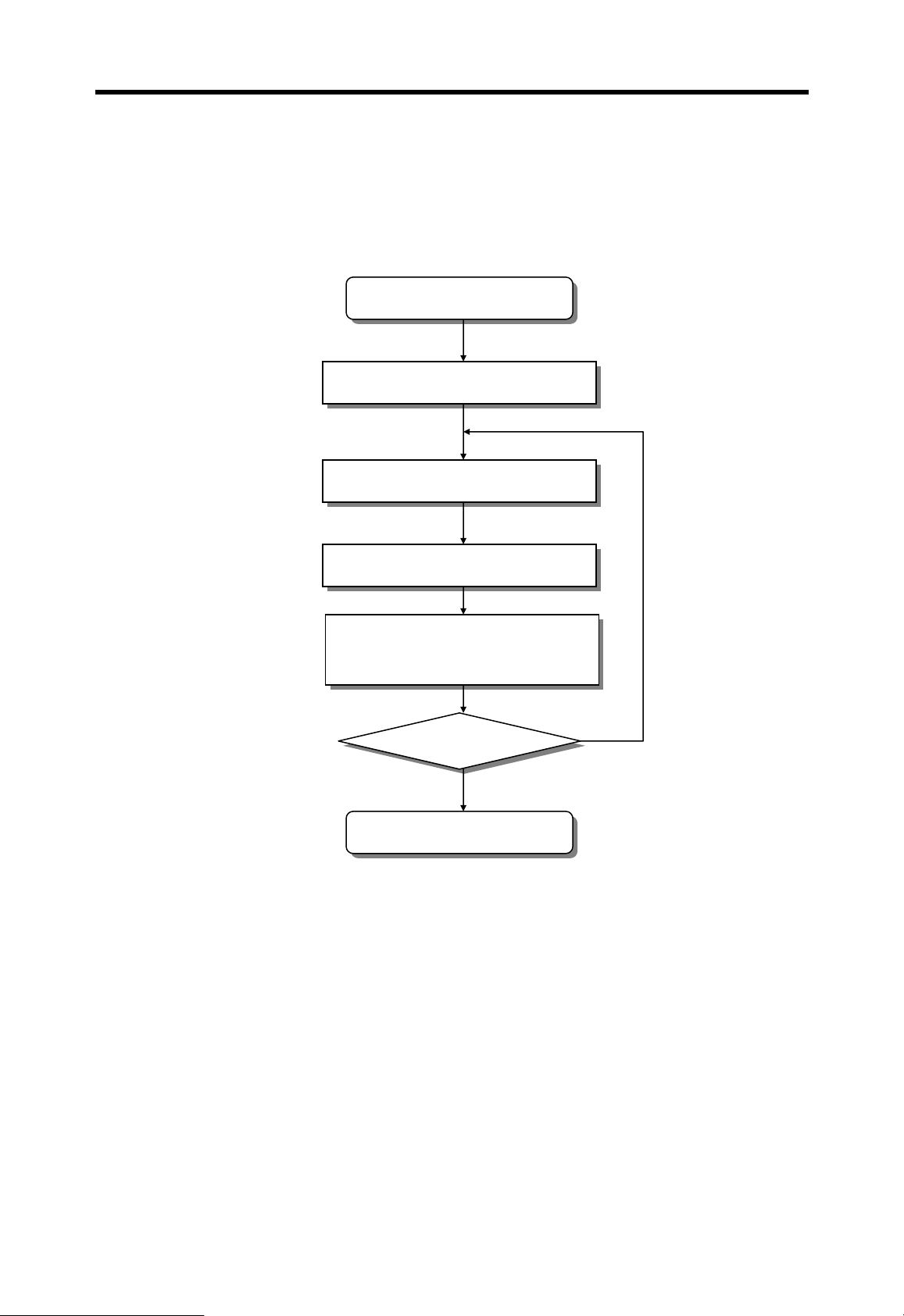

1) The repetitive operation

The repetitive operation method repeats execution of a series of operations. The CPU

repeats the operation processing as following;

Step Description

Start of opera t ion

Initializing operation

Refresh input image data

Program execution

0 step

The preparation step to execute scan operation

Executed only 1 time when power is turned on or

CPU is reset.

The following operation is executed;

- I/O module reset

- Self-diagnosis operation

- Clear non-retentive data

- Read I/O information and assign address

Before start of scan operation, read the status of

input module and store it to the input image data

area.

Execute the user program from step 0 to the last

step

Last step

After the last step is executed, output the operation

Refresh output image data

Execute END operation

result of output image data area to the output

module

Before restart scan operation, the following

operation is executed;

- Self-diagnosis operation

- Update the current value of timer and counter

- Execute data transmission with network module

- Check the operation mode is changed or not

4-2

Chapter 4 CPU modules MASTER-K

2) Interrupt operation

When the CPU detects an interrupt signal, it stops the current operation and execute the

corresponding interrupt routine. After the interrupt routine is completed, the CPU resumes

to execute the previous operation from the stopped point.

The MASTER-K 200S/300S/1000S has two interrupt types that are time-driven interrupt

(TDI) and process-driven interrupt (PDI). Please refer the chapter 4.3.3 for detail s.

4.2.2 The operation during momentary power failure

The MASTER-K 200S/300S/1000S series can detect a momentary power failure, and the

CPU module decides to continue operation or not according to the period of momentary

power failure.

1) Less than 20msec

① The CPU stop to execute sequence program

2) Over 20msec

Less than 20ms

Over 20ms

retaining the state of output.

② The time measurement for internal timer and

time-driven interrupt keeps normal operation

status while the sequence program is

stopped.

③ When the AC power is recovered, the CPU

restarts to execute sequence prog ram.

④ The external output of power supply module

is kept as the rated voltage and current.

The CPU will initialized and restart operation

as the power re-applied.

Remark

Momentary power failure:

The power failure of PLC system means the state that AC input voltage is dropped below the

minimum value of rated input voltage range. When the period of power failure is short (usually,

the 1/2 cycle), it is called as momentary power failure.

4-3

Chapter 4 CPU modules MASTER-K

4.2.3 Scan time

The series of steps from step 0 to the next step 0 or from an END instruction to the next

END instruction is called a scan. The scan time is total time spent to execute a scan.

1) The calculation of scan time

The scan time is calculated as a total of the processing time of sequence program (step 0

to the END), interrupt routine, and internal processing of CPU.

Scan time = Sequence program processing time + Interrupt routine processing time

+ Internal processing time

① Sequence program processing time :

The total processing time to execute step 0 to END instruction

② Interrupt processing time :

The total processing time to execute interrupt routine during a scan

③ Internal processing time :

The total processing time to execute self-diagnosis, I/O refresh, timer/counter update,

and communication operation

2) The scan time varies with executing interrupt routine and communication operation or not.

3) The scan time of CPU module is stored in the following special relays (F area).

- F50 word : The maximum scan time (unit : ms)

- F51 word : The minimum scan time (unit : ms)

- F52 word : The current scan time (unit : ms)

4.2.4 Watchdog timer

1) The watchdog timer is an internal timer of the CPU to detect the error of hardware and

sequence program. The default value of watchdog timer is 200msec, and it can be

changed in parameter setting. (setting range : 10 ~ 6000msec, unit : 10msec)

2) When a scan is not completed before, the watchdog timer error occurs and the operation

of CPU is stopped. At this time, all outputs of I/O module are turned off.

3) The watchdog timer is reset before step 0 is executed (after the END processing is

finished) or the WDT instruction is executed. When write a sequence program contains

FOR ~ NEXT loop or a lot of subroutines, increase watchdog timer setting value or put

WDT instruction to avoid watchdog timer error. The setting range of watchdog timer is 10

~ 6000msec

4) When a watchdog timer error occurs, it can be cleared by power cycle, manual reset

switch (K1000S), or mode change.

4-4

Chapter 4 CPU modules MASTER-K

(PV)

4.2.5 Timers

The MASTER-K 200S/300S/1000S series uses upcount timers. There are 5 timer

instructions such as on-delay (TON), off-delay (TOFF), integral (TMR), monostable

(TMON), and re-triggerable (TRTG) timer.

The measuring time range of 100msec timer is 0.1 ~ 6553.5 sec, and that of 10msec

timer is 0.01 ~ 655.35 sec. Please refer the ‘MASTER-K programming manual’ for details.

1) On delay timer

The current value of timer starts to increase from 0 when the input condition of TON

instruction turns on. When the current value reaches the preset value, the timer output

relay turns on.

When the timer input condition is turned off, the current value becomes 0 and the timer

output relay is turned off.

Timer input condition

Timer output relay

Preset value (PV)

t1

PT PT

t2 t3

t3 + PT t1 + PT

Current value

2) Off delay timer

The current value of timer set as preset value and the timer output relay is turned on

when the input condition of TOFF instruction turns on. When the input condition is turned

off, the current value starts to decrease. The timer output relay is turned off when the

current value reaches 0.

Timer input condition

Timer output relay

Preset value

t1

PT PT

t2 t3

t3 + PTt1 + PT

Current value

4-5

Chapter 4 CPU modules MASTER-K

p

(PV)

(

)

(ig

)

(ig

)

3) Integral timer

In general, its operation is same as on-delay timer. Only the difference is the current

value will not be clear when the input condition of TMR instruction is turned off. It keeps

the elapsed value and restart to increase whe n the input condition is turned on again.

When the current value reaches preset value, the timer output relay is turned on.

The current value can be cleared by the RST instruction only.

Timer input condition

Timer out

ut relay

Timer reset input

Preset value

Current value

t1 t2 t3

PT=t1+t2+t3

4) Monostable timer

In general, its operation is same as off-delay timer. However, the change of input

condition is ignored while the timer is operating (decreasing).

