5.5~18.5kW(200V), 5.5~90kW(400V)

AC Variable Speed Drive

H100 Troubleshooting Manual

Safety Instructions

Read this manual carefully before servicing or inspecting this equipment.

Keep this manual within easy reach for quick reference.

1

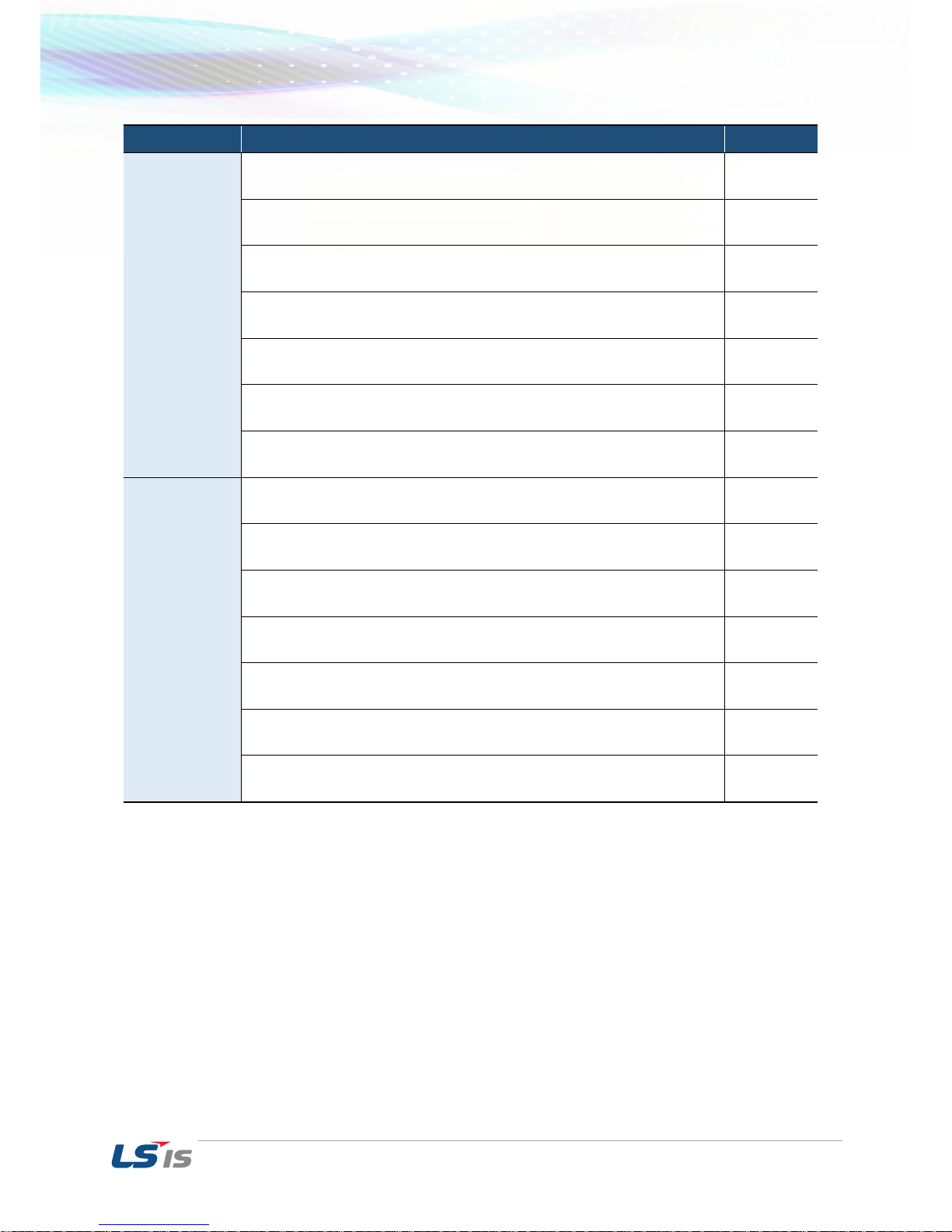

Quick Reference Table

The following table listed situations frequently encountered while working with inverters. Refer to

the typical situations to quickly and easily locate solutions to your questions.

Situation

Reference

The motor is too noisy.

P. 33

I want to review recent fault trip and warning histories.

P. 18

The motor is producing too much heat.

P. 31

The cooling fan is not working.

P. 34

I want to know how I can keep the inverter when I am not using it.

P. 44

I want to initialize all parameters.

P. 16

I want to terminate the inverter.

P. 44

I want to review the input/output module.

P. 38

I want to change the fan when it exceeded the replacement period.

P. 42

I want to change the carrier frequency.

P. 14

I cannot set the parameters.

P. 30

The motor is not working.

P. 30

The motor stops when it is connected to the load or accelerated.

P. 32

2

Contents

INTRODUCTION 3

Manual Composition 3

PRODUCT IDENTIFICATION 4

ASSOCIATION MANUAL 4

SAFETY INFORMATION 5

REVISION RECORD 7

1

BASIC CHECKLIST 8

Before you think it failed 8 1.1

Basic Operations 10 1.2

Parameter Change 14 1.3

Carrier Frequency Change 14 1.3.1

Initializing All Parameters 16 1.3.2

Read and Write Parameters 17 1.3.3

Fault Trip Monitoring 18 1.4

2

TROUBLESHOOTING 21

Trips and Warning 21 2.1

Failure/Warning List 21 2.1.1

Troubleshooting Fault Trips 25 2.1.2

Troubleshooting Other Fault 30

2.2

3

MAINTENANCE 35

Regular Inspection List 35 3.1

Daily Inspections 35 3.1.1

Annual Inspections 36 3.1.2

Bi-Annual Inspections 37 3.1.3

Check Input/Output Module 38 3.1.4

Replace Cooling FAN 42 3.1.5

Storage and Disposal 44 3.2

Storage 44 3.2.1

Disposal 44 3.2.2

3

Introduction

Manual Composition

1.1 Before you think it failed

1.2 Basic Operations

1.3 Parameter Change

1.3.1 Carrier Frequency Change

1.3.2 Initializing All Parameters

1.3.3 Read and Write Parameters

1.4 Fault Trip Monitoring

2.1 Trips and Warning

2.1.1 Failure/Warning List

2.1.2 Troubleshooting Fault Trips

2.2 Troubleshooting Other Fault

3.1 Regular Inspection List

3.1.1 Daily Inspections

3.1.2 Annual Inspections

3.1.3 Bi-Annual Inspections

3.1.4 Check Input/Output Module

3.1.5 Replace Cooling FAN

3.2 Storage and Disposal

3.2.1 Storage

3.2.2 Disposal

This section explains troubleshooting

fault trips and other common faults.

If problems are not solved, please

contact your vendor or LSIS.

This section provides information

on how to maintain the inverters on

a regular basis for different time

periods.

When there is a problem in the

inverter, please check the

input/output module. This is the

basic method to check the

hardware.

This section covers check points

when there is a problem in the

inverter.

Then check the parameter settings

using basic operations and the trip

records.

2 Troubleshooting

1 Basic Checklist

3 Maintenance

4

Product Identification

Note

The H100 75/90 kW, 400 V inverters satisfy the EMC standard EN61800-3 without installation of optional EMC

filters.

Association Manual

H100 user manual can be downloaded through LSIS homepage.

Link : http://www.lsis.com/support/download/

5

Safety Information

Read and follow all safety instructions in this manual precisely to avoid unsafe operating conditions,

property damage, personal injury, or death.

Safety symbols in this manual

Danger

Indicates an imminently hazardous situation which, if not avoided, will result in severe injury or

death.

Warning

Indicates a potentially hazardous situation which, if not avoided, could result in injury or death.

Caution

Indicates a potentially hazardous situation that, if not avoided, could result in minor injury

or property damage.

