Right choice for ultimat e yield !

LSIS strives to maximize customer’s profit in gratitude of choosing us for your partner.

Human Machine Interface

XGT PANEL

User

iXP2

iXP2

iXP2

iXP2

Read this manual carefully before

wiring, operating, servicing

easy reach

iXP2 Series

’s Manu al

-08XXA

-10XXA

-12XXA

-15XXA

installing,

or inspecting this equipment.

Keep this manual within

for quick reference.

Safety Precautions

Before using the product…

To use the product safety and effectively, please read this instruction manual thoroughly before use.

► Please keep to the safety precaution, for it to prevent accidents and potential danger from

occurring.

► Safety precaution is classified into ‘Warming’ and ‘Caution’ and their meanings are as follows.

Warning Violating the instruction may result in serious personal injury or death.

Caution Violating the instruction may result in slight personal injury or product

damage.

► The indicated illustrations on the product and in the manual have the fallowing meanings.

Be cautions, for danger may be present.

Be cautions, for there is a possibility of an electric shock.

► After reading the instruction manual, keep it handy for quick reference.

1

Safety Precautions

Design Precautions

Warning

► Install a safety circuit external to the HMI to protect the whole control system in case of

external power supply trouble.

Serious trouble may occur to the entire system due to erroneous output/operation of the HMI.

Design Precautions

Caution

► In/output signal or communication cable should be at least 100mm apart from High-

voltage/power wires.

Otherwise, it may cause erroneous output/operation.

Installation Precautions

Caution

► Use the HMI in an environment that meets the general specification contained in this

manual or datasheet.

Otherwise, it could result in electric shock, fire, erroneous operation or deterioration.

► In case of much vibration in the installed environment, be sure to insulate the HMI from

direct vibration.

Otherwise, it could result in electric shock, fire, erroneous operation.

► Be sure not to let foreign substances such as conductive debris inside the product.

Otherwise, it could result in electric shock, fire, erroneous operation.

► Do not touch the conductive part of the HMI. It may cause an electric shock,

which may cause malfunction.

2

Safety Precautions

Warning

Wiring Precautions

► Be sure to turn off the HMI and external power before wiring.

Otherwise, it may result in an electric shock or damage to the product.

Caution

► Wire correctly by checking each of the product’s rated voltage and terminal layout.

Otherwise, it may result in fire, electric shock or erroneous operation.

► Tighten terminal screws with specified torque when wiring.

If terminal screws are loose, it may result in short circuits, fire or erroneous operation.

► Use the exclusive HMI 3-type grounding for the FG terminal.

If not grounded, it may result in erroneous operation.

► Be sure not to let any foreign substances such as wiring debris inside the module.

Such debris may cause fire, damage or erroneous operation.

► Tighten the crimp terminal to the specified torque, and crimp the external

connection connector using the specified tool or solder it correctly.

3

Safety Precautions

Warning

Startup and Maintenance Precautions

► Do not touch the terminals while power is on.

Otherwise, it may cause electric shock or erroneous operation.

► Turn off the HMI and external power when cleaning or tightening the terminal.

Otherwise, it may cause electric shock or erroneous operation.

► Do not charge, disassemble, heat, short circuit, solder, etc. other battery.

Mishandling the battery may cause overheating, crack, fire and may result in injury or fire.

Caution

► Do not disassemble PCB from the product case or modify the product.

Otherwise, it may result in fire, electric shock or erroneous operation.

► When mounting or remov ing the HMI f rom the pa nel, be s ure to sh ut off all power

being used by the system . It may cause el ectr ic shock , malfu nction .

► Use cellular phone or walky-talky at least 30cm away from the HMI.

Otherwise, it may result in erroneous operation.

Disposal Precaution

Caution

► When disposing of this product or battery, treat it as industrial waste.

Otherwise, it may cause poisonous pollution or explosion.

4

Revision History

Revision History

Version Date Contents Revised location

V1.0 ‘18.01 First Edition -

※ The number of User’s manual is indicated the right side of the back cover.

ⓒ LSIS Co., Ltd2018 All Rights Reserved.

5

Contents

Chapter 1 General Introduction ...................................................................... 1-1~1-6

1.1

How to use the Instruction Manual ........................................................................................................ 1-1

1.2

Feature .................................................................................................................................................. 1-2

1.3

Terminology .......................................................................................................................................... 1-5

1.4

Specification of product name ............................................................................................................... 1-6

Chapter 2 System Configuration ....................................................................... 2-1~2-4

2.1

Part Names ........................................................................................................................................... 2-1

2.2

System Configuration ............................................................................................................................ 2-4

Chapter 3 Standard Specification...................................................................... 3-1~3-4

3.1

General Standards ................................................................................................................................ 3-1

3.2

Function Standards ............................................................................................................................... 3-3

Chapter 4 Installation and Wiring .................................................................... 4-1~4-9

4.1

Installation ............................................................................................................................................. 4-1

4.1.1 Installation environment............................................................................................................... 4-1

4.1.2 Notice in handling ........................................................................................................................ 4-3

4.1.3 Precautions for panel installa tion ................................................................................................ 4-3

4.2

Wiring .................................................................................................................................................... 4-7

4.2.1 Power Wiring ............................................................................................................................... 4-6

4.2.2 Ground Wiring ............................................................................................................................. 4-9

Chapter 5 XGT Panel Menu Explanation.......................................................... 5-1~5-39

5.1

Settings .................................................................................................................................................. 5-2

5.1.1 Backlight Setting .......................................................................................................................... 5-2

5.1.2 Touch Setting .............................................................................................................................. 5-4

5.1.3 DateTime Setting ........................................................................................................................ 5-5

5.1.4 Environment Setting ................................................................................................................... 5-6

5.1.5 Ethernet Setting ........................................................................................................................ 5-14

5.1.6 Buzzer Setting ........................................................................................................................... 5-15

5.1.7 Sound Setting ............................................................................................................................ 5-16

5.1.8 XP-Remote Setting ................................................................................................................... 5-17

5.2

Diagnostics .......................................................................................................................................... 5-18

5.2.1 Screen Diagnostic ..................................................................................................................... 5-19

5.2.2 Touch Diagnostic ...................................................................................................................... 5-20

5.2.3 Backup Memory Diagnostic ...................................................................................................... 5-21

6

Contents

5.2.4 Flash Memory Diagnostic .......................................................................................................... 5-22

5.2.5 USB Memory Diagnostic ........................................................................................................... 5-23

5.2.6 Serial Diagnostic ....................................................................................................................... 5-24

5.2.7 SD Card Diagnostic ................................................................................................................... 5-26

5.3

PLC Information ................................................................................................................................... 5-27

5.3.1 PLC Communication Setting ..................................................................................................... 5-28

5.3.2 Connection Information ............................................................................................................. 5-29

5.3.3 PLC Information ........................................................................................................................ 5-30

5.3.4 History of PLC error .................................................................................................................. 5-30

5.3.5 PLC Operation Mode Conversion History ................................................................................. 5-31

5.3.6 History of power off of PLC ....................................................................................................... 5-31

5.3.7 PLC System History Information ............................................................................................... 5-32

5.3.8 N:1 Setting................................................................................................................................. 5-33

5.3.9 Program Monitor ....................................................................................................................... 5-34

5.4

XGT Panel Update .............................................................................................................................. 5-35

5.5

Storage Function ................................................................................................................................ 5-36

5.5.1 Overview .................................................................................................................................... 5-36

5.5.2 Downloading a project using a storage device .......................................................................... 5-37

5.5.3 Uploading a project using a storage device ............................................................................... 5-38

5.5.4 Updating the device using a storage device .............................................................................. 5-39

Chapter 6 Backup files by using Storage Devices.…………........................... 6-1~6-7

6.1

Path Structure in case of File Backup.................................................................................................... 6-1

6.2

Operation Setting when there is no s pace for Backup ........................................................................ 6-5

6.3

Monitoring Connection Status of External Storage Equipment .............................................................. 6-6

Chapter 7 Maintenance ..................................................................................... 7-1~7-3

7.1

Maintenance .......................................................................................................................................... 7-1

7.2

Daily Maintenance ................................................................................................................................ 7-1

7.3

Periodical Maintenance ........................................................................................................................ 7-2

Chapter 8 EMC Standard Certification……………………………....................... 8-1~8-3

8.1

Requirement for EMC Standard Certification ........................................................................................ 8-1

8.1.1 CE Standard Certification ............................................................................................................. 8-1

8.1.2 KC Standard Certification ............................................................................................................. 8-2

8.2

Requirement for Low Voltage Command Suitability............................................................................. 8-2

8.2.1 Standard Certification for XGT Panel ........................................................................................... 8-2

8.2.2 Selection of XGT Panel ................................................................................................................ 8-2

7

Contents

Appendix 1 Troubleshooting.............................................................. App1-1~App1-25

1. Type of Problems ................................................................................................................................App 1-1

2. Problems when Starting ......................................................................................................................App 1-2

3. Problems after the Monitor on.............................................................................................................App 1-4

4. Display Problems of Figure and Object ..............................................................................................App 1-6

5. Communication Problems ..................................................................................................................App 1-9

6. USB Removal of Memory Card........................................................................................................App 1-10

7. External memory recognition………………….................................................................................App 1-11

8. Touch recognition……………………………….................................................................................App 1-11

9. Error Message during Execution of Programs.................................................................................App 1-12

Appendix 2 Dimensions ................................................................... App 2-1~App2-4

1. iXP2-08XX…................................................................................................................................... App 2-1

2. iXP2-10XX....................................................................................................................................... App 2-2

3. iXP2-12XX....................................................................................................................................... App 2-3

4. iXP2-15XX…................................................................................................................................... App 2-4

Appendix 3 Warranty and Environmental Policy............................................. App 3-1

1. Warranty contents........................................................................................................................... App 3-1

2. Environmental Policy...................................................................................................................... App 3-1

8

1-1

Chapter 1 General Introduction

Chapter 1 General Introduction

1.1 How to use the Instruction Manual

This instruction manual provides information such as specification, how to use, etc., of the product

needed to operate iXP2 series of XGT Panel.