Timer input condition

Timer output relay

PT

Preset value (PV)

Current value

On operation

nored

nored

4-6

Chapter 4 CPU modules MASTER-K

p

(

)

5) Retriggerable timer

The operation of retriggerable timer is same as that of monostable timer. Only difference

is that the retriggerable timer is not ignore the input condition of TRTG instruction while

the timer is operating (decreasing). The current value of retriggerable timer will be set as

preset value whenever the input condition of TRTG instruction is turn ed on.

Timer input condition

Timer out

ut relay

PT

Preset value (PV)

Current value

On operation

Remark

The accuracy of timer:

The Maximum timing error of timers of MASTER-K series is + 2 scan time ~ - 1 scan time. Refer

the programming manual for details.

4-7

Chapter 4 CPU modules MASTER-K

4.2.6 Counter

The counter counts the rising edges of pulses driving its input signal and counts once

only when the input signal is switched from off to on. MASTER-K series have 4 counter

instructions such as CTU, CTD, CTUD, and CTR. The maximum counter setting value is

hFFFF ( = 65535). The followings shows brief information for counter operation.

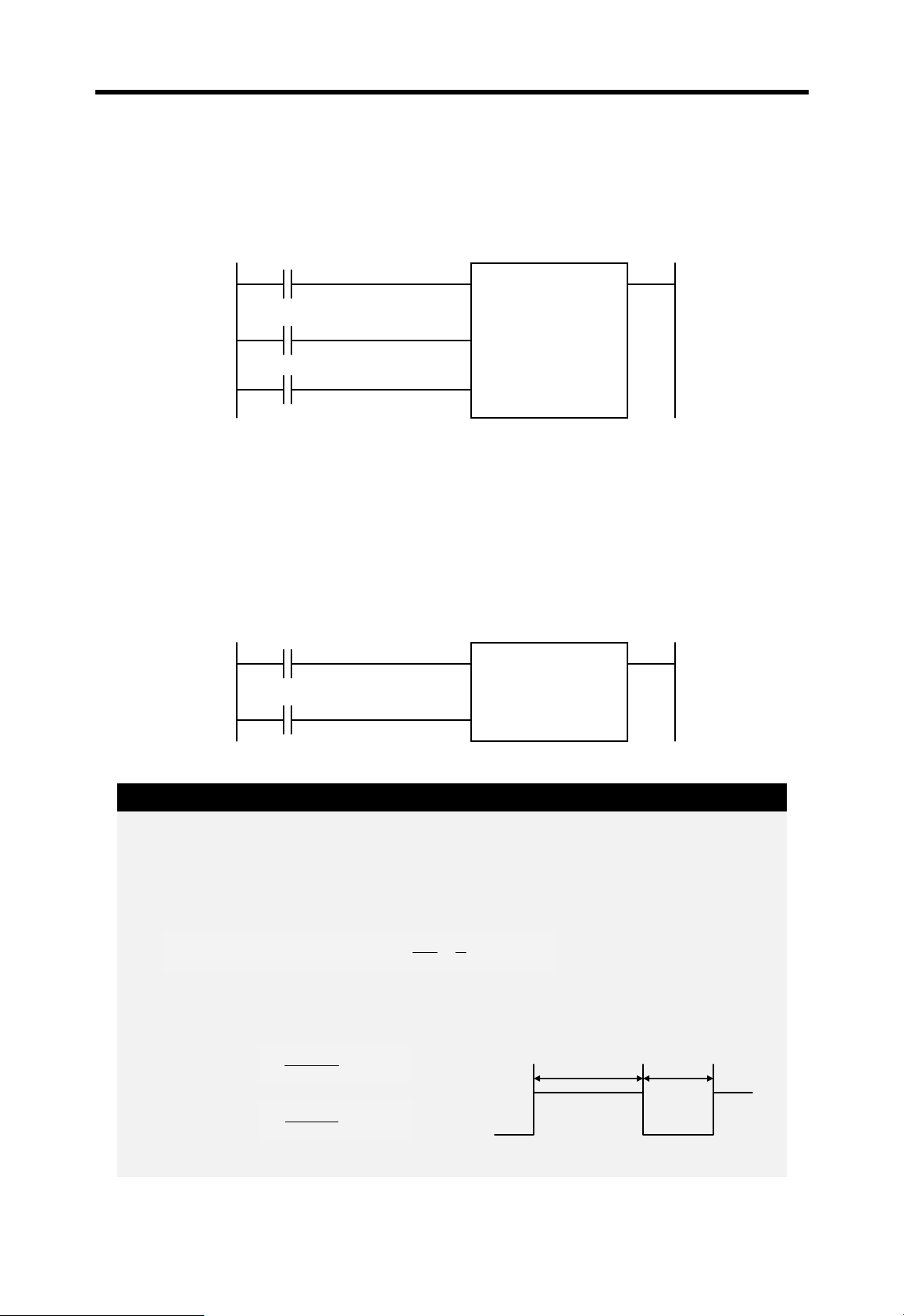

1) Up counter (CTU)

The counter output relay is turned on when the current value reaches the preset value.

After the counter relay output is turned on, the current value will increase until it reaches

the maximum counting value (hFFFF = 65535).

When the reset input is turned on, the counter output relay and current value is cleared

as 0.

U CTU Cxxx

R <S> xxxx

2) Down counter (CTD)

When the CPU is switched to the RUN mode, the current value is set as preset value.

The current value is decreased by 1 with the rising edge of counter input signal. The

counter output relay is turned on when the current value reaches 0.

U CTD Cxxx

R <S> xxxx

1

1

If the retentive counter area is used for down counter, the reset input has to be turned on to

initialize counter.

4-8

Chapter 4 CPU modules MASTER-K

t

3) Up-down counter

The current value is increased with the rising edge of up-count input signal, and

decreased with the rising edge of down-count input signal. The counter output relay is

turned on when the current value is equal or greater than the preset value.

4) Ring counter

The current value is increased with the rising edge of the counter input signal, and the

U CTD Cxxx

D

R <S> xxxx

counter output relay is turned on when the current value reaches the preset value. Then

the current value and counter output relay is cleared as 0 when the next counter input

signal is applied.

U CTR Cxxx

R <S> xxxx

Remark

1. Maximum counting speed

The maximum counting speed of counter is determined by the length of scan time. Counting

is possible only when the on/off switching time of the counter input signal is longer than scan

time.

n

100

1

×=

times/sec) )(C speed counting Maximum max (

s

n : duty (%), ts : scan time

2. Duty

Duty is the ratio of the input signal’s on time to off time as a percentage.

If T1 ≤ T2,

T1

n (%100×

=

T2T1

+

)

T1 T2

ON

If T1 > T2,

T2

n (%100×

=

T2T1

+

)

OFF

4-9

Chapter 4 CPU modules MASTER-K

4.3 Program structure

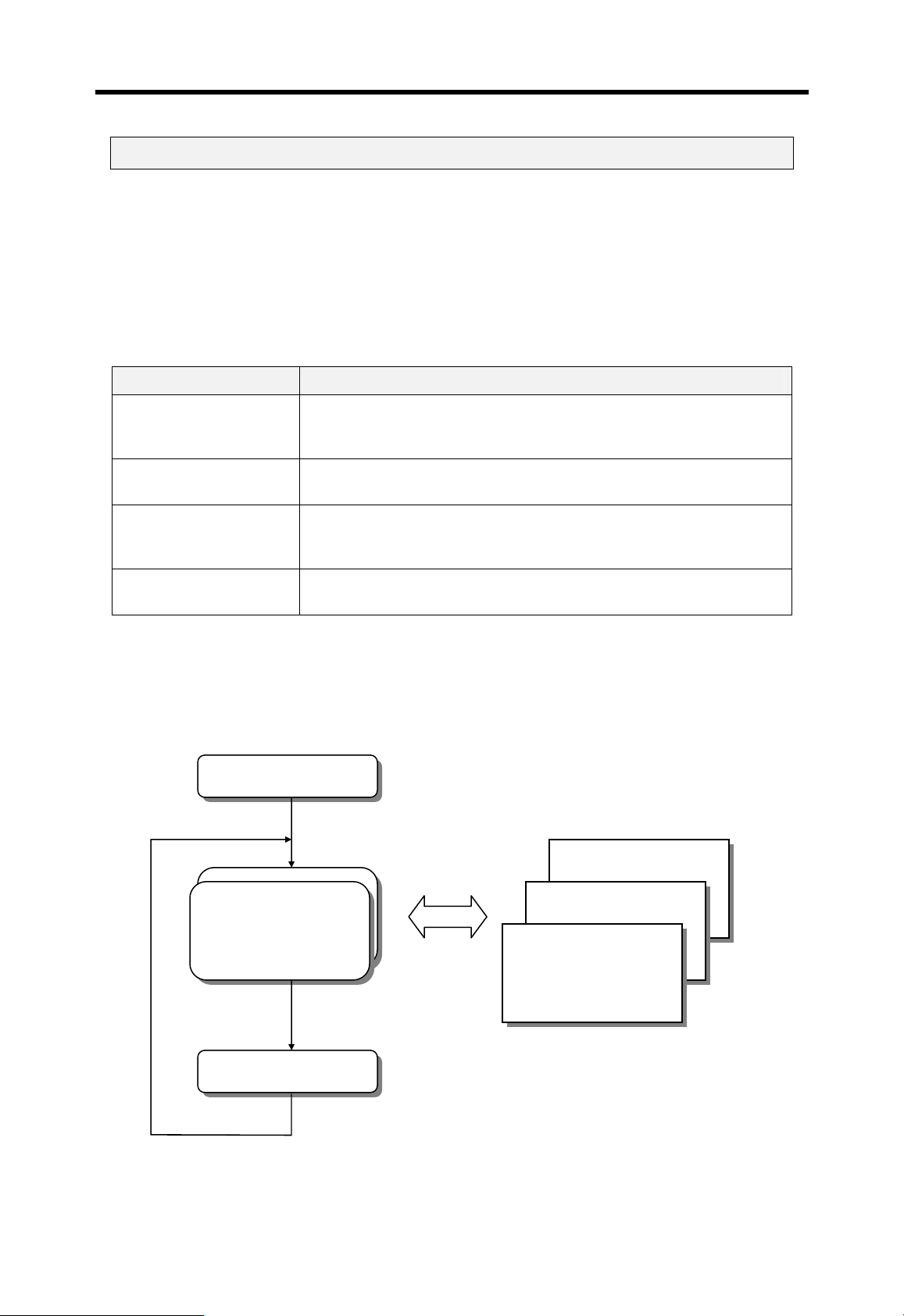

4.3.1 Classification of program

All functional elements need to execute a certain control process are called as a

‘program’. In MASTER-K series, a program is stored in the RAM mounted on a CPU

module or flash memory of a external memory module. The following table shows the

classification of the program.