Safety information

Danger

Do not open the cover of the equipment while it is on or operating. Likewise, do not operate

the inverter while the cover is open. Exposure of high voltage terminals or charging are to the

external environment may cause an electric shock. Do not remove any covers or touch the

internal circuit boards (PCBs) or electrical contacts on the product when the power is on or

during operation. Doing so may cause serious injury, death or serious property damage.

Do not open the cover of the equipment even when the power supply to the inverter has been

turned off unless it is necessary for maintenance or regular inspection. Opening the cover

may lead to an electric shock even when the power supply is off.

The equipment may hold charge long after the power supply has been turned off. Use a multi-

meter to make sure that there is no voltage before working on the inverter, motor, or motor

cable.

6

Warning

This equipment must be grounded for safe and proper operation.

Do not supply power to a faulty inverter. If you find that the inverter is faulty, disconnect the

power supply and have the Inverter repaired.

The Inverter becomes hot during operation. Avoid touching the Inverter until it has cooled

down to avoid burns.

Do not allow external objects, such as screws, metal chips, debris, water, or oil to get inside

the Inverter. Allowing external substances inside the Inverter may cause the Inverter to

malfunction or ignite fire.

Do not operate the Inverter with wet hands. Doing so may cause electric shock.

Caution

Do not modify the interior structure/components of the Inverter. Doing so will void the

warranty.

The Inverter is designed for 3-phase motor operation. Do not use the Inverter to operate 3-

phase motor.

Do not place heavy objects on top of electric cables. Doing so may damage the cable and

cause an electric shock.

7

Revision Record

Version

Date

Changed main contents

Reference Page

V1.0

2016.10

1. First edition

-

8

1

Basic Checklist

Before you think it failed 1.1

Items

Check Point

Result

Installed

Environment /

Input/Output

voltage

Is the installed location appropriate?

Does the environment meet the inverters operating conditions?

Does the power source match the inverter’s rated input?

Is the rated output of the inverter sufficient to supply the equipment?

Power Terminal

Wiring

Is the circuit breaker installed on the input side of the inverter?

Is the circuit breaker correctly rated?

Are the power source cables correctly connected to the R/S/T terminals

of the inverter?

(Caution: Connecting the power source to the U/V/W terminals may

damage the inverter)

Are the motor output cables connected in the correct phase rotation

(U/V/W)?

(Caution: Motors will rotate in reverse direction if three phase cables are

not wired in the correct rotation)

Are the cables used to connect power terminals correctly rated?

Is the inverter grounded properly?

Are the power terminal screws and the ground terminal screws tightened

to their specific torques?

Are the overload protection circuits installed correctly on the motors (if

multiple motors are running using one inverter)?

Is the inverter separated from the power source by a magnetic contactor

(if a braking resistor is in use)?

Are advanced-phase capacitors, surge protection and electromagnetic

interference filters installed correctly?

(These devices MUST NOT be installed on the output side of the

inverter)

1. Basic Checklist

9

Items

Check Point

Result

Control Terminal

Wiring

Are STP (shielded twisted pair) cables used for control terminal wiring?

Is the shielding of the STP wiring properly grounded?

If 3-wire operation is required, are the multi-function input terminals

defined prior to the installation of the control wiring connections?

Are the control cables properly wired?

Are the control terminal screws tightened to their specified torques?

Is the total cable length of all control wiring less than 165ft (50m)?

Is the total length of safety wiring less than 100ft (30m)?

Miscellaneous

Items

Are optional cards connected correctly?

Is there any debris left inside the inverter?

Are there any cables (contacting adjacent terminals) creating a potential

short circuit risk?

Are the control terminal connections separated from the power terminal

connections?

Have the capacitors been replaced if they have been in use for more

than 2 years?

Has a fuse been installed for the power source?

Are the connections to the motor separated from other connections?

1. Basic Checklist

10

Basic Operations 1.2

Key Functions

Refer to the following illustration to identify part names and functions

Operation Keys

The following table lists the names and functions of the keypad’s operation keys.

Key

Key Name

Function Description

[MODE] Key

Used to switch between modes.

[PROG / Ent] Key

Used to select, confirm, or save a parameter value.

[Up] key

Switch between codes or increase or decrease parameter values.

[Down] key

[Left] key

[Right] key

Switch between codes or increase or decrease parameter values.

[MULTI] Key

Used to perform special functions, such as user code registration.

[ESC] Key

Used to cancel an input during parameter setup.

Pressing the [ESC] key before pressing the [PROG / ENT] key reverts the

parameter value to the previously set value.

Pressing the [ESC] key while editing the codes in any function group

makes the keypad display the first code of the function group.

Pressing the [ESC] key while moving through the modes makes the

1. ESC Key

2. LEFT Key

3. MODE Key

4. HAND mode LED indicator

5. HAND Key

6. OFF mode LED indicator

7. OFF Key

8. DOWN Key

9. AUTO Key

10. AUTO mode LED indicator

11. MULTI Key

12. RIGHT Key

13. PROG / Ent Key

14. UP Key

1. Basic Checklist

11

keypad display Monitor mode.

[HAND] Key

Used to switch to HAND (local/manual) operation mode.

[OFF] Key

Used to switch to OFF (standby) mode or to reset the inverter faults.

[AUTO] Key

Used to switch to AUTO (remote) operation mode.

1. Basic Checklist

12

Inverter Operating Status

Multi-function Key

Composition of Display

(1) Monitor Mode

(2) Parameter change display

Display Item List

The following table lists the functions and description of the keypad displays characters.

No.

Function

Display

Description

1

Mode

Display

MON

Monitor Mode

PAR

Parameter Mode

U&M

USR & Macro Mode

TRP

Trip Mode

CNF

Config Mode

2

Operating

Command

K

Keypad operation command

O

FieldBus communication option operation command

A

Application option operation command

E

Time Event operation command

R

Built-in 485 operation command

T

Terminal block operation command

2

Frequency

Command

K

Keypad frequency command

V

V1 input frequency command

I

I2 input frequency command

P

Pulse input frequency command

U

Frequency command during UP operation

Monitor Mode Cursor

Status Display Item

Monitor Mode Display Item 1

Monitor Mode Display Item 2

Monitor Mode Display Item 3

Mode Display

Code No. and Name

Initial Value at the Time

of Product Delivery

Inverter Operating Status

Status Display Item

Parameter Value

Settable Range

Currently Set Value

Mode Display

Operating/Frequency

Group Display

Multi-function Key

Rotational direction

Rotational direction

1. Basic Checklist

13

(Up-Down operation)

D

Frequency command during DOWN operation

(Up-Down operation)

S

Frequency command during STOP operation

(Up-Down operation)

O

FBus Option frequency command

J

Jog frequency command

R

Internal 485 frequency command

1 ~7

Multi-step frequency command

3

Multi

Function

Key Setting

UserGrp

SelKey

Used to register parameters as a user group in the parameter

mode or delete parameters in the user group.