The user manualPanel.el.provides information s

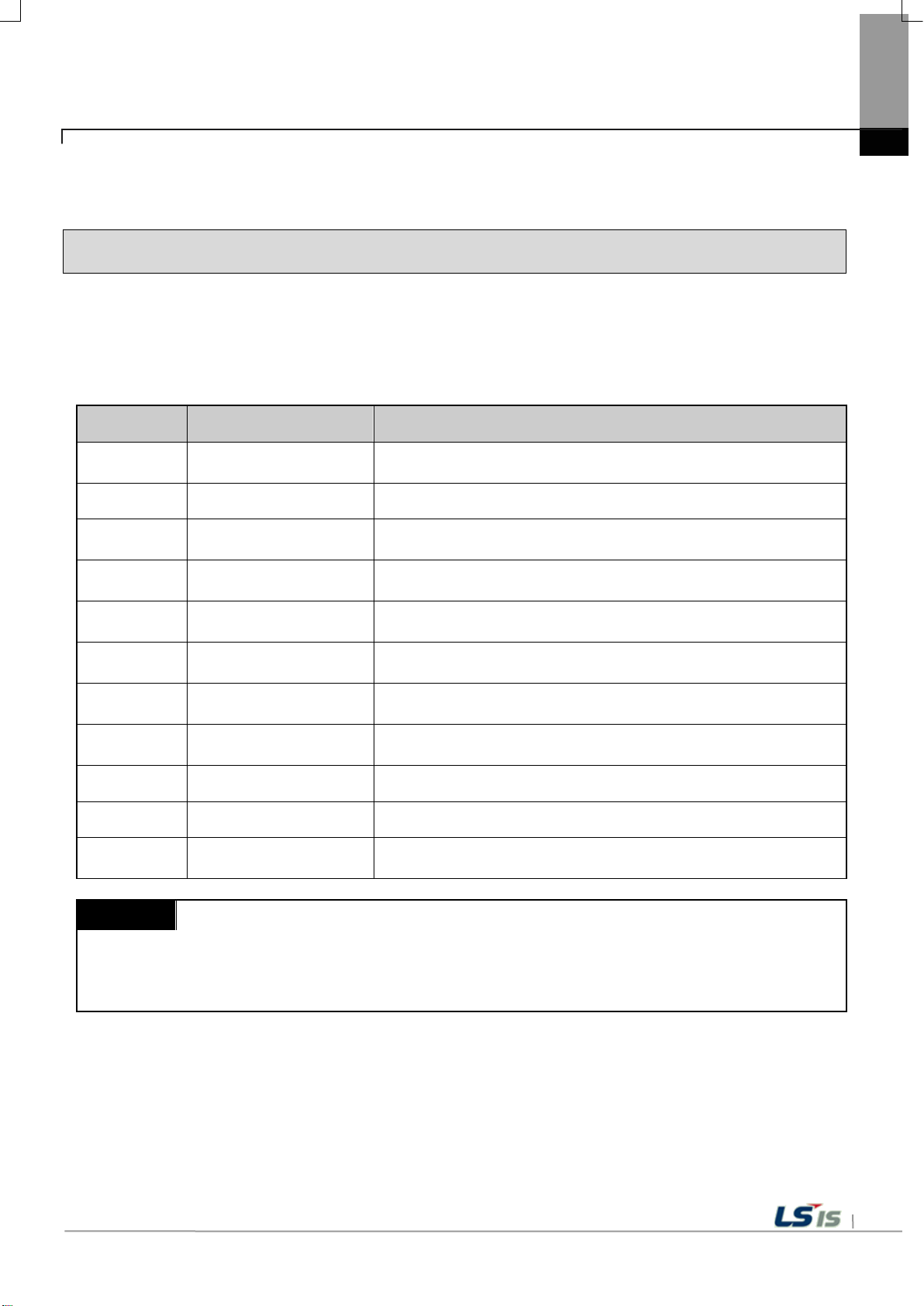

Sequence Category Contents

Chapter1 General Introduction

Chapter2 System Configuration

Chapter3

Chapter4

Chapter5

Chapter6

Chapter7 Maintenance

Chapter8

Appendix 1 Troubleshooting It describes a variety of error contents and measure.

Appendix 2 Dimensions It describes the dimension of XGT Panel.

Appendix 3

Remark

This manual does not explain XP-Builder and PLC connection. Please refer to the related manual for

the function.

Standard

Specification

Installation and

Wiring

XGT Panel Menu

Explanation

Backup files by using

Storage Devices

EMC Standard

Certification

Warranty and

Environment Policy

It describes this manualprovides information suctdescribes

this manual.

It describes feature and system configuration of each XGT Panel.

It describes XGT Panelnd system configuration of each XGT

Panel.

It describes an installation, wiring and caution for

reliability of PLC system.

It describes XGT Panel Menu.

It describes the way to backup recipe, logging and etc.

files by using storage devices.

It describes inspection category and method for long normal

operation of PLC system.

It describes system configuration for EMC standard.

-

1-2

RS-232C/Ethernet

US B Me mor y

USB Loadder

Cable

XP-Builder

Chapter 1 General Introduction

1.2 Feature

The XGT Panel has the following features.

(1) Various types of external interfaces

(a) Supporting various device of USB, Ethernet, it maximizes the customer’s usability.

(b) PLC, Inverter, and other control devices.

• RS-232C , RS-422/485 and Ethernet (10Base-T / 100Base-TX / 1000-Base-T) communication with the control device.

(2) Based on Windows CE

(a) Adopted Mi crosoft Company's WEC 7

• Windows Embedded Compact 7 has been used.

Windows Embedded Compact 7 Features

(b)

• It provides stable software capacity by using Microsoft Company’s platform.

• It can process diverse function simultaneously.

• It provides diverse interface including Ethernet, USB.

• The user interface including mouse and keyboard can be connected.

• It has high flexibility like computer software.

• Fast reaction is available when adding new equipment.

• Wide data sharing and management with upper system is available.

(3) Projects in various ways send

(a) Project transmission using RS-232C communi cation

(b) Project transmission using Ethernet port

(c) Project transfer u sing USB Loadder cable

(d) Project transmission using USB memory

1-3

Chapter 1 General Introduction

(4) Providing a high-quality screen

(a) It adopts high-performance liquid crystal display (LCD) to provide high pi cture quality and sharpness.

• It adopts thin film tran sistor liquid cry stal display (TFT LCD ) which can display 24bit color.

(b) Supports various graphic formats.

• Su pports 1024 X 768 graphic formats precise and realisti c representation.

• Su pports behavior for animations (GIF).

(c) Supports external di splay output.

• HDMI output is supported.

• Duplicate mode and extended mode enable screen output in various configurations.

(5) Application of CAP tou ch panel

(a) Touch sen sitivity is improved by applying electrosta tic touch panel.

(b) Multi-touch and gesture functions.

(c) Various types of touch setting function can be used accordi ng to user's work environment.

(6) Provides multilingual and various fonts

(a) Supports multi-langu age languages.

• It uses the method of transferring the window / use r font used on the computer to XGT Panel .

• No separate multilingual language development is required.

• Multilingual la nguage support is an advantage of Windows CE.

(b) Supports simultaneou s display of 12 language s.

• Simultaneous di splay in 12 languages 12 languages.i

• You can swit ch languages 2 language s 12 languages.indow s CE.ed on t

(c) Various fonts are provid ed.

• Windows / user fonts can be used, so various expression s are possible.

• You can freely adjust font siz e and shape.

1-4

Chapter 1 General Introduction

(7) Providing various convenie nce functions

(a) Various alarm functi ons are provided.

• The history alarm can be divided into several alarm groups and alarm list, and the desired alarm can be displayed on

the screen with the alarm explo rer.

• The flow alarm displays the current alarm at the bottom of the screen.

• The system alarm is displayed when a criti cal problem occurs during operation.

(b) It provides the logging function.

• It provides periodic logging that works repeatedly according to time and device status and conditional logging

according to device conditio ns.

• Backup provide s up to 1 Mbyte.

• You can backup to a USB.

• Backup data i s stored in Excel format, so you can u se it conveniently .

(c) It provides a recipe function.

• It provides read / write function.

• One recipe provides up to 100 double words ( DWORD), 16 blocks.

• You can backup to a USB storage device.

• Backup data i s stored in Excel format, so you can u se it conveniently .

(d) It provides scheduler function.

• Up to 32 schedulers can be set.

(e) It provides printing function.

• Screen / ala rm printing functi on.

• Print out the printout.

(f) It provides scripting capabilities.

• User-written scripts provide more flexibility.

• Global / Object / Screen display.

(8) Stable products conforming to international standards

(a) CE, KC (Electromagnetic compatibility registratio n) standard acquisiti on

1-5

Chapter 1 General Introduction

1.3 Terminology

It describes terms used in this manual.

Term Definition Remarks

A standard element that has a specified function which

Module

Unit

PLC system

XP-Builder Software used to write and edit the project. -

XP-Manager

XP-Remote Software used to remote monitor and control the XGT Panel

Cnet module Computer Link FEnet module Fast Ethernet Network -

RTC

configures the system.

Devices such as I/O board, which inserted onto the mother

board or base unit..

A single module or group of modules that perform an

independent operation as a part of PLC system.

System consisted of PLC and peripheral device which can be

controlled by user program.

It is the software for edition, download, monitoring to

realize data communication between XGT Panels through XP

Link with online control function.

Abbreviation of tworkte monitor and It is used to call

general IC that contains clock function.

Ex) CPU module,

Power Module,

I/O module

Ex) Basic unit,

Extension unit

-

-

1-6

iXP2

-

(A)

(B)(C)(D)

Division

Sign

Contents

Remarks

08

21 cm (8.4”)

-

10

26 cm (10.2”)

-

12

31 cm (12.1”)

-

15

38 cm (15.0”)

-

0

WinCE 7.0 (Core)

-

1

WinCE 7.0 (Pro)

-

RS-232C, RS-422/485,

Ethernet

(D) Power supply

A

AC 100 ~ 240V

-

Chapter 1 General Introduction

1.4 Standard of product name

It describes terms used in this product names.

(A) LCD type

(B) O/S type

(C) Communication 0 Standard type

2-1

1

2

3

4

1) Display the power statu s of the device

Display using high brightness blue LED

1) USB Host 1ch

2) USB Device 1ch

Chapter 2 System Configuration

Characteristic of each iXP2 series and its system configuration are as follow ;

2.1 Part Names

1. iXP2-08XX / 10XX / 12XX / 15XX

Chapter 2 System Configuration

No. Name Function

1 Power LED

2 Front USB

Front Part

3

4 Panel fixing portion 1) Fix ing XGT Panel to Panel with Bracket

※

1) P-CAP touch panel: U ser touch input

2) LCD: Display

2-2

iXP2-1200A

5

7

8

9

10

6

11

422/485 connector

ON

1 2 3 4

A

B

RS-422/485 termination resistance On

(Default)

System reset switch. Pressing the switch will reset the system.

Chapter 2 System Configuration

No. Name Function

PE connector

5

6 Power Connector

Cable fixing hole

7

RS-

8

PE connection

Power and PE connections

Fixing Cable s

RS-422/485 (COM3): PLC / Contr ol device co mmunicati on

<Setting switch>

9

Battery cover,

Reset switch,

Backup battery,

Setting switch

No. 1/2

A Side.

B Side. RS-422/485 termination resistance Off

A Side.

O/S Download

No. 3

B Side.

Nand Flash booting(Default)

A Side. Backup Battery On

No. 4

B Side. Backup Battery Off(Default)

<Reset S/W>

10

11

SD Card Logging / Recipe / Alar m / Project data backup and transfer

Gasket Protecting from water and dust

2-3

17

12 13 14 15 1816

1) USB memory connection: Lo gging / Recipe / Ala rm / Project data

3) Printer connection: Print function

Ethernet: 10Base-T / 100Base-TX

4) PLC / control device c ommunication

Ethernet: 10Base-T / 100Base-TX / 1000Base-T

4) PLC / control device c ommunication

Thanks to anti-drop lock, the Panel can be installed in a panel by a single

operator.

Note

(1) The surface of the touch panel must be kept clean at all times.

(5) Please refer to Chapter 10 for installation details.

Chapter 2 System Configuration

No. Name Function

12

13

14

15

16 Ethernet terminal

17

18

Audio-Out Stereo audio output

HDMI Clone mode display output

USB host

Ethernet terminal

RS-232C connector RS-232C (COM2): PLC / Control device communication

Anti-drop lock

Backup and transfer

2) User Interface Connection: Use mouse / Keyboard

1) Project data transmission

2) Logging / Recipe / Al arm / Screen Data Backu p

3) Upgrading the device software

1) Project data transmi ssion

2) Logging / Recipe / Al arm / Screen Data Backup

3) Upgrading the device software

- Foreign objects (water, oil, etc.) on the touch panel may cause malfunction.

(2) Touching the front of the touch panel may cause malfunction.

- Be careful that conductive objects do not touch the touch panel.

(3) The switch No. 1/2 o f the setting swi tch must be set in th e same direction.

- I f switches 1 and 2 are set in different di rections, communicati on problems may occur.

(4) Refer to the communication manual for details on communication conne ction.

2-4

RS-232C/Ethernet

US B Me mor y

USB Loadder

Cable

XP-Builder

US B Me mor y

SD

Card

Note

(1) It is recommended to u se Ethernet rathe r than RS-232C.

(3) Refer to XP-Builder manual for project transfer method.

Chapter 2 System Configuration

2.2 System Configuration

To use XGT Panel, y ou must create project data in XP-Builder and tran sfer it to XGT Panel.

By default, you can conne ct to XGT Panel u sing USB.

Basically, it can be connected with XGT Panel using RS-232C method.

The maximum communication speed is 115,200 [bps].

With Ethernet, project data can be transferred quickly .

If the LAN environment i s established as shown below, you can use it more easily and e ffectively.

1: 1 connection is also supported in case LAN (LAN) environment i s not established.

If project data can not be transferred using communication, y ou can transfer data u sing USB storage devi ce or SD card.

Please refer to Chapter 5 and XP-Builder User's Guide for more information.

(2) Refer to the communication manual for how to make the Ethernet cable.