Program type Description

The scan program is executed regularly in every scan. If the scan

Scan program

program is not stored, the CPU cannot execute not only the scan

program but also other programs.

Time-driven interrupt

program (TDI)

Process driven interrupt

program (PDI)

Subroutine program

The TDI programs are executed with a constant time interval

specified with parameter setting.

The PDI programs are executed only external interrupt input is

applied and the corresponding interrupt routine is enabled by EI

instruction.

The subroutine programs are executed when they are called by the

scan program with a CALL instruction.

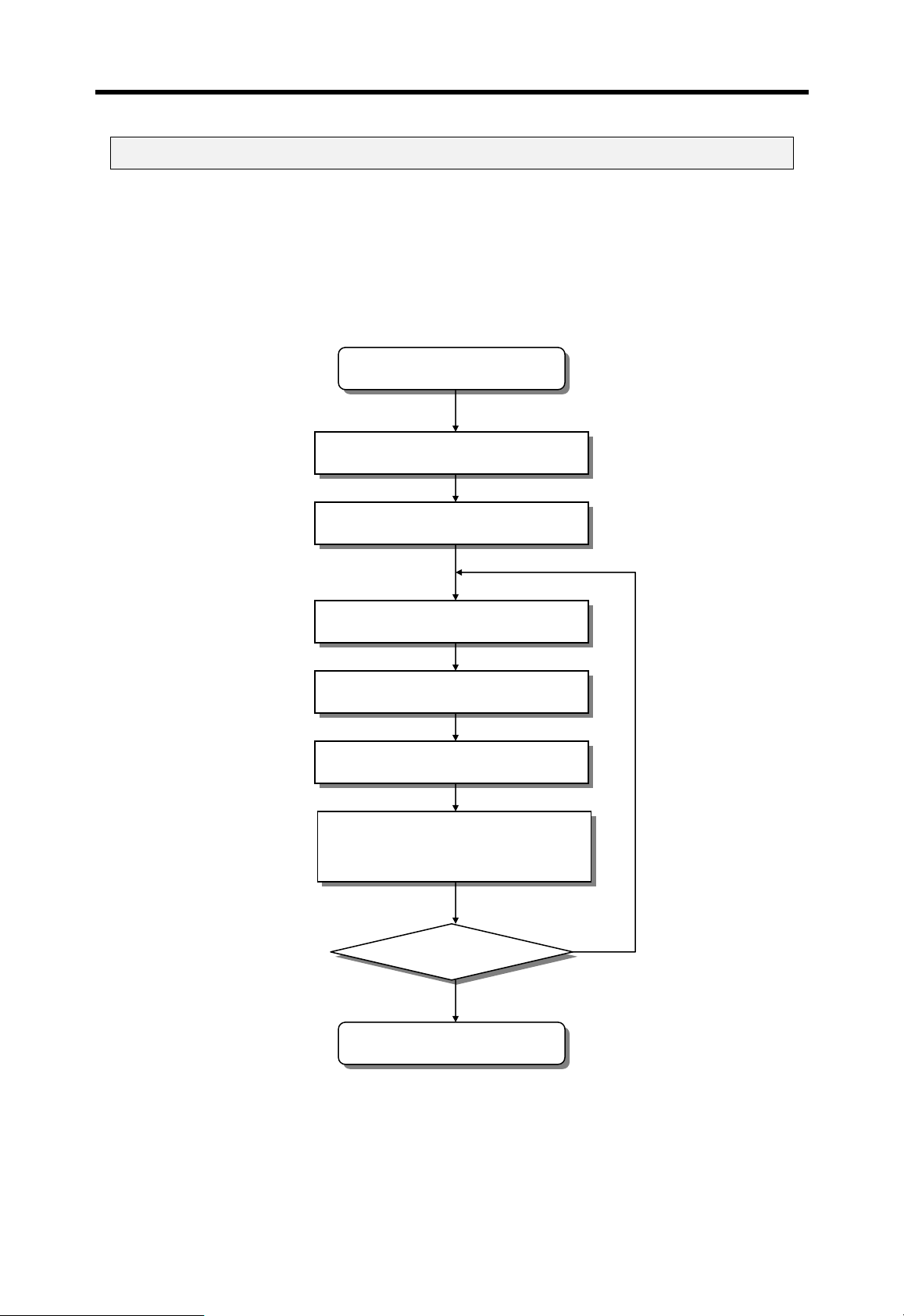

4.3.2 Processing method

The following diagram shows that how the CPU module process programs when th e CPU

module is powered on or switched to RUN mode.

Start operation

Scan program

Subroutine program

PDI program

TDI program

END processing

4-10

Chapter 4 CPU modules MASTER-K

4.3.3 Interrupt processing

When an interrupt occurs, the CPU module will stop the current operation and execute

the corresponding interrupt routine. After finish the interrupt routine, the CPU resume the

sequence program from the stopped step.

MASTER-K series provides 2 types of interrupt. The TDI (Time driven interrupt) occurs

with the constant period, and PDI (Process driven interrupt) occurs with the status of

external input.

Before to use interrupt function in sequence program, the parameter setting should be

done properly. Then the corresponding interrupt routine should be written after END

instruction. (Refer chapter 4 for details) If interrupt routines are not matched with

parameter settings, an error occurs and the operation of CPU will be stopped.

To execute an interrupt routine, use the EI instruction to enable the corresponding

interrupt. The interrupt routine is not executed if an interrupt factor occurs before

execution of an EI instruction. Once an interrupt is enabled with EI instruction, it keeps

the enabled status until DI instruction is executed to disable the interrupt. When a CPU is

turned to RUN mode, all interrupts are disabled by default.

When multiple interrupt factors occur simultaneously, interrupt routines are executed

according to the priority given to the each interrupt. If an interrupt factor that has higher

priority occurs while other interrupt that has lower priority are executing, the interrupt

routine of lower priority will be stopped and the interrupt of higher priority will be executed

first. The following figure shows how a CPU handles multiple interrupts.

Scan Program

Interrupt routine 1

Interrupt routine 2

1

7

5

3

6

Program starts

1

2

Interrupt 2 occurs

2

Stop main program and execute interrupt

3

routine 2

4

Interrupt 1 occurs (higher priority)

5

Stop routine 2 and run routine 1

4

6

Finish routine 1 and return to routine2

7

Finish routine 2 and return to main

4-11

Chapter 4 CPU modules MASTER-K

1) Parameter setting

K200S K300S K1000S

Priority Type Period Priority Type Period Priority Type Period

0

1

2

:

:

7

Remark

Period is the interval of time driven interrupt occurring. It is variable from 10 ms to 60,000 ms

(60ms) by 10 ms.

Remark

Interrupt processing during momentary power failure:

If process-driven interrupts occur during a momentary power failure (power failure less than 20

ms), they are executed after the power is recovered. If a time-driven interrupt occurs two or

TDI0

TDI2

TDI5

:

:

INT7

10ms

25ms

100ms

0

1

2

:

:

:

13

TDI0

TDI2

TDI5

INT7

10ms

25ms

100ms

0

1

2

:

:

:

:

29

TDI0

TDI2

TDI5

INT15

10ms

25ms

100ms

more times during momentary power failure, it is executes only once after powe r is recovered.

During momentary power failure, the CPU keep measuring time and the period of momentary

power failure is included in the period of TDI.

4-12

Chapter 4 CPU modules MASTER-K

2) TDI (Time driven interrupt)

TDI occurs periodically with the constant interval assigned in parameter setting. The

interrupt routine of TDI starts with the TDINT instruction and ends with the IRET

instruction.

When multiple interrupt factors occur simultaneously, interrupt routines are executed

according to the priority given to the each interrupt. If an interrupt factor has higher priority

occurs while other interrupt of lower priority is executing, the interrupt routine of lower

priority will be stopped and the interrupt of higher priority will be executed first. Otherwise,

two interrupts are executed consequently.

The maximum numbers of TDI for K200S / 300S / 1000S are shown as following table.

PLC type Available TDI

K200S TDINT 0 ~ 7

K300S TDINT 0 ~ 13

K1000S TDINT 0 ~ 29

The following figure shows an example of TDI execution.