4

Inverter

Operating

Status

STP

Motor stopped

FWD

Operating forward

REV

Operating reversely

Forward command given

Reverse command given

DC

DC outputting

WAN

Warning

STL

Stalling

SPS

Speed Searching

OSS

Software Over Current controlled

OSH

Hardware Over Current controlled

TUN

Auto Tuning

PHT

Pre-heat

FIR

Fire mode operation

SLP

Sleep mode operation

LTS

Load tuning

CAP

Capacity diagnostics

PCL

Pump clean

1. Basic Checklist

14

Parameter Change 1.3

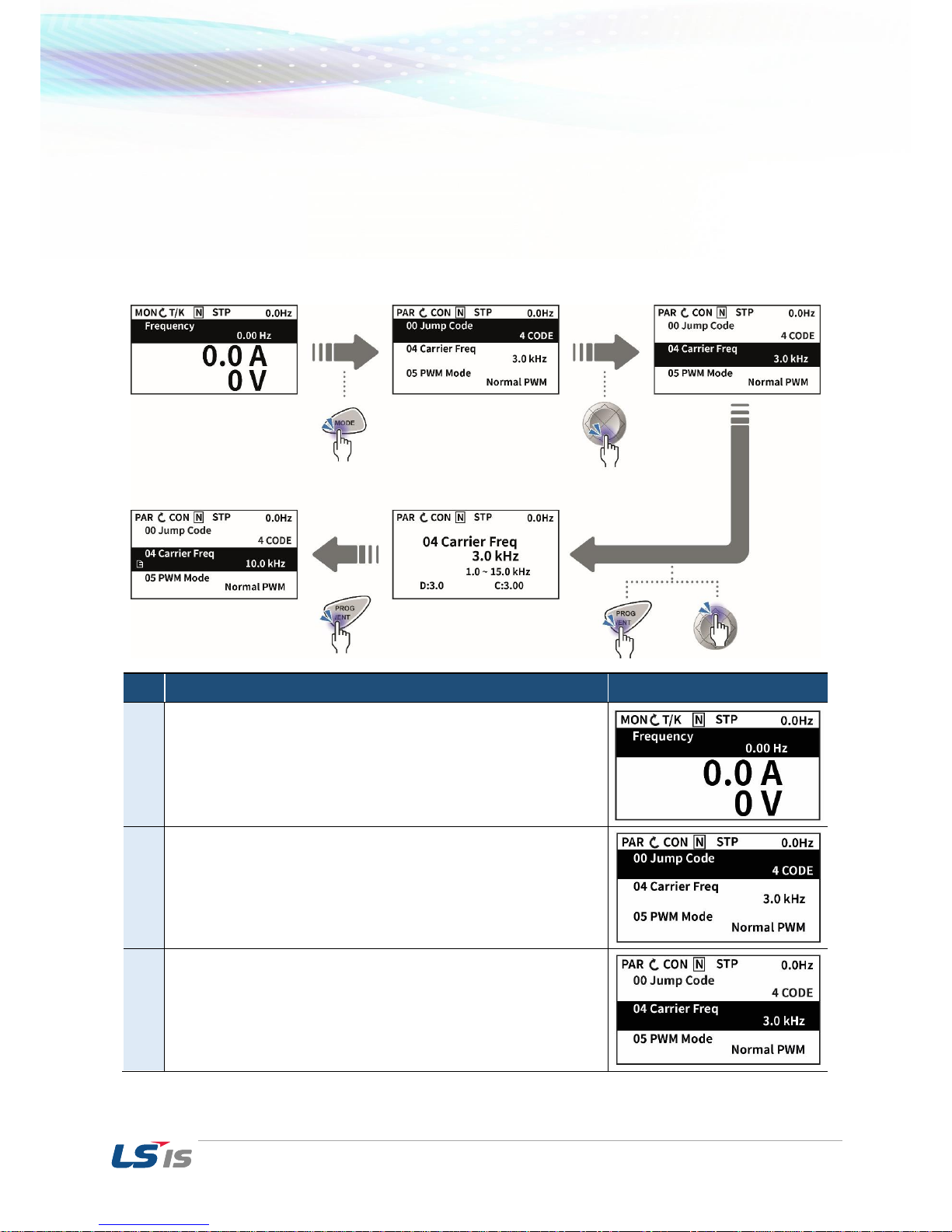

Carrier Frequency Change 1.3.1

The following example demonstrates how to configure Carrier Frequency by modifying CON group 04

code(Carrier Frequency) from 3.00(Hz) to 10.00(Hz). You can configure the parameters for different

codes in any other group in exactly the same way.

Step

Instruction

Keypad Display

1

Monitor Mode is displayed.

2

Shift to CON by using Mode key.

3

Shift to code 04 using Down key.

Press PROG.

1. Basic Checklist

15

4

Change the Carrier Frequency to 10 using Up key.

Press ENT.

5

The display come back to the initialization selection after

finishing Carrier Frequency Change

Adjust motor operational noise by changing carrier frequency settings. Power transistors (IGBT) in the

inverter generate and supply high frequency switching voltage to the motor. The switching speed in this

process refers to the carrier frequency. If the carrier frequency is set high, it reduces operational noise

from the motor, and if the carrier frequency is set low, it increases operational noise from the motor.

Below are advantages and disadvantages according to the sound of the inverter during operation.

Item

Carrier Frequency

LOW

HIGH

Motor noise

↑

↓

Heat generation

↓

↑

Noise generation

↓

↑

Leakage current

↓

↑

1. Basic Checklist

16

Initializing All Parameters 1.3.2

You can initialize the parameter that has been changed by the user to the initial state at the time of

delivery. Not only the entire parameter but a group of the parameter mode can be selected and initialized.

Step

Instruction

Keypad Display

1

Monitor mode is displayed.

2

Press the [MODE] key to move to the Config (CNF) mode.

3

Press the [Down] key to go to CNF-40 (Parameter Init).

Press the [PROG/ENT] key to configure the parameter

initialization options.

1. Basic Checklist

17

Step

Instruction

Keypad Display

4

In the list of options, select ‘1(All Grp),’ and then press the

[PROG/ENT] key to perform parameter initialization.

5

The parameter initialization option is displayed again when the

initialization is complete.

Note

Following parameter initialization, all parameters are reset to factory default values. Ensure that

parameters are reconfigured before running the inverter again after an initialization.