3-1

Related

Standards

Ambient operating

temperature

Square wave

Impulse noise

AC: ± 1,500V

DC: ± 1,000V

LS Industrial

Standard

Electrostatic

Immunity

Emissions

Communication

interface

2kV (LG)

1 kV (LL)

1kV (LG)

0.5 kV (LL)

Chapter 3 Standard Specification

3.1 General Standards

General specifications of XGT Panel are as follows.

No. Item standard

Chapter 3 Standard Specification

1

2 Storage temperature -20 ° C ~ + 60 ° C 3 Operating humidity 10∼85%RH, non-condensing. 4 Storage humidity 10∼85%RH, non-condensing. -

Occasional vibration Count -

frequency acceleration amplitude

5≤f<9 Hz - 3.5mm

9≤f≤150

Hz

5

6 Shock endurance

Vibration

resistance

frequency acceleration amplitude

5≤f< 9

9≤f≤150

* Maximum shock acceleration: 147

* Duration time: 11

* Pulse wave: half sine pulse (3 times each in X, Y and Z directions)

9.8

Continuous vibration

Hz

- 1.75mm

Hz

4.9

ms

0 ° C ~ + 50 ° C -

m/s2 -

m/s2 -

m/s2 (15G)

10 times each

in X, Y and Z

direction

IEC 61131-2

IEC 61131-2

Discharge

Electromagnetic

7

8 Environment Free from corrosive gases and excessive dust -

9 Operating height Below 2,000m (6,562ft) 10 Pollution degree 2 or less 11 Cooling method Natural Air-Cooling -

Noise

Immunity

Radiated

Fast

Transient

/ Burst noise

Surge

Category Power mod ule Communication interface

Voltage 2 kV 1 kV

Category AC power DC power supply

Voltage

± 4 kV (contact discharge), ± 8 kV (air discharge)

80 ~ 1,000 MHz, 10 V / m

1 kV

IEC 61131-2

IEC 61000-4-2

IEC 61131-2

IEC 61000-4-3

IEC 61131-2

IEC 61000-4-4

IEC 61131-2

3-2

Note

body and the operation of the video display device connected to

Chapter 3 Standard Specification

(1) IEC(International Electro technical Commission)

- International private gr oup facilitating int ernational cooper ation of electric/elect ronic standardi zation, issuing

international standards and operating the compliance evaluation systems.

(2) Pollution degree

- As a n index representing the pol lution degree of an environm ent to determine the insulation of a device,

pollution degree 2 generally means the status generating non-conductive contamination. However, it also

contains the status generating temporarily conduction due to condensation.

(3) Noise Immunity

- The noise noise standard is the standard of the HMI

HDMI is not guaranteed.

3-3

Item

iXP2-08XXA

iXP2-10XXA

iXP2-12XXA

iXP2-15XXA

Display type

TFT color LCD

Color indication

Bottom: 60 deg.

Bottom: 75 deg.

Bottom: 80 deg.

Capacitive Touch

Magnetic Buzzer (85dB)

Processor

1GHz, Dual core

Operating RAM

1GB

Backup data

About 3 years (25℃)

1 x 10Base-T / 100Base-TX, 1 x 10Base-T / 100Base-TX / 1000Base-T

3 x USB 2.0 (Front x 1, Rear x 2)

1 x USB 2.0 (Send / Receive front, PC and project data etc.)

RS-232C

1 x RS-232C (DSUB 9 / Male type)

RS-422/485

1 x RS-422/485 (Terminal Block)

Multi-language

Can display 12 languages simultaneously

Animation

GIF format support

Recipe

Support

Script Launcher

Standard Certification

228.5 x 158.5

259.0 x 201.0

301.5 x 227.5

383.5 x 282.5

Power consu mption ( W)

25

25

30

30

Weight (Kg)

1.87

2.35

3.0

4.6

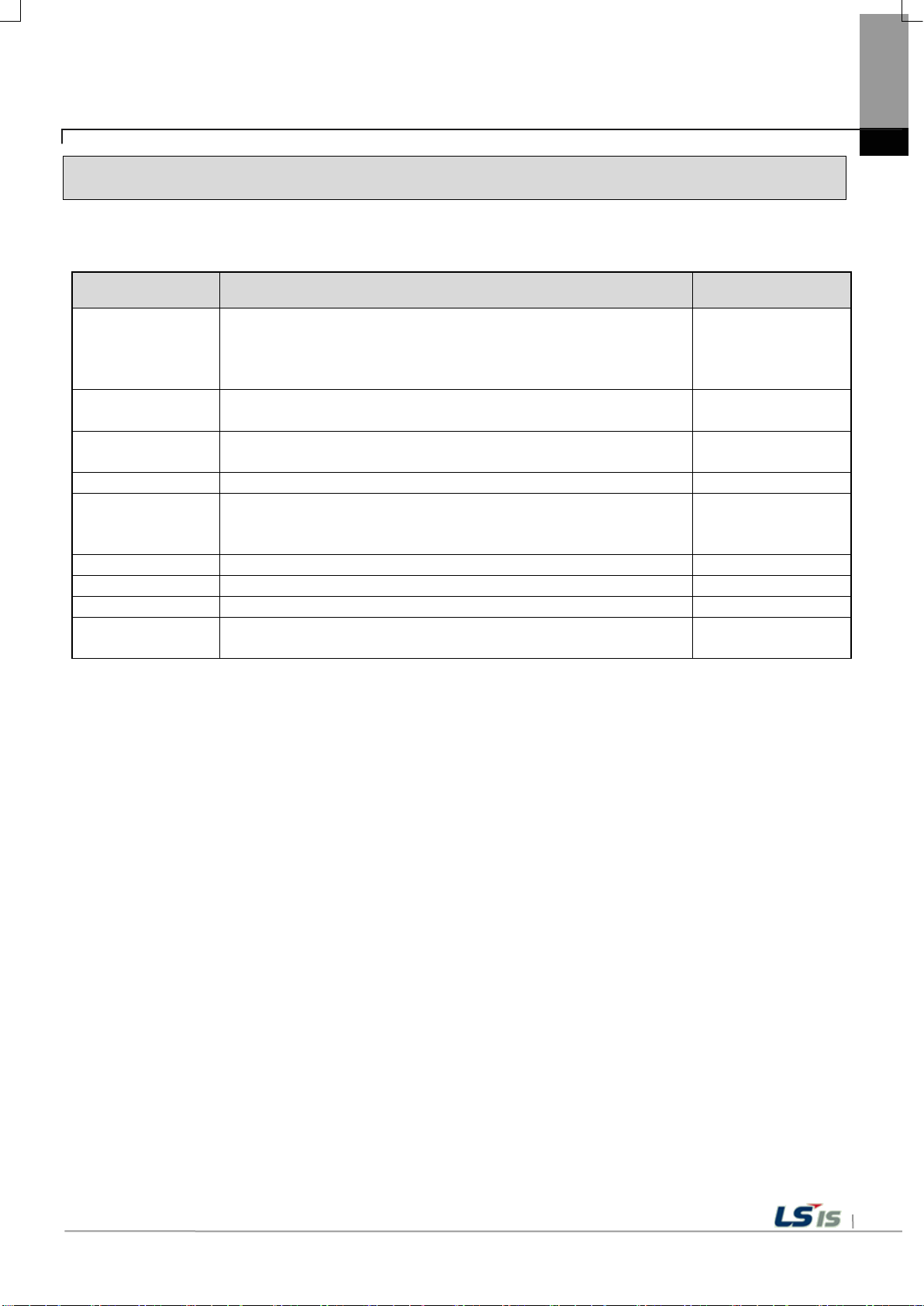

3.2 Function Standards

The functional specifications of XGT Panel are as follows.

Chapter 3 Standard Specification

Screen size

Display resolution

Indication degree

Backlight

Backlight lifetime

T ouch panel

Audio otput

Memory

Battery life

Video Output

Ethernet

USB host

USB device

Flash

Backup RAM

8.4 "

800 x 600 1024 x 768

Right and left: 80 deg.

Top: 80 deg.

10.4 " 12.1 " 15 "

24-bit color (16.7M colors)

Right: 75 deg.

Top: 75 deg.

LED method, automatic On / Off support

Date / Time data, Logging / Alar m / Recipe data, Non-volatile devices

Right and left: 80 deg.

Top: 80 deg.

50,000 hour

1GB

1 Mbyte

1 x HDMI

Data logging

Protection standard

Dimensions (mm)

Panel Cut (mm)

Support

Support

CE, KC, UL

IP66

240 × 180 × 60 271 x 212 x 60 313 × 239 × 60 395 × 2 94 × 66

Power A(AC100~220V), D(19.2~28.8V)

3-4

Note

more details on installation, See Chapter 4.Installation and Wiring.

Chapter 3 Standard Specification

(1) Caution in power connection

- W ith AC power a pplied to DC power dev ice, it ma y cause product damage or fire. Please pay a special

attention to connection.

(2) PE Connection

- For the device PE, please use PE terminal.

(3) Battery discharge-prevention DIP switch

- In order to prevent the battery discharge, turn off the DIP switch No.4.

To use backup function, please turn on DIP switch No. 4.

(4) Battery Operation and Life

- Batter y is used for RT C (date/time) whe n the power of device is off . Battery is not c onsum ed with power

applied.

(5) LCD Backlight Replacement

- Please replace LCD if you want to replace LCD backlight.

(6) Protection standard

- XGT Panel is designed by IP66 Standard in front par t s . Ingr ess Protec ti on( IP) is based on the IEC 60529

Standard for degr ees of protection provided b y enclosures. But XGT Pan el does not guarantee fr om all

installation environm ent. When i nstalling pa nels, m ake sure that dust an d mois ture are not bro ught in. For

4-1

Chapter 4. Installation and Wiring

Chapter 4 Installation and Wiring

4.1 Installation

4.1.1 Installation environment

This machine has high reliability regardless environment. But for reliability and stability, be careful the followings

(1) Environment condition

(a) Install at the panel which can protect this machine from water and dust. XGT Panel is designed by IP66

Standard in front parts and IP20 Standard in rear parts.

(b) Install at the place where impact and vibration is not continuously applied. XGT Panel is designed to

meet IEC standard (IEC 61131-2).

(c) Do not expose this machine to direct light.

(d) Do not install at the place where rapid temperature change can occur. Moisture by rapid temperature

change can cause malfunction and damage.

(e) This machine should be installed within 0~50°C, otherwise the screen may be changed or cause

Malfunction.

(f) This machine should be installed within 10~85% relative-humidit y. Moist ure b y rapid tem per atur e change

can cause malfunction and damage.

(g) Avoid corrosive ga s and burnab le gas.

(2) Installation construction

(a) When doing screw’s processing or wiring construction, be careful that the remains do not enter the XGT

Panel inside.

(b) Install at the place where you can easily control.

(c) Do not install with high voltage machine within same Panel.

(d) Keep distance of more than 100mm from duct for wiring and peripheral machine.

(e) Ground at the place where few noises develop.

(3) Anti-heat design of control panel

(a) In case of installing XGT Panel in the airtight panel, consider the heat by other machine as well as own

heat. In case that the air circulates through a ventilating opening or a general pan, XGT Panel system can

be influenced by in-draft of dust or gas.

(b) We recommend you to install a filter or to use an airtight heat exchanger.

4-2

Note

Chapter 4. Installation and Wiring

(1) Waterproof and dustproof standard

(a) IP66 Standards

1) The protection standards of XGT Panel have been designed to meet the IP66 test conditions,

in accordance with the degrees of protecti on prov id ed b y enclosures of IEC60529.

As this machine installed at the panel, it is not guaranteed with all installation environment even

though its protection standards for the front parts are satisfied.

2) IP66 rating guarantees the enclosure is dust proof (6) and protected against jets of water (6).

3) IP20 rating guarantees protection from solid foreign objects of above 12mm diameter proof (2),

but it does not guarantee protection from water ingress.

(KS C IEC 60529: 2006 standard)

(b) Notice

1) In the environment where the protection grade of XGT Panel is exceeded or not satisfied,

the damage of the device or malfunction can occur due to the failure of protecting the product.