Used TDI

TDI 0 : occurs every 200ms

TDI 1 : occurs every 100ms

TDI 2 : occurs every 400ms

400ms

200ms

100ms 100ms 100ms 100ms

A B C A B A B CB B

Interrupt routines

A : The routine corresponding to TDI 0

B : The routine corresponding to TDI 1

C : The routine corresponding to TDI 2

200ms

4-13

Chapter 4 CPU modules MASTER-K

3) PDI (Process driven interrupt)

PDI occurs when the input status of interrupt module is changed from OFF to ON or from

ON to OFF. (Select by DIP switch setting) Since K200S does not have interrupt module,

PDI will occur when the input assigned as interrupt input by parameter setting is changed

from OFF to ON.

The execution order of multiple interrupts is similar as TDI. The following figure shows an

example of execution order of multiple PDI.

Scan Program

Interrupt routine 0

Interrupt routine 1

Interrupt routine 2

1

2

9

PDI

PDI

5

6

PDI

7

3

8

1

Program starts

2

Interrupt 2 occurs

3

Stop main program and run PDI routine 2

4

Interrupt 0 occurs (higher priority)

5

Stop routine 2 and execute routine 0

4

2 4 6

6

Interrupt 1 occurs (lower priority)

7

Finish routine 0 and execute routine 1

Finish routine 1 and resume routine 2

8

9

Finish routine 2 and back to main program

4-14

Chapter 4 CPU modules MASTER-K

4.3.4 Error handling

1) Error classification

Error occurs due to various causes such as PLC system errors, system configuration fault

or abnormal operation result. Errors are classified into fatal error that stops system

operation for safety, and ordinary error that continue system operation with informing the

user of error warning.

The causes of system error are as following;

- The hardware error

- System configuration error

- Operation error during execution of user program

- External device malfunction

2) Operation mode at error occurrence

In case of error occurrence, the CPU stores corresponding error code at error flags, and

stop / continue operation according to the error type.

① The hardware error

The system is changed to STOP mode when a fatal error such as CPU defection

occurs. When an ordinary error such as battery error occurs, the system keep its

operation status.

② System configuration error

This error occurs when actual hardware configuration conflicts with the configuration

assigned in parameter setting. The syste m is changed to the STOP mode.

③ Operation error during execution of user program

When a arithmetic operation error occurs, the system output error code at the

corresponding error flag and continue operating. If a scan time exceeds the watchdog

timer setting value or mounted I/O module is not normally controlled, the system is

switched to the STOP mode.

④ External device malfunction

The CPU can detect an external device malfunction with user program. If a fatal error

detected, the system is stopped. Otherwise, it continues operating.

Remark

1. When an error occurs, the error code is stored at special relay (F006 word).

2. Refer the appendix 1 ‘Flag list’ for det ails of error flags.

4-15

Chapter 4 CPU modules MASTER-K

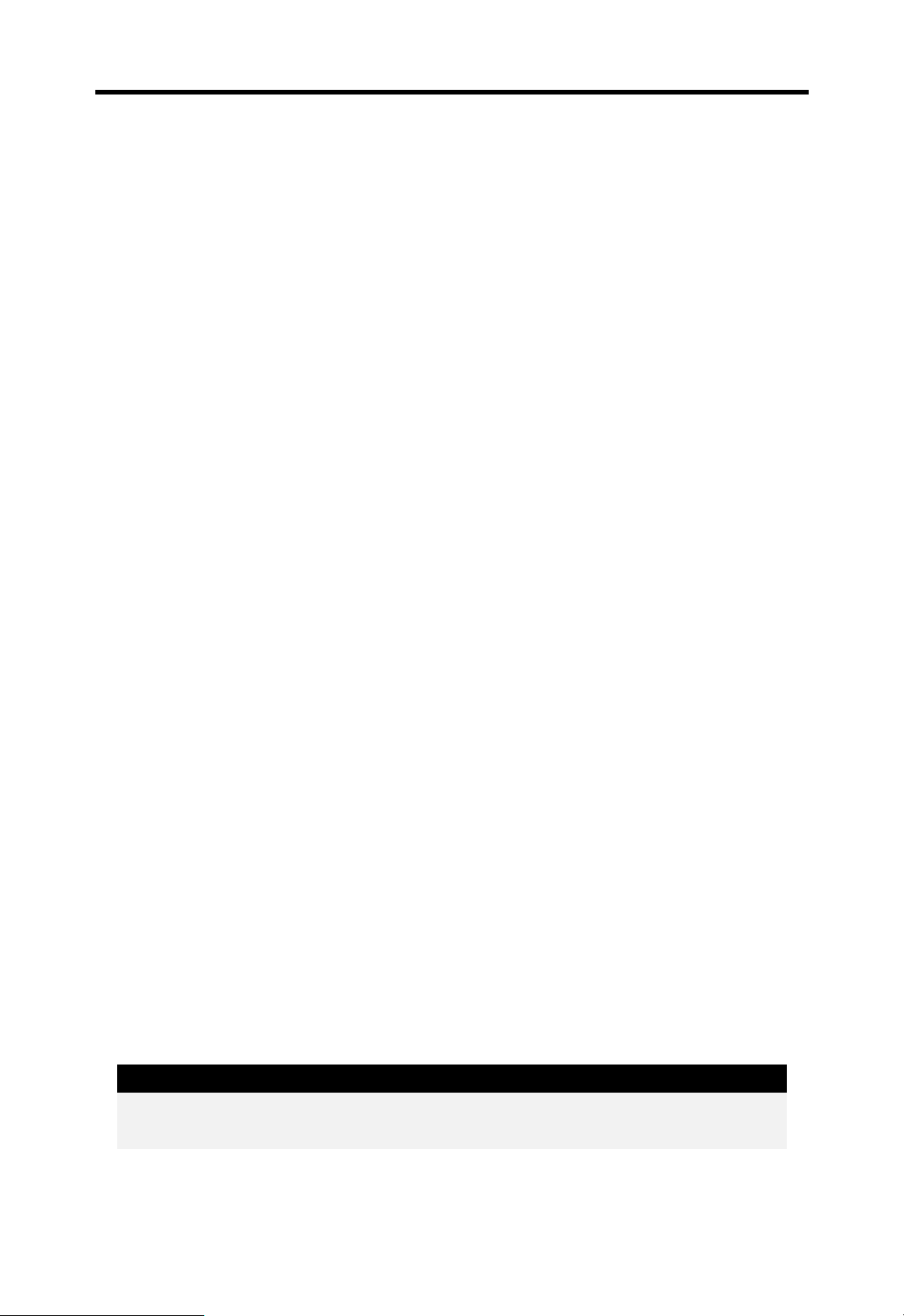

4.4 Operation mode

The operation mode of CPU module can be classified into 4 modes such as RUN, STOP,

PAUSE, and DEBUG modes.

4.4.1 RUN mode

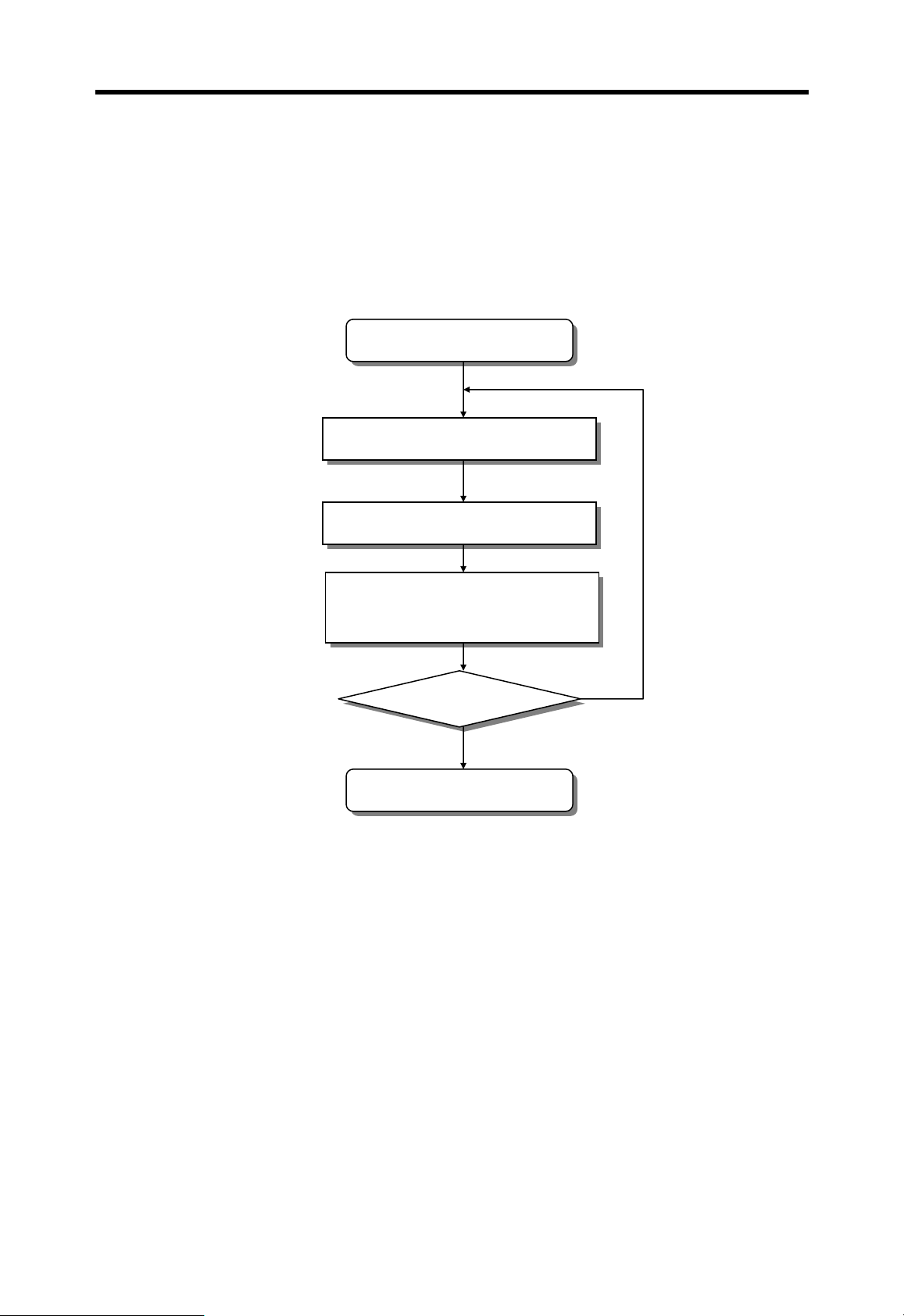

In the RUN mode, the CPU process user programs normally.