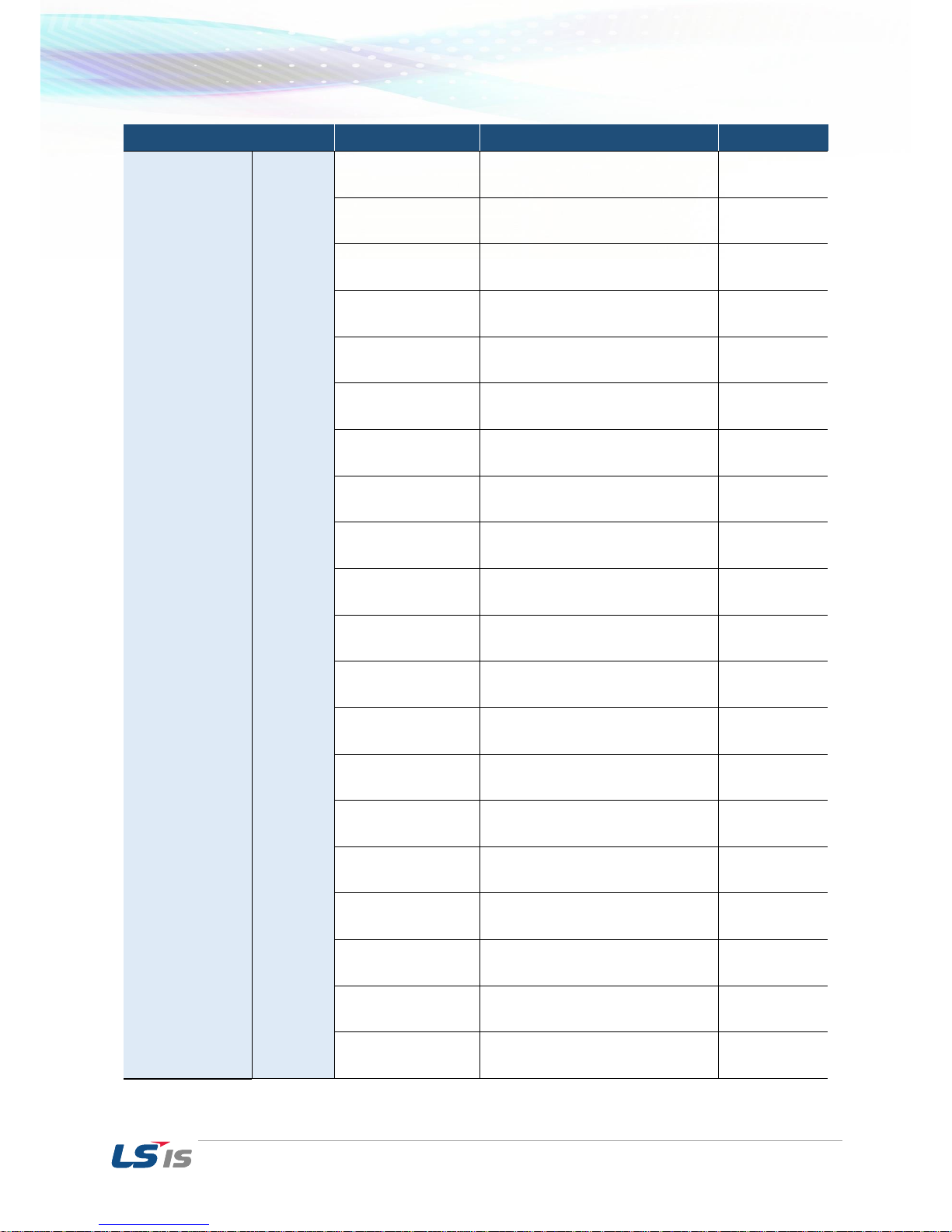

Read and Write Parameters 1.3.3

This is the function of copying the parameter saved in the inverter to the keypad and copying the

parameter saved in the keypad to the inverter.

Group

Code

No.

Function Display

Setting Display

Unit

CNF

46

Parameter Read

1

YES

CNF

47

Parameter Write

1

YES

48

Parameter Save

1

YES

Read and Write Setting Details

Code

Description

CNF-46 Parameter

Read

Copies the parameter in the inverter to the keypad. The existing parameters

saved in the keypad are all deleted.

CNF-47 Parameter

Write

Copies the parameter saved in the keypad to the inverter. The existing

parameters in the inverter are all deleted. In case of an error during

parameter writing motion, the previously saved data can be directly

used. If there is no data saved in the keypad, a message reading “ EEP

Rom Empty “ is displayed.

CNF-48 Parameter

Save

Because the parameters set in communication are saved in the RAM area,

they are all gone

if the inverter power is turned Off/On. If you set parameters in

communication and select Yes in CNF-48 Parameter Save,

the set parameters remain unchanged even if the inverter power is turned

Off/On.

* Available on LCD keypad only.

1. Basic Checklist

18

Fault Trip Monitoring 1.4

Failure during operation

Step

Instruction

Keypad Display

1

If a fault trip occurs during inverter operation, the inverter enters

Trip mode automatically and displays the type of fault trip that

occurred.

2

Press the [Down] key to view the information on the inverter at the

time of fault, including the output frequency, output current, and

operation type.

3

If there were any fault trips that occurred previously, press the

[Right] key to display the fault trip information at the times of

previous fault trips.

4

When the inverter is reset and the fault trip is released, the keypad

display returns to the screen it was at when the fault trip occurred.

1. Basic Checklist

19

Multiple failures at a time

Step

Instruction

Keypad Display

1

If multiple fault trips occur at the same time, the number of fault

trips occurred is displayed on the right side of the fault trip type.

Press the [PROG/ENT] key to view the list of all the fault trips.

2

The list of all the fault trips is displayed.

3

When the inverter is reset and the fault trip is released, the

keypad display returns to the screen it was at when the fault trip

occurred.

1. Basic Checklist

20

Saving and monitoring of failure history

Step

Instruction

Keypad Display

1

In case of a failure during operation, the mode automatically

shifts to Trip Mode with the trip displayed.

2

If you press Reset or the terminal is entered, the failure above

is

Automatically saved and the display goes back to the place

before the failure.

Move to Trip Mode using Mode key.

3

The most recent failure is saved in Last-1 code.

Press Right key.

4

A previous failure is saved in Last-2 code.

If another failure occurs, what was in Last-2 moves to Last-3.

2. Troubleshooting

21

2

Troubleshooting

This chapter explains how to troubleshoot when the protective functions, fault trips, warning signals,

or a fault occurs while operating the inverter. If the inverter does not work as expected after

following the suggested troubleshooting steps, please contact the LSIS Customer Service Center.

Trips and Warning 2.1

The Inverter will stop operating or send out a warning signal when it detected a fault. The keypad

will show brief information of the trip and warning signal. If the model is using the LCD keypad, the

LCD will show detailed information.

The following is how the fault conditions are categorized.

• Level: After the fault is corrected, the trip or warning signal disappears. The fault is not saved

in the fault history.

• Latch: After the fault is corrected, the trip or warning signal disappears once the Inverter is

reset.

• Fatal: After the fault is corrected, the trip or warning signal disappears when conducted the

following procedure. Turn off the Inverter and wait until the charge indicator light goes off. Then,

turn on the Inverter. If the Inverter still failed, please contact the supplier or LSIS Customer

Service Center.

Failure/Warning List 2.1.1

The following table shows a list of faults and warning signals that can occur while operating H100.

Category

LCD Display

Details

Page

Critical

Latch

Over Current1

Over current trip

P. 25

Over Voltage

Over voltage trip

P. 26

External Trip

Trip due to an external signal

-

NTC Open

Temperature sensor fault trip

P.29

Over Current2

ARM short current fault trip

P.28

Option Trip-x*

Option fault trip*

-

Over Heat

Over heat fault trip

-

Out Phase Open

Output open-phase fault trip

P.27

2. Troubleshooting

22

Category

LCD Display

Details

Page

In Phase Open

Input open-phase fault trip

P.28

Ground Trip

Ground fault trip

P.27

FanTrip

Fan fault trip

P.29

E-Thermal

Motor overheat fault trip

P.27

IO Board Trip

IO Board connection fault trip

-

No Motor Trip

No motor fault trip

-

Low Voltage2

Low voltage fault trip during

operation

P.27

ParaWrite Trip

Write parameter fault trip

-

Pipe Broken

Pipe Break fault trip

-

Damper Err

Damper Err trip

-

Over Load

Motor overload fault trip

P.25

Under Load

Motor under load fault trip

P.25

CleanRPTErr

Pump clean trip

-

Level Detect

Level detect trip

-

MMC Interlock

MMC Interlock trip

-

Inverter OLT

Inverter overheating trip

P. 28

Thermal Trip

Motor overheating trip

-

Lost KeyPad

Lost keypad trip

-

Broken Belt

Broken belt trip

Pipe Broken

Pipe Broken trip

2. Troubleshooting

23

Category

LCD Display

Details

Page

Level

Low Voltage

Low voltage fault trip

P.26

BX

Emergency stop fault trip

-

Lost Command

Command loss trip

-

Lost Keypad

Lost keypad trip

-

Fatal

EEP Err

External memory error

-

ADC Off Set

Analog input error

-

IO Board Trip

IO Board connection fault trip

-

Watch Dog-1

Watch Dog-2

CPU Watch Dog fault trip

-

Warning

Lost Command

Command loss fault trip warning

-

Over Load

Overload warning

-

Under Load

Under load warning

-

Inv Over Load

Inverter overload warning

-

FanWarning

Fan operation warning

-

DB Warn %ED

Braking resistor braking rate

warning

-

Low Battery

Low battery warning

-

Fire Mode

Fire mode warning

-

Pipe Broken

Pipe Break warning

-

Level Detect

Level detect warning

-

CAP. Warning

Capacitor lifetime warning

-

Fan Exchange

Fan replacement warning

-

2. Troubleshooting

24

Category

LCD Display

Details

Page

Lost Keypad

Lost keypad warning

-

Load Tune

Load curve tunning warning

-

Broken Belt

Broken belt warning

-

ParaWrite Fail

Smart copier error warning

-

Rs Tune Err

Auto tunning warning(Rs)

-

Lsig Tune Err

Auto tunning warning(Lsigma)

-

Note

• In a latch type trip, the inverter cannot unlock the fault if the user does not reset the inverter, even if the

trip state is released after the trip occurs.