2) Since the protection grade of XGT Panel is the water-proof/dust-proof standards, it cannot be

protected from oil, corrosive gas and metal particles.

3) In case when Gasket is damaged by chemicals and continuous vibration, its water-proof/dust-proof

effect can be weakened.

4) In case when installing the panel, make sure that dust and water are not brought in panels.

4-3

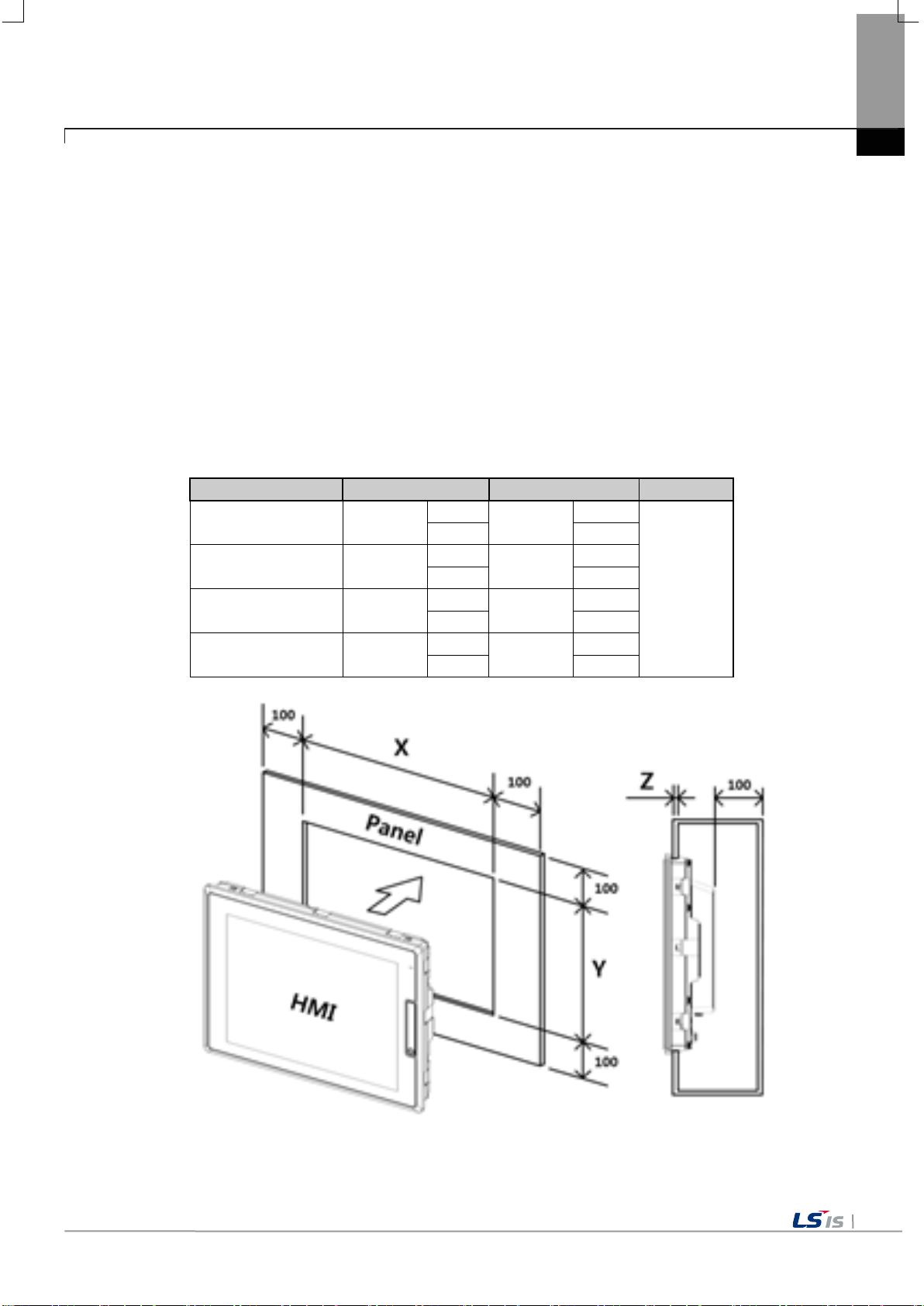

division

X (Horizontal)

Y (Vertical)

Z (Thickness)

+1

+1

-0

-0

+1

+1

-0

-0

+1

+1

-0

-0

+1

+1

-0

-0

Unit: [mm]

Chapter 4. Installation and Wiring

4.1.2 Notice in handling

This section describes the precautions for han dling the XGT Pan el from opening to in stallation.

• Do not drop or subject it to strong impacts.

• Do not open the product case or take any action. In such cases, we are not responsible for the product.

• When wiring, be careful not to let foreign substances such as wiring residue into the XGT Panel.

4.1.3 Precautions for panel in stallation

Describes how to install th e XGT Panel on the panel and notes.

(1) Pan el cut

• Before installing the XGT Panel on the panel, it must be manufactured on the panel as shown in the table below.

iXP2-08XX 228.5

iXP2-10XX 259.0

iXP2-12XX 301.5

iXP2-15XX 383.5

158.5

201.0

1.6 to 9.5

227.5

282.5

4-4

Note

(1) In order to be less affected by el ectromagnetic waves (radia tion noise) or heat ge nerated by other con trol devices,

reference tolerance (0 ~ + 1mm) when making the panel, the gap

The contact area may be reduced, and the waterproof and dustproof effect may be

f and dustproof. The XGT Panel basically has a

(5) If the surface of t he panel on w hich the XGT Panel i s mount ed is uneven, there i s a gap be tween the XG T Panel and th e

It is absolutely

are should be taken becau se it can be significan tly w eakened, and i f a

gasket needs to be repla ced, contact your neare st dealer or serv ice. Pl ease contact the center.

Division

Angle (le ft and ri ght)

Upper

Lower

iXP2-08XX

80 deg.

80 deg.

60 deg.

iXP2-10XX

75 deg.

75 deg.

75 deg.

iXP2-12XX

80 deg.

80 deg.

80 deg.

iXP2-15XX

80 deg.

80 deg.

80 deg.

100

100

100

100

Chapter 4. Installation and Wiring

(2) Panel in stallation

• When mounting the XGT Panel on the panel, please install 100mm or more in each direction.

Unit: [mm]

100

Required.

(2) Install it conside ring the wiring of pow er and communication cables.

(3) When the panel cut dimensions are outside the

between the gasket and the panel.

weakened.

(4) When mounting the product on the panel, use gasket for waterproo

waterproof and dustproof gasket is equipped.

panel, or dust may penetrate. Particularly, depending on the material (steel , aluminum, a crylic, etc.) of the panel, This may

require installation environment review. Also check that the gasket and panel are in close contact.

necessary.

(6) If the condition of the gasket is contaminated or dama g e d du e to deterioration at th e t ime of insta l la t ion or after a c er tain

period of use, the w aterproof and du stproo f effe ct c

•

When installing the product on the panel, use gasket for waterproof and dus tproof. The XGT Panel i s basically equipped w ith

a waterproof and dustproof gasket.

(3) Installation location

• Please consider screen display and touch use for XGT Panel installation.

• If you exceed the display angle bel ow, the screen may not be clearly visible. It is recommended to install the prod uct considering

the angle of view.

4-5

Fixed Bracket

Panel

Note

(1) During installation, XGT Panel should be closely contacted to the panel not to have any gap. In the

cm. Depending on the material type of the panel, the torque value can be

different. The standard screw torque for each bolt size is followed. If it is fixed with the power more than

to the deformation of XGT Panel.

Remark

, contact the

agency or a sales office close by.

(4) Fixing

• Fix the XGT Panel using the brackets on the panels as shown below.

(The bracket is included i n the product.)

Chapter 4. Installation and Wiring

environment requiring water-proof/dust-proof effect, install and fix a bracket on a slope.

(2) The bracket should be fixed symmetrically(Up-Down, Left-Right). In case when it is not fixed

symmetrically, there could be a gap between the panel and XGT Panel.

(3) When fixing the bracket, it should be installed perpendicularly to the panel, and the required bracket

screw torque is 6.7kgf ㆍ

the requir ed s cr ew t orq ue, the to uch m a lfu nct ion or we ak enin g of water -proof/dust-proof ca n happe n due

(5) Removal of protective film

• Be sure to remove the film attached to the panel to protect the front sheet when it is shipped from the factory .

(1) Remove the protection film attached to the front of this machine. Due to the deformation of the

protection film, the touch malfunction or wrong input can occur. It is recommended to use a special

protection sheet to protect the front sheet. In case of purchasing the protection sheet

4-6

power

Product Name

iXP2-1500D

iXP2-0800A

iXP2-1500A

► Connecting AC power to a device that uses DC power may cause product damage or fire.

Caution

Chapter 4. Installation and Wiring

4.2 Wiring

Describes the wiring matte rs when installing the XGT Panel.

4.2.1 Power Wiring

XGT Panel is divided into DC (DC) and A C (AC) products.

DC 24V

iXP2-0800D

iXP2-1000D

iXP2-1200D

AC100-240V

Be careful of connection.

► 'XXD' is a product using DC 24V and 'XXA' is a product using AC100-240.

Be sure to check the polarity of the back of the product before use.

iXP2-1000A

iXP2-1200A

4-7

ground

Note

aid safe terminations.

Power

Supply

L N PE

+ -

PE

Note

(1) When the power flu ctuation is larger than t he specified value range, use a constant vol tage transfor mer.

(3) Momentary power failu re for stable data ba ckup when power on / o ff. Please use.

[AC connection]

[DC connection]

Use the following specifications for the power cable.

Type Cable specification (Unit: ㎟) Wire Type Thermal Resistance Screw Torque

Chapter 4. Installation and Wiring

Power and protection

(1) For installations where there is voltage drop, it is recommended to use stranded wire with a cross

sectional area greater than 2 ㎟.

(2) It is recommended that cable connections are twisted and secure. Short cable runs are also

recommended between the poin t o f supp ly and the XGT panel.

(3) For safety reasons it is recommended that you use color coded outer sheaths on the conductors to

Power connection is as shown below.

1.5(AWG16) ~ 2.5(AWG12) Copper 60℃ 0.51N•m

(2) When there is a lot o f noise in the pow er supply, use an in sulation transformer.

4-8

Main

Power

Noise

Filter

HMI

power

PE

Others

Note

Note

E2

E1

Surge absorber for preventing lightning

Chapter 4. Installation and Wiring

For XGT Panel power supply , I / O devices and pow er devices, separa te the power supply system as shown below.

Do not bring the power line of the XGT Panel close to the main circuit (high voltage , high current) line o r I / O signal

line. Possible 100mm Install at an interval of more than two.

Use the surge absorber as shown in the figure below to prevent su rge such as lightning.

XGT Panel

(1) Separate grounding (E2 ) of the XGT Panel of g round surge absorber (E1).

(2) Select the surge ab sorber so that the surge absorber does not e xceed the maximu m allowable voltage even w hen

the power supply voltage rises to a maximu m please give it to me.

4-9

L N PE

Ferrite Core

(CU1130B, E-TECH)

(CU1330G, E-TECH)

(ZCAT3035-1330, TDK)

Note

Type-3 ground

Type-3 ground

Chapter 4. Installation and Wiring

When there is concern about n oise penetration , use an insulation shi eld transformer or a noise filter.

Be sure to twist the wi ring of the input pow er supply as short as possible and do not let the wiring of the shielding tran sformer or

noise filter pass throug h the duct.

When using a magnetic contactor (MC) for AC / DC, it is recommended to use Ferrite Core at the power input terminal.

EX) Apply a ferrite core to the po wer terminal as show n in the figure.

4.2.2 Ground Wiring

(1) This XG T Panel has enough noise countermeasures, so it can be used without g rounding except when there is a lot of noi se.

However, when grounding, plea se refer to the foll owing.

(2) Grounding should be done by dedicated grounding as much as possible.

Grounding works are clas sified as class 3 gro unding (grounding re sistance 100 Ω Or less).

(3) When dedicated grounding i s not possible, u se common ground as show n in Fig.