Start RUN mode

Clear the non-latched memory area

Check user program

Execution of user program

Self-diagnosis

I/O refresh

Execute communication service,

Update timer / counter

Mode changed?

Yes

Start other mode

4-16

No

Chapter 4 CPU modules MASTER-K

4.4.2 Stop mode

In the STOP mode, the CPU does not execute program. Program change through KGLWIN is possible in the remote STOP mode only.

External wiring check is also possible with the forced I/O on/off function.

Execute communication service,

Start STOP mode

Turn all outputs of f

Self-diagnosis

I/O refresh

Update timer / counter

No

Mode changed?

Yes

Start other mode

4-17

Chapter 4 CPU modules MASTER-K

4.4.3 PAUSE mode

In PAUSE mode, the CPU stops executing user program, but keeps the status of output

and internal memory.

When the mode is changed to RUN mode, the CPU restart executing user program from

the step at which the user program is stopped.

Start PAUSE mode

Execute communication service,

Self-diagnosis

I/O refresh

Update timer / counter

No

Mode changed?

Yes

Start other mode

4-18

Chapter 4 CPU modules MASTER-K

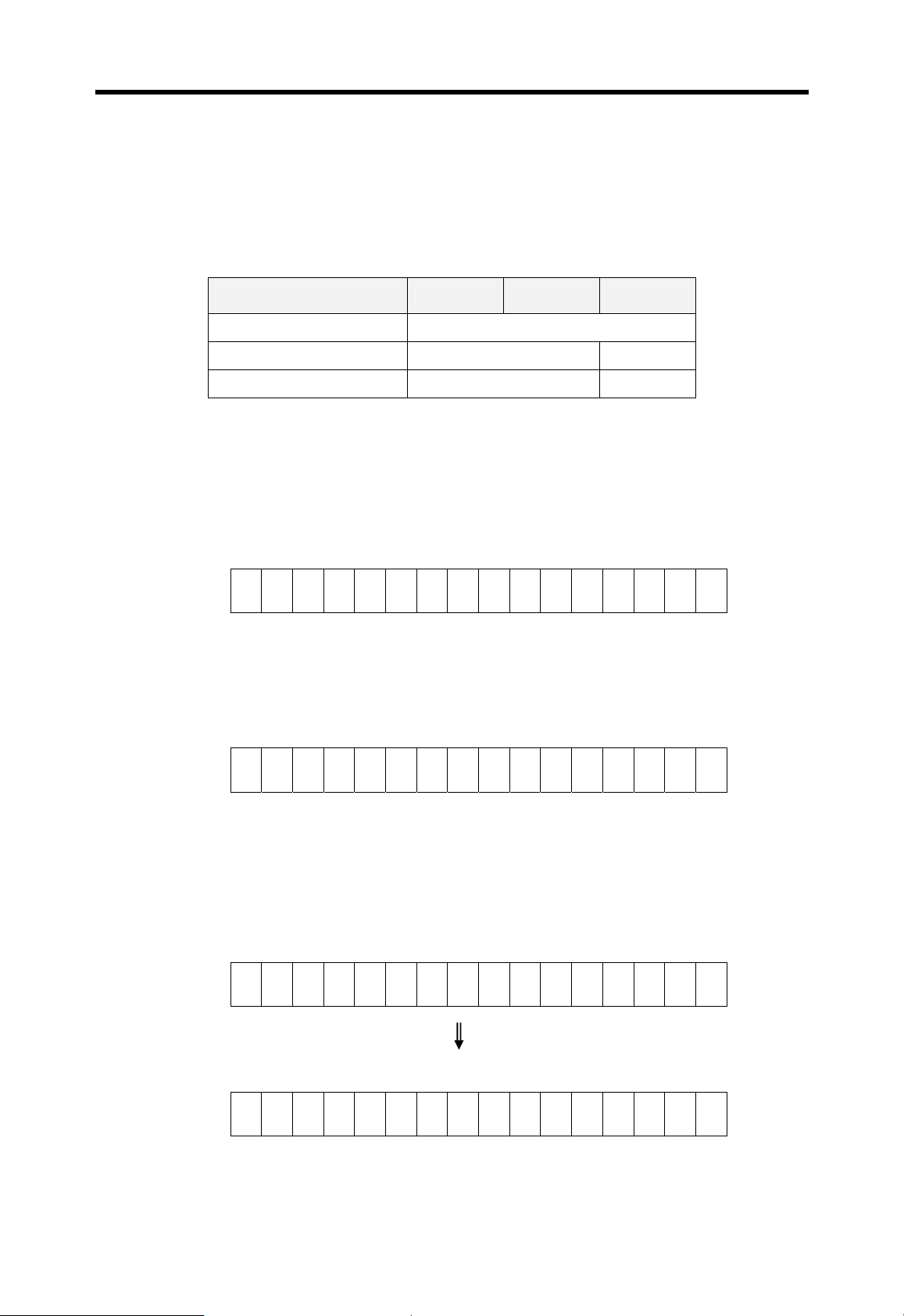

4.4.4 DEBUG mode

For debugging of user program, the MASTER-K 200S/300S/1000S provides the DEBUG

mode. In the DEBUG mode, the CPU executes user program according to the execution

condition as following;

① Step over : Executes just an operation unit (one instruction)

② Break point : Executes user program until the specified step (break point)

③ Device state : Execute user program until a device (bit or word) assigned to be

monitored is changed to the specified status (read, write, value)

④ Scan loop : Execute user program for specified number of scans

Start DEBUG mode

Clear the non-latched memory area

Stop operation

Execution of user program according

to the specified execution condition

Self-diagnosis

I/O refresh

Execute communication service,

Update timer / counter

Mode changed?

Yes

Start other mode

4-19

No

Chapter 4 CPU modules MASTER-K

Remark

It is forbidden to enter DEBUG mode from RUN or PAUSE mode.

Remark

In DEBUG mode, each interrupt program can be enabled / disabled sepa rately.

4.4.5 Operation mode change

1) The operation mode of CPU can be change by following methods;

① The mode key switch on the CPU module

② KGL-WIN connected to the CPU through loader port

③ KGL-WIN connected to the remote CPU through a fieldbus network

④ User command through a FAM or computer link module

⑤ The ‘STOP’ instruction of use r prog ram

2) Mode change by mode key switch

The following table shows how the operation mode is changed by mode key switch

Mode key switch Operation mode

RUN Local RUN

STOP Local STOP

PAU / REM Local PAUSE / Remote (RUN / STOP / PAUSE)

RUN Æ PAU / REM Local RUN Æ Local PAUSE

PAU / REM Æ STOP Local PAUSE / Remote Æ Local STOP

STOP Æ PAU / REM Local STOP Æ Remote STOP

PAU / REM Æ RUN Local PAUSE / Remote Æ Local RUN

Remark

The CPU operates continuously when the operation mode is changed as remote RUN Æ local

RUN

4-20

Chapter 4 CPU modules MASTER-K

3) Remote mode change

To change operation mode with KGL-WIN or KLD-150S, the mode key switch should be

in the remote STOP mode. (Mode key setting : STOP Æ PAU / REM)

Mode key

switch

PAU / REM

Mode change KGL-WIN FAM / Cnet

Remote STOP Æ Remote RUN O O

Remote STOP Æ Remote PAUSE X X

Remote STOP Æ DEBUG O O

Remote RUN Æ Remote PAUSE O O

Remote RUN Æ Remote STOP O O

Remote RUN Æ DEBUG X X

Remote PAUSE Æ Remote RUN O O

Remote PAUSE Æ Remote STOP O O

Remote PAUSE Æ DEBUG X X

DEBUG Æ Remote RUN X X

DEBUG Æ Remote PAUSE X X

DEBUG Æ Remote STOP O O

4-21

Chapter 4 CPU modules MASTER-K

4.5 Special functions of CPU module

4.5.1 RTC (Real Time Clock) function

MASTER-K 200S/300S/1000S series includes RTC function. (K200S-A does not have

RTC function) Clock operation by the RTC function is continued with a battery or super

capacitor when the CPU is powered off.

1) Clock data

Clock data is the data comprised of year, month, day, hour, minute, second, and date.

Data name Description

Year 4 digits of the Christian Era

Month 1 to 12

Day 1 to 31 (A leap year is distinguished automatically)

Hour 0 to 23 (24 hours)

Minute 0 to 59

Second 0 to 59

0 Sunday

1 Monday

2 Tuesday

Date

2) Precision

Max. 1.728 second per day (general temperature)

Remark

1. The RTC data does not have factory default setting. Please write a correct RTC data

before using RTC function first time.