• In level type trip, the inverter can unlock the fault by itself if the trip state is unlocked after the trip

occurs.

• In a fetal type trip, there is no way to unlock the fault other than turning the inverter off then back on

after the trip occurs.

2. Troubleshooting

25

Troubleshooting Fault Trips 2.1.2

Refer to the following tables for solutions to fault trips or warnings.

Keypad Display

Type

Description

Over Load

Overload

Trip

Latch

Occurs when the motor load exceeds the value that was set

for the motor overload trip. Operation will resume after setting

PRT-20 at a value other than 0

Problem

Solution

The load is greater than the

motor’s rated capacity.

Make sure the motor and inverter has the appropriate capacity ratings.

Replace the motor and inverter that has a bigger capacity.

The value set for overload trip

level (PRT-21) is too small.

Increase the setting value.

There is a fault with the output

module (IGBT).

Refer to 3.1.4 Check Input/Output Module to identify the fault cause of

the output module (IGBT).

DO NOT operate the inverter. Contact the retailer or the LSIS Customer

Service Center.

The mechanical brake of the

motor is operating too fast.

Check the mechanical brake.

The torque boost level is too high

Reduce the torque boost level.

Acc/Dec time is too short compared

to the load inertia (GD2).

Increase Acc/Dec time.

Keypad Display

Type

Description

Under Load

Underload

Trip

Latch

Occurs when the motor load is less than the value that was

set for the motor underload level. Operation will resume after

setting PRT-27 at a value other than 0

Problem

Solution

There is a motor-load connection

problem.

Replace the motor and inverter with models with lower capacity.

The set value for underload level

(PRT-24) is less than the system’s

minimum load.

Reduce the set value for the underload level.

Keypad Display

Type

Description

Over Current1

Over

Current Trip

Latch

Occurs when the Inverter output current exceeds 180% of

the rated current.

Problem

Solution

Acc/Dec time is too short

compared to the load inertia

(GD2).

Increase Acc/Dec time.

Inverter load is greater than the

rated capacity.

Replace the inverter that has a bigger capacity.

The inverter produced an output

while the motor was not

operating.

Operate the inverter after the motor stopped or use the speed search

function (CON-70).

The mechanical brake of the

Check the mechanical brake.

2. Troubleshooting

26

motor is operating too fast.

Output wiring is short-circuited /

Ground fault occurred.

Remove the short circuit. Check the motor for ground fault.

There is a problem in the wiring

between the inverter and the

motor.

Check the output wiring as well as the recommended specifications of

the wiring length, thickness, etc..

There is a fault with the output

module (IGBT).

Refer to 3.1.4 Check Input/Output Module to identify the fault cause of

the output module (IGBT).

DO NOT operate the inverter. Contact the retailer or the LSIS Customer

Service Center.

Keypad Display

Type

Description

Over Voltage

Over

Voltage Trip

Latch

Occurs when voltage rate of the DC circuit is higher than the

specific value..

Problem

Solution

The input voltage is too high.

Check whether the input voltage is higher than the specified value.

The actual DC link voltage is

different from the value on the

display.

Need to inspect the Hardware.

Contact the retailer or the LSIS Customer Service Center.

Acc/Dec time is too short

compared to the load inertia

(GD2).

Increase Acc/Dec time.

There is a generative load at the

inverter output.

Use the braking unit.

Keypad Display

Type

Description

Low Voltage

Low

Voltage Trip

Level

Occurs when the DC circuit voltage is lower than the

specified value.

Problem

Solution

The input voltage is too low.

Check whether the input voltage is lower than the specified value.

The actual DC link voltage is

different from the value on the

display.

Need to inspect the Hardware.

Contact the retailer or the LSIS Customer Service Center.

There is a problem with the input

(R, S, T) wiring.

Rewire.

The magnetic contactor

connected the power source is

faulty..

Replace the magnetic contactor.

A load greater than the power

capacity is connected to the

power system. (welder, direct

motor connection, etc.)

Increase power capacity.

2. Troubleshooting

27

Keypad Display

Type

Description

Low Voltage2

Low

Voltage

Trip2

Latch

Occurs when the DC circuit voltage is lower than the specified

value during inverter operation

Problem

Solution

The input voltage has decreased

during the operation.

Check whether the input voltage is lower than the specified value.

An input phase-loss has occurred.

Check the input wiring.

The magnetic contactor

connected the power source is

faulty..

Replace the magnetic contactor.

Keypad Display

Type

Description

Ground Trip

Ground

fault Trip

Latch

Occurs when there is excessive current than the specific

value due to a ground fault in the output. The ground fault

detection current is different per inverter capacity.

Problem

Solution

Ground fault occurred in the

output lead.

Separate the output wiring and check whether the ground fault is

present. Remove the ground fault

There is a problem in the wiring

between the inverter and the

motor.

Check the output wiring as well as the recommended specifications of

the wiring length, thickness, etc. Replace it if necessary.

The insulation of the motor is

damaged.

Replace the motor.

There is too much noise.

Decrease the carrier frequency value.

Keypad Display

Type

Description

E-Thermal

Motor

overheat

fault trip

Latch

Occurs depending on the inverse time (delay) to prevent

overheat of the motor due to overload. Operation will resume

after setting PRT-40 at a value other than 0.

Problem

Solution

The motor has overheated.

Reduce the load or operation frequency.

The inverter load is greater than

the rated capacity.

Replace the inverter that has a bigger capacity.

The value for electronic thermal

protection (ETH) is too low.

Set the ETH level appropriately.

The inverter has been operating

at low speed for a long time.

Replace the motor that supplies extra power to the cooling fan.

Keypad Display

Type

Description

Out Phase Open

Output

open-phase

fault trip

Latch

Occurs when one of the three output phases is phase open.

Operation will resume after setting PRT-05 bit 1 to 1.

2. Troubleshooting

28

Problem

Solution

There is a problem with the

magnetic contactor in the output.

Check the magnetic contactor on the outside.

The output wiring is faulty.

Check the output wiring.

Keypad Display

Type

Description

In Phase Open

Input openphase fault

trip

Latch

Occurs when one of the three input phases is phase open.

Operation will resume after setting PRT05 bit 2 to 1.

Problem

Solution

There is a problem with the

magnetic contactor in the input.

Check the magnetic contactor on the input side.

The input wiring is faulty.

Check the input wiring.

The DC condenser needs to be

replaced.

Replace the DC condenser.

Contact the retailer or the LSIS Customer Service Center.

Keypad Display

Type

Description

Inverter OLT

Inverter

Overload

Trip

Latch

Occurs when the overload time equivalent to 60% of the inverter

overheat protection (inverter IOLT) level, is accumulated. Set the

digital output terminals or relay (OUT-31–35 or OUT-36) to ‘6

(IOL)’ to receive the inverter overload warning output signals.

Problem

Solution

The load is greater than the motor’s

rated capacity

Replace the motor and inverter that has a bigger capacity..

The torque boost level is too

high.

Reduce the torque boost level.

Keypad Display

Type

Description

Over Heat

Over Heat

Trip

Latch

Occurs when the temperature of the heat sink exceeds the

specific value.

Problem

Solution

There is a problem with the

cooling system.

Check whether there are any external substances (dust, etc.) in the air

inlet, outlet or vent.

The cooling fan has been

operating for a long time

Change the cooling fan. (Refer to 3.1.5 Replace cooling fan)

The ambient temperature is too

high.