(4) Ground wire is 2 mm

wire.

XGT Panel

A) Exclusive ground: Best B) Common ground : Good C) Common ground: Bad

2

Other

or more. If possible, place the groundi ng point near the XGT Panel to shorten the length of the g round

XGT Panel

Other

XGT Panel

Other

If the grounding condition is bad or connected as in (C), the XGT Panel may malfunction or communication failure

may occur. Be sure to check grounding.

5-1

WinCE O/S V1.0 XP-Runtime V2.10 B[010]

Configuration menu of

Backlight Setting

Touch Setting

DateTime Setting

Environment Setting

Ethernet Setting

Buzzer Setting

Sound Setting

XP-Remote Setting

Goto MainMenu

Diagnostics function of

Screen

Touch

Backup Memory/

Flash Memory

USB Memory

Serial

SD Card

Chapter 5 XGT Panel Menu Explanation

Chapter 5 XGT Panel Menu Explanation

This chapter describes how to set the environ ment such as XGT Panel ti me setting, Ether net connection setting, backlight setting.

If you press the [Setti ngs] button on the XGT Panel main screen, you can set the environment of XGT Panel.

[XGT Panel Basic]

After booting the XGT Panel after turning on the power, the XP-Runtime main screen is displayed. Functions of each menu are as

follows.

Menu Meaning Details Note

Settings

Diagnostics

XGT Panel

XGT Panel

Refer to 5.1 Settings

Refer to 5.2 Diagnostics

Goto MainMenu

Settings

SHOW INFO

Program Monitor

OK

N:1 Settings

XGT Panel Update

Refer to

5.4 Update XGT Panel

Project Download

Project Upload

XGT Panel Update

Select USB

Cancel

Chapter 5 XGT Panel Menu Explanation

구분 의미 세부 항목 비고

PLC setting menu

PLC Information

Update XGT Panel For updating XGT Panel

Storage Function

connected with

XGT Paenl

It is for using

the storage devices

used in XGT Panel

Refer to

5.3 PLC Information

Refer to

5.5 Storage Function

5-2

5-3

WinCE O/S V1.0 XP-Runtime V2.10 B[010]

5.1 Settings

Chapter 5 XGT Panel Menu Explanation

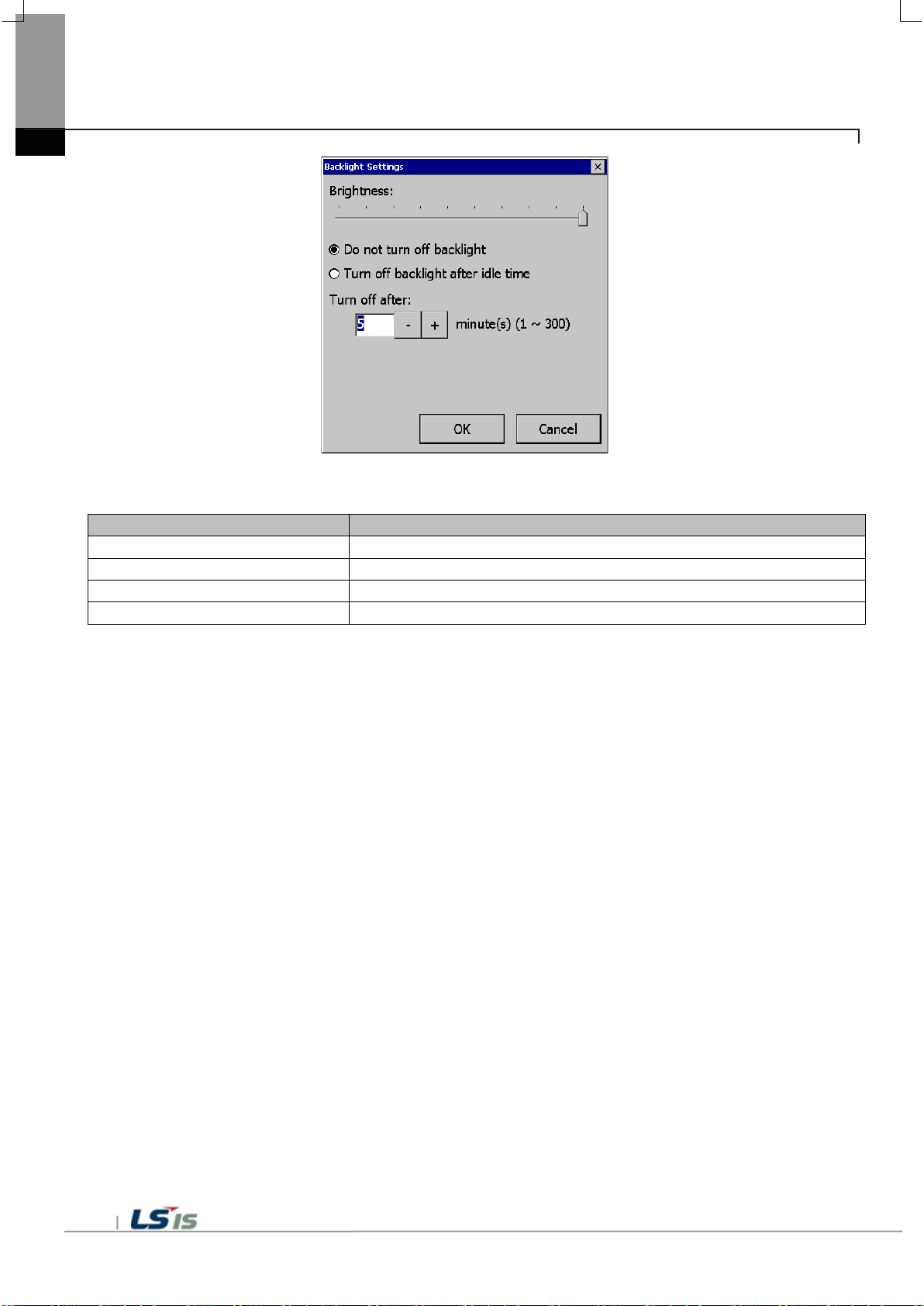

5.1.1 Backlight Setting

Press the [Backlight Settings] button on the [Sy stem Configuration] screen to go to the setup screen as follows.

[XGT Panel Setting]

Menu

Explanation

Brightness

Backlight Brightness can be adjusted.

Do not turn off backlight

Backlight power is always on.

Chapter 5 XGT Panel Menu Explanation

[Backlight setting]

Turn off bac klight after idle time If you do not touch for a certain period of t ime, the backlight auto matically turns off.

Turn off after The backlight turns off after the set time (in minutes).

[Explanation of the dialog box]

5-4

5-5

Note

Chapter 5 XGT Panel Menu Explanation

5.1.2 Touch Setting

You can adjust the sensitiv ity of the touch a ccording to the ty pe of gloves according to the work environ ment during touch ope ration. If

you press [Touch Setting] on the System Configur ation screen as shown below, the setting w indow will be activat ed and you can set

the sensitivity according t o the type of glove . You can set the sensitivity of the to uch by user settin g.

[XGT Panel Setting]

[Touch setting]

(1) By default, XGT Panel h as touch setting. I f the touch position error is large, Please contact us for action.

(2) If touch glass breakage occurs, it may cause touch operation proble m.

2017

Today: 4/23/2017

Note

Chapter 5 XGT Panel Menu Explanation

5.1.3 DateTime Setting

You can set the date and time of XGT Panel by pressing [DateTime Setting] button on [System Configuration] screen as follows.

[XGT Panel Setting]

[Date / Time Setting]

5-6

Date / time view and setting are also available in the device information view of the communication setting dialog of XP-Builder.

For more information,See the XP-Builder User's Guide Chapter 4.4.

5-7

5.1.4 Environment Setting

If you press the [Envir onment Setting] button on the [System Configuration] screen to go to the setup screen as follow s.

Chapter 5 XGT Panel Menu Explanation

[XGT Panel Setting]

Menu

Explanation

Goto screen

After rebooting XGT Panel or downloading edit data,

Button to move to the screen.

Quick start

When I start the screen, I do not cache the image in advance,

It may take a few seconds. The next screen transition is fast.

Show progress

When you start monitoring by selecting [Start] menu on the XGT Panel main screen,

Is displayed. This option can be applied when using the default screen image.

Show always ti tle bar

of popup window

Displays the title bar in a pop-up window. Select the title bar of the pop-up window and

Y ou can move.

Do not show menu bar

In order to exit to the standby screen during screen monitoring,

Y ou need to configure and use a special switch to exit the screen.

Display (right-> left)

Set startup screen

The screen corresponding to the number entered at the start of monitoring is displayed.

Chapter 5 XGT Panel Menu Explanation

(1) Screen

after boot up

on the bottom

Y ou will switch . If you di sable thi s setting ,

It does not appear. However, if you select this option, the initial screen may appear

somewhat late.

There is. In particular, if the screen contains animation objects,

It buffers the used image and shows the progress of the operation. (fast

Do not show progress if you make a start setting). At this time,

If you check the [Show Lower] check box, this progress will be simplified and displayed at

the bottom of the screen.

The window (menu bar) does not appear. If this is the case,

Enable Arabi c text

5-8

Enables the right-to-l eft language.

5-9

Menu

Explanation

Hide mouse cursor

Mouse cursor does not appear after scrolling.

Buzzer On / Off

Y ou can set whether buzzer is used or not.

Buzzer test

Y ou can test the buzzer.

The operation to delete may be repeated, and the screen switching operation may be

results in less memory usage and less load to load and delete images into memory.

Uncheck, power on again an d try again .

Clear SRAM memory

Delete all fil es you'v e downloa ded on your dev ice. How ever , c onnectin g to the devi ce

A device reboot is required to delete files.

(2) General

Chapter 5 XGT Panel Menu Explanation

Low Memory Mode XGT Panel star ts monitori ng the images used on th e screen to speed up the screen

operation.

It will be loaded into memory before use. By the way ,

If a positive image is used, due to memory space constraints, all

The image will not load. In this case, if the screen is not yet loaded

Images are loaded, and there is not enough space, so unused images are retrieved from

memory

slowed down. In this situation

Low Memory Mode "is rec om mended. In Low Memory Mode , you do not load t he image

before monitoring, but use only the original source of the image used in the project, which

Reset USB power

after boot up

When XGT Panel starts, it turns off USB power On to initialize the connected device.

The initial setting is On, and if t he USB reco gnition s peed is sl ow or not wel l recogniz ed

And data files

If a password is set, you must enter the password before you can delete it. The password

is the device connec tion password th at you enter whe n download ing a project, This can

be set in XP-Builder on the Device Information View tab of the Communication dialog box.