2. If unreasonable RTC data is written to the CPU, the RTC function may operate abnormally.

Example : 13 (month) 32 (day)

3 Wednesday

4 Thursday

5 Friday

6 Saturday

4-22

Chapter 4 CPU modules MASTER-K

3) Read / write RTC data

① Read RTC data

The current RTC data

Memory Area

(Word)

F053 Lower 2 digits of year Month h9812

F054 Day Hour h2219

F055 Minute Second h3746

F056 Higher 2 digits of year Date h1902

Example : 1998. 12. 22. 19:37:46, Tuesday

② Write RTC data

There is two ways to write new RTC data to the CPU.

The first one is using a handy loader (KLD-150S) or graphic loader (KGL-WIN). For

detailed information, refer the user’s manual of KLD-150S or KGL-WIN.

The second one is write sequence program. By switching a special bit on, user can

replace the current RTC data with the preset data stored in a specified memory area. The

followings are the memory address of preset data and an example program.

The preset RTC data

Upper byte Lower byte

Description

Data

(BCD format)

Memory Area (Word) Description

K200S / K300S K1000S Upper byte Lower byte

D4990 D9990

D4991 D9991 Day Hour h1711

D4992 D9992 Minute Second h5324

D4993 D9993

Example : 1999. 1. 17. 11:53:24, Sunday

Lower 2 digits

of year

Higher 2 digits

of year

Month h9901

Date h1900

Data

(BCD format)

4-23

Chapter 4 CPU modules MASTER-K

M1904 : RTC data change bit

When the M1904 bit is switched on, the new data in D4990 ~ D4993 (K1000S :

D9990 ~ D9993) will be moved to F53 ~ F56. After data is moved, M1904 has to be

switched off immediately because current data will be updated every scan while

M1904 is on.

<Example program for K200S / K300S>

P000

Start switch

[ MOV h9901 D4990 ]

[ MOV h1711 D4991 ]

[ MOV h5324 D4992 ]

[ MOV h1900 D4993 ]

[ D M1904 ]

:1999 January

:17th 11 o’clock

:53min 24sec

:1999, Sunday

:Changing enable

Other Program

4-24

Chapter 4 CPU modules MASTER-K

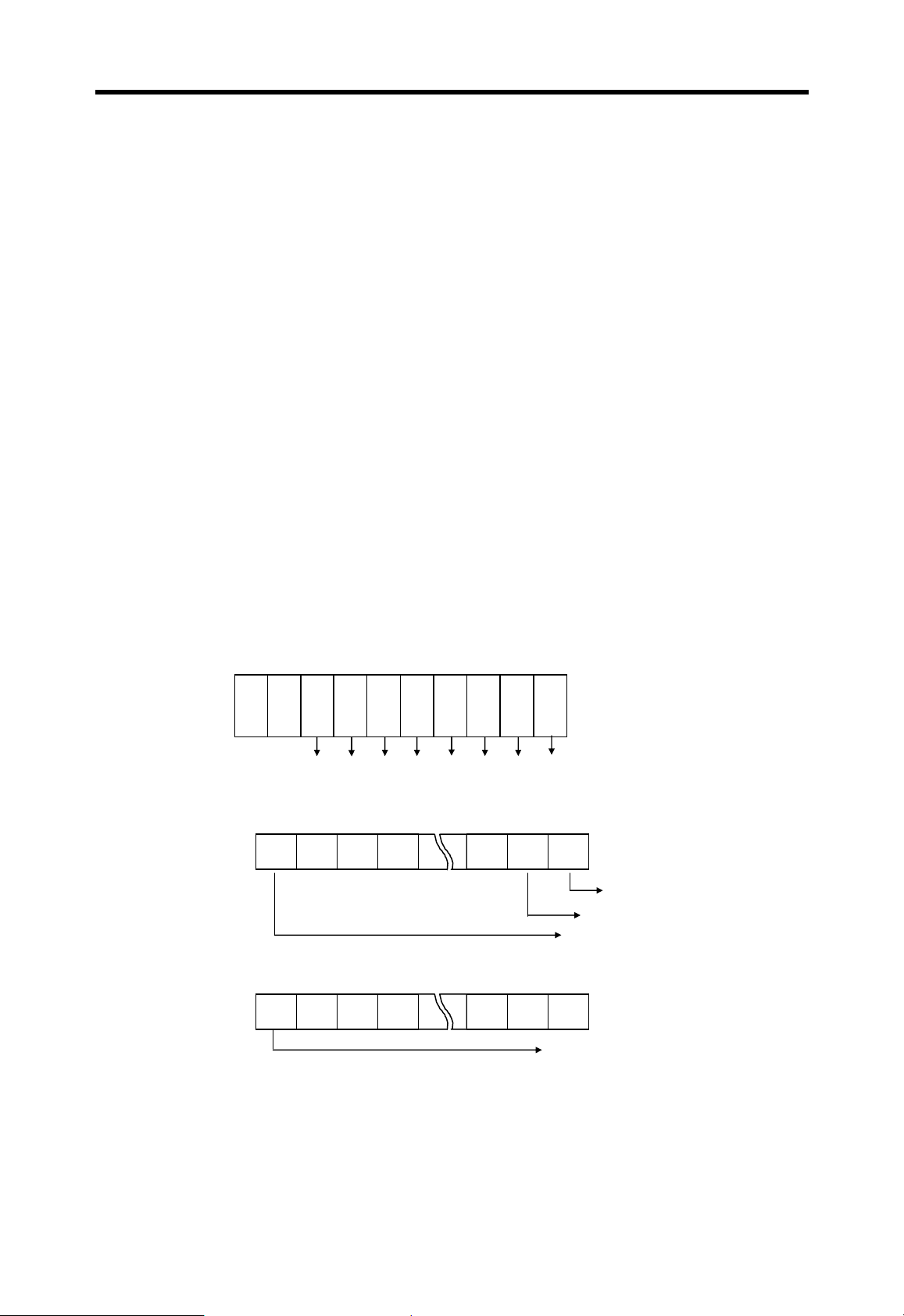

4.5.2 Forced I/O setting

It is possible to output a designated data regardless of the result of operation. This

function is useful to check operation of the output modules and wiring between the output

modules and external devices.

K200S K300S K1000S

Forced I/O request bit M1910

The forced I/O address D4700 ~ D9700 ~

The forced I/O data D4800 ~ D9800 ~

Example 1) Output h8721 to the P10 word by force (K200S / K300S)

a) Write the forced I/O data (h8721) to the corresponding data word. P10 is matched to

the D4810 word.

<D4810 word>

F E D C BA98765432 1 0

1 0 0 0 0 1 1 1 0 0 1 0 0 0 0 1

b) Write the forced I/O address (All bit = hFFFF) to the corresponding address word.

Write hFFFF to the D4710.

<D4710 word> ( 0 = disable forced I/O, 1 = enable forced I/O )

F E D C BA98765432 1 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

c) Switch on the forced I/O request bit (M1910).

d) Output of P10 word

(P : The previous result of operation )

F E D C BA98765432 1 0

P P P P P P P P P P P P P P P P

F E D C BA98765432 1 0

1 0 0 0 0 1 1 1 0 0 1 0 0 0 0 1

4-25

Chapter 4 CPU modules MASTER-K

Example 2) Switch On/Off the last bit of P07 word (K1000S)

a) Write the forced I/O data (h0001) to the corresponding data word. P10 is matched

to the D9807 word.

<D9807 word>

F E D C BA98765432 1 0

0 0 0 0 0000000000 0

b) Write the forced I/O address (last bit = h0001) to the corresponding address word.

Write h0001 to the D9707.

<D9707 word> ( 0 = disable forced I/O, 1 = enable forced I/O )

F E D C BA98765432 1 0

0 0 0 0 0000000000 0

c) Switch on the forced I/O request bit (M1910).

d) Output of P07 word

(P : The previous result of operation )

F E D C BA98765432 1 0

P P P P P P P P P P P P P P P P

1

1

F E D C BA98765432 1 0

P P P P PPPPPPPPPP P

1

4.5.3 Program edit in RUN mode

User can insert, delete, or change instructions of program while the CPU is running.

This function is useful to debugging or test-operation. Please refer the user’s manual

of KLD-150S or KGL-WIN for detail information.

Remark

The program edit in RUN mode can not be performed for the following instructions – JMP,

JME, CALL, SBRT, FOR, and NEXT instructions. Moreover, the program that has very long

scan time (2 seconds or more) can not be edited while the CPU is in the RUN mode.

4-26

Chapter 4 CPU modules MASTER-K

4.5.4 Self-diagnosis

1) WDT (Watch dog timer) function

The watch dog timer is an internal timer of a PLC to detect the error of hardware and a

sequence program. The default value is set as 200msec, and it is changeable with

parameter setting. Refer the MASTER-K programming manual for details on the

parameter setting.

The CPU resets the watch dog timer before step 0 is executed (after the END

processing is finished). When the END instruction has not been executed within the

set value due to an error occurred in the PLC or the long scan time of a sequence

program, the watch dog timer will times out. When a watch dog timer error is occurred,

all outputs of the PLC are turned OFF, and the ERR LED of the CPU will flashes.

(RUN LED will be turned OFF) Therefore, when use FOR ~ NEXT or CALL instruction,

insert WDT instruction to reset the watch dog timer.

2) I/O module check function

If one or more I/O modules are mounted/dismounted while the PLC is powered, the

corresponding bit (F0040 ~ F0050 : 32 bits) will be switched on. If a module is

mounted improperly, the relevant bit will be switched on also.

P

C

W

R

P

U

Slot No :

1 234567

F004

(word)

MSB

1 1 1

LSB

Error occurred at slot 0

Error occurred at slot 1

Error occurred at slot 15

F005

(word)

MSB

1 1 1

LSB

Error occurred at slot 31

3) Battery check function

When the voltage of the battery for back-up the memory IC of CPU are lower than the

minimum back-up voltage, the BAT LED of CPU module will be turned on.