Keep the ambient temperature below 50℃.

Keypad Display

Type

Description

Over Current2

ARM short

current fault

trip

Latch

Occurs when the DC circuit in the inverter detects an

excessive short circuit current.

2. Troubleshooting

29

Problem

Solution

Acc/Dec time is too short

compared to the load inertia

(GD2).

Increase Acc/Dec time.

Output lead is short circuit.

Check the output wiring.

There is a problem in the wiring

between the inverter and the

motor.

Check the output wiring as well as the recommended specifications of

the wiring length, thickness, etc. Replace it if necessary.

There is a fault with the output

module (IGBT).

Refer to 3.1.4 Check Input/Output Module to identify the fault cause of

the output module (IGBT). DO NOT operate the inverter. Contact the

retailer or the LSIS Customer Service Center.

Keypad Display

Type

Description

NTC Open

Temperature

sensor fault

trip

Latch

Occurs when an error is detected in the temperature sensor of

the Insulated Gate Bipolar Transistor (IGBT).

Problem

Solution

The ambient temperature is too

low

Keep the ambient temperature above -10 ℃

There is a fault with the internal

temperature sensor.

Contact the retailer or the LSIS customer service center.

Keypad Display

Type

Description

FAN Trip

Fan fault trip

Latch

Occurs when there is a problem with the cooling fan.

Operation will resume after setting PRT-79 to 0

Problem

Solution

There are external substances

blocking the air vent.

Remove the external substances.

The cooling fan needs to be

replaced.

Change the cooling fan. (Refer to 3.1.5 Replace cooling fan)

2. Troubleshooting

30

Troubleshooting Other Fault 2.2

Refer to the following tables for solutions other than fault trips or warnings.

Setting parameters is not working.

Problem

Solution

The inverter is operating (inverter mode).

Stop the inverter and change to program mode and set

the parameters.

The parameter access level is incorrect.

Check the correct parameter access level and set the

parameter.

The password is incorrect.

Check the password and disable the parameter lock by

setting CNF-52 to Unlock. Then set the parameter.

Low voltage is detected.

Check the power input to resolve the low voltage problem.

Then set the parameter

The motor does not rotate.

Problem

Solution

The setting of the operation command source is

incorrect.

Check the setting of the operation command source.

There is no power supplied to the R/S/T

terminals.

Check the connections of R/S/T and U/V/W terminals.

The charge lamp is turned off.

Turn on the inverter.

The operation command (RUN) is off.

Turn on the operation command (RUN).

The motor is locked.

Unlock the motor or lower the load level.

The load is too high.

Operate the motor independently.

There is an input on the emergency stop signal.

Reset the emergency stop signal.

The wiring for the control circuit terminal is

incorrect.

Check the wiring for the control circuit terminal.

The input option for the frequency command is

incorrect.

Check the input option for the frequency command.

The input voltage or current for the frequency

command is incorrect.

Check the input voltage and current for the frequency

command.

The PNP/NPN mode is selected incorrectly.

Check the PNP/NPN mode.

The frequency command value is too low.

Check the frequency command value and set the

command that is above minimum frequency.

The [STOP/RESET] was pressed.

The motor was stopped normally so run the inverter.

The motor torque is too low.

Change the operation modes (V/F, IM Sensorless). If the

fault remains, replace the inverter that has bigger

capacity.

2. Troubleshooting

31

The motor rotates in the opposite direction to the command.

Problem

Solution

The wiring of the motor output cable is

incorrect.

Check whether the output side is wired correctly to the

phase (U/V/W) of the motor.

The rotation signal connection between the

control circuit terminal (forward/reverse rotation)

and the forward/reverse rotation control panel is

incorrect.

Check the forward/reverse rotation wiring.

The motor only rotates in one direction.

Problem

Solution

Reverse rotation prevention is selected.

Release/Remove the reverse rotation prevention setting

and resume operation.

The reverse rotation signal is not input even

though the 3-wire sequence was selected.

Check the input signal associated with the 3-wire

operation.

The motor is overheating.

Problem

Solution

The load is too high.

Reduce the load. Increase the Acc/Dec time.

Check the motor specifics and set to the correct values.

Replace the motor and inverter appropriate to load

capacity.

The ambient temperature of the motor is too

high.

Lower the ambient temperature.

The phase-to-phase voltage of the motor is

insufficient.

Use the motor that can withstand phase-to-phase voltage

surges, greater than the maximum surge voltage.

Only use motors suitable for inverter applications.

Connect the AC reactor to the inverter output (Set the

carrier frequency to 2kHz in code H39).

The motor fan stopped. / The external

substances are inside/blocking the fan.

Check the motor fan and remove any external substances

(dust, debris, etc.)

2. Troubleshooting

32

The motor stopped when accelerated or connected to load.

Problem

Solution

The load is too high.

Reduce the load.

Replace the motor and inverter appropriate to inverter

capacity.

The motor does not accelerate. / The acceleration time is too long.

Problem

Solution

The frequency command is too low.

Change the setting accordingly.

The load is too high.

Reduce the load. Increase the acceleration time.

Check the status of the mechanical brake.

The acceleration time is too long.

Change the setting accordingly.

The properties of the motor and inverter

parameters are incorrect.

Change the parameters of the motor.

The stall prevention level during acceleration is

low.

Change the stall prevention level.

The stall prevention level during operation is

low.

Change the stall prevention level.

Starting torque is insufficient.

Change to vector control operation mode. If the fault still

exists, replace the inverter that has a bigger capacity.

Motor speed changes during operation.

Problem

Solution

There is high variance in the load.

Replace the motor and inverter that has a bigger capacity.

The input voltage changes.

Reduce the input voltage variance (standard deviation).

The motor speed changes at a specific

frequency.

Adjust the output frequency to avoid resonance.

The motor rotation is different from the setting.

Problem

Solution

The V/F pattern is set incorrectly.

Set a V/F pattern suitable for motor specification.

2. Troubleshooting

33

The deceleration time is too long even with the Dynamic Breaking resistor connected to the

motor.

Problem

Solution

The deceleration time is set too long.

Change the setting accordingly.

The motor torque is insufficient.

If there is no problem with motor parameters, this is due to

motor capacity. Replace the motor with a bigger capacity.

The load is higher than the internal torque limit

(based on the rated current) of the inverter..

Replace the inverter with a bigger capacity.

The control unit is not working or noise is generated when the inverter is in operation.

Problem

Solution

The switching inside the inverter caused noise.

Reduce the carrier frequency in CON-04.

Install a micro surge filer in the inverter output.

The earth leakage breaker is activated when the inverter is in operation.

Problem

Solution

The earth leakage breaker is activated due to

leaking current from the inverter.

Connect the inverter to the ground terminal.

Check the ground resistance is less than 100 Ω for 200V

and less than 10 Ω for 400V inverters.

Check the capacity of the leakage breaker and connect

properly based on the rated current of the inverter.

Reduce the carrier frequency in CON-04.

Make the cable length between the inverter and the motor

as short as possible.

The motor vibrates intensely and does not rotate normally.

Problem

Solution

The phase-to-phase voltage of 3-phase power

source is not balance.

Check the input voltage and stabilize the voltage.

Check and test the insulation of the motor.

The motor makes humming or loud noises.

Problem

Solution

There is resonance between the motor’s natural

frequency and the carrier frequency.

Reduce the carrier frequency in CON-04.

2. Troubleshooting

34

There is resonance between the motor’s natural

frequency and the inverter’s output frequency.

Slightly change the command frequency

Use the frequency jump function to avoid resonance.

The motor vibrates / hunts.

Problem

Solution

The frequency input demand was externally set

to analog command.

Change the input filter time constant if there are

interferences in the frequency command due to noise

from the analog input side.

The wiring between the motor and inverter is

too long.