The files to be deleted include user project data, we b ser v er, VNC startup modul e, op ti on

card Driver, RAPIEnet communication setting data, XP-Manager sett ing data etc. from

user PC All downloaded data is included. Set using the configuration menu of the

machine. The contents are kept uninitialized. If the menu language is not English,

Menu

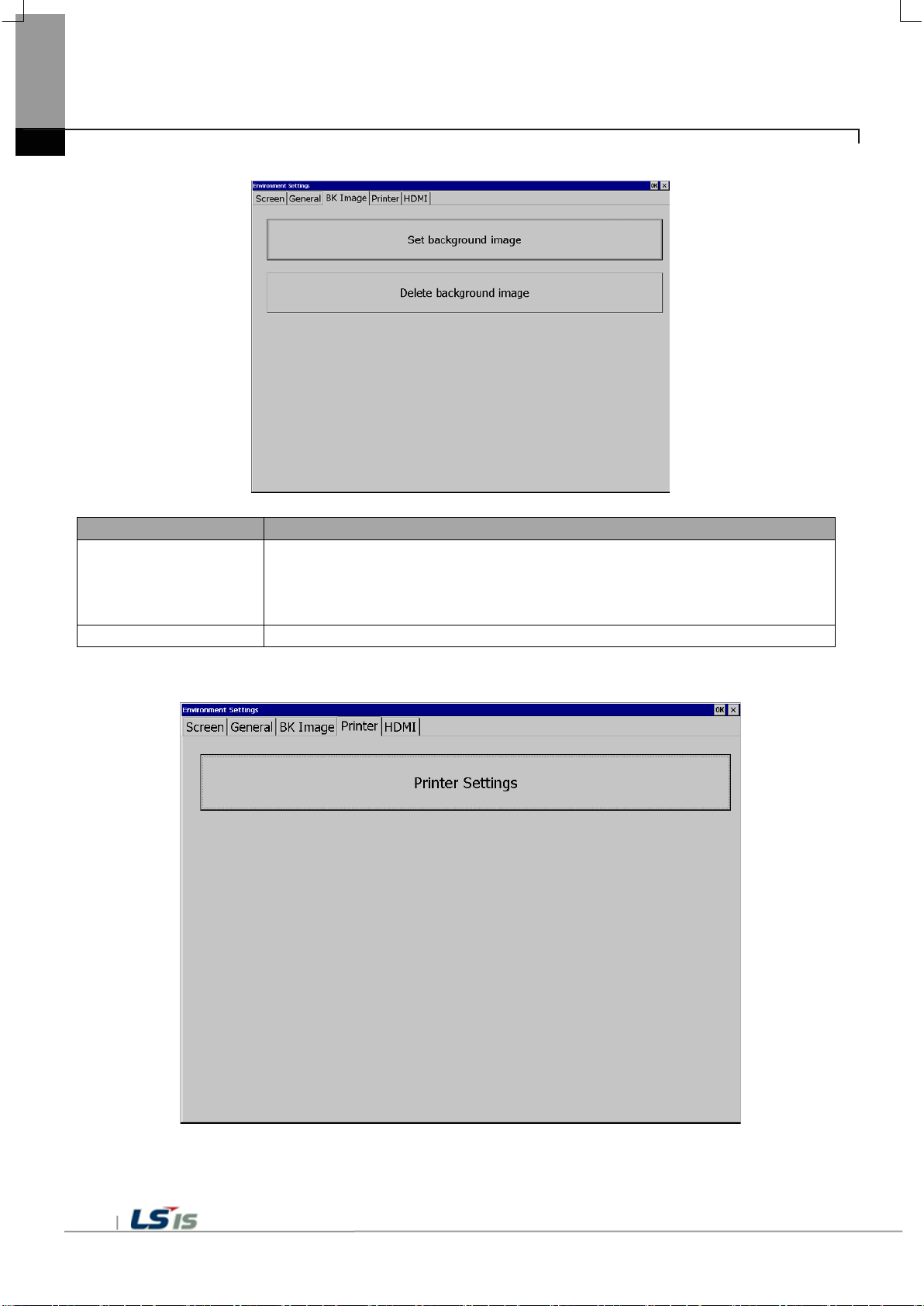

Explanation

Set background image

If you select an image, the standby screen and desktop are selected after the XGT Panel

It can not be used unless it is a 24bit BMP image.

Delete background image

Deletes the set desktop.

Chapter 5 XGT Panel Menu Explanation

(3) BK Image

(4) Printer

is powered on.

If [Use boot image] option is selected, images with resolutions other than XGT Panel,

5-10

5-11

Menu

Explanation

Chapter 5 XGT Panel Menu Explanation

Printer Settings Displays additional printer print settings dialogs. If there is no printer information

Y ou should download from XP-Builder with the following message.

From XP-Runtime, go to Start menu and prepare for downloading.

After using the printer, you can use the menu.

<No printer driver and information Dow nload Requi red>

<Printer Driver and Information Available>

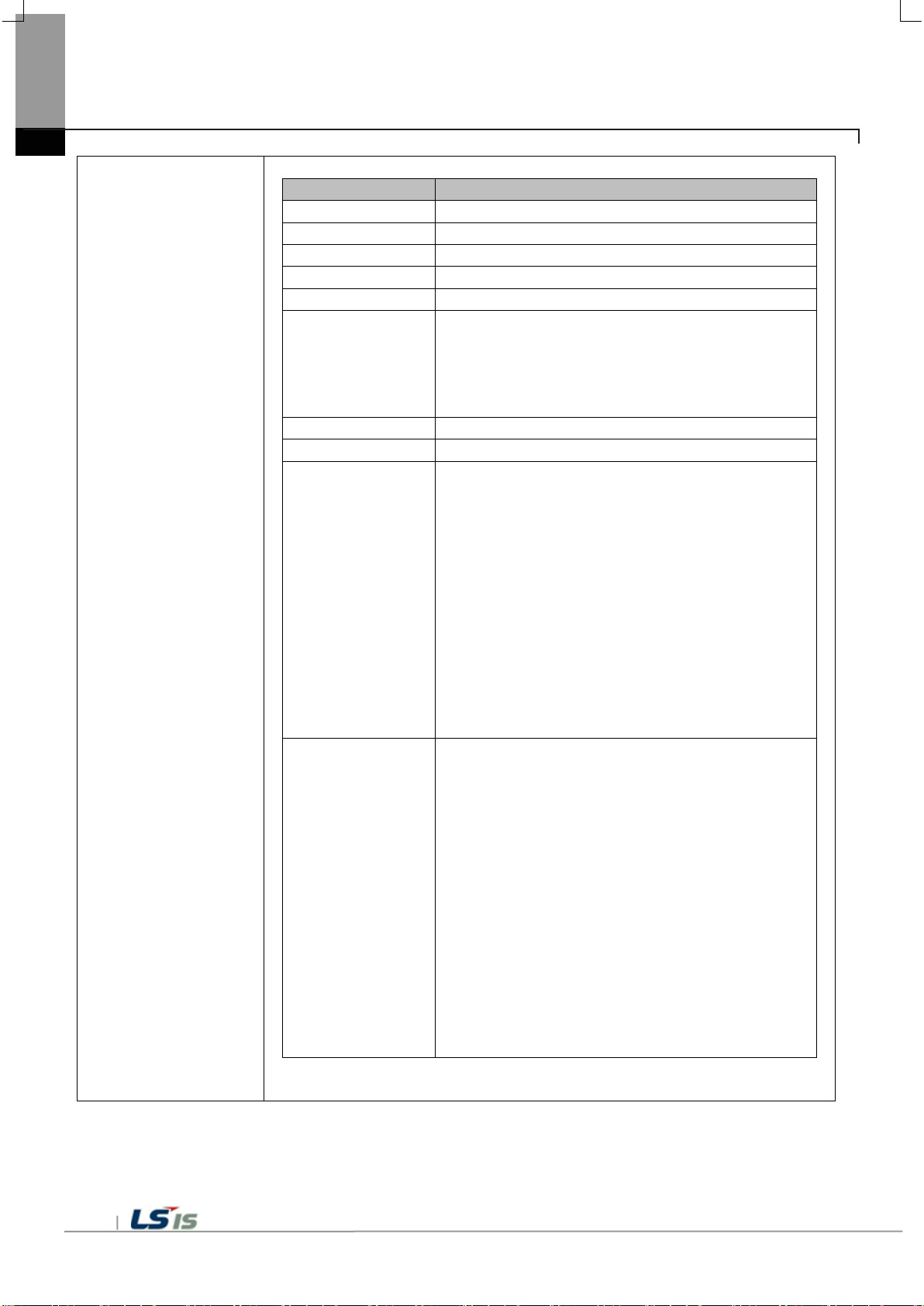

Printer Settings

Menu

Explanation

Port

Connection method: Displays the connection method.

Printer type

Printer type: Displays the printer type.

Print direction

Orientation: Set whether it is horizontal or vertical.

Print color

Print color: Set whether it is color or black and white.

High quality print

Print quality: Set whether to print advanced.

More ...

View add itional properties: Displays additional properties.

Go to the dialog box.

OK

Save the settings.

Cancel

Cancels the setting.

4. Paper Empty: Out of paper

T est Page

T est printing: T o test the printout status

Chapter 5 XGT Panel Menu Explanation

Printer Properties

If you have made any changes, check whether you want to

save it,

Printer Check D ia gn os e connectivity: Diagnoses the connec t io n sta t us of

the printer. this

The functions of the printer (LK-P30, LK-P 41, LK -P43)

Support. Press the button to the right of the current status

Displays a message. If the printer is off

Y ou can turn it on, connect the cable again,

There is.

* Message Ty pe *

One. OK: normal

2. No Printer: Not compatible with printer

3. Cover Open: Paper cover opened

Function. It prints the following information and briefly

Outputs the printing status.

<Example of test page>

***********************************

T est page

***********************************

DateTime: 2014-02-0 4 10:00:00

XP-Runtime version: 1320

Printer driver version: 1.00

Printer name: PCL3 LaserJet

Port: USB

***********************************

5-12

5-13

Menu

Explanation

Not used

HDMI function is disabled.

Clone mode

The same screen is displayed on the monitor connected by HDMI.

(T o be implemented)

(5) HDMI

Chapter 5 XGT Panel Menu Explanation

Extended mode

Expands the screen to a monitor connected via HDMI.

Note

For 1: 1 connection with PC, i t is recommended to set as follows.

- Gateway: 192.168.0.1

- Gateway: 192.168.0.1

Chapter 5 XGT Panel Menu Explanation

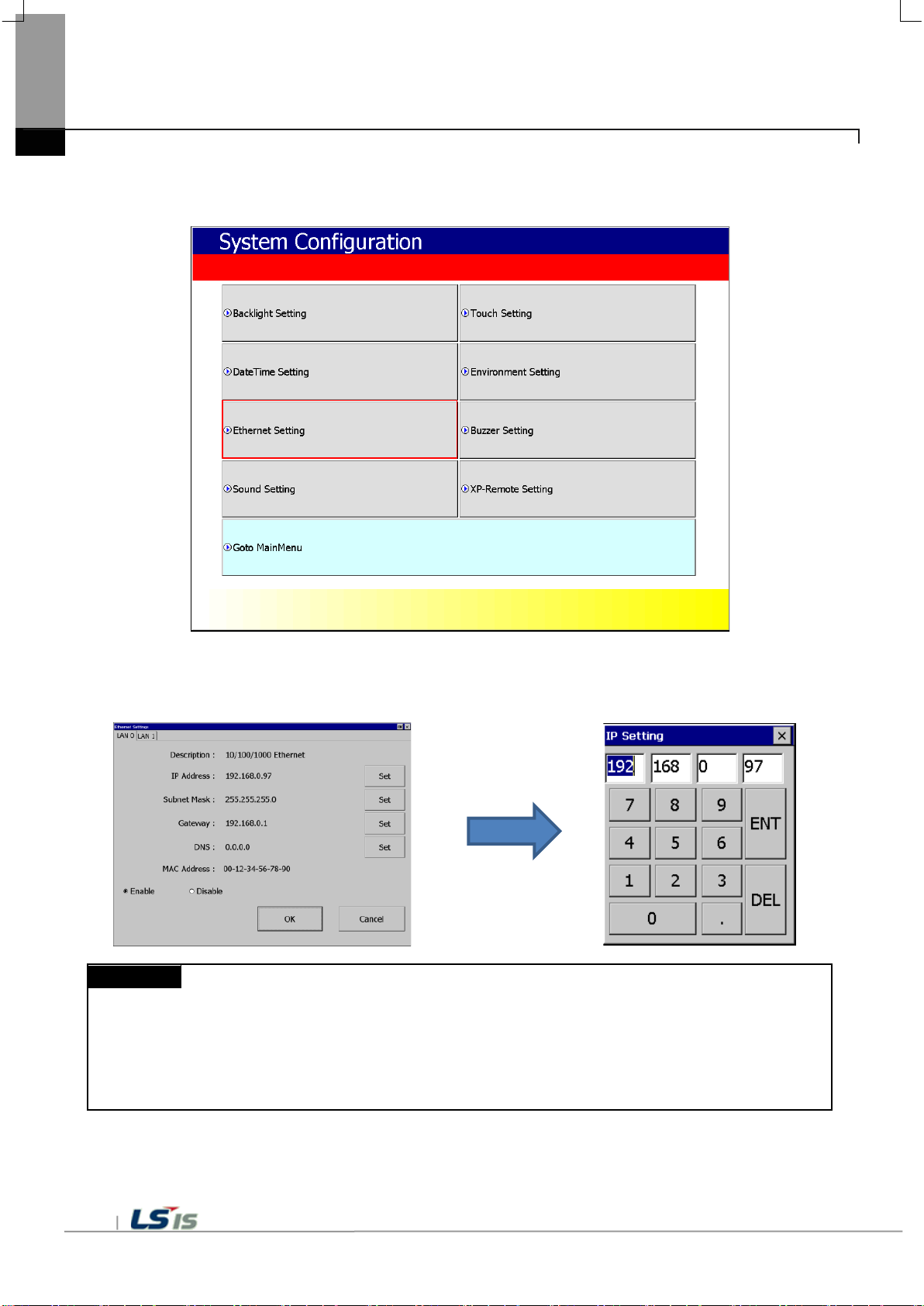

5.1.5 Ethernet Setting

If you press the [Etherne t Setting] button on the [System Config uration] screen as below , you can set the IP to use Ethernet.