4-27

Chapter 4 CPU modules MASTER-K

4.5.5 Direct I/O refresh

To read or write the operation result immediately, MASTER-K 200S/300S/1000S provides

‘IORF’ instruction. When the IORF instruction is executed, the CPU refreshes I/O image

data area immediately. Please refer the MASTER-K instruction manual for details.

4.5.6 System error history

When the system is stopped by error occurrence, the CPU stores the error occurrence

time and error code to the special data register area. The most recent 16 error occurring

times and error codes are stored in the special data register.

1) Special data register

CPU type

K200S K300S K1000S

D4901 ~ D4904 D9901 ~ D9904 The latest error information

D4905 ~ D4908 D9905 ~ D9908 The 2nd latest error information

Device

: : :

D4961 ~ D4964 D9961 ~ D9964 The 16

2) Description of each word

Device

Contents Description

K200S K300S K1000S

D4901 D9901 h9905 Year : 99, Month : 5

D4902 D9902 h2812 Date : 28, Hour : 12

D4903 D9903 h3030 Minute : 30, Second : 30

D4904 D9904 h0001 Error code (h0001)

3) Clear error data

Use a ‘data clear’ function of KGL-WIN or KLD-150S

Description

th

latest error information

Remark

The system error history function is not available with K3P-07AS because it does not have

RTC function.

4-28

Chapter 4 CPU modules MASTER-K

4.6 Memory configuration

4.6.1 Memory map of K200S / K300S

P00

P

1

M189

M190

M191

K00

K31

F00

F63

L00

L63

Bit Data Area Word Data Area User Program Area

0 ~ F 0000 ~ FFFF

D0000

I/O relay

(See the remark

)

“P”

Auxiliary relay

(3,040 points)

Special auxiliary relay

(32 points)

“M”

“M”

Keep relay

(512 points)

“K”

D4500

D4999

T000

T255

T000

Data Register

Reserved for special usage

Timer preset value

(256 words)

Timer elapsed value

(256 words)

“D”

Word

Parameter setting area

User Program

Area

MK300S :

15k steps

MK200S : 7k steps

T255

Special relay

(1,024 points)

“F”

C000

Counter preset value

(256 words)

C255

Link relay

(1,024 points)

“L”

C000

Counter elapsed value

(256 words)

T000

T191

T192

T255

C000

C255

Timer relay (100ms)

192 points

Timer relay (10ms)

64 points

Counter relay

256 points

“T”

“T”

“C”

S00

S99

Remark

P∴∴

Ste p Controller

(100 x 100 steps)

S00.00~S99.99

1

:

“S”

K200S : P15 (256 points)

K300S : P31 (512 points)

P63 (1,024 points) Æ In 3.0 or higher CPU O/S version

4-29

Chapter 4 CPU modules MASTER-K

4.6.2 The memory map of K1000S

Bit Data Area Word Data Area User Program Area

0 ~ F 0000 ~ FFFF

P00

P63

M000

M189

M190

M191

K00

K31

F00

F63

L00

L63

I/O relay

(1,024 points

)

“P”

Auxiliary relay

(3,040 points)

Special auxiliary relay

(32 points)

Keep relay

(512 points)

“M”

“M”

“K”

Special relay

(1,024 points)

Link relay

(1,024 points)

“F”

“L”

D0000

D9500

D9999

T000

T255

T000

T255

C000

C255

C000

Data Register

Reserved for special usage

Timer preset value

(256 words)

Timer elapsed value

(256 words)

Counter preset value

(256 words)

Counter elapsed value

(256 words)

“D”

Parameter setting area

Word

User Program

Area

(30k steps)

T000

T191

T192

T255

C000

C255

Timer relay (100ms)

192 points

Timer relay (10ms)

64 points

Counter relay

256 points

“T”

“T”

“C”

S00

S99

Ste p Controller

(100 x 100 steps)

S00.00~S99.99

“S”

4-30

Chapter 4 CPU modules MASTER-K

4.7 Assign I/O address

To read / write data I/O and special function modules, the CPU assigns I/O address (P

area) to each modules according to the module type. I/O address starts from P00 (word),

and it is assigned from left to right. The following figure shows an example of I/O address

allocation.

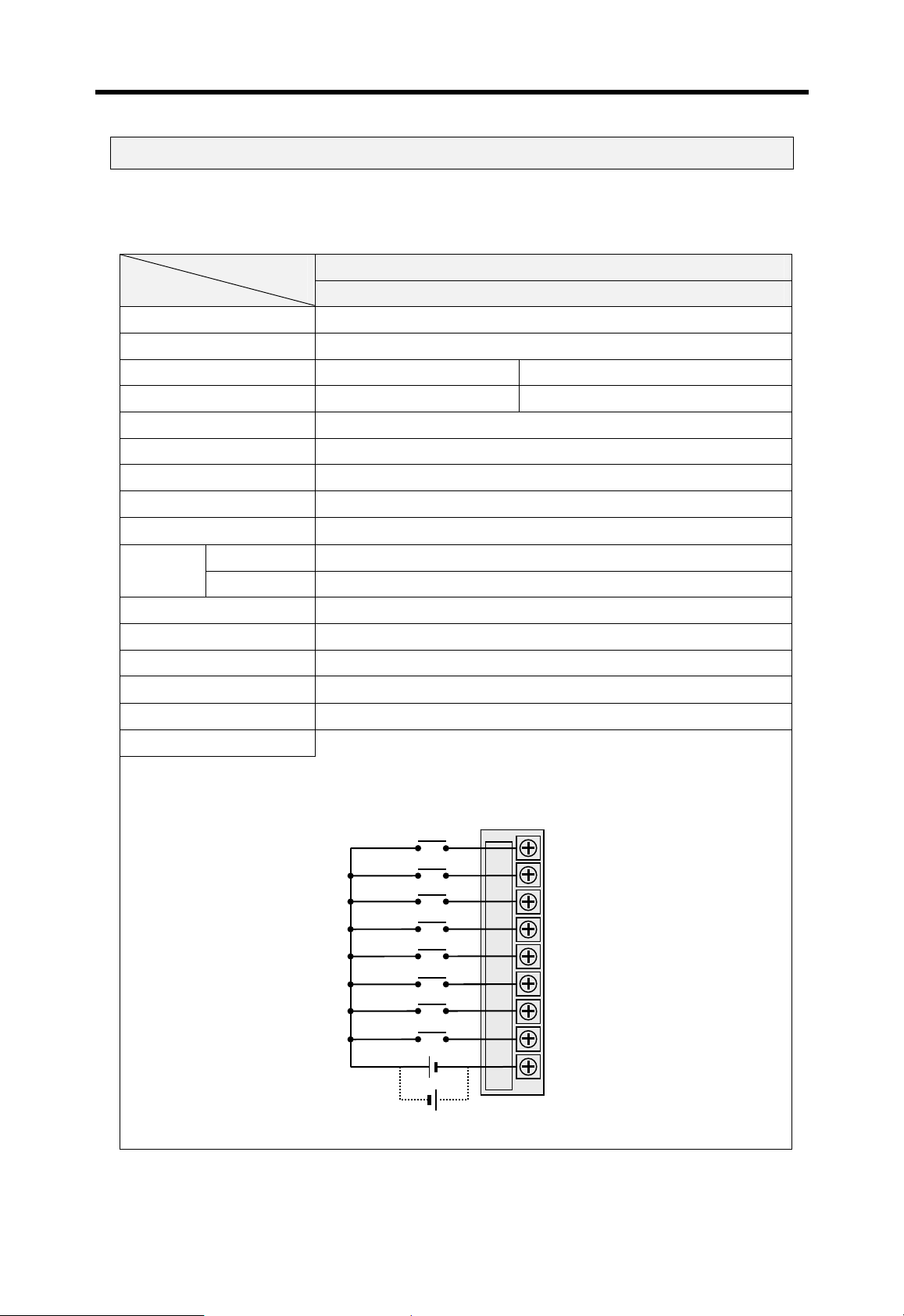

Main base (8 slots)

Remark

Power module

Input (16 points)

CPU module

Output (16 points)

Input (32 points)

Input (64 points)

Output (32 points)

D/A module (8ch)

A/D module(4ch)

Fnet module

P120 ~ P12F (1word)

P1 10 ~ P11F (1 word)

P100 ~ P10F (1 word)

P080 ~ P09F (2 words)

P070 ~ P07F (1 word)

P030 ~ P06F (4 words)

P010 ~ P02F (2 words)

P000 ~ P00F (1 word)

1. Special function modules occupy various I/O addresses according to the type of module.

Please see the user’s manual of each special function module for details

2. Special function modules can be mounted on any slots of main / expansion base. There is

also no limit on the number of special function modules mountable on a base.

3. In 2.0 or lower K300S/1000S CPU OS version , network module can be mounted on the

main base only.