Make sure that the total cable length between the inverter

and the motor is less than 150m (50m for motors rated

3.7kW and lower).

The motor does not stop completely when the inverter output stopped.

Problem

Solution

The motor cannot decelerate sufficiently due to

malfunction of the DC braking.

Adjust the DC braking parameter.

Increase the set value for DC braking current.

Increase the set value for the DC braking stopping time.

Free run stop was selected.

Change the stopping method to decelerating.

The output frequency does not reach the target frequency.

Problem

Solution

The target frequency is within the jump

frequency range.

Set the target frequency higher than the jump frequency

range.

The target frequency is higher than the upper

limit of the frequency command.

Set the upper limit of the frequency command higher than

the target frequency.

The stall prevention function is not working due

to high load.

Replace the inverter with a bigger capacity.

The cooling fan does not rotate.

Problem

Solution

The control parameter for the cooling fan is set

incorrectly.

Check the control parameter settings for the cooling fan in

ADV-64

3. Maintenance

35

3

Maintenance

This chapter covers regular inspections for different time periods, how to replace the cooling fan,

and how to properly store and dispose Inverters. The surrounding environment highly affects the

conditions of the inverters. Meaning, improper management will wear down the components and

lead to malfunction. In order to prevent this from happening, please follow the recommended

maintenance guidelines in this section.

Caution

Read all safety instructions in this manual before inspecting the product.

Make sure the power is off before cleaning the product.

Clean the inverters with dry cloths. Using wet cloths, water, solvents, or detergents may lead

to electric shock or damage to the product.

Regular Inspection List 3.1

Daily Inspections 3.1.1

Part

Category

Check points

Method

Standard

Equipment

All

Ambient

environment

Is the ambient

temperature and

humidity appropriate

within the range?

Is there any dust or

substances nearby?

Refer to

Installation &

Wiring in the

User Manual

Temperature:

10~40℃.

Humidity:

Below 50%

Thermometer,

hygrometer,

recorder

Complete

Inverter

Is there any unusual

vibration or noise?

Visual

inspection

All clear

Power

voltage

Are the input/output

voltages in the

normal range?

Voltage ratings

between R/S/T

phases in the

inverter’s

terminal block

Refer to Input and

Output standards in

the User Manual

Digital multimeter

/ Analog tester

Input/Output

circuit

Smoothing

capacitor

Is there any internal

leakage?

Visual

inspection

All clear

Is the condenser

swollen (change in

shape)?

Cooling

system

Cooling fan

Is there any unusual

vibration or noise?

Check by

rotating the fan

manually when

the system is

turned off

Rotate smoothly

-

3. Maintenance

36

Display

Measuring

device

Is the display value

normal?

Check the

display value on

the panel

Check the rated,

managerial value

Voltmeter,

ammeter, etc.

Motor

All

Is there any unusual

vibration or noise?

Visual

inspection

All clear

-

Is there any unusual

smell (odor)?

Check for

overheat or

damage

Annual Inspections 3.1.2

Part

Category

Check points

Method

Standard

Equipment

Input/Output

circuit

All

Megger test

(between

input/output

terminals and earth

terminal)

Disconnect the

inverter wirings

and short

R/S/T/U/V/W

terminals.

Measure each

terminal to the

ground terminal

using a Megger.

(Refer to 3.1.4

Check

Input/Output

Module)

Above 5MΩ

DC 500V Megger

Are there any loose

parts in the device?

Tighten all

screws

All clear

Are there any

evidence of

overheat?

Visual

inspection

Conductor

Connections

/Cables

Are there any

corroded cables?

Visual

inspection

All clear

Is there any damage

on the wire clothing?

Terminal

block

Is there any

damage?

Visual

inspection

All clear

-

Smoothing

condenser

Measure

electrostatic capacity

Measure with

capacity meter

Above 85% of the

rated capacity

Capacity meter

Relay

Is there any

chattering noise

during operation?

Visual

inspection

All clear

Is there any damage

on the contacts?

Visual

inspection

Resistors

Is there any damage

on the resistors?

Visual

inspection

All clear

Digital multimeter

/ Analog tester

3. Maintenance

37

Part

Category

Check points

Method

Standard

Equipment

Check disconnection

Remove one

side and

measure

Must be within

±10% of the rated

resistance

Control /

Protection

circuit

Check

operation

Check imbalance of

output voltage

during operation

Measure

voltage

between output

terminal U/V/W

Phase-to-phase

voltage balance:

Within 4V for 200V

Within 8V for 400V

Digital multimeter

/ DC Voltemeter

Is there any error in

the display circuit

after the sequence

protection test?

Test inverter

output

protection at

both short and

open circuit

conditions

Circuit must work

according to the

sequence

Cooling

system

Cooling fan

Are there any loose

parts around the

fan?

Tighten all

screws

All clear

-

Display

Display

device

Is the display value

normal?

Check the

command

values on the

display device

Specified values

and manageable

values must match

Voltmeter

Ammeter

Bi-Annual Inspections 3.1.3

Part

Category

Check points

Method

Standard

Equipment

Motor

Insulation

resistors

Megger test

(between

input/output

terminals and earth

terminal)

Disconnect the

cables for

terminals

U/V/ W and test

the wiring

Above 5MΩ

DC 500V Megger

Caution

Do not run the Megger (Insulation Resistance Test) on the control circuit as it may lead to damage

to the product.

3. Maintenance

38

Check Input/Output Module 3.1.4

How to check the diode module and IGBT module (5.5~30kW)

Testing method

1) Disconnect all power cables (R,S,T) and motor output cables (U,V,W).

2) Before testing, check the discharge of electrolytic capacitor (DCP-DCN).

3) When the circuit is open, DMM will indicate high resistance (several MΩ). In some situations, the DMM

may display a closed circuit (low resistance) and then show high resistance due to the capacitors.

When the circuit is closed, the DMM shows resistance of several hundred kΩ or less.

4) Displayed values may not be constant as it depends on the module and tester type. The value

measured between the phases is acceptable if the standard deviation is approximately ±10%.

Module

Test Polarity

Check Value

Module

Test Polarity

Check Value

+ - +

-

Diode

D1

R P Closed

D4

R N Open

P R Open

N R Closed

D2

S P Closed

D5

S N Open

P S Open

N S Closed

D3

T P Closed

D6

T N Open

P T Open

N T Closed

IGBT

Tr1

U P Closed

Tr4

U N Open

P U Open

N U Closed

Tr3

V P Closed

Tr6

V N Open

P V Open

N V Closed

Tr5

W P Closed

Tr2

W N Open

P W Open

N W Closed

3. Maintenance

39

How to check the diode module and IGBT module (37~90kW)

Testing Method

1) Disconnect all power cables (R,S,T) and motor output cables (U,V,W).

2) Before testing, check the discharge of electrolytic capacitor (DCP-DCN).

3) When the circuit is open, DMM will indicate high resistance (several MΩ). In some situations, the DMM

may display a closed circuit (low resistance) and then show high resistance due to the capacitors.

When the circuit is closed, the DMM shows resistance of several hundred kΩ or less.

4) Displayed values may not be constant as it depends on the module and tester type. The value

measured between the phases is acceptable if the standard deviation is approximately ±10%.

Module

Test Polarity

Check Value

Module

Test Polarity

Check Value

+ - +

-

Diode

D1

R

P2

Closed

D4

R N Open

P2 R Open

N R Closed

D2

S

P2

Closed

D5

S N Open

P2 S Open

N S Closed

D3

T

P2

Closed

D6

T N Open

P2 T Open

N T Closed

IGBT

Tr1

U

P3

Closed

Tr4

U N Open

P3 U Open

N U Closed

Tr3

V

P3

Closed

Tr6

V N Open

P3 V Open

N V Closed

Tr5

W

P3

Closed

Tr2

W N Open

P3 W Open

N W Closed

3. Maintenance

40

Example) Checking diode module and IGBT module

Checking Diode D2

1) Measure the resistance of D2 by placing the red lead (positive terminal of DMM) on S phase

and the black lead (negative terminal of DMM) on P.