You can change the IP by pressing the [Set] button for each item o f IP address, Subnet Ma sk and Gateway.

If you click [OK] button, changed IP info rmation will be saved. Two Ethernet port s [LAN 0] and [LAN 1] can be set respectivel y.

1) XGT Panel setting

- IP address: 192.168.0.10

- Subnet Mask: 255.255.255.0

2) PC setting

- IP address: 192.168.0.11

- Subnet Mask: 255.255.255.0

If you press the [Disable ] button and reboot, the device will n ot use Ethernet. I f this is the ca se,

You can get the effect. To use Ethernet again, p ress [Enable] but ton and reboot.

5-14

5-15

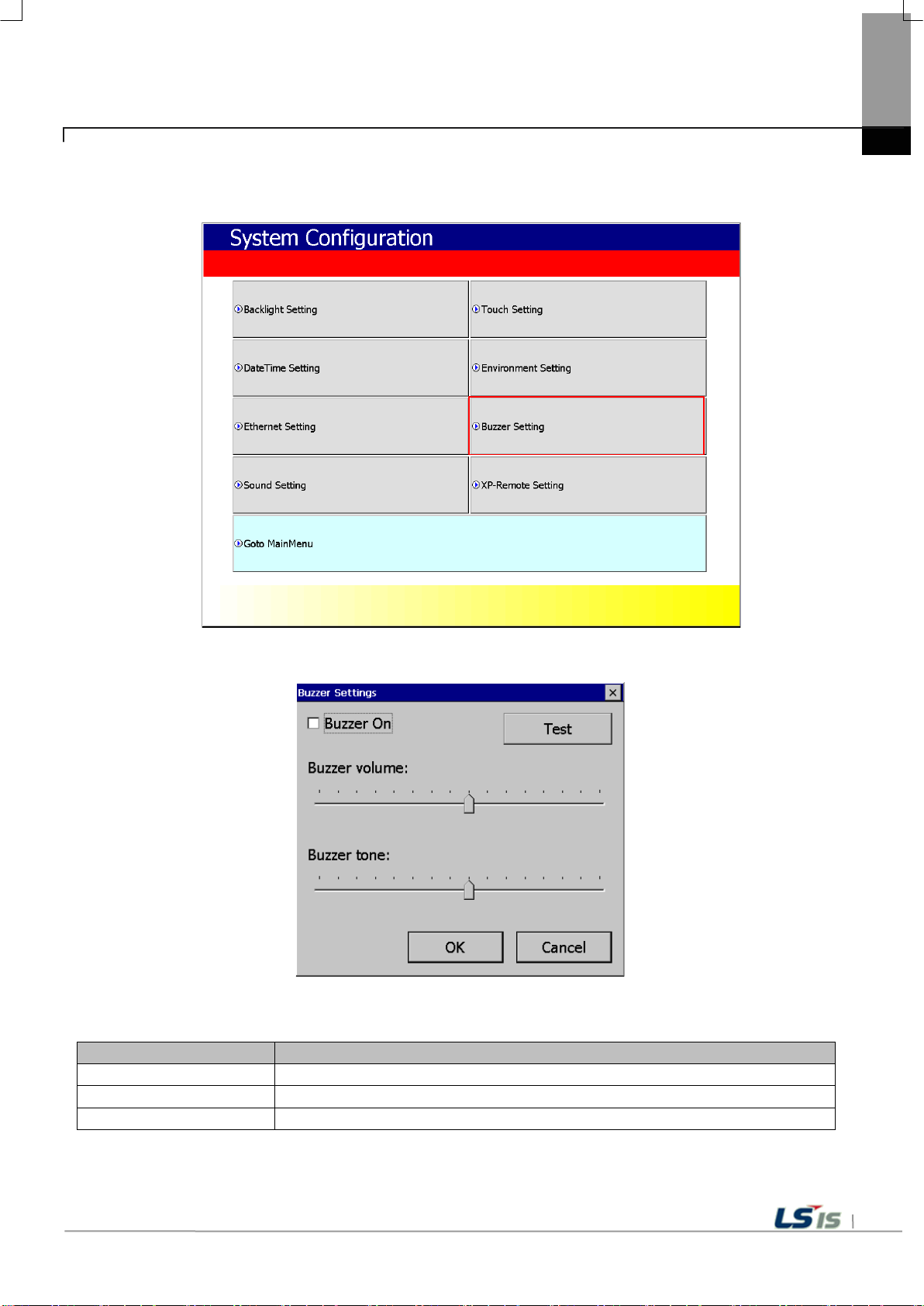

Menu

Explanation

Buzzer On

Y ou can turn on or off the buzzer sound generated when the selection is made.

Buzzer volume

Y ou can adjust the volume of the buzzer.

Buzzer tone

Y ou can adjust the height of the buzzer.

5.1.6 Buzzer Setting

You can adjust the volu me and tone of Buzz er of XGT Panel.

Chapter 5 XGT Panel Menu Explanation

[Explanation of the dialog box]

[XGT Panel Setting]

[Buzzer setting]

Chapter 5 XGT Panel Menu Explanation

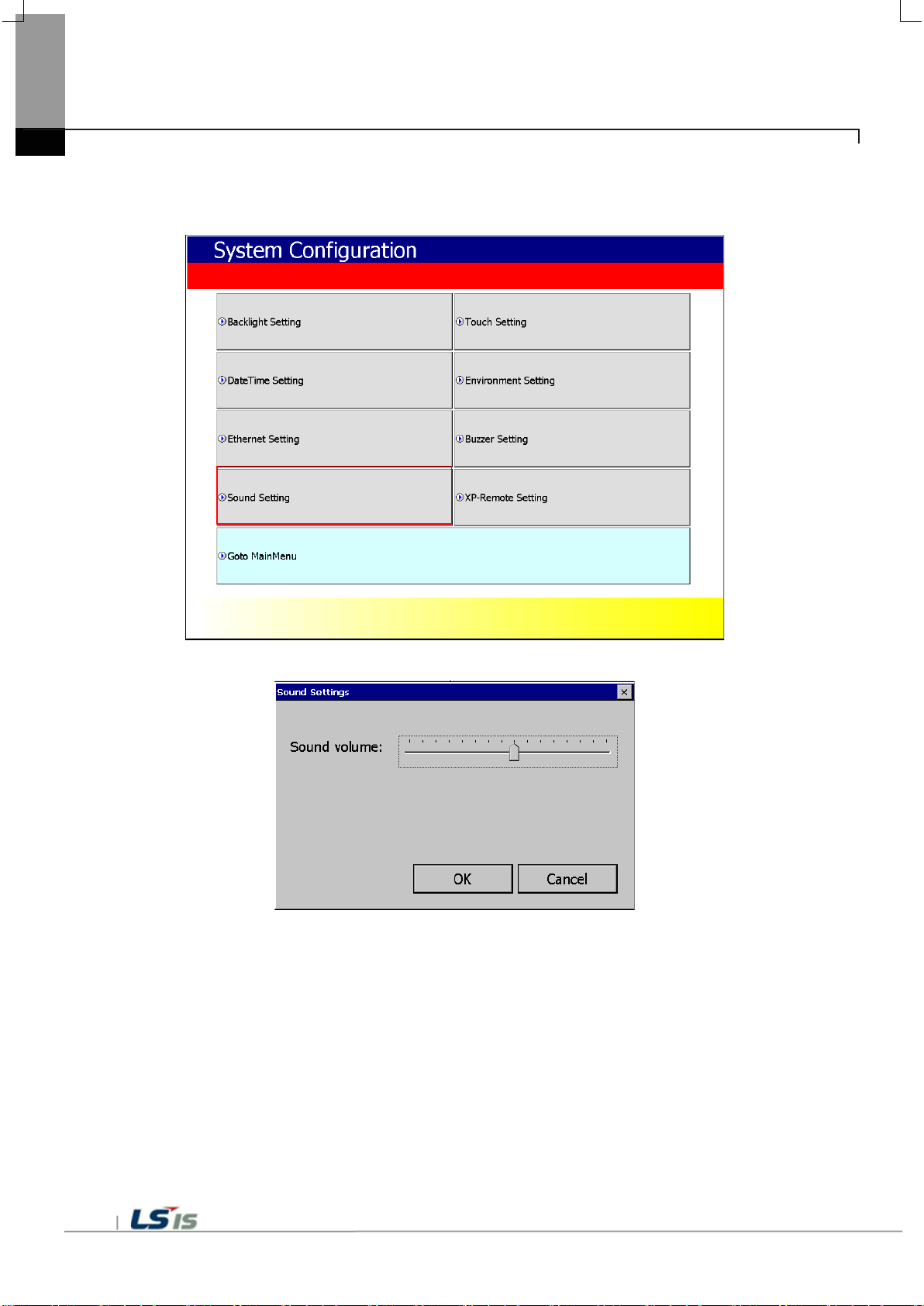

5.1.7 Sound Setting

You can adjust the volu me of XGT Panel.

[XGT Panel Setting]

[Sound setting]

5-16

5-17

Menu

Explanation

Allow XP-Remote to connect

Allow connection of remote XP-Remote.

Max. of XP-Remote

Specify the maximum number of XP-Remote that can be connected to XGT Panel.

(10 seconds ~ 300 seconds)

Enable control by XP-Remote

after Monitor Start

After XGT Panel starts to monitor, operation permission status is automatically set.

Note

Chapter 5 XGT Panel Menu Explanation

5.1.8 XP-Remote Setting

Y ou can change the settings for XP-Remote that can remotely control the XGT Panel.

[XGT Panel Setting]

[XP-Remote setting]

[Explanation of the dialog box]

Timeout value If there is no communicat ion request f rom XP-Remote within th e designate d time,

communication is stopped,

If XP-Remote has operation authority , it recovers operation authority.

For details of XP-Remote, refer to the XP-Remote User's Ma nual.

WinCE O/S V1.0 XP-Runtime V2.10 B[010]

Chapter 5 XGT Panel Menu Explanation

5.2 Diagnostics

This chapter explains the functions that can be used to diagnose co mmunication terminal, screen and touch function of XGT Panel.

If you click the [Diagno sis] button on the main screen of XGT Panel, a menu for diagnosi ng each function of XGT Panel is displayed.

[XGT Panel Basic]

[XGT Panel Diagnostics]

5-18

5-19

order

Chapter 5 XGT Panel Menu Explanation

5.2.1 Screen Diagnostic

When you press the [Screen] button, the screens with different colors are displayed in succession with the buzzer sound. After

all the scre ens for diag nosis are d isplayed, the gr aph will app ear and the [Close] butt on will appear in the upp er left corn er.

When this [Close] button is pressed, Returns to the Diagnostics screen.

Screen

Red Green Blue Black White Graph

[XGT Panel Diagnostics]

[Screen Diagnostic]

Chapter 5 XGT Panel Menu Explanation

5.2.2 Touch Diagnostic

When you press the [Touch ] button, the diagnos tic screen appears.

If you touch the screen , you can see that it is displayed like the picture bel ow.

Press the [OK] button to exit the screen.

[XGT Panel Diagnostics]

[Touch Diagnostic]

5-20

5-21

Note

If the rear setting switch 1 is set to B, set it to ON. B is a mode without backup battery .

5.2.3 Backup Memory Diagnostic

If you press the [Bac kup Memory] button, y ou can see the diagn ostic results in the confirmation wi ndow.