4-31

Chapter 4 CPU modules MASTER-K

8

61 8

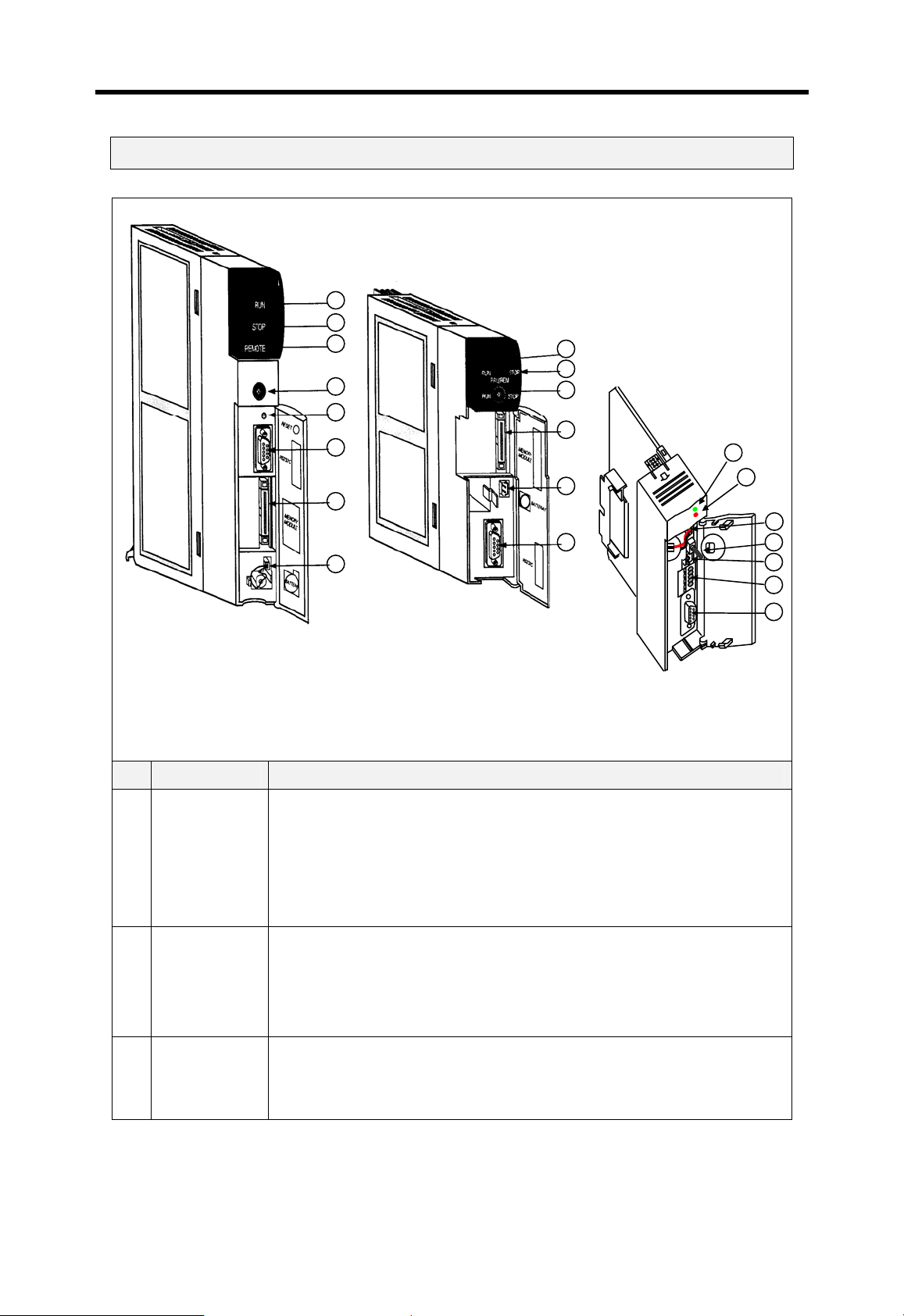

4.8 Parts names

K7P-30AS

1

K4P-15AS

2

4

7

MK1000S

MK300S MK200S

No Name Description

Shows the operation status of CPU module

On : the CPU is on the Local RUN or remote RUN mode

1 RUN LED

Off : the CPU detects improper power supply

the CPU is not on the RUN mode (STOP or PAUSE mode)

the CPU detects an fatal error that stop the operation

Shows the operation status of CPU module

On : the CPU is on STOP mode

2 STOP LED

Off : the CPU is not on the STOP mode (RUN or PAUSE)

4

A

Flickering : An error i s detected during operation

Only K1000S has remote LED.

3 Remote LED

On : the CPU is on the remote (RUN / STOP / PAUSE / DEBUG) mode

Off : the CPU is on the local (RUN / STOP / PAUSE) mode

4-32

Chapter 4 CPU modules MASTER-K

No Name Description

Set a operation mode of CPU module

4 Mode key switch

Manual reset

5

switch

RS-232C

6

connector

Memory module

7

connector

Battery

8

connector

Memory setting

9

DIP switch

Terminal block

for special

A

functions

- RUN : Executes user program

- STOP : Stop executing user program

- PAU / REM : Pause or remote mode

Restart the CPU module ( Available in K1000S only)

Connector for peripheral devices uses RS-232C protocol.

(Example : KGL-WIN)

Connector for external memory module

Connector for back-up battery

Refer the Chapter 6

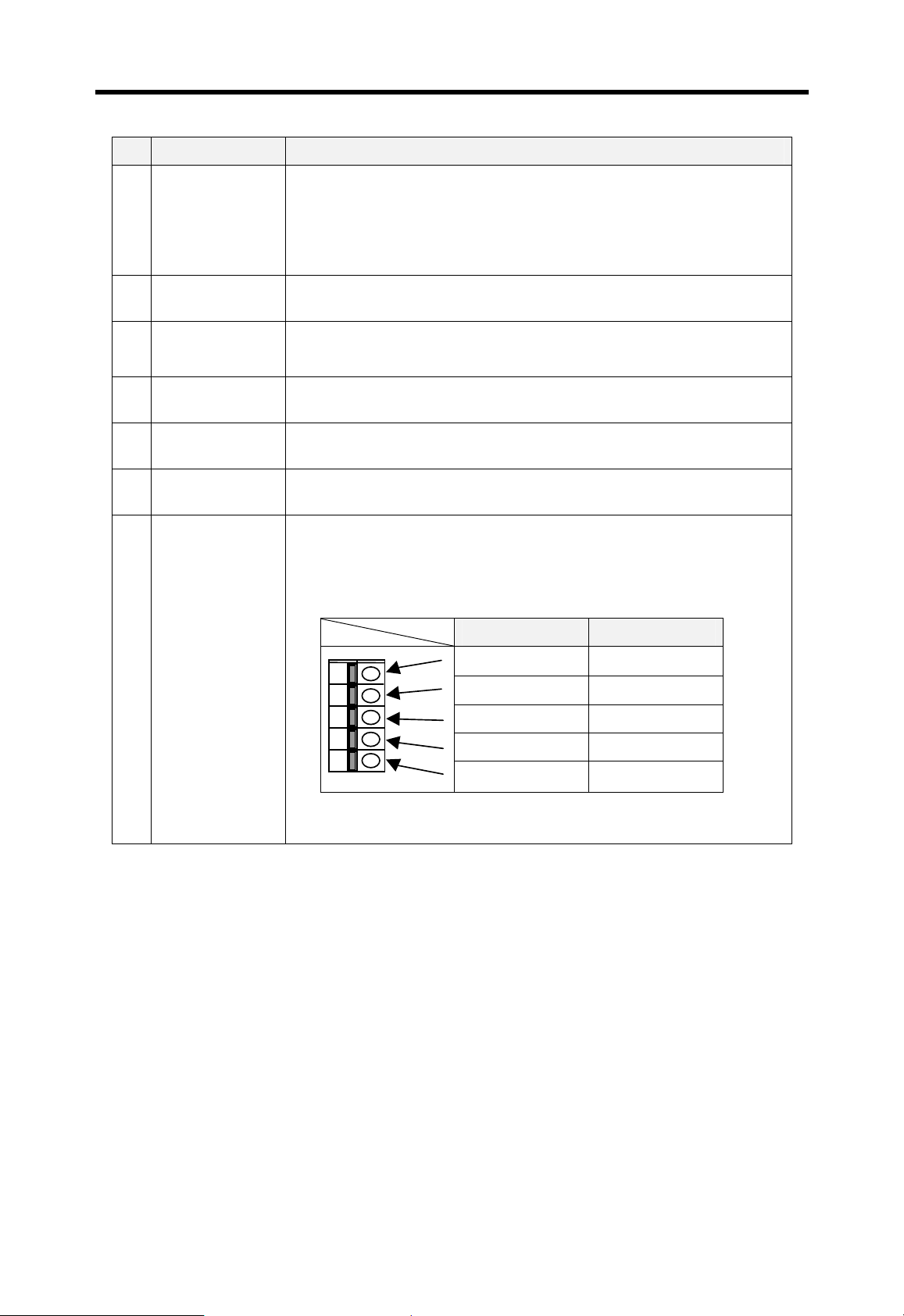

K3P-07AS : Not applicable

K3P-07BS : RS-422/485 interface terminal block

K3P-07CS : High speed counter input terminal block

K3P-07BS K3P-07CS

RDA

RDB

SDA COM

φA 24V

φB 24V

(Please refer chapter 13 and 16 for details)

SDB PRE 24V

SG PRE 0V

4-33

Chapter 5 Battery

5 Battery........................................................................................................ 5-1

5.1 Specifications............................................................................................................ 5-1

5.2 Handling instructions............................................................................................... 5-1

5.3 Replacement procedure........................................................................................... 5-2

Chapter 5 Battery MASTER-K

5 Battery

5.1 Specifications

Item Description

Rated voltage 3.0VDC

Lifetime 5 years

Purpose User program and data back-up, RTC operatio n during power-off

Type Lithium battery, 3VDC

Dimension (mm)

φ 14.5 × 26

5.2 Handling instructions

1) Do not heat or solder the terminals of battery.

2) Do not measure its voltage with a tester, or short circuit.

3) Do not disassemble

Remark

The K300S and K1000S CPU modules have super capacitor to back-up during battery

replacement. The super capacitor can backup the user program and latch area about 30

minutes. However, be careful to finish battery replacement as soon as possible.

Caution