If the resistance indicated on DMM is several hundred kΩ or less, it is acceptable.

2) Measure the resistance of D2 by placing the red lead from the positive terminal of DMM on P

and the black lead from negative terminal of DMM on S phase.

If the resistance indicated on DMM is MΩ, it is acceptable.

3) Measure the resistance of other diodes in the same way.

Caution

Before testing, check the discharge of electrolytic capacitor (DCP-DCN).

3. Maintenance

41

Checking IGBT Tr6

1) Measure the resistance of Tr6 by placing the red lead (positive terminal of DMM) on N and the

black lead (negative terminal of DMM) on V phase.

If the resistance indicated on DMM is several hundred kΩ or less, it is acceptable.

2) Measure the resistance of Tr6 by placing the read lead (positive terminal of DMM) on V phase

and the black lead (negative terminal of DMM) on N.

If the DMM indicates several MΩ, it is acceptable.

3) Measure the resistance of other Tr in the same way.

Caution

Before testing, check the discharge of electrolytic capacitor (DCP-DCN).

3. Maintenance

42

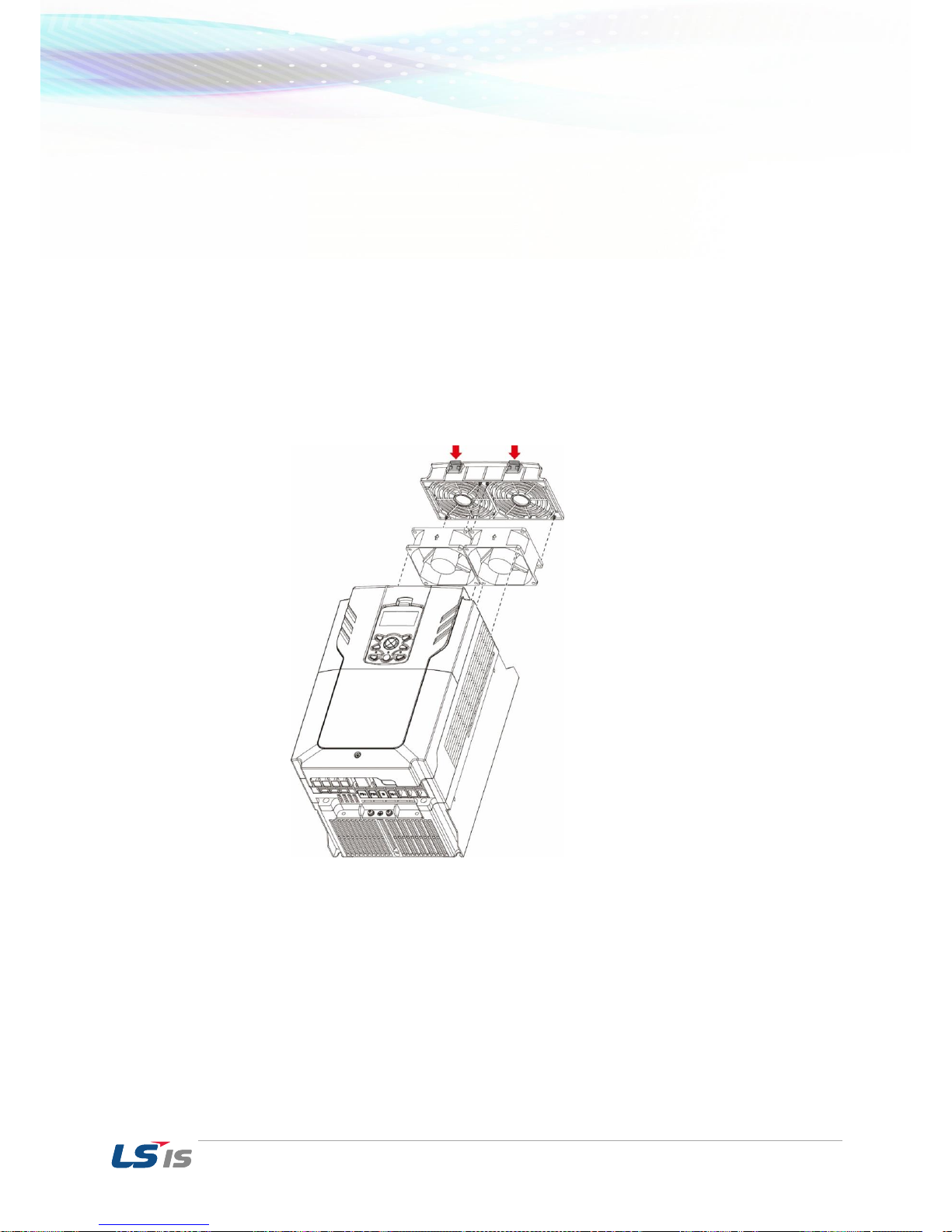

Replace Cooling FAN 3.1.5

If the inverter continued to operate after the cooling fan trip took place, a protective function will be

activated due to overheat in the cooling fan. Increase in temperature may reduce the lifespan of

major components. Make sure to solve the problem in the cooling fan before operating the inverter.

If the cooling fan has been operating longer than its (optimal) replacement period, this may lead to

low performance of the inverter or the cause of inverter failure. The replacement period of the

cooling fans is 3 years. Replace the old cooling fans with the new one

Replacement of 5.5~30kW FAN

1) Remove the fan cover by pressing the hook located by the arrow

2) Disconnect the fan wire and remove the fan from the inverter.

3. Maintenance

43

Replacement of 37~55kW FAN

1) Remove ❶ screws to separate the fan bracket from the inverter.

2) Disconnect the fan wire and remove ❷ screws.

Replacement of 75~90kW FAN

1) Remove ❶ screws to separate the fan bracket from the inverter.

2) Disconnect the fan wire and remove ❷ screws.

3. Maintenance

44

Caution

Turn off the inverter before replacing the fan. There is a possibility of an electric shock due to

the charge voltage. Wait until the inverter is fully discharged to replace the fan. (The time to

discharge varies per capacity, in average 1~3 minutes after turning off the inverter).

Make sure the fan wire and connect is not touching the blades. If touched it leads to

malfunction of the inverter. Make sure the inverter is completely turned off before cleaning.

After replacing the fan, assemble the fan. Before using the inverter, turn on the inverter and

check the condition of the fan by its motion.

Be careful of the direction of the fan.

Storage and Disposal 3.2

Storage 3.2.1

Store the products in the following conditions listed below (if not used for a long period of time).

Store the product in the same appropriate environmental conditions as in operation.

If the product will be stored more than 3 months, keep the ambient temperature between -

10℃~30℃ to prevent degradation of the electrolytic capacitor.

The products should not be exposed to snow, rain, fog and dust.

When packing the inverter, include a dehumidifier (e.g. silica gel) to keep the ambient

temperature inside the package below 70% and prevent in contact with moisture.

If the products will be left in a humid or dusty environment (construction sites or control panel)

separate the products in a location that has the same appropriate environmental conditions as

in operation.

Disposal 3.2.2

Categorize the inverters as general industrial waste when disposing the product. Note that there

are recyclable raw materials in the product, such as packing materials and metalwork. For the sake

of conservation of energy and resources, recycle whenever possible. Depending on the country,

plastic may be recyclable. Please check the local environmental regulations for more details.

Caution

Capacitors lose their charging characteristics if not operated for a long time. In order to prevent

this from happening, turn on the product and allow the device to operate for 30~60 minutes once

a year. Note that operation should be conducted under no-load conditions.

Loading...

Loading...