Chapter 5 XGT Panel Menu Explanation

[XGT Panel Diagnostics]

[Backup Memory Diagnostic]

(1) If 'NVRAM Data Acces s ~~ Fail' occur s, take A/S action.

(2) If 'BATTERY STATUS ~~ BAD' occurs, you have to replace the battery through A/S.

Note

2. Spa ce allocation of Flash Disk may depending on O/S version.

Chapter 5 XGT Panel Menu Explanation

5.2.4 Flash Memory Diagnostic

When you press the [Flash Memory] button, the dia gnostic results app ear in the confirmati on window.

[XGT Panel Diagnostics]

[Flash Memory Diagnostic]

1. I f "Read Disk Infor mation Error!" Occur s, please contact us.

5-22

5-23

Note

If USB memory is installe d and 'Read Disk In formation Error!' Occurs, remove it, in sert it again and te st

do it. If the error mes sage occurs repeatedly , contact Customer Service.

Chapter 5 XGT Panel Menu Explanation

5.2.5 USB Memory Diagnostic

When you press the [USB Me mory] button, the dia gnostic result appear s in the confirmation window.

[XGT Panel Diagnostic]

[USB Memory Diagnostic]

Chapter 5 XGT Panel Menu Explanation

5.2.6 Serial Diagnostic

Diagnostic function for serial communication port such as RS-232C, RS-422. Press the [Serial ] button to diagnose the serial

ports installed on the XGT Panel. (However, for diagnosis, loop bac k terminal must be connected to each port.)

[XGT Panel Diagnostic]

[Serial port selection screen]

[Serial Diagnostic]

5-24

5-25

Pin

er

name

function

One

TX +

Data transmission

2

TX-

Data transmission

3

RX +

Receive data

4

RX-

Receive data

5

SG

Signal Groun d

6

PE

PE

Chapter 5 XGT Panel Menu Explanation

Please make RS-232C port terminal as below. (Connect pins 2 and 3.)

Connect the RS-422/ 485 port t erminal s as shown be low .

(In case of RS-485 c ommunic ation, con nect pin 1, pin 3, pin 2 and pin 4)

nu

mb

Note

If the error message occu rs repeatedly , take A / S action.

Chapter 5 XGT Panel Menu Explanation

5.2.7 SD Card Diagnostic

Displays information of SD card memory i nserted i n XGT Pa nel . Press the [SD Card] button to diagnose the SD memory mounted

on the XGT Panel.

[XGT Panel Diagnostic]

[SD Card Diagnostic]

If 'Read Disk Information Error!' Occurs w hen an SD card is inst alled, remove it, inse rt it again, and tes t it.

5-26

5-27

WinCE O/S V1.0 XP-Runtime V2.10 B[010]

Note

Chapter 5 XGT Panel Menu Explanation

5.3 PLC Information

The PLC informat ion view function is to view the conn ected XGT Panel information an d CPU information and his tory of the

target PLC.

[XGT Panel Basic Screen]

PLC connection status can be viewed only when project data is t ransferred to XGT Panel.

Note

Chapter 5 XGT Panel Menu Explanation

5.3.1 PLC Communication Setting

[Settings] is a function to change communi cation parameters of PLC communicating with X GT Panel, and you can change

PLC communication setting items by clicking [Setti ngs] button

[PLC information]

[PLC Communication Setting]

- PLC communication setting sc reen may be different for each driver.

- Refer to individual PLC manual for PLC communi cation setting change contents.

5-28

5-29

Item

Explanation

Connection No.

Displays the communication connection number. Available from 0 to 15.

Vendor

Displays the manufacturer of the communication target device.

T arget device

Displays the communication target device.

Connection type

Displays the conne ction method. (RS-232, RS-422, TCP/IP , ect.)

Timeout value

Displays the set timeout time.

Send wait value

Displays the transfer waiting time.

Displays the number of retransmissions when a timeout occurs during

communication.

Chapter 5 XGT Panel Menu Explanation

5.3.2 Connection Information

You can check the connection number, PLC manufacturer, ta rget PLC type, connection method, IP address, and timeout ti me set up

for connection with PLC i n XP-Builder.

[PLC information]

[Explanation of the dialog box]

Retry value

Note

- XGK / XGB / XGI / XGR CPU, FEnet, Cnet

Note

The PLC types that can di splay the error histo ry are as follows.

- XGK / XGB / XGI / XGR CPU, FEnet, Cnet

Chapter 5 XGT Panel Menu Explanation

5.3.3 PLC Information

You can check the CPU ty pe, operation mode, statu s, version and scan time of our own PLC model and provide in formation only

when connected with PLC.

PLC types that can view PLC information are a s follows.

- MASTER-K CPU, FEnet, Cnet

- GLOFA-GM CPU, FEnet, Cnet

5.3.4 History of PLC error

You can check the PLC e rror history of y our own PLC model.

- The MASTER-K CPU has no error history.

- GLOFA-GM CPU, FEnet, Cnet

5-30

5-31

Note

- XGK / XGB / XGI / XGR CPU, FEnet, Cnet

Note

Chapter 5 XGT Panel Menu Explanation

5.3.5 PLC Operation Mode Conversion History

You can check the PLC run / stop opera tion mode history of your PLC model.

The following PLC types a re available to view the PLC operation mode switching history .

- MASTER-K CPU does not h ave operation mode switching history .

- GLOFA-GM CPU, FEnet, Cnet

5.3.6 History of power off of PLC

You can check the PLC power shutdown history of your own PLC ty pe.

PLC type that can view th e power off history is as follows.

- MASTER-K CPU has no pow er off history .

- GLOFA-GM CPU, FEnet, Cnet

- XGK / XGB / XGI / XGR CPU, FEnet, Cnet

Note

- XGK / XGB / XGI / XGR CPU, FEnet, Cnet

Chapter 5 XGT Panel Menu Explanation

5.3.7 PLC System History Information

PLC system history can be checked.

The PLC types that can view the system histo ry are as follows.

- The MASTER-K CPU has no system history.

- Only available with the GLOFA-GM CPU (GM4C). Other CPUs have no system history.

5-32

5-33

Menu

Explanation

Use N: 1 Communication

N: 1 Specifies whether to perform communication.

N: 1 station number

Enter the station number of N: 1 communication.

Number of XGT Panel

N: 1 Enter the number of XGT panels on communication.

Master Holding Time

Enter the master execution time of N: 1 communication.

Note

Chapter 5 XGT Panel Menu Explanation

5.3.8 N: 1 Setting

XGT Panel supports N: 1 service which enables communication between sev eral XGT Panels and one PLC. You can set de tails

using the [N: 1 Setting s] menu.

[Explanation of the dialog box]

[PLC information]

[N: 1 setting]

For detailed setting and understanding of N: 1 communication , refer to XP-Builder's N: 1 communication manual.

Note

You must specify the use of the program monitor in the project properties of XP-Builder.

Chapter 5 XGT Panel Menu Explanation

5.3.9 Program Monitor

XGT Panel can monitor ladde r of PLC XGK of LS Indu strial Systems.

[PLC information view s creen]

- Program monitor module s must be installed via XP-Manager.

- LSIS: XGK / XGB CPU, Cnet, and Enet driver.

-

5-34

5-35

WinCE O/S V1.0 XP-Runtime V2.10 B[010]

Note

1. Do not disconnect the communication cable or turn off the device while updating the XGT Panel.

screen.

Chapter 5 XGT Panel Menu Explanation

5.4 XGT Panel Update

The functio ns d esc r ib ed in th is chapter are for up da ti ng t he X G T P an el s of t war e. B y d ef au lt , X GT Pa ne l is a ls o op timized

when downloading project file from XP-Builder. Use this function only if you need to update only the XGT Panel in particular.

The software of the XGT Panel will need to be updated with the new version as new functions and enhancements are

added. Refer to the following procedure.

[Method]

1. Connect XGT Panel and PC.

2. Run the XP-Builder.

3-1. Click [Communication] - [XGT Panel Update].

3-2. Click Connection Setup to select the type of XGT Panel and PC connected.

3-3. Clic k Browse an d select the XP-Runtime file.

4. Select [XGT Panel U pdate] on the XGT Panel menu screen.

5. Click [Update] of the XGT Panel Update(No3-1).

When normal update is completed, return to XP Runtime menu screen.

XGT Panel may not update properly and may malfunction

2. Click Update XGT Panel menu and then click MENU on XP-Runtime screen to return to XP-Runtime menu

WinCE O/S V1.0 XP-Runtime V2.10 B[010]

Menu

Description

Chapter 5 XGT Panel Menu Explanation

5.5 Storage Function

5.5.1 Overview

Download the project edited by the user in XP-Builder from PC or upload the project backed up in the device to PC

Uploading and updating the device are usually done by connecting USB cable or Ethernet cable to XGT Panel series.

Y ou can do it through. In situations where this connection is not possible, you can use the storage device to proceed.

The function description for [Storage Function] is as follows.

1. If you touch [Storage Function] on the menu, the following dialog box is displayed.

2. The contents of each menu are as follows.

Project Download To dow nload a project from an external storage device to the XGT Panel

Project Upload To transfer project data backed up to an external storage device from XGT Panel

XGTPanel Update T o update the XGT Panel Software from an external storage device

5-36

5-37

Chapter 5 XGT Panel Menu Explanation

5.5.2 Downloading a project using a storage device

1. When you touch [Download Project] in the storage function menu, the following dialog box is displayed.

2. Project storage path of USB memory, SD card is displayed as below.

- \ USB Storage \ XP_Project \

- \ SD Storage \ XP_Project \

If you want to download a project using a storage device, it must be stored in the directory in the above path.

3. Select one of the directory listings.

4. T ouch the [OK] button to start the download.

Chapter 5 XGT Panel Menu Explanation

5.5.3 Uploading a project using a storage device

1. If you touch [Upload Project] in the storage function menu, the following dialog box is displayed.

2. The upload path of USB memory and SD card is displayed as below.

- \ USB Storage \ XP_Backup \

- \ SD Storage \ XP_Backup \

3. T ouch the [OK] button to transfer the project backup file in the machine to the path of the selected storage device.

4. The project backup file must be downloaded to download the project backup file when downloading the project.

If not selected, the project backup file is not stored in the device and therefore can not be transferred to the storage device.

5-38

5-39

Chapter 5 XGT Panel Menu Explanation

5.5.4 Updating the device using a storage device

1. If you touch [Update XGT Panel] in the storage function menu, the following d ialog box w ill b e dis play ed.

2. The path of USB memory, SD card is displayed as follows.

- \ USB Storage \ XP_Software \

- \ SD Storage \ XP_Software \

If you want to update the device using an external storage device, the XGT Panel Software file is in the directory in the

above path

It must be saved.

3. T ouch the [OK] button to update the device with the XGT Panel Software stored in the specified path.

6-1

Logging

YYYY.MM.BeginDay.EndDay.0

DD.BeginHour.EndHour.0 (space for one folder is full)

HH.BeginMinute.FF

Lhhmmss0.CSV

Recipe

Rhhmmss0.CSV (same as lower structure of each logging number)

DD.BeginHour.EndHour.1 (There is free space for one folder)

DD.BeginHour. FF (There is free space for one folder)

1 (Logging Number)

2 (same as lower structure 1)

ScreenImage

Shhmmss0.BMP (same as lower structure of each logging number)

Root directory of SD or USB storage equipment.

Chapter 6 Backup files by using Storage Devices

Chapter 6 Backup files by using Storage Devices

This chapter des cribes the m anagem ent functi ons for extern al storage devices th at store back up data of lo gging, rec ipe, and

screen images.

(1) XGT Panel can back up logging, recipe, screen image data to USB storage device according to the settings set in XP-Builder.

(2) If there is no capa ci ty to be backed up on the specified storage device, the existing data is delet ed a cc o rdin g to the settings

set by XP-Builder, and the backup process or backup is stopped.

(3) The XP-Builder monitors whether or not the external storage device specified as the backup device is detached.

6.1 Path Structure in case of File Backup

Backup path structure of logging, recipe, and screen image is as follows.

Chapter 6 Backup files by using Storage Devices